Page 1

Pelletfiring englisch

BIOSTAR

12 / 15 / 23 kW

Operating instructions / Systemlog Book

BS-01

EN-B30-003-V18-0415

Page 2

Information on this documentation

Please read through this documentation carefully.

It is intended as a reference document and contains important

information on the design, safety, operation, maintenance and

care of your heating system.

We are always looking to improve our products and

documentation. Any ideas and suggestions you may have will be

gratefully received.

GUNTAMATIC Heiztechnik GmbH

Bruck 7

A-4722 PEUERBACH

BS-01

Tel: 0043 (0) 7276 / 2441-0

Fax: 0043 (0) 7276 / 3031

Email: office@guntamatic.com

It is important that you pay particular attention to

the safety issues highlighted in the text by these

symbols.

The entire contents of this document are the property of

GUNTAMATIC and therefore protected by copyright.

Reproduction of any kind, communication to third parties by any

means or use for purposes other than those intended without

the written consent of the owner is prohibited.

2

Subject to printing errors and technical amendments.

Page 3

Contents

1 Introduction ............................................................................5

2 Important notes ......................................................................6

2.1 Intended use 6

2.2 operate the heating system 6

2.3 gurantee and liability 7

2.4 Security instructions 7

2.5 Securitynotes on the heatingsystem 10

3 System components ............................................................11

4 Safety Systems.....................................................................13

5 control panel description ....................................................14

6 Overview of Menu and Levels .............................................15

Seite

6.0 Houselevel 16

6.1 Programme selection 17

6.2 Customer level 17

6.2.1 Customer menu 18

6.2.2 Heatingcirculation 18

6.2.4 Box, Buffer or screw feeder pump 19

6.2.5 Pump HP0 20

6.2.6 Servicelevel 21

6.2.6.1 Resetdata 21

6.2.6.2 Beginning Service

6.2.6.3 Parameter Heatingcirculation HK 0-8

Floor heating

23

6.2.6.4 Parameter Warmwater / adition Warmwater 23

6.2.6.5 Parameter HP0 24

6.2.6.6 Parameter trunk blink 24

6.2.6.7 Parameter backrunmixer 24

6.2.6.8 System settings 25

7 User settings ........................................................................26

7.1 Heating

7.2 Heatingprogramme

7.3 Roomtemperature

7.4 Warmwatertemperature

7.5 Roomcontroller

On / Off

how to programme

adapt

28

adapt

use

30

27

29

26

3

Page 4

Contents

Seite

8 Operating the heating system.............................................31

8.1 Controlling of heatingcirculation system 32

8.2 Fuel/ Quality 33

8.3 fill storeroom 34

8.4 attitude combustion air 35

8.5 Emptying the ash 35

9 Cleaning/ care.......................................................................36

9.1 Interim cleaning 37

9.2 General cleaning 38

10 Error/ Fault messages.........................................................39

11 Fault clearance ....................................................................40

12 Replacing fuses...................................................................41

13 System log book .................................................................42

14 Parameter changes .............................................................47

15 Heatingcirculation attitudes ...............................................47

4

Page 5

1 INTRODUCTION

Short description The firing biocom is a modern heating system. The feed ocours

Type approval The BIOCOM is a modern biomass Class 5 boiler available

BC-01

You have made an excellent choice with the purchase of your

GUNTAMATIC boiler.

It is a product of many years’ experience in boiler-making and

it is our sincere wish that your heating system provides you

with many years of satisfaction.

These instructions are intended as a guide to operation and

maintenance. Even the best boiler cannot operate effectively

without proper care and maintenance, so please read through

these instructions carefully and have your appliance

commissioned by an engineer authorised by GUNTAMATIC.

Most importantly, you should follow the safety instructions in

Section 2.

from a store room with a suction system.

with power outputs of 30, 40, 50, 75 or 100 kW. The fuel is fed

to the boiler from a fuel storeroom by a vacuum extraction

system.

Further Information

The documentation consists of the following documents:

• Planning Document

• Installation instructions

• Operating instructions

If you have any questions, please consult our Customer

Support.

5

Page 6

2 IMPORTANT NOTES

2.1 INTENDED USE

Your boiler has been designed and produced in accordance

with the latest technical advances and all applicable safety

regulations. Nevertheless incorrect operation, the use of

unapproved fuels or the failure to carry out necessary

maintenance and repairs can result in personal injury or

damage to property. You will avoid dangerous situations by

only using the boiler for the purpose for which it was designed

and by operating, cleaning and maintaining it correctly. Only

start up the heating system when it is in perfectly safe working

order.

The boiler is designed for heating central heating water and for

use as a central heating boiler.

Do not use the boiler to burn rubbish!

Burning rubbish will cause extensive corrosion

and consequently to a substantial reduction in

the service life of the boiler.

BS-01

2.2 OPERATE THE HEATING SYSTEM

The heating system may only be operated and cleaned by

demonstrably trained persons (as per check list). Children,

unauthorised persons or persons

Even if the opposite is requested, servicing

and repair work may only be carried out by

authorised specialists.

BS-01

6

Page 7

2.3 GURANTEE AND LIABILITY

Gurantee and liability claims for personal injury and/ or

property damage are inadmissible if they are attributable to one

or more of the following causes:

• use of the boiler for purposes other than that intended

• failure to follow the instructions, guidance and safety

• incorrect commissioning, operation, maintenance or

• operation of the boiler when safety systems are

• unauthorised modifications

2.4 SAFETY INSTRUCTIONS

To prevent accidents, small children should not be allowed into

the boiler room or fuel storeroom. Please follow the safety

instructions below. By doing so, you will protect yourself and

prevent damage to your heating system.

precautions given in the documentation

repair of the boiler

inoperative

BS-01

BC-01

Power switch

Mains plug

Repair work

The power switch must remain switched on at

all times and may only switched off when the

system is not in operation

Risk of fatal injury from electric shock!

The mains power supply is brought to the

boiler via the plug marked Mains. That plug

and other components of the system remain

live even when the Power switch on the

control panel is switched off.

Repair work may only be carried out by

authorised technichians!

Touching live electrical components can cause

fatal injury!

Even when the Power switch is „OFF“ some

components of the system are still live.

Therefore, when carrying out repair work it is

imperative that the power supply to the

heating system is disconnected by means of

the „mains plug“ or a circuit breaker

In an

emergeny:

In the event of an electric shock, disconnect the power supply

immediatly. Administer first aid and call the duty doctor

Fault rectification:

If faults occur, the causes must first be

eliminated on the basis of the information

message on the display (F0…) before

resuming operation by means of the “Quit”

button.

7

Page 8

Unauthorised modifications

Servicing work

Emptying ash

Boiler cleaning

Do not make any unplanned changes to the

settings or any modifications to the heating

Loss of guarantee entitkement!

Service the boiler regularly or make use of our

Costumer Service.

Glowing embers can cause fires!

Only remove the ash from the boiler or store it

in non combustible containers.

Touching hot components can cause skin

system.

burns!

Flue gas fan

Gaskets

Air supply

The boiler must only be cleaned when it is

cold (flue gas temperature < 50 °C)

Risk of injury from rotating parts!

The fan must only be removed when it is

disconnected from the power supply

(unplugged)

Risk of gas poisoning.

It is possible that flue gas could escape if

gaskets are damaged.

Have defective gaskets replaced by an

authorised technician.

In an

emergency:

Take the person affected into the open air immediately. Call

the duty doctor!

Risk of suffocation!

Inadequate air supply can be fatal.

Make sure there is an adequate supply of air.

Note: If there is more than one boiler in the same room, a greater

supply of frehs air must be provided.

Flue draught regulator:

Risk of detonation!

8

A flue regulator with a pressure surge

compensator is an essential requirement!

Page 9

Safety clearances

Fire risk!

Do not store any flamable items in the close

vivinity of the boiler.

Follow the local regulations!

when heating

Attention Danger of deflagration!

When the boiler is running please don’t open

the boiler door or cleaning openings

Entering the storeroom

Potentially fatal health risk!

As with all organic materials, stored pellets

can produce gases, which then collect in the

storeroom. Therefore, entering the storeroom

is only allowed when it is empty (max. 1/5 full)

and only after ventilating it thoroughly for at

least 2 hours beforehand.

Entering the storeroom

Anti- freeze function

Storerooms that contain more than the above

amount of fuel may only be entered by

authorised service engineers after prior testing

of the air quality inside the storeroom

Attention LIFE DANGER!

In all biogenic substances may occur during

storage in the formation of gases. You can

enter the storeroom after 2 hours lifting.

Storerooms with a high level might be

measured (the quality of air) from authorised

stuff before you enter he room

As with all organic materials, stored pellets

can produce gases, which then collect in the

storeroom. Therefore, entering the storeroom

is only allowed when it is empty (max. 1/5 full)

and only after ventilating it thoroughly for at

least 2 hours beforehand.

Anti- freeze function

The system can only perform its

freezing prevention function if sufficient fuel

is available and there are no faults.

Fire extinguisher

Provide a fire extinguisher!

There must be a fire extinguisher placed

immediatly outside the boiler room door!

9

Page 10

2.5 SECURITY ADVICES FOR THE HEATING SYSTEM

Warning of dangerous electric voltage

Warning of rotating components

Warning of hot surfaces

Warning of deflagration

PH-01

grounding

Observe operating or installation instructions

Separate electric system from the mains

Pull angle plug aside

power Supply

Do not use rigid cable for installations

10

Page 11

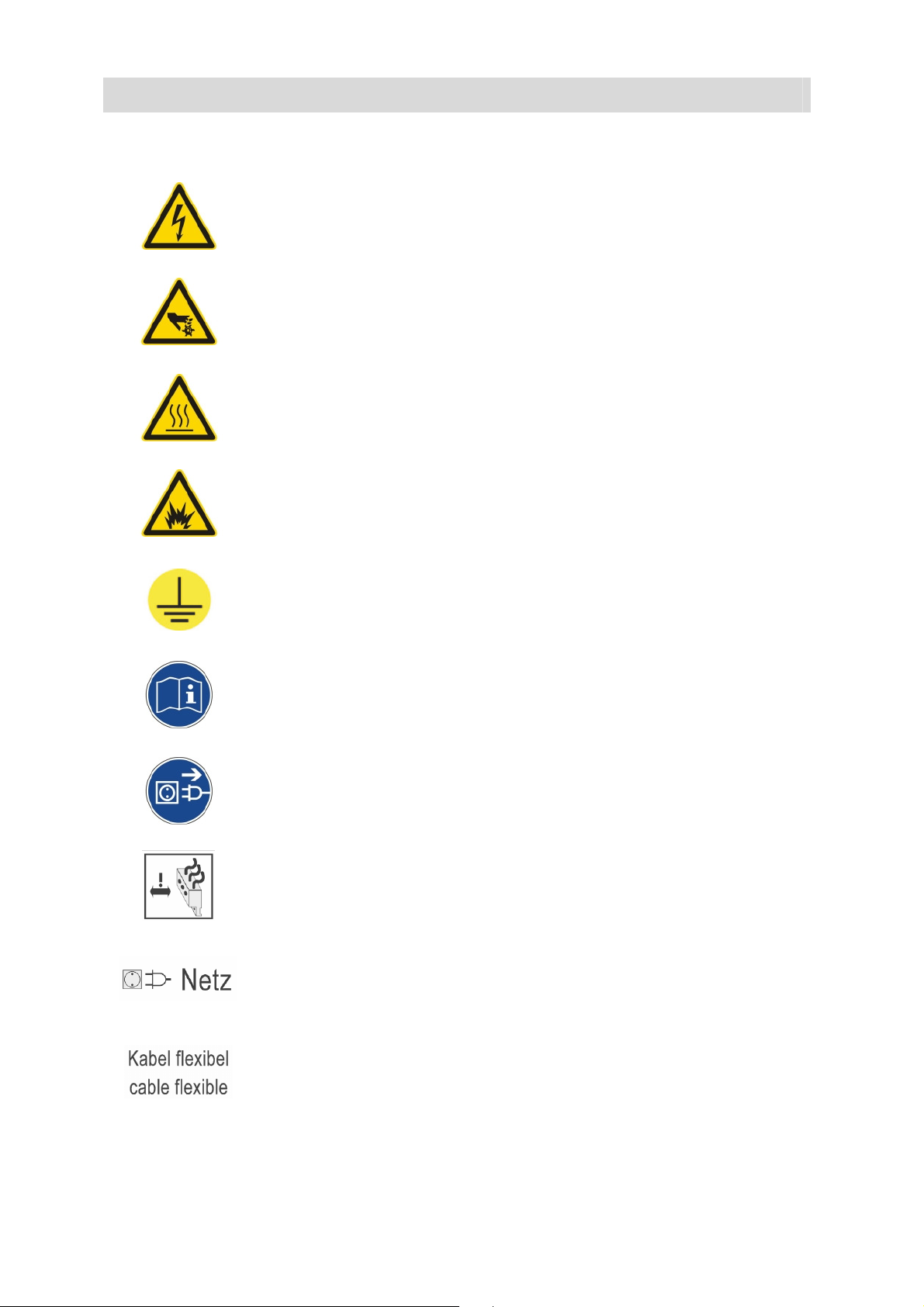

3 SYSTEM COMPONENTS

Flex / Box

BS-01

1. Ash box door

2. Cleaning grate

3. Primary air

4. Self- cleaning grate

5. Secondary air

6. Swirl plate

7. Burn- bacl

8. Expansion zone

9. Automatic heat exchanger cleaning

10. Grate cleaner motor

11. Ignition fan

12. Ceramic insulation

13. Overall insulation

14. Helix baffels

15. Tube- type heat exchanger

16. Flue draught fan

17. Flue gas sensor

18. Lambdasond

19. Control unit

20. Sensor-filler level

21. Motor

22. Drive gear

23. suction fan

24. storing box

25. Pellet spiral

26. Sensor-burning monitioring

27. rotary valve

11

Page 12

Weekbox

BS-01

1. Ash box door

2. Cleaning grate

3. Primary air

4. Self cleaning grate

5. Secondary air

6. Swirl plate

7. Burn- back inhibiting fuel chute

8. Expansion zone

9. Warmchangercleaning

10. Grate cleaner motor

11. Ignition fan

12. Ceramic insulation

13. Overall insulation

14. Helixx baffles

15. tube type exchanger

16. Flue draught fan

17. Flue gas sensor

18. Lambdasond

19. Control unit (controller)

20. Sensor-for fill- level indicator

21. Motor

22. Gear

23. vacuum fan

24. Fuel hopper

25. pellet spiral

12

Page 13

4 SAFETY SYSTEMS

Safety level 1

Safety level 2

Safety level 3

BS-01

To prevent the boiler overheating, the controller reduces the

heat output in certain situations. If the boiler still threatens to

overheat, the controller responds according to a set of defined

safety levels.

15°C above specified temperature

The drive motor Stops the fuel feed system and the flue

draught fan shuts down.

Boiler temperature above 85°C

All heating pumps and the cylinder charging pump are

switched on to carry heat away from the boiler

Boiler temperature above 100°C

The STL (safety temperature limiter) trips and switches all

boiler control functions off while the heating circulation pumps

continue to run. The system remains switched off even if the

boiler temperature drops back below 90 °C. The system must

not be started up again until any faults have been rectified and

the boiler has been checked.

Power failure The controller, the flue draught fan and all circulation pumps

switch of due of electricity if there is a power cut. The glowing

fuel bed on the grate continues burn with the natural draught of

the flue. As this operating mode is not ideal, a larger amount of

ash collechts on the grate as well. As soon as the electricity

supply is restored, the controller takes control of the heating

system again.

Opening the ash box

• the auger motor Stopps feeding in fuel;

• the suctionblower goes to 100 % extraction speed;

• After the firebox door is closed, normal operation is

resumed or re- ignition initiated

13

Page 14

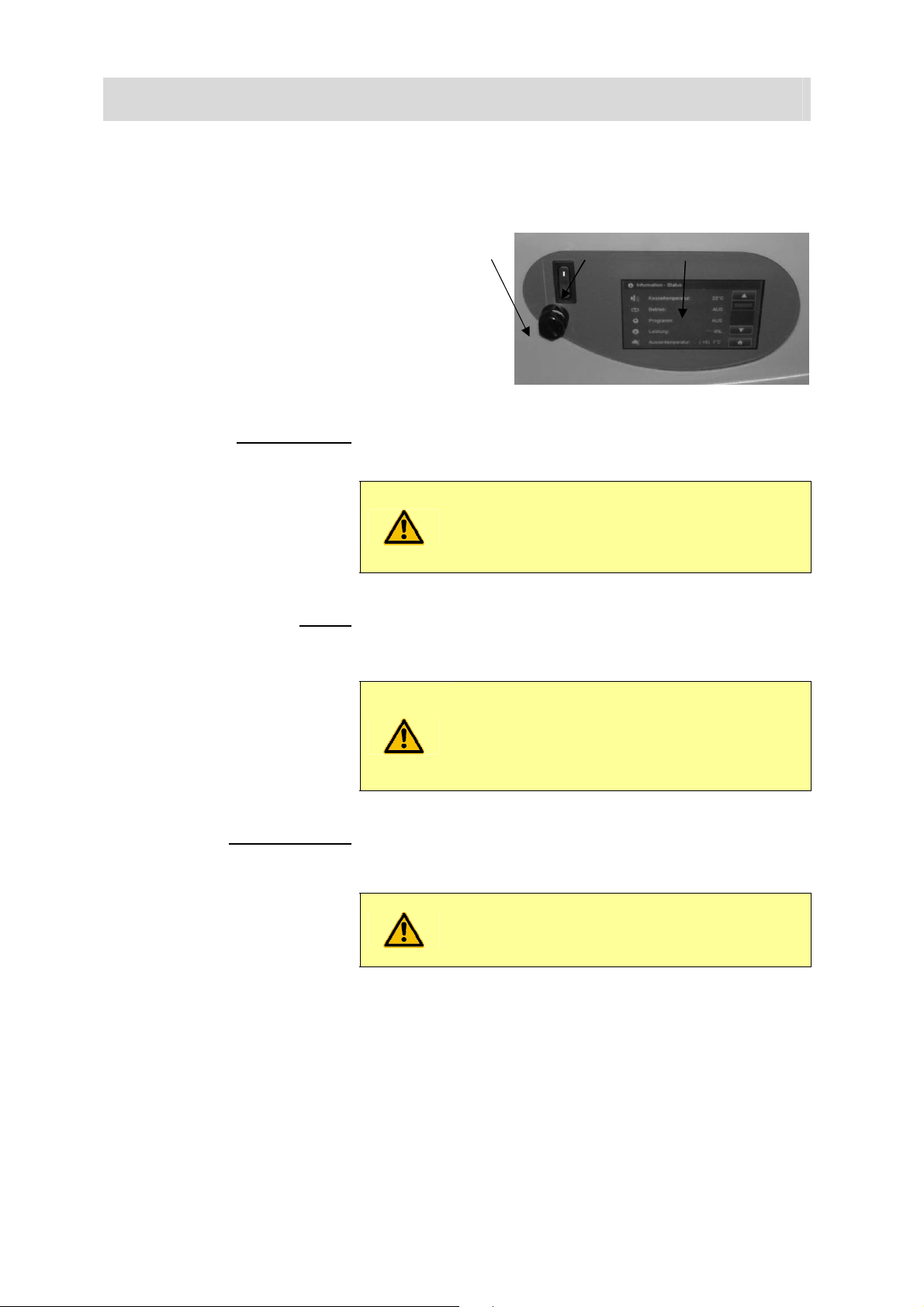

5 CONTROL PANEL DESCRIPTION

The appliance has a large touch- screen control panel with a

meu- based interface. All setting and query options are shown

on the display. All setting could be entered by pressing the

“buttons” on the touch screen. Any system messages are

displayed on the screen.

Power switch (1) Normally remains permanently switched on. The power switch

may only be switched off when the system is not in operation.

The system must be disconnected from the

BS-01

2 1 3

mains by unplugging the power lead when

carrying out repairs or servicing work

BS-01

Excessive temperature trips the safety temperature limiter

STL (2)

(STL) located under the cap (2) appliance operation is

suspended; if the STL has tripped, identify and eliminate the

cause and then press in the STL (button) with a thin object.

The system must not be started up again until

any faults have been rectified and the boiler

has been checked. If necessary, a heating

engineer must be called in.

Pressing lightly with your fingertip on the relevant buttons on

Touch-Display (3)

the display opens the various program levels, menus and

submenus. All settings are made directly on the touch-screen

display.

Never use sharp objects such as ball-point

pens or the like to operate the touch screen

14

Page 15

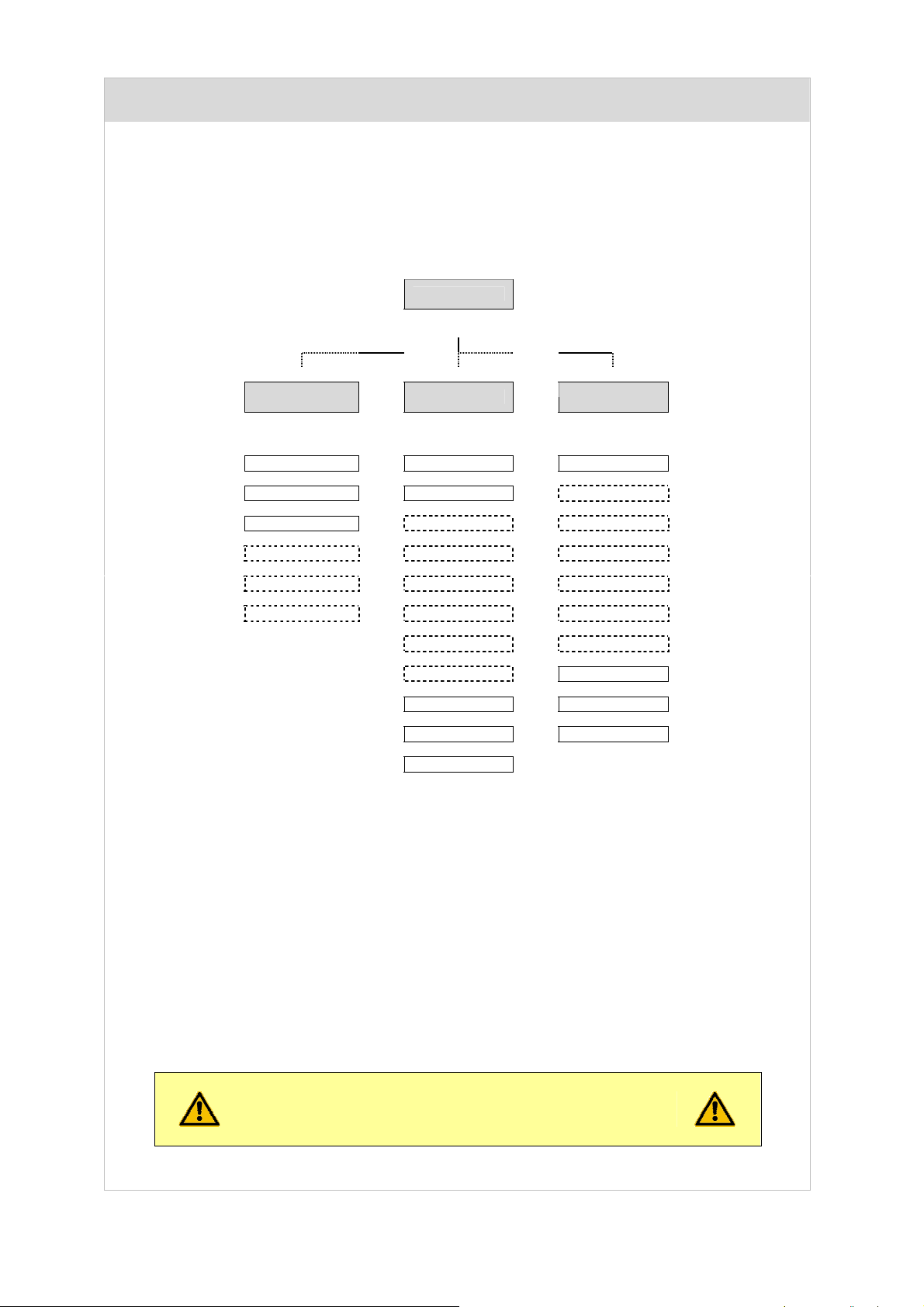

6 OVERVIEW OF MENU LEVELS

Info level

▼ ▼ ▼

INFO-Error

INFO-Status

INFO-Boiler

INFO-Controller 0-2

INFO-Buffer Tank HP0

INFO-Buffer Tank 0-2

Prog. selection

MANUAL OPERATE

House level

Boiler release

OFF

NORMAL

DHW

HEAT

REDUCE

REDUCE TO…

BOOST DHW

Grate cleaning

exhaust. value

PH-01

Customer level

Customer menu

Heating Circ. 0-8

DHW

DHW extra 0-2

Menu HP0

trunk blink 0-2

Blr. cascade

Detail display.

date-time

Service level

Menus shown with a dashed border only appear if

activated on the Commissioning menu.

15

Page 16

6.0 HOUSE LEVEL

About the selection buttons, you switch to the different levels.

BC-01

Info level

see Chapter 6.1

see Chapter 6.2

Customer level

Program selection

*)

*)

INFOBOX

-

Error messages, Temperatures, Scold and operational states, Buffer and

Heating circles could be requested.

**)

***)

***)

16

**) -

Programmes for boilers and heating circulations could be chosen;

-

the boilers release could be broken;

-

the attitudes for boilers, heating circulations could be changed

-

the attitudes in the service area and the parameter menu could just

changed from authorised GUNTAMATIC staff.

Page 17

6.1 PROGRAMMESELECTION

1)

1)

1)

1)

1)

1)

Boiler´s clearance ...........................................

Programme OUT ............................................

Programme NORMAL ....................................

Programme WARMWATER ...........................

Programme HEATING ....................................

Programm LOWER.........................................

Programm LOWER TO ..................................

RELOAD WARMWATER ...............................

Programme MANUAL .....................................

gratecleaning ..................................................

emissions measurement ................................

INFOBOX

1) the selectionbuttons wehre just shown,if a heatingcirculation is actived;

on Attitude „OFF“ the boiler didn´t start

Heiatingrun turned off (mit wittgef. Regelung ist die Frostschutzfunktion aktiv)

Heizung und WW-Bereitung eingeschaltet (nach Uhrenprogramm)

heating turned off – WW- Bereitung eingeschaltet (after Watchpr. summer)

Day and Night heatingrun (Warmwater with watchprogramme)

Day and Night reduced mote (Warmwater with watchprogramme)

Absenkbetrieb bis zu einem bestimmten Zeitpunkt

Duration maximal 90 Minutes

Heatingservice on boilerstarget- or buffertargettrmperature

manual ON and OFF

Programm for Emissionsmeasure

back to HOUSELEVEL..............................

look at Chapter 6.0

PH-01

6.2 COSTUMER LEVEL

2)

2)

2)

2)

2)

2)

Customer menu .................................................................................................................

Heatingcirculatopn 0-8 ......................................................................................................

Warmwater 0-2..................................................................................................................

addition Warmwater 0-2 ....................................................................................................

Loadingpump 0-2...............................................................................................................

bufferpump 0-2 ..................................................................................................................

feederpump 0-2 .................................................................................................................

buffer- / Z-pump HP0.........................................................................................................

boilerscascade...................................................................................................................

Detailscreen .........................................................................

Date-time ..................................................................................................

Servicelevel .......................................................................................................................

INFOBOX

2) the selectionbuttons could just actived in connection with a heatingcircle;

attitudes, condition and measurement of construction will be shown!

Date and time from the machine could be attituded

back to house level ....................................

PH-01

look at Chapter 6.2.1

look at Chapter 6.2.2

look at Chapter 6.2.3

look at Chapter 6.2.3

look at Chapter 6.2.4

look at Chapter 6.2.4

look at Chapter 6.2.4

look at Chapter 6.2.5

look at Chapter 6.2.6

look at Chapter 6.2.7

look at chapter 6.0

17

Page 18

6.2.1 COSTUMERMENU

3)

Ash empty ......................................

Ashwarning .....................................

boiler´s target ..................................

Clearance HKR 0-2 ........................

m³ set Counter to 0 ........................

Attitude m³ Counter ........................

fill the spiral .....................................

fill the suction construction .............

Feed ...............................................

Mode ...............................................

Language ........................................

boiler´s off time ...............................

INFOBOX

3) ECO-ideal ........... Attitude Savemote (Factoryattitude);

high Power......... Attitude needs more cleaning (attitude just shortly);

much dust.......... Attitude for low quality Pellets with am high Dustpart;

viel Schlacke...... Einstellung bei starker Schlackebildung im Brennraum;

after cleaning the Ash the choose the Menüpoint and confirm with „YES“ and „OK“

hours to the new „Ashewarning“ after confirmation of the Function „Ash emptiing“

Attitude possible, when programme houselevel is active.

influenced the state of running of trunkblinkfunction

turns the m³ Counter to 0

influenced the numberspeed (high Value = quicker count)

manueal refill of Stokerchannel (stopps automatically)

manual refilling of storing tank (is stopping automatically)

no refilling with storingtank while the OFF time (excepted forcefilling)

Attittude of burningmode

attiude of countries specific language

attitude possible, wenn HP0 auf Kein, Z-Pumpe oder Pumpe eingestellt ist

back to the Costumerlevel.........................

see Chapter 6.2

BS-01

6.2.2 HEATINGCIRCULATION

4)

5)

6)

7)

8)

9)

10)

Running with Pump ........................

Watchprogramme ...........................

Targettemperature Day ..................

Targettemperaturer Night ...............

Roominfluence ................................

Heatingcurve...................................

Night off OT.....................................

Turn OFF OT ..................................

INFOBOX

4) AUTO .................. the trunkblinkfunction will be turned automatically ON/OFF;

OFF..................... the trunkblinkfunction is turned off

DURATION ......... the trunkblinkfunction is always released; (no mixer control)

5) the rule on target temperature is just active, if the temperature´s value isntß exceeded;

6) the rule on target temperature´s value is just active, if the outsidetemperature´s value isn´t exceeded to the parameter “Night Out

OT”

7) 0 % – 100%.......... with an high outiside temperature „plus degree“ a low room temperatzre will turned on if the whised

T1C° - T3°C ........ the rooms target temperature the heatingcirculation pump will turned off;

8) a higher attituded value of the same outside temperature;

9) while the reduced mote will be fell below, you have to pot the heatingcirculation ON;

Attention: There is no Antifreezefunction up to the reached attitudet temperature!

10) if the heating period will be fell below the heatingcirculation turns off;

roomtemperature is reached;

influenced the state of condition of heatingcirculation

Attitude of heating- and Absenkphasen

for Rule on targettemperature is a roommachine necacerry

zur Regelung auf Solltemperatur ist ein Raumgerät erforderlich

0% - 100% beeinflusst die Vorlauftemperatur / T1°C - T3°C beeinflusst die Heizkreispumpe

beeinflusst die Vorlauftemperatur – (high attitudevalue = high flow temperature)

influenced the heatingcirculation while the flow temperature

influenced the heatingcirculation while the heating measurement is running

back to the costumer level.........................

look at Chapter 6.2

BS-01

18

Page 19

6.2.3 WARMWATER or ADITIONAL WARMWATER

11)

12)

Running Pump ................................

Watchprogramme WW ...................

Watchprogramme. WW Sommer ...

WW Targettemperature..................

WW priority .....................................

WW reload ......................................

influenced the runningstate of warmwater circulation

influenced the warmwater loadingtime with Programme NORMAL

influenced the warmwater loadingtimes while Programme WARMWATER

influenced the watertargettemperature

influenced the heatingcirculations while the warmwaterloading

onced warmwaterloading possible outside the programmed loadingtimes

back to the costumerlevel..........................

INFOBOX

11) AUTO.................. the trunkblinkfunction will be turned automatically ON/OFF;

OFF..................... the trunkblinkfunction is turned off

DURATION ......... the trunkblinkfunction is always released; (no mixer control)

12) NO....................... the heatingcirculations stay running;

YES..................... the heatingcirculations will be shutted off

PH-01

look at Chapter 6.2

6.2.4 BOX, BUFFER or SCREWPUMP

13)

14)

15)

Running Pump ................................

Loadingprogramme ........................

Watchprogramme ...........................

Buffer target ....................................

Buffer min........................................

influenced the runningstate of trunkblink.

influenced the warmwater loadingtime of buffer

influenced the trunkblinks release

influenced the buffertargettemperature

influenced the bufferminimumtemperature

INFOBOX

13) AUTO.................. the trunkblinkfunction will be turned automatically ON/OFF;

OFF..................... the trunkblinkfunction is turned off

DURATION ......... the trunkblinkfunction is always released;

14) Full...................... the trunkblinkbuffer will be so long loaded, till the buffertargettemperature is reached on the buffersensor „ABOVE

Partly .................. the trunkblinkbuffer will be loaded so long, till the buffertargettemperature is reached on the buffersensor „ABOVE

15) if the attituted temperature „buffer min“ will fell below, the buffer will be loaded automatically to the „buffer target“ temperature;

(T3)“ – and the temperaturedifference to the buffersensor „Below T 2“ is just 10 ° degrees;

(T3)“;

back to the costumer level.........................

PH-01

look at chapter 6.2

19

Page 20

6.2.5 EXIT HP0

16)

17)

18)

Running Pump ................................

Boiler´s target..................................

Loadingprogramme ........................

Watchprogramme ...........................

Buffer Target ...................................

Buffer min........................................

INFOBOX

16) AUTO.................. the trunkblinkfunction will be turned automatically ON/OFF;

17) Full...................... the trunkblinkbuffer will be so long loaded, till the buffertargettemperature is reached on the buffersensor

18) if the attituded „buffer min“ temperature will fell below, the buffer will loaded automatically loaded to the „buffer targe t“

PUFFERSPEICHER / Z-PUMPE / PUMPE

influenced the runningstate of trunkblink.

influenced the buffertarget temperature (manual)

influenced the state of charge from the buffers

influences the boiler´s free release

influenced the buffertargettemperature

influenced the bufferminimumtemperature

back to the COSTUMER LEVEL...............

see chapter 6.2

OFF..................... the trunkblinkfunction is turned off

DURATION ......... the trunkblinkfunction is always released;

Partly .................. the trunkblinkbuffer will be loaded so long, till the buffertargettemperature is reached on the buffersensor

temperature

„ABOVE (T3)“ – and the temperaturedifference to the buffersensor „Below T 2“ is just 10 ° degrees;

„ABOVE (T3)“;

BS-01

20

Page 21

6.2.6 SERVICELEVEL

19)

19)

19)

19)

19)

19)

Resetdata...........................................................................................................................

Error list.....................................................................................................................

Test program................................................................................

Begin Service.....................................................................................................................

Parameter HK 0-8 ...................................................................

Parameter Warmwater 0-2................................................................................................

Parameter adition WW 0-2.......................................................................

Parameter HP0 .......................................................................

Parameter FL 0-2................................................................................................

Parameter RLM ..............................................................................................

Constructionattitude...........................................................................................................

Parametermenu ..............................................................

INFOBOX

19) the numbers of the shown parameters are dependent from the system configuration;

Servicecooperator

All systemcomponents could be undergo to an functioning test!

(heatingcirculation / Estrichheizen)

(Adition warmwater)

(Z-Pumpe / Pufferpumpe / Pumpe)

(trunk blinkl)

(backrun mixer)

entrance and changes just allowed with backspeech from GUNTAMATIC!

back to the COSTUMERLEVEL................

PH-01

look Chapter 6.2.7.1

All errors are saved with date and time!

look Chapter 6.2.7.2

look Chapter 6.2.7.3

look Chapter 6.2.7.4

look Chapter 6.2.7.4

look Chapter 6.2.7.5

look Chapter 6.2.7.6

look Chapter 6.2.7.7

look Chapter 6.2.7.8

look at Chapter 6.2

6.2.6.1 RESETDATA

load Costumerparameter................

save Costumerparameter

load Costumerparameter!...............

operatinghours reset.......................

Servicetime reset ............................

Steerege reset ................................

Lambdakalib. reset .........................

BS-01

saved costumerdatas could be imported new, if necaserry

just new or changed parameter were loaded with a new software

reset factorytimer to 0

reset factory hour timer to 0

Attention: the factory setting will be loaded!

reset it after every lambdasondchange

back to the SERVICELEVEL.....................

look at chapter 6.2.3

21

Page 22

6.2.6.2 BEGINNING SERVICE

2)

21)

22)

23)

24)

25)

26)

27)

Construction.......................................................................

Type ...................................................................................

Feed ...................................................................................

Ashfeed ..............................................................................

HKR 0-2 available................................

● WW availabe 0-2 ..............................

● Running HK 0-8 ..................................

○ flow temperature 0-8 max....................................

○ Heatingcurve 0-8 .................................................

○ Room machine HK0-8 .........................................

● Run trunk blink 0-2 .....................................................

● Spring.......................................

● adition 0-2 ..................................................................

Running HP0......................................................................

Sensor HP0........................................................................

Backrunmixer .....................................................................

A1 Suctionlength................................................................

First filling.........................................................

Spiral´s filling......................................................................

save costumer parameter..................................................

(heatingcirculationruler)

(warmwatermemory)

(heatingcirculation)

(on trunkblinkfunction LAP)

(don´t breake)

back to the SERVICELEVEL

Selection: Biocom

Selection: 30 / 40 / 50 / 75 / 100 kW

Selection: Flex

Selection: Yes / No

Selection: No / CAN-Bus / SY-Bus / Yes

Selection: Yes/ No

Selection: No/ pump/ mixer

Selection: 10°C – 90°C

Selection: 0,1 – 3,5

Selection: No / RFF / RS-Voll / RS-HK / RS-HKR

Selection: No / ZUP / PUP / LAP / ERW

Selection: buffer 0 / buffer 1 / buffer 2 / buffer HP0

Selection: No / WWP / Extern

Selection: Z-Pum p / Bufferpump / Pump

Selection: Kessel / HKR0 / HKR1 / HKR2

Selection: Yes / No

Selection: 5 m / 10 m / 15 m / 20 m / 25 m

Selection: OK / OFF

Selection: OK / OFF

Selection: Yes/ No

look at Chapter 6.2.6

BC-01

INFOBOX

20) No ....................... there is no heatingcirculation associated;

SY-Bus ............... the attituded is correct, when the boilerintern rule will be used as heatingruler 0;

CAN-Bus ............ the attitude is right, when the wall mounted construction is used as heatingcirculation;

Yes...................... the standardattitude fort he underfloor heating is right, when the wall mounted construction is used as

21) 0,5 – 0,7.............. the standardattitude for underfloor;

1,2 – 1,4 .............. the standardattitude for the heater;

22) None................... the heatingcirculation isn´t dedicated to a room machine;

RFF ..................... the heatingcirculation isn´t dedicated to an analouge machine;

RS-Voll ............... to the heatingcirculation there is an digital room construction with attituded possibilities for all heating circulations;

RS-HK................. to the heatingcirculation there is an digital room consturikton with attitudepossibillites for this heatingcirculationruler;

RS-HKR .............. to the heatingcirculation there is an digital room construction with attitudepossibilities fort the whole

23) ZUP, PUP, LAP ........... for the correct attitude have a look at the scheme;

ERW............................. the attitude is correct, if a second heatingcirculationruler is attributed to an existing trunk blink;

24) this attitudion determinates from that buffermemory the Energy will get from the trunk blink;

25) the function „adition“ could be actived on the heatingcirculationrulerm, if the H (0, 3 or 6) ehere in service without a mixer;

WWP................... an aditional warmwatermemory could go in service;

Extern................. an external burner could be requested with cascadefunctions;

26) Z-Pump........................ attitude for constructions without buffermemory with heatingregulation;

Pufferpump................. attitude for construction with buffermemory

Pump ........................... attitude for construction without buffermemory and withour heatingcirculationruler;

27) This attituded determinates, on that ruler sensor of buffer HP0 is connected;

heatingcirculationruler 1 or 2;

heatingcirculationtuler;

22

Page 23

6.2.6.3 PARAMETER HK 0-8

In Service HK .....................................................................

Roomconstruction HK........................................................

Mixerruntime ......................................................................

Flow temperature min ........................................................

Flow temperature max.......................................................

boiler cant ..........................................................................

Heatingcirculationpump Freigabe Temperatur .................

Paralleldisplacement heatingcurve ...................................

Floorheating .......................................................................

● advance increase .......................

● advance increase to ...................................................

● Floor advance min. .....................................................

● Floor advance max. ....................................................

● Floor halftime ...........................................

● Start floorprogramme .................................................

HEATINGCIRCULATION / FLOORHEATING

Selection: None/ Pump / Mixer

Selection: None / RFF / RS-Voll / RS-HK / RS-HKR

Selection: 10 – 300 seconds

Selection: 10°C – 90°C

Selection: 10°C – 90°C

Selection: 0°C – 20°C

Selection: 20°C – 100°C

Selection: -10°C – 30°C

Selection: Yes/ No

(daily at programmestart)

(Runtime max.)

back to the servicelevel .............................

Selection: 0°C – 10°C

Selection: 1 – 5 Days

Selection: 10°C – 30°C

Selection: 25°C – 60°C

Selection: 0 – 20 Days

Selection: Yes/ No

look at Chapter 6.2.7

BS-01

The attitude of floorparameter has to occur with the

floormaker!

The compliance of specific temperatures is not in the slipped service

possible, just by the automatic mixes. The compliance couldn´t

guaranted by 100% because of security escapements and special

boiler features could in exception clear temperaturedifferences. If there

are some problems cause of builted damages, you have to make the

floor heater by hand.

6.2.6.4 PARAMETER WARMWATER 0-2

Warmwater / Adition WW availible....................................

Warmwaterer Hysterese....................................................

Warmwaterpump Clearance .............................................

boilerscant..........................................................................

back to the Servicelevel ............................

or ADITION

Selection: Yes / No

Selection: 1°C – 30°C

Selection: 20°C – 90°C

Selection: 0°C – 20°C

WW 0-2

PH-01

look at Chapter 6.2.7

23

Page 24

6.2.6.5 PARAMETER HP0

in Service HP0 ..............................

Clearence HP0 ............................................

Buffer above Loading ON..............

Buffer above Loading OFF.................

Buffer below Loading OFF ...............

Delta T trunkblink......................................

Difference boiler-buffer above...........................................

Sensor HP0...................................

aditional sensor..............................................

BUFFERPUMP / Z-PUMP / PUMP

6.2.6.6 PARAMETER FL 0-2

Service trunkblink ............................

Clearance trunkblink...................................

buffer above Loading ON ..............

Buffer above Loading OFF.................

Buffer below Loadung OFF ..............

Source..........................................

Delta T trunkblink......................................

Differenz boiler-buffer above.............................................

(for attitude hav a look above)

(Pumpclearence)

(Unterschreitung Kesselanf.)

(Überhöhung Kesselanf.)

(Differenz Puffersoll zu T2)

(Temperaturverlust)

(buffersensor conected on →)

(5 buffersensor)

back to the Servicelevel ............................

trunk blink

(Einstellung siehe Schema)

(Unterschreitung Kesselanf.)

(Differenz Puffersoll zu T2)

(bei Fernleitungsfunktion LAP)

(Pumpenfreigabe)

(Überhöhung Kesselanf.)

(Temperaturverlust)

back to the servicelevel .............................

Selection: Z-Pum p / bufferpump / Pump

Selection: 65°C – 80°C

Selection: 0°C – 20°C

Selection: 0°C – 20°C

Selection: 0°C – -20°C

Selection: 0°C – 50°C

Selection: 0°C – 50°C

Selection: boiler/ HKR0 / HKR1 / HKR2

Selection: Yes / No

look at chapter 6.2.6

Selection: None / ZUP / PUP / LAP / ERW

Selection: 40°C / 65°C – 80°C

Selection: 0°C – 20°C

Selection: 0°C – 20°C

Selection: 0°C – -20°C

Selection: buffer 0 / buffer 1 / buffer 2 / buffer HP0

Selection: 0°C – 50°C

Selection: 0°C – 50°C

look at chapter 6.2.6

PH-01

PH-01

6.2.6.7 PARAMETER RLM

28)

29)

Service Backrunmixer........................................................

Backrunmixer Runtime ......................................................

Backrunmixer Target .........................................................

Backrunmixer Delta T ........................................................

Decelerate..........................................................................

INFOBOX

Backrunmixer

Selection: AUTO

Selection: 10 – 300 Seconds

Selection: 20°C – 65°C

Selection: 5°C – 30°C

Selection: YES

back to the servicelevel .............................

PH-01

look at chapter 6.2.7

24

28) determinates the whised spreading between boilerstemperature and boilerbacktemperature;

29) makes the boiler´s target temperature higher on the attituted way (purpose= the boilers target temperature will be quicker reached);

Page 25

6.2.6.8 SYSTEM SETTINGS

30)

31)

32)

33)

33)

34)

Construction.......................................................................

Type ...................................................................................

Feed ...................................................................................

boiler´s cleaning................................

HKR 0-2 .............................................................................

Outside sensor............................

Fuel ....................................................................................

FW availiable .....................................................................

FW kalibrieren....................................................................

FW correcturer bei Pmin ...................................................

FW correcture bei Pmax....................................................

Lambdasond ......................................................................

Lambdaheating ..................................................................

Lambdasonde kalibrieren ..................................................

Lambdasonde Korrektur.........................

Lambdasonde Kennlinie...........................

PC-Überwachung ..............................................................

GSM Rufnummer 1-3 ....................

SD-Logging ...................................

SD-Data .............................................................................

CID-Data ............................................................................

Network ......................................................

DHCP .........................................................

IP-Adress ..................................................

Alert ...................................................................................

First Filling..........................................

ID Fan ................................................................................

Gear G1 .............................................................................

Fwingtype...........................................................................

Menustructure ....................................................................

time, ABS Pump .................................................

HKP Forceon .....................................................................

Restwarme using ...............................................................

HKP Freeze TA..............................

HKP Freeze TV.............................

TÜV Function .....................................................................

(possible up to yom. 2006)

(No = 0°C Outsidetemperature)

(-10,0 mV = Sollwert)

(adaption in service)

(bei aktiviertem GSM-Modul)

(for ending – save parameter)

(VISU via Network)

(VISU via Network)

(VISU via Netzwork)

(don´t break this service))

(1x weekly)

(in Programme „OFF“ active)

( in Programme „OFF“ active )

back to the servicelevel .............................

Selection: Biostar

Selection: 12 / 15 / 23 kW

Selection: Flex / Week

Selection: OUT

Selection: Yes/ No / CAN-Bus / SY-Bus

Selection: Yes

Selection: 1 = 12 kW, 15 kW / 2 = 23 kW

Selection: Yes

Selection: 0 kOhm

Selection: 0 kOhm

Selection: 0 kOhm

Selection: NGK

Selection: AUTO

Selection: ON / OFF

Selection: Correcture maximal ± 6,0 mV

Selection: 0,0%

Selection: Terminal / DAQ / GSM-Module

Selection: insert telephonenumber

Selection: ON / OFF

Selection: overview

Selection: m anufacturer code

Selection: yes

Selection: m anual

Selection: insert free Netzwork IP-Adress

Selection: don´t deactive

Selection: OK

Selection: Tact

Selection: ABM-FGA103

Selection: D140 = 12 kW, 15 kW / D150 = 23 kW

Selection: 3.1

Selection: 60 Seconds

Selection: 85°C

Selection: 65°C

Selection: -3°C

Selection: 3°C

Selection: -

look at chapter 6.2.6

BS-01

INFOBOX

30) Terminal............. Data querying via VISU;

DAQ .................... Data querying via Onlinerecorder (only useable at factory);

GSM-Modul ........ Information and control via GSM-module;

31) all heatingcirculationpumps ON, till the temperature fall below (or the buffer memory) 85 °C

32) Pump HP0 ON till the boilertemperature fell below 65 °C;

33) unterschreitet die Außentemperatur den Parameter HKP Frost TA den eingestellten Wert, schalten alle Heizkreispumpen ein;

Parameter HKP Frost TV ist die Vorlaufsolltemperatur, wenn der Parameter HKP Frost TA aktiv ist (Frostschutzfunktion);

Achtung: Durch eine Störung am Kessel kann die Frostschutzfunktion möglicherweise versagen! → E-Heizstab vorsehen!

34) die Kesseltemperatur wird solange erhöht, bis der STB die Funktion unterbricht;

25

Page 26

7 USER SETTINGS

7.1 HEATING

press the programmeselection

ON / OFF

BS-01

BS-01

Programme

Programme

Programme

OUT ........................

NORMAL ................

WARMWATER .......

some INFO’s more for Programme selection ............................... look at chapter 6.1

back to HOUSELEVEL.............................. look at chapter 6.0

▼

Heating and Warmwater turned off

Heating and Warmwater on

just Warmwater on

26

Page 27

7.2 HEATINGPROGRAMME

how to PROGRAMME

BC-01

For every heatingcirculation there could be up to 3 ON/ OFF switching times installed. With the

function „Weekprogramming“ all days in a week could be programmed at the same time.

1) press Costumer level

2) press on the heating circulation button

3) press on the watchtime progtamme

• Programme „DAILY“

(press 1 x to the weekday)

• Programm „WEEKLY“

(press 2x on the same weekday)

▼

▼

▼

back to houselevel .................................... look at chapter 6.0

27

Page 28

7.3 ROOM TEMPERATURE

adapt heating curve

BC-01

Through changing the heating curve, the room temperature could be adapted.

Through a higher heating curve you might reach a higher room temperature.

Change the heating curve just daily and maximum in a tenth area.

1) press COSTUMERLEVEL

2) press to the heatingbend button

3) press on the heatingcurve button

80

70

60

50

40

flowtemperature °C

30

20

Outsidetemperature °C

3,5 2,53,0 2,0

▼

▼

▼

1,5

1,0

0,5

-20-15-10-505101520

back to HOUSELEVEL.............................. look at chapter 6.0

28

Page 29

7.4 WARMWATERTEMPERATURE

how to ADAPT

BC-01

Through changing the targettemperature the warmwatertemperature could be adapted..

1) press COSTUMERLEVEL

2) press on the warmwaterbutton

3) press on the targettemperature button

• „CHANGE" with or

• „SAVE“ with

▼

▼

▼

back to HOUSELEVEL.............................. look at Chapter 6.0

29

Page 30

7.5 ROOMCONTROLLER

place of construction Mount the room construction in an high of 1,5 m on the internal

adapt room temperature The knobs bringst he the oportunity to change the

how to serve

BS-01

wall. The functionalst room is there, where the occupants are

the most of time (for example: living room). In this room it´s

forbidden to furnish the thermostatvalve.

The room machine shouldn’t stand in an area

with strong influence of sun or a cockle stove.

(

open the valves completly).

roomtemperature. In the plus area (+) of the menu the

roomtemperature could be lifted up to 3 ° C. In the control

range the minus (-) temperature could be depressed up to – 3

degrees.

By turning in the plus (+) or minus (-) area in

the menu the detail.

Low:

Normal:

Heating run OFF

(if the Outsidetemperature is higher then Parameter „Night out OT“)

Heating run ON → to target temperature Night

(wenn die Außentemperatur niedriger ist als der Parameter „Nacht aus AT“)

Heating and reduced mote

(after the in the watchprogramme attiuted times)

Heating:

30

Heat→ on target temperature Day

(heat Day and Night without reduced mote)

Page 31

8 OPERATING THE HEATING SYSTEM

Initial commissioning Initial commissioning and basic adjustment of the system may

only be carried out by GUNTAMATIC engineers or authorised

GUNTAMATIC agents.

Day- to day operation Clean the heating system precisely according to the

instructions in the section Cleaning/Care. The amount of

cleaning work required is heavily dependent on the quality of

the fuel used and lower-quality fuels may necessitate more

cleaning work.

Shutting down the system The system only needs to be shut down at the end of the

heating season, if faults occur or in order to refill the fuel store.

To do so, set the system to the programme "OFF" and allow it

to cool down for approx. 120 minutes. The system can then be

shut down.

If the system is not used for extended periods (summer) also

isolate it from the power supply by disconnecting the mains

plug in order to prevent unnecessary lightning damage.

BS-01

Restarting Before starting up the system again in the autumn/winter, carry

out the annual check of the control and safety systems to

ensure they are safe and functional. We recommend that you

take out a maintenance contract so that the system operates

safely and economically.

31

Page 32

8.1 CONTROLING OF THE HEATINGCIRCULATION SYSTEM

Checking system pressure The operating pressure is normally between 1 bar and 2.5 bar.

If the system pressure is too low, malfunctions may result. If

necessary top up the water in the heating system.

Note Completely draining and refilling the system or topping

up a system filled with anti-freeze or treated water must only

be carried out by a heating engineer.

Topping up the heating system water

• The heating system water must be cold when topping

up → make sure the heating system water temperature is

below 40°C.

• Add water slowly until the required system pressure is

indicated on the system pressure gauge.

• Bleed the heating system.

• Check the system pressure again and add more water if

necessary.

Expansion vessel

Check the air pressure in the expansion tank (circa 1,5 bar)

If necessary call a plumber!

BS-01

Temperature-relief valve

Check the security functions to the right functions

If necessary call a plumber!

Heatungroomlifting Control the air supply of free passage!

If necessary call a plumber!

32

Page 33

................................

........

.............................

............

................................

................................

........

8.2 FUEL/ QUALITY

Properties Calorific value

BC-01

To achieve a smooth heating of the furnace, the quality of

the fuel has to be right. Only with high-quality wood chips

should help to ensure a reliable and trouble-free operation

of the plant. The price should be evaluated always behind

the quality requirements and it is therefore strongly advised

to use only good quality.

Important quality criteria:

• solid;

• smooth surface;

• minimal small particle;

• minimal ash decay;

• high smelting point;

ca. 4,9 kWh / kg

Bulk weight ................................

Pellet size (length)

Diameter ................................

Water content

Fusion point

Ash content ................................

ca. 650 kg / m³

5 – 30 mm

5 – 6 mm

8 – 10 %

ca. 1200°C

< 0,5 %

Quality classes

use just Pellets with EN plus Quality class A1/A2!

The storing has to occour in an dry

condition!

If the pellets are in Contact with water or

moisture they swell and disintegrate!

33

Page 34

8.3 FILL THE STOREROOM

Firstfilling/ Refilling Before first fillimng and after every complete emptying of fuil

dumping height Pellets ....................................... max. 2,5 m

The fuel store can´t be filled when the

heater is in service!

Minimum 1 hour before filling, the construction

should be turned off!

You have to empty the feed spiral

You have to suct bigger dust quantity!

the storeroom couldn´t filled completly. The discharge screw

should be filled prior to complete filling of the fuel storage over

the entire screw length about 10 cm high with pellets.

Thereafter, the fuel storage can be filled up to the maximum fill

height.

minimum all 3 years!

BS-01

Emergency filling If the automatically refilling of pellets isn´t able to run, the store

room could be “emergency refilled”:

Before you try to eliminate the error follow the description as

you can see in the chapter „Rectifying faults“ or „Replacing

fuse“.

approach:

Put he construction to „programme out“and wait till it went to

„run out“. Putt he power switch to „0“. Screw the store tunk in

above direct and screw it and fill it with bagstuff.

After that, you have to close the dished cover. The shown

allertmessage should be receipted. After that you have to

attend the at least used heatingprogramme

Open the hooper The Machine recognices this and turns the

Hooper

hackchipsspiral off. Turn the ID Fan to the full drive. The

container could be filled up to the seal border. Close the

Container lid and lock it tightly. The Service will be leaded out

automatically. Once a year the Operation will be completed

emptied and the dust sediments should be suct completely.

34

Page 35

8.4 EMPTYING THE ASH

emptying the ash Put he construction to „Programme out“and let it cool down

Glowing embers can cause fires!

Only remove the ash from the boiler or store it

Touching of hot parts could lead to skin injury!

Let the boiler cool down minimum a half an hour

Depending on the quality and quantity of uel the ash container

must be emptied often. With inferior fuel quality is shortened by

the higher proportion of dust in the fuel, the drain interval. The

ash in concentrated form. In case of high quality used fuel you

can use the ash as mineral fertilizer.

minimum a half an hour. Then you have to extract and clean

the ashtank.

in non-combustible containers.

before cleaning the ash!

PH-01

Attention: The Ashton could be hot!

Control the seal of ashtank on his correct condition. Then

insert both ashtanks and close it.

Attitude the construction to the at least attituded

heatingprogramme.

Resetting the ash warning

If the ash warning appears on the display, it has to be reset on

the "User" menu. To do so, go to the "User" menu and select

the option "Ash emptied", change the setting to "YES" and

press the "OK" button to confirm. The ash warning has now

been reset to the maximum number of hours before it is next

triggered. The time until the ash warning is issued is preset

and can be adjusted to suit the fuel being used by selecting

"Ash Warning" on the User menu on the User Level.

35

Page 36

9 CLEANING/ CARE

boiler The sophisticated cleaning system on a GUNTAMATIC heating

Attention: Danger of injury!

For safety reasons you must only carry out

servicing and cleaning when the heating

system is switched off and disconnected

from the mains, and has cooled down

Attention: Danger of live!

Servicing work inside the fuel storeroom must

only be carried out under the supervision of a

second person, who must be outside the

storeroom.

system means that regular cleaning work is substantially

reduced. All that is required is regular emptying of the ash.

The flue must be regularly swept. At the same time, the flue

connecting pipe, the flue gas box and the boiler heat

exchanger should be cleared of fly-ash.

PH-01

Depending on the load on the heating system, complete

cleaning – for which the precise procedure is described in the

section "Complete cleaning" – may be required twice a year

but should be carried out at least once a year.

Depending on efficiency, and on ash production you have to

lead interim and general cleaning, this Stepps are descriped

here.

If the heating system is subject to exceptionally high loads,

more extensive cleaning may be required.

Cover panel If there are any Contamination on the cover panel parts and

the control elements, you have to eliminate them with a wet

rag. For wetting you have to use just solvent free, mild cleaning

supplies. Don´t use any cleaning supplies like alcohol,

cleaner´s solvent or diluter, cause these cleaning methods

could be aggressive and could attack the construction´s

surface.

fuel store The fuelstoreroom and the auger feed´s spiral has to be

emptied minimum all 3 years completely (if necaceserry you

have to exhaust it), to suspend any Errors on the Feedsystem

through sediments.

36

Page 37

9.1 INTERIM CLEANING

INFO Interim cleaning must be carried out at intervals of between 2

1

2

Attention Danger of injury!

For safety reasons you must only carry out

servicing and cleaning when the heating system is

switched off and disconnected from the mains, and

week and 3 months , but minimum every half an year.

lead the following Steps in the numbered order:

1) Set the system to the programme "OFF" and allow it to

cool down for at least 1 hours.

2) Open the cover door (1), take of the ash box (2) and

empty it.

Fire danger thoruh rest ember!

has cooled down.

BS-01

3

3

5

4

3) Peel the bouncing plate with the burningchamber (3)

with a poker stick. Insert the poker stick the left ashbox

opening (4).

4) On the User menu, start the function "Clean grate"

(see Section) and allow the stepped grate (5) to clean

itself for a few minutes.

5) The deposite on the grate surface (5) and in the bore

6) Empty the rest ember from the ashbox (6) putt he ash in

7) Attitudes in the costumermenu:

Risk of injury from moving parts!

have to be scratched with a cleaning construction.

the ashroom (6) and close it tight.

Put the parameter „emptying the ash“ to „YES“

and confirm with „OK“

6

6

37

Page 38

9.2 GENERAL CLEANING

7

8

Attention Danger of injury!

For safety reasons you must only carry out

You have to make the generalcleaning twice in one year. The

minimum cleaning is anual. For that you have to lead the

points 1-7 for intermediated cleaning:

lead the following Steps in the numbered order:

1) Open the smokegasbox (7) and pull the cover angel

(8) in above direction. Suct the ash with an ash suction to the

ID Fan (10) between the warmexchangerpipe (9) and the

smokegas.

Fire danger through rest ember!

2) Controll the lambdasond (12) to an tight hub, if

necaserry built it out and clean it with an soft brush.

don´t clean the Lambdasond with highairpressure!

servicing and cleaning when the heating

system is switched off and disconnected

from the mains, and has cooled down.

BS-01

10

12

13

9

11

3) Take off the foto cell (13) and clean it with an soft

cloth. Open the revision lid (14) and check if on the switch

surface are any sediments. If necessary clean it with an

chamber cleaner.

4) Activate the programme „grate cleaning“ and let the

Tipping grate deactivated. At opened tipping grate (5) control

the burning chamber, cotroll and if necessary clean it.

Risk of injury from moving parts!

5) Close the tipping grate again (5) and check if the

chamber is able to close (16).

6) Remove the restember left and right out of the

ashroom (17) with an poking stick. Then out the ashbox inside

and close it.

7) Mount the rebuilted boilerparts carefully again, and

check the cleaningopenings on tightness

8) Attitudes in the Costumermenu:

Took the parameter „ash emptied“ to „YES“ and

confirm with „OK“.

16

14

15

17 17

38

Page 39

10 INFORMATION MESSAGES/ FAULT CODES

Category

F01 Note

F02 Fault

F03 Fault

F04 Fault

F05 Fault

F06 Fault

F07 Fault

F08 Note

F09 Note

F12 Fault

F16 Fault

F19 Note

F21 Fault

F22 Note

F23

Note

Fault

Input TKS1 open longer than "t safe"

smokegassensor > in "Ruler" > after

time Param. "X25" > RGT is + ½ KT is

smaller Param. "RGTk" bt.30-100%

No response from Hall-effect sensor G1

Param. "O2 sensor" or adjusted setting

above the limits of param. "mV top" or

Length of an oxygen sensor pause

Fill level not reached within the time

Ash box wasn´t emptied in the attituted

activator Message Quit. cause

Firebox door or ash box

(door switch)

Clippinggrate could go in 200

seconds not in position

„CO2 after“ will be go under in

20 Minutes when starting

Boiler´s temperature to high!

Fotosensor via time

„parameter“ Tübf

while ignition the Co² value and/

or FW value wouldn´t reached

Para: FW Ignit.

Para: TZ1-TZ4

the filler´s level in the fillingroom

will be not go under

spiralsrunningtime „LZ G1“ min

Fillerlevel in the storeroom is

undercutted

within time "t safe"

STL tripped

"mV btm"

longer than "t stop"

"Outfeed max" .

cleaning time.

Filler levels doesn´t react

above limits. Test oxygen

open

(F01)

Clipgrate could´nt reach

gratecontroll

(F02)

Lambdasondenvalue in

the Start to high

Lambdasondtest!

(F03)

Boiler temperature too

high. Check flue draught

and boiler sensor.

(F04)

burningfail

fuel, grate, sir slider

Controll

(F05)

burning chamber, rust,

drophole, hackchips

controll!

(F06)

Ignition not possible.

Check fuel and grate

(F07)

(F08)

Fillerlevel undercuttet!

refill hackchios!

(F09)

Drive motor G1 jammed

(F12)

Warning STL hightemperature limiter

tripped

(F16)

lambda sond readings

sensor

(F19)

Oxygen sensor pause

timeout. Test oxygen

sensor.

(F21)

Fill level not reached.

Check vacuum system

(F22)

Empty ash box

(F23)

Automatic

Reset

button

Reset

button

Reset

button

Reset

button .

Reset

button

Reset

button .

None

Automatic

Reset

button .

Press STL,

Reset

button .

Reset

button

Reset

button

Reset

button

Reset

button .

BS-01

Door switch defective,

connector faulty, door or ash

box open

ashroom filled, servermotor

faultly, connection faultly

Lambdasond faulty or wrong

pumpfunction not ok, boiler´s

clogged, vacuum system not

attituted

boiler´s function not ok,

feeler faulty

no Fuel;

wrong airattitude;

flue draught wrong;

smokegassensor faulty

no Fuel;

Ignition faultly;

smokegassensor not in

position

no Fuel;

Ignition faulty

Filler levels dusty or faulty

No fuel;

Fillerlevel´s sensor faulty

Fuel chute overfilled

gearmotor faulty

boilerfunctions not OK,

pumpfunctions not ok,

boiler´s target not OK,

boilers sensor faulty, check

covering STB faulty

Lambdasond dirty

Lambdasond faulty

Lambdasond faulty;

flue draught wrong;

RGT to low

No fuel, fill level sensor

defective, vacuum pipes

air-tight, vacuum unit

defective, outfeed motor

jammed

Ash box not emptied or

counter not reset after

emptying

39

Page 40

11 FAULT CLEARENCE

Fault Cause/ Function Remedy

• Power supply disconnected

Control panel cannot be switched on

Smoke escaping into boiler room

Heat output too low

Detonation

Difficult limit output

• Fuse blown

• Flue pipe leaking

• Flue draught regulator

• Flue not clear or not providing any

• Boiler very dirty

• Heating system inadequately

• Boiler priority active

• Flue draught in chimney flue too

• Detonation is only possible if the

• Flue draught is too great

• Wide demand fluctuations on the

unfavourably positioned

draught

balanced

low

firebox is overfilled.

part of heating system

components

PH-01

• Check external mains plug and/or

power supply lead between circuit

boards

• Check fuse in supply lead and on

the control panel circuit board

• Eliminate leaks

• Consult flue installer

• Check flue

• Carry out complete cleaning

• Balance heating system and

heating pumps

• W ait until boiler charging has

finished or deactivate boiler

priority

• Increase flue draught in chimney

flue if necessary

• Carry out complete cleaning or

consult engineer if necessary

• Re-adjust flue draught regulator

• Stagger heating system

component demand over time

Burning fault

Overheating/ STL tripped

Fan to noisy

Drive motor too noisy

• Lambdaprobe dirty

• Lambdaprobe loosley

• Lambdaprobe malfunction

• burningchannel dirty

• The amount of heat produced

cannot be dissipated. A heating

pump may have failed or not

started up.

• Fan is dirty

• Fan or blade loose

• Noise created by bends or rigid

connecting pipe junctions with

chimney flue

• Fan bearing defective

• Noise transmission • If necessary, place the adjustable

• Lambdaprobe cleaning

• Lambdaprobe fix

• Lambdaprobe renew

• clean the burningchannel

• Ensure heat dissipation by

switching on pumps, opening

mixer valve or turning on hot water

taps.

• The cause of the boiler

overheating must be identified (if it

happens frequently a heating

engineer should be called in).

• Check fuses on the boiler circuit

board

• Clean fan

• Eliminate cause

• Fit insulators/sleeves

• Order replacement motor

feet of the boiler on rubber pads

40

Page 41

3 mm using a medium sized

screwdriver and turn it half a turn antilockwise to release it.

12 REPLACING FUSES

2) Switch the Power switch to „0“ and unplug the mains

3) Unfasten the controller cover and remove it.

Repair work may only be carried out by

authorised technicians.!

Touching live electrical components can

cause fatal injury.

Even when the Power switch is "OFF" some

components of the system are still live.

Therefore, when carrying out repair work it is

imperative that the power supply is

disconnected by means of the "mains plug"

or a circuit breaker.

1) Set the system to the programme „OFF“ and allow it to

cool down for at least 10 minutes.

plug on the back of the boiler to fully disconnect it from

the power supply.

BS-01

4) Locate the defective fuse with the aid of the wiring

diagramme in the installation instructions and replace it.

5) Press in the fuse holder 2-

The holder and fuse will then pop out a few mm.

6) Remove the blown fuse and replace with a new one.

7) Insert the fuse holder, press it in 2-3 mm and secure it in

position by turning half a turn clockwise.

41

Page 42

13 SYSTEM LOG BOOK

System operator:

System installer:

Boiler system:

Make: .........................................................................................

Type: .........................................................................................

.........................................................................................

.........................................................................................

.........................................................................................

.........................................................................................

.........................................................................................

.........................................................................................

.........................................................................................

BS-01

Year manufactured: .........................................................................................

Heating output: .........................................................................................

The following checks are to be carried out regularly on

• Weekly visual

inspection

• Monthly checks

the automatic wood-burning boiler system by the system

operator when it is in operation:

Once a week the entire boiler system including the fuel

store is to be visually inspected. Any deficiencies identified

are to be rectified immediately.

The following monthly checks are to be carried out and, if a log

book is maintained, should be recorded in the log book:

• Flue gas passages clean (flue gas channels in boiler, flue

connecting pipe and smoke trap)

• Controller functioning properly

• Fault indication/warning system(s) functioning properly

• Combustion air and flue draught fans functioning properly

• Firebox in good order

• Portable fire extinguisher ready for use

• Correct storage of ash

• No combustibles stored in boiler room

• No accumulation of combustible deposits on roof

Fire safety closures (fire doors self-closing)

• Servicing

42

The heating system must be serviced and inspected in

accordance with the regional, local and statutory regulations of

the country of use.

Page 43

Year:

..................................

Monthly

Check

Controller

Warning system(s)

Fans

Firebox

Portable fire extinguisher

Ash storage

Items stored in boiler room

Deposits on roof

Fire safety closures

Smoke trap cleaning

Signature/initials

System operator:

.....................................................................

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Remarks

Serviced by:

..........................................................................................

Year:

..................................

Monthly

Check

Controller

Warning system(s)

Fans

Firebox

Portable fire extinguisher

Ash storage

Items stored in boiler room

Deposits on roof

Fire safety closures

Smoke trap cleaning

Signature/initials

System operator:

.....................................................................

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Remarks

Serviced by:

..........................................................................................

Year:

..................................

Monthly

Check

Controller

Warning system(s)

Fans

Firebox

Portable fire extinguisher

Ash storage

Items stored in boiler room

Deposits on roof

Fire safety closures

Smoke trap cleaning