Guntamatic POWERCHIP 20, POWERCHIP 30, POWERCHIP 75, POWERCHIP 100, POWERCORN 50 Special Planning And Installation

...Page 1

Woodchip boiler englisch

POWERCHIP

/ POWERCORN 50 Special

Planning and installation

PH-01

EN-B31-009-V17-0815

Page 2

2

Information on this documentation

BS-01

Please read through this documentation carefully.

It is intended as a reference document and contains important

information on the design, safety, operation, maintenance and

care of your heating system.

We are always looking to improve our products and

documentation. Any ideas and suggestions you may have will

be gratefully received.

GUNTAMATIC Heiztechnik GmbH

Bruck 7

A-4722 PEUERBACH

Tel: 0043 (0) 7276 / 2441-0

Fax: 0043 (0) 7276 / 3031

Email: office@guntamatic.com

It is important that you pay particular attention

to the safety issues highlighted in the text by

these symbols.

The entire contents of this document are the property of

GUNTAMATIC and therefore protected by copyright.

Reproduction of any kind, communication to third parties by any

means or use for purposes other than those intended without

the written consent of the owner is prohibited.

Subject to printing errors and technical amendments.

Page 3

3

Contents

PH-01

Page

1 Introduction ............................................................................4

1.1 Safety instructions 4

1.2 Guarantee and liability 4

1.3 Commissioning 4

1.4 Site requirements 4

2 PLANING .................................................................................5

2.1 Fire safety 5

2.2 Minimum fire safety requirements 6

2.3 Boiler room requirements 8

2.4 Flue requirements 10

2.5 Flue draught regulator and pressure-surge compensator 11

2.6 Fuel store requirements 12

2.7 Examples for Planning 15

2.8 Automatically ash System 17

2.9 Heating circuit Rules 19

3 Construction.........................................................................21

3.1 Delivery 21

3.2 Carrying to installation site 21

3.3 Positioning and aligning the boiler 21

3.4 Fuel out feed installation 22

3.5 Plumbing connections 26

3.6 Filling and bleeding the system 29

3.7 Connecting the flue 30

4 Electrical connections .........................................................31

4.1 Heating system electrical connections 33

5 Final checks..........................................................................34

6 Standards / Regulations ......................................................35

7 Plumbing diagrams..............................................................36

7.1 Backup Memory HP0 36

8 Technical data ......................................................................54

8.1 Powerchip 20/30 and 40/50 54

8.2 Powerchip 75 and 100 55

8.3 Powercorn 50 Special 56

8.4 Removal 57

8.5 Celling filling spiral 59

Page 4

4

1 Introduction

BS-01

1.1 Safety instructions

GUNTAMATIC heating systems represent state-of-the-art

technology and meet all applicable safety regulations. Incorrect

installation can endanger life and limb. Heating boilers are

combustion systems and are potentially dangerous if handled

incorrectly. Installation, commissioning and servicing must,

therefore, only be carried out by adequately qualified

technicians observing all regulations and the manufacturer's

instructions.

1.2 Guarantee and liability

The manufacturer's guarantee is subject to correct installation

and commissioning of the heating system. Defects and

damage caused by incorrect installation, commissioning or

operation are not covered by the guarantee. To ensure that the

system functions as intended, the manufacturer's instructions

must be followed. Furthermore, only genuine replacement

parts or parts explicitly approved by the manufacturer may be

fitted to the system.

1.3 Commissioning

Commissioning of the boiler must be carried out by an

authorised GUNTAMATIC specialist or other qualified persons.

They will check whether the system has been installed

according to the plans, adjust the system settings as required

and explain to the system operator how to use the heating

system.

1.4 Site requirements

When establishing the site requirements, it is absolutely

essential to take account of the locally applicable planning,

building and implementation regulations and the dimensional

specifications in the fitting guidelines, installation examples and

technical data. Compliance with the locally applicable

regulations and the correct implementation of the measures

required on site are solely the responsibility of the system

owner and are a requirement of the manufacturer's guarantee.

GUNTAMATIC provides no guarantee of any kind for any type

of site work. Without making any claims as to completeness or

non-applicability of official requirements, we recommend the

following specifications based on the Austrian Guidelines pr

TRVB H 118:

Page 5

5

2 Planning

01

2.1 Fire safety

BS-01

The fire security instroductions are obligatory needed

on the construction place

The Compliance from counties ore states fire security

law is obligatory and stands higher then the

GUNTAMATIC fire security instruction

Austria State legislation of the federal states

Technical Directive on Preventative Fire Safety (pr TRVB H118)

Germany Standard boiler regulations (M-FeuVO)

Hessen and Saarland – in these states §16 FeuVO Hessen applies

Switzerland Fire safety regulations

(www.vkf.ch)

any other exporting countries Any fire safety office

You have to follow you specific country fire safety

rules obligatory. Your country safety rules are higher

then our GUNTAMATIC minimum rules.

If there are no specific fire security rules in your

country, you have to follow the GUNTAMATIC

introductions

Page 6

6

2.2 Minimum fire safety requirements

PH-01

Boiler room Floor of concrete construction, either bare or tiled. All materials

for floor, walls and ceiling must be fire-resistant to F60/REI60

rating.

Boiler rooms door: The Boiler room’s door also might close

single handed and it has to be possible to close off the door.

Connecting doors to the fuel storeroom must also be Class

T30/EI230-C fire doors, self-closing and lockable. There must

be no direct connection to rooms in which flammable gases or

liquids are stored.

Sprinkler: Connected to the outfeed unit there must be a

sprinkler device set to trip at 55°C. With storeroom volumes up

to 50 m³, this is used instead of the temperature monitor. When

the sprinkler is triggered, the sloping outfeed auger enclosure –

which also serves as a burn-back inhibiting device – is

completely flooded. The quantity of water required to do so is

at least 20 litres. If the temperature drops back below 55°C, the

flooding is stopped.

The sprinkler system must be

connected on all systems regardless

of local regulations!

Fuel storeroom The same minimum fire safety requirements apply as for the

boiler room.

Storeroom doors/hatches: Storeroom doors/hatches must be

fire safe to Class T30/EI230-C, self-closing and lockable. There

must be a warning sign carrying the message "Do not enter

when feeder system is running" attached to the storeroom

door/hatch.

> 50 m³

TÜB - Temperature monitor: If it is possible to store 50 m³ of

fuel or more, a temperature monitor connected to a warning

device must be installed in the fuel storeroom at the point

where the fuel conveyor exits the fuel store and enters the

boiler room. The warning device must be triggered when the

temperature exceeds 70°C. Because of the sprinkler system,

the temperature monitor on the outfeed auger is not required

for storerooms with a capacity of less than 50 m³.

> 50 m³

HLE - Manual fire extinguisher: If 50 m³ of fuel or more can

be stored, a manually operated fire extinguishing facility must

be installed. It must be protected against freezing and

connected to a pressurised water pipe (DN20 conduit). The

discharge point must be located directly above where the fuel

outfeed channel exits the storeroom. The fire extinguishing

facility must be identified by a sign carrying the inscription

"Fuel storeroom fire extinguisher".

Page 7

7

SLE - Automatic fire extinguishing facility:

For storage rooms in farm building it is possible to dispense

with a F90 / REI90 cladding for fuel storage and if the fire

compartment is less than 500 sq meters . The fuel but

separately ( wooden planking ) must be stored on other goods

. If furthermore a firewall to a residential wing before, so an

automatic extinguishing device ( SLE ) is also required.

This extinguishing equipment must be connected either directly

to a pressurized water supply or to a water -supply container .

The amount of water to need three times the volume of the

loading device shall be not less than 20 liters .

Inspection covers: There must be a lockable F90-class

inspection hatch above the fuel out feed channel.

Services area: For storerooms in the services area, it is

possible to dispense with F90/REI90 jacketing of the fuel store.

The fuel must be stored separately (wooden boarding) from

other materials and the fire containment zone must be less

than 500 m².

Filler pipes: Filler pipes through rooms where there is a fire

risk must be provided with Class F90/REI90 cladding.

Page 8

8

2.3 Boiler room requirements

PH-01

Minimum room height

PH 30 / 50 / 50 S ideal solution

H 225 cm

1)

possible

H 210 cm

PH 75 / 100 ideal solution

H 240 cm

1)

possible

H 230 cm

1)

= Mindestraumhöhe bei abgeschraubtem Wärmetauscherdeckel

Minimum room size

PH 30 / 50

B 240 cm x

2)

T 230 cm

(

3)

T 240 cm)

PH 75 / 100 / 50 S

B 270 cm x

2)

T 230 cm

(

3)

T 240 cm)

2)

T = The room with boiler´s bodies front seeing from behind

3)

= Minimum size from the automatic ash suction system

Clear access opening

PH 30 / 504) ideal

B 120 cm x H 185 cm

5)

possible

B 80 cm x H 170 cm

7)

possible

B 75 cm x H 165 cm

PH 75 / 100 / 50 S4) ideal

B 195 cm x H 210 cm

(

6)

185 cm)

5)

possible

B 100 cm x H 190 cm

(

6)

170 cm)

7)

possible

B 90 cm x H 180 cm

4)

Contribution from the ready constructed boiler on the pallet

5)

Constribution without Stoker, cleaning unity and pallet

6)

minimum height of boiler type powercorn 50 S

7)

dimensions with additional to point 5) with unrigged cover panel

Combustion air supply The pressure in the boiler room must not be less than 3 Pa

(0.3 mm H2O). The air vents for boiler rooms must have a

clear, net cross-sectional area of at least 200 cm² and must not

be sealable. With combustion boiler systems with a fuel heat

output upwards of 50 kW, the net, clear cross-sectional area

must be increased to at least 5 cm² per kW rated output

according to the combustion air requirement of the boiler

system. The air supply ducting must connect directly to the

outside and if the ducting passes through other rooms, it must

be jacketed to Class F90/REI90. On the outside of the building,

air vents must be covered by a protective grille with a mesh

size of > 5 mm. The supply of combustion air should, if

possible, enter at floor level in order to prevent cooling of the

boiler room.

Electrical installation The lighting and the electrical wiring in the boiler room must be

permanently installed. There must be a clearly marked

emergency off switch in an easily accessible position outside

the boiler room, close to the boiler-room door.

The line connector 400 VAC, 50 Hz, 13 A is needed.

Fire extinguisher A hand-held fire extinguisher (6kg gross weight, EN3) must be

mounted outside the boiler room near the boiler-room door.

Protection against freezing

The boiler room, pipes carrying water and any district heating

pipes must be protected against freezing.

Page 9

9

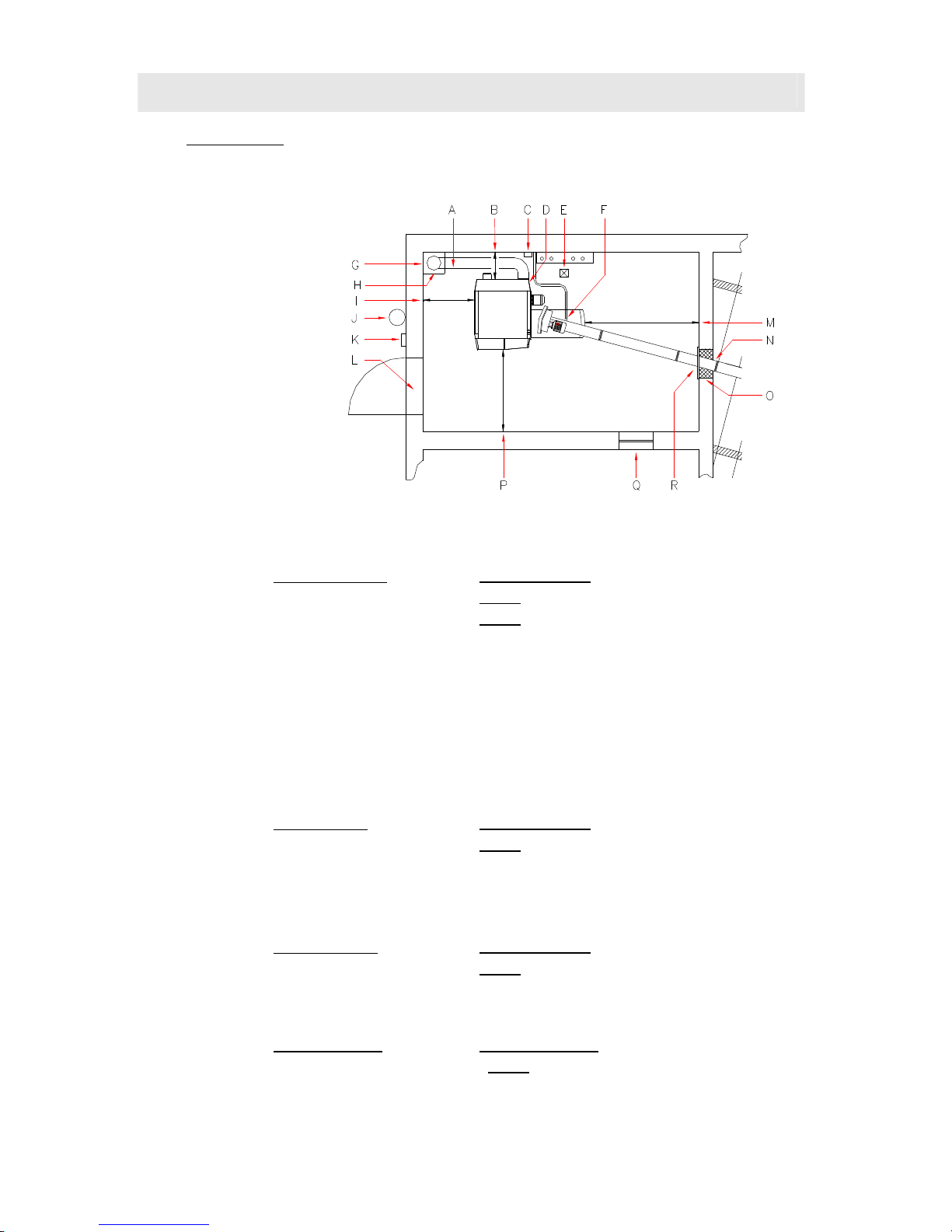

Installation site You have to plan the furnace in the near of the chimney to avoid a long

flue pipe.

A →

Integration version of Energy saving draft regulator with Ex flap and with fire tube

respect the local fire security rules- dust information possible

B →

BEHIND distance

ideal

70 cm minimum

possible

50 cm

without Ash suction system

60 cm

with Ash suction system

C →

The discharge for overheating

D →

Line Connector 400V 13A

E →

Drain

F →

Sparger complex

G →

flue

wet non- sensitive chamotte-flue advised

H →

installation variant energy-saving damper with explosion damper in the flue

c

a. 50 cm under the flue – please follow the local laws

I →

LEFT distance

ideal

70 cm minimum

possible

40 cm

J →

fire extinguisher

6 kg filling weight EN3

K →

escape switcher

L →

fireproof door

T30 / EI230-C lockable and self depended

M →

RIGHT distance

ideal

70 cm minimum

possible

40 cm

N →

HLE manual release arc control device

O →

Mauerdurchbruch

Höhe 70 cm / Breite 45 cm

P →

AHEAD distance

ideal

100 cm minimum

possible

80 cm

Q →

Air combustion supply

R →

TÜB Warning device for to heaters spiral’s temperature

Page 10

10

2.4 Flue requirements

PH-01

Use heat-insulated fireclay flues that are

insensitive to damp.

The flue gas temperature can be less

than 100°C.

The system must only be connected to the flue if the flue

meets the legal requirements and the technical specifications.

The flue must be matched to the boiler output and

dimensioned in accordance with DIN 4705. In order to be able

to accurately dimension the flue, the calculations must be

based on the flue gas figures. When designing new flues, high

thermal insulation chimneys (DIN 18160 T1 heat transmission

resistance group I) or suitable fireclay flues that are

insusceptible to damp and have general building regulation

approval should be used. It is advisable to involve those

responsible for approving the flue system early on in the

planning phase.

Flue height The minimum flue height is 5 - 10 m depending on boiler

output. The flue must terminate at least 0.5 m above the

highest part of the building. In the case of flat rooves, the flue

must terminate at least 1.5 m above the surface of the roof.

Flue diameter The flue hast to adjust on the fire power. The following datas

are approximate values and could be used for planning. We

recommend to calculate the flue by a professional.

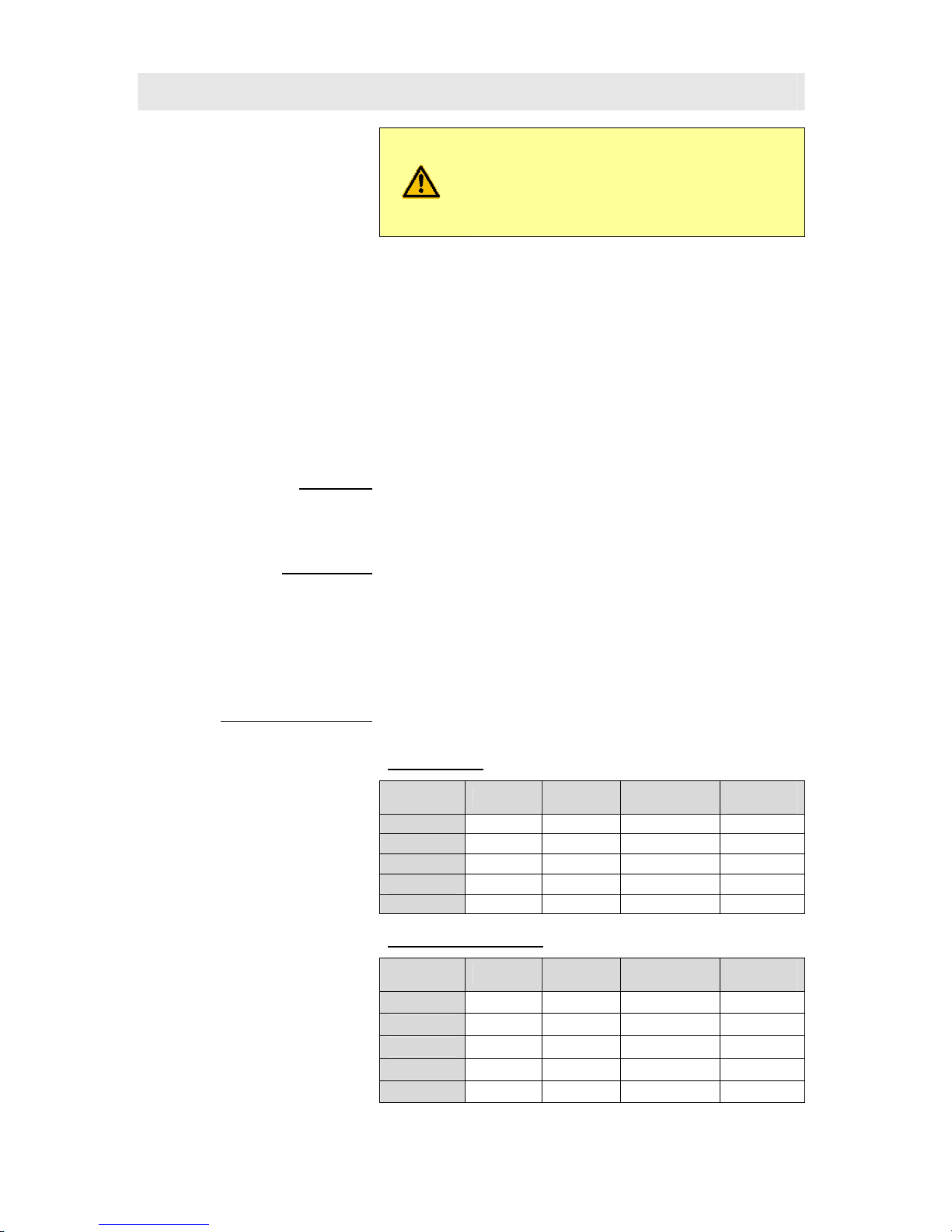

PH 30 / 50 / (PC 50-S)

PH 75 / (100)

eff. high above 6 m D = 160 (180) mm

eff. high under 6 m D = 180 (200) mm

eff. high above 6 m D = 220 (250) mm

eff. high under 6 m D = 250 (250) mm

Flue dimensioning data Dimension the flue for rated output!

(Averaged figures with used heat exchanger)

Rated output:

Type Flue gas CO2 Mass flow rate

Required

draught

PH 30 180°C 12,5% 0,025 kg/s 15 Pascal

PH 50 190°C 13,0% 0,040 kg/s 15 Pascal

PC 50-S 185°C 12,5% 0,040 kg/s 15 Pascal

PH 75 180°C 12,5% 0,065 kg/s 15 Pascal

PH100 195°C 12,5% 0,082 kg/s 15 Pascal

Sub-maximum output:

Type Flue gas CO2 Mass flow rate

Required

draught

PH 30 130°C 9,5% 0,010 kg/s 2 Pascal

PH 50 145°C 10,0% 0,015 kg/s 2 Pascal

PC 50-S 140°C 9,5% 0,015 kg/s 2 Pascal

PH 75 140°C 9,5% 0,020 kg/s 2 Pascal

PH100 150°C 10,5% 0,025 kg/s 2 Pascal

Page 11

11

2.5 Flue draught regulator and pressure-surge compensator

BS-01

Fitting an energy-saving flue draught

regulator/pressure-surge compensator

(Class RE) is absolutely imperative.

The flue draught should not differ by more than +/- 3 pascals

from the figure specified in the flue dimensioning data. If the

flue draught cannot be reduced to the required figure, either a

larger draught regulator should be fitted or an additional flue

baffle fitted between the flue and the draught regulator.

Purpose

• To ventilate the flue when the system is not in operation

• To compensate for pressure surges

• To regulate and limit the flue draught

Fitting requirement The energy-saving flue draught regulator must be fitted in

accordance with the local regulations, preferably in the flue

approx. 0.5 m below the point where the flue connecting pipe

joins or alternatively in the flue connecting pipe close to its

junction with the flue.

Flue draught setting

• Adjusting the flue draught is only of any use at

outside temperatures below +5°C.

•

The system must have been in operation for at least an hour

• Ensure there is sufficient demand for heat for the boiler to

be run at rated output for at least 15 minutes

• Measure the flue draught between the boiler and the flue

draught regulator (distance of measuring point from boiler

ideally 3 x flue diameter from connection between boiler

and flue connecting pipe).

Too much flue draught

May cause the flue gas temperature to increase

and accelerate combustion as a result. Poor

boiler output adjustability, increased dust

discharge and malfunctions can result.

Too little flue draught

Performance problems, incomplete combustion

and malfunctions when operating below rated

output can result.

Page 12

12

2.6 Fuel store requirements

PH-01

Please note:

the specific national rules for your fuel store

(for example. ÖNORM M7137, VDI 3464,..

.) are strictly

adhered blindly

Annual demand for fuel store The fuel store should be able to pick up the stock for a year .

Per 1 kw building heat is expected with the following annual

fuel demand .

→ per 1 kW/Year ca. 2,00 m³ = ca. 550 kg

beech

→ per 1 kW/Year ca. 2,50 m³ = ca. 500 kg

spruce

→ per 1 kW/Year ca. 0,65 m³ = ca. 450 kg

Pellets

→ per 1 kW/Year ca. 0,75 m³ = ca. 550 kg

Energycorn

→ per 1 kW/Year ca. 4,30 m³ = ca. 470 kg

Miscanthus

Fuel store arrangement You have to built your Storeroom in a quadratic frame, to use

the filling spiral optimally.

Fuel store air sparging To avoid an high perilous Co² consentration you have to lift the

store and Broiler room.The opening for the lifting might

discharge into the atmosphere. There must be an air change

between the Storeroom and the ambient atmosphere. If the

natural thermal isnt´t enough you have to take technical

measures.

If the filling stubs (the openings) discharges not into the

atmosphere you have to lift it with another lifting opening. you

have to be careful, that there is no rainwater into the storeroom

from the filfting opening. The construction site from the

permeable to air storage container might have a port in to the

atmosphere. A ventilator shifts from 200cm² is enough.

Up to 30 t storage volume the requirement is prepossessed, if:

• The filling stub (opening) is leading into atmosphere for

minimum 2 caps with an air inlet

• The diameter from 2 ventilation pipes is per pipe

minimum 90 mm

• The ventilator shift from the exhaust port from both

Ventilation pipes from 2 m minimum 40 cm² and must be

higher then a lenghth from 2 me but minimum 60 cm ².

INFO: The whole ventilation shift from 2 caps from our

filling sets is 60 cm².

Over 30 t storage volume the requirements

• a combination between natural and manual lifting, based

on a Co² Sensor. If there is no natural lifting you have to

install forced ventilation- in cas of a high Co²

Concentration ventilation is lifting automatically.

Page 13

13

Storeroom filling The hackchips are delivered by a tip truck. A fired drive at your

house to the storeroom is needed, if it´s possible. Ideally the

storeroom is on the external wall and is reachable and reflable

form the gate. To avoid damages on the agiator during

insertion of the hack chips, you shall fill the storeroom with a

front loader. The filling opening should be 30 up to 40 cm

minimum higher than the deepest point of the springroom. If

the fuel storeage room is pneumatic filled through a pump

carrage. In this kind of fillimg you have to care if there is a

dustproff speration.

Access doors/hatches Above-ground fuel stores must be provided with a door or

hatch that opens outwards. So that the fuel cannot run out if

the fuel store is opened by mistake, the inside of the access

door/hatch opening must be covered with boarding (which

must be removable from the outside). During to the risk of

injury when the system is in operation, access doors/hatches

must be lockable and kept locked when the system is in

operation. There must be a warning sign carrying the message

"Do not enter when feeder system is running" attached to the

access door/hatch.

Electric Installation Electronic installation in the fuel stores are not allowed

Filler couplings must be single ended.

Structural requirements The enclosing walls must be capable of withstanding the

possible static loads created by the fuel and the pressure when

filling the fuel store.

Damp-proofing The fuel must be protected against contact with water or damp

floors/walls. The storeroom must remain dry all year round. If

there is a risk of temporarily damp walls, fitting a backventilated facing to the walls and lining them with wooden

material may be required.

Doors Aboveground fuel stores must be accessible via a door

(lockable) of at least 1,80 m² cross-section to the outside,

inside and planked removable from the outside, so that the fuel

can not fall out when erroneous opening the door.

floor planking For operation with heating corn or pellets, a ground-planking or

a concrete floor is absolutely necessary. If it is only running by

hack chips, dry wood chips may be introduced instead of the

soil.

Page 14

14

Celling agitator The drive motor and the necessary electrical installations must

be installed outside of the storage room. A lockable emergency

stop switch with motor protection must be installed in the

immediate vicinity of the charging slot switches, which

interrupts the power supply of the auger when opening the

door, secured. The filling shaft must be secured with a grating.

.

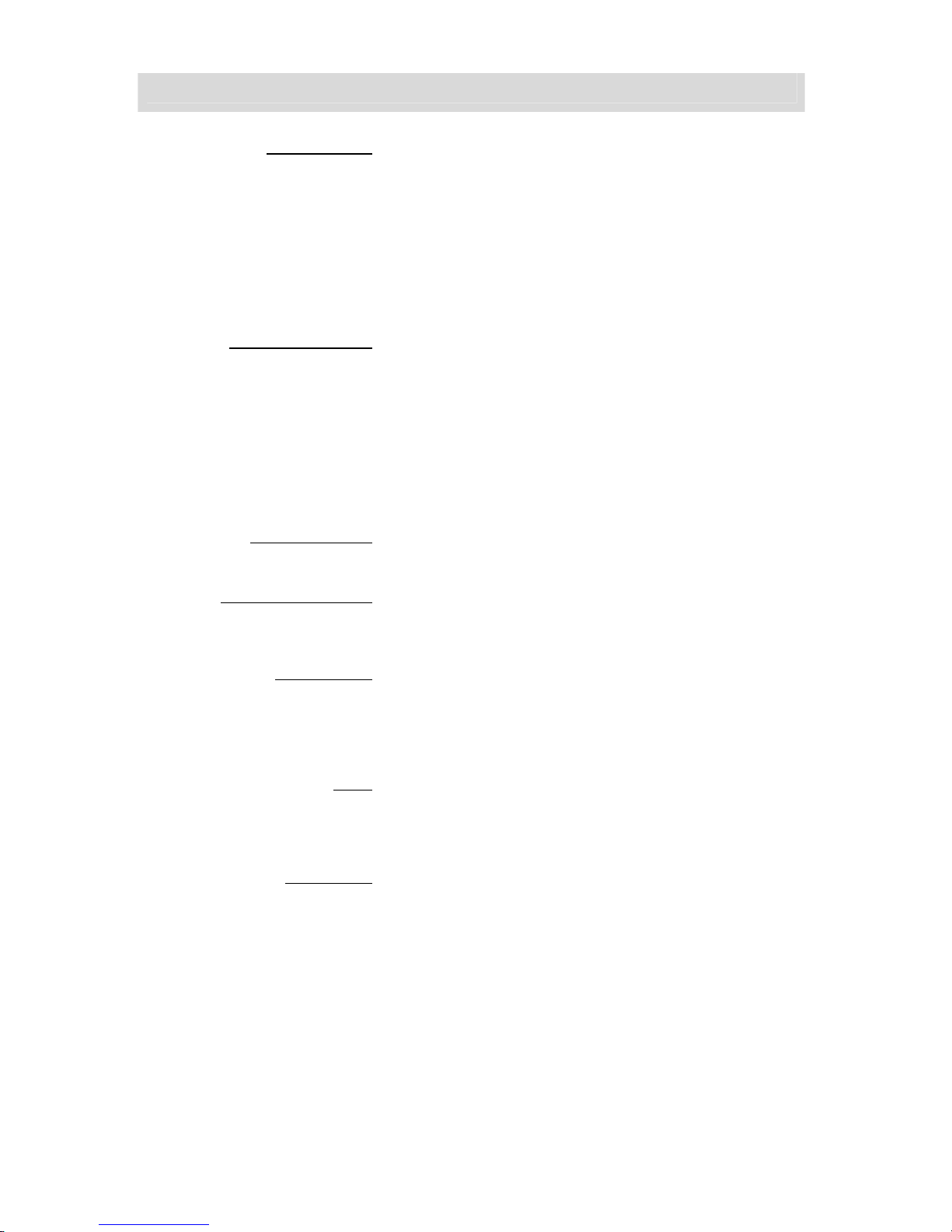

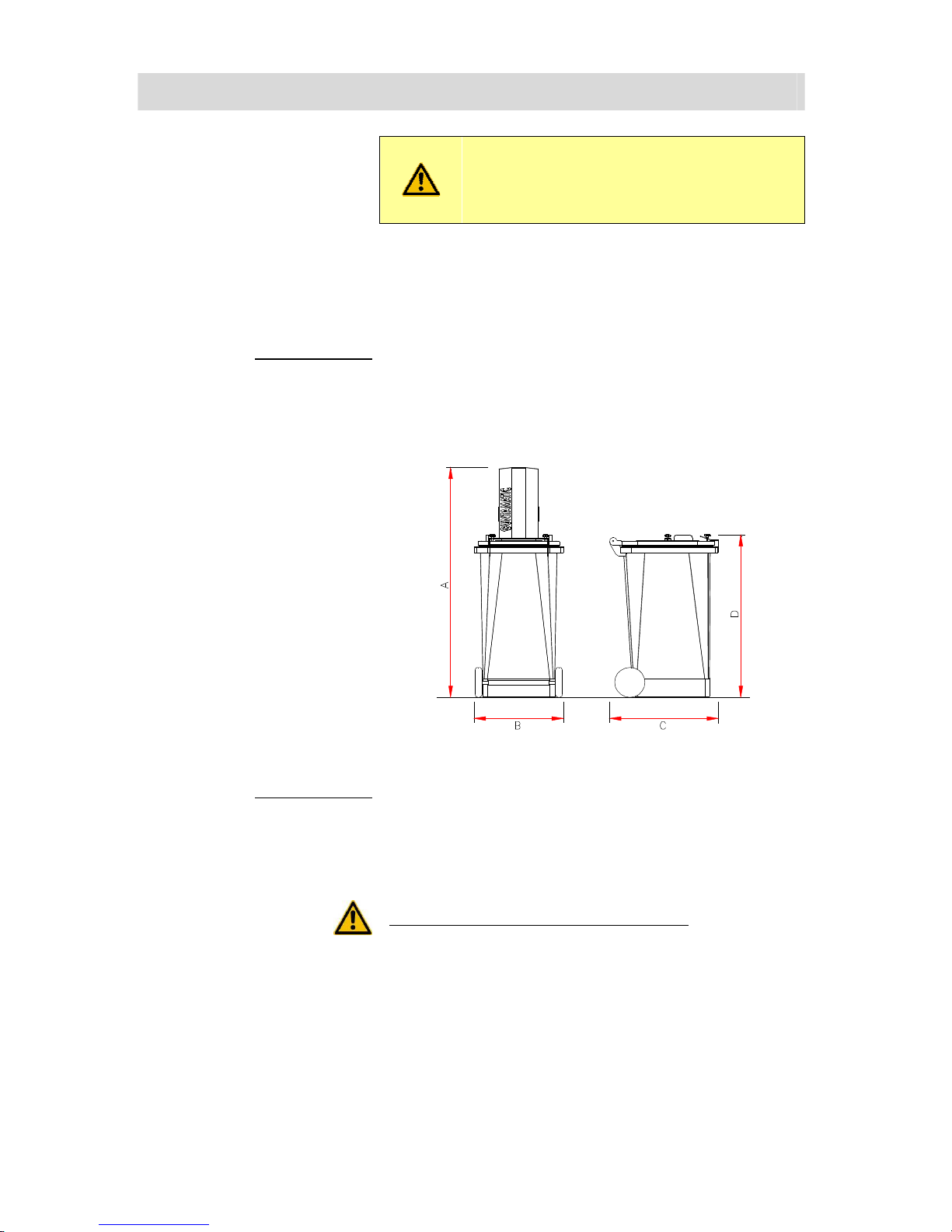

wall breakthrough The following measure table shows the measure for positioning

from the wall breakthrough. The measures apply to the serial

production.

serial production = discharge unity + 0,55 m hutch and agitator

Measure wall breakthrough

wide 45 cm

length 70 cm

Agitator Measure A Measure B

1,5 m 50 cm 37 cm

2,0 m 50 cm 41 cm

2,5 m 50 cm 44 cm

3,0 m 50 cm 47 cm

3,5 m 50 cm 50 cm

4,0 m 50 cm 53 cm

4,5 m 50 cm 54 cm

5,0 m 50 cm 55 cm

Page 15

15

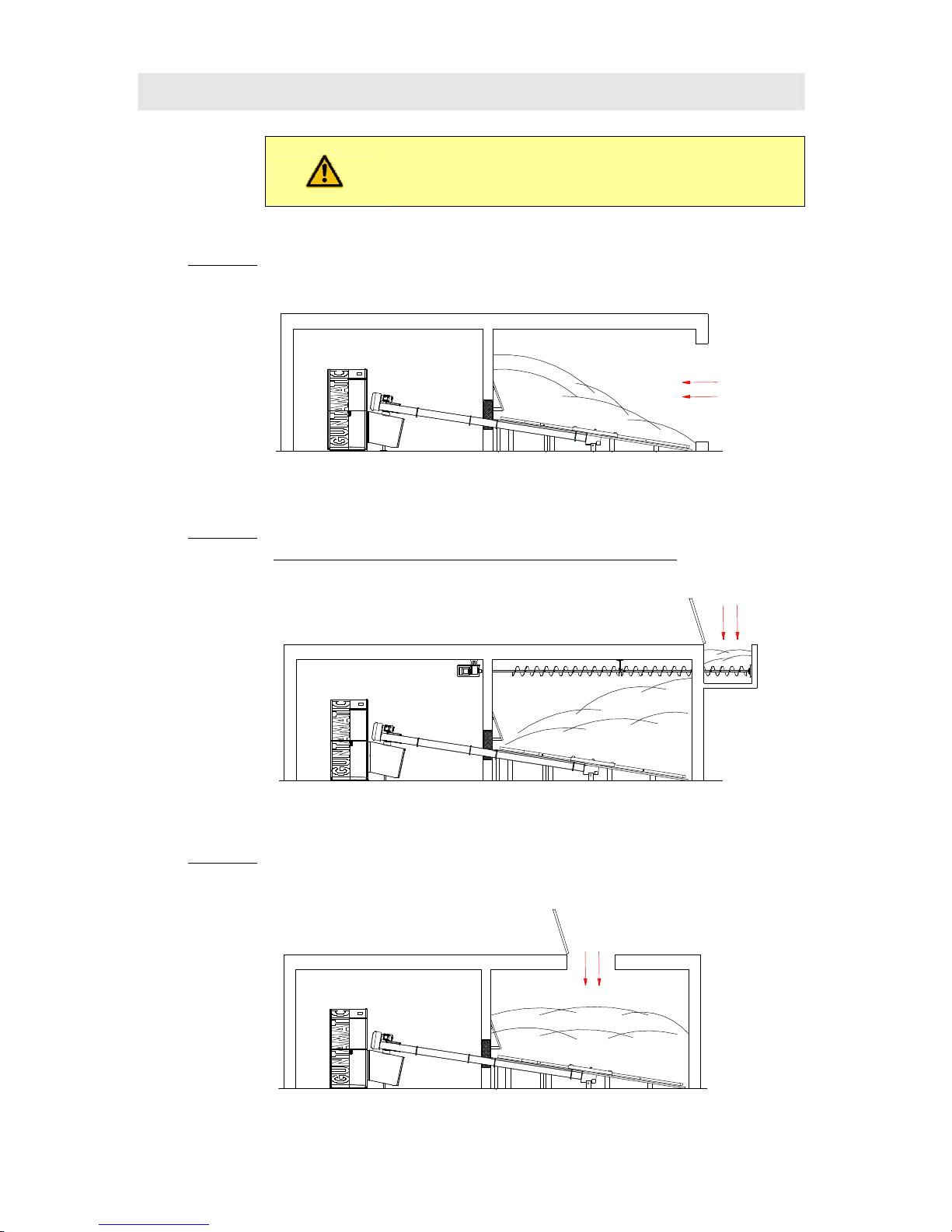

2.7 Examples for planning

PH-01

For working with Pellets oder Energy corn is a own

filling set needed.

(please have a look at the price list).

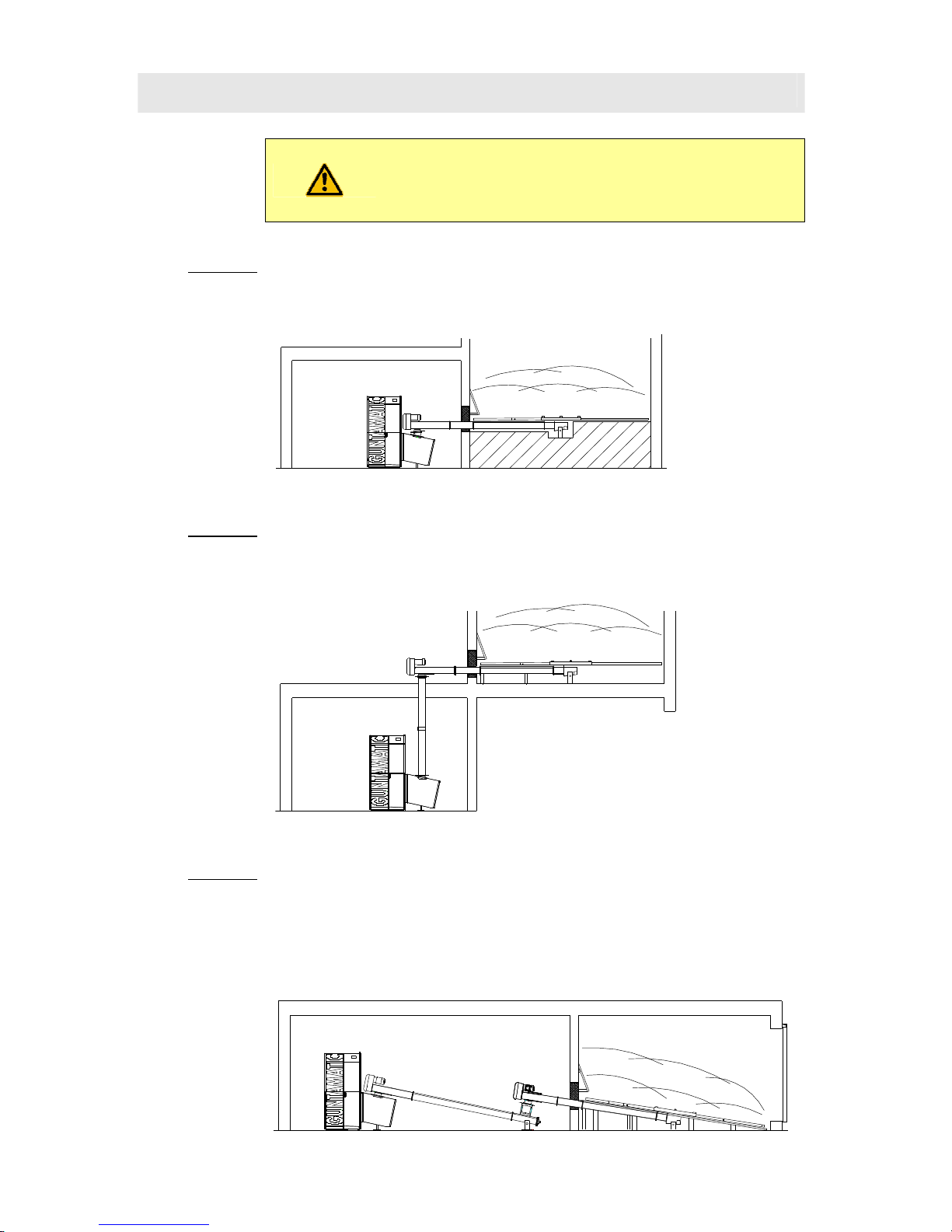

Example 1 The storrage filling occurs through a gate.

The maximal length of feed with the agitator is 7 meter.

Example 2 The storage filling occurs with a ceiling filling spiral through a shaft.

Deliverable ceiling filling spirals are available in following sizes: 3 m, 4 m, 5 m, 6

m or 7 m. The maximal length of holding included the agitator is 7 m.

Example 3 The storage filling occurs through a shift in the storage room ceilling.

The maximal length of holding included the agitator is 7 m.

Page 16

16

For working with Pellets oder Energy corn is a

own filling set needed.

(please have a look at the

price list).

Example 4 The boilers charging occurs with a horizontal installed agitator.

A droft shaft extension is needed. (please have a look on the price list)

The maximal length of holding included the agitator is 7 m.

Example 5 The boilers charging occurs with a horizontal installed agitator.

A in the length shortened downpipe is need.

(Please have a look on the price list).

The maximal length of holding included the agitator is 7 m.

Example 6 The boilers charging occurs with an additional feeder spiral.

A operation set and some spiral´s trags are needed.

(Please have a look on the price

list).

The maximal length of feeder spiral included operation set might have a 7 m

length.

The maximal length of holding included the agitator is 7 m.

Page 17

17

2.8 AUTOMATIC ASH SUCTION SYSTEM

PC-01

The following Introductions are for Device

planning- for installation of ash vacuum suction

system there is another Introduction included.

Optional there is a automatic ash vacuum system. The

accumulated ash will go through the firing build Feedsystem

and flexible metal tube in a big removable ashton. The

deashing is automatically.

Retofit the system It´s possible to retrofit the ash vacuum suction system, if the

minimum difference between the wall and the system ist 60

cm.

A → 153 cm

B → 59 cm

C → 72 cm

D → 107 cm

Construction side: If possible, you have the opportunity to plan the ash ton at a

ground level beside the boiler’s body. Basic requirement for

the construction is a good lifting through the installation site,

The ash ton must have a 25 cm minimum difference to

inflammable materials. You have to be a look that there is no

inflammable ground.

Not permitted construction side for an ash ton:

• in an garage

• in the atmosphere in living rooms;

• in storerooms with inflammable materials or gases.;

Page 18

18

Permited Construction plaeces for the ash ton:

• in the boiler room

• in an secondary

room

Hauling of a suction pipe through fire zones

A → wall penetration with Rockwoolpipesprialclamp;

B → wall penetration with boiled Steel pipe;

C → fire security clamps 54 – 60;

(maximal 1 m difference)

D → flexible suction metal tube

(minimum 10 cm difference)

E → not inflammable mad

Page 19

19

2.9 HEATING CIRCLE RULE

PH-01

The heating circle rule is optional offered.

You can decide between a MKR set or a wall mounted MK 261

set.

●

per construction 3 controlled by atmospheric condition rules

possible

●

per construction could be actived on the MKR Set boiler

●

pro Machine there are 3 remote control möglich;

●

per heatingcircle one analogue room unit possible

Exceptions at five sensors are buffer management

Please note the information in section 5- sensore buffer management of

chapter 7.1 and buffermanagement HP0 !

Set-MKR Following functions could be activated:

Heatingcircle

● Warmwater-Memory

Heatingcirle 0

optional avalible

........

● Pumpenheizkreis

● Zusatz Warmwasser-Speicher

● Externes Heizgerät

Heatingcircle 1

optional avalible

.......

● Pumpenheizkreis

● gemischter Heizkreis

Heatingcircle 2

optional avalible

.......

● Pumpenheizkreis

● gemischter Heizkreis

wall mounted model set-MK261 Following funtions could be active:

Heatingcircle WW

● warmwater- memory

Heatingcircle 0

optional

.................

● pumpingheatingcircle

1)

● third mixed heatingcircle

Heatingcircle 1

optional

.................

● pumpingheatingcircle

● mixed heatingcircle

Heatingcircle 2

optional

.................

● pumpingheatingcircle

● mixed heatingcircle

Trunk link

optional

.........................

● feederpump

(ZUP)

● dumping device pump

(PUP)

● cargo pump

(LAP)

2)

● extension

(ERW)

3)

● third mixed heatingcircle

adition

optional

..............................

● aditional warmwater memory

● external heatingcircle

4)

● third mixed heatingcircle

INFOBOX

1) the third mixed heatingcircle could be actived, if the functions trunk link and addition are not used.

2) through „ERW“ function a heating circle controller with trunk blink can be assigned an other heating circle controller

3) if the function „third mixed heatingcircle“ is activated, the trunk blink functions are not availible.

4) if the „third mixed heatingcircle“ is activated, the additional functions are not availibe.

Page 20

20

NOTES

Sketch:

Page 21

21

3 Construction

01

3.1 Delivery

BS-01

The boiler system is delivered packed in a wooden crate

wrapped in foil. Please check that the delivery is complete

according to the delivery note and in perfect condition.

Deficiencies Please make a note of the deficiencies identified directly on the

delivery note and contact the supplier, heating installer or our

Customer Service.

3.2 Carrying to installation site

BS-01

The system is delivered on a wooden pallet and can be lifted

and carried to the installation site using a pallet truck.

Carrying in dismantled The boiler body can be dismantled into parts for carrying in. If

that is done, a person authorised by GUNTAMATIC must be

consulted.

3.3 Positioning and aligning the boiler

PH-01

Keep to the minimum wall clearances specified by the system

planner and manufacturer. If important details are missing,

please refer to the planning documentation or ask our

Technical Support. Position the system as close as possible to

the flue to avoid having a long flue connecting pipe. The

system must be accessible from the left or right side.

Clearance at back

ideal

70 cm minimum

possible

50 cm

without auto ash extraction system

60 cm

with auto ash extraction system

Clearance on left

ideal

70 cm minimum

possible

40 cm

Clearance on right

ideal

70 cm minimum

possible

40 cm

Clearance at front

ideal

100 cm minimum

possible

80 cm

Floor clearance

ideal

3,5 cm minimum

with screw feet triggered

possible

8 cm

Set the boiler at a slant Unscrew the rear adjustable feet slightly further so that the

boiler is slightly higher at the rear. That will allow the air inside

the boiler to escape easily when the system is filled.

Page 22

22

3.4 Fuel out feed installation

PH-01

Sketch.1

Sketch.2

Sketch.3

1. 1. Set the boiler in accordance with the required minimum

wall-distances in the boiler room place so that sufficient

maintenance space around the boiler, see Sketch.1, exist.

Align the boiler by means of adjustable feet to the rear is

slightly inclined upwards so that existing in the heat

exchanger air can escape easily at the plant filling.Please

note, that the auger feed system has to be constructed right

and just like in sketch 2. , um ca. 90° nach vor oder zurück

geschwenkt werden kann.

2. 2. The storage room should be arranged only slightly lower

than the boiler room. The maximum possible inclinations of

the discharge screw can be seen in the clip values in

sketch 2. With the optional chute extension, see sketch 3,

up to 18 ° tilt are achieved. In disassembled stoker seal the

inlet (A) Sketch 4 insert between stoker unit and Flange

and screw with 4 pieces M08 x 30 hexagon bolts, snap

rings and nuts. The support foot (B) sketch.4. Unscrew the

stoker unit, so that the stoker unit is relieved. The cable

Ignition, TKS, level-tongue, fire engine, Stoker sensor,

actuator G1 and A1 connect drive.

3. Put the propulsive unit (C) Sketch 4 to the Stoker unit and

turn it in direction of the storeroom.

4. Pre assemble the needed Spiraltrogs on the ground.

Construct the in serial delivered trogpiece (F, look at Sketch

4) in the wall breakthrough. Screw the single trogpieces

with M08 x 30 hexagon screw, screw it hard Safety disk

with a locknut and crush. Stick the spirals piece that the

spiral´s lead (G, Sketch 4) is running without a crush or a

break. At least you have to stick the pre assambled Feed

spiral on the drive unit.

5. Construct the agitator (H), look at picture 4 on the Feed

spiral and have a look if the Spirals lead (G) is running

without a break and a pille.

Sketch.4

Page 23

23

Sketch .5

Sketch .6

Sketch .7

Sketch .8

6. The agitator is turning in clockwise direction, look at Sketch

5. The spring arm has to be constructed, that the longest

are in counterpart position. The spring arms have to run 15

to 20 mm above the drawing spiral (look at Sketch 9).

Please don´t fix the screws (J, Sketch 9) on the spring arm.

The feet (K, Sketch 9) on the agitator has to attitude, that

the longest spring and is running 3 to 4 cm over the ground

(look at L, Sketch 9)

7. Fix the unit air tight with screws M10 x 100/ 140 mm (look

at M, Sketch 9) with the Stoker unity. Construct the drive

unit always straight. Look at Sketch 6.

8. Place the agitator in the middle, that the spring arm has a

few cm space to the store room´s wall. The agitator on the

store room´s ground has to screw tightly.

9. Shore the Feed spiral in the store room with the delivered

stanchion below the wall breakthrough- the maximum

distance between the stanchions is 120 cm. The stanchions

have to be on the flanges or on angel brackets. To avoid

the sound transmission you have to put it under an

attenuated mad. You have to attitude the stanchions in

high, that there is enough space fort he spiral. You have to

screw tightly the stanchion. (Look at Sketch 7)

10. The wall breakthrough below (N, Sketch 9). For the closing

of the Feeding spiral you have to close it with the delivered

cover plate and with rock wool. For perforation you have to

cobble the cover plate.

11. You have to screw the bottom plate with M8 x 16 screws

tightly (look at Sketch 8) and you have to insert the bottom

plate below. (look at 0, Sketch 9)

12. The seperation (P) from the inspection opening (look at

picture 7) is sited by manufacture. This measure prohibits

the uncontrolled spread from fuil into the heatingroom. You

have to construct a 40 cm feed spiral which has a wall

distance from 40 cm and got a breadth with 80 cm. You

have to construct also a plank slat in a 20 degree angel.

The construction has to fixed satisfactoired and has to get

fixed enough on the underside.

Sketch .9

Page 24

24

13. The temperature monitoring (TÜB) may be omitted on the

drive unit (Sprinkler 55 ° C) to 50 m³ storage volume due to

the sprinkler device. In stockroom volume greater than 50

cubic meters, the temperature monitoring (segmental) is

also installed on the sprinkler system to the propulsion unit

in the area of the wall and the opening of a warning device

such as ruled at-a bugle. Also from 50 m³ storage volume is

a manually triggered from the boiler room, extinguishing

device (HLE), connected to a pressurized water line and

executed as empty piping DN20, directly to the passage of

space Sweep channel opening out in the fuel storage

installed. The extinguishing equipment must be marked

with a sign "erase fuel storage room".

Sketch .10

14. When wood chips operating a slanted floor is not

mandatory. With grain or pellet operation, however, a

sloping floor should be installed. Sloping floors made of

wood or cement could be constructed on site. With wood

floors slant the boarding of 3 cm thick planed boards or

paste board is finished. The sub-structure of 10 x 10 cm

timber construction, according to Fig.11. customize. The

supports must be on concrete or metal sheets. The

distance between the spring arms to sloping floor must be

15-20 mm. With sloping floor of concrete 2-3 cm away from

the worm trough.

Abb.11

Page 25

25

Sketch .12

Sketch .13

Sketch .14

15. The parellings installation with revisons opening must be

performed like written. In the store room there is a

installade partition (P), look at sketch 7, prohibts at opening

of revisionsquery an uncontrolled spread of stored fuel.

• The Feedspiral has filled out with rockwoll, look at (Q)

picture 12

• The cover plate (R) inside and outside installed (look

at picture 12)

• fix the cover plate (S)- look at picture 12

• Cut the rockwollblock (T) on size of store rooms

opening (look at picture 13)

• The stonewallblock (T), like in picture 13 is delivered

seperatly with a hexagon screw between

revisionsopening (U) and Revisionsbelowside (V)

delivered and installed.

• Put the installed inspection cover (W) and srew it with

wing locknuts.

Q

Q

S

R

T

V

U

W

Page 26

26

3.5 Plumbing connections

PH-01

POWERCHIP 30 - 50 / POWERCORN 50-Special

A → Sensor for temp. relief valve, 1/2"

B → Temperature-relief heat exchanger 3/4“

C → Heating return, 5/4“

D → Heating flow, 5/4”

E → External thermostat, 1/2"

POWERCHIP 75 - 100

A → Sensor for temp. relief valve, 1/2"

B → Temperature-relief heat exchanger 3/4“

C → Heating flow, 2”

D → Heating return, 2“

E → External thermostat, 1/2"

Page 27

27

Temperature-relief heat exchanger The maximum permissible operating temperature of the

boiler is 110°C. In order to prevent the maximum allowable

operating temperature being exceeded, connection of a

temperature-relief valve conforming to Austrian standard

ÖNORM 8131 and DIN 4751 and with a response

temperature of 95°C is required. The supply pressure must

be at least 2 bar but no more than 6 bar.

POWERCHIP 20/30 – 40/50 / POWERCORN 50-Special

A → Cold water supply

B → Sensor for temp. relief valve, 1/2"

C → Temp. relief valve, 95°C

POWERCHIP 75 - 100

A → Cold water supply

B → Sensor for temp. relief valve, 1/2"

C → Temp. relief valve, 95°C

Thermal store Installing a thermal store is not necessary as the boiler is

operated by a modulating control system and the system can

be quickly shut down. However, if the required continuous heat

output in the summer months is below 10 kW for systems up to

50 kW, or 22 kW for systems upwards of 50 kW, combination

with a thermal store is necessary for reasons of efficiency

When you putt he programm „OUT“, the antifreezefunction has

to be secured, if the E heatingsystem is built with an manual

thermostat.

Page 28

28

Return boost The boiler return temperature must be at least 55°C and must

be held at the required level by a bypass pump between the

boiler flow and return pipes. If a thermal store is connected,

the boiler return temperature must similarly be at least 55 °C,

which must be ensured by a return boost (cross-over valve)

set as shown in the plumbing diagram. If this requirement is

not complied with, there is an increased risk of corrosion and

guarantee entitlement will be lost as a result. Connect the

return boost set precisely as specified in our plumbing

diagrams.

The dimensioning of the return boost pump (set) is designed

for the arrangements shown in GUNTAMATIC plumbing

diagrams. If additional components such as heat meters are

incorporated in the system plumbing, or if the overall thermal

store pipe run (flow and return) is more than 30 m, redimensioning of the boiler charging pump (HP0) may be

necessary.

Sludge separator with magnetite Magnetite and the sludge separator in the Heatngwater could

become a problem for energysaver pumps. By installin a

prperly sized and applied sludge sperator with a magnet can

remided cost effenciently.

Either old pipes could be meant

Expansion vessel The boiler operates in a sealed heating system and must be

provided with an expansion vessel for pressure compensation.

To calculate the expansion volume, the volume of the system

when cold must be known. Please select the expansion vessel

on the basis of the manufacturer's specifications. The

expansion volume of the system is calculated as follows:

System volume x Expansion factor x Additional allowance factor

• Expansion factor for wood-fuel boilers = 0.03

• Additional allowance factor = 3.0 for systems under 30 kW

• Additional allowance factor = 2.0 for 30-150 kW systems

Example calculation: 2500 litres x 0.03 x 3 = 225 litres

Pump selection The choice of pump must be made by the installer or building

technology planner on the basis of the friction data, the pipe

cross-sectional area and the required delivery pressure for the

piping system planned.

Plastic piping If plastic piping for underfloor heating or district heating pipes

are connected, they must be protected against excessive

temperatures by using a limiting thermostat for the circulation

pumps.

Danger of overheating Faulty operation, wrong fuil or disturbance could be load to

overheating. To avoid disturbance you have to install

additional fuse protections for maximum process water and

fuses fpr heatingcircle temperatures.

Page 29

29

3.6 Filling and bleeding the system

BS-01

Please note the guidelines on

"Corrosion and boiler protection in

heating and domestic water systems"!

Water quality The water quality of hot water systems with flow temperatures

of max. 100°C is subject to VDI 2035. According to VDI 2035

Part 1, "Avoiding damage to hot water systems", which comply

with EN12828, the first-fill and replenishment water, must be

conditioned (preferably softened) if the following overall

hardness limits [°dH] according to total heat output (kW) are

exceeded:

• < 50kW: if °dH > 16.8

• 50 to 200 kW: if °dH > 11.2

• 200 to 500 kW: if °dH > 8.4

• > 500kW: if °dH > 0.11

Water heater If a water heater is also used in addition to the GUNTAMATIC

boiler, it should be filled according to the installation

instructions for it.

Construction flushing

• Before charging you have to flush the system. When you do

this, it’s the best opportunity to clean magnetit and rust

sludge from the pipe system.

Filling the system

• Match the pressure of the system when cold to the air

charge pressure of the expansion vessel.

• Check the operating pressure on the pressure gauge.

Bleeding the system

• Switch off and bleed circulation pumps.

• Bleed boiler by opening the bleed valve on the boiler and

allowing air to escape until water runs out.

• Bleed radiator heating system (if present) by opening the

bleed valve on every radiator and allowing air to escape

until water runs out.

• Bleed underfloor heating system (if present) by opening

each heating circuit and flushing through thoroughly until

there are no more air bubbles in the heating circuit pipes.

• Important: perform sequence in the correct order!

Start bleeding in the cellar or on the ground floor and finish

in the attic.

• Check the system operating pressure on the pressure

gauge and add more water if necessary.

• Restart circulation pumps.

Only systems that have been properly bled

guarantee effective conveyance of heat.

Page 30

30

3.7 Connecting the flue

PH-01

The boiler is connected to the flue by means of a flue

connecting pipe which must be gas-tight and insulated

between the heating boiler and the chimney.

Flue connecting pipe

→ The following diameters should be used:

• PH 30 - 50 Ø = 150 mm

• PH 75 – 100 / PC 50-S Ø = 180 mm

→ Flue connecting pipes longer than 4 m or with

more than 3 bends:

• PH 30 - 50 Ø = 160 mm

• PC 50-S Ø = 200 mm

• PH 75 – 100 Ø = 220 - 250 mm

The hole in the wall for connecting the flue pipe must be lined

with a built-in double-skinned lining tube or fireproof material.

The flue connecting pipe must rise upwards from the boiler to

the flue at an angle of at least 6° and be connected with gastight joints. An inspection cover must be provided for cleaning

the flue connecting pipe.

A → Flue connecting pipe, min. gradient 6°

B → Flue connecting pipe insulation

C → Flue draught regulator/pressure-surge

compensator in flue

(Preferred fitting arrangement)

D → Alternatively: Flue draught regulator in

flue connecting pipe

(As close as possible to junction with the flue)

• The flue connecting pipe musty be gas-tight

• An energy-saving flue draught regulator with pressure-

surge compensator (Class RE) must be fitted

• Insulate the flue connecting pipe

• Do not brick in the flue connecting pipe (noise

transmission)

• The flue connecting pipe must not extend into the flue

Page 31

31

4 Electrical connections

PH-01

The electrical connections to the boiler system on site may

only be made by an approved electrical installer observing all

the applicable regulations. In addition, it is essential that

electrical system components are protected against damage

from heat radiation.

All boiler system internal wiring is wired up at the factory ready

for use. The work required on site by the electrical installer

consists only of connecting the mains power and wiring up and

connecting the system components such as thermal store,

CAN bus, heating circuit pumps, mixer valve motors, etc.

Opening switch panel

• open the right cover panel (A);

• solve the lock screw (B)

• raise the control cover (C) and hang it below;

• the platine with the connecting plug under accessible

positions

Mains power supply 400 VAC, 50 Hz, 13 A fuse

(surge arrester recommend)

The mains power must be connected by means of the standard

non-reversible power socket on the rear panel of the boiler. It

must possible to isolate the system entirely from the mains

without opening the switch panel cover, e.g. by means of an

automatic circuit-breaker.

Emergency off switch According to prTRVB H 118, it must be possible to switch off

the system using an emergency off switch fitted outside the

boiler room near to the boiler room door. The burner must then

shut down but the heating controller and all safety equipment

must remain functional. Connected to the boiler enabling

switch, terminals 22/23 on the boiler circuit board (see

electrical wiring diagram).

Page 32

32

Cabeling

• Feeder 5 x 1,5 mm²

• Sensor 2 x 1 mm²

• Room stat 2 x 1 mm²

• CAN-Bus 2 x 2 x 0,5 mm²

(twisted pair, shielded)

For low voltage (sensores…) and high voltage, the cable duct

on the boiler, is needed

Surge protection

Where CAN bus cables run between different buildings, the

earthing conductors of the buildings must be connected to each

other for potential equalisation purposes. If the earthing

conductors cannot be interconnected, a 10 mm ring earth must be

laid along with the CAN bus cable in the ground. The earthing

conductors and ring earth must then be connected to one another.

Wiring CAN bus

linear wiring:

(you have to prefer this kind of wiring)

The connection is rewire linear, further cabling the CAN bus,

for example, from the operating unit to the wall unit and the

wall-mounted unit to the remote unity.

wirring radial:

The connection is radial wiring, means the CAN bus, for

example, from the operating unit to the wall unit and the space

station. The total length of the CAN bus connection must not

exceed 100 m in this case.

The terminals +/- and H / L connect each twisted pair.

Boiler cascade

Up to four heating boilers can be operated in a cascade

system (sequential control system) and must be connected inline via a CAN bus. The CAN bus lead must be wired

without connecting the + terminal.

Earthing The entire system is to be joined to the earth circuit conductor

via the connected piping system according to the regulations.

When connecting the earth circuit conductor

pay particular attention to keeping the

connecting runs as short as possible.

Cabel non tensioned to avoid defects or errors all cables strain relieved

Emergency power supply Only use regulated generators.

Page 33

33

4.1 Heating system electrical connections

PH-01

Mains connection

• 400 VAC, 50 Hz, 13 A fuse

Standard specifications

• Boiler control panel

(BCE)

• Boiler circuit board

(230 VAC)

• Router module

(400 VAC)

• Fault signal output

(24VDC 200mA)

• Safety temperature limiter

(STL)

• Boiler sensor

(KVT20 Ω)

• Flue gas temperature sensor

(thermocouple)

• Oxygen sensor

(12V DC)

• Flue draught fan

(230V AC)

• Grate cleaner motor

(230V AC)

• TKS 1

(firebox and ash box door switch, 24VDC)

• TKS 2

(fuel outfeed monitor)

• Stoker drive motor G1

(400V AC)

• Outfeed drive motor A1

(400 VAC)

• Outfeed drive motor A2

(400 VAC – for feeder auger)

• Stoker sensor

(PT1000 Ω)

• Fire safety flap

(24V DC)

• Ignition fan

(230V AC)

• Boiler enabling switch

(emergency off)

• HP0 output

(230 VAC)

• Reflux mixers

(230 VAC)

Optional equipment

• Pump outputs

(230 VAC)

• Mixer valve outputs

(230 VAC)

• sensor entrance

(KVT 20 Ω)

•

anlaloug equipment for furnace

• Digital remote station

Resistances

Temperature

KVT20

Ohm (Ω)

Temperature

PT1000

Ohm (Ω)

-8°C 1537 Ω 0C° 1000 Ω

0°C 1644 Ω 10C° 1039 Ω

10°C 1783 Ω 30C° 1117 Ω

20°C 1928 Ω 40C° 1155 Ω

30°C 2078 Ω 50C° 1194 Ω

40°C 2234 Ω 60C° 1232 Ω

50°C 2395 Ω 70C° 1271 Ω

60°C 2563 Ω 80C° 1309 Ω

70°C 2735 Ω 100C° 1385 Ω

Page 34

34

5 Final checks

BS-01

Final checks

• After completing installation of the system, check again

that all joints and pipes are properly tightened and not

leaking.

• Check that all covers are fitted and secured.

• Check that the fitting of all connections (water, flue,

electrical, ...) has been done correctly.

• Check that all required safety signs and instructions are

attached and hand over all documentation (operating and

installation instructions) for the system.

• Check that all electrical connections have been properly

wired before connecting the system to the power supply.

• Clean the system and clear up the installation site.

• Always leave the boiler room clean.

Initial commissioning Commissioning must only be carried out by GUNTAMATIC or

a qualified specialist. The precondition is that the flue

technician, heating installer and electrician have cleared the

system for operation. The authorised GUNTAMATIC specialist

will carry out the following work during commissioning:

• Check the entire system

• Check the electrical functions

• Adjust the programmer to the system

• Commission the system

• Explain to the user how the system functions and how to

operate and clean it

• Record the details of the customer and the system and

complete the commissioning log

Any deficiencies identified must be recorded in

writing and rectified within the following 4 weeks

in order to maintain guarantee entitlement.

The fully completed commissioning checklist must

be sent to GUNTAMATIC immediately as

otherwise the guarantee will be void.

These installation instructions should not be

destroyed after commissioning but kept

permanently with the system together with the

operating instructions.

Page 35

35

6 Standards / Regulations

BS-01

The heater equates Class 3/ EN 303-5. The original certification report is deposited at the

manufacture, Public Police and Fire safety rules have to be respected.

• ÖNORM / DIN EN 303-5

Heaters for pillar fuel, automatic and manual sanded up to 300 KW. Terms, requirements,

and checkups.

• ÖNORM / DIN EN 12828

heaters for pillar fuel, automatic and manual sanded up to 300 kw, terms, requirements,

checkups and marking

• ÖNORM / DIN EN 12831

Heating for Buildings; method for calculating usual heating board

• ÖNORM M 7137

Requirements on the Pelletstorage at the private customer.

• ÖNORM M 7510

Guideline for the review from central heaters

• ÖNORM H 5195-1

(Austria)

Prevention from damage through nest and Store origin with working temperature.

• VDI 2035

(Germany)

Avoidance from damages in Water heating systems

• SWKI 97-1

(Suisse)

Chalk and Rust Prevention in Waterheaters

• TRVB H 118

(in Austria for automatic sended Machines)

technical heating fire safety rule

• DIN 1988

Technical Rules for drinking water installation

• DIN 4751 Teil 1-4

Safety engineering equipment for water heaters

• Swiss decrees for aircleening

• Swiss decrees with smallfiremachines

• VKF Fire security thermaltechnical construction

(Suisse)

• SIA 384

(Swiss)

Page 36

36

7 Plumbing diagrams

01

7.1 Backup Memory HP0

PH-01

T2

HP0

T3

2 Sensor – Backup Memory

•

Attitude„Part-Charging“

The buffermanagement is charged in the top art. ON and

OFF Switching temperatures could be attitude with

buffermanagement.

•

Attitude „FULL-Charging“

The buffermanagement is charged in the below art. ON

and OFF Switching temperatures could be attitude with

buffermanagement.

HP0

T7

T6

T5

T3

T2

5 Sensor – Backup Memory

PLEASE NOTE:

The buffer sensor additionally required T5, T6 and T7 must

be connected to the boiler board or on a wall unit on the

terminals of the analogue space devices. It can be

programmed for heating circuits therefore this controller no

analogue room device RFF. Alternatively, use digital space

stations RS or an additional wall mounted set-MKR261 for

connecting the analogue room sensor RFF.

•

Attitude „part load border“

The buffer storage tank is loaded up to the adjusted

maximum part load limit at full boiler output. Once this limit

is reached, the boiler output is reduced so much by the

buffer management that this charge state of the buffer can

be kept as long as possible and thus restart the plant are

as far as possible avoided.

Page 37

HP0 mode = Z-pump

37

off 50 kW boiler output

- High-/ lower temperature construction

Attention: In case of very low (less than 30%) decrease of performance like for example a low energy or a passivehouse and

for oversizing, we advice you to install a backup memory.

Diagram no. PH-01

-15

Electrical connections as per operating and installation instructions

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Branch control valve plumber

9. Fault indicator lamp plumber

Important: follow wiring diagram!

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

400VAC

3

2

1

7

9

>55°C

AF

8

HP0

HKP0

5

M

HKP1

HK0

6

RG0

VF1

HK1

RG1

6

SLP0

5

M

HKP2

HK2

VF2

RG2

6

SF0

4

Page 38

HP0 mode = B-pump

38

off 50 kW boiler output

High-/ lower temperature construction with backup memory PSF

Diagram no. PH-02

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. Thermal store PSF as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA50 A H39-021

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Option: flange and heat exchanger as per price list

11. 2 Thermal store sensor S70-003

12. Option: Secondary return unit 045-250

2

3

1

400VAC

9

RLM

HP0RL

>55°C

8

7

AF

SF

M

5

M

5

HKP0 H KP1 HKP2

VF1 VF2

10

T2

11

12

230VAC

T3

HK0

RG0

6

RG2RG1

HK1

6

HK2

6

WW

4

KW

POWERCHIP

Page 39

HP0 mode = B-pump

39

off 50 kW boiler output

High-/ lower temperature construction with backup memory PS

Diagram no. PH-03

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA50 A H39-021

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Thermal store PS as per price list

11. 2 Thermal store sensor S70-003

1

3

2

400VAC

>55°C

RL HP0 RLM

8

9

7

AF

M

HKP0

5

HKP1

M

5

HKP2 SLP0

T2

11

HK0

VF1

HK1

RG0

6

RG1

6

VF2

HK2

RG2

6

SF0

4

T3

10

POWERCHIP

Page 40

TAD13 mode = Prog. 4 HP0 mode = B-pump

40

off 50 kW boiler output

High-/ lower temperature construction with backup memory PSF and inventory boiler.

Diagram no. PH-04

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system or.

Heating circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. Thermal store PSF as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA50 A H39-021

9. Fault indicator lamp plumber

10. Option: Secondary return unit 045-250

11. 2 Thermal store sensor S70-003

12. Flue gas monitor, RGT 80°C H00-801

13. difference scheme TAD 13 S35-101

14. Return boost set RA50 TA H39-022

KFR

PSF

B

e

s

t

a

n

d

s

k

e

s

s

e

l

> 55°C

14

A

RGT 80°C

12

230VAC

S1

TAD13

>55°C

13

3

400VAC

1

2

9

7

AF

RL HP08RLM

230VAC

VF2

M

HKP0

6

RG0

HK0

VF1

M

5

HKP1

5

HKP2

6

RG1

HK1

6

RG2

HK2

10

WW

S2

11

T2

S3

T3

POWERCHIP

TAD13

KW

SF

4

Page 41

HP0 mode = Z-pump

41

off 50 kW boiler output

- High-/ lower temperature construction with with trunk blink.

Attention: In some cases very low power consumption (<30%) such as at a very low energy or passive house, as well as

over-dimensioning, we recommend installing a buffer!

Diagram no. PH-05

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA50 A H39-021

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Flow equaliser plumber

11. District heating pipe plumber

400VAC

1

2

3

>55°C

9

7

AF

10

11

M

HKP0

5

HKP1

RLM

HP0RL

8

HK1HK0

VF1

RG0

6 6

RG1

M

5

HKP2 SLP0

SF0

HK2

VF2

6

RG2

4

Page 42

HP0 mode = B-pump

42

off 50 kW boiler output

High-/ lower temperature construction with backup memory with trunk blink.

Diagram no. PH-06

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA50 A H39-021

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Thermal store PS as per price list

11. District heating pipe plumber

12. 2 Thermal store sensor S70-003

RG0

HKP0

11

3

2

1

400VAC

6

8

RL HP0 RLM

AF

7

9

>55°C

T2

4

SF0

RG2

6

VF2

HK2

SLP0HKP2

5

M

RG1

6

VF1

HK0 HK1

HKP1

5

M

12

POWERCHIP

10

T3

Page 43

HP0 mode = Z-pump

43

off 50 kW boiler output

- High-/ lower temperature construction

Attention: In some cases very low power consumption (<30%) such as at a very low energy or passive house, as well as

over-dimensioning, we recommend you to install a buffer!

Diagram no. PH-07

-15

Electrical connections as per operating and installation instructions

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Branch control valve plumber

9. Fault indicator lamp plumber

Important: follow wiring diagram!

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1

2

3

>55°C

400VAC

9

HP0

8

M

5

M

5

HKP0 HKP1 HKP2 SLP0

VF1

HK0 HK1

VF2

HK2

SF0

4

7

AF

RG0

6 6

RG1

6

RG2

Page 44

HP0 mode = B-pump

44

off 50 kW boiler output

High-/ lower temperature construction with backup memory PSF

Diagram no. PH-08

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. Thermal store PSF as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA100 A H39-023

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Option: flange and heat exchanger as per price list

11. 2 Thermal store sensor S70-003

12. Option: Secondary return unit 045-250

3

1

2

RL

>55°C

8

RLM

HP0

M

7

400VAC

9

AF

5

M

5

M

T2

10

11

HKP0

HK0

HKP1 HKP2

VF1

HK1

VF2

HK2

6

RG0

6

RG1

6

RG2

230VAC

12

T3

SF

WW

4

KW

POWERCHIP

Page 45

HP0 mode = B-pump

45

off 50 kW boiler output

High-/ lower temperature construction with backup memory PS

Diagram no. PH-09

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA100 A H39-023

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Thermal store PS as per price list

11. 2 Thermal store sensor S70-003

2

3

1

400VAC

RL

>55°C

RLM8HP0

M

9

7

AF

HKP0

5

HKP1

M

SLP0

5

M

HKP2

HK0

VF1

HK1

6

RG0 RG1

6

VF2

HK2

SF0

RG2

6

T2

11

4

T3

10

POWERCHIP

Page 46

HP0 mode = Z-pump

46

off 50 kW boiler output

- High-/ lower temperature construction with trunk blink

Attention: In some cases very low power consumption (<30%) such as at a very low energy or passive house, as well as

over-dimensioning, we recommend you to install a buffer!

Diagram no. PH-11

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA100 A H39-023

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Flow equaliser plumber

11. District heating pipe plumber

11

RLM

RL HP0

8

3

2

>55°C

M

1

400VAC

10

M

5

M

5

HKP0 HKP1 HKP2 SLP0

SF0

9

7

AF

HK0 HK1 HK2

VF1 V F2

6

RG0

6

RG1

6

RG2

4

Page 47

HP0 mode = B-pump

47

from 50 kW

High-/ lower temperature construction with backup memory PS and trunk blink

Diagram no. PH-12

-15

Electrical connections as per operating and installation instructions

* Heating circuit 0 can be used with a fixed-setting controller for a low-temperature heating system orHeating

circuit 0 can be room-temperature controlled using an room stat for a radiator heating system.

1. Powerchip as per price list

2. Flue draught regulator RE as per price list

3. Outside temp. based controller set MKR S30-031

4. DHW cylinder ECO as per price list

5. Mixer valve positioner motor S50-501

6. Room stat as per price list

7. GSM module S15-002

8. Return boost set RA100 A H39-023

9. Fault indicator lamp plumber

Important: follow wiring diagram!

10. Thermal store PS as per price list

11. District heating pipe plumber

12. 2 Thermal store sensor S70-003

3

1

2

400VAC

>55°C

RL HP0

8

M

RLM

11

7

9

AF

HKP0

M

5

HKP1

5

M

HKP2 SLP0

HK0

RG0

6

HK1

VF1

6

RG1

VF2

HK2

6

RG2

SF0

T2

12

4

10

T3

POWERCHIP

Page 48

48

DIESES DOKUMENT QURDE VON STEFFEN MÜN ZENBE RG ERSTELL T:

Objekt supply for maximal 3 buildings

trunkblink functions ZUP, LAP oder PUP

Site 1 / Diagram no. PH-13

-15

Electrical connections as per operating and installation instructions

• Line connector 400 VAC / 13 A;

• per System just one Sensor;

(if possible on the boiler)

• per System 3 Wall mounted Set-MK261 possible;

• per System 3 digital Remotestationens possible;

• per Heatingcircle one analouge Remot unit

possible.

Heatingrooms opportunitys

1. Firing Powerchip as Pricelist

2. Flue draught regulator RE with Ex-Clap as Pricelist

3. Regulation wall mounted unit Set-MK261 S30-030

4. W armwater memory ECO as Pricelist

5. Mixer Stellmotor S50-501

6. Remote / Remotestation as Pricelist

7. Backupmemory PS / PSF / 2PS as Pricelist

8. Reverse raising group as Pricelist

9. circulation unity 045-250

10. Backup memory sensor S70-003

11. Flange or recuperator as Pricelist

12. GSM-Modul S15-002

13. Hydraulic switch by client

14. Fernleitung und Fernleitungspumpen by client

15. Pipesystem, by client

16. Alertlamp (look at the circuit diagram) by client

7

HP0 / 2PS

>55°C

1

2

AF

M

RLMRL HP0

8

12

16

10

T2

T3

T5

T6

T7

15

ZUP / LAP

ZUP / LAP

ZUP / LAP

CAN−Bus

HP0 mode = B-pump

15

>55°C

2

1

8

HP0RL RLM

M

ZUP / PUP

ZUP / PUP

ZUP / PUP

AF

12

16

13

CAN−Bus

HP0 mode = Z-pump

Site 2 / Diagram no.

PH-13

-15

Page 49

49

Site 2 / Diagram no. PH-13

-15

Connected size

SLP0

FL

HKP−xHKP−x

M

5

VF−x

HKP−x

M

5

VF−x

14

HK−x HK−x HK−x

LAP

PUP

M M

AF

AF

FL

CAN−Bus

3

3

CAN−Bus

FL

13

666

HKR-x

HKR-x

RG−x

230VAC

RG−x

M

5

RG−x

M

5

HKP−x

HK−x

HKP−x

VF−x

HK−x

6

RG−x

230VAC

6

RG−x

HKP−x

HK−x

VF−x

6

RG−x

14

14

16

16

ZUP

LAP

PUP

CAN−Bus

HKR-x

6

RG−x

230VAC

HKP−x

HK−xHK−x

VF−x

HKP−x

HK−x

HKP−x

VF−x

SLP−x

6

RG−x

6

RG−x

3AF16

5 5

SF0

T2

T3

PS

7

10

4

HKR

11

T2

10

9

WW

KW

7

Netz 230 V

T3

SF

HKR

PSF

4

SF−x

Page 50

HP0 mode = B-pump

50

cascade circuit for 2 Firings

Diagram no. PH-14

-15

Electrical connections as per operating and installation instructions

• Line connector per construction 400 VAC / 13 A;

• connect the system linear with CAN BUS

(lead the wirring without )

• per System 3 mounted system Set-MK261 possible;

• per System 3 digital mounted system possible;

• per Heatingcircle a analouges wall mounted unity possible;

(Exceptions on 5 Feeler buffermanagement)

• at cascades <150 kW could 3“ T-Pipes and the 3“ Bufferconnection dispensed (2“);

1. Firing Powerchip as Pricelist

2. Flue draught regulator RE with Ex-Clap as Pricelist

3. GSM-Modul S15-002

4. recirculationincreasinggroup as Pricelist

5. Buffermemory PS as Pricelist

6. Outdoorsensor S70-001

required on every System without atmosperic Conditions, with additional

above the turned of fOFF Temperature;

7. Buffermemory sensorm S70-003

Advice: alertlamp 5 Sensors per System - minimum 2 per System required

8. Alertlamp (circuit diagram beachten) by client

HP0

6

2"

2" 2"

3"

3"

4

2

11

2

3

AFAF

CAN−Bus

A

RL

>55°C>55°C

RLMRL HP0

M

B

7

55

T5

T3

T3

3"

3"

3"

3"

2"

3"

3"

4

M

RLM

HP0 / 2PS HP0 / 2PS