Gunnebo GlasStile GSR Installation, Operation And Maintenance Manual

GlasStile GSR

Installation Operation and Maintenance Manual

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

3

Contents

Page

SECTION 1 INTRODUCTION ...................................................................................................................................... 5

General .............................................................................................................. 5

Electrical Warnings ............................................................................................ 5

Mechanical Warnings ........................................................................................ 5

Errors.................................................................................................................. 5

Proprietary Notices ............................................................................................ 5

Rotating Machinery ........................................................................................... 6

Warnings, Cautions and Notes .......................................................................... 6

Static Sensitive Devices ...................................................................................... 6

Good Practices ................................................................................................... 7

Risk Assessment ................................................................................................. 7

CE - Marking....................................................................................................... 8

SECTION 2 PRODUCT DESCRIPTION ........................................................................................................................... 9

Product Description ............................................................................................ 9

Technical Specification ..................................................................................... 10

SECTION 3 INSTRUCTIONS FOR USE ......................................................................................................................... 11

Starting the GlasStile ....................................................................................... 11

Operating Modes ............................................................................................. 12

Card Reader Control - Push to Go .................................................................... 12

Reset ................................................................................................................ 12

Unauthorised passage ..................................................................................... 12

Blocking or forcing GlasStile GSR during rotation ............................................ 12

Power Failure ................................................................................................... 12

Fire Alarm......................................................................................................... 12

SECTION 4 TECHNICAL INFORMATION ...................................................................................................................... 13

Technical Information ...................................................................................... 13

Material Finishes .............................................................................................. 13

Flexibility of Design .......................................................................................... 13

Standard Dimensions ....................................................................................... 14

Component Location ........................................................................................ 20

SECTION 5 INSTALLATION ...................................................................................................................................... 21

Unpacking ........................................................................................................ 21

Tools Required ................................................................................................. 21

Site Preparation ............................................................................................... 21

Installation Kit .................................................................................................. 21

Installation Routines ........................................................................................ 22

Customer Connections ..................................................................................... 31

Programming ................................................................................................... 32

Program Options .............................................................................................. 33

Programming the GlasStile GSR ....................................................................... 33

Programming the Wing Positions .................................................................... 33

Testing after Installation .................................................................................. 34

Adjusting the encoder home position .............................................................. 34

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

4

SECTION 6 MAINTENANCE..................................................................................................................................... 35

General Care .................................................................................................... 35

Trouble Shooting .............................................................................................. 37

SECTION 7 SPARE PARTS ....................................................................................................................................... 39

Recommended Spare Parts .............................................................................. 39

SECTION 8 DECLARATION OF CONFORMITY ............................................................................................................... 40

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

5

Section 1 Introduction

Introduction

General

Please read this manual carefully, it contains information that will assist you with all aspects of

installation and maintenance, including unpacking. Correct installation & Maintenance will

ensure smooth functionality and increase the lifespan of components.

Gunnebo makes every effort to ensure that this manual is reviewed whenever significant

changes are made to the design. However, our policy of continuous improvement may result in

some small differences between the unit supplied and the description in this document.

Enquiries in this respect should, in the first instance be directed to our Technical Department.

Telephone +44 (0) 1825 746105, Fax +44 (0) 1825 763835,

E-mail turnsupport.entrancecontrol@gunnebo.com

Electrical Warnings

The electrical power used in this equipment is at a voltage high enough to endanger life. Before

carrying out maintenance or repair, you must ensure that the equipment is isolated from the

electrical supply and tests made to verify that the isolation is complete.

When the supply cannot be disconnected, functional testing, maintenance and repair of the

electrical units is to be undertaken only by persons fully aware of the danger involved and who

have taken adequate precautions and training.

Mechanical Warnings

Safety systems and controls, such as interlocks, covers and guards, must not be overridden or

by passed by personnel other than authorised staff who are qualified to carry out prescribed

actions within specified Warnings.

Only trained individuals should work on the unit as it has many moving parts and there is a

possibility of serious injury.

Errors

Reports on errors, comments and suggestions concerning this manual are requested and

encouraged. They should be submitted to:

Technical Department, Gunnebo Entrance Control Ltd, Bellbrook Business Park, Uckfield, East

Sussex, TN22 1QQ, UK.

Telephone +44 (0) 1825 746105, Fax +44 (0) 1825 763835,

E-mail Turnsupport.entrancecontrol@gunnebo.com

Proprietary Notices

All data appearing herein, is of a proprietary nature, with exclusive title to it held by Gunnebo.

The possession of this Manual and the use of the information are therefore restricted only to

those persons duly authorised by Gunnebo.

Do not reproduce, transcribe, store in a retrieval system or translate into any human or

computer language, any part of this Manual without prior permission of Gunnebo.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

6

Changes

No hardware or software changes may be made without authority from Gunnebo who will be

responsible for ensuring that the proposed change is acceptable in all safety aspects. Only

personnel authorised by Gunnebo may make changes.

Any maintenance or modification of Emergency Stop and Guarding Circuitry must be followed

by safety checks on the whole hardwired Emergency Stop and Guarding Circuitry.

Prior to a hardware change, records must be made of the change, one of which MUST be sent

to the Technical Department at Gunnebo.

Rotating Machinery

Rotating industrial machinery may possess huge amounts of stored energy. On no account

must you commence maintenance if you do not fully understand what you are doing and/or

have not taken all the safety precautions normally associated with industrial electronic control

systems and machines.

Before starting work on the equipment, please make yourself familiar with all the system subassemblies, including control loops, mechanics, drives, transducers and electric circuits. Please

read this Manual if you are unfamiliar with the equipment before you commence work.

Warnings, Cautions and Notes

Where necessary within this technical manual, Warnings, Cautions and Notes may be given.

Warnings

Are for conditions that might endanger people. The instructions given in Warnings must be

followed precisely. They are given to avoid injury or death.

Cautions

Are for conditions that may cause damage to equipment, or may spoil work. The instructions

given in Cautions must be followed to avoid spoilt work or damage to equipment.

Notes

Alert the user to pertinent facts and conditions.

Static Sensitive Devices

The PCB in the equipment covered by this Technical Manual contains Static Sensitive Devices.

It is recommended that maintenance and service engineers are fully aware of the Local Industry

Regulations and procedures when handling such devices.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

7

Good Practices

Equipment being installed must not be left unattended, unless all potential mechanical and

electrical hazards have been made safe. A competent person must be left in charge when the

equipment is to be left while potentially unsafe.

The following points indicate good practice that will contribute to safety and avoid equipment

damage.

I. Ensure that all electrical power supplies are turned OFF and disconnected

before working on any of the equipment.

II. Never leave the equipment in a potentially dangerous state.

III. Use only the correct tools for the task in hand.

IV. When working on the equipment, remove any personal jewellery that may be

conductive, or clothing that may become entangled with mechanical parts.

Equipment Safety Systems

Safety systems and controls, such as interlocks, covers and guards, must not be overridden or

bypassed by personnel other than authorised staff who are qualified to carry out prescribed

actions within specified Warnings.

Risk Assessment

Risk assessment is graded into categories of safety, rated 1 to 8 (where 8 is the highest risk

level). The following activities are covered.

Rating Activity

1 Cleaning

2 General Installation

3 Servicing

4 Servicing

General Maintenance

Using Chemical Fixers

5 Commissioning

8 Floor Drilling

Glass Panel Installation

Rating 1: Cleaning.

Who is at Risk Engineers or Site Personnel

Hazard Misuse of Cleaning Fluids

Current Controls Compliance with COSSH regulations

Rating 2: General Installation

Who is at Risk Site Personnel

Hazard Objects/Tools in Installation area

Current Controls Trained Installation Engineers

Rating 4: General Maintenance

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

8

Who is at Risk Site Personnel

Hazard Electric Shock

Current Controls Isolation of Power/Trained Service Personnel

Using Chemical Fixer

Who is at Risk Site Personnel within the Vicinity of the Work Area

Hazard Fume Inhalation

Current Controls Compliance with COSSH regulations

Rating 5: Commissioning

Who is at Risk Site Engineer

Hazard Power Supply/Moving Parts

Current Controls Isolate Power

Rating 8: Floor Drilling

Who is at Risk Installation Engineer

Hazard Flying Debris and Noise

Current Controls Protective Equipment must be worn

Glass Panel Installation

Who is at Risk Installation Engineer

Hazard Glass Breaking

Incorrect handling techniques

Current Controls Protective Equipment must be worn.

CE - Marking

The Gunnebo GlasStile GSR is CE marked, developed and manufactured and tested according

to the EU‟s Machinery, Low-Voltage and EMC-Directives.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

9

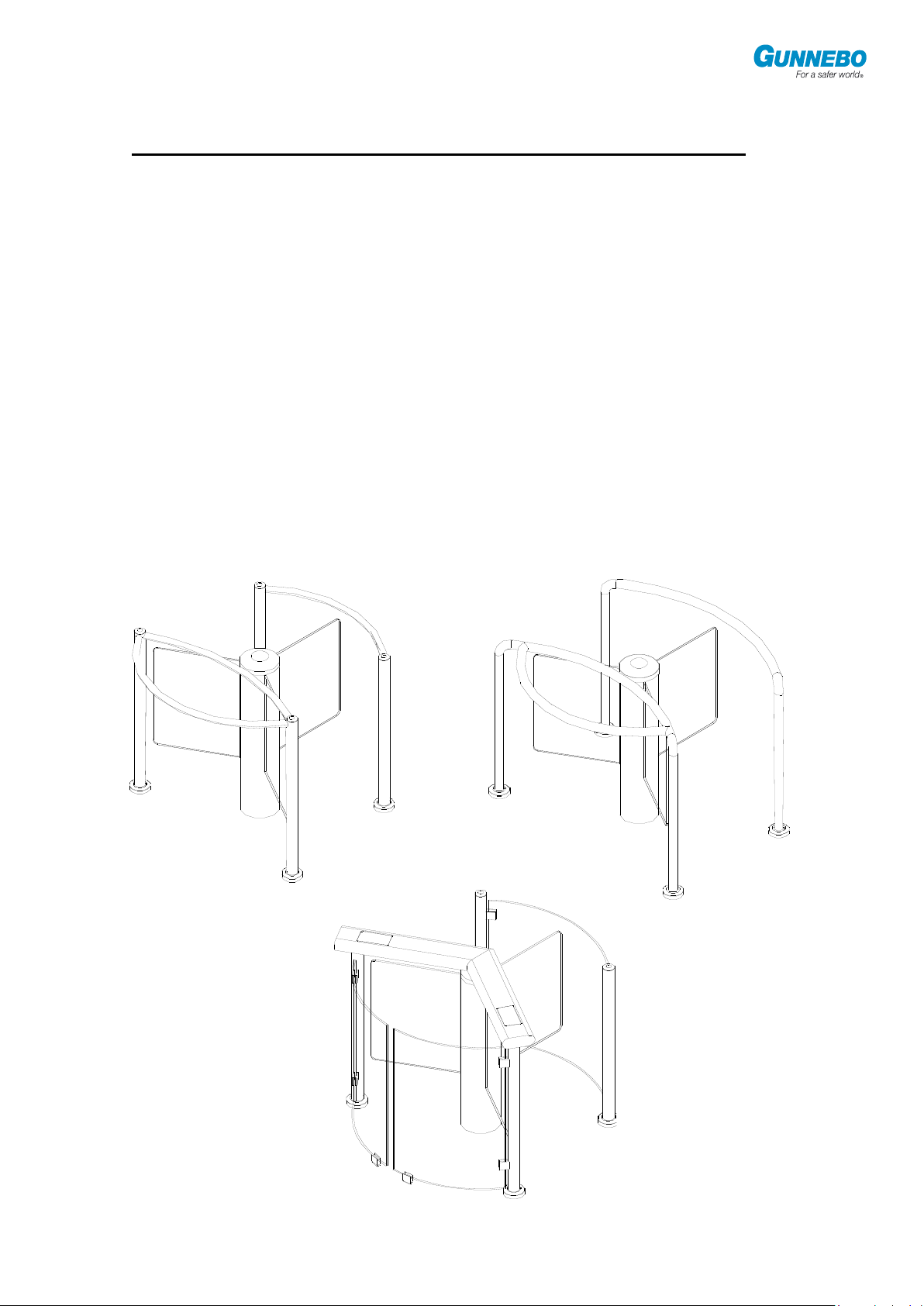

Type "A" Casework

Type "B" Casework

Type “C” Casework

Section 2 Product Description

Product Description

The Gunnebo GlasStile GSR is a revolving entrance gate with glazed panels. The GlasStile

GSR rotates clockwise or counter-clockwise 120 before being locked by an electro-magnetic

brake. The GlasStile GSR is activated in each direction by impulses to the driving electronics

unit from the reception or impulse unit (e.g. card reader or pushbutton).

Any impulse unit with a dry contact closing for between 0.5 - 1.0 seconds can be connected to

GlasStile GSR. Acknowledgement output pulse of completed rotations is given before and after

each rotation is completed. Optional status lights can show the status of the gate.

The speed, time delay, drive mode and individual setting of the panel‟s home positions can be

altered using an optional Hand Programming Unit. In the event of a power failure the

programmable functions are stored in a non-volatile memory.

The drive electronics are mounted on a printed circuit board that has connection points for

power, motor, brake, sensors, impulse units and status lights.

A 24V DC motor with gearbox drives the gate. An encoder is connected to the outgoing shaft

by a gear belt. The encoder‟s function is to monitor the position of the gate.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

10

Casework

Size

Casework

Type

Height

mm

Depth

mm

Width

mm

1350

A

1050

1189

1387

1350

B

1050

1350

1350

1350

C

1076

1350

1350

Technical Specification

Unit Dimensions Column Height: 1000mm

Column Diameter: 220mm

Note: Casework is also available to special order in size 1500.

Drive 24V DC Motor and gearing

Orientation Vertical

Materials Cladding - Stainless Steel Grade 304

Panels -Toughened Glass

Power Failure Gate Rotate freely with any power loss or emergency signal

Power Supply Voltage: 110/230 VAC 50/60Hz

Power rating: 250 W, fuse 1.0 A

Note - Class C mains circuit breaker is required.

Other dimensions and materials are available upon request to Gunnebo.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

11

Section 3 Instructions for Use

Instructions for Use

Starting the GlasStile

When power is switched on, the unit automatically searches for its internal zero position, moving

at a lower speed than normal. Once it has reached the blocking panel, it then automatically

moves to its programmed home position. The first time the gate is powered up it will move to its

default home position.

When the internal zero and home positions are being sought, the alarm output flashes slowly.

When searching has been completed the brake engages and the gate closed output switches.

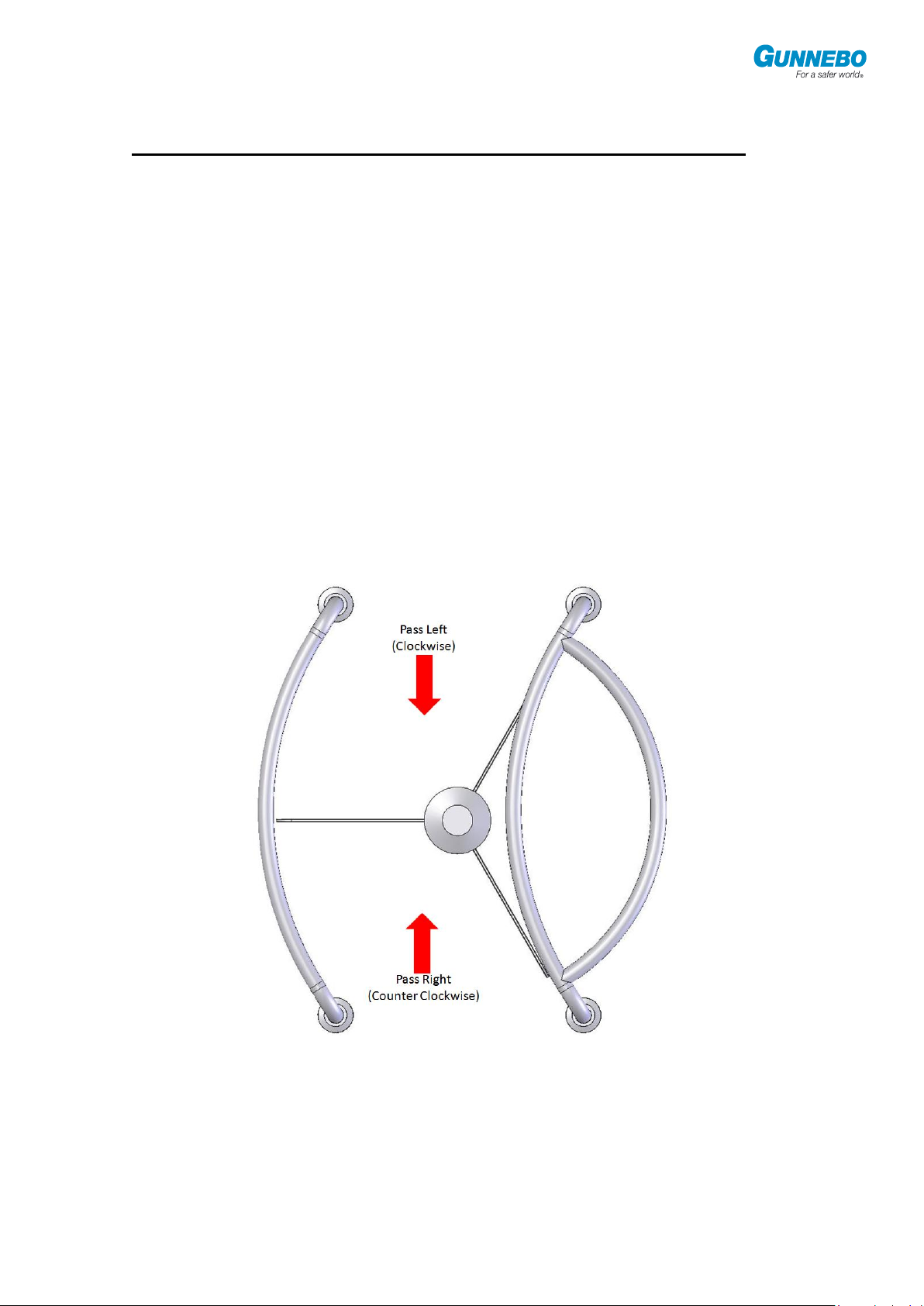

Reception Control Pass Left / Pass Right

There are two reception inputs, one each for PASS LEFT and PASS RIGHT directions.

The GlasStile GSR is passable for as long as the contact remains closed. On contact opening

the gate returns to its home position, where the electro-mechanical brake locks the wing back in

the barrier position.

No intrinsic acknowledgement of the rotation is given. The closed gate lamp illuminates and the

Status lights change from green to red.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

12

Operating Modes

Card Reader Control - Push to Go

When a signal is applied to one of the two card reader inputs the unit releases the brake and

switches the gate closed output. Passage can now occur within the selected time, if no passage

is started within this time the GlasStile GSR will lock and a new impulse must be given.

The GlasStile GSR starts to rotate in the selected direction once the panel is moved from its

home position. The GlasStile GSR has acknowledgement outputs that are used when

interfacing with card reader systems. These relay contacts are, by nature, open circuit. They

can be programmed via the Hand Programmer to occur during or after a passage.

When rotation has completed and the gate is locked, the closed gate lamp comes on.

If Acknowledgement A (after rotation) is selected from the programming options, once the

rotation is completed another signal may be given from the impulse unit.

If Acknowledgement D (during rotation) is selected from the programming options then signals

may be given to the unit during a rotation, a maximum of five of these signals can be stacked.

Reset

The alarm period lasts for a period of 20 seconds, the unit‟s blocking panel will then return to the

correct position and normal operation is commenced.

Unauthorised passage

When the gate is locked, the electro-magnetic brake is activated on full power for 0.5 second.

The power is then reduced to a steady rate. This is to reduce the risk of heat build up in the

brake.

When unauthorised passage through the GlasStile GSR is attempted the braking power is less

than 240Nm, but when the lock is disturbed, the brake moves from its steady power rate to

maximum power for 5 minutes before returning to the steady rate.

Blocking or forcing GlasStile GSR during rotation

If the GlasStile GSR is blocked completely during operation for more than 10 seconds, the unit

will go into alarm mode and then commence the reset cycle detailed above.

The maximum force exerted by a unit at its highest speed during opening or closing is

45.6 Newton‟s.

The maximum force needed to break the force of the break when it is locked is 312.8

Newton‟s.

Power Failure

In the event of power failure, the brake will release & the gate will rotate freely. When the power

returns the gate searches first for its internal zero position and then for the home position similar

to when the GlasStile GSR is first started.

Fire Alarm

The GlasStile GSR has a facility for an external fire alarm input. The fire alarm output should be

a normally closed voltage free (0V) pair. When this pair is open the unit will freewheel in both

directions, this continues until the input is re-closed.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

13

Section 4 Technical Information

Technical Information

The central column stands totally independent of the surrounding framework, housing the drive

motor, gearbox and electronics. All electronics and mechanical components are housed in the

centre column.

Toughened transparent glass panels are at 120O intervals.

The unit is supplied to integrate fully with all proprietary card reader systems, with a variety of

outputs and inputs, i.e. passage confirmed for updating anti-passback systems, inhibits, fire

alarm.

All that is required is a GO signal of duration between 0.5 and 1 second from the access control

system (voltage-free contact, normally open).

Material Finishes

Alternative materials, such as polished or grained stainless steel, brass or painted finishes can

be supplied to special order. Handrails can be supplied made from various materials, e.g. metal

or wood, please consult Gunnebo for further information.

Standard finish is cladding of brushed stainless steel with gate panels of 10mm transparent

toughened glass.

Flexibility of Design

Integrated design makes installation simple with a minimum of intrusion on the existing

environment.

This concept allows architects and designers the ability to design a security system that fits their

requirements for any situation. The GlasStile GSR is often installed with the addition of a

GlasStile GSS to provide disabled access.

.............................

CCEC/ OM Manual GlasStile GSR 1.6 EN 07.2009

Loading...

Loading...