Page 1

Guidance Marine Ltd, 5 Tiber Way, Meridian Business Park, Leicester LE19 1QP, UK www.guidance.eu.com

T: +44 116 229 2600 E: sales@guidance.eu.com www.marine.direct

RadaScan® View Installer’s Guide

W

A

R

R

A

N

T

Y

S

e

e

o

u

r

s

t

a

n

d

a

r

d

t

e

r

m

s

o

f

s

a

l

e

Q

U

A

L

I

T

Y

A

S

S

U

R

E

D

3

YEAR

Page 2

Guidance Marine Ltd,

5 Tiber Way

Meridian Business Park

Leicester

LE19 1QP

UK

Tel: +44 116 229 2600

UK Support:

+44 116 229 2665

(365 days a year, 08:00 - 20:00 hours UTC)

customerservices.uk@guidance.eu.com

USA Support: +1 504 305-1120

customerservices.us@guidance.eu.com

Asia Support: +65 6734 6365

customerservices.sg@guidance.eu.com

Web: www.guidance.eu.com/customer-support

RadaScan View Installer’s Guide

Issue Date: 02/03/2016

Document No: 94-0492-4-A

Copyright © 2016 Guidance Marine Limited. All Rights Reserved.

Copyright in the whole and every part of this document belongs to Guidance Marine Limited

(the “Owner”) and may not be used, sold, transferred, copied or reproduced in whole or in part

in any manner or form or in or on any media to any person other than in accordance with the

terms of the Owner’s Agreement or otherwise without the prior written consent of the Owner.

“RadaScan View” is a trademark and “RadaScan” is a registered trademark of Guidance Marine

Ltd. ”Windows” is a trademark of Microsoft Corporation. All other brand or product names are

trademarks or registered trademarks of their respective companies or organisations.

Serial No:

Date of Shipment from UK:

Sensor Software Version: RSI Software Version:

VYMRADASCAN

Page 3

Document Number Changes Issue Date

94-0492-4-A First release of RadaScan View Installer's Guide 02/03/2016

Document History

3

Page 4

Introduction

Welcome ................................................................................................................... 6

System Overview ....................................................................................................... 7

Important Safety Notes .............................................................................................. 8

Non-ionising Radiation .......................................................................................................8

Risk of Electric Shock ........................................................................................................8

Isolating the Sensor ...........................................................................................................8

Lifting the Sensor ...............................................................................................................8

Serial Numbers and Software Versions ......................................................................9

Product Labels ..................................................................................................................9

Software Version Information .............................................................................................9

To Display the About System Pane ....................................................................................9

Installing the Sensor Hardware and Software

Mounting the Sensor ............................................................................................... 11

Avoiding Other Sources of Radiation ................................................................................12

Operating Area Astern (e.g. PSV) .....................................................................................13

Operating Area Forward (e.g. Shuttle Tanker) ...................................................................14

Operating Area to Port or Starboard (e.g. Track and Follow) .............................................15

Sensor Dimensions .................................................................................................. 16

Mounting Template .................................................................................................. 17

Universal Mounting Bracket ..................................................................................... 18

Sensor Connections—Direct ................................................................................... 19

Sensor Connections—Separate Connection Box ..................................................... 20

Cable Routing Diagram - Direct Connection ............................................................ 21

Cable Routing Diagram - Separate Connection Box ................................................ 22

Cable Routing Diagrams - Processor and Monitor Options ...................................... 23

Sensor Information Display ...................................................................................... 24

Installing the Sensor Software .................................................................................. 26

Installing the Marine Processor

Installing RadaScan View Client Software onto a Type 3 Marine Processor .............. 28

Installing RadaScan View Client Software onto other Types of Computer ................. 29

Conguring the RadaScan View System

Using the RadaScan Service Interface ..................................................................... 31

Network Communication Settings ........................................................................... 32

Vessel Definition .......................................................................................................34

Blanking Zone ......................................................................................................... 38

DP Feed Configuration ............................................................................................ 39

Information Tabs ...................................................................................................... 41

Installing Responders

Responder Overview ............................................................................................... 44

Positioning Responders ........................................................................................... 46

Mounting Responders ............................................................................................. 47

Charging Responders .............................................................................................. 49

Operating Responders ............................................................................................ 50

Appendices

International Standards Compliance ........................................................................ 52

RadaScan View Transceiver .............................................................................................52

RadaScan Responders ....................................................................................................52

Part Numbers .......................................................................................................... 53

DP Message Types .................................................................................................. 54

UPS and Cable Specifications ................................................................................. 58

Installation Checklist ................................................................................................ 59

Index ....................................................................................................................... 61

Table of Contents

4

Page 5

This section provides an introduction and overview of the RadaScan View system.

It contains the following pages:

•

Welcome (page 6)

•

System Overview (page 7)

•

Important Safety Notes (page 8)

•

Serial Numbers and Software Versions (page 9)

FCC ID: VYMRADASCAN

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT

TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL

INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

NOTE: THE GRANTEE IS NOT RESPONSIBLE FOR ANY CHANGES OR MODIFICATIONS

NOT EXPRESSLY APPROVED BY THE PARTY RESPONSIBLE FOR COMPLIANCE. SUCH

MODIFICATIONS COULD VOID THE USER’S AUTHORITY TO OPERATE THE EQUIPMENT.

Introduction

5

Page 6

Welcome to the RadaScan View Installer’s Guide. It explains how to mount and install

the RadaScan View system onto a vessel. For instructions on how to use the system,

please see the RadaScan View Operator’s Guide (Doc No. 94-0491-4).

Please read the Important Safety Notes on page 8 before beginning the installation.

The Installing the Sensor Hardware and Software section on page 10 describes

where to mount the RadaScan View sensor on the vessel, and how to connect it to the

RadaScan View marine processor and the vessel’s DP system. It also explains how to

upgrade the sensor software, if required.

The Installing the Marine Processor section on page 27 gives relevant information

for mounting and setting up the marine processor and explains how to upgrade the

RadaScan Dashboard software, if required.

The Configuring the RadaScan View System section on page 30 explains how to

configure the system for your vessel.

The Installing Responders section on page 43 explains how to mount and use

RadaScan Responders.

!

NOTE: Installation of a RadaScan View system should be carried out by a

suitably qualified and competent engineer.

Welcome

6

Page 7

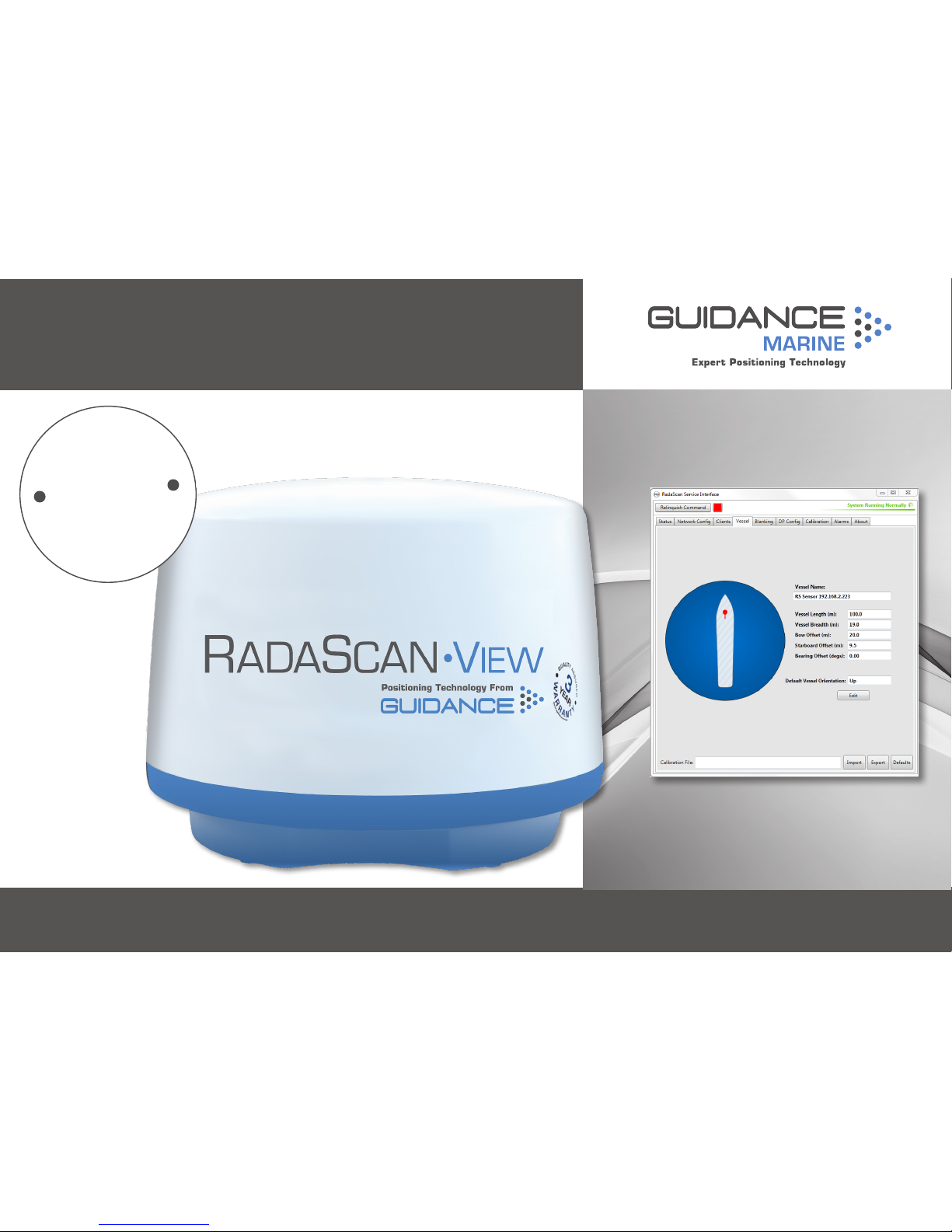

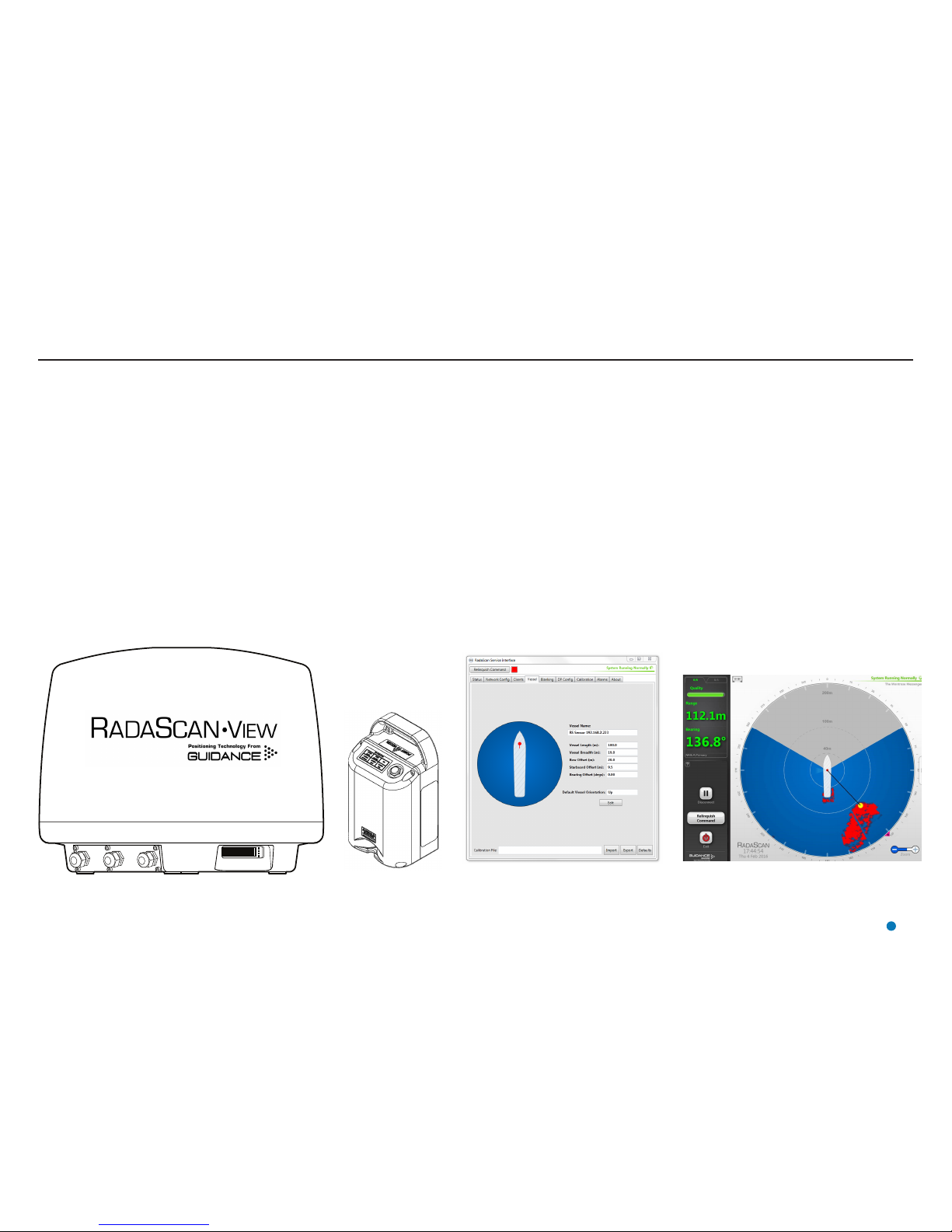

The RadaScan View system is the latest generation of Guidance Marine’s radar-based position

reference products, suitable for use within the 500m safety zone. Delivering accurate positional

data to marine vessel DP (dynamic positioning) control systems for automated approach

and station keeping, it has the additional capability to display a radar image representing the

surroundings of the vessel.

With similar all-weather capabilities and precision as the larger-scale RadaScan system, the

reduced size and weight of the RadaScan View sensor allows it to be used on smaller vessels

than those traditionally associated with RadaScan systems. Both RadaScan and RadaScan View

sensors are compatible with RadaScan responders.

The RadaScan View System consists of three main parts: The Sensor, the Client Software and the

Responder:

RadaScan View Sensor

The RadaScan View Sensor is a rotating radar scanner mounted on the DP-equipped vessel. It

emits a microwave beam and detects the reflections returned by any RadaScan Responders that

are within range. It is connected to the vessel’s DP system and to the Dashboard, and can output

the radar image in ASTERIX Category 240 open data format for use by a third party application

(contact Guidance Marine for instructions on how to enable the ASTERIX output channel).

System Overview

RadaScan View Client Software

The RadaScan Service Interface (RSI) and RadaScan View Dashboard are software applications

used to configure, control and monitor the RadaScan View system. They are installed on one

or more marine-specification Type 3 Marine Processors or other computers running Microsoft

WindowsTM, usually mounted on the bridge near to the controls of the vessel’s DP system.

The RSI is used for system configuration and replaces the Service Access mode of the Dashboard

or Console in earlier versions of the RadaScan system.

The Dashboard gives the DP operator control of the RadaScan View system and the data stream

being fed to the DP system.

RadaScan Responder (Target)

One or more responders are mounted on the target platform or vessel. Each responder returns a

modulated radar reflection that carries its unique ID number back to the RadaScan View Sensor.

The precise range and bearing of each responder is measured by the sensor. This is used to

calculate the exact position of the RadaScan View Vessel relative to the target structure or vessel.

The positional data is fed directly into the vessel’s DP system.

RadaScan View Sensor RadaScan

Responder

RadaScan Service Interface RadaScan View Dashboard

7

Page 8

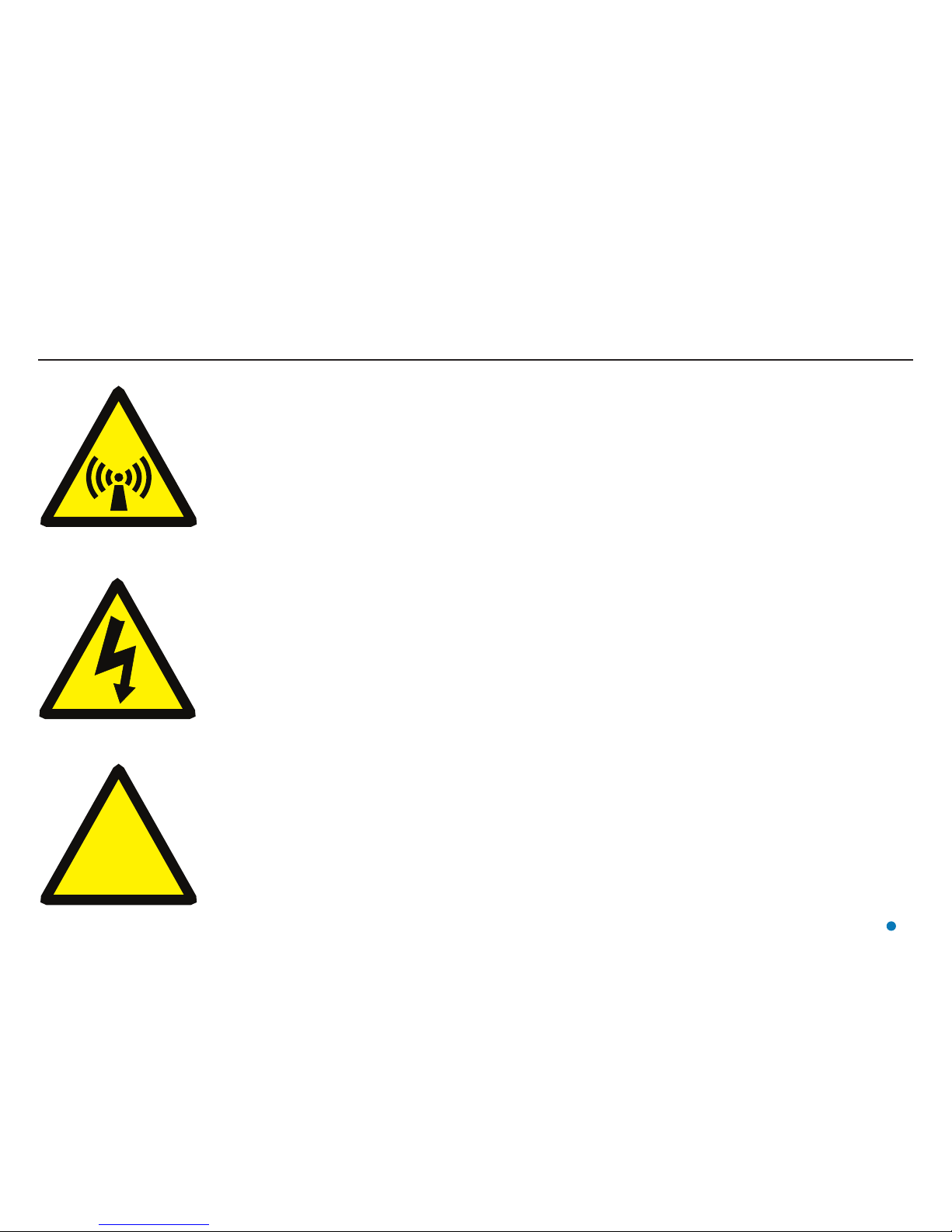

Non-ionising Radiation

The RadaScan View sensor emits non-ionising radiation with

an output power of 1 Watt when transmitting.

This equipment should be treated with the same safety

precautions as other marine radar devices.

ALWAYS keep a minimum safe distance of 1 metre

from the dome when the unit is operational.

Risk of Electric Shock

Disconnect the mains electricity supply before opening the

connection panel or removing the radome cover.

CAUTION—DOUBLE POLE/NEUTRAL FUSING.

Isolating the Sensor

For PERMANENTLY CONNECTED EQUIPMENT, a readily

accessible disconnect device shall be incorporated external to

the equipment.

For PLUGGABLE EQUIPMENT, the socket-outlet shall be

installed near the equipment and shall be easily accessible.

Lifting the Sensor

On install, the sensor should be moved to the top of the ship

in its STTC (Special to Type Transit Case). The transit case

must be carried using a correctly specified and weight-rated

cargo-net.

!

The transport case handles are not rated or weight

tested, and should not be used as lifting points for this

task.

Important Safety Notes

!

8

Page 9

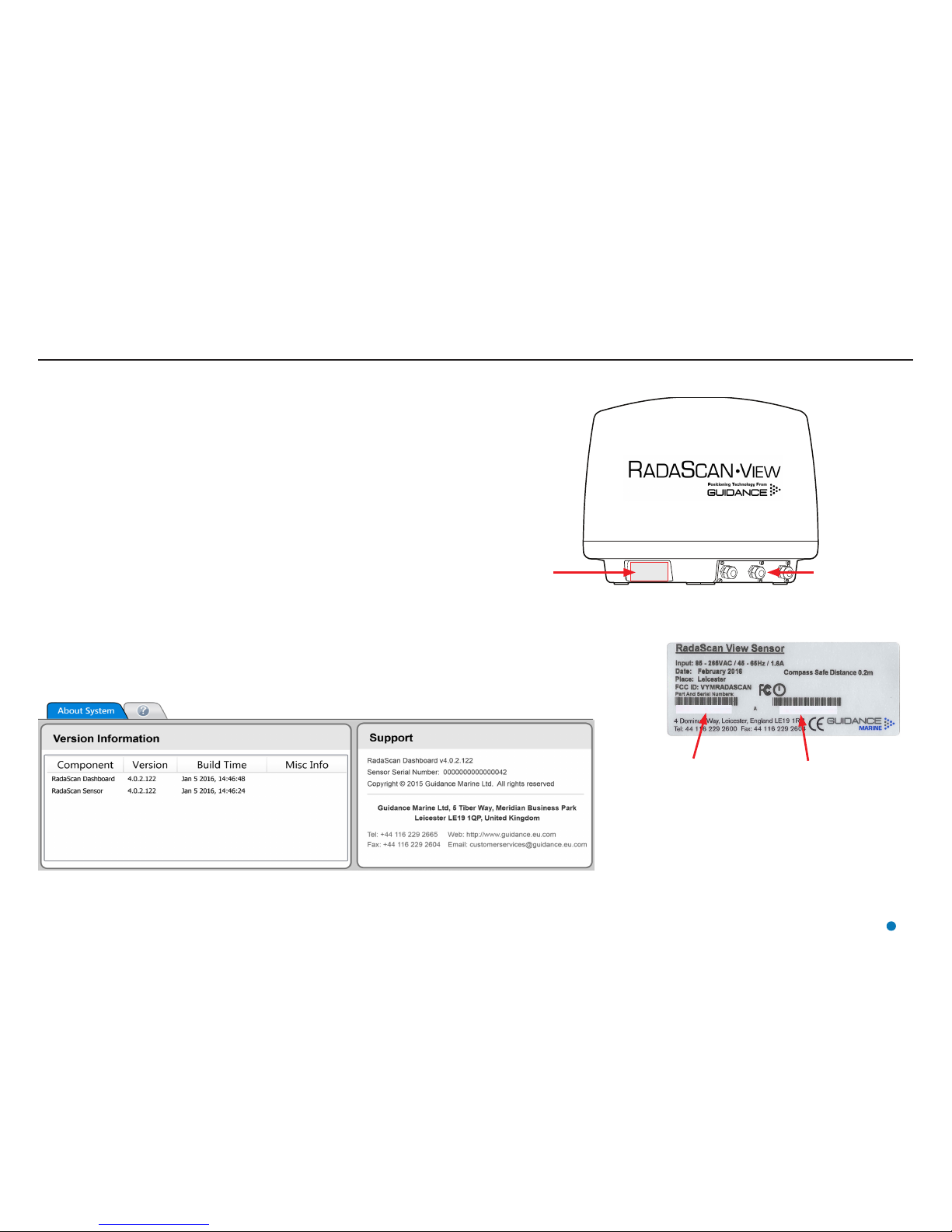

Serial Numbers and Software Versions

Product Label

Connection Panel

Software Version Information

The About System pane provides version information about the Dashboard and the software within

the RadaScan View sensor. It also contains the serial number of the sensor.

Serial Numbers and Software Version Numbers are used to identify the hardware configuration and

product revision of each RadaScan View sensor. They will be requested by Guidance Marine in the

event of an application service or support call to the company.

Product Labels

Part Numbers and Serial Numbers can be found on the product label fixed on the side of the

sensor, above the connection panel.

RadaScan View Sensor

Part Number

RadaScan View Sensor

Serial Number

To Display the About System Pane

1. Click on the Advanced button.

2. Click on the About System button.

Alternatively, click F7 or the About System button via the Hotkey tab.

XX-XXXX-X-X

XXXXXXXXX

9

Page 10

This section explains where and how to mount the RadaScan View Sensor on the vessel.

It contains the following pages:

•

Mounting the Sensor (page 11)

Avoiding Other Sources of Radiation (page 12)

Operating Area Astern (e.g. PSV) (page 13)

Operating Area Forward (e.g. Shuttle Tanker) (page 14)

Operating Area to Port or Starboard (e.g. Track and Follow) (page 15)

•

Sensor Dimensions (page 16)

•

Mounting Template (page 17)

•

Universal Mounting Bracket (page 18)

•

Sensor Connections—Direct (page 19)

•

Sensor Connections—Separate Connection Box (page 20)

•

Cable Routing Diagram - Direct Connection (page 21)

•

Cable Routing Diagram - Separate Connection Box (page 22)

•

Cable Routing Diagrams - Processor and Monitor Options (page 23)

•

Sensor Information Display (page 24)

•

Installing the Sensor Software (page 26)

10

Installing the Sensor Hardware and Software

Page 11

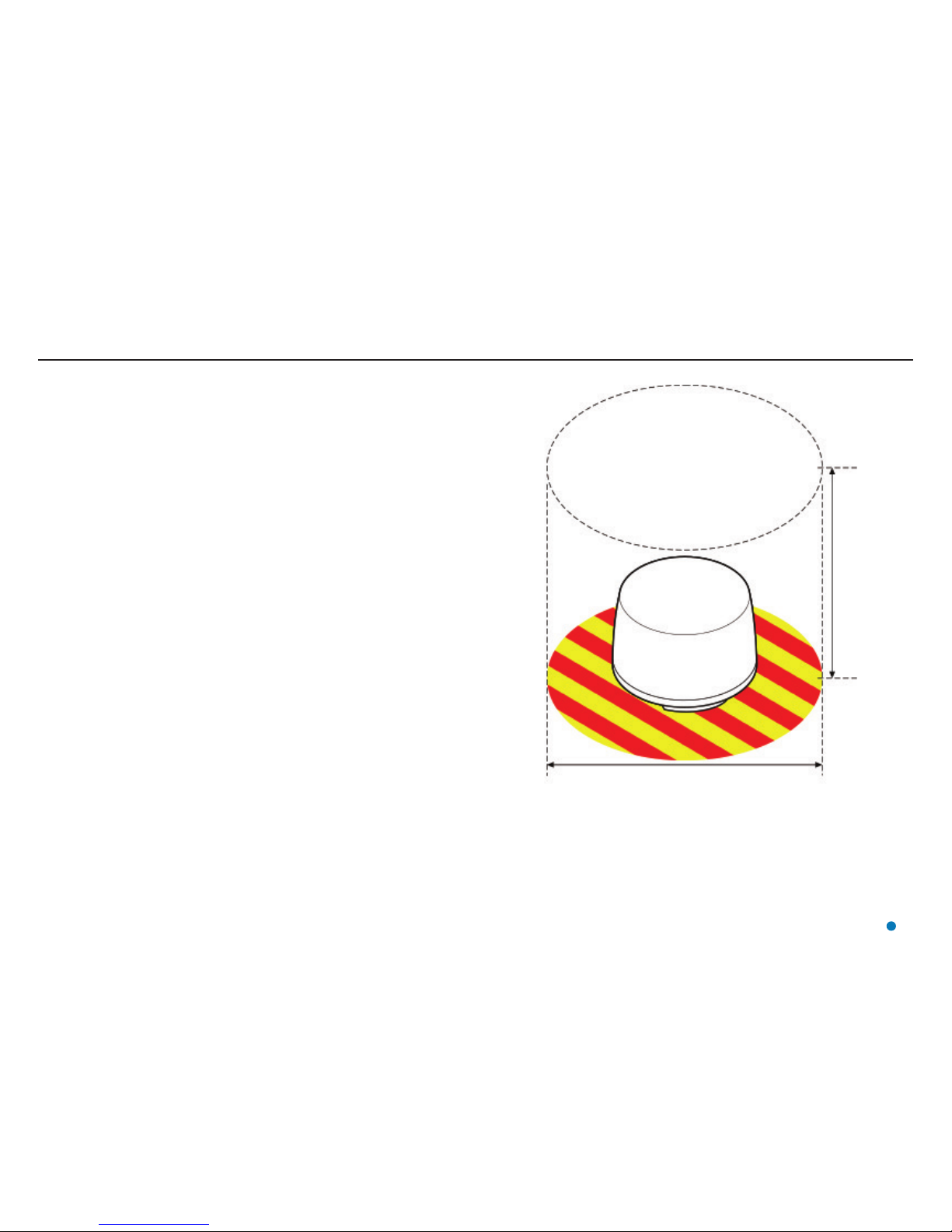

Mounting the Sensor

Applications and Vessel Types

The sensor’s mounting position depends on the application for which it is used. If your particular

application does not match the ones covered in this manual, please contact Guidance Marine and

your DP supplier to ensure that the RadaScan View and DP systems are configured correctly.

•

Operating Area Astern (e.g. PSV) (page 13)

•

Operating Area Forward (e.g. Shuttle Tanker) (page 14)

•

Operating Area to Port or Starboard (e.g. Track and Follow) (page 15)

Generic Mounting Guidelines

The following guidelines apply to all vessel types and applications. The Sensor should be mounted:

•

With the connection panel facing away from the operating area.

•

With an unobstructed view in the expected direction of the responder structure or vessel.

•

At the same height above sea level as the responders that the vessel will be using.

•

Well above sea-level to prevent swamping or immersion.

•

Allowing for easy access to the connection panel and Sensor Information Display.

•

On a different vertical level to any X-band radar systems.

(See Avoiding Other Sources of Radiation on page 12).

Mounting Plinths and Brackets

The sensor can be mounted using Guidance Marine’s Universal Mounting Bracket (see page

18), or on a custom-made plinth. (See Mounting Template on page 17).

Bearing Osets

The sensor’s orientation and position on the vessel must be set up in the RSI software.

(See Bow and Starboard Offsets on page 35 and Bearing Offset on page 36).

1000mm

800mm

Leave sufficient clearance around the sensor to allow access to

the cable connection plate.

Ensure that there is a clear line of sight to the Information Display

Screen. (See Sensor Information Display on page 24).

Leave sufficient

vertical clearance

to allow the

radome to be

removed.

11

Page 12

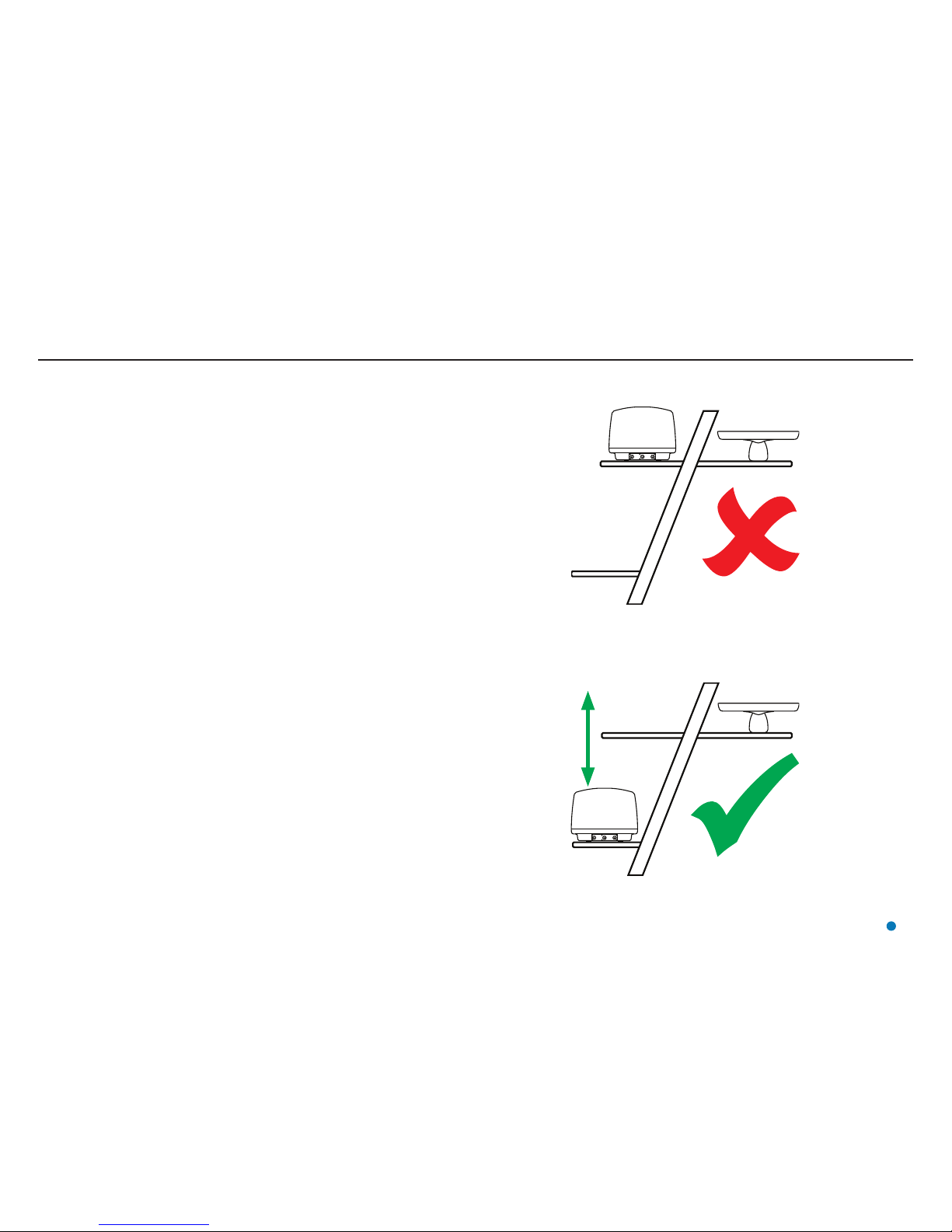

Mounting the Sensor (continued)

Avoiding Other Sources of Radiation

There should be as much vertical separation as possible between the RadaScan View Sensor and

any X-band radar or Artemis systems, to prevent the RadaScan View signal from being jammed.

Wherever possible, the RadaScan View Sensor should not be installed at the same vertical level as

an X-band radar or Artemis sensor.

If vertical separation of the two systems is impossible, they must be shielded from one another

with a metal screen. The screen must be large enough to physically shield the RadaScan View

sensor from the whole width of the x-band/Artemis antenna. In some cases, the vessel’s metal

superstructure may be used to provide part or all of the shielding between the two systems.

The RadaScan View Sensor does not need to be shielded from radar-based systems mounted on

other vessels or structures.

RadaScan

View

RadaScan

View

Incorrect—No Vertical Separation

Correct—Good Vertical Separation

X-Band Radar

X-Band Radar

12

Page 13

Mounting the Sensor (continued)

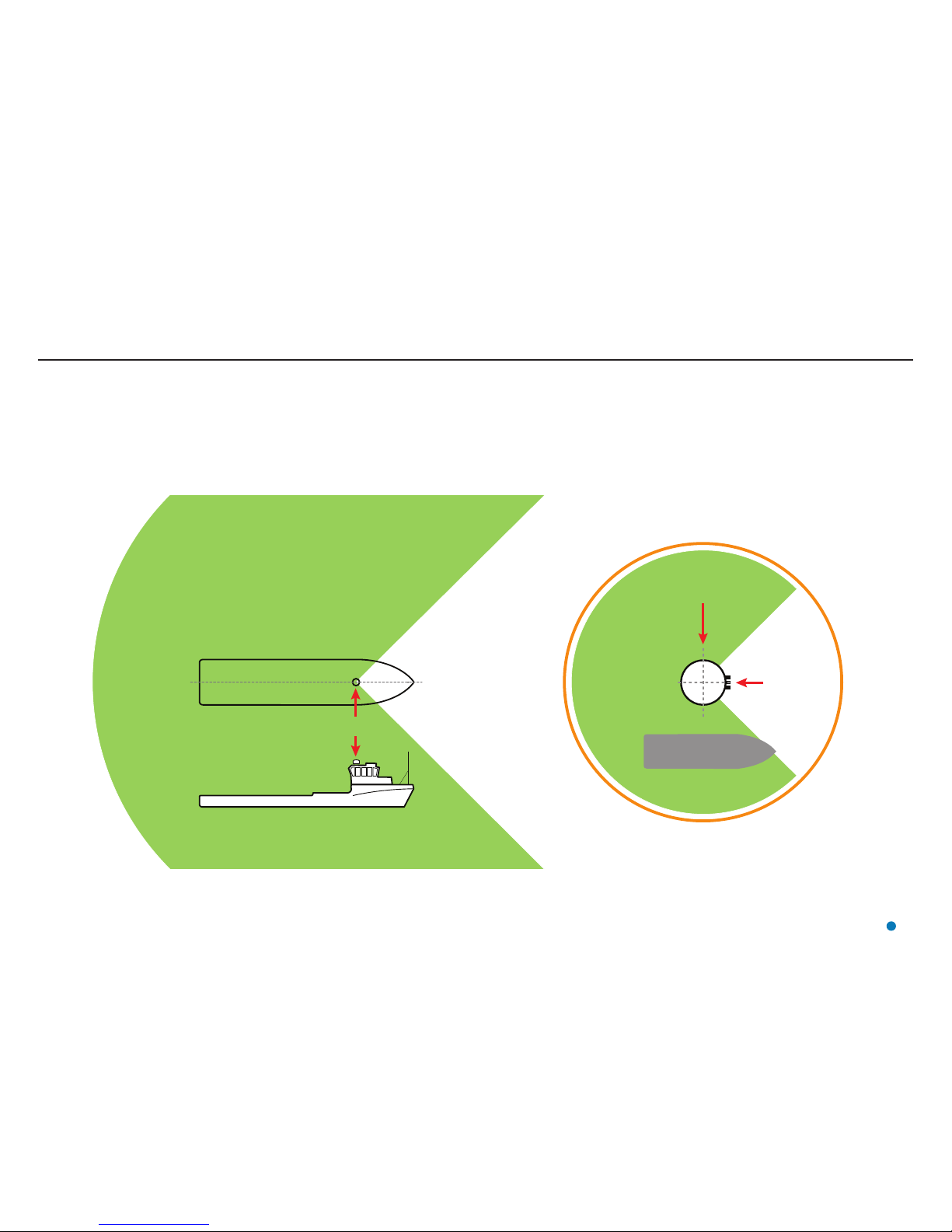

Operating Area Astern (e.g. PSV)

Mount the RadaScan View sensor with its connection panel facing towards the vessel’s bow.

(Connection panel faces away from the operating area).

The sensor’s position (Bow and Starboard Offsets) and orientation (Bearing Offset) must be set up

in the RadaScan Service Interface.

Operating

Area

RadaScan View Sensor

Operating

Area

Stern Bow

Connection

Panel

RadaScan View

Sensor

13

Page 14

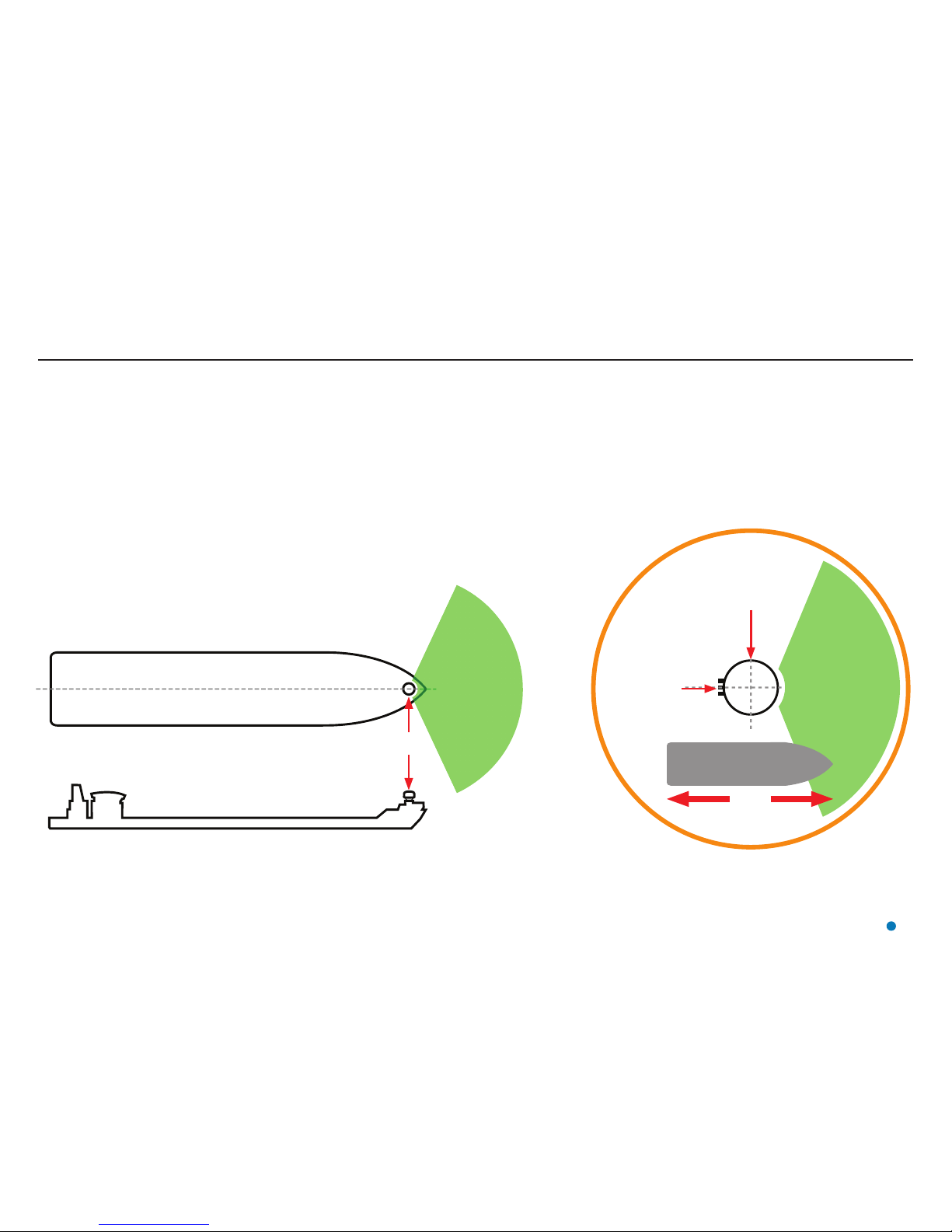

Mounting the Sensor (continued)

Operating Area Forward (e.g. Shuttle Tanker)

Mount the RadaScan View sensor with its connection panel facing towards the vessel’s stern.

(Connection panel faces away from the operating area).

The sensor’s position (Bow and Starboard Offsets) and orientation (Bearing Offset) must be set up

in the RadaScan Service Interface.

RadaScan View

Sensor

RadaScan View

Sensor

Connection

Panel

Operating

Area

Operating

Area

Stern Bow

14

Page 15

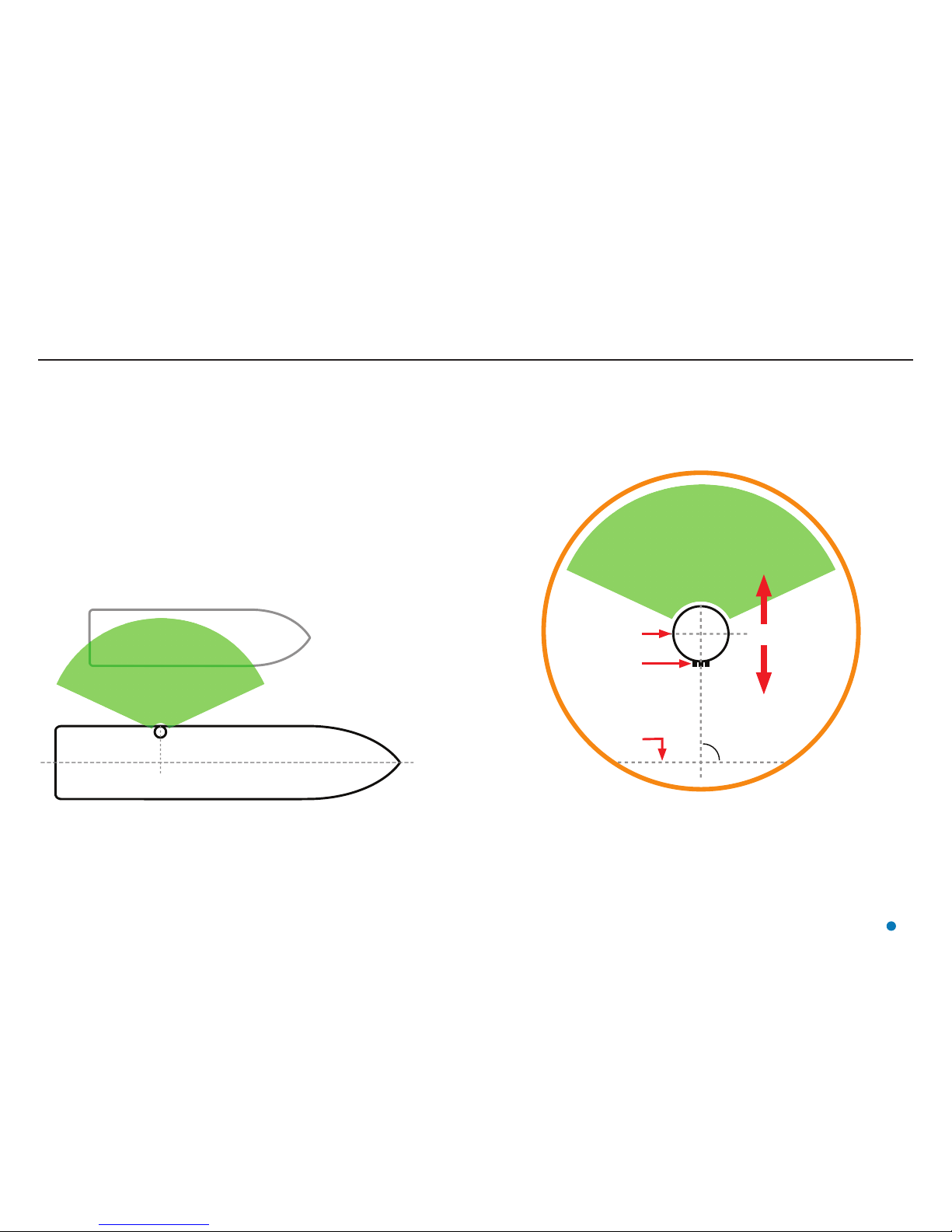

Mounting the Sensor (continued)

Operating Area to Port or Starboard (e.g. Track and Follow)

Mount the RadaScan View sensor with its connection panel facing inboard, towards the vessel’s centre line.

(Connection panel faces away from the operating area).

The sensor’s position (Bow and Starboard Offsets) and orientation (Bearing Offset) must be set up in the

RadaScan Service Interface.

a = angle from vessel’s centre line (See Bearing Offset on page 36).

RadaScan View Sensor

Responder Vessel

RadaScan View

Sensor

Connection Panel

Vessel

Centre

Line

a

Operating Area

Operating Area

Outboard

Inboard

15

Page 16

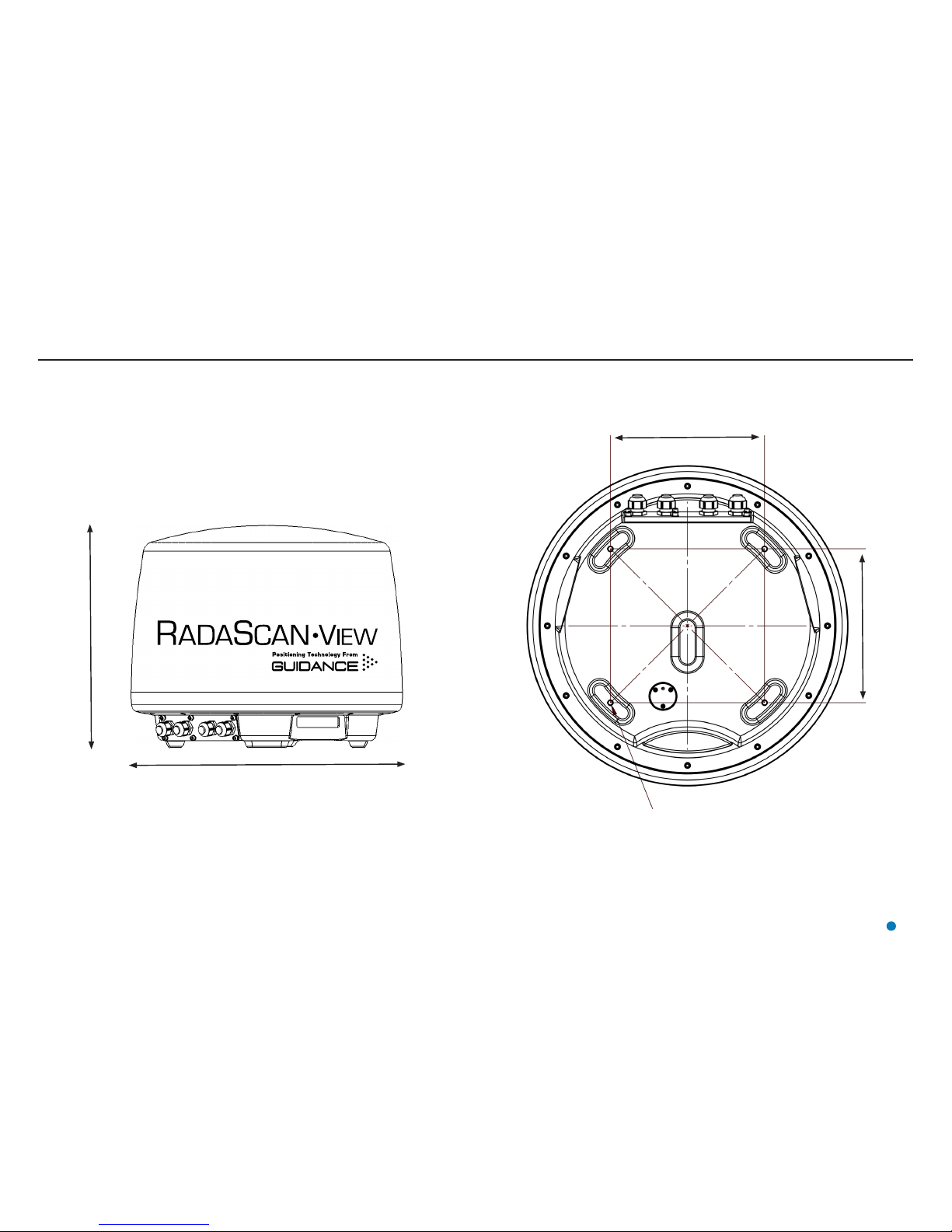

Sensor Dimensions

16

Bottom View

Ø 500mm

410mm

Side View

240mm

Mounting Holes

240mm

4XM8 MOUNTING HOLES

Page 17

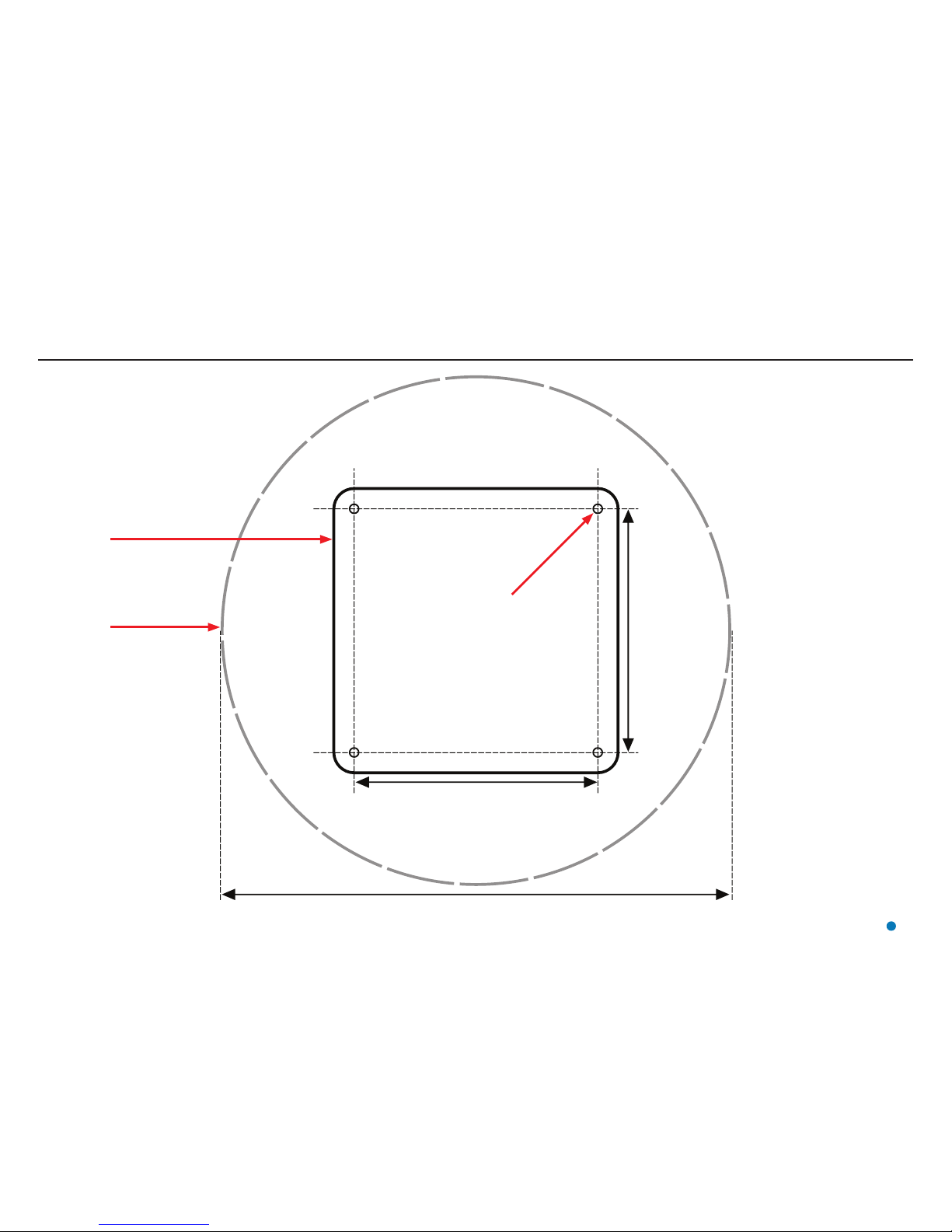

Mounting Template

240mm

500mm

240mm

Mounting Plate

NOT TO SCALE

Edge of

Radome

Four 9mm holes

(to take M8 bolts)

Ensure that any custom-made plinth is flat, rigid and

horizontal, able to support 25kg and to receive four M8

mounting bolts.

17

Page 18

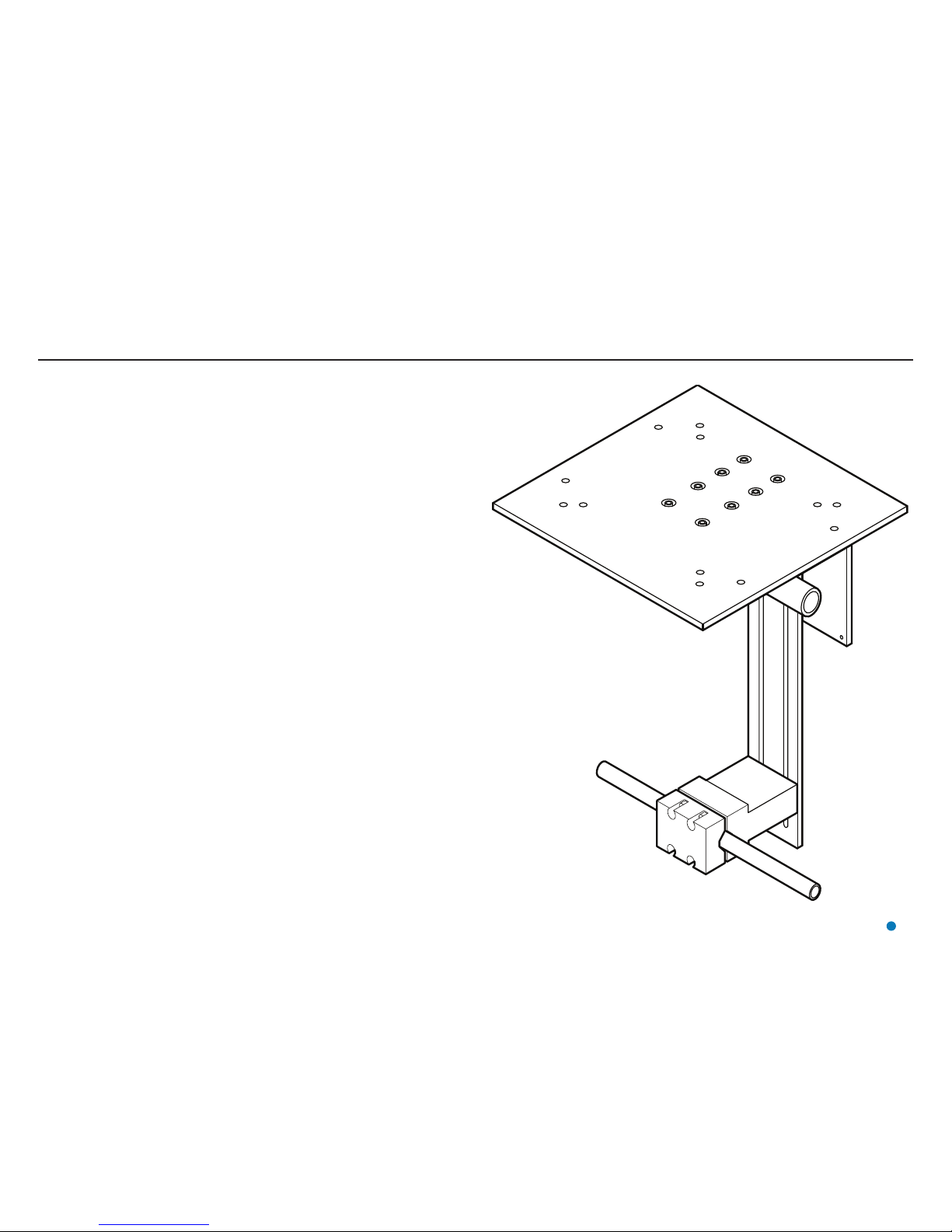

Universal Mounting Bracket

18

The Universal Mounting Bracket (Part No. 20-0120-1) can be used to mount the

RadaScan View sensor to a handrail or other suitable railing.

!

Ensure that the railing is strong enough to support the combined weight

of the sensor and bracket.

Page 19

19

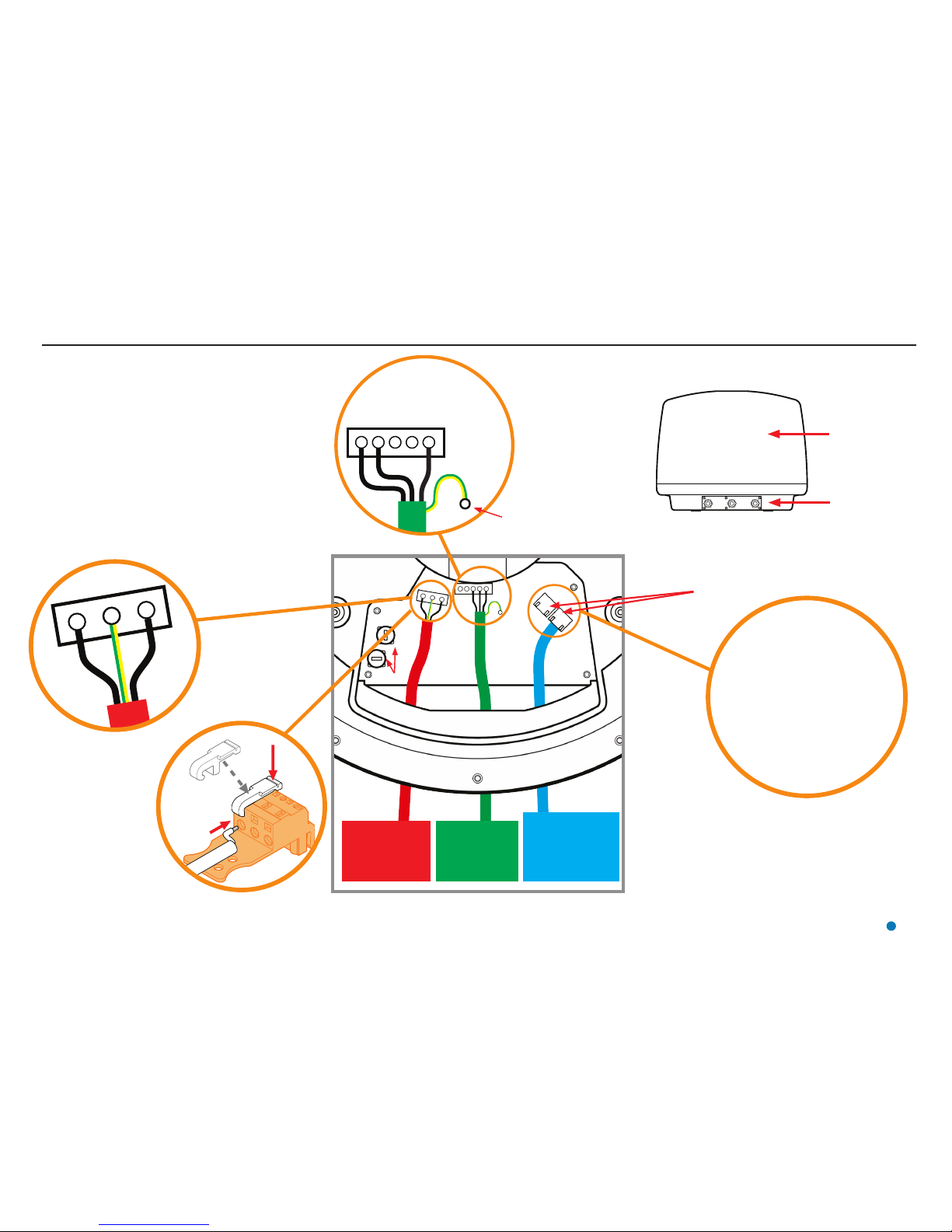

Sensor Connections—Direct

1

2

345

†See Network

Communication

Settings on page

32 or contact

Guidance Marine if

alternative settings

are required.

Default IP Addresses:†

RadaScan View Sensor:

192.168.2.231

Subnet Mask:

255.255.255.0

Marine Processor (LAN1):

192.168.2.241

Subnet Mask:

255.255.255.0

Radome

Connection Panel

Either Ethernet

socket may be

used

To Connect Cables to

Power/Serial Plugs:

Hook operation lever into

slot above connectorhole in plug.

Whilst holding down

lever, insert cable end

into connector-hole.

Release and remove

the operation lever.

TX +

TX −

RX −

RX +

GND

RS422 Link

9600 baud

8 bits

1 stop bit

No parity

!

The RadaScan View sensor installation should include a

double-pole disconnect device in the mains input wiring.

To Connect the Sensor:

1. Remove the radome and connection panel.

2. Feed the cables through the glands on the connection panel.

3. Connect the Ethernet, RS422 and Mains Power cables as

shown.

4. Lock the Ferrite Bead around the power cable as shown.

5. Apply DC4 silicone grease to the edge of the connection

panel, around the rim of the unit and into the cable glands.

6. Replace the connection panel and tighten the cable glands.

7. Replace the radome.

!

CAUTION

Double Pole/

Neutral Fusing.

Ethernet Link

to RadaScan

View Marine

Processor

RS422 Link

to Vessel’s

DP System

Mains Power

85–264V AC

45–65Hz 1.6A

Fuses

Fuse

Rating

250V T1.6A

(5 x 20mm)

CAT 5e

Cable

123

Live Earth Neutral

!

Sensor performance is

not guaranteed unless it

is properly earthed.

Attach cable screen

to DP earthing point

Page 20

Sensor Connections—Separate Connection Box

Live

Neutral

Earth

TXTX+

Signal GND

Signal GND

Screen

Earth

Lid and

Case Earth

1

2

3

6

1

2

3

6

Mains Power

85–264V AC

45–65Hz 45W

20

RS422 Link

to Vessel’s

DP System

Ethernet Link

to RadaScan

View Marine

Processor

RS422 Link

9600 baud

8 bits

1 stop bit

No parity

Default IP Addresses:†

RadaScan View Sensor:

192.168.2.231

Subnet Mask: 255.255.255.0

Marine Processor (LAN1):

192.168.2.241

Subnet Mask: 255.255.255.0

RadaScan View

Sensor

Connection

Box

Connection Box

Cables from

RadaScan

View Sensor

Power

DP Feed

Dashboard

Patch Cable

The Patch Cable can be disconnected at one end and

connected to a service laptop.

The laptop can then be used to check the Ethernet

link by ‘pinging’ either the Marine Processor or the

RadaScan View Sensor.

!

CAUTION

Double Pole/

Neutral Fusing.

!

The RadaScan View sensor

installation should include a

double-pole disconnect device

in the mains input wiring.

Fuse Rating:

2 x 250V T1.6A

(5 x 20mm)

CAT 5e Cable

CAT 5e Cable

†See Network

Communication Settings

on page 32 or contact Guidance

Marine if alternative settings are

required.

Page 21

Cable Routing Diagram - Direct Connection

Note: The Ethernet cable connecting

the Sensor to the Marine Processor

should not exceed 90 metres in

length.

Please contact Guidance Marine if

longer distances are required.

DP Instrument Room

Bridge

Mast

Emergency Breaker Box

Ethernet

Sensor Power

RS-422 Data

Monitor Cable

Monitor Power

Cable

Marine Processor

Power Cable

Power Cable

P/N 33-0121-3

(40m)

Data Cable

P/N 33-0451-3 (40m)

Ethernet Cable

P/N 33-0124-3 (40m)

16A

5A

5A

DP System UPS

DP System UPS

Interface Cabinet

RadaScan View

Sensor

Monitor

Link Cable

Dashboard

DP Feed

Power

Marine Processor

See page 23 for processor and monitor options

Power Adaptor

21

Page 22

Cable Routing Diagram - Separate Connection Box

Note: The Ethernet cable connecting

the Sensor to the Marine Processor

should not exceed 90 metres in

length.

Please contact Guidance Marine if

longer distances are required.

DP Instrument Room

Bridge

Mast

Emergency Breaker Box

Ethernet

Sensor Power

RS-422 Data

Monitor Cable

Monitor Power

Cable

Marine Processor

Power Cable

Power Cable

P/N 33-0121-3

(40m)

Data Cable

P/N 33-0451-3 (40m)

Ethernet Cable

P/N 33-0124-3 (40m)

16A

5A

5A

DP System UPS

DP System UPS

Interface Cabinet

RadaScan View

Sensor

Monitor

Link Cable

Dashboard

DP Feed

Power

Marine Processor

See page 23 for processor and monitor options

Power Adaptor

22

Connection

Box

Page 23

Cable Routing Diagrams - Processor and Monitor Options

Alternative Processor and Monitor Options

Any of the following configurations may be used (see pages 21, 22)

Processor: Type 3 Marine Processor (Part

Number 20-0231-0)

Monitor: 15” Desktop Monitor

(Part Number 20-0115-1)

Marine Processor

Desktop

Monitor

Monitor Power Cable

Monitor Cable

Power

Adaptor

Marine Processor

Power Cable

Marine Processor

Monitor Power Cable

Monitor Cable

Power

Adaptor

Marine Processor

Power Cable

Hatteland

Touchscreen

Monitor

Processor: Type 3 Marine Processor (Part

Number 20-0231-0)

Monitor: Hatteland Marine Touchscreen

Monitor (Part Number 20-0211-4)

Optional brackets: Hatteland Mounting

Bracket (Part Number 24-0259-4)

Hatteland VESA Bracket for Wall or Ceiling

(Part Number 24-0258-4)

Power Cable

Processor and Monitor: Hatteland

Panel PC (Integrated PC and Touchscreen

Monitor, Part Number 20-0182-1)

Optional brackets: Hatteland Mounting

Bracket (Part Number 24-0259-4)

Hatteland VESA Bracket for Wall or Ceiling

(Part Number 24-0258-4)

Hatteland

Panel PC

Ethernet

Ethernet

Ethernet

23

Page 24

Sensor Information Display

When the sensor has been powered up, the Sensor Information Display shows the sensor’s status

and network details. The display automatically cycles through the screens listed on the right. The

display cannot be paused. If the display sticks on one screen, the sensor should be restarted.

Information Display Location

The Sensor’s Information Display (VFD Screen) is on the side of the sensor, underneath the

radome:

Information Display Messages

Connection Status Indicators

The Connection Status Indicators are on the right-hand-side of the Information Display:

Information Display

ISO

TX

RX

5V

Isolated 5V Power

Ethernet Transmit

Ethernet Receive

5V Power

STATE: Idle

m, CPU: 2% RAM: 69MB

STATE: Idle

m, CPU: 2% RAM: 69MB

FPGA: 4.0.2.153

SERVER: 4.0.2.155

FPGA: 4..2.153

SERVER: 4..2.155

1: 00-50-C2-7A-7A-AD

IP: 192.168.2.231

1: -5-C2-7A-7A-AD

IP: 192.168.2.231

Sensor State

(Tracking or Idle)

Time since sensor powered up

CPU Usage

Network IP

Address

Server Version

FPGA Version

MAC Address

Second line: UpTime: xxd xxh xxm, CPU:xx% RAM: xxMB

Memory Usage

First line: LAN1: xx-xx-xx-xx-xx-xx

Each line of the Information Display is 20 characters in width. Messages that are wider than this

scroll from right to left.

24

Page 25

Sensor Information Display (continued)

When the sensor is booting, the Sensor

Information Display shows progress via the

following sequence of messages.

MiniRS booting...MiniRS booting...

Messages upon power-up

Operating System

Ver: 4.0.2.155

Operating System

Ver: 4..2.155

Starting Sensor

....

Starting Sensor

....

Resetting Done

....

Resetting Done

....

Host: Compact

Searching for IP -

Host: Compact

Searching for IP -

Host: Compact

IP: 192.168.2.231

Host: Compact

IP: 192.168.2.231

STARTING... BOOT: OK

IP: 192.168.2.231

STARTING... BOOT: OK

IP: 192.168.2.231

Second Stage boot

Ver: 4.0.2.155

Second Stage boot

Ver: 4..2.155

Operating System

Ver: 4.0.2.155

Operating System

Ver: 4..2.155

Starting Sensor

....

Starting Sensor

....

A self-test is run. If this fails and a reboot

takes place, the following messages are

also seen:

If any of the following messages are displayed, take the action stated.

Troubleshooting

Cause: Missing SD card.

Action: Contact Guidance Marine.

No SD card image

Booting via Ethernet

No SD card image

Booting via Ethernet

Cause: SD card error.

Action: Contact Guidance Marine.

SD card Error

Rebooting

SD card Error

Rebooting

Cause: Missing server application.

Action: Reinstall the sensor software

(see page 26).

No Application

Run remote install

No Application

Run remote install

Cause: Server problem.

Action: Reinstall the sensor software (see page 26).

Application failed

Loading Backup

Application failed

Loading Backup

25

Page 26

Your RadaScan View sensor will have been shipped from Guidance Marine with software

already installed. However, it may be necessary from time to time to upgrade the software

with a newer version.

To

Upgrade the Sensor Software:

1. Locate the RadaScan.Installer.Remote.exe file on the USB memory stick on which it

was supplied.

2. Double-click on the RadaScan.Installer.Remote.exe file.

The RadaScan Installation Configuration screen is displayed.

3. If the IP Address shown is not correct for your sensor, amend it.

4. Click on OK.

After a couple of minutes, if the installation is successful, the RadaScan Installation

Summary screen shows “Installation Complete”.

If you needed to amend the IP Address in step 3, follow the instructions in Network

Communication Settings on page 32.

If there are problems during the installation, refer to the file InstallLog_<Date_Time>.txt,

which can be found at the same location as the RadaScan.Installer.Remote.exe file.

RadaScan Installation

Configuration Screen

RadaScan Installation

Summary Screen

26

Installing the Sensor Software

In the unlikely event that the installation has become corrupted, contact Guidance Marine

or an approved service representative.

Page 27

27

Before setting up the RadaScan View client computer(s), refer to the relevant installation sheet(s) for

dimensions and connection information:

For a Type 3 Marine Processor:

•

94-0465-4 Type 3 Marine Processor and Display Installation Sheet

For a Hatteland Panel PC:

•

94-0466-4 Hatteland Panel PC Installation Sheet

The following pages explain how to install the client software:

•

Installing RadaScan Client Software onto a Type 3 Marine Processor (page 28)

•

Installing RadaScan Client Software onto other Types of Computer (page 29)

Installing the Marine Processor

Page 28

Installing RadaScan View Client Software onto a Type 3 Marine Processor

This section explains how to install the RadaScan View client software onto a Type 3 Marine Processor.

If this Marine Processor has been supplied by Guidance Marine, it will have been shipped with the client

software already installed. However, it may be necessary to upgrade the software with a newer version. If

so, first uninstall the existing software in the usual way, following on-screen prompts.

To Install the Dashboard:

1. Locate the RadaScanDashboardSetup.exe and RadaScanServiceInterfaceSetup.exe files on the

USB memory stick on which they were supplied.

2. Double-click on the RadaScanDashboardSetup.exe file.

The Welcome screen is displayed.

3. Click on the Install button.

4. When prompted, click on the Restart button.

After the restart, the RadaScan Dashboard Setup screen is displayed.

5. If required, change any of the settings from the default values shown.

6. Click on the OK button.

7. When prompted, click on the Restart button.

The installation process is complete following the restart.

8. Repeat steps 2..7 for RadaScanServiceInterfaceSetup.exe.

Welcome Screen

RadaScan Dashboard Setup Screen

Setup Successful Screen

!

NOTE: The RadaScan

Service Interface should

only be installed onto one

computer in the system.

The Dashboard may be

installed onto multiple

computers.

Conguration Settings

When installing the Dashboard, adjust the following setings or allow to default:

Communications Parameters

Ensure that the sensor’s IP address is shown, otherwise enter “127.0.0.1” in order to run the Dashboard

with a RadaScan Emulator on the same computer.

Display

If the Enable Dashboard On-Screen Keyboard box is ticked, the OSK will pop up when you focus on a

text or numerical entry field (typically used on a system without a keyboard).

Data Logging

The Minimum Free Disk Space (Mb) field defines an amount of disk space that the Dashboard will leave

free when writing log files. The Dashboard automatically begins to trim log data when the disk space falls

below a threshold determined by [Minimum Free Disk Space (Mb) + Additional Free Disk Space

Buffer (Mb)].

28

Page 29

Installing RadaScan View Client Software onto other Types of Computer

This section explains how to install the RadaScan View client software onto a computer running Windows 7

that does not have a File-Based Write Filter. This PC should have the following installed:

•

Full .NET Framework 4.0 or later

•

Visual C++ 2012 Redistributable (x86)

If you are upgrading to newer versions of the RadaScan View client software, first uninstall the existing

versions in the usual way, following on-screen prompts.

To Install the Dashboard:

1. Locate the RadaScanDashboardSetup.exe and RadaScanServiceInterfaceSetup.exe files on the

USB memory stick on which they were supplied.

2. Double-click on the RadaScanDashboardSetup.exe file.

The Welcome screen is displayed.

3. Click on the Install button.

The RadaScan Dashboard Setup screen is displayed.

4. If required, change any of the settings from the default values shown.

5. Click on the OK button.

When the installation has finished, the Setup Successful screen is displayed.

6. Click on the Close button.

7. Repeat steps 2..6 for RadaScanServiceInterfaceSetup.exe.

Welcome Screen

RadaScan Dashboard Setup Screen

Setup Successful Screen

!

NOTE: The RadaScan

Service Interface should

only be installed onto one

computer in the system.

The Dashboard may be

installed onto multiple

computers.

29

Page 30

Conguring the RadaScan View System

30

This section contains the following pages:

•

Using the RadaScan Service Interface (page 31)

•

Network Communication Settings (page 32)

•

Vessel Definition (page 34)

•

Blanking Zone (page 38)

•

DP Feed Configuration (page 39)

•

Information Tabs (page 41)

Page 31

Using the RadaScan Service Interface

The RadaScan Service Interface (RSI) is a tool for configuring the RadaScan View system.

To open the RadaScan Service Interface

Ensure that the sensor is powered on and connected to the control computer.

1. Double-click on the RSI icon:

(Alternatively, run from the Start menu:

Start > All Programs > Guidance Marine Ltd > RadaScan > RadaScan Service Interface).

Screen Layout of the RSI

The upper part of the RSI window contains fields relating to communications, as follows:

Take Command / Relinquish Command – This button allows the user to toggle the command

mode of the RSI between In Command and Monitoring.

Connect – Replaces Take Command / Relinquish Command when the RSI is disconnected from

the sensor, allowing re-connection.

Resume - Replaces Take Command / Relinquish Command when the sensor is suspended,

allowing it to be resumed.

In Command Indicator – This red block symbol is visible when the RSI is In Command mode.

Status Display – Indicates the current status of the system, e.g. “System Running Normally” or

“System Suspended”.

Activity Wheel – A green rotating animation when the RSI is connected to the sensor; green and

stationary when disconnected; red and stationary if there is an error condition.

The remainder of the RSI screen is occupied by one of several tab areas.

The Status Tab

The Status tab gives an overview of the operational state of the system; it contains the following

fields and control buttons:

Connected State – Whether the RSI is “Connected” to the sensor or “Disconnected”.

Sensor State - “Running” or “Suspended” when the RSI is connected; “Unknown” when not

connected.

Suspend / Resume – Allows the sensor to be suspended when running or resumed when

suspended; enabled only when the RSI is In Command. Displays “---“ when not connected.

Sensor Type – “Mini”, “Mini with Radar Image” or “Maxi” if the RSI is connected to a physical

sensor, “Emulator” if connected to the RadaScan Emulator application or blank if not yet

connected.

Tracking State – “Not Tracking”, “Starting Tracking” or “Tracking”.

#Tracked Targets – How many targets are being tracked, including any that are rejected or

obscured. Displays “N/A” when tracking is not in progress.

Last Time Feedback Received – In hh:mm:ss format; updated once per second. Blank when

the RSI is not connected.

Reboot Sensor – Enabled only when the RSI is in command mode and tracking is not in

progress.

31

Page 32

Network Communication Settings

The Network Config tab of the RSI is used to view and amend the RSI’s record of the sensor’s

network IP address and also to remotely amend the address on board the sensor.

The network IP address is displayed on the Sensor Information Display (see page 24).

!

NOTE: Where the Dashboard and RSI are installed on the same computer, they share a

common record of the sensor’s network IP address. If it is amended using one application,

the other picks up the change when next opened.

To Modify the RSI’s Record of the Sensor’s Network IP Address

1. Click on the Network Config tab of the RSI.

2. Click on the Disconnect button if the RSI is connected to the sensor.

3. Click on the Edit button in the Service Interface to Sensor Communications section.

4. Amend the Sensor Address as required.

5. Click on Apply to save the changes or on Cancel to discard.

To Modify the Dashboard’s Record of the Sensor’s Network IP Address

1. Click on the Guidance button to open the Guidance Home menu.

2. Unless the Dashboard is already in Monitoring mode, click on Relinquish Command.

3. Click on Disconnect.

4. Navigate to Advanced > Comms Settings.

5. Click on Edit.

6. Amend the Address field as required.

7. Click on the Apply button to confirm.

32

Page 33

Network Communication Settings (continued)

To Remotely Modify the Sensor’s On-Board Network IP Address

1. Ensure that the RSI is in command and that no tracking is in progress.

2. Click on the Network Config tab of the RSI.

3. Click on the Edit button in the Sensor On-Board Network Configuration section.

4. Amend the Sensor Address as required.

5. Click on Apply to save the changes.

Communications between the RSI and sensor are then lost as the sensor is rebooted. After a

minute or two, the Rebooting pop-up window is replaced by Reboot Request Succeeded. Click

on the OK button to return to normal operation.

33

Page 34

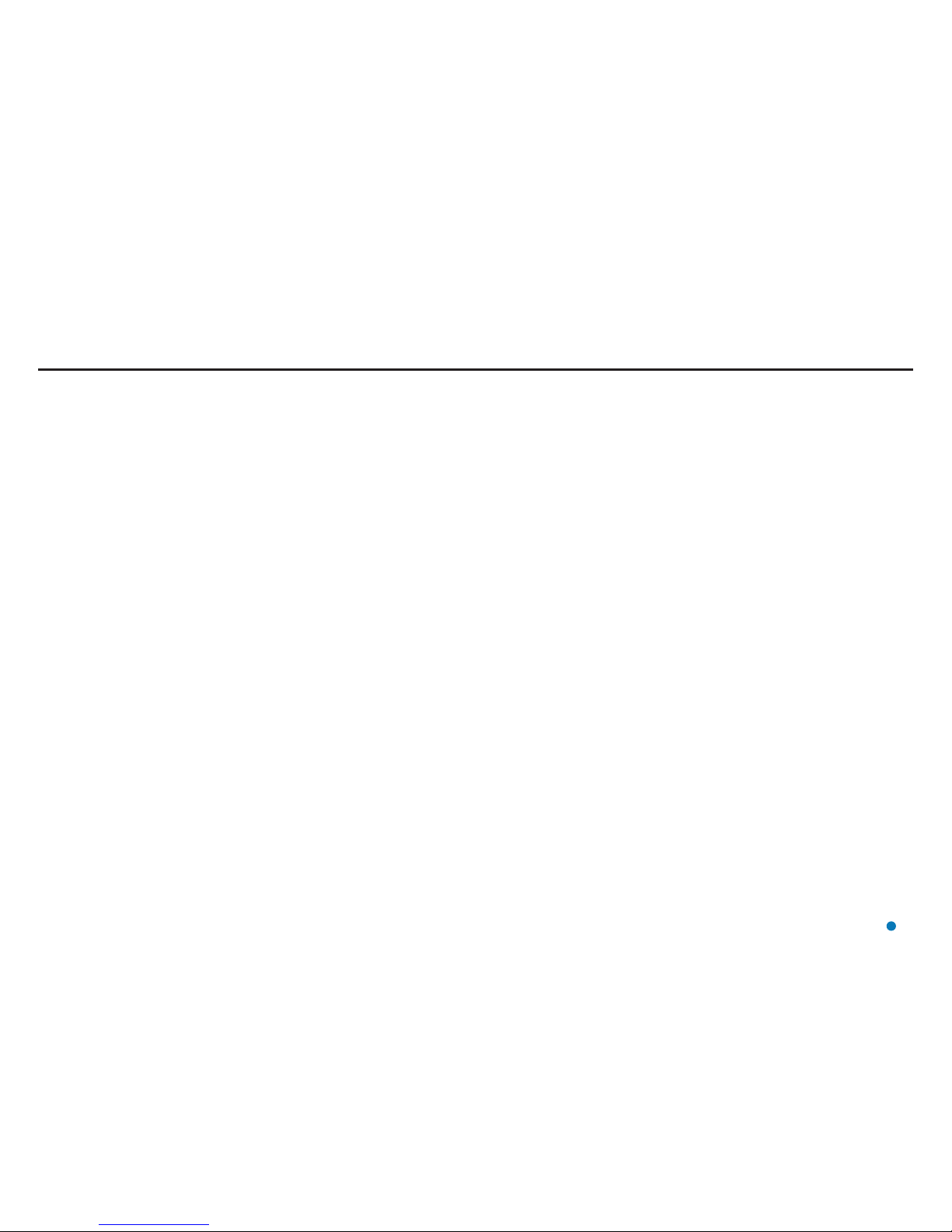

Vessel Denition

The Vessel tab allows you to define the dimensions of the vessel outline on the Bird’s Eye

View of the Dashboard, the name of the vessel and other items as follows:

•

Vessel Name: The name of your ship. This is displayed beneath the primary system

status near the top right corner of the Dashboard screen.

•

Vessel Length: The distance from the bow to the stern of the vessel, in metres.

•

Vessel Breadth: The width or beam of the vessel in metres.

•

Bow Offset: Distance from the centre of the RadaScan View sensor to the vessel’s bow,

in metres.

•

Starboard Offset: Distance from the centre of the sensor to the vessel’s starboard side,

in metres.

•

Bearing Offset: This should be 0° if the sensor is facing aft, mounted exactly parallel

to the vessel’s centre-line running from bow to stern. If the sensor is at a slight angle

to the centre-line, enter a positive or negative Bearing Offset to compensate for this.

See Bearing Offset on page 36 for the value to use if the sensor is facing in another

direction.

•

Display Vessel Orientation: The default direction of the vessel bow as displayed on

the Dashboard BEV. Changing this setting rotates the whole BEV but does not affect

the data sent to the DP system. Note that this setting can be overridden for the current

Dashboard session via Advanced > Display Options > Screen Layout, but the BEV

reverts to the default orientation when the Dashboard is closed and re-opened.

.

Modifying Vessel Definition

In order to amend any of the above parameters:

1. Click on the Take Command button if the RSI is not already in command mode.

2. On the Vessel tab, click on the Edit button.

3. Amend the vessel definition as required.

4. Click on Apply to save the changes or on Cancel to discard.

34

Page 35

Vessel Denition (continued)

Starboard Offset

Bow Offset

RadaScan

View Sensor

Port Side Starboard Side

Bow and Starboard Osets

Enter the correct Bow and Starboard Offset values on the Vessel tab

(See Vessel Definition on page 34)

35

Page 36

Vessel Denition (continued)

RadaScan View

Sensor

Vessel Centre-line

Connection

Panel

Operating

Area

Sensor Facing Aft

Connection panel facing forward,

Sensor parallel with vessel centre-line.

Bearing Offset = 0°

Sensor Facing Forward

Connection panel facing aft,

Sensor parallel with vessel centre-line.

Bearing Offset = 180°

Sensor Facing Port

Connection panel facing starboard,

Sensor perpendicular to vessel

centre-line.

Bearing Offset = 90°

Sensor Facing Starboard

Connection panel facing port,

Sensor perpendicular to vessel centre-line.

Bearing Offset = −90°

180°

−90°

90°

0°

Key

Bearing Oset

Enter the correct Bearing Offset value on the Vessel tab

(See Vessel Definition on page 34)

•

If the sensor is facing directly Aft,

enter a 0° bearing offset.

•

If the sensor is facing directly Forward,

enter a 180° bearing offset.

•

If the sensor is pointing to Port,

enter a Positive bearing offset, e.g. 90°

•

If the sensor is pointing to Starboard,

enter a Negative bearing offset, e.g. −90°.

36

Page 37

Vessel Denition (continued)

Reset, Import and Export of Vessel Denition

The Vessel Definition can be reset to factory defaults, imported from an XML or CTF file or

exported to an XML file.

To Reset to Factory Defaults:

1. Ensure that no target tracking is in progress.

2. Click on the Take Command button if the RSI is not already in command mode.

3. On the Vessel tab, click on the Defaults button.

To Import Vessel Definition from a File:

1. Ensure that no target tracking is in progress.

2. Click on the Take Command button if the RSI is not already in command mode.

3. On the Vessel tab, click on the Import button.

4. Locate the required .xml or .ctf file in the file browser window.

5. Click on the Open button.

To Export Vessel Definition to a File:

1. Ensure that no target tracking is in progress.

2. Click on the Take Command button if the RSI is not already in command mode.

3. On the Vessel tab, click on the Export button.

4. Specify a destination and file name in the file browser window.

5. Click on the Save button.

37

Page 38

Blanking Zone

A Blanking Zone can be used to mask the segment of the scan rotation that is obscured by the

vessel’s superstructure. The start and end of the zone can be set to any positions around the circle

to the nearest degree.

Generally, once the blanking zone has been set, it will not need to be changed.

!

The option to change the blanking zone

is not available whilst tracking.

To Dene a Blanking Zone

1. Ensure that no target tracking is in progress.

2. Click on the Take Command button if the RSI is not already in command mode.

3. On the Blanking tab, click on the Edit button.

4. Amend the blanking zone Start and Stop fields as necessary (if you wish to delete a zone,

set Start and Stop to the same value).

5. Click on Apply to save the changes or on Cancel to discard.

38

Page 39

DP Feed Conguration

The RadaScan View system provides positional data messages to your vessel’s DP (Dynamic

Positioning) system and the format and behaviour of this output stream needs to meet the

requirements of the DP system.

The current DP configuration settings are displayed on the DP Config tab of the RSI, along with

the data output relating to the primary (or only) target. See DP Message Types (page 54) for

details of each available message format and DP Feed Behaviour (see right) for the function of

the Keep Feed Enabled and Allow Zero Strings tick-boxes.

Modifying the DP Conguration

1. Ensure that no target tracking is in progress.

2. Click on the Take Command button if the RSI is not already in command mode.

3. On the DP Config tab, click on the Edit button.

4. Amend the settings as required.

5. Click on Apply to save the changes or on Cancel to discard.

DP Feed Behaviour

The DP Feed Behaviour options are two tick-boxes available on the DP Feed pane in Service

Access Mode:

Keep DP feed always enabled

Allow refresh timer & zero strings

These determine what data is sent to the DP system if a target is lost during tracking. Also when

the system is running but not tracking, or is suspended.

The DP Feed Behaviour settings must be set correctly for the vessel’s DP system. Incorrect

settings can cause serious problems. Refer to the vessel’s DP system supplier for the

required configuration.

The following behaviour applies when target tracking:

For all DP formats except for MT Custom:

Keep Feed

Enabled

Allow Zero

Strings

Output when tracking and target is lost

Null data (gaps in data string)

Null data (gaps in data string)

Zero data (coordinates set to zero, status = V †)

Zero data (coordinates set to zero, status = V †)

For the MT Custom DP format, Zero data (coordinates set to zero, status = V) is output when the

target is lost. The DP Feed Behaviour options have no effect.

Keep Feed

Enabled

Allow Zero

Strings

Output when target is visible but not tracked

Null data (gaps in data string)

Void data (actual coordinates but status = V)

Zero data (coordinates set to zero, status = V)

Void data (actual coordinates but status = V)

† Denotes that not all of these DP formats include a Status field, but for those that do, it is set to

“V”.

The following behaviour applies whilst the system is operational but not tracking:

For NMEA Raw and NMEA Primary DP formats:

39

Page 40

For Rolls Royce Custom DP format:

Keep Feed

Enabled

Allow Zero

Strings

Output when target is visible but not tracked

Null data (gaps in data string)

Available data (actual co-ordinates, status = A)

Zero data (coordinates set to zero, status = V)

Available data (actual co-ordinates, status = A)

For the MT Custom DP format, Available data (actual co-ordinates, status = A) is output when a

target is visible but not tracked. The DP Feed Behaviour options have no effect.

The following behaviour applies when the system is suspended:

For all DP formats except for MT Custom:

Keep Feed

Enabled

Allow Zero

Strings

Output when system is suspended

Null data (gaps in data string)

Null data (gaps in data string)

Zero data (coordinates set to zero, status = V †)

Zero data (coordinates set to zero, status = V †)

DP Feed Conguration (continued)

For the MT Custom DP format, Zero or Stale data (coordinates set to zero or to previous known

values, status = V) is output when the system is suspended. The DP Feed Behaviour options

have no effect.

† Denotes that not all of these DP formats include a Status field, but for those that do, it is set

to “V”.

For MDL Standard, MDL Multi-Target and Kongsberg Standard DP formats:

Keep Feed

Enabled

Allow Zero

Strings

Output when target is visible but not tracked

Null data (gaps in data string)

Null data (gaps in data string)

Zero data (coordinates set to zero)

Zero data (coordinates set to zero)

40

Page 41

Information Tabs

The RSI contains several tabs that contain read-only information about the RadaScan View

system.

The Clients Tab

This lists each Dashboard currently connected to the RadaScan View sensor, in addition to the

RSI itself. It gives the command mode and computer name of each.

The Alarms Tab

This lists each sensor-based alarm event that has occurred since the RSI was opened. Alarms

sourced in the Dashboard are not included. Note that there are separate entries for starting and

stopping the same alarm, unlike the Dashboard Alarms pane which gives start and stop times on

one line.

41

Page 42

Information Tabs (continued)

The About Tab

This contains version information for the RSI and sensor, the serial number of the sensor, contact

details for Guidance Marine Ltd and a button for opening an on-screen copy of this Installer’s

Guide.

42

Page 43

This section explains how to install and maintain RadaScan View Responders.

It contains the following pages:

•

Responder Overview (page 44)

•

Positioning Responders (page 46)

•

Mounting Responders (page 47)

•

Charging Responders (page 49)

•

Operating Responders (page 50)

Installing Responders

43

Page 44

Responder Overview

Series 2 and 3 Responders can be used with RadaScan and RadaScan View systems. One or

more Responders should be mounted on the target platform or vessel.

The following models of RadaScan Series 2 Responder are no longer available but may be

encountered in the field.

•

Rechargeable (Part No. 20-0108-1)

•

Rechargable - Low Temperature (Part No. 20-0108-L-1)

•

Primary Cell Responder (Part No. 20-0138-1)

The Primary Cell Responder is powered by a Primary Cell Pack (Part No. 21-0314-1). This

requires battery replacement as routine maintenance. This should be undertaken by Guidance

Marine, or by a suitably qualified service technician.

There are four models of RadaScan Series 3 Responder:

•

Rechargeable (Part No. 20-0189-2)

•

Mains Powered (Part No. 20-0195-2)

•

Primary Cell Responder (Part No. 20-0194-2)

•

Narrow Beam Primary Cell Responder (Part No. 20-0196-2)

The Mains Powered Responder is used with Responder AC/DC power supply (Part No.

21-0377-2).

Both types of Primary Cell Responder are powered by a Primary Cell Pack (Part No. 21-0375-

1). This requires battery replacement as routine maintenance. This should be undertaken by

Guidance Marine, or by a suitably qualified service technician.

!

Do not open the Responder. It should only

be serviced by Guidance Marine,

or a suitably qualified service technician.

If you experience any problems with the unit,

please contact:

Guidance Marine Ltd

5 Tiber Way

Meridian Business Park

Leicester

LE19 1QP

United Kingdom

Tel: +44 116 229 2665

Email: customerservices@guidance.eu.com

RadaScan Series 2

Responder

ATEX Certification Label (for illustration

purposes – actual label may be

formatted differently)

RadaScan Series 3

Responder

44

Page 45

Instructions for Safe Selection, Installation, Use, Maintenance, Repair and

Transport

User instructions (in compliance with ATEX 94/9/EC Directive, Annex II, 1.0.6)

Unit Part No. Temperature Range ATEX Certification No.

Series 2

Rechargeable 20-0108-1 -25°C to +55°C SIRA 11ATEX2254X

Rechargeable 20-0108-L-1 -40°C to +55°C SIRA 11ATEX2254X

Primary Cell Responder 20-0138-1 -40°C to +55°C SIRA 11ATEX2286X

Primary Cell Pack 21-0314-1 -40°C to +55°C SIRA 11ATEX2286X

Series 3

Rechargeable 20-0189-2 -40°C to +55°C SIRA 15ATEX2015X

Mains Powered 20-0195-2 -40°C to +47°C SIRA 15ATEX2047X

Primary Cell Responder 20-0194-2 -40°C to +55°C SIRA 15ATEX2048X

Narrow Beam Primary

20-0196-2 -40°C to +55°C SIRA 15ATEX2048X

Cell Responder

Primary Cell Pack 21-0375-1 -40°C to +55°C SIRA 15ATEX2048X

Use in Hazardous Environments

•

Series 2 responders and primary cell packs may be used in zones 1 or 2 with flammable gases.

•

Series 3 responders and primary cell packs may be used in zones 0, 1 or 2 with flammable

gases.

•

All Series 2 and 3 responders and primary cell packs may be used in the presence of flammable gases

and vapours with apparatus groups IIB or IIA and with temperature classes T1 or T2 or T3 or T4.

•

The equipment is certified for use in ambient temperatures in the applicable range shown above and

should not be used outside this range.

Installation and Maintenance

•

Responders must be installed by suitably trained personnel in accordance

with the applicable code of practice (typically IEC EN 60079-14).

•

Responders must be inspected regularly by suitably trained personnel in accordance

with the applicable code of practice to ensure they are maintained in a satisfactory condition.

•

Responders are not intended to be repaired by the user. They must only be repaired or serviced by

Guidance Marine, or by an approved service representative of Guidance Marine, in accordance with

the applicable code of practice.

•

Responders do not require assembly or dismantling.

They do not contain any customer-replaceable parts, and no user adjustment is required.

Responder Overview (continued)

Responder Colours

Each Series 2 or 3 Responder uses one of four different modulation frequencies. These are

characterised as colours: Red, Yellow, Green and Blue. The colour of a responder is clearly

marked on the outside of its case, and is shown next to its ID number on the Reflections and

Extended Information panes of the Dashboard.

This scheme makes it easier for the RadaScan View system to separate the signal from one

responder from the signal from a responder of a different colour. If you use more than one

responder at once, then for best results make sure that you use a different colour for each

responder.

Electrostatic Hazard

•

Responders must not be installed where external conditions could cause an electrostatic build-up

on their outer casing.

•

The Responder’s outer casing presents a static hazard and must only be cleaned using a damp

cloth.

Corrosive Substances

•

Responders should be protected from solvents, or acidic gases or liquids that may affect the

integrity of the outer case.

Transport

•

Responders must be transported in a suitable transit case.

45

Page 46

Positioning Responders

The location, range and orientation of the Responders in relation to the Sensor have a significant

effect on the tracking performance of the RadaScan View system, and hence on the quality of the

position data sent to the DP system.

The RadaScan View system is based on radar technology. Metallic structures reflect the

microwave beam transmitted by the sensor, and can cause multipath interference, where ghost

images are reported by the system. However, this unwanted phenomenon can be prevented by

carefully positioning the responders according to the following guidelines:

Responders Should be Mounted:

With a clear, unobstructed view towards the RadaScan View-equipped vessel.

At a height no lower than two metres below the vessel-mounted Sensor.

At a height no higher than five metres above the vessel-mounted Sensor.

On outside corners of the rig or platform to minimise the amount of

metallic structure around them.

Good Location

Good angle of incidence.

Lower angle of elevation allows

vessel to pick up responder on

approach.

Longer range aids performance

in high sea states.

Usually clear of obstructions

and away from enclosed corners.

Provides adequate cover

during vessel manœuvres.

R

Rig/Platform RadaScan View Vessel

Good

Responder

Locations

Poor Location

Good angle of incidence.

Steep angle of elevation prevents

vessel from picking up responder

on approach.

Shorter range inhibits performance

in high sea states.

Often surrounded by obstructions

and radar-reflecting metalwork.

Does not provide adequate cover

during all vessel manœuvres.

R

Rig/Platform RadaScan View Vessel

Poor

Responder

Location

Responders Should NOT be Mounted:

On inside corners.

Below an overhang.

On lower service decks below a main-deck overhang.

Suspended from a lanyard or length of rope.

46

Page 47

Mounting Responders

Loosen the nut to swivel the

bracket in the required direction.

!

Tighten the nut with a

spanner to fix the bracket’s

position.

The responder can be used with or without a swivel bracket, as

long as it is mounted with its longest side vertical, and its carryinghandle at the top.

To Mount the Responder:

1. Hook the foot of the responder underneath the knob on the

bottom of the mounting plate. (See below).

2. Rotate the responder backwards until it is held in place by its

magnet against the mounting plate.

3. (Optional) Attach safety lanyard onto the responder and the

swivel bracket or other fixture.

Knob

Mounting

Plate

Magnet

Swivel Bracket

The swivel bracket (Part No. 21-0328-1) should be used to point

the responder towards the RadaScan View Vessel’s working area.

It can be mounted on either a horizontal or vertical bar:

Swivel Bracket

Mounting on Horizontal Bar Mounting on Vertical Bar

Swivel Bracket

47

Page 48

Mounting a Primary Cell Responder

with a Primary Cell Pack:

Mounting Responders (continued)

Responder Swivel-

bracket with 2 x U-bolts

Primary cell pack bracket

(Part No. 21-0340-1)

with 2 x thumb screws

Bracket tail to provide

additional support

Primary Cell Pack

(Part No. 21-0314-1 for Series 2

or 21-0375-1 for Series 3)

Lanyard attachment points

48

Page 49

Charging Responders

The rechargeable responder should be fully charged before use.

A full charge takes approximately 24 hours.

!

DO NOT charge responders in an explosive

atmosphere or other hazardous environment.

The responder should be switched off while charging.

To Charge the Responder:

!

Note: Only use the supplied charger. Only charge at ambient temperatures of 0°C to

+45°C.

1. Switch the responder off and unscrew the charging socket cap on the rear of the unit.

2. Connect the supplied mains charger (Part No. 39-0049-2).

(Input: 100–240VAC, 50–60Hz, 1.5A Output: 24VDC, 2.5A, 60W).

3. When charging is complete, disconnect the power from

the unit and replace the charging socket cap.

Rechargeable Responder—Rear

Charging

Socket

49

Page 50

Operating Responders

The responder must always be used with its longest side vertical,

and its carrying handle at the top.

Switch the unit off when not in use to preserve the battery.

!

The responder is water resistant.

However, do not submerge the unit in water.

To Switch the Responder ON:

•

Press the ON/OFF button at the top of the unit.

•

For a rechargeable responder, the green light in the centre of the

button indicates how much battery charge is remaining (assuming

24/7 operation):

Light solidly on Up to 22 days left

1 flash in 5 seconds Up to 10 days left

3 flashes in 5 seconds Up to 1 day left

•

For a mains powered responder, the light should flash with an

interval of 5 seconds.

•

For a primary cell responder, the light indicates the state of the

primary cell pack:

1 flash in 5 seconds PCP normal

3 flashes in 5 seconds PCP low

Under normal conditions, the primary cell responder will operate for up

to one year before the batteries need replacing.

!

When a rechargeable responder is switched on and the green

light is not illuminated, recharge the battery.

!

When a primary cell responder is switched on and the green

light does not flash at all, replace the primary cell. The batteries

within the primary cell may be replaced, but this must only be

done in an ATEX safe environment, using batteries supplied by

Guidance Marine or authorised partners.

ON/OFF Button

50

Page 51

This section contains the following appendices:

•

International Standards Compliance (page 52)

•

Part Numbers (page 53)

•

DP Message Types (page 54)

•

UPS and Cable Specifications (page 58)

•

Installation Checklist (page 59)

•

Index (page 61)

Appendices

51

Page 52

International Standards Compliance

RadaScan View Transceiver

European Union

The equipment is permitted to be used in all EU member states

without the need for a specific administrative licence.

The RadaScan View X-band Transceiver meets the requirements of Directive 2004/108/EC.

The equipment complies with EN 60945:2002.

Norway

Note that in Norwegian waters a maritime radio licence is required for

the use of the RadaScan View Dynamic Positioning Sensor.

Please contact Telenor Maritime Radio to obtain a licence:

Telenor Maritime Radio

Radio Licensing Department

N-1331 FORNEBU

NORWAY

Tel: +47 22 77 43 50

Fax: +47 22 42 70 72

Web: www.maritimradio.no

USA

Use of the RadaScan View system in the United States of America is authorised

by the Federal Communications Commission. FCC ID: VYMRADASCAN.

RadaScan Responders

EU ATEX Directive 94/9/EC, Annex II, 1.06

RadaScan responders are certified as intrinsically safe and can be used with flammable gases and

vapours belonging to gas groups IIA/B.

Series 2 responders can be used in zones 1 and 2.

Series 3 responders can be used in zones 0, 1 and 2.

US

(See page 45)

52

Page 53

Sensor

Component Part Number

RadaScan View Sensor 20-0174-0

Universal Mounting Bracket 20-0120-1

Guidance Marine System Level USB 180-0011-4

Operator’s Guide 94-0491-4

Installer’s Guide 94-0492-4

Marine Processor

Component Part Number

Type 3 Marine Processor 20-0231-0

Hatteland Panel PC 20-0182-1

Cables

Component Part Number

Power Cable (40m) 33-0121-3

Data Cable (40m) 33-0451-3

Ethernet Cable (40m) 33-0124-3

Ethernet Connector Plug 80-0075-4

Part Numbers

Responders

Component Part Number

Series 2

Responder (Rechargeable) 20-0108-1

Responder (Rechargeable) 20-0108-L-1

Primary Cell Responder 20-0138-1

Primary Cell Pack 21-0314-1

Recharger 39-0033-2

Series 3

Responder (Rechargeable) 20-0189-2

Responder (Mains Powered) 20-0195-2

Primary Cell Responder 20-0194-2

Narrow Beam Primary Cell Responder 20-0196-2

Primary Cell Pack 21-0375-1

PCP Interface cable 33-0392-3

Recharger 39-0049-2

Mains Power Supply 21-0377-2

Mains PSU Interface Cable 33-0395-3

Lanyard 24-0260-2

Common

Swivel Bracket 21-0328-1

Primary Cell Bracket 21-0340-1

53

Page 54

NMEA Raw Format

A 42-character string:

$RLS,±AAA.AA,±BBB.BB,S1,XXX.XXX,S2,HHHH*CC<CR><LF>

Where:

•

$RLS message header

•

AAA.AA resolved raw position in A axis [metres]

•

BBB.BB resolved raw position in B axis [metres]

•

S

1

status of position data in A and B axis, [A] available; [V] void

•

XXX.XXX resolved heading of vessel with respect to A axis [degrees]

•

S

2

status of bearing data, [A] available; [V] void

•

HHHH status word in hexadecimal. Up to 16 bits defined by Guidance Marine in a separate

specifications document

•

CC computed checksum in hex

•

<CR> Carriage return (ASCII 0D hex)

•

<LF> Line feed (ASCII 0A hex)

!

Note: Although NMEA Raw and NMEA Primary share the same syntax, they produce different

values for AAA.AA and BBB.BB for a given layout of responders and are therefore not

interchangeable. The message type selected on the Dashboard must always match the

message type selected on the vessel’s DP system.

NMEA Primary Format

A 42 character string:

$RLS,±AAA.AA,±BBB.BB,S1,XXX.XXX,S2,HHHH*CC<CR><LF>

Where:

•

$RLS message header

•

AAA.AA resolved primary position in A axis [metres]

•

BBB.BB resolved primary position in B axis [metres]

•

S

1

status of position data in A and B axis, [A] available; [V] void

•

XXX.XXX resolved heading of vessel with respect to A axis [degrees]

•

S

2

status of bearing data, [A] available; [V] void

•

HHHH status word in hexadecimal. Up to 16 bits defined by Guidance Marine in a separate

specifications document.

•

CC computed checksum in hex

•

<CR> Carriage return (ASCII 0D hex)

•

<LF> Line feed (ASCII 0A hex)

DP Message Types

54

Page 55

DP Message Types (Continued)

MT Custom DP String

The MT Custom DP String adopts NMEA0183 conventions with a minimum length of 63 and maximum length of 80 characters.

It provides the same type of information for both CyScan and RadaScan sensors, including range and bearing to all tracked responders (similar to the MDL Multi-Target format). It also provides quality

information.

$PGNMT,T,HH˽MM˽SS.SSS,[NNNN]N,E,[IIII]I,S,[RRR]R.RR,ZR.ZRZR,[BB]B.BB,ZB.ZBZB,[Q]Q,[AAA]A,XXXX*CC<CR><LF>

Where:

•

$PGNMT Proprietary header 6 chars

•

T Type field indicating RadaScan system [R] 1 char

•

HH˽MM˽SS.SSS Real-time clock time at message transmission to DP 12 chars

•

[NNNN]N 16-bit revolution counter in decimal 1–5 chars

•

E Sequence identifier 1 char

•

[IIII]I RadaScan 16-bit responder ID 1–5 chars

•

S Status [V]oid, [A]vailable or [N]avigating 1 char

•

[RRR]R.RR Range in metres 4–7 chars

•

Z

R.ZRZR

Range standard deviation in metres 4 chars

•

[BB]B.BB Bearing in degrees (clockwise from bow) 4–6 chars

•

Z

B.ZBZB

Bearing standard deviation in degrees 4 chars

•

[Q]Q Merit value 1–2 chars

•

[AAA]A

†

Age of measurement in ms 1–4 chars

•

XXXX Reserved – 16-bit flags in hex 4 chars

•

* Delimiter 1 char

•

CC Checksum 2 chars

•

<CR><LF> Carriage return and line feed 2 chars

†

The ‘age’ is the accumulated time in milliseconds from the moment the

measurement was made until the moment the message string is constructed,

prior to being transmitted to the DP system. It effectively gauges the lag through

the system, which may not be constant. Having a value for the lag allows for

subsequent correction of the measurement.

55

Page 56

DP Message Types (Continued)

Rolls-Royce Custom DP String

The Rolls-Royce Custom DP String adopts NMEA0183 conventions with a minimum length of 82 characters and maximum length of 101 characters.

It provides the same type of information for both CyScan and RadaScan sensors, including range and bearing to all tracked responders (similar to the MDL multi-responder format).

It also provides quality information.

$PGNRR,T,YYYY˽MM˽DD,HH˽MM˽SS.SSS,[NNNN]N,[IIII]I,S,[RRR]R.RR,ZR.ZRZR,[BB]B.BB,ZB.ZBZB,[Q]Q,±[r]r.r,±[p]p.p,

[AAA]A,XXXX*CC<CR><LF>

Where:

•

$PGNRR Proprietary header 6 chars

•

T Type field indicating RadaScan system [R] 1 char

•

YYYY˽MM˽DD Real-time clock date at message transmission to DP 10 chars

•

HH˽MM˽SS.SSS Real-time clock time at message transmission to DP 12 chars

•

[NNNN]N 16-bit revolution counter in decimal 1–5 chars

•

[IIII]I RadaScan 16-bit responder ID 1–5 chars

•

S Status [V]oid, [A]vailable and [N]avigating 1 char

•

[RRR]R.RR Range in metres 4–7 chars

•

ZR.ZRZ

R

Range standard deviation in metres 4 chars

•

[BB]B.BB Bearing in degrees (clockwise from bow) 4–6 chars

•

ZB.ZBZ

B

Bearing standard deviation in degrees 4 chars

•

[Q]Q RadaScan SNR [dB] 1–2 chars

•

±[r]r.r Sensor roll in degrees at time of measurement 4–5 chars

•

±[p]p.p Sensor pitch in degrees at time of measurement 4–5 chars

•

[AAA]A

†

Age of measurement in ms at transmission time 1–4 chars

•

XXXX Reserved – 16-bit flags in hex 4 chars

•

* Delimiter 1 chars

•

CC Checksum 2 chars

•

<CR><LF> Carriage return and line feed 2 chars

†

The ‘age’ is the accumulated time in milliseconds from the moment the

measurement was made until the moment the message string is constructed,

prior to being transmitted to the DP system. It effectively gauges the lag through

the system, which may not be constant. Having a value for the lag allows for

subsequent correction of the measurement.

56

Page 57

MDL Standard

A 19 character string delimited only by <CR> and <LF> with bearing measured bow clockwise.

Character Index Description Format

0-1 ID nn

2 Space (0x20h) X

3-9 Range (m) nnnn.nn

10 Space (0x20h) X

11-16 Bearing (degrees) nnn.nn

17 carriage return (0x0Dh) X

18 line feed (0x0Ah) X

MDL Multi-Target

A 22 character string delimited only by <CR> and <LF> with bearing measured bow clockwise.

Character Index Description Format

0-1 ID nn

2 Space (0x20h) X

3-9 Range (m) nnnn.nn

10 Space (0x20h) X

11-16 Bearing (degrees) nnn.nn

17 Space (0x20h) X

18-19 NMEA style checksum in hex CC

20 carriage return (0x0Dh) X

21 line feed (0x0Ah) X

Kongsberg Standard

A 9 character string in BCD format.

BB BB B0 RR RR RR 00 00 FF

Sequence Description

BB BB B Bearing (degrees x 100) in BCD

0 Zero half-character

RR RR RR Range (metres x 10) in BCD

00 00 FF Two zero (0x00h) characters and a 0xFFh delimiter

DP Message Types (Continued)

57

Page 58

UPS and Cable Specications

UPS Specications

The main power supply to the RadaScan View Sensor and Dashboard must come directly from

a UPS (Uninterruptible Power Supply), which will also act as the power disconnection point. The

RadaScan View system comprises the following components and the UPS system used must

meet these minimum specifications.

The RadaScan View UPS should be able to run on back-up power for at least the same duration

as that specified for the DP System UPS. The power cable to the RadaScan View Sensor must be

rated to withstand the maximum current output of the UPS.

!

Note: The specifications given below apply when the

UPS is connected to a RadaScan View system only.

RadaScan View Sensor

•

The UPS must be Marine Type Approved

•

Input Power = 104W

•

Voltage Range = 100-240 Vac

•

Peak Current draw at 110V = 1.14A RMS

•

Nominal Current draw at 110V = 0.68A RMS

•

Peak Current draw at 240V = 0.52A RMS

•

Nominal Current draw at 240V = 0.4A RMS

Type 3 Marine Processor Power Adaptor

•

Voltage Range = 100-240V

•