Page 1

Wood logs for 1/2 m split logs englisch

BMK

Planing und Installation

BMK-02

EN-B31-004-V09-1215

Page 2

Information on this documentation

Please read through this documentation carefully.

It is intended as a reference document and contains important

information on the design, safety, operation, maintenance and

care of your heating system.

We are always looking to improve our products and

documentation. Any ideas and suggestions you may have will be

gratefully received.

GUNTAMATIC Heiztechnik GmbH

Bruck 7

A-4722 PEUERBACH

BS-01

Tel: 0043 (0) 7276 / 2441-0

Fax: 0043 (0) 7276 / 3031

Email: office@guntamatic.com

It is important that you pay particular attention to

the safety issues highlighted in the text by these

symbols.

The entire contents of this document are the property of

GUNTAMATIC and therefore protected by copyright.

Reproduction of any kind, communication to third parties by any

means or use for purposes other than those intended without

the written consent of the owner is prohibited.

2

Subject to printing errors and technical amendments.

Page 3

CONTENTS

BMK-02

Page

1 Introduction ............................................................................4

1.1 Safety instructions 4

1.2 Gurantee and warranty 4

1.3 Commissioning 4

1.4 Site requirements 4

2 PLANING .................................................................................5

2.1 Fire safety 5

2.2 Minimum fire safety requirements 6

2.3 Heatingroom 7

2.4 Flue requirements 9

2.5 Flue draught regulator and pressure surge compensator 10

2.6 Heatingcirculation rule 11

3 CONSTRUCTION ..................................................................13

3.1 Delivery 13

3.2 Carrying to installation site 13

3.3 Locate and angle the boiler 14

3.4 Plumbing connections 15

3.5 Filling and blending the System 17

3.6 Connecting the Flue 18

4 ELECTRICAL CONNECTIONS .............................................19

4.1 Connections on the Constructions 21

5 FINAL CHECKS.....................................................................22

6 STANDARDS / REGULATIOS ..............................................23

7 CONNECTING DIAGRAMS...................................................25

8 TECHNICHIAL DATA............................................................31

3

Page 4

1 Introduction

1.1 Safety instructions

BMK-01-PI-01

1.2 Guarantee and warranty

GUNTAMATIC heating systems represent state-of-the-art

technology and meet all applicable safety regulations. Incorrect

installation can endanger life and limb. Heating boilers are

combustion systems and are potentially dangerous if handled

incorrectly. Installation, commissioning and servicing must,

therefore, only be carried out by adequately qualified

technicians observing all regulations and the manufacturer's

instructions.

The manufacturer's guarantee is subject to correct installation

and commissioning of the heating system. Defects and

damage caused by incorrect installation, commissioning or

operation are not covered by the guarantee. To ensure that the

system functions as intended, the manufacturer's instructions

must be followed. Furthermore, only genuine replacement

parts or parts explicitly approved by the manufacturer may be

fitted to the system.

1.3 Commissioning

1.4 Site requirements

Commissioning of the boiler must be carried out by an

authorised GUNTAMATIC specialist or other qualified persons.

They will check whether the system has been installed

according to the plans, adjust the system settings as required

and explain to the system operator how to use the heating

system.

When establishing the site requirements, it is absolutely

essential to take account of the locally applicable planning,

building and implementation regulations and the dimensional

specifications in the fitting guidelines, installation examples and

technical data. Compliance with the locally applicable

regulations and the correct implementation of the measures

required on site are solely the responsibility of the system

owner and are a requirement of the manufacturer's guarantee.

GUNTAMATIC provides no guarantee of any kind for any type

of site work.

4

Page 5

2 Planning

2.1 Fire safety

01

BS-01

The fire security introductions are obligatory needed on

the construction place

The Compliance from counties ore states fire security

law is obligatory and stands higher then the

GUNTAMATIC fire security instruction

Austria State legislation of the federal states

Technical Directive on Preventative Fire Safety (pr TRVB H118)

Germany Standard boiler regulations (M-FeuVO)

Hessen and Saarland – in these states §16 FeuVO Hessen applies

Switzerland Fire safety regulations

any other exporting countries Any fire safety office

You have to follow you specific country fire safety

rules obligatory. Your country safety rules are higher

then our GUNTAMATIC minimum rules.

If there are no specific fire security rules in your

country, you have to follow the GUNTAMATIC

introductions

(www.vkf.ch)

5

Page 6

2.2 Minimum fire safety requirements

Boiler room Floor of concrete construction, either bare or tiled. All materials

for floor, walls and ceiling must be fire-resistant to F60 rating.

The boiler room door must be a Class T30 fire door which

opens in the direction of escape and is self-closing. Connecting

doors to the fuel storeroom must also be Class T30 fire doors,

self-closing and lockable. There must be no direct connection

to rooms in which flammable gases or liquids are stored

garage).

(e.g.

01

6

Page 7

2.3 HEATING ROOM

BMK-02

Minimum Roomheight

Minimum Room tallnes

BMK with Ignition

BMK without Ignition

Minimum Access opening

ideal

H 220 cm

possible at BMK 20-30

possible ati BMK 40-50

ideal

B 200 cm x T 240 cm

left 50 cm / right 50 cm / below 45 cm / above 100 cm

possible

possible

Ideal

possible

possible

B 147 cm x T 209 cm

left 20 cm / right 30 cm / below 45 cm / above 70 cm

B 147 cm x T 199 cm

left 20 cm / right 30 cm / below 35 cm / above 70 cm

T = seeing from the boiler´s rear

B 100 cm x H 160 / 180 cm

Openining lift truck on the transport wood

(Boiler completely constructed / above Transportwood shortened)

B 85 cm x H 150 / 170 cm

Openining lift truck on the transport wood

(Boiler completely constructed / above Transportwood shortened)

B 80 cm x H 80 cm

Openining lift truck on the transport wood

(Boiler completely constructed / above Transportwood shortened)

H 145 cm

H 185 cm

BMK 20-30 / 40-50

Combustion air supply The pressure in the boiler room must not be less than 3 Pa

(0.3 mm H2O). The air vents for boiler rooms must have a

clear, net cross-sectional area of at least 400 cm² and must not

be sealable. The air supply ducting must connect directly to the

outside and if the ducting passes through other rooms, it must

be jacketed to Class F90. On the outside of the building, air

vents must be covered by a protective grille with a mesh size

of > 5 mm. The supply of combustion air should, if possible,

enter at floor level in order to prevent cooling of the boiler

room.

Electrical installation The lighting and the electrical wiring in the boiler room must be

permanently installed.

An Net connector 230 VAC, 50 Hz, 13 A is needed.

Fire extinguisher A hand-held fire extinguisher (6kg gross weight, EN3) must be

mounted outside the boiler room near the boiler-room door.

Protection against freezing The boiler room, pipes carrying water and any district heating

pipes must be protected against freezing.

7

Page 8

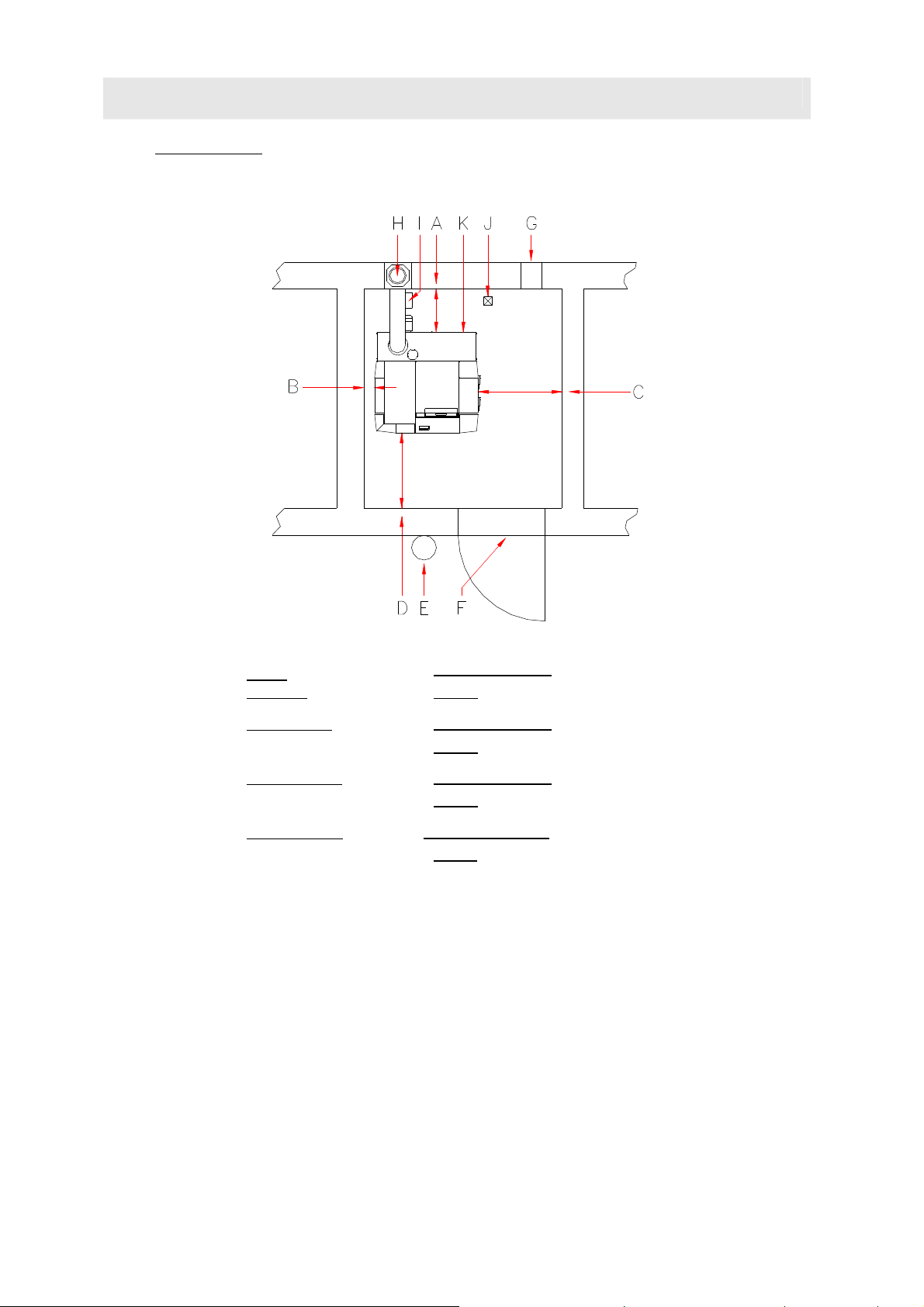

Installation side You have to plan the furnace in the near of the chimney to avoid a long

flue pipe. The heating has to be accesable from the left and the right site.

The Outreach of burningroom and ashdoor must be kept free.

A →

B →

C →

D →

E →

F →

G →

H →

I →

below

Distance

left Distance

right Distance

front Distance

Fire extingiusher

Fire safety door

ideal

possible

ideal

possible

ideal

possible

ideal

possible

6 kg Filler´s weightt EN3

T30 unlockable and self acted closed

Combustion air supply

Flue

wet imun Chamotte-flue advised

45 cm minimum

35 cm

when the BMK is without Ignition

50 cm minimum

20 cm

necaserry Distance for opening of the left door

50 cm minimum

30 cm

necaserry Distance for Serviccing of Servermotor

100 cm minimum

70 cm

Einbauvariante Energiesparzugregler mit Ex-Klappe im Kamin

ca. 50 cm under the flieconnector- please attend the local laws.

Einbauvariante Energiesparzugregler mit Ex-Klappe im Rauchrohr

möglichst nahe am Kaminanschluss – die örtlichen Vorschriften beachten – mögliche Staubbildung

J →

Drain

8

K →

Netconnector 230VAC 13A

Page 9

2.4 Flue requirements

Flue height The minimum flue height is 5 - 10 m depending on boiler

01

Use heat-insulated fireclay flues that are

insensitive to damp.

GUNTAMATIC accepts no liability where

stainless steel flues are used.

The system must only be connected to the flue if the flue

meets the legal requirements and the technical specifications.

The flue must be matched to the boiler output and

dimensioned in accordance with DIN 4705. In order to be able

to accurately dimension the flue, the calculations must be

based on the flue gas figures. When designing new flues, high

thermal insulation chimneys (DIN 18160 T1 heat transmission

resistance group I) or suitable fireclay flues that are

insusceptible to damp and have general building regulation

approval should be used. It is advisable to involve those

responsible for approving the flue system early on in the

planning phase.

output. The flue must terminate at least 0.5 m above the

highest part of the building. In the case of flat rooves, the flue

must terminate at least 1.5 m above the surface of the roof.

Flue diameter The flue must be matched to the boiler output. The following

details are guide figures and can be used for planning

purposes. However, we recommend that the flue dimensions

are calculated precisely by an expert.

BMK 20/30/40/50

eff. flue height over 6 m D = 180 mm

eff. flue height under 6 m D = 200 mm

Flue dimensioning data Dimension the flue for rated output!

(Averaged figures with used heat exchanger)

Rated output:

Type Flue gas temp. CO2 Mass flow rate

BMK 20-30

BMK 40-50

200 - 220°C 13 – 14 % 0,020 kg/s 15-20 Pa

200 – 230°C 13 – 14 % 0,034 kg/s 15-20 Pa

Sub-maximum output:

Type Flue gas temp. CO2 Mass flow rate

BMK 20-30

BMK 40-50

170 – 200°C 10 – 12 % 0,011 kg/s 2 Pascal

170 – 200°C 10 – 12 % 0,013 kg/s 2 Pascal

Required

draught

Required

draught

9

Page 10

2.5 Flue draught regulator and pressure-surge compensator

Fitting an energy-saving flue draught

regulator/pressure-surge compensator

The flue draught should not differ by more than +/- 3 pascals

from the figure specified in the flue dimensioning data. If the

flue draught cannot be reduced to the required figure, either a

larger draught regulator should be fitted or an additional flue

baffle fitted between the flue and the draught regulator.

Purpose

• To ventilate the flue when the system is not in operation

• To compensate for pressure surges

• To regulate and limit the flue draught

Fitting requirement The energy-saving flue draught regulator must be fitted in

accordance with the local regulations, preferably in the flue

approx. 0.5 m below the point where the flue connecting pipe

joins or alternatively in the flue connecting pipe close to its

junction with the flue.

(Class RE) is absolutely imperative.

(if possible 200 mm)

BS-01

Flue draught setting

• Adjusting the flue draught is only of any use at

outside temperatures below +5°C.

•

The system must have been in operation for at least an hour

• Ensure there is sufficient demand for heat for the boiler to

be run at rated output for at least 15 minutes

• Measure the flue draught between the boiler and the flue

draught regulator (distance of measuring point from boiler

ideally 3 x flue diameter from connection between boiler

and flue connecting pipe).

Too much flue draught

May cause the flue gas temperature to increase

and accelerate combustion as a result. Poor

boiler output adjustability, increased dust

discharge and malfunctions can result.

Too little flue draught

Performance problems, incomplete combustion

and malfunctions when operating below rated

output can result.

10

Page 11

2.6 HEATINGCIRCULATION RULE

The heating circle rule is optional offered.

You can decide between a MKR set or a wall mounted MK 261

set.

●

per construction 3 controlled by atmospheric condition rules

possible

●

per construction could be actived just 1 MKR Set boiler

●

pro Machine there are 3 remote control possible;

●

possible

without Heatingcirculation rule

Following functions could be activated:

Heatingcircle WW .......................

Heatingcircle 0............................

Heatingcircle 1............................

BMK-01

per heatingcirculation one analogue room unit

● Warmwater- Memory

● Pumping heatingcirculation

● Pumping heatingcirculation

Set-MKR

wall mounted Set-MK261

Heatingcircle 2............................

● Pumpe heatingcirculation

Following functions could be activated:

Heatingcircle

Heatingcirle 0

Heatingcircle 1

Heatingcircle 2

optional avalible

optional avalible

optional avalible

● Warmwater-Memory

........

● pump heating circulation

● aditional warmwater memory

● external heatingcirculation

.......

● Pump heatingcirculation

● mixed heatingcirculation

.......

● Pump heatingcirculation

● mixed heatingcirculation

Following functions could be activated:

Heatingcirculations WW ..............

Heatingcirculation 0.....................

Heatingcirculation 1

Heatingcirculation 2

wahlweise als..● Pumping heatingcirculation

wahlweise als..● Pump heatingcirculation

● Warmwater-Memory

● Pumping heatingcirculation

● mixed heatingcirculation

● mixed heatingcirculation

11

Page 12

NOTES

Sketch:

12

Page 13

C

3 CONSTRUCTION

01

3.1 Delivery

BMK-01

The boiler system is delivered packed in a wooden crate

wrapped in foil. Please check that the delivery is complete

according to the delivery note and in perfect condition.

Deficiencies Please make a note of the deficiencies identified directly on the

delivery note and contact the supplier, heating installer or our

Customer Service.

3.2 CARRYING TO INSTALLATION SITE

The system is delivered on a wooden pallet and can be lifted

and carried to the installation site using a pallet truck.

Carrying in dismantled The boiler body can be dismantled into parts for carrying in. If

that is done, a person authorised by GUNTAMATIC must be

consulted.

BMK-01

B

D

B

A

B

B

To be able to undo the heat exchanger unions, all of the

insulation must be removed from the boiler. Take care not to

damage the gaskets (B) when lifting off the heat exchanger.

Important: damaged gaskets must always be replaced

without exception.

Pull in carrying straps and position lower section (A) in boiler

room; place gasket strips (B) precisely in position all the way

round; place gasket cord (C) precisely in position on upper

section

Contribute the upper part (D) of the boiler with harrnes or 1

pipes in the heatingroom and put it carefully to the boiler´s

lower part.

ATTENTION: The Sealing strip (B) and the rope seal (C)

might not slipped away!

ATTENTION: The warmwaterexchanger with shirp and srew

it with maximal 30 Nm torque.

13

Page 14

3.3 LOCATE AND ANGLE THE BOILER

Keep to the minimum wall clearances specified by the system

planner and manufacturer. If important details are missing,

please refer to the planning documentation or ask our

Technical Support. Position the system as close as possible to

the flue to avoid having a long flue connecting pipe. The

system must be accessible from the left or right side.

Clearance at rear

Clearance on left

Clearance on right

Clearance at front

Floor clearance

ideal

BMK with Ignition

possible

ideal

possible

ideal

possible

ideal

possible

ideal

possible

45 cm minimum

35 cm

50 cm minimum

20 cm

50 cm minimum

30 cm

100 cm minimum

70 cm

2,5 cm minimum

8 cm

BMK-01

BMK without Ignition

Freespace fort he left cover panel´s door

Freespace for Servermotor Servicing

attend with screwfeed

Set the boiler at a slant Unscrew the rear adjustable feet slightly further so that the

boiler is slightly higher at the rear. That will allow the air inside

the boiler to escape easily when the system is filled.

14

Page 15

3.4 Plumbing connections

A → Flow 5/4“

B → Security warm

heatexchanger 3/4“

C → Emtying 1/2"

D → Backrun 5/4

E → therm. drainvalve 3/4"

residual operation

temperaturer 95°C

F → Cold water supply

G → Security valve 1/2"

Inlet DN15

Outlet DN20

Security warmexchanger A temperature-relief valve to ÖNORM B 8131 and DIN 4751

BMK-03

with an opening temperature of 95°C must be provided on site

and connected to the temperature-relief heat exchanger. The

supply pressure must be at least 2 bar but no more than 6 bar.

The temperature-relief valve must be connected to the cold

water mains supply by a connection that cannot be turned off.

The outlet of the discharge pipe must be routed and installed in

such a way that functional capacity cannot be impaired and no

danger can arise when the temperature-relief valve responds.

The instructions for the temperature-relief valve must be

followed.

Security valve A security valve ½ for heatingcontens after EN 128 28 with

opening pressure has to be installed. The Finish of the

sequence pipe has to be so misplaced, that there is no

impairment of Functionality and there is no Danger. The

instruction for security valves are attented.

buffer memory Installation of an adequately dimensioned thermal store is

absolutely imperative. No guarantee liability is accepted for

systems with a thermal store capacity under 1,000 litres

(= 1,000 litres excluding DHW capacity in the case off combination cylinders).

• Min. thermal store capacity 1,000 litres

• Recommended thermal store capacity Over 1,400 litres

• Ideal thermal store capacity 2,000 – 3,000 litres

Make sure any regulations regarding thermal store size are

observed.

In system with a pure thermal store capacity under 1,400

litres (= 1,400 litres excluding DHW capacity in the case of

combination cylinders) the boiler must be fuelled according to

required output, i.e. it should only be loaded with as much

wood as can be coped with by the system and the thermal

store in the hours that follow.

15

Page 16

When you put the programme „OUT“, the antifreeze function

has to be secured, if the E heating system is built with an

manual thermostat..

Return boost The boiler return temperature must be at least 55°C and must

be held at the required level by a return boost set. Returntemperature regulators in the bypass are not allowed. If this

requirement is not complied with, there is an increased risk of

corrosion and guarantee entitlement will be lost as a result.

If aditional components, such as e.g heat equality counter

integrated into the system hydraulics, ort he total buffer line

length over 30 m (flow and return) can make reinterpreting

boiler/ charge pump (KLP) necaserry.

When using foreign return boost which is not correspond to

these in the flow or control speed of GUNTAMATIC, any

warranty is rejected.

Sludge separator with magnetite Magnetite and the sludge separator in the Heatngwater could

become a problem for energysaver pumps. By installin a

prperly sized and applied sludge sperator with a magnet can

remided cost effenciently.

Either old pipes could be meant

Expansion vessel The boiler operates in a sealed heating system and must be

provided with an expansion vessel for pressure compensation.

To calculate the expansion volume, the volume of the system

when cold must be known. Please select the expansion vessel

on the basis of the manufacturer's specifications. The

expansion volume of the system is calculated as follows:

System volume x Expansion factor x Additional allowance factor

• Expansion factor for wood-fuel boilers = 0.03

• Additional allowance factor = 3.0 for systems under 30 kW

• Additional allowance factor = 2.0 for 30-150 kW systems

Example calculation: 2200 litres x 0,03 x 3 = ~ 200 litres

Pump selection The choice of pump must be made by the installer or building

technology planner on the basis of the friction data, the pipe

cross-sectional area and the required delivery pressure for the

piping system planned.

Plastics pipeline At connection for plastic pipelines for floorheating or district

heating pipeline these temperatures are aditional protected for

a limit thermostat.

Danger of overheating Faulty operation, wrong fuil or disturbance could be lead to

overheating. To avoid disturbance you have to install additional

fuse protections for maximum process water and fuses for

heatingcircle temperatures. You have to install an aditional

16

door for the tap water.

Page 17

3.5 Filling and blending the system

Water quality The water quality of hot water systems with flow temperatures

of max. 100°C is subject to VDI 2035. According to VDI 2035

Part 1, "Avoiding damage to hot water systems", which comply

with EN12828, the first-fill and replenishment water, must be

conditioned (preferably softened) if the following overall

hardness limits [°dH] according to total heat output (kW) are

exceeded:

• < 50kW: with circulating flow heaters, if °dH > 16.8

• 50 to 200 kW: if °dH > 11.2

• 200 to 500 kW: if °dH > 8.4

• > 500kW: if °dH > 0.11

Water heater If a water heater is also used in addition to the GUNTAMATIC

boiler, it should be filled according to the installation

instructions for it.

BS-01

Please attend the guideline for

corrision and boiler´s protection in

heating and service water system!

Flush the Construction

Filling the system

Bleeding the system

• Before filling of the construction flush the whole

pipesystem, to eliminate rust mud and magnetite

• Match the pressure of the system when cold to the air

charge pressure of the expansion vessel

• Check the operating pressure on the pressure gauge

• Switch off and bleed circulation pumps.

• Bleed boiler by opening the bleed valve on the boiler and

allowing air to escape until water runs out.

• Bleed radiator heating system (if present) by opening the

bleed valve on every radiator and allowing air to escape

until water runs out.

• Bleed underfloor heating system (if present) by opening

each heating circuit and flushing through thoroughly until

there are no more air bubbles in the heating circuit pipes.

• Important: perform sequence in the correct order!

Start bleeding in the cellar or on the ground floor and finish

in the attic.

• Check the system operating pressure on the pressure

gauge and add more water if necessary.

• Restart circulation pumps.

Only systems that have been properly

bled guarantee effective conveyance of

heat.

17

Page 18

3.6 Connecting the flue

Flue connecting pipe

BMK-01

The boiler is connected to the flue by means of a flue

connecting pipe which must be gas-tight and insulated

between the heating boiler and the chimney.

→ The following diameters should be used:

BMK 20/30/40/50 Ø = 150 mm

→ Flue connecting pipes longer than 4 m or

with more than 3 bends:

BMK 20/30/40/50 Ø = 180 mm

The hole in the wall for connecting the flue pipe must be lined

with a built-in double-skinned lining tube or fireproof material.

The flue connecting pipe must rise upwards from the boiler to

the flue at an angle of at least 6° and be connected with gastight joints. An inspection cover must be provided for cleaning

the flue connecting pipe.

A → Smokepipe

B → Isolation

(minimum 6° grade)

(z.B. Rockwool)

C → Flue draft regulator with Ex-Clape in the

Flue

(you have to prefer this method)

D → Flue draft regulator with Ex-Klap in the

Smokepipe

(If possible in the near of the flue connector)

• The flue connecting pipe must be gas-tight

• An energy-saving flue draught regulator with pressure-

• Insulate the flue connecting pipe

• Do not brick in the flue connecting pipe

surge compensator

(Class RE)

must be fitted

(noise transmission)

• The flue connecting pipe must not extend into the

flue

18

Page 19

4 ELECTRICAL CONNECTIONS

The electrical connections to the boiler system on site may

only be made by an approved electrical installer observing all

the applicable regulations. In addition, it is essential that

electrical system components are protected against damage

from heat radiation.

All boiler system internal wiring is wired up at the factory ready

for use. The work required on site by the electrical installer

consists only of connecting the mains power and wiring up and

connecting the system components such as thermal store,

CAN bus, heating circuit pumps, mixer valve motors, etc.

BMK-01

open the control panel

• solve the security screw (A);

• cap the control panel (B);

• the circuit board with connecting plugs and securitys is

under in a good accesible position.

Net connector 230 VAC, 50 Hz, 13 A

(over voltage conductor advised)

The mains power must be connected by means of the standard

non-reversible power socket on the rear panel of the boiler. It

must possible to isolate the system entirely from the mains

without opening the switch panel cover, e.g. by means of an

automatic circuit-breaker

Attend on the correct phase Net connection!

Please attend on in that Phase (L) and zero

Signal (N) can´t be changed, becauseo of

the bypassfunction and the securitychain

couldn´t be warranted.

19

Page 20

Cabeling

• Feeder 3 x 1,5 mm²

• Sensor 2 x 1 mm²

• Roomconstruction 2 x 1 mm²

• CAN-Bus 2 x 2 x 0,5 mm²

(paired cable / screened)

Overvoltage protection Where CAN bus cables run between different buildings, the

earthing conductors of the buildings must be connected to

each other for potential equalisation purposes. If the earthing

conductors cannot be interconnected, a 10 mm ring earth must

be laid along with the CAN bus cable in the ground. The

earthing conductors and ring earth must then be connected to

one another.

CAN-Bus cabeling

wirring linear:

(you have to prefer this variation)

The connection is rewire linear, further cabling the CAN bus,

for example, from the operating unit to the wall unit and the

wall-mounted unit to the remote unity.

wirring radial:

The connection is radial wiring, means the CAN bus, for

example, from the operating unit to the wall unit and the space

station. The total length of the CAN bus connection must not

exceed 100 m in this case.

The terminals +/- and H / L connect each twisted pair.

Potencial equalizer splint The whole construction and the conneced pipesystem has to

be connected as prescribed on the potencial equalize splint

system.

Attend on the connection on the potencial

equalizer splint on a short connection.

Cable stain relieved To avoid electrical defects or errors all cables have to be stain

relieved.

Emergency power supply Only use regulated generators.

20

Page 21

4.1 Connections on the Constructions

Net connecting

Standard specifications

• 230 VAC, 50 Hz, 13 A

• Boiler control panel

• Boiler circuit board

• Safety temperature limiter

• Boiler sensor

• Flue gas temperature sensor

• Oxygen sensor

• Flue draught fan

• TKS 1

• Primary/secondary air vent motor

• Ignition fan

• Boiler charging pump output KLP

• Special output HP0

• Backrunmixer

• 1 Memoryloadingpumpexit

• 3 Heatingpumpexit

(right casing door switch, 24V DC)

(BCE)

(230 VAC)

(STB)

(KVT 20 Ω)

(12 VDC)

(230V AC – optional)

(230 VAC)

(230 VAC)

(230 VAC)

(230 VAC – just time controlled)

(thermocouple)

(24 VDC)

(230 VAC)

(230 VAC)

BMK-09

Optional equipment

• Pump outputs

• Mixer valve outputs

• Sensor´s entrance

• Analouge Roomconstruction

• Digital Roomstations

(230 VAC)

(KVT 20 Ω)

(230 VAC)

Resistances

Temperature KVT20

-20°C 1383 Ω

-16°C 1434 Ω

-8°C 1537 Ω

-4°C 1590 Ω

0°C 1644 Ω

10°C 1783 Ω

20°C 1928 Ω

30°C 2078 Ω

40°C 2234 Ω

50°C 2395 Ω

60°C 2563 Ω

70°C 2735 Ω

80°C 2914 Ω

21

Page 22

5 Final checks

Final checks

Initial commissioning Commissioning must only be carried out by GUNTAMATIC or

BS-05-PI-01

• After completing installation of the system, check again

that all joints and pipes are properly tightened and not

leaking.

• Check that all covers are fitted and secured.

• Check that the fitting of all connections (water, flue,

electrical) has been done correctly.

• Check that all required safety signs and instructions are

attached and hand over all documentation (operating and

installation instructions) for the system.

• Check that all electrical connections have been properly

wired before connecting the system to the power supply.

• Clean the system and clear up the installation site.

• Always leave the boiler room clean.

a qualified specialist. The precondition is that the flue

technician, heating installer and electrician have cleared the

system for operation. The authorised GUNTAMATIC specialist

will carry out the following work during commissioning:

• Check the entire system

• Check the electrical functions

• Adjust the programmer to the system

• Commission the system

• Explain to the user how the system functions and how to

operate and clean it

• Record the details of the customer and the system and

complete the commissioning log

Any deficiencies identified must be recorded in

writing and rectified within the following 4 weeks

in order to maintain guarantee entitlement.

The fully completed commissioning checklist

must be sent to GUNTAMATIC immediately as

otherwise the guarantee will be void.

These installation instructions should not be

destroyed after commissioning but kept

permanently with the system together with the

operating instructions.

22

Page 23

6 Standards / Regulations

BS-01

The heater equates Class 3/ EN 303-5. The original certification report is deposited at the

manufacture, Public Police and Fire safety rules have to be respected.

• ÖNORM / DIN EN 303-5

Heaters for pillar fuel, automatic and manual sanded up to 300 KW. Terms, requirements,

and checkups.

• ÖNORM / DIN EN 12828

heaters for pillar fuel, automatic and manual sanded up to 300 kw, terms, requirements,

checkups and marking

• ÖNORM / DIN EN 12831

Heating for Buildings; method for calculating usual heating board

• ÖNORM M 7137

Requirements on the Pelletstorage at the private customer.

• ÖNORM M 7510

Guideline for the review from central heaters

• ÖNORM H 5195-1

(Austria)

Prevention from damage through nest and Store origin with working temperature.

• VDI 2035

(Germany)

Avoidance from damages in Water heating systems

• SWKI 97-1

(Suisse)

Chalk and Rust Prevention in Waterheaters

• TRVB H 118

(in Austria for automatic sended Machines)

technical heating fire safety rule

• DIN 1988

Technical Rules for drinking water installation

• DIN 4751 Teil 1-4

Safety engineering equipment for water heaters

• Swiss decrees for aircleening

• Swiss decrees with smallfiremachines

• VKF Fire security thermaltechnical construction

• SIA 384

(Swiss)

(Suisse)

23

Page 24

NOTES

Sketch:

24

Page 25

Heatingcirculations time controlled – without atmospheric controlled rule

Warmwatermemory ECO – Buffermemory PS

Diagram no : BMK-01

-14

Electrical connections as per operating and installation instructions

HK0

HK1

HK2

1. Firing BMK as pricelist

2. flue draft regulator with Ex-Clap RE20 H38-160

3. Return boost group RA50 A H39-021

4. Warmwatermemoryr ECO as price list

5. buffermemory PS as price list

BMK

5

T3

230VAC

HP0 HP1

>55°C

1

2

M

RLMKLPRL

3

HP2 SLP0

SF0

4

T5

T2

25

Page 26

Heatingcirculation time controlled – with atmospheric condition loaded rule

Warmwatermemory ECO – 2 buffermemory PS

Diagramme Nr.: BMK-02

-14

Electrical connections as per operating and installation instructions

* The heating circulation could be operated roomtemperature controlled...

RG2RG1RG0

6

AF

HK0

9

HK1

VF1 VF2

HK2

1. Firing as Price list

2. Flue draft regulator with Ex-Klappe RE20 H38-160

3. Rule Set-MKR S30-031

4. Return boost group RA50 A H39-021

5. Mixer Servermotor S50-501

6. Roomconstruction / Roomstation as Price list

7. Warmwasserspeicher ECO as Price list

8. buffermemory PS as Price list

9. GSM-Module S15-002

BMK

8

T3

8

T5

230VAC

HKP0 HKP1

>55°C

1

2

3

M

RL

RLMKLP

4

M

HKP2 SLP0

5

M

7

T2

26

Page 27

Heatingcirculation time contolled – with atmospheric controlled rules

1 Pufferspeicher PSF incl. Freshwaterstation – 1 buffer memory PS - Solarconstruction

Diagramme No.: BMK-03

-14

Electrical connections as per operating and installation instructions

* The heating circulation could be operated roomtemperature controlled..

RG0 RG1 RG2

AF

HK0

11

HK1 HK2

VF1

6

VF2

WW

230VAC

KW

1. Firing BMK as pricelist

2. Flue draught regulator mit Ex-Klappe RE20 H38-160

3. Rule Set-MKR S30-031

4. Return boost group RA50 A H39-021

5. Mixer servemotor S50-501

6. Roomconstruction / Roomstation as pricelist

7. buffermemory PSF inkl. FWS as pricelist

8. Option Cirkulationsunit 045-250

9. buffermemory PS as pricelist

10. Option Flange and warmheatexchanger as pricelist

11. GSM-Module S15-002

BMK

7

T3

9

T5

230VAC

HKP0 HKP1

>55°C

1

2

3

M

RLMRL KLP

4

HKP2

5

M M

8

10

T2

27

Page 28

Combination with existing oil/ gas boiler

ATTENTION: non qualified for gas thermics!

- controlled by atmospheric conditions heatingcirculationrule in the existing boiler

Scheme No.: BMK-05

-15

Electrical connections as per operating and installation instructions

INFO: 1) The oil and gas boiler will be through the function ZP always kept on temperature – please attend on good isolation of the

FUNCTION:

boiler.

2) The radiation loose on the oil/ gas boiler has to be respected.

3) A smokegasthermostat in the flue is just necaserry, when both boiler are conducted in the same flue.

About the difference control T3 - T5 of BMK system pump is driven (ZP), thus supplying the oil / gas boiler with heat.

The oil / gas boiler starts only when enough energy from the buffer memory in the oil / gas boiler is supplied.

AF

5

T3

HK0

1. Firing BMK as pricelist

2. Flue draft regulator with Ex-Clap RE20 H38-160

3. Oil / Gasboiler by client

4. Return boost group RA50 A H39-021

5. buffermemory PS as pricelist

6. smokegasthermostat H00-801

HK2HK1

e

s

T5

Bestandskessel

a

h

p

r

e

n

n

e

r

B

3

M M

RGT > 88°C6

1

2

230VAC

>55°C

RL KLP

RLM

M

4

T2

HP0

Attiude HP0 = ZP 28

Page 29

Combination with blocking of an Oil/ Gasconstruction

ATTENTION 1) qualificated for oil or gasboiler and gas thermics

2) for gasthermics there is an hydraulic seperation advicable

by armospheric conditions heatingcirculation with BMK

Diagramme No.: BMK-16-8

Electrical connections as per operating and installation instructions

-14

INFO: 1) By gasthermic in the Parameter „HP0“ the parameter has to be attituded to „burn cont.“ to 2- 3 minutes.

2) all securityconstructions on the oil/ gasconstruction have to run correctly.

3) Switch USV to oil/ gasconstruction= Exit „HP1“= Order „OFF“

FUNCTION: The oil / gas appliance is required by the "lockup" of BMK, if the temperature at the "Buffer sensor UP" (T3) is less than the

highest required target temperature of a heating or hot water circuit.

Following conditions must be leaded out::

1) The parameter „HP0“ in the costumer menu is attituded to „AUTO“ or „DURATION“.

2) The temperature on „buffer sensor ABOVE“ (T3) is smaller then the highes wanted target temperature.

3) The temperature on the „buffersensor BELOW “ (T3) iss maller then the in the parameter „TP0 blocked temperature“.

4) The exhaust gas temperature of BMK is smaller, then the in the parameter „RGT Burner“ attituded temperature.

5) For boiler with automatically „Ignitionblocking“ the Ignition has to be runned over.

AF

11

5 5

RG0 RG1

T5T3

HK0

1. Firing BMK as Pricelist

2. Flue draft regulator with Ex-Clap RE20 H38-160

3. Rule Set-MKR S30-031

4. return boost grouo RA50 A H39-021

5. buffermemory PS as Pricelist

6. USV 5/4“ by client

use just zone valves with off turned and tight closed mixer

7. aditional boiler sensor for Oil-/ Gasconstr. S70-004

8. Mixer Servermotor S50-501

9. Roomconstruction / Roomstation as Pricelist

10. Warmwatermemory ECO as Pricelist

11. GSM-Module S15-002

RG2

9

HK1 HK2

VF1

VF2

230VAC

HKP0 HKP1

6

HP2

B

USV

ABM

HP1

A

HP0 −

>55°C

1

2

3

M

RL

KLP

RLM

4

T2

230VAC−2A

T4

t

ä

7

r

e

g

s

a

G

/

−

l

Ö

HKP2

8

M

SLP0

M

10

29

Page 30

NOTES

Sketch:

30

Page 31

8 TECHNICHAL DATA

BMK-02

Type BMK 20 BMK 30 BMK 40 BMK 50 Unity

Fuel Split log

natural finish

rating 20 30 40,3 (39,4*) 50 (42,5*) kW

boiler temperature

Return boost temperaturer

Flue draft

Water content

Opration pressure

A – Smoke pipe (Diameter)

B - Backrun

C – Vorlauf

D – Securitywarmexchanger

Waterside resistance 10K

Wasserseitiger Widerstand 20K

65 – 85

> 55

2 - 20 2 - 20 2 - 20 2 - 20 Pascal

125

max. 3

150

5/4

5/4

3/4

1710 l/h

3,8

860 l/h

1,1

Split log

natural finish

65 – 85

> 55

125

max. 3

150

5/4

5/4

3/4

2570 l/h

8,1

1290 l/h

2,5

Split log

natural finish

65 – 85

> 55

175

max. 3

150

5/4

5/4

3/4

3430 l/h

15,4

1710 l/h

3,9

Split log

natural finish

65 – 85

> 55

175

max. 3

150

5/4

5/4

3/4

4290 l/h

24,1

2140 l/h

6,0

-

°C

°C

Litre

bar

mm

Zoll

Zoll

Zoll

l/h - kg/h

mbar

kg/h

mbar

Volume filling roo0m 166 166 215 215 Liter

boiler´s weigh ca.

weight warmexchanger

weight lower part

Power supply

630

240

350

230VAC / 13A 230VAC / 13A 230VAC / 13A 230VAC / 13A

630

240

350

730

320

350

730

320

35

* Powerrating for Germany

kg

kg

kg

31

Page 32

GUNTAMATIC Heiztechnik GmbH

A-4722 Peuerbach / Bruck 7

Tel: 0043-(0) 7276 / 2441-0

Fax: 0043 (0) 7276 / 3031

Email: office@guntamatic.com

www.guntamatic.com

Misprints and technichal Changes reserved

32

Loading...

Loading...