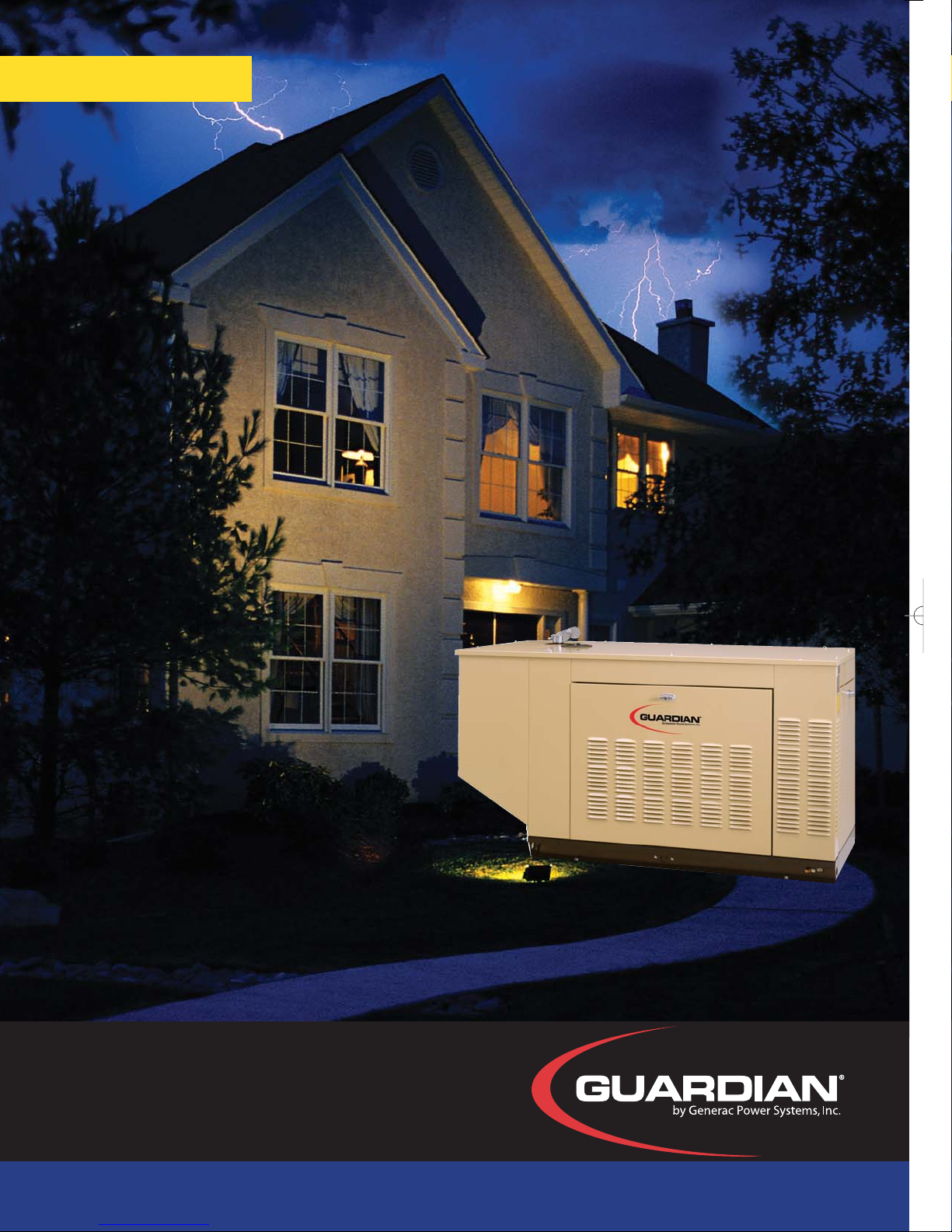

Guardian 4721, 4722, 4723, 4724, 4725 Repair Manual

...

Models: 4721, 4722, 4723, 4724, 4725, 4726

1.5L HOME STANDBY GENERATORS

www.guardiangenerators.com

LIQUID-COOLED

DIAGNOSTIC

REPAIR MANUAL

Page ii

Study these SAFETY RULES carefully before installing, operating or servicing this equipment. Become familiar with the Owner’s Manual and with the unit. The generator can operate safely, efficiently and reliably only

if it is properly installed, operated and maintained. Many accidents are caused by failing to follow simple and

fundamental rules or precautions.

Generac cannot anticipate every possible circumstance that might involve a hazard. The warnings in this

manual, and on tags and decals affixed to the unit are, therefore, not all-inclusive. If using a procedure,

work method or operating technique that Generac does not specifically recommend, ensure that it is safe

for others. Also make sure the procedure, work method or operating technique utilized does not render

the generator unsafe.

Despite the safe design of this generator, operating this equipment imprudently, neglecting its maintenance or being careless can cause possible injury or death. Permit only responsible and capable

persons to install, operate or maintain this equipment.

Potentially lethal voltages are generated by these machines. Ensure all steps are taken to render the

machine safe before attempting to work on the generator.

Parts of the generator are rotating and/or hot during operation. Exercise care near running generators.

!

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe operation be copied and posted in potential hazard areas. Safety should be stressed to all operators and potential operators of this equipment.

!

Important Safety Notice

Proper service and repair is important to the safe, economical and reliable operation of all

standby electric power systems. The troubleshooting, testing and servicing procedures recommended by Generac and described in this manual are effective methods of performing such

operations. Some of these operations or procedures may require the use of specialized equipment. Such equipment should be used when and as recommended.

It is important to note that this manual contains various DANGER, CAUTION, and NOTE blocks.

These should be read carefully in order to minimize the risk of personal injury or to prevent

improper methods or practices from being used. Use of improper or unauthorized practices

may damage equipment or render it unsafe. The DANGER, CAUTION and NOTE blocks are not

exhaustive. Generac could not possibly know, evaluate and advise the service trade of all conceivable ways in which operations described in this manual might be accomplished or of the

possible hazardous consequences of each way. Consequently, Generac has not taken any such

broad evaluation. Accordingly, anyone who uses any troubleshooting, testing or service procedure that is not recommended by Generac must first satisfy himself that neither his safety nor

the equipment's safety will be jeopardized by the procedure or the method he selects.

!

DANGER

Page iii

GENERAL HAZARDS

• For safety reasons, Generac recommends that this equipment be installed, serviced and repaired by an

authorized service dealer or other competent, qualified electrician or installation technician who is

familiar with applicable codes, standards and regulations. The operator also must comply with all

such codes, standards and regulations.

• Installation, operation, servicing and repair of this (and related) equipment must always comply with

applicable codes, standards, laws and regulations. Adhere strictly to local, state and national electrical

and building codes. Comply with regulations the Occupational Safety and Health Administration

(OSHA) has established. Also, ensure that the generator is installed, operated and serviced in accordance with the manufacturer’s instructions and recommendations. Following installation, do nothing

that might render the unit unsafe or in noncompliance with the aforementioned codes, standards, laws

and regulations.

• The engine exhaust fumes contain carbon monoxide gas, which can be DEADLY. This dangerous gas, if

breathed in sufficient concentrations, can cause unconsciousness or even death. For that reason, adequate ventilation must be provided. Exhaust gases must be piped safely away from any building or

enclosure that houses the generator to an area where people, animals, etc., will not be harmed. This

exhaust system must be installed properly, in strict compliance with applicable codes and standards.

• Keep hands, feet, clothing, etc., away from drive belts, fans, and other moving or hot parts. Never

remove any drive belt or fan guard while the unit is operating.

• Adequate, unobstructed flow of cooling and ventilating air is critical to prevent buildup of explosive

gases and to ensure correct generator operation. Do not alter the installation or permit even partial

blockage of ventilation provisions, as this can seriously affect safe operation of the generator.

• Keep the area around the generator clean and uncluttered. Remove any materials that could become

hazardous.

• When working on this equipment, remain alert at all times. Never work on the equipment when physically or mentally fatigued.

• Inspect the generator regularly, and promptly repair or replace all worn, damaged or defective parts

using only factory-approved parts.

• Before performing any maintenance on the generator, disconnect its battery cables to prevent accidental start-up. Disconnect the cable from the battery post indicated by a NEGATIVE, NEG or (–) first.

Reconnect that cable last.

• Never use the generator or any of its parts as a step. Stepping on the unit can stress and break parts,

and may result in dangerous operating conditions from leaking exhaust gases, fuel leakage, oil leakage,

etc.

ELE

CTRICAL HAZARDS

• All generators covered by this manual produce dangerous electrical voltages and can cause fatal electrical shock. Utility power delivers extremely high and dangerous voltages to the transfer switch as well as

the standby generator. Avoid contact with bare wires, terminals, connections, etc., on the generator as

well as the transfer switch, if applicable. Ensure all appropriate covers, guards and barriers are in place

before operating the generator. If work must be done around an operating unit, stand on an insulated,

dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while standing in water, while barefoot, or while hands or

feet are wet. DANGEROUS ELECTRICAL SHOCK MAY RESULT.

• If people must stand on metal or concrete while installing, operating, servicing, adjusting or repairing

this equipment, place insulative mats over a dry wooden platform. Work on the equipment only while

standing on such insulative mats.

!!

Page iv

• The National Electrical Code (NEC), Article 250 requires the frame and external electrically conductive

parts of the generator to be connected to an approved earth ground and/or grounding rods. This

grounding will help prevent dangerous electrical shock that might be caused by a ground fault condition in the generator set or by static electricity. Never disconnect the ground wire.

• Wire gauge sizes of electrical wiring, cables and cord sets must be adequate to handle the maximum

electrical current (ampacity) to which they will be subjected.

• Before installing or servicing this (and related) equipment, make sure that all power voltage supplies

are positively turned off at their source. Failure to do so will result in hazardous and possibly fatal

electrical shock.

• Connecting this unit to an electrical system normally supplied by an electric utility shall be by means of

a transfer switch so as to isolate the generator electric system from the electric utility distribution system when the generator is operating. Failure to isolate the two electric system power sources from each

other by such means will result in damage to the generator and may also result in injury or death to

utility power workers due to backfeed of electrical energy.

• Generators installed with an automatic transfer switch will crank and start automatically when NORMAL (UTILITY) source voltage is removed or is below an acceptable preset level. To prevent such automatic start-up and possible injury to personnel, disable the generator’s automatic start circuit (battery

cables, etc.) before working on or around the unit. Then, place a “Do Not Operate” tag on the generator

control panel and on the transfer switch.

• In case of accident caused by electric shock, immediately shut down the source of electrical power. If

this is not possible, attempt to free the victim from the live conductor. AVOID DIRECT CONTACT

WITH THE VICTIM. Use a nonconducting implement, such as a dry rope or board, to free the victim

from the live conductor. If the victim is unconscious, apply first aid and get immediate medical help.

• Never wear jewelry when working on this equipment. Jewelry can conduct electricity resulting in electric shock, or may get caught in moving components causing injury.

FIRE HAZARDS

• Keep a fire extinguisher near the generator at all times. Do NOT use any carbon tetra-chloride type

extinguisher. Its fumes are toxic, and the liquid can deteriorate wiring insulation. Keep the extinguisher

properly charged and be familiar with its use. If there are any questions pertaining to fire extinguishers, consult the local fire department.

EXPLOSION HAZARDS

• Properly ventilate any room or building housing the generator to prevent build-up of explosive gas.

• Do not smoke around the generator. Wipe up any fuel or oil spills immediately. Ensure that no combustible materials are left in the generator compartment, or on or near the generator, as FIRE or

EXPLOSION may result. Keep the area surrounding the generator clean and free from debris.

• Generac generator sets may operate using one of several types of fuels. All fuel types are potentially

FLAMMABLE and/or EXPLOSIVE and should be handled with care. Comply with all laws regulating

the storage and handling of fuels. Inspect the unit’s fuel system frequently and correct any leaks immediately. Fuel supply lines must be properly installed, purged and leak tested according to applicable

fuel-gas codes before placing this equipment into service.

• Diesel fuels are highly FLAMMABLE. Gaseous fluids such as natural gas and liquid propane (LP) gas

are extremely EXPLOSIVE. Natural gas is lighter than air, and LP gas is heavier than air; install leak

detectors accordingly.

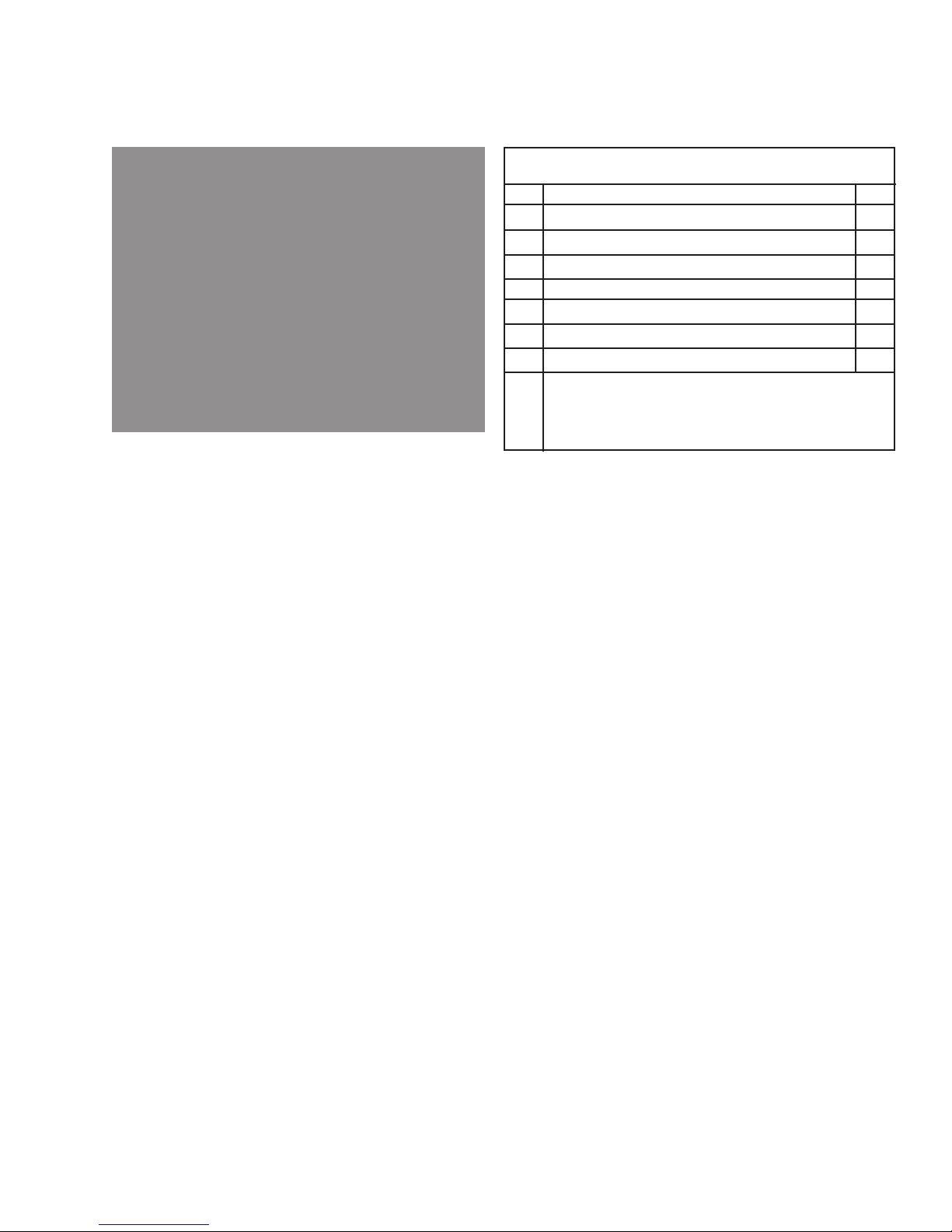

Page 1

PART TITLE PAGE

SPECIFICATIONS 2

1 General Information 3

2 Prepackaged Liquid Cooled AC Generators 19

3 V-Type Prepackaged Transfer Switches 39

4 DC Control- Units with Liquid-Cooled Engine 57

5 Operational Tests and Adjustments 95

6 Electrical Data 101

TABLE OF CONTENTS

1.5 LITER PREPACKAGED

HOME STANDBY

GENERATORS

DIAGNOSTIC

REPAIR MANUAL

Page 2

GENERATOR SPECIFICATIONS

Phase ............................................................ Single

Rated Max. Cont. AC Power Output (kW) ......... 15*

Rated Voltage (volts) ................................. 120/240

No. of Rotor Poles - 15 kW ................................... 2

No. of Rotor Poles - 20/25 kW .............................. 4

Driven Speed of Rotor - 15 kW ....................... 1800

Driven Speed of Rotor - 20/25 kW .................. 3600

Rotor Excitation System .. Direct excited brush type

Rotor/Stator Insulation ................................ Class F

* Rated power of generator is subject to and limited

by such factors as ambient temperature, altitude,

engine condition, and other factors. Engine power

will decrease about 3% for each 1000 feet above

600 feet and will decrease an additional 1.65% for

each 10°F above 77°F. Maximum output power of

the generator is limited by maximum engine power.

ENGINE SPECIFICATIONS

Make .........................................................Mitsubishi

Displacement.............................................92 inches

(1.5 liters)

Cylinder Arrangement .................................4, in-line

Valve Arrangement...........................Overhead Cam

Firing Order ...................................................1-3-4-2

Number of Main Bearings .......................................5

Compression Ratio ..........................................9 to 1

No. of Teeth on Flywheel....................................104

Ignition Timing

at 1800 rpm..................................35 degrees BTDC

Spark Plug Gap..............................0.020-0.025 inch

Recommended Spark Plugs

Champion .................................................RN11YC4

Oil Pressure ...............................................30-50 psi

Crankcase Oil Capacity ...3.0 U.S. quarts (2.8 liters)

Recommended Engine Oil ...................SAE 15W-40

Type of Cooling SystemPressurized, closed recovery

Cooling Fan ..........................................Pusher Type

Cooling System Capacity ..2 U.S. gallons (7.6 liters)

Recommended Coolant........Use a 50-50 mixture of

ethylene glycol base.

FUEL CONSUMPTION

25 kW Models

Using Natural Gas .................... 441 cu. ft. per hour

Using LP Gas.......... 175 cubic ft. (4.8 gal.) per hour

20 kW Models

Using Natural Gas .................... 359 cu. ft. per hour

Using LP Gas ......... 143 cubic ft. (4.0 gal.) per hour

15 kW Models

Using Natural Gas .................... 277 cu. ft. per hour

Using LP Gas .......... 110 cubic ft.(3.1 gal.) per hour

NOTE: Fuel consumption is given at rated maximum continuous power output when using natural

gas rated at 1000 Btu per cubic foot and LP gas

rated 2520 Btu per cubic foot. Actual fuel con-

sumption obtained may vary depending on such

variables as applied load, ambient temperature,

engine conditions and other environmental factors.

Fuel pressure for a natural gas set up should be five

inches to 14 inches of water column (0.18 to 0.5 psi)

at all load ranges.

Fuel pressure for an LP vapor set up should be 11

inches to 14 inches of water column (0.4 to 0.5 psi) at

all load ranges.

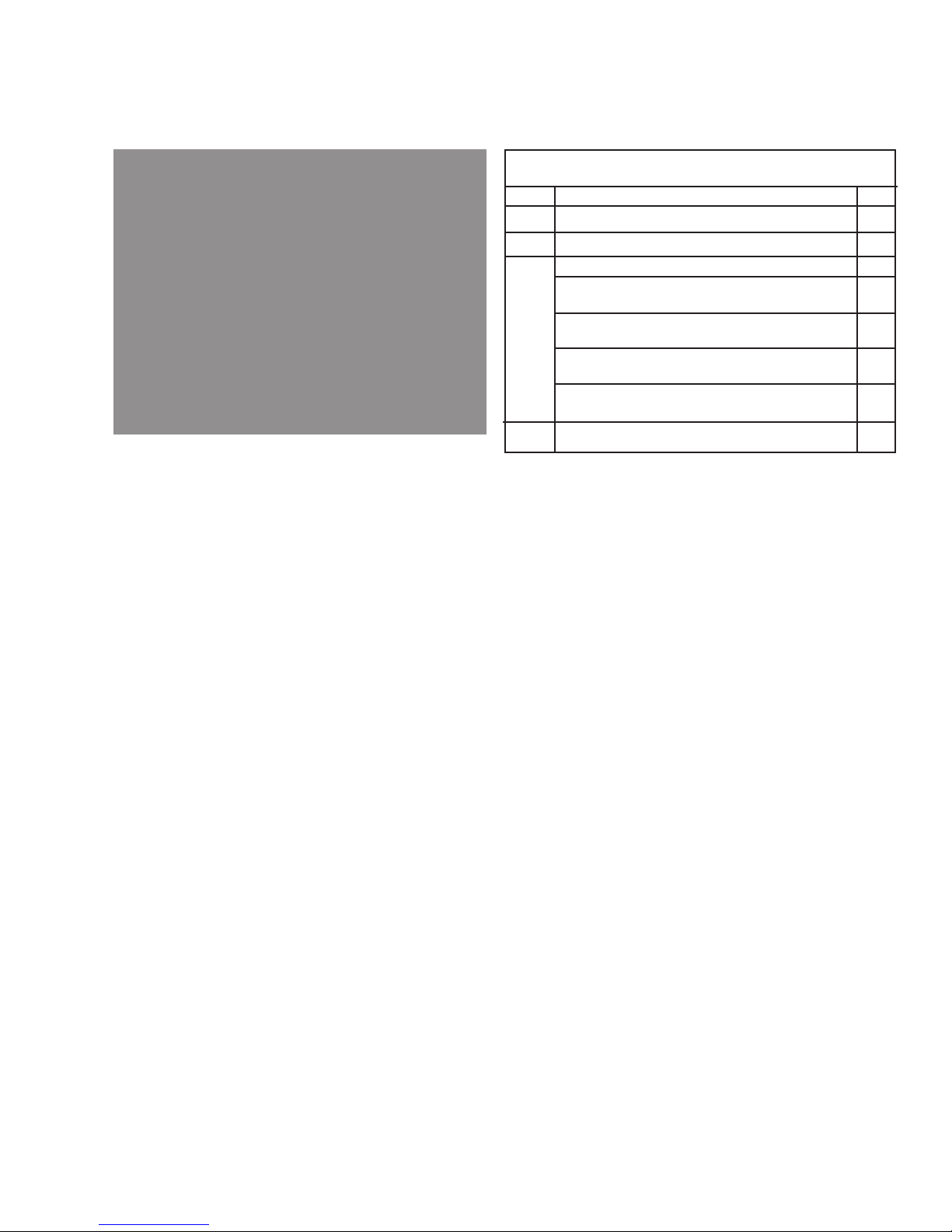

ENGINE OIL RECOMMENDATIONS

The unit has been filled with 15W-40 engine oil at the

factory. Use a high-quality detergent oil classified “For

Service SJ or latest available.” Detergent oils keep

the engine cleaner and reduce carbon deposits. Use

oil having the following SAE viscosity rating, based on

the ambient temperature range anticipated before the

next oil change:

NOTE: Synthetic oil is highly recommended when

the generator will be operating in ambient temperatures which regularly exceed 90° F and/or fall

below 30° F.

ANY ATTEMPT TO CRANK OR START THE

ENGINE BEFORE IT HAS BEEN PROPERLY

SERVICED WITH THE RECOMMENDED OIL

MAY RESULT IN AN ENGINE FAILURE.

COOLANT RECOMMENDATIONS

Use a mixture of half low silicate ethylene glycol base

anti-freeze and deionized water. Cooling system

capacity is about 8 U.S. quarts (7.6 liters). Use only

deionized water and only low silicate anti-freeze. If

desired, add a high quality rust inhibitor to the recommended coolant mixture. When adding coolant,

always add the recommended 50-50 mixture.

DO NOT USE ANY CHROMATE BASE RUST

INHIBITOR WITH ETHYLENE GLYCOL BASE

ANTI-FREEZE OR CHROMIUMHYDROXIDE

(“GREEN SLIME”) FORMS AND WILL CAUSE

OVERHEATING. ENGINES THAT HAVE BEEN

OPERATED WITH A CHROMATE BASE RUST

INHIBITOR MUST BE CHEMICALLY CLEANED

BEFORE ADDING ETHYLENE GLYCOL BASE

ANTI-FREEZE. USING ANY HIGH SILICATE

ANTI-FREEZE BOOSTERS OR ADDITIVES WILL

ALSO CAUSE OVERHEATING. IT IS ALSO RECOMMENDED THAT ANY SOLUBLE OIL

INHIBITOR IS NOT USED FOR THIS EQUIPMENT.

!

!

SPECIFICATIONS

Temperature Oil Grade (Recommended)

Above 80° F (27° C) SAE 30W or 15W-40

32° to 80° F (-1° to 27° C) SAE 20W-20 or 15W-40

Below 32° F (0° C) SAE 10W or 15W-40

Page 3

PART TITLE PAGE

1.1 Generator Identification 4

1.2 Prepackaged Installation Basics 6

1.3 Preparation Before Use 9

1.4 Testing, Cleaning and Drying 10

1.5 Engine-Generator Protective Devices 13

1.6 Operating Instructions 15

1.7 Automatic Operating Parameters 17

TABLE OF CONTENTS

1.5 LITER PREPACKAGED

HOME STANDBY

GENERATORS

PART 1

GENERAL

INFORMATION

PART 1

GENERAL INFORMATION

SECTION 1.1

GENERATOR IDENTIFICATION

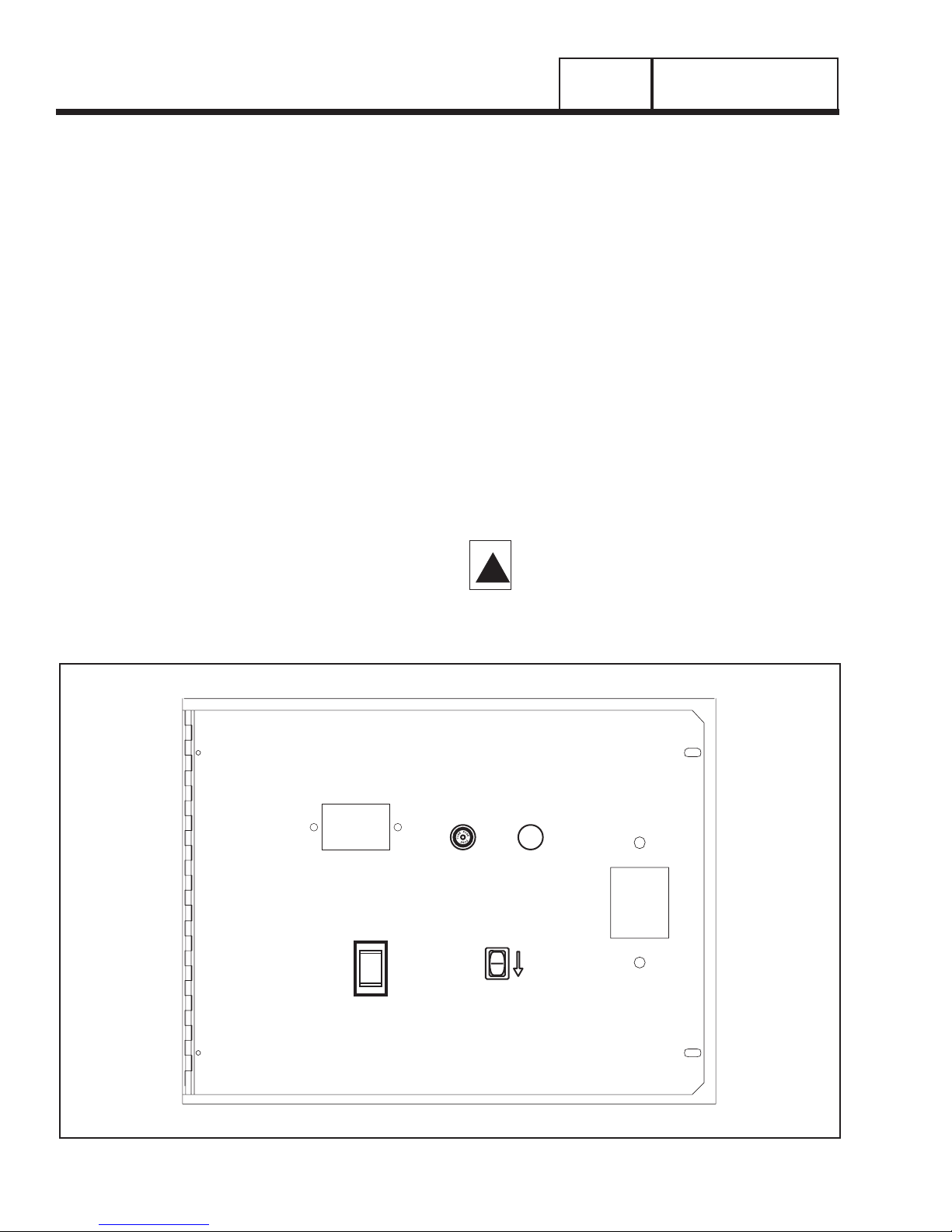

Page 4

STARTER

DATA PLATE

FUSE

FAULT

15-A

INDICATOR

HOURMETER

AGC

AUTO

SET

EXERCISE

TIME

OFF

ON

MANUAL

CONTROL PANEL

HOURMETER

15 AMP FUSE

FAULT INDICATOR

SET EXERCISE SWITCH

AUTO-OFF-MANUAL SWITCH

ALTERNATOR

DISTRIBUTOR

CIRCUIT BREAKER

CARBURETOR

MUFFLER

RADIATOR

ENGINE

FUEL REGULATOR

BATTERY

PART 1

GENERAL INFORMATION

SECTION 1.1

GENERATOR IDENTIFICATION

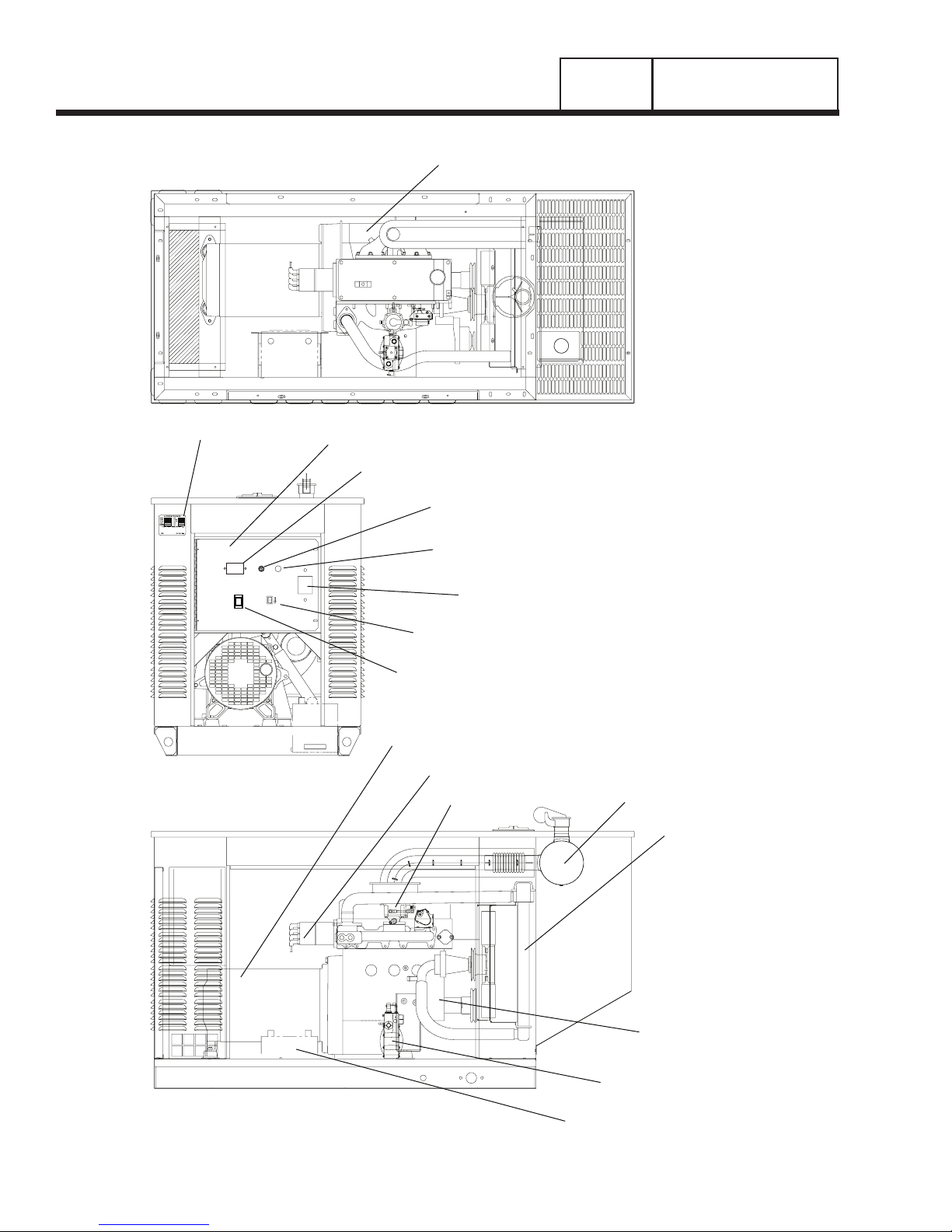

INTRODUCTION

This Diagnostic Repair Manual has been prepared

especially for the purpose of familiarizing service personnel with the testing, troubleshooting and repair of

prepackaged home standby generator systems.

Every effort has been expended to ensure that information and instructions in the manual are both accurate and current. However, the manufacturer reserves

the right to change, after or otherwise improve the

product at any time without prior notification.

The manual has been divided into several PARTS.

Each PART has been divided into SECTIONS. Each

SECTION consists of two or more SUBSECTIONS.

It is not the manufacturers intent to provide detailed

disassembly and reassembly instructions in this manual. It is the manufacturers intent to (a) provide the

service technician with an understanding of how the

various assemblies and systems work, (b) assist the

technician in finding the cause of malfunctions, and

(c) effect the expeditious repair of the equipment.

UNITS WITH LIQUID COOLED ENGINE

A typical prepackaged generator with liquid cooled

engine is shown on Page 4 at front of this manual.

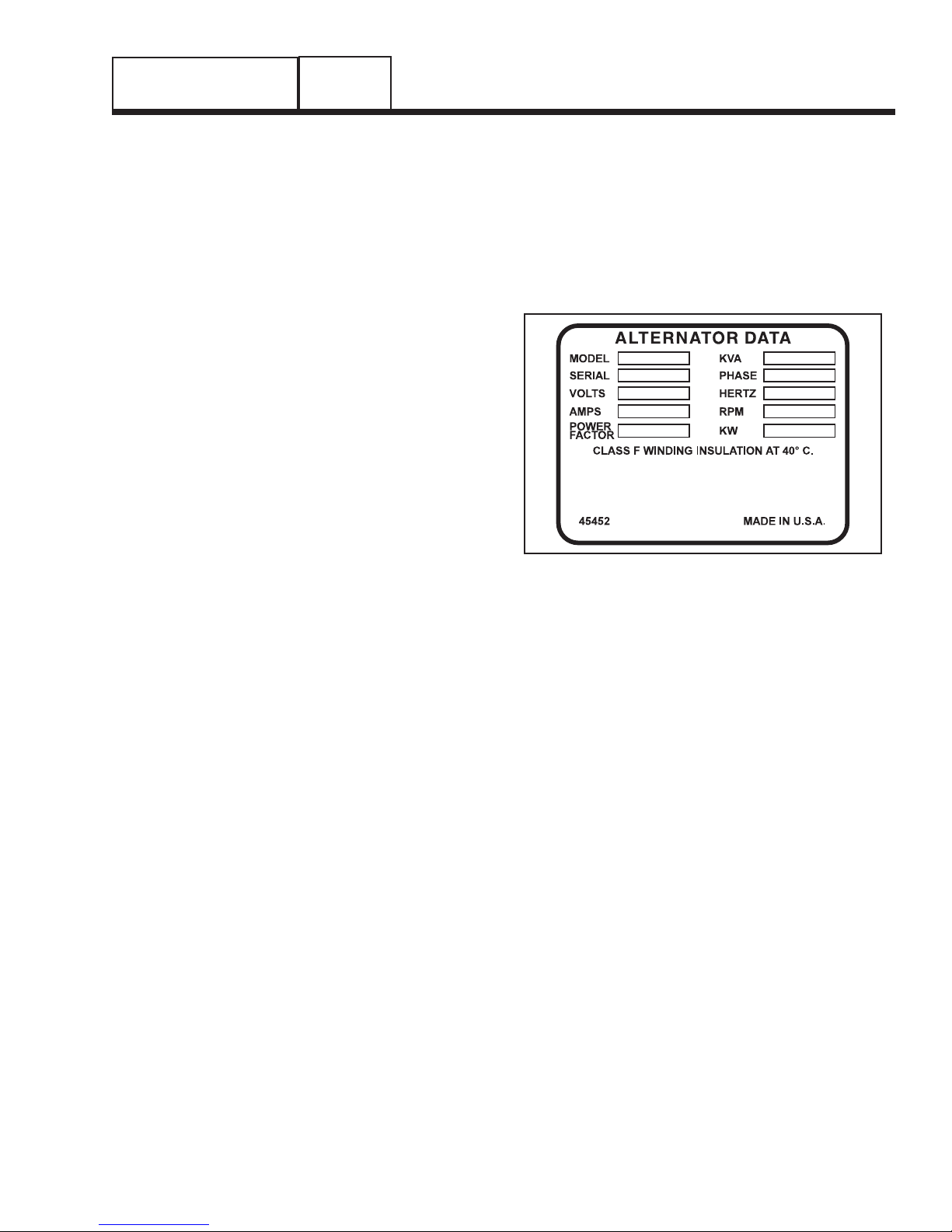

A DATA PLATE, affixed to the unit, contains important information pertaining to the unit, including its

Model Number, Serial Number, kW rating, rated rpm,

rated voltage, etc. The information from this data

plate may be required when requesting information,

ordering parts, etc.

Figure 1. A Typical Data Plate

Page 5

INTRODUCTION

Information in this section is provided so that the service technician will have a basic knowledge of installation requirements for prepackaged home standby

systems. Problems that arise are often related to poor

or unauthorized installation practices.

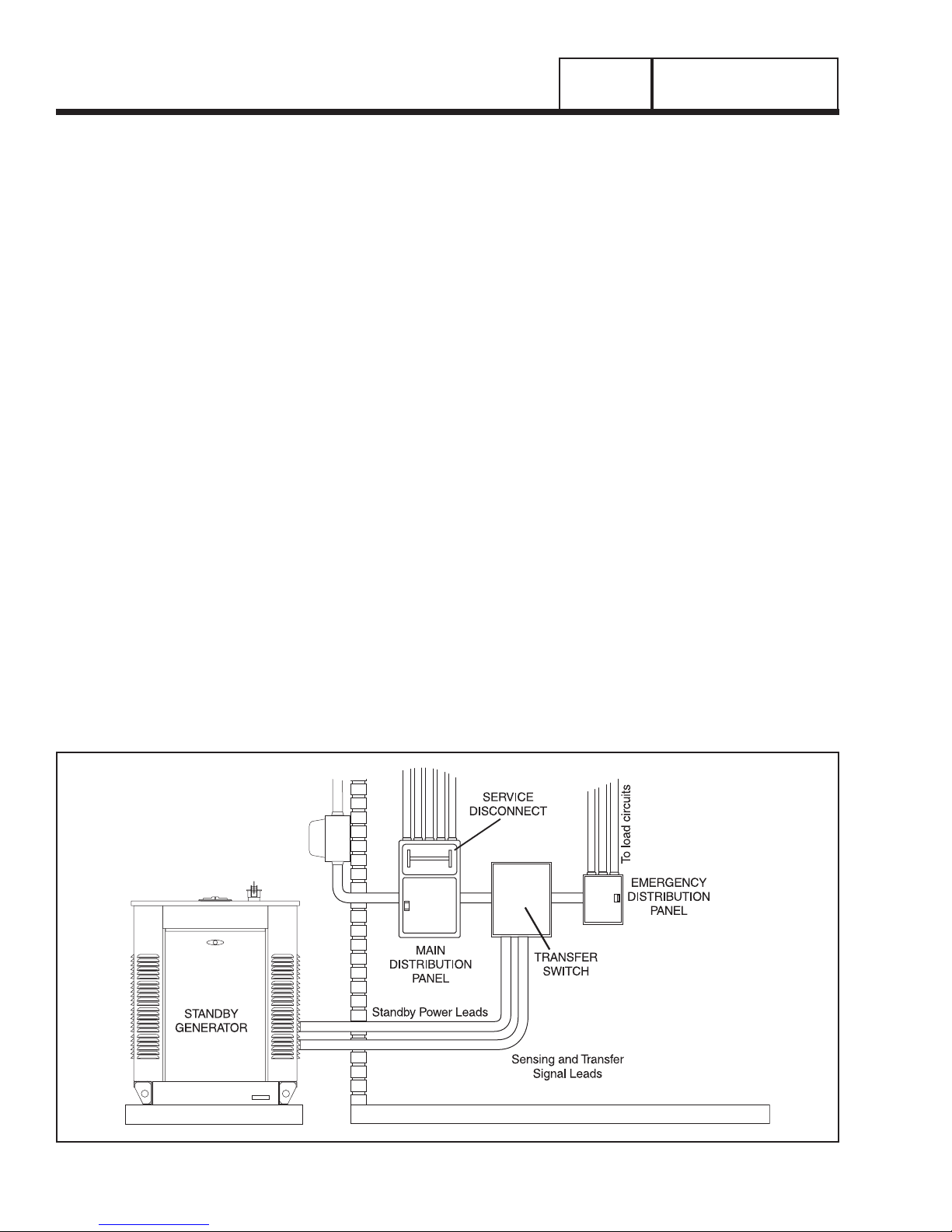

A typical prepackaged home standby electric system

is shown in Figure 1, below. Installation of such a system includes the following:

• Selecting a Location

• Mounting of the generator.

• Grounding the generator.

• Providing a fuel supply.

• Mounting the transfer switch.

• Connecting power source and load lines.

• Connecting system control wiring.

• Post installation tests and adjustments.

SELECTING A LOCATION

Install the generator set as close as possible to the

electrical load distribution panel(s) that will be powered

by the unit, ensuring that there is proper ventilation for

cooling air and exhaust gases. This will reduce wiring

and conduit lengths. Wiring and conduit not only add to

the cost of the installation, but excessively long wiring

runs can result in a voltage drop.

MOUNTING THE GENERATOR

Mount the generator set to a concrete slab. The slab

should extend past the generator and to a distance of at

least twelve (12) inches on all sides. The unit can be

retained to the concrete slab with masonry anchor bolts.

GROUNDING THE GENERATOR

The National Electric Code requires that the frame

and external electrically conductive parts of the generator be property connected to an approved earth

ground. Local electrical codes may also require proper grounding of the unit. For that purpose, a grounding lug is attached to the unit. Grounding may be

accomplished by attaching a stranded copper wire of

the proper size to the generator’s grounding lug and

to an earth-driven copper or brass grounding-rod

(electrode). Consult with a local electrician for grounding requirements in your area.

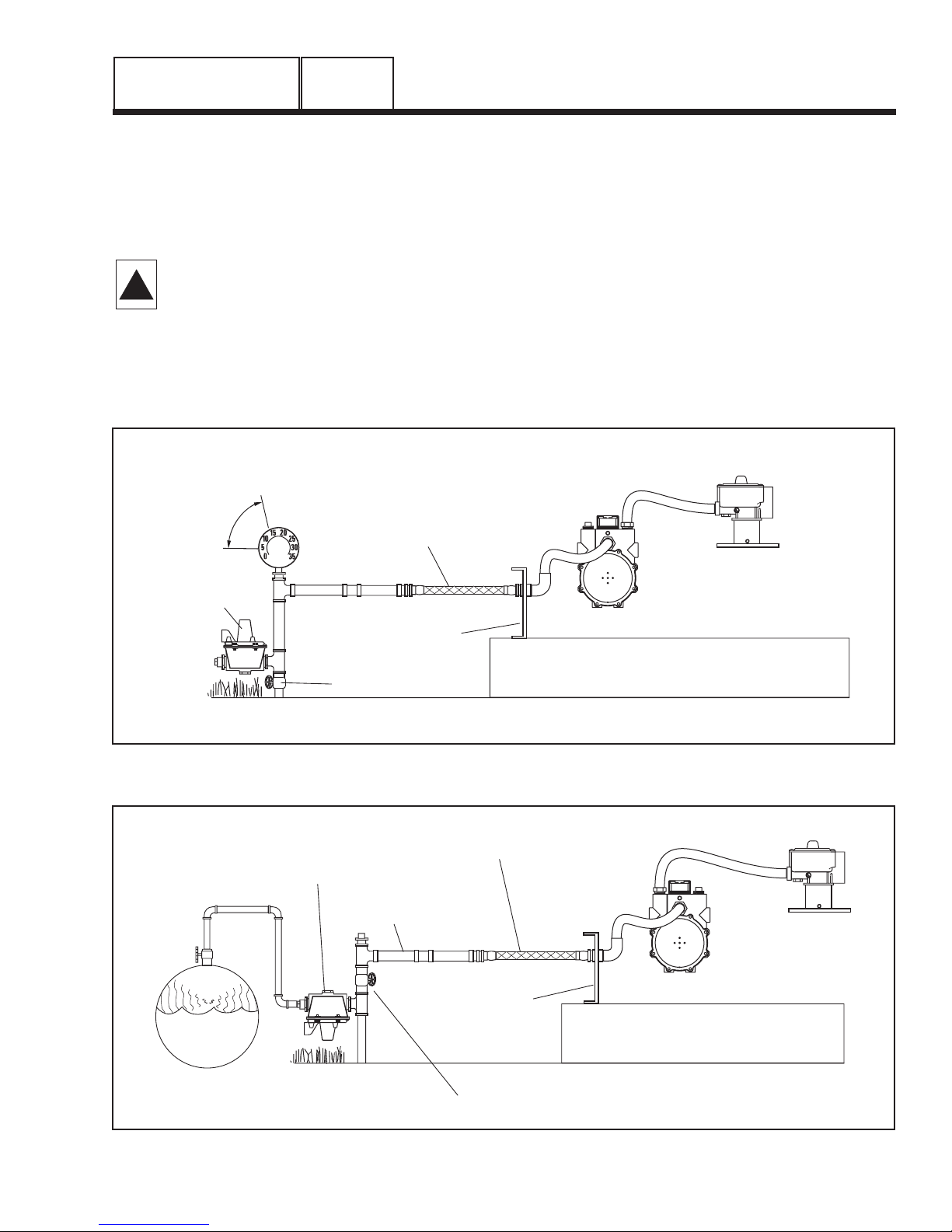

THE FUEL SUPPLY

Units with liquid cooled engines are shipped from the

factory to run on natural gas (Figure 2). Units that will

use LP (propane) gas fuel (Figure 3) must be converted in the field per instructions located in the

Installation Manual.

LP (propane) gas is usually supplied as a liquid in

pressure tanks. Liquid cooled units require a "vapor

withdrawal" type of fuel supply system when LP

(propane) gas is used. The vapor withdrawal system

utilizes the gaseous fuel vapors that form at the top of

the supply tank.

The pressure at which LP gas is delivered to the generator’s fuel solenoid valve may vary considerably,

depending on ambient temperatures. In cold weather,

supply pressures may drop to "zero". In warm weather, extremely high gas pressures may be encountered. A primary/secondary supply regulator is

required to maintain correct gas supply pressure to

the generator demand regulator.

Minimum recommended gaseous fuel pressure at

the inlet side of the generator’s fuel solenoid valve is

Figure 1. Typical Prepackaged Installation

PART 1

Page 6

GENERAL INFORMATION

SECTION 1.2

PREPACKAGED INSTALLATION BASICS

GENERAL INFORMATION

SECTION 1.2

PREPACKAGED INSTALLATION BASICS

PART 1

Page 7

11 inches water column for LP gas (6.38 ounces per

square inch), and 5 inches water column for natural

gas (2.89 ounces per square inch). The maximum

recommended pressure is 14 inches water column

(8.09 ounces per square inch). A primary regulator

may be required to ensure that proper fuel supply

pressures are maintained.

DANGER: LP AND NATURAL GAS ARE

BOTH HIGHLY EXPLOSIVE. GASEOUS FUEL

LINES MUST BE PROPERLY PURGED AND

TESTED FOR LEAKS BEFORE THIS EQUIPMENT IS PLACED INTO SERVICE AND PERIODICALLY THEREAFTER. PROCEDURES

USED IN GASEOUS FUEL LEAKAGE TESTS

MUST COMPLY STRICTLY WITH APPLICA-

BLE FUEL GAS CODES. DO NOT USE

FLAME OR ANY SOURCE OF HEAT TO TEST

FOR GAS LEAKS. NO GAS LEAKAGE IS

PERMITTED. LP GAS IS HEAVIER THAN AIR

AND TENDS TO SETTLE IN LOW AREAS.

NATURAL GAS IS LIGHTER THAN AIR AND

TENDS TO SETTLE IN HIGH PLACES. EVEN

THE SLIGHTEST SPARK CAN IGNITE THESE

FUELS AND CAUSE AN EXPLOSION.

Use of a flexible length of hose between the generator fuel line connection and rigid fuel lines is required.

This will help prevent line breakage that might be

caused by vibration or if the generator shifts or settles. The flexible fuel line must be approved for use

with gaseous fuels.

!

Figure 3. Typical LP Gas Fuel System (Liquid Cooled Units)

Figure 2. Typical Natural Gas Fuel System (Liquid Cooled Units)

5-14 INCHES WATER COLUMN OPTIMUM

APPROVED FLEX LINE

(CAUTION! — KEEP FLEX FUEL LINE STRAIGHT)

NATURAL GAS

PRIMARY

REGULATOR

GAS CARBURETOR

GENERATOR

DEMAND

REGULATOR

LP PRIMARY/SECONDARY

SUPPLY REGULATOR

VAPOR

LIQUID

GENERATOR BASE

MANUAL SHUTOFF VALVE

APPROVED FLEX LINE

(CAUTION! — KEEP FLEX FUEL LINE STRAIGHT)

11-14 INCHES WATER

COLUMN OPTIMUM

GENERATOR BASE

GAS CARBURETOR

GENERATOR

DEMAND

REGULATOR

MANUAL SHUTOFF VALVE

THE TRANSFER SWITCH

A transfer switch is required by electrical code, to prevent electrical feedback between the utility and standby power sources, and to transfer electrical loads

from one power supply to another safely.

PREPACKAGED TRANSFER SWITCHES:

Instructions and information on prepackaged transfer

switches may be found in Part 3 of this manual.

POWER SOURCE AND LOAD LINES

The utility power supply lines, the standby (generator)

supply lines, and electrical load lines must all be connected to the proper terminal lugs in the transfer

switch. The following rules apply:

In 1-phase systems with a 2-pole transfer switch, connect the two "Utility" source hot lines to transfer

switch Terminal Lugs N1 and N2. Connect the

"Standby" source hot lines (E1, E2) to transfer switch

Terminal Lugs E1 and E2. Connect the load lines

from transfer switch Terminal Lugs T1/T2 to the electrical load circuit. Connect "Utility", "Standby" and

"Load" neutral lines to the neutral block in the transfer

switch.

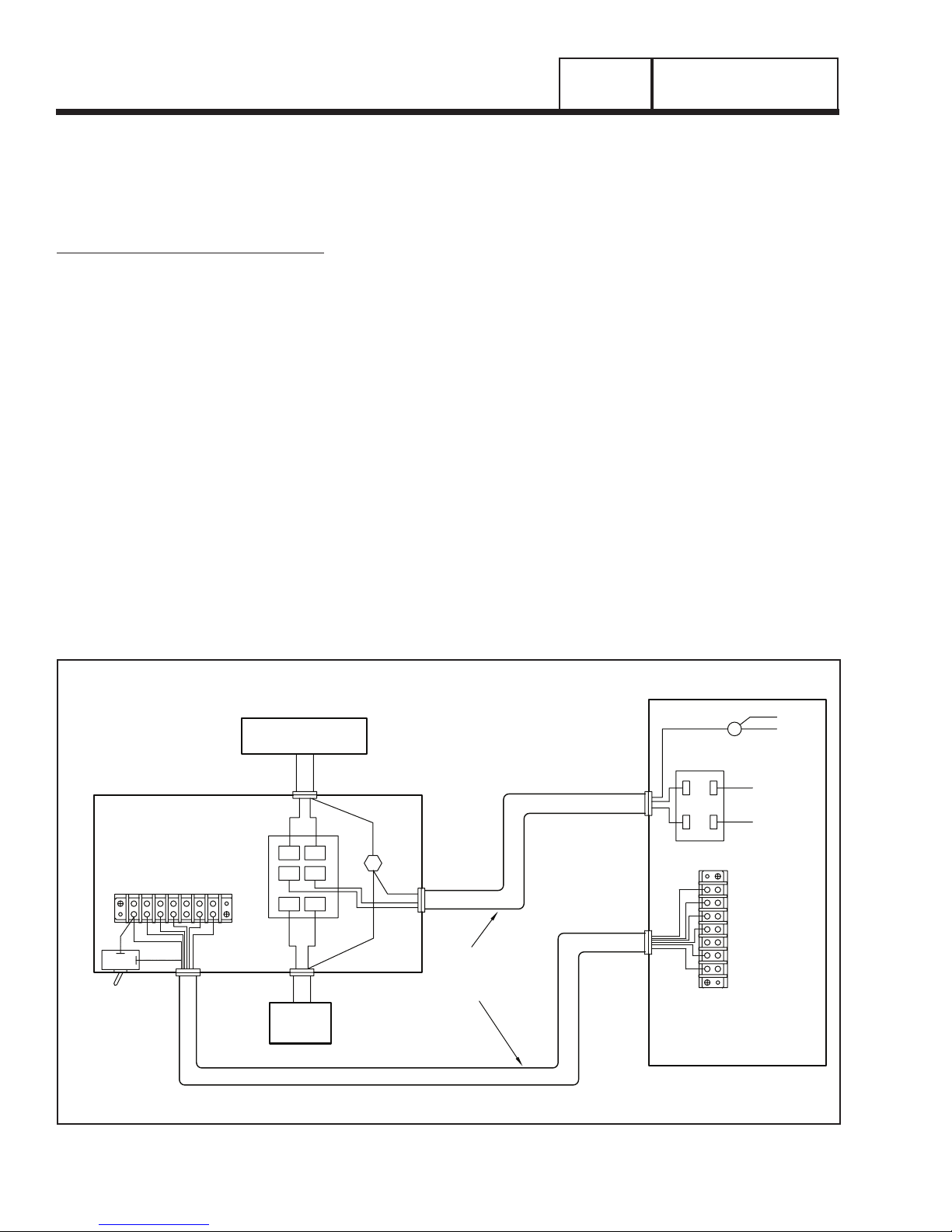

SYSTEM CONTROL INTERCONNECTIONS

Prepackaged home standby generators are equipped

with a terminal board identified with the following ter-

minals: (a) utility 1, (b) utility 2, (c) load 1, (d) load 2,

(e) 23, and (f) 194. Prepackaged transfer switches

house an identically marked terminal board. Suitable,

approved wiring must be interconnected between

identically numbered terminals in the generator and

transfer switch. When these six terminals are properly

interconnected, dropout of utility source voltage below

a preset value will result in automatic generator startup and transfer of electrical loads to the "Standby"

source. On restoration of utility source voltage above a

preset value will result in retransfer back to that source

and generator shutdown. System control wiring must

be routed through its own separate conduit.

A control board, mounted on the standby generator

set, provides a "7-day exercise" feature. This feature

allows the standby generator to start and run once

every 7 days, on a day and at a time of day selected.

The timer clock that controls this automatic exercise

of the unit must be powered by voltage from the

transfer switch Load 1/Load 2 terminals. If the exercise function is to be made available, connect suitable

wiring from the ATS transfer switch load terminal lugs,

to the "Load 1/Load 2" terminals in the generator.

The control board in the generator also provides a

battery "trickle charge" circuit. This circuit, when powered by utility source voltage, will deliver a charging

voltage to the battery during non-operating periods to

keep the battery charged. To use the trickle charge

feature, connect suitable wiring to the generator’s

"Utility 1/Utility 2" terminals and to the appropriate terminals in the "ATS" transfer switch.

PART 1

Page 8

GENERAL INFORMATION

SECTION 1.2

PREPACKAGED INSTALLATION BASICS

Figure 4. Prepackaged Interconnection Diagram

TRANSFER

SWITCH

UTILITY 1

REMOTE TEST

SWITCH (OPTIONAL)

- OPEN SWITCH TO TEST -

SWITCH TYPE, SPST

ELECTRICAL RATINGS,

2A @ 250Vac MIN.

LOAD 1

LOAD 2

UTILITY 2

22

UTILITY SUPPLY WITH

SERVICE DISCONNECT

NEUTRAL

N1 N2

23

194

E1 E2

T1 T2

CUSTOMER

LOAD

LUG

NOTE:

POWER LEADS AND

TRANSFER SWITCH

LEADS MUST BE

RUN IN TWO

DIFFERENT CONDUITS.

NEUTRAL

CONNECTION

CB1

AC GENERATOR

CONTROL PANEL

33

11

44

UTILITY 1 (N1)

UTILITY 2 (N2)

LOAD 1 (T1)

LOAD 2 (T2)

23

194

GENERAL INFORMATION

SECTION 1.3

PREPARATION BEFORE USE

PART 1

Page 9

GENERAL

The installer must ensure that the home standby generator has been properly installed. The system must

be inspected carefully following installation. All applicable codes, standards and regulations pertaining to

such installations must be strictly complied with. In

addition, regulations established by the Occupational

Safety and Health Administration (OSHA) must be

complied with.

Prior to initial startup of the unit, the installer must

ensure that the engine-generator has been properly

prepared for use. This includes the following:

• An adequate supply of the correct fuel must be

available for generator operation.

• The engine must be properly serviced with the recommended oil.

• The engine cooling system must be properly serviced with the recommended coolant.

FUEL REQUIREMENTS

Liquid cooled engine units are shipped from the factory to run on natural gas. The installer must ensure

that the correct fuel supply system has been installed

and is compatible with engine-generator requirements. Read "The Fuel Supply" in Section 1.3 carefully.

ALL UNITS:

• When natural gas is used as a fuel, it should be

rated at least 1000 BTU’s per cubic foot.

• When LP (propane) gas is used as a fuel, it should

be rated at 2520 BTU’s per cubic foot.

ENGINE OIL RECOMMENDATIONS

For prepackaged generators with liquid cooled

engine, use a high quality detergent oil that meets or

exceeds API Service SC, SD, SE or SF. Detergent

oils keep the engine cleaner and reduce carbon

deposits. Use oil having the following SAE viscosity

rating, based on the anticipated ambient temperature

range before the next oil change:

Engine crankcase oil capacities for the 1.5 Liter

engine covered in this manual can be found in the

specifications section at the beginning of the book.

RECOMMENDED ENGINE COOLANT

Use a mixture of 50 percent soft water and 50 percent

ethylene glycol base anti-freeze in the engine cooling

system. Use only SOFT WATER and LOW SILICATE

anti-freeze. If so equipped, a coolant recovery bottle

must also be properly serviced with the recommended 50-50 mixture. When adding coolant to the radiator

or to the coolant recovery bottle, use only the recommended mixture.

If desired, a high quality rust inhibitor may be added

to the recommended coolant mixture.

CAUTION: Do NOT use any chromate base

rust inhibitor with ethylene glycol base antifreeze, or the formation of chromium hydroxide (called "green slime") may result and

cause overheating of the engine. The use of

high silicate antifreeze boosters or additives

may also cause overheating. In addition, use

of any soluble oil type rust Inhibitor Is NOT

recommended.

!

AMBIENT TEMPERATURE

RANGE RECOMMENDED OIL

Above 80° F (27° C) SAE 30W or 15W-40

32° to 80° F (-1° to 27° C) SAE 20W-20 or 15W-40

Below 32° F (0° C) SAE 10W or 15W-40

VISUAL INSPECTION

When it becomes necessary to test or troubleshoot a

generator, it is a good practice to complete a thorough visual inspection. Remove the access covers

and look closely for any obvious problems. Look for

the following:

• Burned or broken wires, broken wire connectors,

damaged mounting brackets, etc.

• Loose or frayed wiring insulation, loose or dirty connections.

• Check that all wiring is well clear of rotating parts.

• Verify that the Generator properly connected for the

correct rated voltage. This is especially important

on new installations. See Section 1.2, "AC

Connection Systems".

• Look for foreign objects, loose nuts, bolts and other

fasteners.

• Clean the area around the Generator. Clear away

paper, leaves, snow, and other objects that might

blow against the generator and obstruct its air

openings.

MEASURING VOLTAGES

When troubleshooting and testing the generator set,

the technician will be required to measure both AC

and DC voltages. Measurement of voltage requires

that the user be thoroughly familiar with the meter

being used for such tests. Consult the instruction

manual for the meter being used.

When measuring voltage, it is best to connect the

meter test leads to the terminals being tested while

the generator is shut down or while power to those

terminals is turned off.

DANGER: POWER VOLTAGES GENERATED

BY THIS EQUIPMENT ARE EXTREMELY HIGH

AND DANGEROUS. USE EXTREME CARE

WHEN MEASURING POWER VOLTAGES

SUCH AS GENERATOR AC OUTPUT VOLTAGE. CONTACT WITH LIVE TERMINALS AND

CONDUCTORS MAY RESULT IN HARMFUL

AND POSSIBLY LETHAL ELECTRICAL

SHOCK. DO NOT ATTEMPT TO READ

POWER VOLTAGES WHILE STANDING ON

WET OR DAMP GROUND, OR WHILE HANDS

OR FEET ARE WET. STAY WELL CLEAR OF

HIGH VOLTAGE POWER TERMINALS. CONNECT METER TEST LEADS TO TERMINALS

AND LEADS WHILE THE GENERATOR IS

SHUT DOWN OR WHEN THE POWER SUPPLY TO SUCH LEADS AND TERMINALS IS

TURNED OFF. THE USE OF INSULATIVE

RUBBER MATS IS RECOMMENDED. TAKE

POWER VOLTAGE READINGS ONLY WHILE

STANDING ON SUCH INSULATIVE MATS.

MEASURING CURRENT

Alternating current (AC) can be measured with a

clamp-on ammeter. Most clamp-on ammeters will not

measure direct current (DC). Load current readings

should never exceed the generator’s data plate rating

for continuous operation. However, momentary

surges in load current may be encountered when

starting electric motors.

On 1-phase generators, the data plate generally lists

rated line-to-line and line-to-neutral current.

MEASURING RESISTANCE

The resistance (in ohms) of generator stator and rotor

windings can be measured using an ohmmeter or an

accurate volt-ohm-milliammeter (VOM).

The resistance of some windings is extremely low.

Some readings are so low that a meter capable of

reading in the "milliohms" range would be required.

Many meters will simply read CONTINUITY.

However, a standard volt-ohm-milliammeter (VOM)

may be used to test for continuity, or for a shorted or

grounded condition.

INSULATION RESISTANCE

The insulation resistance of stator and rotor windings

is a measurement of the integrity of the insulating

materials that separate the electrical windings from

the generator’s steel core. This resistance can

degrade over time or due to such contaminants as

dust, dirt, oil, grease and especially moisture. In

most cases, failures of stator and rotor windings is

due to a breakdown in the insulation. And, in many

cases, a low insulation resistance is caused by moisture that collects while the generator is shut down.

When problems are caused by moisture buildup on

the windings, they can usually be corrected by drying the windings. Cleaning and drying the windings

can usually eliminate dirt and moisture built up in the

generator windings.

!

PART 1

GENERAL INFORMATION

SECTION 1.4

TESTING, CLEANING AND DRYING

Page 10

GENERAL INFORMATION

SECTION 1.4

TESTING, CLEANING AND DRYING

PART 1

Page 11

MEGGERS:

The normal resistance of generator winding insulation

is on the order of millions of ohms. This high resistance can be measured with a device called a "megger". The megger is a megohm meter ("meg" stands

for million) and a power supply. The power supply

voltage varies between megger models and is selectable on some models. The most common power supply voltage is 500 volts. Use of power supplies

greater than 500 volts are not recommended on

prepackaged generators.

CAUTION: Before attempting to measure

Insulation resistance, first disconnect and

Isolate all leads of the winding to be tested.

Electronic components, diodes, surge protectors, relays, voltage regulators, etc., can

be destroyed if subjected to high megger

voltages.

HI-POT TESTER:

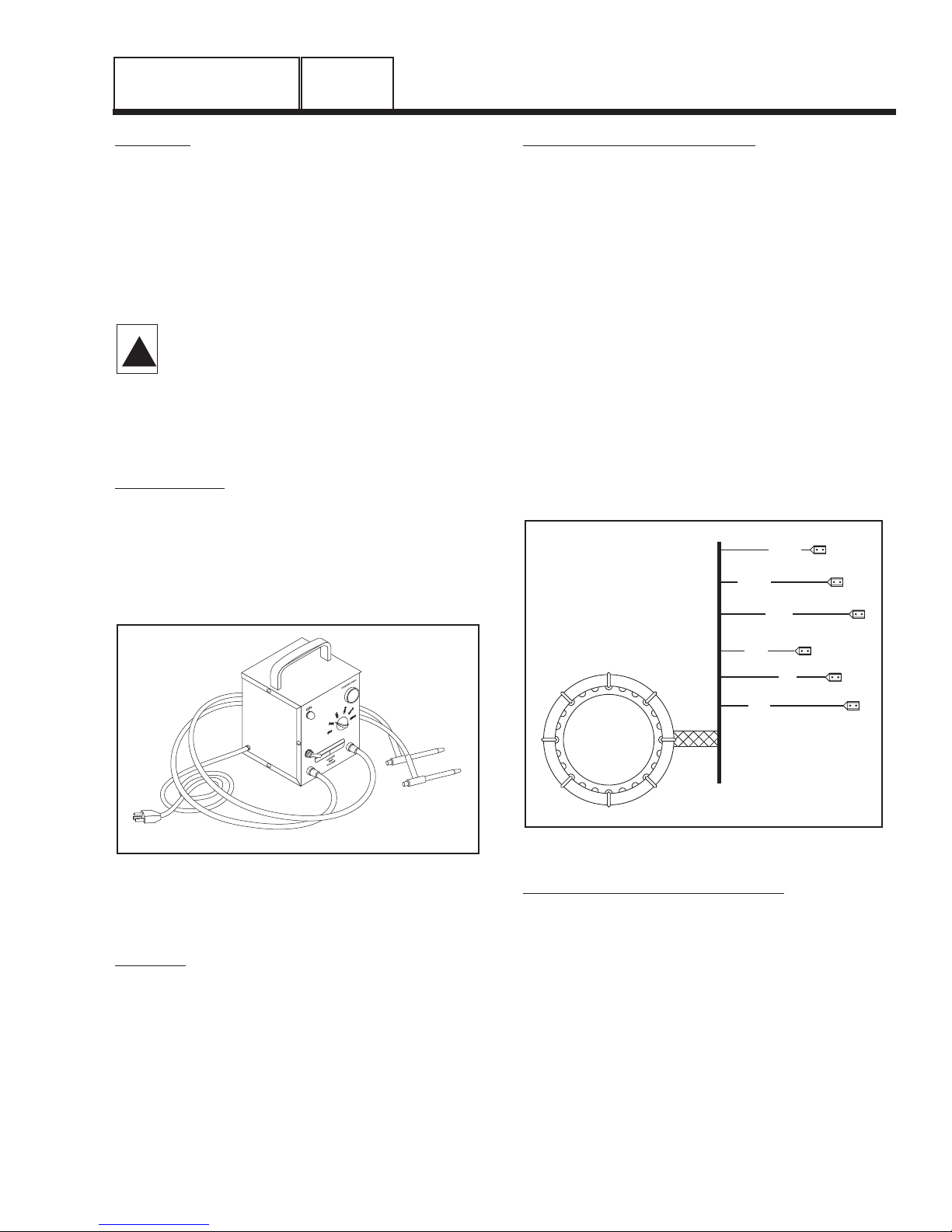

A "Hi-Pot" tester is shown in Figure 1. The model

shown is only one of many that are commercially

available. The tester shown is equipped with a voltage selector switch that permits the power supply

voltage to be selected. It also mounts a breakdown

lamp that will illuminate to indicate an insulation

breakdown during the test.

Figure 1. One Type of Hi-Pot Tester

STATOR INSULATION TESTS

GENERAL:

Units with liquid cooled engine and 1 -phase stator

windings are equipped with (a) dual stator AC power

windings, and (b) an excitation or DPE winding.

These units are not equipped with a battery charge

winding. Stator winding insulation tests consist of (a)

testing all windings to ground, (b) testing between isolated windings, and (c) testing between parallel windings. Figure 3 represents the various stator AC output

leads on 1 -phase units with liquid-cooled engine.

TEST ALL WINDINGS TO GROUND:

1.Disconnect and isolate Stator Leads 11, 22, 33, 44,

2 and 6.

2.Connect terminal ends of all stator leads together.

Make sure all wire terminal ends are completely

isolated from frame ground.

3.Connect the red test probe of the Hi-Pot tester to

the terminal ends of all stator leads. Connect the

black tester probe to a clean frame ground on the

stator can. Then, proceed as follows:

a.Turn the Hi- Pot tester switch OFF

b.Plug the tester cord into a 120 volts AC wall

socket and set its voltage selector switch to

"500 volts".

c.Turn the tester switch ON and observe the

breakdown lamp. After one (1) second, turn the

tester switch OFF.

If the breakdown lamp turned on during the one (1)

second test, clean and dry the stator. Then, repeat

the test. If breakdown lamp comes on during the second test, replace the stator assembly.

Figure 3. Stator Winding Leads (Liquid Cooled Units)

TEST BETWEEN ISOLATED WINDINGS:

1.Connect the red test probe to stator lead 2, the

black probe to stator lead 11.

2.Set the tester switch to "500 volts".

3.Turn the tester switch ON and check that the pilot

lamp is lighted.

4.Wait one (1) second while observing the tester

breakdown lamp. DO NOT EXCEED ONE SECOND. After one (1) second, turn the tester switch

OFF.

5.Connect the red test probe to stator lead 2, the

black probe to stator lead 33. Then, repeat Steps 2,

3 and 4.

!

11

22

33

44

6

2

If the breakdown lamp turned on during any one (1)

second test, the stator should be cleaned and dried.

After cleaning and drying, repeat the test. If the breakdown lamp turns on during the second test, replace

the stator assembly.

TEST BETWEEN PARALLEL WINDINGS:

1 Set the tester’s voltage switch to "500 volts".

2.Connect the red tester probe to stator lead 11, the

black probe to stator lead 33.

3.Turn the tester switch ON and check that the pilot

lamp is on.

4.Waft one (1) second while observing the breakdown lamp. Then, turn the tester switch OFF.

If the breakdown lamp came on during the one (1)

second test, clean and dry the stator. Then, repeat

the test. If breakdown lamp comes on during second

test, replace the stator assembly.

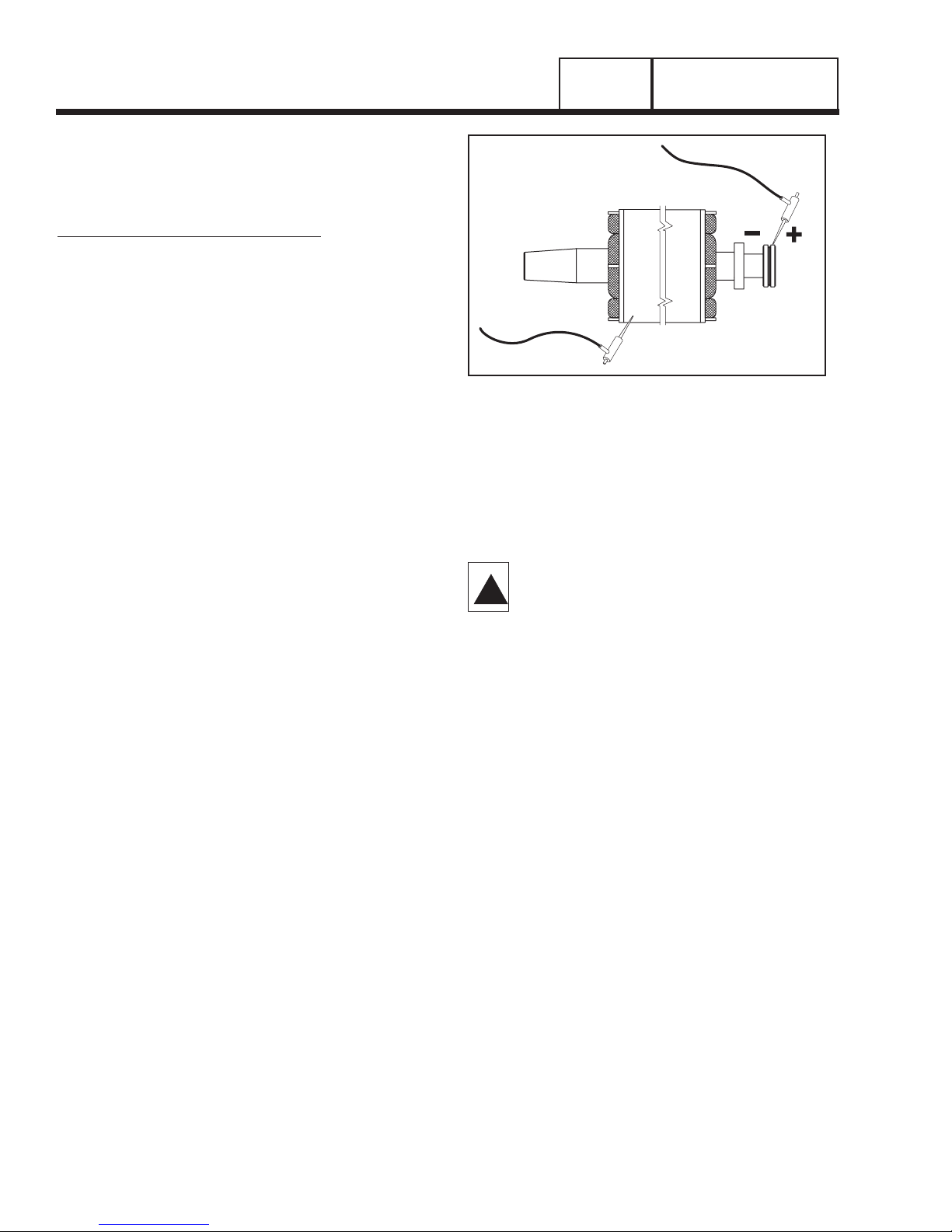

TESTING ROTOR INSULATION

Before attempting to test rotor insulation, either the

brush leads must be completely removed from the

brushes or the brush holders must be completely

removed. The rotor must be completely isolated from

other components before starting the test.

1.Connect the red tester lead to the positive (+) slip

ring (nearest the rotor bearing).

2.Connect the black tester probe to a clean frame

ground, such as a clean metal part of the rotor.

3.Turn the tester switch OFF.

4.Plug the tester into a 120 volts AC wall socket and

set the voltage switch to "500 volts".

5.Turn the tester switch ON and make sure the pilot

light has turned on.

6.Observe the breakdown lamp, then turn the tester

switch OFF. DO NOT APPLY VOLTAGE LONGER

THAN ONE (1) SECOND.

If the breakdown lamp came on during the one (1)

second test, cleaning and drying of the rotor may be

necessary. After cleaning and drying, repeat the insulation breakdown test. If breakdown lamp comes on

during the second test, replace the rotor assembly.

Figure 6. Testing Rotor Insulation

CLEANING THE GENERATOR

Caked or greasy dirt may be loosened with a soft

brush or a damp cloth. A vacuum system may be

used to clean up loosened dirt. Dust and dirt may also

be removed using dry, low-pressure air (25 psi maximum).

CAUTION: Do not use sprayed water to clean

the generator. Some of the water will be

retained on generator windings and terminals, and may cause very serious problems.

DRYING THE GENERATOR

To dry a generator, proceed as follows:

1.Open the generator main circuit breaker. NO ELECTRICAL LOADS MUST BE APPLIED TO THE

GENERATOR WHILE DRYING.

2.Disconnect all wires No. 4 from the voltage regulator.

3.Provide an external source to blow warm, dry air

through the generator interior (around the rotor and

stator windings. DO NOT EXCEED 185° F. (85°

C.).

4.Start the generator and let it run for 2 or 3 hours.

5.Shut the generator down and repeat the stator and

rotor insulation resistance tests.

!

PART 1

Page 12

GENERAL INFORMATION

SECTION 1.4

TESTING, CLEANING AND DRYING

RED TEST LEAD

BLACK TEST LEAD

GENERAL INFORMATION

SECTION 1.5

ENGINE-GENERATOR PROTECTIVE DEVICES

PART 1

Page 13

GENERAL

Standby electric power generators will often run unattended for long periods of time. Such operating parameters as (a) engine oil pressure, (b) engine temperature, (c) engine operating speed, and (d) engine

cranking and startup are not monitored by an operator

during automatic operation. Because engine operation will not be monitored, the use of engine protective

safety devices is required to prevent engine damage

in the event of a problem.

Prepackaged generator engines mount several engine

protective devices. These devices work in conjunction

with a control circuit board, to protect the engine

against such operating faults as (a) low engine oil

pressure, (b) high temperature, (c) overspeed, and (d)

overcrank. On occurrence of any one or more of those

operating faults, control board action will effect an

engine shutdown.

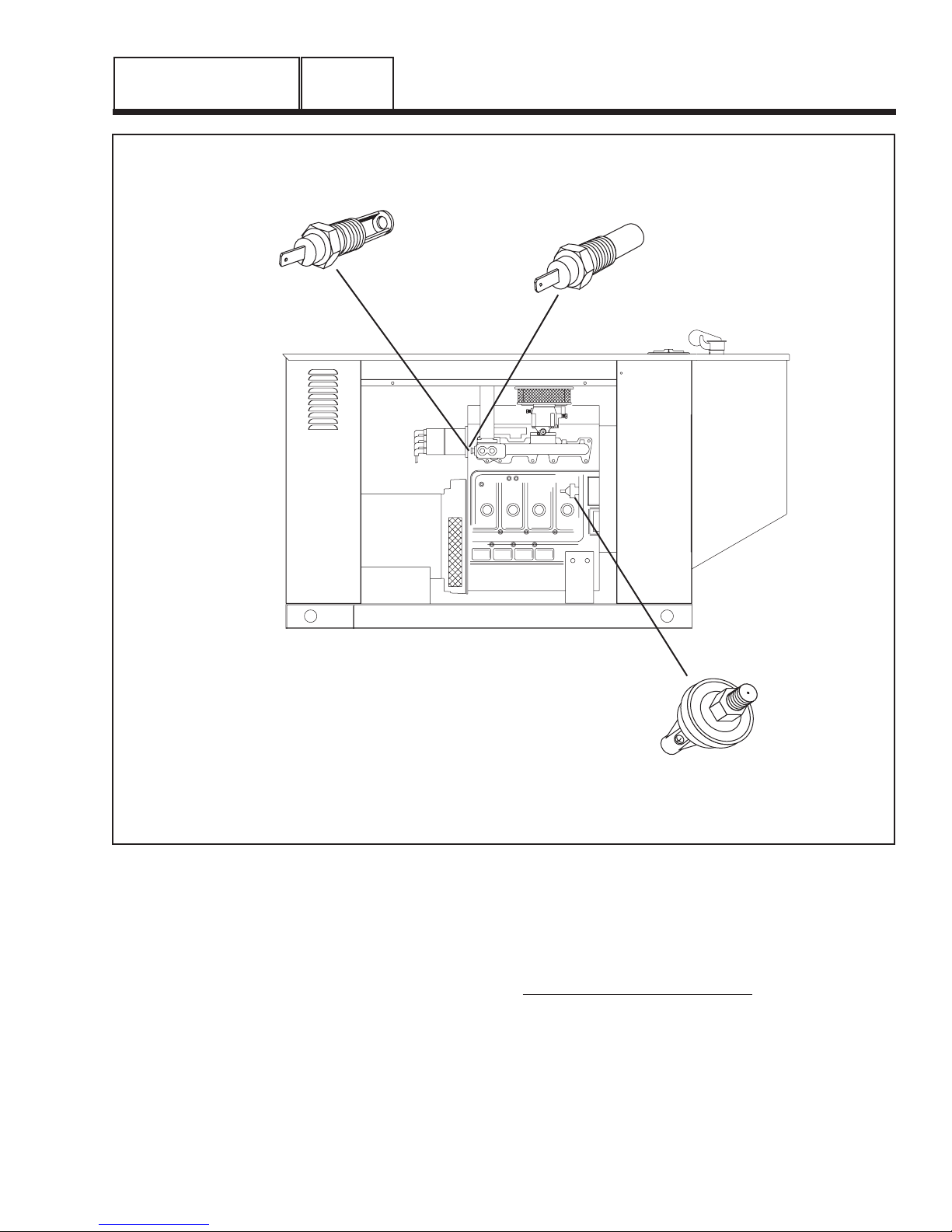

LOW OIL PRESSURE SHUTDOWN:

See Figure 1. Prepackaged generators with liquid

cooled engine are equipped with an oil pressure

switch having a closing pressure of about 10 psi.

Should oil pressure drop below that value, an automatic engine shutdown will occur. Circuit operation is

similar to that of air-cooled units.

Figure 1. Protective Devices on Liquid Cooled Engine

LOW COOLANT

LEVEL SWITCH

HIGH COOLANT

TEMPERATURE

SWITCH

OVERCRANK AND OVERSPEED

SHUTDOWN ARE CONTROLLED

BY THE CIRCUIT BOARD

LOW OIL

PRESSURE

SWITCH

PART 1

Page 14

GENERAL INFORMATION

SECTION 1.5

ENGINE-GENERATOR PROTECTIVE DEVICES

HIGH COOLANT TEMPERATURE SHUTDOWN:

The engine is equipped with a coolant temperature

switch. Should engine coolant temperature exceed

approximately 284° F. (140° C.), the engine will be

shut down automatically by control board action.

LOW COOLANT LEVEL SENSOR:

It is possible that engine coolant level might drop low

enough so that the high temperature switch is no

longer immersed in the liquid coolant. If this happens

engine temperatures could increase rapidly but the

temperature switch would not sense the high temperature condition and the engine would continue to run.

To prevent this occurrence, a low coolant level sensor

is provided. The sensor is immersed in cooling system liquid. If coolant level drops below the level of the

low coolant level sensor, the device will complete a

Wire 85 circuit to ground. Engine shutdown will occur.

OVERSPEED SHUTDOWN:

The control board on liquid cooled units receives AC

frequency (rpm) signals directly from the stator AC

power windings, via sensing leads S15 and S16.

Should AC frequency exceed approximately 72 Hz,

circuit board action will initiate an automatic engine

shutdown.

NOTE: For units rated 1800 rpm, 72 Hz is equal to

2160 rpm.

NOTE: The control board also uses the sensing

lead signals (S15, S16) (a) to terminate cranking

at about 50% of rated frequency, and (b) as an

“engine running” signal. The circuit board will not

initiate transfer of electrical loads to the

"Standby" source until sensing voltage and frequency is greater than 50 % of the unit’s rated

values.

OVERCRANK SHUTDOWN:

Automatic engine cranking and startup normally

occurs when the control board senses that utility

source voltage has dropped below approximately 60

percent of its nominal rated voltage and remains at

that low level longer than six (6) seconds. At the end

of six (6) seconds, control board action will energize a

crank relay and a run relay (both relays are on the

control board). On closure of the crank relay contacts,

control board action will deliver 12 volts DC to a control contactor (CC). The control contactor will energize and battery power will be delivered across its

closed contacts to the starter motor (SM). The engine

will then crank.

During a manual startup (AUTO-OFF-MANUAL

switch at "Manual"), action is the same as during an

automatic start, except that cranking will begin immediately when the switch is set to "Manual".

Control board action (during both a manual and an

automatic start) will hold the crank relay energized for

about 7-9 seconds. The relay will then de-energize for

about 7-9 seconds, and then energize again. In this

manner, the engine will be cranked for 7-9 seconds,

will rest for 7-9 seconds, and will crank again, and so

on until the engine starts.

If the engine has not started after approximately 90 seconds of these crank-rest cycles, cranking will automatically terminate and shutdown will occur. The control

board uses AC signals from the stator battery charge

windings as an indication that the engine has started.

Page 15

CONTROL PANEL

GENERAL:

See Figure 1 (Page 16). A typical prepackaged control

panel on units with liquid cooled engine includes: (a)

an auto-off-manual switch, (b) a fault indicator lamp,

(c) a 15 amp fuse, and (d) a set exercise switch.

AUTO-OFF-MANUAL SWITCH:

Use this switch to (a) select fully automatic operation,

(b) to crank and start the engine manually, and (c) to

shut the unit down or to prevent automatic startup.

1. AUTO position:

a.Select AUTO for fully automatic operation.

b.When AUTO is selected, circuit board will moni-

tor utility power source voltage.

c. Should utility voltage drop below a preset level

and remain at such a low level for a preset time,

circuit board action will initiate engine cranking

and startup.

d.Following engine startup, circuit board action

will initiate transfer of electrical loads to the

“Standby” source side.

e.On restoration of utility source voltage above a

preset level, circuit board action will initiate

retransfer back to the “Utility Source” side.

f. Following retransfer, circuit board will shut the

engine down and will then continue to monitor

utility source voltage.

2. OFF Position:

a.Set the switch to OFF to stop an operating

engine.

b.To prevent an automatic startup from occurring,

set the switch to OFF.

3. MANUAL Position:

a.Set switch to MANUAL to crank and start unit

manually.

b.Engine will crank cyclically and start (same as

automatic startup, but without transfer). The unit

will transfer if utility voltage is not available.

DANGER: WHEN THE GENERATOR IS

INSTALLED IN CONJUNCTION WITH AN

AUTOMATIC TRANSFER SWITCH, ENGINE

CRANKING AND STARTUP CAN OCCUR AT

ANY TIME WITHOUT WARNING (PROVIDING

THE AUTO-OFF-MANUAL SWITCH IS SET TO

AUTO). TO PREVENT AUTOMATIC STARTUP

AND POSSIBLE INJURY THAT MIGHT BE

CAUSED BY SUCH STARTUP, ALWAYS SET

THE AUTO-OFF-MANUAL SWITCH TO ITS

OFF POSITION BEFORE WORKING ON OR

AROUND THIS EQUIPMENT.

FAULT INDICATOR LAMP:

The fault indicator lamp will turn on in the event that

any one or more of the following engine fault conditions should occur: (a) low oil pressure, (b) high

coolant temperature, (c) low coolant level, (d) overspeed, and (e) overcrank.

15 AMP FUSE:

This fuse protects the DC control system, including

the control board, against overload. If the fuse has

blown, engine cranking and running will not be possible. Should fuse replacement become necessary, use

only an identical 15 amp replacement fuse.

THE SET EXERCISE SWITCH:

Use this switch to select the time and day for system

exercise.

TO SELECT AUTOMATIC OPERATION

The following procedure applies to those installations

in which the prepackaged home standby generator is

installed in conjunction with a prepackaged transfer

switch. Prepackaged transfer switches do not have an

intelligence circuit of their own. Instead, automatic

operation on prepackaged transfer switch and generator combinations is controlled by a control circuit

board housed in the generator.

To select automatic operation when a prepackaged

transfer switch is installed along with a prepackaged

home standby generator, proceed as follows:

1. Check that the prepackaged transfer switch main contacts are at their “Utility” position, i.e., the load is connected to the utility power supply. If necessary, manually actuate the switch main contacts to their “Utility” source side.

See Part 3 of this manual for instructions.

2. Check that utility source voltage is available to transfer

switch Terminal Lugs N1 and N2 (2-pole, 1-phase transfer

switches).

3.Set the generator’s AUTO-OFF-MANUAL switch to its

AUTO position.

4. Actuate the generator’s main line circuit breaker to its ON

or “Closed” position. With the preceding Steps 1 through

4 completed, a dropout in utility supply voltage below a

preset level will result in automatic generator cranking

and start-up. Following startup, the prepackaged transfer

switch will be actuated to its “Standby” source side, i.e.,

loads powered by the standby generator.

MANUAL TRANSFER TO “STANDBY” AND

MANUAL STARTUP

To transfer electrical loads to the "Standby" (generator) source and start the generator manually, proceed

!

GENERAL INFORMATION

SECTION 1.6

OPERATING INSTRUCTIONS

PART 1

PART 1

Page 16

GENERAL INFORMATION

SECTION 1.6

OPERATING INSTRUCTIONS

as follows:

1.On the generator panel, set the AUTO-OFF-MANUAL switch to OFF.

2.On the generator, set the main line circuit breaker

to it’s OFF or "Open" position.

3.Turn OFF the utility power supply to the transfer

switch, using whatever means provided (such as a

utility-source line circuit breaker).

4.Manually actuate the transfer switch main contacts

to their “Standby” position, i.e., loads connected to

the “Standby” power source side.

5.On the generator panel, set the AUTO-OFF-MANUAL switch to MANUAL. The engine should crank

and start.

6.Let the engine warm up and stabilize for a minute

or two at no-load.

7.Set the generator’s main line circuit breaker to its

ON or "Closed" position. The generator now powers

the electrical loads.

MANUAL SHUTDOWN AND RETRANSFER

BACK TO "UTILITY"

To shut the generator down and retransfer electrical

loads back to the "Utility" position, proceed as follows:

1.Set the generator’s main line circuit breaker to its

OFF or "Open" position.

2.Let the generator run at no-load for a few minutes,

to cool.

3.Set the generator’s AUTO-OFF-MANUAL switch to

OFF. Wait for the engine to come to a complete

stop.

4.Turn OFF the “Utility” power supply to the transfer

switch using whatever means provided (such as a

“Utility” source main line circuit breaker)

5.Manually actuate the prepackaged transfer switch

to its “Utility” power source side, i.e., “Load” connected to the “Utility” source.

6.Turn ON the “Utility” power supply to the transfer

switch, using whatever means provided.

7.Set the generator’s AUTO-OFF-MANUAL switch to

AUTO.

THE SET EXERCISE TIME SWITCH

The prepackaged home standby generator will start

and exercise once every seven (7) days, on a day

and at a time of day selected by the owner or operator. The set exercise time switch is provided to select

the day and time of day for system exercise.

See Part 5, Section 5.2 ("The 7-Day Exercise Cycle")

for instructions on how to set exercise time.

DANGER: THE GENERATOR WILL CRANK

AND START WHEN THE SET EXERCISE

TIME SWITCH IS SET TO "ON". DO NOT

ACTUATE THE SWITCH TO "ON" UNTIL

AFTER YOU HAVE READ THE INSTRUCTIONS IN SECTION 1.6.

!

Figure 1. Control Panel

HOURMETER

AUTO

OFF

MANUAL

FUSE

15-A

AGC

FAULT

INDICATOR

SET

EXERCISE

TIME

ON

Page 17

GENERAL INFORMATION

SECTION 1.7

AUTOMATIC OPERATING PARAMETERS

PART 1

INTRODUCTION

When the prepackaged generator is installed in conjunction with a prepackaged transfer switch, either

manual or automatic operation is possible. Manual

transfer and engine startup, as well as manual shutdown and retransfer are covered in section 1.7.

Selection of fully automatic operation is also discussed in that section. This section will provide a

step-by-step description of the sequence of events

that will occur during automatic operation of the system.

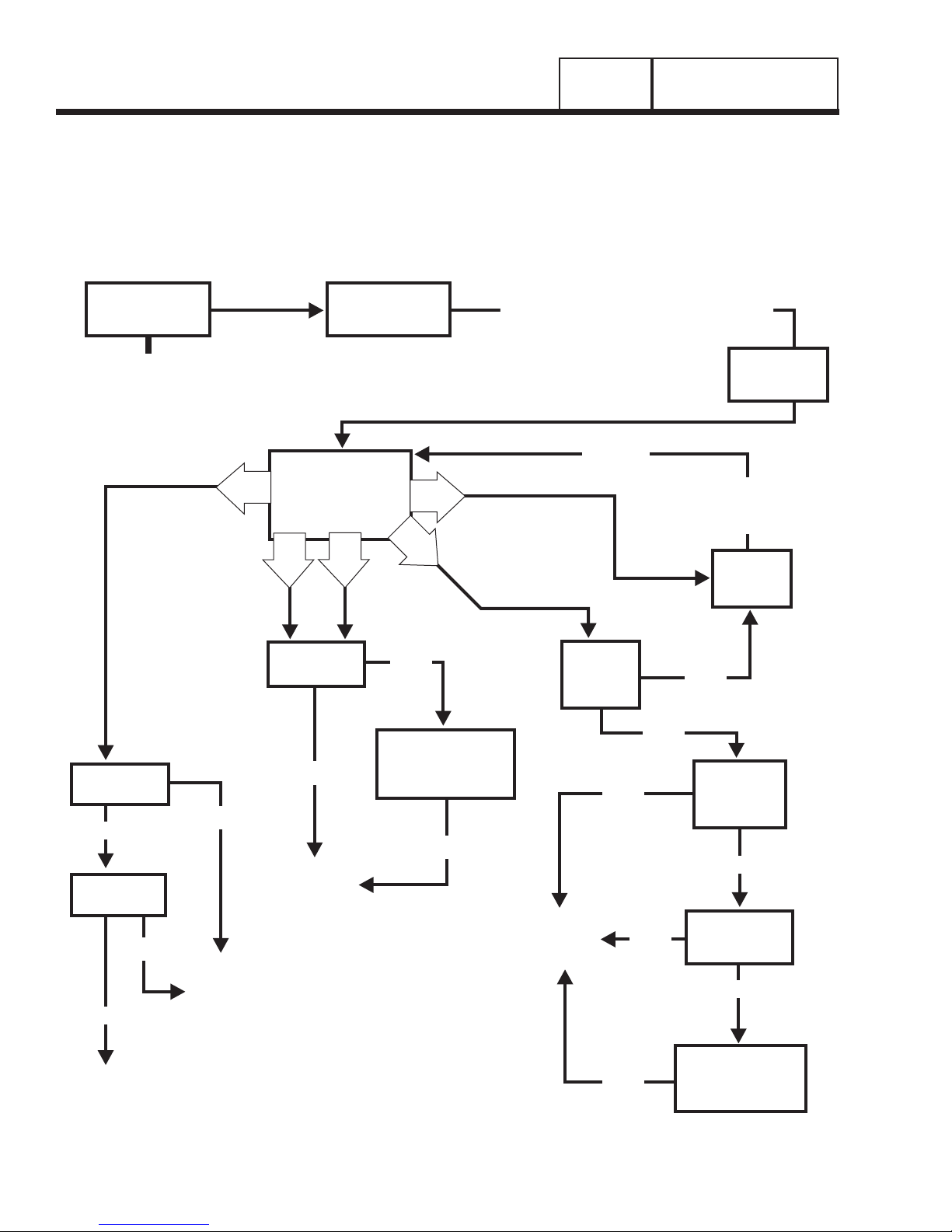

AUTOMATIC OPERATING SEQUENCES

PHASE 1 - UTILITY VOLTAGE AVAILABLE:

With utility source voltage available to the transfer

switch, that source voltage is sensed by a control

board in the generator panel and the circuit board

takes no action.

Electrical loads are powered by the "Utility" source

and the AUTO-OFF-MANUAL switch is set to AUTO.

PHASE 2 - UTILITY VOLTAGE DROPOUT:

If a dropout in utility source voltage should occur

below about 60 percent of the nominal utility source

voltage, a 12 second timer on the control board will

start timing. This timer is required to prevent false

generator starts that might be caused by transient utility voltage dips.

PHASE 3 - ENGINE CRANKING:

When the control board’s 12 second timer has fin-

ished timing and if utility source voltage is still below

60 percent of the nominal source voltage, control

board action will energize a crank relay and a run

relay. Both of these relays are mounted on the control

board.

Control board action will hold the crank relay energized for about 7-9 seconds. The relay will then be

de-energized for about 7-9 seconds, energized again

for 7-9 seconds, and so on. When the crank relay

energizes the engine will crank, when it is de-energized, engine cranking will stop. This cyclic action of

crank/rest, crank/rest, etc., will continue until either (a)

the engine starts, or (b) until ninety (90) seconds have

elapsed.

If the engine has not started within ninety (90) seconds, cranking will terminate and shutdown will occur.

On liquid cooled engine units, a fault indicator lamp

(LED) on the generator panel will illuminate.

If the engine starts, cranking will terminate when generator AC output frequency reaches approximately 30 Hz.

PHASE 4 - ENGINE STARTUP AND RUNNING:

The control board senses that the engine is running

by receiving a voltage/frequency signal from the generator stator windings.

When generator AC frequency reaches approximately

30 Hz, an engine warm-up timer on the control board

turns on. That timer will run for about fifteen (15) seconds. At the same time, an engine minimum run timer

will turn on.

The engine warm-up timer lets the engine warm-up

and stabilize before transfer to the "Standby" source

can occur.

The engine minimum run timer prevents a cold engine

from being shut down, as might happen if utility

source power is restored very quickly. The minimum

run timer will run for about 10-12 minutes. That

means the engine must run for 10-12 minutes before

it can be shut down automatically.

NOTE: The engine can be shut down manually at

any time, by setting the AUTO-OFF-MANUAL

switch to OFF.

PHASE 5 - TRANSFER TO “STANDBY”:

When the control board’s engine warm-up timer has

timed out, control board action completes a transfer

relay circuit to ground. The transfer relay is housed in

the prepackaged transfer switch enclosure.

The transfer relay energizes and transfer of loads to

the “Standby” power source occurs. Loads are now

powered by standby generator AC output.

PHASE 6 - “UTILITY” POWER RESTORED:

When utility source voltage is restored above about

80 percent of the nominal supply voltage, a fifteen

(15) second timer on the control board starts timing. If

utility voltage remains sufficiently high at the end of

fifteen (15) seconds, a “retransfer time delay” will start

timing and will time for about six (6) seconds.

PHASE 7 - RETRANSFER BACK TO “UTILITY”:

When the retransfer time delay has finished timing,

control board action will open a circuit to a transfer

relay (housed in the transfer switch). The transfer

relay will then de-energize and retransfer back to the

“Utility” source will occur. Loads are now powered by

“Utility” source power. On retransfer, an “engine cooldown timer” starts timing and will run for about one (1)

minute.

PHASE 8 - GENERATOR SHUTDOWN:

When the engine cool-down timer has finished timing,

and if the minimum run timer has timed out, engine

shutdown will occur.

PART 1

GENERAL INFORMATION

SECTION 1.7

AUTOMATIC OPERATING PARAMETERS

Page 18

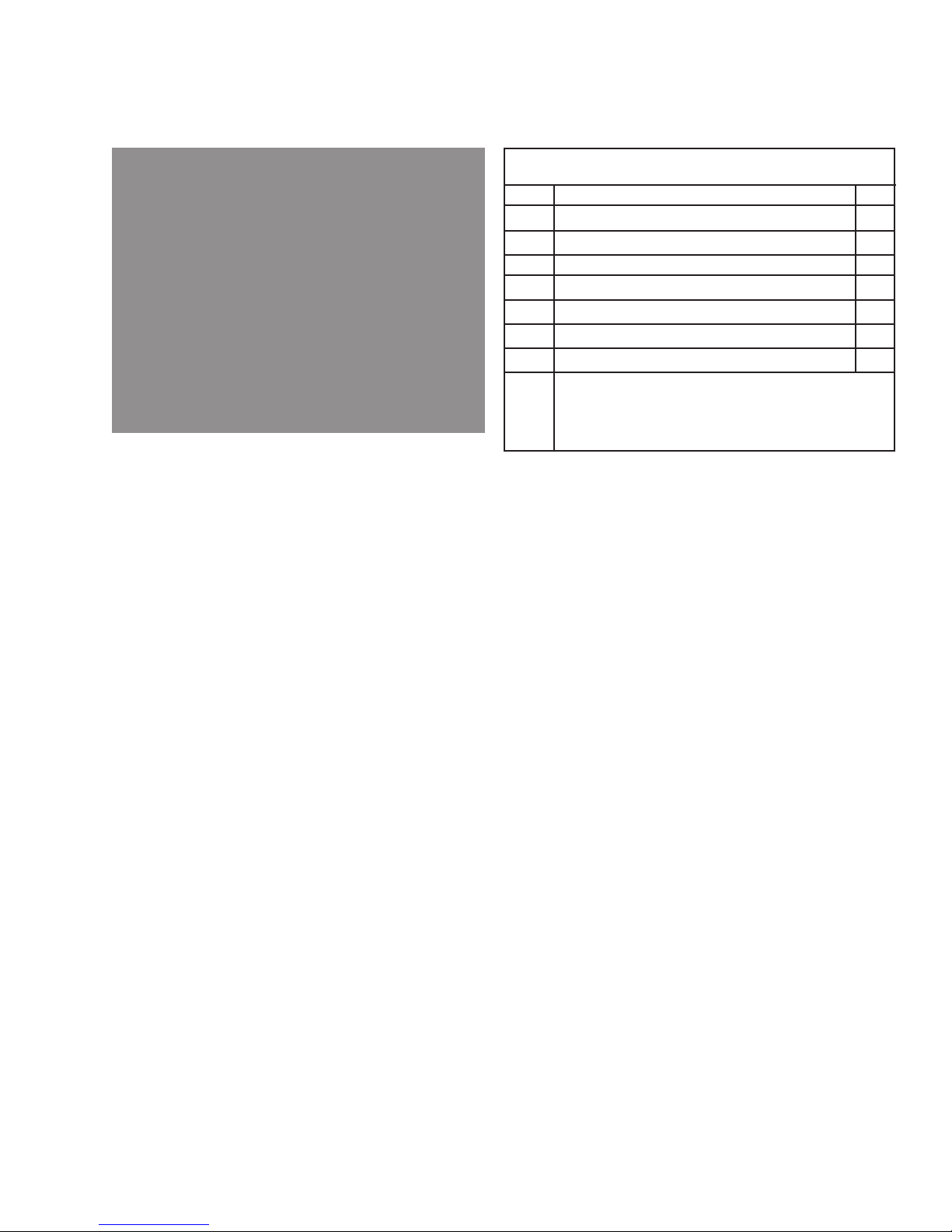

AUTOMATIC OPERATING SEQUENCES CHART

SEQ. CONDITION ACTION SENSOR, TIMER OR OTHER

1 “Utility” source voltage is No action Voltage Dropout Sensor on control

available. circuit board.

2 “Utility” voltage dropout below A 6-second timer on control Voltage Dropout Sensor and 6

60% of rated voltage occurs. board turns on. second timer on control board.

3 “Utility” voltage is still below 6-second timer runs for 6 Voltage Dropout Sensor and 6

60% of rated voltage. seconds, then stops. second timer.

4 “Utility” voltage is still low after Control board action energizes a Control board crank and run

6 seconds. crank relay and a run relay. The relays.

engine cranks for 7-9 seconds,

rests for 7-9 seconds, and so on

until engine starts. See NOTE 1.

5 “Utility” voltage still low and Control board’s “engine warmup Engine Warmup Timer (15 seconds)

the engine has started. timer” and “engine minimum run Minimum Run Timer (13 minutes)

timer” both turn on.

6 Engine running and “engine Control board action energizes a Control board transfer relay circuit

warmup timer” times out. transfer relay in transfer switch Transfer switch transfer relay.

and transfer to “Standby” occurs.

7 Engine running and load is No further action Control board’s “voltage pickup

powered by “Standby” power. sensor” continues to seek an

acceptable “Utility voltage.

8 “Utility” source voltage is Control board’s “voltage pickup Voltage Pickup Sensor (80%)

restored above 80% of rated sensor” reacts and a “return to Return to Utility Timer (10 seconds)

source voltage. utility timer” turns on.

9 “Utility voltage still high after 6 “Return to utility timer” times out Return to Utility Timer

seconds.

10 “Utility” voltage still high. Control board action opens the Control board transfer relay circuit

transfer relay circuit to ground. Transfer switch transfer relay.

Transfer relay de-energizes and

retransfer to “Utility” occurs.

11 Engine still running, loads are Control board’s “engine cooldown control board’s Engine Cooldown

powered by “Utility” source. timer” starts running. Timer (1 minute)

12 After 1 minute, “engine cooldown Engine Cooldown Timer

timer” stops and control board’s control board Run Relay.

run relay de-energizes. Engine

shuts down.

13 Engine is shut down, loads are No action. Voltage Dropout Sensor on control

powered by “Utility” source. circuit board.

Return to Sequence 1.

Note1: In Sequence 4, if engine has not started in 90 seconds cranking will end and shutdown will occur.

Page 19

PART TITLE PAGE

2.1 Description and Major Components 20

2.2 AC Output Operational Analysis 24

2.3 AC Output Troubleshooting Flow Charts 26

Problem 1 - Generator Produces ZeroVoltage or

ResidualVoltage 26

Problem 2 - Generator Produces

LowVoltage at No-Load 28

Problem 3 - Generator Produces High

Voltage at No-Load 28

Problem 4 -Voltage and Frequency Drop

ExcessivelyWhen Loads Are Applied 29

2.4 AC Output Diagnostic Tests 30

TABLE OF CONTENTS

1.5 LITER PREPACKAGED

HOME STANDBY

GENERATORS

PART 2

PREPACKAGED

LIQUID-COOLED

AC GENERATORS

TEST DESCRIPTION ......................................PAGE

1 Check Main Circuit Breaker ................................ 30

2 Check AC Output Voltage .................................. 31

3 Test Excitation Circuit Breaker .......................... 31

4 Test Thermal Protector ...................................... 32

5 Fixed Excitation Test/Rotor

Amp Draw Test .................................................. 32

6 Wire Continuity .................................................. 33

7 Check Field Boost .............................................. 33

8 Testing the Ststor with a VOM ............................ 34

9 Resistance Check of Rotor Circuit .................... 35

TEST DESCRIPTION ......................................PAGE

10 Check Brushes

and Slip Rings .................................................... 35

11 Test Rotor Assembly .......................................... 35

12 Check AC Output Frequency ............................ 36

13 Check and Adjust Governor Board

and Stepper Motor .............................................. 36

14 Check and Adjust

Voltage Regulator .............................................. 38

15 Check Voltage and Frequency Under Load ...... 38

16 Check for Overload Condition ............................ 38

17 Check Engine Condition .................................... 38

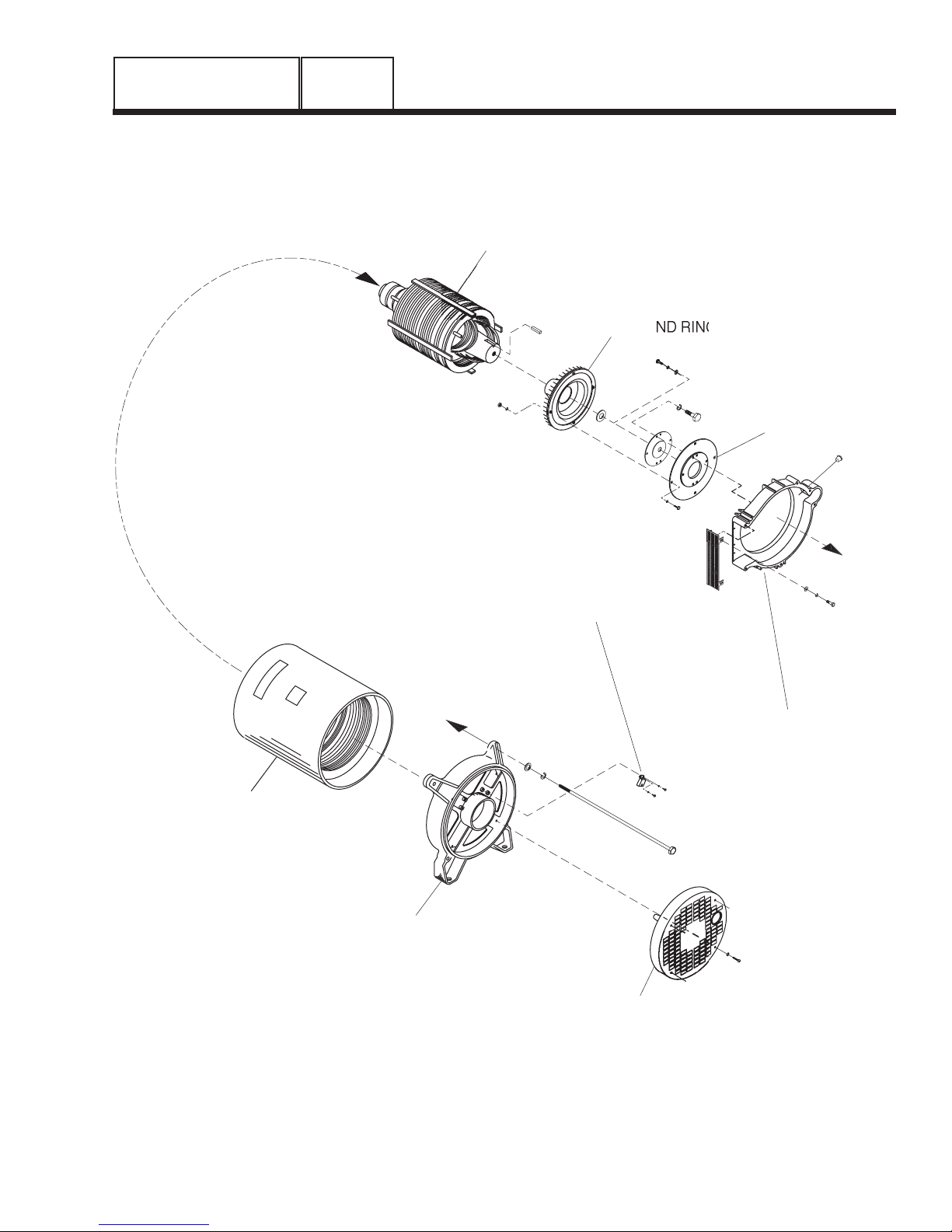

INTRODUCTION

This section covers the major components of the AC

generator proper, i.e., those generator assemblies

that provide for the production of AC electrical power.

The single bearing rotor (revolving field) is driven by a

1.5 liter, liquid cooled gas engine. The rotor is coupled to the engine flywheel, by means of a flexible

coupling and a fan and ring gear assembly, so the

engine crankshaft and rotor operate at the same

speed.

Major components of the AC generator are shown in

Figure 1 on the next page. These components are (a)

a flexible coupling, (b) fan and ring gear, (c) rotor, (d)

blower housing, (e) stator assembly, (f) rear bearing

carrier, and (g) a rear bearing carrier cover.

BLOWER HOUSING

The blower housing is bolted to the engine and supports the engine end of the AC generator. It houses

the fan and ring gear assembly. A cutout area on one

side of the housing allows a blower air outlet screen

to be mounted.

FLEXIBLE DISK

A flexible disk bolts to the engine flywheel and to the

fan and ring gear assembly. The disk maintains proper alignment between the engine and generator parts.

FAN AND RING GEAR ASSEMBLY

The fan and ring gear assembly are retained to the

flexible disk which, in turn, is retained to the engine

flywheel. The fan draws cooling air into the generator

interior through slots in a rear bearing carrier cover,

then expels the heated air outward through a screen

on the blower housing. The ring gear teeth mate with

teeth on a starter motor pinion gear, when the engine

is cranked.

ROTOR ASSEMBLY

The rotor assembly on units rated 1800 rpm is a 4pole type, having two north magnetic poles and two

south magnetic poles.

The rear end of the rotor is bolted and keyed to the

fan and ring gear. A ball bearing has been pressed

onto the rotor’s front shaft, which is retained, in a

machined bore in the rear bearing carrier.

A positive (+) and a negative (-) slip ring is provided

on the rotor shaft that retains the ball bearing.

Brushes will ride on these slip rings.

The combination of slip rings and brushes allow rotor

excitation current to be transmitted from stationary

components into the rotating rotor windings. The positive (+) slip ring is the one nearest the rotor bearing.

REAR BEARING CARRIER

The rear bearing carrier supports the front of the generator. Mounting feet at the carrier bottom permit the

carrier to be bolted to the generator’s mounting base.

A machined bore, in the center of the carrier, accepts

the rotor bearing. Bosses allow for the retention of

brush holders. Long stator bolts pass through holes in

the carrier’s outer periphery, to sandwich and retain

the stator can between the carrier and the blower

housing. A rear bearing carrier gasket helps prevent

dust from entering the bearing area.

STATOR ASSEMBLY

The stator can is sandwiched between the blower

housing and the rear bearing carrier, and retained in

that position by four (4) stator bolts.

A notched cutout has been provided in the rear bearing carrier end of the stator can. A rubber grommet

has been placed into that notch, for protection of the

stator leads that are brought out of the stator.

REAR BEARING CARRIER PLATE

This plate is retained to the rear bearing carrier by

four (4) capscrews, lockwashers and flatwashers. The

plate provides slotted air inlet openings for the passage of cooling and ventilating air into the generator.

BRUSH HOLDERS AND BRUSHES

Brushes are retained in a brush holder which is

retained to drilled and threaded bosses on the rear

bearing carrier. In most cases, two brush holders are

used having two brushes per holder. Brush holders

are precisely positioned so that one of the two brushes slides on a positive (+) slip ring, the other on a

negative (-) slip ring. The positive (+) brush and slip

ring are nearest the rotor bearing. The positive (+)

side of the DC excitation circuit (Wire No. 4, red) connects to the positive (+) brush; the negative (-) or

grounded side (Wire No. 0) to the negative (-) brush.

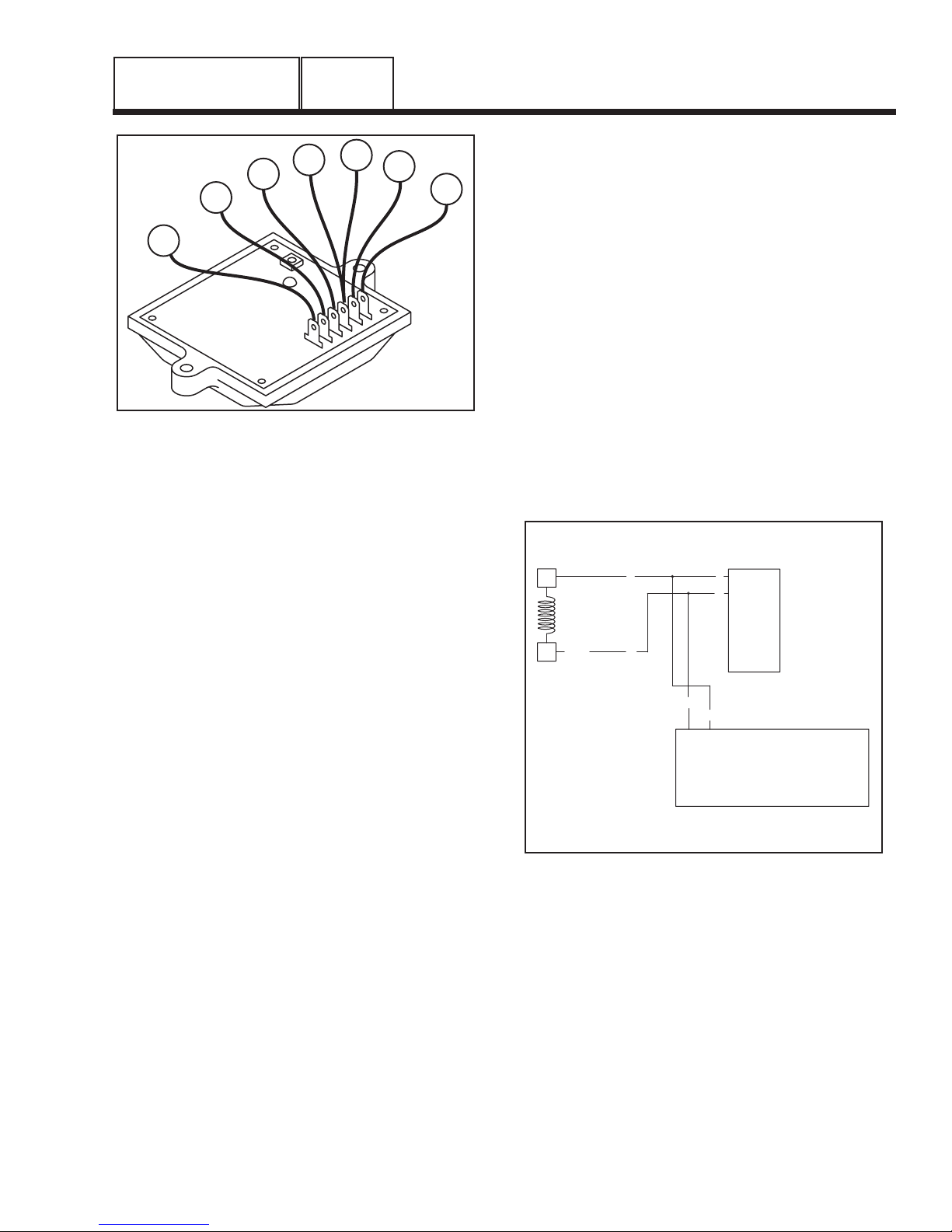

Brushes and brush holders are illustrated in Figure 2,

on Page 22.

PART 2

Page 20

PREPACKAGED LIQUID

COOLED AC GENERATORS

SECTION 2.1

DESCRIPTION AND MAJOR COMPONENTS

PREPACKAGED LIQUID

COOLED AC GENERATORS

SECTION 2.1

DESCRIPTION AND MAJOR COMPONENTS

PART 2

Page 21

S

OR

er

g

OR

OUSING

SK

S

R

E

e

t

Figure 1. Generator Major Components

ROT

FLEXIBLE DI

TAT

REAR BEARING CARRIE

BRUSH HOLDERS AND BRUSHE

To Blow

Housin

REAR BEARING CARRIER PLAT

To Engin

rankshaf

BLOWER H

Figure 2. Brush Holders and Brushes

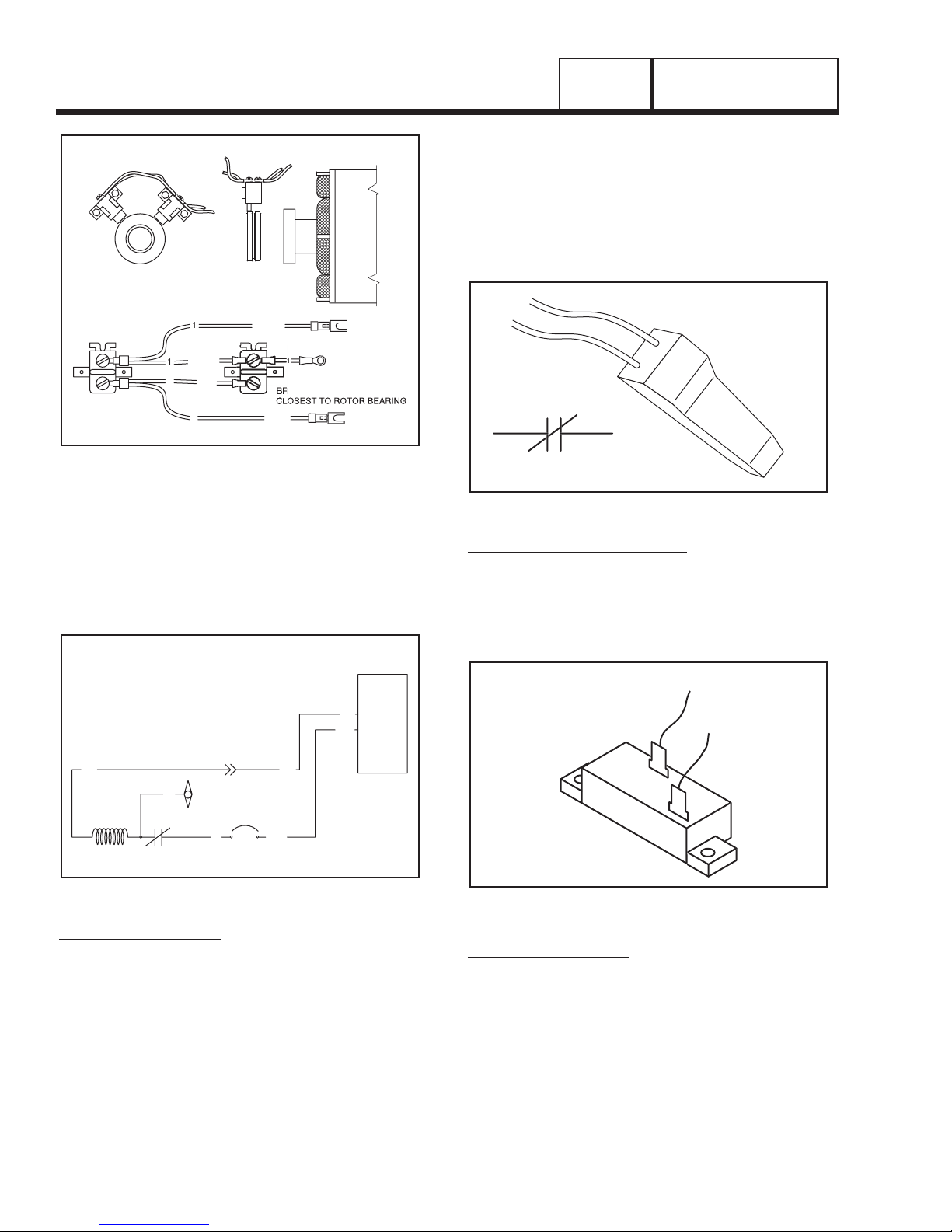

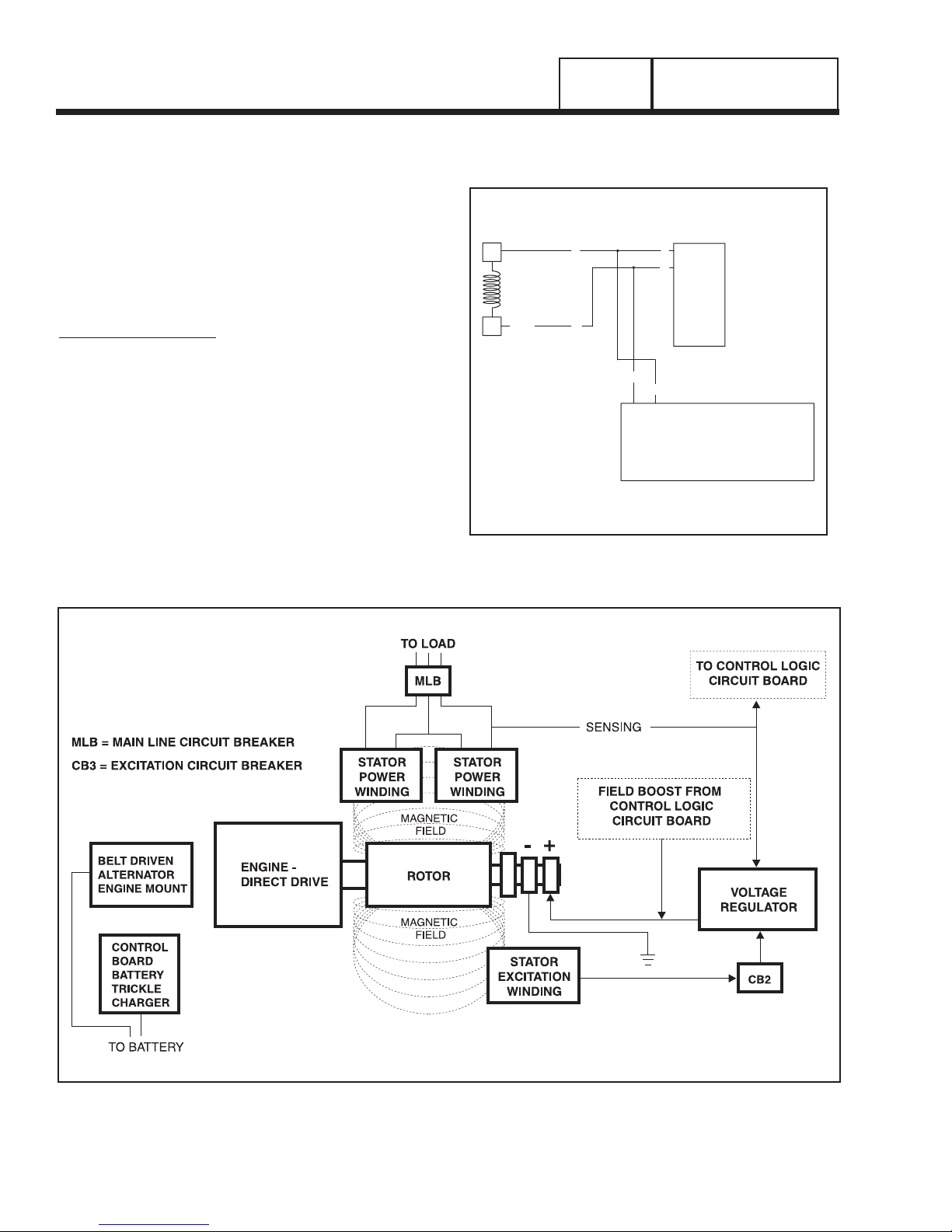

THE EXCITATION CIRCUIT

AC output from the stator excitation (DPE) winding is

delivered to the voltage regulator, via a thermal protector (TP), Wire No. 2, an excitation circuit breaker

(CB1), Wire No. 162, and Wire No. 6. This is “unregulated” excitation current.

Figure 3. Schematic - Excitation Circuit

THERMAL PROTECTOR:

This normally closed thermal switch protects the stator

windings against excessively high internal temperatures. The switch is physically imbedded in the stator

windings and electrically connected in series with the

DPE winding AC output to the regulator. If internal stator temperatures exceed a safe value, the switch contacts will open and the DPE output to the voltage regulator will be terminated. Without excitation current flow

to the rotor, generator AC output voltage will drop to a

value commensurate with rotor residual magnetism.

The thermal protector is self-resetting. That is, when

internal stator temperatures drop to a safe value, its

contacts will re-close and normal DPE output to the

regulator will resume.

Wire No. 5 is a thermal protector “bypass” lead. If the

thermal switch has failed in its open position, it can be

bypassed. The Wire No. 5 bypass lead is brought out

of the stator and has a wire nut on its end.

Figure 4. The Thermal Protector

EXCITATION CIRCUIT BREAKER:

This circuit breaker protects the regulator against high

voltage surges. If the breaker has tripped open, loss

of excitation current will occur. Stator power winding

AC output voltage will then drop to a value commensurate with residual magnetism in the rotor. The

breaker is self-resetting.

Figure 5. Excitation Circuit Breaker

VOLTAGE REGULATOR:

See Figure 6. Unregulated AC output from the stator

DPE winding is delivered to the voltage regulator, via

Wires No. 6 and 162. Stator power winding AC voltage and frequency signals are delivered to the regulator, via “sensing” Wires No. S15 and S16. The regulator rectifies the DPE output and, based on the sensing

lead signals, regulates the DC current output. An LED

(light emitting diode) is incorporated on the regulator.

This red light senses the “sensing” (S15/S16) input.

62

CK

CK

D

D

PART 2

Page 22

PREPACKAGED LIQUID

COOLED AC GENERATORS

SECTION 2.1

DESCRIPTION AND MAJOR COMPONENTS

+ -

BLA

BLA

H WITH RED LEA

RE

DPE - STATOR EXCITATION WINDING

CB2 - EXCITATION CIRCUIT BREAKER

VR - VOLTAGE REGULATOR

TP - THERMAL PROTECTOR

6

DPE TP

WIRE

5

NUT

(BYPASS)

2

CB2

6

162

162

6

VR

1

PREPACKAGED LIQUID

COOLED AC GENERATORS

SECTION 2.1

DESCRIPTION AND MAJOR COMPONENTS

PART 2

Page 23

Figure 6. Prepackaged Voltage Regulator

If the red LED goes “out”, sensing signals to the regulator have been lost. The following rules apply:

• Loss of sensing can be caused by an “open” circuit

condition in sensing leads S15 and S16. These

sensing leads also operate the generator’s panel

mounted AC frequency meter. Thus, if the red LED

is out, it may be assumed that an open circuit exists

in the sensing circuit.

• Loss of sensing to the regulator will usually result in

a “full field” condition and resultant high voltage output from stator AC power winding. The maximum

voltage that regulator action can deliver is limited by

a “clamming” action on the part of the regulator.

• A complete open circuit condition in the stator AC

power windings will cause loss of sensing voltage

and frequency. However, this will result in a zero

voltage output from the stator windings.

Based on the “sensing” signals, the regulator delivers

direct current (DC) to the rotor, via Wire No. 4 and the

positive (+) brush and slip ring. This regulated current

flows through the rotor and to frame ground, via the

negative (-) slip ring and brush and Wire No. 1. The

following apply:

• The concentration of magnetic flux lines around the

rotor will be proportional to the regulated excitation

current flow through the rotor plus any residual

magnetism.

• An increase in excitation current flow through the

rotor windings will increase the concentration of

“magnetic flux” lines around the rotor which, in turn,

will increase the AC voltage induced into the stator

AC power windings.

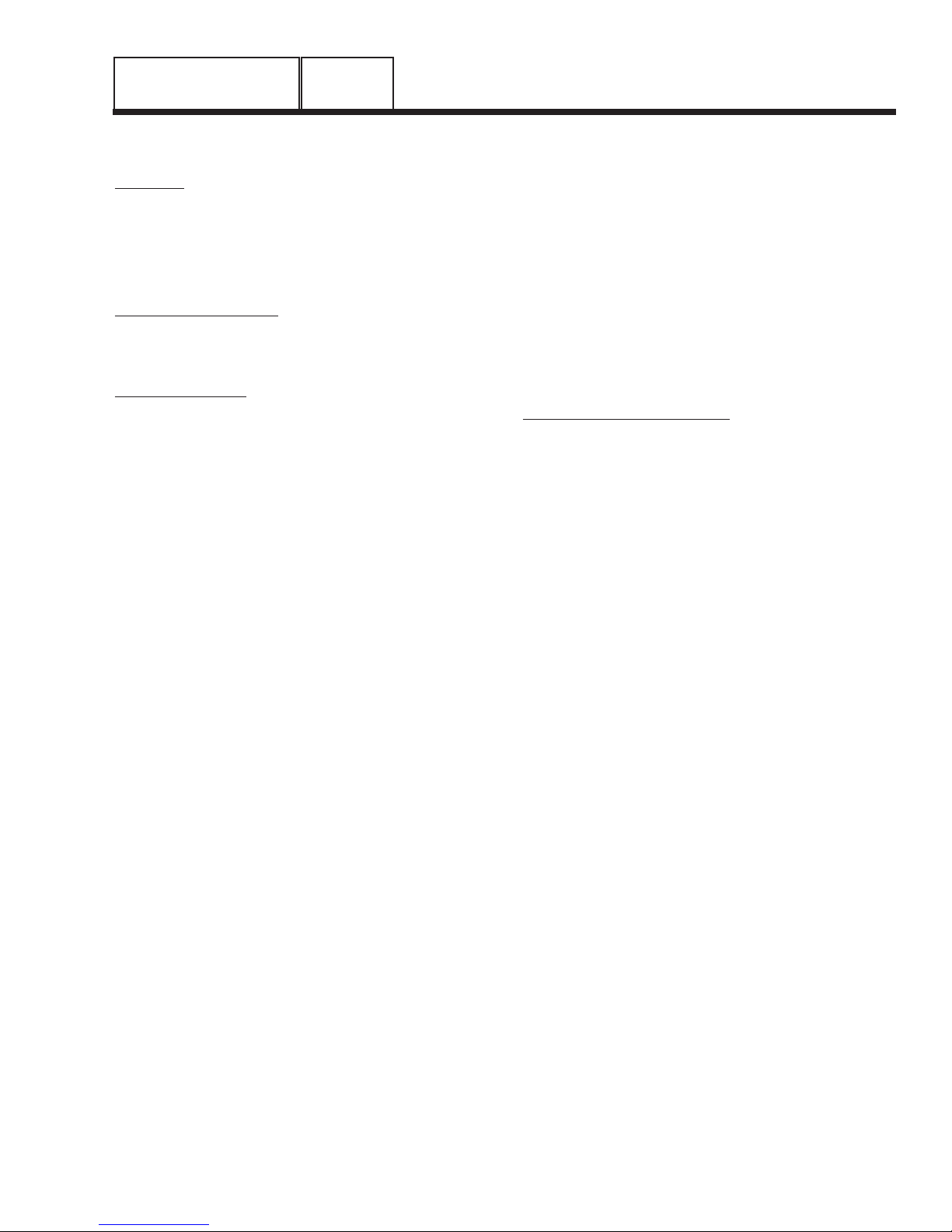

FIELD BOOST

See Figure 7. The prepackaged system provides a

“field boost” feature. Field boost, in effect, “flashes the

field” whenever the engine is cranking to ensure an

early “pickup voltage” in the stator windings.

A field boost diode and a field boost resistor are

installed in a printed circuit board. Field boost DC output to the rotor is reduced to approximately 9-10 volts

by the field boost resistor.

Manual and automatic cranking is initiated by PCB

board action, when that board energizes a crank relay

(K1). When the relay is energized, battery voltage is

delivered across its closed contacts and to the rotor,

via a field boost resistor, field boost diode, and Wire

No. 4. Notice that field boost current flow is available

only while the engine is cranking.

Figure 7. The Field Boost Circuit

(from Schematic Drawing #0F5244)

0

6

4

4

S16

S15

162

1

AR

RED

4

1

4

0

4

VR

4

0

2

17A

7D119

5

PCB

16

10

12

E

4

3

14

15

13

1

B

ROTOR RESIDUAL MAGNETISM

The generator revolving field (rotor) may be considered to be a permanent magnet. Some ‘residual”

magnetism is always present in the rotor. This residual magnetism is sufficient to induce a voltage into

the stator AC power windings that is approximately 212 volts AC.

FIELD BOOST

FIELD BOOST CIRCUIT:

When the engine is cranking, direct current flow is

delivered from a circuit board to the generator rotor

windings, via Wire 4.

The field boost system is shown schematically in

Figure 2. Manual and automatic engine cranking is

initiated by circuit board action, when that circuit

board energizes a crank relay. Battery voltage is then

delivered to field boost Wire 4 (and to the rotor), via a

field boost resistor and diode. The crank relay, field

boost resistor and diode are all located on the circuit

board.

Notice that field boost current is available only while

the crank relay is energized, i.e., while the engine is

cranking.

Field boost voltage is reduced from that of battery

voltage by the resistor action and, when read with a

DC voltmeter, will be approximately 9 or 10 volts DC.

Figure 7. The Field Boost Circuit

(from Schematic Drawing #0F5244)

Figure 1. Operating Diagram of AC Generator

PART 2

Page 24

PREPACKAGED LIQUID

COOLED AC GENERATORS

SECTION 2.2

OPERATIONAL ANALYSIS

1

AR

RED

4

1

4

0

4

VR

4

0

2

13

1

B

17A

7D119

5

PCB

16

10

12

E

4

3

14

15

PREPACKAGED LIQUID

COOLED AC GENERATORS

SECTION 2.2

OPERATIONAL ANALYSIS

PART 2

Page 25

OPERATION

STARTUP: