Gulfstream Aerospace G550 Operating Manual

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

INDICATING / RECORDING

2A-31-10: General

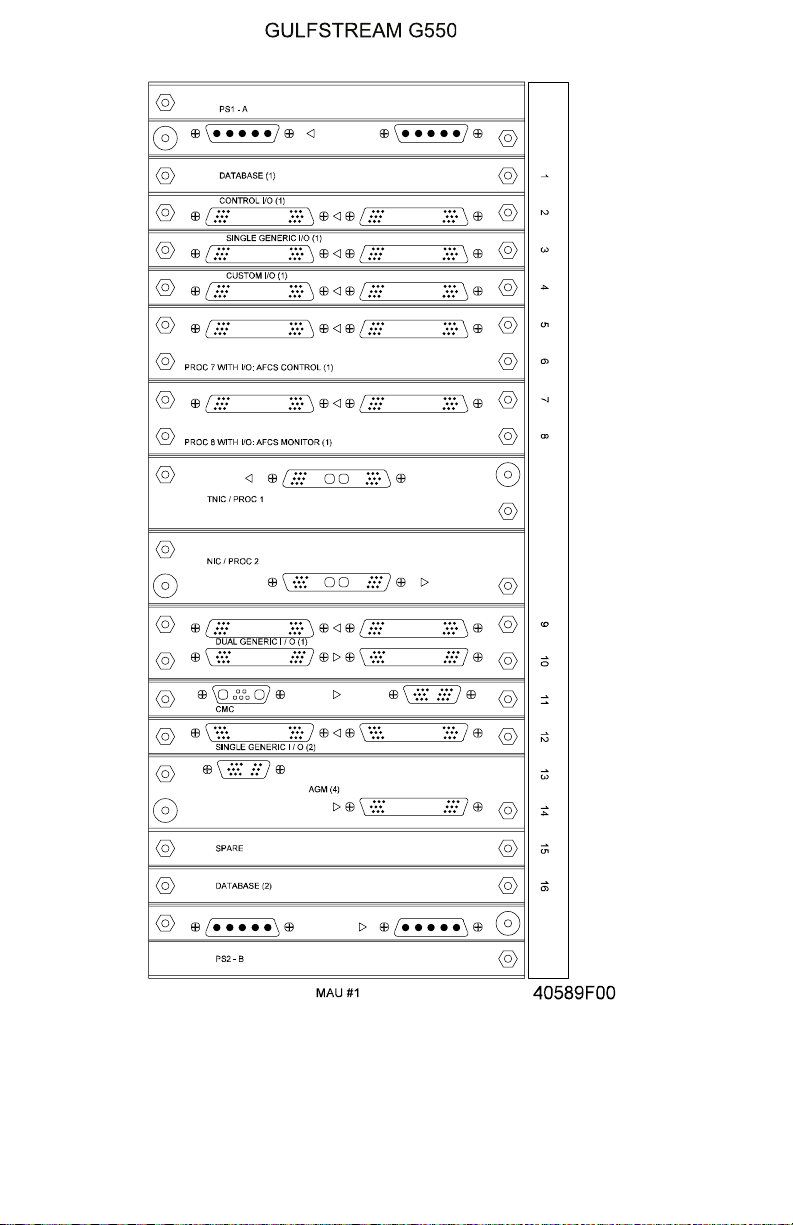

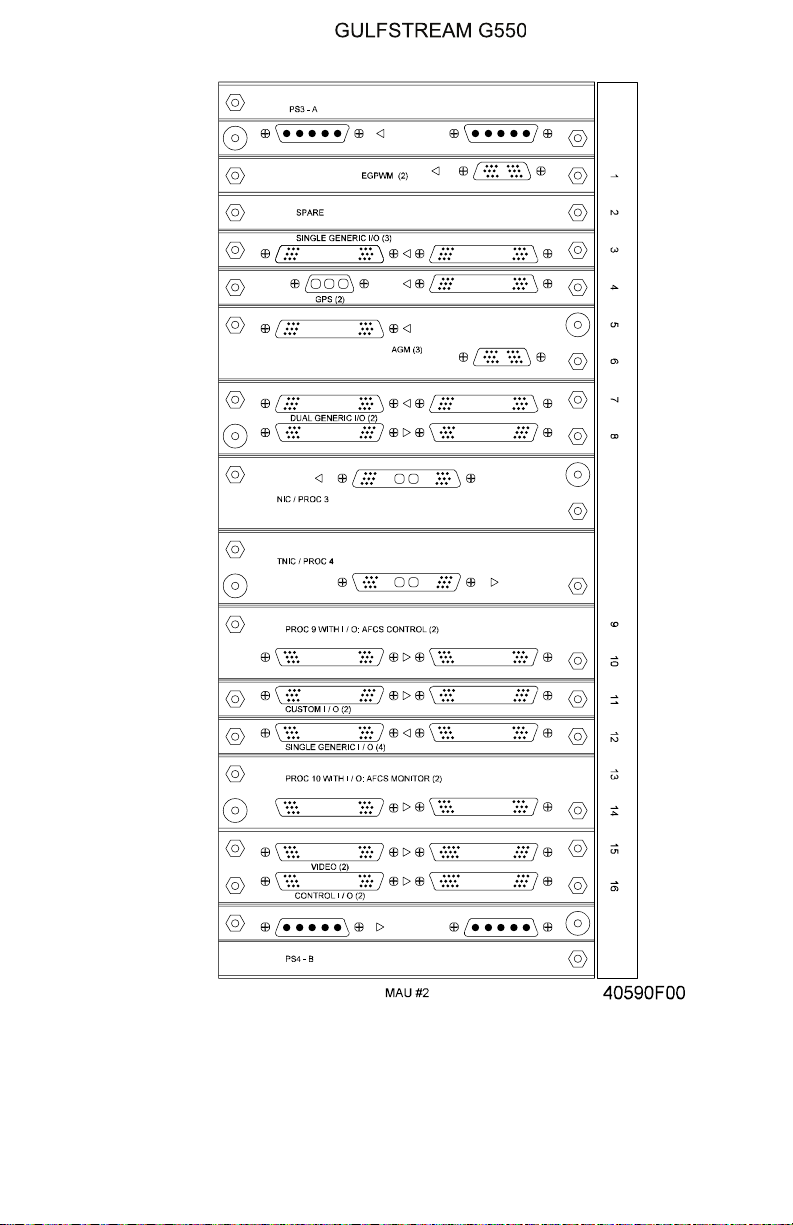

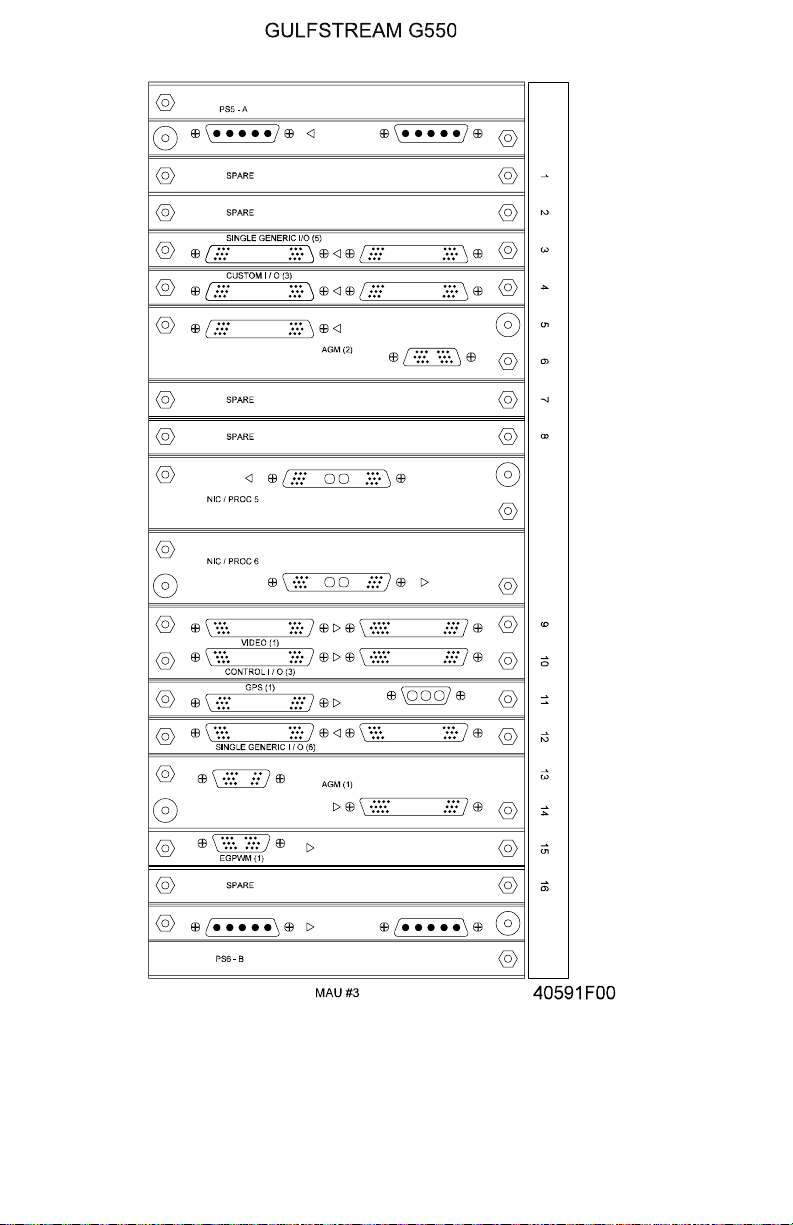

1. Honeywell PlaneView System Indicating and Recording Architecture:

The indicating and recording systems of the Gulfstream G550 reside within a

highly integrated hardware and software architecture provided by the Honeywell

PlaneView system. PlaneView incorporates software avionics functions hosted on

processor cards and modules installed in three (3) Modular Avionics Units (MAUs)

and two (2) Modular Radio Cabinets (MRCs). (The MAUs are depicted in Figure

1, Figure 2 and Figure 3.) The avionics functions communicate within the MAUs

over a digital bus called the Virtual Backplane Peripheral Component Interconnect

(VbPCI) using a Periodic Device Driver (PDD) and a Backplane Interface

Controller (BIC). Each MAU has two (2) channels, A and B with each channel

powered redundantly powered by a primary and secondary DC power source. The

dual channel, dual power source configuration provides both redundancy and

flexibility for module installation, since some modules require connection to only a

single channel while other modules must have dual channel connections. Each

MAU is also equipped with an internal fan to provide module cooling.

The processor cards and modules within the MAUs and the communication

modules residing in the MRCs exchange data over four (4) redundant version D

Avionics Standard Communication Buses (ASCB-Ds) through Network Interface

Controllers (NICs). The ASCBs and NICs provide bidirectional software

communications at 20 Mb/sec with a frame rate of 80 Hz. The ASCBs are

supplemented with a Local Area Network (LAN) that provides both a Data

Management Unit (DMU) and Personal Computer (PC) interface for loading

software data and performing maintenance analysis and testing. All data flow

within the PlaneView system is governed by a Digital Engine Operating System

(DEOS) that provides space partitioning to ensure the memory integrity within all

avionics functions and additionally provides the timing separation that allows

multiple software functions to run simultaneously.

Aircraft analog devices and independent digital avionics components connect to

the ASCB-Ds, linking to the MAUs and MRCs over other buses and interfaces

(such as ARINC-429 buses) through Input / Output (I/O) modules. The I/O

modules are directly connected to the ASCB-Ds and are integral to the MAUs.

Different types of I/O modules are incorporated in the MAUs to provide

accommodations for the various types of components requiring ASCB-D interface:

• Control I/O modules - used for communicating command data from (and to)

components that provide tuning, display choices or option selections such

as the flight guidance panel, weather radar controller, Traffic and Collision

Avoidance System (TCAS) and the Multi-function Control and Display Units

(MCDUs)

• Actuator I/O modules - provide actions such as position commands to the

aircraft flight controls from the Automatic Flight Control System (AFCS) and

the stall barrier / stick pusher system, trim control, yaw damper monitoring

and autothrottle control

• Generic I/O modules - used to interface data from components such as the

engine Full Authority Digital Electronic Controller (FADEC), Air Data

Modules (ADMs) and radio altimeters

• Custom I/O modules - provide specialized interfaces for specific external

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 1

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

components that require a high volume of data interchange such as the

flight data recorder.

In addition to the I/O modules, the MAUs contain:

• Aircraft Personality Modules (APMs) - two (2) housed within Timing

Network Interface Controllers (TNICs) in MAUs #1 and #2 that retain

aircraft configuration data such as installation serial numbers, identifiers,

and configuration options (SELCAL addresses, MagnaStar phone

numbers, etc.). Two (2) additional APMs are incorporated in the Modular

Radio Cabinets to store communication management functions.

• Data Base Modules (DBMs) - provide non-volatile memory for navigation

and terrain data bases and store aircraft maintenance data. The DBMs are

accessed through the cockpit data management unit (DMU) or through the

remote Personal Computer (PC) Local Area Network (LAN) data ports

located on the test and monitor panel.

• Central Maintenance Computer (CMC) module - monitors the condition

and health of all aircraft components interfaced with the MAUs, storing

detected faults, constructing a fault history database and providing a

diagnostic guide for system troubleshooting. The CMC module is equipped

with a D-sub connector, enabling use of a PC for fault downloading and

system checks.

• Advanced Graphics Modules (AGMs) - generate the visual information

shown on cockpit display units including Primary Flight Displays (PFDs),

Navigation displays, CrewAlerting System (CAS) messages, Synoptic and

System Window displays, uploaded weather overlays and real-time video

from aircraft cameras

• EGPWS module - provides all of the functionality of the Enhanced Ground

Proximity Warning System and stores the terrain database

• Global Positioning System (GPS) modules - interpret data received by the

GPS antenna to compute aircraft position. Position information is

communicated to using elements within the MAUs over a dedicated

ARINC-429 bus rather than through the MAU backplane. The GPS

modules have separate direct bus paths to the Inertial Reference System

(IRS) to provide full initial and continuous alignment data.

• Video Module - provides initial formatting of aircraft camera analog video

for subsequent use by the AGMs in constructing the Cameras system

display window.

The high degree of integration of all modules and functions residing in the MAUs

and MRCs offers the flight crew instantaneous comprehensive oversight for all on

board aircraft systems.

2. Indicating and Recording Subsystems:

Although all indicating and recording functions are distributed throughout the

PlaneView system, The specific functions of the indicating / recording system are

divided into the following subsystems:

• 2A-31-20: Cockpit Clock System

• 2A-31-30: Digital Flight Data Recorder System

• 2A-31-40: Data Management Unit

• 2A-31-50: Cockpit Printer

Page 2

July 15/04

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

• 2A-31-60: Central Maintenance Computer System

• 2A-31-70: Monitor and Warning System

• 2A-31-80: Electronic Display System

• 2A-31-90: Weather Radar and Lightning Sensor Systems

3. Controls and Indications:

A. Circuit Breakers (CBs):

The following CBs power the MAUs:

Circuit Breaker Name: CB Panel Location: Power Source:

MAU #1A PRI POP A-10 L ESS DC Bus

MAU #1A SEC CPOP A-10 R MAIN DC Bus

MAU #1B PRI CPOP A-9 R ESS DC Bus

MAU #1B SEC POP A-9 L MAIN DC Bus

MAU #2A PRI CPOP A-8 R MAIN DC Bus

MAU #2A SEC POP A-8 L MAIN DC Bus

MAU #2B PRI CPOP A-7 R ESS DC Bus

MAU #2B SEC POP A-7 R MAIN DC Bus

MAU #3A PRI POP A-6 L MAIN DC Bus

MAU #3A SEC CPOP A-6 R MAIN DC Bus

MAU #3B PRI POP A-5 L ESS DC Bus

MAU #3B SEC CPOP A-5 R MAIN DC Bus

B. Crew Alerting System (CAS) Messages:

The following CAS messages are associated with the MAUs:

Area Monitored CAS Message Message Color

AGMs AGM 1-2-3-4 Fail Amber

APMs APM 1-2-3-4 Fail Amber

APMs APM Miscompare Amber

MAU Fans MAU 1-2-3 Fan Fail Amber

MAU MAU 1A-1B-2A-2B-

MAU MAU 1A-1B-2A-2B-

3A-3B OVRHT

3A-3B Fail

Amber

Amber

AGMs AGM 1-2-3-4 Fail Blue

APMs APM 1-2-3-4 Fail Blue

The listed caution messages may be displayed individually or in various

permutations according to the configuration of the malfunction. For instance, MAU

1A-2B-3A OVRHT or MAU 1B-3A-3B Fail might be displayed if conditions warrant.

Because of the extensive number of message combinations possible, only the

representative root messages are included in this tabulation.

NOTE

C. Limitations:

There are no limitations specific to the MAUs as of this writing.

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 3

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 4

July 15/04

MAU #1

Figure 1

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

MAU #2

Figure 2

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 5

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 6

July 15/04

MAU #3

Figure 3

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

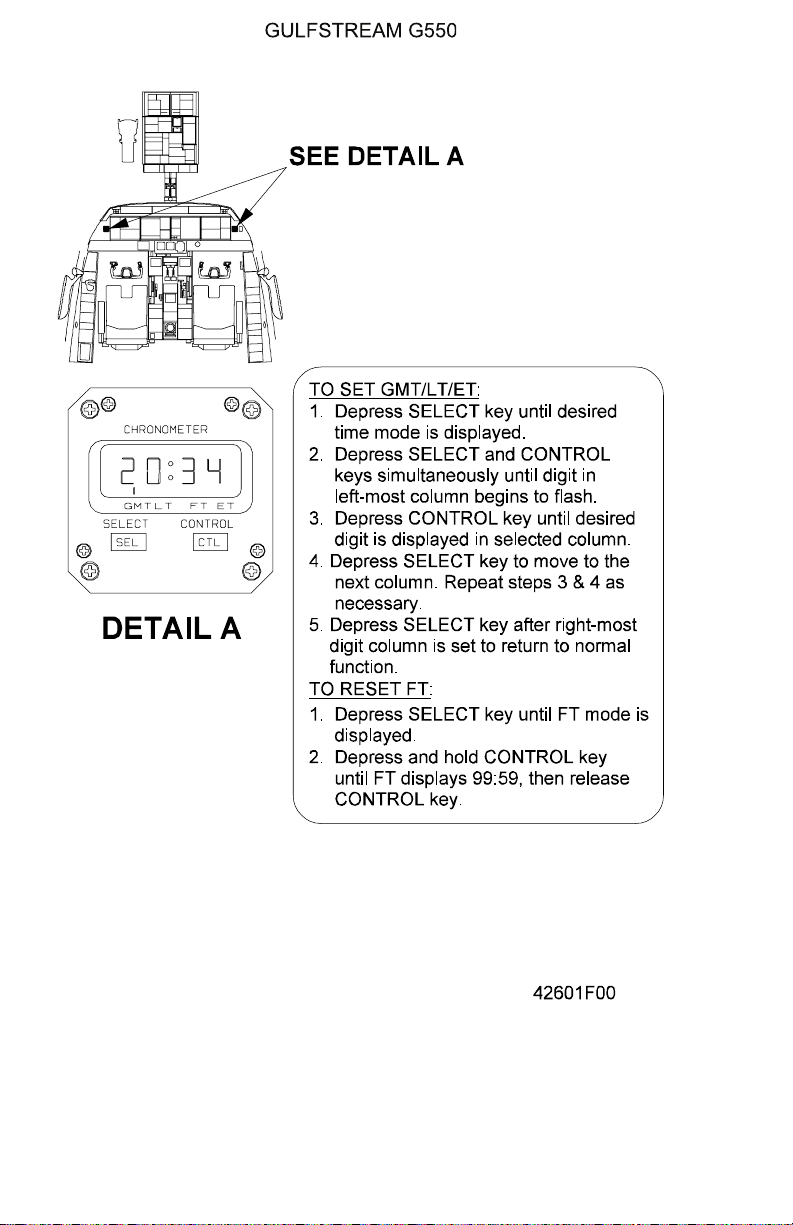

2A-31-20: Cockpit Clock System

1. General Description:

The cockpit chronometers provide accurate time displays to the flight crew.

2. Description of Subsystems, Units, and Components:

There are two chronometers on the outboard sides of the forward instrument

panel: #1 on the pilot side and #2 on the copilot side. Each is capable of the

following time displays:

• Greenwich Mean Time (GMT)

• Local time (LT)

• Flight time (FT)

• Elapsed time (ET)

Greenwich and local time are displayed in hours and minutes. Flight and elapsed

time is displayed in minutes and seconds. Both are displayed in decimal form. The

flight time display, when selected, records the elapsed time since the weight-onwheels switch transitions from ground to flight mode.

Each chronometer receives power from the essential flight instrument bus, and

has replaceable batteries to ensure operation if aircraft power is interrupted. Each

installation has a two inch digital display containing the microprocessor controlled

chronometer and incandescent lighting. See Figure 4.

3. Controls and Indications:

(See Figure 4.)

A. Circuit Breakers (CBs):

The chronometers are protected by the following circuit breakers (CBs):

Circuit Breaker Name: CB Panel: Location: Power Source:

CLOCK # 1 POP B-4 ESS FLT INST Bus

CLOCK # 2 CPOP B-4 ESS FLT INST Bus

4. Limitations:

There are no limitations established for the cockpit clocks system at the time of

this writing.

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 7

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 8

July 15/04

Cockpit Clocks

Figure 4

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

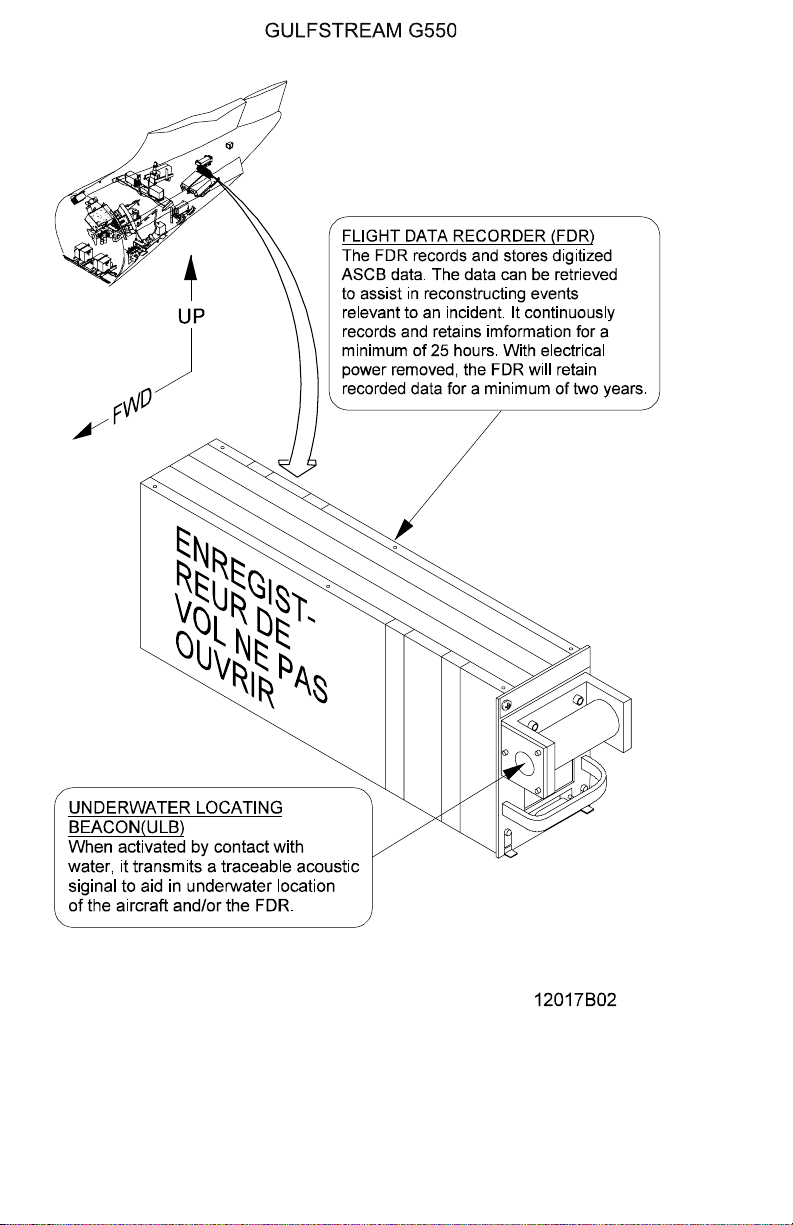

2A-31-30: Digital Flight Data Recorder System

1. General Description:

The digital flight data recorder (DFDR) system receives digitized dynamic aircraft

flight environmental data received from the Modular Avionics Units (MAUs). In

addition to the environmental data, the recorder tracks control column, control

wheel forces, and has an accelerometer input. The data is transmitted to the

DFDR and stored in digital memory.The DFDR is located in the tail compartment

aft of the cockpit voice recorder (CVR). See Figure 6.

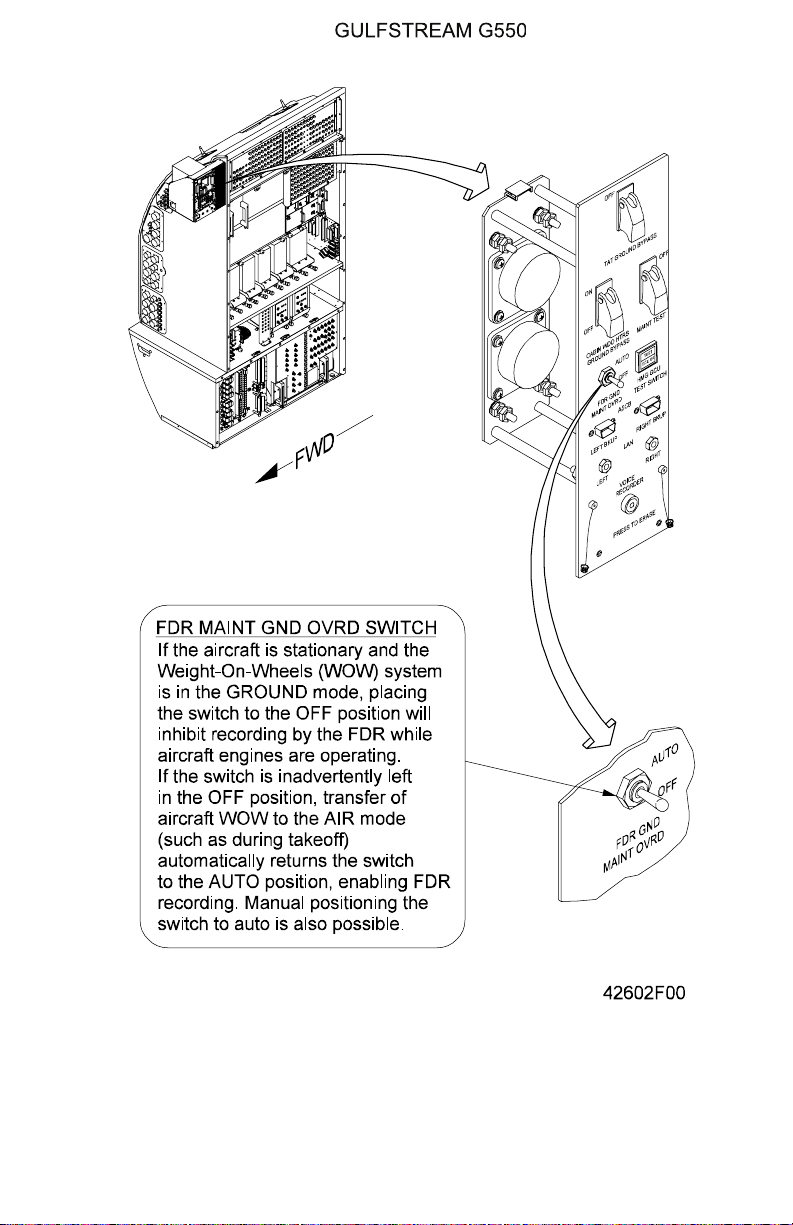

DFDR operation is limited by integrated relays to record data only when the

aircraft engines are running and the weight-on-wheels (WOW) switches are in the

air mode. A maintenance override switch installed on the monitor and test panel

will bypass the engine fuel pressure and WOW relays to allow maintenance on

the DFDR system while the aircraft is static. The switch is illustrated in Figure 5.

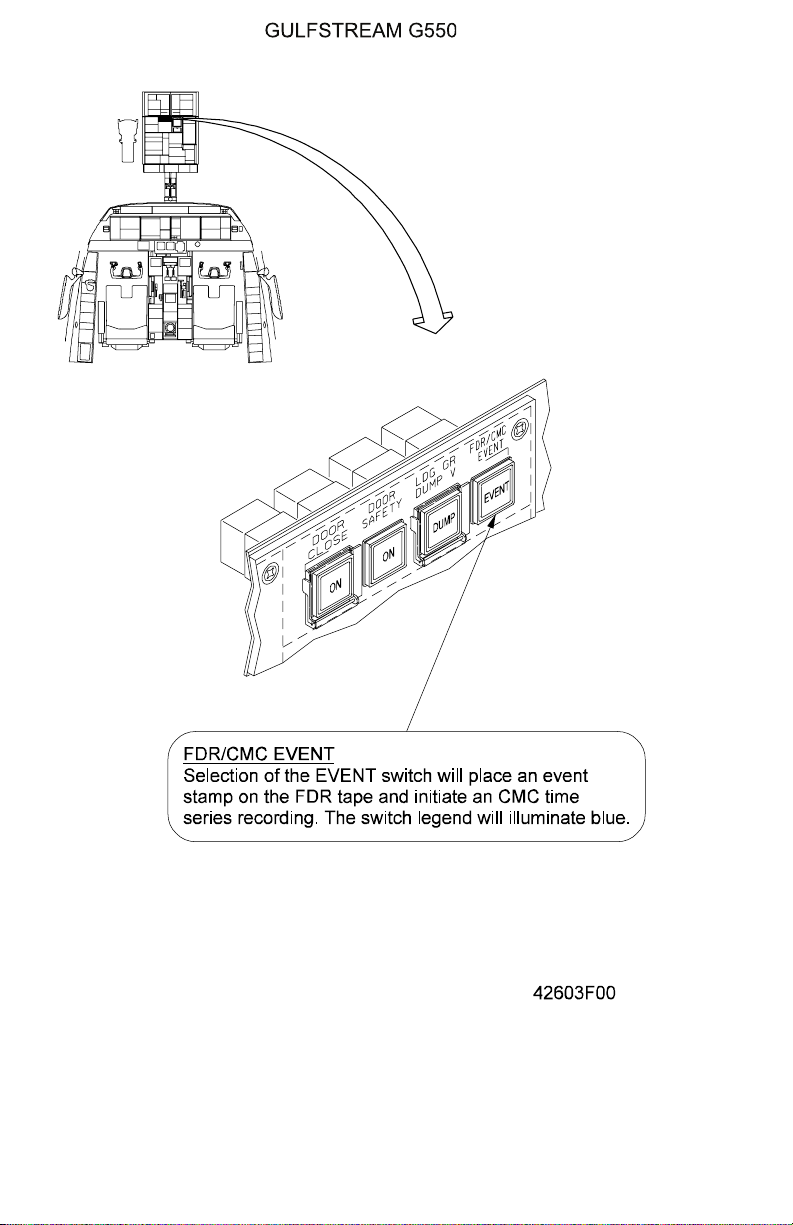

The flight crew may imprint an event stamp on the recorded data in the DFDR to

note a significant instance of flight operations that may warrant subsequent

review, for example, encountering severe air turbulence. The combined DFDR/

CMC EVENT button is located on the cockpit overhead panel above the display

system switching controls as shown in Figure 8.

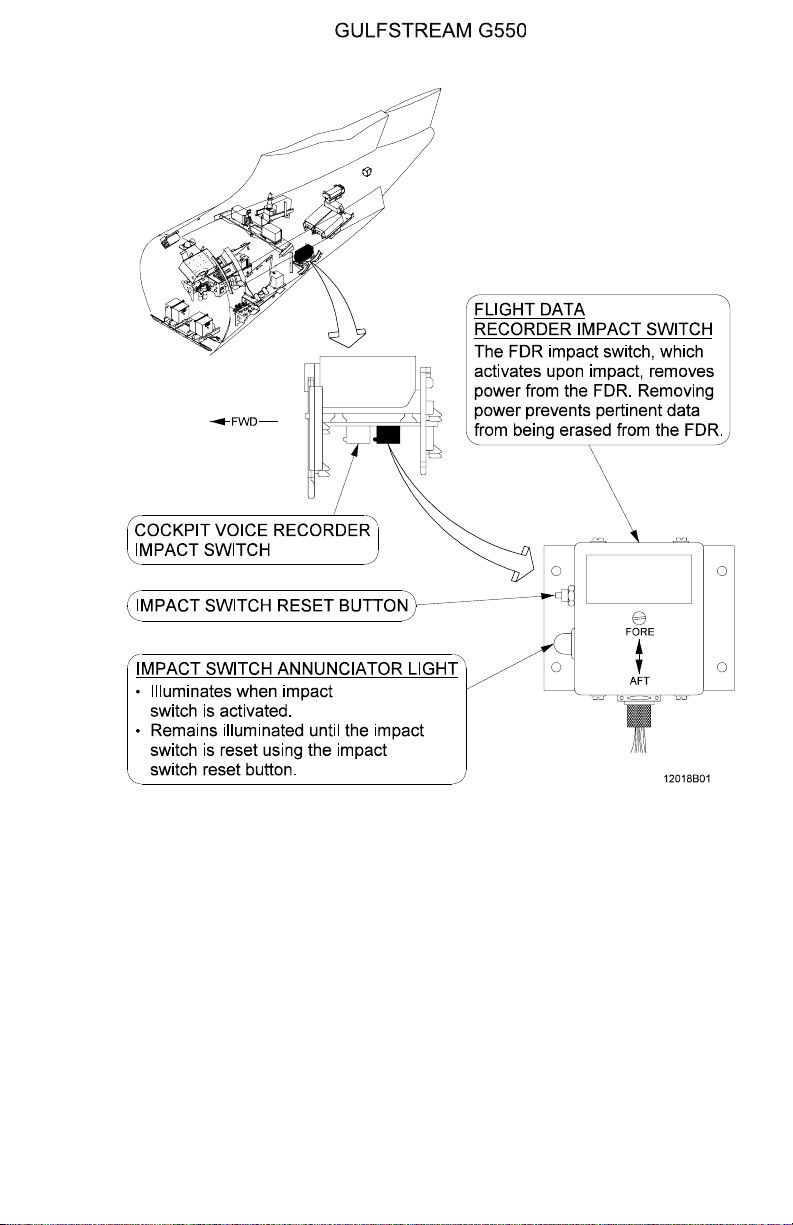

Like the CVR, the DFDR has an impact switch that closes at 2.5 G to stop the

recording process and preserve recorded data. When the impact switch has been

activated, an adjacent indicator light illuminates signalling that the DFDR has

ceased recording. The impact switch may be reset on the ground. See the

illustration in Figure 7.

An underwater locator device (see Figure 6) is attached to the DFDR to facilitate

recovering the recorder if the aircraft is lost over water.

2. Description of Subsystems, Units and Components:

A. Digital Flight Data Recorder (FDR):

The DFDR records and stores digitized MAU data. The data can be

retrieved to assist in reconstruction of events relevant to an incident. The

DFDR continuously records a minimum of 25 hours of flight data and

retains data in a crash survivable memory unit (CSMU). With electrical

power removed, recorded data is retained for a minimum of two years. The

DFDR is located in the tail compartment aft of the CVR. It is international

orange in color for high visibility and the attached CSMU has two reflective

stripes.

B. DFDR Impact Switch:

The DFDR impact switch, which activates at an acceleration of 2.5 G,

removes power from the DFDR and preserves the data in the CSMU. The

impact switch is mounted in the tail compartment underneath the CVR

mounting shelf. Activation of the impact switch also causes an annunciator

on the switch housing to illuminate until the impact switch is reset. A reset

switch is located on the switch housing.

C. Underwater Locating Beacon (ULB):

An acoustic underwater locating beacon (ULB) is attached to the DFDR.

When activated by contact with water, it transmits an audible signal to aid

underwater location of the aircraft and/or DFDR. The ULB receives power

from a self-contained battery that has an expected life of six years. The

protective casings of the DFDR and CSMU are designed to protect data

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 9

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

memory to a water depth of twenty thousand (20,000) feet.

D. DFDR Maintenance Ground Override Switch:

The DFDR maintenance ground override switch is located on the Right

Electrical Equipment Rack (REER) on the system monitor test panel, and

is labeled FDR MAINT GRD OVRD. If the aircraft is stationary and the

Weight-On-Wheels (WOW) system is in the GROUND mode, placing the

switch in the OFF position will inhibit recording by the DFDR while aircraft

engines are operating. If the switch is inadvertently left in the OFF position,

transfer of WOW to the AIR mode (such as during takeoff) automatically

returns the switch to the AUTO position, enabling DFDR recording. Manual

positioning the switch to the AUTO position is also possible.

E. DFDR / CMC EVENT Switch:

The FDR / CMC EVENT switch is located on the cockpit overhead panel.

When momentarily depressed, an event stamp is placed on the FDR tape.

When the event switch is depressed, the Central Maintenance Computer

(CMC) saves a data block of information that spans from 30 seconds prior

to switch activation and continues for one minute following release of the

switch. A blue Event Record advisory message is also displayed on the

Crew Alerting System (CAS).

3. Controls and Indications:

(See Figure 5 and Figure 8.)

A. Circuit Breakers (CBs):

The flight data recording system is protected by the following CBs:

Circuit Breaker Name: CB Panel: Location: Power Source:

FDR LEER J-10 L ESS DC Bus

L FORCE SENSORS LEER J-9 #2 ESS AC Bus

R FORCE SENSORS REER E-4 #1 ESS AC Bus

B. Crew Alerting Systems (CAS) Messages:

CAS messages associated with the flight data recording system are:

Area Monitored: CAS Message: Message Color:

DFDR FDR System Fail Blue

FDR/CMC EVENT switch Event Record Blue

4. Limitations:

There are no limitations established for the flight data recording system at the time

of this writing.

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

Page 10

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

FDR Maintenance Ground Override Switch

Figure 5

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 11

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 12

July 15/04

Flight Data Recorder (FDR) / Underwater Locating Beacon (ULB)

Figure 6

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

FDR Impact Switch

Figure 7

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 13

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 14

July 15/04

FDR / CMC EVENT Switch

Figure 8

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

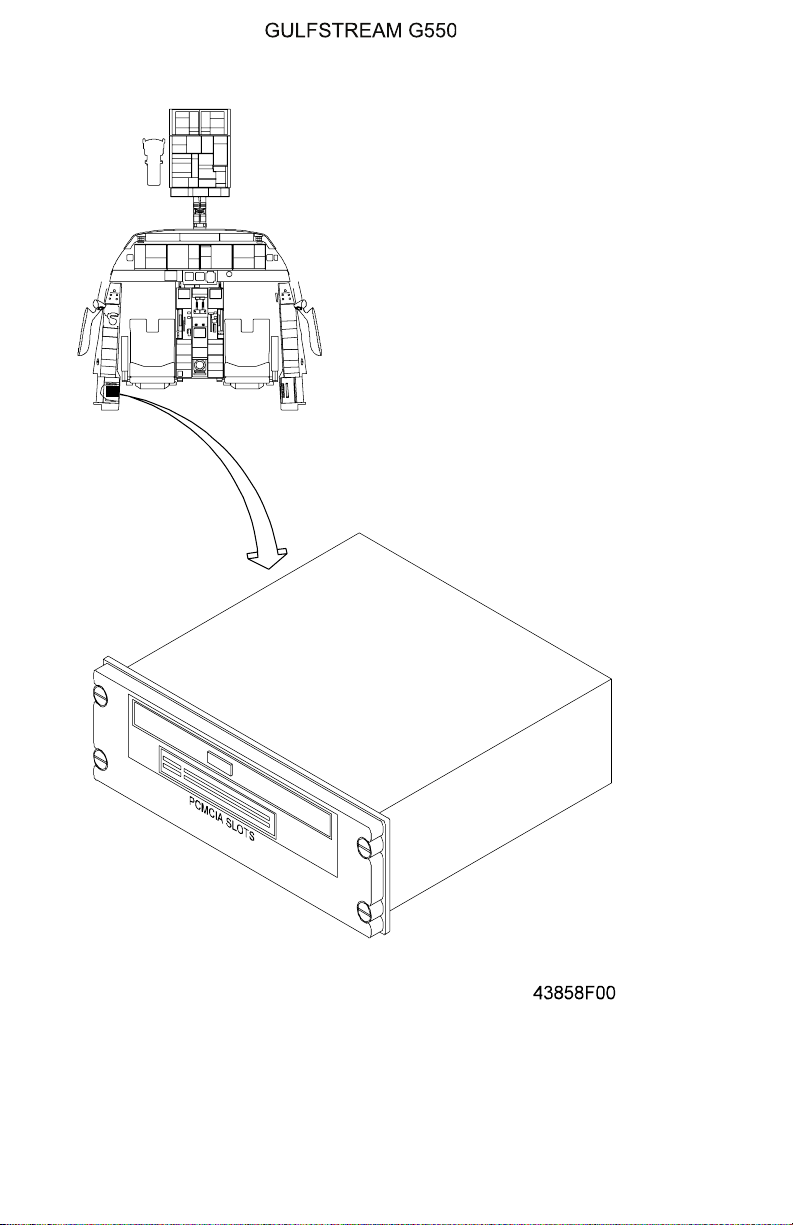

2A-31-40: Data Management Unit

1. General:

AHoneywellDataManagementUnit(DMU) is installed in the pilot side console for

use in uploading navigation and approach plate data to the Flight Management

Systems (FMS), updating the terrain database in the Enhanced Ground Proximity

Warning System (EGPWS), or for maintenance diagnostics. The DMU is

equipped with a tray accommodating Digital Versatile Discs (DVDs) and two (2)

slots for insertion of type II and type III Personal Computer Memory Card

International Association (PCMCIA) flash memory cards. The DMU is illustrated in

Figure 9.

The DMU communicates with components and systems within the PlaneView

avionics suite over a Local Area Network (LAN) connection, with data exchange

operations controlled with the Multi-function Control and Display Units (MCDUs)

or through a Personal Computer (PC) connected to a sub-D outlet on the Testand

Monitor Panel. The database transfer operations are described in Section 2B-23-

00. If a fault is detected within the DMU, DVD or PCMCIAcard during the transfer

operation, the MCDU(s) will display a message associated with the fault. A list of

DMU fault messages is contained in Section 2B-34-00.

2. Controls and Indications:

A. Circuit Breaker (CB):

The following CB powers the DMU:

Circuit Breaker Name: CB Panel: Location: Power Source:

DMU REER D-5 R MAIN DC Bus

B. Crew Alerting System (CAS) messages:

There are no CAS messages associated with the DMU. See Section

2B-33-00 for MCDU fault messages associated with the DMU and Section

2B-34-00 for a list of DMU fault codes.

3. Limitations:

There are no limitations associated with the DMU as of this writing.

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 15

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 16

July 15/04

Data Management Unit

Figure 9

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

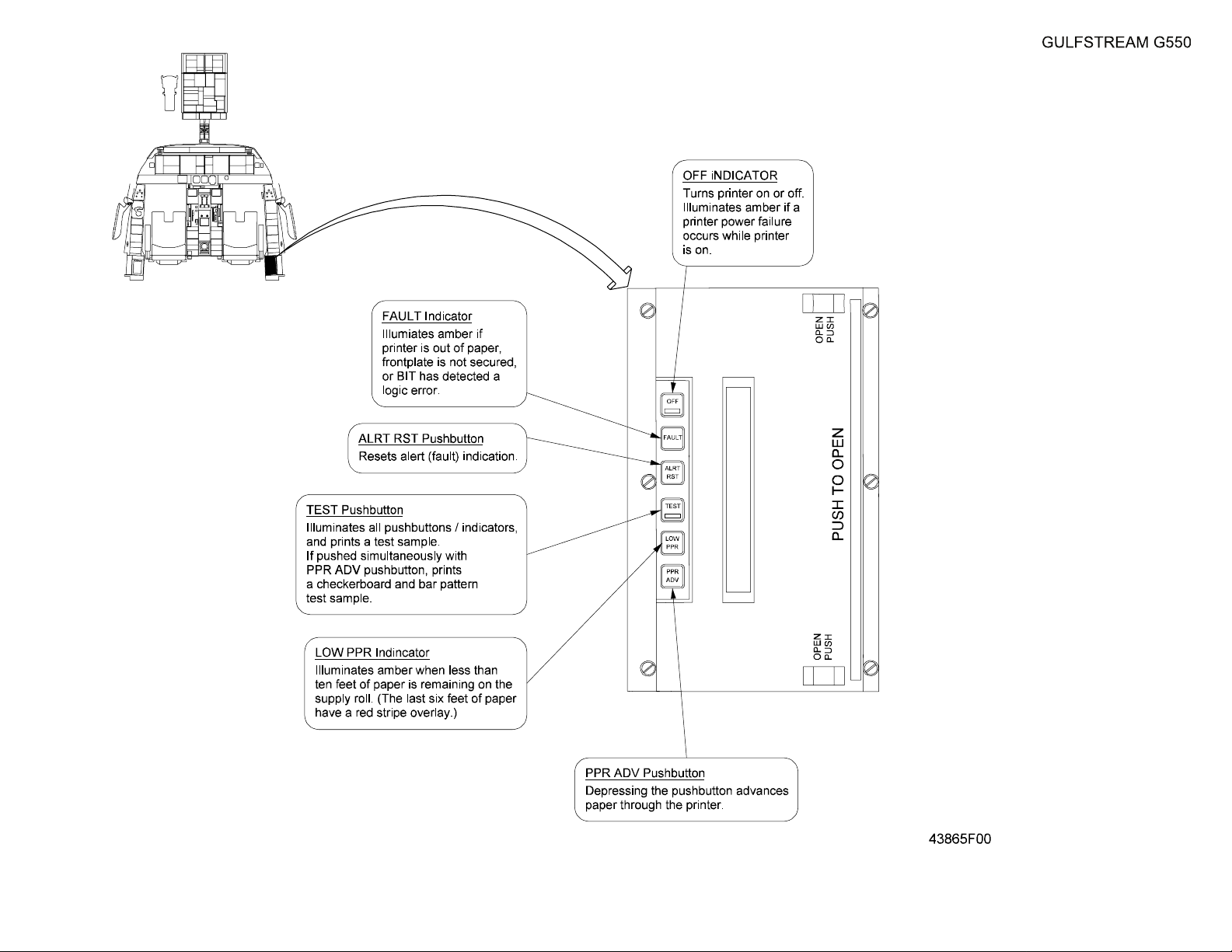

2A-31-50: Cockpit Printer

1. General:

A Miltope Corporation Model TP4840 dot-matrix thermal printer is installed in the

copilot side console. (See Figure 10.) The printer is interfaced with ARINC-429

bus connections to allow communication with the Mult-function Control and

Display Units (MCDUs) with an additional Local Area Network (LAN) ethernet

connection for data exchange with the Central Maintenance Computer (CMC)

module, or a Personal Computer (PC) connected to sub-D installations on the

CMC module face or the Test and Monitor Panel. The printer may be used to

produce hard copies of approach plates, Notice(s) to Airmen (NOTAMS), weather

information or other operational documents useful to the flight crew.

The printer is capable of producing three hundred (300) characters per second

over the ARINC-429 bus connections or four (4) pages per minute over the LAN

interface. In addition to printing a standard ninety-six (96) character set, the printer

will also reproduce bit-map formats. Printing is accomplished on a continuous roll

of thermal paper eight and one half (8.5) inches wide (216 mm) and one hundred

twenty-five (125) feet (38.1 meters) long. The paper is stored inside the printer

face with the bottom of the faceplate configured to provide a convenient tearing

surface. Paper replenishment is accomplished by opening the faceplate with two

push latches on either side of the printer.

2. Controls and Indications:

A. Printer Indications:

Ahorizontal row of indicators / pushbuttons is installed on the upper face of

the printer. The legends within the indicators / pushbuttons are arranged

vertically and may require the operating crew member to view the text

sideways. The indicators and associated actions are:

• OFF - selects the printer on or off. Illuminates amber when printer

power is on and printer is selected off or if a power fault occurs with

printer selected on

• FAULT - illuminates amber if printer is out of paper, the printer

faceplate is not secured closed, or the Built-In-Test (BIT) function

has detected a fault. (The printer automatically performs a BIT

whenever the printer is selected ON).

• ALRT RST - resets the alert (fault) function

• TEST - illuminates all of the indicators on the faceplate, performs a

BIT test and prints a test sample. (NOTE: pressing the TEST and

PPR ADV pushbuttons simultaneously will print a checkerboard and

solid bar pattern sample.)

• LOW PPR - illuminates amber when only ten (10) feet (3.04 meters)

of paper are remaining on the supply roll. The last six (6) feet (1.8

meters) of paper remaining are indicated by a red stripe.

• PPR ADV - advances the paper through the printer

B. Circuit Breaker (CB):

The following CB powers the cockpit printer:

Circuit Breaker Name: CB Panel: Location: Power Source:

COCKPIT PRINTER REER C-5 R MAIN DC Bus

PRODUCTION AIRCRAFT SYSTEMS 2A-31-00

Page 17

July 15/04

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

C. Crew Alerting System (CAS) Messages:

There are no CAS messages associated with the cockpit printer.

D. Limitations:

There are no limitations applicable to the cockpit printer as of this writing.

Page 18

July 15/04

PRODUCTION AIRCRAFT SYSTEMS2A-31-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Cockpit Printer

Figure 10

2A-31-00

Page 19 / 20

July 15/04

Loading...

Loading...