Page 1

INSTALLATION MANUAL

WARNING

W

ARNING

!

WAND with 50, 100 or 150 feet of

Direct Burial Cable

Range

Adjustment Board

Warning Signs (2)

Wire Nuts (3)

Battery Connection

Wires (2)

Double Spade

Connectors (2)

Ty

-Wraps (4)

Wire Clamp

!

WARNING

GATE OPENING

SENSOR IN USE

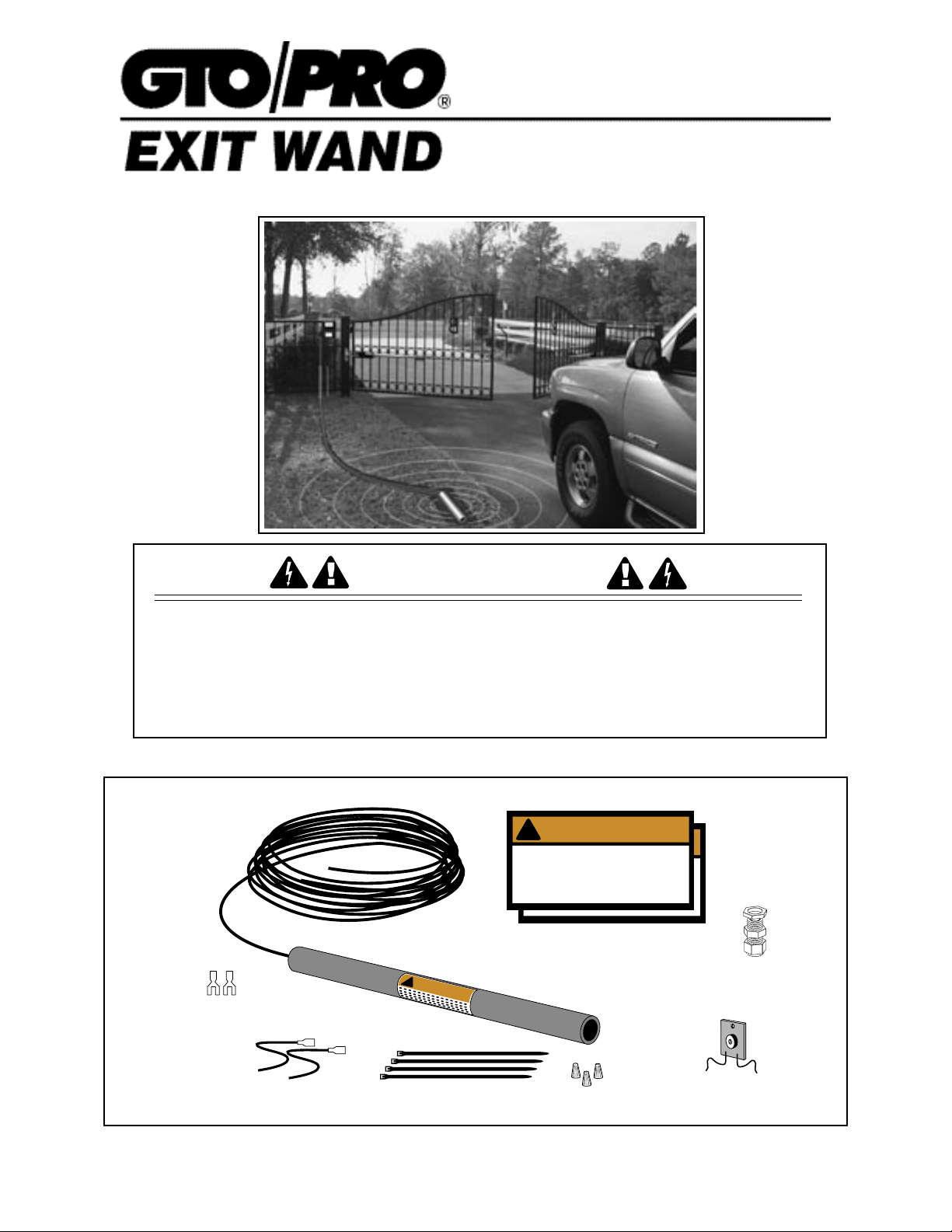

The Automatic Gate Opener is activated when a

vehicle comes within range of the sensor buried

along side the driveway and could possibly be

activated by a child on a bicycle, tricycle or other

metal play equipment.

WARNING

When an EXIT WAND is in use, the automatic gate operator could be activated by a

child on a bicycle, tricycle or other metal play equipment. This product is not recommended for applications exposed to children.

If you are installing this product on an AC powered gate operator, we recommend you

consult a certified electrician.

Parts Identification:

GTO, Inc. • 3121 Hartsfield Road • Tallahassee, Florida 32303

1-800-543-GATE (4283) • www.gtoinc.com

Technical Support (800) 543-1236

RWINSTPRO

rev-7/26/06

Page 2

Thank You ...

for purchasing the GTO/PRO® EXIT WAND. This product requires no maintenance and will give you years

of enjoyment by providing hands free operation of your gate. GTO, Inc. has been designing and manufacturing

reliable, high quality products since 1987. Our corporate headquarters and state of the art manufacturing facility

is located in Tallahassee, Florida. One of our highest priorities is to provide outstanding technical service to our

customers. Therefore, if you have any questions or require any technical assistance, please call 800-543-1236 or

850-543-4144 and ask to speak to one of our technicians.

The EXIT WAND you have purchased is designed with some of the most advanced technology available. In

layman’s terms, the wand detects a change in the earth’s magnetic field caused by a mass of metal in motion and

automatically opens your gate. The range adjustment potentiometer (POT) that connects to the control box provides you with the ability to increase or decrease the wand’s sensitivity range.

If a metal object is placed directly above the wand (with little motion) it may cause the wand to activate, thus

opening your gate. For this reason we do not recommend the EXIT WAND in environments exposed to children.

Prior to installing your wand please read the manual thoroughly. There are important safety recommendations

of which you should be aware. This product, and any accessory you purchase, should only be installed on a gate

operator that meets the current safety standard (UL325). If you have a gate operator that is not listed with the

current standards, please contact the GTO Sales Department toll free (800) 543-4283 for consultation on a gate

operator that can meet your specific needs.

Joe Kelley, President of GTO, Inc.

Contents

Before You Start ----------------------------------------------------------------------page 1

Terms and Definitions: -----------------------------------------------------------page 1

How the EXIT WAND Works: --------------------------------------------------page 1

How the EXIT WAND’s RANGE ADJUSTMENT Works: -----------------page 1

Placement of the WAND: --------------------------------------------------------page 2

Installation Overview: ------------------------------------------------------------page 2

Installing the EXIT WAND ---------------------------------------------------------page 3

Determining WAND Location: --------------------------------------------------page 3

Installing the WIRE CLAMP: ---------------------------------------------------page 3

Wiring the WAND to GTO/PRO Low Voltage Operators: -------------------page 4

Accessory Terminal Connection ------------------------------------------------page 4

Connecting the Range Adjustment Control Board: --------------------------page 5

Power Supply Connection: ------------------------------------------------------page 5

Powering Up the WAND: -------------------------------------------------------page 6

Adjusting the Range: ------------------------------------------------------------page 6

Wiring the WAND to GTO/PRO AC Powered Operators: -------------------page 7

Accessory Terminal Connection ------------------------------------------------page 7

Connecting the Range Adjustment Control Board: --------------------------page 8

Power Supply Connections: ----------------------------------------------------page 9

Powering Up the WAND: --------------------------------------------------------page 9

Adjusting the Range: ------------------------------------------------------------page 9

Installation on Other Brand Gate Operators -----------------------------------page 10

Technical Specifications ------------------------------------------------------------page 11

Trouble Shooting ---------------------------------------------------------------------page 11

Other GTO Products ----------------------------------------------------------------page 12

Page 3

Conversion Chart

Converting Metric Units to English Equivalents

When You Know Multiply By To Find Symbol

centimeters 0.3937 inches in. (or “)

meters 3.2808 feet ft. (or ‘)

kilograms 2.2046 pounds lb. (or #)

Converting English Units to Metric Equivalents

When You Know Multiply By To Find Symbol

inches 2.5400 centimeters cm

feet 0.3048 meters m

pounds 0.4535 kilograms kg

Converting Temperature

deg. Celsius (ºC x 1.8) + 32 deg. Fahrenheit ºF

deg. Fahrenheit (ºF-32) ÷ 1.8 deg. Celsius ºC

This product and any accessory you purchase should only be installed on a gate

operator that meets the current safety standard, UL325, latest edition. If you have

a gate operator that is not listed with the current standard please contact the GTO

sales department for consultation on a gate operator that can meet your specific

needs.

GTO Limited One Year Warranty:

GTO, Inc., gate operators and accessories are warranted by the manufacturer against defects in materials and manufacturer workmanship

for a period of one (1) year from date of purchase, provided the recommended installation procedures have been followed.

In the case of product failure due to defective material or manufacturer workmanship within the one (1) year warranty period, the product

will be repaired or replaced (at the manufacturer’s option) at no charge to the customer, if returned freight prepaid to GTO, Inc., 3121

Hartsfield Road, Tallahassee, Florida, USA 32303. IMPORTANT: Call (850) 575-4144 or Fax (850) 575-8950 for a Return Goods

Authorization (RGA) number before returning accessory to factory. Products received at the factory without an RGA number will not

be accepted. Replacement or repaired parts are covered by this warranty for the remainder of the one (1) year warranty period or six (6)

months, whichever is greater. GTO, Inc. will pay the shipping charges (equal to United Parcel Service GROUND rate) for return to the

owner of items repaired under warranty.

The manufacturer will not be responsible for any charges or damages incurred in the removal of the defective parts for repair, or for the

reinstallation of those parts after repair. This warranty shall be considered void if damage to the product(s) was due to improper installation

or use, connection to an improper power source, or if damage was caused by lightning, wind, fire, flood, insects or other natural agent.

After the one (1) year warranty period, GTO, Inc. will make any necessary repairs for a nominal fee. Call GTO at (800) 543-1236 for

more information. This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.

This warranty is in lieu of all other warranties, expressed or implied. NOTE: Verification of the warranty period requires copies of

receipts or other proof of purchase. Please retain these records.

If you have any questions call Technical Support at (800) 543-1236

Page 4

Before You Start ...

Please read the instructions completely before you begin the installation.

Terms and Definitions:

• METAL OBJECT: anything that is made of iron based metal, from a child’s toy to a car or truck.

• WAND: the magnetic device inside the waterproof tube that detects METAL OBJECTS in motion.

• MAGNETIC FIELD: an area around the WAND where metal in motion can be detected.

• MAGNETIC DISTURBANCE: a change in the MAGNETIC FIELD which lets the WAND know that it needs

to send a signal to the gate operator to open the gate.

• RANGE: the distance from the WAND in which a MAGNETIC DISTURBANCE can be detected in the

MAGNETIC FIELD.

• RANGE ADJUSTMENT: the RANGE is adjustable from a 3 to 12 foot* radius by tuning the ADJUSTMENT

POTENTIOMETER (POT) on the RANGE ADJUSTMENT CONTROL BOARD (shown on page 5). Within

this RANGE, the closer you get to the WAND, the less metal and motion an object needs to cause a DISTURBANCE in the MAGNETIC FIELD.

CAUTION This principle explains why a child’s tricycle, bicycle and other metal play equipment moving

close to the WAND may have the same DISTURBANCE as a car or truck at a greater distance, and can cause

the gate to open.

• WIRE CLAMP: a device which provides a secure and weatherproof opening for the wire from the WAND to

be brought into a control box (see Parts Identification on cover).

• DOUBLE SPADE CONNECTOR: a wire connector which allows the connection of two wires to be connected to a single terminal (see Parts Identification on cover).

How the EXIT WAND works:

• When a metal object such as a car, truck or motorcycle in motion disturbs the MAGNETIC FIELD around the

WAND, a signal is sent to the automatic gate operator’s control board, signaling it to open the gate.

• The metal object must be in motion to disturb the MAGNETIC FIELD, thus activating the gate operator. A

stationary vehicle or object will not disturb the MAGNETIC FIELD.

How the EXIT WAND’s RANGE ADJUSTMENT works:

• The RANGE distance can be adjusted from a 3 to 12 foot* radius from the WAND.

• The potentiometer varies the sensitivity range of the WAND to avoid unwanted moving metal objects from

activating the gate operator, such as: other moving gates; metal play equipment; garage doors; other vehicular

traffic; etc.

• With the RANGE adjusted to the maximum of 12 feet*, a large metal object moving slowly will be detected

12 feet* from the WAND, while a small metal object moving slowly might not be detected at the same

distance. As you move closer toward the WAND, the small moving metal object will at some point cause a

DISTURBANCE in the MAGNETIC FIELD and activate the gate operator.

* Range distance is approximate and will vary due to outside interference, type of soil, vehicle mass, speed, etc.

1

Page 5

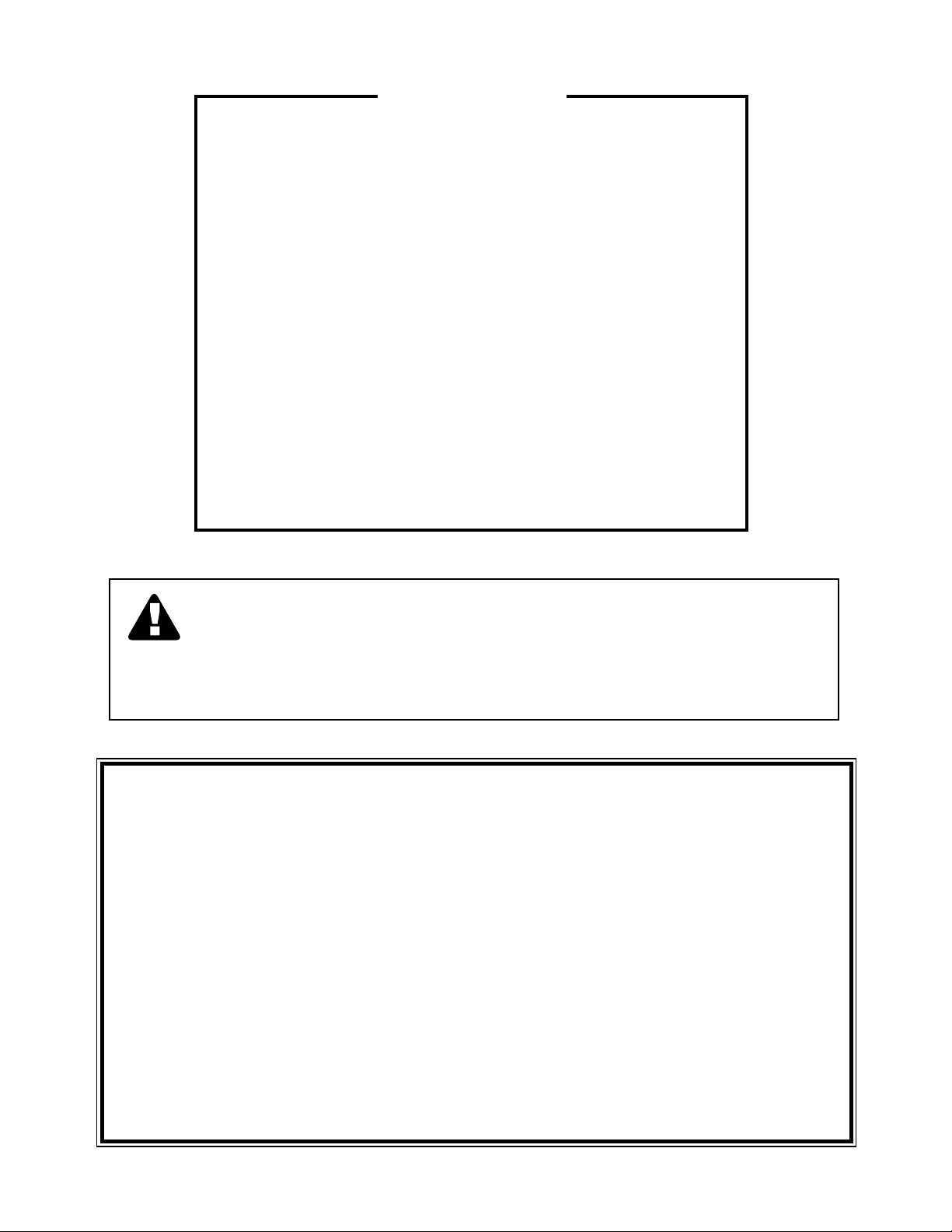

Placement of the WAND:

Gate Operator

Control Box

Driveway

RANGE:

12 ft. radius

(max)

up to 145 ft.

of Cable (max)

WAND:

2 feet from

driveway (max)

Open Gate

Outside

Sensor Range

25 ft. from

gate (min)

• The WAND comes with 50, 100 or 150 feet of

cable. A typical installation will require about 5 feet

of wire to come from the ground up and into the

control box for connection to the power supply and

control board. Check your specific installation for

exact dimensions.

• From the point on the ground where you will run

the WAND cable into the control box, lay the wire

out on a path as far as you can from the control box.

The WAND should be no more than two (2) feet

from the edge of the driveway and no closer than 25

feet from the end of the open gate.

• The WAND’s RANGE can be adjusted to a maximum of 12 feet*. The movement of a gate in its

open position could cause a DISTURBANCE in the

MAGNETIC FIELD of the WAND if it comes within the RANGE of the WAND. Make sure the end

of the open gate is a minimum of 25 feet from the

WAND. If you have a situation where the WAND

has to be buried closer than 25 feet you will have to

adjust the RANGE of the WAND to compensate for

the closeness.

Installation Overview:

• Once the best location for the WAND is determined, you are ready to bury the WAND and run the cable

underground to the control box. Connect the WAND wires and the RANGE ADJUSTMENT CONTROL

BOARD to the gate operator control board and power supply. Adjust the RANGE if necessary. Finally, place

the WARNING signs on the gate. That’s it!

For Optimum Performance:

• Locate the WAND as far as possible away from power transformers, power lines, under ground gas

line, and telephone lines.

• Locate the WAND away from general moving traffic to prevent unwanted activation. Remember that

the WAND detects MAGNETIC DISTURBANCES caused by a vehicle’s mass and velocity.

• It is recommended that you run the WAND cable inside PVC conduit.

• Do not run WAND cable in conduit with other wires such as power or other control wires.

• The WAND cable CAN NOT be spliced. If you need more wire, contact the GTO Sales Department

at 1-800-543-GATE (4283).

* Range distance is approximate and will vary due to outside interference, type of soil, vehicle mass, speed, etc.

2

Page 6

Sealing Nut

Hub

Lock Nut

Wire Clam

p

Installing the EXIT WAND ...

Gate operator

control box

Driveway

Minimum of 25 feet

RANGE:12 foot radius (max)

WAND: 2 feet from driveway

edge and 1 foot in ground

Open gate outside

wand range

PVC conduit in ground and

up to control box recommended

WIRE CLAMP for

Opener Power Cord

PRO-SW3000 & PRO-SW4000

Control Box

O

N

/O

F

F

Knockout Disk

Knockout Disk

WIRE CLAMP for

Operator Power Cord

PRO-SW1000/2000 & PRO-SL1000/2000

Control Box

Drill 7/8" Diameter

Hole For Dual Gate

System

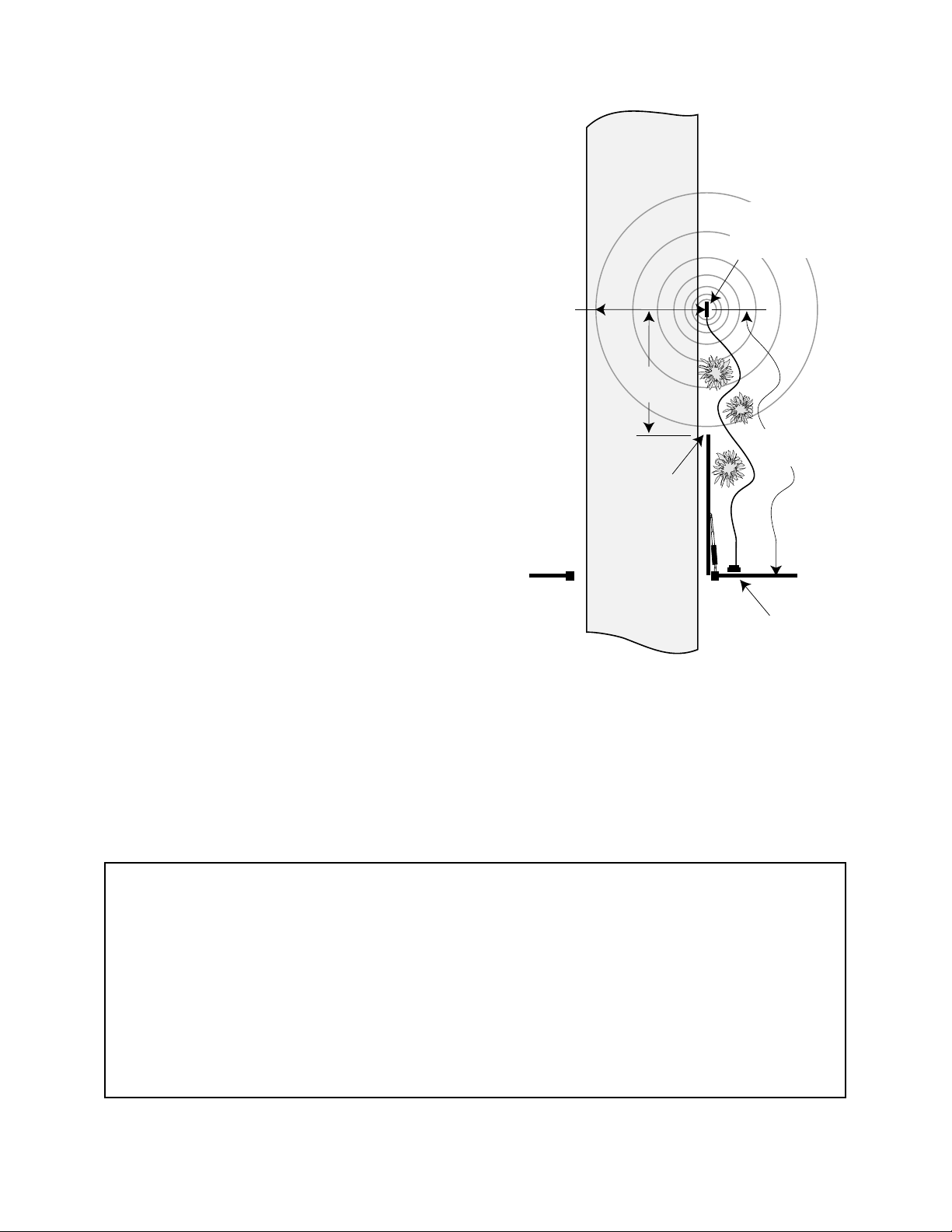

Determining WAND Location:

Step 1: Determine the optimum location for the EXIT WAND using the information found in “Placement of the

WAND” on page 2. Then dig a hole approximately 12 inches deep and 24 inches long within two (2) feet and

parallel to the edge of the driveway. Next, dig a trench from this hole to a spot under the gate operator control box

to run the wire from the WAND to the control box.

Keep the WAND and the cable uncovered at this time.

We recommend that the cable be run in PVC conduit to the control box to prevent damage to the cable from lawn

mowers, weed eaters and grazing animals. Do not run any other type of wire or cable in conduit with WAND

cable.

Installing The WIRE CLAMP: The WIRE CLAMP (includ-

ed) is used to secure the WAND cable where it enters the control box to

prevent it from being accidently pulled out.

Step 2: If you are installing the WAND on a GTO/PRO low voltage

single gate operator, use a screwdriver or steel punch to carefully remove

the thin plastic knockout disk (see illustrations at right) at the bottom

of the control box. If you have a dual gate operator system on a PROSW1000/2000 or PRO-SL1000/2000 system or are installing the WAND

on a GTO/PRO AC powered operator, drill a 7/8” diameter hole at the

bottom of the control box and install the WIRE CLAMP. On non-GTO

operators, see page 10 of this manual, as well as, consult the manufacturers intallation maunal.

Be careful with tools to avoid contact or damage to the control

board!

Step 3: Use a sharp knife or deburring tool to clean the rough edges from

the hole.

Step 4: Unscrew and remove the lock nut from the WIRE

CLAMP hub (included with hardware). From the outside of

the control box, insert the WIRE CLAMP hub and sealing

nut (see illustration right) into the new WIRE CLAMP

hole. Finger tighten the lock nut onto the threaded end of the

WIRE CLAMP hub from inside the box.

3

Page 7

WAND Wires

ON

ALARM ACCESSORY RCVR

SEQ1

2

LEARN

BLU

ORG

WHT

GRN

R B G

BLACK

BLUE

Wiring the WAND to GTO/PRO Low Voltage Gate Operators:

PVC Conduit

WIRE CLAMP in Knockout

Bottom of Control Box

CABLE from

the Opening Sensor

WIRE from

the Operator

STALL FORCE

M

I

N

M

A

X

GRN

BLK

RED

RECEIVER

COM

COM

CYCLE

CLOSE

SAFETY

EXIT

OPEN

SHADOW

LOOP

CLOSE

EDGE

OPEN

EDGE

J11

J8

J12

WAND

Wires

BLACK

BLUE

PRO-SW1000/2000, PRO-SW3000/4000 and PRO-SL1000/2000

If you are installing the WAND on an AC Powered Operator skip forward to Page 7.

For installation on other brands of operators, see page 10.

IMPORTANT: TURN OFF the power and disconnect

the battery wires before you begin to connect the WAND

wires to any gate operator.

Step 5: Run the cable from the WAND through the WIRE

CLAMP into the control box. Pull about 8 - 10 inches of wire

into the control box to reach the ACCESSORY TERMINAL

BLOCK and BATTERY WIRES in the control board. Now

tighten the WIRE CLAMP nut to secure the wires in the WIRE

CLAMP.

Step 6: Strip about 3/8 of an inch of insulation from the YELLOW, BLACK, RED and BLUE wires in the WAND CABLE.

Accessory terminal connection for PRO-SW3000

& PRO-SW4000 gate operators:

Step 7: Connect the BLUE wire from the WAND CABLE to

the EXIT/OPEN terminal on the operator control board.

Step 8: Connect the BLACK wire from the WAND CABLE

to one of the the COMMON terminals on the operator control board.

Accessory terminal connection for PRO-SW1000/2000

& PRO-SL1000/2000 gate operators.

Step 7a: Connect the BLUE wire from the SENSOR CABLE to the

BLU Accessory Terminal on the opener control board.

Step 8b: Connect the BLACK wire from the SENSOR CABLE to

the GRN Accessory Terminal on the opener control board.

NOTE: The SHIELD is the braided metal wire wrapped

around the insulated wires inside the WAND CABLE.

4

Page 8

Connecting the Range Adjustment Control Board:

Potentiometer (POT)

Range Adjustment

Control Board

Wire NutWire Nut

Optional Mounting Hole

YELLOW wire

from WAND Cable

YELLOW

BLACK

BLACK BATTERY

CONNECTOR wire provided

MIN MAX

RED Wire from WAND Cable

SHIELD from WAND Cable

BLACK W

ire from Range

Adjustment control board

BLACK Opener Battery Wire

BLACK BATTERY CONNECTION Wire

with Spade Connector included with W

AND

RED BATTERY CONNECTION Wire

with Spade Connector included with WAND

Double Spade Connectors

included with WAND

RED Operator Battery Wire

Step 9: Connect the YELLOW wire from the WAND CABLE to the YELLOW wire from the Range Adjustment control board using one of the WIRE NUTS provided.

Step 10: Connect the BLACK wire from the Range Adjustment control board to the BLACK BATTERY

CONNECTOR wire (provided), along with the SHIELD wire from the WAND CABLE (see Step 13 below).

Step 11: Secure the RANGE ADJUSTMENT CONTROL BOARD inside the gate operator control box. The control box has a slot on the side and bottom for extra control boards, or you can use the optional mounting hole.

IMPORTANT: DO NOT let exposed wiring or components on the control board make contact with other exposed

wiring or components.

Power supply connection:

Step 12: With Power Off, connect the

RED and BLACK control board wires

from the operator to the DOUBLE SPADE

CONNECTORS (provided) as shown.

Step 13: Using a WIRE NUT, connect the

SHIELD wire from the WAND CABLE

(along with the BLACK wire from the

Range Adjustment board) to the BLACK

BATTERY CONNECTION wire provided

Using the remaining WIRE NUT connect

the RED wire from the WAND CABLE to

the RED BATTERY CONNECTION wire

provided. (Do not connect to battery yet).

Step 14: Connect these wires to the DOUBLE SPADE CONNECTORS as shown.

IMPORTANT: Be sure to connect both

RED wires to the same DOUBLE SPADE

CONNECTOR and both BLACK wires to

the other DOUBLE SPADE CONNECTOR. You will connect the DOUBLE

SPADE CONNECTORS to the battery

in the next step.

5

Page 9

SHIELD from WAND Cable

BLACK wire from Range

Adjustment control board

RED wire from WAND Cable

BLACK Operator Battery Wire

BLACK BATTERY CONNECTION Wire

with Spade Connector included with WAND

RED BATTERY CONNECTION Wire

with Spade Connector included with WAND

Double Spade Connectors

included with WAND

RED Operator Battery Wire

MIN MAX

!

WARNING

GA

TE OPENING

SENSOR IN USE

The Automatic Gate Opener is activated when a

vehicle comes within range of the sensor buried

along side the driveway and could possibly be

activated by a child on a bicycle, tricycle or other

metal play equipment.

8.5"

REWWARN01

Powering Up the WAND:

IMPORTANT: When the WAND is

first powered up it must be undisturbed for 60 seconds to perform

the self test and calibrations. Before

powering the WAND make sure

there are no moving metal objects or

moving vehicles within range of the

WAND.

Step 15: Connect the DOUBLE SPADE CON-

NECTORS to the battery terminals (RED WIRES to

POSITIVE (+) battery terminal and BLACK WIRES

to NEGATIVE (–) battery terminal). Turn power on,

do not activate operator yet. Wait 60 seconds, then

activate the operator and test the WAND.

NOTE: If you have other accessories connected to your

battery with double spade connectors you may need

to connect a double spade connector to a double spade

connector in order to

connect all the accessories.

Adjusting the Range:

Step 16: Test the WAND to see if it is working properly and if the

RANGE needs adjusting for optimum performance.

• Turn the potentiometer (POT) clockwise to increase range.

• Turn the potentiometer (POT) counter-clockwise to decrease range.

Replace the control box cover and bury the WAND and wire.

Safety Precautions:

Step 17: Place the WARNING SIGNS on both

sides of the gate using tywraps included.

6

Page 10

Wiring the WAND to GTO/PRO AC Powered Gate Operators:

–

+

G

R

B

GTO

RCVR.

1/2 amp

slow blow fuse

CLOSE

OPEN

FIRE DEPT

.

SHAD. LOOP

SAFE LOOP

ENTRY LOOP

FREE EXIT

CYCLE

COMMON

COMMON

COMMON

COMMON

LOCK 1

LOCK 2

AUX 2

AUX 1

ACCES. PWR

Class

2

24VDC

REV

FWD

GTO Inc., Tallahassee, FL

copyright 1999

TB11

TB10

TB9

TB8

TB7

TB6

TB5

TB4

TB3

RED

SHIELD

BLACK

BLACK

BLUE

YELLOW

YELLOW

Range Adjustment

Control Board

Wire Nut

MIN MAX

Cable from Sensor

GTO/PRO AC SL-5000/6000 and SW-5000/6000 BASIC Control Board

PRO-SL5000/6000, Series and PRO-SW5000/6000 Series

IMPORTANT: TURN OFF the power before you begin to connect the WAND wires to the control board.

Step 5a: Run the cable from the WAND through the WIRE CLAMP into the control box. Pull about 8 -10 inches

of cable into the control box to reach the ACCESSORY TERMINAL BLOCKs on the control board. Now tighten

the WIRE CLAMP nut to secure the cable in the WIRE CLAMP.

Step 6a: Strip about 3/8 of an inch of insulation from all the wires.

Accessory terminal connection: (See Illustration A below for BASIC unit control boards and Illustra-

tion B on page 8 for ADVANCED unit control boards.)

Step 7a: Connect the BLUE wire from the WAND CABLE to the FREE EXIT Accessory Terminal on the control

board.

Step 8a: Connect the BLACK wire from the WAND CABLE to the COM (Common) Accessory Terminal on the

control board.

Illustration A

7

Page 11

Connecting the Range Adjustment Control Board:

Potentiometer (POT)

Range Adjustment

Control Board

Wire Nut

Optional Mounting Hole

YELLOW wire

from WAND

YELLOW

BLACK

To

NEGATIVE (–) Terminal

of the 24VDC Accessory

Terminal on the Control Board

MIN MAX

YELLOW

MIN MAX

INERTIA

EDGE 6

EDGE

5

EDGE

4

EDGE

3

EDGE

2

EDGE

1

COM

COM

–

+

DUAL GATE

INTERFAC

E

RX

TX

GRN

RED

BLK

GTO

RCVR.

LOCK 1

LOCK 2

ALARM

AUX 2

ACCES.

PWR.

24VDC

–+–

+

MIN MAX

CLS. SENS.

MIN MAX

OPN. SENS.

CYCLE

FREE

EXIT

CLOSE

OPEN

FIRE

DEPT.

SHAD

.

LOOP

SAFETY

LOOP

ENTRY

LOOP

1 120

TIMER

COM

COM

COM

COM

RED

SHIELD

BLACK

BLACK

BLUE

YELLOW

Wire Nut

Cable from Sensor

GTO/PRO AC SL-5100/6100 and SW-5100/6100 ADVANCED Control Board

Range Adjustment

Control Board

MIN MAX

Step 9a: Connect the YELLOW wire from the WAND CABLE to the YELLOW wire from the Range Adjustment control board using the WIRE NUT provided.

Step 10a: Connect the BLACK wire from the Range Adjustment control board and the SHIELD wire from

the WAND CABLE to the NEGATIVE (–) side of the 24 VDC Accessory Terminal on the control board.

Step 11a: Secure the RANGE ADJUSTMENT CONTROL BOARD inside the gate operator control box.

IMPORTANT: DO NOT let exposed wiring or components on the control board make contact with other exposed

wiring or components.

Illustration B

8

Page 12

MIN MAX

!

WARNING

GA

TE OPENING

SENSOR IN USE

The Automatic Gate Opener is activated when a

vehicle comes within range of the sensor buried

along side the driveway and could possibly be

activated by a child on a bicycle, tricycle or other

metal play equipment.

8.5"

REWWARN01

Power supply connection: (See Illustration A on page 7 for BASIC unit control boards and Illustration B

on page 8 for ADVANCED unit control boards.)

Step 12a: Connect the RED wire from the WAND CABLE to the POSITIVE (+) terminal of the 24 VDC Accessory Power Terminal Block on the control board.

Step 13a: Connect the SHIELD from the WAND CABLE to the NEGATIVE (–) terminal of the 24 VDC Accessory Power Terminal Block on the control board.

Powering Up the WAND:

IMPORTANT: When the WAND is first powered up it

must be undisturbed for 60 seconds to perform the self

test and calibrations. Before powering the WAND make

sure there are no moving metal objects or moving vehicles within range of the WAND.

Step 14a: Turn power to the operator on, wait 60 seconds before activating the operator and testing the WAND.

Adjusting the Range:

Step 15a: Test the WAND to see if it is working properly and if the

RANGE needs adjusting for optimum performance.

• Turn the potentiometer (POT) clockwise to increase range.

• Turn the potentiometer (POT) counter-clockwise to decrease range.

Replace the control box cover and bury the WAND and wire.

Safety Precautions:

Step 16a: Place the WARNING SIGNS on both

sides of the gate.

9

Page 13

For Installation on Other Brand Gate Operators ...

Input

Voltage (+)

Input

Voltage (–)

Relay Output

Common

Relay Output

Normally Open

Range

Adjustment

Range

Adjustment

Board

Input Voltage

11 - 36 Vdc or

8 - 26 Vac

–

+

Free Exit/Entry

Connections

WAND

RED

SHIELD

BLACK

BLACK

BLUE

YELLOW

YELLOW

Generic Wiring Diagram

If you are using the EXIT WAND on any other automatic gate operator brand, use the information

below for wiring the system. If you do not understand the instructions below, please call GTO’s

Technical Support at 1-800-543-1236.

Typical Gate Wiring Connection:

• Reference Wires:

o RED => Input Voltage (+)

o SHIELD => Ground/Common (–)

o BLACK => Relay’s Common

o BLUE => Relay’s Normally Open

o YELLOW => Remote WAND [Range adjustment potentiometer (POT)]

• Terminology Definitions:

o ‘FREE EXIT/ENTRY’: defined as input terminals (2) that upon activation (momentarily connected together) will

cause the gate to run in the open direction only. Note: In most gate operators, one of the two terminals is the ‘COMMON/GND’.

• Power supply connection:

o DC power supply: (11-36 Vdc)

ß Connect the positive (+) wire of the power supply to the RED wire.

ß Connect the negative (-) wire of the power supply to the SHIELD wire.

o AC power supply: (8-26 Vac)

ß Connect the power supply to the RED & SHIELD wires. There is no polarity for AC power supply.

• Relay output connection:

o Connect the BLUE from the WAND to the ‘FREE EXIT/ENTRY’ of the gate operator.

o Connect the BLACK from the WAND to the ‘COMMON/GND’ of the gate operator.

• Range (POT) board connection:

o Connect the YELLOW from the WAND to the YELLOW from the Range Adjustment Board.

o Connect the BLACK from the Range Adjustment Board to a negative input voltage.

o Turn the POT clockwise to increase range.

o Turn the POT counter-clockwise to decrease range.

10

Page 14

TECHNICAL SPECIFICATIONS:

• Power supply: 8-26 Vac/dc.

• Current consumption: 1.5 mA typical.

• Relay rating: Latching relay

Nominal switching capacity (resistive load) 1 Amp 30 Vdc, 0.5 Amp 125 Vac

Max. switching power (resistive load) 30 Watt, 62.5 V A

Max. switching voltage 110 Vdc, 125 Vac

Max. switching current 1 Amp

• Relay Trip Time: 2 seconds

• Operating Temperature: -25°F (-14°C) to 125°F (69°C)

• Dimensions: 1-3/4” (44.5 mm) diameter x 16.5” (42 cm) long.

• Adjustable range: 3 -12 feet typical installation.

• Very low power consumption, ideal for battery application.

Trouble Shooting: Make sure all connections are correct.

If the WAND is not working:

1. Make sure the Range Adjustment is set at maximum range.

2. Disconnect the power to the WAND.

3. Reconnect the power to the WAND and make sure that no metal object or vehicle is moving around

the WAND for 60 seconds while it is calibrating.

4. Activate the gate operator and test the WAND to verify that it is working properly.

11

Page 15

Other GTO Products for Your Safety and Convenience:

1

2

ABC

3

DEF

4

GHI

5

JKL

6

MNO

7

PRS

8

TUV

9

WXY

0

Automatic Gate Lock (FM144)

A MUST for securing the gate against forced entry or exit. Solenoid driven,

plated steel bolt lock with a zinc plated steel housing. The horizontal electronic

lock is used with the GTO/PRO system for maximum stability and security.

Recommended for gates over 8 feet long or where high winds are common.

GTO Digital Keypad (F300)

This specially designed Digital Keypad can be easily installed as a wireless or wired keypad.

It can be programmed to use up to fifteen different personal identification number (PIN)

codes. Each code is face programmable with additional security features built in. Requires

Three (3) AA batteries (not included).

Pin Lock (RB975) for GTO/PRO 1000/1200 and SL-1000/2000 …

Pin Lock (FM320) for GTO/PRO 2000/2200 …

The Pin Lock is a substitute for the clevis pin at front mounting point of the GTO/PRO low voltage operator arms. They help prevent theft of the operator arm while allowing quick release of the

operator. The pin lock can be inserted in the chain brackets of the GTO/PRO SL-1000 and SL2000 to prevent unauthorized removal of the quick release pins.

Pin Lock (FM318) for GTO/PRO SL-5000/6000 series operator housings …

Pin Lock (FM319) for GTO/PRO SW-5000/6000 series operator housings …

Used to prevent unauthorized removal of the operator housing.

5 Watt Solar Panel (FM122) / 10 Watt Solar Panel (FM123)

The Solar Panel is a solar powered battery charger for use with the GTO/PRO gate operator

system. Particularly suited for remote installations, the Solar Panel comes with tubular steel

support, mounting clips, wire connectors, and 8 ft. of low voltage wire. The GTO/PRO

control board has clearly labeled terminal connections for easy installation of the Solar Panel.

Installation in some regions of the world may require multiple solar panels for adequate

charging power.

Entry Transmitter (RB741)

The GTO Entry Transmitter, with adjustable code settings, is standard equipment with

GTO/PRO systems. Battery included.

Key Chain Mini Transmitter (RB744)

The Key Chain Mini Transmitter is a miniature version of the entry transmitter and has the

same adjustable code settings. Battery included.

Push Button (Doorbell) Control (RB101)

Unlighted Doorbell Button for remote entry or exit control. Connects directly to the control board

and uses 16 gauge, multi-stranded low voltage wire (not included).

For your nearest dealer, please call the GTO/PRO® Sales Department at

1-800-543-GATE (4283)

12

Loading...

Loading...