GUILIN WOODPECKER Ai-Motor, MotoPex Instruction Manual

Contents

1 Product introduction .............................................................................. 1

2 Installation ............................................................................................ 6

3 Function and operation of product .................................................... 13

4 Operation instruction ......................................................................... 16

5 Troubleshooting .................................................................................. 30

6 Cleaning, Disinfection and Sterilization ............................................. 31

7 Storage, maintenance and transportation ........................................... 34

8 Environmental protection ................................................................... 35

9 After service ....................................................................................... 35

10 European authorized representative .................................................. 35

11 Symbol instruction ........................................................................... 35

12 Statement .......................................................................................... 36

13 EMC-Declaration of conformity ....................................................... 36

Note: the description on reciprocating mode is only applicable

for the device that has reciprocating mode.

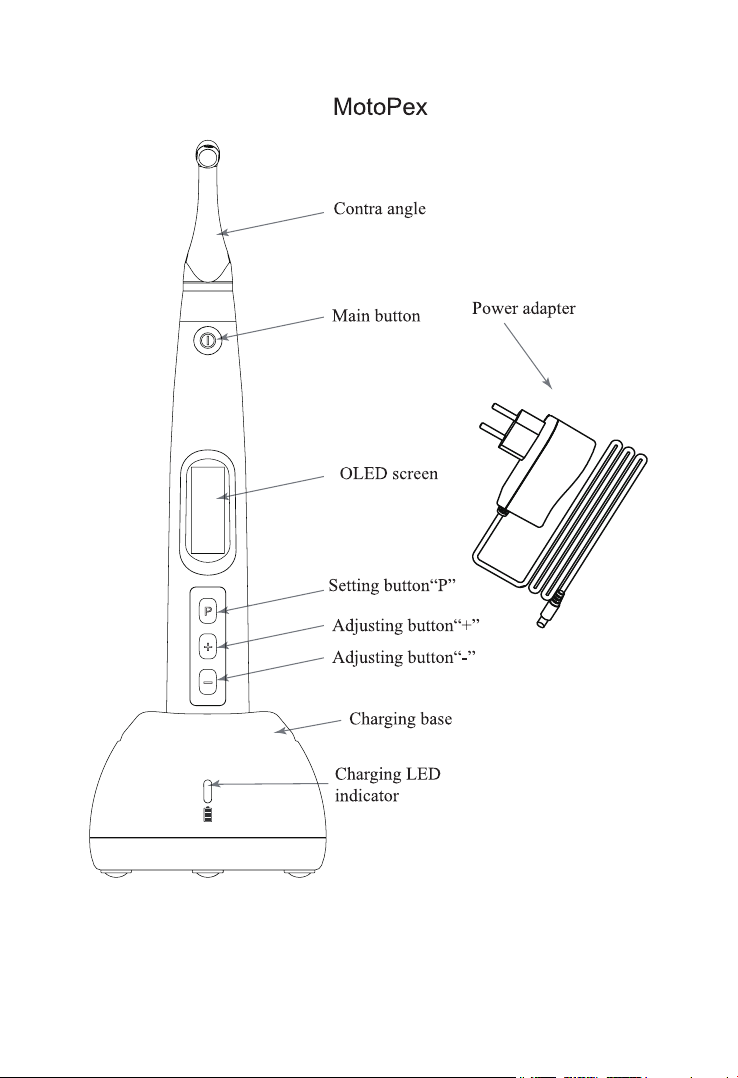

1 Product introduction

1.1 Preface

Guilin Woodpecker Medical Instrument Co., Ltd is a professional

manufacturer researching, developing, and producing dental products.

Woodpecker owns a sound quality control system. Guilin Woodpecker

Medical Instrument Co., Ltd has two brands, Woodpecker and DTE.

Its main products include Ultrasonic Scaler, Curing light, Apex locator,

Ultrasurgery, Endo Motor, etc.

1.2 Product description

Endo Motor (mode:Ai-Motor、MotoPex) is mainly used in

Endodontic treatment. It is a cordless endo motor with root canal

measurement capability. It can be used as a endo motor for preparation

and enlargement of root canals, or device for measuring canal length. It

can be used to enlarge the canals while monitoring the position of the le

tip inside the canal.

Features:

a) Ecient brushless motor, low noise, long service life.

b) Cordless portable endo motor with combined length determination.

c) 360 degrees rotation of contra angle.

d) Adopt real-time feedback technology and dynamic torque control,

eectively preventing le separation.

1.3 Model and specication

Ai-Motor、MotoPex

Please refer to packing list for device congurations.

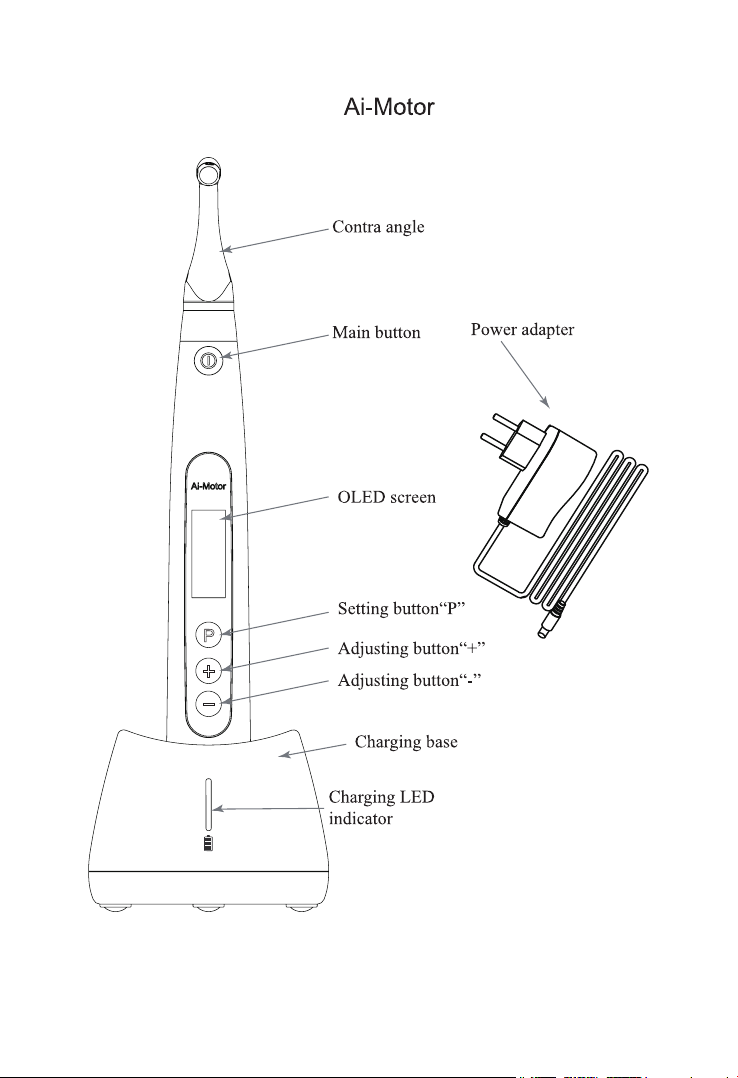

1.4 Performance and composition

The device is composed of charging base, motor handpiece, contra

angle, measuring wire, lip hook, file clip, power adapter, protective

silicon cover, etc.

1

234

1.5 Scope of application

1.5.1 The device can be used for preparation and enlargement of root

canals, or device for measuring canal length.

1.5.2 The device must be operated in hospital and clinic by the qualied

dentists.

1.6 Contraindication

a) The doctor with a pacemaker is disabled.

b) patients with cardiac pacemakers (or other electrical equipment)

are warned not to use small appliances (such as Electric razors, hair

dryers, etc.) patients are disabled.

c) Hemophilia patients are banned.

d) Use with caution in patients with heart disease, pregnant women

and young children.

1.7 Warnings

1.7.1 Please carefully read this Instruction Manual before first

operation.

1.7.2 This device should be operated by professional and qualified

dentist in qualied hospital or clinic.

1.7.3 Do not directly or indirectly place this device near heat source.

Operate and store this device in reliable environment.

1.7.4 This device requires special precautions regarding

electromagnetic compatibility (EMC) and must be in strict accordance

with the EMC information for installation and use. Do not use this

equipment especially in the vicinity of fluorescent lamps, radio

transmitting devices, remote control devices, handheld and mobile highfrequency communication devices.

1.7.5 Long time use of Reciprocating Motion Mode may result in

motor handpiece overheat, thus it should be left to cool for use. If the

motor handpiece is overheated frequently, please contact local distributor.

1.7.6 Please use the original contra angle. Otherwise it will not be

used or cause adverse consequences.

1.7.7 Please do not make any changes to the device. Any changes

may violate safety regulations, causing harm to the patient. There will be

no promises of any modication.

1.7.8 Please use original power adapter. Other power adapter will

result in damage to lithium battery and control circuit.

1.7.9 The motor handpiece cannot be autoclaved. Use disinfectant of

neutral pH value or ethyl alcohol to wipe its surface.

1.7.10 Before the contra angle stopping rotating, do not press the

push cover of contra angle. Otherwise the contra angle will be broken.

1.7.11 Before the motor handpiece stopping rotating, do not remove

the contra angle. Otherwise the contra angle and the gear inside motor

handpiece will be broken.

1.7.12 Please confirm whether the file is well installed and locked

before starting the motor handpiece.

1.7.13 Please set torque and speed as per the recommended

specications of le manufacturer.

1.7.14 Error in replacing lithium batteries can lead to unacceptable

risks, so use the original lithium battery and replace the lithium battery

according to the correct steps in the instructions.

1.7.15 Not to position equipment to make it dicult to operate the

disconnection device.

1.7.16 Please remove the battery if the motor handpiece is not likely

to be used for some time.

1.7.17 Wireless charging will generate heat, and the surface

temperature of charging base and motor handpiece will rise. It is

recommended that the time of contacting motor handpiece and charging

base during wireless charging should not exceed 10 seconds(only for AiMotor).

1.8 Device safety classication

1.8.1 Type of operation mode: Continuous operating device

1.8.2 Type of protection against electric shock: Class II equipment

with internal power supply

1.8.3 Degree of protection against electric shock: B type applied part

1.8.4 Degree of protection against harmful ingress of water: Ordinary

equipment (IPX0)

1.8.5 Degree of safety application in the presence of a flammable

anesthetic mixture with air, oxygen, or nitrous oxide: Equipment cannot

be used in the presence of a flammable anesthetic mixture with air,

oxygen, or nitrous oxide.

1.8.6 Applied part: contra angle, lip hook, le clip, touch probe.

1.8.7 The contact duration of applied part: 1 to 10 minutes.

1.8.8 The temperature of the surface of applied part may reach

46.6℃.

5

1.9 Primary technical specications

1.9.1 Battery

Lithium battery in motor handpiece: 3.7V /2000mAh

1.9.2 Power adapter(Model: DJ-0500100-A5)

Input: ~100V-240V 50Hz/60Hz 0.5-0.2A

Output: DC5V/1A

1.9.3 Torque rang: 0.4Ncm-5.0Ncm(4mNm ~ 50mNm

1.9.4 Speed rang: 100rpm~1200rpm

1.9.5 Wireless charging(only for Ai-Motor)

Frequency range: 112-205KHz

Maximum RF output power of the product: 9.46dBuA/m@3m

)

1.10 Environment parameters

1.10.1 Environment temperature: +5℃ ~ +40℃

1.10.2 Relative humidity: 30% ~ 75%

1.10.3 Atmospheric pressure: 70kPa ~ 106kPa

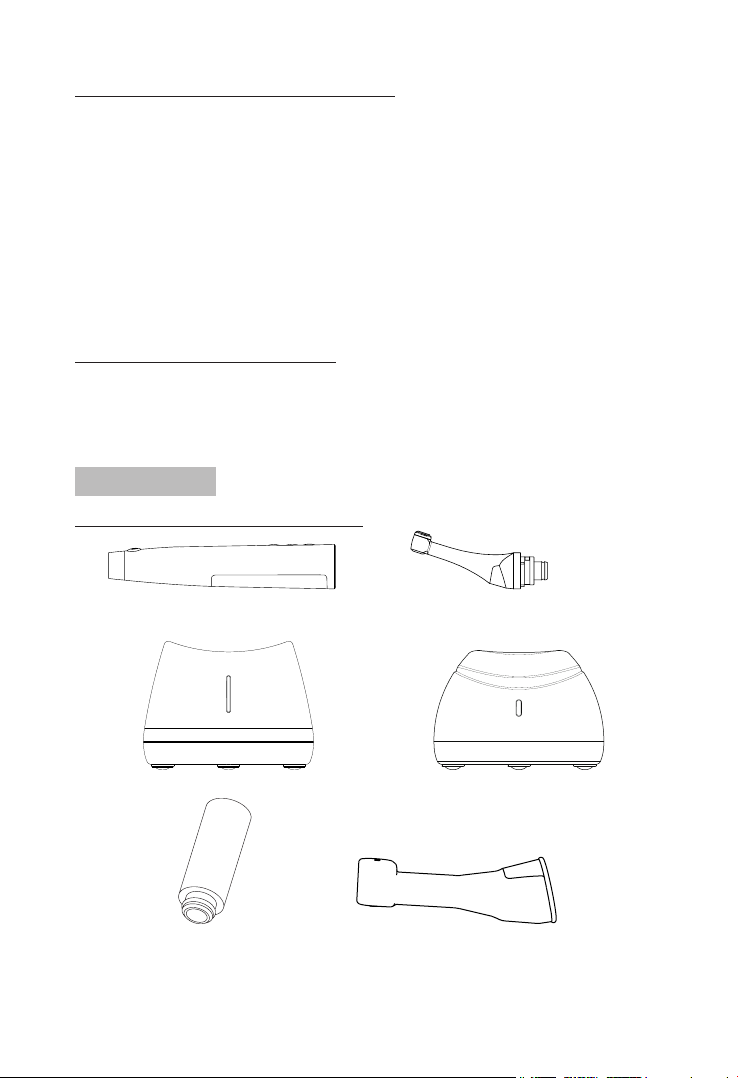

2 Installation

2.1 Basic accessories of product

Motor handpiece Contra angle

Ai-Motor Charging base MotoPex Charging base

Nozzle Protective silicon cover

6

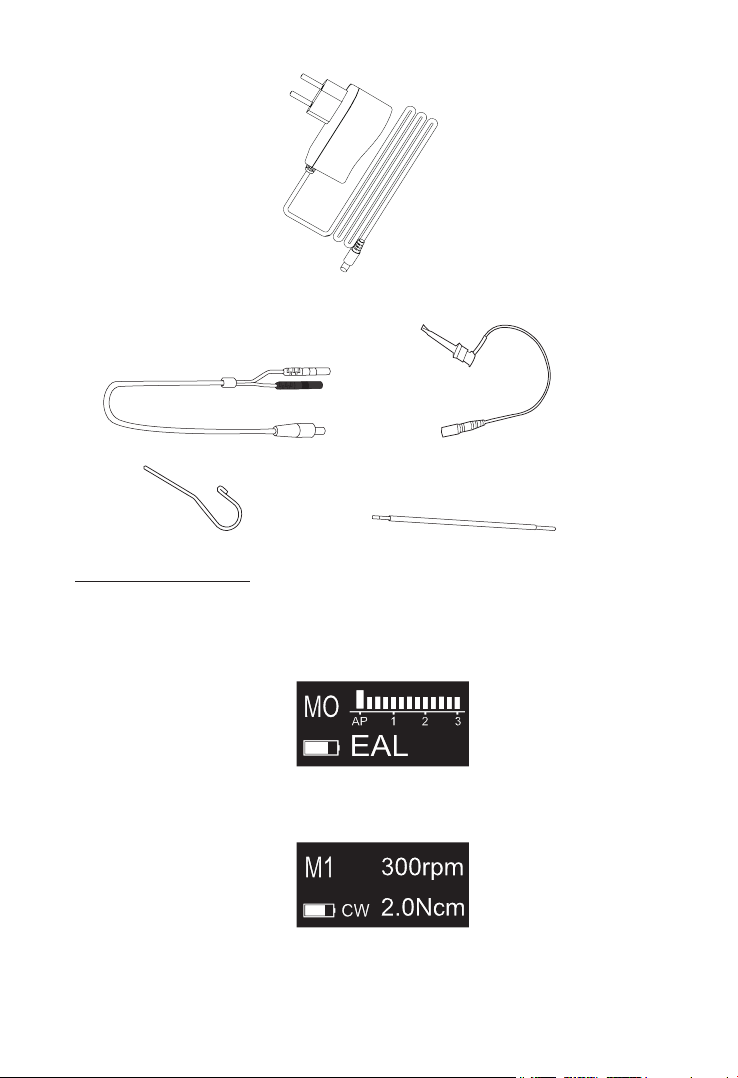

Power adapter

Measuring wire File clip

Lip hook Touch probe

2.2 Display Screens

2.2.1 Display Screens for 5 Operation Modes and Standby

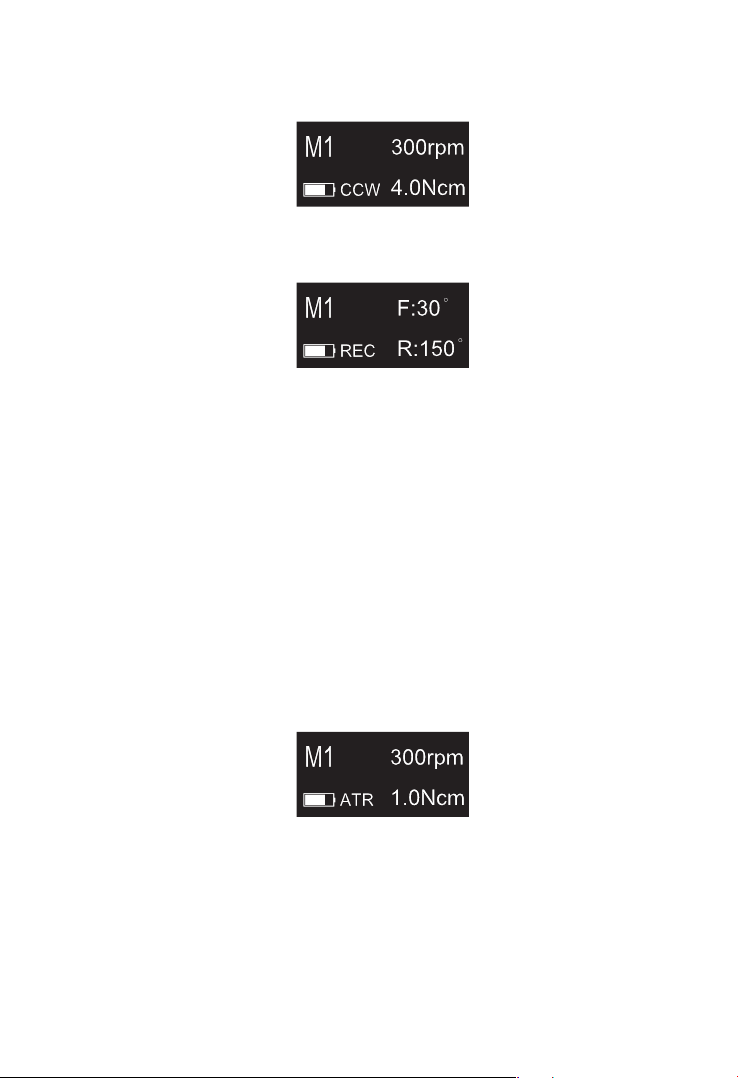

2.2.1.1 EAL Mode

This mode is for canal measurement. The motor handpiece does not

run in this mode

2.2.1.2 CW Mode

The motor handpiece rotates forward 360º, clockwise direction. Used

rotaty les likes DENTSPLY Protaper or WOODPECKER W3-Pro

2.2.1.3 CCW Mode

The motor handpiece rotates counterclockwise direction only. This

.

7

.

mode is used to inject calcium hydroxide and other medicant. When this

mode is being used, a double-beep sounds continuously.

2.2.1.4 REC Mode

Recprocating mode.

F: Forward angle, R: Reverse angle

Adjustable every 10 degrees, adjustment range: 20º-340º.

It is suggested that the difference between the forward angle and

reverse angle should be greater than or equal to 120 degrees, otherwise,

root canals cannot be prepared eectively.

Forward Angle<Reverse Angle, such as F: 30/R: 150, eective cutting

angle is Reverse Angle, it is suitable for used the reciprocating les likes

DENTSPLY WAVEONE or WOODPECKER W3-ONE.

Forward Angle>Reverse Angle, such as F: 180/R: 30, eective cutting

angle is Forward Angle, it is suitable for used the reciprocating les likes

SENDONELINE S1.

Torque limit: 2.0Ncm~5.0Ncm

Speed: 100rpm,150rpm, 200rpm, 250rpm, 300rpm, 350rpm, 400rpm,

450rpm, 500rpm.

2.2.1.5 ATR Mode

ATR: Adaptive Torque Reverse function.

Normal continuous forward rotation, the forward angle can be

stepped by 10°, the angle is set between 120°-340°, and the reverse angle

defaults to 90°. When the load of the le is greater than the set torque

limit, the le will start to rotate alternately at the set angle.

Trigger torque: 0.4Ncm, 0.6Ncm, 0.8Ncm, 1Ncm, 1.2Ncm, 1.5Ncm

Speed: 100rpm, 150rpm, 200rpm, 250rpm, 300rpm, 350rpm,

400rpm, 450rpm, 500rpm

8

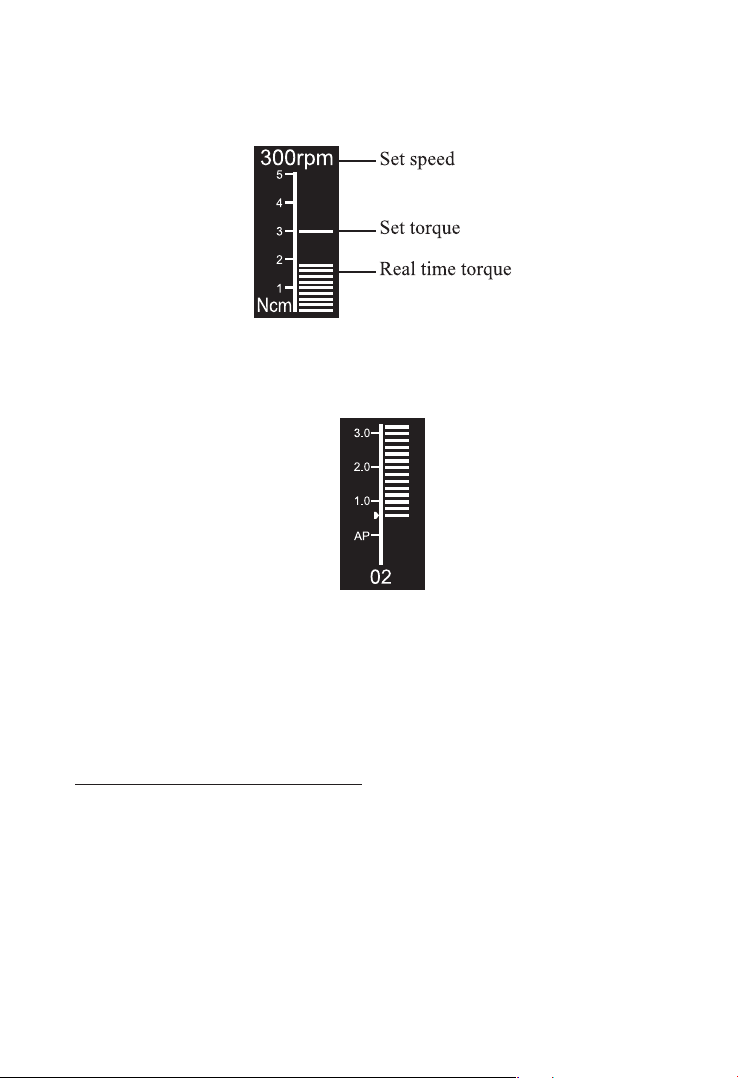

2.2.2 Torque Display

This appears when the motor is running. Meter shows the torque load

on the le.

2.2.3 Canal Measurement Display

This appears when a file is inside the canal and the lip hook is

contacting the patient mouth. Bars in meter show the location of the le

tip.

The meter numbers 1.0, 2.0, 3.0 and digital numbers 00-16 do not

represent the actual length from the apical foramen. It simply indicates

the file progression towards the apex. The digital numbers -1 and -2

indicate that the le has passed the apex foramen. The digital number “00”

indicate that the file has reached the apex foramen. Subtract 0.5-1mm

from the measured le length as the working length. These numbers are

used to estimate the canal’s working length.

2.3 Instructions for contra angle

2.3.1 The contra angle adopts precision gear transmission, and the

transmission ratio is 6:1.

2.3.2 Before the first use and after treatments, please clean and

disinfect contra angle with disinfectant of neutral PH value. After

disinfection, lubricate it with specific cleaning oil. Finally, sterilize

it under high temperature and high pressure (134℃, 2.0bar~2.3bar

(0.20MPa~0.23MPa)).

2.3.3 The contra angle can only be used cooperatively with this

9

device. Otherwise the contra angle will be damaged.

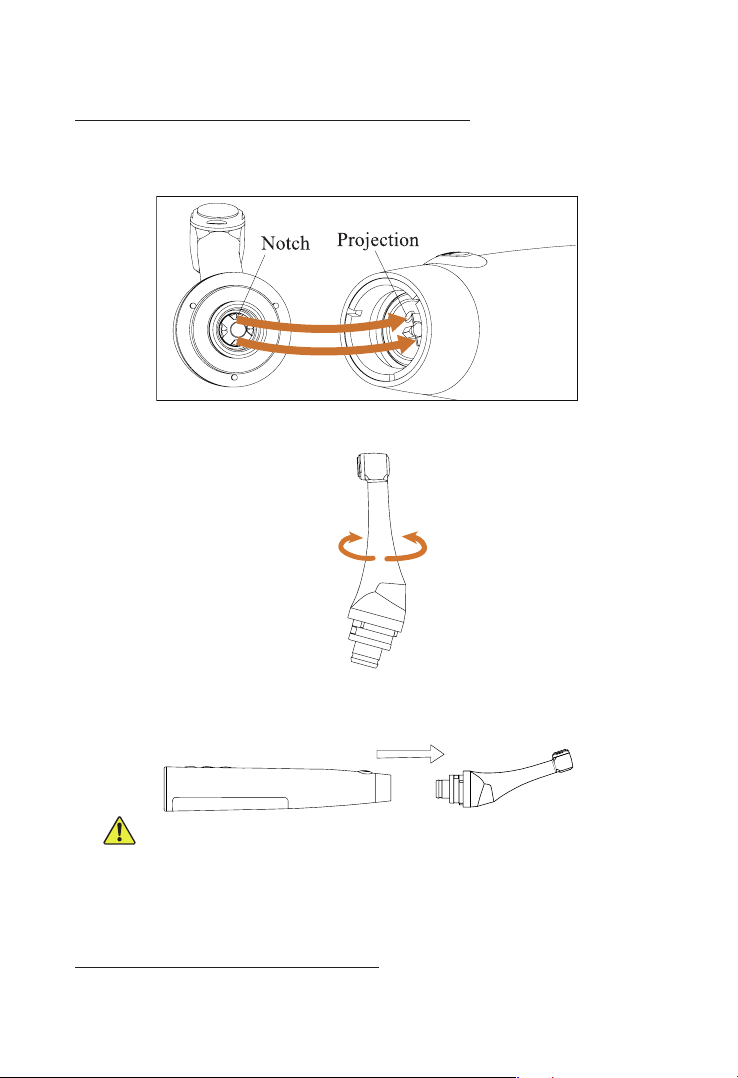

2.4 Installation and removal of contra angle.

2.4.1 Installation

Line up the notch inside the contra angle with the projection inside

the motor handpiece and slide it in until it clicks securely into place.

The contra angle rotates 360° so that the OLED display can always

be viewed easily.

2.4.2 Removal

Pull out the contra angle horizontally when the motor handpiece does

not run.

Warnings:

a) Before plugging in or pulling out contra angle, please rst stop the

motor handpiece.

b) After installation, please check and conrm that the contra angle

has been well installed.

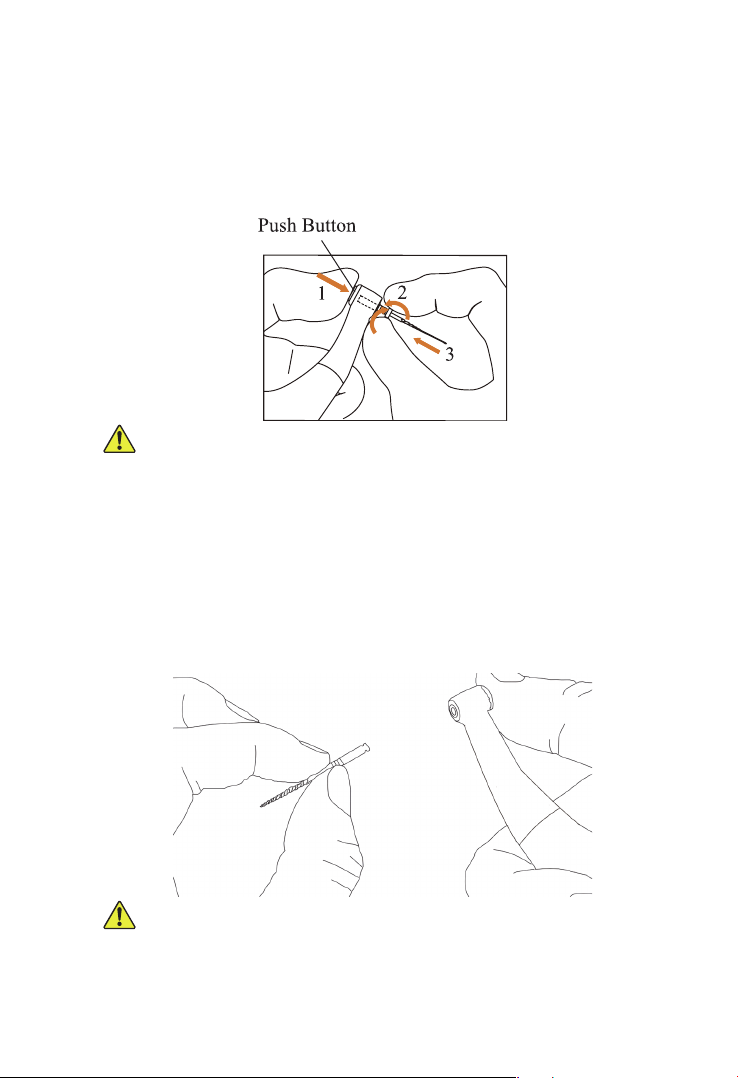

2.5 Installation and removal of le

2.5.1 Installation of le

10

Before starting the device, plug the le into the hole of contra angle

head.

Hold down the push button on the contra angle and insert the file.

Turn the le back and forth until it is lined up with interior latch groove

and slips into place. Release the but-ton to lock the le into the contra

angle.

Warnings:

After plugging the file into contra angle, let go the hand on push

cover to assure that the le cannot be taken out.

Be careful when inserting les to avoid injury to ngers.

Inserting and removing files without holding the push button may

damage the chuck of contra angle.

Please use files with shanks meet the ISO standard. (ISO standard:

Ø2.334 – 2.350 mm)

2.5.2 Removal of le

Pressing the push cover, and then directly pull out the le.

Warnings:

Before plugging and pulling out the le, the motor handpiece must be

stopped.

11

Be careful when removing les to avoid injury to ngers.

Removing files without holding the push button will damage the

chuck of contra angle.

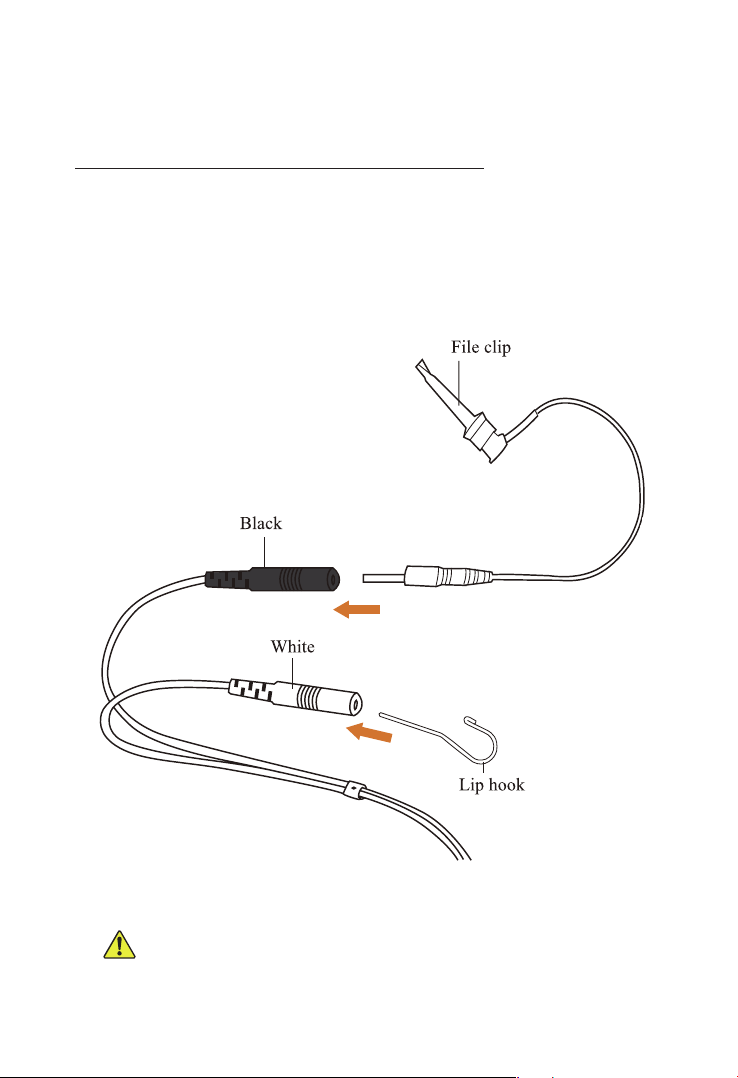

2.6 Canal measurement functional connection

This is not required if the canal measurement function will not be

used.

Connect the measuring wire to the motor handpiece. Line up the

measuring wire plug with the notch on the back of the motor and push it

all the way in.

Connect the file clip plug into the socket (black) on the measuring

wire. Connect the lip hook to the socket (white) on the measuring wire.

Warnings:

Connect the lip hook to the socket (white) on the measuring wire.

12

Loading...

Loading...