Gundlach 1027 Series, 1037 Series Owner's Manual

Manual De Operacion

Nos. 1027 / 1037 Serie Sierras

Espanol

SDT 1027

Before operating the unit, please read this

manual thoroughly, and retain it for future

reference.

Antes de usar esta maquina, favor de leer

este manual profundamente, y guarde para

referencia futura.

No. 1027

No. 1037

Owner’s Manual

Nos.1027 /1037 Series Bridge Saws

SDT 1027No. 1027

No. 1037

1

2

3

3

4

5

6

7

8

9

9

10

10

11

11, 12

13

14

14

15

16

17, 18

19, 20, 21

22

23, 24, 25

26

27, 28

29, 30, 31, 32, 33, 34, 35

36

37

Table of Contents

Safety Precautions

General Safety Rules

Health Warnings

Unpack, Assembly & Set-up

Specifications

Features

Saw Stand Assembly

Blade Installation

Cutting Head Installation

Side Table & Splash Guard Installation

Water Pump Installation

Water Level Tube

The Rip Guide

Operating the Saw

The Cutting Table

Cutting Depth

Choose the Right Blade

Optional Accessories

Do’s & Don’ts for Blades

Saw Maintenance

Water Pump Maintenance

Troubleshooting

Notes

Warranty

Replacement Parts List

No.1027 Saw Exploded View

No.1037 Saw Exploded View

Electric Motor Specifications

Saw blade should be inspected daily for excessive wear, core

cracks, and arbor damage. Replace any blade that shows

signs of damage.

. To mount blade, clean arbor and outer flanges,

tightening nut securely.

. DO NOT place any portion of body in line with blade

while it is rotating.

. Wet cutting blades must be used with water.

. To reduce risk of electrical shock, we recommend the

use of GFCI and to refer servicing to a qualified

professional.

OUR COMPANY recommends the use of these Safety

Items when Operating the Saw:

WEAR BREATHING PROTECTION

USE BLADE GUARD WHEN

OPERATING SAW

WEAR EYE PROTECTION

WEAR HEARING PROTECTION

TABLE OF CONTENTS

SAFETY PRECAUTIONS

Page

2

1

• Never use the machine improperly or work in an unsafe manner.

• Always wear safety goggles, dust mask, and ear protection while operating

the saw (to comply with ANSI-Z87.1).

• Always remain alert when the saw is in use. Failure to pay attention on the

operator’s part may lead to serious injury.

• Before you start working, familiarize yourself with the work site and its

surroundings. Take notice of circumstances which may impede working or

traffic, observe soil conditions (good bearing or not), and take measures to

ensure safety (i.e. the shielding of roadworks from public traffic).

• Take measures to ensure that the machine is in a safe and trouble-free

condition prior to usage. Use the machine only when all protective devices

(i.e. guards, noise absorbers, emergency-off devices) are operating in the

intended locations.

• A visual check of the machine must be made at least once a shift to ensure

that visible damages or faults are recognized. Any changes (including

changes in the performance or behavior of the machine) must be reported

to the supervisor. If necessary, stop the machine at once and secure it.

• In the case of a malfunction stop the machine immediately and secure it.

Fix the problem as soon as possible.

• For starting and stopping the machine follow the operating instruction steps

and observe any indicator lights.

• Before switching the machine on make sure that the activated machine will

be of no danger to anyone.

• Be sure to connect the plug to a properly grounded receptacle to reduce the

risk of electric shock.

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

.

Lead from lead based paints,

.

Crystalline silica from bricks and cement and other masonry products,

.

Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated are, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

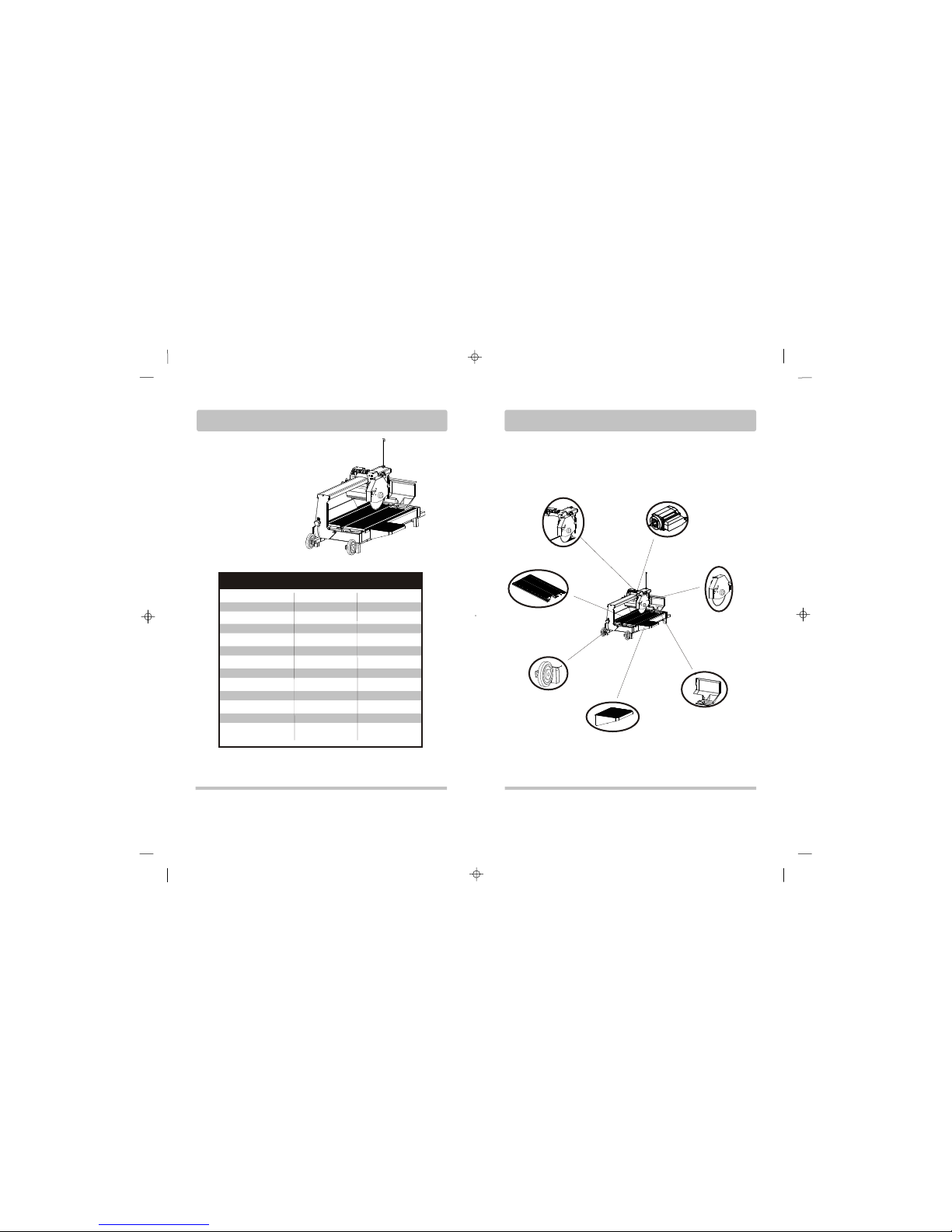

Open the container, carefully lift

the saw frame handles and

place it on a flat, level working

area. Be certain that you have

the following items before you

discard the container:

Saw

Slide-In Legs with Wheels

(1037 model only)

10” Saw Blade

Multiple Rip Guide

Multiple Wrench

Water Pump

Water Level Tube

Owner’s Manual

Drain Plug

Proceed to the following section

to complete assembly of the

saw.

Assembly & Set-Up

1. Remove the carton box cover

from the wooden frame.

2. Remove saw from the crate.

3. Loosen the lock knob on top

of the cutting head.

4. Install the side extension

table, side splash guard and

back splash guard.

5. Install the spring holder on

top of the sliding rail to hold the

power cable and the water hose.

6. Fill the tray with water before

operating the saw.

General Safety Rules

Unpack, Assembly & Set-Up

4

3

Unpack

Health Warnings:

These saws are professional

saws used for cutting floor tiles,

paving stones, stairs, largesized natural stones , and

similar materials.

These saws are designed with water flow control in mind. The water

pump, inside the tray or as an option it can be used inside a bucket, a

water control valve and splash guards ensure proper water flow during

operation.

Position Lock

Cutting Head

Removable Extension

Table adds Xtra Workspace

Splash Guard reduces

Water Waste

Rubber Matted

Cutting Table

Blade Capacity of 10”

enhances Cutting Capacity

Powerful 1-1/2HP Induction

Motor cuts larger materials

Sturdy Wheels for

Easy Transport

Induction Motor

3450 rpm

Horse Power

Volts

115 votls

Amps

15 A

Hertz (Cycles)

60 Hz

Motor Type

Stand (Optional)

1010-ST

RPM

Maximum Blade Size

Arbor Size

Maximum Depth of Cut

Straight Cut Length

SPECIFICATIONS 1027 1037

Diagonal Cut Length

Weight

8”-10”

5/8”

2-5/8”

27”

19”

125 lbs.

1-1/2 HP 1-1/2 HP

115 volts

15 A

60 Hz

Induction Motor

3450 rpm

8”-10”

5/8”

2-5/8”

37”

26”

166 lbs.

Slide-In Legs w/Wheels

SPECIFICATIONS

FEATURES

6

5

1. Remove the folding stand

from its box.

2. Swing the working bench

up-right. Open the two legs

and place the work bench on

top of the folding stand.

3. After the saw stand is

completely assembled, place

the saw on top of the saw

stand.

1. Loosen the knurled nuts

securing the blade guard

and remove the guard.

2. Loosen the cutting shaft nut

(left-hand thread); while

loosening the nut, block

the cutting shaft from

turning.

3. Remove the blade

clamping flange. Check

that the contact area

between the blade holder

assembly and the diamond

saw blade is clean.

4. Install the saw blade on the

supporting flange, ensuring

the correct sense of

rotation marked by the

arrow on the blade.

5. Install the blade clamping

flange.

!

Setting the blade too low may damage the

cutting table and if set too high, the blade may

grab the material being cut, causing damage

and possibly injury.

WARNING:

6. Retignten the cutting shaft

nut. Block the cutting shaft

from turning while

tightening the nut.

7. Lightly turn the installed saw

blade by hand and check

the blade for true running.

8. Mount the blade guard.

knurled nuts

Folding Stand (1027 Optional)

1. Make sure the cutting head

is locked.

2. Lifting up one side of the

saw, slide in the legs (with no

wheels) to the front side of

the saw. Lock the wing nut to

tighten the legs in place.

3. Lift up the other side of the

saw and slide in the legs with

the wheels. Lock the wing nut

to fasten the legs in place.

Slide-In Legs (1037)

Easy Transport (1037)

1. Make sure the cutting head is locked.

2. Unlock the wing nut. Lift up the back side of the saw and slide

the legs with wheels,lock the wing nut.

3. Go to the other side of the saw and unlock the wing nut. Lift up

the other side of the saw and insert the legs, lock the wing nut.

Using the legs as handles, tilt the saw diagonally and roll the saw

on the wheels like a dolley.

No. 1010-ST SAW STAND ASSEMBLY

BLADE INSTALLATION

8

7

1. Remove the water pump

from the box and check

that it is not damaged.

2. Place the pump into the

bracket at the right front

corner of the water tray

along its side so that the

water outlet is positioned

horizontally. Connect the

water hose from the blade

guard to the pump and

plug the power cord into

the 3-prong receptacle.

1. Slide the motor into the body of

the cutting head mainframe, holding

the motor front (outer) ring insert into

the mainframe bracket.

2. Holding the cutting head steady,

insert 4 bolts onto the front end of

the motor through the cutting head

mainframe. Lock the bolts tight to

hold the motor in position.

3. Insert the inner flange onto the

blade shaft against the motor’s front

end.

4. Place the blade onto the shaft

making sure the directional arrows

are pointing in the direction of the

shaft rotation. Secure in place with

the outer flange and blade shaft nut.

5. Insert the main long bolt in the

upright of the front plate while

holding the cutting head mainframe,

lock it tight in position. Insert the

second long bolt into the height

adjustment slot and lock it tight in

position. Place the tension spring

into position for height adjustment.

Install the side table and splash

guard as shown in the

illustration to the side. Fasten

the screws respectively to the

saw frame.

CUTTING HEAD INSTALLATION

WATER PUMP INSTALLATION

10

9

SIDE TABLE & SPLASH GUARD

INSTALLATION

WARNING:

!

Disconnect the pump before attempting to handle the pump.

Never operate pump without water in the tray.

3. Fill the water tray so that

the water intake is fully

immersed.

4. Be sure to support the

pump during installation to

prevent pump failure or

damage.

WATER LEVEL TUBE

A tube at the rear end of

the saw filters the debris from the

water produced during the cutting

operation. Debris settles in the water

tray while the water is allowed to

pass through the tube and into the

water bucket, where fresh and filtered

water reside.

Remove the water level tube

from the plastic bag.

Inser t the thin end o f the

tube into the rea r hole

nex t to the wate r pump ,

as shown in the illustration.

1.

2.

3. Fill the water

tray with water.

á The No. 884 Universal Tile

Guide is a two-piece

assembly consisting of a

template base and a

unique detachable ruler

guide. This permits any

cutting angle between 0

and 45 , with 22 and

30 clearly designated.

The ruler guide also

doubles as a measurement

tool to accurately measure

slabs up to a foot in length.

á The Universal Tile Guide

has a locking mechanism

that secures the ruler guide

firmly to the template base.

°

°°

°

°

°°

°

WARNING:

!

Always lock the rip guide prior to transporting the saw.

1. After you have made

yourself familiar with the

components of your saw,

the machine has been

properly set up, the bucket

or water tray is filled with

water, and the electrical

connection is established in

accordance with the

relevant safety regulations,

you may now begin with the

cutting operation.

2. Before you start operation

open the water shut-off

valve.

5. After the cutting operation

is finished, prevent

accidental restarting of the

saw by pushing the

emergency stop from the

switch bracket and

unplugging the power

cable.

3. During the operation, the

user must stand in front side

of the saw, holding the

handle of the swivel-joint

cutting head with his left

hand. The workpiece must

rest on the work table and

should be pressed tightly

against the side and limit

stops with the right hand.

4. Always turn off the saw

before you leave the

machine unattended.

When cutting at constant depth

the cutting head must be pulled

against the workpiece.

1. Before you start cutting, set

the cutting head at the

desired fixed cutting depth.

2. Then use the handle to pull

the cutting head slowly and

uniformly along the guide

rail and across the

workpiece.

3. Push the cutting head fully

back after you finished the

cut.

The handling of larger cutting

depths can be simplified using

the plunge cutting method.

1. In this case, the cutting head

will not be set to a fixed

position while performing

the cut.

2. As you have not fixed the

saw at a defined depth,

Cutting at Constant Depth

Plunge Cuts

The cutting head is freely

movable during seesaw

operations.

3. Hold the handle of the

cutting head with your left

hand and move it to and fro

across the workpiece while

lightly pressing the cutting

head downwards in a

discontinuos movement.

TEMPLATE BASE

DETACHABLE RULER

THE RIP GUIDE (Optional)

OPERATING THE SAW: continued

12

11

OPERATING THE SAW

Loading...

Loading...