Guardair Corporation N301BC User Manual

OPERATING INSTRUCTIONS

FOR GUARDAIR STANDARD AND STATIC CONDUCTIVE COMPRESSED AIR-POWERED VACUUMS

DO NOT DISCARD THESE INSTRUCTIONS

FOR YOUR SAFETY

Turn off all compressed air connections to the compressed

air source at the nearest valve. Disconnect compressed

air connections only after the compressed air supply has

been turned off and the air supply hose has been vented

by opening the valve on the vacuum head. NEVER disconnect

a pressurized compressed air hose.

AIR SUPPLY

An adequate supply of compressed air is essential

for the proper performance of your Guardair vacuum.

Compressed air requirements for vacuum units and

vacuum generating heads equipped with the following

Venturi types are listed below:

“Dual B” Venturi

N552B Series ..................................................................... 110 cfm

“B” Type Venturi

N551B Series, N301B Series ................................................68 cfm

“D” Type Venturi

N551D Series, N301D Series, N201DC, N101DC ..................47 cfm

“S” Type Venturi

N201SC, N101SC ................................................................20 cfm

“M” Type Venturi

N101MC, N051MC ............................................................... 20 cfm

industrial interchange male connector. 3⁄8" ID or

larger compressed air supply hose is recommended

for these models.

FOR ALL MODELS: To ensure maximum performance,

clean or replace the internal filter as necessary. In

addition, clean or replace the exhaust silencer (inside

the exhaust housing) as necessary. Inspect the cover

gasket for deterioration and replace if necessary. On

all vacuum units, use of a smaller diameter air supply

hose or smaller diameter air fittings will seriously restrict

performance. Use the recommended hoses and fittings.

Be certain that the drum has no dents along the seams

and is airtight. The cover gasket under the vacuum

generating head must form a complete seal with the

top edge of the drum.

CAUTION: Drums used with Guardair vacuum generating

heads must meet the gauge (thickness) requirements in

the table below. Thinner gauges of steel run the risk of

drum collapse.

DRUM 55 gal 30 gal 20 gal 10 gal 5 gal

GAUGE 19 18 18 20 20

Please note that these requirements are for compressed air volume, not

pressure. The recommended compressed air inlet operating pressure is

100 psi for all vacuum units. All units will function at lower operating

pressures, but with a corresponding reduction in performance.

Units featuring a “Dual B”, “B” or “D” Type Venturi

include a Chicago-style connector. 3/4" ID or larger

compressed air supply hose is recommended for

these models.

Units featuring an “S” Type Venturi include a 1⁄2"

industrial interchange male connector. 1⁄2" ID or larger

compressed air supply hose is recommended for these

models. Units featuring an “M” Type Venturi include a 3⁄8"

REPLACING GASKETS

On 55, 30 & 20 Gallon Models, remove the gasket to

be replaced. Remove the protective tape covering the

adhesive on the new gasket, then apply to lid.

On 10 & 5 Gallon Models, the lid gasket is adhered to

the lid by hot glue. The hot glue can easily be removed

with rubbing alcohol. Let the rubbing alcohol sit for one

minute, then peel off with a flat head screwdriver. We

recommend using hot glue when installing new gasket.

1

SET-UP AND OPERATION, 55-GALLON, 30-GALLON

HEX BOLT

AND 20-GALLON MODELS:

Place the vacuum generating head on the drum. There

are no clamps required to form an airtight seal. When

the vacuum is in operation, the negative pressure within

the drum will create the airtight seal between the head

and drum.

Connect the vacuum hose to the vacuum generating head

by inserting the hose adapter into the inlet elbow. Slip the

hose end onto the adapter. Connect vacuum attachments

to the vacuum hose.

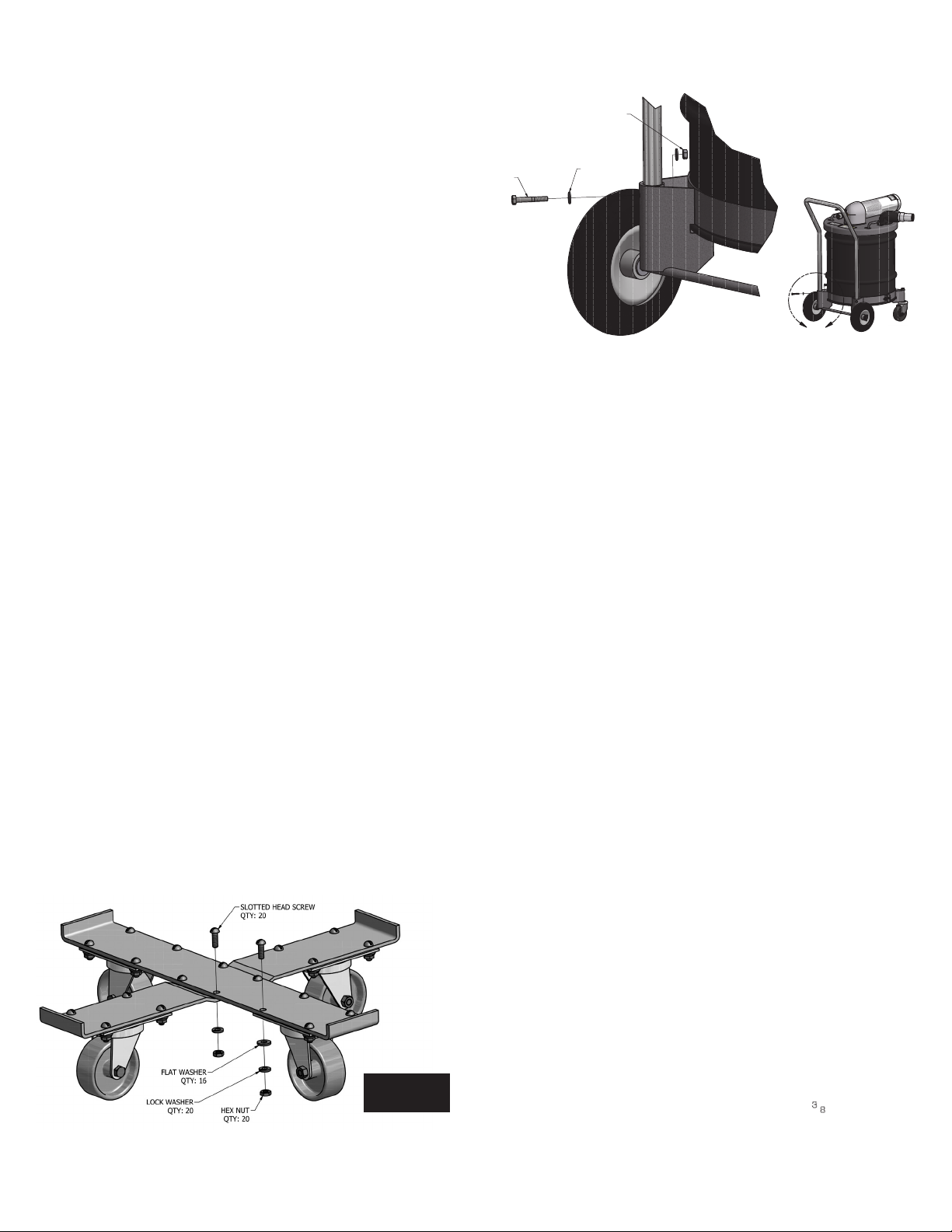

20 Gallon Drum Dolly: Assemble the drum dolly for

20-gallon model as shown below (Compatible with 30 gallon).

HEX NUT

QTY: 2

FLAT WASHER

QTY: 2

QTY: 4

Turn off the compressed air supply valve at the compressor.

Dual B, B & D Venturis

Connect the compressed air supply hose to the vacuum

generating head via the Chicago-style coupler. Twist together and be sure they lock. Install the safety clips.

Connect the compressed air supply hose to the compressor.

Turn on the compressed air supply. Open the shut-off

valve to operate.

S Venturis

Connect the compressed air supply hose to the vacuum

generating head via the ½” industrial interchange male

connector. Connect the compressed air supply hose to the

compressor. Turn on the compressed air supply. Open the

shut-off valve to operate.

Liquid Shut-off Accessory

Before picking up liquids, remove the internal filter, which

is held in place by three springs. For continuous liquid

pick-up, the liquid shut-off accessory (optional) should be

installed in place of the internal filter and held in place by

the same three springs.

55 & 30 Gallon Drum Dolly Assemble the drum dolly for

55-gallon and 30-gallon models as shown below.

A

Caution: Dolly maximum load capacity is 1,000 pounds.

SET-UP & OPERATION, 10-GALLON MODELS:

The vacuum generating head, which mounts on top of the

drum, seals to the drum via the lid clamps.

Connect the vacuum hose to the vacuum hose inlet by

slipping the hose end onto the connector. This is an

intentionally tight fit. Connect vacuum attachments to

the vacuum hose.

The vacuum comes with a liquid shutoff assembly built

internally within the cartridge filter. The cartridge filter

can be removed for maintenance or replacement by

removing the wing nut and washer on the bottom of

the filter.

Turn off the compressed air supply valve at the compressor.

Model N101DC - Connect the compressed air supply

hose to the vacuum generating head via the Chicago-style

coupler. Twist together, making sure that they lock. Install

the safety clips. Connect the compressed air supply hose

to the compressor. Turn on the compressed air supply.

Open the shut-off valve to operate.

55 gallon: N668

30 gallon: N667

Caution: Dolly maximum load capacity is 1,000 pounds.

Model N101SC - Connect the compressed air supply

hose to the vacuum generating head via the ½” industrial

interchange male connector. Connect the compressed air

supply hose to the compressor. Turn on the compressed

air supply. Open the shut-off valve to operate.

Model N101MC - Connect the compressed air supply

hose to the vacuum generating head via the 3⁄8" industrial

interchange male connector. Connect the compressed air

supply hose to the compressor. Turn on the compressed

2

air supply. Open the shut-off valve to operate.

SET-UP & OPERATION, 5-GALLON MODELS:

The vacuum generating head, which mounts on top of the

drum, seals to the drum via the lid clamps.

Connect the vacuum hose to the vacuum hose inlet by

slipping the hose end onto the connector. This is an

intentionally tight fit. Connect vacuum attachments to

the vacuum hose.

The vacuum comes with a liquid shutoff assembly built

internally within the cartridge filter. The cartridge filter

can be removed for maintenance or replacement by

removing the wing nut and washer on the bottom of

the filter.

Turn off the compressed air supply valve at the compressor.

Connect the compressed air supply hose to the vacuum

generating head via the 3⁄8" industrial interchange male

connector. Connect the compressed air supply hose to the

compressor. Turn on the compressed air supply. Open the

shut-off valve to operate.

STATIC CONDUCTIVE MODELS:

Guardair also manufactures Static Conductive, also

known as NED (non-electrical discharge) models, designed

to eliminate static electricity by incorporating static

conductive components to suppress static electricity

charges. Should stray static charges become generated,

these charges are immediately dissipated through the

electrically interconnected, static conductive components.

For an added measure of protection, users can ground

the vacuum by connecting the grounding lug to an external

electrical ground using a grounding clamp and cable

(available as an accessory item).

To ensure proper electrical bonding (connectivity between

components), make sure that only static conductive,

factory-supplied parts and accessories are used with

Guardair NED vacuums. All components must fit together

firmly, including the static conductive vacuum hose, which

must mount securely on the vacuum hose inlet, and all

static conductive vacuum accessories.

Always inspect all static conductive vacuum components

before use, and replace worn or rusted parts as needed.

If you have questions about the necessity for grounding,

consult with a qualified safety engineer.

WARNING

FIRE/EXPLOSION DANGER

Guardair vacuums, like all other pneumatic and electric

vacuums, generate static electric charges. Factory

installed kits to control static electricity, the use of

static conductive hoses and grounding straps, and

Guardair Static Conductive Pneumatic Vacuums are

intended to control and eliminate static electric shocks

only to the operators of the vacuums. Guardair vacuums

are NOT APPROVED OR SAFE to use in any hazardous

(classified) location, such as locations determined under

NFPA 70 (National Electrical Code) to be Class I

(flammable liquids, gases and vapors – includes all Class

I Divisions and IEC Zones), Class II (combustible dust –

includes all Class II Divisions and IEC Zones) and Class III

(ignitable fibers and flyings – includes all Class III Divisions

and IEC Zones).

FOREVER WARRANTY:

Guardair Corporation (“Guardair”) warrants that its

compressed air-powered vacuums are free from defects

in materials and workmanship for as long as the original

end-user purchaser owns the product, except as provided

below. Guardair will, at its option, repair or replace with

a comparable product, any product, part, or component

that fails under normal use as a result of such defect.

This warranty does not apply to damage caused by the

carrier; normal wear and tear; deterioration due to

solvents, corrosives, environmental conditions, or harsh

vacuumed material; soiling, saturation, or perforation of

filters or exhaust silencers; consumable components;

modifications to the product; attachments to the product

not sold by Guardair; or any product not installed, used,

or maintained in accordance with the foregoing and other

published Guardair instructions and warnings. Consumables

purchased from Guardair, including attachments, vacuum

hose, filters, exhaust silencers, and cover gaskets are

warrantied for a period of 90 days against defects in

materials and workmanship, subject to the same

exclusions noted above.

This warranty covers the original purchase of a new

product by an end-user for normal industrial or

commercial use only when installed and used as specified

and in accordance with published operating instructions

and within all applicable regulatory rules, limits,

and guidelines.

3

Loading...

Loading...