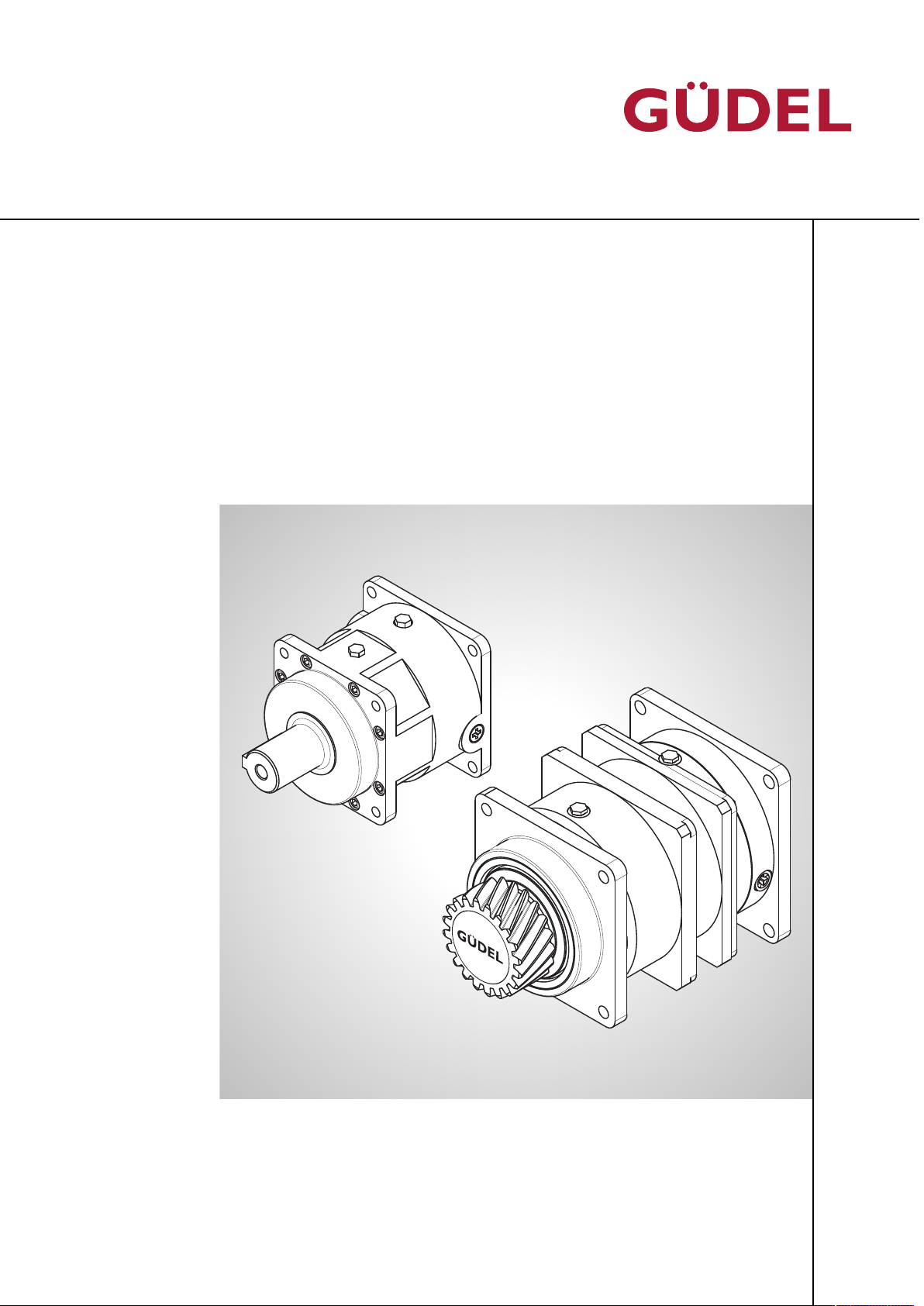

SERVICE MANUAL

SERVICEANLEITUNG GÜDEL PLANETARY GEAR NR, SR, PR9007199543219723_V1.1_EN-US

B1M.1xxxxxxx-xxxx

10xxxxxxxxx

991xxxxxxx

2019

Güdel planetary gear NR, SR, PR

Project / Order:

Bill of materials:

Serial number:

Year of manufacture:

© GÜDEL

Translation of the original instructions

This manual contains standard illustrations that may deviate from the original.

In the case of special models, options, or technical changes, the scope of delivery may differ from the descriptions here. Reprinting the instructions, in whole

or in part, requires our permission. Subject to change due to technical improvements.

9007199543219723_v1.1_EN-US

Revision history

Version Date Description

1.0 09.07.2018 Basic version

Table-1 Revision history

Revision historySERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

3

Revision history SERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

4

Table of contentsSERVICE MANUAL Güdel planetary gear NR, SR, PR

Table of contents

1 General 11

1.1 Further applicable documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Purpose of the document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.3 Explanation of symbols/abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Safety 13

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.1.1 Product safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 14

9007199543219723_v1.1_EN-US

2.1.2.1 Operating companies. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.2.2 Fitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.2.3 Commissioning technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.2.4 Manufacturer's technicians. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.2.5 Maintenance technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.1.2.6 Service technicians . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.2.7 Disposal specialists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.3 Disregarding safety regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.4 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Hazard symbols in the manual . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . 19

2.2.1 Hazard warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.2 Explanation of warning symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Hazard symbols on the product .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3.1 Danger label "Hot surfaces". . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . 21

2.3.2 Danger label "Heavy Components". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4 Fundamentals of safety. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 22

2.4.1 Separating protective equipment, monitoring equipment . . . . . . . . . . . . . . . . . 22

2.4.2 Product-specific hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

2.4.3 Material safety data sheets (MSDS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5

Table of contents SERVICE MANUAL Güdel planetary gear NR, SR, PR

3 Product description 25

3.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.2 Non-intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.1.3 Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2 Product designation .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.2.1 Identifying lubricant amount . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .26

3.3 Technical data .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Design, function 29

4.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...............................29

4.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Transport 31

5.1 Packaging symbols. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .32

5.2 Transport securing devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.1 Removing the transport securing device . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 34

5.3 Slings .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3.1 Attaching the slings: Planetary gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6 Commissioning 37

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Intermediate storage. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . 37

9007199543219723_v1.1_EN-US

6.3 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3.1 Attaching the slings: Planetary gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.3.2 Mounting the motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6

Table of contentsSERVICE MANUAL Güdel planetary gear NR, SR, PR

7 Maintenance 43

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2 Maintenance tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.2.1 General prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.2 Maintenance intervals. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2.3 Maintenance tasks after 150 hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.2.3.1 Lubricating the pinion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.2.4 Maintenance tasks after 2,250 hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

7.2.4.1 General inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.5 Maintenance tasks after 22,500 hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2.5.1 Replacing the Güdel planetary gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Attaching the slings: Planetary gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Attaching the slings: Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Remove motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Replacing the Güdel planetary gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Mounting the motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Final tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3 Maintenance schedule: Planetary gear NR, SR, PR. . . . . . . . . . . . . . . . 59

7.4 Maintenance table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

7.5 Intervention protocol: Maintenance. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 63

7.6 Feedback on the instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

8 Repairs 70

9007199543219723_v1.1_EN-US

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.2.1 General prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.2.2 Replacing lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7

Table of contents SERVICE MANUAL Güdel planetary gear NR, SR, PR

8.2.2.1 Identifying lubricant amount . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .75

8.2.3 Replacing the pinion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.2.3.1 Removing the pinion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.2.3.2 Installing the pinion. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.3 Intervention report: Repairs.................... . . . . . . . . . . . . . . . . . . . . 81

8.4 Service departments .. . . . . . . . . . . . . . . . . . . . . . ......................... 83

9 Decommissioning, storage 84

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1.1 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 84

9.2 Storage conditions . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .84

9.3 Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3.1 Cleaning, rust-proofing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3.2 Transport securing devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3.3 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10 Disposal 87

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............................. 87

10.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.1.2 Personnel qualifications . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . 88

10.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.3 Waste management compliant assemblies . . . . . . . . . . . . . . . . . . . . . . . . 89

10.3.1 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10.3.2 Material groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

10.4 Disposal facilities, authorities . . . . . . . . . . . . . . . . . . . ....................90

9007199543219723_v1.1_EN-US

11 Spare parts supply 91

11.1 Service departments .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

11.2 Explanations regarding the spare parts list .. . . . . . . . . . . . . . . . . . . . . . . 99

11.2.1 Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8

Table of contentsSERVICE MANUAL Güdel planetary gear NR, SR, PR

11.2.2 Position drawings . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .99

12 Torque tables 100

12.1 Tightening torques for screws................... .. . . . . . . . . . . . . . . . . . 100

12.1.1 Zinc plated screws . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . 101

12.1.2 Black screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

12.1.3 Stainless steel screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

List of illustrations 105

List of tables 107

Index 109

9007199543219723_v1.1_EN-US

9

Table of contents SERVICE MANUAL Güdel planetary gear NR, SR, PR

10

9007199543219723_v1.1_EN-US

1 General

Read the entire manual before working with the product. The manual contains important information for your personal safety. The manual must be

read and understood by all persons who work on the product in any of the

product life phases.

1.1 Further applicable documentation

All documents delivered with this manual are further applicable documentation. They must be observed in addition to this operating manual for the safe

handling of the product.

1.2 Purpose of the document

GeneralSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

This manual describes the following product life phases of the product:

• Maintenance

• Service

• Disposal

The manual contains the information required for using the product as intended. It is an essential component of the product.

The manual must be available at the product site throughout the entire service life of the product. If the product is sold, the manual must be transferred

to the new owner.

11

Ü

2

General SERVICE MANUAL Güdel planetary gear NR, SR, PR

1.3 Explanation of symbols/abbreviations

The following symbols and abbreviations are used in this manual:

Symbol/Abbreviation

Fig. Designation of graphics Figure

Table Designation of tables Table

Table1-1 Explanation of symbols/abbreviations

Use Explanation

For cross-reference See

Possibly for cross-ref-

Page

erence

In the tip Information or tip

9007199543219723_v1.1_EN-US

12

2 Safety

2.1 General

Read the entire manual before working with the product. The manual contains important information for your personal safety. The manual must be

read and understood by all persons who work on the product in any of the

product life phases.

2.1.1 Product safety

SafetySERVICE MANUAL Güdel planetary gear NR, SR, PR

Residual danger

Operation

The product is built using state-of-the-art technology. It was designed and

constructed in accordance with the accepted safety regulations. However,

some residual danger remains during its operation.

There is danger to the personal safety of the operator as well as for the product and other property.

When operating the product, always observe this manual and ensure that the

system is always in perfect working order.

9007199543219723_v1.1_EN-US

13

Safety SERVICE MANUAL Güdel planetary gear NR, SR, PR

2.1.2 Personnel qualifications

WARNING

Lack of safety training

Incorrect behavior of untrained or insufficiently trained technicians can result

in severe or fatal injuries!

Before technicians work on safety-related aspects of the product:

• Ensure that the technicians are trained with regard to safety

• Train and instruct the technicians specifically for their area of responsibility

Only appropriately trained and authorized technicians are allowed to work on

the product.

Persons are authorized if:

• they are familiar with the relevant safety regulations for their area of responsibility

• they have read and understood this manual

• they meet the requirements for an area of responsibility

• they were assigned an area of responsibility by the operator

The technician is responsible to third parties in his area of responsibility.

During a training session or instruction, the technician may only work on the

product under the supervision of an experienced manufacturer's technician.

2.1.2.1 Operating companies

The operating company is responsible for ensuring that:

• the product is used as intended

• the product is sufficiently lubricated at all times

• all safety aspects are complied with

• the product is put out of operation if the functioning of the safety equipment is not fully guaranteed

• the technician working on the product is appropriately trained

• the technician is provided with personal protective equipment

• the operating manual is available to the technician at the operation site of

the product at all times

• the technicians are kept up-to-date regarding best practice

• the technicians are informed about technical progress, modifications, and

the like.

• the contracted cleaning staff only work under the supervision of a maintenance technician

9007199543219723_v1.1_EN-US

14

2.1.2.2 Fitters

The fitter:

• has very good mechanical and/or electrical knowledge

• is flexible

• has assembly experience

2.1.2.3 Commissioning technicians

The commissioning technician:

• has good programming knowledge

• has mechanical and/or electrical knowledge

• is flexible

The commissioning technician is responsible for the following tasks:

• commissioning the product

• testing the functions of the product

SafetySERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

2.1.2.4 Manufacturer's technicians

The manufacturer's technician:

• is employed on site at the premises of the manufacturer or representative

• has very good mechanical and/or electrical knowledge

• has good software knowledge

• has maintenance, service and repair experience

• has experience with Güdel products

The manufacturer's technician is responsible for the following tasks:

• performing mechanical and electrical maintenance work in accordance with

the manual

• performing mechanical and electrical service work in accordance with the

manual

• cleaning the product

• replacing spare parts

• localizing and fixing malfunctions

15

Safety SERVICE MANUAL Güdel planetary gear NR, SR, PR

2.1.2.5 Maintenance technicians

The maintenance technician:

• was trained by the operating company or the manufacturer

• has very good mechanical and/or electrical knowledge

• has software knowledge

• has maintenance experience

• bears responsibility for the safety of the cleaning staff

The maintenance technician is responsible for the following tasks:

• performing mechanical and electrical maintenance work in accordance with

the manual

• cleaning the product

• replacing spare parts

• monitoring and instructing the cleaning staff in the safety zone during the

cleaning process

2.1.2.6 Service technicians

The service technician:

• was trained by the operating company or the manufacturer

• has very good mechanical and/or electrical knowledge

• has software knowledge

• has service and repair experience

• is flexible

The service technician is responsible for the following tasks:

• performing mechanical and electrical service work in accordance with the

manual

• replacing spare parts

2.1.2.7 Disposal specialists

The disposal specialist:

• is able to separate waste

• is familiar with the country-specific disposal regulations

• has experience in environmentally-friendly disposal

• works carefully and safely

9007199543219723_v1.1_EN-US

16

2.1.3 Disregarding safety regulations

DANGER

Disregarding safety regulations

Disregarding safety regulations can result in damage to property, severe or

fatal injuries.

• Always comply with the safety regulations

SafetySERVICE MANUAL Güdel planetary gear NR, SR, PR

Liability

Güdel shall not be held liable under any of the following circumstances:

• The installation regulations were disregarded

• Included protective equipment was not installed

• Included protective equipment was modified

• Included monitoring equipment was not installed

• Included monitoring equipment was modified

• The product was not used as intended

• The maintenance work was not performed in the specified intervals, or

was carried out incorrectly.

9007199543219723_v1.1_EN-US

17

Safety SERVICE MANUAL Güdel planetary gear NR, SR, PR

2.1.4 Installation instructions

Protective mea-

sures

Modifications

General rules for

occupational

safety

The operating company is responsible for ensuring safe conditions in the vicinity of the product. In particular, he must ensure compliance with the general

safety regulations, guidelines and standards. Before commissioning the system

the operating company must check whether all the protective measures have

been implemented. These must cover all hazards. This is the only way to ensure that application of the product conforms to CE regulations.

As stipulated by the Machinery Directive, the protective measures must:

• Correspond to best practices

• Comply with the required safety category

The product must never be modified or used in a manner contrary to its intended use. Ü225

The generally accepted occupational safety rules must be observed and implemented.

18

9007199543219723_v1.1_EN-US

2.2 Hazard symbols in the manual

2.2.1 Hazard warnings

The hazard warnings are defined for the following four types of danger levels:

DANGER

DANGER

DANGER refers to hazards with a high risk of severe physical injury or immediate fatality.

WARNING

WARNING

WARNING refers to hazards with a moderate risk of severe physical injury

or potential fatality.

SafetySERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

CAUTION

CAUTION

CAUTION refers to hazards with a slight risk of moderate physical injury.

NOTE

NOTE

NOTE refers to hazards that can lead to property damage.

19

Safety SERVICE MANUAL Güdel planetary gear NR, SR, PR

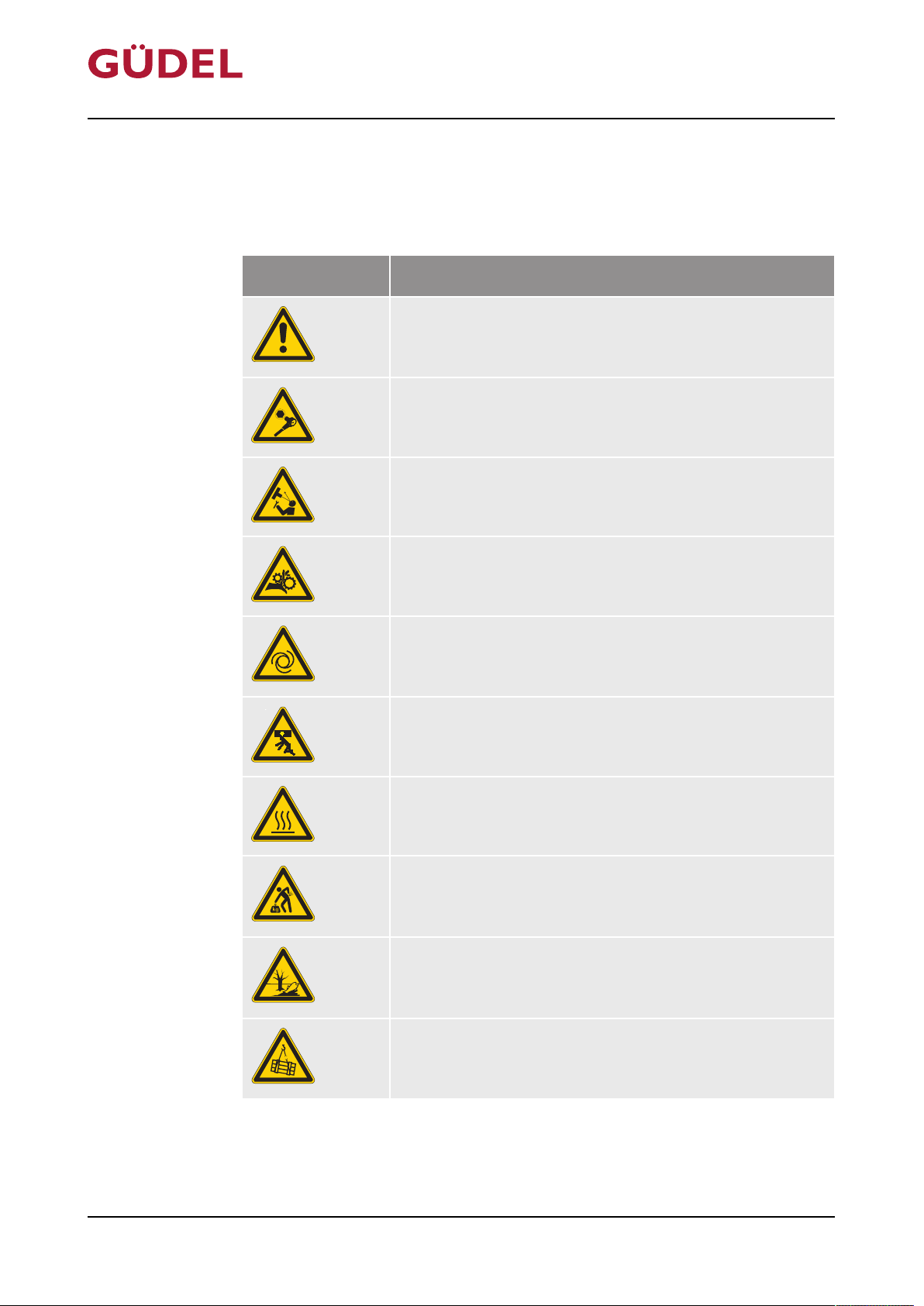

2.2.2 Explanation of warning symbol

Hazard warnings for personal injuries contain the symbol of the corresponding hazard.

Symbol Explanation of symbols

Hazards due to general causes

Hazards due to loose connecting elements

Hazards due to overpressure

Hazards due to toothed wheels

Hazards resulting from automatic startup

Hazards due to falling axles

Hazards due to heat

Hazards due to heavy components

Hazards due to environmental pollution

9007199543219723_v1.1_EN-US

20

Hazards due to suspended loads

Symbol Explanation of symbols

Danger of slipping

2.3 Hazard symbols on the product

The following warning labels are attached to the product:

2.3.1 Danger label "Hot surfaces"

Fig.2-1 Danger label "Hot surfaces"

SafetySERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

The danger label "Hot surfaces" warns against touching hot components.

2.3.2 Danger label "Heavy Components"

Fig.2-2 Danger label "Heavy Components"

The danger label "Heavy Components" warns against lifting heavy components.

21

Safety SERVICE MANUAL Güdel planetary gear NR, SR, PR

2.4 Fundamentals of safety

2.4.1 Separating protective equipment, monitoring equipment

WARNING

Missing separating protective equipment and monitoring equipment

Missing or modified separating protective equipment and monitoring equipment may result in damage to property or serious injuries!

• Do not remove or modify separating protective equipment and monitoring

equipment

• After commissioning the system, correctly attach all the separating protective equipment and monitoring equipment

For more information on separating safety and monitoring equipment, refer

to the documentation on the complete system.

2.4.2 Product-specific hazards

WARNING

Hot oil squirting out

Overpressure in the gearbox is created by overload or incorrect performance parameters. Hot oil can squirt out. This can lead to severe burns or

eye injuries!

• Operate the gearbox within the performance parameters as defined in the

catalog

• Do not overload the gearbox

• Wear appropriate protective clothing

9007199543219723_v1.1_EN-US

22

SafetySERVICE MANUAL Güdel planetary gear NR, SR, PR

WARNING

Loose components

Vibrations can loosen connecting elements. Persons are surprised by unexpected situations and seriously injured as a result.

Observe the following points:

• Secure the connection elements by appropriate means

• Check the tightening torques regularly

WARNING

Risk of injury

Contact with rotating parts causes severe injuries!

Observe the following points:

• Attach separating protective equipment

9007199543219723_v1.1_EN-US

• Keep extremities away from the danger area

• Wear appropriate protective clothing

CAUTION

Oil, greases

Oils and greases are harmful to the environment!

• The oils and greases must not get into the drinking water supply. Take appropriate measures

• Observe the country-specific safety data sheets

• Oils and greases must be disposed of as hazardous waste, even if the total

quantity is small

23

Safety SERVICE MANUAL Güdel planetary gear NR, SR, PR

2.4.3 Material safety data sheets (MSDS)

Safety data sheets contain safety information about the materials. They are

country-specific. Safety data sheets are issued, for example, for materials such

as oils, greases, cleaning agents, etc. The operating company is responsible for

obtaining safety data sheets for all materials used.

Safety data sheets can be obtained as follows:

• Suppliers of chemicals usually supply their substances together with safety

data sheets

• Safety data sheets are available on the Internet.

(Enter "msds" and the name of the material in a search engine. Safety information about the material will be displayed.)

Read the safety data sheets carefully. Follow all the instructions. We recommend that you store the safety data sheets for future reference.

The safety data sheet for Güdel H1 can be found in the download area of our

company Web site http://www.gudel.com

24

9007199543219723_v1.1_EN-US

3 Product description

3.1 Use

3.1.1 Intended use

Operate the product exclusively with motors acc. to DIN 42955 R.

The product is used to transfer torques and for reduction of speeds. It is intended exclusively for installation in a machine or an incomplete machine.

Any other or additional use is not considered to be intended use. The manufacturer assumes no liability for any resulting damage. All risks are borne

solely by the user!

Product descriptionSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

3.1.2 Non-intended use

The product is not intended:

• for the movement of toxic goods

• for the movement of explosive goods

• for operation in potentially explosive areas

• for operation outside of the performance data specified by Güdel

Any use other than the specified intended use will be considered improper

use and is prohibited!

The permitted input speed, output torque and the permitted additional

forces must not be exceeded. Güdel's design guidelines must be observed.

For detailed information, refer to Güdel's cataloghttp://www.gudel.com/prod-

ucts/gearboxes

Do not make any modifications to the product.

25

GUDEL- SUMER

REF : NR240-280-A1-z20-m3H-TP-P12-AM

Made in France

OIL Qty : 2000 cc OF:34274/4

N° 53953 DATE: 3/3/2018

ADAPT : R130/M8-S110-t3.5-d32x58

A B C D E

Product description SERVICE MANUAL Güdel planetary gear NR, SR, PR

3.1.3 Definition

Flange gearboxes are assemblies in accordance with Machinery Directive

2006/42/EC. They are defined as machine components according to paragraph

35 of the guide for the application of the Machinery Directive. For this reason,

Güdel will not issue a declaration of incorporation for the product.

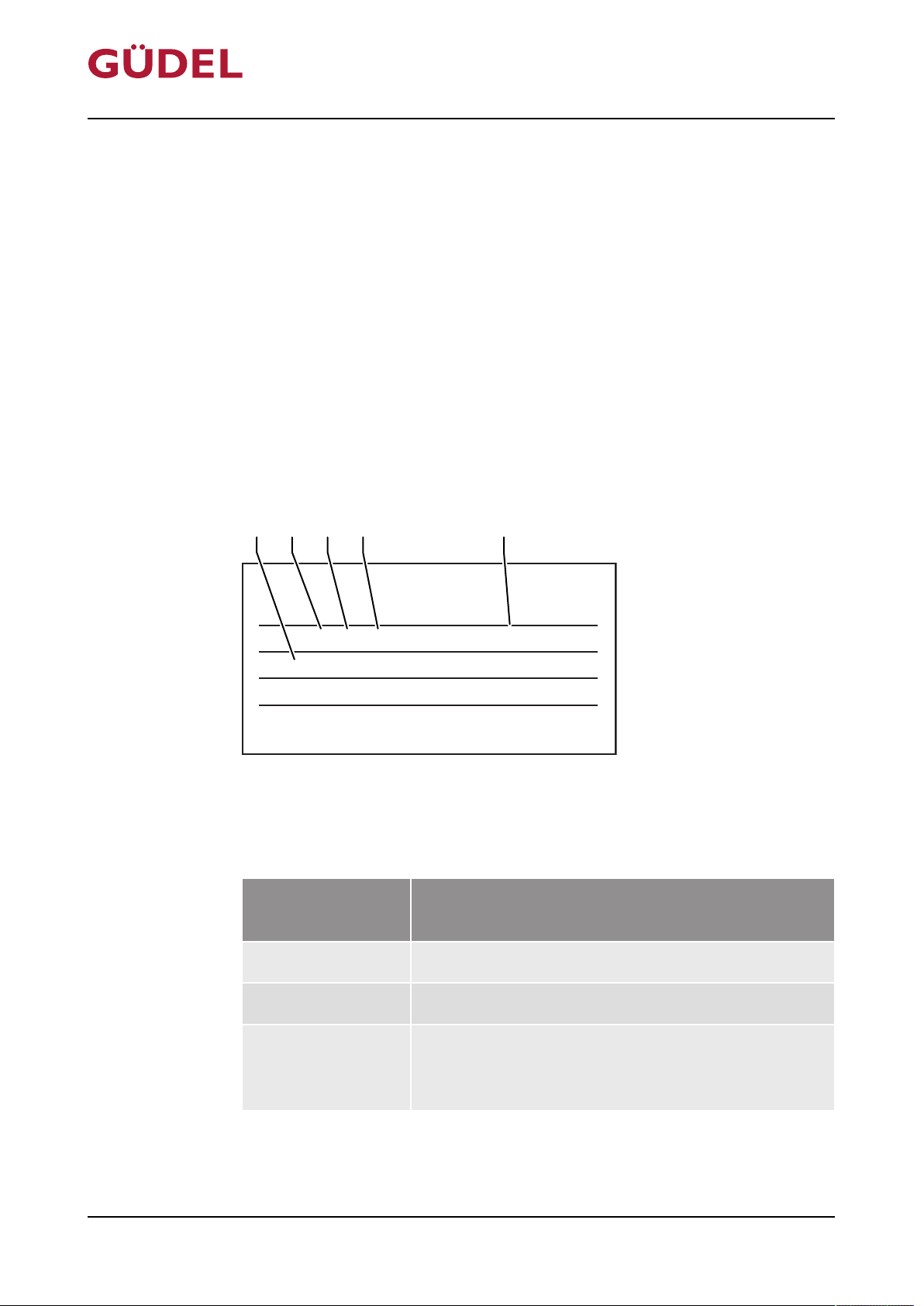

3.2 Product designation

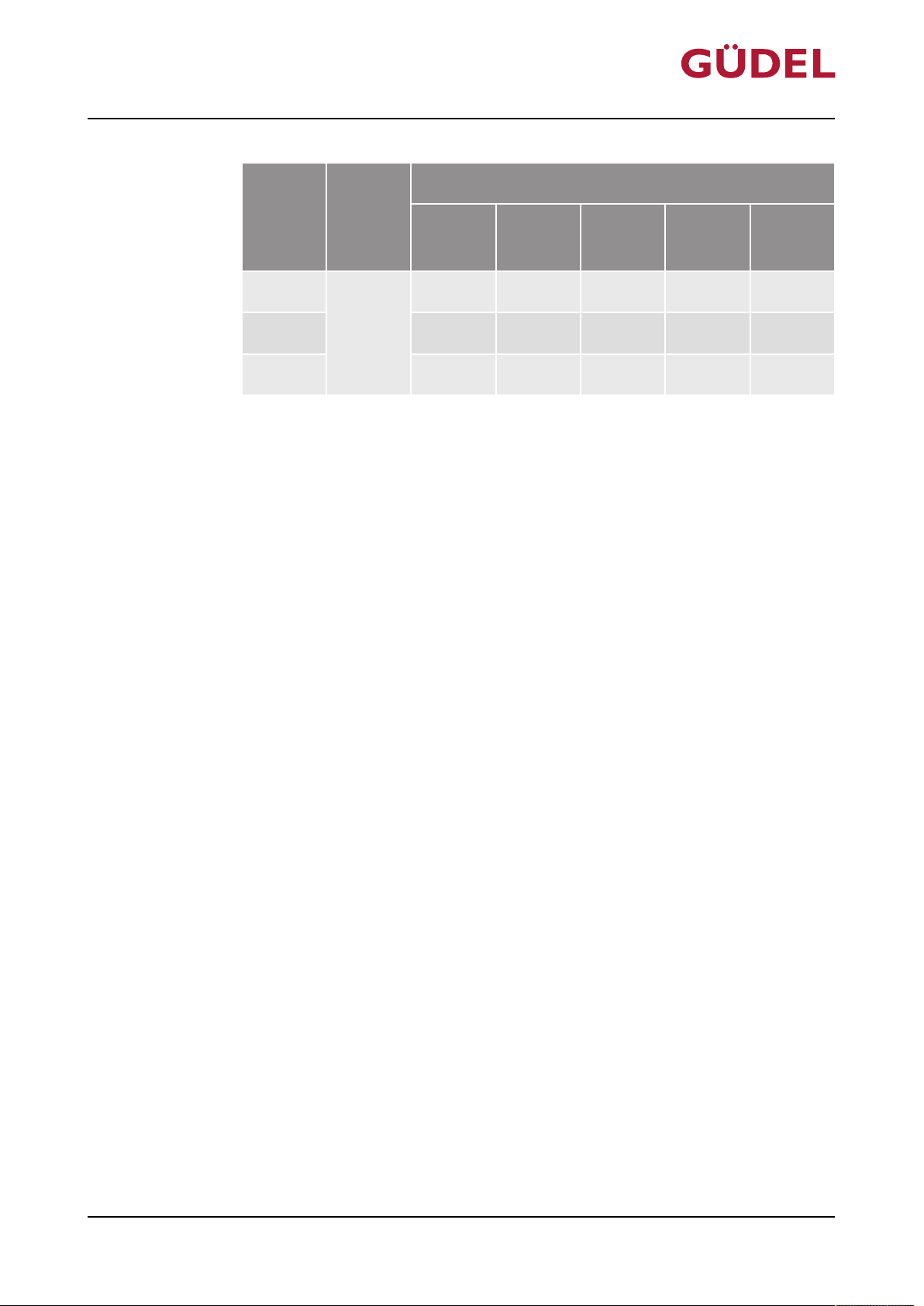

3.2.1 Identifying lubricant amount

The lubricant amount can be found on the type plate or the type key of the

spare parts list. If you have any questions, please contact our service departments.

Fig.3-1 Güdel planetary gearbox: Identifying lubricant quantity

A Lubricant quantity [cm3] D Ratio

B Type E Installation position

C Size

Number of

stages

1 3,4,5,7,10

2 9,12,12R,15,16,20,21,25,28,30,35,40,49,50,70,100

3 27,36,36R,45,48,60,63,64,75,80,84,90,105,

Table3-1 Güdel planetary gearbox: Number of stages

26

Ratios

9007199543219723_v1.1_EN-US

112,120,125,140,147,150,160,175,196,200,210,245,25

0,280, 300,343,350,400,490,500,700,1000

Product descriptionSERVICE MANUAL Güdel planetary gear NR, SR, PR

Stages Instal-

Type / Size

lation

position

80 100 /

110

1 TP 30 90 170 250 600

2 50 130 315 500 1200

3 70 190 400 800 2000

Table3-2 Güdel planetary gearbox: Lubricant quantity [cm3]

140 180 240

9007199543219723_v1.1_EN-US

27

Product description SERVICE MANUAL Güdel planetary gear NR, SR, PR

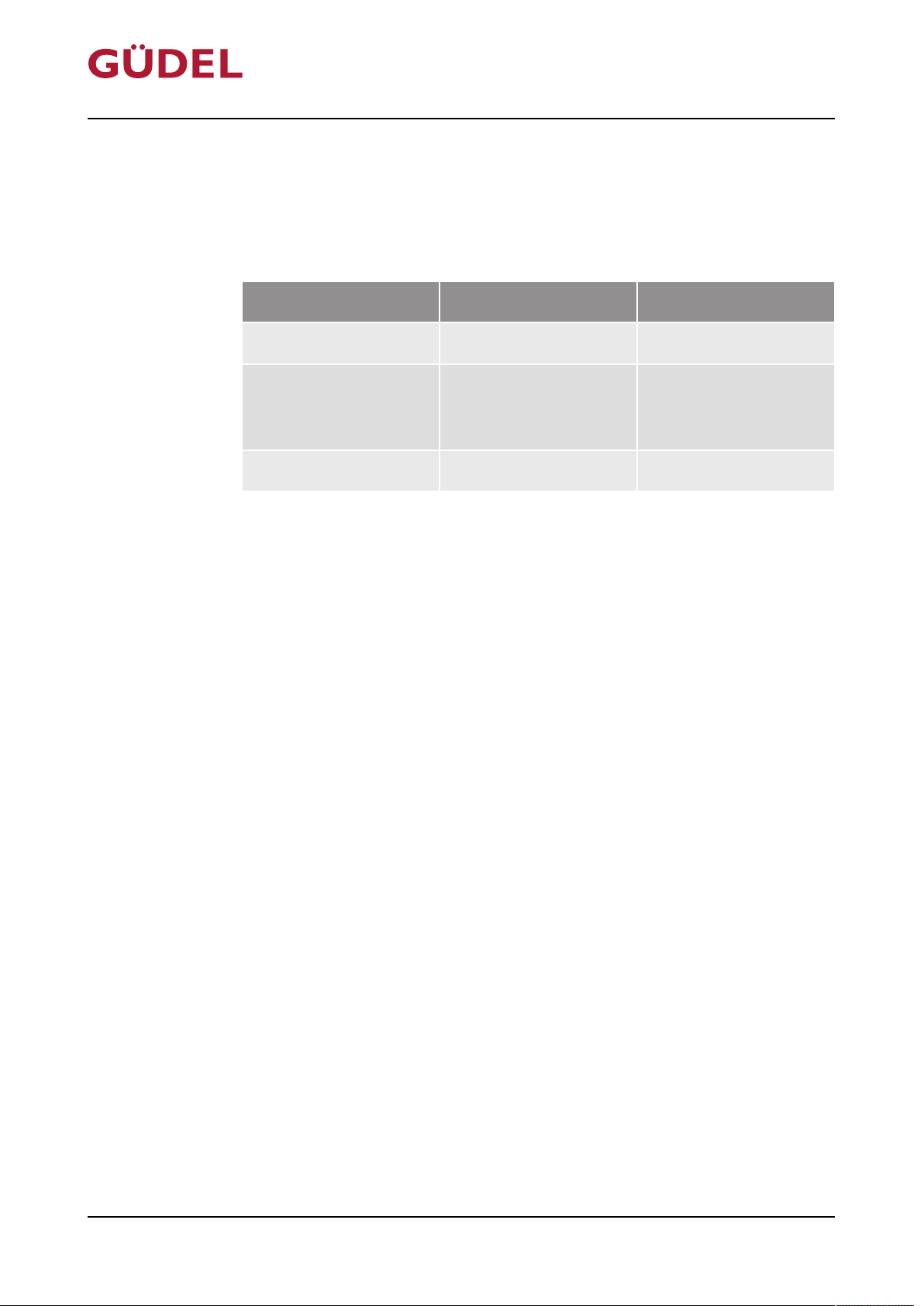

3.3 Technical data

Refer to the catalog for the performance data.

Temperature

ranges

The following ambient temperatures and air humidities apply:

Product life phase Temperature range Air humidity

Transport -10 to +60 °C

Operation -15 to +40 °C Up to and at 85%, con-

Bearing -10 to +40 °C Up to 75 %

Table3-3 Temperature ranges

densation formation is

not permissible

28

9007199543219723_v1.1_EN-US

4 Design, function

A B C D E

F

G

I H

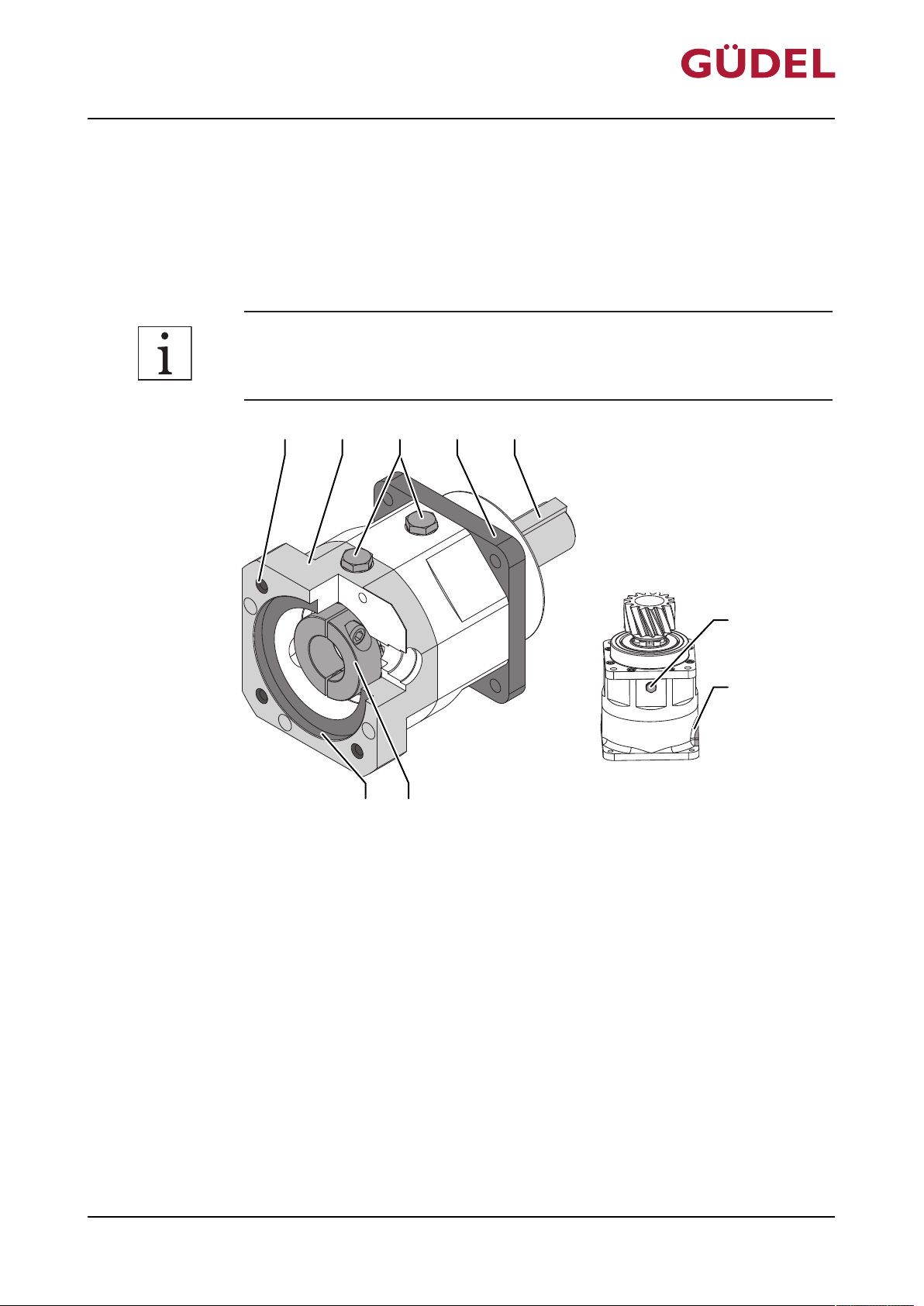

4.1 Structure

The designs of output and planetary gear differ according to customer requirements and gearbox ratio.

Design, functionSERVICE MANUAL Güdel planetary gear NR, SR, PR

Fig.4-1 Güdel planetary gear design

A Bore / Thread for motor F Drain screw

B Motor flange G Plug

9007199543219723_v1.1_EN-US

C Bleed screw and filler screw H Coupling

D Flange I Centering diameter, motor

E Shaft

4.2 Function

The planetary gear is used to transfer torques and speeds.

29

Design, function SERVICE MANUAL Güdel planetary gear NR, SR, PR

30

9007199543219723_v1.1_EN-US

5 Transport

The product is transported by air, land, or water. The packaging depends on

the mode of transport.

Truck = Shipped on a transport pallet

Aircraft = Shipped in a crate

Ship = Shipped in a case or container

Only perform the tasks described in this chapter after you have read and understood the chapter "Safety". Ü213

It concerns your personal safety!

Ripping of lifting belts

TransportSERVICE MANUAL Güdel planetary gear NR, SR, PR

WARNING

9007199543219723_v1.1_EN-US

The sharp edges cut the lifting belts. This can lead to severe or fatal injuries!

• Always protect the lifting belts with an edge guard

WARNING

Suspended loads

Improper handling of suspended loads can lead to severe injuries or death!

• Use appropriate lifting units

• Wear appropriate protective clothing

• Always keep sufficient distance from suspended loads

• Never enter the area below a suspended load

NOTE

Improper transport

Improper handling of the crates can lead to transport damage!

• Do not tip over the crates

• Avoid heavy vibrations and shocks

• Observe the symbols on the packaging

31

CENTER OF

GRAVITY

D003601

SLING

HERE

SLING

HERE

D003600

A B

FRAGILE

D000098

D000099

CRAINT L'HUMIDITE

D000100

HANDLE

WITH CARE

D000101

A B C D

Transport SERVICE MANUAL Güdel planetary gear NR, SR, PR

5.1 Packaging symbols

When moving the transport pallets / crates / cases, observe the following

symbols:

Fig.5-1 Attaching slings

A Center of gravity

B Fastening point

Depending on the contents, the packaging units are marked with the symbols

shown below. Observe these at all times.

Fig.5-2 Packaging symbols

A Fragile C Keep dry

B This side up D Handle with care

9007199543219723_v1.1_EN-US

32

Remove the packaging only to the degree necessary for company-internal

transport.

Transport the pallet, crate, or case to the intended installation location. Use

appropriate transport devices.

5.2 Transport securing devices

At delivery, a transport securing device is in effect at the gearbox. Remove all

transport securing devices before moving the axes. Store the transport securing devices for future work.

WARNING

Falling axes

After removing the transport securing device, brakes or motors, the vertical

axes fall downwards. Carriages may run off to the side. This can lead to severe or fatal injuries!

TransportSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

• If necessary, secure the vertical axes and the carriages before removing

transport securing devices, brakes or motors

33

A B C D E

C A F

Transport SERVICE MANUAL Güdel planetary gear NR, SR, PR

5.2.1 Removing the transport securing device

Fig.5-3 Removing transport securing device: Güdel planetary gearbox

A Coupling screw D Transport securing device

B Planetary gearbox E Motor screw

C Plug F Motor

Remove the transport securing device as follows:

1 Switch off the system and secure it with a padlock against being switched

on again

2 Remove the plug

3 Release the coupling screws

4 Remove the motor screws

5 Remove the transport securing device from the planetary gearbox

The transport securing device has been removed.

9007199543219723_v1.1_EN-US

34

5.3 Slings

D002990

A

B

C

Slings, chains, ropes or belts must be suitable for the load of weight of the

crate. Fasten the slings to stable parts. Secure the slings against slipping. Make

sure that no attachments are damaged by the slings.

5.3.1 Attaching the slings: Planetary gearbox

WARNING

Suspended loads

Improper handling of suspended loads can lead to severe injuries or death!

• Use appropriate lifting units

• Wear appropriate protective clothing

• Always keep sufficient distance from suspended loads

TransportSERVICE MANUAL Güdel planetary gear NR, SR, PR

• Never enter the area below a suspended load

9007199543219723_v1.1_EN-US

Fig.5-4 Attaching the slings: Planetary gearbox

A Crane hook

B Lifting belt

C Gearbox

35

Transport SERVICE MANUAL Güdel planetary gear NR, SR, PR

Attach the slings as follows:

1 Loop the lifting belt around the planetary gear (be aware of center of

gravity!)

2 Hook the lifting belt into the crane hook

3 Carefully lift the load

4 Check horizontal alignment of the load

5 If the load tilts, reposition the lifting belt loop

The slings are in place.

36

9007199543219723_v1.1_EN-US

6 Commissioning

6.1 Introduction

6.1.1 Safety

Only perform the tasks described in this chapter after you have read and understood the chapter "Safety". Ü213

It concerns your personal safety!

Ripping of lifting belts

The sharp edges cut the lifting belts. This can lead to severe or fatal injuries!

• Always protect the lifting belts with an edge guard

CommissioningSERVICE MANUAL Güdel planetary gear NR, SR, PR

WARNING

9007199543219723_v1.1_EN-US

WARNING

Suspended loads

Improper handling of suspended loads can lead to severe injuries or death!

• Use appropriate lifting units

• Wear appropriate protective clothing

• Always keep sufficient distance from suspended loads

• Never enter the area below a suspended load

6.1.2 Personnel qualifications

Only appropriately trained and authorized technicians are allowed to commission the product.

6.2 Intermediate storage

Observe the storage conditions if the product needs to be stored for a certain amount of time before assembly. Ü284

37

D002990

A

B

C

Commissioning SERVICE MANUAL Güdel planetary gear NR, SR, PR

6.3 Installing

6.3.1 Attaching the slings: Planetary gearbox

WARNING

Suspended loads

Improper handling of suspended loads can lead to severe injuries or death!

• Use appropriate lifting units

• Wear appropriate protective clothing

• Always keep sufficient distance from suspended loads

• Never enter the area below a suspended load

Fig.6-1 Attaching the slings: Planetary gearbox

A Crane hook

38

B Lifting belt

C Gearbox

9007199543219723_v1.1_EN-US

CommissioningSERVICE MANUAL Güdel planetary gear NR, SR, PR

Attach the slings as follows:

1 Loop the lifting belt around the planetary gear (be aware of center of

gravity!)

2 Hook the lifting belt into the crane hook

3 Carefully lift the load

4 Check horizontal alignment of the load

5 If the load tilts, reposition the lifting belt loop

The slings are in place.

9007199543219723_v1.1_EN-US

39

A B C D E F

GH

Commissioning SERVICE MANUAL Güdel planetary gear NR, SR, PR

6.3.2 Mounting the motor

If possible, mount the motor in the vertical direction (motor at top, motor

shaft below)

Fig.6-2 Mounting the motor: Güdel planetary gear

A Motor E Coupling screw

B Motor screw (if necessary with washers

according to motor manufacturer specifications)

C Motor shaft G Gearbox contact surface

D Sealing plug H Motor contact surface

Cleaning agents

mild universal cleaner free from aromatic compounds (e.g. Motorex OPAL

5000)

Table6-1 Cleaning agents: Coupling, contact surfaces, and motor shaft

40

F Drill hole

9007199543219723_v1.1_EN-US

CommissioningSERVICE MANUAL Güdel planetary gear NR, SR, PR

Type / Size Diameter,

motor shaft

Coupling

screw, quality

12.9

80-140 ≤14 M6 19.1

80-180 15-24 M8 46

100 / 110 25-35 M8 46

140-240 25-48 M10 92

Table6-2 Tightening torques, coupling screws: Güdel planetary gearbox

Mount the motor as follows:

1 Remove the sealing plug

2 If necessary, remove the burr of the keyway at the motor shaft

3 Clean the coupling, contact surfaces, and motor shaft to ensure that they

are free of grease

4 Position the coupling as shown in the illustration and do not tighten the

coupling screws

Tightening

torque [Nm]

9007199543219723_v1.1_EN-US

5 Mount the motor so that both contact surfaces fit flush on each other

6 Install the motor screws, but do not tighten

7 Tighten the coupling screws to about 60 % of the tightening torque

8 Tighten the motor screws

9 Tighten the coupling screws alternately in three consecutive sequences

up to the tightening torque

10 Slightly loosen the motor screws

11 Tighten the motor screws cross-wise (tightening torque acc. to motor

manufacturer specifications)

The motor has been installed.

41

Commissioning SERVICE MANUAL Güdel planetary gear NR, SR, PR

42

9007199543219723_v1.1_EN-US

7 Maintenance

7.1 Introduction

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Work sequences

Original spare

parts

Tightening torques

7.1.1 Safety

Perform the work sequences in the order described. Perform the described

tasks at the specified times. This ensures a long service life for your product.

Only use original spare parts. Ü291

Unless otherwise indicated, adhere to the tightening torques of Güdel.

ÜChapter12,2100

Only perform the tasks described in this chapter after you have read and understood the chapter "Safety". Ü213

It concerns your personal safety!

WARNING

Automatic startup

During work on the product, there is danger of the machine starting up automatically. This can lead to severe or fatal injuries!

9007199543219723_v1.1_EN-US

Before working in the danger area:

• Secure vertical axes (if equipped) against falling.

• Switch off the superordinate main power supply. Secure it against being

switched on again (main switch for the complete system)

• Before switching on the system again, make sure that no one is in the danger area

43

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

WARNING

Slipping hazard

Liquids run out if there is a leak. Persons may slip and injure themselves seriously!

• Take application-specific protective measures

• Repair any leaks promptly

• Prevent any new leaks. Replace or modify the leaking component or assembly

• Check the fill level and refill if necessary

WARNING

Falling axes, workpieces

Falling axes or workpieces can cause physical damage, serious or fatal injuries!

• Set down any workpieces before working in the danger area

• Never enter the area below suspended axes and workpieces

• Secure suspended axes using the stipulated equipment

• Check the belts of the telescope axes for signs of breakage and tears

WARNING

Heavy components

Components can be very heavy. Improper handling can cause severe or fatal

injuries!

• Use appropriate lifting units

• Use suitable means to secure the components against tipping over

• Only remove the safety devices after the product has been completely assembled

7.1.2 Personnel qualifications

Only appropriately trained and authorized technicians are allowed to work on

the product.

9007199543219723_v1.1_EN-US

44

7.2 Maintenance tasks

7.2.1 General prerequisites

Prior to performing repair and maintenance tasks, do the following:

• If vertical axes are present, secure them against falling

• Switch off the system and padlock it to secure it against being switched on

again

• Make sure that all necessary spare parts and wearing parts are at hand

Ü291

7.2.2 Maintenance intervals

The product is subject to natural wear and tear. When it wears out, unplanned downtimes of your system can result. Güdel specifies the service life

and maintenance intervals of the product so as to ensure safe and continuous

operation. The maintenance intervals relate to the effective operating hours

of the product at a power-on time (POT) of 100%. Normal operating conditions are assumed. These correspond with the parameters used by Güdel

when designing the product. If the conditions are rougher than assumed,

products may fail earlier. Adjust the maintenance intervals to your operating

conditions if necessary.

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

The definition is based on 5/7 working days per week.

45

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

Operating

hours

1-shift operation

2-shift operation

150 every 4 weeks every 2 weeks Weekly

2'250 yearly every 6 months every 4 months

6'750 every 3 years every 1.5 years yearly

11'250 every 5 years every 2.5 years every 20 months

13'500 every 6 years every 3 years every 2 years

22'500 every 10 years every 5 years every 3.3 years

31'500 every 14 years every 7 years every 4.5 years

54'000 every 24 years every 12 years every 8 years

Table7-1 Maintenance intervals in shift operation (5 days a week)

Operating

hours

1-shift operation

2-shift operation

3-shift operation

3-shift operation

150 every 18 days every 9 days every 6 days

2'250 every 9 months every 4.5

months

6'750 every 2.5 years every 15 months every 10 months

11'250 every 4 years every 2 years every 16 months

13'500 every 4.5 years every 3 years every 1.5 years

22'500 every 7.75 years every 3.8 years every 2.5 years

31'500 every 11 years every 5.5 years every 3.5 years

54'000 every 18.5 years every 9.25 years every 6.25 years

Table7-2 Maintenance intervals in shift operation (7 days a week)

every 3 months

9007199543219723_v1.1_EN-US

46

7.2.3 Maintenance tasks after 150 hours

D003856

7.2.3.1 Lubricating the pinion

If available, lubricate the pinion after 150 operating hours or 100 km. Lubricate several times if tribocorrosion (reddish discoloration) occurs.

CAUTION

Danger of being crushed

When performing work on the product, there is a risk of being crushed in

the area around the exposed pinions.

Observe the following points:

• Never reach into the area around the pinions

• Use a brush to apply the lubrication to the pinions

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

Lubrication ex

works

Mobil Mobilux EP 2 KP2K-30 in accordance

Table7-3 Lubricants: Pinion

Specification Lubrication quantity

with DIN 51502

47

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

7.2.4 Maintenance tasks after 2,250 hours

7.2.4.1 General inspection

Performing a gen-

eral inspection

For the general inspection, perform a rough check of the entire product.

Perform the general inspection as follows:

1 Switch off the system and padlock it to secure it against being switched

on again

2 Check the inspection points as described in the inspection table

3 Take measures as described in the inspection table

The general inspection is complete.

48

9007199543219723_v1.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Inspection

Description Measures

point

Contamination Check the planetary

gear for contamination

Damage Check the planetary

gear for damage:

• Paint damage

• Bent components

• General damage

Loose components

Check the fit of the

components:

• Screws

• Clamping sets

Loss of oil Check the planetary

gear and its surroundings for signs of the following:

• Puddles of oil and oil

spills on the floor or

in the drip sheets

• Leaks on the planetary gear

Immediately clean away any

contamination

Immediately remedy all discovered damage

Immediately tighten loose

screws to the required

torque

• Repair or replace the

gearbox

• Remove puddles of oil

and oil spills on the floor

or in the drip sheets

9007199543219723_v1.1_EN-US

Setting Check the planetary

Table7-4 Inspection table

Set the tooth flank backlash

gear for correct setting:

• Pinions

49

D002990

A

B

C

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

7.2.5 Maintenance tasks after 22,500 hours

7.2.5.1 Replacing the Güdel planetary gearbox

Attaching the slings: Planetary gearbox

WARNING

Suspended loads

Improper handling of suspended loads can lead to severe injuries or death!

• Use appropriate lifting units

• Wear appropriate protective clothing

• Always keep sufficient distance from suspended loads

• Never enter the area below a suspended load

Fig.7-1 Attaching the slings: Planetary gearbox

50

A Crane hook

B Lifting belt

C Gearbox

9007199543219723_v1.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Attach the slings as follows:

1 Loop the lifting belt around the planetary gear (be aware of center of

gravity!)

2 Hook the lifting belt into the crane hook

3 Carefully lift the load

4 Check horizontal alignment of the load

5 If the load tilts, reposition the lifting belt loop

The slings are in place.

9007199543219723_v1.1_EN-US

51

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

Attaching the slings: Motor

WARNING

Suspended loads

Improper handling of suspended loads can lead to severe injuries or death!

• Use appropriate lifting units

• Wear appropriate protective clothing

• Always keep sufficient distance from suspended loads

• Never enter the area below a suspended load

Fig.7-2 Attaching the slings: Motor (image source: Bosch Rexroth)

Attach the slings as follows:

1 Remove fan from motor if necessary

2 Mount lifting screw if necessary

3 Attach the slings as shown in the illustration

4 Carefully lift the load

5 Check horizontal alignment of the load

6 If the load tilts: Repeat process from step 3

The slings are in place.

52

9007199543219723_v1.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Remove motor

WARNING

Moving the axis

The work requires moving the axis. This can lead to severe or fatal injuries!

• Ensure that no persons are in the danger area while the axis is moving

WARNING

Falling axes

After removing the transport securing device, brakes or motors, the vertical

axes fall downwards. Carriages may run off to the side. This can lead to severe or fatal injuries!

• If necessary, secure the vertical axes and the carriages before removing

transport securing devices, brakes or motors

9007199543219723_v1.1_EN-US

CAUTION

Hot parts/surfaces

Hot surfaces present a burn hazard during work on this product!

• Protect yourself by wearing heat-resistant gloves

• Allow the parts to cool down first

53

A B C D E F

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

Fig.7-3 Remove motor: Planetary gearbox Güdel

A Motor D Plug

B Motor screws (if necessary with spacers

according to motor manufacturer specifications)

C Motor shaft F Drill hole

Remove the motor as follows:

1 Remove the plug

2 Check if the coupling screws can be reached through the drill hole

3 If there are deviations: Adjust axis until the coupling screws can be

reached through the drill hole

4 Switch off the system and padlock it to prevent it from being switched on

again

5 Attach slings to the motor Ü252

6 Release the coupling screws

7 Remove the motor screws

8 Remove motor

E Coupling screws

9007199543219723_v1.1_EN-US

54

The motor has been removed.

A B C D E F

GH

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Replacing the Güdel planetary gearbox

Replace the Güdel planetary gearbox as follows:

1 Replacing the Güdel planetary gearbox

The planetary gear has been replaced.

Mounting the motor

If possible, mount the motor in the vertical direction (motor at top, motor

shaft below)

Fig.7-4 Mounting the motor: Güdel planetary gear

A Motor E Coupling screw

9007199543219723_v1.1_EN-US

B Motor screw (if necessary with washers

according to motor manufacturer specifications)

C Motor shaft G Gearbox contact surface

D Sealing plug H Motor contact surface

F Drill hole

55

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

Cleaning agents

mild universal cleaner free from aromatic compounds (e.g. Motorex OPAL

5000)

Table7-5 Cleaning agents: Coupling, contact surfaces, and motor shaft

Type / Size Diameter,

motor shaft

Coupling

screw, quality

12.9

80-140 ≤14 M6 19.1

80-180 15-24 M8 46

100 / 110 25-35 M8 46

140-240 25-48 M10 92

Table7-6 Tightening torques, coupling screws: Güdel planetary gearbox

Mount the motor as follows:

1 Remove the sealing plug

2 If necessary, remove the burr of the keyway at the motor shaft

3 Clean the coupling, contact surfaces, and motor shaft to ensure that they

are free of grease

4 Position the coupling as shown in the illustration and do not tighten the

coupling screws

Tightening

torque [Nm]

56

5 Mount the motor so that both contact surfaces fit flush on each other

6 Install the motor screws, but do not tighten

7 Tighten the coupling screws to about 60 % of the tightening torque

8 Tighten the motor screws

9 Tighten the coupling screws alternately in three consecutive sequences

up to the tightening torque

10 Slightly loosen the motor screws

11 Tighten the motor screws cross-wise (tightening torque acc. to motor

manufacturer specifications)

The motor has been installed.

9007199543219723_v1.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Final tasks

Perform the following final tasks:

1 Set the tooth flank backlash as described in the superordinate operating

manual

2 Calibrate the reference plane of the motor (this procedure is described

in the documentation for the overall plant or the motor)

The final tasks have been performed.

9007199543219723_v1.1_EN-US

57

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

58

9007199543219723_v1.1_EN-US

7.3 Maintenance schedule: Planetary gear NR, SR, PR

h

2'250

h

2'250

h

22'500

h

22'500

h

150

h

150

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

Fig.7-5 Maintenance schedule: Planetary gear NR, SR, PR

Grease Replacing Replacing lubricant

Oil Clean Visual inspection

59

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

60

9007199543219723_v1.1_EN-US

7.4 Maintenance table

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Maintenance work Maintenance cycle [h] Duration [min] Target readership Lubricants

Lubricating the pinion 150

General inspection 2,250

Replacing the Güdel planetary gearbox

This table does not purport to be exhaustive.

Table7-7 Maintenance table

22,500 60

Maintenance technicians

The manufacturer's technicians

Maintenance technicians

The manufacturer's technicians

Service technicians

The manufacturer's technicians

Maintenance technicians

Further information

Cleaning agents

Mobil Mobilux EP 2 ÜChapter7.2.3.1,247

ÜChapter7.2.4.1,248

ÜChapter7.2.5.1,250

9007199543219723_v1.1_EN-US

61

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

62

9007199543219723_v1.1_EN-US

7.5 Intervention protocol: Maintenance

9007199543219723_V1.1_EN-US

B1M.1xxxxxxx-xxxx

10xxxxxxxxx

991xxxxxxx

2019

Send

SERVICE MANUAL Güdel planetary gear NR, SR, PR

Project / Order: Company :

Bill of materials: Address :

Serial number: Location :

Year of manufacture: Country :

Complete the intervention report after every intervention. You can overwrite the data each time you complete the report. Send the intervention report to Güdel electronically. Use the "Send" button. Sending only works if you have completed the operator details in the intervention report as specified in the Maintenance chapter. Save the generated XML file as a backup. Copy the empty intervention report and scan it in after completing it if you are not working electronically. Send it to service@ch.gudel.com after every intervention.

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

Maintenance work Maintenance cycle

[h]

Lubricating the pinion 150

Effective operating

hours

1

Name

2

Comments

3

Date

9007199543219723_v1.1_EN-US

Effective operating hours1 : Service hours [h] of the entire system according to service hour counter in the control panel / Service hours [h] or kilometers [km] of the corresponding axis

Name2 : First and last name of the service or maintenance technician

Comments3 : Amount of contamination, anomalies, defects, replaced components

63

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

64

9007199543219723_v1.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_V1.1_EN-US

B1M.1xxxxxxx-xxxx

10xxxxxxxxx

991xxxxxxx

2019

Send

Intervention protocol: Maintenance

SERVICE MANUAL Güdel planetary gear NR, SR, PR

Project / Order:

Bill of materials:

Serial number:

Year of manufacture:

Complete the intervention report after every intervention. You can overwrite the data each time you complete the report. Send the intervention report to Güdel electronically. Use the "Send" button. Sending only works if you have completed the operator details in the intervention report as specified in the Maintenance chapter. Save the generated XML file as a backup. Copy the empty intervention report and scan it in after completing it if you are not working electronically. Send it to service@ch.gudel.com after every intervention.

Maintenance work Maintenance cycle

[h]

General inspection 2,250

Effective operating

hours

1

Name

2

Comments

3

Date

9007199543219723_v1.1_EN-US

Effective operating hours1 : Service hours [h] of the entire system according to service hour counter in the control panel / Service hours [h] or kilometers [km] of the corresponding axis

Name2 : First and last name of the service or maintenance technician

Comments3 : Amount of contamination, anomalies, defects, replaced components

65

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

66

9007199543219723_v1.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_V1.1_EN-US

B1M.1xxxxxxx-xxxx

10xxxxxxxxx

991xxxxxxx

2019

Send

Intervention protocol: Maintenance

SERVICE MANUAL Güdel planetary gear NR, SR, PR

Project / Order:

Bill of materials:

Serial number:

Year of manufacture:

Complete the intervention report after every intervention. You can overwrite the data each time you complete the report. Send the intervention report to Güdel electronically. Use the "Send" button. Sending only works if you have completed the operator details in the intervention report as specified in the Maintenance chapter. Save the generated XML file as a backup. Copy the empty intervention report and scan it in after completing it if you are not working electronically. Send it to service@ch.gudel.com after every intervention.

Maintenance work Maintenance cycle

[h]

Replacing the Güdel planetary gearbox

This table does not purport to be exhaustive.

22,500

Effective operating

hours

1

Name

2

Comments

3

Date

9007199543219723_v1.1_EN-US

Effective operating hours1 : Service hours [h] of the entire system according to service hour counter in the control panel / Service hours [h] or kilometers [km] of the corresponding axis

Name2 : First and last name of the service or maintenance technician

Comments3 : Amount of contamination, anomalies, defects, replaced components

67

Maintenance SERVICE MANUAL Güdel planetary gear NR, SR, PR

68

9007199543219723_v1.1_EN-US

9.3.7 Maintenance tasks after 6,750 hours

9.3.7.1 Replacing the lubricating pinion

A pinion soaked in lubricant runs along next to the drive pinion. It ensures a

continuous lubrication of the rack and the drive pinions.

Replace the lubricating pinion to ensure uniform lubrication.

A B C D E F G

Fig.9-7 Replacing the lubricating pinion

A Lubrication point E Fastening screw

B Screw F Lubricating pinion

C Hexagonal socket wrench G Carriage

D Covering

Lubrication ex

works

Specification Lubrication quantity

ÜChapter9.2.2.1,

2116

ÜChapter9.2.2.1,

2116

Table9-12 Lubricants: Guideways, racks, and pinions

Removing the lu-

bricating pinion

Remove the lubricating pinion as follows:

1 Switch o the plant and padlock it to secure it against being switched on

again

2 Remove the line of the automatic lubrication if necessary

3 Remove screws and covering

4 Remove the fastening screw

5 Remove lubricating pinion

The lubricating pinion has been removed.

MaintenanceOPERATING MANUAL ZP 1-5

45035996409887627_v3.1_EN-US

129

9.3.7 Maintenance tasks after 6,750 hours

9.3.7.1 Replacing the lubricating pinion

A pinion soaked in lubricant runs along next to the drive pinion. It ensures a

continuous lubrication of the rack and the drive pinions.

Replace the lubricating pinion to ensure uniform lubrication.

A B C D E F G

Fig.9-7 Replacing the lubricating pinion

A Lubrication point E Fastening screw

B Screw F Lubricating pinion

C Hexagonal socket wrench G Carriage

D Covering

Lubrication ex

works

Specification Lubrication quantity

ÜChapter9.2.2.1,

2116

ÜChapter9.2.2.1,

2116

Table9-12 Lubricants: Guideways, racks, and pinions

Removing the lu-

bricating pinion

Remove the lubricating pinion as follows:

1 Switch o the plant and padlock it to secure it against being switched on

again

45035996409887627_v3.1_EN-US

MaintenanceSERVICE MANUAL Güdel planetary gear NR, SR, PR

7.6 Feedback on the instructions

Your feedback helps us to keep improving these instructions. Thank you!

mailto: docufeedback@ch.gudel.com

Please provide the following information with your feedback:

• Identification number of the instructions

• Product, type

• Project number, order number

• Material number / serial number

• Year of manufacture

• Location of the product (country, ambient conditions, etc.)

• Photos, comments, feedback with clear reference to the section in the instructions

• Your contact data for clarifications if necessary

You can find most of the information on the type plate or the title page of the

instructions. The identification number of the instructions is given on each

page, as shown here:

9007199543219723_v1.1_EN-US

Fig.7-6 Identification number of the instructions

69

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

8 Repairs

8.1 Introduction

Work sequences

Original spare

parts

Tightening torques

8.1.1 Safety

Perform the work sequences in the order described. Perform the described

tasks at the specified times. This ensures a long service life for your product.

Only use original spare parts. Ü291

Unless otherwise indicated, adhere to the tightening torques of Güdel.

ÜChapter12,2100

Only perform the tasks described in this chapter after you have read and understood the chapter "Safety". Ü213

It concerns your personal safety!

WARNING

Automatic startup

During work on the product, there is danger of the machine starting up automatically. This can lead to severe or fatal injuries!

Before working in the danger area:

• Secure vertical axes (if equipped) against falling.

• Switch off the superordinate main power supply. Secure it against being

switched on again (main switch for the complete system)

• Before switching on the system again, make sure that no one is in the danger area

WARNING

Falling axes, workpieces

Falling axes or workpieces can cause physical damage, serious or fatal injuries!

• Set down any workpieces before working in the danger area

• Never enter the area below suspended axes and workpieces

• Secure suspended axes using the stipulated equipment

• Check the belts of the telescope axes for signs of breakage and tears

9007199543219723_v1.1_EN-US

70

WARNING

Heavy components

Components can be very heavy. Improper handling can cause severe or fatal

injuries!

• Use appropriate lifting units

• Use suitable means to secure the components against tipping over

• Only remove the safety devices after the product has been completely assembled

8.1.2 Personnel qualifications

Only appropriately trained and authorized technicians are allowed to work on

the product.

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

71

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

8.2 Repairs

8.2.1 General prerequisites

Prior to performing repair and maintenance tasks, do the following:

• If vertical axes are present, secure them against falling

• Switch off the system and padlock it to secure it against being switched on

again

• Make sure that all necessary spare parts and wearing parts are at hand

Ü291

8.2.2 Replacing lubricant

Replace the lubricant at the latest every:

• 3 years in heavy-duty application conditions

• 5 years in normal application conditions

WARNING

Hot gearbox oil

Working on the gearbox carries the risk of severe injury due to burns!

• Let the gearbox cool before commencing any work

CAUTION

Oil, greases

Oils and greases are harmful to the environment!

• The oils and greases must not get into the drinking water supply. Take appropriate measures

• Observe the country-specific safety data sheets

• Oils and greases must be disposed of as hazardous waste, even if the total

quantity is small

NOTE

Unsuitable lubricants

9007199543219723_v1.1_EN-US

72

Using unsuitable lubricants can cause damage to the machine!

• Only use the lubricants listed

• If uncertain, please contact our service departments

D003857

A B

C

Fig.8-1 Replacing lubricant

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

A Bleed screw

B Filler screw

C Drain screw

Lubrication ex

works

Fuchs Renolin PG220 CLP PG 220 as per DIN

Table8-1 Lubricants: Güdel planetary gearbox

Specification Lubrication quantity

51517-3, polyglycol

based

73

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

Replace the lubricant as follows:

1 Position the gearbox:

Drain screw at the bottom

Filler and bleed screw at the top

2 Position a suitable container below the drain screw

3 Remove the bleed, filler, and drain screws

4 Drain the lubricant

5 Rinse the gearbox with fresh lubricant

6 Allow the gearbox to drain

7 Screw in the drain screw

8 Fill up the gearbox through the filler screw

9 Screw in the bleed and filler screws

The lubricant has been replaced.

74

9007199543219723_v1.1_EN-US

8.2.2.1 Identifying lubricant amount

GUDEL- SUMER

REF : NR240-280-A1-z20-m3H-TP-P12-AM

Made in France

OIL Qty : 2000 cc OF:34274/4

N° 53953 DATE: 3/3/2018

ADAPT : R130/M8-S110-t3.5-d32x58

A B C D E

The lubricant amount can be found on the type plate or the type key of the

spare parts list. If you have any questions, please contact our service departments.

Fig.8-2 Güdel planetary gearbox: Identifying lubricant quantity

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

A Lubricant quantity [cm3] D Ratio

B Type E Installation position

C Size

Number of

Ratios

stages

1 3,4,5,7,10

2 9,12,12R,15,16,20,21,25,28,30,35,40,49,50,70,100

3 27,36,36R,45,48,60,63,64,75,80,84,90,105,

112,120,125,140,147,150,160,175,196,200,210,245,25

0,280, 300,343,350,400,490,500,700,1000

Table8-2 Güdel planetary gearbox: Number of stages

75

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

Stages Instal-

Type / Size

lation

position

80 100 /

110

1 TP 30 90 170 250 600

2 50 130 315 500 1200

3 70 190 400 800 2000

Table8-3 Güdel planetary gearbox: Lubricant quantity [cm3]

140 180 240

76

9007199543219723_v1.1_EN-US

8.2.3 Replacing the pinion

Œ

‘

•

”“

Ž

•

•

’

A B C

F E D

If pins are defective, the gearbox will also be damaged internally! Send the

gearbox to Güdel for repairs.

8.2.3.1 Removing the pinion

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

Fig.8-3 Removing the pinion

A Fastening screw D Headless set screw

B Hexagonal socket wrench E Cover

C Elongation piece F Pin

Property Type / Size

80 110 140 180 240

Dimen-

M5x40 M8x45 M8x60 M8x70 M10x80

sion

Quality 12.9 12.9 12.9 12.9 12.9

Table8-4 Properties of the headless set screws

77

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

Remove the pinion as follows:

1 Remove gearbox unit from machine

2 Remove the cover using a screwdriver

3 Block the coupling, if necessary

4 Remove the fastening screw (elongation piece permitted)

5 Screw the headless set screws into the pins up to the limit stop

6 Pull the pinion off the pins using the headless set screws

(Screw in the headless set screws in the order shown in the figure)

6.1 Screw in the first headless set screw by ⅛ of a rotation

6.2 Repeat the previous step for the remaining headless set screws un-

til the pinion is completely pulled off

6.3 Remove the headless set screws from pinion

The pinion is removed.

78

9007199543219723_v1.1_EN-US

8.2.3.2 Installing the pinion

D003921

ü

û

A B C

D

E

F

G

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

Fig.8-4 Installing the pinion

A Fastening screw E Pin

B Cover F Thread

C Torque wrench G Gearbox

D Pinion

9007199543219723_v1.1_EN-US

79

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

Size Module Properties

Size Tightening

Quality

torque

[Nm]

80 2 M8x50 31 12.9

110 2 M12x65 104

3 M12x70 96

140 3 M16x70 200

4 M16x70 180

180 4 M20x80 400

5 M20x90 350

240 5 M24x130 960

6 M24x130 920

Table8-5 Properties of the fastening screw, depending on the pinion module

Install the pinion as follows:

1 Position the gearbox vertically

2 Lubricate the pins, thread, and bottom of the fastening screw head with a

universal grease

3 Place the pinion exactly axial on the pins

4 Press the pinion up to the limit stop using the fastening screw

5 Remove the fastening screw

6 Degrease the fastening screw and thread

7 Apply Loctite 243 to the thread

8 Install and tighten the fastening screw

(Select tightening torque according to above table)

9 Mount the cover using Loctite 243

The pinion has been installed.

9007199543219723_v1.1_EN-US

80

8.3 Intervention report: Repairs

9007199543219723_V1.1_EN-US

B1M.1xxxxxxx-xxxx

10xxxxxxxxx

991xxxxxxx

2019

Send

SERVICE MANUAL Güdel planetary gear NR, SR, PR

Project / Order:

Bill of materials:

Serial number:

Year of manufacture:

Complete the intervention report after every intervention. You can overwrite the data each time you complete the report. Send the intervention report to Güdel electronically. Use the "Send" button. Sending only works if you have completed the operator details in the intervention report as specified in the Maintenance chapter. Save the generated XML file as a backup. Copy the empty intervention report and scan it in after completing it if you are not working electronically. Send it to service@ch.gudel.com after every intervention.

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

Work

1

Component

2

Effective operating

hours

3

Name

4

Comments

5

Date

9007199543219723_v1.1_EN-US

Work1 : Work carried out during the unplanned maintenance

Component2 : Affected component/assembly

Effective operating hours3 : Service hours [h] of the entire system according to service hour counter in the control panel / Service hours [h] or kilometers [km] of the corresponding axis

Name4 : First and last name of the service or maintenance technician

Comments5 : Amount of contamination, anomalies, defects, replaced components

81

Repairs SERVICE MANUAL Güdel planetary gear NR, SR, PR

82

9007199543219723_v1.1_EN-US

8.4 Service departments

If you have questions, please contact the service departments. Ü293

RepairsSERVICE MANUAL Güdel planetary gear NR, SR, PR

9007199543219723_v1.1_EN-US

83

Decommissioning, storage SERVICE MANUAL Güdel planetary gear NR, SR, PR

9 Decommissioning, storage

9.1 Introduction

Only perform the tasks described in this chapter after you have read and understood the chapter "Safety". Ü213

It concerns your personal safety!

9.1.1 Personnel qualifications

Only appropriately trained and authorized technicians are allowed to work on

the product.

9.2 Storage conditions

Leaking fluids