Guardian 5240, 5241, 5282, 5281, 5280 Diagnostic Repair Manual

...

AIR-COOLED

MODELS:

5240, 5280 (7 kW NG, 6 kW LP)

5241, 5281 (9 kW NG, 10 kW LP)

5242, 5282 (13 kW NG, 13 kW LP)

5243, 5283 (15 kW NG, 16 kW LP)

5244, 5284 (15 kW NG, 16 kW LP)

DIAGNOSTIC

DIAGNOSTIC

REPAIR MANUAL

REPAIR MANUAL

AUTOMATIC STANDBY GENERATORS

www.guardiangenerators.com

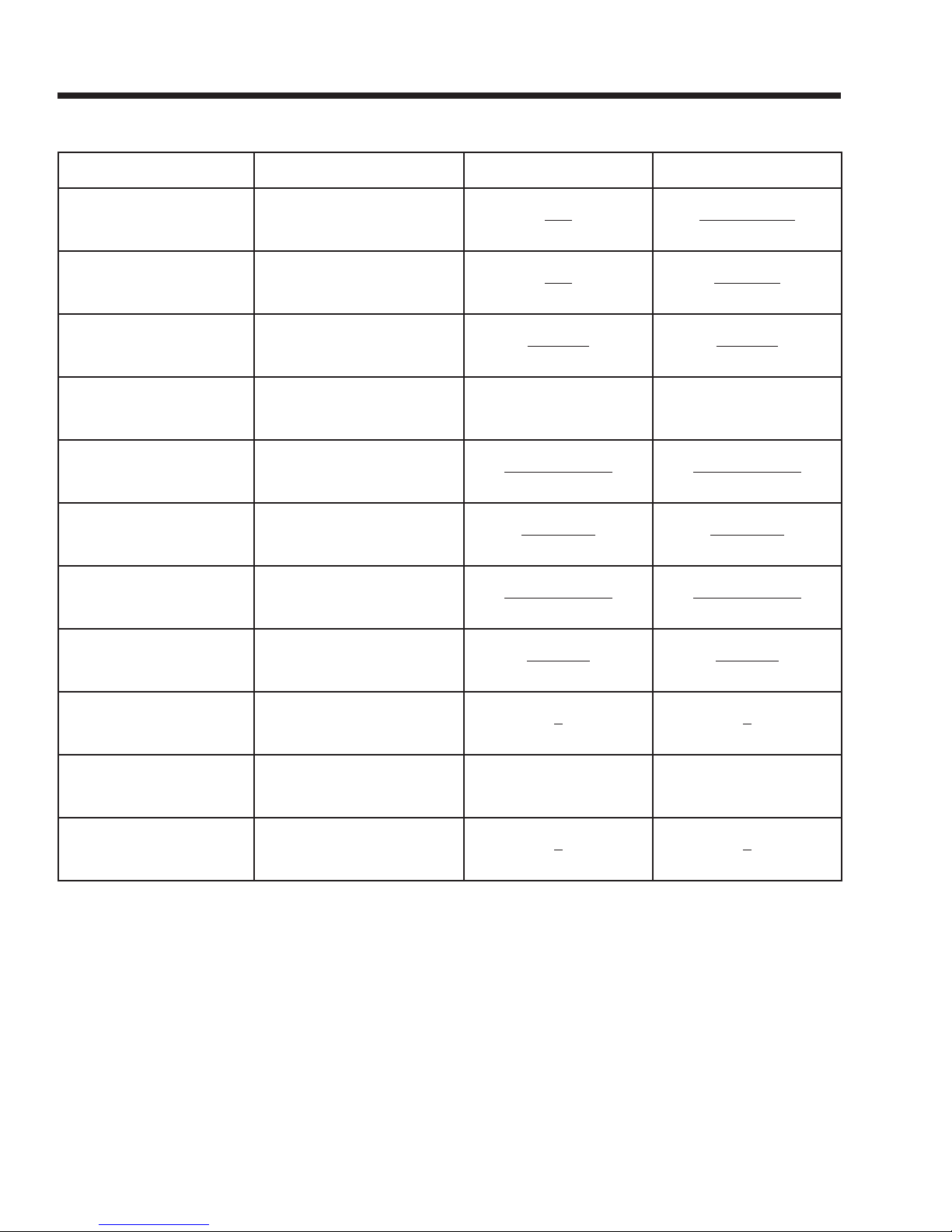

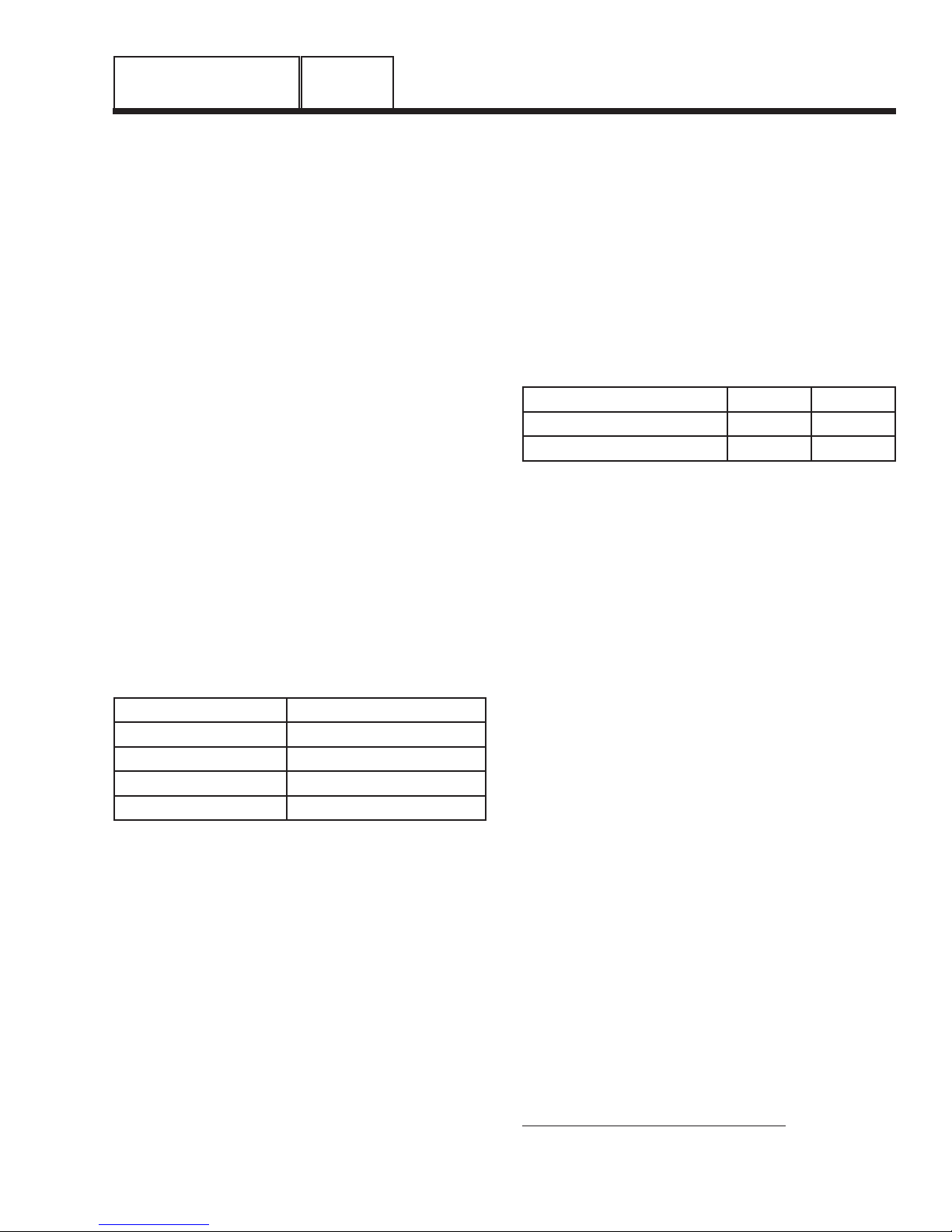

ELECTRICAL FORMULAS

TO FIND KNOWN VALUES 1-PHASE 3-PHASE

KILOWATTS (kW)

KVA

AMPERES

WATTS

NO. OF ROTOR POLES

FREQUENCY

RPM

kW (required for Motor)

Volts, Current, Power Factor

Volts, Current

kW, Volts, Power Factor

Volts, Amps, Power Factor Volts x Amps E x I x 1.73 x PF

Frequency, RPM

RPM, No. of Rotor Poles

Frequency, No. of Rotor Poles

Motor Horsepower, Efficiency

E x I

1000

E x I

1000

kW x 1000

E

2 x 60 x Frequency

RPM

RPM x Poles

2 x 60

2 x 60 x Frequency

Rotor Poles

HP x 0.746

Efficiency

E x I x 1.73 x PF

1000

E x I x 1.73

1000

kW x 1000

E x 1.73 x PF

2 x 60 x Frequency

RPM

RPM x Poles

2 x 60

2 x 60 x Frequency

Rotor Poles

HP x 0.746

Efficiency

RESISTANCE

VOLTS

AMPERES

E = VOLTS I = AMPERES R = RESISTANCE (OHMS) PF = POWER FACTOR

Volts, Amperes

Ohm, Amperes I x R I x R

Ohms, Volts

E

I

E

R

E

I

E

R

Contents

SPECIFICATIONS..................................................... 4

Generator ................................................................ 4

Stator Winding Resistance Values/

Rotor Resistance ..................................................... 4

Engine ..................................................................... 5

Fuel Consumption ................................................... 5

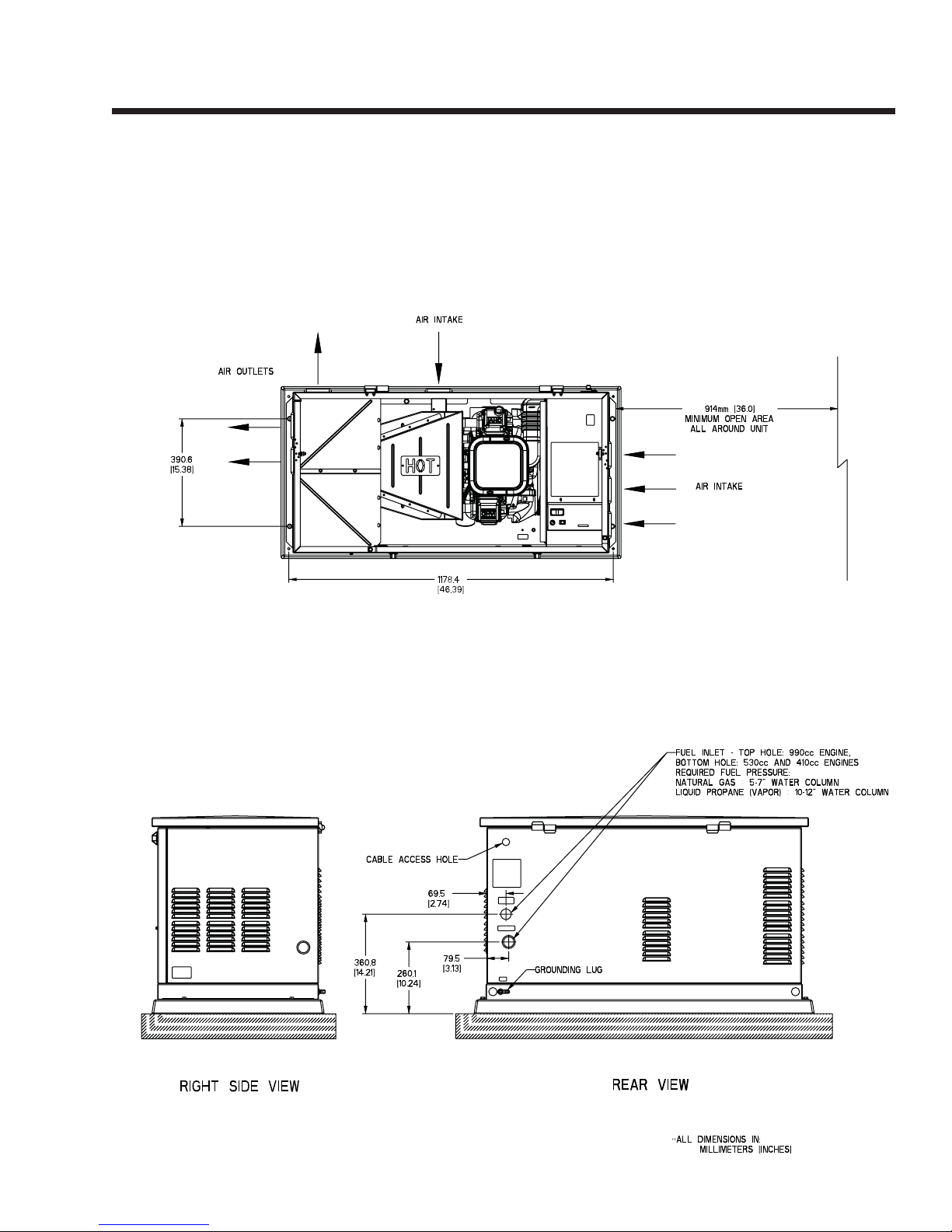

Mounting Dimensions ........................................... 6-7

Major Features ........................................................ 8

PART 1 - GENERAL INFORMATION ....................... 9

1.1 Generator Identification ................................... 10

1.2 Prepackaged Installation Basics ..................... 11

Introduction ......................................................11

Selecting A Location ........................................11

Grounding The Generator ................................11

The Fuel Supply ...............................................11

The Transfer Switch / Load Center ...................11

Power Source And Load Lines .........................13

System Control Interconnections .....................13

1.3 Preparation Before Use ................................... 14

General ............................................................14

Fuel Requirements...........................................14

Fuel Consumption ............................................14

Reconfiguring The Fuel System .......................14

Engine Oil Recommendations .........................16

1.4 Testing, Cleaning and Drying........................... 16

Meters ............................................................17

The VOM ..........................................................17

Measuring AC Voltage .....................................17

Measuring DC Voltage .....................................17

Measuring AC Frequency ................................17

Measuring Current ...........................................18

Measuring Resistance .....................................18

Electrical Units .................................................19

Ohm's Law .......................................................19

Visual Inspection ..............................................20

Insulation Resistance .......................................20

The Megohmmeter...........................................20

Stator Insulation Resistance Test .....................21

Rotor Insulation Resistance Test ......................22

Cleaning The Generator...................................22

Drying The Generator ......................................22

1.5 Engine-Generator Protective Devices ............. 23

General ............................................................23

Low Battery ......................................................23

Low Oil Pressure Shutdown .............................23

High Temperature Switch .................................23

Overspeed Shutdown ......................................23

RPM Sensor Failure .........................................23

Overcrank Shutdown .......................................24

1.6 Operating Instructions ..................................... 25

Control Panel ...................................................25

To Select Automatic Operation ........................26

Manual Transfer To “Standby” And

Manual Startup ....................................26

Manual Shutdown And Retransfer

Back To “Utility” ....................................27

1.7 Automatic Operating Parameters .................... 28

Introduction ......................................................28

Automatic Operating Sequences .....................28

PART 2 - AC GENERATORS.................................. 29

2.1 Description and Components .......................... 30

Introduction ......................................................30

Engine-generator Drive System .......................30

The AC Generator ............................................30

Rotor Assembly ................................................30

Stator Assembly ...............................................31

Brush Holder And Brushes ..............................31

Other AC Generator Components ...................31

2.2 Operational Analysis ....................................... 33

Rotor Residual Magnetism...............................33

Field Boost .......................................................33

Operation .........................................................34

2.3 Troubleshooting Flowcharts ............................. 35

Problem 1 - Generator Produces Zero

Voltage or Residual Voltage .......... 35-36

Problem 2 - Generator Produces

Low Voltage at No-Load ......................37

Problem 3 - Generator Produces

High Voltage at No-Load .....................37

Problem 4 - Voltage and Frequency Drop

Excessively When Loads are Applied .38

2.3 Diagnostic Tests .............................................. 39

Introduction ......................................................39

Safety ............................................................39

Test 1 - Check Main Circuit Breaker.................39

Test 2 - Check AC Output Voltage ....................39

Test 4 - Fixed Excitation Test/Rotor

Amp Draw Test ....................................40

Test 5 - Wire Continuity ....................................41

Test 6 - Check Field Boost ...............................42

Test 7 - Testing The Stator With a VOM ...........42

Test 8 - Resistance Check of Rotor Circuit ......44

Test 9 - Check Brushes and Slip Rings ............44

Test 10 - Test Rotor Assembly .........................45

Test 11 - Check AC Output Frequency.............45

Page 1

Test 12 - Check And Adjust Engine Governor

(Single Cylinder Units) .........................46

Test 12A - Check Stepper Motor Control

(V-twin Engine Units) ...........................46

Test 13 - Check And Adjust

Voltage Regulator ................................48

Test 14 - Check Voltage And

Frequency Under Load ........................48

Test 15 - Check For Overload Condition ..........48

Test 16 - Check Engine Condition ....................48

PART 3 - "V-TYPE PREPACKAGED

TRANSFER SWITCHES.......................... 49

3.1 Description and Components .......................... 50

General ............................................................50

Enclosure .........................................................50

Transfer Mechanism .........................................51

Transfer Relay .................................................51

Neutral Lug ......................................................52

Manual Transfer Handle ..................................52

Terminal Block .................................................52

Fuse Holder .....................................................53

3.2 Operational Analysis ....................................... 54

Utility Source Voltage Available .......................56

Utility Source Voltage Failure ..........................57

Transfer To Standby ........................................58

Transfer To Standby ........................................59

Utility Restored.................................................60

Utility Restored, Transfer Switch

De-energized .......................................61

Utility Restored,

Retransfer Back To Utility ....................62

Transfer Switch In Utility ...................................63

3.3 Troubleshooting Flow Charts ........................... 64

Introduction To Troubleshooting .......................64

Problem5-InAutomatic Mode,

No Transfer to Standby ........................64

Problem6-InAutomatic Mode, Generator

Starts When Loss of Utility Occurs,

Generator Shuts Down When Utility

Returns But There Is

No Retransfer To Utility Power .............65

Problem 7 - Blown F1 or F2 Fuse ....................65

3.4 Diagnostic Tests .............................................. 66

General ............................................................66

Test 21 - Check Voltage at

Terminal Lugs E1, E2 ..........................66

Test 22 - Check Voltage at

Standby Closing Coil C2 .....................67

Test 23 - Test Transfer Relay TR ......................67

Test 24 - Check Manual Transfer

Switch Operation .................................68

Test 25 - Test Limit Switch XB1 ........................69

Test 26 - Check 23 And 194

Wiring/Connections .............................69

Test 27- Check Voltage At

Terminal Lugs N1, N2 ..........................70

Test 28 - Check Voltage At Utility 1

And Utility 2 Ter minals .........................70

Test 29 - Check Voltage At

Utility Closing Coil C1 ..........................71

Test 30 - Check Fuses F1 And F2 ...................71

Test 31 - Test Limit Switch Xa1 ........................72

Test 32 - Continuity Test Of Wiring (C1) ...........72

Test 33 - Continuity Test Of Wiring (C2) ...........72

Test 34 - Check N1 And N2 Wiring ..................73

Test 35 - Check Transformer (Tx) .....................73

PART 4 - DC CONTROL ......................................... 75

4.1 Description and Components .......................... 76

General ............................................................76

Terminal Strip / Interconnection Ter minal .........76

Transformer (TX) ..............................................76

Circuit Board ....................................................76

AUTO-OFF-MANUAL Switch ...........................80

15 Amp Fuse....................................................80

4.2 Operational Analysis ....................................... 82

Introduction ......................................................82

Utility Source Voltage Available ........................82

Initial Dropout Of Utility Source Voltage ...........84

Utility Voltage Dropout And

Engine Cranking ..................................86

Engine Startup And Running ...........................88

Initial Transfer To The “Standby” Source ...........90

Utility Voltage Restored /

Re-transfer To Utility ............................92

Engine Shutdown ........................................... 94

4.3 Troubleshooting Flow Charts ........................... 96

Problem 8 - Engine Will Not Crank

When Utility Power Source Fails .........96

Problem 9 - Engine Will Not Crank

When AUTO-OFF-MANUAL Switch

is Set to "MANUAL" .............................96

Problem 10 - Engine Cranks

but Won't Start .....................................97

Problem 11 - Engine Starts Hard and

Runs Rough / Lacks Power .................98

Problem 12 - Engine Starts and Runs,

Then Shuts Down ................................99

Problem 13 - No Battery Charge ...................100

Problem 14 - Unit Starts and Transfer Occurs

When Utility Power is Available ........101

Page 2

Problem 15 - Generator Starts

Immediately in Auto - No Transfer to

Standby. Utility Voltage is Present .....101

Problem 16 - 15 Amp Fuse (F1) Blown ..........102

Problem 17 - Generator Will Not Exercise .....102

Problem 18 - No Low Speed Exercise ...........102

4.4 Diagnostic Tests ............................................ 103

Introduction .................................................. 103

Test 41 - Check Position Of

AUTO-OFF-MANUAL Switch ........... 103

Test 42 - Try A Manual Start ......................... 103

Test 43 - Test AUTO-OFF-MANUAL Switch . 103

Test 44 - Check Wire 15/15A/15B/239/0

Voltage ..............................................104

Test 45 - Check 15 Amp Fuse ........................105

Test 46 - Check Battery .................................105

Test 47 - Check Wire 56 Voltage ...................106

Test 48 - Test Starter Contactor Relay

(V-twin Only) ......................................106

Test 49 - Test Starter Contactor .....................106

Test 50 - Test Starter Motor ............................107

Test 51 - Check Fuel Supply

And Pressure.....................................109

Test 52 - Check Circuit Board

Wire 14 Output ..................................110

Test 53 - Check Fuel Solenoid .......................111

Test 54 - Check Choke Solenoid

(V-twins Units Only) ...........................112

Test 55 - Check For Ignition Spark .................113

Test 56 - Check Spark Plugs ..........................114

Test 57 - Check Engine / Cylinder Leak Down

Test / Compression Test114

Test 58 - Check Shutdown Wire .....................115

Test 59 - Check And Adjust

Ignition Magnetos ..............................116

Test 60 - Check Oil Pressure Switch

And Wire 86 .......................................117

Test 61 - Check High Oil

Temperature Switch ...........................118

Test 62 - Check And Adjust Valves ................119

Test 63 - Check Fuel Regulator

(7 Kw Natural Gas Units Only) ..........117

Test 64 - Check Battery Charge Output .........120

Test 65 - Check Transformer (TX)

Voltage Output ...................................118

Test 66 - Check AC Voltage At

Battery Charger .................................121

Test 67 - Check Battery Charge

Relay (BCR) ......................................122

Test 68 - Check Battery Charge

Winding Harness ...............................122

Test 69 - Check Battery Charger Wiring .......123

Test 70 - Check Wire 18 Continuity ................123

Test 71 - Check N1 And N2 Voltage ...............123

Test 72 - Check Utility Sensing Voltage

At The Circuit Board ..........................124

Test 73 - Test Set Exercise Switch .................124

Test 75 - Check Battery Voltage Circuit ..........124

Test 76 - Check Cranking And

Running Circuits ................................124

Test 77 - Test Exercise Function ....................126

Test 78 - Check Dip Switch Settings ..............126

Test 79 - Check Idle Control Transformer

(V-twin Units Only) .............................126

Test 80 - Check LC1 & LC2 Wiring ................126

Test 81 - Check Idle Control Transformer

Primary Wiring ...................................127

PART 5 - OPERATIONAL TESTS......................... 129

5.1 System Functional Tests ................................ 130

Introduction ....................................................130

Manual Transfer Switch Operation .................130

Electrical Checks ...........................................130

Generator Tests Under Load ..........................131

Checking Automatic Operation ......................132

Setting The Exercise Timer ............................132

PART 6 - DISASSEMBLY ..................................... 133

6.1 Major Disassembly ........................................ 134

Major Disassembly .........................................134

Front Engine Access. .....................................136

Torque Requirements

(Unless Otherwise Specified) ............136

PART 7 - ELECTRICAL DATA .............................. 137

Drawing 0F7820 Wiring Diagram,

7kWHSB

Models 005240 & 005280 ................................... 138

Drawing 0F7821 Wiring Schematic,

7kWHSB

Models 005240 & 005280 ................................... 140

Drawing 0F7822 Wiring Diagram,

10, 13 & 16 kW HSB

Models 005241 & 005281

Models 005242 & 005282

Models 005243 & 005283

Models 005244 & 005284 ................................... 142

Drawing 0F7823 Schematic,

10, 13 & 16 kW HSB

Models 005241 & 005281

Models 005242 & 005282

Models 005243 & 005283

Models 005244 & 005284 ................................... 144

Drawing 0F9070 Wiring Diagram,

Transfer Switch

8 Circuit/16 Circuit ............................................... 146

Drawing 0F9775 Wiring Diagram,

Schematic

8 Circuit/16 Circuit ............................................... 147

Page 3

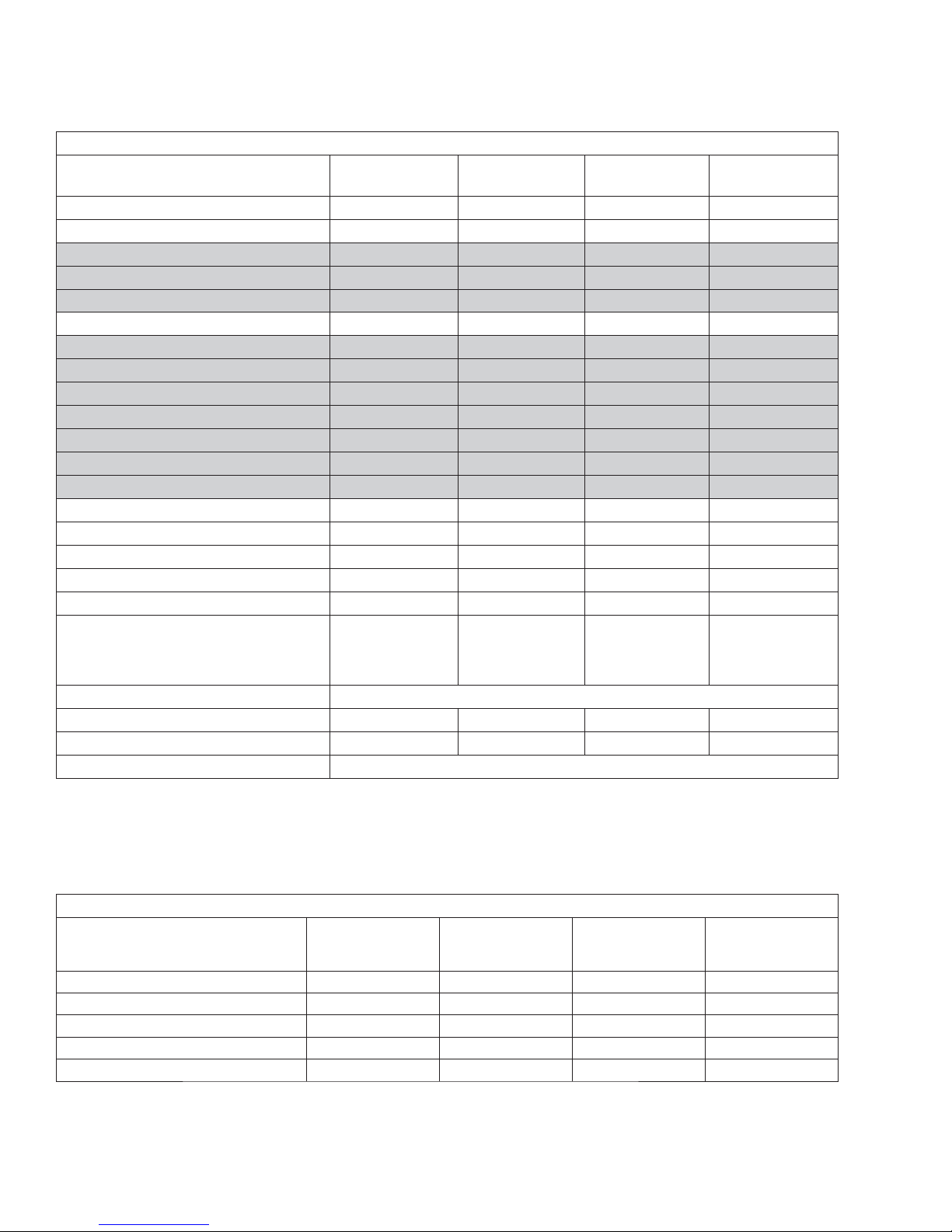

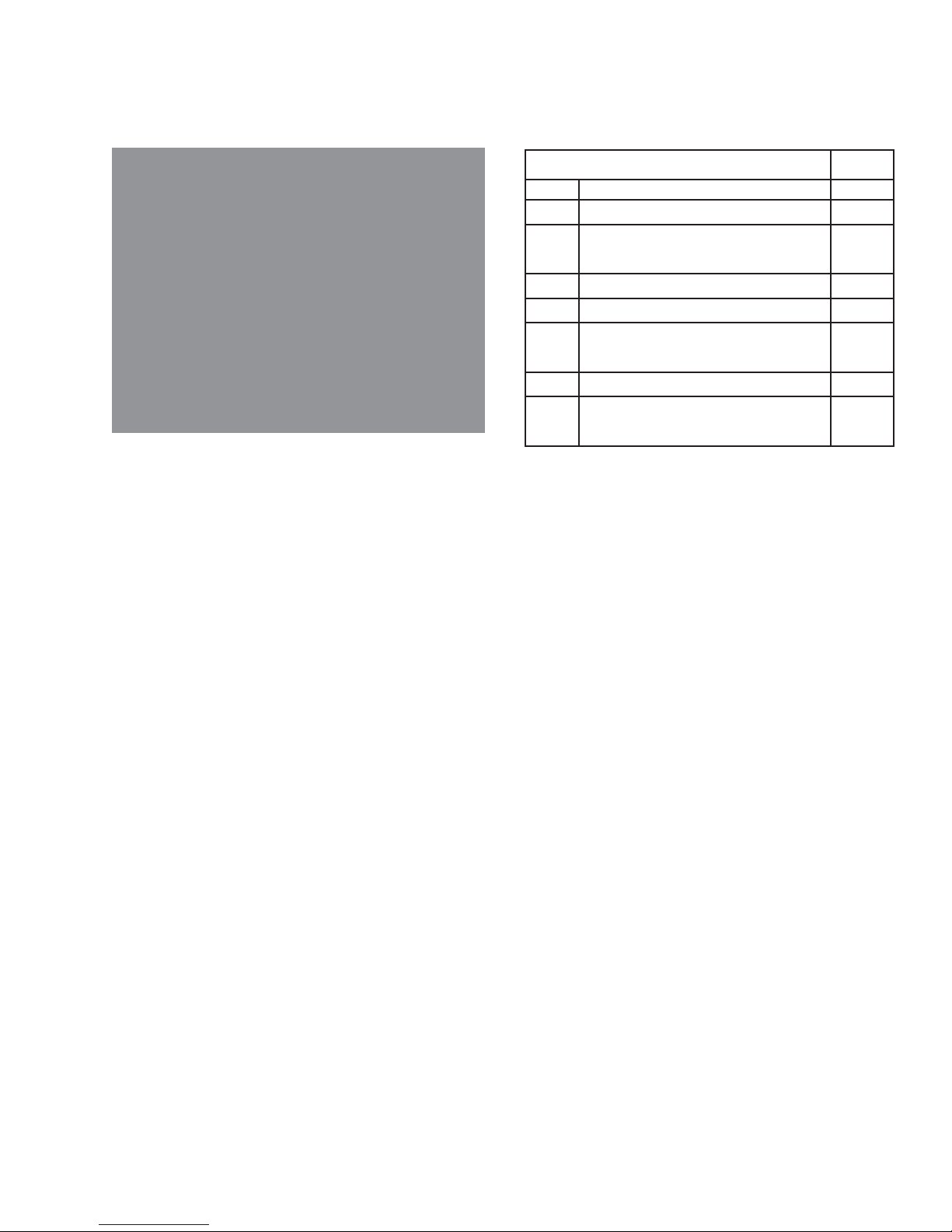

SPECIFICATIONS

GENERATOR

Model

005240 & 005280 005241 & 005281 005242 & 005282

Rated Max. Continuous Power Capacity (Watts*) 6,000 NG/7,000 LP 9,000 NG/10,000 LP 13,000 NG/13,000 LP 15,000 NG/16,000 LP

Rated Voltage 120/240 120/240 120/240 120/240

Rated Max. Continuous Load Current (Amps)

120 Volts** 50.0 NG/58.3 LP 75.0 NG/83.3 LP 108.3 NG/108.3 LP 125 NG/133.3 LP

240 Volts 25.0 NG/29.2 LP 37.5 NG/41.7 LP 54.1 NG/54.1 LP 52.5 NG/66.6 LP

Main Line Circuit Breaker 30 Amp 45 Amp 55 Amp 65 Amp

Circuits***

50A, 240V - - - 1

40A, 240V - - 1 1

30A, 240V 1 1 1 -

20A, 240V - 1 - 1

20A, 120V 1 3 3 5

15A, 120V 5 3 5 5

Phase 1 1 1 1

Number of Rotor Poles 2 2 2 2

Rated AC Frequency 60 Hz 60 Hz 60 Hz 60 Hz

Power Factor 1 1 1 1

Recommended Air Filter Part # 0C8127 Part # 0E9581 Part # 0C8127 Part # 0C8127

Battery Requirement Group 26

12 Volts and

350 Cold-cranking

Amperes Minimum

Group 26

12 Volts and

525 Cold-cranking

Amperes Minimum

Group 26

12 Volts and

525 Cold-cranking

Amperes Minimum

Battery Warming Blanket 0F6148DSRV

Weight (Unit Only) 336 Pounds 375 Pounds 425.5 Pounds 445 & 414 Pounds

Enclosure Steel/Aluminum

Normal Operating Range -20°F (-28.8°C) to 104°F (40°C)

005243 & 005283

005244 & 005284

Group 26

12 Volts and

525 Cold-cranking

Amperes Minimum

* Maximum wattage and current are subject to and limited by such factors as fuel Btu content, ambient temperature, altitude, engine power and condition, etc.Maximum power

decreases about 3.5 percent for each 1,000 feet above sea level; and also will decrease about 1 percent for each 6° C (10° F) above 16° C (60° F) ambient temperature.

** Load current values shown for 120 volts are maximum TOTAL values for two separate circuits.The maximum current in each circuit must not exceed the value stated for 240 volts.

*** Circuits to be moved from main panel to transfer switch load center must be protected by same size breaker. For example, a 15 amp circuit in main panel must be a 15 amp circuit in

transfer switch.

STATOR WINDING RESISTANCE VALUES / ROTOR RESISTANCE

Power Winding: Across 11 & 22 0.223-0.259 ohms 0.144 ohms 0.115 ohms 0.080 ohms

Power Winding: Across 33 & 44 0.223-0.259 ohms 0.144 ohms 0.115 ohms 0.080 ohms

Excitation Winding: Across2&6 1.528-1.769 ohms 1.238 ohms 1.256 ohms 1.092 ohms

Battery Charge Winding: Across 66 & 77 0.146-0.169 ohms 0.158 ohms 0.164 ohms 0.130 ohms

Rotor Resistance 11.88-13.76 ohms 11.8 ohms 12.6 ohms 22.0 ohms

Page 4

005240, 005280

(6/7 kW)

005241, 005281

(9/10 kW)

005242, 005282

(13/13 kW)

005243, 005283

005244, 005284

(15/16 kW)

ENGINE

SPECIFICATIONS

Model 005240 & 005280 005241 & 005281 005242 & 005282

005243 & 005283

005244 & 005284

Type of Engine GH-410 GT-530 GT-990 GT-990

Number of Cylinders 1 2 2 2

Rated Horsepower 14.5 @ 3,600 rpm 18 @ 3,600 rpm 30 @ 3,600 rpm 30 @ 3,600 rpm

Displacement 410cc 530cc 992cc 992cc

Cylinder Block

Aluminum w/Cast Iron

Sleeve

Aluminum w/Cast Iron

Sleeve

Aluminum w/Cast Iron

Sleeve

Aluminum w/Cast Iron

Sleeve

Valve Arrangement Overhead Valves Overhead Valves Overhead Valves Overhead Valves

Ignition System Solid-state w/Magneto Solid-state w/Magneto Solid-state w/Magneto Solid-state w/Magneto

Recommended Spark Plug RC14YC BPR6HS RC12YC RC12YC

Spark Plug Gap 0.76 mm (0.030 inch) 0.76 mm (0.030 inch) 1.02 mm (0.040 inch) 1.02 mm (0.040 inch)

Compression Ratio 8.6:1 9.5:1 9.5:1 9.5:1

Starter 12 VDC 12 VDC 12 VDC 12 VDC

Oil Capacity Including Filter Approx. 1.5 Qts Approx. 1.7 Qts Approx. 1.7 Qts Approx. 1.7 Qts

Recommended Oil Filter Part # 070185B Par t # 070185B Part # 070185B Part # 070185B

Recommended Air Filter Part # 0C8127 Part # 0E9581 Part # 0C8127 Part # 0C8127

Operating RPM 3,600 3,600 3,600 3,600

FUEL CONSUMPTION

Model # Natural Gas* LP Vapor**

1/2 Load Full Load 1/2 Load Full Load

005240, 005280 (6/7 kW) 66 119 0.82/30 1.47/54

005241, 005281 (9/10 kW) 102 156 1.25/46 1.93/70

005242, 005282 (13/13 kW) 156 220 1.55/57 2.18/80

005243, 005283 (15/16 kW)

005244, 005284 (15/16 kW)

* Natural gas is in cubic feet per hour.

**LP is in gallons per hour/cubic feet per hour.

Values given are approximate.

173 245 1.59/59 2.51/92

Page 5

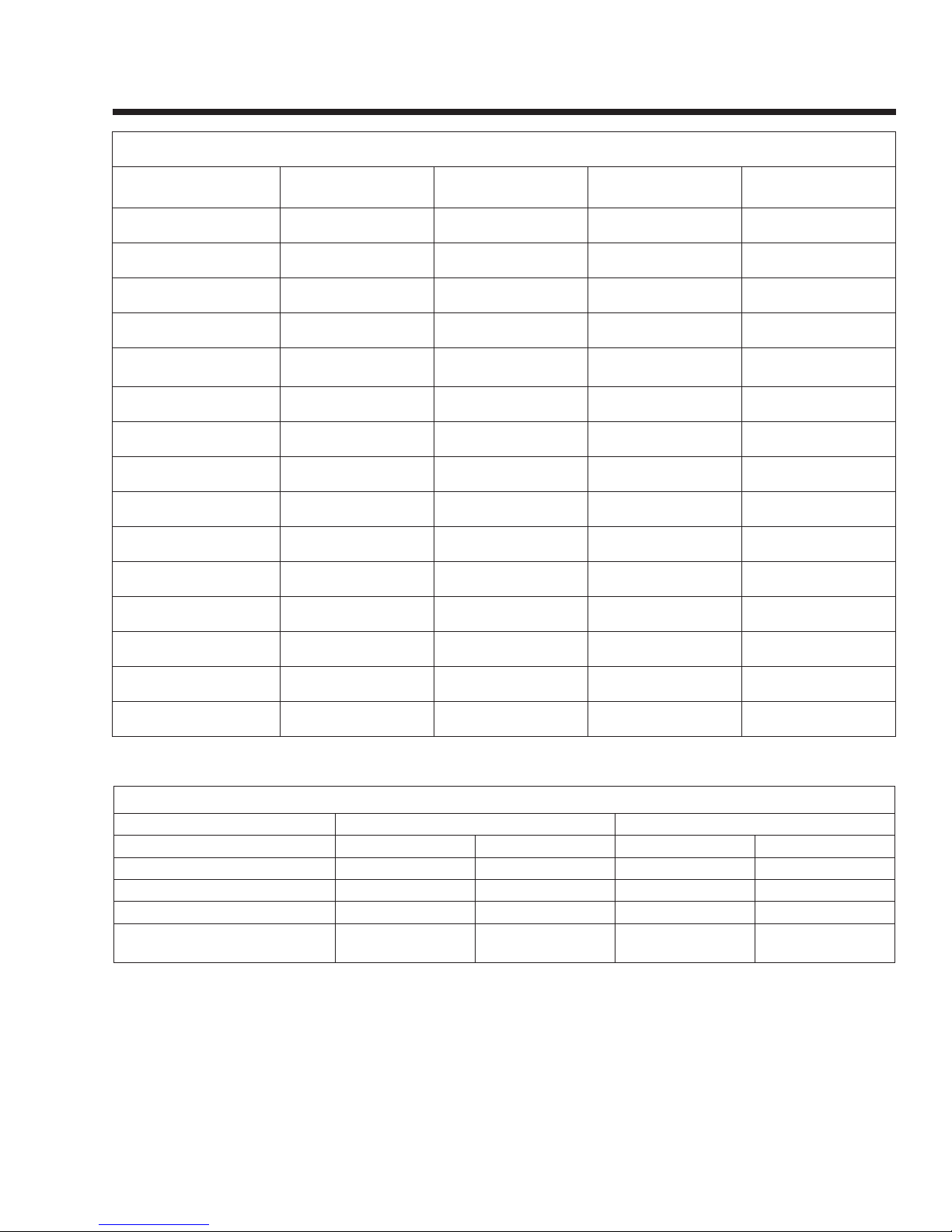

SPECIFICATIONS

MOUNTING DIMENSIONS

Page 6

MOUNTING DIMENSIONS

SPECIFICATIONS

Page 7

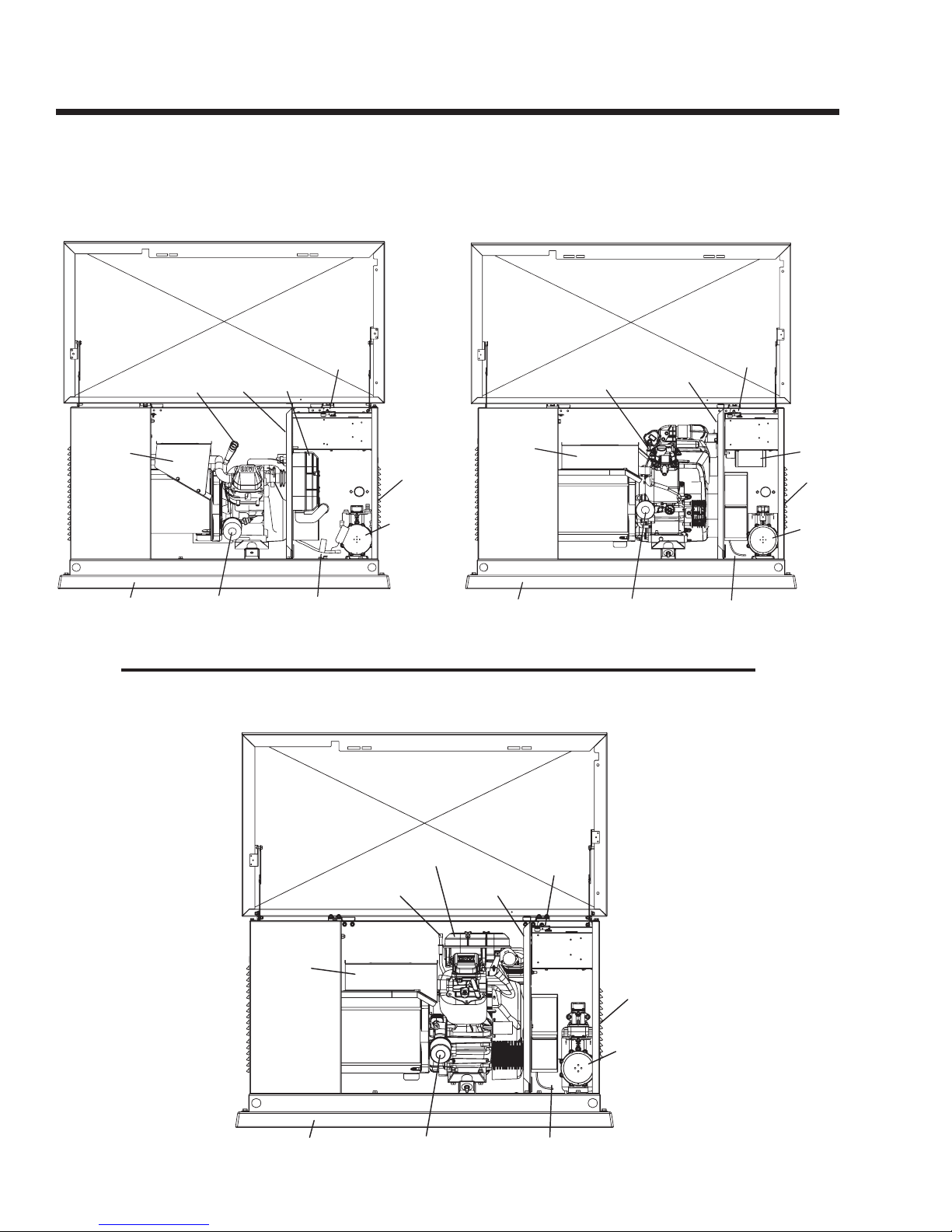

SPECIFICATIONS

MAJOR FEATURES

7 kW, Single Cylinder GH-410 Engine

Exhaust

Enclosure

Composite Base

Oil

Dipstick

Data

Decal

Air Filter

Cover

Battery CompartmentOil Filter

Control

Panel

Fuel

Inlet

(Back)

Fuel

Regulator

Exhaust

Enclosure

Composite Base

10 kW, V-twin GT-530 Engine

Control

Oil

Dipstick

Data

Decal

Battery CompartmentOil Filter

Panel

Air Filter

Fuel

Inlet

(Back)

Fuel

Regulator

13 kW and 16 kW, V-twin GT-990 Engine

Air Filter

Cover

Oil

Dipstick

Exhaust

Enclosure

Composite Base

Data

Decal

Control

Panel

Fuel

Inlet

(Back)

Fuel

Regulator

Battery CompartmentOil Filter

Page 8

PART 1

GENERAL

INFORMATION

Air-cooled, Prepackaged

Automatic Standby Generators

TABLE OF CONTENTS

PART TITLE PAGE

1.1 Generator Identification 10

1.2 Prepackaged Installation

Basics

1.3 Preparation Before Use 14

1.4 Testing, Cleaning and Drying 16

1.5 Engine-Generator Protective

Devices

1.6 Operating Instructions 25

1.7 Automatic Operating

Parameters

11

23

28

1.1 Generator Identification

1.2 Prepackaged Installation Basics ..................... 11

Introduction ......................................................11

Selecting A Location ........................................11

Grounding The Generator ................................11

The Fuel Supply ...............................................11

The Transfer Switch / Load Center ...................11

Power Source And Load Lines .........................13

System Control Interconnections .....................13

1.3 Preparation Before Use ................................... 14

General ............................................................14

Fuel Requirements...........................................14

Fuel Consumption ............................................14

Reconfiguring The Fuel System .......................14

Engine Oil Recommendations .........................16

1.4 Testing, Cleaning and Drying........................... 16

Meters ............................................................17

The VOM ..........................................................17

Measuring AC Voltage .....................................17

Measuring DC Voltage .....................................17

Measuring AC Frequency ................................17

Measuring Current ...........................................18

Measuring Resistance .....................................18

Electrical Units .................................................19

Ohm's Law .......................................................19

................................... 10

Visual Inspection ..............................................20

Insulation Resistance .......................................20

The Megohmmeter...........................................20

Stator Insulation Resistance Test .....................21

Rotor Insulation Resistance Test ......................22

Cleaning The Generator...................................22

Drying The Generator ......................................22

1.5 Engine-Generator Protective Devices ............. 23

General ............................................................23

Low Battery ......................................................23

Low Oil Pressure Shutdown .............................23

High Temperature Switch .................................23

Overspeed Shutdown ......................................23

RPM Sensor Failure .........................................23

Overcrank Shutdown .......................................24

1.6 Operating Instructions ..................................... 25

Control Panel ...................................................25

To Select Automatic Operation ........................26

Manual Transfer To “Standby” And

Manual Startup ....................................26

Manual Shutdown And Retransfer

Back To “Utility” ....................................27

1.7 Automatic Operating Parameters .................... 28

Introduction ......................................................28

Automatic Operating Sequences .....................28

Page 9

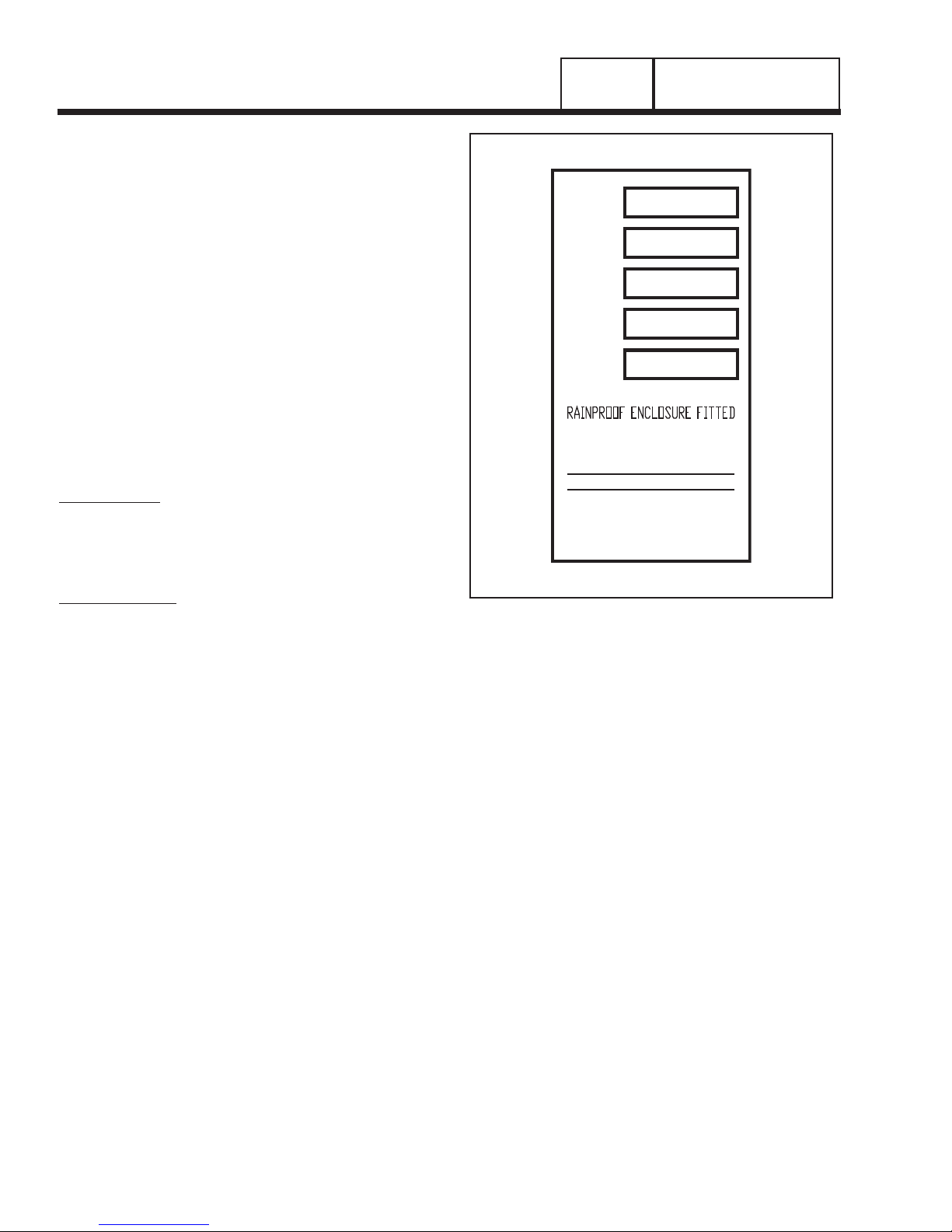

SECTION 1.1

GENERATOR IDENTIFICATION

INTRODUCTION

This Diagnostic Repair Manual has been prepared

especially for the purpose of familiarizing service personnel with the testing, troubleshooting and repair of

air-cooled, prepackaged automatic standby generators. Every effort has been expended to ensure that

information and instructions in the manual are both

accurate and current. However, Generac reserves the

right to change, alter or otherwise improve the product

at any time without prior notification.

The manual has been divided into seven PARTS.

Each PART has been divided into SECTIONS. Each

SECTION consists of two or more SUBSECTIONS.

It is not our intent to provide detailed disassembly and

reassemble instructions in this manual. It is our intent

to (a) provide the service technician with an under

standing of how the various assemblies and systems

work, (b) assist the technician in finding the cause of

malfunctions, and (c) effect the expeditious repair of

the equipment.

ITEM NUMBER:

Many home standby generators are manufactured

to the unique specifications of the buyer. The Model

Number identifies the specific generator set and its

unique design specifications.

PART 1

Item #

Serial

Volts

Amps

Watts

-

1 PH, 60 HZ, RPM 3600

MAX OPERATING AMBIENT

FOR STANDBY SERVICE

0055555

1234567

120/240 AC

108.3/108.3

13000

CLASS F INSULATION

TEMP - 120F/49C

GENERAL INFORMATION

NEUTRAL FLOATING

MAX LOAD UNBALANCED - 50%

GENERAC POWER SYSTEMS

WAUKESHA, WI

MADE IN U.S.A.

SERIAL NUMBER:

Used for warranty tracking purposes.

Figure 1. A Typical Data Plate

Page 10

GENERAL INFORMATION

PART 1

SECTION 1.2

PREPACKAGED INSTALLATION BASICS

INTRODUCTION

Information in this section is provided so that the service technician will have a basic knowledge of installation requirements for prepackaged home standby

systems. Problems that arise are often related to poor

or unauthorized installation practices.

A typical prepackaged home standby electric system

is shown in Figure 1 (next page). Installation of such a

system includes the following:

• Selecting a Location

• Grounding the generator.

• Providing a fuel supply.

• Mounting the load center.

• Connecting power source and load lines.

• Connecting system control wiring.

• Post installation tests and adjustments.

SELECTING A LOCATION

Install the generator set as close as possible to the

electrical load distribution panel(s) that will be powered by the unit, ensuring that there is proper ventilation for cooling air and exhaust gases. This will reduce

wiring and conduit lengths. Wiring and conduit not

only add to the cost of the installation, but excessively

long wiring runs can result in a voltage drop.

Control system interconnections non-prepackaged

generator consist of N1 and N2, and leads 23 and

194. Control system interconnection leads must be

run in a conduit that is separate from the AC power

leads. Recommended wire gauge size depends on

the length of the wire:

Max. Cable Length Recommended Wire Size

460 feet (140m) No. 18 AWG.

461 to 730 feet (223m) No. 16 AWG.

731 to 1,160 feet (354m) No. 14 AWG.

1,161 to 1850 feet (565m) No. 12 AWG.

GROUNDING THE GENERATOR

The National Electric Code requires that the frame

and external electrically conductive parts of the generator be property connected to an approved earth

ground. Local electrical codes may also require proper grounding of the unit. For that purpose, a grounding lug is attached to the unit. Grounding may be

accomplished by attaching a stranded copper wire of

the proper size to the generator grounding lug and to

an earth-driven copper or brass grounding-rod (electrode). Consult with a local electrician for grounding

requirements in your area.

THE FUEL SUPPLY

Prepackaged units with air-cooled engines were operated, tested and adjusted at the factory using natural

gas as a fuel. These air-cooled engine units can be

converted to use LP (propane) gas by making a few

adjustments for best operation and power.

LP (propane) gas is usually supplied as a liquid in

pressure tanks. Both the air-cooled and the liquid

cooled units require a “vapor withdrawal” type of fuel

supply system when LP (propane) gas is used. The

vapor withdrawal system utilizes the gaseous fuel

vapors that form at the top of the supply tank.

The pressure at which LP gas is delivered to the

generator fuel solenoid valve may vary considerably,

depending on ambient temperatures. In cold weather,

supply pressures may drop to “zero”. In warm weath

er, extremely high gas pressures may be encountered.

A primary regulator is required to maintain correct gas

supply pressures.

Current recommended gaseous fuel pressure at the inlet

side of the generator fuel solenoid valve is as follows:

LP NG

Minimum water column 10 inches 5 inches

Maximum water column 12 inches 7 inches

A primary regulator is required to ensure that proper

fuel supply pressures are maintained.

DANGER: LP AND NATURAL GAS ARE BOTH

Use of a flexible length of hose between the generator fuel line connection and rigid fuel lines is required.

This will help prevent line breakage that might be

caused by vibration or if the generator shifts or settles.

The flexible fuel line must be approved for use with

gaseous fuels.

Flexible fuel line should be kept as straight as possi

ble between connections. The bend radius for flexible

fuel line is nine (9) inches. Exceeding the bend radius

can cause the fittings to crack.

HIGHLY EXPLOSIVE. GASEOUS FUEL LINES

MUST BE PROPERLY PURGED AND TESTED

FOR LEAKS BEFORE THIS EQUIPMENT IS

PLACED INTO SERVICE AND PERIODICALLY

THEREAFTER. PROCEDURES USED IN

GASEOUS FUEL LEAKAGETESTS MUST

COMPLY STRICTLY WITH APPLICABLE FUEL

GAS CODES. DO NOT USE FLAME OR ANY

SOURCE OF HEAT TO TEST FOR GAS LEAKS.

NO GAS LEAKAGE IS PERMITTED. LP GAS IS

HEAVIER THAN AIR AND TENDS TO SETTLE IN

LOW AREAS. NATURAL GAS IS LIGHTER THAN

AIR AND TENDS TO SETTLE IN HIGH PLACES.

EVEN THE SLIGHTEST SPARK CAN IGNITE

THESE FUELS AND CAUSE AN EXPLOSION.

THE TRANSFER SWITCH / LOAD CENTER

A transfer switch is required by electrical code, to prevent electrical feedback between the utility and standby power sources, and to transfer electrical loads from

one power supply to another safely.

PREPACKAGED TRANSFER SWITCHES:

Instructions and information on prepackaged transfer

switches may be found in Part 3 of this manual.

Page 11

-

-

SECTION 1.2

PREPACKAGED INSTALLATION BASICS

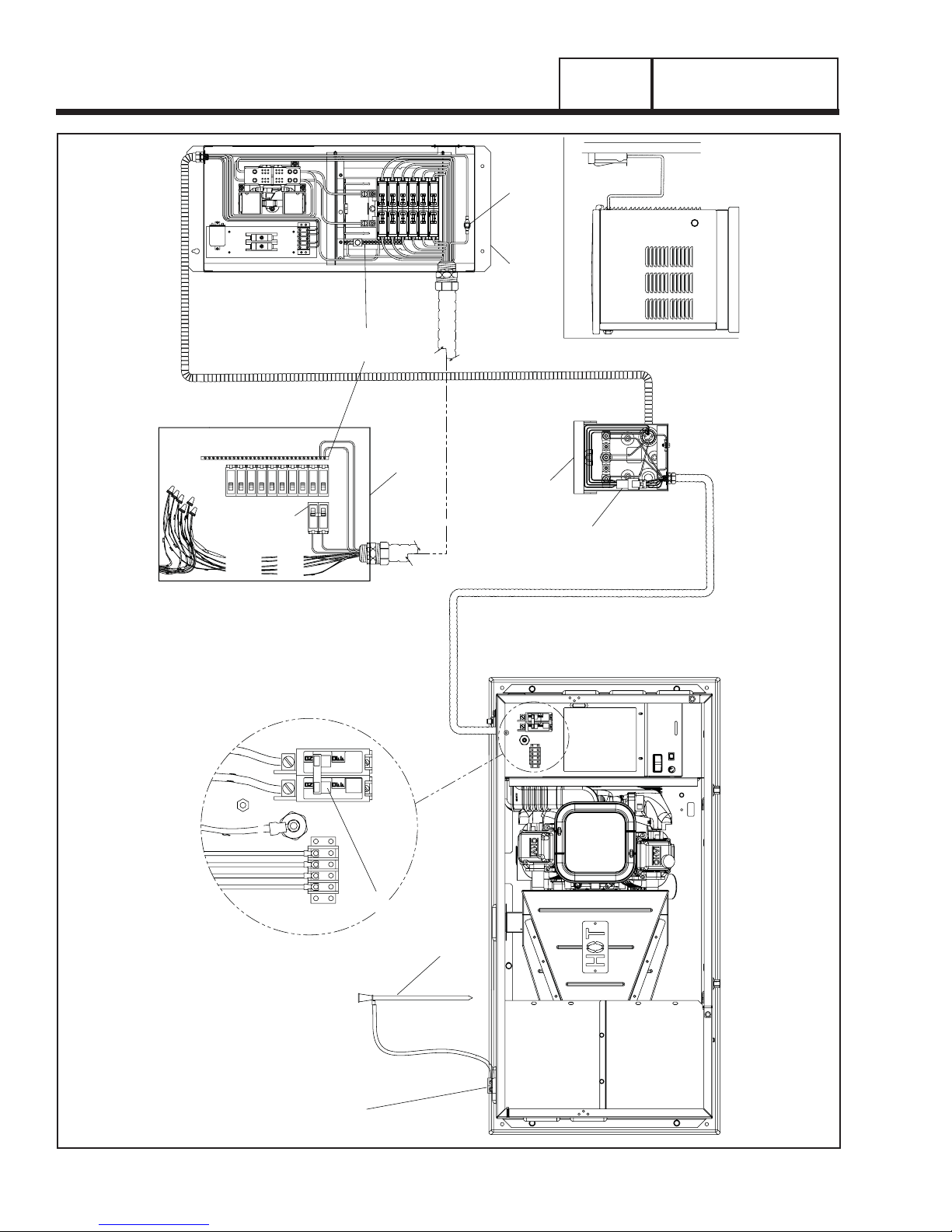

BAR

NEUTRAL

100A OR 200A

HOUSE MAIN

SERVICE

GROUND

PANEL BOARD

TRANSFER SWITCH)

GENERAC UL LISTED

(8, 10, 12 OR 16 CIRCUIT

PART 1

CONNECTION OF GENERATOR

TO EXTERNAL CONNECTION PANEL

GENERAL INFORMATION

TO HOUSE BRANCH

CIRCUITS SPLICED

USING WIRE NUTS

GROUND

CIRCUITS

EMERGENCY

STUD

NEUTRAL

40A OR 70A 2-POLE

CIRCUIT BREAKER

194N1 N2 23

2 POLE

EARTH

GENERATOR OUTPUT CIRCUIT BREAKER

SPIKE

CONNECTION BOX

4 PIN

EXTERNAL CUSTOMER

CONNECTOR

Page 12

Figure 1. Typical Prepackaged Installation

GENERATOR GROUND

(LOCATED ON THE REAR OF UNIT)

GENERAL INFORMATION

PART 1

SECTION 1.2

PREPACKAGED INSTALLATION BASICS

POWER SOURCE AND LOAD LINES

The utility power supply lines, the standby (generator) supply lines, and electrical load lines must all be

connected to the proper terminal lugs in the transfer

switch. The following rules apply: In 1-phase systems

with a 2-pole transfer switch, connect the two utility

source hot lines to Transfer Switch Terminal Lugs N1

and N2. Connect the standby source hot lines (E1,

E2) to Transfer Switch Terminal Lugs E1 and E2.

Connect the load lines from Transfer Switch Terminal

Lugs T1 and T2 to the electrical load circuit. Connect

UTILITY, STANDBY and LOAD neutral lines to the

neutral block in the transfer switch.

SYSTEM CONTROL INTERCONNECTIONS

Prepackaged home standby generators are equipped

with a terminal board identified with the following terminals: (a) UTILITY 1, (b) UTILITY 2, (c) 23, and (d)

194. Prepackaged load centers house an identically

marked terminal board. When these four terminals

are properly interconnected, dropout of utility source

voltage below a preset value will result in automatic

generator startup and transfer of electrical loads to

the “Standby” source. On restoration of utility source

voltage above a preset value will result in retransfer

back to that source and generator shutdown.

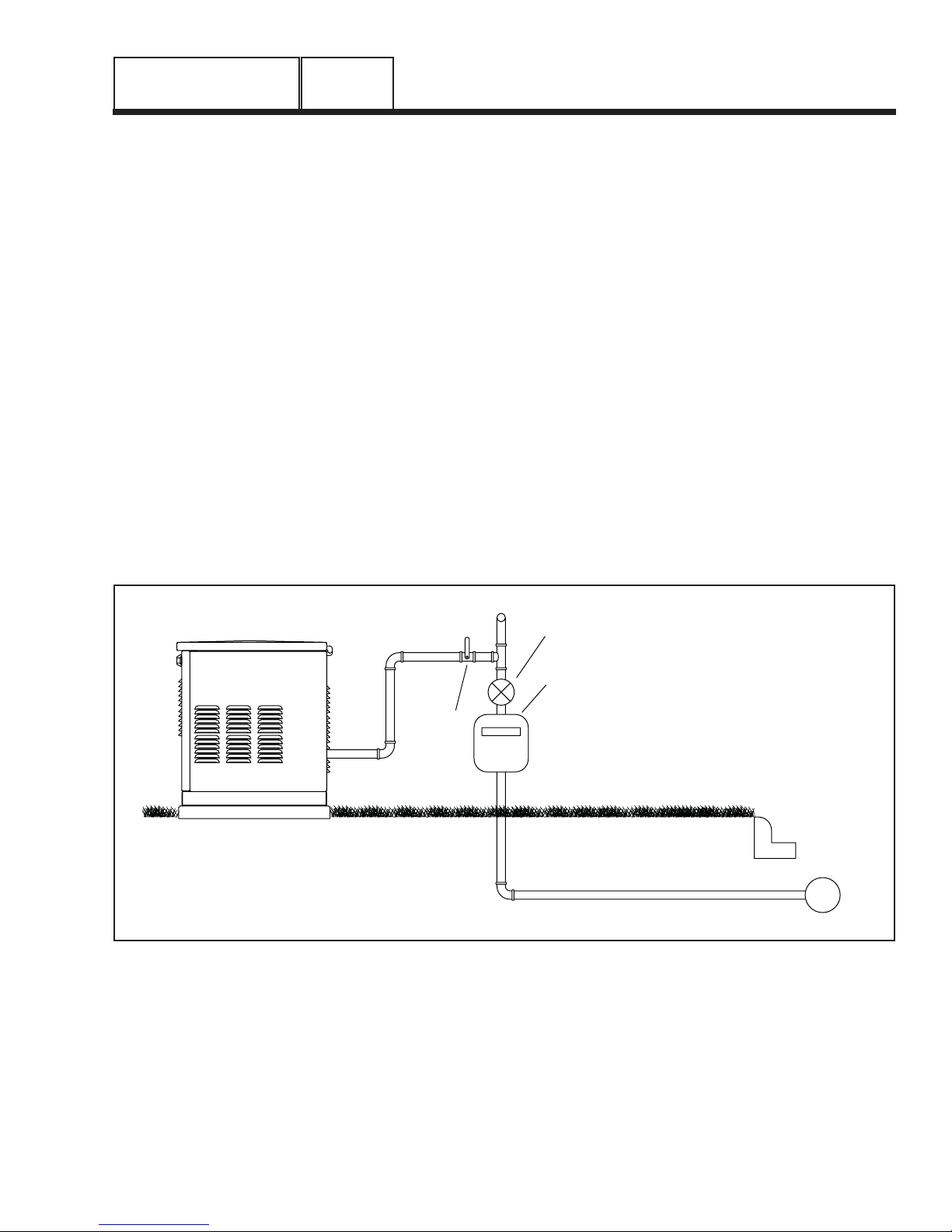

5-7" WC REGULATOR

TO HOUSEHOLD

GAS METER CAPABLE

OF PROVIDING FUEL

SAFETY

SHUT OFF

VALV E

0000001

Figure 2. Proper Fuel Installation

FLOW OF:

119,000 (6/7KW)

156,000 (9/10KW)

220,000 (13kW)

245,000 (15/16KW)

+HOUSEHOLD APPLIANCES

(BASED ON 1000 BTU/CU FT)

BTU/HOUR

}

GAS MAIN

2-5 PSI

Page 13

SECTION 1.3

PREPARATION BEFORE USE

PART 1

GENERAL INFORMATION

GENERAL

The installer must ensure that the home standby generator has been properly installed. The system must

be inspected carefully following installation. All applicable codes, standards and regulations pertaining to

such installations must be strictly complied with. In

addition, regulations established by the Occupational

Safety and Health Administration (OSHA) must be

complied with.

Prior to initial startup of the unit, the installer must

ensure that the engine-generator has been properly

prepared for use. This includes the following:

• An adequate supply of the correct fuel must be

available for generator operation.

• The engine must be properly serviced with the rec

ommended oil.

FUEL REQUIREMENTS

With LP gas, use only the vapor withdrawal system.

This type of system uses the vapors formed above

the liquid fuel in the storage tank.

The engine has been fitted with a fuel carburetion

system that meets the specifications of the 1997

California Air Resources Board for tamper-proof dual

fuel systems. The unit will run on natural gas or LP

gas, but it has been factory set to run on natural gas.

Should the primary fuel need to be changed to LP

gas, the fuel system needs to be reconfigured. See

the Reconfiguring the Fuel System section for instruc

tions on reconfiguration of the fuel system.

Recommended fuels should have a Btu content of

at least 1,000 Btus per cubic foot for natural gas; or

at least 2,520 Btus per cubic foot for LP gas. Ask the

fuel supplier for the Btu content of the fuel.

Required fuel pressure for natural gas is 5 inches to

7 inches water column (0.18 to 0.25 psi); and for liq

uid propane, 10 inches to 12 inches of water column

(0.36 to 0.43 psi).

NOTE: All pipe sizing, construction and layout

must comply with NFPA 54 for natural gas applica

tions and NFPA 58 for liquid propane applications.

Once the generator is installed, verify that the

fuel pressure NEVER drops below four (4) inches

water column for natural gas or 10 inches water

column for liquid propane.

Prior to installation of the generator, the installer

should consult local fuel suppliers or the fire marshal

to check codes and regulations for proper installation.

Local codes will mandate correct routing of gaseous

fuel line piping around gardens, shrubs and other

landscaping to prevent any damage.

Special considerations should be given when install

ing the unit where local conditions include flooding, tornados, hurricanes, earthquakes and unstable

ground for the flexibility and strength of piping and

their connections.

Use an approved pipe sealant or joint compound on

all threaded fitting.

All installed gaseous fuel piping must be purged and

leak tested prior to initial start-up in accordance with

local codes, standards and regulations.

FUEL CONSUMPTION

The fuel consumption rates are listed in the

SPECIFICATIONS section at the front of this manual.

BTU FLOW REQUIREMENTS - NATURAL GAS:

BTU flow required for each unit based on 1000 BTU

per cubic foot.

6/7 kW — 119,000 BTU/Hour

9/10 kW — 156,000 BTU/Hour

-

13 kW — 220,000 BTU/Hour

15/16 kW — 245,000 BTU/Hour

DANGER

Gaseous fuels such as natural gas and liquid

propane (LP) gas are highly explosive. Even

the slightest spark can ignite such fuels and

cause an explosion. No leakage of fuel is permitted. Natural gas, which is lighter than air,

tends to collect in high areas. LP gas is heavi-

-

-

-

-

er than air and tends to settle in low areas.

NOTE: A minimum of one approved manual shutoff valve must be installed in the gaseous fuel

supply line. The valve must be easily accessible.

Local codes determine the proper location.

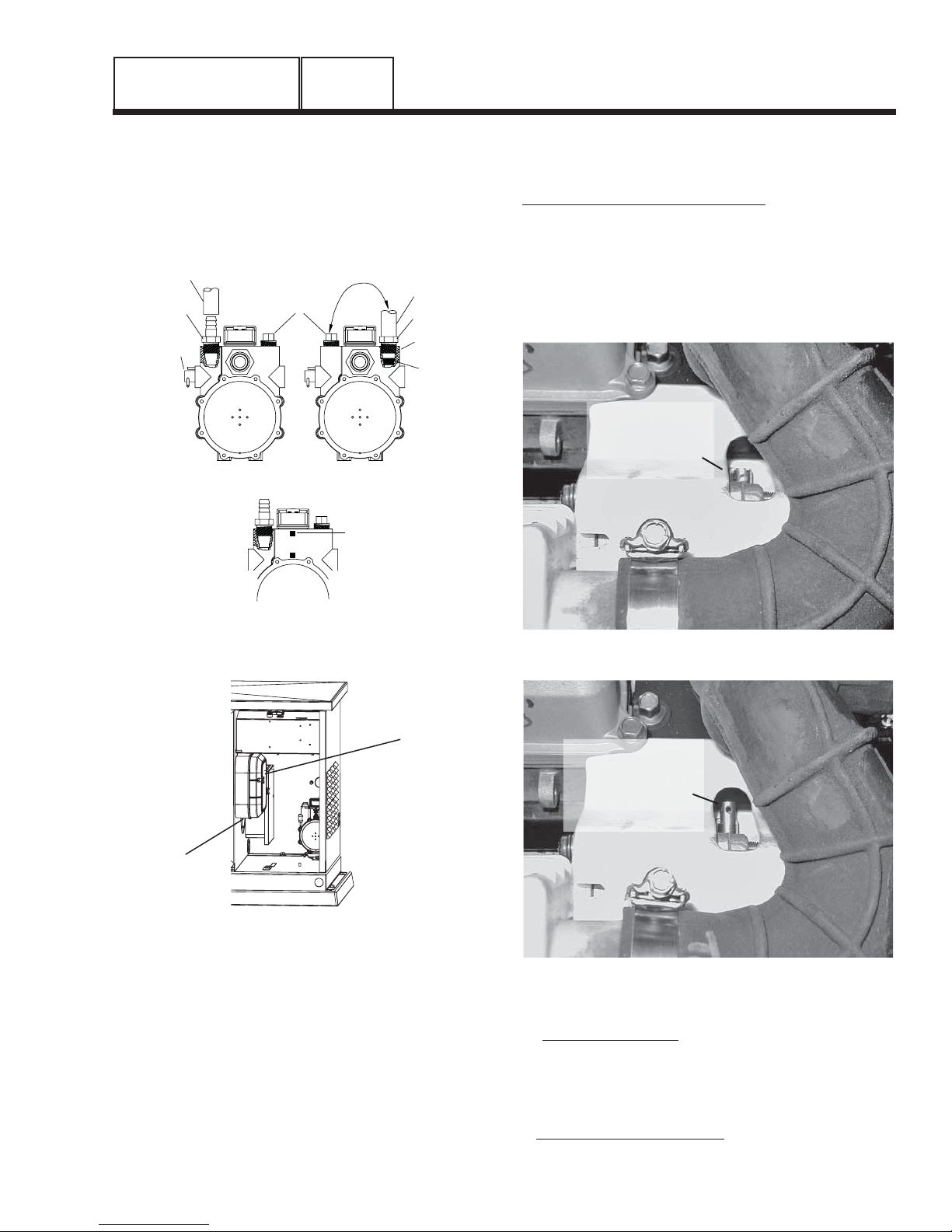

RECONFIGURING THE FUEL SYSTEM

7 KW, 410CC ENGINE:

To reconfigure the fuel system from NG to LP, follow

these steps (Figure 1):

NOTE: The primary regulator for the propane sup

ply is NOT INCLUDED with the generator. A fuel

pressure of 10 to 12 inches of water column (0.36

to 0.43 psi) to the fuel inlet of the generator must

be supplied.

1. Turn off the main gas supply (if connected).

2. Open the roof and remove the door.

3. Remove the battery (if installed).

4. Disconnect Wire 0 and Wire 14 from the gas solenoid on

top of the demand regulator.

5. Remove the carburetor fuel hose from the outlet port of

the demand regulator.

6. Remove the demand regulator by removing the fastener

that retains the regulator mounting bracket.

-

Page 14

GENERAL INFORMATION

FUEL SELECTION

LEVER -

“IN” POSITION FOR

NATURAL GAS

FUEL SELECTION

LEVER -

“OUT” POSITION FOR

LIQUID PROPANE

(VAPOR) FUEL

PART 1

SECTION 1.3

PREPARATION BEFORE USE

7. Remove the square headed steel pipe plug from outlet port #1 and the brass hose barb fitting from outlet

port #2.

8. Refit the brass hose barb fitting to outlet port #1 and the

square headed steel pipe plug to outlet port #2.

PIPE

HOSE & PLUG

SWITCHED SIDES

LP FUEL SYSTEM

PRESSURE

TAP

FUEL HOSE

BRASS HOSE

FITTING

OUTLET

PORT

FUEL JET

FUEL HOSE

BRASS HOSE

FITTING

ADJUSTMENT

SCREW

PLUG

NG FUEL SYSTEM

12.Check for gas leakage at the pipe plug, hose connection

and fittings.

10, 13 AND 16 KW, V-TWIN ENGINES:

To reconfigure the fuel system from NG to LP, follow

these steps:

NOTE: The primary regulator for the propane sup

ply is NOT INCLUDED with the generator. A fuel

pressure of 10 to 12 inches of water column (0.36

to 0.43 psi) to the fuel inlet of the generator must

be supplied.

-

3/4” HOLE

NOTE: Use an approved pipe sealant or joint com

pound on all threaded fittings to reduce the possibility of leakage.

9. Reverse procedure Steps 1-6 to reinstall demand

regulator.

10.Take the plastic plug supplied in the poly-bag with the

generator and press it into the 3/4” hole on the bottom

of the air cleaner base (Figure 2).

11.Reverse the procedure to convert back to natural gas.

Figure 1. Demand Regulator

Figure 2. Demand Regulator

AIR

CLEANER

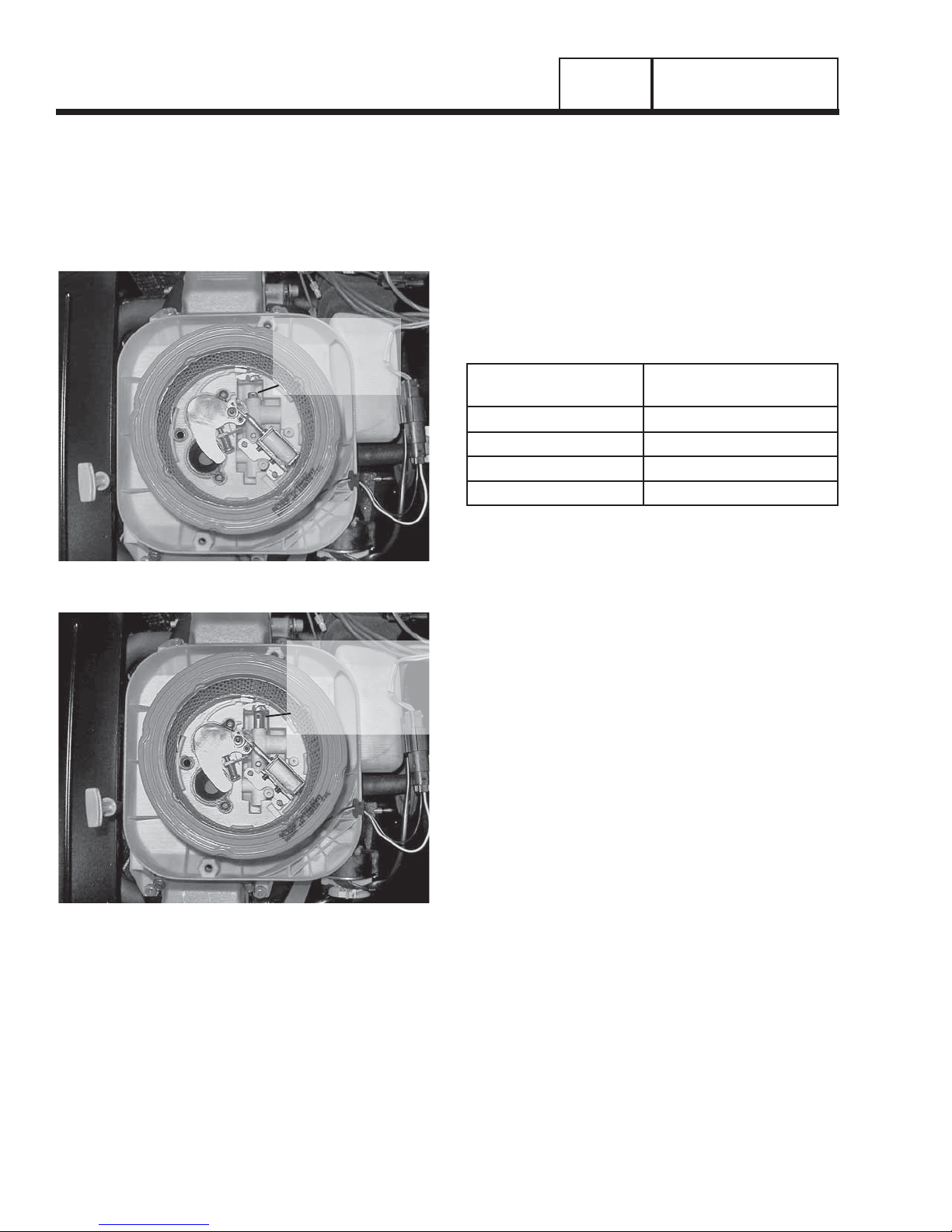

Figure 3. 10 kW, GT-530 (Inlet Hose Slid Back)

-

Figure 4. 10 kW, GT-530 (Inlet Hose Slid Back)

1. Open the roof.

2. For 10 kW units: Loosen clamp and slide back the

air inlet hose.

• Slide fuel selector on carburetor out towards the

back of the enclosure (Figures 3 and 4).

• Return the inlet hose and tighten clamp securely.

For 13 and 16 kW units: remove the air cleaner

cover.

Page 15

SECTION 1.3

PREPARATION BEFORE USE

PART 1

GENERAL INFORMATION

• Slide the selector lever out towards the back of the

enclosure (Figures 5 and 6).

• Return the air cleaner cover and tighten the two

thumb screws.

3. Close the roof.

4. Reverse the procedure to convert back to natural gas.

FUEL SELECTION

LEVER -

“IN” POSITION FOR

NATURAL GAS

Figure 5. 13/16 kW, GT-990 (Airbox Cover Removed)

ENGINE OIL RECOMMENDATIONS

The primary recommended oil for units with aircooled, single cylinder or V-Twin engines is synthetic

oil. Synthetic oil provides easier starts in cold weather

and maximum engine protection in hot weather. Use

high quality detergent oil that meets or exceeds API

(American Petroleum Institute) Service class SG, SH,

or SJ requirements for gasoline engines. The following chart lists recommended viscosity ranges for the

lowest anticipated ambient temperatures.

Engine crankcase oil capacities for the engines cov

ered in this manual can be found in the specifications

section at the beginning of the book.

Lowest Anticipated

Ambient Temperature

Above 60° F (16° C) Use SAE 30 oil

20° to 59° F (-7° to 15° C) Use SAE 10W-30 oil

Below 20° F (-7° C) SAE 5W-20/5W-30

For all seasons Use SAE 5W-30 Synthetic oil

Oil Grade (Recommended)

-

FUEL SELECTION

LEVER -

“OUT” POSITION FOR

LIQUID PROPANE

(VAPOR) FUEL

Figure 6. 13/16 kW, GT-990 (Airbox Cover Removed)

Page 16

GENERAL INFORMATION

PART 1

SECTION 1.4

TESTING, CLEANING AND DRYING

METERS

Devices used to measure electrical properties are

called meters. Meters are available that allow one

to measure (a) AC voltage, (b) DC voltage, (c) AC

frequency, and (d) resistance In ohms. The following

apply:

• To measure AC voltage, use an AC voltmeter.

• To measure DC voltage, use a DC voltmeter.

• Use a frequency meter to measure AC frequency In

“Hertz” or “cycles per second”.

• Use an ohmmeter to read circuit resistance, in

“ohms”.

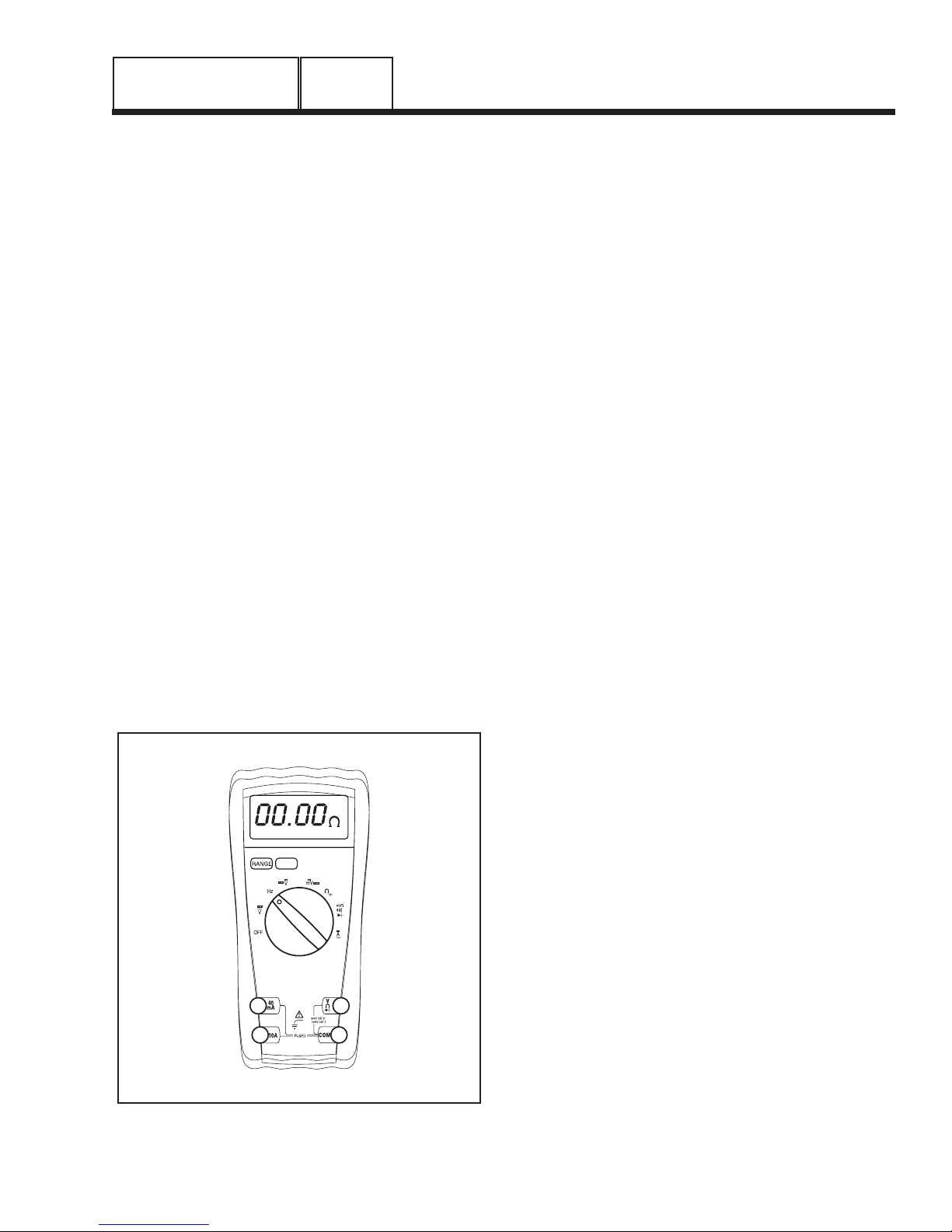

THE VOM

A meter that will permit both voltage and resistance to

be read is the “volt-ohm-milliammeter” or “VOM”.

Some VOMs are of the “analog” type (not shown).

These meters display the value being measured by

physically deflecting a needle across a graduated

scale. The scale used must be Interpreted by the user.

“Digital” VOM's (Figure 1) are also available and are

generally very accurate. Digital meters display the

measured values directly by converting the values to

numbers.

NOTE: Standard AC voltmeters react to the

AVERAGE value of alternating current. When

working with AC, the effective value is used. For

that reason a different scale is used on an AC

voltmeter. The scale is marked with the effective

or “rms” value even though the meter actually

reacts to the average value. That is why the AC

voltmeter will give an Incorrect reading if used to

measure direct current (DC).

MEASURING AC VOLTAGE

An accurate AC voltmeter or a VOM may be used to

read the generator's AC output voltage. The following

apply:

1. Always read the generator's AC output voltage only at

the unit's rated operating speed and AC frequency.

2. The generator's Voltage Regulator can be adjusted for

correct output voltage only while the unit is operating at

its correct rated speed and frequency.

3. Only an AC voltmeter may be used to measure AC

voltage. DO NOT USE A DC VOLTMETER FOR THIS

PURPOSE.

DANGER!: GENERATORS PRODUCE HIGH

AND DANGEROUS VOLTAGES. CONTACT

WITH HIGH VOLTAGE TERMINALS WILL

RESULT IN DANGEROUS AND POSSIBLY

LETHAL ELECTRICAL SHOCK.

MEASURING DC VOLTAGE

A DC voltmeter or a VOM may be used to measure

DC voltages. Always observe the following rules:

1. Always observe correct DC polarity.

a. Some VOM's may be equipped with a polar-

ity switch.

b. On meters that do not have a polarity switch,

DC polarity must be reversed by reversing

the test leads.

2. Before reading a DC voltage, always set the meter to a

higher voltage scale than the anticipated reading. If in

doubt, start at the highest scale and adjust the scale

downward until correct readings are obtained.

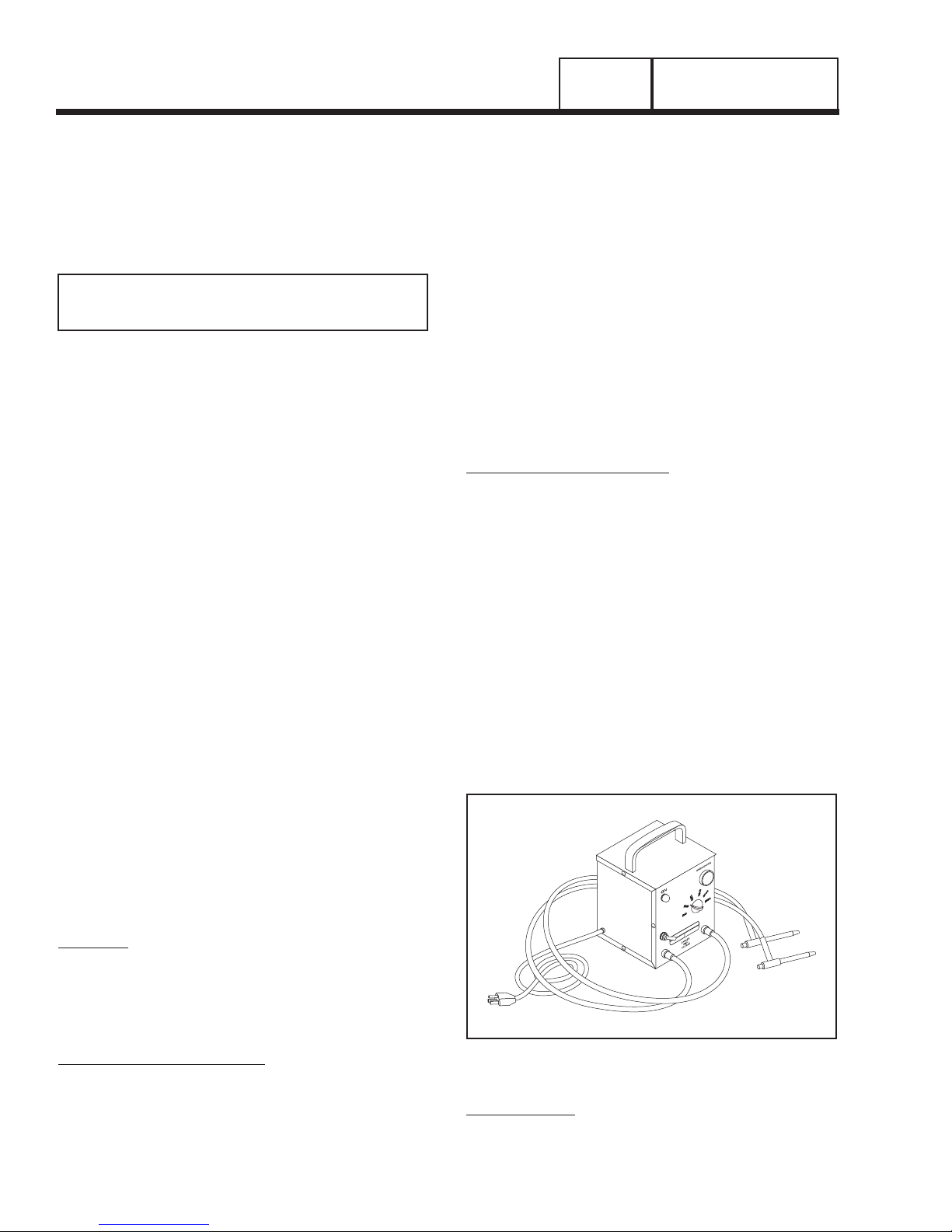

Figure 1. Digital VOM

3. The design of some meters is based on the “current

flow” theory while others are based on the “electron

flow” theory.

a. The “current flow” theory assumes that

direct current flows from the positive (+) to

the negative (-).

b. The “electron flow” theory assumes that cur-

rent flows from negative (-) to positive (+).

NOTE: When testing generators, the “current flow”

theory is applied. That is, current is assumed to

flow from positive (+) to negative (-).

MEASURING AC FREQUENCY

The generator's AC output frequency is proportional

to Rotor speed. Generators equipped with a 2-pole

Rotor must operate at 3600 rpm to supply a frequency

of 60 Hertz. Units with 4-pole Rotor must run at 1800

rpm to deliver 60 Hertz.

Page 17

SECTION 1.4

TESTING, CLEANING AND DRYING

PART 1

GENERAL INFORMATION

Correct engine and Rotor speed is maintained by an

engine speed governor. For models rated 60 Hertz,

the governor is generally set to maintain a no-load frequency of about 62 Hertz with a corresponding output

voltage of about 124 volts AC line-to-neutral. Engine

speed and frequency at no-load are set slightly high

to prevent excessive rpm and frequency droop under

heavy electrical loading.

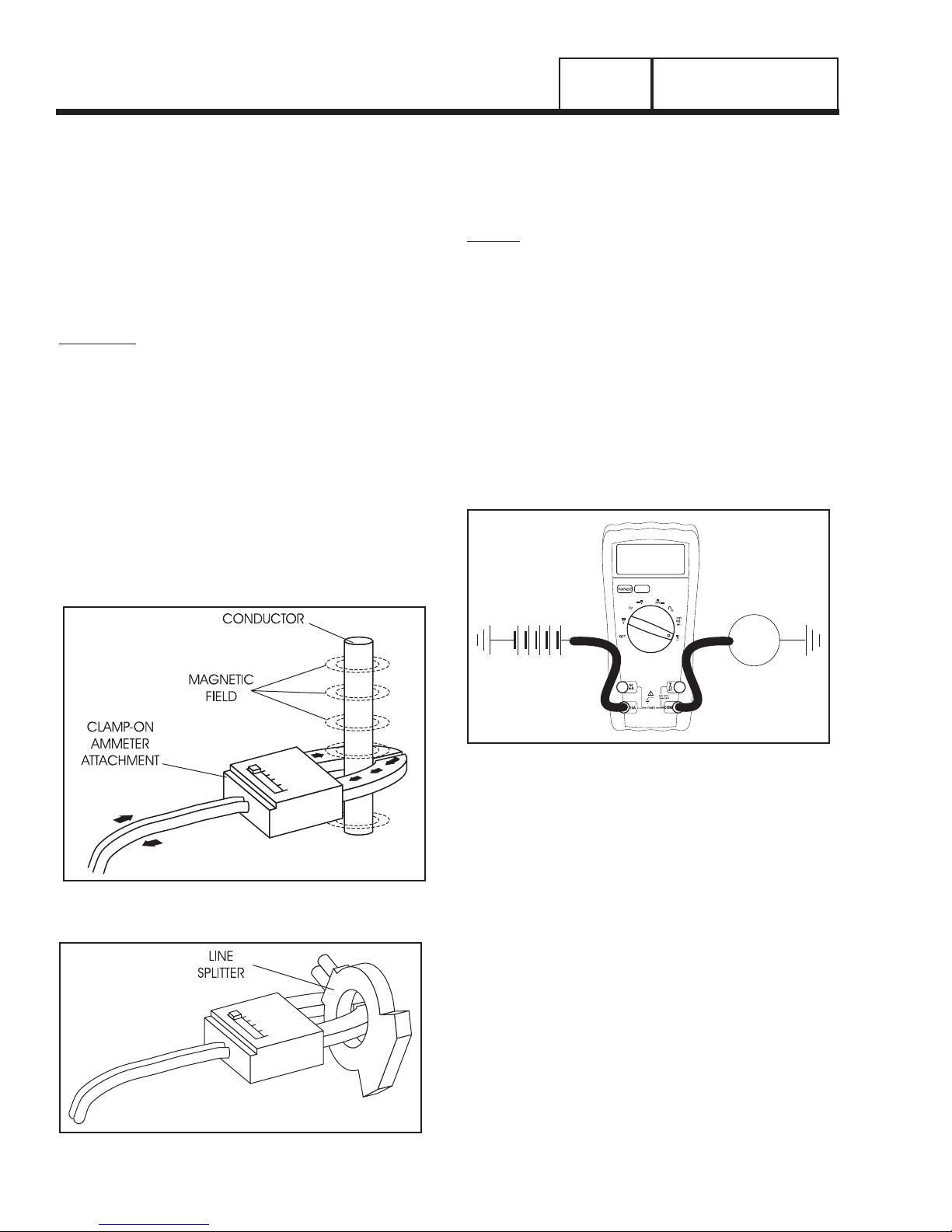

MEASURING CURRENT

CLAMP-ON:

To read the current flow, in AMPERES, a clamp-on

ammeter may be used. This type of meter indicates

current flow through a conductor by measuring the

strength of the magnetic field around that conductor.

The meter consists essentially of a current transformer with a split core and a rectifier type instrument

connected to the secondary. The primary of the current transformer is the conductor through which the

current to be measured flows. The split core allows

the Instrument to be clamped around the conductor

without disconnecting it.

Current flowing through a conductor may be mea

sured safely and easily. A line-splitter can be used

to measure current in a cord without separating the

conductors.

NOTE: If the physical size of the conductor or

ammeter capacity does not permit all lines to be

measured simultaneously, measure current flow

in each individual line. Then, add the Individual

readings.

IN-LINE:

Alternatively, to read the current flow in AMPERES,

an in-line ammeter may be used. Most Digital Volt

Ohm Meters (VOM) will have the capability to measure amperes.

This usually requires the positive meter test lead to be

connected to the correct amperes plug, and the meter

to be set to the amperes position. Once the meter is

properly set up to measure amperes the circuit being

measured must be physically broken. The meter will

be in-line or in series with the component being mea

sured.

In Figure 4 the control wire to a relay has been

removed. The meter is used to connect and supply

voltage to the relay to energize it and measure the

amperes going to it.

-

1.00 A

-

Figure 2. Clamp-On Ammeter

BATTERY

+-

Figure 4. A VOM as an In-line meter

RELAY

MEASURING RESISTANCE

The volt-ohm-milliammeter may be used to measure

the resistance in a circuit. Resistance values can be

very valuable when testing coils or windings, such as

the Stator and Rotor windings.

When testing Stator windings, keep in mind that the

resistance of these windings is very low. Some meters

are not capable of reading such a low resistance and

will simply read CONTINUITY.

If proper procedures are used, the following condi

tions can be detected using a VOM:

• A “short-to-ground” condition in any Stator or Rotor

winding.

• Shorting together of any two parallel Stator wind

ings.

• Shorting together of any two isolated Stator wind

ings.

• An open condition in any Stator or Rotor winding.

-

-

-

Figure 3. A Line-Splitter

Page 18

GENERAL INFORMATION

PART 1

SECTION 1.4

TESTING, CLEANING AND DRYING

Component testing may require a specific resistance value or a test for INFINITY or CONTINUITY.

Infinity is an OPEN condition between two electrical

points, which would read as no resistance on a VOM.

Continuity is a closed condition between two electrical

points, which would be indicated as very low resistance or “ZERO” on a VOM.

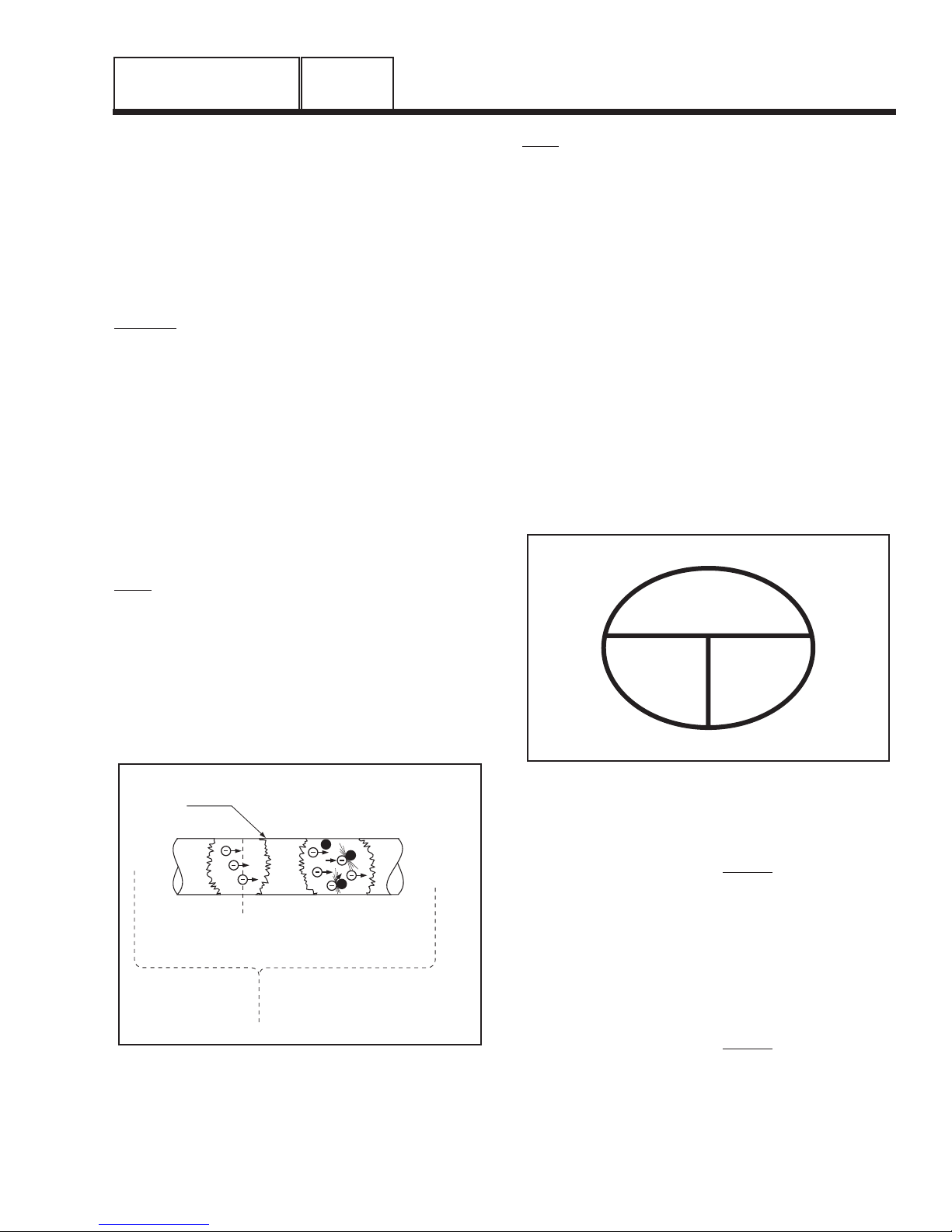

ELECTRICAL UNITS

AMPERE:

The rate of electron flow in a circuit is represented

by the AMPERE. The ampere is the number of electrons flowing past a given point at a given time. One

AMPERE is equal to just slightly more than six thousand million billion electrons per second.

With alternating current (AC), the electrons flow first

in one direction, then reverse and move in the oppo

site direction. They will repeat this cycle at regular

intervals. A wave diagram, called a “sine wave” shows

that current goes from zero to maximum positive

value, then reverses and goes from zero to maximum

negative value. Two reversals of current flow is called

a cycle. The number of cycles per second is called

frequency and is usually stated in “Hertz”.

VOLT:

The VOLT is the unit used to measure electrical

PRESSURE, or the difference in electrical potential

that causes electrons to flow. Very few electrons will

flow when voltage is weak. More electrons will flow as

voltage becomes stronger. VOLTAGE may be considered to be a state of unbalance and current flow as

an attempt to regain balance. One volt is the amount

of EMF that will cause a current of 1 ampere to flow

through 1 ohm of resistance.

OHM:

The OHM is the unit of RESISTANCE. In every circuit

there is a natural resistance or opposition to the flow

of electrons. When an EMF is applied to a complete

circuit, the electrons are forced to flow in a single

direction rather than their free or orbiting pattern. The

resistance of a conductor depends on (a) its physical

makeup, (b) its cross-sectional area, (c) its length,

and (d) its temperature. As the conductor's temperature increases, its resistance increases in direct proportion. One (1) ohm of resistance will permit one (1)

ampere of current to flow when one (1) volt of electromotive force (EMF) is applied.

OHM'S LAW

A definite and exact relationship exists between

VOLTS, OHMS and AMPERES. The value of one can

be calculated when the value of the other two are

-

known. Ohm's Law states that in any circuit the current

will increase when voltage increases but resistance

remains the same, and current will decrease when

resistance Increases and voltage remains the same.

VOLTS

(E)

AMPS

(I)

OHMS

(R)

Conductor of a

Circuit

OHM - Unit measuring resistance

-

AMPERE - Unit measuring rate of

Figure 5. Electrical Units

current flow (number of electrons

past a given point)

VOLT - Unit measuring force or

difference in potential

causing current flow

or opposition to flow

+

Figure 6. Ohm's Law

If AMPERES is unknown while VOLTS and OHMS are

known, use the following formula:

=

AMPERES

VOLTS

OHMS

VOLTS

Page 19

AMPERES =

If VOLTS is unknown while AMPERES and OHMS are

known, use the following formula:

VOLTS = AMPERES x OHMS

If OHMS is unknown but VOLTS and AMPERES are

known, use the following:

OHMS

SECTION 1.4

TESTING, CLEANING AND DRYING

PART 1

GENERAL INFORMATION

VISUAL INSPECTION

When it becomes necessary to test or troubleshoot a

generator, it is a good practice to complete a thorough

visual inspection. Remove the access covers and look

closely for any obvious problems. Look for the following:

• Burned or broken wires, broken wire connectors,

MINIMUM INSULATION

RESISTANCE =

(in “Megohms”)

damaged mounting brackets, etc.

• Loose or frayed wiring insulation, loose or dirty con

nections.

• Check that all wiring is well clear of rotating parts.

• Verify that the Generator properly connected for the

correct rated voltage. This is especially important on

new installations. See Section 1.2, “AC Connection

Systems”.

• Look for foreign objects, loose nuts, bolts and other

fasteners.

• Clean the area around the Generator. Clear away

paper, leaves, snow, and other objects that might

blow against the generator and obstruct its air

openings.

GENERATOR RATED VOLTS

__________________________

1000

+1

INSULATION RESISTANCE

Use a megger power setting of 500 volts. Connect

one megger test lead to the junction of all stator

leads, the other test lead to frame ground on the stator can. Read the number of megohms on the meter.

The MINIMUM acceptable megger reading for stators

may be calculated using the following formula:

EXAMPLE: Generator is rated at 120 volts AC.

Divide “120” by “1000” to obtain “0.12”. Then add

“1” to obtain “1.12” megohms. Minimum Insulation

resistance for a 120 VAC stator is 1.12 megohms.

If the stator insulation resistance is less than the cal

culated minimum resistance, clean and dry the stator.

Then, repeat the test. If resistance is still low, replace

the stator.

Use the Megger to test for shorts between isolated

windings as outlined “Stator Insulation Tests”.

Also test between parallel windings. See “Test

Between Windings” on next page.

TESTING ROTOR INSULATION:

Apply a voltage of 500 volts across the rotor posi-

tive (+) slip ring (nearest the rotor bearing), and

a clean frame ground (i.e. the rotor shaft). DO

NOT EXCEED 500 VOLTS AND DO NOT APPLY

VOLTAGE LONGER THAN 1 SECOND. FOLLOW

THE MEGGER MANUFACTURER’S INSTRUCTIONS

CAREFULLY.

ROTOR MINIMUM INSULATION RESISTANCE:

1.5 megohms

-

The insulation resistance of stator and rotor windings

is a measurement of the integrity of the insulating

materials that separate the electrical windings from

the generator steel core. This resistance can degrade

over time or due to such contaminants as dust, dirt,

oil, grease and especially moisture. In most cases,

failures of stator and rotor windings is due to a breakdown in the insulation. And, in many cases, a low insulation resistance is caused by moisture that collects

while the generator is shut down. When problems are

caused by moisture buildup on the windings, they can

usually be corrected by drying the windings. Cleaning

and drying the windings can usually eliminate dirt and

moisture built up in the generator windings.

THE MEGOHMMETER

GENERAL:

A megohmmeter, often called a “megger”, consists of

a meter calibrated in megohms and a power supply.

Use a power supply of 500 volts when testing stators

or rotors. DO NOT APPLY VOLTAGE LONGER THAN

ONE (1) SECOND.

TESTING STATOR INSULATION:

All parts that might be damaged by the high meg-

ger voltages must be disconnected before testing.

Isolate all stator leads (Figure 8) and connect all of

the stator leads together. FOLLOW THE MEGGER

MANUFACTURER’S INSTRUCTIONS CAREFULLY.

Page 20

CAUTION: Before attempting to measure

HI-POT TESTER:

A “Hi-Pot” tester is shown in Figure 7. The model

shown is only one of many that are commercially

available. The tester shown is equipped with a voltage

Insulation resistance, first disconnect and

Isolate all leads of the winding to be tested.

Electronic components, diodes, surge protectors, relays, voltage regulators, etc., can be

destroyed if subjected to high megger voltages.

Figure 7. One Type of Hi-Pot Tester

GENERAL INFORMATION

PART 1

SECTION 1.4

TESTING, CLEANING AND DRYING

selector switch that permits the power supply voltage

to be selected. It also mounts a breakdown lamp that

will illuminate to indicate an insulation breakdown during the test.

STATOR INSULATION RESISTANCE TEST

GENERAL:

Units with air-cooled engines are equipped with (a)

dual stator AC power windings, (b) an excitation

or DPE winding, and (c) a battery charge winding.

Insulation tests of the stator consist of (a) testing all

windings to ground, (b) testing between isolated windings, and (c) testing between parallel windings. Figure

8 is a pictorial representation of the various stator

leads on units with air-cooled engine.

TESTING ALL STATOR WINDINGS TO GROUND:

1. Disconnect stator output leads 11 and 44 from the generator main line circuit breaker.

2. Remove stator output leads 22 and 33 from the neutral

connection and separate the two leads.

3. Disconnect C2 Connector from the side of the control

panel. The C2 Connector is the closest to the back

panel (see Figure 9, Section 6.1).

c.Turn the tester switch ON and observe the

breakdown lamp on tester. DO NOT APPLY

VOLTAGE LONGER THAN 1 SECOND. After

one (1) second, turn the tester switch OFF.

If the breakdown lamp comes on during the one-sec

ond test, the stator should be cleaned and dried. After

cleaning and drying, repeat the insulation test. If, after

cleaning and drying, the stator fails the second test,

the stator assembly should be replaced.

6. Now proceed to the C2 Connector. Each winding will be

individually tested for a short to ground. Insert a large

paper clip (or similar item) into the C2 Connector at the

following pin locations:

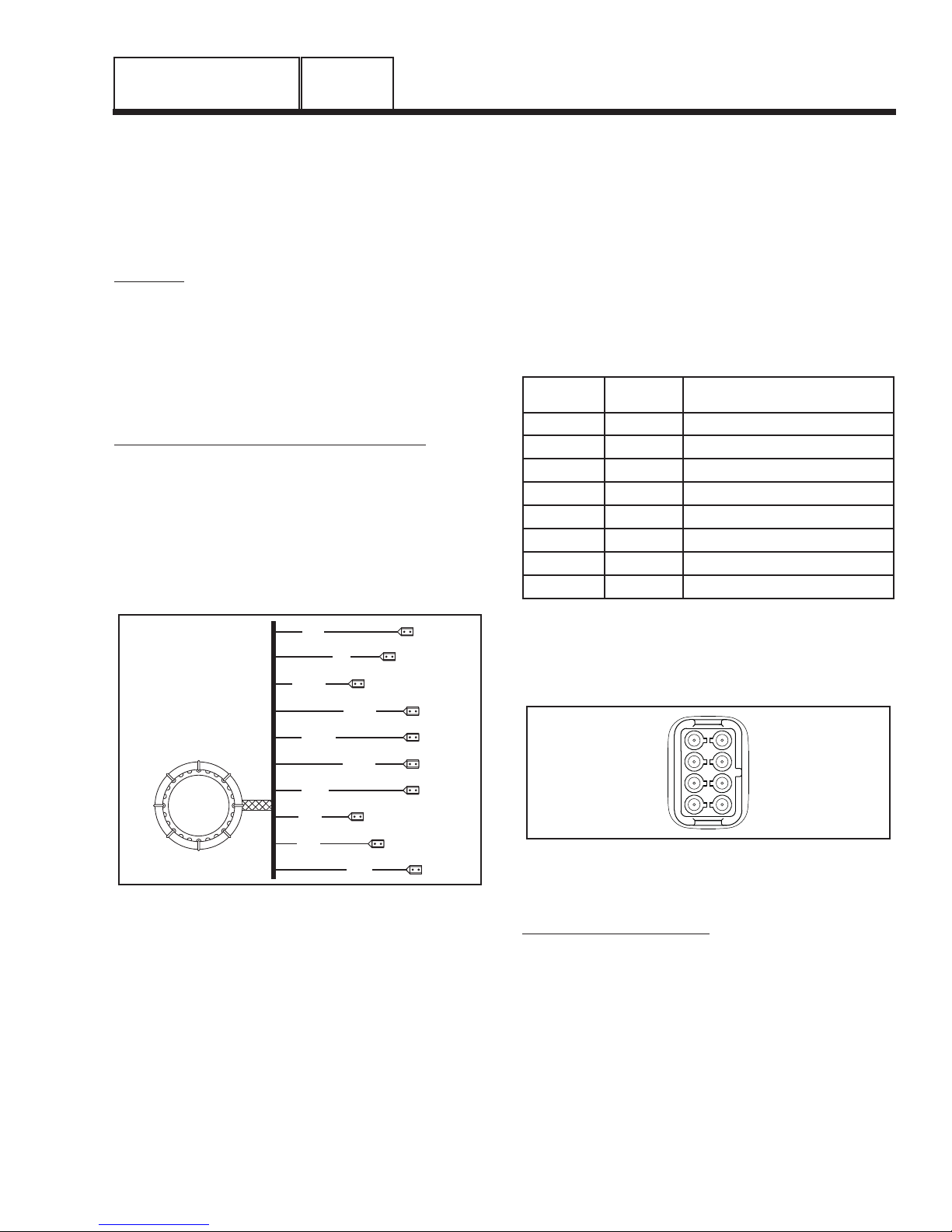

Pin

Location

1 77 Battery Charge

2 66 Battery Charge

3 22 Sense Lead Power

4 11 Sense Lead Power

5 6 Excitation

6 2 Excitation

7 0 Ground

8 4 Positive to Brush

Wire

Number

Winding

-

2

6

11P

11S

22P

22S

33

44

66

77

Figure 8. Stator Winding Leads

4. Connect the terminal ends of Wires 11, 22, 33 and 44

together. Make sure the wire ends are not touching any

part of the generator frame or any terminal.

5. Connect the red test probe of the Hi-Pot tester to the

joined terminal ends of stator leads 11, 22, 33 and 44.

Connect the black tester lead to a clean frame ground

on the stator can. With tester leads connected in this

manner, proceed as follows:

a.Turn the Hi-Pot tester switch OFF.

b.Plug the tester cord into a 120 volt AC wall

socket and set its voltage selector switch to

“1500 volts”.

Next refer to Steps 5a through 5c of the Hi-Pot procedure.

Example: Insert paper clip into Pin 1, Hi-Pot from

Pin 1 (Wire 77) to ground. Proceed to Pin 2, Pin 3,

etc. through Pin 8.

5

6

7

8

Figure 9. C2 Connector Pin Location Numbers

(Female Side)

TEST BETWEEN WINDINGS:

1

2

3

4

1. Insert a large paper clip into Pin Location 1 (Wire 77).

Connect the red tester probe to the paper clip. Connect

the black tester probe to Stator Lead 11. Refer to Steps

5a through 5c of “TESTING ALL STATOR WINDINGS

TO GROUND” on previous page.

2. Repeat Step 1 at Pin Location 5 (Wire 6) and Stator

Lead 11.

3. Connect the red test probe to Stator Lead 33. Connect

the black test probe to Stator Lead 11. Refer to Steps 5a

through 5c of “TESTING ALL STATOR WINDINGS TO

GROUND” on previous page.

Page 21

SECTION 1.4

TESTING, CLEANING AND DRYING

4. Insert a large paper clip into Pin Location No. 1 (Wire

77). Connect the red tester probe to the paper clip.

Connect the black tester probe to Stator Lead 33. Refer

to Steps 5a through 5c of “TESTING ALL STATOR

WINDINGS TO GROUND” on the previous page.

5. Repeat Step 4 at Pin Location 3 (Wire 6) and Stator

Lead 33.

For the following Step (7) an additional large paper

clip (or similar item) will be needed:

7. Insert a large paper clip into Pin Location 1 (Wire 77).

Connect the red tester probe to the paper clip. Insert the

additional large paper clip into Pin Location 5 (Wire 6).

Connect the black tester probe to this paper clip. Refer

to Steps 5a through 5c of “TESTING ALL STATOR

WINDINGS TO GROUND” on the previous page.

PART 1

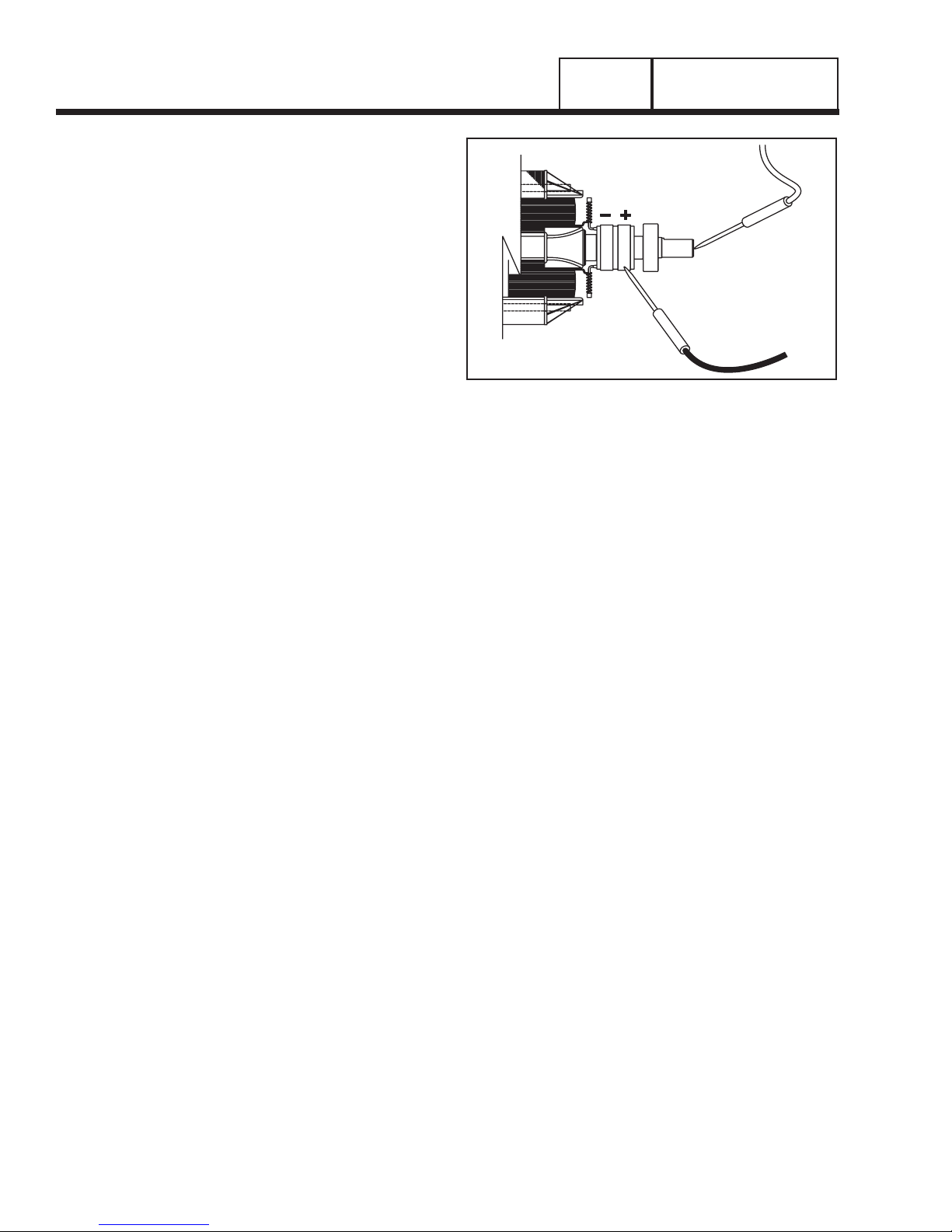

POSITIVE (+)

TEST LEAD

Figure 10. Testing Rotor Insulation

GENERAL INFORMATION

ROTOR INSULATION RESISTANCE TEST

Before attempting to test rotor insulation, the brush

holder must be completely removed. The rotor must

be completely isolated from other components before

starting the test. Attach all leads of all stator windings

to ground.

1. Connect the red tester lead to the positive (+) slip ring

(nearest the rotor bearing).

2. Connect the black tester probe to a clean frame ground,

such as a clean metal part of the rotor shaft.

3. Turn the tester switch OFF.

4. Plug the tester into a 120 volts AC wall socket and set

the voltage switch to “1500 volts”.

5. Turn the tester switch “On” and make sure the pilot light

has turned on.

6. Observe the breakdown lamp, then turn the tester switch

OFF. DO NOT APPLY VOLTAGE LONGER THAN ONE

(1) SECOND.

If the breakdown lamp came on during the one (1)

second test, cleaning and drying of the rotor may be

necessary. After cleaning and drying, repeat the insulation breakdown test. If breakdown lamp comes on

during the second test, replace the rotor assembly.

CLEANING THE GENERATOR

Caked or greasy dirt may be loosened with a soft

brush or a damp cloth. A vacuum system may be

used to clean up loosened dirt. Dust and dirt may

also be removed using dry, low-pressure air (25 psi

maximum).

CAUTION: Do not use sprayed water to clean

the generator. Some of the water will be

retained on generator windings and terminals,

and may cause very serious problems.

DRYING THE GENERATOR

To dry a generator, proceed as follows:

1. Open the generator main circuit breaker. NO

ELECTRICAL LOADS MUST BE APPLIED TO THE

GENERATOR WHILE DRYING.

2. Disconnect all Wires 4 from the voltage regulator.

3. Provide an external source to blow warm, dry air through

the generator interior (around the rotor and stator windings. DO NOT EXCEED 185° F. (85° C.).

4. Start the generator and let it run for 2 or 3 hours.

5. Shut the generator down and repeat the stator and rotor

insulation resistance tests.

Page 22

GENERAL INFORMATION

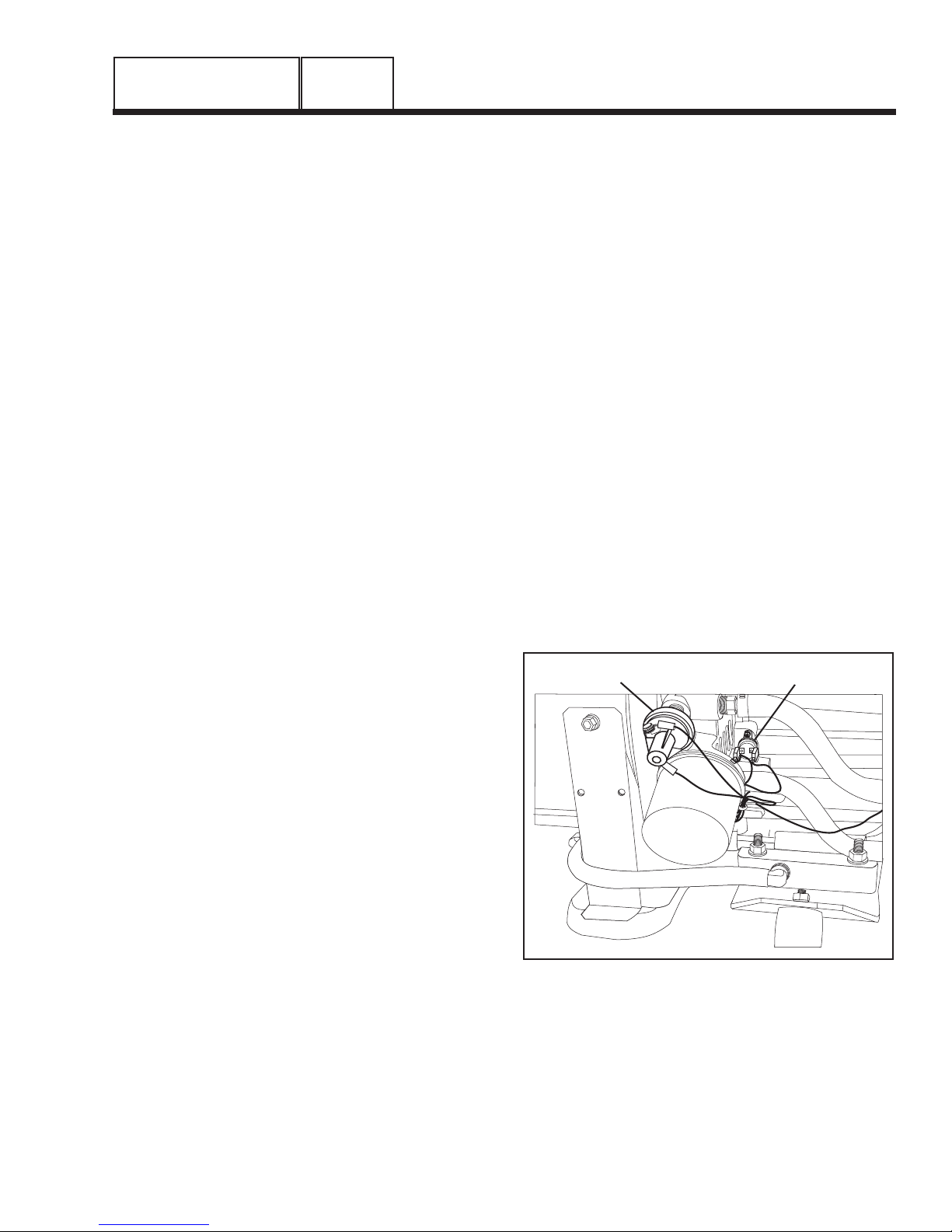

LOW OIL SWITCH HIGH TEMP SWITCH

PART 1

SECTION 1.5

ENGINE-GENERATOR PROTECTIVE DEVICES

GENERAL

Standby electric power generators will often run

unattended for long periods of time. Such operating

parameters as (a) battery voltage, (b) engine oil pressure, (c) engine temperature, (d) engine operating

speed, and (e) engine cranking and startup are not

monitored by an operator during automatic operation.

Because engine operation will not be monitored, the

use of engine protective safety devices is required to

prevent engine damage in the event of a problem.

Prepackaged generator engines mount several engine

protective devices. These devices work in conjunction

with a circuit board, to protect the engine against

such operating faults as (a) low battery, (b) low engine

oil pressure, (c) high temperature, (d) overspeed, and

(e) overcrank. On occurrence of any one or more of

those operating faults, circuit board action will effect

an engine shutdown.

LOW BATTERY

The microprocessor will continually monitor the battery voltage and turn on the Low Battery LED if the

battery voltage falls below 11.0 volts for one (1) minute. No other action is taken on a low battery condition. Low battery voltage is a non-latching alarm

which will automatically clear if the battery voltage

rises above 11.0 volts. Battery voltage is NOT monitored during the crank cycle.

OVERSPEED SHUTDOWN

During engine cranking and operation, the circuit

board receives AC voltage and frequency signals from

the ignition magneto, via Wire 18. Should the speed

exceed approximately 72 Hz (4320 rpm), circuit board

action will de-energize a “run relay” (mounted on the

circuit board). The relay’s contacts will open, to terminate engine ignition and close a fuel shutoff solenoid.

The engine will then shut down. This feature protects

the engine-generator against damaging overspeeds.

NOTE: The circuit board also uses rpm sensing to

terminate engine cranking.

RPM SENSOR FAILURE

During cranking, if the board does not see a valid

RPM signal within three (3) seconds, it will shut down

and latch out on RPM sensor loss.

During running, if the RPM signal is lost for one full

second the board will shut down the engine, wait 15

seconds, then re-crank the engine.

• If an RPM signal is not detected within the first three

(3) seconds of cranking, the control board will shut

the engine down and latch out on RPM sensor loss.

• If the RPM signal is detected the engine will start

and run normally. If the RPM signal is subsequently

lost again, the control board will try one more recrank attempt before latching out and flashing the

overspeed LED.

LOW OIL PRESSURE SHUTDOWN

See Figure 1. An oil pressure switch is mounted on

the engine oil filter adapter. This switch has normally

closed contacts that are held open by engine oil pressure during cranking and startup. Should oil pressure

drop below approximately 8 psi, the switch contacts

will close. On closure of the switch contacts, a Wire

86 circuit from the circuit board will be connected to

ground. Circuit board action will then de-energize a

“run relay” (on the circuit board). The run relay’s normally open contacts will then open and a 12 volts DC

power supply to a Wire 14 circuit will then be terminated. This will result in closure of a fuel shutoff solenoid

and loss of engine ignition.

HIGH TEMPERATURE SWITCH

This switch’s contacts (Figure 1) close if the temperature should exceed approximately 140° C (284° F),

initiating an engine shutdown. The generator will automatically restart and the LED on the generator control

panel will reset once the temperature has returned to

a safe operating level.

Figure 1. Engine Protective Switches on an

Air-Cooled Engine

Page 23

SECTION 1.5

ENGINE-GENERATOR PROTECTIVE DEVICES

OVERCRANK SHUTDOWN

This feature prevents the generator from damaging

itself when it continually attempts to start and another

problem, such as no fuel supply, prevents it from starting. The unit will crank and rest for a preset time limit.

Then, it will stop cranking, and the LED on the generator control panel will light indicating an overcrank

failure. The AUTO/OFF/MANUAL switch will need to

be set to OFF and then back to AUTO to reset the

generator control board.

NOTE: If the fault is not repaired, the overcrank

feature will continue to activate.

APPROXIMATE CRANK CYCLE TIMES:

7 KW UNITS:

15 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

7 seconds ON

If the unit fails to start, the overcrank alarm LED will

be illuminated.

PART 1

GENERAL INFORMATION

10 KW, 13 KW AND 16 KW UNITS:

16 seconds ON

7 seconds OFF

16 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

7 seconds ON

7 seconds OFF

If the unit fails to start, the overcrank alarm LED will

be illuminated.

Page 24

GENERAL INFORMATION

PART 1

SECTION 1.6

OPERATING INSTRUCTIONS

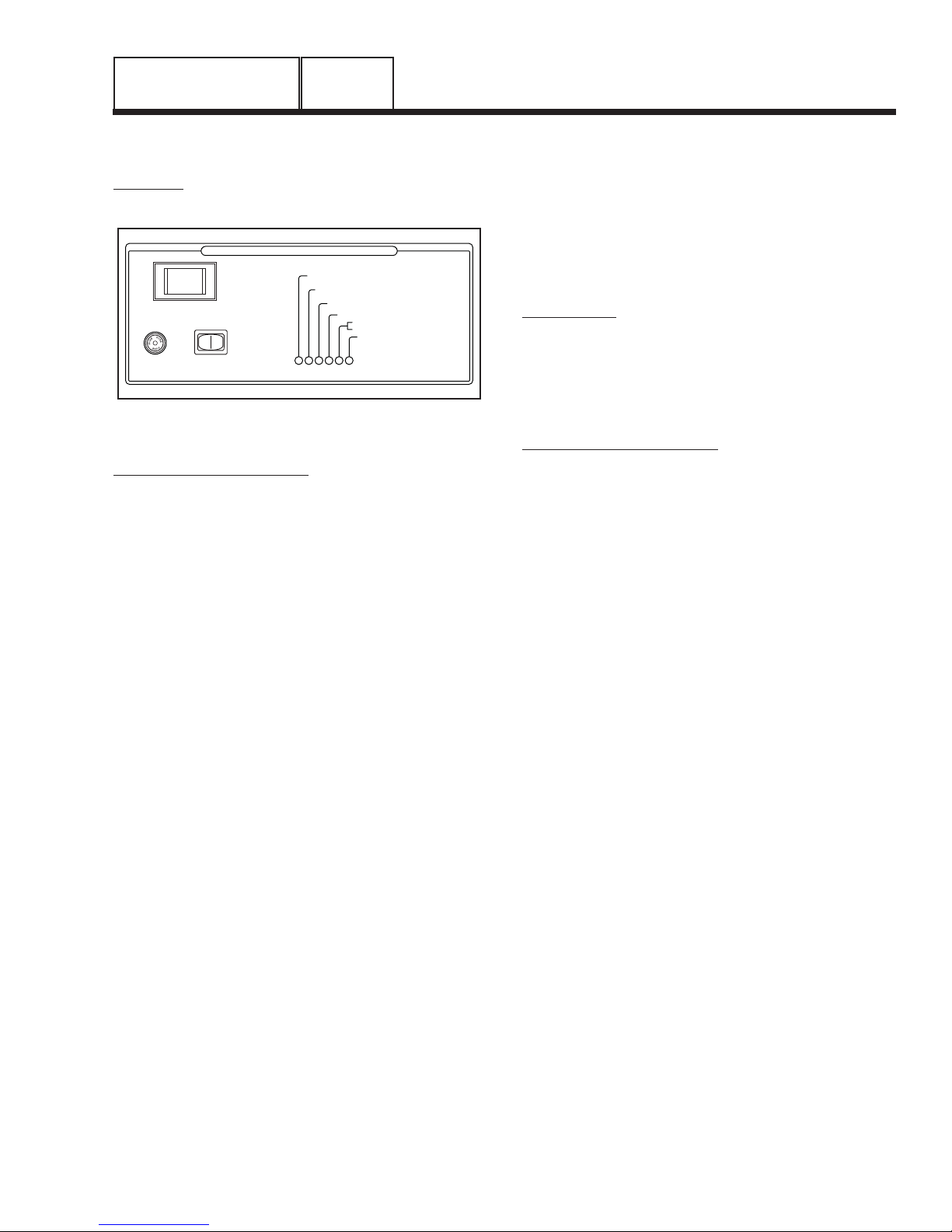

CONTROL PANEL

GENERAL:

See Figure 1 for control panel configurations.

CONTROL AND INFORMATION CENTER

SYSTEM SET

LOW BATTERY

OFF

AUTO. MAN.

SYSTEM FUSE

15A

ASSY: 0F8418/0F8419

SET

EXERCISE

TIME

Figure 1. Control Panel

AUTO-OFF-MANUAL SWITCH:

Use this switch to (a) select fully automatic operation,

(b) to crank and start the engine manually, and (c) to

shut the unit down or to prevent automatic startup.

1. AUTO position:

a.Select AUTO for fully automatic operation.

b.When AUTO is selected, circuit board will moni-

tor utility power source voltage.

c. Should utility voltage drop below a preset level

and remain at such a low level for a preset time,

circuit board action will initiate engine cranking

and startup.

d.Following engine startup, circuit board action

will initiate transfer of electrical loads to the

“Standby” source side.

e.On restoration of utility source voltage above

a preset level, circuit board action will initiate

retransfer back to the “Utility Source” side.

f. Following retransfer, circuit board will shut the

engine down and will then continue to monitor

utility source voltage.

2. OFF Position:

a.Set the switch to OFF to stop an operating

engine.

b.To prevent an automatic startup from occurring,

set the switch to OFF.

3. MANUAL Position:

a.Set switch to MANUAL to crank and start unit

manually.

b.Engine will crank cyclically and start (same as

automatic startup, but without transfer). The unit

will transfer if utility voltage is not available.

DANGER: WHEN THE GENERATOR IS

INSTALLED IN CONJUNCTION WITH AN

AUTOMATIC TRANSFER SWITCH, ENGINE

CRANKING AND STARTUP CAN OCCUR AT

LOW OIL

HIGH TEMP

OVER SPEED

NO RPM SENSE IF FLASHING

OVER CRANK

FLASHING GREEN LED=

NO UTILITY SENSE

5 FLASHING RED LEDS=

EXERCISER NOT SET

ANY TIME WITHOUT WARNING (PROVIDING

THE AUTO-OFF-MANUAL SWITCH IS SET TO

AUTO). TO PREVENT AUTOMATIC STARTUP

AND POSSIBLE INJURY THAT MIGHT BE

CAUSED BY SUCH STARTUP, ALWAYS SET

THE AUTO-OFF-MANUAL SWITCH TO ITS

OFF POSITION BEFORE WORKING ON OR

AROUND THIS EQUIPMENT.

15 AMP FUSE:

This fuse protects the DC control circuit (including the

circuit board) against overload. If the fuse element

has melted open due to an overload, engine cranking

or running will not be possible. Should fuse replacement become necessary, use only an identical 15

amp replacement fuse.

THE SET EXERCISE SWITCH:

This generator is equipped with an exercise timer.

Once it is set, the generator will start and exercise

once every seven days, on the day of the week and at

the time of day the following sequence is completed.

During this exercise period, the unit runs for approximately 12 minutes and then shuts down. Transfer of

loads to the generator output does not occur during

the exercise cycle unless utility power is lost.

A switch on the control panel (see Figure 1) per

mits selection of the day and time for the system to

exercise. At the chosen time, perform the following

sequence to select the desired day and time of day

the system will exercise. Remember seasonal time