Gulfstream IV Operating Manual

OPERATING MANUAL

FLIGHT CONTROLS

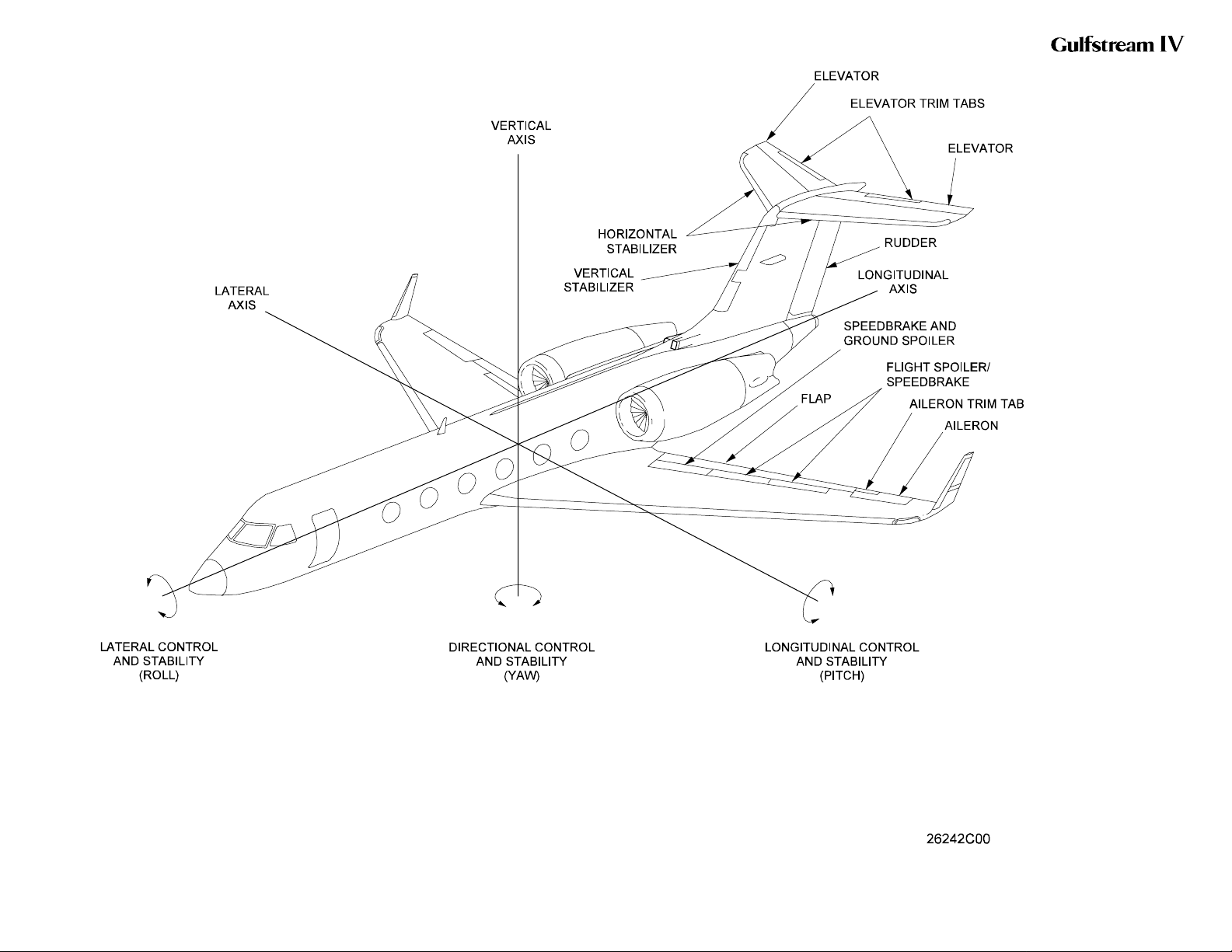

2A-27-10: General

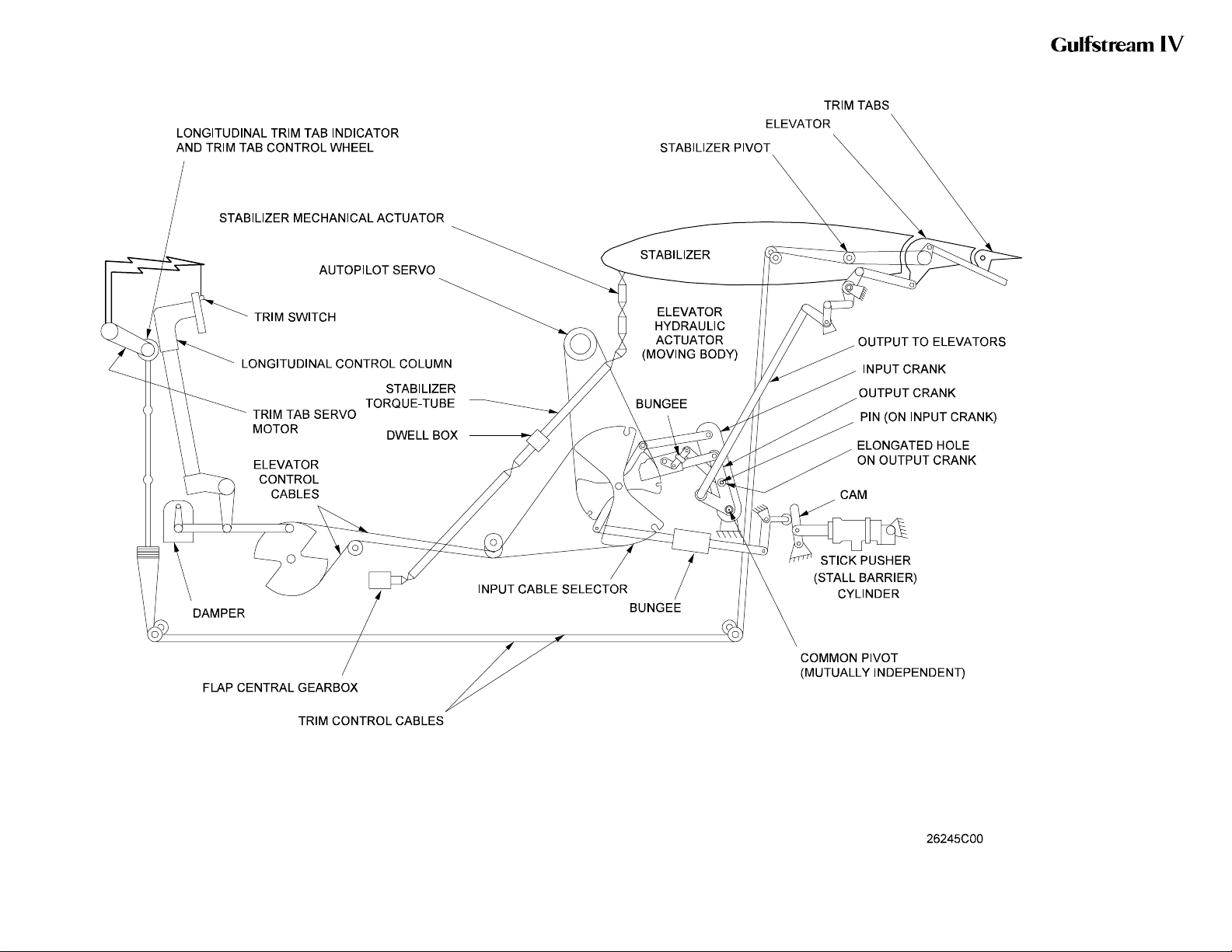

The Gulfstream IV primary flight controls system, shown in Figure 1, is a mechanically

actuated, hydraulically operated system that provides boosted surface control to

overcome the aerodynamic forces associated with high speed flight. This allows the

aircraft to be comfortably and reliably steered through the pitch, roll and yaw axes.

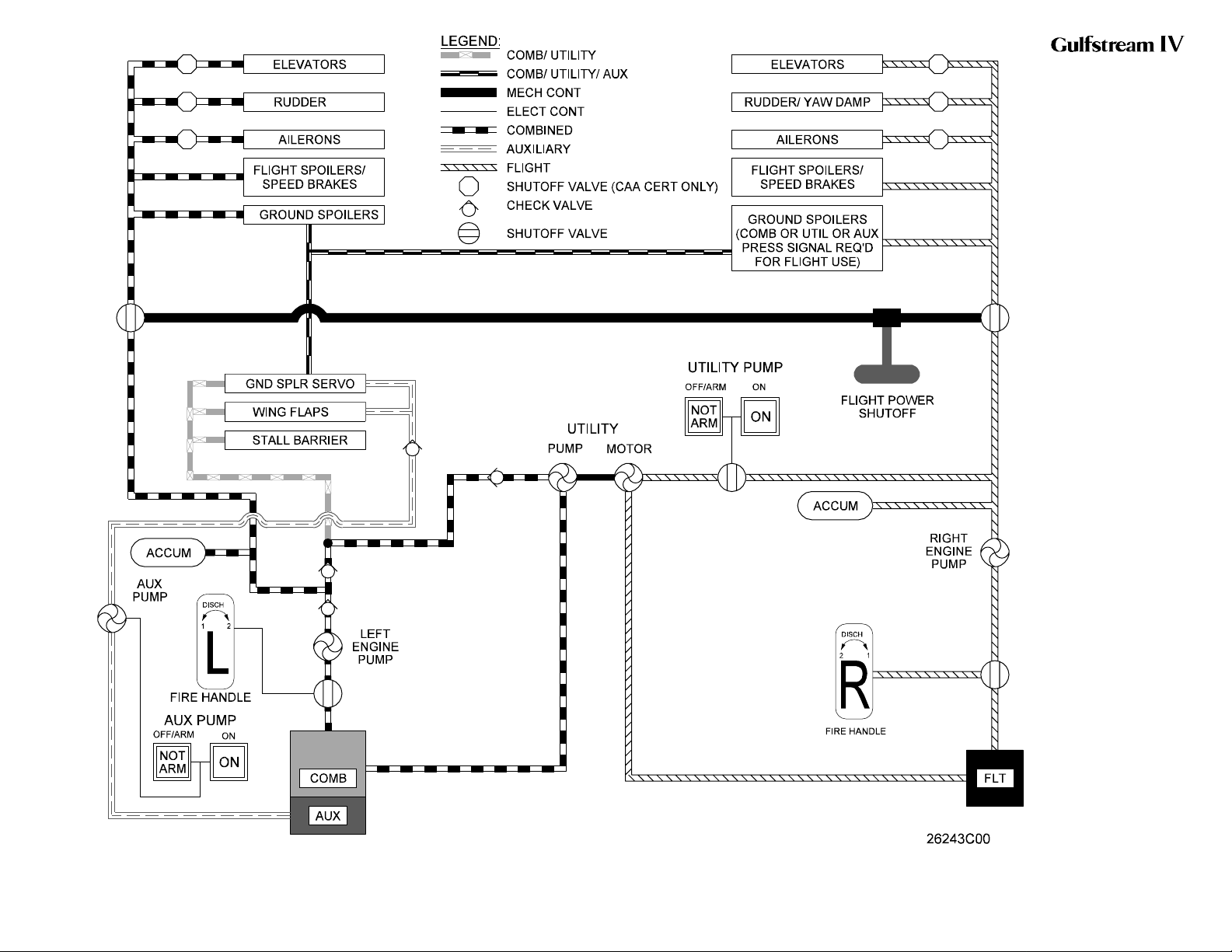

The primary flight control surfaces (elevators, ailerons and rudder) are positioned by

tandem type hydraulic actuators. The actuators receive hydraulic operating pressure

from both the Combined and Flight hydraulic systems, as shown in Figure 2. Both

hydraulic systems maintain a system pressure of 3000 psi. Loss of a single hydraulic

system has no effect on operation of the primary flight controls, as the remaining system

is capable of maintaining actuator load capacity. In the event of total loss of hydraulic

pressure in bothhydraulic systems, the primary flight controls revert to manual operation.

Mechanical pitch, roll and yaw trim systems allow the flight crew to trim the aircraft. The

pitch trim system can also be controlled electrically by pitch trim switches on the control

wheels.

A gust lock secures the elevators, ailerons and rudder to prevent wind gust damage to

the surfaces.

Secondary flight controls, shown in Figure 1, include flaps, ground spoilers and

speedbrakes. These flight controls are hydraulically powered and electrically or

mechanically controlled. The mechanically operated horizontal stabilizer moves in

conjunction with the flaps to maintain longitudinal trim.

AnAngle-of-Attack (AOA) system provides outputs to the control column shakers, control

column pusher, approach indexers, normalized AOA display and stall barrier system. The

control column shakers provides early warning of a stall scenario by vibrating the control

column before the stall while the control column pusher automatically initiates lowering

the nose if the stall is imminent.

The Gulfstream IV uses an aircraft configuration warning system to monitor landing gear,

flap, speed brake and power lever position. If an unsafe configuration is detected, the

system provides a visual and / or aural warning.

On CAA certified aircraft, a flight control automatic failure detection system compares

control inputs to actuator outputs. If a malfunction is detected, the system shuts off power

to the affected actuator.

The flight controls system is divided into the following subsystems:

• 2A-27-20: Pitch Flight Control System

• 2A-27-30: Yaw Flight Control System

• 2A-27-40: Roll Flight Control System

• 2A-27-50: Horizontal Stabilizer System

• 2A-27-60: Flaps System

• 2A-27-70: Spoiler System

• 2A-27-80: Gust Lock System

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 1

January 31/02

Revision 6

OPERATING MANUAL

THIS PAGE IS INTENTIONALLY LEFT BLANK.

Page 2

January 31/02

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

GIV Flight Controls /

Aerodynamic Axes

Figure 1

2A-27-00

Page 3 / 4

January 31/02

OPERATING MANUAL

GIV Flight Controls Fluid

Power Diagram

Figure 2

2A-27-00

Page 5 / 6

January 31/02

OPERATING MANUAL

2A-27-20: Pitch Flight Control System

1. General Description:

Aircraft movement about the lateral axis (pitch) is controlled by the position of the

elevators. The elevators are manually controlled, mechanically actuated and

hydraulically boosted airfoils mounted on the trailing edge of the horizontal

stabilizer.Total elevator travel ranges from 24° trailing edge up to 13° trailing edge

down.

The elevators are positioned by a tandem type hydraulic actuator. The actuator

receives hydraulic operating pressure simultaneously from both the Combined

and Flight hydraulic systems during normal operations. Loss of a single hydraulic

system has no effect on operation of the elevators, as the remaining system is

capable of maintaining actuator load capacity. In the event of total loss of

hydraulic pressure in both systems, the elevators revert to manual operation.

Manual reversion is also possible through use of a flight power shutoff valve and

its pedestal-mounted control handle.

A pitch trim system is used to position a trim tab attached to the trailing edge of

each elevator. The tabs are positioned either manually by a pedestal-mounted

control wheel or electrically by pitch trim switches on the control wheels.

An Angle-of-Attack (AOA) system provides outputs to the control column shakers,

control column pusher, approach indexers, normalized AOA display and stall

barrier system. The control column shakers provides early warning of a stall

scenario by vibrating the control column before the stall while the control column

pusher automatically initiates lowering the nose if the stall is imminent.

On CAA certified aircraft,aflight control automatic failure detection system

compares control column inputs to elevator actuator outputs. If a malfunction is

detected, the system shuts off either or both hydraulic power sources to the

affected actuator.

The pitch flight control system consists of the following subsystems, units and

components:

• Control column system

• Mechanical actuation system

• Hydraulic boost system

• Manual reversion system

• Pitch trim system

• Angle-of-attack / stall barrier system

• Failure detection system (CAA aircraft only)

2. Description of Subsystems, Units and Components:

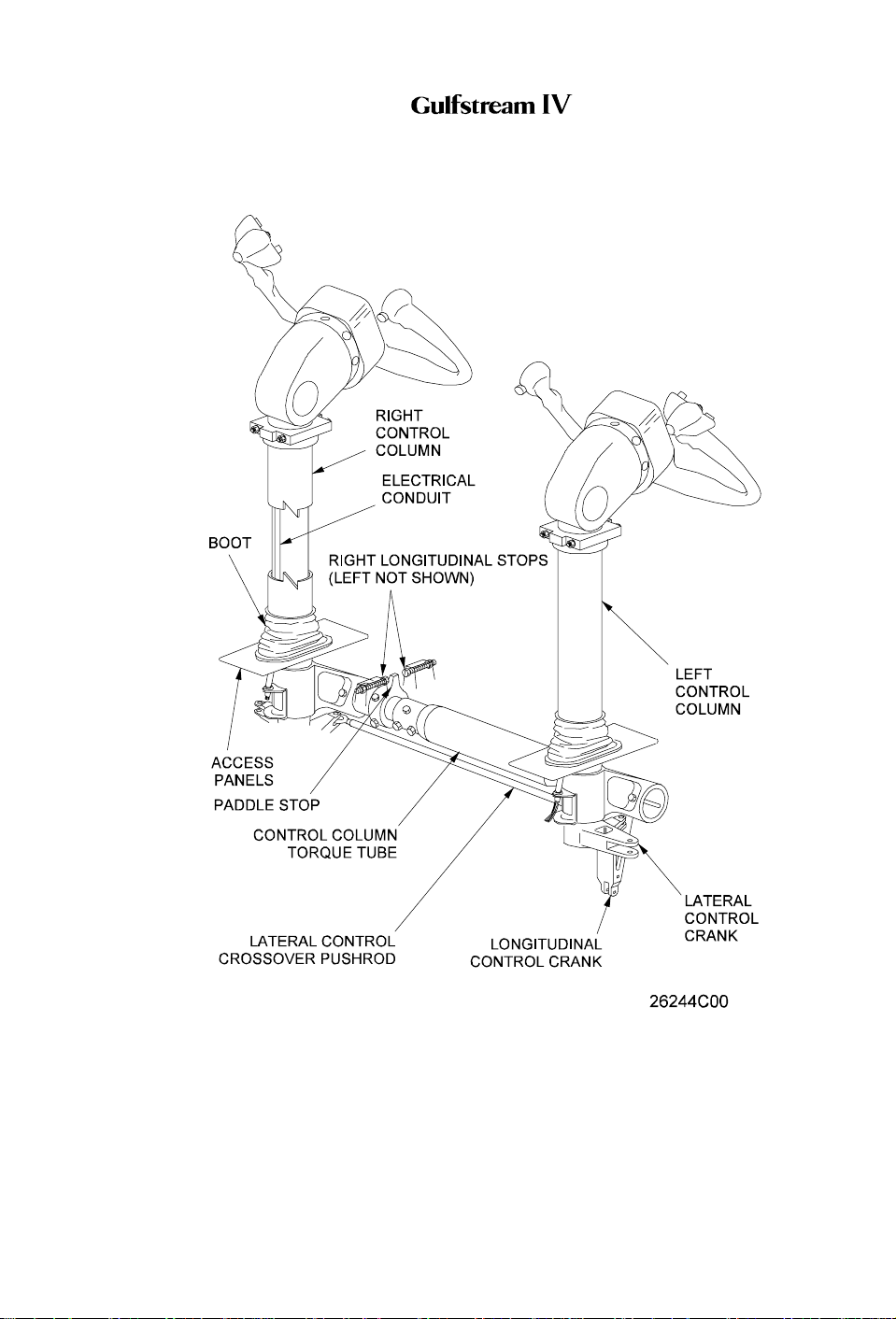

A. Control Column System:

(See Figure 7.)

The pilot’s and copilot’s control columns mount to a common transverse

torque tube supported by a bearing on each end. Moving the control

column fore and aft rotates the torque tube that, in turn, transmits the

inputs rearward through conventional mechanical linkage. Adjustable stops

on the torque tube limit control column movement to eight inches aft and

five inches forward of the neutral position.

An eddy current damper is connected to the bottom of the control column

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 7

January 31/02

Revision 6

OPERATING MANUAL

output crank. The damper is designed to sense control column movement

and provide a counteracting damping force or artificial feel. Damping force

is generated in proportion to control column velocity. Should the eddy

current damper jam or fail, its internal clutch releases to allow control

column movement.

B. Mechanical Actuation System:

(See Figure 3.)

Control column inputs are transmitted rearward through a system of push-

pull rods, bellcranks, cables and a sector assembly to an input cable sector

below the base of the vertical stabilizer in the tail compartment. Connected

to the input cable sector are the elevator actuator, autopilot servo and

stability springs. Final output of the sector is to the elevator actuator input

lever.

Movement of the actuator input lever displaces the elevator actuator’s

servo control valve, directing Combined and Flight hydraulic system

pressure to the actuator cylinders. When under pressure, the actuator body

moves while the its piston remains motionless. Movement of the actuator

body in turn moves its output crank. Output crank movement is transmitted

upward and aft to the left and right elevators through a system of push-pull

rods and cranks, resulting in the desired elevator deflection.

Stability springs, commonly referred to as down springs, provide

approximately 13 pounds of pull on the control columns. This pulling force

keeps pilot feel forces out of the friction band at low airspeeds.

C. Hydraulic Boost System:

The elevator actuator is a dual tandem actuator consisting of two pistons

secured to a common shaft. The pistons move inside a common cylinder

divided to create two separate cylinders. One cylinder receives Flight

hydraulic system pressure while the other cylinder receives Combined

hydraulic system pressure.

Mechanical movement of the actuator input lever moves the servo control

valve from its neutral position. The servo control valve then directs

hydraulic pressure to one of the actuator’s two cylinders and connects

each cylinder’s opposite side to return. When the elevator reaches the

desired deflection, the servo control valve shifts to its neutral position to

lock hydraulic pressure within the actuator, in effect preventing further

surface movement.

The elevator actuator also has an internal hydraulic damper that provides

damping force proportional to the square of its input velocity. This damping

action ensures operational stability for the elevators when hydraulically

boosted whereby a portion of the actuator’s output is fed back to the input

system.

D. Manual Reversion System:

During normal flight operations, the Combined and Flight hydraulic

systems each supply and maintain 3000 psi to the elevator actuator. Loss

of system pressure due to a single system failure has no effect on

operation of the pitch flight control system.

Loss of system pressure from both hydraulic systems will automatically

revert the pitch flight control system to manual control. As pressure at the

Page 8

January 31/02

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Revision 6

OPERATING MANUAL

actuator drops below 60 psi, bypass valves within the actuator open to

allow the actuator piston to idle. With the actuator piston idling, the system

is said to be in manual reversion, technically explained in the following

paragraph.

The actuator input crank and output crank rotate on a common pivot point.

They are linked by a pin and elongated slot arrangement. The input crank

is on the pin and the output crank is on the slot. With the actuator piston

idling, the pin moves within the slot until it reaches either end. At this point,

mechanical contact is made and the input crank now drives the output

crank. The output crank in turn drives the left and right elevators through its

push-pull rods and cranks.

Manual reversion of the pitch flight control system is also possible by

closing a normally open flight power shutoff valve. The flight power shutoff

valve is a mechanically operated shutoff valve located between the

Combined and Flight hydraulic system pressure sources and the elevator

actuator (as well as the aileron, rudder and flight / ground spoiler actuator)

pressure lines. The valve consists of two mechanically connected but

hydraulically isolated sections. A controlex cable connects the valve to a

FLIGHT POWER SHUT OFF handle located on the left aft side of the

cockpit center pedestal. See Figure 8.

Moving the FLIGHT POWER SHUT OFF handle up from its stowed

(horizontal) position to the vertical position mechanically closes the flight

power shutoff valve. With the valve closed, operating pressure is removed

from the actuator, allowing the piston to idle.

The resultant advantage of the flight power shutoff provision is the ability to

bypass a malfunctioning actuator (such as would be the need in the

unlikely event of an actuator jam) and manually fly the aircraft. Although

control column effort and response time to inputs are increased while in

manual reversion, the aircraft remains capable of positive and harmonious

control.

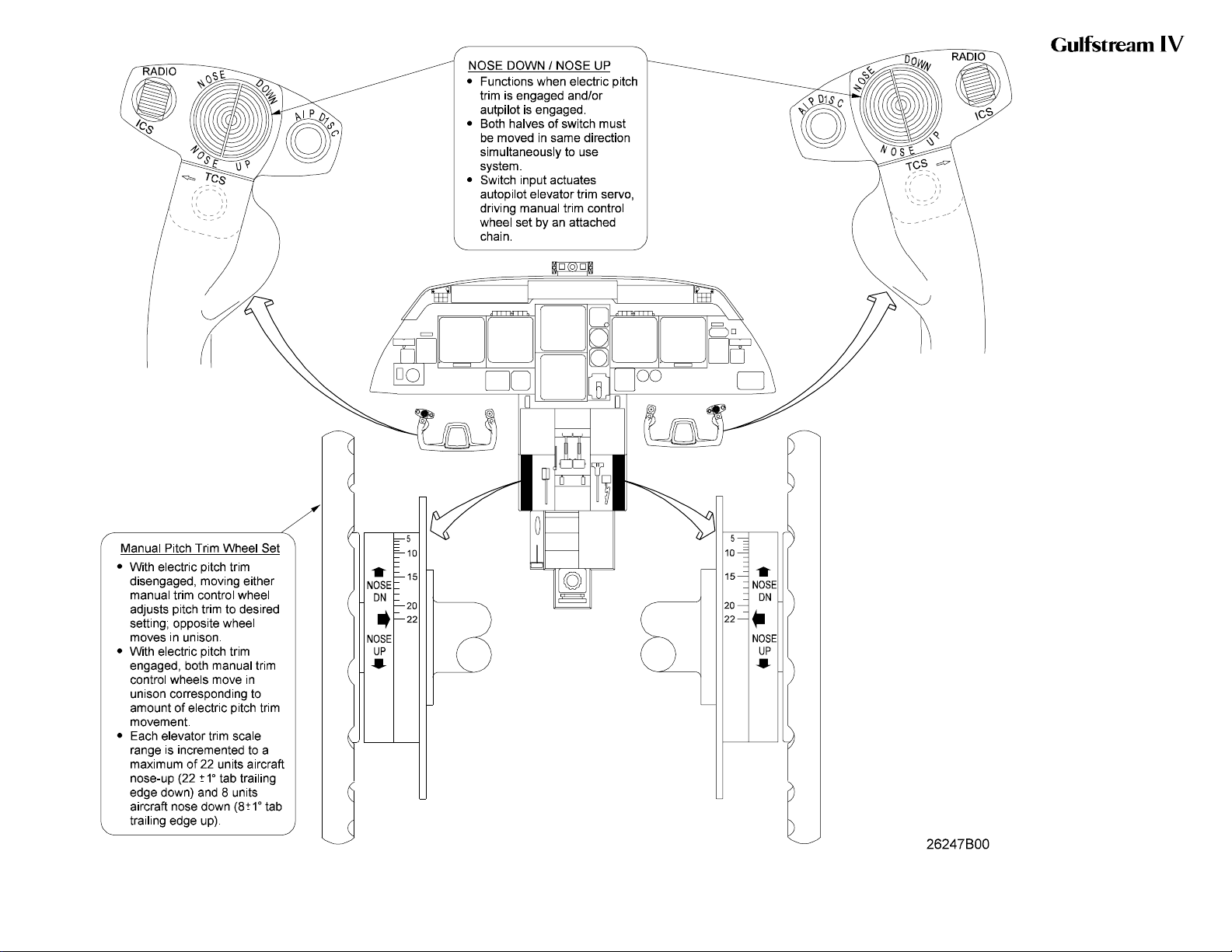

E. Pitch Trim System:

(See Figure 5 and Figure 9.)

(1) Elevator Trim Tabs:

A trim tab is installed on the trailing edge of each elevator. The tabs

are mechanically positioned through cable-driven drum actuators

located in each elevator. The trim actuators can be operated

manually or electrically as described in the following paragraphs.

Elevator trim tab travel ranges from 22 ±1° tab trailing edge down

(aircraft nose up) to 8 ±1° tab trailing edge up (aircraft nose down).

(2) Manual Trim Control:

Manual control of pitch trim is accomplished by an interconnected

manual trim control wheel set. A trim control wheel and elevator trim

scale are provided on each side of the cockpit center pedestal. With

electric pitch trim disengaged, moving either manual trim control

wheel adjusts pitch trim to the desired setting; the opposite wheel

moves in unison. With electric pitch trim engaged, both manual trim

control wheels move in unison corresponding to the amount of

electric pitch trim movement. Each elevator trim scale range is

incremented to a maximum of 22 units aircraft nose-up (22 ±1° tab

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 9

January 31/02

Revision 6

OPERATING MANUAL

trailing edge down) and 8 units aircraft nose-down (8 ±1° tab trailing

edge up).

Mechanical stops limit elevator trim wheel movement to 6.6 turns

from each stop. A shear rivet installed in the cockpit portion of the

system prevents application of excessive force by shearing at

approximately 31 pounds of force.

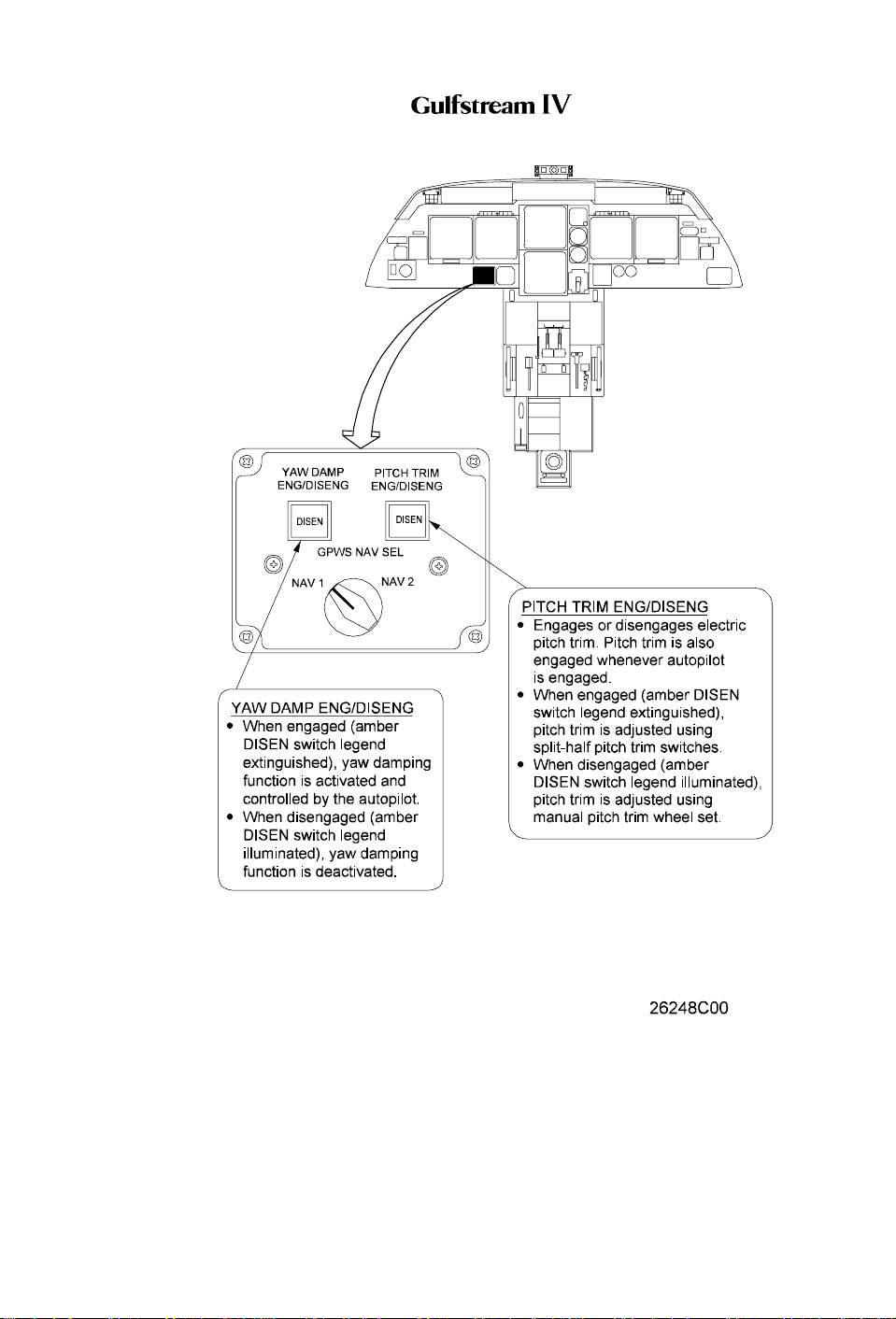

(3) Electric Pitch Trim:

Located on the pilot’s flight panel, the PITCH TRIM ENG / DISENG

switch engages or disengages the electric pitch trim. Pitch trim is

also engaged whenever the autopilot is engaged. With electric pitch

trim engaged (amber DISEN switch legend extinguished), pitch trim

can be adjusted through use of a split-half pitch trim switch

(sometimes referred to as a “beep” switch) installed on the outboard

grip of each control wheel. Switch positions are labeled NOSE

DOWN and NOSE UP. Inadvertent actuation of pitch trim, including

runaway, is minimized through the split-half switch design. In order

for the pitch trim to be actuated, both halves of the switch must be

simultaneously moved in the same direction.

Movement of the electric pitch trim switch to NOSE DOWN or NOSE

UP actuates the autopilot elevator trim servo. The trim servo is

connected to the manual trim control wheel set by a chain. The

chain-driven movement of the manual trim control wheel set in turn

positions the elevator trim tabs.

The electric pitch trim is normally checked by the flight crew on the

first flight of the day, during the Before Starting Engines checklist. A

check usually consists of running the elevator trim fully up, then fully

down, using normal methods, i.e., using both halves of the switch

simultaneously. This is followed by attempting to run the pitch trim

using each half of the switch alone. Any movement resulting from

using either half of the switch alone indicates a malfunction that

should be corrected before flight. The check is concluded by setting

pitch trim for the takeoff Center of Gravity (CG) condition as

determined using the Airplane Flight Manual.

(4) Elevator Trim TabActuator Heat System:

Electrically-heated elevator trim tab actuators are incorporated on

airplanes SN 1380 and subsequent and SN 1000 through 1379

havingASC 342. These actuators are designed to alleviate frozen or

stiff trim tab actuators possible in extreme cold temperatures. The

system receives power from Phase C of the Left Main AC bus.

Operation of the system is automatic and transparent to the flight

crew.

F. Angle-of-Attack / Stall Barrier System:

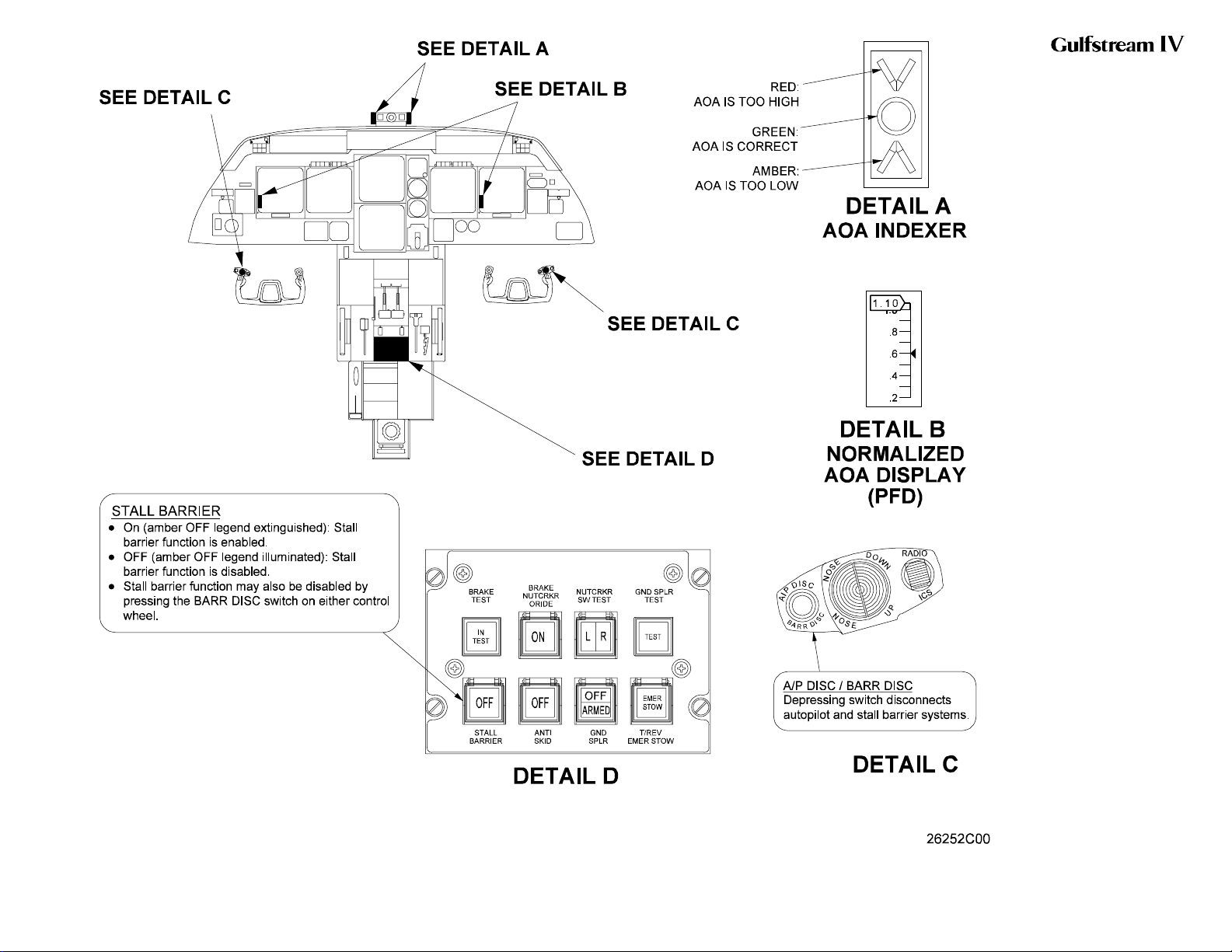

(See Figure 4, Figure 10 and Figure 11.)

While in flight, the Angle-of-Attack (AOA) system monitors aircraft AOA to

provide warnings of an approaching stall. If AOA continues to increase

toward aerodynamic stall, the system applies a nose down control input

through the stall barrier system.

The AOA / stall barrier system consists of the following units and

components:

Page 10

January 31/02

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Revision 6

OPERATING MANUAL

• AOA probes

• AOA display and approach indexer

• Stall warning computers

• Pilot and copilot control column shaker motors

• Stall barrier system

AOA becomes fully functional as the aircraft becomes airborne, i.e., when

the nutcracker shifts to theAIR mode. The control column shaker, however,

is disabled for the first five seconds following rotation to eliminate nuisance

activity. Pulling the SHAKER #1 and / or SHAKER #2 circuit breakers, as

appropriate, is the only way to disable a control column shaker in flight;

however, such action completely disables the associated stall warning

computer(s). System design is such that either stall warning computer is

capable of operating the control column shaker and control column pusher

should the other computer become disabled.

(1) AOA Probes:

AnAOA probe / transducer assembly is installed on the left and right

forward fuselage. The cone-shaped probes freely rotate in the

airstream to provide AOA reference data for the stall warning / stall

barrier systems and AOA display data for the flight crew. The left

AOA probe provides data the No. 1 stall warning computer while the

right AOA probe provides data the No. 2 stall warning computer.

Heating elements prevent ice accumulation on the probe and

condensation within the transducer case.

(2) AOA Display and Approach Indexer:

AOA display data supplied by the probes includes the normalized

AOA display and the approach indexer. Normalized AOA display is

shown on the lower left portion of the Primary Flight Display (PFD)

and consists of a vertical scale marked from 0.2 to 1.1 in 0.1

increments. At the bottom of the scale is a three-digit display

surrounded by a pointer that provides AOA indication within a 0.01

resolution. As AOA changes, the display / pointer moves up and

down to correspond with the indication on the scale.

An AOA approach indexer on either side of the windshield center

post indicates the optimum AOA for approach and landing. The No.

1 AOA system drives the pilot’s indexer while the No. 2 AOA system

drives the copilot’s indexer. During approach and landing, the AOA

system illuminates each indexer’s red chevron if AOA is too high, a

green circle if AOA is correct or an amber chevron if AOA is too low.

(3) Stall Warning Computers:

The No. 1 and No. 2 stall warning computers receive the following

inputs and then provide outputs to the control column shaker motors

and stall barrier system:

• AOA reference data from the associated probes

• Altitude data from the DADCs

• Nutcracker mode from the nutcracker relays

• Flaps position from the 39°flap relay

(4) Control Column Shaker Motors:

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 11

January 31/02

Revision 6

OPERATING MANUAL

A control column shaker motor is attached to the pilot and copilot

control columns. When activated by a stall warning computer, the

motor drives an off-center weight that vibrates the control column.

Activation of one motor affects both control columns due to their

mechanical interconnection.

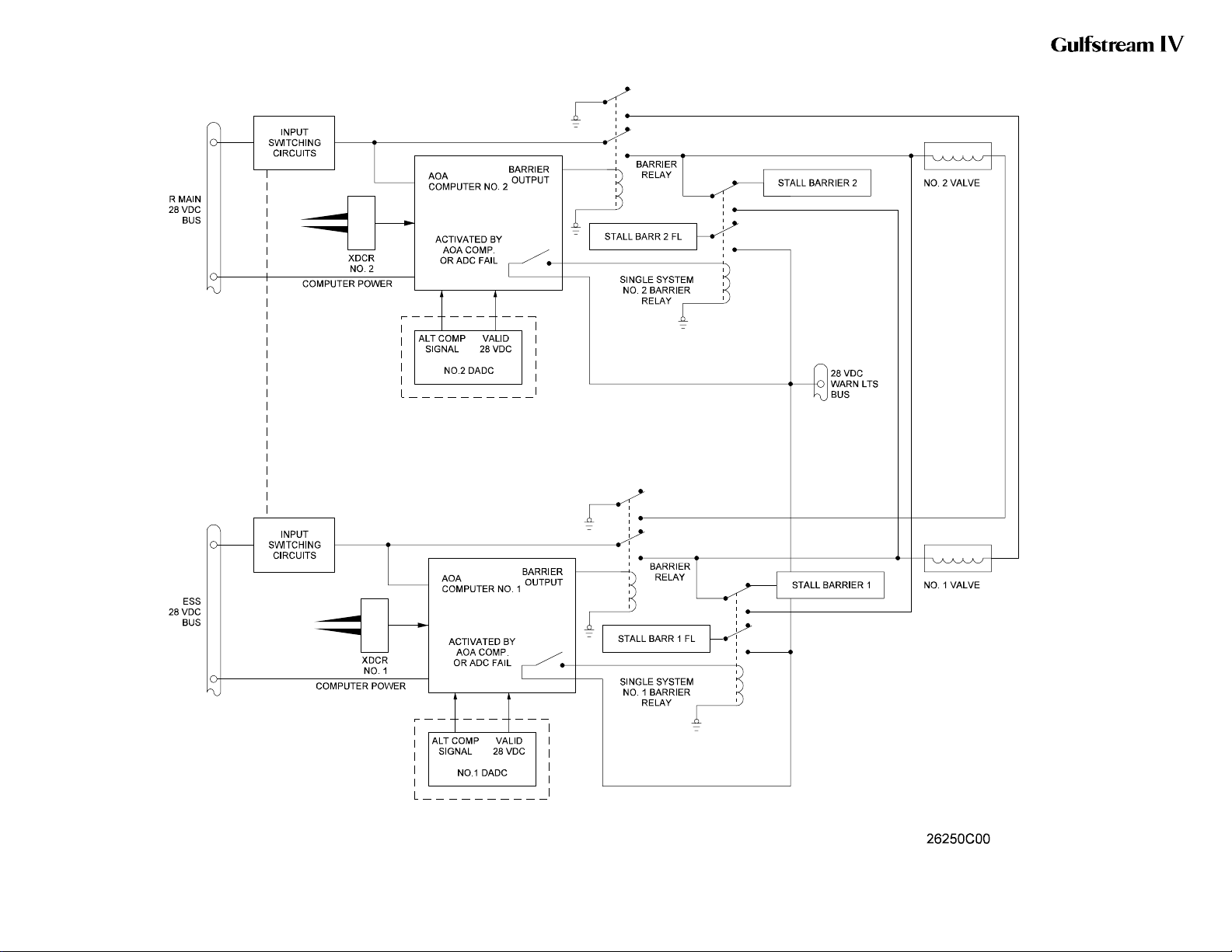

(5) Stall Barrier System:

A stall barrier system (control column pusher) is incorporated in the

pitch flight control system to prevent a stall by forcing the control

columns forward when the flight crew fails to respond to either visual

indications or to the control column vibrations that warn of

impending stall. The system consists of two normally closed stall

barrier valves and an actuating cylinder that is mechanically linked

to the elevator actuator input sector. One valve receives signals

from the No. 1 stall warning computer while the other valve receives

signals from the No. 2 stall warning computer. If one system fails,

the remaining system is capable of operating the system.

When a high AOA is reached, the control column shaker motors are

activated. When a more severe AOA is reached, the control column

pusher trip detector activates its respective stall barrier valve. The

activation signal will originate from whichever system is operating No. 1, No. 2 or both. When a stall barrier valve is activated,

Combined (or Utility) hydraulic system pressure is ported to the

extend side of the stall barrier actuating cylinder. As the cylinder

extends, it applies an input to the elevator actuator input sector.This

input causes the elevator actuator to drive the elevator trailing edges

down; the control column drives forward accordingly, to

approximately one inch forward of neutral. When AOA has

decreased more than one degree, the stall barrier system

disengages.

The force generated by the stall barrier system is sufficient to

overcome any autopilot force, however, the system can be manually

overcome by the flight crew.

The stall barrier system can be deactivated by pressing the BARR

DISC button on either control wheel. The BARR DISC button also

serves as the autopilot disconnect button, thus is also labeled A/P

DISC accordingly. Deactivation of the stall barrier system is also

possible through selection of the STALL BARRIER switchlight to

OFF. The switchlight is located on the cockpit center pedestal just

below the left HP fuel cock. An amber OFF legend in the switchlight

will illuminate when the system is deactivated and will extinguish

when activated.

(6) Stall Warning / Stall Barrier System Test:

The stall warning / stall barrier system is normally tested by the flight

crew on the first flight of the day or every eight hours of flight time.

The test is performed only on the ground and cannot be tested in

flight. It consists of the following steps:

(a) Select the STALL BARRIER switch to on. Verify amber OFF

legend is extinguished.

(b) On both the pilot’s and copilot’s display controllers, depress

the TEST function key.

Page 12

January 31/02

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Revision 6

OPERATING MANUAL

(c) On both the pilot’s and copilot’s display controllers,

simultaneously depress and hold the Sea Level (S/L) line

select key.

(d) Continue holding both S/L line select keys until the

normalized AOA indicator pointer slews to full scale and

observe the following:

• Stall warning (control column shaker) occurs between

0.70 and 0.80

• Stall barrier (control column pusher) occurs between

0.95 and 1.07

• Check that the BARR DISC button will override the

pusher

(e) On both the pilot’s and copilot’s display controllers,

simultaneously depress and hold the ALT line select key.

(f) Continue holding both ALT line select keys until the

normalized AOA indicator pointer slews to full scale and

observe the following:

• Stall warning (control column shaker) occurs between

0.54 and 0.65

• Stall barrier (control column pusher) occurs between

0.79 and 0.90

• Check that the BARR DISC button will override the

pusher

NOTE:

Both pilot’s and copilot’s sides have to be tested

simultaneously in order to activate the control column

pusher.

NOTE:

Another momentary push of the TEST function key

may be required to ensure the AOA indicator is in the

normal area prior to takeoff.

G. Failure Detection System:

CAA Certified Aircraft Only: A flight control automatic failure detection

system monitors flight control inputs from the control columns and

compares them to the elevator actuator outputs. If the system detects a

failure, it automatically shuts off hydraulic pressure to the actuator and

triggers the appropriate warning on the Crew Alerting System (CAS). Once

activated by a malfunction, hydraulic pressure is inhibited until power to the

respective monitoring system is interrupted, for instance, by pulling and

resetting the appropriate circuit breaker.

The monitoring system is a dual-channel system. One channel controls the

Combined hydraulic system pressure source while the other controls the

Flight hydraulic system pressure source. Power for the system is received

from the 28 VDC Essential DC bus.

A pair of limit switches monitor applied control column input while a pair of

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 13

January 31/02

Revision 6

OPERATING MANUAL

reed switches monitor actuator output in response to the input.

If a disagreement occurs between control column input and actuator

output, the associated limit switch and reed switch close to complete a

circuit to the respective hydraulic shutoff delay relay. If the relay remains

energized for more than ½ second, it energizes the respective hydraulic

shutoff control relay. The control relay in turn powers its hydraulic shutoff

valve to the closed position. Activation of the shutoff valve also causes an

amber EL CMB HYD OFF (or EL FLT HYD OFF) message to be displayed

on CAS.

3. Controls and Indications:

(See Figure 6 and Figure 7 through Figure 9.)

A. Circuit Breakers (CBs):

Circuit Breaker Name: CB Panel: Location: Power Source:

SHAKER #1 CPO A-10 Essential DC Bus

SHAKER #2 CPO B-10 R Main DC Bus

STALL BARR DUMP

VALVE

CPO A-8 Essential DC Bus

STALL BARR VALVE #1 CPO A-12 Essential DC Bus

STALL BARR VALVE #2 CPO B-12 R Main DC Bus

STALL BARRIER #1 CPO A-9 Essential DC Bus

STALL BARRIER #2 CPO B-9 R Main DC Bus

STALL WARN CMPTR #1 CPO A-11 Essential DC Bus

STALL WARN CMPTR #2 CPO B-11 R Main DC Bus

ELEV COMB HYD S/O (1) CPO B-15 Essential DC Bus

ELEV FLT HYD S/O (1) CPO A-15 Essential DC Bus

ELEV TRIM TAB ACTR

HTR (2)

CP L-9 L Main AC Bus, φC

NOTE(S):

(1) CAA certified aircraft only.

(2) SN 1380 & subs; SN 1000 - 1379 having ASC 342.

B. Warning (Red) Messages and Annunciations:

Annunciation: Cause or Meaning:

Red chevron illuminated on pilot’s /

copilot’s AOA indexer.

AOA for approach and landing is too

high.

C. Caution (Amber) Messages and Annunciations:

CAS Message: Cause or Meaning:

AOA HEAT 1-2 FAIL Angle of attack probe heater failed.

EL CMB HYD OFF (1) The flight control automatic failure detection system has

EL FLT HYD OFF (1) The flight control automatic failure detection system has

EL MISTRIM NOSE

UP/DN

shut off Combined hydraulic system pressure to the

elevator actuator.

shut off Flight hydraulic system pressure to the elevator

actuator.

Autopilot elevator trim out of trim in direction indicated.

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Page 14

January 31/02

Revision 6

OPERATING MANUAL

CAS Message: Cause or Meaning:

MACH TRIM LIMIT Elevator trim has reached electrical trim limit while

MACH TRIM OFF PITCH TRIM switch selected OFF or electric pitch trim has

operating airplane in Mach Trim speed region (greater

than 0.80 Mach).

failed. (This message is inhibited at less than 0.82 Mach.)

STALL BARRIER 1-2 Stall barrier system giving stall angle indication.

STALL BARR 1-2 FAIL Stall barrier failed.

It is normal for STALL BARR 1 FAIL message to be

displayed any time EMERGENCY FLAPS are used and

flaps position is greater than 22°.

STALL BARRIER OFF STALL BARRIER switch is OFF or system not powered.

TRIM LIMIT Autopilot elevator trim has reached electrical trim limits.

NOTE(S):

(1) CAA certified aircraft only.

Annunciation: Cause or Meaning:

Amber chevron illuminated on pilot’s/

copilot’s AOA indexer.

AOA for approach and landing is too low.

4. Limitations:

A. Angle-of-Attack (AOA) System:

(1) Use As A Reference:

Angle-of-Attack (AOA) may be used as reference, but does not

replace airspeed as the primary reference.

(2) Indication Parameters:

AOA indication must be within white band once forward airspeed is

attained during takeoff roll.

(3) Use As A Speed Reference:

AOA shall not be used as a speed reference for takeoff rotation.

B. Stall Barrier / Stall Warning:

(1) Takeoff Requirements:

Both stall warning / stall barrier systems must be operative for

takeoff.

(2) Use of System:

Stall barrier systems must be ON during all flight operations except

as noted in Section 05-15-40, Stall Barrier Malfunction. Refer to this

system description for a description of the stall warning / stall barrier

system checkout procedure.

C. Mach Trim Compensation / Electric Elevator Trim:

(1) Use of mach trim compensation:

Mach trim compensation must be ON during all flight operations

except as provided for in Section 05-03-40, Mach Trim

Compensation Failure.

(2) If mach trim compensation failure is coupled with yaw damper

failure:

When mach trim compensation failure is coupled with yaw damper

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 15

January 31/02

Revision 6

OPERATING MANUAL

failure, observe speed limitations for both failures and limit altitude

to 41,000 ft.

D. Mach Trim / Electric Elevator Trim Inoperative Speed:

With both mach trim compensators inoperative or electric elevator trim

inoperative, the maximum operating limit speed is 0.75 MT.

Page 16

January 31/02

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Revision 6

OPERATING MANUAL

Pitch Flight Control

System Simplified Block

Diagram

Figure 3

2A-27-00

Page 17 / 18

January 31/02

OPERATING MANUAL

Stall Barrier / Angle of

Attack Wiring Schematic

Figure 4

2A-27-00

Page 19 / 20

January 31/02

OPERATING MANUAL

Pitch Trim Controls

Figure 5

2A-27-00

Page 21 / 22

January 31/02

OPERATING MANUAL

Stall Barrier / Angle of

Attack Controls and

Indications

Figure 6

2A-27-00

Page 23 / 24

January 31/02

OPERATING MANUAL

Control Columns

Figure 7

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 25

January 31/02

Revision 6

OPERATING MANUAL

Page 26

January 31/02

FLIGHT POWER SHUT OFF Handle

Figure 8

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

Revision 6

OPERATING MANUAL

Yaw Damper / Pitch Trim Control Panel

Figure 9

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 27

January 31/02

Revision 6

Loading...

Loading...