Gullberg Janson V80-3P, V130-3P, V250-3P Installation And Maintenance Manual

Installation and Maintenance guide

V80-3P/V130-3P/V250-3P

EN

________________________________________________________________________________________________

Rev. 2015.1

Preface

Congratulations on your purchase of a pool heat pump from Gullberg & Jansson AB. We hope

it meets your expectations and provides you with many years of energy ecient heating.

In this Installation and Maintenance Guide you can read how installation, operation, service

and maintenance are to be performed to ensure correct function. It is therefore important

that you read through the manual carefully before starting or serving the unit. Gullberg

& Jansson can not be held responsible for damage resulting from incorrect installation,

incorrect fault tracing or incorrect maintenance.

Yours sincerely,

Gullberg & Jansson AB

Subject to possible misprints and design alterations. Gullberg & Jansson AB is not responsible for misinterpretations, any obvious

misprints and consequences resulting from these.

FOR YOUR OWN RECORDS

Please complete the details below. Keep these close to hand should anything happen.

Product:

Installed by: Telephone:

Serial number:

Date of installation:

The proof of installation for registration at

Gullberg & Jansson AB is enclosed with the

installation. It is important that this is completed

and posted at the earliest possible date!

!

Table of contents

General information

Product description 4

Functional principle 4

Component part and accessories 5

Important information 5

Transport and storage 5

Installation 5

Use and operation 5

Maintenance procedures 5

Service and support 5

Checklist installation 6

Guarantee conditions 6

Safety Regulations 6

Installation

Outline diagram 7

Positioning the unit 7

Set up 7

Leading o condensation water 8

Pipe connections 8

Bypass coupling 8

Interconnection of multiple units 8

Electrical installation 9

Starting up the unit 9

Use and operation

LCD display 10

Start screen 10

Temperature setting 10

Main menu 11

Temperature values 11

Digital inputs 11

Relay outputs 11

About the software 11

Setting time and date 12

Error messages 12

Maintenance, service and

fault tracing

Winter drainage 13

Maintenance 13

Fault tracing 13

Error code table 13

Fault charting table 14

Technical specication

Connection key PC4001 15

V80-3P/V130-3P 16

Wiring diagram 16

Technical data 17

Dimensions and connections 17

V250-3P 18

Wiring diagram 18

Technical data 19

Dimensions and connections 19

General information

Product description

The models V80-3P/V130-3P/V250-3P are a range of

specically developed air/water heat pumps designed for

energy ecient heating of swimming pools or spa facilities.

The models have been developed and designed for the

Nordic climate. The pool heat pumps are designed to

work with good eciency and a low noise level.

All models feature:

• Titanium heat exchangers resistant to chlorine and salt

water

• Environmentally friendly and eective refrigerant (R410a)

• Digital LED control

• Dynamic defrost function

• Built-in ow switch

• Union or anged connections depending on model

Functional principle

The pool heat pumps are V80-3P/V130-3P/V250-3P primarily

used for heating, but can also be used for cooling. The

models are controlled via a ow

switch and in order to work the pool’s circulation pump must

be running.

The pool heat pump works with the greatest energy

eciency when there are small dierences in temperature

between the inlet and outlet. The recommendation is 1-2

degrees dierence between the inlet and outlet. The water

ow is regulated via a bypass coupling. Read more about the

bypass coupling in section 2 – Installation.

All models are developed to guarantee good eciency in

the Nordic climate. However, it is important to be aware that

the degree of eciency is dependent on the surrounding

outdoor temperature and the temperature of the pool

water. The heat pump can be seen to perform with dierent

eciency during dierent parts of the year depending on

the outdoor conditions. At the start of the season, when

the water in the pool is cold, the heat pump needs to

work continuously for a long period to produce the right

temperature in the pool. When the pool water has reached

the required temperature, the heat pump automatically stops

and starts as required. It is always cost-eective to cover the

pool when not in use, especially at night. Approximately 60

– 70 % of the heat disappears from the water surface of the

pool. Covering also reduces the heat pump’s running time.

The heat pump must always be installed outside as it draws

its energy from the surrounding air. It must be well ventilated

and must not be enclosed or in any other way shielded so the

air circulation is impaired. The circulation of the air between

the intake and exhaust impairs eciency

Frost or ice can form on the heat pump’s evaporator. This is

completely normal. An automatic defrosting cycle will start to

melt the ice. After the defrosting cycle the heat pump starts

its standard program and continues to heat the pool.

The swimming pool heat pump normal working

condition is between 5 and 40 °C ambient temperature and

between 15 and 40 °C inlet water temperature.

This chapter provides background information about the pool heat pumps covered in this Installation and Maintenance Guide.

Important information, guarantee conditions and safety instructions are also presented here. This chapter is intended for both users

and installation engineers.

1

4

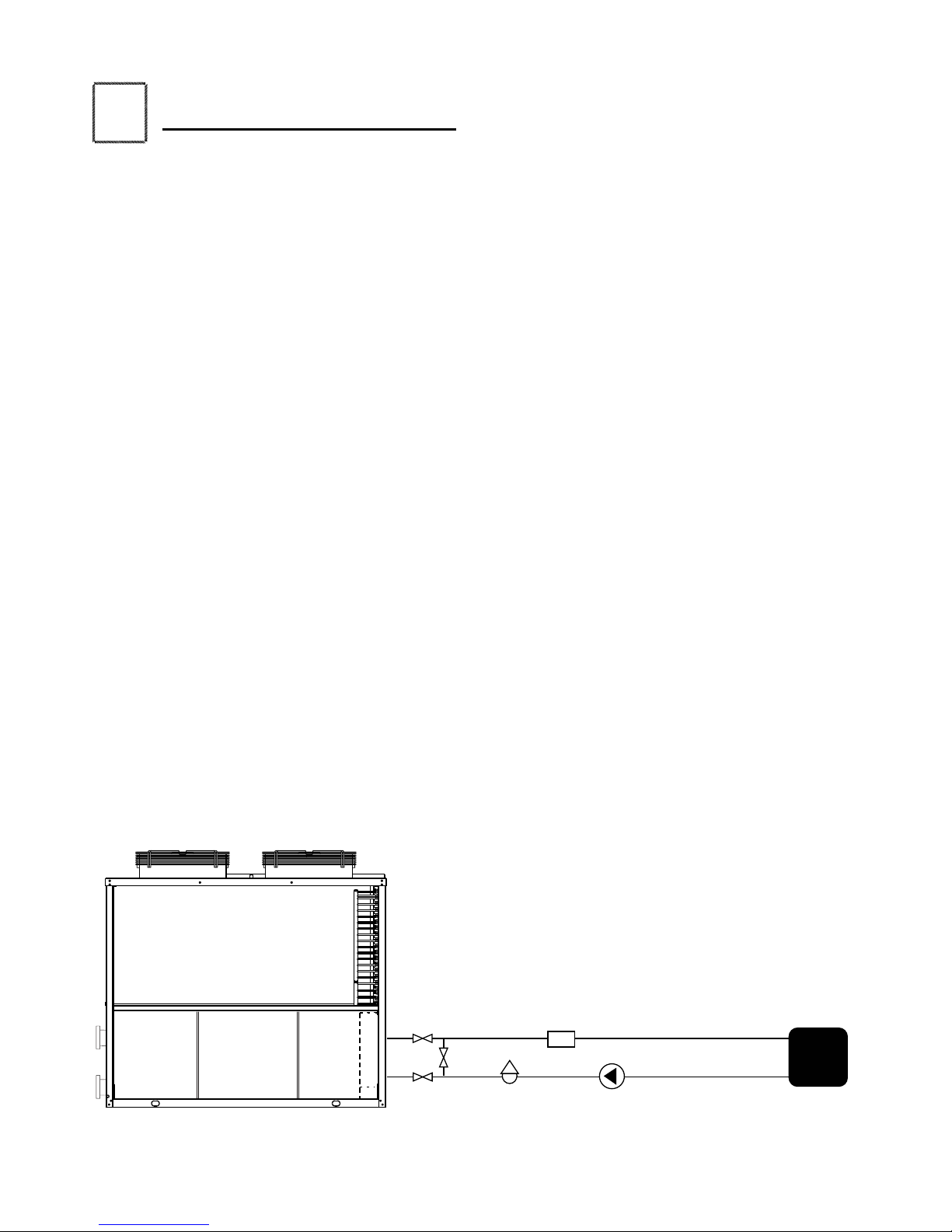

POOL

Refer to the labels on the unit before connecting the inlet and outlet.

Chlorinator

Sand lter

Circulation pump

General information

5

Component part and accessories

1. Main unit – V80-3P/V130-3P/V250-3P

2. Installation accessories

• Installation instructions

• LCD display with 20 metres of cabling

• Union couplings (V80-3P/V130-3P only)

• Damping rubber blocks (V80-3P/V130-3P only)

Important information

You can read about some especially important points

concerning transport and storage, installation, usage,

maintenance and fault tracing below.

Transport and storage

Models designed to be transported vertically must be

transported in this way. This is because the suspension inside

the compressor can be damaged if the unit is laid down. If

the heat pump is tilted during installation or draining this

should be done with care and for the shortest time possible.

The original packaging is intended to be used to reduce the

risk of transport damage.

Installation

The pool heat pump must be installed by a qualied

installation engineer and placed outdoors. The unit must

stand rmly, straight and raised from ground level. Provide a

rm and at surface.

Noise propagation must be taken into consideration when

positioning during installation. Positioning of the unit must

be done so that noise from the compressor and fan disturb

the environment as little as possible.

Large amounts of melt and condensation water can be

discharged during defrosting and operation. Consequently, it

is important to provide good drainage and run-o. The

units must stand freely so that air is not prevented to pass

the evaporator. Avoid a placement that produces cold air

circulation as this reduces the output of the heat pump.

In a combination involving solar collectors, you should

ensure that hot solar collector water does not ow directly to

the pool heat pump. If the solar collector water becomes too

hot you risk damaging the heat pump beyond repair.

Use and operation

The parameters on the display are set at the factory and do

normally not need to be adjusted. The temperature is set

to 27 °C. If you wish to increase the temperature, check rst

to ensure that your wishes of a high temperature do not

contravene any guarantees concerning the general pool

construction.

Maintenance procedures

Perform regular checks to ensure that the inlet grille is not

blocked by leaves, snow, etc. In addition, make sure that

excessive frost or ice does not build up below the unit during

cold weather conditions.

The outer case can be cleaned using a damp cloth if

necessary. Take care not to scratch the unit.

If the pool heat pump should be out of service over the

winter, it is important to drain the unit of water. The

guarantee does not cover damage due to freezing on

account of insucient maintenance. The heat exchanger can

also be ushed out to remove any remaining deposits ahead

of winter drainage. Read more about drainage in section 4 Maintenance, service and fault tracing.

Service and support

The pool heat pumps are designed for reliable operation and

a long life. If a fault should occur you are advised to contact

the installation engineer who carried out the installation.

Always specify the product serial number, which you will nd

under the rating plate on the long side of the heat pump.

A basic guide to fault tracing is presented in section 4 Maintenance, service and fault tracing.

The unit may only be repaired by a qualied installation

engineer or an accredited workshop. Original spare parts

must be used for repairs.

Installation material is enclosed inside the

machine. Open the cover and remove the

material before installation. Note that the

installation engineer provides pipes and

the bypass coupling for the installation.

!

General information

6

Checklist installation

The following checklist provides a general description of how

the installation is carried out.

; Place the heat pump on a rm and horizontal surface.

; Open the service hatch and remove the enclosed

installation kit. Ensure that all component parts have

been delivered.

; Route the pipes for incoming and outgoing water.

Exercise care to ensure the inlet and outlet are installed

correctly. Mount the heat pump after the sand lter.

; Install a bypass for regulating the right partial ow for

the pool heat pump.

; Connect the electricity.

; Energise and check the settings.

; Put in operation and adjust the ow to the pool heat

pump to the right level.

Read more about start up in section 2 under the heading –

Starting up the unit.

Guarantee conditions

The component parts of the system must be transported,

stored and installed in accordance with the provisions

set out in the manual.

Repairs must be carried out by a qualied engineer. Original

parts must be used for repairs.

The guarantee becomes void if the conditions above are

violated.

Safety Regulations

It is especially important to take into account the following

safety instructions when handling, installing and using the

heat pump:

• Only qualied persons may work on the product’s

cooling system.

• Always disconnect the power supply before working on

the system.

Loading...

Loading...