Page 1

Owner’s

Manual

• SAFETY

• ASSEMBLY

ULTRA SOURCE

Portable Generator

• OPERATION

• TROUBLESHOOTING

• ELECTRICAL DATA

• PARTS

• WARRANTY

AUTHORIZED DEALER SUPPORT:

COMMERCIAL • INDUSTRIAL • RESIDENTIAL

MODEL: 004582-2

15,000 Watt Portable Generator

1-800-333-1322

Page 2

Table of Contents

Commercial-Industrial-Residential Portable Generator System

Safety Rules .................................................................. 1

Section 1 – General Information ................................. 4

1.1 Unpacking ............................................................................. 4

1.1.1 Accessory Box ........................................................ 4

1.2 Assembly .............................................................................. 4

1.2.1 Assembling the Wheel Kit ....................................... 4

1.2.2 Assembling the Handle ........................................... 4

1.2.3 Battery Connection ................................................. 5

Section 2 – Operation .................................................. 6

2.1 Know The Generator ............................................................ 6

2.2 Cord Sets and Connector Plugs ........................................... 7

2.2.1 120 VAC, 20 Amp, Duplex Receptacle ................... 7

2.2.2 120 VAC, 20 Amp, GFCI Receptacle ...................... 7

2.2.3 120 VAC, 30 Amp Receptacle ................................ 7

2.2.4 120/240 VAC, 30 Amp, Receptacle ........................ 8

2.2.5 12 Volt DC, 10 Amp Receptacle ............................. 8

2.2.6 120/240 VAC, 50 Amp, Receptacle ........................ 8

2.3 How To Use The Generator .................................................. 8

2.3.1 Grounding The Generator .......................................8

2.3.2 Connecting Electric Loads ...................................... 9

2.4 Don’t Overload The Generator ............................................. 9

2.5 Wattage Reference Guide .................................................... 9

2.6 Before Starting The Generator ........................................... 10

2.6.1 Adding Engine Oil ................................................. 10

2.6.2 Adding Gasoline ................................................... 10

2.7 To Start The Engine ............................................................ 11

2.8 Stopping The Engine .......................................................... 11

2.9 Automatic Idle Control ........................................................ 12

2.10 Cold Weather Operation/De-Icer ........................................ 12

2.11 Low Oil Pressure Shutdown System .................................. 12

2.11.1 Initial Start-up ....................................................... 12

2.11.2 Sensing Low Oil Pressure .................................... 12

2.11.3 Restarting ............................................................. 12

2.12 Charging a Battery ............................................................. 12

Section 3 – Maintenance ...........................................13

3.1 Maintenance Schedule ....................................................... 13

3.2 Product Specifications ........................................................ 13

3.2.1 Generator Specifications ...................................... 13

3.2.2 Engine Specifications ........................................... 13

3.3 General Recommendations ................................................ 14

3.3.1 Generator Maintenance ........................................ 14

3.3.2 To Clean The Generator ....................................... 14

3.3.3 Engine Maintenance ............................................. 14

3.3.4 Checking Oil Level ................................................ 14

3.3.5 Changing The Oil & Oil Filter ................................ 14

3.3.6 Replacing The Spark Plug ................................... .15

3.4 Service Air Cleaner ............................................................ 15

3.5 Clean Spark Arrestor Screen ............................................. 15

3.6 Adjusting Valve Clearance .................................................. 16

3.7 General .............................................................................. 16

3.8 Long Term Storage ............................................................. 17

3.9 Other Storage Tips ............................................................. 17

Section 4 – Troubleshooting ......................................18

4.1 Troubleshooting Guide ........................................................ 18

Section 5 – Electrical Data ........................................ 19

Section 6 – Exploded Views and Parts Lists .......... 22

Section 7 – Warranty .................................................. 32

Page 3

INTRODUCTION

Thank you for purchasing this model by Generac Power Systems, Inc.

This model is a compact, high performance, air-cooled, engine driven

generator designed to supply electrical power to operate electrical

loads where no utility power is available or in place of utility due to a

power outage.

READ THIS MANUAL THOROUGHLY

If any portion of this manual is not understood, contact the nearest

Authorized Dealer for starting, operating and servicing procedures.

Throughout this publication, and on tags and decals affixed to the

generator, DANGER, WARNING, CAUTION and NOTE blocks are

used to alert personnel to special instructions about a particular

operation that may be hazardous if performed incorrectly or carelessly.

Observe them carefully. Their definitions are as follows:

DANGER

After this heading, read instructions that, if

not strictly complied with, will result in serious

personal injury, including death and/or property

damage.

After this heading, read instructions that, if not

strictly complied with, may result in serious

personal injury and/or property damage.

After this heading, read instructions that, if not

strictly complied with, could result in damage to

equipment and/or property.

NOTE:

After this heading, read explanatory statements that require

special emphasis.

These safety warnings cannot eliminate the hazards that they indicate.

Common sense and strict compliance with the special instructions

while performing the service are essential to preventing accidents.

Four commonly used safety symbols accompany the DANGER,

WARNING and CAUTION blocks. The type of information each

indicates is as follows:

This symbol points out important safety

information that, if not followed, could endanger

personal safety and/or property of others.

This symbol points out potential explosion

hazard.

This symbol points out potential fire hazard.

This symbol points out potential electrical shock

hazard.

The operator is responsible for proper and safe use of the

equipment. We strongly recommend that the operator read this

manual and thoroughly understand all instructions before using

the equipment.

We also strongly recommend instructing other users to properly

start and operate the unit. This prepares them if they need to

operate the equipment in an emergency.

Always disconnect spark plug wires and place

the wires where they cannot contact the spark

plugs to prevent accidental starting when

setting up, transporting, adjusting or making

repairs to the generator.

•

The generator produces dangerously high voltage that can cause

extremely hazardous electrical shock. Avoid contact with bare

wires, terminals, etc. Never permit any unqualified person to

operate or service the generator.

•

Never handle any kind of electrical cord or device while standing

in water, while barefoot or while hands or feet are wet. Dangerous

electrical shock will result.

•

The National Electric Code requires the frame and external

electrically conductive parts of the generator be properly connected

to an approved earth ground. Local electrical codes may also

require proper grounding of the generator. Consult with a local

electrician for grounding requirements in the area.

•

Use a ground fault circuit interrupter in any damp or highly

conductive area (such as metal decking or steel work).

•

Do not use worn, bare, frayed or otherwise damaged electrical

cord sets with the generator.

•

Operate generator only on level surfaces and where it will not be

exposed to excessive moisture, dirt, dust or corrosive vapors.

•

Gasoline is highly FLAMMABLE and its vapors are EXPLOSIVE.

Do not permit smoking, open flames, sparks or heat in the vicinity

while handling gasoline. Avoid spilling gasoline on a hot engine.

Comply with all laws regulating storage and handling of gasoline.

•

Never add fuel while unit is running.

Do not overfill the fuel tank. Always allow room

for fuel expansion. If tank is over-filled, fuel can

overflow onto a hot engine and cause FIRE or

an EXPLOSION.

Never store generator with fuel in tank where gasoline vapors

•

might reach an open flame, spark or pilot light (as on a furnace,

water heater or clothes dryer). FIRE or EXPLOSION may result.

Generator exhaust gases contain DEADLY carbon monoxide gas.

•

This dangerous gas, if breathed in sufficient concentrations, can

cause unconsciousness or even death. Operate this equipment

only in the open air where adequate ventilation is available.

Allow at least two (2) feet of clearance on all sides of generator or

•

damage could be done to the unit. Never operate the unit inside

any room or enclosure where the free flow of cooling air into and

out of the unit might be obstructed. Review the “Cold Weather

Operation” section.

NEVER operate the generator indoors, in an attached garage

or near an open window.

1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

Commercial-Industrial-Residential Portable Generator System

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe operation be copied and posted near the unit's

installation site. Safety should be stressed to all operators and potential operators of this equipment.

Never start or stop the unit with electrical loads connected to

•

receptacles AND with connected devices turned ON. Start

the engine and let it stabilize before connecting electrical

loads. Disconnect all electrical loads before shutting down the

generator.

Do not insert objects through unit's cooling slots.

•

Never operate generator: indoors or in any enclosed compartment;

•

in rain; if connected electrical devices overheat; if electrical output

is lost; if engine or generator sparks; if flames or smoke are

observed while unit is running; if unit vibrates excessively.

NOTE:

This generator is equipped with a spark arrestor muffler. The

spark arrestor must be maintained in effective working order by

the owner/ operator. In the State of California, a spark arrestor is

required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply

on federal lands.

Despite the safe design of this generator,

operating this equipment imprudently,

neglecting its maintenance or being careless

can cause possible injury or death. Permit only

responsible and capable persons to operate or

maintain this equipment.

Potentially lethal voltages are generated by

these machines. Ensure all steps are taken to

render the machine safe before attempting to

work on the generator.

Parts of the generator are rotating and/or hot

during operation. Exercise care near running

generators.

DANGER

GENERAL HAZARDS

Study these SAFETY RULES carefully before installing, operating or

servicing this equipment. Become familiar with this manual and with

the unit. The generator can operate safely, efficiently and reliably only

if it is properly installed, operated and maintained. Many accidents

are caused by failing to follow simple and fundamental rules or

precautions.

The engine exhaust from this product

•

contains chemicals known to the state

This product contains or emits chemicals

•

known to the state of California to cause

cancer, birth defects or other reproductive harm.

The manufacturer cannot anticipate every possible circumstance that

might involve a hazard. The warnings in this manual, and on tags and

decals affixed to the unit are, therefore, not all inclusive. If using a

procedure, work method or operating technique that the manufacturer

does not specifically recommend, ensure that it is safe for others. Also

make sure the procedure, work method or operating technique utilized

does not render the generator unsafe.

WARNING:•

of California to cause cancer, birth

defects or other reproductive harm.

WARNING:•

Never operate in an enclosed area or indoors.

•

For safety reasons, the manufacturer recommends that the

•

maintenance of this equipment is carried out by an Authorized

Dealer.

The engine exhaust fumes contain carbon monoxide, which

•

can be DEADLY. This dangerous gas, if breathed in sufficient

concentrations, can cause unconsciousness or even death. This

exhaust system must be properly maintained. Do nothing that

might render the exhaust system unsafe or in noncompliance with

any local codes and/or standards.

Keep hands, feet, clothing, etc., away from drive belts, fans, and

•

other moving or hot parts. Never remove any drive belt or fan guard

while the unit is operating.

Adequate, unobstructed flow of cooling and ventilating air is critical

•

to correct generator operation. Do not alter the installation or

permit even partial blockage of ventilation provisions, as this can

seriously affect safe operation of the generator. The generator

MUST be operated outdoors.

When working on this equipment, remain alert at all times. Never

•

work on the equipment when physically or mentally fatigued.

Inspect the generator regularly, and contact the nearest Authorized

•

Dealer for parts needing repair or replacement.

Before performing any maintenance on the generator, disconnect

•

its battery cables to prevent accidental start up. Disconnect the

cable from the battery post indicated by a NEGATIVE, NEG or (–)

first. Reconnect that cable last.

Never use the generator or any of its parts as a step. Stepping on

•

the unit can stress and break parts, and may result in dangerous

operating conditions from leaking exhaust gases, fuel leakage, oil

leakage, etc.

2

Page 5

IMPORTANT SAFETY INSTRUCTIONS

Commercial-Industrial-Residential Portable Generator System

ELECTRICAL HAZARDS

•

All generators covered by this manual produce dangerous electrical

voltages and can cause fatal electrical shock. Utility power delivers

extremely high and dangerous voltages as does the generator

when it is in operation. Avoid contact with bare wires, terminals,

connections, etc., while the unit is running. Ensure all appropriate

covers, guards and barriers are in place before operating the

generator. If work must be done around an operating unit, stand on

an insulated, dry surface to reduce shock hazard.

•

Do not handle any kind of electrical device while standing in water,

while barefoot, or while hands or feet are wet. DANGEROUS

ELECTRICAL SHOCK MAY RESULT.

•

The National Electrical Code (NEC) requires the frame and external

electrically conductive parts of the generator to be connected to an

approved earth ground. Local electrical codes also may require

proper grounding of the generator electrical system.

•

In case of accident caused by electric shock, immediately shut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a non-conducting implement,

such as a rope or board, to free the victim from the live conductor.

If the victim is unconscious, apply first aid and get immediate

medical help.

•

Never wear jewelry when working on this equipment. Jewelry can

conduct electricity resulting in electric shock, or may get caught in

moving components causing injury.

EXPLOSION HAZARDS

•

Do not smoke around the generator. Wipe up any fuel or oil spills

immediately. Ensure that no combustible materials are left on or

near the generator, as FIRE or EXPLOSION may result. Keep the

area surrounding the generator clean and free from debris.

•

Gasoline is extremely EXPLOSIVE.

STANDARDS INDEX

In the absence of pertinent standards, codes, regulations and laws,

the published information listed below may be used as a guideline

for operation of this equipment. Always reference the latest revision

available for the standards listed.

1. NFPA No. 70, NFPA HANDBOOK OF NATIONAL ELECTRIC

CODE.

2. Article X, NATIONAL BUILDING CODE, available from the

American Insurance Association, 85 John Street, New York, N.Y.

10038.

3. AGRICULTURAL WIRING HANDBOOK, available from the Food

and Energy Council, 909 University Avenue, Columbia, MO

65201.

4. ASAE EP-3634, INSTALLATION AND MAINTENANCE OF FARM

STANDBY ELECTRICAL SYSTEMS, available from the American

Society of Agricultural Engineers, 2950 Niles Road, St. Joseph,

MI 49085.

5. NFPA No. 30, FLAMMABLE AND COMBUSTIBLE LIQUIDS

CODE.

FIRE HAZARDS

For fire safety, the generator must be operated and maintained

•

properly. Operation must always comply with applicable codes,

standards, laws and regulations. Adhere strictly to local,

state and national electrical and building codes. Comply with

regulations the Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the generator is

operated in accordance with the manufacturer’s instructions and

recommendations. Do not alter the construction of the generator

or change controls which might create an unsafe operating

condition.

Keep a fire extinguisher near the generator at all times. Extinguishers

•

rated “ABC” by the National Fire Protection Association are

appropriate for use on the standby electric system. Keep the

extinguisher properly charged and be familiar with its use. If there

are any questions pertaining to fire extinguishers, consult the local

fire department.

3

Page 6

Section 1 – General Information

Commercial-Industrial-Residential Portable Generator System

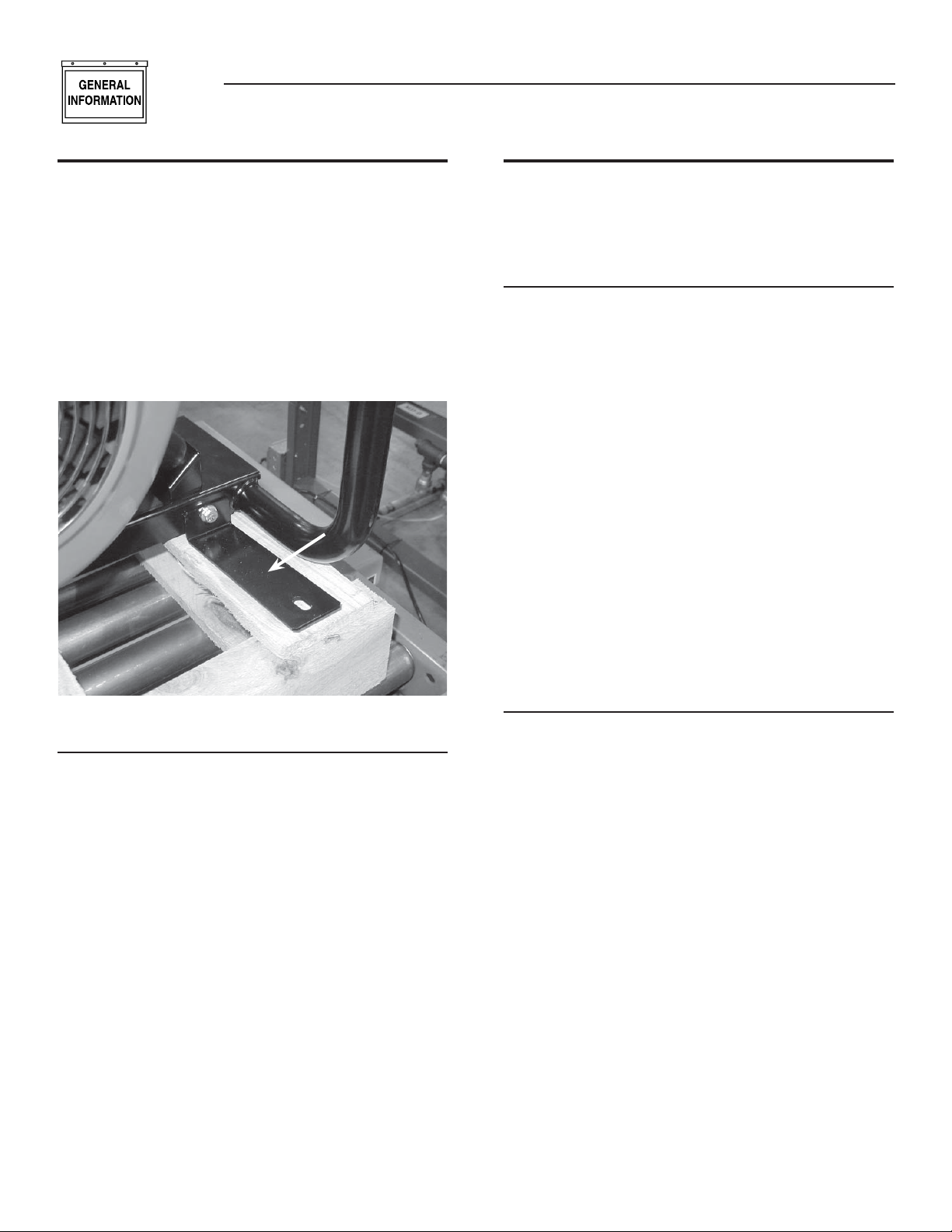

1.1 UNPACKING

•

Set the palleted carton on a rigid flat surface.

•

Remove staples along bottom of carton that fasten carton to pallet.

Open carton from top.

•

Remove all packaging material.

•

Remove separate accessory box.

•

Lift carton off the generator.

•

Remove generator from shipping pallet by removing bolts through

the shipping brackets (Figure 1).

Figure 1 - Bracket Removal

Shipping

Bracket (x4)

1.2 ASSEMBLY

The generator requires some assembly prior to using it. If problems

arise when assembling the generator, please call the Generator

Helpline at 1-800-333-1322.

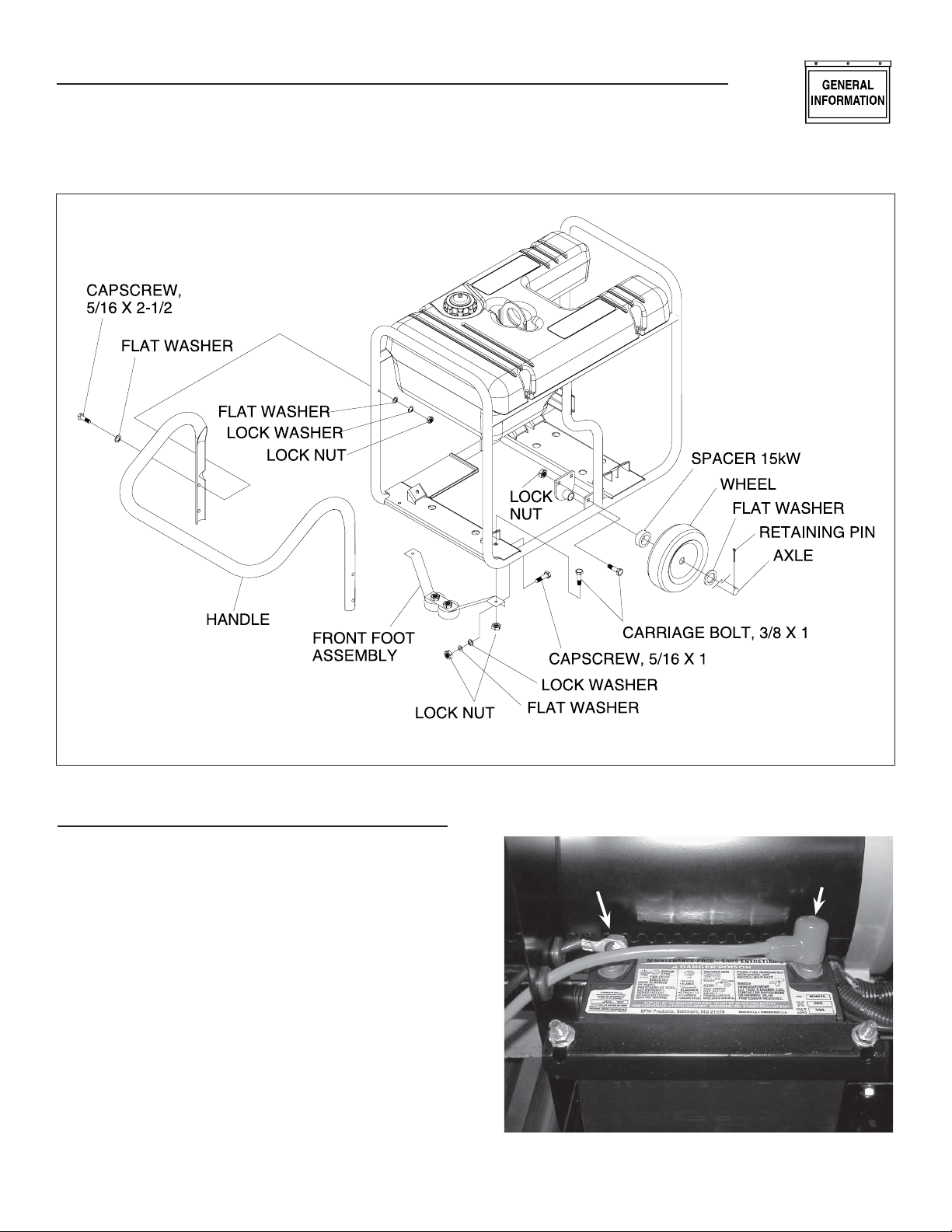

1.2.1 ASSEMBLING THE WHEEL KIT

The wheel kit is designed to greatly improve the portability of the

generator. A socket wrench with a 9/16” socket, a 1/2” socket, a

1/2” wrench and a pair of pliers are the tools that will be needed for

assembly of the wheel kit.

NOTE:

The wheel kit is not intended for over-the-road use.

•

Refer to Figure 2 and install the wheel kit as follows:

•

Place the generator on a hard flat surface.

•

Stand at the engine end of the unit and gently tilt the generator

forward, high enough to place wooden blocks beneath the cradle.

This will allow space to install the wheel assemblies.

•

Attach an axle bracket assembly with attached sleeve to either side

of the frame. Ensure the sleeve faces outward.

•

Slide the axle through the sleeves on the axle brackets.

•

Slide one wheel with flat washer to the outside and a spacer to the

inside onto each end of the axle. Make sure the air inflation valve

on the wheel is facing outward.

•

Insert retaining pins and using pliers, bend out the ends to prevent

the pins from falling out of the axle. Remove the wooden blocks.

1.1.1 ACCESSORY BOX

Check all contents. If any parts are missing or damaged locate an

authorized dealer at 1-800-333-1322.

Contents include:

Wheel Axle • Bolt-on tubular handle

•

2 – Washers • 2 – Pneumatic Wheels

•

2 – Wheel Spacers • 2 – Axle Bracket Assemblies

•

2 – Cotter Pins • Bolt-on Foot

•

2 – Spark Plugs • Spark Plug Wrench

•

Air Filter • Oil Filter

•

Pre-cleaner • Battery Charge Cable

•

6 – Carriage Bolts, Washers, Nuts

•

1.2.2 ASSEMBLING THE HANDLE

Attach the handle by aligning one side of the handle on the cradle,

•

then spread the handle around the cradle and let it spring into

place. Secure the handle to the frame using the 5/16’ hex head

bolts provided. Check each fastener to ensure that it is secure.

Using the handle, lift the unit high enough to place wooden blocks

•

under the unit. Attach the front support foot to the underside of the

cradle using the 3/8” carriage bolts provided.

Remove the shipping brackets from the cradle, if it has not already

•

been done.

4

Page 7

Section 1 - General Information

Commercial-Industrial-Residential Portable Generator System

Figure 2 - Handle Assembly

1.2.3 BATTERY CONNECTION

The battery shipped with the generator has been provided fully

•

charged. Caution must be taken when connecting the battery.

NOTE:

A battery may lose some of it’s charge when not in use for

prolonged periods of time.

Cut the tie wrap cable holding the RED and BLACK battery cables

•

to the stator.

Connect the RED battery cable to the battery Positive terminal (+).

•

After making sure that the connection is tight, slip the rubber boot

over the terminal connection.

Connect the BLACK battery cable to the battery Negative terminal

•

(–). Make sure the connection is tight.

Double check all connections to ensure they are in the correct

•

location and secure. See Figure 3.

Figure 3 - Battery Connections

Negative

Cable

Positive

Cable

5

Page 8

Section 2 – Operation

Commercial-Industrial-Residential Portable Generator System

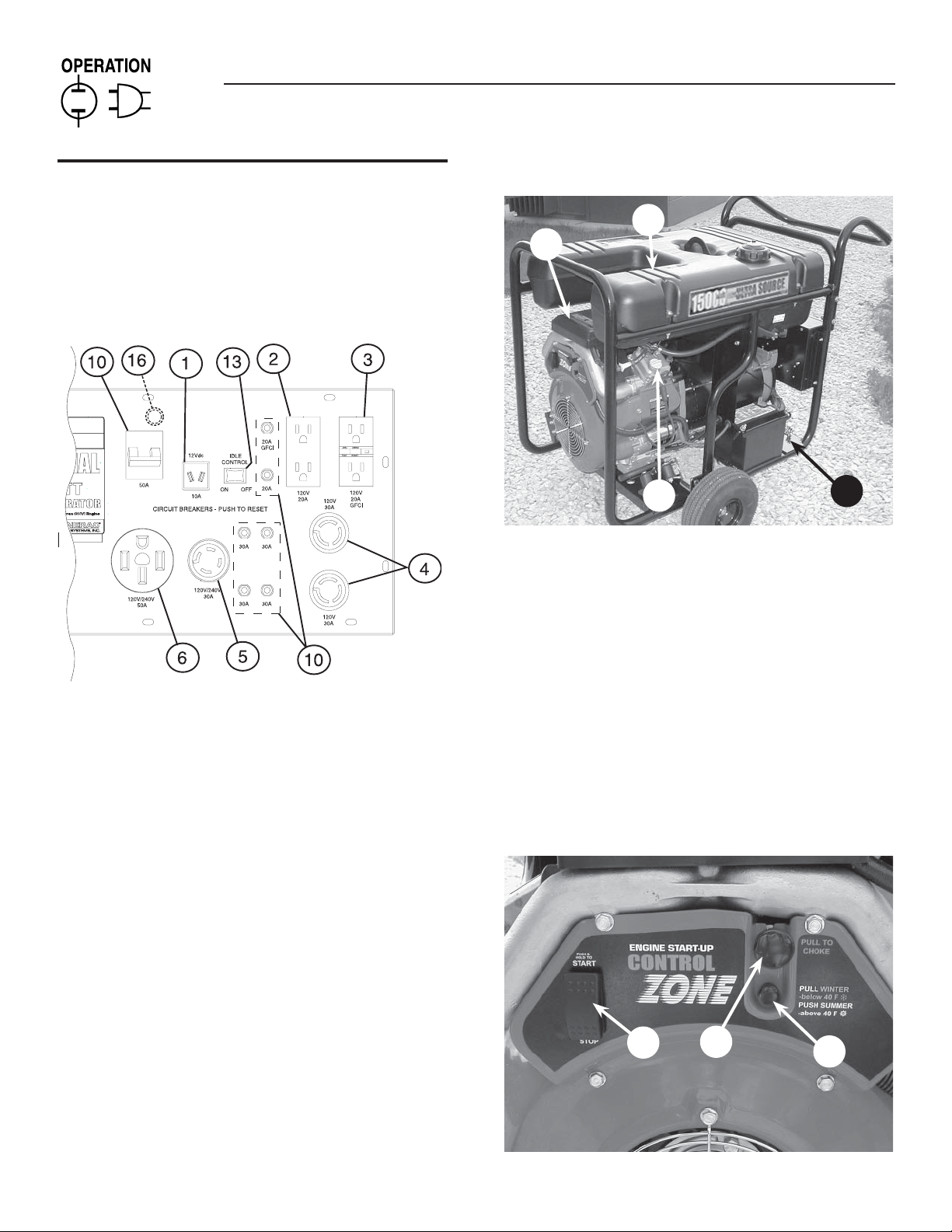

2.1 KNOW THE GENERATOR

Read the Owner’s Manual and Safety Rules before operating this

generator.

Compare the generator to Figures 4 through 6 to become familiarized

with the locations of various controls and adjustments. Save this

manual for future reference.

Figure 4 - Control Panel

1. 12 Volt DC, 10 Amp Receptacle – This receptacle allows the

capability to recharge a 12 volt DC storage battery with provided

battery charge cables.

2. 120 Volt AC, 20 Amp, Duplex Receptacle – Supplies electrical

power for the operation of 120 Volt AC, 20 Amp, single-phase, 60

Hz electrical lighting, appliance, tool and motor loads.

3. 120 Volt AC, 20A Duplex GFCI Receptacle – Supplies ground

fault protected electrical power for operation of 120 volt AC 20

amp, single-phase, 60 Hz electric lighting, appliances, tools and

motor loads.

4. 120 Volt AC, 30 Amp Locking Receptacle – Supplies electrical

power for the operation of 120 Volt AC, 30 Amp, single-phase, 60

Hz electrical lighting, appliance, tool and motor loads.

5. 120/240 Volt AC, 30 Amp Locking Receptacle – Supplies

electrical power for the operation of 120 and/or 240 Volt AC, 30

Amp, single-phase, 60 Hz, electrical lighting, appliance, tool and

motor loads.

6. 120/240 Volt AC, 50 Amp Receptacle (Located on underside

of control panel)– Supplies electrical power for the operation of

120/240 Volt AC, 50 Amp, single-phase, 60 Hz, welder or motor

loads.

7. Air Cleaner – Filters intake air as it is drawn into the engine.

8. Choke Knob – Used when starting a cold engine.

9. Winter/Summer Valve – See “Cold Weather Operation/De-icer”

section.

Figure 5 - Generator Controls

11

7

15

10. Circuit Breakers (AC) – Each receptacle is provided with a

push-to-reset circuit breaker to protect the generator against

electrical overload. (50 amp uses toggle reset)

11. Fuel Tank – Tank holds 16 U.S. gallons of fuel.

12. Grounding Lug – Ground the generator to an approved earth

ground here. See "Grounding the Generator" for details.

13. Idle Control Switch – The idle control runs the engine at normal

(high) speeds when there is an electrical load present and runs

the engine at idle (low) speeds when a load is not present.

14. Start/Run/Stop Switch – Controls the operation of the

generator.

15. Oil Fill – Use this point to add oil to engine.

16. Fuse - 10 Amp (Located at rear of control panel) – Protects

the DC control circuit from overload. If this fuse element has

melted open the engine will not be able to crank and start.

Figure 6 - Engine Control Panel

14

8

12

9

6

Page 9

Section 2 – Operation

Commercial-Industrial-Residential Portable Generator System

2.2 CORD SETS AND CONNECTION PLUGS

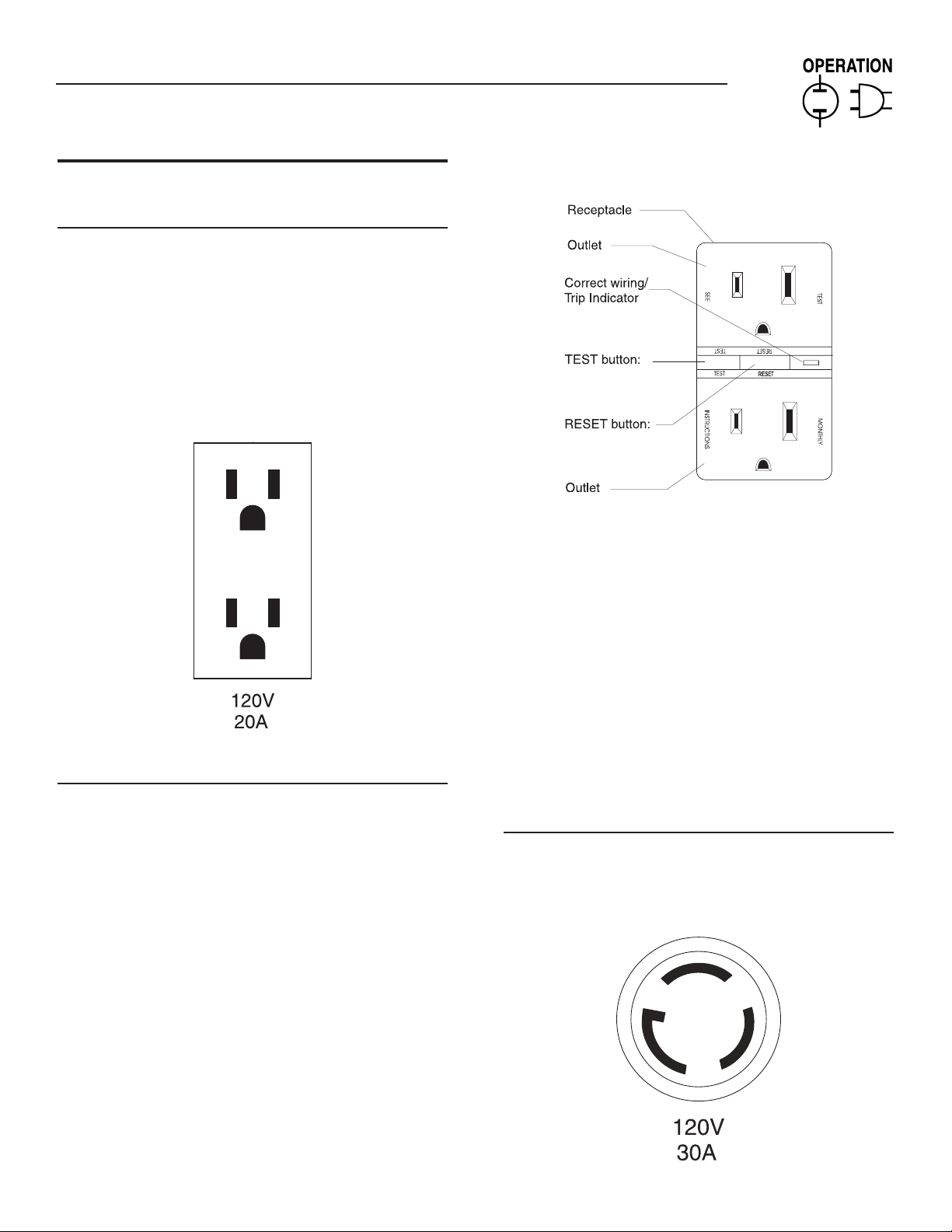

2.2.1 120 VAC, 20 AMP, DUPLEX RECEPTACLE

This is a 120 Volt outlet protected against overload by a 20 Amp

push-to-reset circuit breaker (Figure 7). Use each socket to power

120 Volt AC, single phase, 60 Hz electrical loads requiring up to a

combined 2400 watts (2.4 kW) or 20 Amps of current. Use only high

quality, well-insulated, 3-wire grounded cord sets rated for 125 Volts

at 20 Amps (or greater).

Keep extension cords as short as possible, preferably less than 15

feet long, to prevent voltage drop and possible overheating of wires.

Figure 7 - 120 Volt AC, 20 Amp, Duplex Receptacle

2.2.2 120 VAC, 20 AMP, GFCI RECEPTACLE

This unit is equipped with a ground fault circuit interrupter (GFCI). This

device meets applicable federal, state and local codes (Figure 8).

A GFCI receptacle is different from conventional receptacles. In the

event of a ground fault, a GFCI will trip and quickly stop the flow of

electricity to prevent serious injury.

Definition: Instead of following its normal safe path, electricity passes

through a persons body to reach the ground. For example, a defective

appliance can cause a ground fault.

A GFCI receptacle does NOT protect against circuit overloads, short

circuits, or shocks. For example, electric shock can still occur if a

person touches charged electrical wires while standing on a nonconducting surface, such as a wood floor.

Figure 8 - 120 VAC, 20 Amp GFCI Receptacle

Testing the GFCI: Test the GFCI outlet every month as follows:

Plug a test lamp into the receptacle.

•

Start the generator, the test lamp should be on.

•

Press the “Test” button located on the front of the receptacle to

•

trip the device.

This should stop the flow of electricity making the lamp shut off.

•

The yellow trip indicator should now be on.

To restore the flow of electricity, press the “Reset” button on the

•

front of the receptacle. If the GFCI does not perform in this manner,

do not use the receptacle. Contact a local service dealer.

This outlet is protected against overload by a 20A push-to-reset

•

circuit breaker. Use the outlet to power 120V AC, single-phase,

60 Hz, electrical loads requiring up to a combined 2400 watts (2.4

kW) or 20 amps of current.

2.2.3 120 VAC, 30 AMP RECEPTACLE

Use a NEMA L5-30 plug with this receptacle. Connect a 3-wire cord

set rated for 125 Volts AC at 30 Amps (or greater) to the plug (Figure

9).

Figure 9 - 120 VAC, 30 Amp Receptacle

7

Page 10

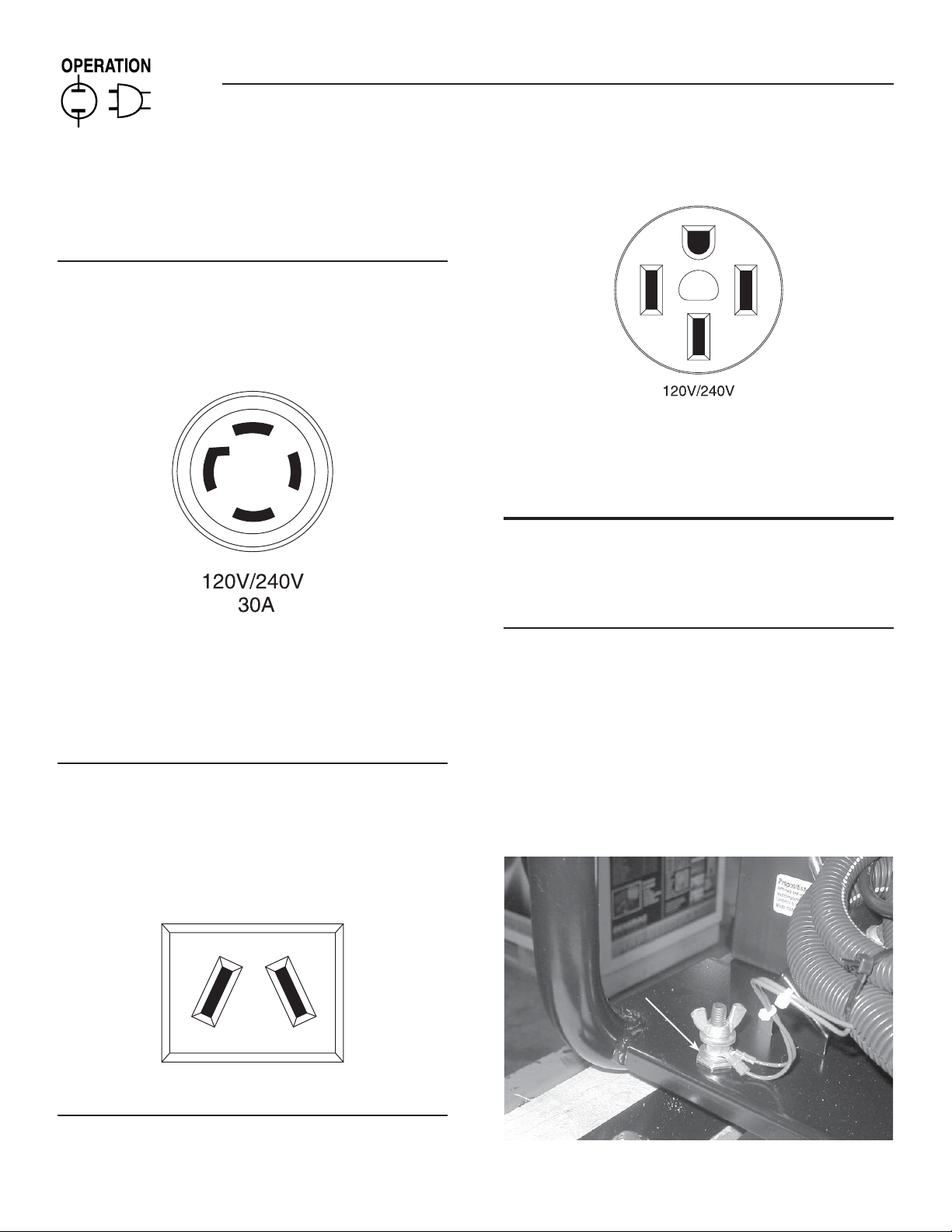

Section 2 – Operation

Commercial-Industrial-Residential Portable Generator System

Use this receptacle to operate 120 Volt AC, 60 Hz, single phase loads

requiring up to 3600 watts (3.6 kW) of power at 30 Amps. The outlet

is protected by a 30 Amp push-to-reset circuit breaker.

2.2.4 120/240 VAC, 30 AMP RECEPTACLE

Use a NEMA L14-30 plug with this receptacle. Connect a suitable 4wire grounded cord set to the plug and to the desired load. The cord

set should be rated for 250 Volts AC at 30 Amps (or greater) (Figure

10).

Figure 10 - 120/240 VAC, 30 Amp Receptacle

Use this receptacle to operate 120 Volt AC, 60 Hz, single phase loads

requiring up to 3600 watts (3.6 kW) of power at 30 Amps or 240 Volt

AC, 60 Hz, single phase loads requiring up to 7200 watts (7.2 kW)

of power at 30 Amps. The outlet is protected by two 30 Amp push-toreset circuit breakers.

2.2.5 12 VOLT DC, 10 AMP RECEPTACLE

This receptacle permits recharging a 12 Volt automotive or utility style

storage battery with the battery charge cables provided (Figure 11).

This receptacle can not recharge 6 Volt batteries and can not be

used to crank an engine having a discharged battery. See the section

"Charging a Battery" before attempting to recharge a battery.

Figure 12 - 120/240 VAC, 50 Amp Receptacle

50 A

Use this receptacle to operate 120/240 Volt AC, 60 Hz electrical loads

requiring up to 12,000 watts (12.0 kW) of power. This receptacle is

protected by a 50 Amp 2-pole circuit breaker.

2.3 HOW TO USE THE GENERATOR

If there are any problems operating the generator, please call the

generator helpline at 1-800-333-1322.

2.3.1 GROUNDING THE GENERATOR

The National Electrical Code requires that the frame and external

electrically conductive parts of this generator be properly

connected to an approved earth ground (Figure 13). Local

electrical codes may also require proper grounding of the unit. For

that purpose, generally, connecting a No. 10 AWG (American Wire

Gauge) stranded copper wire to the grounding wing nut and to an

earth-driven copper or brass grounding rod (electrode) provides

adequate protection against electrical shock. However, local codes

may vary widely. Consult with a local electrician for grounding

requirements in the area.

Figure 13 - Grounding the Generator

Figure 11 - 12 Volt DC, 10 Amp Receptacle

2.2.6 120/240 VAC, 50 AMP RECEPTACLE

Use a NEMA 14-50 plug with this receptacle. Connect a 4-wire cord

set rated for 250 Volts AC at 50 Amps to the plug (Figure 12).

8

Generator Ground Lug

Page 11

Section 2 – Operation

Commercial-Industrial-Residential Portable Generator System

Proper grounding of the generator will help prevent electrical

shock in the event of a ground fault condition in the generator or in

connected electrical devices. Proper grounding also helps dissipate

static electricity, which often builds up in ungrounded devices.

2.3.2 CONNECTING ELECTRICAL LOADS

DO NOT connect 240 Volt loads to 120 Volt receptacles. DO NOT

connect 3-phase loads to the generator. DO NOT connect 50 Hz loads

to the generator.

Let engine stabilize and warm up for a few minutes after starting.

•

Plug in and turn on the desired 120 or 240 Volt AC, single phase,

•

60 Hz electrical loads.

Add up the rated watts (or amps) of all loads to be connected

•

at one time. This total should not be greater than (a) the rated

wattage/amperage capacity of the generator or (b) circuit breaker

rating of the receptacle supplying the power. See "Don't Overload

the Generator" below.

2.4 DON’T OVERLOAD THE GENERATOR

Overloading a generator in excess of its rated wattage capacity can

result in damage to the generator and to connected electrical devices.

Observe the following to prevent overloading the unit:

Add up the total wattage of all electrical devices to be connected

•

at one time. This total should NOT be greater than the generator's

wattage capacity.

The rated wattage of lights can be taken from light bulbs. The rated

•

wattage of tools, appliances and motors can usually be found on a

data plate or decal affixed to the device.

If the appliance, tool or motor does not give wattage, multiply volts

•

times ampere rating to determine watts (volts x amps = watts).

Some electric motors, such as induction types, require about three

•

times more watts of power for starting than for running. This surge

of power lasts only a few seconds when starting such motors.

Make sure to allow for high starting wattage when selecting

electrical devices to connect to the generator:

1. Figure the watts needed to start the largest motor.

2. Add to that figure the running watts of all other connected loads.

The Wattage Reference Guide is provided to assist in determining

how many items the generator can operate at one time.

NOTE:

All figures are approximate. See data plate on appliance for

wattage requirements.

2.5 WATTAGE REFERENCE GUIDE

Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Running Watts

*Air Conditioner (12,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1700

*Air Conditioner (24,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3800

*Air Conditioner (40,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6000

Battery Charger (20 Amp). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Belt Sander (3") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000

Chain Saw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Circular Saw (6-1/2"). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .800 to 1000

*Clothes Dryer (Electric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5750

*Clothes Dryer (Gas). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

*Clothes Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1150

Coffee Maker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1750

*Compressor (1 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000

*Compressor (3/4 HP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1800

*Compressor (1/2 HP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1400

Curling Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

*Dehumidifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650

Disc Sander (9") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Edge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Electric Blanket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Electric Nail Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Electric Range (per element) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500

Electric Skillet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1250

*Freezer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..700

*Furnace Fan (3/5 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 875

*Garage Door Opener. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500 to 750

Hair Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Hand Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250 to 1100

Hedge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 450

Impact Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

*Jet Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800

Lawn Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Light Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Microwave Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .700 to 1000

*Milk Cooler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1100

Oil Burner on Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Oil Fired Space Heater (140,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . 400

Oil Fired Space Heater (85,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . 225

Oil Fired Space Heater (30,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . 150

*Paint Sprayer, Airless (1/3 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600

Paint Sprayer, Airless (handheld) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Radio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 to 200

*Refrigerator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700

Slow Cooker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

*Submersible Pump (1-1/2 HP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2800

*Submersible Pump (1 HP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000

*Submersible Pump (1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500

*Sump Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .800 to 1050

*Table Saw (10") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1750 to 2000

Television . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200 to 500

Toaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1000 to 1650

Weed Trimmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

* Allow 3 times the listed watts for starting these devices.

9

Page 12

5W -3 0

Sy nt he ti c 5 W- 30

SA E 30 , 1 0W -3 0

Section 2 – Operation

Commercial-Industrial-Residential Portable Generator System

2.6 BEFORE STARTING THE GENERATOR

Prior to operating the generator, engine oil and gasoline will need to

be added, as follows:

2.6.1 ADDING ENGINE OIL

NOTE:

When adding oil to the engine crankcase in the future, use only

high quality detergent oil rated with API service classification

SG, SH or SL SAE 30 weight. Use no special additives.

SAE 30, 10W-30

Synthetic 5W-30

5W-30

Select the oil’s viscosity grade according to the expected operating

temperature. Do not use SAE 10W-40.

NOTE:

Synthetic oil should only be used after first oil change.

Above 40°F, use SAE 30, synthetic 5W-30 or SAE 10W-30.

•

Below 40°F, use synthetic 5W-30 or 5W-30.

•

Although multi-viscosity oils (5W-30, 10W-30, etc.) improve starting

in cold weather, these multi-viscosity oils will result in increased oil

consumption when used above 32°F. Check the engine oil level more

frequently to avoid possible damage from running low on oil.

Place generator on a level surface.

•

Clean area around oil fill and remove oil fill cap and dipstick.

•

Wipe dipstick clean.

•

Slowly fill engine with oil through the oil fill opening until it reaches

•

the full mark on the dipstick. Stop filling occasionally to check oil

level. DO NOT OVERFILL.

Install dipstick. Install oil fill cap and finger tighten securely.

•

Check engine oil level before starting each time thereafter.

•

2.6.2 ADDING GASOLINE

Never fill fuel tank indoors. Never fill fuel tank

when engine is running or hot. DO NOT light a

cigarette or smoke when filling the fuel tank.

Do not overfill the fuel tank. Always leave room

for fuel expansion.

•

Use regular UNLEADED gasoline with the generator engine. Do

not use premium gasoline. Do not mix oil with gasoline.

•

Clean area around fuel fill cap, remove cap.

•

Slowly add unleaded regular gasoline to fuel tank. Be careful not

to overfill. Allow about 1/2" of tank space for fuel expansion, as

shown here (Figure 14).

•

Install fuel cap and wipe up any spilled gasoline.

Figure 14 - Fuel Tank

IMPORTANT: It is important to prevent gum deposits from forming

in fuel system parts such as the carburetor, fuel hose or tank during

storage. Alcohol-blended fuels (called gasohol, ethanol or methanol)

can attract moisture, which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system of an engine

while in storage. To avoid engine problems, the fuel system should

be emptied before storage of 30 days or longer. See the "Storage"

section. Never use engine or carburetor cleaner products in the fuel

tank as permanent damage may occur.

10

Page 13

Commercial-Industrial-Residential Portable Generator System

2.7 TO START THE ENGINE

Never start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

Unplug all electrical loads from the unit's receptacles before

•

starting the engine.

Make sure the unit is in a level position.

•

Open the fuel shut-off valve (Figure 15).

•

Figure 15 - Fuel Shut-off Valve

Section 2 – Operation

•

Move engine CHOKE knob outward to “Full Choke” position

(Figure 17).

Figure 17 - Full Choke Position

Locate the Idle Control ON/OFF switch on the control panel and

•

set it to the “OFF” position(Figure 16).

Figure 16 - Idle Control Switch

To start engine, press and hold the Start/Run/Stop switch in the

•

“Start” position. The engine will crank and attempt to start. When

the engine starts, release the switch to the run position.

When the engine starts, move choke knob to “1/2 Choke” position

•

until the engine runs smoothly and then fully in to the “Run” position.

If engine falters, move choke knob back out to “1/2 Choke” position

until the engine runs smoothly and then to “Run” position.

NOTE:

If engine fires, but does not continue to run, move choke lever to

“Full Choke” and repeat starting instructions.

IMPORTANT: Do not overload the generator. Also, do not overload

individual panel receptacles. These outlets are protected against

overload with push-to-reset-type circuit breakers. If amperage rating

of any circuit breaker is exceeded, that breaker opens and electrical

output to that receptacle is lost. Read “Don’t Overload the Generator”

carefully.

2.8 STOPPING THE ENGINE

Shut off all loads, then unplug the electrical loads from generator

•

panel receptacles. Never start or stop the engine with electrical

devices plugged in and turned on.

Turn “Off” the Idle Control switch (if on).

•

Let engine run at no-load for several minutes to stabilize the

•

internal temperatures of engine and generator.

Move Start/Run/Stop switch to “Off” position.

•

Close fuel valve.

•

11

Page 14

Section 2 – Operation

Commercial-Industrial-Residential Portable Generator System

2.9 AUTOMATIC IDLE CONTROL

This feature is designed to greatly improve fuel economy. When

this switch is turned “On,” the engine will only run at its normal fast

governed engine speed when electrical load is connected. When

the load is removed, the engine will run at a reduced speed of 2100

RPM. With the switch “Off,” the engine runs at the normal fast engine

speed all the time. Always have the switch OFF when starting and

stopping the engine.

2.10 COLD WEATHER OPERATION/ DE-ICER

Under certain weather conditions (temperatures below 40° F (4°

C) and a high dew point), the engine may experience icing of the

carburetor and/or the crankcase breather system. To eliminate this

problem, this generator engine is fitted with a winter/summer valve.

This directs hot air into the carburetor during cold weather operation.

Always make sure the winter/summer valve is in the correct location

relative to the weather conditions.

2.11 LOW OIL PRESSURE SHUTDOWN SYSTEM

The engine is equipped with a low oil pressure sensor that shuts down

the engine automatically when the oil pressure drops below 10 psi. If

the engine shuts down by itself and the fuel tank has enough gasoline,

check engine oil level.

2.11.1 INITIAL START-UP

A delay built into the low oil shutdown system allows oil pressure to

build during starting. The delay allows the engine to run for about 10

seconds before sensing oil pressure.

2.11.2 SENSING LOW OIL PRESSURE

If the system senses low oil pressure during operation, the engine

shuts down.

2.11.3 RESTARTING

If trying to restart the engine within 10 seconds after it shuts down, the

engine may NOT start. The system needs 5 to 10 seconds to reset.

If the engine is restarted after such a shutdown and the low oil

pressure has not been corrected, the engine will run for about 10

seconds as described above and then stop.

2.12 CHARGING A BATTERY

DANGER

Storage batteries give off explosive hydrogen

gas while recharging. An explosive mixture will

remain around the battery for a long time after

it has been charged. The slightest spark can

ignite the hydrogen and cause an explosion.

Such an explosion can shatter the battery and

cause blindness or other serious injury.

DANGER

Do not permit smoking, open flame, sparks

or any other source of heat around a battery.

Wear protective goggles, rubber apron and

rubber gloves when working around a battery.

Battery electrolyte fluid is an extremely caustic

sulfuric acid solution that can cause severe

burns. If spill occurs flush area with clear water

immediately.

This generator has the capability of recharging a discharged 12 Volt

automotive or utility style storage battery. Do not use the unit to

charge any 6 Volt batteries. Do not use the unit to crank an engine

having a discharged battery.

This battery charger is a pulse type designed to provide a quality

charge current into the battery. The voltage measured at the outlet

should be 8-12 VDC. This is normal and does not indicate a faulty

charging system.

To recharge 12 Volt batteries, proceed as follows:

Check fluid level in all battery cells. If necessary, add ONLY distilled

•

water to cover separators in battery cells. Do not use tap water.

If the battery is equipped with vent caps, make sure they are

•

installed and are tight.

If necessary, clean battery terminals.

•

Connect battery charge cable connector plug to panel receptacle

•

identified by the words "12-VOLT D.C."

Connect battery charge cable clamp with red handle to the positive

•

(+) battery terminal.

Connect battery charge cable clamp with black handle to the

•

negative (-) battery terminal.

Start engine. Let the engine run while battery recharges. Engine

•

idle control switch must be in off position for battery charging.

When battery has charged, shut down engine.

•

NOTE:

Use an automotive hydrometer to test battery state of charge and

condition. Follow the hydrometer manufacturer's instructions

carefully. Generally, a battery is considered to be at 100% state

of charge when specific gravity of its fluid (as measured by

hydrometer) is 1.260 or higher.

12

Page 15

Section 3 — Maintenance

Commercial-Industrial-Residential Portable Generator System

3.1 MAINTENANCE SCHEDULE

Follow the calendar intervals. More frequent service is required when operating in adverse conditions noted below.

Operation Maintenance Daily Every Season Every Season Every Season

Check Oil Level

Service Air Pre-Cleaner **

Change Oil and Oil Filter‡ *

Clean Spark Arrestor Screen

Check Valve Clearance ***

Service Air Cleaner **

Replace Spark Plugs

‡ Change oil after first 8 hours of operation then every season.

* Change oil and oil filter every month when operating under heavy load or in high temperatures.

** Clean more often under dirty or dusty operating conditions. Replace air cleaner parts if very dirty.

*** Check valve clearance and adjust if necessary after first 50 hours of operation and every 100 hours thereafter.

3.2 PRODUCT SPECIFICATIONS

3.2.1 GENERATOR SPECIFICATIONS

MODEL GPS 15,000

Model # 004582-2

Rated Max. Power 15.0 kW

Surge Power 22.5 kW

Rated AC Voltage 120/240

Rated Max AC Load

Current @ 240V 62.5 Amps

Current @ 120V 125.0 Amps

Rated Frequency 60 Hz @ 3600 RPM

Phase Single Phase

Rated DC Voltage 12 Volts

Rated Max DC Load

Current @ 12 Volts 10 Amperes

3.2.2 ENGINE SPECIFICATIONS

Rated Horsepower

@ 3600 RPM 30

Displacement 992cc

Spark Plug Type Champion RC14YC or Equivalent

Spark Plug Gap 0.040 inch or (1.01 mm)

Gasoline Capacity 16 U.S. gallons

Oil Type Summer – SAE 30 or 10W-30 or Synthetic 5W-30 Winter – 5W-30 or Synthetic 5W-20

Oil Capacity w/ Filter Change = 1.7 Qts. w/o Filter Change = 1.4 Qts.

Run Time/Fuel 10 Hours / 1.6 gallons per hour

Consumption-1/2 Load

13

Page 16

Section 3 — Maintenance

Commercial-Industrial-Residential Portable Generator System

3.3 GENERAL RECOMMENDATIONS

The warranty of the generator does not cover items that have been

subjected to operator abuse or negligence. To receive full value from

the warranty, the operator must maintain the generator as instructed

in this manual.

Some adjustments will need to be made periodically to properly

maintain the generator.

All adjustments in the Maintenance section of this manual should

be made at least once each season. Follow the requirements in the

"Maintenance Schedule".

NOTE:

Once a year replace the spark plug and replace the air filter. A

new spark plug and clean air filter assure proper fuel-air mixture

and help the engine run better and last longer.

3.3.1 GENERATOR MAINTENANCE

Generator maintenance consists of keeping the unit clean and dry.

Operate and store the unit in a clean dry environment where it will not

be exposed to excessive dust, dirt, moisture or any corrosive vapors.

Cooling air slots in the generator must not become clogged with snow,

leaves, or any other foreign material.

Check the cleanliness of the generator frequently and clean when

dust, dirt, oil, moisture or other foreign substances are visible on its

exterior surface.

Never insert any object or tool through the air

cooling slots, even if the engine is not running.

NOTE:

DO NOT use a garden hose to clean generator. Water can enter

the engine fuel system and cause problems. In addition, if water

enters the generator through cooling air slots, some water will

be retained in voids and crevices of the rotor and stator winding

insulation. Water and dirt buildup on the generator internal

windings will eventually decrease the insulation resistance of

these windings.

3.3.2 TO CLEAN THE GENERATOR

Use a damp cloth to wipe exterior surfaces clean.

•

A soft, bristle brush may be used to loosen caked on dirt, oil, etc.

•

A vacuum cleaner may be used to pick up loose dirt and debris.

•

Low pressure air (not to exceed 25 psi) may be used to blow away

•

dirt. Inspect cooling air slots and openings on the generator. These

openings must be kept clean and unobstructed.

3.3.3 ENGINE MAINTENANCE

DANGER

When working on the generator, always

disconnect negative cable from battery. Also

disconnect spark plug wires from spark plug

and keep wire away from spark plug.

3.3.4 CHECKING OIL LEVEL

See the “BEFORE STARTING THE GENERATOR” section for

information on checking the oil level. The oil level should be checked

before each use, or at least every eight hours of operation. Keep the

oil level maintained.

3.3.5 CHANGING THE OIL AND OIL FILTER

Change the oil and filter after the first eight hours of operation.

Change the oil every 100 hours thereafter. If running this unit under

dirty or dusty conditions, or in extremely hot weather, change the oil

more often.

NOTE:

Whenever possible, run engine for approximately 5 minutes to

get the engine oil hot. This will aid in draining the oil.

Use the following instructions to change the oil while the engine

is still warm:

Clean area around oil drain hose and plug.

•

Remove oil drain plug from end of hose and oil fill plug to drain oil

•

completely into a suitable container.

When oil has completely drained, install oil drain plug and tighten

•

securely.

Place a suitable container beneath the oil filter and turn

•

filter counterclockwise to remove. Discard according to local

regulations.

Coat gasket of new filter with clean engine oil. Turn filter clockwise

•

until gasket contacts lightly with filter adapter. Then tighten an

additional 3/4 turn.

Fill oil sump with recommended oil. (See “Before Starting the

•

Generator” for oil recommendations).

Wipe up any spilled oil.

•

14

Page 17

Section 3 — Maintenance

Commercial-Industrial-Residential Portable Generator System

3.3.6 REPLACING THE SPARK PLUG

Use Champion RC14YC spark plug or equivalent. The correct air gap

is 1.01 mm (0.040 in.) (Figure 18). Replace the plug once each year.

This will help the engine start easier and run better.

1. Stop the engine and pull the spark plug wire off of the spark

plug.

2. Clean the area around the spark plug and remove it from the

cylinder head.

3. Set the spark plug's gap to 1.01 mm (0.040 in.). Install the

correctly gapped spark plug into the cylinder head.

Figure 18 - Spark Plug Gap

3.4 SERVICE AIR CLEANER

The engine will not run properly and may be damaged if using a dirty

air cleaner. Clean or replace the air cleaner paper filter once a year

(Figure 19). Clean or replace more often if operating under dusty

conditions. Clean foam pre-cleaner every month or more often under

dusty conditions.

Figure 19 - Air Cleaner

Cover

Pre-Cleaner

To clean or replace foam pre-cleaner:

Remove air cleaner cover, then foam pre-filter.

•

Wash pre-cleaner in soapy water. Squeeze pre-filter dry in clean

•

cloth (DO NOT TWIST).

Clean air cleaner cover before re-installing it.

•

To clean or replace paper air filter:

Remove air cleaner cover; then remove foam pre-filter (service if

•

necessary) and remove paper filter.

Clean paper filter by tapping it gently on a solid surface. If the

•

filter is too dirty, replace it with a new one. Dispose of the old filter

properly.

Clean air cleaner cover then slip pre-cleaner over filter. Next insert

•

new paper filter into the base of the air cleaner. Re-install air

cleaner cover.

NOTE:

To order a new air filter, please contact the nearest authorized

service center at 1-800-333-1322.

3.5 CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor screen. Inspect and

clean the screen at least once each year (Figure 20). If unit is used

regularly, inspect and clean more often.

NOTE:

If using the generator on any forest-covered, brush-covered

or grass-covered unimproved land, it must equipped with a

spark arrestor. The spark arrestor must be maintained in good

condition by the owner/operator.

Clean and inspect the spark arrestor as follows:

Remove the screen retaining bracket by removing the screw.

•

Slide the spark arrestor screen out from the tail pipe.

•

Inspect screen and replace if torn, perforated or otherwise

•

damaged. DO NOT USE a defective screen. If screen is not

damaged, clean it with commercial solvent.

Replace the screen and the retaining bracket.

•

Figure 20 - Spark Arrestor

Filter

Base

15

Page 18

Section 3 — Maintenance

Commercial-Industrial-Residential Portable Generator System

3.6 ADJUSTING VALVE CLEARANCE

After the first 50 hours of operation, check the valve clearance in

the engine and adjust if necessary.

Important: If feeling uncomfortable about doing this procedure or the

proper tools are not available, please take the generator to the nearest

service center to have the valve clearance adjusted. This is a very

important step to insure longest life for the engine.

To check valve clearance:

Make sure the engine is at room temperature (60° - 80° F).

•

Make sure that the spark plug wire is removed from the spark plug

•

and out of the way.

Remove the four screws attaching the valve cover.

•

Make sure the piston is at Top Dead Center (TDC) of its

•

compression stroke (both valves closed). To get the piston at

TDC, remove the intake screen at the front of the engine to gain

access to the flywheel nut. Use a large socket and socket wrench

to rotate the nut and hence the engine in a clockwise direction

while watching the piston through the spark plug hole. The piston

should move up and down. The piston is at TDC when it is up as

high as it can go.

Insert a 0.002 - 0.004 inch (0.05 - 0.1mm) feeler gauge between

•

the rocker arm and valve stem. Correct clearance is when a slight

drag is felt when sliding the gauge back and forth. If the clearance

is either excessively loose or tight the rocker arms will need

adjusting.

To adjust valve clearance:

Loosen the rocker jam nut (Figure 21). Use an 10mm allen wrench

•

to turn the pivot ball stud while checking clearance between

the rocker arm and the valve stem with a feeler gauge. Correct

clearance is 0.002-0.004 inch (0.05-0.1 mm).

NOTE:

The rocker arm jam nut must be held in place as the pivot ball

stud is turned.

When valve clearance is correct, hold the pivot ball stud in place with

the allen wrench and tighten the rocker arm jam nut. Tighten the jam

nut to 174 in/lbs. torque. After tightening the jam nut, recheck valve

clearance to make sure it did not change.

Figure 21 - Valve Clearance Adjustment

•

Install new valve cover gasket.

•

Re-attach the valve cover.

NOTE:

Start all four screws before tightening or it will not be possible

to get all the screws in place. Make sure the valve cover gasket

is in place.

•

Re-attach the spark plug wire to the spark plug.

•

Repeat the process for the other cylinder.

3.7 GENERAL

The generator should be started at least once every seven days

and be allowed to run at least 30 minutes. If this cannot be done

and the unit must be stored for more than 30 days, use the following

information as a guide to prepare it for storage.

DANGER

NEVER store engine with fuel in tank indoors

or in enclosed, poorly ventilated areas where

fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes dryer

or other gas appliance.

16

Page 19

Section 3 — Maintenance

Commercial-Industrial-Residential Portable Generator System

3.8 LONG TERM STORAGE

It is important to prevent gum deposits from forming in essential fuel

system parts such as the carburetor, fuel hose or tank during storage.

Also, experience indicates that alcohol-blended fuels (called gasohol,

ethanol or methanol) can attract moisture, which leads to separation

and formation of acids during storage. Acidic gas can damage the fuel

system of an engine while in storage.

To avoid engine problems, the fuel system should be emptied before

storage of 30 days or longer, as follows:

•

Remove all gasoline from the fuel tank.

DANGER

Drain fuel into approved container outdoors,

away from open flame. Be sure engine is cool.

Do not smoke.

•

Start and run engine until engine stops from lack of fuel.

•

While engine is still warm, drain oil from crankcase. Refill with

recommended grade.

•

Remove spark plugs and pour about 1/2 ounce (15 ml) of engine

oil into the cylinders. Cover spark plug hole with rag. Press the

“Start” button and allow engine to crank for 2 seconds. Then press

the “Stop” button.

3.9 OTHER STORAGE TIPS:

•

Do not store gasoline from one season to another.

•

Replace the gasoline can if it starts to rust. Rust and/or dirt in the

gasoline will cause problems with the carburetor and fuel system.

•

If possible, store the unit indoors and cover it to give protection

from dust and dirt. BE SURE TO EMPTY THE FUEL TANK.

•

If it is not practical to empty the fuel tank and the unit is to be stored

for some time, use a commercially available fuel stabilizer added to

the gasoline to increase the life of the gasoline.

•

Cover the unit with a suitable protective cover that does not retain

moisture.

DANGER

NEVER cover the generator while engine and

exhaust area are warm.

Avoid spray from spark plug holes when

cranking engine.

Install and tighten spark plugs. Do not connect spark plug wires.

•

Clean the generator outer surfaces. Check that cooling air slots and

•

openings on generator are open and unobstructed.

Store the unit in a clean, dry place.

•

17

Page 20

Section 4 — Troubleshooting

Commercial-Industrial-Residential Portable Generator System

4.1 TROUBLESHOOTING GUIDE

PROBLEM CAUSE CORRECTION

Engine is running, but no AC

output is available.

1. Circuit breaker is open.

2. Poor connection or defective cord set.

3. Connected device is bad.

4. Fault in generator.

1. Reset circuit breaker.

2. Check and repair.

3. Connect another device that is in good condition.

4. Contact Authorized Service Facility.

Engine runs good but

bogs down when loads are

connected.

Engine will not crank.

Engine will not start; or

starts and runs rough.

Engine shuts down during

operation.

1. Short circuit in a connected load.

2. Generator is overloaded.

3. Engine speed is too slow.

4. Shorted generator circuit.

1. 10 amp fuse at rear of generator control panel

has melted open.

2. Battery weak or dead.

1. Dirty air cleaner.

2. Out of gasoline.

3. Stale gasoline.

4. Spark plug wire not connected to spark plug.

5. Bad spark plug.

6. Water in gasoline.

7. Overchoking.

8. Low oil level.

9. Excessive rich fuel mixture.

10. Intake valve stuck open or closed.

11. Engine has lost compression.

1. Out of gasoline.

2. Low oil level.

3. Fault in engine.

1. Disconnect shorted electrical load.

2. See “Don’t Overload the Generator” .

3. Contact Authorized Service Facility.

4. Contact Authorized Service Facility.

1. Replace fuse with only an identical 10-amp

replacement fuse.

2. Recharge or replace battery.

1. Clean or replace air cleaner.

2. Fill fuel tank.

3. Drain fuel tank and fill with fresh fuel.

4. Connect wire to spark plug.

5. Replace spark plug.

6. Drain fuel tank; fill with fresh fuel.

7. Put choke knob to No Choke position.

8. Fill crankcase to proper level.

9. Contact Authorized Service Facility.

10. Contact Authorized Service Facility.

11. Contact Authorized Service Facility.

1. Fill fuel tank.

2. Fill crankcase to proper level.

3. Contact Authorized Service Facility.

Engine lacks power.

Engine “hunts” or falters.

No Battery Charge DC

output.

18

1. Load is too high.

2. Dirty air filter.

3. Engine needs to be serviced.

1. Choke is opened too soon.

2. Carburetor is running too rich or too lean.

1. Battery posts are corroded.

2. Battery cable is bad.

3. Battery is defective.

4. Receptacle is bad.

1. See “Don’t Overload the Generator”.

2. Replace air filter.

3. Contact Authorized Service Facility.

1. Move choke to halfway position until engine runs

smoothly.

2. Contact Authorized Service Facility.

1. Clean battery posts.

2. Replace cable.

3. Check battery condition; replace if defective.

4. Contact Authorized Service Facility.

Page 21

Section 5 — Electrical Data

Electrical Schematic – Drawing No. 0G0733

19

19

Page 22

Section 5 — Electrical Data

Wiring Diagram – Drawing No. 0G0731

20

Page 23

Section 5 — Electrical Data

Wiring Diagram – Drawing No. 0G0731

21

Page 24

Section 6 — Exploded Views and Parts Lists

Handle, Frame & Wheel Kit – Drawing No. 0E0695-B

22

Page 25

Section 6 — Exploded Views and Parts Lists

Handle, Frame & Wheel Kit – Drawing No. 0E0695-B

ITEM PART NO. QTY. DESCRIPTION

1 057058 4 SCREW HHC M6-1.0 X 55

2 0D5315 4 RUBBER TANK MOUNT

3 0D4570 1 CAP, FUEL WITH GAUGE & VENT

4 0D22850SRV 1 KIT, FUEL TANK

5 045771 4 NUT HEX M8-1.25

6 022129 10 WASHER LOCK M8-5/16

7 022145 14 WASHER FLAT 5/16

8 0D4565 1 BRACKET BATTERY

9 0D3545 2 BOLT,BATTERY J-BOLT

10 022287 2 SCREW HHC 1/4-20 X 3/4 G5

11 022473 2 WASHER FLAT 1/4

12 022097 2 WASHER LOCK M6-1/4

13 022127 2 NUT HEX 1/4-20

14 0388040AK0 1 BATTERY CABLE, RED

15 0D4575 1 BATTERY U1

16 0D5202 1 NUT WING 5/16-18 BRASS

17 0D5199 4 WASHER FLAT 5/16 BRASS

18 029809 1 NUT HEX 5/16-18 BRASS

19 0C3168 1 5/16 SPECIAL L/WASH

20 0D5198 1 SCREW HHC 5/16-18 X 1.5 BRASS

21 0E0317 1 BRACKET FRONT FOOT (15 kW)

0D2498 1 BRACKET FRONT FOOT (12.5 kW)

22 027007 2 VIB MOUNT

23 0D5303 4 WASHER FLAT .25ID X 1"OD

24 042909 2 SCREW HHC M8-1.25 X 30

25 090388 4 SCREW HHTT M6-1.0 X 12

26 064101 6 NUT LOCK FL 3/8-16

27 039214 6 BOLT CARR 3/8-16 X 1

28 0D9165 1 AXLE, 3/4"DIA X 30" (15 kW)

0D2496 1 AXLE, 3/4"DIA X 27.25" (12.5 kW)

29 045900 2 WASHER FLAT 3/4” (15 kW)

045900 4 WASHER FLAT 3/4” (12.5 kW)

30 0D7668 2 12.3" PNEUM WHEEL 3/4" AXLE (15 kW)

0D2495 2 10" PNEUM WHEEL 3/4" AXLE (12.5 kW)

31 0D4999 2 PIN COTTER 1/8 X 1-1/4

32 0D4044 2 BRACKET, WHEEL SPACER

33 0D3700 4 NUT FLANGE M6-1.0 NYLOK

34 0D2497 1 HANDLE

35 022532 4 SCREW HHC 5/16-18 X 2-1/2 G5

36 027028 6 NUT LOCK HEX 5/16-18 NYLON INSERT

37 0D2271 1 FRAME

38 052762 4 SCREW HHC M5-0.8 X 45 G8.8

39 051713 8 WASHER FLAT M5

40 049226 4 WASHER LOCK M5

41 051716 4 NUT HEX M5-0.8

42 050190 2 WASHER FLAT 1”

43 078299 1 BUSHING TANK DEXTOR

44 080270 1 VALVE, PLASTIC TANK

45 0D5142 1 AIR DEFLECTOR

46 096021 2 GROMMET .75 X .06 X .50

47 048031C 2 CLAMP HOSE BAND ¼

48 0F9176 18” HOSE ¼ ID

49 075763 1 BOOT BATTERY CABLE

50 075763A 1 BOOT STARTER CABLE

51 0E0318 2 SPACER, AXLE (15 kW)

52 030795 2 SCREW HHC 5/16”-18 X 1”

23

Page 26

Section 6 — Exploded Views and Parts Lists

Control Panel – Drawing No. 0G0727-B

24

Page 27

Section 6 — Exploded Views and Parts Lists

Control Panel – Drawing No. 0G0727-B

ITEM PART NO. QTY. DESCRIPTION

1 087968 1 SWITCH, ROCKER -/0

2 090418 1 OUTLET, 12VDC SNAP

3 0D6640 1 COVER, GOVERNOR CONTROL

4 090987 6 SCREW PPHM M3-0.5 X 12

5 0D8740 1 PANEL, SHEET METAL (15 KW)

0G0309 1 PANEL, SHEET METAL (17.5 KW)

6 068868 2 OUTLET 30A 120V RECEPT

7 0G1093 4 SCREW SFILHM #8-32 X 5/8 LG (17.5 KW

ONLY)

8 043182 4 WASHER LOCK M3

9 0D9784 6 NUT HEX LOCK M3-0.5 NY INS

10 075207A 4 CIRCUIT BREAKER 30A

11 075207 2 CIRCUIT BREAKER 20A

12 0G1493 1 OUTLET 50A 250V (17.5 KW ONLY)

13 043437 1 OUTLET 30A 125/250V

14 0D4968 1 OUTLET 20A 120V DPLX

15 0D4966 1 OUTLET 20A 120V GFCI

16 0D1004E 1 CIRCUIT BREAKER 50A 400V 2POLE

17 0E6480 4 NUT HEX M4-0.5 NYINS

18 022471 4 NUT HEX #8-32 (17.5 KW ONLY)

19 0D5045 1 DIN RAIL 59.5mm LONG

20 0F9719 1 ASSY PCB VREG AIR COOLED

21 0D4409 1 ELECTRONIC GOVERNOR / IDLE

CONTROLLER

22 052844 1 RELAY PNL 12VDC SPST 30A

23 0F3100 1 RELAY 3PDT 12VDC

24 0G0503 1 CONTROL PANEL BOX (15 KW)

0F7424 1 CONTROL PANEL BOX (17.5 KW)

25 023484S 1 BUSHING SNAP

26 0A1661 2 RIVET POP .156 X .160-.164 / #20

27 048766 1 BLOCK TERMINAL 20A 2 X 6 X 1100V

28 0D3550 1 BLOCK DOUBLE ROW TERMINAL 8

POSITION

29 049939 1 RECTIFIER MSC 12A 600V

30 070370 1 WASHER MICA .203

31 030468 1 WASHER STEP NYLON .20

32 022158 1 NUT HEX #10-32

33 023897 1 WASHER FLAT #10

34 057405 1 RESISTOR 25R 5% 25W

35 022473 1 WASHER FLAT 1/4

36 022097 1 WASHER LOCK M6-1/4

ITEM PART NO. QTY. DESCRIPTION

37 049813 1 NUT HEX M6-1.0 G8

38 065795 2 RECTIFIER-BATTERY CHARGER

39 0D4804 2 TRANSFORMER, IDLE CURRENT

40 0C1085 4 SCREW PPHM M3-0.5 X 8

41 051715 12 NUT HEX M4-0.7 G8 (15 KW)

8 NUT HEX M4-0.7 G8 (17.5 KW)

42 022264 14 WASHER LOCK M4

43 048505 1 CIRCUIT BREAKER 6 X 1

44 087962 1 CIRCUIT BREAKER 10 X 1 12VDC 1/4"QC

45 036261 2 RIVET POP .125 X .250 SS

46 0A2769 1 LUG GROUND 8 TABS

47 032300 1 HOLDER FUSE

48 028578 1 FUSE 10A X AGC10

49 055444 1 HEATSINK

50 075475 2 SCREW PPHM M4-0.7 X 10

51 082025 6 NUT HEX LOCK M5-0.8 NYINS

52 0A2053 1 SCREW HHC M6-1.0 X 65 G8.8

53 055440 2 SCREW HHC M5-0.8 X 25 G8.8

54 045770 1 SCREW HHC M5-0.8 X 10 G8.8

55 0G0923 2 SPACER .25 X .50 X 2.5 (17.5 KW)

0D5734 2 SPACER .25 X .50 X 1.5 (15 KW)

56 074908 10 SCREW HHTT M5-0.8 X 10

57 075235 3 SCREW PPHM M5-0.8 X 30

58 077682 2 SCREW PPHM M5-0.8 X 80 (17.5 KW)

080823 2 SCREW PPHM M5-0.8 X 50 (15 KW)

59 038150 14 WASHER FLAT #8 (15 KW)

10 WASHER FLAT #8 (17.5 KW)

60 0D6140 1 GASKET, PORTABLE CONTROL PANEL

61 075476 2 SCREW PPHM M4-0.7 X 16

62 027565 A/R TAPE ELEC UL PERMACEL

63 058000K 2 NUT TRIC M5-0.8

64 0F3101 1 RELAY BASE 3PDT 12VDC

65 0D4969 1 OUTLET 50A 125/250V (15 KW ONLY)

66 0F5483 1 HARNESS, CONTROL PANEL BACK (NOT

SHOWN)

67 0D3546 1 HARNESS, CONTROL PANEL FRONT (NOT

SHOWN)

68 0D5809 1 HARNESS, TERMINAL STRIP TO PCB (NOT

SHOWN)

69 0G0615 1 SPRING RETAINER

25

Page 28

Section 6 — Exploded Views and Parts Lists

Generator – Drawing No. 0G0742-A

26

Page 29

Section 6 — Exploded Views and Parts Lists

Generator – Drawing No. 0G0742-A

ITEM PART NO. QTY. DESCRIPTION

1 0C6934 1 ADAPTOR, ENGINE

2 0G1177 1 STATOR 15KW

0D2136 STATOR 17.5KW

3 0G11760SRV 1 ASSEMBLY, ROTOR WITH FAN 15KW

0D21350SRV ASSEMBLY, ROTOR WITH FAN 17.5KW

4 0C6043B 1 CARRIER, REAR BEARING

5 0D2492 1 EXHAUST MANIFOLD

6 0D2726 1 MUFFLER

7 0C4138 2 GASKET, EXHAUST

8 0D3547 1 COVER, ALTERNATOR AIR IN

9 031971 1 BEARING

10 0C3168 3 5/16 SPECIAL LOCK WASHER

11 0D1838 1 SCREW IHHC 3/8-24 X 15.50 G5

12 0D3549 4 SCREW IHHC M8-1.25 X 400 G8.8

13 0C7038E 1 BRACKET, ALT MOUNTING

14 032712 4 SCREW HHTT #10-32 X 1.75

15 0D4662 1 SCREW HHTT M8-1.2 X 20

16 0C7038D 1 ENGINE MOUNTING PLATE

17 0C7758 6 RUBBER MOUNT

18 0388050AF0 1 BATTERY CABLE, BLACK

19 0C2417A 1 EARTH STRAP 3/8X 3/8

20 082121C 1 CLIP-J VINYL COAT .625 ID

21 066386 1 ASSEMBLY, BRUSH HOLDER

22 0C2824 1 SCREW TAP-R #10-32 X 9/16

23 0A2038 1 WASHER FLAT 3/8 ZINC

24 022237 5 WASHER LOCK 3/8

25 022511 4 SCREW HHC 3/8-16 X 1-1/4 G5

26 022131 4 WASHER FLAT 3/8-M10 ZINC

27 051731 4 SCREW HHC M8-1.25 X 50 G8.8

28 022145 21 WASHER FLAT 5/16 ZINC

29 049820 4 NUT LOCK HEX M8-1.25 NYLON INSERT

30 043116 7 SCREW HHC M6-1.0 X 12

31 022129 18 WASHER LOCK M8-5/16

32 022259 12 NUT HEX 5/16-18 STEEL

33 059637 2 SCREW TAPTITE 3/8-16 X 3/4 BP

34 0D5100 1 SHIELD, MUFFLER HEAT

35 0D5823 1 U-BOLT & SADDLE

36 0C8565 4 SCREW SHC M8-1.25 X 18

37 0D5833 1 PANEL, MUFFLER BOX BACK

38 0D5834 1 PANEL, MUFFLER BOX END

39 090388 3 SCREW HHTT M6-1.0 X 12

40 022473 7 WASHER FLAT M6-1/4

41 022097 7 WASHER LOCK M6-1/4

42 0D5133 1 SPARK ARRESTOR SCREEN

43 0D5133A 1 RETAINER, SPARK ARREST SCREEN

44 045764 1 SCREW HHTT M4-0.7 X 8

45 0D6214 1 SHIELD, RUBBER MOUNT

46 066849 2 SCREW HHTT M5-0.8 X 16

27

Page 30

Section 6 — Exploded Views and Parts Lists

GT-760/990 Engine – Drawing No. 0E8589-W - Part 1

28

Page 31

Section 6 — Exploded Views and Parts Lists

GT-760/990 Engine – Drawing No. 0E8589-W - Part 1

ITEM PART NO. QTY. DESCRIPTION

1 0C5729 1 ASSEMBLY, CRANKCASE HOUSING WITH

SLEEVE

2 0E9843 1 SEAL, 38 I.D. CRANKSHAFT

3 090388 3 SCREW, TAPTITE M6-1.0 X 12 BP

4 0C5372 1 ASSEMBLY, BREATHER

5 0C3005 1 GASKET, BREATHER COVER

6 0E3372B 1 SEPARATOR, OIL BREATHER

7 0D8067A 1 ASSEMBLY, HEAD #1

8 071983 4 RETAINER, PISTON PIN 20

9 0G0693 1 ASSY, ROCKER COVER W/BARB

10 043790 1 BARBED EL 90 3/8NPT X 3/8

11 0E2950 2 PISTON, LC (GT-990)

0E2985 2 PISTON, HC (GT-760)

12 021533 2 SET, PISTON RING 90MM

13 0E1466 2 PIN PISTON

14 0D4041 1 ASSEMBLY, CAMSHAFT & GEAR

16 093064 1 ASSEMBLY, OIL FILL CAP

17 0C2977 1 GASKET, CRANK CASE

18 0C5943 1 SEAL, OIL PASSAGE

19 0E3791E 1 ASSEMBLY, CRANKSHAFT HORIZONTAL

DIRECT DRIVE (GT-990)

0E3790E 1 ASSEMBLY, CRANKSHAFT HORIZONTAL

DIRECT DRIVE (GT-760)

20 0E3223 2 ASSEMBLY, CONNECTING ROD (GT-990)

0E3222 2 ASSEMBLY, CONNECTING ROD (GT-760)

21 0D2157 2 SCREW SHC M6-1.0 X 50 G8.8

22 0E6098 1 SCREEN, OIL PICKUP