Gunnebo Lifting CH, CHE, CHS, CHP, CHD Owner's Manual

...

1

Användarhandbok - Lyfthandskar

Gebrauchsanleitung - Sicherheits-greifklemmen

Lifting Systems

Owners Manual - Safety plate lifting clamp

www.gunnebolifting.com

Manual do Utilizador - Pinça de segurança de elevação

CH, CHE, CHS, CHD, CHP, CHNM

2

Please carefully read the safety instructions of this owner’s manual before using

the safety lifting clamp. In case of any doubts, please refer to your dealer!

Our manuals are intended to be a reference source throughout the lifetime

of your product.We appreciate any suggestions, and/or comments regarding this manual.

Due to continuing research and development activities, product specifi cations are subject

to change without notice.

English

Läs anvisningarna i denna användarhandbok noggrant innan du använder lyfthandsken.

Vid frågor, rådgör med återförsäljaren. Våra handböcker är avsedda att vara en referenskälla

under produktens livslängd. Vi uppskattar förslag och/eller kommentarer angående

denna handbok. På grund av kontinuerligt undersöknings- och utvecklingsarbete, kan

produktspecifi kationer ändras utan föregående meddelande.

Lesen Sie die Gebrauchsanleitung vor Benutzung des Produkts sorgfältig durch.

Bei Fragen wenden Sie sich bitte an Ihren Zulieferer. Die Gebrauchsanleitung dient

während der gesamten Lebensdauer des Produkts als ständige Informationsquelle.

Für Hinweise oder Anmerkungen zur Verbesserung des Inhalts dieser Gebrauchsanleitung

sind wir dankbar. Aufgrund kontinuierlicher Forschungs- und Entwicklungsprozesse

behalten wir uns technische Änderungen und/oder Änderungen äußerlicher

Leia atentamente as instruções de segurança deste manual do utilizador antes de utilizar

a pinça de segurança de elevação. Em caso de dúvida, consulte o seu revendedor! Os

nossos manuais devem ser um ponto de referência ao longo da vida útil do seu produto.

Agradecemos quaisquer sugestões e/ou comentários relativos a este manual. Devido às

contínuas actividades de investigação e desenvolvimento, as especifi cações do produto

estão sujeitas a alterações sem aviso prévio.

Svenska

DeutschPortuguês

3

Contents

1 General 3

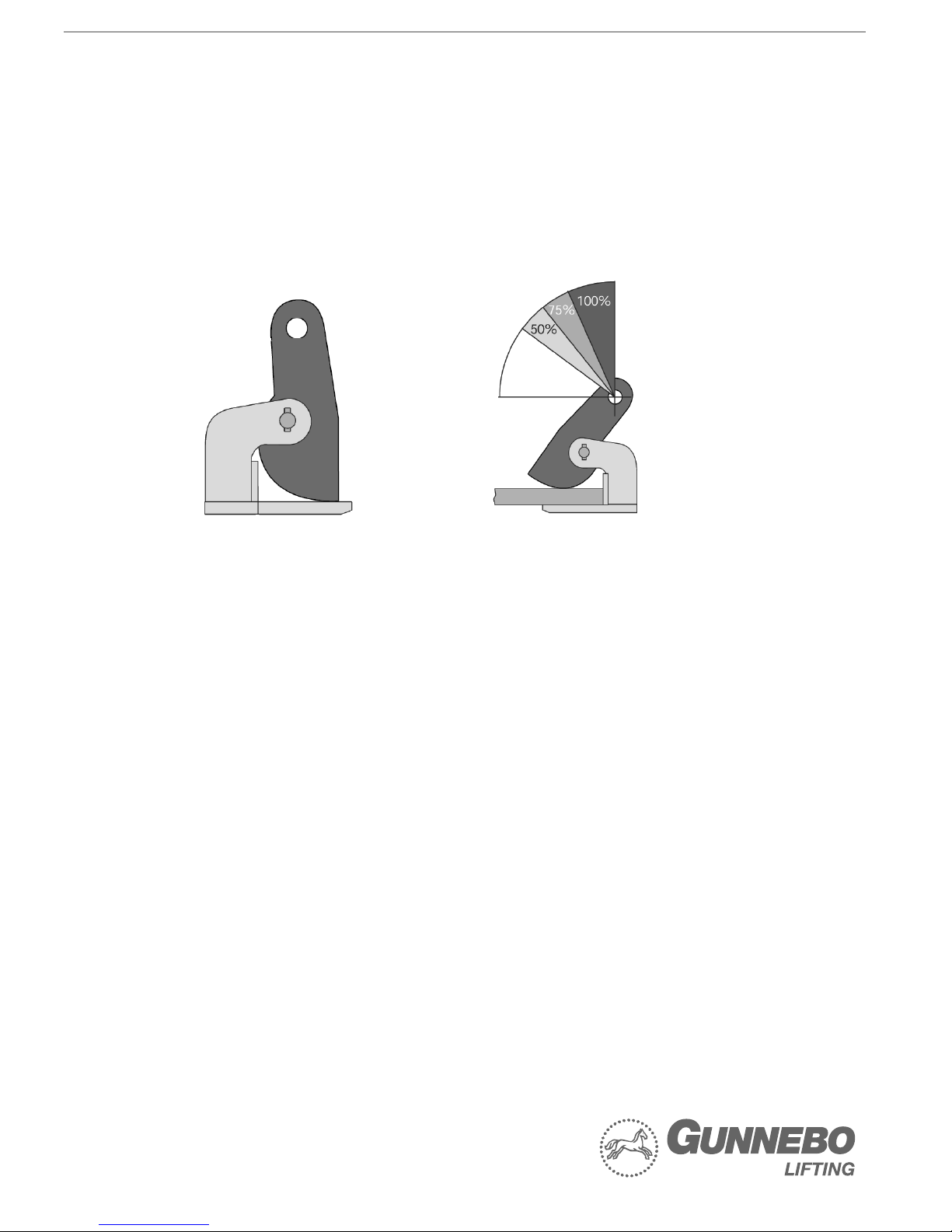

2 Operating principle 3

3 Permitted applications 3

4 Safety instructions 4

5 Lifting 5

- CH, CHE, CHD, CHNM

- CHP

6 Maintenance 6

7 Disassembling/Assembling 6

- CH, CHE, CHS, CHD

- CHP

- CHNM

8 Overhauling 7

9 Disposal 7

10 Troubleshooter’s checklist 8

11 Warranty 8

1 General

Congratulations with the acquisition of a Gunnebo Lifting safety plate lifting clamp.The quality

systems of management and services of Gunnebo Lifting fully comply with ISO 9001

standards. The many years of vast experience are a guarantee of optimum quality and safety.

Gunnebo Lifting Clamps are made of top quality steel and fully comply with European standards

as laid down in Machine Directive 2006/42/EG.

2 Operating Principle

The CH, CHE, CHS, CHNM and CHP horizontal safety lifting clamps have specifi cally

been designed for the horizontal lifting and transporting of non-bending steel plates. The

clamps consist of a body, cam, and cam pin. The cam also functions as a lifting shackle and

ensures that the load is held fi rm-ly while it is being lifted.

3 Permitted Applications

CH, CHE, CHS and CHNM

Gunnebo Lifting CH, CHE and CHNM lifting clamps are only suitable for lifting and horizontal

movement of non-bending steel plates and structures where it is possible to position the clamp

on a fl at point of contact. The clamps should always be used in pairs, or multiples thereof.

In the latter case, however, preferably with a load spreader beam.

CHD

Gunnebo Lifting CHD lifting clamps are only suitable for lifting and horizontal movement of both

bending steel plates and formed steel plates, where it is possible to position the clamp on

a fl at point of contact. CHD clamps should always be used in pairs, or multiples thereof.

CHP

Gunnebo Lifting CHP clamps are only suitable for horizontal movement of steel plates and packages

of steel plates, where it is possible to position the clamp on a fl at point of contact. The clamps should

always be used in pairs, or multiples thereof. In the latter case, however, preferably with a load

equalising beam. Provided that the steel plate of plates do net bend (defl ect), one or more plates can

be hoisted at once per Iift. When pairs or multiple clamps are used, each damp should carry en

equal part of the load.

English

4

4 Safety Instructions

Safety fi rst! Guarantee your personal safety by carefully reading the following safety

instructions fi rst.

Ensure your own safety and continue to benefi t from our product safety by having the

clamp inspected, tested and, if necessary, overhauled at least once a year by Gunnebo Lifting

or a recognized mechanical repair and service centre. See also Chapter 8 - Overhauling.

Contact Gunnebo Lifting for further information.

Avoid situations dangerous to life

Prevent dangerous situations by seriously taking care of the following precautions:

- Never work with an untested clamp.

- Keep your distance when lifting and never stand under the load.

- Do not use the clamp if (it has been) damaged; have the clamp immediately repaired by Gunnebo

Lifting or a recognized mechanical repair centre. If in doubt consult your supplier.

- Never lift more than one plate or a package of plates at a time.

- Never lift plates heavier than the working load limit (W.L.L.), as indicated on the clamp and in the

test certifi cate.

- Do not lift plates which are thicker or thinner than the jaw opening, as indicated on the clamp and

in the test certifi cate.

- When using a number of lifting damps at the same time, please provide lifting slings or chains of

a suffi cient length to ensure that the angle between the slings or chains never exceeds 60°.

- When simultaneously operating a number of lifting clamps time side by side, please use a lifting

beam (equalizer) and lifting slings or chains of a suffi cient length to ensure that the lifting shackles

on the clamps are never subjected to lateral load.

- Do not place the clamp on tapered or conical sections of the plate or structure to be lifted.

- Remove all grease, oil, dirt, corrosion and mill scale from the plate at the point where the clamp is

to be attached.

- Ensure that the damp(s) is (are) positioned so as to balance the load when it is being lifted.

- The surface hardness of the plate must not exceed 37 HrC (345 Hb, 1166 N/mm2).

- The clamp is only suitable for use in normal atmospheric conditions.

Safety precautions

Ensure that the cam can never be subjected to lateral load.

- A free fall or uncontrolled swaying at the crane hook resulting in objects being struck, may cause

impact damage to the clamp. If this happens check whether the clamp is still in good working

order before using it.

- Lifting clamps are not suitable for creating permanent joints.

- Maintenance of the clamp should take place on a regular monthly basis, see Chapter 6 - Maintenance.

- Do not modify the clamp (by welding, grinding, etc.), as this can adversely affect its operation and

safety, thereby nullifying any forms of guarantee and product liability.

- For the very same reason, use only original Gunnebo Lifting components.

- Any improper use of the clamp and/or failure to observe any directions and warnings in these

operating instructions concerning the use of this product may endanger the health of the user

and/or bystanders.

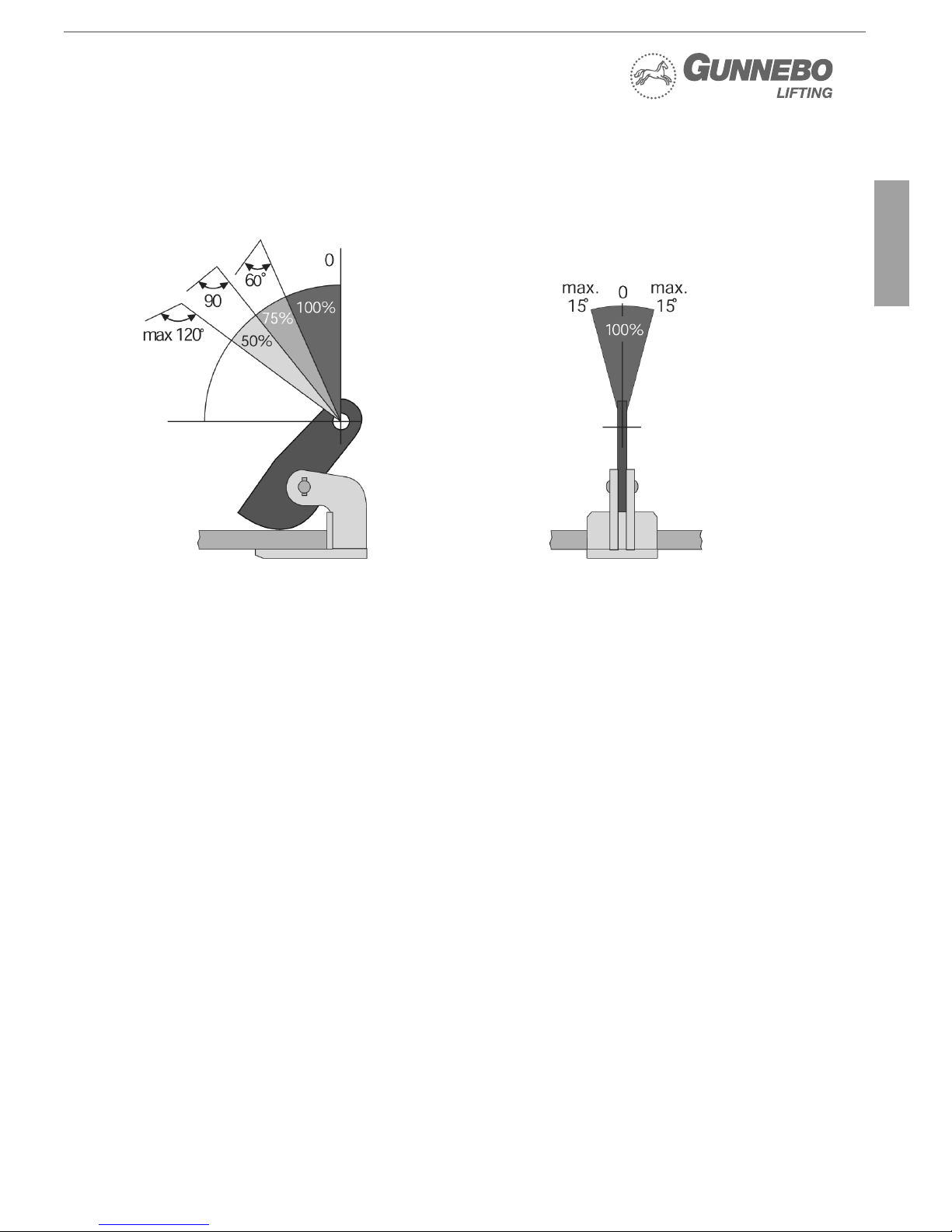

The following additional safety precautions are applicable to the CH, CHE CHS, CHNM

CHD and CHP model

The clamps can be loaded laterally at a maximum angle of 15°, only when they are not loaded

more than the maximum W.L.L. and the permitted top angle. The capacity of the clamps has been

calculated on basis of a maximum top angle of 60°. In case of situations with larger top angles, then

5

the WL.L. should be reduced proportionally, according the following loading drawing.

With shored up usage, a maximum top angle of 60° is applicable and the W.L.L. is 50% of

the maxi-mum permissible working Ioad. The environmental temperature for use of the

standard lifting clamps is between minus 40 and 100 °C.

The clamps can be loaded laterally at a maximum angle of 15’.

5a Lifting with CH, CHE, CHS, CHD and CHNM Clamps

- Check whether the working load limit (W.L.L.) of the clamp is suffi cient for the load created in the

lifting situation. Note: The working load limit (W.L.L.) is shown on the lifting clamp.

- Attach the lifting clamp to the hoisting mechanism either by means of a:

- Safety shackle directly to a crane hook,

- Coupling link or D-shackle,

- Sling or chain, if necessary in conjunction with a coupling link or D-shackle.

- Ensure that all attachments have been tested and are of the correct tonnage. Make sure that coupling

links and shackles are large enough to allow the clamp to move freely in the hook.

- Check whether the clamp has any visible damage. Check whether the cam opens and closes

smoothly.

- Check whether the teeth of the cam are free from dirt, and if necessary clean with a wire brush.

- Remove any grease, dirt and mill scale from the plate at the site of the lifting clamp.

- Open the clamp.

- Place the jaws as far as they will go over the plate, making sure that the clamp is positioned so as to

balance the load when it is being lifted.

- Lift gently so that the lifting force can be applied; check whether the clamp is rotating or tilting.

- If the clamp is rotating or tilting read the fore mentioned remarks on lifting again.

- Ensure that the load is in a stable position.

5b Lifting with CHP Clamps

- Place the clamp onto the plate (cable or chain already attached to the tooth segment; and take care

that the chain of cable is not twisted);

- Tighten the clamps fi rmly by hand;

English

6

- Tension the cables or chains with the crane hook, while the inside of the jaws presses fi rmy against

the edge of the plate (note: due to the fact that the clamp does not have a con-stant pre-tension

available on the tooth segment, it will be necessary to watch the position of the clamps until the

cables are tensioned: make sure the clamps stay in the correct posi-tion).

- The load can now be lifted carefully.

- During the transport of the load, take care that a constant tension is maintained on chains or slings.

- To unhook, the crane hook should be lowered so far that the clamp is completely free of any load

(note: make sure that when the load is lowered, there are no obstacles underneath where the load

could rest on during lowering and whereby the clamps will become unloaded to early by accident).

- The clamps can now be removed from the load.

6 Maintenance

- Check the general condition of the clamp at least once a month, see Chapter 7 - Disassembling/

Assembling.

- Do not use the clamp if:

- the body is split or deformed, in particular in way of the jaw corners,

- the cam has been visibly deformed,

- the cam teeth are no longer sharp,

- the shackle pins have visibly been deformed,

- any retaining pins are missing,

- the marking on the clamp is no longer legible.

Depending on the defects noted:

Disassemble and clean the clamp (see Chapter 7 - Disassembling/Assembling) or have the

clamp overhauled by Gunnebo Lifting or another recognized mechanical repair

center (see Chapter 8 - Overhauling).

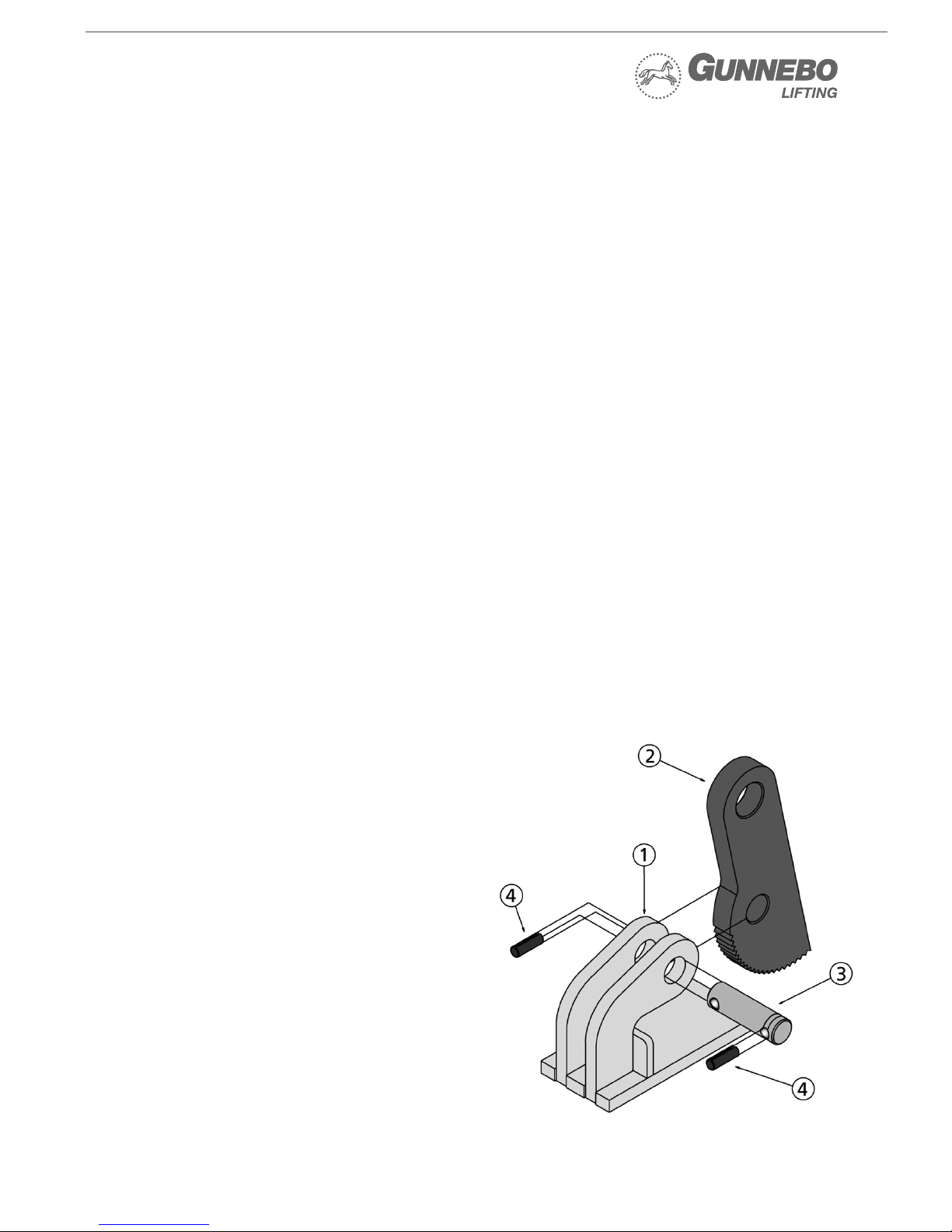

7a Disassembling/Assembling CH, CHE, CHS, CHD, Clamps

The clamps can be easily disassembled for cleaning

and inspection purposes. Please make use of the

following procedure.

- Remove the retaining pin (4) and the cam pin (3).

- Remove the cam (2).

- Clean all parts with a stan-dard degreasant.

- Grease the cam pin (3) with bearing grease.

- Assembling the clamp is in reverse order.

- Always insert new original retaining pins (4) with

the aid of a hammer, combination pliers and pin

punch.

- Always use original Gunnebo Lifting components

when replacing parts.

- Remove any burr with a fi le.

7

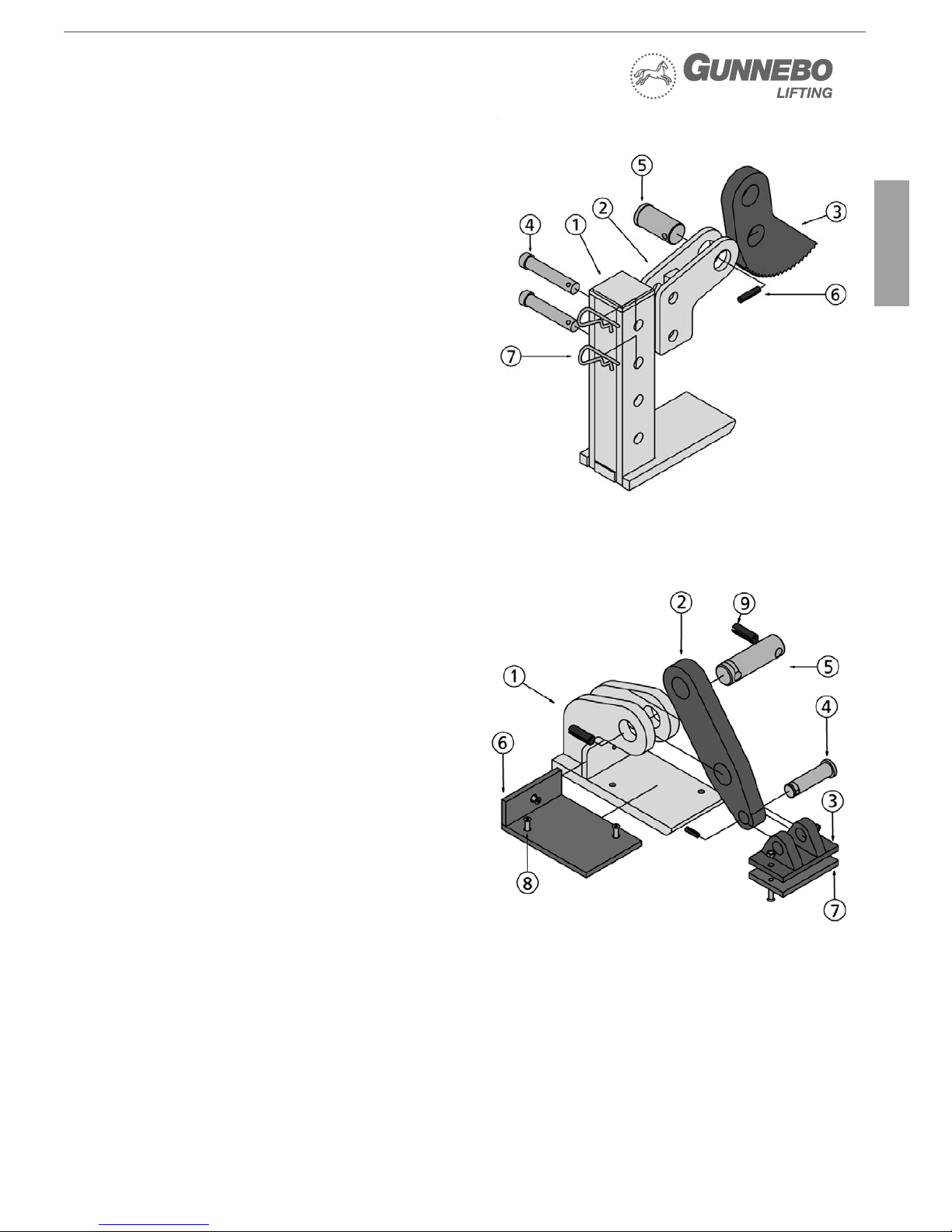

7b Disassembling/Assembling CHP Clamps

The CHP clamp can be easily disassembled

for cleaning and inspection. Please make use of

the following procedure.

- Remove the tension pin (6) with the use of a pin

driver from the tooth segment shaft (5).

- The tooth segment shaft can now be pushed

out of the frame and the tooth segment (3) can

be removed.

- Remove the hairpin pegs (7) and the pins (4),

and the two side plates (2) can be taken from the

clamp.

- Clean all the parts with a standard degreasant.

- Assembling of the clamp is in reverse order.

- Always use original Gunnebo Lifting components

when replacing parts.

- Remove any burr with a fi le.

7c Disassembling/Assembling CHNM Clamps

The CHNM clamp can be easily disassembled

for cleaning and inspection. Please make use

of the following procedure.

- Remove the retaining pin (9) and the cam pin (5).

- Remove the cam (2).

- Remove the small retaining pin (9) and the cam

pin (4).

- Clean all parts with a stan-dard degreasant.

- If necessary you can remove the fabric pads

(6 & 7) by removing the bolts (8)

- Grease the cam pin (4 & 5) with bearing grease.

- Assembling the clamp is in reverse order.

- Always insert new original retaining pins (9) with

the aid of a hammer, combination pliers and pin

punch.

- Always use original Gunnebo Lifting components

when replacing parts.

- Remove any burr with a fi le.

8 Overhauling

At least once a year or in case of any damage to the clamp, the clamp should be inspected,

tested and if necessary overhauled by Gunnebo Lifting or a recognized mechanical repair centre.

9 Disposal

Once it has reached the end of its useful life the clamp can be treated as scrap iron, provided

that the clamp is rendered unfi t for further use.

lamps

English

8

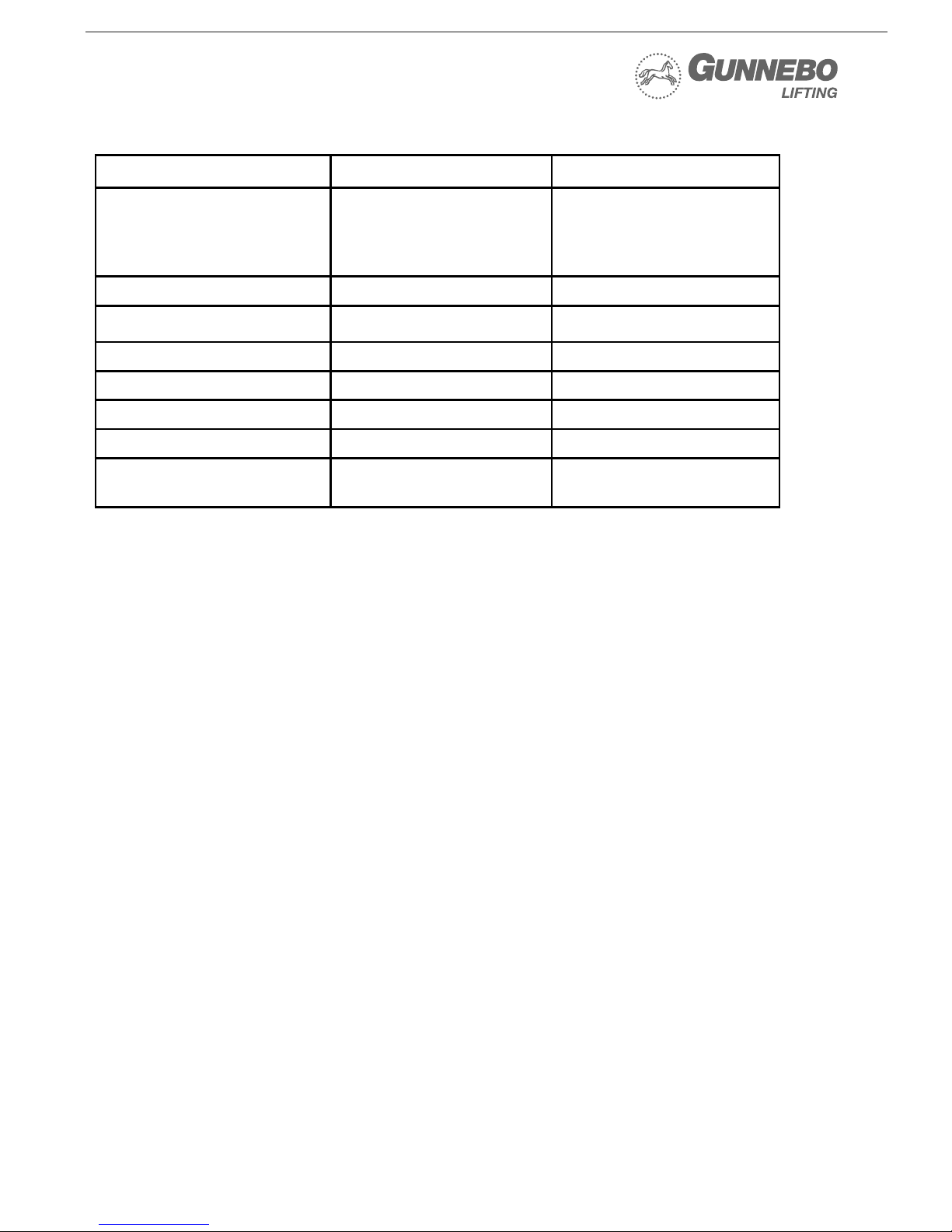

10 Troubleshooters Checklist

Failure/malfunction Possible Cause Action

Load slipping Load dirty

Pivot and/or cam dirty

Pivot and/or cam blunt

Jaws bent open

Clean load

Clean clamp

Overhaul clamp

Reject clamp

Cam pivoting badly Cam overloaded Reject clamp

Body bent Clamp overloaded Reject clamp

Cam shackle oval Clamp overloaded Reject clamp

Cam pin bent Clamp overloaded Renew cam pin

Adjustable pins bent Clamp overloaded Reject clamp

Retaining pins missing Incorrectly assembled Fit new retaining pins

Clamp diffi cult to open/close Clamp worn out

Clamp contaminated

Reject clamp

Clean clamp

11 Warranty

Gunnebo Lifting provides a 5 year warranty on its lifting clamps. This warranty is applicable

to the original end user of the lifting clamps. Only if the clamp has been inspected,

checked and maintained by this instructions and by an offi cial dealer. This warranty period

of 5 years is valid from the day of purchase, and is liable to all conditions and measurements

stated in this document.

11a Conditions

This warranty only covers failures in the lifting tools which is the consequence of production

errors which occur during normal use. The warranty covers no wear to components such as

pivots, cam assemblies, lock springs etc. Should there be any kind of failure within this guarantee

period, the lifting tool will be replaced or repaired to insight of the producer

No warranty is given to clamps due to the following failures:

- Regular wear

- Overload.

- Wrong and/or carelessly use

- Damages

- Not following procedures and measures

- Hoisting differing material other then indicated on clamp or stated in the user-manual

- Adapting and/or modifying of the Gunnebo Lifting clamp.

- The injudicious use of the clamp, and not succeeding all indications which are stated in the users

manual.

- When maintenance and/or revision has not been carried out by an authorised Gunnebo Lifting

distributor.

The producer is not responsible for incidental damage or damage due to use of the lifting

tools as well as from violation of this manual.

9

11b Procedure Safety Inspection

All inspections and repairings must be written down in the maintenance diagram. This counts

not only for your own inspections but also for inspections which are carried out by your

authorised Gunnebo Lifting distributor. When the clamp is handed in for maintenance and

inspection you always must provide the maintenance diagram.

Defective Lifting Clamps

When a form of wear or damage is indicated, you must take the following measures.

1 Take the lifting clamp out of use. (Note the date of failure of the lifting clamp)

2 Try to recover the cause of the failure, for example (complete list is available in

chapter 1):

- Overload

- Wrong and/or carelessly use

- etc

These claims stated in no.2 do not fall under the guarantee! To guarantee the security of

you and your colleagues you are obliged to follow up this procedure.

3 Return your lifting clamp (with the maintenance history) to your authorised

Gunnebo Lifting distributor.

4 If the lifting clamp has been revised / repaired by your distributor, you can safely

use your clamp again.

Please note this date in your maintenance chart (see page 35).

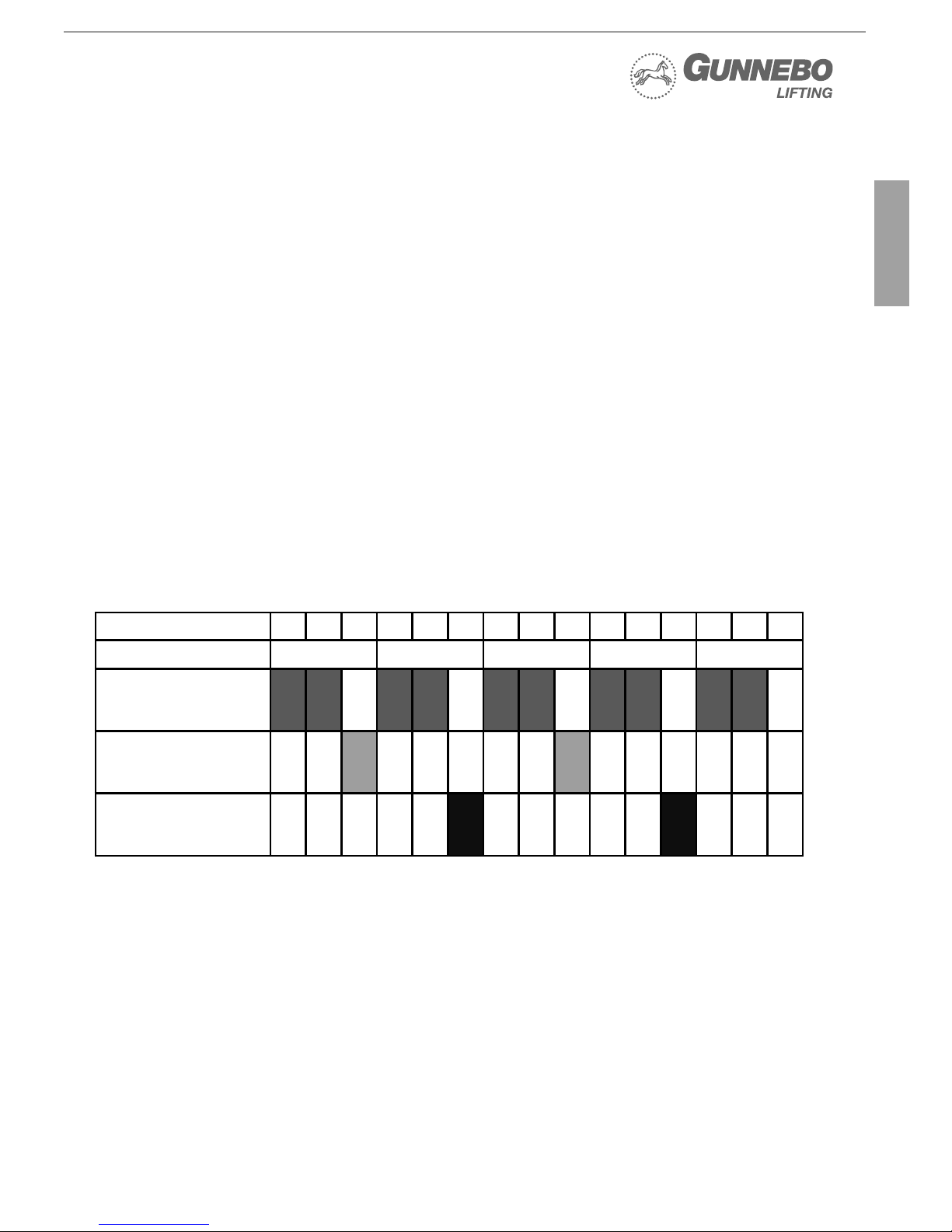

11c Inspection Schedule

Months 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60

Years

12345

Safety inspections by

your own inspector

Maintenance by a

offi cial Gunnebo Lifting

distributor

Revision by a offi cial

Gunnebo Lifting

distributor

English

10

Innehåll

1 Allmänt 10

2 Arbetsprincip 10

3 Tillåtna applikationer 10

4 Säkerhetsanvisningar 11

5 Lyfta 12

- CH,CHE, CHD, CHNM

- CHP

6 Underhåll 13

7 Demontering/Montering 13

- CH,CHE, CHS, CHD

- CHP

- CHNM

8 Service 14

9 Kassation 14

10 Checklista för felsökning 15

11 Garanti 15

1 Allmänt

Grattis till köpet av ny Gunnebo Lifting lyfthandske för balkar. Kvalitetssystemen för

hantering och tjänster från Gunnebo Lifting är helt i enlighet med ISO 9001-krav.

Många års omfattande erfarenhet är en garanti för optimal kvalitet och säkerhet.

Gunnebo Liftings lyfthandskar är tillverkade av legerat stål av bästa kvalitet och uppfyller

europeiska normer och krav som fastställs i Maskindirektivet 2006/42/EG.

2 Arbetsprincip

Horisontella lyfthandskarna CH, CHE, CHS, CHNM och CHP har särskilt utformats för

horisontella lyft och transport av oböjliga stålplåtar. Lyfthandskarna består av en stomme,

en kam och en kambult. Kammen fungerar även som en lyftbygel och garanterar att lasten

hålls fast ordentligt när den lyfts.

3 Tillåtna Applikationer

CH, CHE, CHS and CHNM

Gunnebo Liftings lyfthandskar CH, CHE och CHNM är endast lämpliga för lyft och horisontell förfl yttning av oböjliga stålplåtar och strukturer där det är möjligt att placera handsken på en

plan kontaktpunkt. Lyfthandskarna skall alltid användas i par, eller fl era par. I det senare fallet

rekommenderas dock användning med en lastfördelare.

CHD

Gunnebo Liftings lyfthandskar CHD är endast lämpliga för lyft och horisontell transport av böjliga och

formade stålplåtar, där det är möjligt att placera handsken på en plan kontaktpunkt.

CHD-lyfthandskarna skall alltid användas i par, eller fl era par.

CHP

Gunnebo Liftings lyfthandskar CHP är endast lämpliga för horisontell transport av stålplåtar och paket

av stålplåtar, där det är möjligt att placera handsken på en plan kontaktpunkt.

Lyfthandskarna skall alltid användas i par, eller fl era par. I det senare fallet rekommenderas dock användning med en lastutjämnare. En eller fl era plåtar kan lyftas på en gång per lyft under förutsättning

att stålplåten eller -plåtarna inte böjs (defl ekterar). När par eller fl era lyfthandskar används, skall lasten

fördelas lika över lyfthandskarna.

11

Svenska

4 Säkerhetsanvisningar

Säkerheten främst! Garantera din personliga säkerhet genom att först läsa igenom

säkerhetsanvisningarna noggrant.

Garantera din egen säkerhet och fortsätt att dra nytta av vår produktsäkerhet genom att

låta lyfthandsken inspekteras, testas och, om nödvändigt, servas minst en gång om året av

Gunnebo Lifting eller ett auktoriserat mekaniskt reparations- eller servicecenter.

Se även kapitel 8 - Service. Kontakta Gunnebo Lifting för mer information.

Undvik livshotande situationer

Förebygg farliga situationer genom att iakttaga följande försiktighetsåtgärder:

- Arbeta aldrig med en otestad lyfthandske.

- Håll avståndet när du lyfter och stå aldrig under lasten.

- Använd inte lyfthandsken om den är skadad; låt lyfthandsken repareras omgående av Gunnebo

Lifting eller ett auktoriserat mekaniskt reparationscenter. Rådgör med leverantören om du är osäker.

- Lyft aldrig mer än en plåt eller ett paket med plåtar åt gången.

- Lyft aldrig plåtar tyngre än den tillåtna arbetsbelastningen (W.L.L.), som anges på lyfthandsken och

i testcertifi katet.

- Lyft aldrig plåtar som är tjockare eller tunnare än gripklons öppning, som anges på lyfthandsken

och i testcertifi katet.

- När du använder fl era lyfthandskar samtidigt, nyttja lyftslingor eller -kättingar av tillräcklig längd

för att garantera att vinkeln mellan lyftslingorna eller

- kättingarna aldrig överskrider 60°.

- När du använder ett antal lyfthandskar samtidigt sida vid sida, använd en lyftbom (utjämnare)

och lyftslingor eller

- kättingar som har en tillräcklig längd för att garantera att lyftbyglarna på lyfthandskarna aldrig

utsätts för sidobelastning.

- Placera inte lyfthandsken på avsmalnande eller koniska delar på plåten eller strukturen som skall

lyftas.

- Avlägsna fett, olja, smuts, korrosion och glödspån från plåten där lyfthandsken skall fästas.

- Se till att lyfthandsken/lyfthandskarna är placerade så att lasten är balanserad när den lyfts.

- Plåtytans hårdhet får inte överskrida 37 HrC (345 Hb, 1166 N/mm²).

- Lyfthandsken är endast lämplig för användig under normala atmosfäriska förhållanden.

Säkerhetsanvisningar

- Kontrollera att kammen aldrig kan utsättas för sidobelastning.

- Fritt fall eller okontrollerad svajning från lyftkroken som leder till att föremål fastnar, kan leda till

stötskador på lyfthandsken. Om detta händer, kontrollera om lyfthandsken fortfarande är i användbart

skick innan du använder den igen.

- Lyfthandskar är inte lämpliga för att skapa permanenta fogar.

- Underhåll av lyfthandsken skall ske regelbundet varje månad, se kapitel 6 - Underhåll.

- Ändra inte lyfthandsken (genom svetsning, slipning, etc.), då detta kan påverka dess funktion och

säkerhet negativt, och därmed upphäva garanti och produktansvar.13

- Av samma skäl får endast Gunnebo Lifting originalkomponenter användas.

- Felaktig användning av lyfthandsken och/eller underlåtenhet att iakttaga anvisningar och varningar

i denna handbok som gäller användningen av denna produkt kan utsätta användarens och/eller

kringståendes hälsa för fara.

Loading...

Loading...