Page 1

Digital Loop Detector

GTO, Inc. • 3121 Hartsfield Road • Tallahassee, Florida 32303

1-800-543-GATE (4283) • www.gtoinc.com

Technical Support (800) 543-1236

RWLOPPRO

rev-4/5/06

Page 2

GTO/PRO Loop Detector Settings and Layout

1) DIP SWITCH SETTING:

a) DIP 1: PRESENSE TIMER

OFF (Factory default): The loop will automatically re-tune if an object is present for more than 1

hour.

ON: Automatic retune as described above is disabled.

b) DIP 2: SAFE/SECURE

OFF: Fail-safe mode. When the controller detects a fault (shorted or open loop) the output relay

is activated. Typically, the normally open output relay is connected to the ‘FREE EXIT’ input on

the gate’s controller that would hold the gate open.

ON: Fail-secure mode. When the controller detects a fault (shorted or open loop) the output

relay is NOT activated.

c) DIP 3: ENTER/LEAVE

OFF: The output relay is activated when a vehicle enters the loop.

ON: The output relay is activated when a vehicle is leaves the loop.

d) DIP 4: CONTINUOUS/PULSE

OFF: Continuously activates the output relay when a vehicle is detected.

ON: Momentarily activate the output relay when a vehicle is detected.

e) DIP 5: INSTANT/DELAY

OFF: Instantly activate the output relay when a vehicle is detected.

ON: Delay for 2 seconds before activating the output relay when a vehicle is detected. If the

vehicle is moved in less than 2 seconds relay will not be activated.

f) DIP 6,7,8: SENSITIVITY

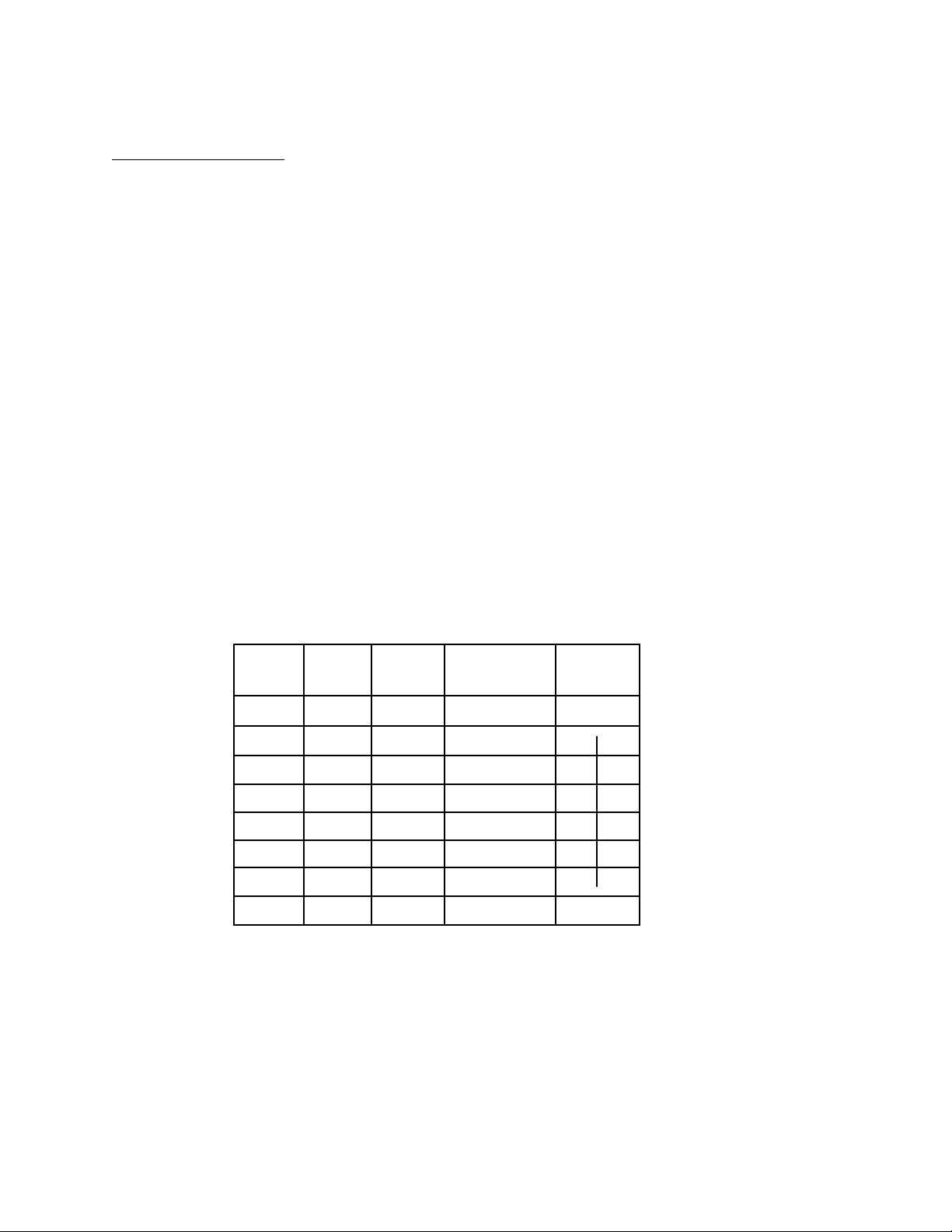

DIP 6 DIP 7 DIP 8 Inductance Vehicle

change size

OFF OFF OFF 2% Larger

OFF OFF ON 1%

OFF ON OFF .5%

OFF ON ON .25%

ON OFF OFF .125%

ON OFF ON .06%

ON ON OFF .04%

ON ON ON .02% Smaller

g) DIP 9,10: FREQUENCY SELECT

These two switches provide four selectable loop frequencies. This allows multiple loops of the same

design to co-exist in close proximity without interference with each other. The actual frequency is

dependent on the loop inductance.

Page 3

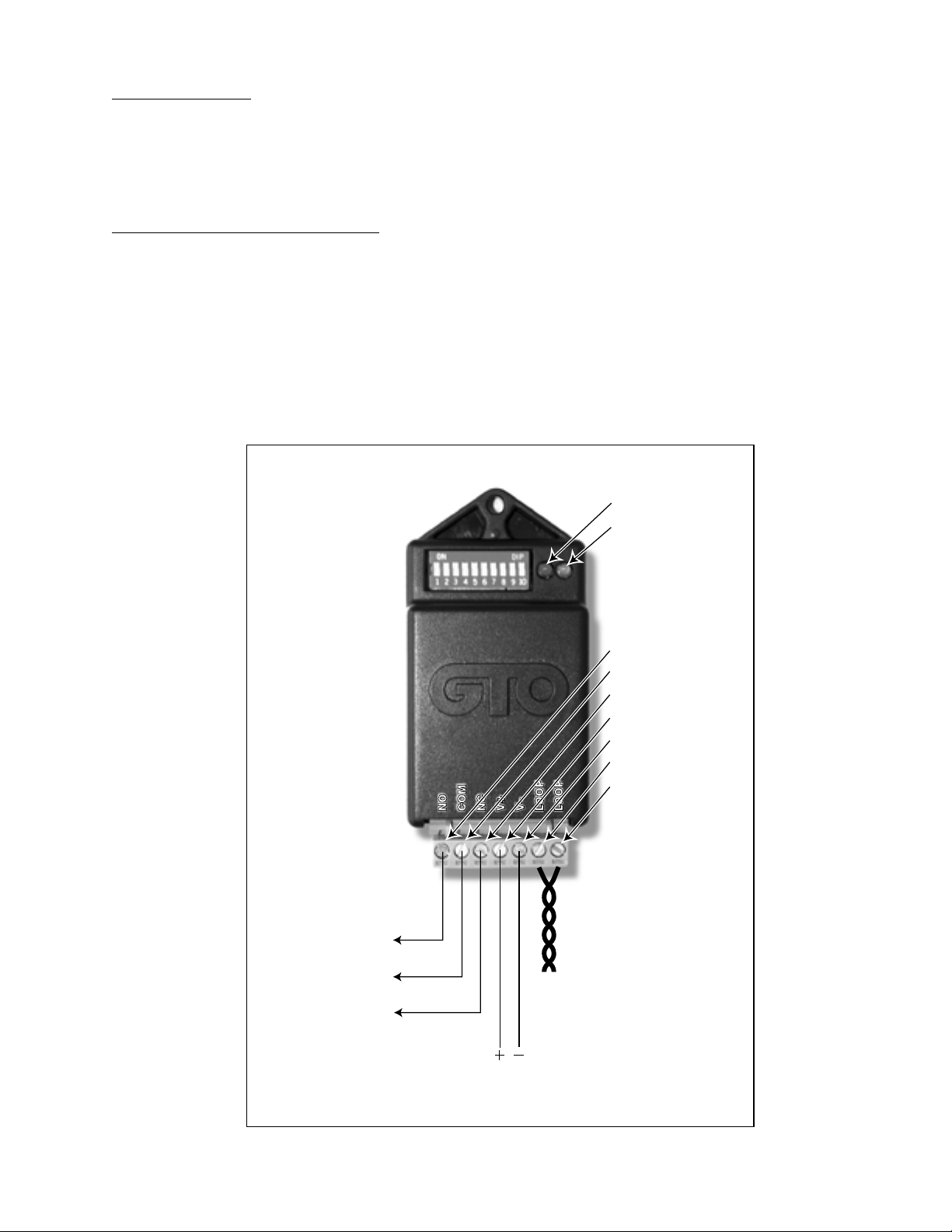

2) LED INDICATORS:

Relay output:

Normally Open

Relay output:

Common

Relay output:

Normally Close

Po

wer supply input:

8-26 Vac/dc

Loop: wire use for loop

should be continuous with

no splice. Wire pair leaving

the loop should be twisted.

DIP SWITCHS

DIP 1: PRESENCE TIMER

DIP 2: SAFE/SECURE

DIP 3: ENTER/LEAVE

DIP 4: CONT/PULSE

DIP 5: INST/DELAY

DIP 6: SENS 0

DIP 7: SENS 1

DIP 8: SENS 2

DIP 9: FREQ 0

DIP 10: FREQ 1

LED LIGHTS

LED RED: POWER

LED GRN: DETECT

NO

COMNCV+V–LOOP

LOOP

TERMINALS

TB1-1: NO

TB1-2: COM

TB1-3: NC

TB1-4: Power in +

TB1-5: Power in –

TB1-6: LOOP

TB1-7: LOOP

a) RED LED: The red LED blinks when power is present.

b) GREEN LED: The green LED blinks when detection occurs.

NOTE: Both LEDs blink when fault is detected at the loop.

3) TERMINAL BLOCK (PLUGGABLE):

a) OUTPUT RELAY: Relay is ‘dry-contact’ output.

i) TB1-1: Normally open side of output relay.

ii) TB1-2: Common side of output relay.

iii) TB1-3: Normally closed side of output relay.

b) POWER SUPPLY INPUT:

i) TB1-4: 8-26 Vac/Vdc positive input.

ii) TB1-5: 8-26 Vac/Vdc negative input.

Page 4

2“

Sealant

Backer Rod every

2 (two) feet.

Loop Wire / 3 turn

s

1/4” Saw Slot

Pavement Surface

SAW SLOT CROSS SECTION

Loop

Perimeter

6’ to 12’

13’ to 20’

21’ to 60’

61’ to 240’

240’ & Up

# of

Turns

6

5

4

3

2

Loop wires must be twisted together - 6 twists per

foot from the end of the saw slot to the detector.

Loop Installation Guidelines

The typical sensing height is 2/3 of the shortest leg of a loop (in feet). Therefore a 4’ x 8’ loop typically

has a detection range of 2.6’.

The inductance of a conventional four-sided loop can be estimated using the formula:

L = P x (T2 + T) / 4 Where L = Loop Inductance in microHenries

P = Loop Perimeter in feet

T = Number of turns of wire in saw slot

Therefore a 4’ x 8’ loop with 3 turns would be:

L + (4 + 8 + 4 + 8) x (32 + 3) / 4

L = 24 x (9 + 3) / 4

L = (24 x 12) / 4

L = 24 x 3

L = 72 microHeneries

NOTE: Loop feeder cable typically

adds 0.22 microHeneries of inductance

per foot of cable.

The following are suggested guidelines for

loop installation:

1. Make sure the pavement surface in the

area that the loops are to be installed is

dry and free of debris.

2. Design the loop geometry considering the

area of detection, the type of vehicles to

be detected and the distance between the

loop and the loop dectector.

3. The outline of the loop(s) should be

marked on the pavement in such a way

that the lines can be followed easily by

the saw operator and not be erased by the

water feed from the saw.

Page 5

4. When the outline of the loop and the lead-in has been marked the pavement can be cut. The

saw cut should be approximately 2.0 inches deep and 0.25 inches wide. All 90 degree corners

should be chamfered so that the course of the loop wire does not change direction sharply but

rather at shallow angles of 45 degrees or less. The saw slot should be cleaned out and allowed

to dry.

5. Loop wire is typically 14, 16, 18, or 20 AWG with cross-linked polyethylene insulation, rated

for direct burial. Since moisture can cause significant changes in the dielectric constant of

the insulation, which results in excessive loop (frequency) drift, choose an insulation which

is most impervious to moisture. PVC, TFFN, THHN and THHN-THWN should be avoided

since they tend to absorb moisture and crack easily. XLPE (cross-linked polyethylene) is very

resistant to moisture absorption and provides good abrasion resistance.

6. If long lead-ins are required, it is suggested that the loop cable be spliced onto shielded, pretwisted, lead-in wire (IMSA specification 50-2 is recommended) at a convenient pull box

location close to the loop. The shield may be connected to earth ground at the cabinet end but

should then be insulated and isolated from earth ground at the loop end.

7. Start laying the loop wire from the termination of the lead-in out towards the loop, continue

around the loop for the number of turns required and finally return to the lead-in termination.

Leave the lead-in wire out of the slot so that it may be twisted together before being laid in the

slot. Lead-ins should be twisted with a minimum of 4 to 6 twist per foot to prevent any separation of the lead-in wires.

8. Make sure that the loop wire is pushed fully to the bottom of the saw slot. The wire must be

held firmly in the bottom of the slot using a plastic foam material called “backer rod”, before

applying loop sealent.

9. Many different types of loop sealant are now available. Single part types are the easiest to apply since no mixing is required, but they also tend to be more expensive in terms of linear feet

of saw slot filled. When applying the sealant, make sure that it is able to sink to the bottom

of the slot and completely encase the loop wire. The wire should not be able to move when

the sealant is set. Ensure that there is enough sealant to completely fill the slot; if possible

the sealant should protrude slightly above the surface of the pavement so that small rocks or

other debris cannot collect in the slot. The sealant manufacturer’s instructions concerning cure

time should be noted - especially when determining the length of time to wait before allowing

vehicles to cross the loop area.

10. It is very important that any splices be soldered and each splice point be protected with a

moisture proof seal. Failure to do so will result in system problems, if not imediately then

sometime in the near future.

Page 6

Wiring the Loop Detector to GTO Systems

Wires from relay output

on detector

STALL FORCE

M

I

N

M

A

X

GRN

BLK

RED

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

J11

J8

J12

Wires from relay output

on detector

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

Wires from relay output

on detector

STALL FORCE

M

I

N

M

A

X

GRN

BLK

RED

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

J11

J8

J12

Wires from relay output

on detector

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

ON

ALARM ACCESSORY RCVR

SEQ1

SEQ2

LEARN

BLU

ORG

WHT

GRN

R B G

Wires from relay

output on detector

Always make sure the power switch to the operator is turned off before connecting accessory device

wiring to the terminal blocks. Unplugging the transformer does not turn power to the operator OFF.

Wiring the detector as a Shadow Loop

PRO-SW3000 & PRO-SW4000

Connect one of the relay output wires

from the detector to the COMMON

(COM) terminal and the other to the

SHADOW LOOP terminal.

Mighty Mule 500 & 502

Connect one of the relay output wires

from the detector to the COMMON

(COM) terminal and the other to the

SHADOW LOOP terminal.

Wiring the detector as a Safety Loop

PRO-SW3000 & PRO-SW4000

Connect one of the relay output wires

from the detector to the COMMON

(COM) terminal and the other to the

SAFETY terminal.

Mighty Mule 500 & 502

Connect one of the relay output wires

from the detector to the COMMON

(COM) terminal and the other to the

SAFETY terminal.

PRO-SL1000 & PRO-SL2000

Connect one of the relay output wires

from the detector to the GREEN

(GRN) terminal and the other to the

ORANGE (ORG) terminal.

Page 7

Wiring the detector as a Free Exit Loop

ON

ALARM ACCESSORY RCVR

SEQ1

SEQ2

LEARN

BLU

ORG

WHT

GRN

R B G

Wires from relay

output on detector

Wires from relay output

on detector

STALL FORCE

M

I

N

M

A

X

GRN

BLK

RED

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT

OPEN

SHADO

W

LOOP

CLOSE

EDGE

OPEN

EDGE

J11

J8

J12

Wires from relay output

on detector

RECEIVER

COM COM

CYCLE

CLOSE

SAFETY

EXIT/

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

BLKGRN RED

STALL FORCE

M

I

N

M

A

X

PRO-SW3000 & PRO-SW4000

Connect one of the relay output wires

from the detector to the COMMON

(COM) terminal and the other to the

EXIT OPEN terminal.

Mighty Mule 500 & 502

Connect one of the relay output wires

from the detector to the COMMON

(COM) terminal and the other to the

EXIT OPEN terminal.

PRO-SL1000 & PRO-SL2000

Connect one of the relay output wires

from the detector to the GREEN

(GRN) terminal and the other to the

BLUE (BLU) terminal.

Page 8

Conversion Chart

Converting Metric Units to English Equivalents

When You Know Multiply By To Find Symbol

centimeters 0.3937 inches in. (or “)

meters 3.2808 feet ft. (or ‘)

kilograms 2.2046 pounds lb. (or #)

Converting English Units to Metric Equivalents

When You Know Multiply By To Find Symbol

inches 2.5400 centimeters cm

feet 0.3048 meters m

pounds 0.4535 kilograms kg

Converting Temperature

deg. Celsius (ºC x 1.8) + 32 deg. Fahrenheit ºF

deg. Fahrenheit (ºF-32) ÷ 1.8 deg. Celsius ºC

This product and any accessory you purchase should only be installed on a gate

operator that meets the current safety standard, UL325, latest edition. If you have

a gate operator that is not listed with the current standard please contact the GTO

sales department for consultation on a gate operator that can meet your specific

needs.

GTO Limited One Year Warranty:

GTO, Inc., gate operators and accessories are warranted by the manufacturer against defects in materials and manufacturer workmanship

for a period of one (1) year from date of purchase, provided the recommended installation procedures have been followed.

In the case of product failure due to defective material or manufacturer workmanship within the one (1) year warranty period, the product

will be repaired or replaced (at the manufacturer’s option) at no charge to the customer, if returned freight prepaid to GTO, Inc., 3121

Hartsfield Road, Tallahassee, Florida, USA 32303. IMPORTANT: Call (850) 575-4144 or Fax (850) 575-8950 for a Return Goods

Authorization (RGA) number before returning accessory to factory. Products received at the factory without an RGA number will not

be accepted. Replacement or repaired parts are covered by this warranty for the remainder of the one (1) year warranty period or six (6)

months, whichever is greater. GTO, Inc. will pay the shipping charges (equal to United Parcel Service GROUND rate) for return to the

owner of items repaired under warranty.

The manufacturer will not be responsible for any charges or damages incurred in the removal of the defective parts for repair, or for the

reinstallation of those parts after repair. This warranty shall be considered void if damage to the product(s) was due to improper installation

or use, connection to an improper power source, or if damage was caused by lightning, wind, fire, flood, insects or other natural agent.

After the one (1) year warranty period, GTO, Inc. will make any necessary repairs for a nominal fee. Call GTO at (800) 543-1236 for

more information. This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.

This warranty is in lieu of all other warranties, expressed or implied. NOTE: Verification of the warranty period requires copies of

receipts or other proof of purchase. Please retain these records.

If you have any questions call Technical Support at... (800) 543-1236

or GTO/PRO Sales at... (800) 543-4283

Loading...

Loading...