Page 1

SceneScan User’s Guide

W

A

R

R

A

N

T

Y

S

e

e

o

u

r

s

t

a

n

d

a

r

d

t

e

r

m

s

o

f

s

a

l

e

Q

U

A

L

I

T

Y

A

S

S

U

R

E

D

3

YEAR

Guidance Marine Ltd, 5 Tiber Way, Meridian Business Park, Leicester, LE19 1QP, UK

T: +44116 229 2600 E: sales@guidance.eu.com

Targetless position

reference sensor

www.guidance.eu.com

www.marine.direct

Page 2

SceneScan User’s Guide

LASER

1M

Print Colour

Black

Print Colour

Yellow

100.00 mm

Scale 1:1

Material

White

Issue Date: 11/10/2018

Document No: 94-0561-A

Serial No:

Sensor Software Version: Client Software Version:

Date of Shipment from UK:

Guidance Marine Ltd,

5 Tiber Way

Meridian Business Park

Leicester

LE19 1QP

UK

Tel: +44 116 229 2600

UK Support: +44 116 229 2665

(365 days a year, 08:00 - 20:00 hours UTC)

customerservices.uk@guidance.eu.com

USA Support: +1 504 305-1120

customerservices.us@guidance.eu.com

Asia Support: +65 6734 6365

customerservices.sg@guidance.eu.com

Web: www.guidance.eu.com/customer-support

Class 1M Laser Product

Complies with EN 60825-1

Complies with USA CFR 1040.10 & 1040.11

except for deviations pursuant to Laser Notice

No 50 26 Jul 2001

Copyright © Guidance Marine Limited. All Rights Reserved.

Copyright in the whole and every part of this document belongs to Guidance Marine

Limited (the “Owner”) and may not be used, sold, transferred, copied or reproduced in

whole or in part in any manner or form or in or on any media to any person other than

in accordance with the terms of the Owner’s Agreement or otherwise without the prior

written consent of the Owner. “SceneScan” is a registered trademark of Guidance Marine

Ltd. All other brand or product names are trademarks or registered trademarks of their

respective companies or organisations.

l 2l

Page 3

Table of Contents

Introduction ......................................................................................................5

Welcome �����������������������������������������������������������������������������������������������������������������������6

System Overview ����������������������������������������������������������������������������������������������������������7

SceneScan Sensor Part Names ����������������������������������������������������������������������������������� 8

Getting Started.................................................................................................9

Start Up and Shut Down ��������������������������������������������������������������������������������������������10

Start Up ����������������������������������������������������������������������������������������������������������������������������������������������� 10

Shut Down ������������������������������������������������������������������������������������������������������������������������������������������� 10

Targetless Tracking ����������������������������������������������������������������������������������������������������� 11

Overview of Targetless Tracking ����������������������������������������������������������������������������������������������������������11

Blanking Zones ������������������������������������������������������������������������������������������������������������������������������������ 11

Tracking Overview ������������������������������������������������������������������������������������������������������������������������������� 12

Screen Layout ������������������������������������������������������������������������������������������������������������13

Main Screen and Bird's Eye View (BEV) ����������������������������������������������������������������������������������������������14

Side Bar ����������������������������������������������������������������������������������������������������������������������������������������������� 16

Hotkey Buttons ������������������������������������������������������������������������������������������������������������������������������������ 17

Menu Pane ������������������������������������������������������������������������������������������������������������������������������������������18

Tracking Information Quality ��������������������������������������������������������������������������������������� 19

Display Settings ����������������������������������������������������������������������������������������������������������20

Vessel Orientation �������������������������������������������������������������������������������������������������������22

To set Vessel Orientation ���������������������������������������������������������������������������������������������������������������������22

1� Navigate to Advanced > Display Options > Layout� �����������������������������������������������������������������������22

2� Click on the vessel outline that points in the required direction� �����������������������������������������������������22

Tracking Basics .............................................................................................. 23

Operating Blanking Zones ������������������������������������������������������������������������������������������ 24

Dynamic Blanking Zone ����������������������������������������������������������������������������������������������������������������������24

Setting the Dynamic Blanking Zone ���������������������������������������������������������������������������������������������������� 24

Scanner Tilt Controls �������������������������������������������������������������������������������������������������� 25

Scanner Tilt Modes �����������������������������������������������������������������������������������������������������������������������������25

Spirit Level ������������������������������������������������������������������������������������������������������������������������������������������� 25

Tracking ���������������������������������������������������������������������������������������������������������������������� 26

To Start Tracking ���������������������������������������������������������������������������������������������������������������������������������� 26

To Stop Tracking ���������������������������������������������������������������������������������������������������������������������������������� 26

Adjusting the Scene Reference Point �������������������������������������������������������������������������������������������������� 27

Enabling DP Output ����������������������������������������������������������������������������������������������������������������������������� 28

Tracking Lost ��������������������������������������������������������������������������������������������������������������������������������������� 28

Manual Tilt Mode ��������������������������������������������������������������������������������������������������������������������������������� 28

Positional Display Modes ������������������������������������������������������������������������������������������� 29

Range, Bearing & Heading ������������������������������������������������������������������������������������������������������������������ 29

A and B Axes (A Pos and B Pos) ��������������������������������������������������������������������������������������������������������� 30

Multi-Dashboard SceneScan Systems .................................................. 31

SceneScan Dashboard - Monitoring Mode ���������������������������������������������������������������� 32

SceneScan Dashboard - In Command Mode ������������������������������������������������������������33

Support Information ................................................................................... 34

Low Temperature Operation ���������������������������������������������������������������������������������������35

Working with Alarms ���������������������������������������������������������������������������������������������������36

Filtering Alarms ������������������������������������������������������������������������������������������������������������������������������������ 36

Dynamic Positioning Feed ������������������������������������������������������������������������������������������37

Network Communications Settings ����������������������������������������������������������������������������38

Data Logging ������������������������������������������������������������������������������������������������������������� 39

Serial Numbers & Software Versions �������������������������������������������������������������������������� 41

Product Label �������������������������������������������������������������������������������������������������������������������������������������� 41

Software Version Information ��������������������������������������������������������������������������������������������������������������41

Troubleshooting ........................................................................................... 42

Contact Details ������������������������������������������������������������������������������������������������������������������������������������ 42

How to report issues ���������������������������������������������������������������������������������������������������������������������������42

Problems and Possible Remedies������������������������������������������������������������������������������43

SceneScan Fuse Information �������������������������������������������������������������������������������������44

Installing the SceneScan Hardware ....................................................... 45

3

Page 4

Table of Contents (continued)

Where to Mount the Sensor ���������������������������������������������������������������������������������������46

Sensor Dimensions and Mounting Template ��������������������������������������������������������������47

Installing the Cables .................................................................................... 48

Cable Specifications ��������������������������������������������������������������������������������������������������49

UPS Specifications ����������������������������������������������������������������������������������������������������� 50

SceneScan Sensor Connections ��������������������������������������������������������������������������������51

To Connect a Cable to the SceneScan Sensor ����������������������������������������������������������������������������������� 51

Connecting the Power Cable ��������������������������������������������������������������������������������������������������������������51

SceneScan Client and DP Feed Connections ����������������������������������������������������������� 52

Cable Routing Diagrams ��������������������������������������������������������������������������������������������53

Installing the Control PC ............................................................................ 55

Installing SceneScan Client Software onto a Computer ��������������������������������������������56

Upgrading the Sensor Software ��������������������������������������������������������������������������������� 57

Conguring the SceneScan System ..................................................... 58

Using the Service Interface ����������������������������������������������������������������������������������������59

Network Communication Settings �����������������������������������������������������������������������������60

Vessel Parameters ������������������������������������������������������������������������������������������������������62

Static Blanking Zones ������������������������������������������������������������������������������������������������65

Dynamic Positioning Feed Configuration ������������������������������������������������������������������� 66

DP Feed Behaviour ����������������������������������������������������������������������������������������������������67

System Parameters ���������������������������������������������������������������������������������������������������� 69

DP Message Types �����������������������������������������������������������������������������������������������������71

NMEA0183R Format ���������������������������������������������������������������������������������������������������������������������������71

NMEA0183P Format ����������������������������������������������������������������������������������������������������������������������������71

ASCII17 Format ����������������������������������������������������������������������������������������������������������������������������������� 72

Kongsberg Standard ���������������������������������������������������������������������������������������������������������������������������72

MT Custom DP String �������������������������������������������������������������������������������������������������������������������������73

Rolls-Royce Custom DP String ����������������������������������������������������������������������������������������������������������� 74

Kongsberg (Custom) ���������������������������������������������������������������������������������������������������������������������������75

Service Schedule ��������������������������������������������������������������������������������������������������������76

SceneScan Installation Checklist ������������������������������������������������������������������������������� 77

Index ��������������������������������������������������������������������������������������������������������������������������� 78

Document History ������������������������������������������������������������������������������������������������������80

l

4

Page 5

Introduction

This section provides an introduction and overview of the SceneScan system.

It contains the following sections:

Welcome (page 6)

•

System Overview (page 7)

•

SceneScan Sensor Part Names (page 8)

•

l

5

Page 6

Welcome

Welcome to the SceneScan User Guide. It explains how to:

• Use the SceneScan system

• Physically install the system

• Install and operate the Dashboard software

• Install the Service Interface

Note: Installation of a SceneScan system should be

!

carried out by a suitably qualied and competent

engineer.

l

6

Page 7

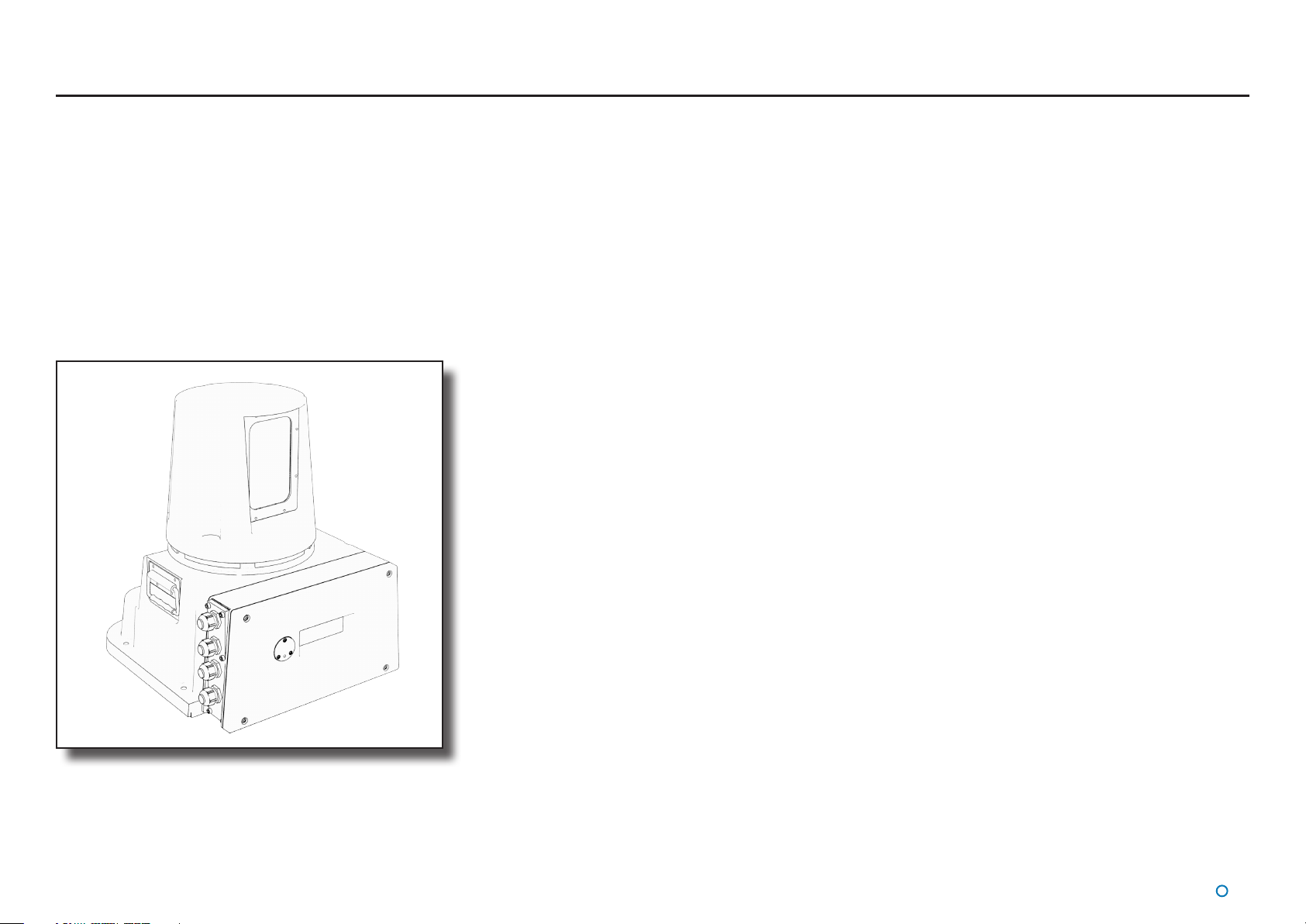

System Overview

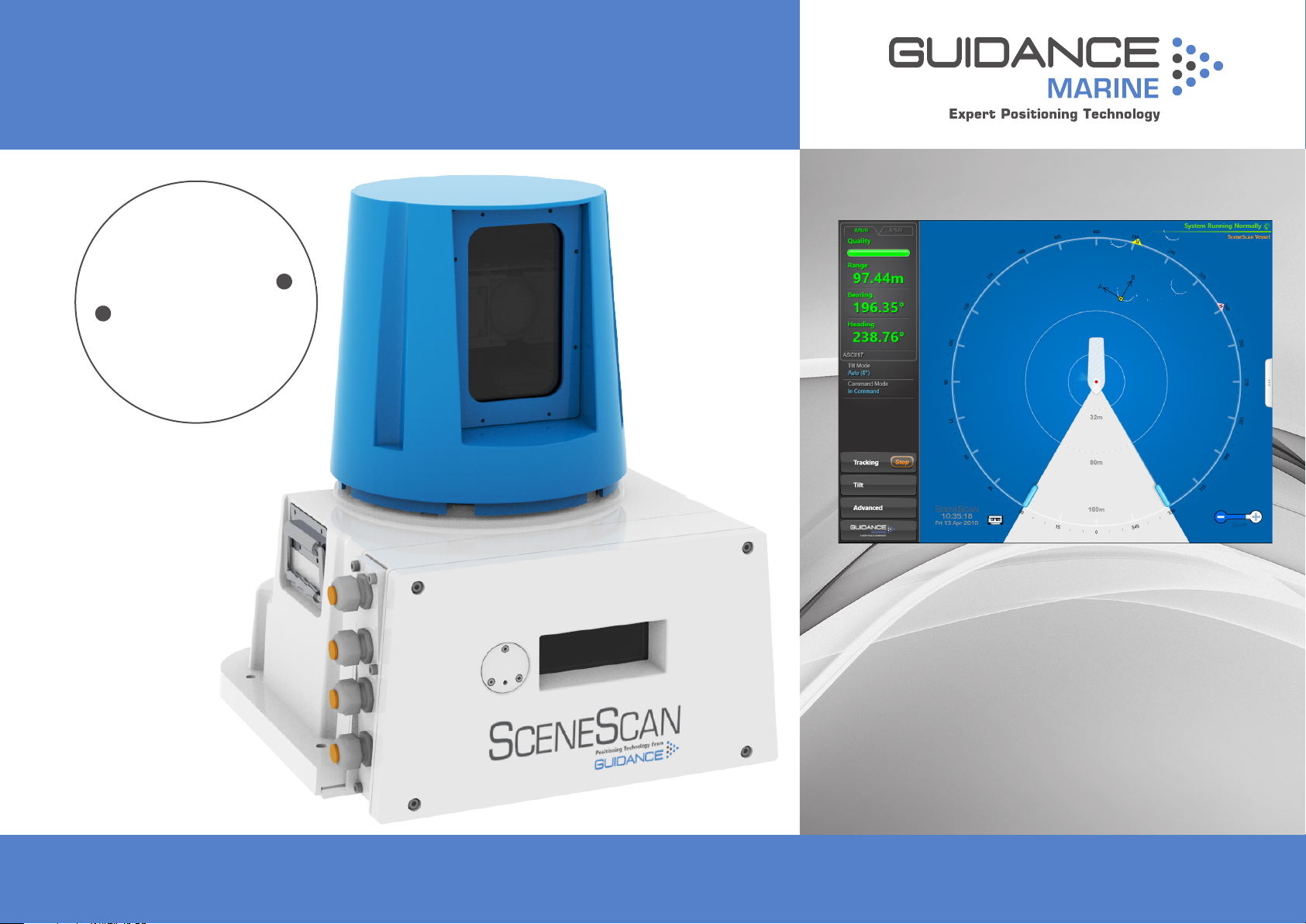

The SceneScan System is a high accuracy rotating laser Sensor that provides positional

information to allow automated approach and/or station keeping relative to a structure or

vessel. It is designed to be semi-portable and straightforward to operate.

Its key elements are:

The SceneScan Sensor: The marine grade SceneScan Sensor is mounted on the

•

vessel (typically on the wheelhouse) as required. The SceneScan Sensor emits eye-safe

infrared light and detects the reections received back from one or more designated

structures or vessels.

The SceneScan Client Software: There are two key pieces of software:

•

The SceneScan Service Interface: The SceneScan Service Interface is used

•

for system installation and maintenance.

The SceneScan Dashboard: The SceneScan Dashboard generates a visual

•

representation of the scene detected by the SceneScan Sensor. It gives the

DP Operator control of the system and the data stream being fed to the DP

system.

Both pieces of software run under Windows™ on a Type 3 Marine Processor or other

computer providing the minimum system requirements (See page 55).

The SceneScan system operates dierently to other local position reference systems in that

it does not require any type of target to be placed on the asset that is being approached or

used for station keeping.

It scans the vessel or structure and produces a map. This map is compared to the current

scan by the SceneScan Sensor navigation algorithm, which is used to track a local position.

l

7

Page 8

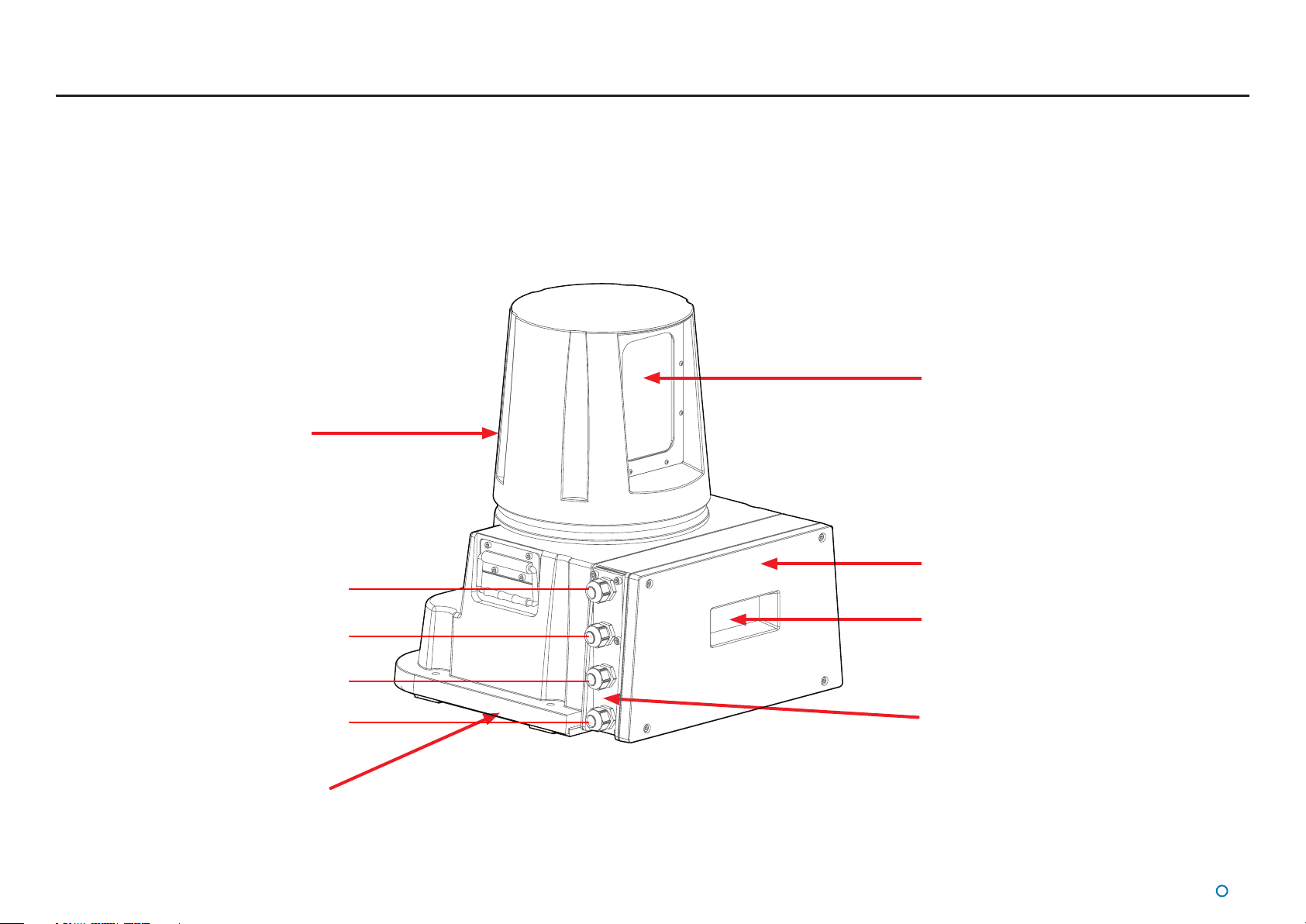

SceneScan Sensor Part Names

The diagram below shows the key parts of the Sensor unit and the various names that are

used throughout this guide:

Rotor

Optical Window

Power

DP Feed 2

DP Feed 1

Client Data

Base Plate

Access Plate

Sensor Information

Display

Cable Gland Plate

l

8

Page 9

Getting Started

This section contains the following pages:

Start Up and Shut Down (page 10)

•

Targetless Tracking (page 11)

•

Screen Layout (page 13)

•

Tracking Information Quality (page 19)

•

Display Settings (page 20)

•

Vessel Orientation (page 22)

•

l

9

Page 10

Start Up and Shut Down

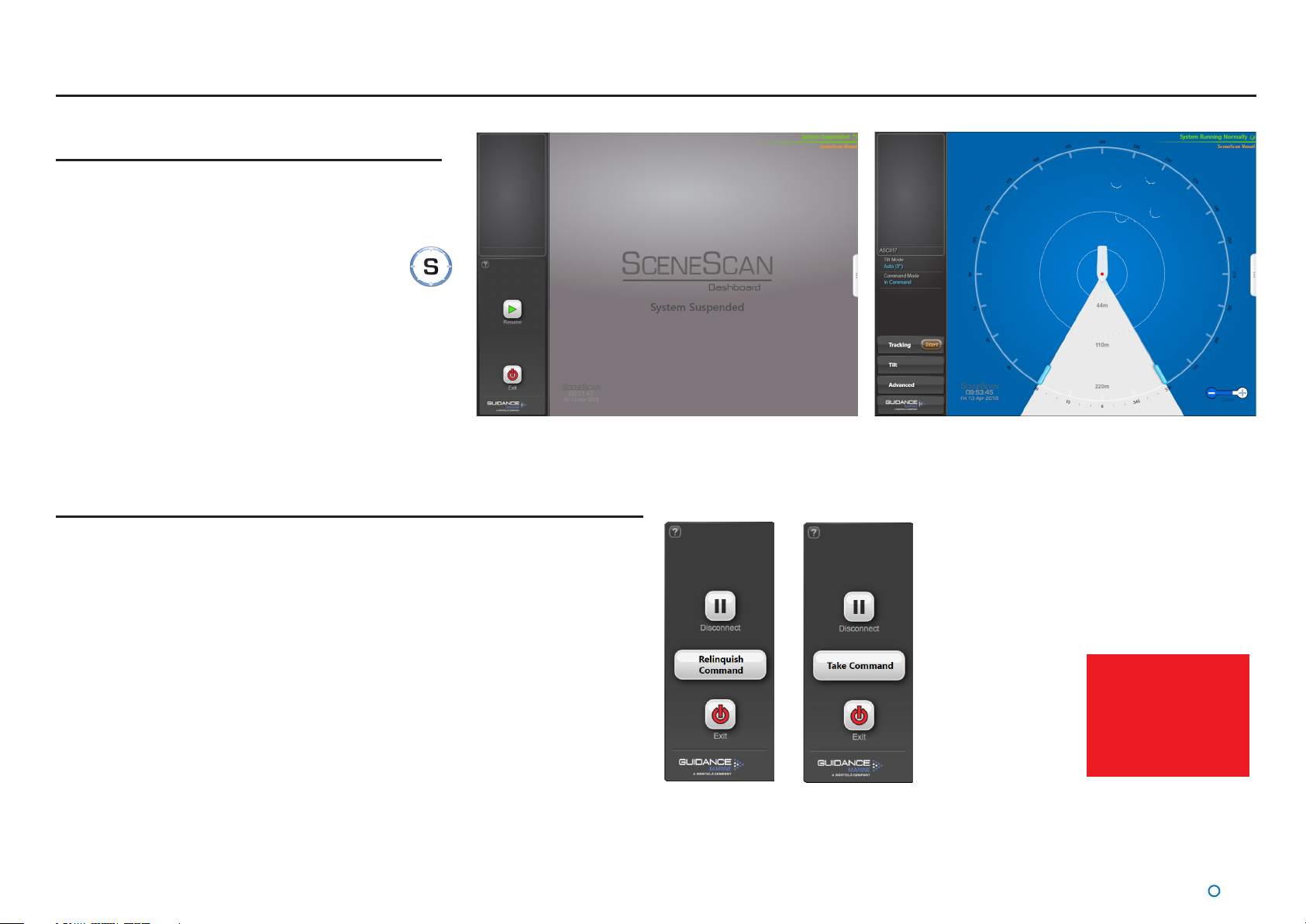

Start Up

To Start SceneScan Dashboard

1. Ensure that the SceneScan Sensor is powered on.

2. Double-click on the SceneScan Dashboard icon.

(Or run the SceneScan Dashboard from

Start > All Programs > Guidance Marine Ltd >

SceneScan > SceneScan Dashboard).

3. The Dashboard display screen will appear.

If the Sensor is currently suspended, the main part of the

screen will be greyed out. Click on the Resume button

in the side bar in order for the Sensor to begin scanning

and for the results to be displayed on the screen. If the

Sensor was already scanning, then the current scene

will be displayed.

Shut Down

Dashboard screen with Sensor suspended Dashboard screen with Sensor scanning

To Suspend, Exit or Disconnect

1. Click on the Guidance button in the lower left corner of the screen.

This will reveal buttons in the side bar as follows: (see right).

Suspend - Places the Sensor into a ‘sleep mode’. The rotor ceases spinning and the

•

scanner tilt returns to a xed state. The unit can be returned to full operation via a

Resume command from the Dashboard. This mode is suitable for use when travelling

between locations.

Disconnect - Ceases communications between the Dashboard and Sensor and

•

causes the main part of the screen to be greyed out. Does not cause the Sensor to stop

spinning or tracking the scene.

Suspend And Exit - Places the Sensor into the same ‘sleep mode’ as the suspend

•

command (discussed above) and also closes the SceneScan Dashboard program.

Exit - Closes down the Dashboard without aecting the Sensor.

•

Dashboard

In Command

Dashboard

Monitoring

See Multi-Dashboard

SceneScan Systems

(page 31) for

information on In

Command/Monitoring

functionality.

l

10

Page 11

Targetless Tracking

Overview of Targetless Tracking

Traditional relative positioning Sensors rely on placing targets on the structure or vessel

which the Sensor then detects and can report a position relative to. SceneScan removes

the requirement to place targets into the scene and instead provides tracking information

relative to natural or man-made structures within the Sensor eld of view. It achieves this

by matching its current observation of the scene against previous observations of the same

scene, in order to determine the motion of the Sensor between observations.

In order to maximise the performance of this approach, the Sensor rst calculates the most

reliable and informative section of the scene to track o. This step is called tilt optimisation,

and involves the Sensor scanning through various sections of the scene to work out which

tilt angle to track at.

Once a suitable section has been selected the system starts tracking and reporting the

position of the Sensor within the scene. As the Sensor moves and the view of the scene

changes, the Sensor will automatically update its model of the scene while tracking without

any need for user intervention.

Blanking Zones

Warning: Before starting tracking it is critical that Blanking Zones have been

!

correctly congured to mask out regions of the scene that we do not wish to

track.

Two types of blanking zone can be congured on a SceneScan system:

Fixed Blanking Zones – These can be exclusively congured using the SceneScan

•

Service Interface. Fixed blanking zones are the Vessel Blanking Zone (Vessel

Parameters) and the Static Blanking Zones.

Operating Blanking Zones – These can be amended in the Dashboard when the

•

system is running, even during tracking. Operating blanking zones are the Dynamic

Blanking Zone and the Minimum Range Filter.

For information on how to set Blanking Zones see the following sections:

Operating Blanking Zones on page 24

•

Vessel Parameters on page 62

•

Static Blanking Zones on page 65

•

l

11

Page 12

Targetless Tracking (Continued)

Tracking Overview

Start Tracking

Once Blanking Zones have been congured the operator can command the Sensor to start

tracking.

SceneScan Tracking is inuenced by the operator’s choice of tilt mode (see the Scanner Tilt

Controls section on page 25 for further information):

Auto - When starting tracking, the scanner will automatically “sweep” through a

•

range of angles to determine the most stable scene for tracking purposes.

Manual - This mode is used to manually tilt the optics to point at the desired part of the

•

scene. When starting tracking, the scanner will use the currently selected angle and no

“sweep” will be performed.

Once a suitable tilt angle has been chosen tracking will start and the scanner tilt angle will

automatically adjust as the range to the asset changes. This is to ensure that the same part

of the scene is used throughout the tracking session.

Scene Reference Point

Once the Sensor has started tracking, it will start reporting its position relative to the Scene

Reference Point.

By default SceneScan will select the centre of the tracked scene for the scene reference

point, with a heading of 0°.

This behaviour should be sucient for most users. However users are also able to edit the

Scene Reference Point, altering both its position and heading. This might be done to align

to the heading of a tracked vessel, or to position oneself against the edge of a platform or

quayside.

Enabling DP Output

Once tracking, the Dashboard will display tracking and scene data, but the Sensor will not

output a DP feed. The reason for this is to allow the operator to review the detected scene,

and to set a Scene Reference Point of their choice before enabling DP Feed output.

When the operator is happy with the tracking data displayed on the Dashboard the DP

output can be enabled and the Sensor will start to report valid position telegrams to the DP

system.

Warning: Changing the Scene Reference Point will disable the DP Feed. This is

done because altering the point can dramatically alter the output from the DP

!

Feeds. The DP Feeds must be re-enabled by following the below procedure.

l

12

Page 13

Screen Layout

The SceneScan Dashboard screen

is split into three distinct sections,

these are:

1. Main Screen and Bird's

•

Eye View (BEV) (see page

14)

2. Side Bar (see page 16)

•

3. Menu Pane (see page

•

18)

l

13

Page 14

Screen Layout (Continued)

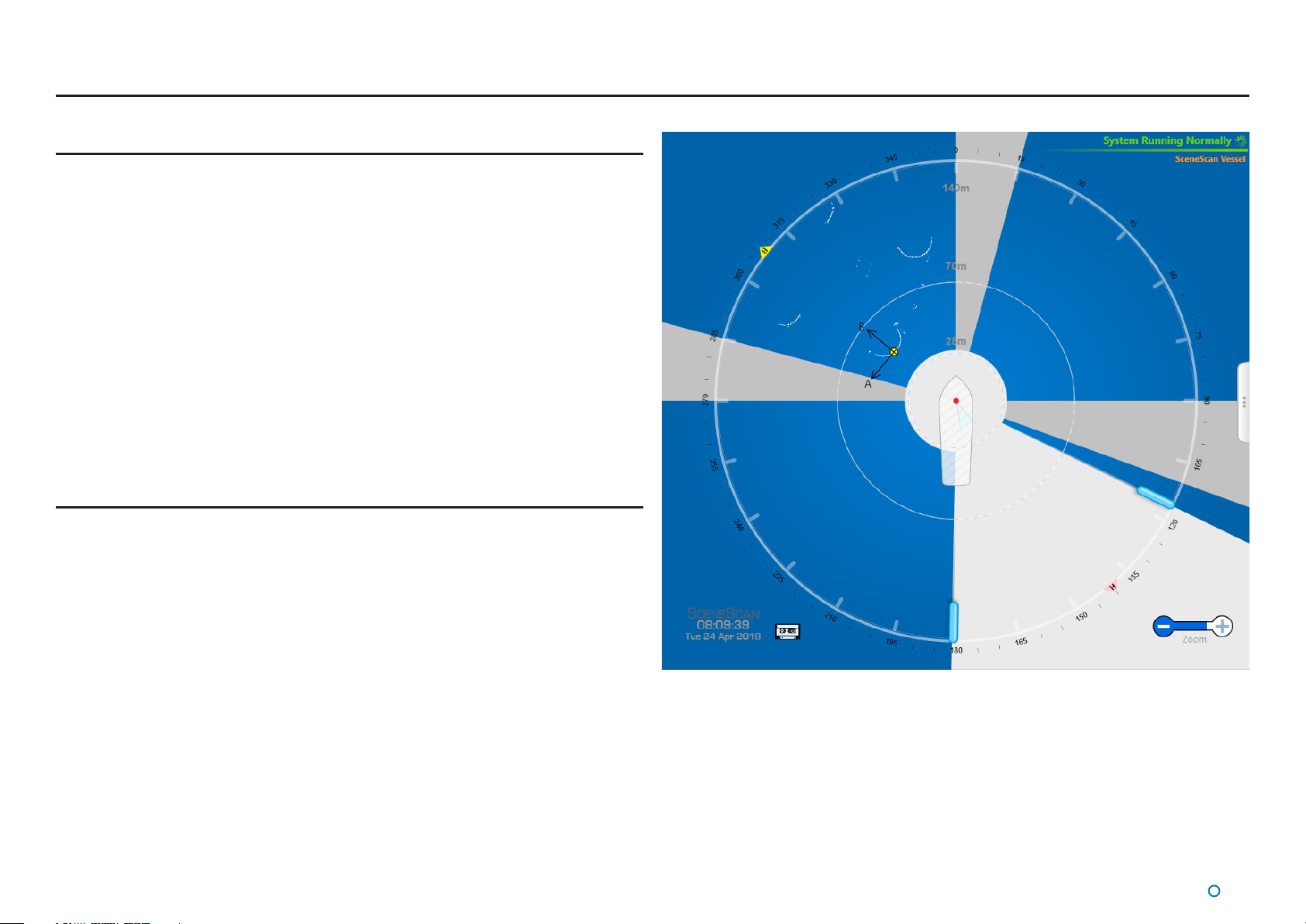

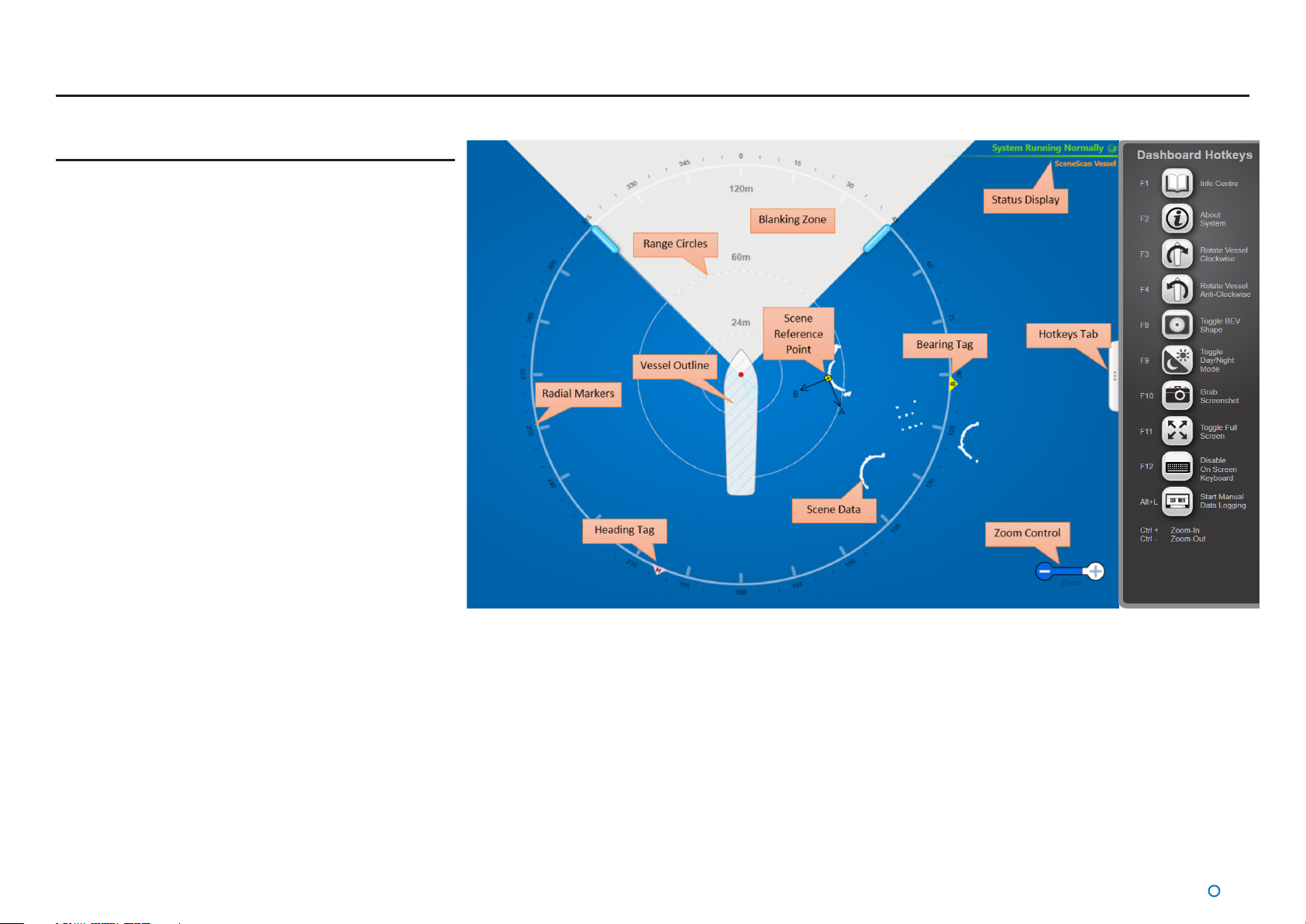

Main Screen and Bird's Eye View (BEV)

The circular BEV shows the observable scene and Scene

Reference Point relative to the Sensor and vessel.

The Figure on the right labels elements on the BEV and its

periphery.

Vessel Outline

The Vessel Outline in the centre of the BEV represents the

ship on which the SceneScan system is located, and the red

dot denotes the SceneScan Sensor. The rotating fan-shaped

symbol represents the laser beam emitted by the rotor as it

turns.

The whole BEV can be rotated in steps of 90° to allow for

dierent positions of the monitor. The size and shape of the

vessel outline and the position of the Sensor’s red dot within it

can be congured using the SceneScan Service Interface.

Blanking Zone

The Blanking Zone is an area dened by the user in order

to blank-out parts of the scene that should not be used for

tracking. During each revolution of the Sensor, when the rotor

enters this sector the laser stops pulsing. The Blanking Zone is

adjusted to suit the current operating conditions.

Range Circles

The Range Circles are a visual guide that help to show the

distances between the Sensor vessel and the detected

reections. Distances are given in metres from the centre of

the Sensor.

Radial Markers

Around the circumference of the BEV are marked angles in

degrees, clockwise from the bow of the vessel.

l

14

Page 15

Screen Layout (Continued)

Scene Data

The Scene Data shows the scene detected by the SceneScan Sensor.

Note: The Scene Data can be constrained to a traditional circular BEV, or expanded to ll

the central area using the Toggle BEV Shape button on the Hotkeys Tab, or by pressing

F8.

Scene Reference Point

The Scene Reference Point shows the point within the scene about which SceneScan is

tracking.

Bearing and Heading Tags

The bearing tag and the heading tag are displayed when tracking is in progress, to indicate

the target’s bearing and the vessel heading on the Radial Marker.

Data Logging Indicator

This symbol is displayed when data is being logged to disk.

Zoom Control

Allows a user to zoom in (+) and zoom out (-) of the BEV. Click on the left-hand side of the

control (marked '-') to zoom out of the display and on the right-hand side ('+') to zoom in.

Hotkeys Tab

The Hotkeys Tab is located on the right hand edge of the main pane. Clicking on the tab will

open the Hotkeys Menu.

System Status

This consists of two elds:

Primary

The primary status display is positioned in the upper-right corner of the main pane. It

indicates the current status of the system, for example System Running Normally or System

Suspended.

Secondary

The secondary status display is positioned in the lower-right corner of the main pane. It

displays a ashing message for a number of seconds in order to conrm an action taken

by the user. It can also display a persistent, static message if there is a communications

problem.

l

15

Page 16

Screen Layout (Continued)

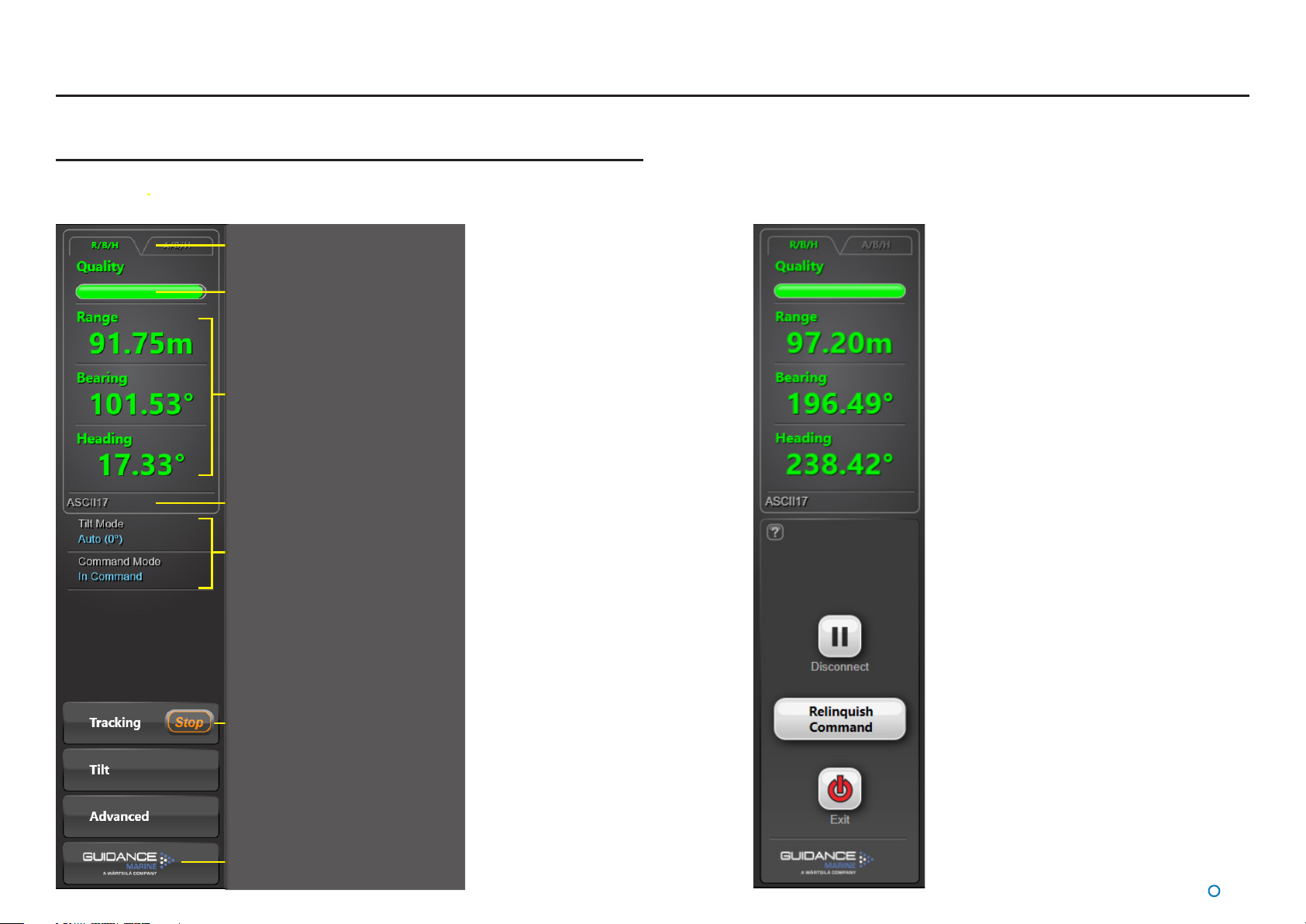

Side Bar

The Side Bar, the black pane on the left of the BEV, contains control and display

components in addition to the coordinates panel.

Toggle Coordinate Type

Signal Quality

Coordinate Data

DP Message Format

Current Tilt Mode

and Command Mode

After pressing the

Guidance button:

Start/Stop Tracking Button

(It is always visible for SceneScan)

Guidance Button

l

16

Page 17

Screen Layout (Continued)

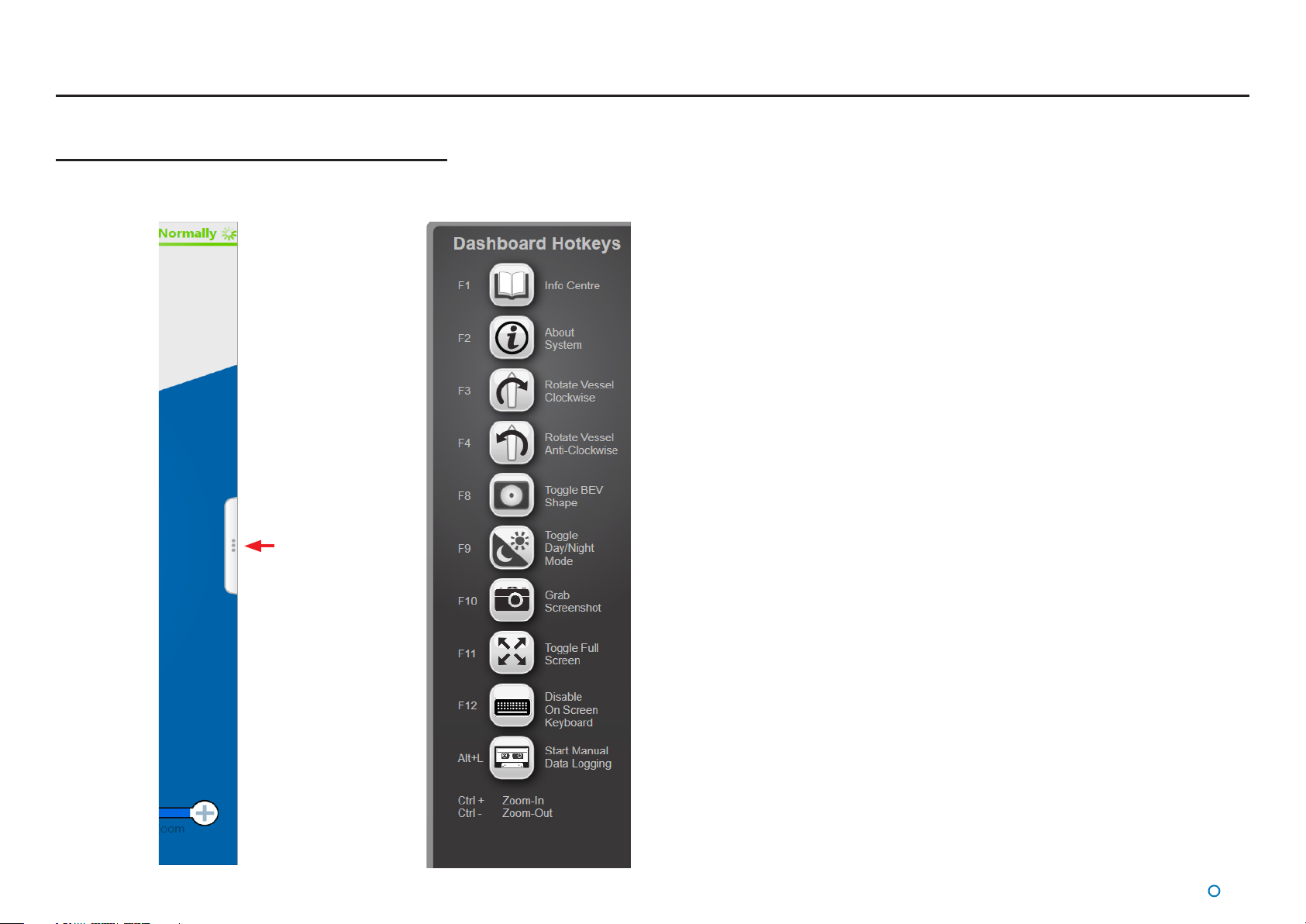

Hotkey Buttons

Selecting the Hotkeys tab on the right-hand side of the main

screen activates the Dashboard Hotkeys menu.

The following keys - and the corresponding buttons on the Dashboard Hotkeys menu - act as

shortcuts to application functions.

F1 Display Help Menu

F2 Toggle between the About System pane and the BEV display

F3 Rotates the Vessel Clockwise

F4 Rotates the Vessel Anti-Clockwise

F8 Toggle between displaying a traditional circular BEV or Full Scene mode

F9 Toggle between the day view and night view

F10 Capture a screenshot of the Dashboard interface and save it to disk

F11 Toggle between normal window layout and full screen layout

F12 Toggle between enabling and disabling the on-screen keyboard

Hotkeys Tab

Alt+L Start Manual Data Logging (available when no tracking operation is in progress):

Starts data logging and changes the button to Stop Data Logging

Ctrl + Zoom-In

Ctrl - Zoom-Out

Esc When in operation conrmation mode, cancel the current operation request

Enter When in operation conrmation mode, conrm the current operation request

l

17

Page 18

Screen Layout (Continued)

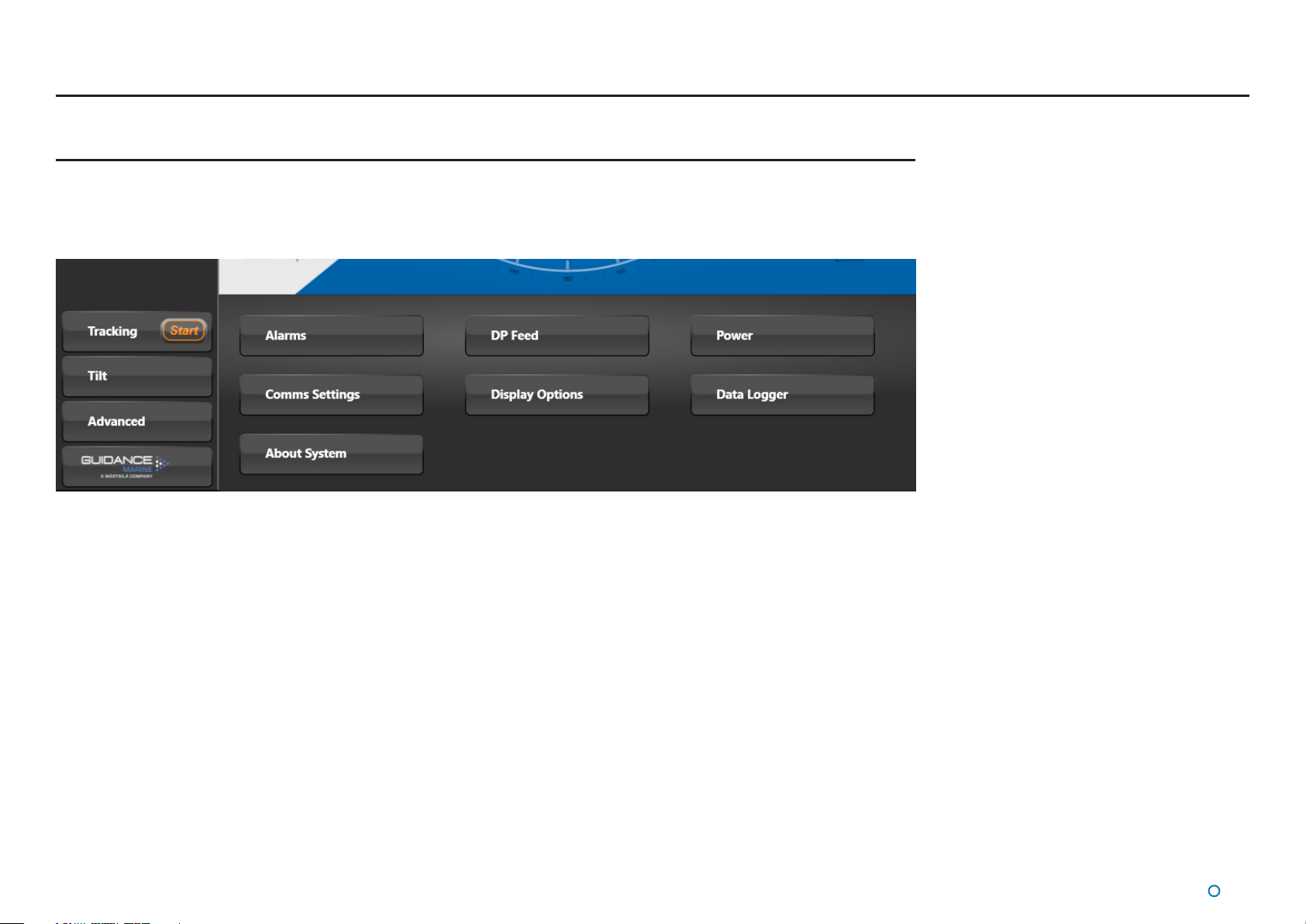

Menu Pane

The Menu Pane, located across the bottom of the SceneScan Dashboard Screen, is not always visible. It appears when one of the

Tracking, Tilt or Advanced buttons near the foot of the Side Bar are pressed, which causes the Bird's Eye View (BEV) to contract

towards the top of the screen. Clicking the same button for a second time causes the Menu Pane to disappear and the BEV to be

restored to full size.

l

18

Page 19

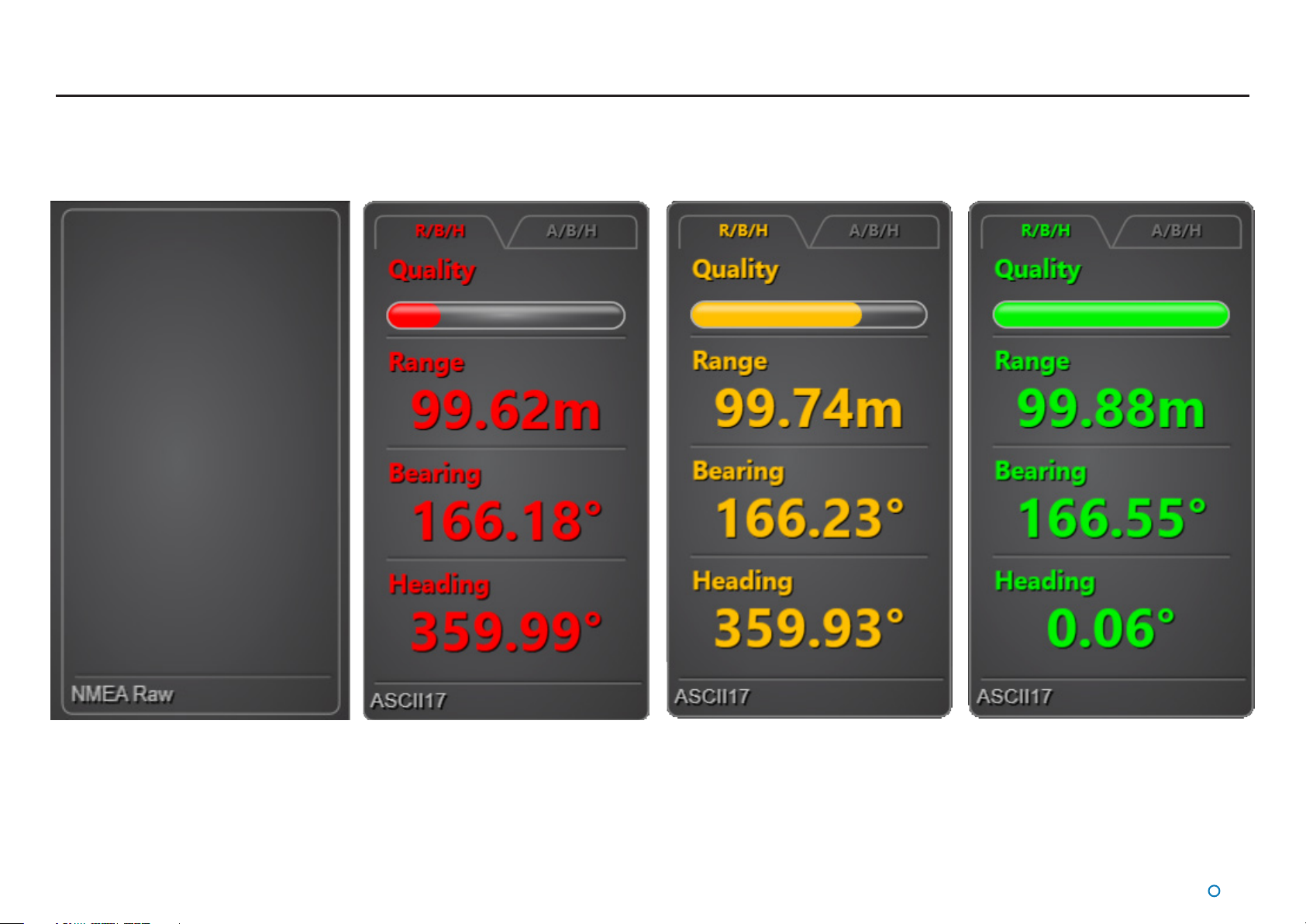

Tracking Information Quality

Once tracking is under way the Data Quality Bar indicates the level of condence the system has in the quality of the scene data that is being acquired. The greater the size of the lled

portion of the Data Quality Bar, the greater the level of condence in the information.

The colour of the Data Quality Bar and positional data also reects the level of condence: RED, YELLOW or GREEN, with GREEN meaning highest condence.

When tracking, the Data Quality Bar and positional data disappear and are replaced with a warning message if the system loses track of the scene.

l

19

Page 20

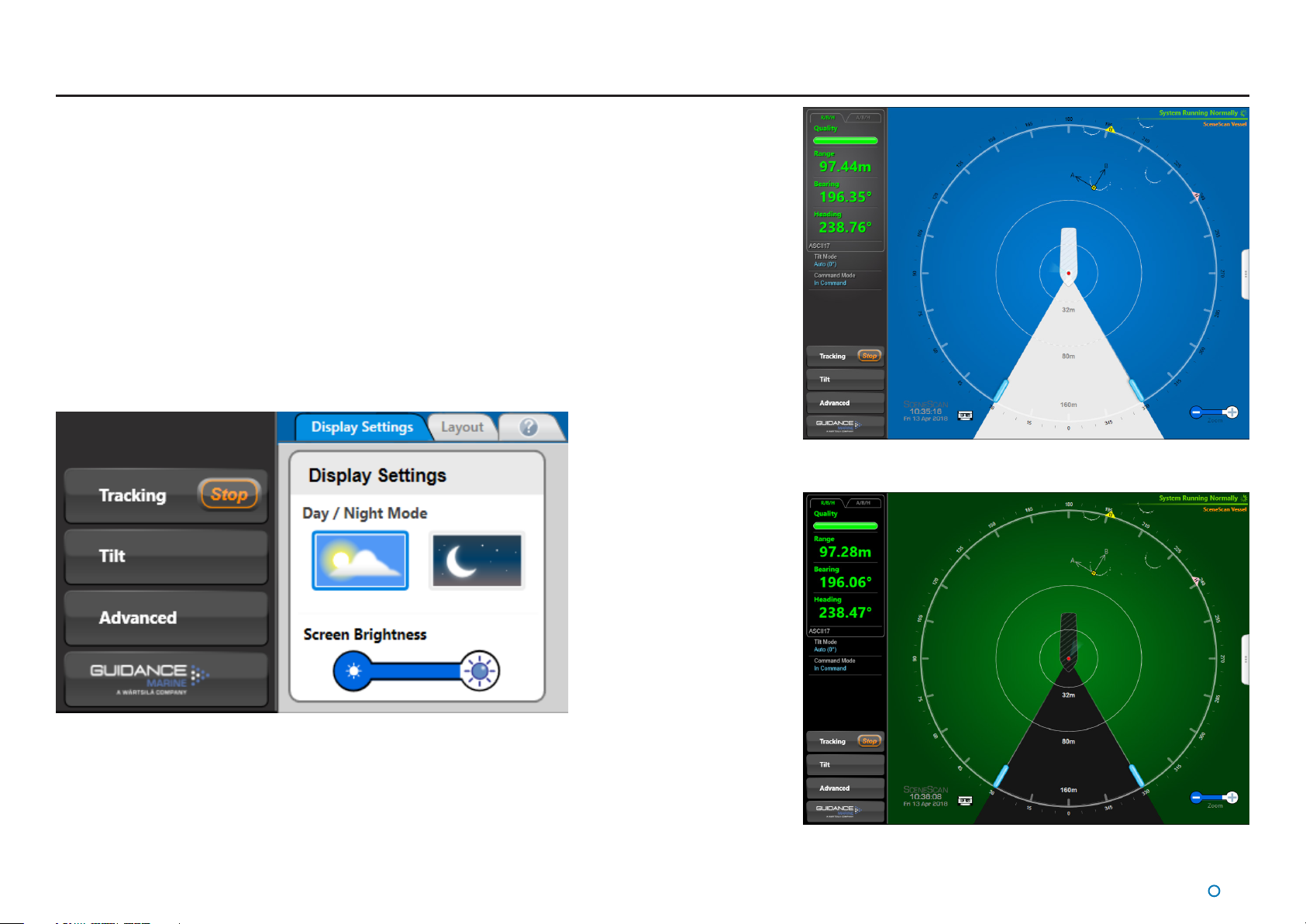

Display Settings

To provide ample visibility during daytime operation and to limit glare during night shifts,

SceneScan Dashboard oers two display settings: Day Mode and Night Mode. In either

mode the brightness can be further adjusted by the Screen Brightness control.

To change day/night mode and adjust brightness:

1. Navigate to Advanced > Display Options > Display Settings.

2. Click on one of the Day / Night Mode symbols.

3. Click on the left side of the Screen Brightness control to dim the screen and on the

right to make it brighter.

Alternatively, to toggle between day and night mode, use the keyboard shortcut F9 or the

Toggle Day/Night Mode button in the Dashboard Hotkeys panel.

Day Mode

Night Mode

l

20

Page 21

Display Settings (Continued)

The central BEV can be toggled between a traditional circular BEV, and a full scene mode.

Press F8 to toggle modes, or use the Toggle BEV Shape hotkey. The latter is useful when

viewing complex scenes such as harbours.

The BEV can be further expanded to a full screen mode by pressing F11, or using the

Toggle Full Screen hotkey

This mode maximises the space available for tracking. Whilst this removes the Side Bar from

view, it can be restored by pressing F11 again, or clicking the Tab along the left edge of the

screen.

l

21

Page 22

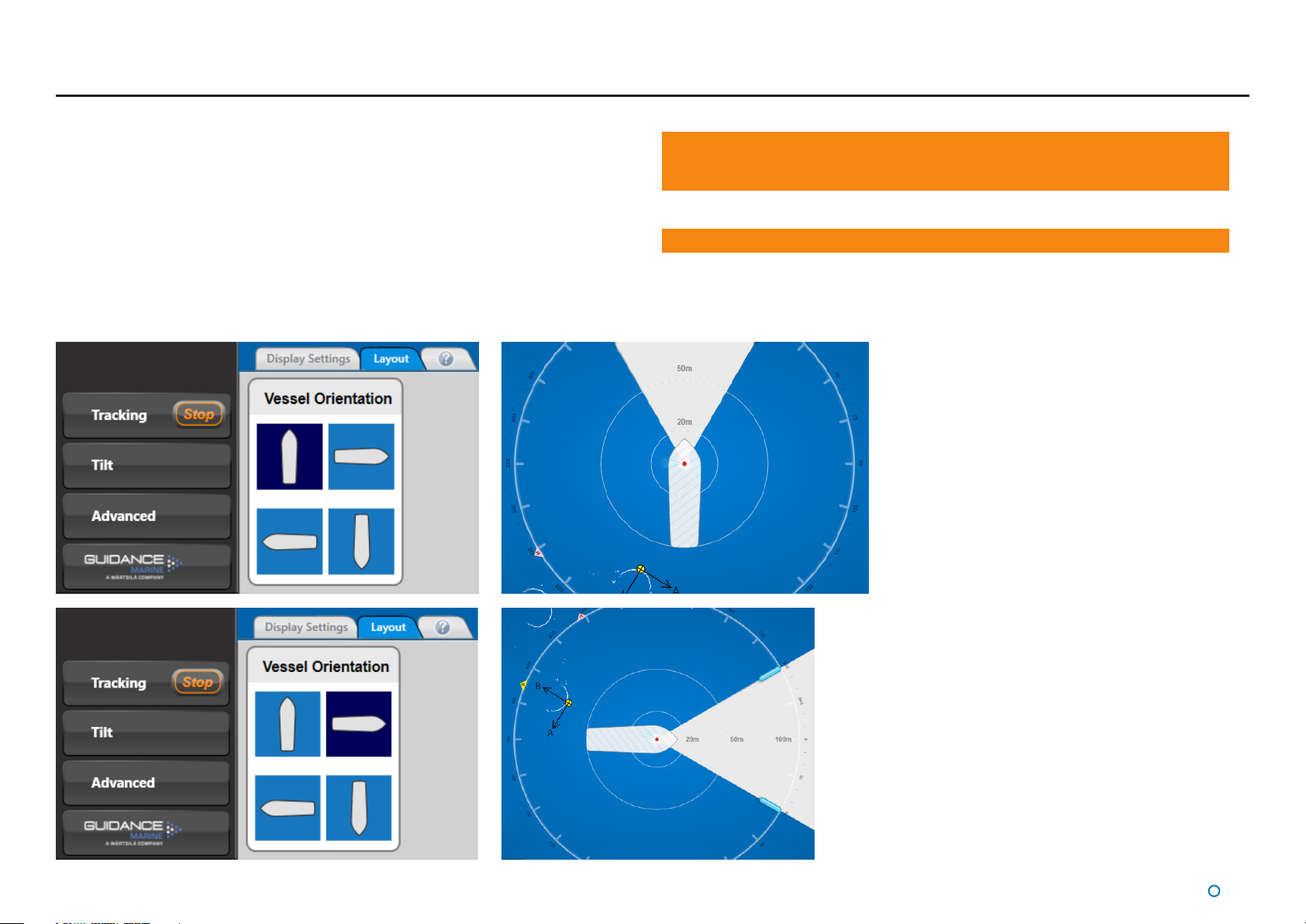

Vessel Orientation

SceneScan Dashboard supports four dierent layouts of the Bird’s Eye View so that the

operator can choose the one which best represents the vessel’s surroundings.

To set Vessel Orientation

1. Navigate to Advanced > Display Options > Layout.

2. Click on the vessel outline that points in the required direction.

Note: Changes made to the vessel orientation using the Dashboard are temporary

and will revert back to the default setting when the Dashboard is restarted� The

default orientation can by changed from within the SceneScan Service Interface�

Note: This is a Dashboard display function only and will not affect the DP output�

l

22

Page 23

Tracking Basics

This section contains the following pages:

Dynamic Blanking Zone (page 24)

•

Scanner Tilt Controls (page 25)

•

Tracking (page 26)

•

Positional Display Modes (page 29)

•

l

23

Page 24

Operating Blanking Zones

Dynamic Blanking Zone

The Dynamic Blanking Zone is used to mask a segment of the scan rotation. When the

scanner passes through the dynamic blanking zone, the laser is switched o to prevent any

unwanted reections.

N.B. Even if the Sensor has a clear 360° view, there must be a dynamic blanking zone of

at least 23°. The user interface will not allow smaller blanking zones.

Generally the dynamic blanking zone will not need to be changed. However, there may be

occasions when it is necessary to adjust the dynamic blanking zone, for example to mask

out another vessel in the Sensor eld of view..

Note: Up to four additional static blanking zones can be congured from within the

SceneScan Service Interface. These are used to mask segments of the scan rotation that

are obscured by the vessel’s superstructure. See the Static Blanking Zones section on page

64 for further information.

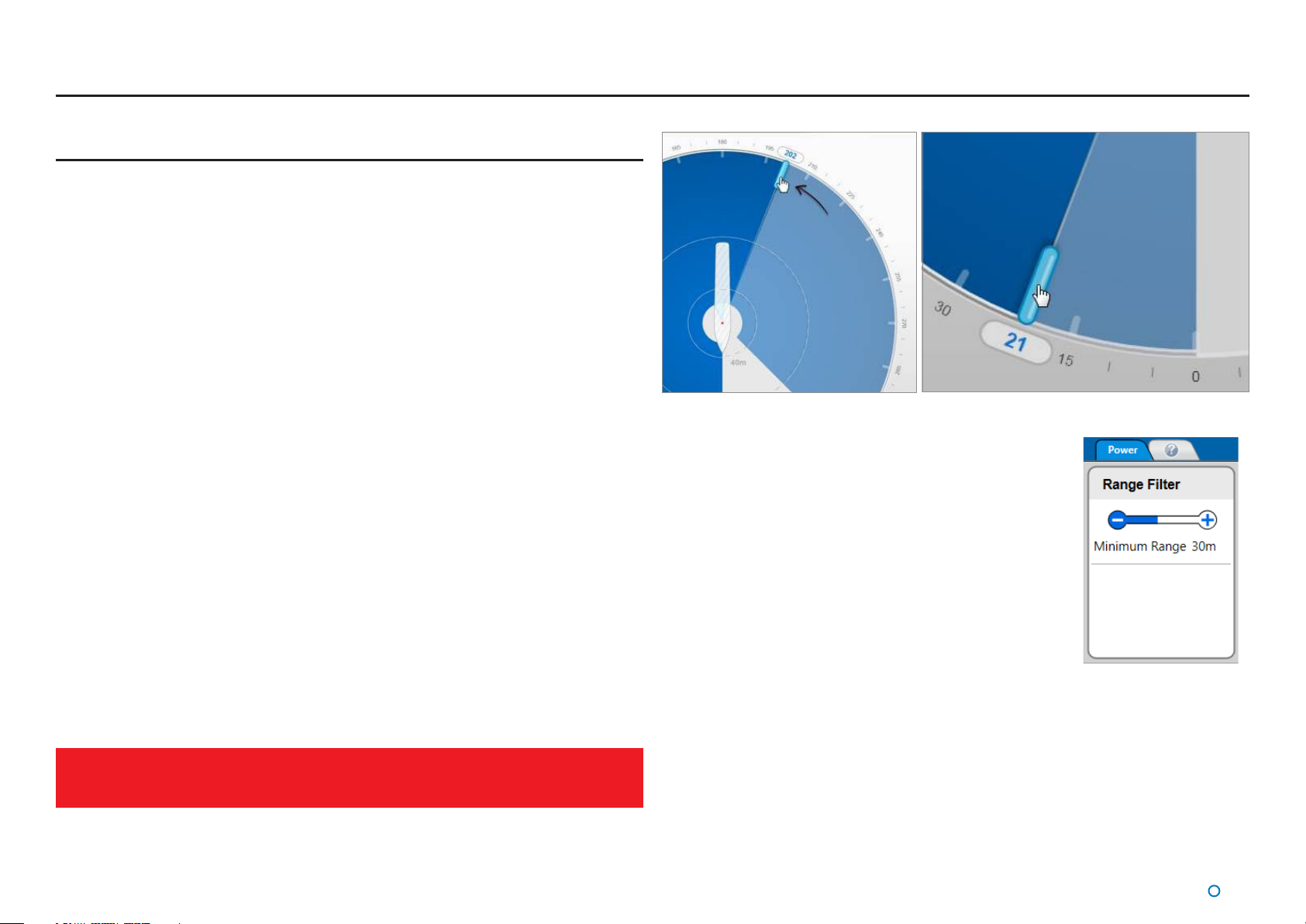

Setting the Dynamic Blanking Zone

The start and end of the zone can be set to any positions around the circle to the nearest

degree, subject to the minimum and maximum sizes of the zone (see red box below).

To dene the Dynamic Blanking Zone

The Dashboard needs to be in Command Mode to make changes to the dynamic blanking

zone.

1. Click one of the dynamic blanking zone handles and, holding down the left mouse

button, drag to the desired position. Alternatively - on a touchscreen - touch and drag.

As the handle is moved, its current position (in degrees clockwise from the vessel bow)

is displayed in blue numerals outside the perimeter of the circle.

2. If required, drag the second zone handle in the same way.

3. The Apply-Cancel buttons will have popped up after step 1. Click on the Apply button

to set the dynamic blanking zone, or on Cancel to restore the dynamic blanking zone to

its previous state.

The Dynamic Blanking Zone must cover at least 23° but no more than 337°. The

user interface will not allow larger blanking zones. It is not possible to change the

blanking zone when in full screen mode.

Range Filters

The Range Filters function on the Power menu allows

the user to set minimum range. Any objects at a shorter

range than the range threshold will no longer be visible

to the Sensor and so will be excluded from tracking. This

mechanism is useful when a structure/vessel other than that

being used for tracking cannot be eliminated by means of the

dynamic blanking zone function alone. It can be used at any

time, even during tracking.

The range threshold can be adjusted between 1 and 70

metres by clicking on the end of the lter bar marked ‘+’ or ‘-’

as required. A corresponding exclusion zone is shown in the

centre of the BEV.

l

24

Page 25

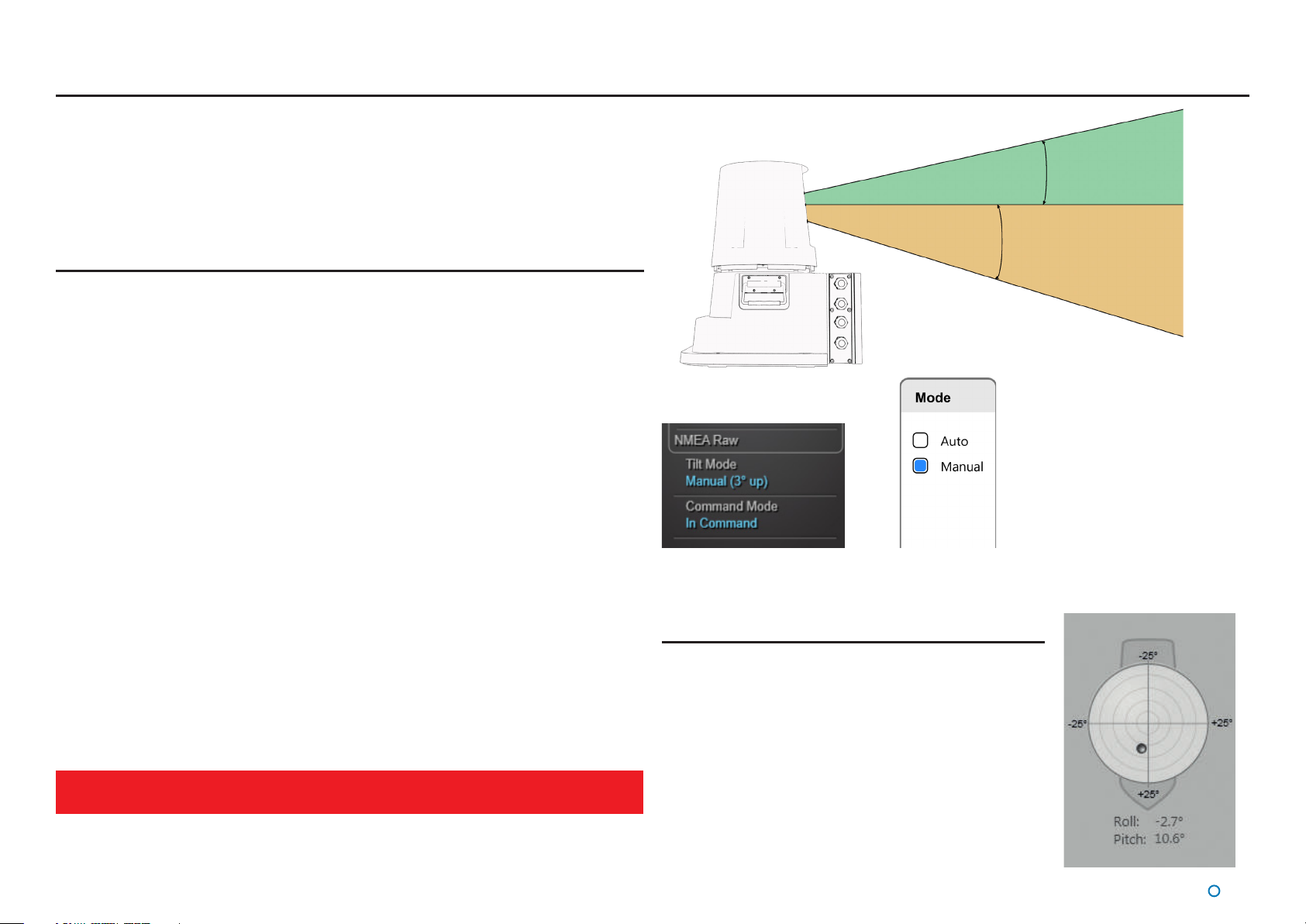

Scanner Tilt Controls

The scanner tilt mechanism automatically compensates for the pitch and roll of the vessel

caused by wave motion.

Motion Sensors and a tilting optics mechanism ensure that the scanning optics remain at

the correct level to see the scene.

16° Scanner Tilt

Scanner Tilt Modes

The scanner can be operated in either of the following tilt modes:

Auto - When starting tracking, the scanner will automatically “sweep” through a range of

•

angles to determine the most stable scene for tracking purposes.

Manual - This mode is used to manually tilt the optics to point at the scene. For

•

example, when station-keeping close to a platform where the superstructure is high up

and the SceneScan beam must be tilted upwards. When starting tracking, the scanner

will initially use the currently selected angle. No “sweep” will be performed. Manual Tilt

can also be used to visually survey the scene around the vessel without tracking.

Once a suitable tilt angle has been chosen tracking will start and the scanner tilt angle will

automatically adjust as the range to the asset changes. This is to ensure that the same part

of the scene is used throughout the tracking session.

When the Sensor is rebooted the tilt mode defaults to Auto.

The current tilt mode and leveller angle are displayed in the ‘Tilt Mode’ section of the Side

Bar.

To change the scanner tilt mode and leveller angle

1. Click on the Tilt button in the Side Bar.

2. Select the required mode and click on the Apply button to conrm.

3. Click on the +/- buttons to adjust the angle.

4. Click on the Apply button to conrm your changes.

Once the scanner starts tracking, it is not possible to change the tilt mode or leveller

angle

Sidebar Tilt Mode section

Tilt Mode Selection

Spirit Level

The Spirit Level control, on the left hand side of the Tilt

pane, displays the roll and pitch of the vessel as measured

by the Vertical Reference Unit within SceneScan. The

graphical display represents the roll and pitch angles in the

same manner as a bull’s eye spirit level. The current values

are displayed in text at the bottom of the control. A ship

outline is shown in the background to indicate orientation

relative to the vessel.

20° Scanner Tilt

l

25

Page 26

Tracking

To Start Tracking

1. Ensure that the Dashboard is In Command (see

Command Mode).

2. Press the Start Tracking button.

3. Press Apply on the Apply/Cancel pop-up.

Tilt Optimisation will start. The angle chosen will depend upon the

current mode:

Auto Tilt - The Sensor will sweep through all possible tilt angles

•

to determine the optimum angle for the scene tracking. The left

pane of the dashboard will show the progress of this operation.

Note that the Sensor may not nd a viable scene for

tracking. This can occur (for example) when in open water.

In this scenario the Sensor will continue Tilt Optimisation

by repeating the sweep process indenitely until a suitable

/ adequate scene is found. This process can be halted by

Stopping Tracking (see below).

Manual Tilt - The Sensor will use the current tilt angle for tracking.

•

Tracking will start once a tilt angle has been selected by the Sensor in Auto Tilt mode,

otherwise the operator / user selects the tilt angle.

To Stop Tracking

While tracking is in progress, a Stop button is nestled

within the Tracking button. Click on the Stop button to

stop tracking.

l

26

Page 27

Tracking (Continued)

Adjusting the Scene Reference Point

Scene Reference Point

This is the point within the scene that SceneScan will report its position relative to. By

default SceneScan will select the centre of the tracked scene as its Scene Reference

Point, with a heading of 0°.

This behaviour should be sucient for most users. However, users are also able to edit

the Scene Reference Point, altering both its position and heading. This might be done

to align to the heading of a tracked vessel, or to position oneself against the edge of a

platform or quayside.

To Edit the Scene Reference Point:

1. Ensure that the Dashboard is In Command (see In Command Mode on page 33)

and is Tracking. It does not matter whether DP Feed is enabled or not.

2. Press the Tracking button to bring up the Tracking Menu.

3. Press the Edit Tracking button.

4. Now the Scene Reference Point can be edited as follows:

1. Left Click on the scene with the mouse to move the reference point to the

clicked location. If Snap To Scene is selected then clicking the scene will

move the reference point to the closest point of Scene Data. This is useful

when trying to align with the edge of a structure.

2. Right Click + Drag on the scene with the mouse to rotate the reference

point, altering its heading.

3. Select Rotate to change the mouse behaviour such that Left Click + Drag

now rotates the reference point. This is useful for touch screens.

4. Use the Align Heading control on the Tracking Menu to precisely control the

heading.

Note that Edits are not live - changes made will only take eect when the “Apply” button

is pressed. The “Cancel” button will undo any pending changes.

Warning: Changing the Scene Reference Point will disable the DP Feed. This is

!

done because changing the reference point can dramatically alter the output

from the DP Feed. The DP Feed must be re-enabled by following the below

procedure.

Note that pressing the Reset button at any point during the edit will undo your

changes without Cancelling your Edit. In addition, the zoom controls can still be

5. Once you are done, press Apply on the Apply/Cancel pop-up.

used to alter the zoom level of the central BEV while selecting the reference point.

l

27

Page 28

Tracking (Continued)

Enabling DP Output

Once tracking, the dashboard will display tracking and scene data, but

the Sensor will not have the DP Feed enabled. The reason for this is to

allow the operator to review the detected scene, and to set a Scene

Reference Point of their choice before enabling DP Feeds.

To Enable the DP Feed:

1. Ensure that the Dashboard is In Command (see Command Mode).

2. Press the Enable DP Feed button.

3. Press “Apply” on the Apply/Cancel pop-up.

The DP Feed will now be enabled, and the dashboard will change to

indicate that tracking is fully enabled.

Tracking Lost

If the SceneScan loses track then the following message will be

displayed in the coordinates pane:

At this point the operator will need to stop and restart tracking.

Manual Tilt Mode

It is highly recommended that Auto tilt mode is used to start tracking when using

SceneScan. However, if a situation is encountered where tracking performance is

unacceptable when using Auto tilt mode then the option is available to manually select a tilt

angle.

Here are some general guidelines to follow when using Manual tilt mode:

1. Try to select regions of the scene that have a high level of vertical consistency.

2. If the vessel will be maneuvering around the structure then consider whether structure

on dierent sides of the structure are also vertically consistent.

3. Watch the BEV to see how consistent the image of the structure is before starting

tracking. If the scene is changing dramatically then tracking is unlikely to be stable and a

dierent tilt angle should be chosen.

4. Small tilt angles will generally provide better tracking performance. This is particularly

true when the range to the asset will be changing signicantly during a tracking session.

5. When tracking o a rig, substructure tends to provide more robust tracking performance

than superstructure.

Vertical features visible from

multiple sides of a rig are good

when wanting to transition around

the asset.

Dierent features closely located

at slightly dierent elevations are

oor targets to track o. Protruding

features of the assest are also not

advised to track o.

l

28

Page 29

Positional Display Modes

The relative positions of the SceneScan vessel and the Scene Reference Point can be

expressed either as Range and Bearing values, or as 'A' and 'B' positions on a rectangular

coordinate frame.

The position of the tracked scene can be displayed as Range/Bearing/Heading or A/B/

Heading.

Users can select the required mode by clicking the appropriate tab above the Data Quality

area:

Range, Bearing & Heading

Range, Bearing and Heading (R/B/H) mode displays the distance and the bearing of the

Scene Reference Point from the Sensor. The radial markers around the outside of the BEV

are zeroed in line with the vessel bow and a magenta tag marks the bearing which is the

angle of the target clockwise from the bow.

A purple tag represents the heading, which is the angle of the vessel bow clockwise from

the heading axis.

l

29

Page 30

Positional Display Modes (Continued)

A and B Axes (A Pos and B Pos)

In this mode, the position of the Sensor vessel is expressed in metres from the scene along

A and B axes which have their origin at the Scene Reference Point.

The vessel's relative heading is measured clockwise from the A axis.

A and B Axes

l

30

Page 31

Multi-Dashboard SceneScan Systems

This section contains the following pages:

SceneScan Dashboard - Monitoring Mode (page 32)

•

SceneScan Dashboard - In Command Mode (see page 33)

•

l

31

Page 32

SceneScan Dashboard - Monitoring Mode

SceneScan supports multiple Dashboards running simultaneously on the same system.

No more than one of these can be in Command mode at any given time; the others are in

Monitoring mode.

When the Dashboard is running in Monitoring mode, the controls relating to the Dashboard

itself will be active, but those relating to the SceneScan Sensor will be disabled. A

Monitoring Dashboard displays the same scene as the In Command Dashboard. It cannot

initiate or stop tracking operations, nor alter the power control, nor tilt settings.

Examples of inactive controls in Monitoring Mode

To switch a Dashboard from In Command mode to Monitoring mode:

1. Click on the Guidance button.

2. Click on the Relinquish Command button.

l

32

Page 33

SceneScan Dashboard - In Command Mode

When the SceneScan Dashboard is running in Command mode all control functions are

available. Any changes made to the tracking or Sensor-related settings at the In Command

Dashboard will be visible on the screens of the Monitoring Dashboards. On the other hand,

display options such as Screen Brightness or Zoom level can be set dierently on each

individual Dashboard, whether it is Monitoring or In Command.

When the In Command Dashboard is used to suspend the SceneScan Sensor, a message

will appear on the screens of the Monitoring Dashboards indicating that the system is

suspended. The same message is displayed if a Dashboard is opened whilst the Sensor is

suspended (See Start Up and Shut Down on page 10).

In this state, clicking the Resume button on any Dashboard will automatically put that

Dashboard In Command. Clicking Exit will close that individual Dashboard only.

Whenever the system is running, a Monitoring Dashboard can be promoted to In Command

as shown on the right.

Examples of active controls only available in Command mode

To switch a Dashboard from Monitoring mode to In

Command mode:

1. Click the Guidance button.

2. Click on the Take Command button.

When the Dashboard is

in Command mode, it will

automatically switch to

Monitoring mode when another

Dashboard takes command.

l

33

Page 34

Support Information

This section contains the following pages:

Low Temperature Operation (page 35)

•

Working with Alarms (page 36)

•

Dynamic Positioning Feed (page 37)

•

Network Communications Settings (page 38)

•

Data Logging (page 39)

•

Seial Numbers & Software Versions (page 41)

•

l

34

Page 35

Low Temperature Operation

Introduction

The SceneScan Sensor is a precision electromechanical device with hardware components

that, out of necessity, are mounted in an external position on a vessel’s superstructure. It

is recognised that industrial marine operations may subject these components to harsh

environments, including low temperature.

The SceneScan hardware complies with the requirements of IEC 60068-2-1 and is able

to operate for prolonged periods at temperatures down to – 25°C provided that certain

operating conditions are maintained.

Operating Conditions

The following recommendations are made for low temperature use:

If it is necessary for the system to be switched on after a prolonged period at

•

temperatures below -5°C (and down to – 25°C) the Sensor will warm itself, but will

require 2 hours to reach optimum operating condition.

If the unit is switched on after a period at temperatures between -15 to -25°C it will

•

not communicate with the Dashboard and the rotor will not rotate until the internal

temperature of the base unit rises above -15°C.

When the system is not in use (i.e. un-powered or suspended) the Sensor should be

•

protected by means of a suitable insulating and protective cover to prevent the external

build-up of ice.

Technical Considerations

The SceneScan Sensor uses a sophisticated rotating infrared laser range-nder to

•

accurately measure the distance and bearing to features in the scene. Movement

sensors allow mechanically driven optics to compensate for vessel motion due to wave

action. The internal mechanism may become disabled if it is allowed to cool in a low

temperature environment.

A safety interlock prevents activation of the range-nder laser if the scanner rotor head

•

stops or is prevented from rotating by ice build-up.

l

35

Page 36

Working with Alarms

During operation, the SceneScan system produces an audit trail of event messages. These

range in increasing order of severity from: Information, Warning, and Error to Fatal. As these

alarms are raised, the Dashboard lists them within the Alarms pane.

Click on any alarm to display details about it in the right-hand section of the Alarm pane:

The severity and current state of an alarm are reected in its colour and shape:

Information—grey symbols

•

Warning—orange symbols

•

Error and Fatal—red symbols

•

The ‘Play’ symbol indicates that an alarm condition is persisting. These are known as Active

alarms. An alarm in this state will show a Start time but not a Stop time.

The ‘Stop’ symbol means that the alarm condition no longer exists, i.e. it has Stopped,

therefore the alarm will show both Start and Stop times.

The ‘Pause’ symbol indicates an instantaneous alarm. In this case, the Start and Stop

times are identical.

When an Error or Fatal alarm is raised, the Advanced button glows red. Once the glowing

Advanced button has been clicked, it will take you to the Alarms pane. If the pane is

closed, the Advanced button returns to its normal grey shading.

Fatal Alarms indicate a serious problem with the SceneScan system. Users should review

the alarm details and follow any recommendations listed. Typically these involve powering

down the Sensor and restarting it, along with restarting the Dashboard. If necessary contact

Support.

Filtering Alarms

A lter is available to suppress the display of particular alarm by severity. By default, the lter

is activated and causes information messages to be hidden.

Click on the Alarm Filter button to toggle between activated and de-activated .

Click on the Filter Selection button to choose which types of alarm are to be ltered out:

Alarm types that are ticked are always displayed in the alarms list; un-selected types are

hidden when the lter is activated.

l

36

Page 37

Dynamic Positioning Feed

The Dynamic Positioning (DP) Feed is the data that SceneScan transmits to the vessel’s

DP system. SceneScan supports several dierent data message formats and it is important

that SceneScan and the DP system are both congured to use matching formats. However,

this cannot be done from the Dashboard; in order to change the SceneScan DP settings,

use the SceneScan Service Interface (see page 66 for the Dynamic Positioning Feed

Configuration and See page 71 for the DP Message Types.

The state of the Sensor’s DP output channel, the message format used and the most recent

data output can be viewed on the Dashboard.

To View DP Feed Details:

1. Click on the Advanced button on the side bar.

2. Click on the DP Feed button on the Menu Pane.

l

37

Page 38

Network Communications Settings

The Comms Settings Menu Pane displays the conguration of communications between

the Dashboard and Sensor. This menu only changes the local dashboard record of the

Sensor IP address. Changing the Sensor's IP address (stored in the connect.ini le) is NOT

possible from the dashboard but IS possible from the SceneScan Service Interface Network

Cong tab 'Sensor on-board network conguration' section (See page 59 for the Network

Communication Settings).

To View the Network Comms Settings:

1. Click on the Advanced button on the sidebar.

2. Click on the Comms Settings button on the Menu Pane.

To Modify the Dashboard’s Record of the Sensor’s IP

Address:

1. Navigate to Advanced > Comms Settings.

2. Click on the Edit button.

3. Modify the IP Address eld as required.

4. Click on Apply to conrm.

l

38

Page 39

Data Logging

Manual data logging button enabled. Manual data logging not active.

During tracking, the system automatically generates a set of operation logs that can be

analysed by a service engineer to diagnose any system faults. Logging can also be started

manually, when the system is not tracking (see below).

When logging is in progress, the following symbol is displayed in the bottom left-hand corner of

the main pane.

Logs can be exported and e-mailed to Guidance Marine (customerservices.uk@

guidance.eu.com) or your DP supplier in the event of a problem.

Starting and Stopping Manual Logging

To start manual logging:

Firstly ensure that the Dashboard is in command (see Dashboard – In Command mode

on page 32) then either:

1. Navigate to Advanced > Data Logger.

2. Click on the Start button.

Or

Press Alt+L.

Or

1. Click on the Hotkeys tab.

2. Click on the Start Manual Data Log button.

To stop manual logging:

Either

1. Navigate to Advanced > Data Logger.

2. Click on the Stop button.

Or

Press Alt+L.

Or

1. Click on the Hotkeys tab.

2. Click on the Stop Manual Data Log button.

Or

Click on the ashing Data Logging Indicator in the top left of the main screen.

Or

Manual logging automatically stops when a Dashboard suspends the sensor or relinquishes

command, or when another Dashboard takes command.

DataLogging with Multiple Dashboards

On a SceneScan system with multiple Dashboards, data logs are written by whichever

Dashboard is in command. If another Dashboard then takes command, data logging ceases

on the Dashboard that is no longer in command and starts automatically on the Dashboard

that takes command.

Exporting Data Logs

The most recent data logs can be exported to a remote drive on the Dashboard computer.

To Export Data Logs:

1. Insert a USB or other removable drive into the Dashboard computer.

2. Select the period for which you wish to export logs

(Last Hour, Last 4 Hours, etc).

3. Select Destination Drive from drop-down list, if not already displayed.

4. Click on Export Data Logs.

Use the Refresh button to update the list of USB drives and the Available Space value.

N.B. In addition to data logs, screenshots from the selected time period and a list of alarms

are also exported.

l

39

Page 40

Data Logging (Continued)

Taking Screenshots

The Grab Screenshot option records every detail of the current screen and stores it at the

same location as the data logs. Up to ten screenshots are held and if a further screenshot

is taken, the oldest of the existing ten is automatically deleted.

To take a screen shot:

Either

1. Click on the Hotkeys tab.

2. Click on Grab Screenshot.

Or

Press the F10 key.

l

40

Page 41

Serial Numbers & Software Versions

Serial numbers and Software Version numbers are used to identify the hardware conguration and product revision of each SceneScan unit. They will be requested by Guidance Marine in

the event of an application service support call to the company.

Product Label

The Part Number and

Serial Number can be

found on the product label

xed to the SceneScan

unit, see below.

SceneScan Sensor

Product Label

Software Version Information

The About tab of the SceneScan Service Interface displays software version

information and the Sensor serial number.

Software Version

Information

SceneScan Sensor

Serial Number

SceneScan

Sensor Part

Number

SceneScan Sensor

Serial Number

l

41

Page 42

Troubleshooting

If you experience problems when installing or using the SceneScan system, please check

through this section for a possible solution. It contains the following pages:

Problems and Possible Remedies (page 43)

•

SceneScan Fuse Information (page 44)

•

If your problem is not listed or you cannot resolve the issue, please contact the system

installer or equipment provider who are trained to assist with installation and operational

problems.

If the problem cannot be resolved by the system installer or equipment provider, please

contact Guidance Marine Limited:

Contact Details

UK Support: +44 116 229 2665

(365 days a year, 08:00 - 20:00 hours UTC)

customerservices.uk@guidance.eu.com

USA Support: +1 504 305-1120

customerservices.us@guidance.eu.com

How to report issues

By reporting issues with enough information it is possible for our customer support engineers to quickly diagnose and solve your diculties. When reporting issues we can give you best advice if you include the following:

A description of what you were trying to do.

•

An indication of whether this was a repeated issue or if it was a single

•

occurrence.

Sensor logs from the time of the issue. Details of how to extract these can be

•

found on page 39

Should the issue cover a period when the system was not tracking then a

•

manual log is very informative. This can be started via either the logging menu,

via the hotkey menu or by pressing Alt+L. See page 39.

If possible a picture of the scene.

•

If possible the name of the asset you are positioning alongside.

•

Asia Support: +65 6734 6365

customerservices.sg@guidance.eu.com

Web: www.guidance.eu.com/customer-support

l

42

Page 43

Problems and Possible Remedies

No communication between SceneScan Dashboard and

the Sensor

The Dashboard screen turns grey, the Primary Status Display reads “Communications

•

Error” “Unable to communicate with the Sensor”. Click the Disconnect button then the

Connect button.

Check the power and client connections to the Sensor.

•

Check that the unit is displaying the current time on the Sensor Information Display. If it

•

is showing any errors then power cycle the Sensor.

Check that the Sensor is displaying the same IP address on the Sensor Information

•

Display as the Dashboard Sensor Comms pane

Rotor does not rotate

Check the temperature of the unit is above -15°C degrees. Below this the rotor is

•

prevented from spinning to protect the Sensor mechanics.

Check that the Dashboard is not showing a ‘Motor Stall’ alarm; if so, suspend and then

•

resume the unit to restart the motor.

The Sensor rotor might be prevented from rotating due to mechanical

•

blockage. Investigate and remove blockage.

Check the Sensor Information Display on the system unit. Ensure that there are no

•

errors displayed. Otherwise power cycle the unit and observe the messages on the

display.

Check for ice build up under the rotor. Remove any ice which may be present.

•

Vessel Blanking Zone

SceneScan applies a blanking zone based on the dimensions of the vessel and position of

the Sensor on the vessel. The following settings are used in the SceneScan Service Interface

to congure the size of the vessel blanking zone:

Vessel Length

•

Vessel Breadth

•

Bow Oset

•

Starboard Oset

•

See section on Vessel parameters for details of these settings.

To test that the vessel blanking zone is correctly congured you should tilt the Sensor optics

downwards the back of the vessel and ensure that no pulses from the vessel structure are

observed outside of the vessel outline in the Dashboard.

System appears to be operational but no scene is

displayed when the Sensor is close enough to a structure

to be able to detect it

Check that the dynamic and static blanking zones are congured correctly.

•

Clean the SceneScan Sensor window.

•

Check whether there are any pulses on the Dashboard Power menu and that the Zoom

•

control on the main screen is set appropriately.

Check that the Tilt controls are set appropriately.

•

Check that the Power controls on the Power menu are set appropriately.

•

Check that the Minimum Range Filter on the Power menu is set appropriately.

•

Check that the Sensor has a clear view of the scene.

•

System tracking but no data is received by the vessel’s

DP system

Check the DP Feed connection from the Sensor.

•

Check that the DP Message Format matches the conguration of the vessel’s DP

•

system.

Check that the Enable DP Output button is not visible on the Dashboard. If it is then

•

press it to enable the DP output.

System operates correctly but in cold weather loses

scene.

Check for condensation or ice on the window of the Sensor. Clean if necessary.

•

l

43

Page 44

SceneScan Fuse Information

The SceneScan system contains two replaceable fuses; one for the Live and the other for

the Neutral. These are located on the connector board as shown below.

Connector Board Fuse

Please refer to SceneScan Sensor connections on page 51 on how

to access the connector board.

To remove a fuse from its housing, t a at-head screwdriver into

the slot in the insert - then push it in and turn it anti-clockwise until

the insert releases and can be pulled out.

Reverse the above procedure to replace the fuse.

Both fuses have the same specication.

Ensure the replacement fuse has the same specication as

the original fuse.

1 GND

1 RX+

1 RX-

1 TX-

1 TX+

Live

Neutral

The fuses should be 20mm anti-surge glass fuses rated for 250V.

The current rating should be determined by the table below.

Voltage Supply 230v 110v

Normal Operation 630mA 630mA

Low temperature operation 1.25A 2A

Normal operation is where the Sensor is operated at -10°C or

above.

When operating at below this temperature internal heaters warm

the unit at start up.

CAUTION: DOUBLE POLE/NEUTRAL FUSING

1 GND

1 RX+

1 RX-

1 TX-

1 TX+

l

44

Page 45

Installing the SceneScan Hardware

This section contains the following pages:

Where to Mount the Sensor (page 46)

•

Sensor Dimensions and Mounting Template (page 47)

•

l

45

Page 46

Where to Mount the Sensor

Sensor Mounting Locations

The SceneScan system is designed for permanent or semi-permanent installation on-board a

vessel. Often, a custom-fabricated plinth is used to provide the optimum height and location

for mounting the SceneScan Sensor.

On all types of vessel the Sensor should be mounted:

With an unobstructed view in the expected direction of the scene (structure or vessel).

•

Well above sea level to prevent swamping or immersion.

•

On a at, rigid, horizontal surface able to support 30kg and receive 4x M8 xing bolts.

•

Allowing for easy access to the connector board and Sensor Information Display.

•

Clear of VHF emergency band antennae, S-band and X-band ship’s radars (5 meter

•

minimum horizontal separation from RF sources (VHF, S and X band) and ideally vertical

separation of one deck).

Clear of likely emissions from exhausts or other particulate sources to reduce the need

•

for cleaning the optical windows.

The eld of view o the vessel should be clear of retroreective material

•

Exhaust emissions contain particulates which will degrade the optics.

The Sensor should be mounted with the Access Cover available for easy maintenance (see

page 9). Any deviation from the centre-line alignment must be corrected in the SceneScan

Service Interface. See the Bearing Oset section on page 61 for further information.

A typical mounting position is above the wheelhouse for a vessel with a

superstructure like that of a platform supply vessel.

l

46

Page 47

Sensor Dimensions and Mounting Template

Sensor Clearance

The exact dimensions of the SceneScan unit’s footprint are shown below.

Additional information shown on the right could be benecial when mounting the SceneScan

unit. Please refer to Document No: 94-0062-4 CyScan Mounting Template to view the

information in larger format.

407

190

4 x

9 THRU

360

405

300

705

Mounting Template

Mount the baseplate horizontally.

Allow 150mm

clearance for

access to the

rotor screws.

150

Allow a Sensor height of 460mm

from the mounting plate, plus an

additional 30mm clearance to

remove the rotor from the shaft.

460

150

150

Allow 150mm

clearance at either side

of the unit for use of

the lifting handles.

47

327

150

857

80

150 150

Ensure a clear

line of sight to the

Display Screen in

the access plate.

857

300

705

Allow 300mm

clearance at the

access plate to

manoeuvre internal

assemblies in/out.

All dimensions in mm

NOT TO SCALE

47

l

Page 48

Installing the Cables

This section contains the following pages:

Cable Specifications (page 49)

•

UPS Specifications (page 50)

•

SceneScan Sensor Connections (page 51)

•

SceneScan Client and DP Feed Connections (page 52)

•

Cable Routing Diagrams (page 53)

•

l

48

Page 49

Cable Specications

The SceneScan system is usually supplied without the cables that are necessary to connect the Sensor to the DP system and the Client Software computer(s). Guidance recommends that

exible multicore cables are used in all applications. Cables should meet the requirements of IEC 60228 Class 2 or Class 5. Cables must be supplied and tted by the installer to match the

particular requirements for each vessel. All cables should be properly secured.

The cable glands will t cables from 7-13mm diameter.

All cables should be

• External marine standard including UV and chemical resistance

• 500V rated voltage

• Diameter 7-13mm

• Operate between -30°C to +70°C.

Note: Data cables should not be run across or next to power cables to avoid signal

interference problems.

Cable Description Guidance Marine Part Numbers m lengths

Ethernet Connection to

Client Software Computer

CAT 5e screened cable (maximum

length 90m).

33-0124-3

Ethernet Cable

Power Cable 3 core power cable

Serial Signal Wiring to DP

System

Refer to the cable routing diagrams on page 53 - 54 to determine which cables you require.

Minimum core shielded data

cable

33-0121-3

3-core power cable

30-0451-3

core shielded data cable

l

49

Page 50

UPS Specications

The power supply to the SceneScan Sensor and the computer(s) running the SceneScan

Service Interface and Dashboard must come directly from a Un-interruptible Power Supply

(UPS), which will also act as the power disconnection point.

The SceneScan system has the following requirements; the UPS system used must meet

these minimum specications:

SceneScan Sensor

The UPS must be Marine Type Approved

•

Input Power = 130W †

•

Voltage Range = 86-264V AC

•

Peak Current draw at 110V = 1.6A

•

Nominal Current draw at 110V = 1.2A RMS

•

Peak Current draw at 230V = 0.7A

•

Nominal Current draw at 230V = 0.6A RMS

•

The SceneScan UPS should be able to run on back-up power for at least the same duration

as that specied for the DP System UPS.

The power cable to the SceneScan Sensor must be rated to withstand the maximum

current output of the UPS.

† Worst case power consumption when operated at -25°C

Type 3 Marine Processor Power Adaptor

Voltage Range = 100-240V

•

Frequency Range = 50-60Hz

•

Peak Current draw = 1.8A

•

Hatteland Panel PC

Voltage Range = 115 & 230V

•

Frequency Range = 50-60Hz

•

Nominal Current draw at 115V = 0.52A RMS

•

Nominal Current draw at 230V = 0.26A RMS

•

The specications given above apply when the UPS is connected to a

SceneScan system only.

l

50

Page 51

SceneScan Sensor Connections

To Connect a Cable to the SceneScan Sensor

1. Remove the 4 screws from the access cover and remove the plate from the Sensor unit

to expose the connector board. (See SceneScan Sensor Part Names on page8).

2. Remove the screw head from the appropriate watertight cable gland. See SceneScan

Sensor Part Names on page8 to identify the correct cable gland.

3. Feed the cable through the screw head and gland.

4. Connect the cable to the correct socket/terminal on the Sensor connector board.

5. When all the connections have been made, replace the access cover and tighten all of

the cable glands to ensure a watertight seal.

Connecting the Power Cable

1. Having fed the cable through the watertight cable gland, Strip 10mm of insulation from

the end of each of the three cable cores.

2. Connect the 3 cores to the appropriate terminals as labelled on the terminal block

(see right).

3. When the connections to the terminal block have been made, use two cable ties to

secure the terminal block and cable together.

4. Plug the terminal block securely into the socket on the connector board as shown on

the right.

Cable ties

Power terminal block with cable cores

connected

Please see page 44 for the fuse recommendations.

Watertight

cable gland

Power terminals on

connector board

Live

Earth

Neutral

To Connect Cables to

Power/Serial Plugs:

Insert Operation

M

Lever-tool (part

number: 190-0003-4)

into slot above

connector-hole in plug.

Whilst holding down

R

lever, insert cable end

into connector-hole.

Release and remove

C

the lever-tool.

1 GND

1 RX+

1 RX-

1 TX-

1 TX+

1 GND

1 RX+

1 RX-

1 TX-

1 TX+

Base of SceneScan with the access cover removed to expose the connector board

51

l

Page 52

SceneScan Client and DP Feed Connections

Connect Ethernet Port 0 to the Marine Processor, Serial Port 1 to DP System 1 and Serial Port 0 to DP system 2.

Congure the serial connections as shown below:

To Connect Cables to

Power/Serial Plugs:

Insert Operation Lever-

M

tool into slot above

connector-hole in

plug.

Whilst holding down

R

lever, insert cable end

into connector-hole.

Release and remove

C

the lever-tool.

19.6mm

4.1mm

10mm

Serial 1

DP

Feed 1

1 GND

2 RX+

3 RX4 TX5 TX+

Note: Either Serial 0 or Serial

1 can be used. The DP feed is

output from both ports.

RS422 Link

9600 baud

8 bits

1 stop bit

No parity

Serial 0

DP

Feed 2

1 GND

2 RX+

3 RX4 TX5 TX+

(Optional)

†Contact Guidance

Marine if

alternative settings

are required.

Note: the Ethernet

and the Serial screen

should be connected

at the Sensor only.

Do not terminate at

both ends.

6.6mm

Connect earth cable

to earthing point.

Default Ethernet Settings:†

IP Address: 192.168.0.86

Subnet Mask:

255.255.255.0

Note: The default IP address

may need to be changed prior

to installation through the

SceneScan Service Interface

software (SSI)

Mains Power

86–264V AC

RS422

Link to DP

System 1

RS422

Link to DP

System 2

Ethernet

Link to

Marine

Processor

Ethernet 1

Ethernet 0

Serial 1

Serial 0

1 GND

1 RX+

1 RX-

1 TX-

1 TX+

1 GND

1 RX+

1 RX-

1 TX-

1 TX+

Power

Fuses

VFD Screen

Service Connections

Power LED

l

52

Page 53

Cable Routing Diagrams

DP Instrument Room

16A

DP System UPS

Bridge

See page 53 for processor and monitor options

SceneScan

Monitor

Monitor Cable

SceneScan Client Computer

Power

Marine Processor

Monitor Power Cable

Emergency Breaker Box

Power Cable

5A

Adaptor

Ethernet

Ethernet Cable

P/N 33-0124-3 (40m)

Mast

Link Cable

SceneScan

Client

DP Feed

Power

SceneScan

Sensor

Connection

Box (Optional)

Note: The Ethernet cable connecting the

SceneScan Sensor to the Type 3 Marine

Processor should not exceed 90 metres

in length.

Please contact Guidance Marine if longer

distances are required.

DP System 1

Interface Cabinet

DP System 2

Interface Cabinet

(Optional)

5A

Sensor Power

Power Cable

P/N 33-0121-3 (40m)

RS-422 Data

Data Cable

P/N 33-0451-3 (40m)

RS-422 Data

(Optional)

Data Cable

P/N 33-0451-3 (40m)

l

53

Page 54

Cable Routing Diagrams (Continued)

Alternative Processor and Monitor Options

Any of the following congurations may be used (see page 53)

KME

Monitor

Monitor Cable

Type 3 Marine Processor

Power

Marine Processor

Power Cable

Monitor Power Cable

Processor:

Type 3 Marine Processor

(Part Number 20-0280)

Monitor: KME 15” Desktop Monitor

(Part Number 20-0115-1)

Note: In the rst two congurations, a Type 3

Marine Processor is used

Adaptor

Ethernet

Cable

Hatteland

Touchscreen

Monitor

Monitor Cable

Type 3 Marine Processor

Power

Marine Processor

Power Cable

Monitor Power Cable

Adaptor

Processor: or

Type 3 Marine Processor

(Part Number 20-0280)

Monitor: Hatteland Marine Touchscreen

Monitor (Part Number 20-0211-4)

Optional brackets: Hatteland Mounting

Bracket (Part Number 24-0259-4)

Hatteland VESA Bracket for Wall or Ceiling

(Part Number 24-0258-4)

Ethernet

Cable

Hatteland

Panel PC

Power Cable

Ethernet

Cable

Processor and Monitor: Hatteland

Panel PC (Integrated PC and Touchscreen

Monitor, Part Number 20-0182-1)

Optional brackets: Hatteland Mounting