Gulfstream G550 Operating Manual

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

FLIGHT CONTROLS

2A-27-10: General

1. General Description:

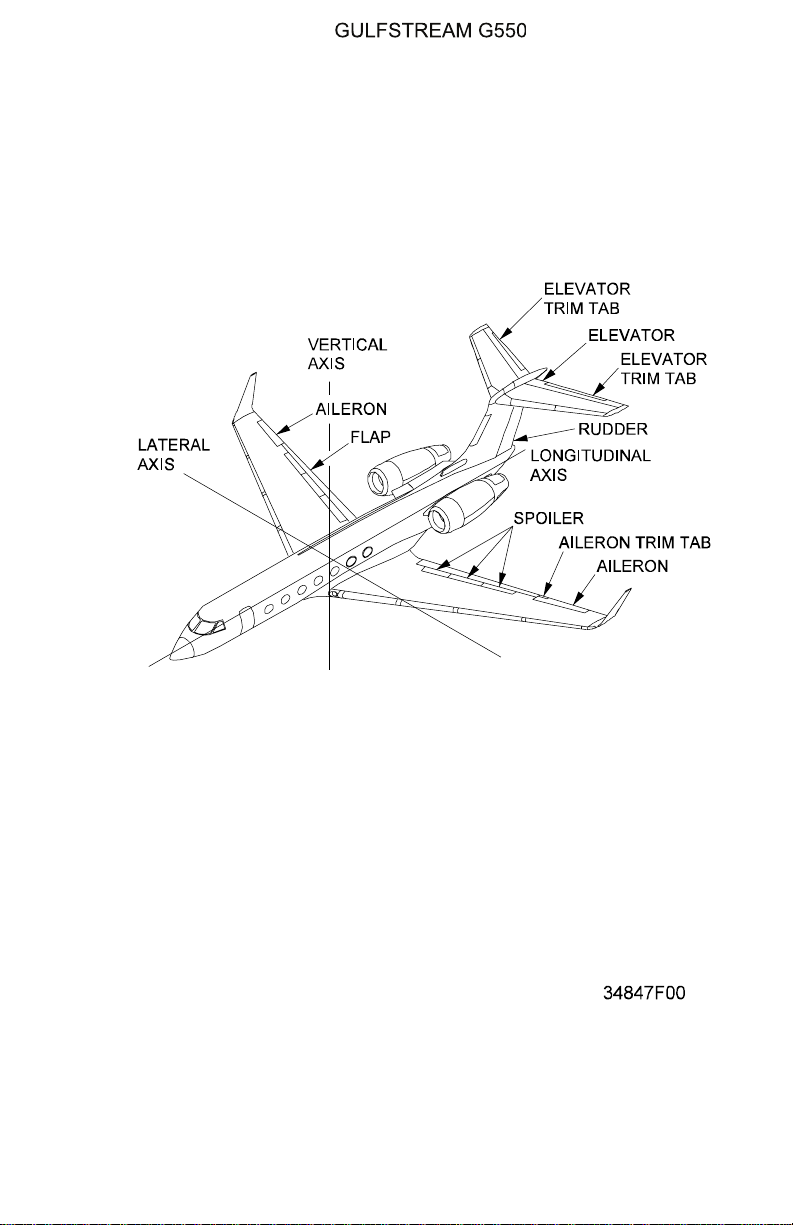

The aircraft flight controls allow the flight crew to guide the aircraft in the

longitudinal, vertical and horizontal axes (see Figure 2). The primary flight controls

are:

• Elevator to control aircraft pitch

• Rudder to control aircraft yaw

• Aileron to control aircraft roll

The primary flight controls are positioned by moving the pilot and copilot control

yokes and rudder pedals. Both yokes are mechanically linked together so that

either crew position has full control authority and control inputs are transparent to

both crew members since movement of one set of controls will move the

corresponding set of controls. Each yoke has a dedicated cable connection to the

elevator and aileron control on that respective side, but since the yokes are

mechanically linked, moving one side elevator or aileron will move the flight

controls on both sides. For instance, the copilot yoke is cable-linked to the right

elevator and the right aileron but any movement of the copilot yoke also moves

the pilot yoke that is in turn cable-linked to the left aileron and left elevator. This

system of split control authority and linked yoke movement provides a means to

maintain some flight control movement if one of the flight controls or associated

linkages becomes jammed. If a malfunction prevents movement of either the

elevators or ailerons, the mechanical links joining the two pilot yokes can be

severed, thereby allowing movement of the left or right elevator or aileron that

remains operational by commands using the yoke connected to the side of the

free control surface.

The two sets of rudder pedals are similarly mechanically linked together, but both

are connected to the rudder by a single cable. For this reason, there is no

provision for interrupting the linkage between the two sets of pedals, since each

set does not have an independent route to the rudder.

The cable connections from the yokes and rudder pedals are continuous loop

installations, providing feedback to the moveable controls. The control cables

engage bell cranks that translate cable movement into displacement commands

for hydraulic actuators that boost contol inputs to move the flight controls. Each

hydraulic actuator has a single shaft, but dual piston chambers in order that the

actuator may be driven by both (or either) left and right hydraulic system. (The

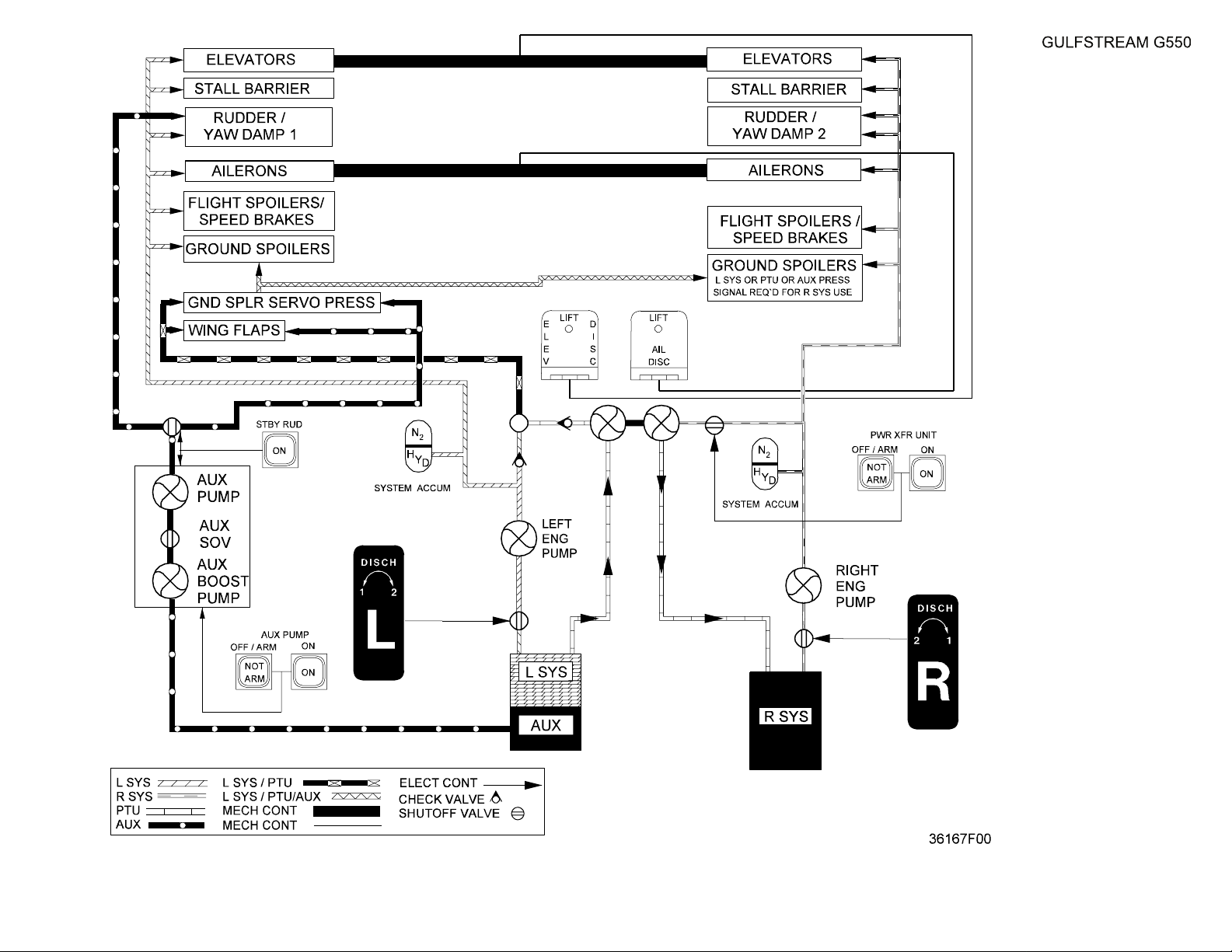

hydraulic system power sources for the flight controls are shown in Figure 1.) The

rudder actuator may also be powered by the Auxiliary (AUX) hydraulic system in

the event of dual hydraulic power failure. Each of the hydraulic actuators is

connected to the associated flight control by pushrods and bell cranks to impart

mechanical movement to the control surface. A bungee piston filled with hydraulic

fluid moderates the rate of actuation of the flight control and provides an artificial

feel input to the flight crew through the closed loop cable system. The failure of a

single hydraulic system does not degrade flight control operation - the remaining

system provides adequate power for flight control movement, and the actuator

chamber for the failed system bypasses fluid so there is no resistance to flow. If

both (or all, in the case of the rudder) hydraulic systems fail, both actuator

chambers bypass fluid, and pilot input through the cable connection moves the

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 1

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

internal shaft of the actuator and the associated pushrods and bellcranks without

powered assistance. More pilot force is required, but full movement of the flight

controls is attainable.

The autopilot is interfaced with the primary flight controls through electric servos

to move parallel cable linkages to the hydraulic actuators. Each flight control

surface has a Linear Variable Displacement Transducer (LVDT) that provides an

electrical signal proportional to flight control surface displacement from neutral.

The LVDT signal provides feedback to the autopilot for positioning the flight

controls, and also communicates control surface position for display on systems

and synoptic windows through interface with the Modular Avionics Units (MAUs).

The description of the Digital Automatic Flight Control Systems (autopilot) makes

up the entire content of Section 2B of this manual, and for that reason is not

covered in this Section. However, for the convenience of the reader, a tabulation

of the Crew Alerting System (CAS) messages associated with the autopilot is

included below.

The elevators and ailerons have trim tabs to position the flight controls with

aerodynamic forces to moderate the amount of physical effort to maintain the

control surfaces in the desired steady-state condition. The rudder is not equipped

with a trim tab, but instead has a mechanical trim input to reset the neutral

position of the rudder. The mechanical trim uses the hydraulic actuator to project

the rudder slightly into the windstream in the desired direction to compensate for

induced yaw.

The secondary flight controls and functions are:

• Wing flaps - enhance wing lift characteristics

• Flight and Ground Spoilers - reduce wing lift and add overall drag

• Movable horizontal stabilizer - aligns the elevator with aircraft angle of

attack

• Yawdamper - uses the autopilot rudder servo to moderate aircraft heading

oscillation

Some functions of the secondary flight controls are integrated with the operation

of the primary flight controls and other functions mutually complement the

operation of other secondary controls.

• As flaps extend, moving the wing center of lift aft, a downward pitch

moment is created - the moveable stabilizer automatically compensates for

the pitch moment by trimming downward. The opposite movement occurs

as flaps are retracted and the nose of the aircraft pitches up.

• When ailerons are used, flight spoilers on the downward wing activate to

increase roll rate and provide yaw into the turn. Ground spoilers decrease

ground roll distance during landings and aborted takeoffs.

• The yaw damper provides a degree of turn coordination for aileron roll

commands, provided wing flaps are not selected to more than thirty

degrees (30°).

Safety features incorporated into the flight controls system include:

• A stick shaker warning and a stick pusher stall prevention actuator.

• A gust lock that prevents damage to flight controls while the aircraft is

secured on the ground.

Page 2

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

2. Primary and Secondary Flight Controls Subsections:

The primary and secondary flight controls are discussed in the following

subsections:

• 2A-27-20: Elevator Pitch Control

• 2A-27-30: Rudder Yaw Control

• 2A-27-40: Aileron Roll Control

• 2A-27-50: Horizontal Stabilizer and Wing Flaps

• 2A-27-60: Stall Warning and Prevention System

• 2A-27-70: Speed Brake and Ground Spoilers

• 2A-27-80: Flight Controls Gust Lock

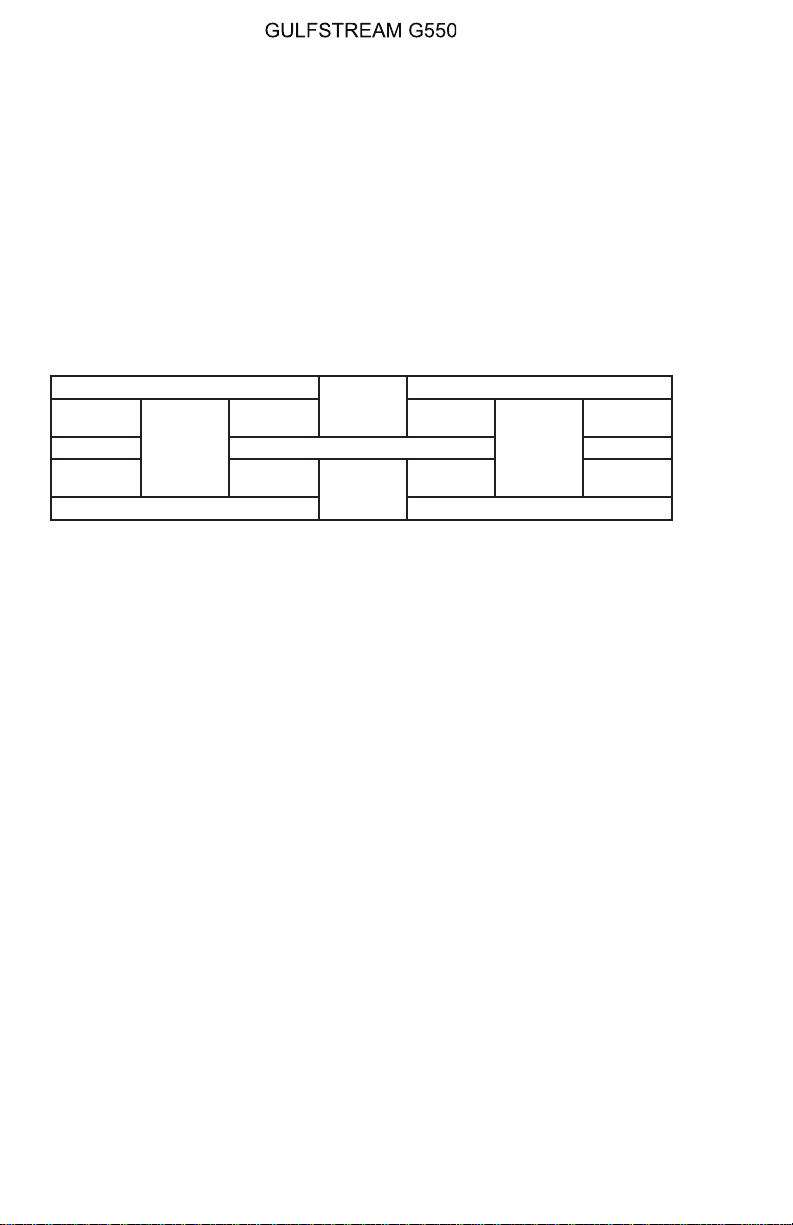

3. Autopilot Crew Alerting System (CAS) Messages:

The following CAS messages are associated with the operation of the autopilot

and integrated subsystems:

Area Monitored: CAS Message: Message Color:

Flight Guidance Computer

Internal Monitor

Flight Guidance Panel AP

Engage Switch

AP Engage Switches AP Engage Inhibit -Sw

AP 1-2 Fail Amber

AP Control Switch

Stuck

Active

Blue

Blue

Air Data System AP Inhibit - ADS Blue

Inertial Reference System AP Inhibit - IRS Blue

Control Column Force AP Inhibit - Left Column Blue

Control Column Force AP Inhibit - Right

Column

Blue

Control Wheel Force AP Inhibit - Left Wheel Blue

Control Wheel Force AP Inhibit - Right Wheel Blue

Manual Trim Wheel AP Inhibit - Man Trim

Autopilot Quick Disconnect

Switch

Active

AP Inhibit - QD Blue

Blue

Stall Shaker AP Inhibit - Stall Blue

Autopilot Touch Control

Steering Switch

Control Wheel Electric Trim

Switch

Weight On Wheels (WOW)

System

AP Inhibit - TCS Blue

AP Inhibit -Trim Cmd Blue

AP Inhibit - WOW Blue

Autopilot Power Source AP 1-2 Power Fail Blue

Autopilot Elevator Trim Servo AP / Trim Fail Blue

Flight Guidance Panel Speed

Window

Flight Guidance Computer /

WOW System

Take Off and Go Around

(TOGA) Engage Switch / Flight

Guidance Panel Manual Speed

Check Speed Target Blue

FGC - WOW Fault Blue

Go Around Pitch Blue

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 3

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

THIS PAGE IS INTENTIONALLY LEFT BLANK.

Page 4

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Flight Controls System:

Simplified Fluid Power

Diagram

Figure 1

2A-27-00

Page 5 / 6

August 14/03

Title Page

Prev Page

Next Page

TOC

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Flight Controls System Components

Figure 2

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 7

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

2A-27-20: Elevator Pitch Control

1. General Description:

The aircraft has a dual elevator installation to control aircraft pitch attitude. The

elevators are composed of a baked graphite-epoxy material. Each of the cockpit

yokes is connected to one of the aircraft elevators. The pilot yoke is connected to

the left elevator,the copilot yoke to the right elevator.Eachyokeisalsoconnected

to the other by a mechanical torque tube beneath the cockpit floor. Since both

yokes are interconnected, moving one yoke moves both elevators.

Braided steel cables run from each yoke to hydraulic assist actuators in the tail of

the aircraft. The cables are routed beneath the aircraft floor using pulley

connections to clear other installed equipment. The cables mate with the hydraulic

assist actuators via bellcranks that translate pulley rotational motion into forward

and aft motion. The actuators each have a single shaft powered by two piston

chambers, one chamber for each (left and right) hydraulic system. Both hydraulic

systems normally power the actuators, but one system is sufficient for full elevator

movement. The actuators are connected to the respective elevator by linkages

and bellcranks, moving the elevator up or down about the pivot points on the aft of

the horizontal stabilizer. The deflection range of the elevators is twenty-four

degrees (24°) up and thirteen degrees (13°) down.

Each connection of yoke to elevator is a continuous loop. Incorporated into the

loops adjacent to the actuators is a bungee cylinder filled with viscous fluid to

resist yoke / elevator movement in order to provide artificial feel to each yoke.

Each elevator also has a stability spring incorporated into the cable linkage to

provide a forward pull to the control yoke and to contribute additional feel input.

Both sides of the hydraulic actuators are monitored to assure correct operation.

The cockpit cable input motion must result in a corresponding actuator output

motion, and similarly the output side of the actuator should not move without

cockpit input. If input and output do not correspond, actuator hydraulic pressure is

bypassed to prevent movement of the elevator.

Anytime hydraulic pressure to the actuators is bypassed or lost (in the instance of

dual hydraulic system failure) the elevators remain operable with manual yoke

movement that positions the actuator shaft and connecting linkages to the

elevator. Control forces will be higher, since normal hydraulic assist provides a six

(6) to one (1) boost advantage to move the elevator surfaces.

Each elevator is equipped with a trim tab that uses aerodynamic pressure to aid in

positioning the control surface. The trim tabs are controlled manually by rotating a

wheel on the cockpit pedestal or electrically using switches on the control yokes.

Manual trim uses a dedicated braided wire connection from the cockpit to a

mechanical linkage in the tail. Electrical switch trim movement commands an

electric servo to move the same linkage.

Both the elevators and elevator trim incorporate Rotary Variable Differential

Transducers (RVDTs) to feed back position information to the autopilot for

elevator control and trim and to the ModularAvionics Units (MAUs) for formulation

of control surface position display on the Flight Controls 2/3 synoptic page. RVDTs

measure the angle of the elevators and trim tabs and transmit an electrical signal

proportional to displacement from a neutral position.

When the autopilot is engaged, the elevators are positioned by electric servos that

move parallel cable connections to the hydraulic actuators. The autopilot also

uses the electric trim servo to move the trim tabs, minimizing hydraulic actuator

force.

Page 8

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

If a malfunction or failure in any portion of the loopbetweenacockpityokeandthe

corresponding elevator prevents control surface movement, the mechanical

torque tube connection between the two control yokes can be separated to allow

control of the aircraft with the free (unjammed) elevator. The autopilot may be

used in single elevator operation.

2. Description of Subsystems, Units and Components:

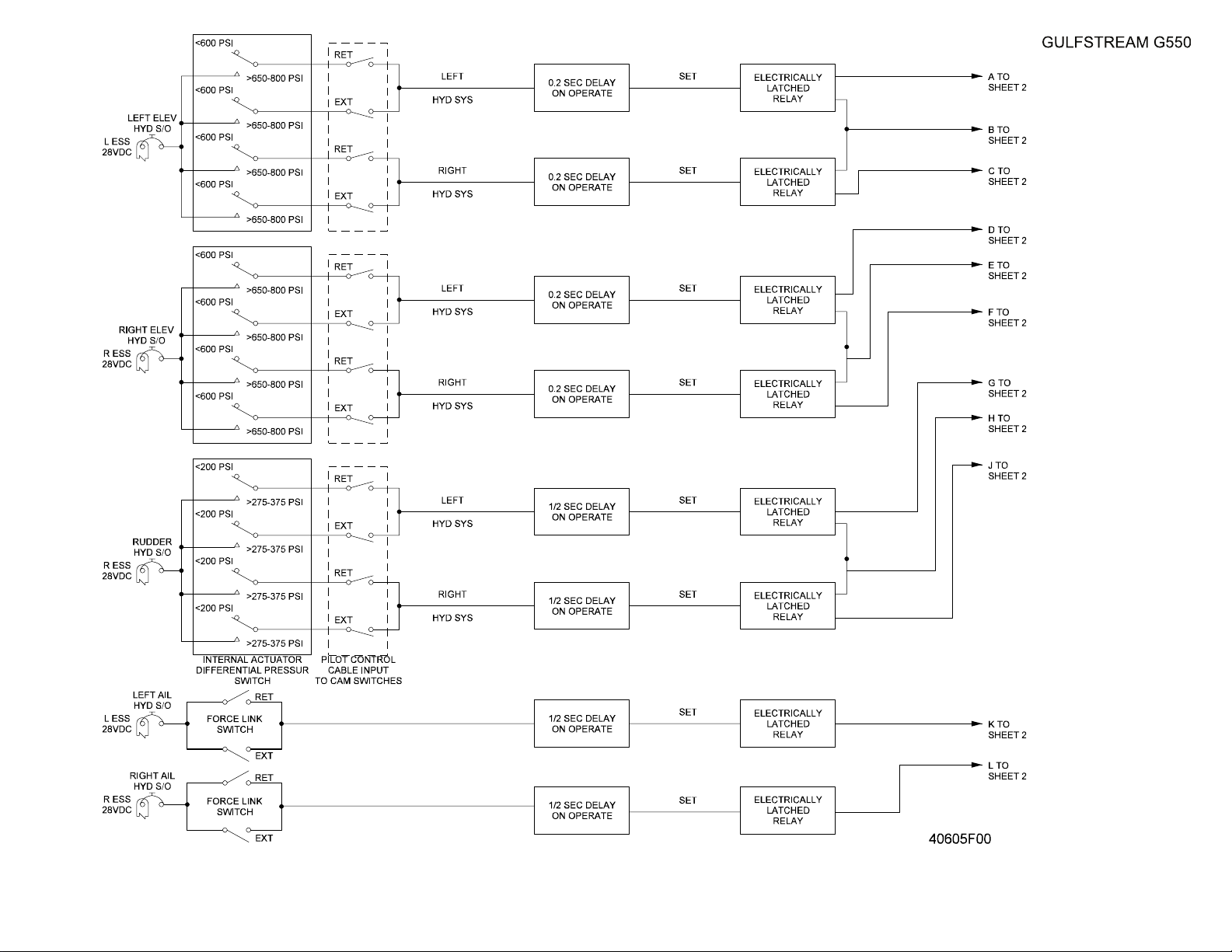

A. Elevator Hard Over Prevention System (HOPS):

Movements of the elevators contrary to the commanded position are

limited by a Hard Over Prevention System (HOPS), illustrated in Figure 3.

The system incorporates eight switches for each elevator to monitor

mechanical and hydraulic elevator operation. Four external mechanical

switches are integrated into the elevator control linkage to provide a

comparison reference for four switches mounted internally within the

hydraulic actuator. Of the four external switches, two are for left hydraulic

system reference and two are for right hydraulic system reference. Of the

two switches for each hydraulic system, one provides a up elevator

command reference and the other provides a down elevator command

reference. The switches are plunger-type contact switches, and are

installed on each side of a bracket attached to the command input side of

the elevator actuator. On one side of the bracket are the up elevator

command input switches for the left and right hydraulic systems. On the

other side of the bracket are the down elevator command input switches for

the left and right hydraulic systems. Inserted between the switches in the

bracket is a cam-type arm mated to the elevator hydraulic actuator output

linkage. The cam arm is positioned with a defined amount of clearance

between the plunger-type switches. Under normal conditions, the bracket

holding the switches moves with elevator command input and the cam arm

moves with the elevator hydraulic actuator output, so the clearance

between the switches and the arm is maintained.

If a malfunction occurs and the elevator moves opposite to or further from

the commanded direction, the cam arm that is attached to the output

linkage of the elevator actuator will move to close the clearance gap

between the cam arm and the plunger-type switches, making contact with

the switches on the side of the bracket. When the plungers of the switches

are depressed, a relay closes and an electrical signal is sent to a

corresponding set of switches mounted internally within the hydraulic

actuator.

Four pressure switches monitor left and right hydraulic system pressures

within the pistons of the elevator actuator. In normal conditions, all four

switches sense stabilized pressures since hydraulic outputs positioning the

elevator are balanced by air load pressures on the elevator surface acting

against actuator pressures. When a malfunction occurs and the elevator

moves contrary to the commanded direction, the hydraulic actuator shaft

moves in the contrary direction, causing an increase in hydraulic pressure

on the opposite sides of the pistons within the actuator. The left and right

system opposite side pressure switches close, completing the circuit

initiated by closure of the bracket plunger switches, and an electrical signal

is sent to a timing relay. If the contrary elevator movement persists for

longer than one tenth (1/10) of a second, hydraulic pressure from both left

an right systems is shut off to the elevator actuator.

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 9

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Left Hydraulic System Right Hydraulic System

Up

Elevator

←

Down

Elevator

→

Up

Elevator

←

Hydraulic Actuator Shaft

Pressure

Switch

Pressure

Switch

Pressure

Switch

In a similar manner, if a hydraulic malfunction causes the shaft of the

actuator to move in a direction opposite the commanded elevator direction,

the increased pressures in the wrong direction sides of the pistons would

close the monitoring switches, and movement of the actuator shaft would

cause the cam arm to contact the plunger switches on the external bracket,

and hydraulic pressure would be shut off to the elevator actuator after a

one tenth (1/10) of a second delay.

If a hydraulic malfunction in a single system (left or right) side of the

actuator moves the actuator shaft in a wrong direction, only the hydraulic

pressure of the malfunctioning system is shut off. For instance in a

stabilized condition, if the left hydraulic system piston attempts to move the

actuator shaft in the up direction, the increased pressure in the down

elevator side of the left piston will close the monitor switch and actuator

shaft displacement will close both the left and right hydraulic system up

elevator bracket plunger switches, completing the shut off circuit for the left

hydraulic system after a one tenth (1/10) second delay. (In this case

hydraulic pressure in the up elevator side of the right hydraulic system

piston will decrease due to the increase in area caused by actuator shaft

movement.) The elevator hydraulic actuator will continue to function using

the remaining hydraulic system.

The operation of the hydraulic shut off valves by the HOPS is signaled to

the MAUs (left elevator to MAU #1, right elevator to MAU #2) over ARINC429 connections. The shut off condition is monitored by the MWS, and a

CAS message corresponding to the condition is displayed on the CAS

window. If either or both hydraulic systems are shut off, an amber caution

message of “L (or) R Elevator Hydraulics Off” is displayed. If only a single

hydraulic system has been shut off, the remaining hydraulic system will

provide full elevator operation. If both hydraulic systems have been shut

off, manual elevator control may remain possible, depending upon the

cause of the hardover condition. If the cause of the condition is thought to

be momentary, and the use of the elevator is deemed necessary for

continued safe flight and landing, the hydraulic shut off valve(s) may be

reset by cycling the RIGHT ELEV HYD S/O and/or LEFT ELEV HYD S/O

circuit breaker. If the cause has not been rectified, the shut off valve(s) will

close and hydraulic boost for the elevator will be unavailable if both

hydraulic systems have been shut off. (HOPS is powered by the left

essential DC bus for the left elevator and the right essential DC bus for the

right elevator.)

To prevent the HOPS from shutting off hydraulic system pressure to the

elevator during normal flight maneuvers that may involve rapid changes in

elevator direction, HOPS activation is buffered by three elements:

• The clearance between bracket plunger switches and the actuator

Down

Elevator

→

Pressure

Switch

Page 10

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

cam arm

• Inertia in the build up of hydraulic pressures in the elevator actuator

• The one tenth (1/10) second delay in electrically latching the shut off

of hydraulic pressure

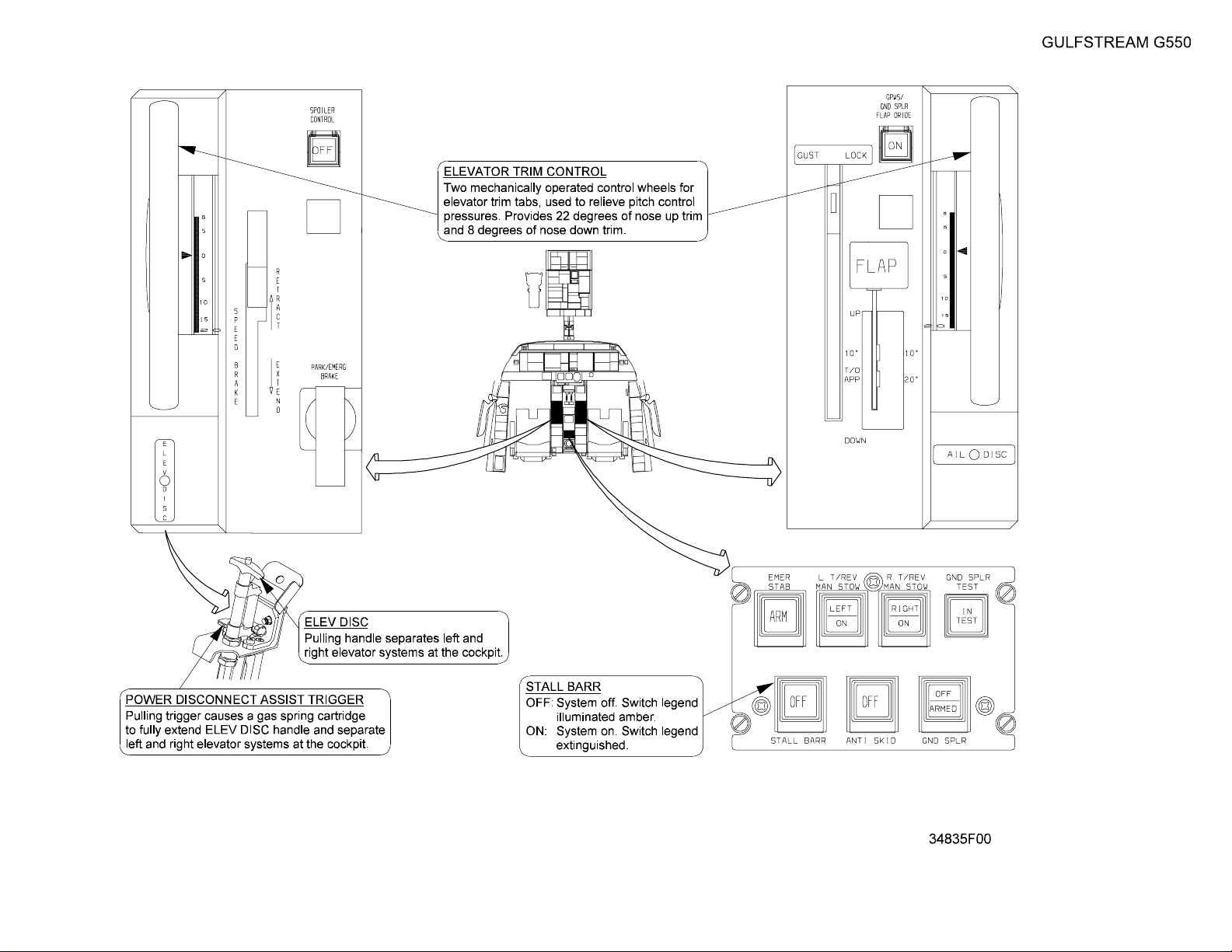

B. Elevator Disconnect Handle:

(See Figure 4.)

The mechanical torque tube beneath the cockpit connecting the pilot and

copilot yokes may be disconnected if a malfunction in one of the cable

connections, hydraulic actuators or elevators renders the respective

elevator inoperative. Disconnecting the torque tube prevents both elevators

from being disabled by a malfunction in one elevator linkage.

An elevator disconnect handle is located on the pilot side of the center

pedestal beneath a protective cover. The handle is connected by a cable to

a pin securing the two halves of torque tube together. Pulling out on the

disconnect handle removes the pin and allows each yoke to move

independently. If the elevator linkage malfunction has resulted in opposite

movement between the two yokes, making retraction of the mating pin

difficult, a power assist gas-spring cartridge may be activated to provide

additional force to remove the pin. The power assisted disconnect is

activated by pulling a trigger beneath the disconnect handle, and provides

an upward lifting moment of thirty-three feet per second (33 ft./sec).

After the yokes have been separated, the malfunctioning elevator is

isolated and the operable elevator may be used to control the aircraft. with

manual or autopilot inputs. If it is discovered that separating the yokes

freed the previously malfunctioning elevator linkage, the yokes may be

reconnected by pushing in on the disconnect handle when the yokes are

aligned, provided that the power assist disconnect was not used.Areset of

the yoke torque tube coupling is not possible without special maintenance

tools after activation of the power assist disconnect.

C. Pitch Trim System:

(See Figure 4 through Figure 6.)

Each elevator has a trim tab installed on the trailing edge. The trim tabs are

manufactured from the same graphite-epoxy material as the elevators, but

incorporate a ceramic heating element that is continuously electrically

powered to maintain a temperature of one hundred seventy-five degrees

Fahrenheit, plus or minus twenty degrees (175°F±20) around the tab

actuator linkage. Elevator trim heat is powered by 115V AC from the right

main bus. The trim tabs have a range of movement of twenty-two degrees

(22°) trailing edge down (aircraft nose up) to eight degrees (8°) trailing

edge up (aircraft nose down). Limit switches are installed at the travel limits

that will prompt the display of Crew Alerting System (CAS) messages

notifying the crew that the elevator trim tabs are at maximum displacement.

If a trim limit message is displayed while the autopilot is engaged, extreme

care should be taken prior to disengaging the autopilot. An abrupt attitude

change will occur if trim displacement is not moderated prior to

disengaging the autopilot.

Operation of the trim tabs employs aerodynamic force to maintain the

elevator in the desired position. As the trim tab is moved from the neutral

position (faired with the elevator) into the airstream, the air impinging on

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 11

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

the tab forces the hinged elevator into the opposite direction. As the

elevator is moved from the neutral position (faired with the horizontal

stabilizer), it also encounters pressure forces from the airstream, thus the

amount of elevator movement from neutral is determined by a balance of

airstream forces acting on both the trim tab and the elevator. Since the

surface area of the trim tab exposed to the airstream is less than the

surface area of the elevator, the elevator is deflected in much smaller

increments than trim tab displacement (excluding other factors, trim tab

effectiveness is a ratio of tab surface area to elevator surface area).

The flight crew manually controls the amount of trim tab deflection by

moving control wheels on either side of the center console. The wheels are

hubs connected to a common axial shaft, so that moving one wheel moves

the other. The shaft is connected to a continuous loop of wire cables that

connect through a series of pulleys and bellcranks to the elevator trim tabs.

Rotating a trim wheel forward positions the trim tab up forcing the elevator

down resulting in an aircraft nose down moment. Trim wheel rotation aft

results in an aircraft nose up moment.

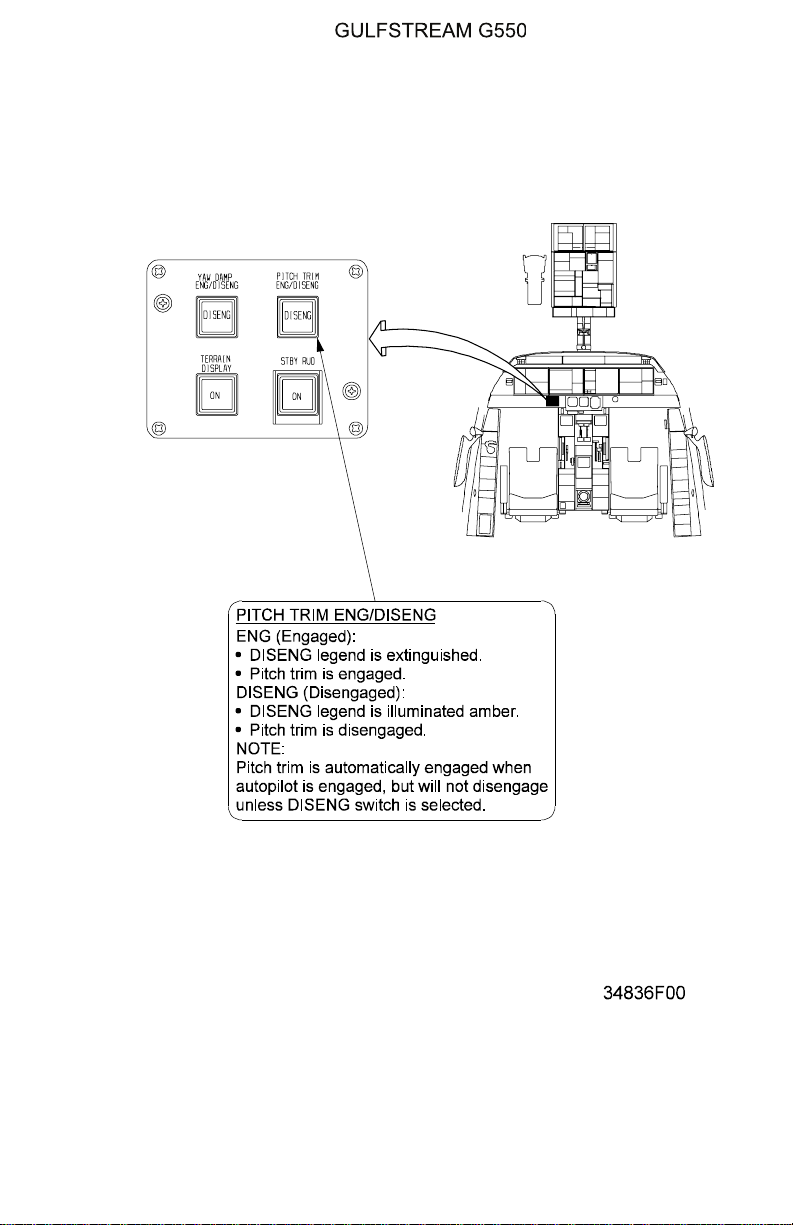

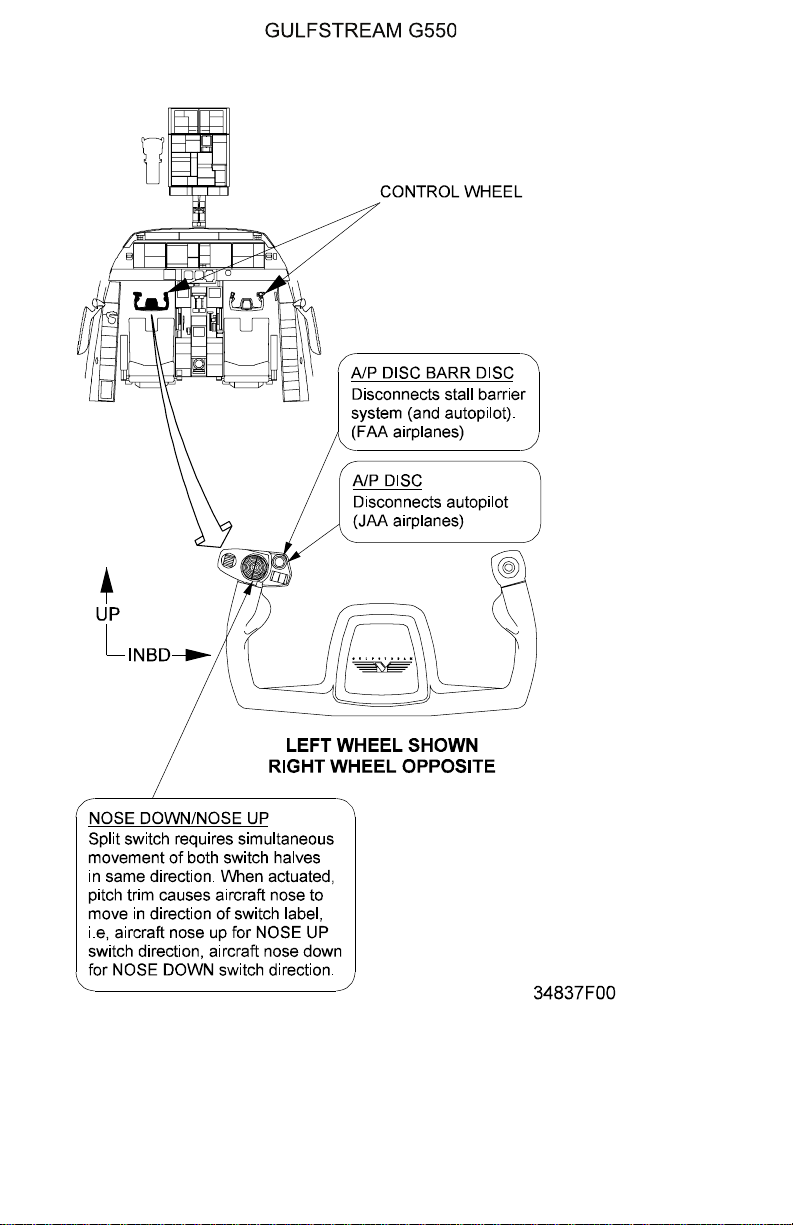

The flight crew has the option of electrically moving the elevator trim tabs.

A pushbutton, labelled PITCH TRIM ENG / DISENG, located to the left of

the standby flight instruments on the lower instrument panel enables

electrical operation of trim switches mounted on the outboard side of the

control yokes. Electric pitch trim is normally engaged. The amber DISENG

legend in the pushbutton will illuminate if the button is not pushed in to

engage electric trim. The yoke trim switches are composed of split halves.

Both halves must be moved in the same direction to move the elevator

trim. The split switch design helps to prevent accidental trim input. The

switches are wired to an electric servomotor that is located in the tail of the

aircraft and incorporated into the cable linkage to the trim tabs. An electric

signal from a cockpit trim switch results in the servomotor rotating an

attached pulley, moving the elevator trim cable loop in the desired

direction. The manual trim wheels on the pedestal will rotate with electric

trim inputs, since the control cabling is a continuous loop.

When the autopilot is engaged, autopilot servomotors move the elevators

and also control elevator trim with the same servomotor employed by the

yoke electric trim switches. The PITCH TRIM ENG / DISENG switch is

automatically engaged whenever the autopilot is engaged (to enable

autopilot trim). However the reverse is not true - electric pitch trim will not

disengage when the autopilot is disengaged, but must be selected off with

the switch.

Elevator trim must be within a defined range for takeoff, with the specific

setting within the range determined by aircraft Center of Gravity (COG) and

takeoff gross weight. The limits of the acceptable pitch trim range are eight

degrees nose up to nineteen degrees nose up (8° - 19° up). The takeoff

elevator trim range is marked in green on the trim setting indices of the

manual trim wheels at each side of the center pedestal. The same limits

are shown in a green band on the trim scale of the Flight Controls 2/3

synoptic page. Failure to set pitch trim within the defined range will result in

a warning annunciation and CAS message as the power levers are

advanced for takeoff.

Page 12

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

D. Mach Trim:

The autopilot employs elevator control to provide the aircraft with Mach

trim. Mach trim is necessary because at high speed flight the center of lift

on the wing transits aft with increases in speed, producing a nose down

pitch moment termed Mach tuck. The autopilot electrically repositions the

elevator trim to neutralize the nose down force. Mach trim is an automatic

function of the Flight Guidance Computers.

NOTE:

The autopilot does not have to be engaged to provide

Mach trim. Automatic Mach trim is available whenever

the PITCH TRIM ENG/DISENG switch is engaged.

3. Controls and Indications:

(See Figure 4 through Figure 6.)

NOTE:

A full description of the Flight Controls 2/3 synoptic

page appears in section 2B-07-00.

A. Circuit Breakers (CBs):

The following CBs protect elevator pitch control:

Circuit Breaker Name: CB Panel: Location: Power Source:

ELEV SERVO #1 POP D-4 L ESS DC Bus

ELEV SERVO #2 CPOP D-4 R ESS DC Bus

PITCH TRIM SERVO #1 POP E-2 L ESS DC Bus

PITCH TRIM SERVO #2 CPOP E-1 R ESS DC Bus

L ELEV TRIM HEAT REER E-16 R MAIN AC Bus

R ELEV TRIM HEAT REER F-16 R MAIN AC Bus

LEFT ELEV HYD S/O POP C-5 L ESS DC Bus

RIGHT ELEV HYD S/O CPOP C-5 R ESS DC Bus

B. Crew Alerting System (CAS) Messages:

The following CAS messages are associated with the elevator pitch

controls:

Area Monitored: CAS Message: Message Color:

Elevator Trim Tab RVDTs vrs

takeoff range

Elevator and Trim Tab RVDTs and

MAUs

Elevator and Trim Tab RVDTs and

MAUs

L/R Elevator HOPS and MAUs L/R Elevator Hydraulics

Aircraft Configuration Red

Elevator Mistrim Nose

Down

Amber

Elevator Mistrim Nose Up Amber

Off

Amber

Electric Pitch Trim Servos Elevator Trim 1-2 Fail Amber

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 13

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Area Monitored: CAS Message: Message Color:

Electric Pitch Trim Servos / Trim

ENG/DISENG Switch

Electric Pitch Trim Servos and

MAUs

Electric Pitch Trim Servos and

MAUs

Electric Pitch Trim Servos and

MAUs

Mach Trim Off

(inhibited below 0.82

Mach)

NOTE

Amber

Pitch Trim 1-2 Power Fail Blue

Elevator Trim Down Limit Blue

Elevator Trim Up Limit Blue

4. Limitations:

A. Mach Trim / Electric Elevator Trim Functions:

(1) Use of Mach Trim / Electric Elevator Trim Functions:

Mach trim / electric elevator trim must be ON during all flight

operations except as provided for in Section 05-02-40: Mach Trim

Failure.

(2) With both Mach Trim / Electric Elevator Trim Inoperative:

M

is reduced to 0.80MT.

mo

Page 14

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Hard Over Prevention

System (HOPS)

Figure 3 (Sheet 1 of 2)

2A-27-00

Page 15 / 16

August 14/03

Title Page

Prev Page

Next Page

TOC

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Hard Over Prevention

System (HOPS)

Figure 3 (Sheet 2 of 2)

2A-27-00

Page 17 / 18

August 14/03

Title Page

Prev Page

Next Page

TOC

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Pitch Flight Controls

System Controls and

Indications (Cockpit

Center Pedestal)

Figure 4

2A-27-00

Page 19 / 20

August 14/03

Title Page

Prev Page

Next Page

TOC

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Electric Pitch Trim Engage / Disengage Switch Controls and Indications

Figure 5

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 21

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

Page 22

August 14/03

Electric Pitch Trim / Stall Barrier System Controls and Indications

Figure 6

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

2A-27-30: Rudder Yaw Control

1. General Description:

The flight crew controls the direction of the aircraft around the vertical axis by

movement of the rudder. The rudder panel is composed of graphite-epoxy fabric

baked at high temperatures to form a strong but light weight structure. The rudder

is positioned by inputs from the pilot or copilot rudder pedals, or by autopilot

electro-servos. The pilot and copilot rudder pedals are connected by a common

torque tube so that either may control rudder movement. (The individual pedal

pairs are adjustable to accommodate differences in pilot leg length.) The common

torque tube is connected by a bellcrank to a single stranded wire cable loop

located on the right side of the aircraft beneath the cockpit and cabin floor.(Since

there is only one rudder flight control surface, there is no need for dual cable

linkages from both yokes to the rudder, nor is there a need for a system to

separate pilot and copilot rudder pedal inputs to the rudder.) The cable loop

incorporates pulleys and bellcranks to route the cable around other installations

beneath the aircraft floor. At the end of the loop is a bellcrank connected to a dual

piston hydraulic actuator. The bellcrank translates movement of the control cable

into lateral displacement inputs to the actuator. The rudder control cable linkage is

illustrated in Figure 7 and the termination of the cable linkage at the rudder

actuator is shown in Figure 8. The actuator has a single shaft with a piston

chamber for each (left and right) hydraulic system. Both hydraulic systems

provide up to three thousand (3,000) psi pressure to assist in moving the rudder

surface. Internal regulator valves limit the pressure output of the two pistons within

the hydraulic actuator to a maximum of fifteen hundred (1,500) psi each to prevent

structural damage to the rudder and vertical stabilizer. The output end of the

hydraulic actuator shaft is connected to linkages that move the rudder around the

pivot point connections on the vertical stabilizer. If one hydraulic system fails, the

regulator valve of the remaining system shifts to provide up to three thousand

(3,000) psi to move the rudder. Additionally, in the event of dual hydraulic system

failures, the auxiliary (AUX) hydraulic pump will power the rudder using the left

system piston in the actuator provided sufficient fluid remains in the auxiliary

reservoir of the left hydraulic system. AUX hydraulic system power for the rudder

is activated by the selection of the STBY RUD (Standby Rudder) switch on the

lower portion of the pilot instrument panel to the left of the standby flight

instruments.

Mechanical stops are incorporated into the rudder mounting structure to physically

limit rudder displacement to a maximum of twenty-two degrees (22°) either side of

neutral, although full displacement is available only at low airspeeds. As airspeed

increases, the airload on the rudder surface increases proportionally. When the

airload on the rudder surface equals the available hydraulic pressure output of the

rudder actuator, no further rudder displacement is possible. The Monitor and

Warning System (MWS) software monitors aircraft speed, angle of attack and

rudder displacement to formulate an advisory message informing the flight crew

when maximum rudder displacement has been reached.

2. Description of Subsystems, Units and Components:

A. Yaw Damper and Autopilot Rudder Operation:

Automatic rudder compensation for aircraft yaw produced by dutch roll

inherent to swept-wing aircraft is provided by the yaw damper function of

the autopilot. The yaw damper function is engaged with the YAW DAMP

ENG / DISENG switch located on the lower pilot side instrument panel

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 23

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

adjacent to the STBY RUD switch, shown in Figure 9. The yaw damper is

normally engaged even if the autopilot is not operating. (The DISENG

legend in the switch will be illuminated amber if the yaw damper is not

engaged.) If the autopilot is engaged, the yaw damper must be engaged,

since autopilot rudder commands use the yaw damper circuits to displace

the rudder.

The yaw damper function is a redundant dual-channel installation. Yaw

damper channel #1 is controlled by the autopilot function hosted in

processor modules in Modular Avionics Unit (MAU) #1, channel #2 by MAU

#2. Each channel has a dedicated Electro-Hydraulic Servo Valve (EHSV)

internal to the rudder actuator. The autopilot processor detects an

uncommanded yaw displacement by monitoring data from the Inertial

Reference Units (IRUs). The autopilot processor signals a rudder

displacement to counter the aircraft yaw through an Actuator Input/Output

Processor (AIOP) module via ARINC-429 bus connection to the EHSV on

the rudder actuator. The amount of rudder displacement necessary is a

function of airspeed / Mach number, and the AIOP uses information from

the Air Data Application (ADA) in the MAU to determine the amount of

rudder to apply. A feedback loop from a Rotary Variable Displacement

Transducer to the AIOP confirms the rudder position. The maximum

amount of rudder displacement available to the yaw damper is five degrees

(5°).

Since only one yaw damper channel is necessary for rudder control, the

active channel alternates on each flight segment (a function of weight-onwheels) to prolong system life. If the active channel fails, the standby

channel will automatically assume yaw damper control.

The yaw damper function also provides a rudder input for aircraft turn

coordination provided the flaps are not set to thirty degrees (30°) or more.

The yaw damper will add up to five degrees (5°) of rudder in the direction

of turn without pilot rudder input.

Autopilot control of the rudder is the same functional process as the yaw

damper, but the amount of rudder displacement available to the autopilot is

greater (up to the 22° limit). Larger rudder inputs are necessary for the

lower airspeeds associated with coupled approaches or during single

engine operations.

B. Rudder Trim:

The rudder is trimmed by manual inputs from the trim wheel mounted on

the cockpit aft center pedestal (see Figure 10). There is no trim tab on the

rudder, rather the whole rudder panel moves in response to trim input. The

rudder may be displaced up seven and a half degrees (7½°) left or right

with trim commands. Rotation of the trim wheel moves a cable linkage to a

drum mounted adjacent to the rudder hydraulic actuator. Movement of the

trim wheel rotates the drum and a linkage attached to the drum moves the

shaft of the rudder actuator. The rudder actuator hydraulically positions the

rudder by the commanded amount of deflection, and the linkage from the

drum establishes the trimmed rudder position as a new neutral setting for

the actuator. Manual or yaw damper / autopilot rudder deflections are then

summed to the existing trimmed rudder displacement. (The autopilot does

not have a separate trim input to the rudder.)

Page 24

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

C. Rudder Limiting:

The G550 does not have a separate load limiter unit, but relies instead

upon MWS software to compute maximum rudder deflection for a given

airspeed, matching airloads on the rudder surface with the hydraulic

function of the rudder actuator.Although at low airspeeds full rudder travel

of twenty-two degrees (22°) is available, at higher airspeeds less rudder

travel is necessary to achieve the desired amount of aircraft heading

control. To avoid excessive loads, the rudder hydraulic actuator uses

internal pressure switches to signal the MWS when full hydraulic pressure

output of the actuator has been reached. The MWS formulates a CAS blue

advisory message text of “Rudder Limit” for display on the CAS window

indicating the maximum rudder hydraulic power assist condition.

The amount of rudder deflection at which maximum rudder hydraulic assist

occurs is dependent upon airspeed. As speed increases, air loads increase

as the rudder is displaced. Since the rudder surface is linked mechanically

to the rudder hydraulic actuator shaft, the force of the rudder airload

opposes the force of the hydraulic system(s) moving the actuator.

Whenever the airload force equals hydraulic system force (1,500 psi with

both left and right systems operating or 3,000 psi with a single hydraulic

system) no further rudder displacement is possible, and the “Rudder Limit”

advisory message is displayed on the CAS window.

D. Rudder Hard Over Prevention System (HOPS):

Movements of the rudder contrary to the commanded position are limited

by a Hard Over Prevention System (HOPS) that incorporates eight

switches to monitor mechanical and hydraulic rudder operation (see Figure

3. Four external mechanical switches are integrated into the rudder control

linkage to provide a comparison reference for four switches mounted

internally within the hydraulic actuator. The external HOPS switches are

noted on Figure 8. Of the four external switches, two are for left hydraulic

system reference and two are for right hydraulic system reference. Of the

two switches for each hydraulic system, one provides a left rudder

command reference and the other provides a right rudder command

reference. The switches are plunger-type contact switches, and are

installed on each side of a bracket attached to the command input side of

the rudder actuator. On one side of the bracket are the left rudder

command input switches for the left and right hydraulic systems. On the

other side of the bracket are the right rudder command input switches for

the left and right rudder systems. Inserted between the switches in the

bracket is a cam-type arm mated to the rudder hydraulic actuator output

linkage. The cam arm is positioned with a defined amount of clearance

between the plunger-type switches. Under normal conditions, the bracket

holding the switches moves with rudder command input and the cam arm

moves with the rudder hydraulic actuator output, so the clearance between

the switches and the arm is maintained.

If a malfunction occurs and the rudder moves opposite to or further from

the commanded direction, the cam arm that is attached to the output

linkage of the rudder actuator will move to close the clearance gap

between the cam arm and the plunger-type switches, making contact with

the switches on the side of the bracket. When the plungers of the switches

are depressed, a relay closes and an electrical signal is sent to a

corresponding set of switches mounted internally within the hydraulic

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 25

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

actuator.

Four pressure switches monitor left and right hydraulic system pressures

within the pistons of the rudder actuator. In normal conditions, all four

switches sense stabilized pressures since hydraulic outputs positioning the

rudder are balanced by air load pressures on the rudder surface acting

against actuator pressures. When a malfunction occurs and the rudder

moves contrary to the commanded direction, the hydraulic actuator shaft

moves in the contrary direction, causing an increase in hydraulic pressure

on the opposite sides of the pistons within the actuator. The left and right

system opposite side pressure switches close, completing the circuit

initiated by closure of the bracket plunger switches, and an electrical signal

is sent to a timing relay. If the contrary rudder movement persists for longer

than one half (½) second, hydraulic pressure from both left an right

systems is shut off from the rudder actuator.

Left Hydraulic System Right Hydraulic System

Left

Rudder ←

Right

Rudder →

Left

Rudder ←

Hydraulic Actuator Shaft

Pressure

Switch

Pressure

Switch

Pressure

Switch

In a similar manner, if a hydraulic malfunction causes the shaft of the

actuator to move in a direction opposite the pilot or yaw damper / autopilot

commanded direction, the increased pressures in the wrong direction sides

of the pistons would close the monitoring switches, and movement of the

actuator shaft would cause the cam arm to contact the plunger switches on

the external bracket, and hydraulic pressure would be shut off to the rudder

actuator after a one half (½) second delay.

If a hydraulic malfunction in a single system (left or right) side of the

actuator moves the actuator shaft in a wrong direction, only the hydraulic

pressure of the malfunctioning system is shut off. For instance in a

stabilized rudder condition, if the left hydraulic system piston attempts to

move the actuator shaft to the right, the increased pressure in the right side

of the left piston will close the monitor switch and actuator shaft

displacement will close both the left and right hydraulic system bracket

plunger switches, completing the shut off circuit for the left hydraulic

system after a one half (½) second delay. (In this case hydraulic pressure

in the right rudder side of the right hydraulic system piston will decrease

due to the increase in area caused by actuator shaft movement.) The

rudder hydraulic actuator will continue to function using the remaining

hydraulic system. During single hydraulic system operation the pressure

regulator valve will open, allowing the remaining hydraulic system pressure

output to increase up to three thousand (3,000) psi for rudder actuation.

The operation of the hydraulic shut off valves by the HOPS is signaled to

MAU #2 over an ARINC-429 connection. The shut off condition is

monitored by the MWS, and a CAS message corresponding to the

condition is displayed on the CAS window. If both hydraulic systems are

shut off, an amber caution message of “Rudder Hydraulics Off” is

displayed. Manual rudder control may remain possible, depending upon

Right

Rudder →

Pressure

Switch

Page 26

August 14/03

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

the cause of the hardover condition. If the cause of the condition is thought

to be momentary, and the use of the rudder is deemed necessary for

continued safe flight and landing, the hydraulic shut off valves may be reset

by cycling the RUDDER HYD S/O circuit breaker. If the cause has not been

rectified, the shut off valves will close and hydraulic boost for the rudder will

be unavailable. Loss of rudder hydraulic pressure will also prevent yaw

damper (and autopilot rudder) operation.

If only one hydraulic system is shut off to the rudder, the remaining system

will provide full boost to the rudder and yaw damper / autopilot rudder

operation. The amber caution CAS message of ”Rudder Hydraulics Off will

be accompanied by a blue advisory “Single Rudder” message.

To prevent the HOPS from shutting off hydraulic system pressure to the

rudder during normal flight maneuvers that may involve rapid changes in

rudder direction, HOPS activation is buffered by three elements:

• The clearance between bracket plunger switches and the actuator

cam arm

• Inertia in the build up of hydraulic pressures in the rudder actuator

• The one half (½) second delay in electrically latching the shut off of

hydraulic pressure

E. Standby Rudder System:

In the event that both hydraulic systems fail during flight, the Auxiliary

(AUX) hydraulic pump can be used to pressurize the left hydraulic system

to actuate the rudder and yaw damper provided that fluid remains in the left

system reservoir and there is no leak in the left hydraulic system lines

connecting to the rudder actuator. The AUX hydraulic pump, located in the

right main landing gear wheel well, is powered by left essential DC bus and

can provide three thousand (3,000) psi at a flow rate of two (2) gallons per

minute. Normally the AUX is used to actuate the flaps, ground spoiler

servos, brakes and nose wheel steering in the event of a dual hydraulic

system failure. However a valve in the left hydraulic system plumbing,

controlled by the STBY RUD switch on the lower portion of the pilot

instrument panel, can be used to divert the total output of the AUX

hydraulic pump to the left hydraulic system piston of the rudder actuator.

Powering the rudder and yaw damper, especially at higher altitudes,

provides dutch roll compensation and avoids the airspeed restrictions

necessary without an operating yaw damper. As the aircraft descends to

lower altitudes and airspeeds during the approach phase, airloads on the

rudder are reduced and manual rudder control is adequate for steering

commands. The STBY RUD switch can then be selected off to enable the

AUX hydraulic pump to provide the pressure for flap extension, pressurize

ground spoiler servos, wheel brakes and nose wheel steering during

landing. If the STBY RUD switch is not selected off prior to landing, the

standby rudder valve will automatically close when the nose gear weighton-wheels (WOW) switch is compressed on landing, enabling AUX pump

power for stopping and steering the aircraft.

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 27

August 14/03

OPERATING MANUAL

Title Page

Prev Page

Next Page

TOC

3. Controls and Indications:

(See Figure 9 and Figure 10.)

NOTE:

A full description of the Flight Controls 2/3 and

Hydraulics 2/3 synoptic pages appears in section

2B-07-00.

A. Circuit Breakers (CBs):

The following CBs protect the rudder flight controls:

Circuit Breaker Name: CB Panel: Location: Power Source:

RUDDER HYD S/O CPOP C-3 R ESS DC Bus

YAW DAMP SERVO #1 POP D-6 L ESS DC Bus

YAW DAMP SERVO #2 CPOP D-6 R ESS DC Bus

AUX HYD PUMP LEER C-16 L ESS DC Bus

B. Crew Alerting System (CAS) Messages:

The following CAS messages are associated with the yaw flight controls

system:

Area Monitored: CAS Message: Message Color:

Rudder Hydraulic Shutoff Valves Rudder Hydraulics Off Amber

Yaw Damper Servo Valves Yaw Damper 1-2 Fail Amber

YAW DAMP ENG/DISENG Switch Yaw Damper Off Amber

Autopilot, YAW DAMP ENG/

DISENG Switch

MWS Software, Aircraft Speed,

Rudder Position (RVDT)

No YD Turn Coordination Blue

Rudder Limit Blue

Rudder Hydraulic Shutoff Valves Single Rudder Blue

Standby Rudder Switch / AUX

Pump

Standby Rudder Hyd On Blue

Yaw Damper Servo Valves YD 1-2 Power Fail Blue

4. Limitations:

Page 28

August 14/03

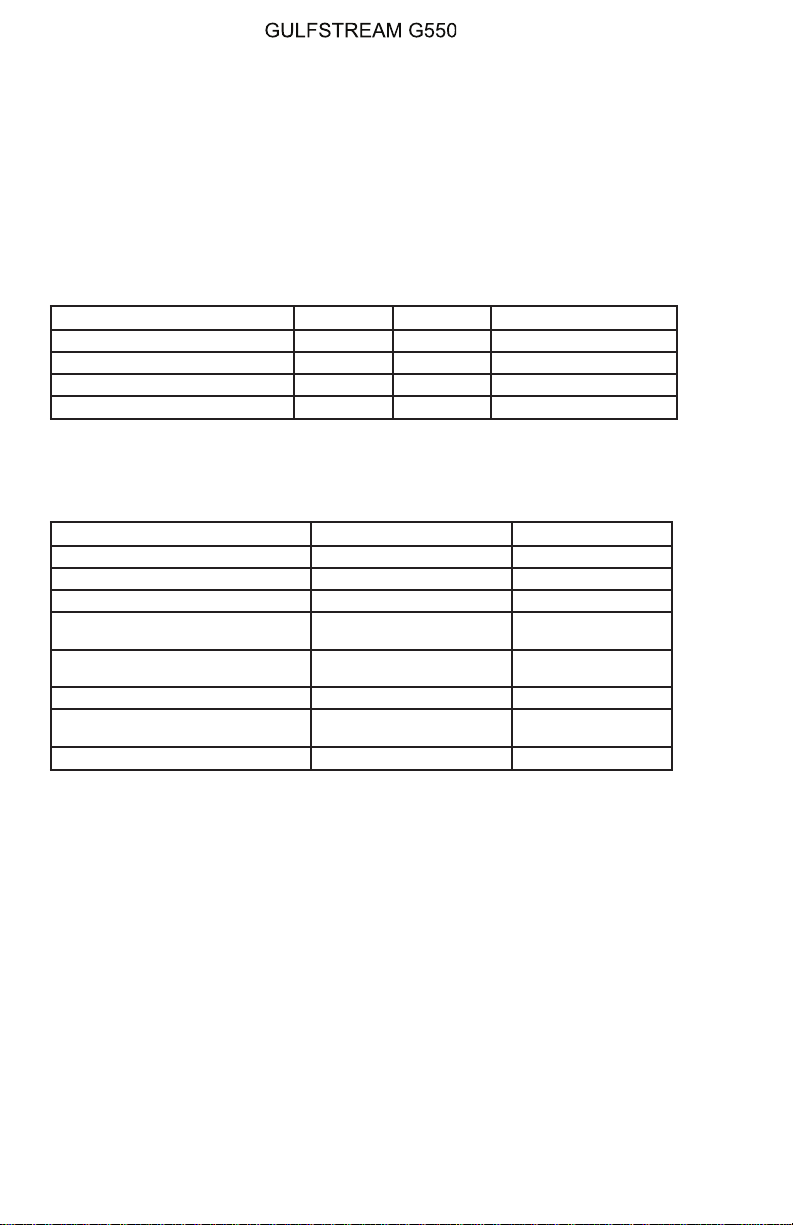

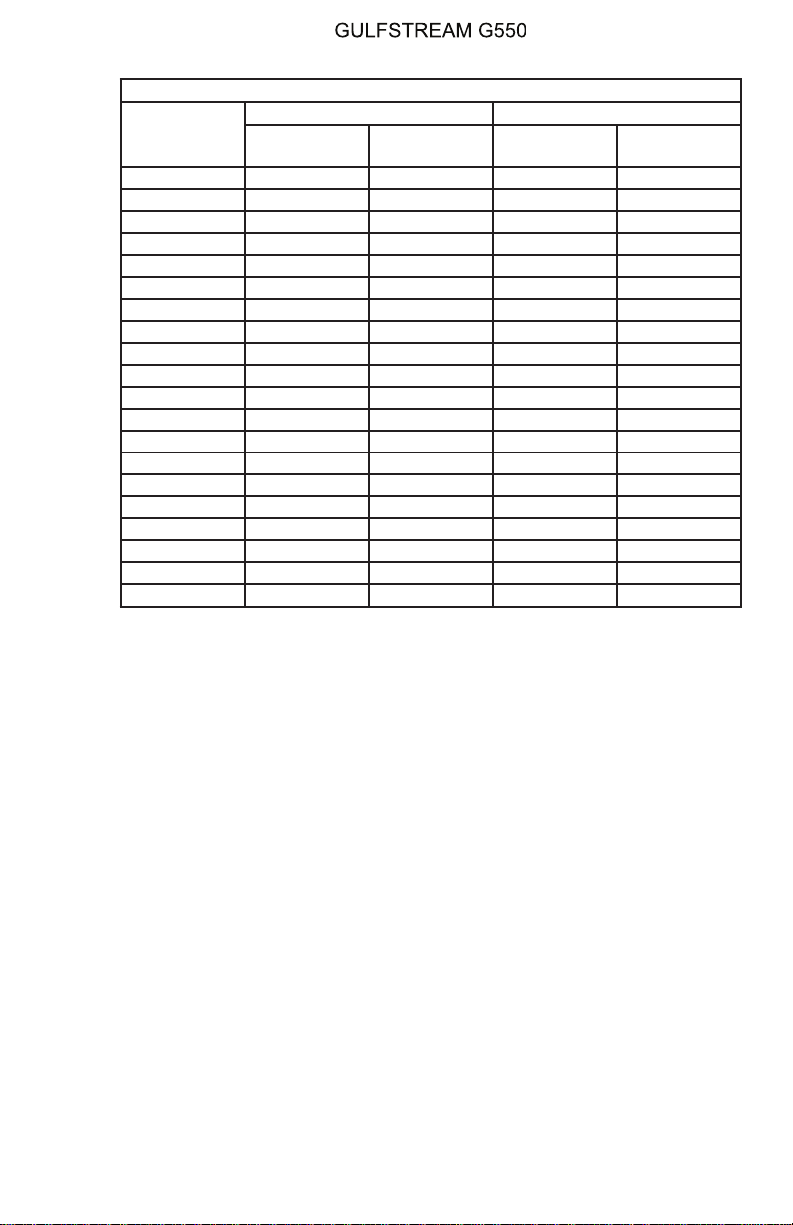

A. Yaw Damper Inoperative Speeds:

Maximum Speeds:

• Above 10,000 Feet: 260 KTS / 0.80 MT

• Below 10,000 Feet: 250 KCAS

Minimum Speeds:

• Above 20,000 Feet: 210 KTS

• Below 20,000 Feet:

The minimum speed is in accordance with the following schedule

until ready to configure for approach and landing. V

the airspeed tape of the PFD, is the approach speed for landing for

the current flap setting.

PRODUCTION AIRCRAFT SYSTEMS2A-27-00

REF, as shown on

Minimum Speeds: Yaw Damper Inoperative

Title Page

Prev Page

Next Page

TOC

Flaps 0, 10,

Fuel - lb

23,000 V

24,000 V

25,000 V

26,000 V

27,000 V

28,000 V

29,000 V

30,000 V

31,000 V

32,000 V

33,000 V

34,000 V

35,000 V

36,000 V

37,000 V

38,000 V

39,000 V

40,000 V

41,000 V

41,300 V

OPERATING MANUAL

Sea Level to 5000 ft 5000 to 20,000 ft

20

REF VREF VREF 135

REF VREF VREF 141

REF VREF VREF 147

REF VREF VREF 153

REF VREF VREF 159

REF VREF 147 160

REF VREF 153 160

REF VREF 158 160

REF VREF 163 160

REF VREF 168 160

REF VREF 174 160

REF VREF 179 160

REF VREF 184 160

REF VREF 189 160

REF VREF 195 160

REF VREF 200 160

REF VREF 205 160

REF VREF 211 160

REF VREF 216 160

REF VREF 217 160

Flaps 39

Flaps 0, 10,

20

Flaps 39

PRODUCTION AIRCRAFT SYSTEMS 2A-27-00

Page 29

August 14/03

Loading...

Loading...