Page 1

l

www.guardall.com | +1 877.249.9993

sales@guardall.com +1 905.206.8434 | hotline@guardall.com +1 905.206.8436 | Fax: +1 905.629.4970

Guardal

5201 Explorer Drive, Mississauga, Ont., Canada. L4W-4H1

21-3618v1.1 MONITOR ISM™ / AFx™ Suite Security 4 Zone Keypad Installation

!! Do's & Don’ts !!

• Static can destroy IC chips! Always take

proper precautions when handling or

transporting circuit boards.

• Remove all power (AC and back-up

battery) before servicing this unit.

• Always conform to local fire and building

regulations (if unsure, find out).

• Refer to the system commissioning guide,

and follow the details therein regarding:

+ General installation guidelines;

+ Upgrading an existing system;

+ Standards and emissions issues;

+ Input-point circuit-wiring reference;

+ Setting up a new system.

• Then, be sure to follow the details in this

document, pertaining to: Page

+ System Overview................................ 1

+ System grounding requirements ........ 2

+ Mounting details ................................. 2

+ Wiring reference ................................ 2

+ Power and Cable requirements ......... 3

+ Keypad Service Commands ............... 3

+ Specifications ..................................... 4

These instructions describe the hardware installation of the MONITOR ISM/AF x 4 Zone

Suite Security Keypad. This keypad can only be configured through the Monitor ISM/AFx

Director Software in “Suite Security” programming (software and main panel firmware

version 4.58E or greater is required). For details, refer to the Director software on-line

help or latest Monitor ISM/AFx Director Software User’s Guide.

For 4 zone keypad command entries, keypad tones and light display descriptions, please

refer to the Multi-Tenant Apartment Security System User Guide, P/N 21-3615.

System Overview

The 4 zone keypad provides suite security for a wide range of applications from

a simple strip plaza to a multi-tower residential apartment. When using suite

security keypads only, each main control panel can support a maximum of 60

keypads.

cde Typical Steps cde

1) Read "Do's & Don’ts" above, & ensure

all installation instructions are present.

2) Unpack and check all items.

(Ensure you have all necessary items

including: Director software, main panel, all

modules and peripherals, sensors, all

cabling, and all related documentation).

3) Plan device and sensor locations, and

run all cables as required. To prevent

damage, run cables before

mounting the specific modules.

4) Install sensors in desired locations. Be

sure to distance all cables from sources

of electromagnetic interference (arc

welders, motors, ballasts, etc.).

5) Mount these units and supplementary

power supplies (see Power

Requirements, page 3).

6) Complete the wiring. Refer to the

illustration(s) that follow, in addition to

the input-point circuit details in the

system-commissioning guide.

7) Power up and test as necessary.

8) Install other modules, peripherals, etc.

Refer to the instructions for each item.

Tip: Record five digit serial numbers on

each keypad to program into the system

during Suite Security programming.

9) Install your software and set up the

system. Refer to the on-line help or

user's guide provided with your system

software, or the commissioning

reference guide for your system.

10) When finished, ensure all wires are

clear, and secure the cover (or door).

11) Hand over to the customer, answer

questions and perform training and

tests as necessary.

System Grounding

Cabinet Grounding: Each metal cabinet in

the system must be connected to a locallyapproved earth ground, using at least 18

AWG (stranded) cable.

Cable Shield Grounding: The module bus

cable shield is to be earth-grounded only at

the main panel, and connected together at

each module.

Module Logical Grounding: The module

bus ( – ) connection provides a common

ground reference for all controller modules.

Do not connect this to the cabinet earth

ground.

Power Supply Grounding: For any

supplementary power supplies, the 0V /

Ref. Gnd. line must NOT be earth

grounded.

Warning

Changes or Modifications not expressly

approved by the manufacturer could void

the user's authority to operate this

equipment.

CSG Security Corp. / Sécurité CSG Corp. Page 1 of 4

Page 2

l

www.guardall.com | +1 877.249.9993

sales@guardall.com +1 905.206.8434 | hotline@guardall.com +1 905.206.8436 | Fax: +1 905.629.4970

Guardal

5201 Explorer Drive, Mississauga, Ont., Canada. L4W-4H1

21-3618v1.1 MONITOR ISM™ / AFx™ Suite Security 4 Zone Keypad Installation

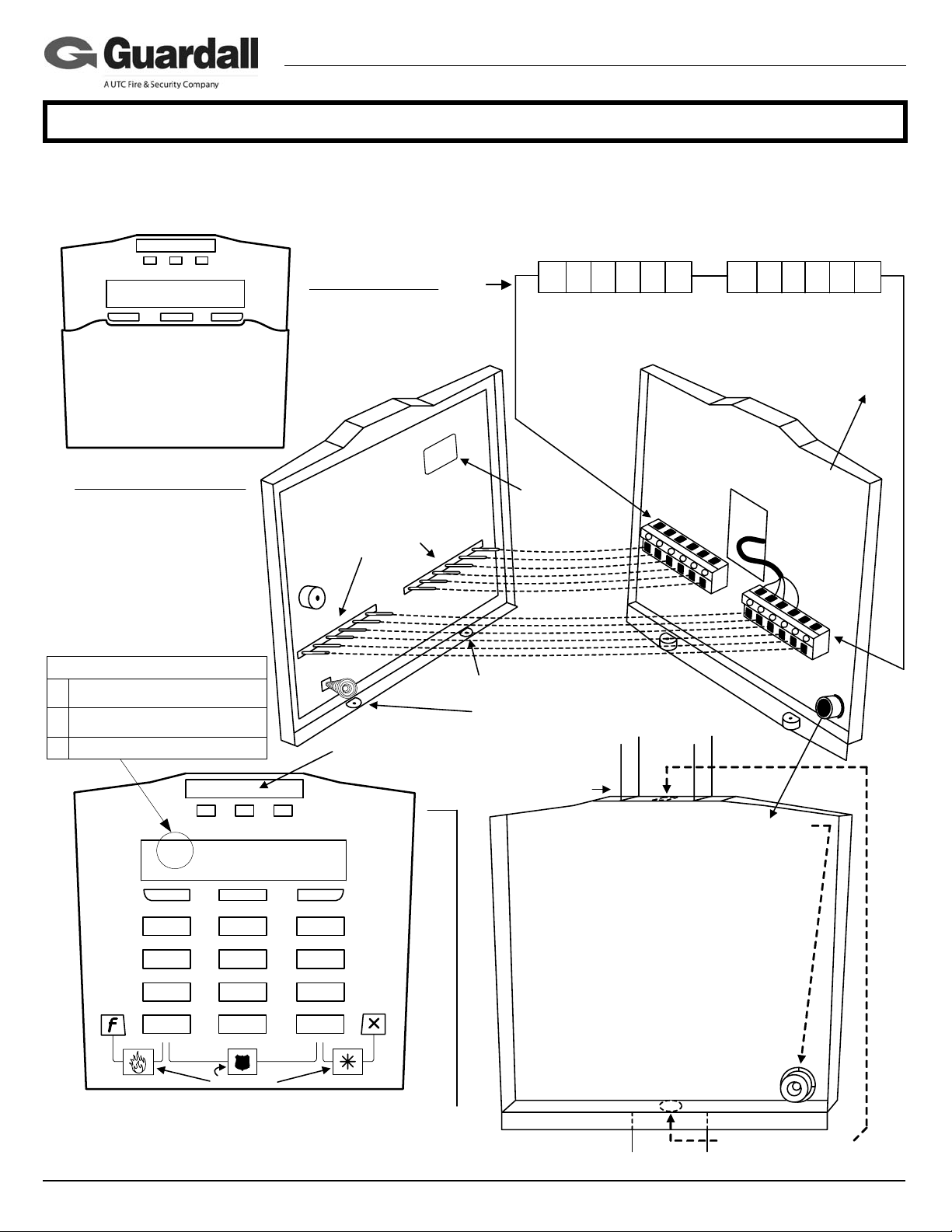

Mounting and Wiring Reference:

Keypad Terminal Block Wiring

Ratings:

LCD Keypad with Reader

Input: 12 – 13.8VDC, 110mA

Output: 12VDC, 1x10mA

Temp : -10°C to +55°C (14°F

to 131°F) @ 93%

Point

1 – 4

Standard and G-ProxII

143256

PT1

Input 1

0V

PT2 PT3 PT4

Common

Input 2

Input 3

0V

Input 4

Common

Module Bus

143256

A

+12V

B0V

Future

OUT

Flip Cover

Module Point Assignment:

7 points total.

Points 1 – 4 are hard wire

inputs.

Point 5: Fire Alert buttons

Point 6: Panic (Hold-Up)

buttons

Point 7: Auxiliary Alert

buttons

Bus Status Indicator

Online

:

;

Unit not enrolled

_

No comms on SNAPP bus

Red GreenYellow

15:25 18Sep OOO

Pin:-----

,

- #

1

45

78

X

Point 5

Red Flashing:

Protection ON

Solid: Partial

protection (STAY)

Green On Solid

with power present.

ABC

2

JKL

TUV

Z_Q

0

Point 6

Alert Labels

t

n

o

r

F

d

a

p

y

e

K

X

X

X

Circuit board pin connectors insert

into fixed terminal blocks on inside

of keypad back. This allows the

keypad to make wire connections

in the terminal blocks.

Sonalert

Tamper Spring

Apply dealer's logo label (supplied) in

the indented space at the top of the

keypad. Apply the Alert Button labels

as required.

Keypad LEDs

DEF

3

MNOGHI

6

WXYPRS

9

X

Point 7

Yellow On Solid when

points not normal or

when point in tamper.

X

X

Serial # sticker

for programming

into Module

Programming.

After placing the keypad on its back

section, make sure the keypad's securing

screws (supplied) are always I N !

Rectangular Conduit

(Trunking)

To use the keypad tamper spring as a wall tamper

break out this plastic cylinder inside the back cover.

Screw it to the wall, keeping it in the same hole as it

was attached, so the back cover fits over it.

The plastic cylinder prevents the spring from being

affected by flat objects wedged in behind the

keypad.

The additional keypad base is optional. For

installations using it there is a similar, shorter,

washer style, plastic break out.

Place it behind the plastic cylinder and screw

them down together.

Then place the holes in the base and keypad

backing over top of them.

Fit the spring insi de the plastic cylinder part

and secure the keypad front to the keypad

back. The spring compr essing should reset

the keypad tamper condition.

Output

K

e

y

p

a

d

B

a

c

k

Keypad Output

goes negative.

T

e

r

m

i

n

a

l

B

l

o

c

k

Knock outs for rectangular

conduit using additional

keypad base.

Interface with a

relay or power

Cable

supply. Common

their negatives

with keypad 0V.

Terminal

Block

Wall tamper

knock out

CSG Security Corp. / Sécurité CSG Corp. Page 2 of 4

Page 3

l

www.guardall.com | +1 877.249.9993

sales@guardall.com +1 905.206.8434 | hotline@guardall.com +1 905.206.8436 | Fax: +1 905.629.4970

Guardal

5201 Explorer Drive, Mississauga, Ont., Canada. L4W-4H1

21-3618v1.1 MONITOR ISM™ / AFx™ Suite Security 4 Zone Keypad Installation

Power and Cable Requirements:

Power Requirements

• Each 4 zone keypad’s current draw is 110 mA. Multiple modules cannot be powered direct from the module bus. A

local power supply must be used.

• Power supplies must be located very locally t o their 4 zone keypads.

• All power supply negatives must be common and connected to the ISM panel module bus negative.

• Power supply wiring has to be of a gauge large enough to provide correct voltage at the last module in a run, belonging

to that power supply. Typically 18 gauge or larger. 18 gauge power cable: Guardall P/N 947-3400.

• In a multiple floor, riser installation with a height of 10 feet (3.1 meters)/floor, using 18 gauge power cable with a lead in

of up to 100 feet (30.5 meters) from power supply to the first module, the power supply will be limited to powering

seven modules, only. This will ensure 12V at the last module of the group. The next group of 7 modules up in a vertical

formation, would then need their own power supply, located within 100 feet (30.5 meters) of that next group’s first

module.

• Seven modules will require a minimum 1 AMP power supply. A larger capacity power supply can be used, however, it

is still limited to seven modules, due to the power loss in the cable.

• A 4 zone keypad requires 12 to 13.8 volts DC to function normally. However, under extreme conditions (e.g. primary

power loss) it can still process activities marginally at 10VDC.

• The module communication cable must not carry the power supply current because of the smaller wire gau ge.

• Both wires in the power cable must be of the same gauge (e.g. 18AWG).

• However, the spare wire pair of the communication cable can be used to common the negatives of the various power

supplies with each other and the ISM module bus 0V negative, which, is required.

Cable Requirements for Module Bus Data A and B

• 24AWG, 2 twisted stranded pair, shielded, with an impedance value of 120 ohm, low capacitance: 12.5-pF/1 foot (41pF/1 meter), e.g. Belden 9842. Guardall P/N 947-3401 communication cable meets these specifications.

• The communication cable shield is grounded at the ISM main panel end (e.g. panel ground lug). “B” connected

together at each module interconnection and cut off, not connected to anything, at the last module in the group.

• The maximum module cable distance is 2000 ft (610 meters) per ISM main panel module bus 1 or 2 at the main control

unit motherboard. Module star wiring configurations cannot be used. Module connections must run on a straight trunk,

with no straight out, branch offs to another module. You must go out to the module and come back with the cable to go

to the next module.

• For ISM main panel module Bus 1 and 2 should be evenly balanced with up to 30 Suite Security keypads each to equal

the system capacity of 60.

• If more than 30 modules are required to be on a single bus, a SNAPP Expander module should be placed in series with

the SNAPP bus to split the modules into approximately two equal groups along the length of the SNAPP bus. The

SNAPP Expander module should be located near a power supply to provide power to the expander as well as the 4

zone modules.

Special Installation and Servicing 4 Zone Keypad Command Features:

Display a 4 Zone Keypad’s 5-Digit Programming Serial Number:

Prevents the need to remove the keypad housing from its base to review the Suite Security programming serial number

label on the back of the keypad’s printed circuit board.

1. Number is displayed for 4 seconds after the 7 second power up delay.

2. If unit is already powered then

• enter a valid ‘PIN’,

• select “Status”

• select “Other”

• Display will show the F/W version and unit serial number.

CSG Security Corp. / Sécurité CSG Corp. Page 3 of 4

Page 4

l

www.guardall.com | +1 877.249.9993

sales@guardall.com +1 905.206.8434 | hotline@guardall.com +1 905.206.8436 | Fax: +1 905.629.4970

Guardal

5201 Explorer Drive, Mississauga, Ont., Canada. L4W-4H1

21-3618v1.1 MONITOR ISM™ / AFx™ Suite Security 4 Zone Keypad Installation

View 4 Zone Keypad Module Bus Data Communications

3. Observe the time display on the LCD screen of the module. The character used to separate the hours from the minutes

is used to display the communication status according to the following table:

Character Meaning Possible Causes

:

;

_

Specifications:

System Architecture

RS485 communications from Module to MONITOR main panel.

Single Output

Switches to negative when activated. This is not a positive “voltage going high” output.

4 Programmable Protection Point Input Types:

h Normally Closed

h Normally open with 2.2K End of Line resistor.

Enclosure Dimensions and Mounting:

4.6” (117 mm) wide, 5.4” (137mm) high, 1.125” (29 mm) deep , (1.29” (33 mm) deep with optional trun king spacer plate)

Suitable for mounting over North American single gang electrical box or surface mount on drywall etc.

Material:

Moulded Plastic, White.

Environmental:

-10°C to 55°C (14°F to 131°F)

Humidity Range:

10% to 93%

FCC Compliance Statement:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:(1) This device may not cause harmful

interference, and (2) This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by GUARDALL could void the user's authority to operate this equipment.

Canadian Compliance Statement:

This Class B digital apparatus complies with Canadian ICES-003.

Online All is OK

Module does not see messages addressed to itself on

SNAPP bus, (not enrolled)

Module serial # may have been incorrectly

entered at the main control

No bus communications at all cable, connections, or module fault

CSG Security Corp. / Sécurité CSG Corp. Page 4 of 4

Loading...

Loading...