X16-1D

USB Accelerometer

Data Logger

User Manual

Document Revision: Rev B

Firmware Version: 1110

Date: March 22, 2016

Table of Contents

1 Introduction..........................................................................................................................................1

1.1 About This Manual..................................................................................................................1

1.2 Document Conventions............................................................................................................1

1.3 Appendix..................................................................................................................................1

1.4 Product Summary.....................................................................................................................2

1.5 Feature List..............................................................................................................................2

1.6 Items Included with X16-1D...................................................................................................3

1.6.1 Single Unit Purchase..........................................................................................................3

1.6.2 5 Unit Kit...........................................................................................................................3

1.7 Component Names...................................................................................................................4

1.8 Quick Start Guide....................................................................................................................5

2 Operation..............................................................................................................................................8

2.1 USB Interface...........................................................................................................................8

2.2 Memory Card...........................................................................................................................8

2.3 Battery......................................................................................................................................8

2.4 Setting The RTC.......................................................................................................................9

2.5 Status Indicators.....................................................................................................................11

2.6 System Configuration Options...............................................................................................11

2.6.1 deadband..........................................................................................................................12

2.6.2 deadbandtimeout..............................................................................................................13

2.6.3 dwell.................................................................................................................................13

2.6.4 microres............................................................................................................................14

2.6.5 rebootondisconnect..........................................................................................................14

2.6.6 samplesperfile..................................................................................................................14

2.6.7 samplerate........................................................................................................................14

2.6.8 starttime and stoptime......................................................................................................14

2.6.9 stoponvusb.......................................................................................................................15

2.6.10 statusindicators.................................................................................................................15

2.7 Example Configuration Files.................................................................................................15

2.7.1 Example A........................................................................................................................15

2.7.2 Example B........................................................................................................................15

2.7.3 Example C........................................................................................................................16

3 Data Interpretation.............................................................................................................................16

3.1 Data Files...............................................................................................................................16

3.2 Data Format...........................................................................................................................17

3.3 Data Conversion.....................................................................................................................18

4 System Details...................................................................................................................................18

4.1 Sensor.....................................................................................................................................18

4.1.1 Sensor Special Features...................................................................................................19

4.2 Operating and Storage Conditions ........................................................................................20

4.3 Dimensions............................................................................................................................20

5 Troubleshooting.................................................................................................................................21

6 Appendix............................................................................................................................................23

6.1 What is an Accelerometer......................................................................................................23

A

6.2 Using “R” to Analyze Data....................................................................................................25

6.2.1 What is “R”......................................................................................................................25

6.2.2 Introduction to R Commands...........................................................................................26

6.2.3 Online Resources for R....................................................................................................27

6.2.4 Example Scripts in R.......................................................................................................28

Index of Figures

Figure 1: X16-1D Data Logger..................................................................................................................2

Figure 2: X16-1D and Accessories............................................................................................................3

Figure 3: 5 Unit kit of Loggers..................................................................................................................3

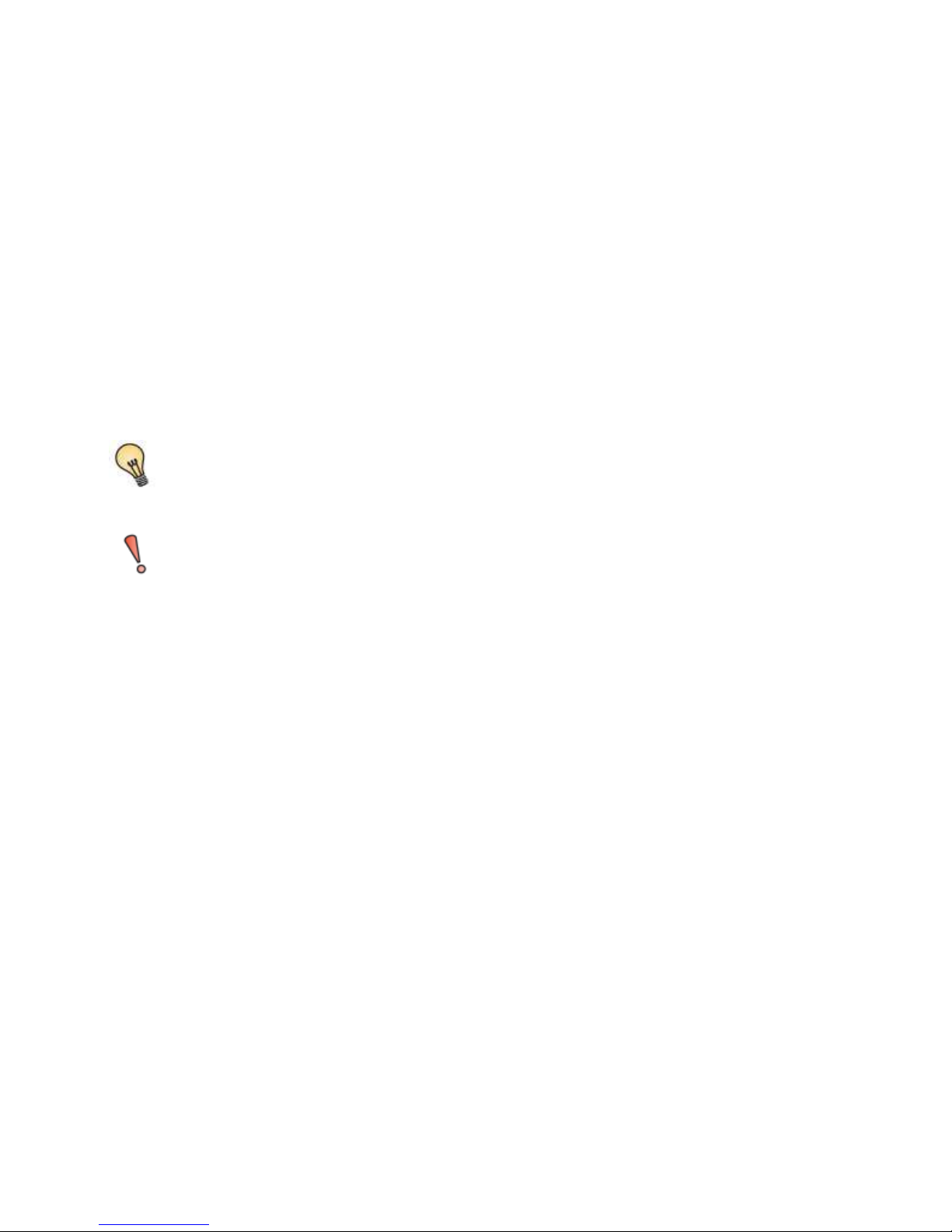

Figure 4: X16-1D Data Logger Components.............................................................................................4

Figure 5: Exploded View of the X16-1D..................................................................................................4

Figure 6: Installing Battery........................................................................................................................5

Figure 7: Connecting to PC........................................................................................................................5

Figure 8: Editing Config.txt File................................................................................................................6

Figure 9: Starting the X16-1D...................................................................................................................7

Figure 10: Sensor Orientation....................................................................................................................7

Figure 11: Expected Battery Life...............................................................................................................9

Figure 12: Example Time Entry in time.txt File.....................................................................................10

Figure 13: LED Status Indicators............................................................................................................11

Figure 14: Graphical Illustration of the Deadband Feature....................................................................13

Figure 15: Graphical Illustration of the Dwell Feature...........................................................................13

Figure 16: Configuration File Example A..............................................................................................15

Figure 17: Configuration File Example B..............................................................................................15

Figure 18: Configuration File Example C..............................................................................................16

Figure 19: Example Data File.................................................................................................................17

Figure 20: 800Hz sample configuration.................................................................................................20

Figure 21: Enclosure Dimensions...........................................................................................................20

Figure 22: Spring-mass Accelerometer...................................................................................................23

Figure 23: Simplified MEMS Accelerometer Design (L) and Actual MEMS Accelerometer (R).........24

Figure 24: R Command Line Interface ..................................................................................................25

Figure 25: RStudio Interface ..................................................................................................................26

Index of Tables

Table 1: Configuration File Tags and Descriptions..................................................................................12

Table 2: Data File Header Tags................................................................................................................17

Table 3: Example Data Conversion.........................................................................................................18

Table 4: Accelerometer Sensor Characteristics........................................................................................19

Table 5: Operating and Storage Conditions.............................................................................................20

B

1 Introduction

1.1 About This Manual

Thank you for purchasing the X16-1D accelerometer data logger. Gulf Coast Data Concepts spent

considerable efforts developing an easy to use data logger for the scientific researcher, student, or

hobbyist. Please read this manual to understand the operation and capabilities of the X16-1D. If the

logger fails to operate as expected, please refer to the troubleshooting guide (page 21).

1.2 Document Conventions

The quick start guide in section 1.8 provides a basic summary of operation to begin using the X16-1D

data logger. This user manual continues into further details of configurations and capabilities starting

in section 2. Each section also presents relevant tips and warnings to help the user.

This icon indicates a helpful tip that may enhance the performance of the logger or aide in

the application of the logger.

This icon indicates a warning, restriction, or limitation that the user should be aware of

regarding the logger operation.

1.3 Appendix

The appendices to this document include several educational discussions regarding accelerometers

(section 6.1) as well as software and analysis procedures (section 6.2). These short discussions will

help new users learn about the X16-1D and how to use the data.

Gulf Coast Data Concepts Page 1 X16-1D, Rev B

1.4 Product Summary

The X16-1D is a low cost and compact self-recording accelerometer data logger. Data from the digital

3-axis accelerometer sensor is time stamped using a real time clock and stored to a microSD card in

simple text format. When connected via the USB to a personal computer, the X16-1D appears as a

standard mass storage device containing the comma delimited data files and the user setup file. The

X16-1D is powered from a replaceable AA type alkaline battery (or LR6).

1.5 Feature List

• 3-axis ±16g accelerometer

• 16-bit resolution

• User selectable sample rate of 12, 25, 50, 100, 200, 400 Hertz

• Finite Impulse Response filter

• Accurate time stamped data using Real Time Clock (RTC)

• Convenient on/off button

• Data recorded to a removable microSD card (8GB included)

• Easily readable comma separated text data files

• Data transfer compatible with Windows or Linux via Universal Serial Bus (USB) interface (no

special software required)

• Uses a standard replaceable “AA” type alkaline battery

• Weight 2oz (55g) with alkaline battery

• Size 1x1x4.1 inch (26x26x104 mm)

Gulf Coast Data Concepts Page 2 X16-1D, Rev B

Figure 1: X16-1D Data Logger

1.6 Items Included with X16-1D

1.6.1 Single Unit Purchase

The X16-1D is packaged with the logger, a USB extender cable, a screwdriver, and an AA

alkaline battery.

Figure 2: X16-1D and Accessories

1.6.2 5 Unit Kit

A kit includes 5 X16-1D loggers, a USB extender cable, and a screwdriver. Batteries are not

included with kits.

Figure 3: 5 Unit kit of Loggers

Gulf Coast Data Concepts Page 3 X16-1D, Rev B

1.7 Component Names

0.75" Length

#6-32 Machine Screw

PCB Enclosure

(Top)

PCB Enclosure

(Cap)

Printed Circuit Board

PCB Enclosure

(Bottom)

#6-32 Hex Nut

M

I

D

K

H

N

A

F

L

B

O

C

Figure 4: X16-1D Data Logger Components

A Type-A USB connector I Enclosure top

B Blue LED status indicator J Enclosure bottom

C Red LED data indicator K Enclosure cap

D AA Battery holder L Enclosure hinge

E Positive terminal M #6-32 3/4” screw

F Negative terminal N #6 nut

G On/Off button O ADXL345 sensor

E

G

J

H MicroSD card (under circuit board)

Figure 5: Exploded View of the X16-1D

Gulf Coast Data Concepts Page 4 X16-1D, Rev B

1.8 Quick Start Guide

The X16-1D is a simple, economical solution to capture continuous motion data and quickly deliver the

information for analysis. The following instructions outline the steps to begin using the X16-1D.

Configuration settings and mounting methods will depend on the particular application.

Step 1: Disassemble the enclosure by unscrewing the #6 machine screw and opening the parts

like a clam shell. Place an AA type battery into the battery holder with the positive

battery terminal facing away from the USB connector. Reassemble the enclosure.

Figure 6: Installing Battery

Step 2: Plug the X16-1D into a computer and allow the computer operating system to register

the device as a Mass Storage Device. Notice that the logger will mount with a drive

label using the last digits of the serial number.

Gulf Coast Data Concepts Page 5 X16-1D, Rev B

Figure 7: Connecting to PC

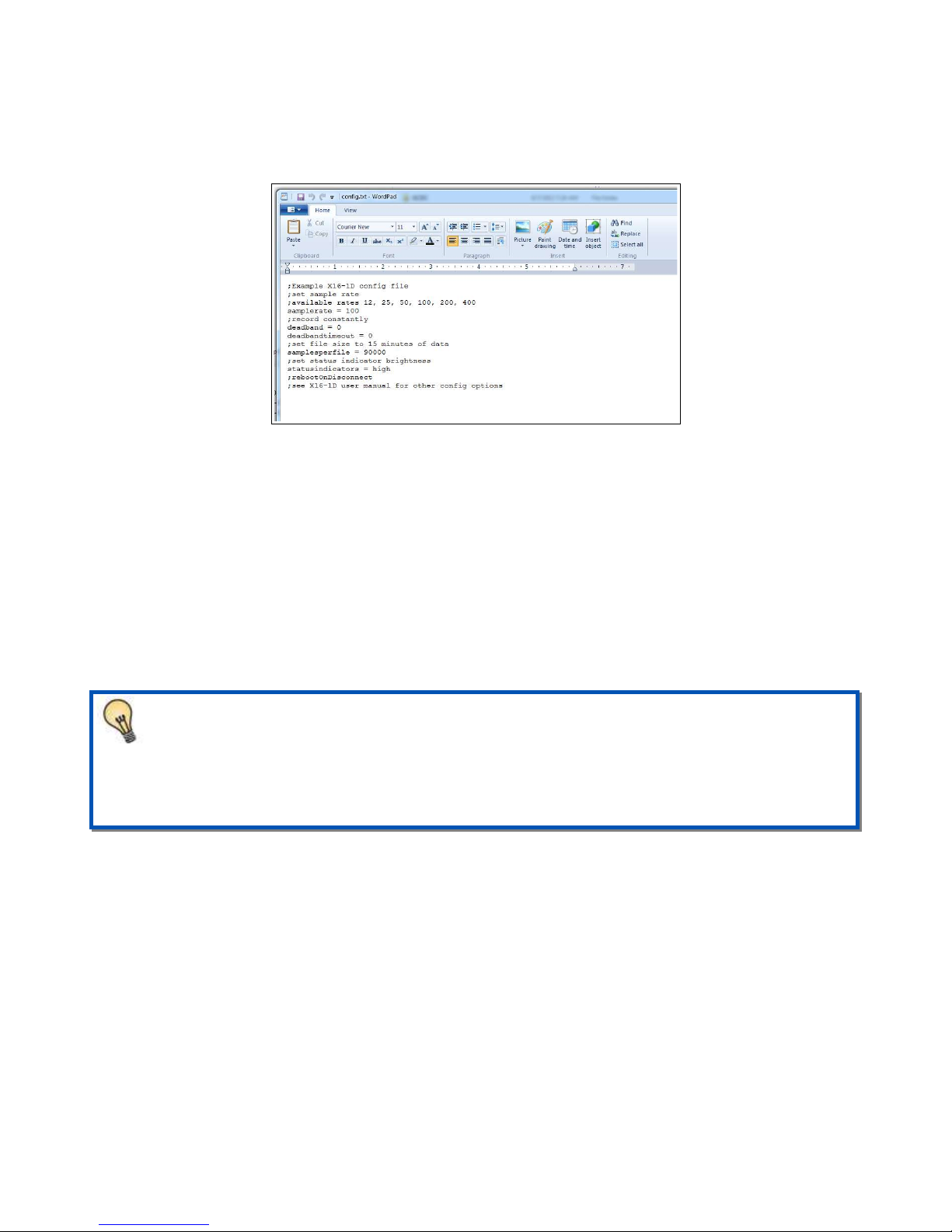

Step 3: Configure the X16-1D by editing the appropriate tags in the config.txt file using a

simple text editor. In Windows, do not use Notepad as the editor does not terminate new

lines properly. GCDC recommends Windows Wordpad or Notepad++ to edit the

config.txt file. Refer to section 2.6 for a complete list of configuration options.

Figure 8: Editing Config.txt File

Step 4: If necessary, initialize the RTC clock by creating a time.txt file (see section 2.4). Once

the time.txt file is saved, immediately unplug the logger to start the initialization

process. The logger will load the time.txt file, initialize the clock, and delete the time.txt

file. Initializing the RTC ensures the data files include the correct year, month, and day

and that the data samples can be correlated to a specific date and time.

Step 5: After removing from the USB port, attach the X16-1D logger to the target object. The

logger is small and light weight so double-sided tape, Velcro, or a spot of cyanoacrylate

glue are sufficient methods of attachment.

The X16-1D is small and light weight so attachment methods do not need to be

substantial. Double-sided tape, a spot of cyanoacrylate glue (contact cement), zip-ties,

magnetic base, or adhesive putty are example methods of attachment. These methods do

not cause adverse signal attenuation considering the relatively low frequency bandwidth

of the X16-1D logger. Command Poster Adhesive strips by 3M offer excellent temporary

attachment of the logger to most surfaces.

Step 6: Press the on/off button located at the rear of the enclosure to initiate data recording, (see

Figure 9). Logging will start about 3-5 seconds after pressing the button. The red LED

will blink as the configuration file is accessed. If the time.txt file is present, the RTC is

initialized with the time written in the file. Then, the blue LED will begin to blink at a 1

second interval indicating the system is operating. The red LED will blink periodically

as data is written to the microSD card.

Gulf Coast Data Concepts Page 6 X16-1D, Rev B

Figure 9: Starting the X16-1D

Step 7: To stop recording, press and hold the button for about 3 seconds. The red and blue

LEDs will begin to blink rapidly for 2 seconds and then turn off. Release the button and

the X16-1D turns off. Pressing the button again restarts the logger and data is recorded

to a new file.

Step 8: Plug the logger into a PC and allow the logger to mount as a USB drive. The data file

will appear in the “GCDC” directory.

Step 9: The data recorded to the files must be converted to determine acceleration in “g” units.

Divide the Ax, Ay, Az columns by 2048 to determine g units. See section 3.3 for a

complete discussion of data conversion.

Gulf Coast Data Concepts Page 7 X16-1D, Rev B

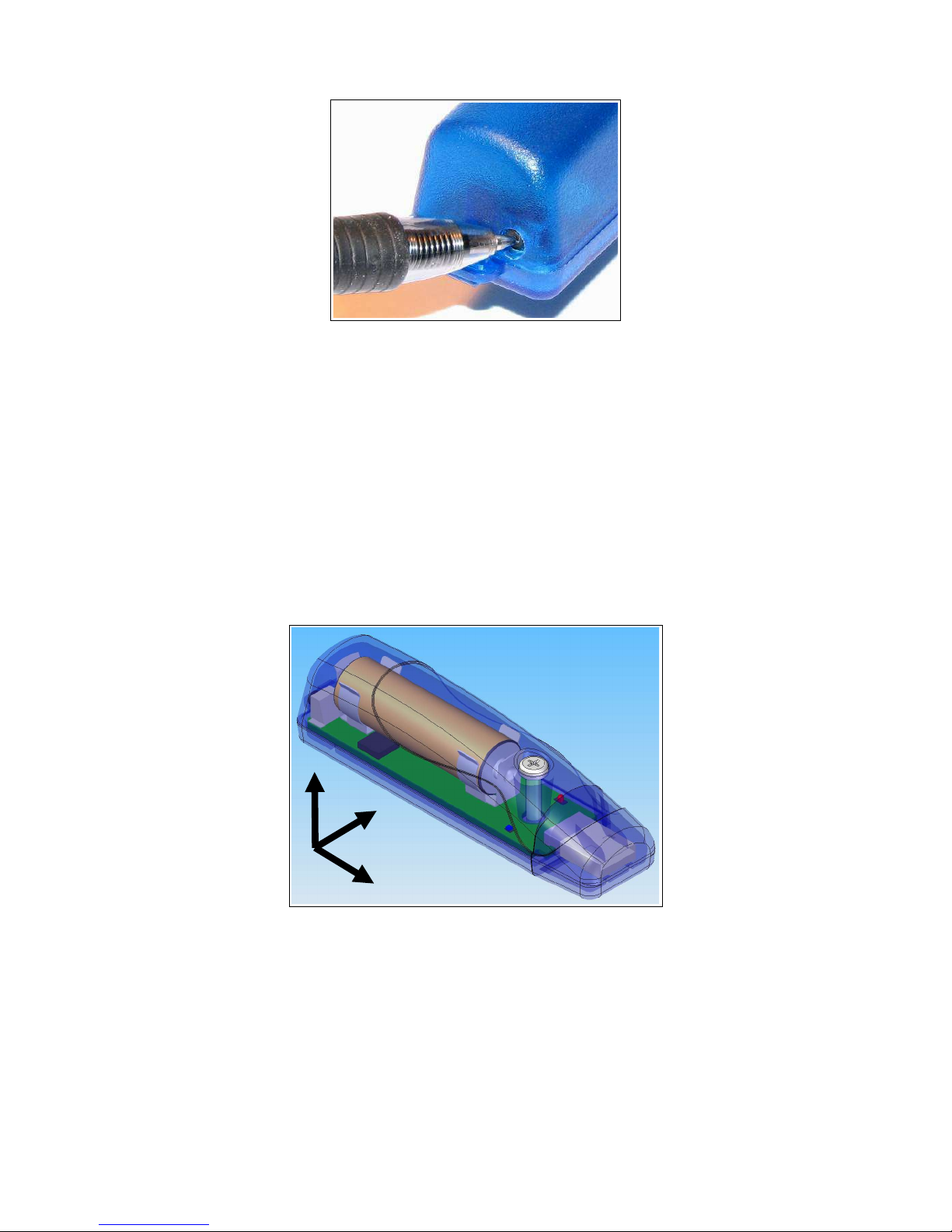

+Z

+Y

+X

Figure 10: Sensor Orientation

2 Operation

2.1 USB Interface

The X16-1D connects to a PC using a standard Type-A USB connector and supports the USB mass

storage device interface for file access and file transfers. Nearly all computer operating systems

recognize the X16-1D as a typical USB external memory drive. When connected to a PC, the X16-1D

deactivates logging and operates only as a USB interface to the microSD card. Note that some tablet

operating systems block access to USB mass storage devices and will not recognize the X16-1D.

2.2 Memory Card

The X16-1D stores data to a removable 8GB microSD flash memory card and is compatible with

microSD and microSDHC type cards. The logger needs only the config.txt file to operate. The X161D will use default configuration settings if the config.txt is not present. The “config.txt” and

“time.txt” files must occur in the root directory (see section 2.6 and section 2.4). The X16-1D will

create a folder called “GCDC”, if not already present, to place the data files.

Interrupting the power to the logger can result in corruption of the microSD card. For

example, removing the logger from the USB port during file transfers to the PC or

removing the battery during logging activity. Reformat the card if it becomes corrupted

(FAT32 file structure). If data transfers to/from the card become slow, consider formatting

the card using “SD Card Formatter” software provided by the SD Association

(www.sdcard.org).

2.3 Battery

The X16-1D is powered by a single “AA” sized battery. Gulf Coast Data Concepts recommends an

alkaline battery (ANSI type 15A or IEC type LR6) or lithium battery (ANSI type 15L or IEC FR6) to

operate the X16-1D. The battery is not used when the device is connected to a computer USB port.

The X16-1D will log constantly for approximately 48 hours at 50 Hz and approximately 28 hours at

100 Hz when using a standard alkaline AA battery. Figure 11 illustrates the expected continuous

logging time versus sample rate.

The RTC continues to operate from the battery when the device is “off”. The RTC should be

reinitialized if the battery is removed or completely depleted (see Section 2.4).

Use a lithium primary AA battery to improve low temperature performance and extend

operating time. The lithium chemistry has a wider operating temperature -40°F – 140°F

(-40°C – 60°C) and about 30% more capacity over a standard alkaline battery.

Gulf Coast Data Concepts Page 8 X16-1D, Rev B

A 5v supply via the USB connector provides extended operation of the device independent

of the internal battery. Common USB power adapters or USB battery packs for consumer

electronics can provide the required 5v supply. The logger does not implement power

saving features when connected to an external power supply so power consumption will

be higher than when using the AA battery.

The logger is always “on” maintaining the real time clock and will eventually discharge the

battery completely after several months. The discharged battery may leak chemicals and

corrode the electronics. Remove the AA battery prior to long term storage of the X16-1D.

The X16-1D is not compatible with NiMH type rechargeable batteries. The NiMH battery

delivers 1.2 volts nominally, which is near the voltage cut-off limit of the logger. The X161D will not operate very long or may activate at all.

2.4 Setting The RTC

A real time clock (RTC) integrated into the X16-1D determines the time for each line of data recorded.

The RTC is initialized using a user-created text file named “time.txt” located in the root directory of the

microSD card. This is a separate file from the config.txt file and it is needed only when initializing the

RTC. The system looks for the time.txt file upon booting. If the file exists, the time stored in the file is

loaded to the RTC and the time.txt file is deleted. The time information in the time.txt file must be in

Gulf Coast Data Concepts Page 9 X16-1D, Rev B

Figure 11: Expected Battery Life

the exact “yyyy-MM-dd HH:mm:ss” 24-hour format, occur on the first line, and end with a newline

character. Figure 12 provides an example time.txt file that will initialize the RTC to 2:26:30 pm June

16, 2014.

The time file method of setting the RTC does not require special communication drivers so it can be

implemented using a simple text editor. Direct initialization of the RTC is possible but requires

specific device drivers and software from Gulf Coast Data Concepts.

The RTC maintains ±50ppm accuracy (-40°C to +85°C), which means that the accuracy may drift

about 4 seconds every day. The RTC is powered by the battery at all times, even when the logger is

“off”.

Figure 12: Example Time Entry in time.txt File

Initializing the RTC ensures that the start time and individual time stamps can be

correlated to an absolute time – the year, month, day, hour, minute, second, and fractional

second. An uninitialized RTC or reset of the RTC will lead to indeterminate start time

recorded in the data file header.

After unplugging the logger from the USB port, the logger will load the config.txt file and

time.txt file, if present. Therefore, there is a delay between when the time.txt was created

and when the logger actually loads the time information. For most applications, this simple

method of initializing the clock results in sufficient accuracy.

Initialization of the RTC is limited to +/-1 second. The RTC register that handles the

fractional seconds counter is not accessible so the initialization process can not reset the

seconds to an even value.

Gulf Coast Data Concepts Page 10 X16-1D, Rev B

2.5 Status Indicators

System status is indicated by the two LEDs located near the USB connector. The blue LED indicates

system operation and blinks once per second to indicate a properly operating system. The blue LED

blinks when the X16-1D is recording data, in standby mode, or is connected to a computer via the USB

port. The red LED blinks when data is written or read from the microSD memory card. In data

logging mode, the period at which the red LED blinks depends on the sample rate and other

configuration settings. The LEDs will flicker during user initiated shutdown. The “statusindicators”

tag in the configuration file turns off or changes the brightness of the status indicators (see section

3.2.4.10).

Figure 13: LED Status Indicators

2.6 System Configuration Options

The X16-1D is configured using a set of tags and settings stored in a text file named “config.txt”,

which is located in the root directory of the microSD card. The system reads the configuration file at

boot time. Table 1 lists the configuration file tags. A tag is followed by an equal sign (“=”) and an

applicable tag setting. A line finishes with a newline character. Tags are not case sensitive. Tab and

space characters are ignored. Lines starting with a semicolon (“;”) are treated as comments and

ignored by the system. The system will use the default settings listed in Table 1 if the config.txt file is

not found.

Do not use the Windows Notepad editor because it does not terminate new lines properly.

GCDC recommends Windows Wordpad or Notepad++ to edit the config.txt file.

Gulf Coast Data Concepts Page 11 X16-1D, Rev B

Table 1: Configuration File Tags and Descriptions

Tag Valid Settings Default Description

deadband An integer between

0 and 16384

deadbandtimeout An integer between

0 and 65535

dwell An integer between

0 and 65535

microres - Off The presence of this tag sets the device to record

rebootondisconnect - off on disconnect The presence of this tag causes the system to start

samplesperfile An integer greater

than 0

samplerate 12, 25, 50, 100,

200, 400

starttime and stoptime See section 2.6.8 - Defines when to start and stop recording

stoponvusb - Off Stops data logging if 5v USB power is present (see

statusindicators “Normal”, “High”,

“Off”

0 Sets the deadband to a range expressed in “counts”.

A new sample is recorded if any sensor axis

exceeds the previous recorded reading by the

deadband value

3 Specifies the period in seconds when a sample is

recorded regardless of the deadband setting. This

feature ensures periodic data is recorded during

very long periods of inactivity.

1 The number of samples recorded after a deadband

threshold triggered event

time stamps with 0.1ms effective precision.

recording after disconnect from a USB port.

90000 The number of lines of data per data file before a

new file is created

100 Sets the rate at which data is collected and recorded

to the microSD card.

section 2.6.9)

Normal LED status indicators can be activated with normal

brightness (Normal), activated with high brightness

(High), or completely deactivated (Off).

2.6.1 deadband

“deadband” defines the minimum difference between recorded sensor readings. A new sample from

the accelerometer sensor must exceed the previous recorded reading before the logger records the data.

The deadband setting is expressed in "counts" units and is applied to the output of each axis. The

deadband value can be set to an integer between 0 and 32767. The deadband function is an effective

way to reduce the amount of data collected by defining the granularity of the data.

The deadband functions as a event threshold limit when used in conjunction with the “dwell” feature.

Figure 14 illustrates the deadband feature filtering out small changes in acceleration from the recorded

data. Only when the deadband limit is exceeded will a new data sample be pushed to the file. Note

that this feature will result in samples with inconsistent time periods. Therefore, the data sets should be

re-sampled to establish uniform time periods.

Gulf Coast Data Concepts Page 12 X16-1D, Rev B

Figure 14: Graphical Illustration of the Deadband Feature

2.6.2 deadbandtimeout

“deadbandtimeout” defines the period in seconds when a sample is recorded by the logger regardless of

the deadband setting. This feature ensures periodic data is recorded during extended periods of

inactivity. A valid setting for the deadbandtimeout is an integer between 0 and 16384.

2.6.3 dwell

Use “dwell” together with “deadband” to create an event trigger configuraion. The “dwell” tag defines

the number of consecutive samples recorded at the set sample rate after a deadband threshold event.

The deadband threshold event occurs when a sensor reading exceeds the last recorded value by the

deadband setting. A valid dwell setting is an integer between 0 and 65535. See section 2.7.2 for an

example implementation of the deadband/dwell features.

Figure 15: Graphical Illustration of the Dwell Feature

Gulf Coast Data Concepts Page 13 X16-1D, Rev B

2.6.4 microres

The “microres” option sets the device to record time stamps with 0.1ms precision. In micro-resolution

mode, the time stamps are recorded as XX.YYYYZZ where XX are seconds, YYYY are 0.1

milliseconds, and ZZ are spurious digits beyond the precision capability. The micro-resolution option

should be implemented at sample rates greater than 200 hertz to provide the best timing precision.

Micro-resolution is best suited for applications requiring precise timing, such as vibration

analysis, and is recommended for sample rates above 200 Hz. The standard timing

precision (default) of 1 milli-second is suitable for most general applications, such as

monitoring human motion.

2.6.5 rebootondisconnect

The X16-1D incorporates an on/off button for initiating and terminating the data recording process.

Data recording is automatically started upon disconnect from a computer USB port if the tag word

“rebootondisconnect” is included in the configuration file.

2.6.6 samplesperfile

“samplesperfile” defines the number of data lines each file can have before a new file is created. This

tag controls the size of the data files into easily manageable lengths for later processing. This setting is

loaded as a signed 32-bit integer, which can translate into very large data files. The user should

exercise caution before setting large files and test the end-user software application for data limitations.

2.6.7 samplerate

The “samplerate” tag defines the data rate in Hertz, or samples per second. Valid sample rate settings

are 12, 25, 50, 100, 200, and 400 Hz. See section 4.1 for special features regarding the sample rates.

2.6.8 starttime and stoptime

The X16-1D starts and stops data recording based on the times defined using the “starttime” and

“stoptime” tags. The times must be in “MM HH DD” 24-hr format with the three entries separated by

a space. Entries marked with “*” operate as a wild card. The X16-1D continues to record after the

start time unless defined otherwise by the stoptime tag. Note that the configuration option does not

include the month. Example timing configurations:

Example 1: On the 15th day, start recording at 12:30pm and

stop recording at 6:00pm.

starttime = 30 12 15

stoptime = 00 18 15

Example 2: Start recording at the beginning of every hour

and stop recording 45 minutes later.

starttime = 00 *

stoptime = 45 *

Gulf Coast Data Concepts Page 14 X16-1D, Rev B

2.6.9 stoponvusb

The “stoponvusb” tag stops data logging operations when a 5v supply is detected on the USB

connector. Without the stoponvusb option (default), the device switches power from the internal

battery to the USB 5v and continues to log data.

2.6.10 statusindicators

The brightness intensity of the LED status indicators is defined using the “statusindicators” tag and

valid settings of “normal”, “high”, and “off”.

2.7 Example Configuration Files

2.7.1 Example A

The following configuration records data at 100 hertz. Deadband and deadbandtimeout are set to zero

so the logger will record constantly at the set sample rate. Each data file is 90,000 lines long, which is

15 minutes of data. The status indicators are set to high brightness. The logger is activated with the

on/off button (notice “rebootondisconnect” is not active).

;Example X16-1D config file

;set sample rate

;available rates 12, 25, 50, 100, 200, 400

samplerate = 100

;record constantly

deadband = 0

deadbandtimeout = 0

;set file size to 15 minutes of data

samplesperfile = 90000

;set status indicator brightness

statusindicators = high

;rebootOnDisconnect

;see X16-1D user manual for other config options

Figure 16: Configuration File Example A

2.7.2 Example B

The deadband and dwell settings configure the device to record at least 5 seconds of data when a

change greater than 0.1g is detected. The deadbandtimeout setting forces a sample write every hour.

; Example X16-1D Config file

; set to 25Hz

samplerate = 25

; trigger at 0.1g

deadband = 100

; record 5 seconds of data

dwell = 125

;force a write every hour

deadbandtimeout = 3600

; set file length

samplesperfile = 30000

; LEDs on

statusindicators = normal

Figure 17: Configuration File Example B

Gulf Coast Data Concepts Page 15 X16-1D, Rev B

2.7.3 Example C

The logger must be turned on with the on/off button. It will enter a standby mode (blue LED blinks)

while it waits for the start time. The logger will start recording at 10:30am and turn off at 2:00pm. The

logger will record constantly at 400Hz and create 51 data files in the 3.5 hours. The micro-resolution is

activated to provide the best timing precision at the 400 Hz sample rate.

; Example X16-1D Config file

; set to 400Hz

samplerate = 400

; activate precision timing

microres

; record constantly

deadband = 0

deadbandtimeout = 0

; set file length

samplesperfile = 100000

; set logger to turn on with clock

starttime = 30 10

stoptime = 00 14

; LEDs on

statusindicators = normal

Figure 18: Configuration File Example C

3 Data Interpretation

3.1 Data Files

The X16-1D creates a new data file when the system is booted or when the maximum number of data

lines is reached in the previous data file. A system boot condition occurs when the on/off button is

pressed, 5v power is restored to the system via the USB connector, or when the X16-1D is removed

from a computer USB port with the “rebootondisconnect” feature enabled. Data files are placed in a

folder named “GCDC” and are named data-XXX.csv, where XXX is a sequential number starting with

001. The system will create up to 999 files. At the beginning of each file, a header is written

describing the system configuration and the current time when the file was created. Figure 19

represents an example data file.

A short gap in data may occur between sequential files as data is purged from the cache

and a new file is allocated on the microSD card.

Gulf Coast Data Concepts Page 16 X16-1D, Rev B

;Title, http://www.gcdataconcepts.com, x16-1d, ADXL345

;Version, 1110, Build date, Dec 30 2015, SN:CCDC4016131F31B

;Start_time, 2016-01-04, 10:25:14.000

;Temperature, -999.00, deg C, Vbat, 1444, mv

;SampleRate, 100,Hz

;Deadband, 0, counts

;DeadbandTimeout, 0,sec

;Headers, time,Ax,Ay,Az

0.003,799,650,-1773

0.013,805,661,-1808

0.023,766,687,-1844

0.033,790,670,-1818

0.042,801,663,-1808

0.052,769,657,-1786

0.062,790,683,-1795

0.072,813,719,-1853

0.081,824,670,-1784

Figure 19: Example Data File

3.2 Data Format

Data is written to files in comma separated text format starting with the file header information and

followed by event data entries. Table 2 lists the valid header tags, although not all tags may occur in

the header. Each data line contains a time entry and the raw accelerometer sensor readings from the X,

Y, and Z axes. The time entry is seconds elapsed from the start time recorded in the header. Add the

elapsed time to the start time to determine the complete date and time of the sample.

The last line of the final data file records the reason for the termination, such as “shutdown: switched

off”, “shutdown: low battery”, “shutdown: max files exceeded”, “shutdown: vbus disconnect”, or

“connected to computer”. The line is designated as a comment with a semicolon (“;”).

Table 2: Data File Header Tags

Tag Description

Deadband A new sample from the sensor must exceed the last reading by the

deadband value

DeadbandTimeout The period in seconds when a sample is recorded regardless of the

deadband setting

Headers The names of each column of data in the file

SampleRate Rate at which data is recorded to the microSD card

Start_Time The current time when the data file was created

Temperature Not supported on X16-1D, reports -999

Title The name of the USB Accelerometer X16-1D unit and sensor type

Vbat Battery voltage measured at the file start time

Version The version control information of the firmware, including unique

serial number

Gulf Coast Data Concepts Page 17 X16-1D, Rev B

3.3 Data Conversion

The X16-1D records the raw digital data from the accelerometer sensor. This helps reduce processor

load, increase sample rate capability, and avoids data errors due to floating point calculations. The 16bit data, or 65536 discreet counts, covers the full range of the +/-16g sensor. Therefore, the conversion

factor is 65536 / 32 = 2048 counts/g.

Table 3 lists the converted data using the example raw data in Figure 19.

Table 3: Example Data Conversion

Raw Data (Low Gain) Converted Data

Time Ax Ay Az Time Ax (g) Ay (g) Az (g)

0.003 799 650 -1773 01/04/2016 10:25:14.003 0.390137 0.317383 -0.865723

0.013 805 661 -1808 01/04/2016 10:25:14.013 0.393066 0.322754 -0.882813

0.023 766 687 -1844 01/04/2016 10:25:14.023 0.374023 0.335449 -0.900391

0.033 790 670 -1818 01/04/2016 10:25:14.033 0.385742 0.327148 -0.887695

0.042 801 663 -1808 01/04/2016 10:25:14.042 0.391113 0.323730 -0.882813

0.052 769 657 -1786 01/04/2016 10:25:14.052 0.375488 0.320801 -0.872070

0.062 790 683 -1795 01/04/2016 10:25:14.062 0.385742 0.333496 -0.876465

0.072 813 719 -1853 01/04/2016 10:25:14.072 0.396973 0.351074 -0.904785

0.081 824 670 -1784 01/04/2016 10:25:14.081 0.402344 0.327148 -0.871094

To determine acceleration in g's, divide the raw data by 2048. A “g” is 32.174 ft/sec2 or

9.807 m/sec2.

4 System Details

4.1 Sensor

The X16-1D uses the Analog Devices ADXL345 3-axis digital accelerometer sensor, which is based on

micro-electro machined semiconductor technology (MEMS). This accelerometer sensor is similar to

those used in cellphones, laptops, hard drives and other consumer electronics. Appendix 6.1 describes

how a MEMS accelerometer sensor works. Table 4 lists the basic sensor and logger performance

parameters but refer to Analog Devices for detailed sensor specifications.

Gulf Coast Data Concepts Page 18 X16-1D, Rev B

Table 4: Accelerometer Sensor Characteristics

Parameter Condition Min Typical Max Units

Acceleration range ±16.0 g

Sensitivity 2048 count/g

Sensitivity Deviation ±1.0 %

Nonlinearity X, Y, Z axis ±0.5 %FS

Zero-g Offset Level

Accuracy

Inter-Axis Alignment Error

Cross-Axis Sensitivity

X, Y axis -150 +150 mg

Z axis -250 +250 mg

±0.1 Degrees

±1 %

The ADXL345 accelerometer sensor “pushes” data to the logger at selected rates based on a clock

internal to the sensor. The sensor's clock precision and drift are undefined. For example, a selected

sample rate of 50 Hz may actually push data at 52 Hz. The X16-1D incorporates a precise real time

clock to independently time stamp the data as it leaves the sensor and to ensure that accurate timing is

recorded to the data file. Therefore, the time stamps should be used as the reference for determining

the actual sample rates.

The accelerometer sensor is based on microelectromechanical systems (MEMS)

technology and is not affected by magnetic fields. Glue a magnet to the bottom of the

plastic enclosure to facilitate easy attachment to iron surfaces.

The MEMS accelerometer sensor will detect the acceleration of gravity, which is a

convenient feature for validating the sensor operation. Setting the logger on a flat level

surface will result in -2048 counts (-1g) in the z-axis.

4.1.1 Sensor Special Features

The X16-1D implements an 8X over-sample and finite impulse response (FIR) filter algorithm at

sample rates up to 400Hz. This means that the digital accelerometer sensor provides 8X the sample

rate requested in the config.txt file. For example, “samplerate=400” sets the sensor to stream at 3200

Hz, which is the maximum capability of the ADXL345. The eight samples are averaged and processed

through the FIR filter to improve the response characteristics. The oversampling and FIR algorithm

increases the sensor's native 13-bit resolution to the 16-bit data recorded in the data file.

The X16-1D will support sample rates of 800, 1600, and 3200 Hz but the X16-1D deactivates the

oversampling and FIR filter and records the native 13-bit resolution from the sensor. However, these

sample rates are not guaranteed and the time stamps may become inaccurate or the logger operation

could become unstable. Performance is dependent on the microSD card capability.

Figure 20 shows an example configuration setting the logger to record at 800 Hz. The 13-bit data from

the sensor is right padded (LSB) into a 16-bit value to maintain consistency with the oversampled data.

Therefore, the conversion factor is still 2048 counts/g.

Gulf Coast Data Concepts Page 19 X16-1D, Rev B

; Example X16-1D Config file

1.01

1.04

4.10

; set to 800Hz

samplerate = 800

; record constantly

deadband = 0

deadbandtimeout = 0

; set file length

samplesperfile = 100000

; set logger to turn on with clock

statusindicators = normal

Figure 20: 800Hz sample configuration

4.2 Operating and Storage Conditions

The X16-1D is protected from general handling conditions by the plastic enclosure but is not protected

from adverse environmental conditions, such as rain, sweat, splashes, and water submersion. The

temperature range is limited primarily by the AA battery capabilities.

Table 5: Operating and Storage Conditions

Parameter Value

Temperature Range (alkaline battery) -0°F ~ 130°F (-18°C ~ 55°C)

Relative Humidity (alkaline battery) <90%

4.3 Dimensions

The X16-1D electronics are enclosed in a three-part semi-transparent blue plastic enclosure. The top

and bottom enclosure components and the printed circuit board are secured together with a 0.75” long

#6-32 screw and nut. A slip-on cap protects the USB connector. The X16-1D weighs 2oz (55g) with an

alkaline battery.

Gulf Coast Data Concepts Page 20 X16-1D, Rev B

Figure 21: Enclosure Dimensions

5 Troubleshooting

Problem Resolution

I press the on/off button but the logger does not

appear to activate and no LEDs blink.

I press the on/off button, the blue LED blinks

once per second but the red LED does not indicate

logging.

The blue LED blinks slowly. The microSD card is not present or is corrupted.

I press the on/off button but the logger records

only for a short period of time.

The logger seems to ignore the config.txt file and

use default settings.

Install a new battery.

The logger could be operating correctly but the

status indicators are turned off. Check the

“statusindicator” option in the config.txt file.

The deadband setting is set too high and the

logger is waiting to detect an event.

The logger is in standby mode waiting for a start

time to occur. Check the config.txt file for the

start/stop settings.

Check that the card is inserted properly and the

card is not corrupted.

Install a new battery.

The microSD card is full and data files must be

deleted.

Check that the config.txt file is properly formatted

and not corrupted. Each setting should occur on a

separate line.

The blue LED blinks irregularly and/or the red

LED stays lit. The logger will not mount to a PC.

Some IT organizations implement an automatic

encryption of all removable media devices. This

will encrypt the config.txt file and the logger will

not be able to access the file. Do not allow

encryption of the device.

The logger is unstable due to a configuration

problem. Remove the microSD card and use a

card reader to access the config.txt file. Edit the

config.txt file such that samplerate is 400 Hz or

less. Re-install the microSD card. Pull and

replace the battery to reset the system. Press the

on/off button and the logger will return to normal

operation.

Gulf Coast Data Concepts Page 21 X16-1D, Rev B

Problem Resolution

I plug the logger into a USB port but the PC does

not indicate an external drive present.

The microSD card is not present in the logger or

is not inserted properly. Remove and reinsert the

card to ensure that the card is correctly seated into

the card holder.

The microSD card is corrupted or damaged.

Reformat the card or replace the card.

The on/off button could be jammed in the plastic

enclosure and the logger is stuck in the “off” state.

Check that the button moves freely and “clicks”

when pressed.

The USB connection could be faulty or the

extender cable (if present) could be faulty.

Remove the extender cable and plug the logger

into another USB port.

The start time in the data file header is incorrect. Initialize the RTC.

The Z-axis data is missing in the file. No, it's present but the column headers are shifted

due to the presence of the “headers” tag.

The logger is stationary but it registers 1g. This is normal and indicates Earth's gravity is

fully operational and stable.

But the logger actually registers something other

than 1g when stationary.

The sensor will exhibit a slight offset error. Add

or subtract the appropriate amount to correct the

error. A 3-axis tumble calibration test is the best

method to determine the sensor offset error. The

errors are particular to the sensor and are normally

consistent throughout all data sets.

Gulf Coast Data Concepts Page 22 X16-1D, Rev B

6 Appendix

Acceleration

(gravity)

Spring

Proof

Mass

X = displacement

Force = −K × X

where : k= spring constant

x= displacement

6.1 What is an Accelerometer

Acceleration is the change in velocity. A stationary body has no acceleration and a body moving at a

constant velocity has no acceleration. However, a body changing from a stationary condition to motion

experiences acceleration by means of a force. Newton's second law establishes this relationship as

F=ma.

An accelerometer [ak-se-lə-ˈrä-mə-tər] sensor measures the force acting on a known mass to determine

“proper” acceleration. There are many ways to measure force with each method having benefits and

limitations. A simple method measures the displacement of a spring-mass system (see Figure 22). As a

force acts upon the mass, such as gravity, the spring will stretch a certain distance relative to the spring

constant. Knowing the spring constant and spring displacement, the force acting upon the mass is

calculated. Acceleration is the force divided by the mass.

Figure 22: Spring-mass Accelerometer

Micro electro machined sensor (MEMS) technology takes the spring-mass concept and miniaturizes it

onto a semiconductor chip. Figure 23 illustrates the general concept of a MEMS accelerometer system

and Error: Reference source not found shows the internal layout of an actual MEMS accelerometer

sensor. The mass and spring system is etched into the semiconductor layer. When the sensor

experiences an acceleration, the proof mass moves and the distance between the interleaving “fingers”

changes. The change in electrical capacitance between the fingers is proportional to the displacement

of the spring-mass system. The capacitance is measured, filtered, and converted to a digital output

representing acceleration.

Gulf Coast Data Concepts Page 23 X16-1D, Rev B

Figure 23: Simplified MEMS Accelerometer Design (L) and Actual MEMS

Proof

Mass

Springs

Position

Sensing

Fingers

Axis

(Direction of Motion)

Accelerometer (R)

Accelerometer sensors exhibit several types of limitations, including offset error, drift error, sensitivity

error, and noise. Offset and sensitivity errors are corrected by calibrating the sensor against known

accelerations. Drift errors are typically related to temperature changes but can be minimized by

maintaining a consistent environment temperature. Noise is the random variations introduced into the

sensor system. Oversampling algorithms and signal filters minimize the effects of sensor noise. Each

of these sensor errors affect how the data is processed into a usable result. For example, integrating

acceleration to determine displacement is heavily skewed due to the drift and noise characteristics of

the sensor.

Accelerometer sensors detect translation motion within the axis of the proof-mass. Rotational motion

causes centripetal acceleration that is interpreted as translational motion by the accelerometer. For

example, spinning about the z-axis will cause acceleration in the x/y axes even though there is no

translational motion in the x/y plane. A gyroscope sensor, which measures rotational velocity about an

axis, is needed to discern rotational motion from translational motion. An accelerometer sensor and

gyroscope sensor are required to determine the six variables of 3D motion. This combination of

sensors is considered an inertial measurement unit (IMU) system. Some IMU systems include an

additional magnetometer sensor (compass) and GPS to further aid the calculations of motion.

Gulf Coast Data Concepts Page 24 X16-1D, Rev B

6.2 Using “R” to Analyze Data

6.2.1 What is “R”

You collected a data set using a GCDC logger and realized, “Wow, that's a lot

of data! Now what?”. Data analysis is tedious and the process is particular to

each user's application. Don't expect to find a magic software solution that

will reduce your data into your perfect answer. However, don't despair.

There are several options available, combined with a little bit of user effort,

that provide powerful and versatile analysis capabilities.

Spreadsheets, such as Microsoft Excel or OpenOffice Calc, are great choices for plotting moderately

sized data sets. The user interfaces are highly polished and customized plotting is easy to handle.

Although, most spreadsheets can handle only about 100,000 lines of data before performance begins to

slow. Furthermore, scripting complex analysis procedures in a spreadsheet is cumbersome. We

recommend trying “R” because it is more powerful than a spreadsheet and it is easy to learn.

“R” is a high-level programming language used most commonly for statistical analysis of data. R is

based on the “S” language, which was developed by the Bell Laboratories in the 1970s. R provides a

simple workspace environment that can manipulate large data sets using simple math commands and

complex function libraries. R is widely used by statisticians and data miners and the language is well

supported by the open source community. The software is compact, free, and available for Windows,

Mac, and Linux (visit www.r-project.org).

Matlab is another common software application for analyzing data but it is usually reserved to

universities or businesses with copious budgets (it's expensive software!). Octave is a free open source

adaptation of Matlab with nearly the same capabilities. Although, Octave is a significantly larger

download and more complicated installation than R. We favor R because it's small, easy to learn, and

free.

Figure 24: R Command Line Interface

Gulf Coast Data Concepts Page 25 X16-1D, Rev B

R is implemented from a command line interface as seen in Figure 24. If you are an experienced

programmer, you may even cringe at some of the constructs used in R. Don't worry, it just works.

User input occurs at the “>” prompt and the R interpreter responds with the results. A single result is

preceded by a [1] to indicate the response number. The “;” character is used to add comment

information that the R interpreter ignores.

The R workspace includes a single command line interface window and a separate graphics window for

displaying plots. “RStudio” is free software package that provides a more versatile interface to the R

interpreter. RStudio is available at www.rstudio.com

Figure 25: RStudio Interface

6.2.2 Introduction to R Commands

R recognizes basic math operators, such as +,-,*, and /. Assignments are made using “<-”. For

example:

> 2+2

[1] 4

> a<-2+2 ;assign “a” the result of 2+2

> a

[1] 4

In the above example, 'a' was assigned the value '4' and can be used later. R works with vectors and

matrices as well.

> b<-c(1,2,3) ;”c” is a function call that creates a vector

> b

[1] 1 2 3

> a*b

[1] 4 8 12

Gulf Coast Data Concepts Page 26 X16-1D, Rev B

More complex math steps are handled in separate functions or external scripts.

> fun<-function(a,b){

+ c<-a+b ; the “+” indicates the user input wrapped into next line

+ return(c)

+ }

> fun(2,2)

[1] 4

R will read a data file from the X16-1D data logger using the “read.table” function.

> data<-read.table(“d:\\GCDC\\data-001.csv”, sep=”,”,comment=”;”, fill=TRUE)

“data” is a matrix of 4 columns containing the time, Ax,Ay,Az values from the file. Values within the

matrix are accessed as follows:

> data[100,2] ;row 100, column 2

[1] 101

> a*data[100,2]

[1] 404

The raw data is converted and assigned to new vectors.

> dataX_g<-data[,2]/2048 ;convert the x-axis to g and assign to new vector

> dataY_g<-data[,3]/2048

> dataZ_g<-data[,4]/2048

Now, the acceleration in g's is plotted against the elapsed time.

> plot(data[,1], dataX_g, type=”l”) ; create a line plot of x-axis values

> lines(data[,1], dataY_g, type=”l”, col=”blue”) ; add another line to plot

The converted data can be combined into a new matrix and then exported to a new csv data file.

> output<-array(c(data[,1],dataX_g, dataY_g, dataZ_g), dim=c(length(data[,1]),4))

> write.table(output, “c:\\output_data.csv”, sep=”,”)

An analysis can be automated by saving the commands into an external text file. Use “source” to call

the file and R will execute the script inside workspace.

>source(“d:\\hello_world.r”)

[1] hello world

Documentation of the available commands is accessed using “help” or by using an internet search

engine.

> help(“plot”) ; opens a browser with the help documentation for “plot”

6.2.3 Online Resources for R

Home page for R to download the software:

https://www.r-project.org/

A complete introduction to R at their website:

https://cran.r-project.org/doc/manuals/r-release/R-intro.html

Another good tutorial for R beginners:

http://www.cyclismo.org/tutorial/R/

Gulf Coast Data Concepts Page 27 X16-1D, Rev B

R is widely supported by user created packages that expand the capabilities of the language. These

packages are libraries of functions built for specific applications. Here is a list of available packages:

https://cran.r-project.org/web/packages/available_packages_by_name.html

If you ever get stuck trying to solve an issue with R, it's very likely someone else faced the same

challenge and posted the question to R forums. Search the internet and you will find a solution to get

you back on track.

6.2.4 Example Scripts in R

Several example applications using R scripts are available at the GCDC website or are included with

the X16-1D data logger. These examples educate the user on basic operation of the data logger,

interpretation of acceleration data, and the use of R scripts.

End of User Manual

Gulf Coast Data Concepts Page 28 X16-1D, Rev B

Loading...

Loading...