Guntamatic Biocom series, Biocom 40, Biocom 30, Biocom 100, Biocom 75 Planning And Installation Manual

...

Pellet firing englisch

BIOCOM

Planning and installation

BC-01

EN-B31-007-V12-0515

2

Information on this documentation

BS-01

Please read through this documentation carefully.

It is intended as a reference document and contains important

information on the design, safety, operation, maintenance and

care of your heating system.

We are always looking to improve our products and

documentation. Any ideas and suggestions you may have will

be gratefully received.

GUNTAMATIC Heiztechnik GmbH

Bruck 7

A-4722 PEUERBACH

Tel: 0043 (0) 7276 / 2441-0

Fax: 0043 (0) 7276 / 3031

Email: office@guntamatic.com

It is important that you pay particular attention

to the safety issues highlighted in the text by

these symbols.

The entire contents of this document are the property of

GUNTAMATIC and therefore protected by copyright.

Reproduction of any kind, communication to third parties by any

means or use for purposes other than those intended without

the written consent of the owner is prohibited.

Subject to printing errors and technical amendments.

3

Contents

BC-01

Page

1 Introduction ............................................................................4

1.1 Safety instructions 4

1.2 Gurantee and liablitiy 4

1.3 Commissioning 4

1.4 Site requrirements 4

2 Planning..................................................................................5

2.1 Fire safety 5

2.2 Minimum fire safety requirements 6

2.3 Boiler room requirements 7

2.4 Flue requirements 9

2.5 Flue draught regulator and pressure- surge compensator 10

2.6 Fuel store requirements 11

2.7 Examples for planning 13

2.8 Automatically ash System 15

2.9 Heating circuit Rules 17

3 Constructiom........................................................................19

3.1 Delivery 19

3.2 Carrying to installation site 19

3.3 Positioning and aligned the boiler 19

3.4 Plumbing connections 20

3.5 Filling and bleeding system 23

3.6 Flue connection 24

3.7 Construction holding 25

3.7.1 System FLEX 25

3.7.2 System BOX 29

4 Electrical connections .........................................................30

4.1 Heating system electrical connections 32

5 Final checks..........................................................................33

6 Standards/ Regulations .......................................................34

7 Plumbing diagrams..............................................................35

7.1 Backup Memory HP0 35

8 Technical data ......................................................................54

8.1 Biocom 30 / 40 / 50 54

8.2 Biocom 75 / 100 55

8.3 Holding System FLEX 56

8.4 Holding System BOX 56

4

1 Introduction

BS-01

1.1 Safety instructions

GUNTAMATIC heating systems represent state-of-the-art

technology and meet all applicable safety regulations. Incorrect

installation can endanger life and limb. Heating boilers are

combustion systems and are potentially dangerous if handled

incorrectly. Installation, commissioning and servicing must,

therefore, only be carried out by adequately qualified

technicians observing all regulations and the manufacturer's

instructions.

1.2 Guarantee and liability

The manufacturer's guarantee is subject to correct installation

and commissioning of the heating system. Defects and

damage caused by incorrect installation, commissioning or

operation are not covered by the guarantee. To ensure that the

system functions as intended, the manufacturer's instructions

must be followed. Furthermore, only genuine replacement

parts or parts explicitly approved by the manufacturer may be

fitted to the system.

1.3 Commissioning

Commissioning of the boiler must be carried out by an

authorised GUNTAMATIC specialist or other qualified persons.

They will check whether the system has been installed

according to the plans, adjust the system settings as required

and explain to the system operator how to use the heating

system.

1.4 Site requirements

When establishing the site requirements, it is absolutely

essential to take account of the locally applicable planning,

building and implementation regulations and the dimensional

specifications in the fitting guidelines, installation examples and

technical data. Compliance with the locally applicable

regulations and the correct implementation of the measures

required on site are solely the responsibility of the system

owner and are a requirement of the manufacturer's guarantee.

GUNTAMATIC provides no guarantee of any kind for any type

of site work. Without making any claims as to completeness or

non-applicability of official requirements, we recommend the

following specifications based on the Austrian Guidelines pr

TRVB H 118:

5

2 Planning

01

2.1 Fire safety

BS-01

The fire security instroductions are obligatory needed

on the construction place

The Compliance from counties ore states fire security

law is obligatory and stands higher then the

GUNTAMATIC fire security instruction

Austria State legislation of the federal states

Technical Directive on Preventative Fire Safety (pr TRVB H118)

Germany Standard boiler regulations (M-FeuVO)

Hessen and Saarland – in these states §16 FeuVO Hessen applies

Switzerland Fire safety regulations

(www.vkf.ch)

any other exporting countries Any fire safety office

You have to follow you specific country fire safety

rules obligatory. Your country safety rules are higher

then our GUNTAMATIC minimum rules.

If there are no specific fire security rules in your

country, you have to follow the GUNTAMATIC

introductions

6

2.2 Minimum fire safety requirements

BC-01

Boiler room Floor of concrete construction, either bare or tiled. All materials

for floor, walls and ceiling must be fire-resistant to F60/REI60

rating.

Boiler rooms door: The Boiler room’s door also might close

single handed and it has to be possible to close off the door.

Connecting doors to the fuel storeroom must also be Class

T30/EI230-C fire doors, self-closing and lockable. There must

be no direct connection to rooms in which flammable gases or

liquids are stored.

Fuel storeroom The same minimum fire safety requirements apply as for the

boiler room.

Storeroom doors/hatches: Storeroom doors/hatches must be

fire safe to Class T30/EI230-C, self-closing and lockable. There

must be a warning sign carrying the message "Do not enter

when feeder system is running" attached to the storeroom

door/hatch.

Fireproof collars: If the storeroom is not situated directly

adjacent to the boiler room, a fireproof collar must be fitted to

the extraction and air return pipes at their wall exit points from

the boiler room. If the outfeed auger goes directly into the

boiler room, it is factory fitted with a special fire safety lining.

No additional fireproof collars are required on the air pipes. If

the outfeed auger is sited entirely inside the storeroom (i.e. if

the outfeed auger does not extend out of the storeroom),

fireproof collars must similarly be fitted to the extraction and air

return pipes at their wall exit points from the storeroom.

> 50 m³

HLE - Manual fire extinguisher: If 50 m³ of fuel or more can

be stored, a manually operated fire extinguishing facility must

be installed. It must be protected against freezing and

connected to a pressurised water pipe (DN20 conduit). The

discharge point must be located directly above where the fuel

outfeed channel exits the storeroom. The fire extinguishing

facility must be identified by a sign carrying the inscription

"Fuel storeroom fire extinguisher".

Filler pipes: Filler pipes through rooms where there is a fire

risk must be provided with Class F90/REI90 cladding.

7

2.3 Boiler room requirements

BC-01

Minimum room height

BC 30 / 40 / 50 ideal solution

H 225 cm

1)

possible

H 210 cm

BC 75 / 100 ideal solution

H 240 cm

1)

possible

H 230 cm

1)

= minimum height on upscrewed heat exchanger

Minimum room size

BC 30 / 40/50

B 240 cm x

2)

T 230 cm

(

3)

T 240 cm)

BC 75 / 100

B 270 cm x

2)

T 230 cm

(

3)

T 240 cm)

2)

T = The room with boiler’s bodies front seeing from behind

3)

= Minimum size from the automatic ash suction system

Clear access opening

BC 30 / 40 / 50

4)

ideal

B 120 cm x H 205 cm

5)

possible

B 80 cm x H 170 cm

6)

possible

B 75 cm x H 165 cm

BC 75 / 100

4)

ideal

B 180 cm x H 210 cm

5)

possible

B 100 cm x H 190 cm

6)

possible

B 90 cm x H 180 cm

4)

= Contribution of ready mounted boiler on transportwood

5)

= Contribution without Stoker, cleaning impulse and Transportwood

6)

= Measures with aditional to Point 5) unrigged

Combustion air supply The pressure in the boiler room must not be less than 3 Pa

(0.3 mm H2O). The air vents for boiler rooms must have a

clear, net cross-sectional area of at least 200 cm² and must not

be sealable. With combustion boiler systems with a fuel heat

output upwards of 50 kW, the net, clear cross-sectional area

must be increased to at least 5 cm² per kW rated output

according to the combustion air requirement of the boiler

system. The air supply ducting must connect directly to the

outside and if the ducting passes through other rooms, it must

be jacketed to Class F90/REI90. On the outside of the building,

air vents must be covered by a protective grille with a mesh

size of > 5 mm. The supply of combustion air should, if

possible, enter at floor level in order to prevent cooling of the

boiler room.

Electrical installation The lighting and the electrical wiring in the boiler room must be

permanently installed. There must be a clearly marked

emergency off switch in an easily accessible position outside

the boiler room, close to the boiler-room door.

The line connector 230 VAC, 50 Hz, 13 A is needed.

Fire extinguisher A hand-held fire extinguisher (6kg gross weight, EN3) must be

mounted outside the boiler room near the boiler-room door.

Protection against freezing

The boiler room, pipes carrying water and any district heating

pipes must be protected against freezing.

8

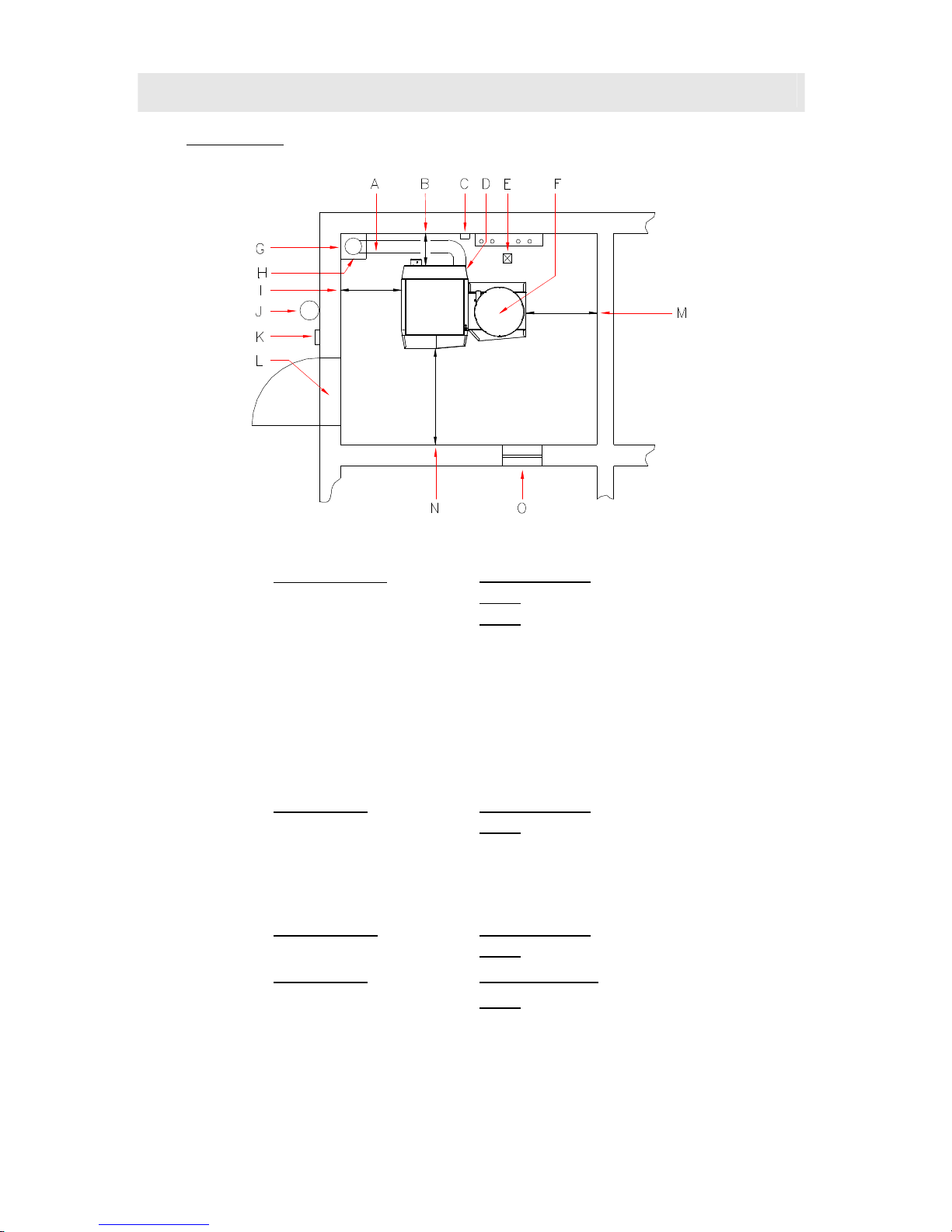

Installation site You have to plan the furnace in the near of the chimney to avoid a long

flue pipe.

A →

Integration version of Energy saving draft regulator with Ex flap and with fire tube

respect the local fire security rules- dust information possible

B →

BEHIND distance

ideal

70 cm minimum

possible

50 cm

without Ash suction system

60 cm

with Ash suction system

C →

The discharge for overheating

D →

Line Connector 230 VAC 13A

E →

Drain

F →

Sparger complex

G →

flue

wet non- sensitive chamotte-flue advised

H →

installation variant energy-saving damper with explosion damper in the flue

c

a. 50 cm under the flue – please follow the local laws

I →

LEFT distance

ideal

70 cm minimum

possible

40 cm

J →

fire extinguisher

6 kg filling weight EN3

K →

escape switcher (emergency stop)

L →

fireproof door

T30 / EI230-C lockable and self depended

M →

RIGHT distance

ideal

70 cm minimum

possible

40 cm

N →

LEFT distance

ideal

100 cm minimum

possible

80 cm

O →

Combustion air supply

9

2.4 Flue requirements

BC-01

Use heat-insulated fireclay flues that are

insensitive to damp.

The flue gas temperature can be less

than 100°C.

The system must only be connected to the flue if the flue

meets the legal requirements and the technical specifications.

The flue must be matched to the boiler output and

dimensioned in accordance with DIN 4705. In order to be able

to accurately dimension the flue, the calculations must be

based on the flue gas figures. When designing new flues, high

thermal insulation chimneys (DIN 18160 T1 heat transmission

resistance group I) or suitable fireclay flues that are

insusceptible to damp and have general building regulation

approval should be used. It is advisable to involve those

responsible for approving the flue system early on in the

planning phase.

Flue height The minimum flue height is 5 - 10 m depending on boiler

output. The flue must terminate at least 0.5 m above the

highest part of the building. In the case of flat rooves, the flue

must terminate at least 1.5 m above the surface of the roof.

Flue diameter The flue hast to adjust on the fire power. The following dates

are approximate values and could be used for planning. We

recommend calculating the flue by a professional.

BC 30 / 40 / 50

BC 75 / 100

eff. high above 6 m D = 160 mm

eff. high under 6 m D = 180 mm

eff. high above 6 m D = 200 - 220 mm

eff. high under 6 m D = off 220 mm

Flue dimensioning data Dimension the flue for rated output!

(Averaged figures with used heat exchanger)

Rated output:

Type exhaust CO2 massflow

draft

requirement

BC 30 160°C 12,5% 0,024 kg/s 15 Pascal

BC 40 170°C 13,0% 0,030 kg/s 15 Pascal

BC 50 175°C 13,0% 0,030 kg/s 15 Pascal

BC 75 190°C 13,0% 0,042 kg/s 15 Pascal

BC100 190°C 13,0% 0,055 kg/s 15 Pascal

Sub-maximum output:

Type exhaust CO2 massflow

draft

requirement

BC 30 100°C 9,5% 0,010 kg/s 2 Pascal

BC 40 105°C 10,0% 0,012 kg/s 2 Pascal

BC 50 115°C 10,0% 0,009 kg/s 2 Pascal

BC 75 120°C 10,0% 0,013 kg/s 2 Pascal

BC100 120°C 10,0% 0,017 kg/s 2 Pascal

10

2.5 Flue draught regulator and pressure-surge compensator

BS-01

Fitting an energy-saving flue draught

regulator/pressure-surge compensator

(Class RE) is absolutely imperative.

The flue draught should not differ by more than +/- 3 pascals

from the figure specified in the flue dimensioning data. If the

flue draught cannot be reduced to the required figure, either a

larger draught regulator should be fitted or an additional flue

baffle fitted between the flue and the draught regulator.

Purpose

• To ventilate the flue when the system is not in operation

• To compensate for pressure surges

• To regulate and limit the flue draught

Fitting requirement The energy-saving flue draught regulator must be fitted in

accordance with the local regulations, preferably in the flue

approx. 0.5 m below the point where the flue connecting pipe

joins or alternatively in the flue connecting pipe close to its

junction with the flue.

Flue draught setting

• Adjusting the flue draught is only of any use at

outside temperatures below +5°C.

•

The system must have been in operation for at least an hour

• Ensure there is sufficient demand for heat for the boiler to

be run at rated output for at least 15 minutes

• Measure the flue draught between the boiler and the flue

draught regulator (distance of measuring point from boiler

ideally 3 x flue diameter from connection between boiler

and flue connecting pipe).

Too much flue draught

May cause the flue gas temperature to increase

and accelerate combustion as a result. Poor

boiler output adjustability, increased dust

discharge and malfunctions can result.

Too little flue draught

Performance problems, incomplete combustion

and malfunctions when operating below rated

output can result.

11

2.6 FUEL STORAGE

BS-01

Please note:

the specific national rules for your fuel store

(for example. ÖNORM M7137, VDI 3464,..

.) are strictly

adhered blindly

Jahresbedarfsschätzung The fuel store should be able to pick up the stock for a year .

The fuel store volume is circa 2/3 when the fuel supply is

active. The storeroom should be recantugular and wider then

3,5 m. So narrower the store room is, so less storeroom is

available.

→ per 1 kW/Year ca. 0,65 m³ = ca. 450 kg Pellets

wetprotection The fuil is to protect from wet floors or walls. The storeroom

has to be dry during the whole year. In case of temporary

wettnes walls, we advice you to install a ventilated facin on the

wall. You also have to clad the walls with derived timber

product.

Cold area

Suction pipes and order units in the cold areas might be

isolated freezeproof.

Danger of condensation!

filling set There has to mounted two filling stuts

minimum distance 0,5 m – maximum distance 1,5 m.

Location The fuil will delivered in an pump truck. The storeroom ort he

filling conections has to be ordered, that they are reachable

form a tube which has a maximum length from 30 m. On the

second filling connection the Transport air will be aspirated the

transport air.

Statics

With Flex store systems on the floor and the containment walls

must have the static requirement withstand by the stored fuel

and the pressure during filling. In Box store systems requires

particicular attention to the sustainability to the substed, as at

full filling in the Box acting on the individual support points.

BOX placement

The box must be installed basically separated from the boiler in

another room. In some countries, the fabric tank could be set

up in the room where the furnance if there is a minimum

distance of 2 m between the BOX and the boiler could be

maintained and the thermal output does not reach 50 Kw.

Therefore observe the regulations in force addition! For

outdoor positioning, no F90/ REI90 trim is required , if the

minimum distances were respected. The fabric tank must be

protected against rain, wetness and UV Light.

FLEX wall breakthrough Breadth 33 cm / High 25 cm

(for FLEX propulsive unit)

12

Fuel store air sparging

To avoid an high perilous Co² consentration you have to lift the

store and Broiler room.The opening for the lifting might

discharge into the atmosphere. There must be an air change

between the Storeroom and the ambient atmosphere. If the

natural thermal isnt´t enough you have to take technical

measures.

If the filling stubs (the openings) discharges not into the

atmosphere you have to lift it with another lifting opening. you

have to be careful, that there is no rainwater into the storeroom

from the filfting opening. The construction site from the

permeable to air storage container might have a port in to the

atmosphere. A ventilator shifts from 200cm² is enough.

Up to 30 t storage volume the requirement is prepossessed, if:

• The filling stub (opening) is leading into atmosphere for

minimum 2 caps with an air inlet

• The diameter from 2 ventilation pipes is per pipe

minimum 90 mm

• The ventilator shift from the exhaust port from both

Ventilation pipes from 2 m minimum 40 cm² and must be

higher then a lenghth from 2 me but minimum 60 cm ².

INFO: The whole ventilation shift from 2 caps from our

filling sets is 60 cm².

Over 30 t storage volume the requirements

• a combination between natural and manual lifting, based

on a Co² Sensor. If there is no natural lifting you have to

install forced ventilation- in case of a high Co²

Concentration ventilation is lifting automatically.

Access doors/hatches Above-ground fuel stores must be provided with a door or

hatch that opens outwards. So that the fuel cannot run out if

the fuel store is opened by mistake, the inside of the access

door/hatch opening must be covered with boarding (which

must be removable from the outside). During to the risk of

injury when the system is in operation, access doors/hatches

must be lockable and kept locked when the system is in

operation. There must be a warning sign carrying the message

"Do not enter when feeder system is running" attached to the

access door/hatch.

Electric Installation At FLEX storesystems electroinstallations in the fuil aren´t

permissible.

At box level systems electroinstallations in the show room

aren´t allowed.

Filling couplings have to be grounded.

13

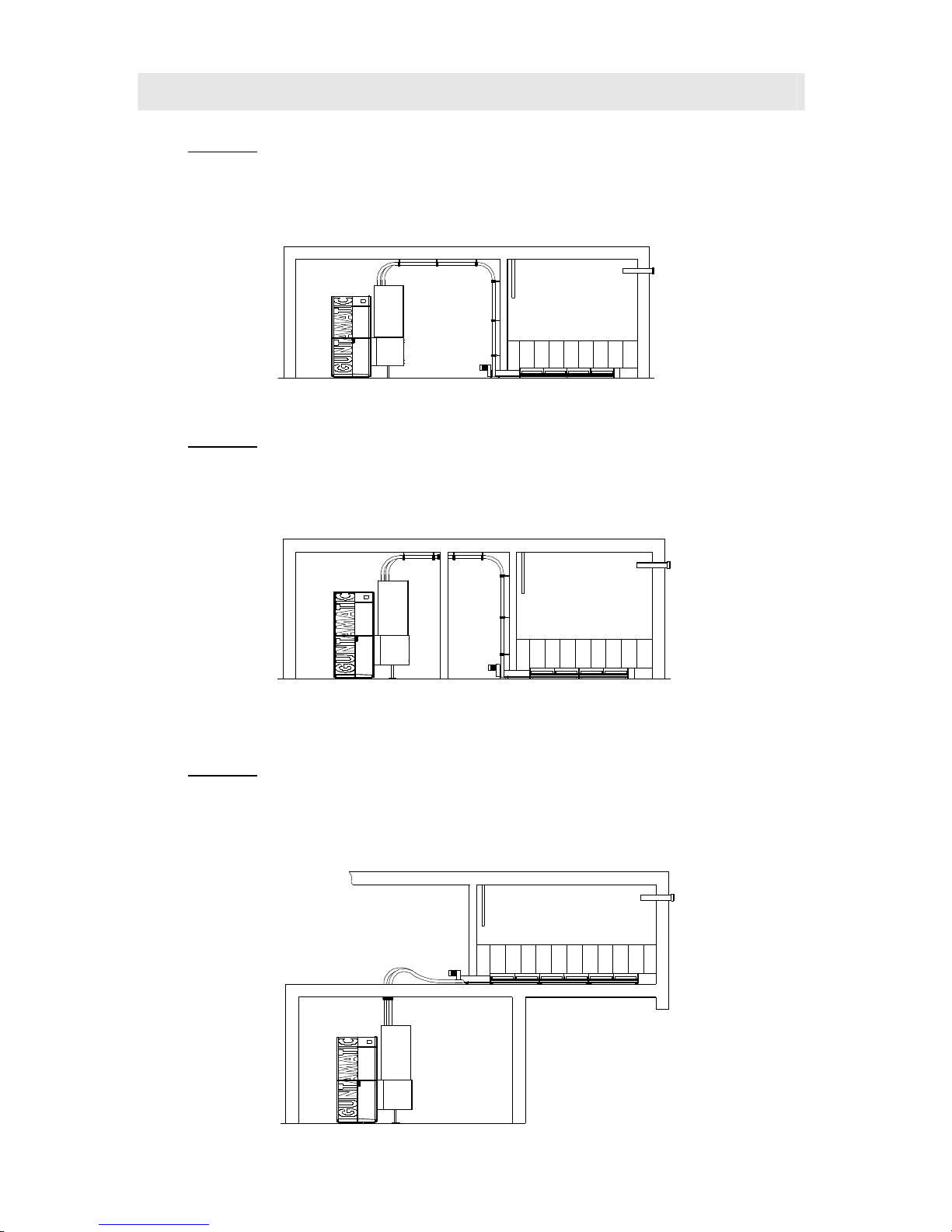

2.7 EXAMPLES FOR PLANING

BC-01

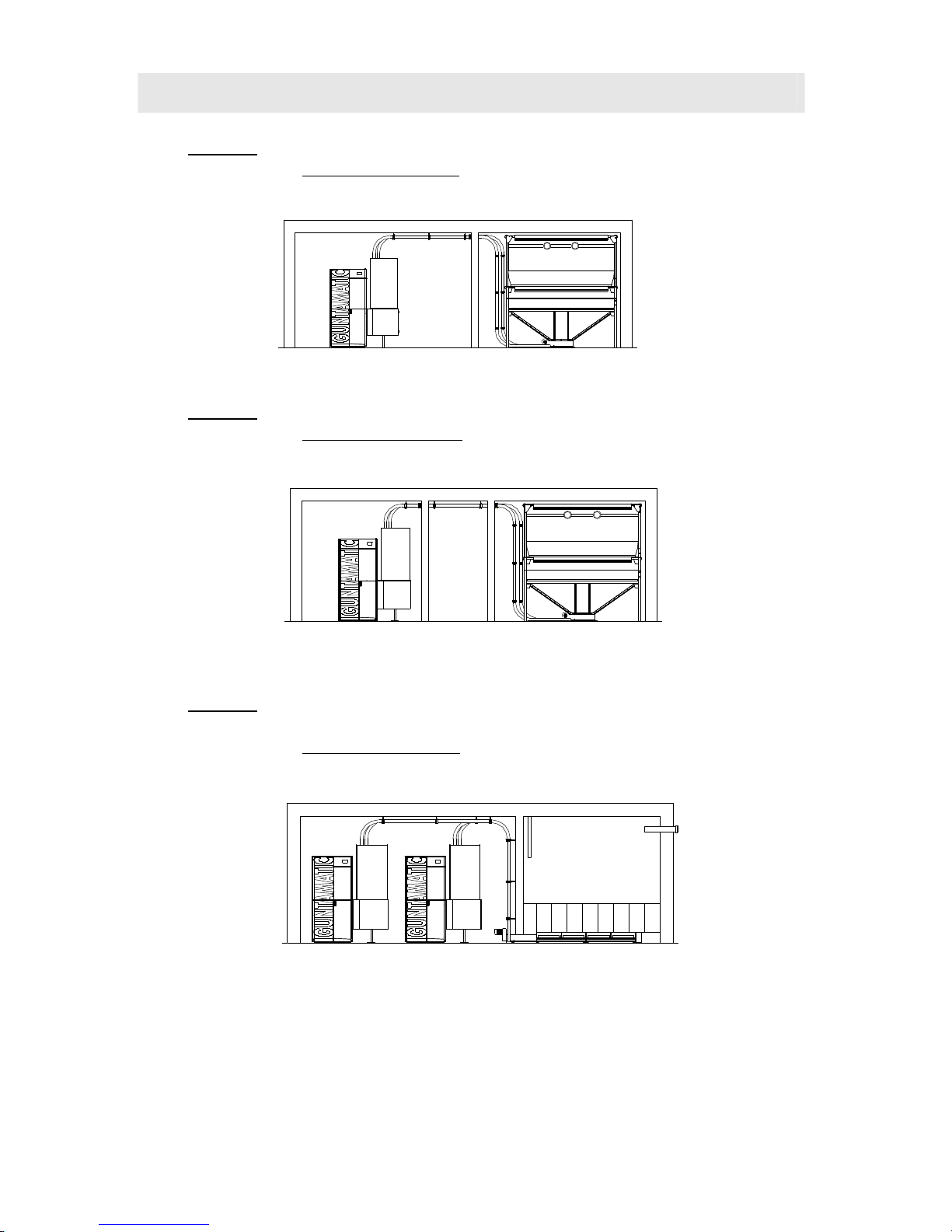

Example 1 Construction with Flex fuel supply next to the heating room.

The maximum length of agitator is 5m.

The maximum suction length is 25 m.

Minimum 2 fire security wristbands needed – please respect the minimum fire security rules!

Example 2 Machine with Flex fuel supply with annother building section.

The maximal length of extracting screw amounts 5 m.

The maximal suction length is 25 m.

Minimum 2 fire security wristbands needed – please respect the minimum fire security rules!

Example 3 Machine with Flex fuel supply with annother building section.

The maximal length of extracting screw amounts 5 m.

The maximal suction length is 25 m.

Minimum 2 fire security wristbands needed – please respect the minimum fire security rules!

14

Example 4 Consruction with BOX- fabrictank direktly above the heatingroom.

The maximum Suctionlength is 25 m.

Minimum 2 fire security wristbands needed – please respect the minimum fire security rules!

Example 5 Construction with BOX- fabrictank in a other building section.

The maximum Suction length is 25 m.

Minimum 4 fire security wristbands needed – please respect the minimum fire security rules!

Example 6 Cascade construction with 2 FLEX-R directly below with the heating room.

The maximal length of extruding screw constitudes 5 m.

The maximum suction length is 25 m.

No fire security wristbands needed – please respect the minimum fire security rules!

15

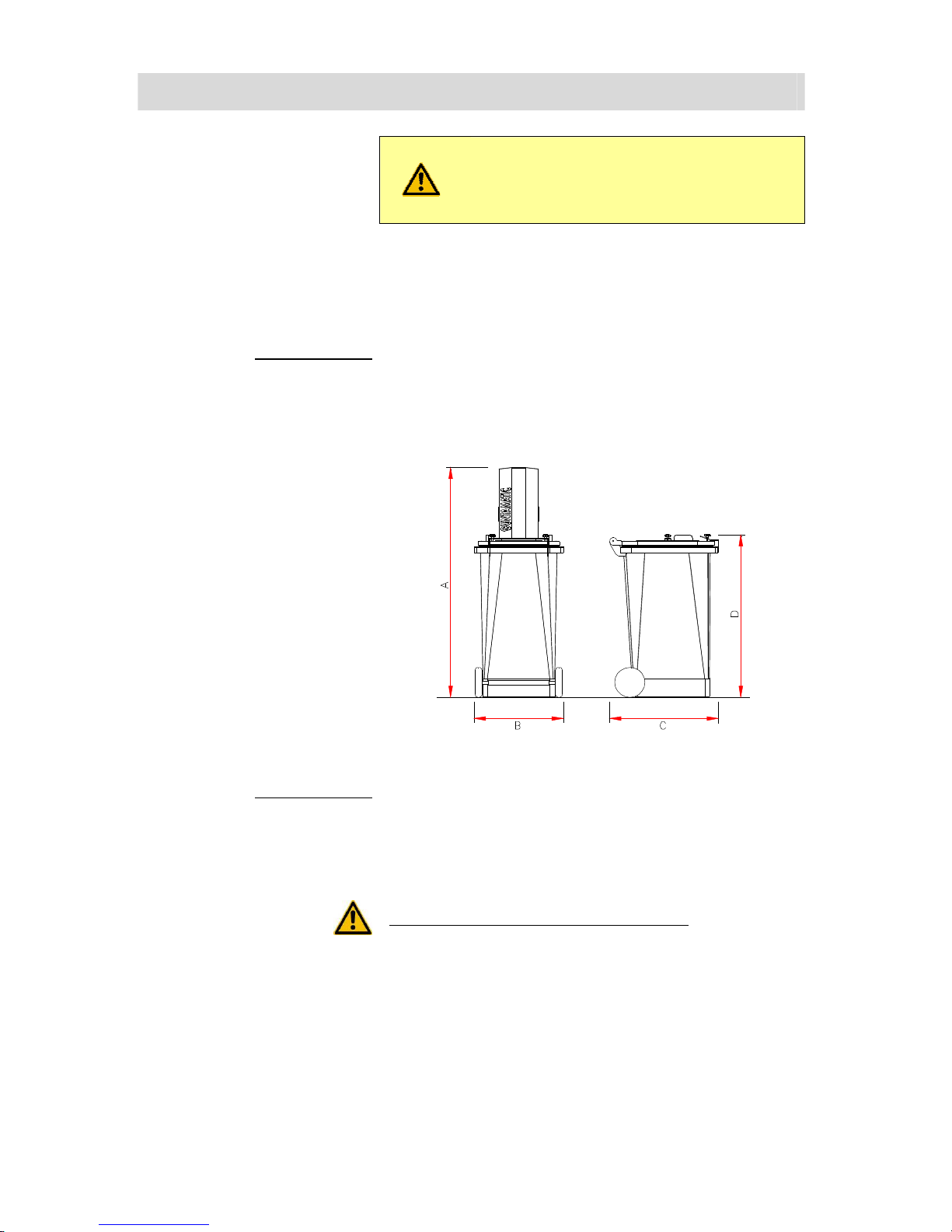

2.8 AUTOMATIC ASH SUCTION SYSTEM

PC-01

The following Introductions are for Device

planning- for installation of ash vacuum suction

system there is another Introduction included.

Optional there is a automatic ash vacuum system. The

accumulated ash will go through the firing build Feedsystem

and flexible metal tube in a big removable ashton. The

deashing is automatically.

Retofit the system It´s possible to retrofit the ash vacuum suction system, if the

minimum difference between the wall and the system ist 60

cm.

A → 153 cm

B → 59 cm

C → 72 cm

D → 107 cm

Construction side: If possible, you have the opportunity to plan the ash ton at a

ground level beside the boiler’s body. Basic requirement for

the construction is a good lifting through the installation site,

The ash ton must have a 25 cm minimum difference to

inflammable materials. You have to be a look that there is no

inflammable ground.

Not permitted construction side for an ash ton:

• in an garage

• in the atmosphere in living rooms;

• in storerooms with inflammable materials or gases.;

16

Permitted Construction places for the ash ton:

• in the boiler room

• in an secondary

room

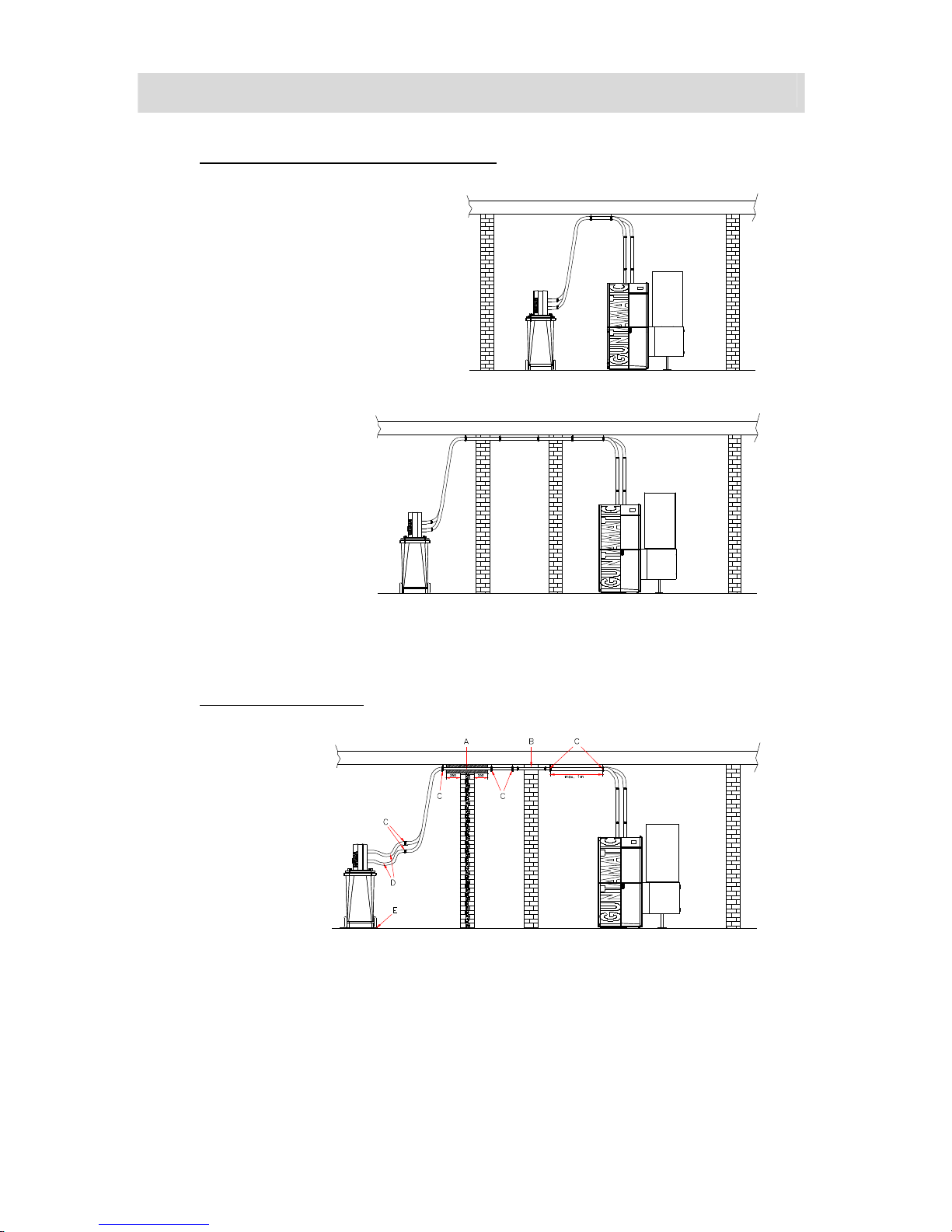

Hauling of a suction pipe through fire zones

A → wall penetration with Rockwoolpipesprialclamp;

B → wall penetration with boiled Steel pipe;

C → fire security clamps 54 – 60;

(maximal 1 m difference)

D → flexible suction metal tube

(minimum 10 cm difference)

E → not inflammable mad

17

2.9 HEATING CIRCLE RULE

PH-01

The heating circle rule is optional offered.

You can decide between a MKR set or a wall mounted MK 261

set.

●

per construction 3 controlled by atmospheric condition rules

possible

●

per construction could be actived just 1 MKR Set boiler

●

pro Machine there are 3 remote control möglich;

●

per heatingcircle one analogue room unit possible

Exceptions at five sensors are buffer management

Please note the information in section 5- sensore buffer management of

chapter 7.1 and buffermanagement HP0 !

Set-MKR Following functions could be activated:

Heatingcircle

● Warmwater-Memory

Heatingcirle 0

optional avalible

........

● pump heating circulation

● aditional warmwater memory

● external heatingcirculation

Heatingcircle 1

optional avalible

.......

● Pumpenheizkreis

● gemischter Heizkreis

Heatingcircle 2

optional avalible

.......

● Pumpenheizkreis

● gemischter Heizkreis

wall mounted model set-MK261 Following funtions could be active:

Heatingcircle WW

● warmwater- memory

Heatingcircle 0

optional

.................

● pumpingheatingcircle

1)

● third mixed heatingcircle

Heatingcircle 1

optional

.................

● pumpingheatingcircle

● mixed heatingcircle

Heatingcircle 2

optional

.................

● pumpingheatingcircle

● mixed heatingcircle

Trunk link

optional

.........................

● feederpump

(ZUP)

● dumping device pump

(PUP)

● cargo pump

(LAP)

2)

● extension

(ERW)

3)

● third mixed heatingcircle

adition

optional

..............................

● aditional warmwater memory

● external heatingcircle

4)

● third mixed heatingcircle

INFOBOX

1) the third mixed heatingcircle could be actived, if the functions trunk link and addition are not used.

2) through „ERW“ function a heating circle controller with trunk blink can be assigned an other heating circle controller

3) if the function „third mixed heatingcircle“ is activated, the trunk blink functions are not availible.

4) if the „third mixed heatingcircle“ is activated, the additional functions are not availibe.

Loading...

Loading...