GlasStile GSS

Installation Operation and Maintenance Manual

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

3

Contents

Page

SECTION 1 INTRODUCTION ...................................................................................................................................... 5

General .............................................................................................................. 5

Electrical Warnings ............................................................................................ 5

Mechanical Warnings ........................................................................................ 5

Errors.................................................................................................................. 5

Proprietary Notices ............................................................................................ 5

Rotating Machinery ........................................................................................... 6

Warnings, Cautions and Notes .......................................................................... 6

Static Sensitive Devices ...................................................................................... 6

Good Practices ................................................................................................... 6

Risk Assessment ................................................................................................. 7

CE - Marking....................................................................................................... 8

SECTION 2 PRODUCT DESCRIPTION .......................................................................................................................... 9

Product Description ............................................................................................ 9

Technical Specification ..................................................................................... 10

SECTION 3 INSTRUCTIONS FOR USE ........................................................................................................................ 11

Starting the GlasStile GSS ................................................................................ 11

Reception Control Pass Left/Right (Option) ..................................................... 11

Operating Modes ............................................................................................. 12

Reset ................................................................................................................ 12

Remote Push Button Activation (Optional) ...................................................... 12

Safety ............................................................................................................... 12

Blocking the GlasStile GSS ................................................................................ 12

Power Failure ................................................................................................... 12

Fire Alarm......................................................................................................... 12

SECTION 4 TECHNICAL INFORMATION ..................................................................................................................... 13

Technical Information ...................................................................................... 13

Material Finishes .............................................................................................. 13

Flexibility of Design .......................................................................................... 13

Standard Dimensions ....................................................................................... 14

Component Location ........................................................................................ 15

SECTION 5 INSTALLATION ..................................................................................................................................... 16

Unpacking ........................................................................................................ 16

Tools Required ................................................................................................. 16

Site Preparation ............................................................................................... 16

Installation Kit .................................................................................................. 16

Installation Routines ........................................................................................ 17

Power Supply and Cables ................................................................................. 20

Customer Connections ..................................................................................... 23

Programming the Wing ‘Home Position’ ......................................................... 25

Testing after Installation .................................................................................. 25

Programming Options ...................................................................................... 26

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

4

SECTION 6 MAINTENANCE .................................................................................................................................... 27

General Care .................................................................................................... 27

Brake Adjustment ............................................................................................ 29

Encoder Replacement ...................................................................................... 29

Replacing the Control Card .............................................................................. 29

Trouble Shooting .............................................................................................. 29

SECTION 7 SPARE PARTS ...................................................................................................................................... 31

Recommended Spare Parts .............................................................................. 31

SECTION 8 DECLARATION OF CONFORMITY .............................................................................................................. 32

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

5

Section 1 Introduction

Introduction

General

Please read this manual carefully, it contains information that will assist you with all aspects of

installation and maintenance, including unpacking. Correct installation & Maintenance will ensure

smooth functionality and increase the lifespan of components.

Gunnebo Entrance Control Ltd makes every effort to ensure that this manual is reviewed whenever

significant changes are made to the design. However, our policy of continuous improvement may

result in some small differences between the unit supplied and the description in this document.

Enquiries in this respect should, in the first instance, be directed to our Technical Department.

Telephone +44 (0) 1825 746105, Fax +44 (0) 1825 763835, or alternatively E-mail

turnsupport.entrancecontrol@gunnebo.com

Electrical Warnings

The electrical power used in this equipment is at a voltage high enough to endanger life. Before

carrying out maintenance or repair, you must ensure that the equipment is isolated from the electrical

supply and tests made to verify that the isolation is complete.

When the supply cannot be disconnected, functional testing, maintenance and repair of the electrical

units is to be undertaken only by persons fully aware of the danger involved and who have taken

adequate precautions and training.

Mechanical Warnings

Safety systems and controls, such as interlocks, covers and guards, must not be overridden or by

passed by personnel other than authorised staff who are qualified to carry out prescribed actions

within specified Warnings.

Only trained individuals should work on the unit as it has many moving parts and there is a possibility

of serious injury

Errors

Reports on errors, comments and suggestions concerning this manual are requested and encouraged.

They should be submitted to:

Technical Department, Gunnebo Entrance Control Ltd, Bellbrook Business Park, Uckfield, East

Sussex, TN22 1QQ, UK.

Telephone +44 (0)1825 746105, Fax +44 (0)1825 763835 or alternatively E-mail

turnsupport.entrancecontrol@gunnebo.com

Proprietary Notices

All data appearing herein is of a proprietary nature, with exclusive title to it held by Gunnebo. The

possession of this Manual and the use of the information are therefore restricted only to those persons

duly authorised by Gunnebo.

Do not reproduce, transcribe, store in a retrieval system or translate into any human or computer

language, any part of this Manual without prior permission of Gunnebo.

Hardware Changes

No hardware changes may be made without authority from Gunnebo who will be responsible for

ensuring that the proposed change is acceptable in all safety aspects. Personnel authorised by

Gunnebo may only make hardware changes.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

6

Any maintenance or modification of Emergency Stop and Guarding Circuitry must be followed by

safety checks on the whole hardwired Emergency Stop and Guarding Circuitry.

Prior to a hardware change, records must be made of the change, one of which MUST be sent to the

Technical Department at Gunnebo.

Rotating Machinery

Rotating industrial machinery may possess huge amounts of stored energy. On no account must you

commence maintenance if you do not fully understand what you are doing and/or have not taken all

the safety precautions normally associated with industrial electronic control systems and machines.

Before starting to work on the equipment, please make yourself familiar with all the associated blocks

in the system, including control loops, mechanics, drives, transducers and electrics. Please read all

the Manuals of the equipment you are unfamiliar with first.

Warnings, Cautions and Notes

Where necessary within the technical manual, Warnings, Cautions and Notes may be given.

Warnings

Are for conditions that might endanger people. The instructions given in Warnings must be followed

precisely. They are given to avoid injury or death.

Cautions

Are for conditions that may cause damage to equipment, or may spoil work. The instructions given in

Cautions must be followed to avoid spoilt work or damage to equipment.

Notes

Alert the user to pertinent facts and conditions.

Static Sensitive Devices

Some of the PCB’s in the equipment covered by this Technical Manual contain Static Sensitive

Devices. It is recommended that maintenance and service engineers are fully aware of the Local

Industry Regulations and procedures when handling such devices.

Good Practices

Equipment being installed must not be left unattended unless all potential mechanical and electrical

hazards have been made safe. A competent person must be left in charge when the equipment is to

be left while potentially unsafe.

The following points indicate good practice that will contribute to safety and avoid equipment damage.

i Ensure that all electrical power supplies are turned OFF and disconnected before

working on any of the equipment.

ii Never leave the equipment in a potentially dangerous state.

iii Use only the correct tools for the task in hand.

iv When working on the equipment, remove any personal jewellery that may be

conductive, or clothing that may become entangled with mechanical parts.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

7

Equipment Safety Systems

Safety systems and controls, such as interlocks, covers and guards, must not be overridden or

bypassed by personnel other than authorised staff who are qualified to carry out prescribed actions

within specified Warnings.

Risk Assessment

Risk assessment is graded into categories of safety, rated 1 to 8 (where 8 is the highest risk level).

The following activities are covered.

Rating Activity

1 Cleaning

2 General Installation

3 Servicing

4 Servicing

General Maintenance

Using Chemical Fixers

5 Commissioning

8 Floor Drilling

Glass Panel Installation

Rating 1: Cleaning.

Who is at Risk Engineers or Site Personnel

Hazard Mis-use of Cleaning Fluids

Current Controls Compliance with COSSH regulations

Rating 2: General Installation

Who is at Risk Site Personnel

Hazard Objects/Tools in Installation area

Current Controls Trained Installation Engineers

Rating 4: General Maintenance

Who is at Risk Site Personnel

Hazard Electric Shock

Current Controls Isolation of Power/Trained Service Personnel

Using Chemical Fixer

Who is at Risk Site Personnel within the Vicinity of the Work Area

Hazard Fume Inhalation

Current Controls Compliance with COSSH regulations

Rating 5: Commissioning

Who is at Risk Site Engineer

Hazard Power Supply/Moving Parts

Current Controls Isolate Power

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

8

Rating 8: Floor Drilling

Who is at Risk Installation Engineer

Hazard Flying Debris and Noise

Current Controls Protective Equipment must be worn

Glass Panel Installation

Who is at Risk Installation Engineer

Hazard Glass Breaking

Incorrect handling techniques

Current Controls Protective Equipment must be worn.

CE - Marking

The Gunnebo GlasStile GSS is CE marked, developed and manufactured according to the EU’s

Machinery, Low-Voltage and EMC-Directives.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

9

Section 2 Product Description

Product Description

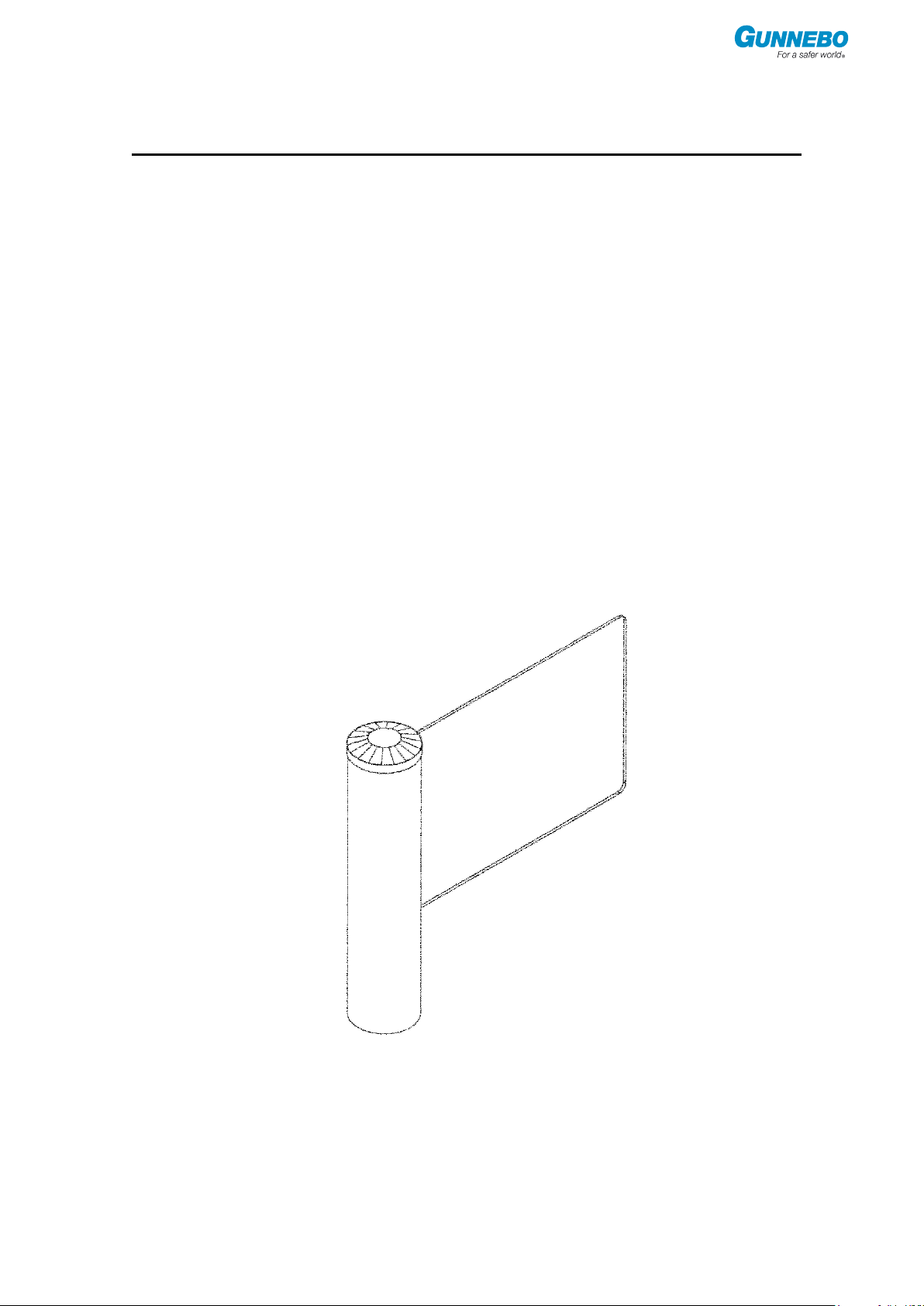

The Gunnebo GlasStile GSS is a revolving entrance gate with glazed panels. The gate rotates

clockwise or counter-clockwise to its User Programmed opening positions and then returns to the

home position, where it is locked by an electro-mechanical brake. The gate is activated by impulses to

the driving electronics unit from either a reception area or impulse unit (e.g. card reader) which

determines the direction of rotation.

Any impulse unit with a dry contact closing for between 0.5 - 1.0 seconds can be connected to the

gate. An acknowledgement impulse of completed rotations is given before or after each rotation is

started/complete. The status of the gate is indicated on its volt free alarm output.

The speeds, opening time, drive mode and individual settings of the panels opening and home

positions are set using a special programming unit. In the event of a power failure the programmable

functions are stored in a non volatile memory.

The drive electronics are mounted on a printed circuit board which has connection points for power,

motor, brakes, sensors, impulse units and LED’s.

A 24V DC motor with planetary gears controls the gate. An opto-sensor is connected to the outgoing

shaft by a gear belt. Its function is to monitor the position of the gate.

Fig 2.1 – Typical Unit

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

10

Technical Specification

Unit Dimensions Column Height: 1000mm

Column Diameter: 220mm

Standard Clear Opening: 1000mm

Drive: 24V DC Motor with gearing

Orientation: Pass Left or Pass Right

Materials: Mechanical parts: 304 grade Stainless Steel

Glass Wing: 10mm Toughened Glass

Power Failure: Gate Rotates freely with any power loss or emergency signal

Power Supply Voltage: 110/230 VAC 50/60Hz

Power rating: 250 W, fuse 1.0 A

Mains Input Fuse 2A

Operating Temperature: 0 to 55C

Transportation and Storage: -25 to +55 C

Relative Humidity: 95% Maximum

Note - Class C mains circuit breaker is required.

- Other finished and sizes are available upon request to Gunnebo

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

11

Section 3 Instructions for Use

Instructions for Use

Starting the GlasStile GSS

When the power is switched on, the gate automatically searches for its internal zero position, moving

at a lower speed than normal. The blocking panel then automatically moves to its programmed home

position. The first time the gate is powered up it will move to a factory pre-set home position.

When the internal zero and home positions are being sought the alarm output flashes slowly. When

searching has been completed the closed gate closed output switches.

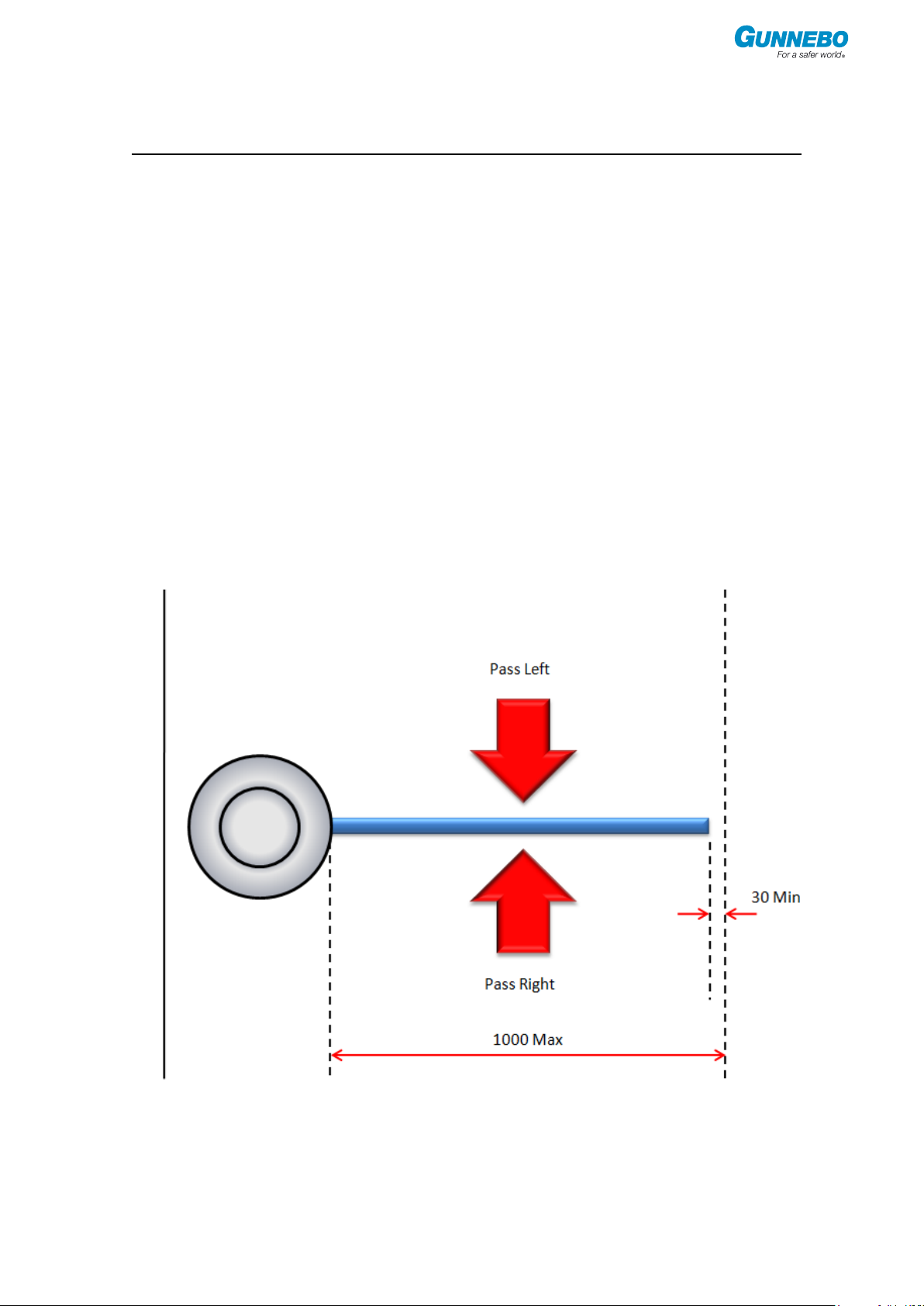

Reception Control Pass Left/Right (Option)

There are two momentary pushbuttons, one each for PASS LEFT and RIGHT entry, which instantly

affect the rotation of the gate.

The gate opens for as long as the pushbutton remains pressed. Upon release the gate returns to its

home position, where the electro-mechanical brake locks it.

Walkway Details

Fig 3.1 - Walkway Details

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

12

Operating Modes

Instant Start

This is similar to Push to Go, with the difference that the gate starts immediately when it receives an

impulse. If a pre-rotation acknowledgement has been selected, it is possible to stack up to 5

authorisations per direction. If passage is authorised in both directions, the queue in the first direction

selected is cleared before the gate begins to rotate in the other direction.

Push to Go

A signal applied at one of the impulse unit inputs releases the brake, switches the gate closed output.

Passage can now occur within the selected time. If no passage is started within this time, the gate is

locked and a new impulse must be given. The gate starts to rotate in the selected direction once the

panel is released from its home position. When the gate starts, the acknowledgement relay is

activated for 0.5 seconds.

Depending upon the program set up, an acknowledgement of 0.5 seconds is given when the opening

is completed. The gate closed output is then activated.

Reset

After repeated incorrect use or blocking of the unit, the GlasStile GSS will go into alarm mode, with an

optional remote alarm indication being set in the reception area. There are three ways to reset the unit

to normal operation:

New impulse from pulse transmitter

Reset from (option) reception push buttons via depressing both buttons simultaneously.

If these resets do not happen within 10 seconds after alarm, the GlasStile GSS will

automatically reset itself and return to the home position.

Remote Push Button Activation (Optional)

A reset button in the reception area is connected via diodes to both Left and Right entry reception

inputs. The external diode to reception is connected to the closed gate input on the PCB.

Safety

When the gate is locked, the electro-mechanical brake is activated on full power for 0.5 seconds the

power is then reduced to a steady rate. This is to reduce the risk of heat build up in the brake.

Blocking the GlasStile GSS

If the GlasStile GSS is blocked completely during operation for more than 10 seconds the unit will go

into alarm mode and will reset via the receipt of a valid reset, passage authorisation or time out signal.

Power Failure

In the event of power failure the gate rotates freely. When the power returns the gate searches first for

its internal zero position and then for the home position similar to when the gate is started up.

Fire Alarm

There is a facility for an external fire alarm input contact in the gate. The fire alarm N/C contact is

connected so that it will interrupt the power to the gate. The unit will freewheel until the contact is

remade.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

13

Section 4 Technical Information

Technical Information

The central column stands totally independent of the surrounding framework, housing the drive motor,

gearbox and local electronics.

The unit is supplied to integrate fully with all proprietary card reader systems, with a variety of outputs

and inputs i.e.; passage confirmed for updating and anti-passback system, inhibits and fire alarm.

All that is required is a GO signal of >0.5 / <1 second from the access control technical system

(voltage-free contact normally open).

Material Finishes

Alternative materials, such as polished or grained stainless steel, brass or painted finishes can be

supplied to special order. please consult Gunnebo for further information.

Flexibility of Design

The integrated design makes the GlasStile GSS simple to install with a minimum of intrusion to the

existing environment.

This concept allows architects and designers the ability to design a security system that fits their

requirements for any situation. The central column forms the basis of the system

Because of the servo drive, each individual can pass through the GlasStile GSS at whatever speed

they find most convenient. The GlasStile GSS adapts itself automatically and the only purpose of the

motor drive is to facilitate passage and return the gate back to its neutral position.

The standard GlasStile GSS is clad with brushed stainless steel and the gate panels are of 10mm

transparent toughened glass.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

Standard Dimensions

Fig 4.1 – Standard GlasStile GSS Dimensions

14

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

15

Component Location

Fig 4.2 – Main Component Identification

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

16

Item

Quantity

Rotor Assembly

1

Cladding Kit

1

Top Cap

1

Cladding Cover

1

Glass Panel

1

Anchor Bolts (72544001)

3

Section 5 Installation

Installation

Unpacking

Check that all the material has been delivered intact. Gunnebo does not accept any responsibility for

damage that occurs by transportation or installation.

Electrical installation must be carried out by authorised staff. The placing, installation and

specifications of all cables must comply with the instructions given in this document.

Gunnebo does not accept responsibility for any injury or damage incurred due to departure from the

instructions in this Technical Manual.

Tools Required

Industrial hammer drill

Concrete drill bit 12mm

Socket 17mm AF (x2)

Torque wrench

8mm Spanner

Metric Allen Keys (1 x set)

Please read carefully before commencing the installation

Site Preparation

The following illustrations show the site preparation details that are required for the various units.

Concrete to BS 5328:1997 specifications - Type ST5

The base must be flat and level to +/-5mm over the GlasStile GSS area.

The base must be laid with under floor conduits with a minimum diameter of 20mm rising in the

positions indicated on the particular illustration, to accommodate the cables for power supplies and

any remote control devices.

It is recommended that the mains power to the unit passes through a Residual Current Circuit Device

for maximum safety.

A second conduit should be provided for any remote control cables that may be required. On units

controlled by pushbuttons or footswitches a four-core cable having a minimum conductor size of

0.5mm sq. should be laid and a 1.5m tail left. (Screened cables are NOT normally required)

For units that are to be controlled by Card Access or similar it is recommended that Gunnebo

Technical Personnel are advised prior to starting the installation routines.

Installation Kit

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

17

Installation Routines

Note - The GlasStile GSS should NOT be installed under a desk.

When planning the installation, it is important that everything is measured accurately and that

all cable ways are marked out. All cables must be laid according to the specification indicated before

installation begins.

All Electrical work MUST be carried out by a qualified engineer

1. Place the foundation plate and the centre column in the selected position. Turn the centre

column so that the marking ‘INDEX 0’ on the non-rotating part, ends up as shown in Fig 5.1 to

ensure that the panel can rotate without interference from the walls

Fig 5.1 – Opening in Both Directions (180O)

Fig 5.2 – Opening in Both Directions (90O)

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

18

Fig 5.3 - Column Mounting Plate

2. Mark out and drill the M10 holes, using the appropriate fixing items.

3. Place the centre column on the foundation plate and adjust the unit vertically, using the

adjusting grub screws on the centre column’s base plate. Lock in position using the fixing

screws.

4. Fit the M4 x 8 Top Cladding Retaining screw into the chassis leaving approximately 2mm

clearance between the head and surface.

5. Insert the glazed panel making sure that the plastic insulator, packing strip and the plastic

spacer sit between the glass and the metal surrounds to avoid the risk of the glass cracking.

Fig 5.4 – Glazed Panel Fitting Detail

6. Using a spirit level adjust the glass so that the top is horizontal.

7. Rotate the gate manually to check that it rotates freely.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

19

Top Cover

Glass Wing

Cladding

M8 x 25 countersunk screws

and packing washers

M4 x 8 Top Retaining

Strip screw

M4 x 8 Bottom Retaining Strip screw

Retaining Strip

Fig 5.5 - Cladding Fitting Details

8. Prise the Cladding apart and slide into position.

9. Fit 2NO packing washers and 1NO M8 x 25 countersunk screw to each of the 3NO positions

through the Cladding into the top of the Rotor Column.

10. Mount the Top Cover on the centre column, so that the countersunk screws locate in the

keyholes and rotate anti clockwise direction to lock into position.

11. Align the cladding edge profiles so that they interlock. This is achieved by compressing the

middle of the cladding and engaging the ‘lock’ profile on the bottom edge.

12. Slot the Retaining Strip into the cladding key slots and slide upwards, taking care that the top

cut out in the Retaining Strip, locates on the screw in the Rotor Column.

Note – The cladding may need to be compressed together to aid this function.

Lock the Retaining Strip into position using M4 x 8 security fixing.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

20

Power Supply and Cables

Power supply

The power to the logic board, motor and brake is supplied through a Toroidal transformer specification

below.

Transformer wiring differences between 230Vac and 110Vac

Suitable cables for connecting to the main power supply and external signals such as impulse units

are:

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

21

Glass Fuse Holder

5 x 20 LBC 2A

Main power supply

110 to 230 VAC single phase 1.0 A, 250W.

Connection

Check that mains power is off with a certificated and calibrated voltage meter – when safe to do so

connect the Earth first, and then the Neutral and then the Live connection last.

Three-core cable with a conductor area of 1.5mm (min), approved for the specific installation.

1. Strip the sheath to expose 60mm

2. The power cable must be laid so that its sheath is secured in the clamp. See Fig 5.7a.

3. Connect the cores to the terminal block placed on one of the vertical bars, see Fig 5.7.

4. Ensure all connections are secure.

5. Ensure all the cables are contained within the centre column.

Disconnection

Check that mains power is off with a certificated and calibrated voltage meter – when safe to do so,

remove the live connection first, then the Neutral and then the Earth.

To switch of the power locally in the unit you can simply unclip the glass fuse breaker as shown in the

image below

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

22

Input/output signals Shielded multi-core cable with conductor area of 0.22mm (min).

1. Strip the sheath to the require length ensuring enough length for the shielding to be fixed to

the terminal.

2. Secure the cable by its sheath in the clamp provided.

3. Connect the shield to the terminal provided.

4. Make all required connections ensure all cable contained within the centre column.

Load-relieving clamps on the adjustment plate shall secure the cables as follows:

Fig 5.6 - Electrical Connections

Fig 5.7a – Cable Fixing Locations

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

P7 Motor Connections

Pin

Description

1

Red positive

2

Black Negative

Fig 5.7 – Customer Connections

23

Customer Connections

Note: - The GlasStile should always have an independent fire signal. If an echo signal is used the unit

will not function correctly.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

24

Serial Port

LED Indicators O

Push Buttons

Programming (Program Options are given on page 25)

Warning – Programming must be undertaken with the mains power switched on.

Settings

The mode of operation can be selected for standard firmware program options that are accessible via

the Hand Held Programmer. This device should be ordered with the main equipment purchase, it is

not supplied as part of the standard installation kit.

To program the GlasStile GSS the cladding must be moved. The Hand Held Programmer is then

connected to the serial port on the Control PCB.

How the gate operates depends on certain selected functions.

DF = Factory settings.

Selection of the Programming Position

Press PRG. The red programme diode lamp will come on.

When the brake has been released the yellow lamp extinguishes. The gate now transmits its set

parameters to the programming unit.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

25

Programming the Wing ‘Home Position’

Select a position, using the POS switches on the programming unit.

Place the panel in the desired position, manually.

Press the SET POS button. The green lamp will flash in acknowledgement.

Repeat this process for the next position as required.

Always end by selecting POS 0 on the programming unit.

Programming Options

Set by pressing the relevant buttons to the required settings.

When everything has been set as desired, press the SEND button. The information is then sent to the

gate and the green lamp on the Hand Held Programmer flashes in acknowledgement. Make sure that

the green lamp flashes otherwise the settings will not be confirmed.

End Programming

Press PRG. The brake is applied.

If any settings have been made which affect the home position of any of the panels an automatic

search is now made.

Testing after Installation

When the installation is complete, test the system. The GlasStile GSS will now search for a zero

position (INDEX 0). Do not interfere with the gate until this has been achieved and the brake has

been activated in the home position.

Allow the unit to calculate and store its stopping distances by pressing ‘PRG’ followed by ‘T’ from

the mode options, then press SEND and finally ‘PRG’. A ten minute test procedure will start, once

you exit the Program Mode.

Important note; the wing on the GlasStile should not be touched or interfered with during

this teaching procedure

Should the GlasStile GSS not operate as desired, carry out the following checks…

Press ‘PRG’.

Make a note of the current settings from the Hand Held Programmer.

Select mode ‘DF’, followed by SEND.

Exit the programming mode by pressing ‘PRG’.

Adjust the gate panels home position and settings as described in this manual.

Return to the procedure detailed above and repeat the set-up with new settings. This should also

include the Home Position settings plus ten minutes test etc.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

26

Programming Options

Operational Mode (MODE)

N Normal, instant start, stacking of 5 card reader impulses (DF)

P Push and Go, no stacking of card reader impulses.

T Teach, on start the auto calculation of brake distances.

DF Reset all settings to those set during factory testing.

Speed (SPEED)

1 8 rpm (1.88 seconds to travel 90O)

2 10 rpm (DF) (1.50 seconds to travel 90O)

3 13 rpm (1.15 seconds to travel 90O)

4 16 rpm (0.94 seconds to travel 90O)

Hold Open Time (TIME)

1 0.8 second (DF)

2 1.6 second

3 4 seconds

4 8 seconds

Acknowledgement Signal and Counter Impulse (Card Ack)

Normal – Instant Start (N)

D When the Gate has opened.

A After the rotation (DF)

Push and Go (PG)

D When the Gate is pushed

A After the rotation

Selection of Panel at Programming (POS)

0 No panel selection, this is the normal position when panel is to be programmed.

1 Opening Position CW Rotation - Position 90O (DF)

2 Home Position - Position 100 (DF)

3 Opening Position CCW Rotation - Position 90O (DF)

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

27

Section 6 Maintenance

Maintenance

General Care

The GlasStile GSS Entrance Gate should be cleaned and greased, where directed, at regular

intervals, using the following approved materials.

Routine Cleaning, all finishes

Cleaning agent. Soap or mild detergent water.

Action: Sponge rinse with clean water, wipe dry as necessary

Fingerprints

Cleaning agent: Soap or warm water or organic solvent (acetone, alcohol, genciene)

Action: Rinse with clean water and wipe if necessary

Stubborn Stains and Discoloration, all Finishes

Cleaning agent: Mild cleaning solutions or domestic service cleaners.

Action: Rinse well with clean water and wipe dry.

Oil, Grease Marks, all Finishes

Cleaning agent: Organic solvents (acetone, alcohol genciene, trichlorethane)

Action: Clean after with soap and water, rinse well with clean water and wipe

dry.

Rust and other Corrosion products, Stainless Finishes

Cleaning agent: Oxalic acid. The cleaning solution should be applied with a swab and allowed

to stand for 15 to 20 minutes before being washed away with water. May

continue using a domestic surface cleaner to give final clean

Action: Rinse well with clean water (precautions for acid cleaners should be

observed).

Minor Scratches on Painted Surfaces

Cleaning agent: Lightly rub with cutting paste. Rinse area with water and dry.

Apply touch-up paint in fine layers.

Action: Allow 2 weeks to harden. Blend into surrounding paintwork, using a fine

cutting paste.

Deep Scratches on Painted Finishes Causing Rust

Cleaning agent: Remove rust with a small sharp knife. Apply rust inhibiting paint (red

oxide). Fill scratch with fine body filler to just under finished surface. Follow

procedure for minor scratches.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

28

Scratches on Brush (Satin) Finish

Cleaning agent: For slight scratches, use impregnated nylon pads then polish with scruffs

dressed with iron free abrasives. For deeper scratches, apply in direction of

polishing. Then clean with soap or detergent as per routine cleaning.

Action: Do not use ordinary steel wool, iron particles can become embedded in

stainless steel and cause further surface problems.

Greasing

Service Engineer carries out this action during service visits.

General Indications

The mechanism should be inspected and cleaned at regular intervals in order to maintain the

components in good working order and to check for signs of wear.

Note: The following indications refer to an installation where the average number of transits per year

is equal to one million.

When used in dusty conditions, increase the inspection intervals.

Warning - To avoid the risk of electric shock, always ensure that the electrical power is disconnected

before inspecting the mechanism.

Lubricants

For the lubrication of parts subject to wear, use Molycote BR2 Plus grease or equivalent grease

containing graphite or molybdenum sulphide (MoS)

Do not grease moving parts unless specifically indicated in this manual. The use of grease can lead to

a build up of dust that can impair operation of the mechanism.

Components

Annual Checks (Operations to be carried out with the power supply disconnected)

Cables and Connectors (Operations to be carried out with the power supply disconnected)

Check that the wire connectors are firmly attached.

Check that the terminals are fully tightened.

Check that the insulation of the wires is in good condition and that no conductors are exposed.

Electrical Circuits

No general maintenance is required apart from replacement fuses in the event of a failure.

General Component Maintenance

Ensure the assembly is kept clean.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

29

Symptom

Check

Action

Unit Free Wheels

Mains Supply is correct and

present.

Switch on

Fuses on Control Board

Replace blown fuses

Unit will not stop and lock

Encoder is fitted correctly

Adjust and/or replace timing

belt or encoder

Desired position may not be

obtainable.

Reprogram new positions

At power up the unit

moves at great speed

Encoder is fitted correctly

Adjust and/or replace timing

belt or encoder

Unit Fails to reach the

target position

Brake setting

Adjust brake

Bearing for correct alignment.

Loosen and re-tighten bearing

Transmission to the Optical

Unit

Check connections and

replace if unserviceable

Pulley Belt for tension

Adjust and replace if

unserviceable

Brake Adjustment

Should it become necessary to adjust the Brake during set up or routine servicing the following

procedure should be used.

Loosen the three adjustment screw locking nuts.

Adjust the screws Clockwise to their lowest position and then back-off a quarter to half a turn.

Operate the Program button to release the brake.

Manually move the unit through 360º- checking for freedom of rotation without the brake

noise.

If noise is heard during the above operation - adjust the screws upwards slightly.

Engage the brake - if a harsh metallic noise is heard - adjust the screws downwards.

Repeat these actions until the unit functions correctly - lock the nuts.

Encoder Replacement

If an encoder must be replaced, effect the following operations.

Disconnect the power supply

Replace the device

Check all relevant connections

Restore the power supply

Re-set to normal functioning

Replacing the Control Card

Disconnect the power supplies.

Remove all connectors from the PCB.

If necessary remove the PCB supports.

Reconnect the cables and connectors.

Replace the PCB.

Reconnect the power supplies.

Switch ON the Unit and return it to normal operation.

Trouble Shooting

Table 6.1 – Fault Finding

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

30

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

31

Code

Description

Qty

SM-BO-GS-0001

Motor/Gearbox G42x40 40VDC

1

SE-FU-GS-0001

Fuse Q/B 20mm 2.A

1

SM-TR-GS-0001

Transformer Toroidal

1

SM-CB-GS-0001

Timing Belt (2.5 x 80T)

1

SE-EL-GS-0007

Electromagnetic Brake

1

SA-MC-MU-0008

Optical Sensor Assembly (Encoder)

1

SE-LB-GS-0004

PCB excluding Chip

1

SA-FM-GS-0002

GSS Firmware

1

SM-DA-GS-0001

Damper Magnetic Brake

3

SK-LK-GS-0002

Shaft Key (Top Cradle)

1

SK-LK-GS-0003

Shaft Key For top of coupler

1

SM-LK-MU-0047

Shaft Key

1

SE-EL-GS-0006

Motor Coupler

1

Section 7 Spare Parts

Spare Parts

Recommended Spare Parts

Quantities listed are per GlasStile GSS over a 24 month period.

Table 7.1 – Recommended Spare Parts

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

32

Section 8 Declaration of conformity

Declaration of conformity

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

33

Notes

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

34

For further information please contact:

Competence Centre Entrance Control

c/o Gunnebo Entrance Control Ltd. Bellbrook Business Park, Uckfield, East Sussex, TN22 lQQ, UK.

Tel +44 (0) 1825 761022 Fax +44 (0) 1825 763835

E-mail info.entrancecontrol@gunnebo.com

Web www.gunnebo.com

A COMPANY WITHIN THE GUNNEBO GROUP

HEAD OFFICE SWEDEN

Gunnebo AB, Box 5181, SE-402 26 Goteborg, SWEDEN. Tel +46-31 83 68 00, Fax +46-31 83 68 10

www.gunnebo.com

Note: In pursuit of its policy of continuous refinement and improvement, Gunnebo Entrance Control Ltd reserves the right to modify design and details.

.............................

CCEC/ OM Manual GlasStile GSS 1.6 EN 07.2009

Loading...

Loading...