Page 1

Note: This is a control system which must be cleaned and maintained regularly (see Maintenance Guide and Record card included with valve shipment).

1

Guardian Equipment

1140 N North Branch St

Chicago, IL 60642

312 447 8100 telephone

312 447 8101 facsimile

gesafety.com

rev. 1215 / © 2015 Guardian Equipment

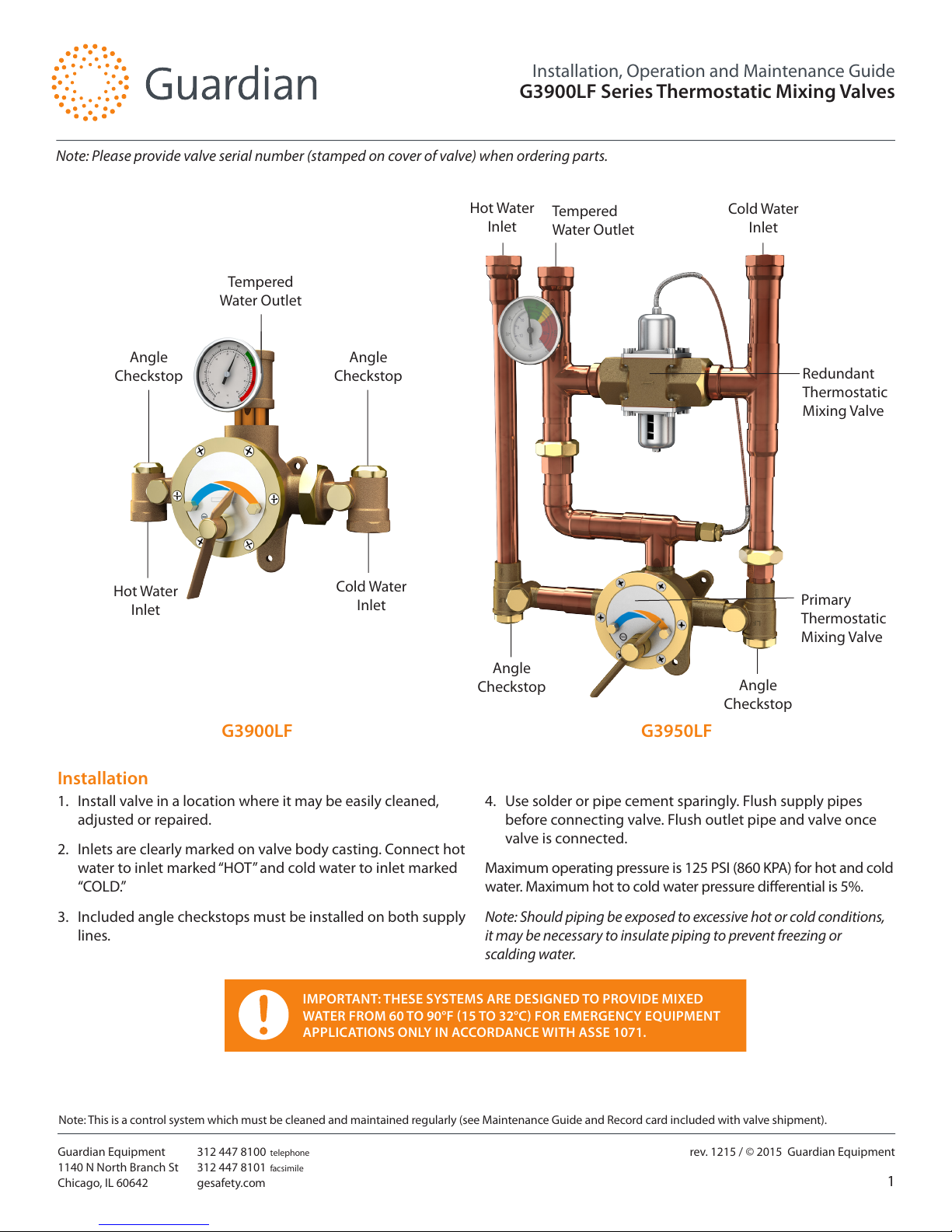

Installation, Operation and Maintenance Guide

G3900LF Series Thermostatic Mixing Valves

Angle

Checkstop

Angle

Checkstop

Angle

Checkstop

Angle

Checkstop

IMPORTANT: THESE SYSTEMS ARE DESIGNED TO PROVIDE MIXED

WATER FROM 60 TO 90°F (15 TO 32°C) FOR EMERGENCY EQUIPMENT

APPLICATIONS ONLY IN ACCORDANCE WITH ASSE 1071.

Hot Water

Inlet

G3900LF

Installation

1. Install valve in a location where it may be easily cleaned,

adjusted or repaired.

2. Inlets are clearly marked on valve body casting. Connect hot

water to inlet marked “HOT” and cold water to inlet marked

“COLD.”

3. Included angle checkstops must be installed on both supply

lines.

4. Use solder or pipe cement sparingly. Flush supply pipes

before connecting valve. Flush outlet pipe and valve once

valve is connected.

Maximum operating pressure is 125 PSI (860 KPA) for hot and cold

water. Maximum hot to cold water pressure dierential is 5%.

Note: Should piping be exposed to excessive hot or cold conditions,

it may be necessary to insulate piping to prevent freezing or

scalding water.

Cold Water

Inlet

Tempered

Water Outlet

Cold Water

Inlet

Hot Water

Inlet

Tempered

Water Outlet

G3950LF

Note: Please provide valve serial number (stamped on cover of valve) when ordering parts.

Redundant

Thermostatic

Mixing Valve

Primary

Thermostatic

Mixing Valve

Page 2

Note: This is a control system which must be cleaned and maintained regularly (see Maintenance Guide and Record card included with valve shipment).

2

Guardian Equipment

1140 N North Branch St

Chicago, IL 60642

312 447 8100 telephone

312 447 8101 facsimile

gesafety.com

rev. 1215 / © 2015 Guardian Equipment

Installation, Operation and Maintenance Guide

G3900LF Series Thermostatic Mixing Valves

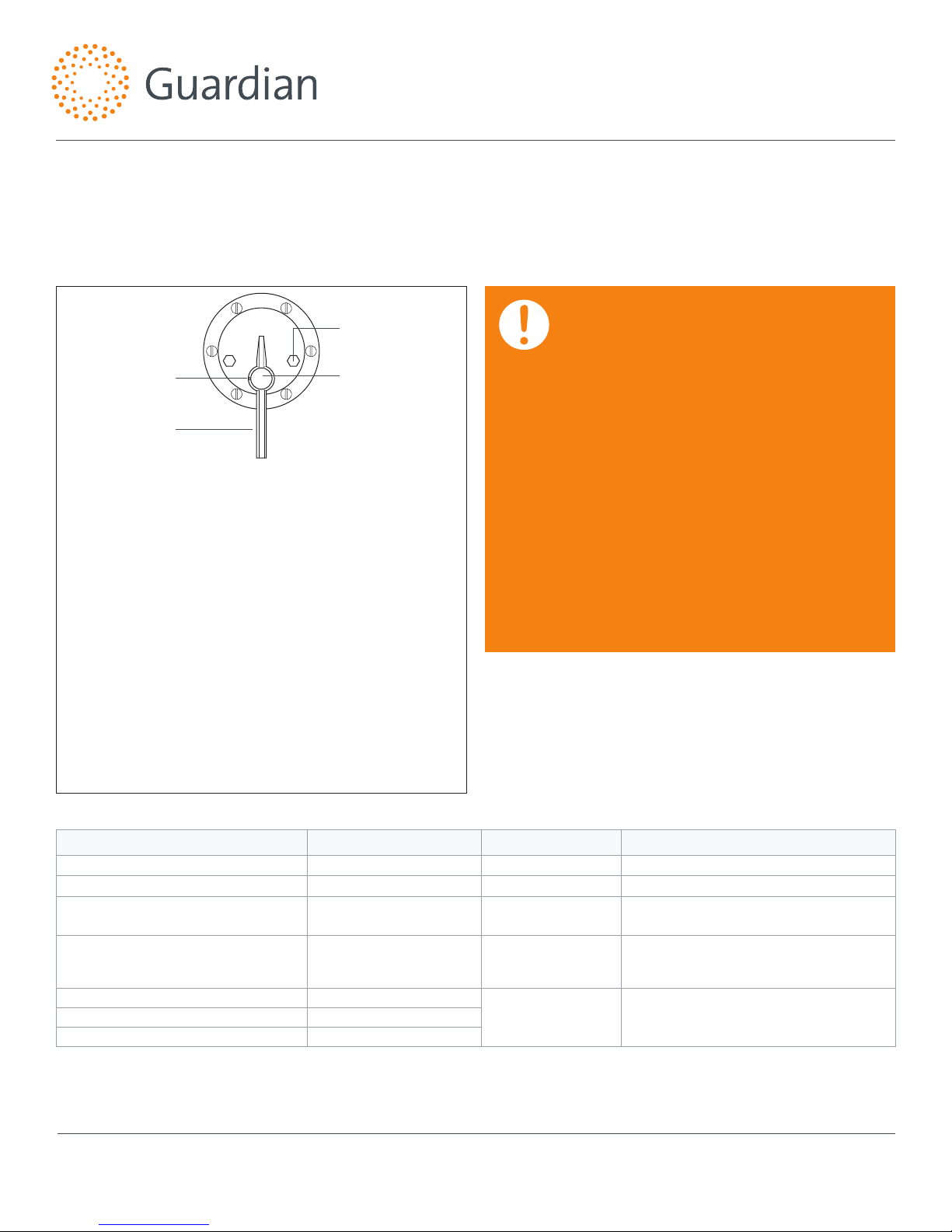

Adjustment and Service

Guardian thermostatic mixing valves may be easily cleaned,

adjusted and repaired. Servicing may be possible without

disconnecting valve.

Note: Thermostatic water mixing valves are regulating mechanisms

which must be regularly maintained to provide best performance.

Local water quality and usage conditions dictate cleaning frequency.

(See Maintenance Guide and Record card included with valve

shipment and reference ANSI Z358.1)

WARNING: THIS THERMOSTATIC MIXING VALVE HAS

AN ADJUSTABLE HIGH TEMPERATURE LIMIT STOP

WHICH MUST BE CHECKED. IF TEMPERATURE IS

TOO HIGH, THE INSTALLER MUST RESET THIS STOP

IMMEDIATELY. ALWAYS CHECK THE TEMPERATURE

OF THE MIXED WATER WHEN THE LEVEL

HANDLE IS TURNED TO FULL HOT. THE WATER

TEMPERATURE OF EACH INDEPENDENT OUTPUT

MUST BE CHECKED IF USING A COMBINATION

UNIT. EXCESSIVE HOT WATER TEMPERATURE IS

DANGEROUS AND MAY CAUSE SCALDING.

THE HIGH TEMPERATURE LIMIT STOP IS FACTORY

SET AT APPROXIMATELY 90°F (32°C) WITH AN

INCOMING HOT WATER SUPPLY TEMPERATURE

OF 135°F (57°C). IF THE INCOMING HOT WATER

IS HIGHER THAN 135°F (57°C), THE VALVE

(WHEN TURNED TO FULL HOT) WILL DELIVER

WATER IN EXCESS OF 90°F (32°C) AND THE HIGH

TEMPERATURE LIMIT STOP MUST BE RESET.

1. Loosen set screw. Remove snap cap, pointer screw,

washer, and pointer.

2. Activate emergency xture.

3. Temporarily place pointer on pointer rod and turn handle

to the left, allowing cold water to ow. Then, slowly

adjust handle to the right until the required maximum

temperature is reached. Note: Temperatures above 90°F

are not recommended. Consult a medical advisor for correct

temperature settings.

4. Once maximum temperature has been reached, remove

pointer and replace on pointer rod such that its right

edge rests against the stop screw located on the right

side of the cover.

5. Tighten set screw and replace washer, pointer screw, and

snap cap. Hold a thermometer under water ow to verify

maximum temperature has been set appropriately. Then

set desired operating temperature.

If installed on a circulated hot water system, verify the valve is piped according to Required Piping Method on page 3.

See page 5 for complete parts breakdown and parts kits.

Symptom Component Type Part No. Description

Leak at pointer rod. Packings and Gaskets

MU-5A

O-Ring

Leak between valve cover and body.

Packings and Gaskets

TM-21/125

Flange Packing

Valve outlet temperature will not mix

consistently.

Port Sleeve Assembly

TGM-1/125M or

R/125M

Port Sleeve Assembly or

Repair Kit

After cleaning or replacing port

sleeve assembly, valve will not hold

temperature.

Thermostat Group

TGM-2/125 or

R/125M

Thermostat Group or

Repair Kit

Hot water bypass into cold line. Checkstops

2/50M

Checkstop KitSupplies cannot be shut o completely. Checkstops

Leak at checkstop bonnet. Checkstops

To Reset Adjustable High Temperature Limit Stop:

Troubleshooting

Set Screw

Pointer

Snap Cap

Stop Screw

Distributed by:

Safety Emporium

PO Box 1003

Blackwood, NJ 08012

Ph: (866) 326-5412 toll-free

Fax: (856) 553-6154

esupport@safetyemporium.com

www. safetyemporium.com

Page 3

Note: This is a control system which must be cleaned and maintained regularly (see Maintenance Guide and Record card included with valve shipment).

3

Guardian Equipment

1140 N North Branch St

Chicago, IL 60642

312 447 8100 telephone

312 447 8101 facsimile

gesafety.com

rev. 1215 / © 2015 Guardian Equipment

Installation, Operation and Maintenance Guide

G3900LF Series Thermostatic Mixing Valves

Hot Supply

Cold Supply

To Hot Water Source

Hot Inlet

Cold Inlet

Hot Supply

Adjustment

Screw

Cold Supply

To Hot Water Source

Primary Thermostatic

Mixing Valve

Hot Inlet Cold Inlet

Required Piping Method

G3900LF G3950LF

This unit must be cycled each time the emergency equipment is inspected (See ANSI Z358.1, Maintenance and Training Section).

1. Set the thermostatic mixing valve to full hot. (primary

thermostatic mixing valve on the G3950LF)

2. Activate emergency equipment and allow temperature to

reach set point.

3. Turn (primary) thermostatic mixing valve to full cold and

wait ten seconds.

4. Turn (primary) thermostatic mixing valve to full hot and wait

ten seconds.

5. Verify outlet temperature does not exceed 90°F (32°C).

6. Turn (primary) thermostatic mixing valve to full cold and

wait ten seconds.

7. If necessary, adjust high temperature limit stop (see page

2). Then set (primary) mixing valve to desired operating

temperature and deactivate emergency equipment.

The G3950LF Redundant Thermostatic Mixing Valve has been factory set at 90°F (32°C). This set point can be adjusted with a 3/8” wrench

(see above). Twisting the adjustment screw clockwise will increase the temperature. Maximum set point is 100°F (38°C).

Required when hot water must be circulated to a thermostatic mixing valve that is a substantial distance from the hot water

source. Recommended hot water inlet temperature is 135°F (57°C).

Page 4

Note: This is a control system which must be cleaned and maintained regularly (see Maintenance Guide and Record card included with valve shipment).

4

Guardian Equipment

1140 N North Branch St

Chicago, IL 60642

312 447 8100 telephone

312 447 8101 facsimile

gesafety.com

rev. 1215 / © 2015 Guardian Equipment

Installation, Operation and Maintenance Guide

G3900LF Series Thermostatic Mixing Valves

To Dismantle Valve:

Shut o hot and cold water supplies to valve. Loosen set

screw. Remove snap cap, pointer screw, washer, pointer and

friction spring (see Figure 1). Remove cover screws and cover

(thermostat and gears are attached to cover).

When reassembling, insert ange packing into valve body and

replace cover and cover screws. Then replace friction spring,

pointer, washer, screw, and snap cap.

After replacing parts, pointer must be reset. Refer to page 2

instructions “To Reset Adjustable High Temperature Stop.”

To Clean Port Sleeve Assembly:

Screw (twist) the check nut away from valve body towards port

sleeve assembly. Then twist port sleeve nut away from port

sleeve assembly (towards valve body) to release port sleeve

and thimble (Figure 2).

Clean with non-corrosive agent and soft cloth. DO NOT

USE ABRASIVES. Wash parts thoroughly after cleaning and

reassemble.

Install port sleeve with elongated holes nearest the check

nut and tighten port sleeve nut against port sleeve assembly.

DO NOT OVERIGHTEN. Tighten check nut against valve body.

Driving ball on thermostat group should then be inserted into

ball socket for nal reassembly (Figure 1).

To Replace Pointer Rod With Gear:

Loosen set screw and remove snap cap, pointer screw, washer,

pointer and friction spring (Figure 1). Remove cover screws

and cover. Then remove coil sleeve stud and thermostat group.

Replace pointer rod with gear, and reassemble.

To Replace or Clean Thermostat Group:

See “To Replace Pointer Rod with Gear” (above) to disassemble

valve. Clean any collected deposits from thermostatic coil with

brush and non-corrosive cleaning solution.

Elongated Holes

(nearest the check nut)

Pointer Set

Screw

Coil Sleeve

Stud

Flange Packing

and Cover Screws

Pointer Rod

with Gear

Ball

Socket

Driving

Ball

Pointer

Friction

Spring

Cover

Elongated Holes

(nearest the check nut)

Pointer Set

Screw

Coil Sleeve

Stud

Flange Packing

and Cover Screws

Pointer Rod

with Gear

Ball

Socket

Driving

Ball

Pointer

Friction

Spring

Cover

Check Nut

Port Sleeve

Thimble

Port Sleeve

Nut

Figure 1

Figure 2

Page 5

Note: This is a control system which must be cleaned and maintained regularly (see Maintenance Guide and Record card included with valve shipment).

5

Guardian Equipment

1140 N North Branch St

Chicago, IL 60642

312 447 8100 telephone

312 447 8101 facsimile

gesafety.com

rev. 1215 / © 2015 Guardian Equipment

Installation, Operation and Maintenance Guide

G3900LF Series Thermostatic Mixing Valves

Thermostatic Mixing Valve Parts

Checkstop Parts

Repair Kits

Lockable Pointer (sux “LTR”)

Notes:

1. After installing new parts, the

adjustable high temperature limit

stop must be reset (see page 2).

2. All G3900LF and G3950LF valves

are furnished with lockable

pointers.

Repair kit Includes parts to repair both hot and cold checkstops

21 3 4 6 875 9 10 11 12 13 14

16

16

24 25

25

26

26

22

23

TM-36

Point er Se t Sc rew

171718

18

20

20

2119

15

Item Part No. Description

1 57-L Snap Cap

2 TM-29/29A Pointer Screw

3 TM-25C Pointer

4 30 Friction Spring

5 617 Dial Plate

6 TM-25D Stop Screw

7 TM-16 Cover Screws (6)

8 TM-15B/125 Cover

9 TM-21/125 Flange Packing

10 TGM-2/125 Thermostat Group

11 TGM-1/125M Port Sleeve Assembly

12 TM-3/125M Port Sleeve Nut Assembly

13 TM-8 Coil Sleeve Stud

14 TM-28A Pointer Rod

Item Part No. Description

15 MU-5A O-Ring

16 03 Lower Stem & Packing

17

011 Spring (Hot Side)

015 Spring (Cold Side)

18 MU-5A O-Ring

19 MU-4A Upper Stem

20 05 Packing

21 02 Bonnet

22 04/125 Swivel

23 09/125 Swivel Nut

24 06 Strainer Cap

25 014 Cap Packing

26 013 Screen

R/125M

Repair Kit

2/50M

Checkstop Kit

Page 6

Note: This is a control system which must be cleaned and maintained regularly (see Maintenance Guide and Record card included with valve shipment).

6

Guardian Equipment

1140 N North Branch St

Chicago, IL 60642

312 447 8100 telephone

312 447 8101 facsimile

gesafety.com

rev. 1215 / © 2015 Guardian Equipment

Installation, Operation and Maintenance Guide

G3900LF Series Thermostatic Mixing Valves

Flow Capacities

System Pressure Drop (PSI)

0

12.5

25

37.5

50

Flow Rate (GPM)

5060708090

100

110

120

130

CAUTION: ALL THERMOSTATIC MIXING VALVES HAVE

LIMITATIONS. THEY WILL NOT PROVIDE THE DESIRED

ACCURACY OUTSIDE OF THEIR FLOW CAPACITY

RANGE. CONSULT THE CAPACITY CHART AND DO NOT

OVERSIZE. MINIMUM FLOW MUST BE NO LESS THAN

SHOWN ABOVE.

IMPORTANT: THESE SYSTEMS ARE DESIGNED TO

PROVIDE MIXED WATER FROM 60 TO 90°F (15 TO

32°C) FOR EMERGENCY EQUIPMENT APPLICATIONS

ONLY IN ACCORDANCE WITH ASSE 1071.

G3900LF/G3950LF

MODEL IN OUT

MINIMUM

FLOW

(GPM)

INTERNAL

COLD WATER

BYPASS

MINIMUM

SYSTEM PRESSURE DROP

5 10 15 20 25 30 35 40 45 PSI

L/MIN .3 .7 1.0 1.4 1.7 2.1 2.4 2.8 3.1 BAR

G3900LF

G3950LF

1-1/4" 1-1/2"

3 40 53 64 72 81 90 99 108 117 126 GPM

11 151 201 242 273 307 341 374 409 443 477 L/MIN

MAXIMUM FLOW CAPACITY

Limited Warranty

Guardian Equipment warrants the original purchaser that its products will be free from defects in materials and workmanship under normal usage conditions,

and when properly installed and maintained according to manufacturer's instructions for a period of two years from date of shipment. During the warranty

period, Guardian Equipment will (at its discretion) repair or replace any product or part thereof, which shall be returned, freight prepaid to Guardian's factory

and determined by the manufacturer to be defective in materials or workmanship. There are no warranties, expressed or implied, which extend beyond verbiage

contained herein. There are no implied warranties of merchantability or tness for a particular purpose. Guardian Equipment will not be held liable for labor,

incidental or consequential damages. Any alteration or improper installation or improper use of the product will void this limited warranty.

Loading...

Loading...