Page 1

Service Manual for the

Accutherm Ultra Printer

2-ACU-003-01

January 2014

Page 2

Page 3

Copyright

Windows is a registered trademark of Microsoft Corporation in the United States and other

countries.

All other trademarks in this document are owned by or licensed to GTECH S.p.A. or Spielo

International Canada ULC and are registered or pending registration in the United States and other

countries.

This document is the property of GTECH S.p.A., Providence, RI, and Spielo International Canada

ULC. It contains confidential and trade secret information. This document, including all

information within it, may not be used, transferred, reproduced, published, or disclosed, in whole

or in part, directly or indirectly, except as expressly authorized by an officer of GTECH S.p.A.

pursuant to written agreement.

Copyright © 2014 GTECH S.p.A. and Spielo International Canada ULC. All rights reserved.

Page 4

Page 5

Revision History

This document describing the Accutherm Ultra has a revision number. Each time

this document is updated, the document revision number is updated. The number

below represents the current revision of this manual.

Service Manual for the Accutherm Ultra Printer

2-ACU-003-01

For future documentation revisions, the last two digits of the number above will

increment by 1 (for example, when revision 01 is revised, the last two digits in the

number above will become 02). Revision details are tracked in the table below.

Revision # Description Date Writer

2-ACU-003-01 DRAFT for Review 9/13/2010 M. Brown

2-ACU-002-02 Final for Delivery 11/02/2010 J. Pearson

2-ACU-002_03 Updates from trainer 1/15/2014 J. Pearson

2-ACU_003_01 Release as updated Service Manual 1/28/2014 J.Pearson

No provisions exist for automatic, on-site updates of this manual.

2-ACU-003-01 RH-i

Page 6

This manual is intended for use as a training guide. Accordingly, although we

strive to be as accurate as possible at print time, product information contained in

this manual should not be construed as official product specification information

or as legally-binding promises of product performance. Each chapter also has a

revision level since chapters may be edited before new manuals are published. If

you believe your manual is out of date, contact GTECH Learning Technology

Services to obtain the latest edition level.

Stephanie Lataille, Documentation Manager

GTECH Technical Training and Support Services

(401)-392-7961 or ttssdocs@gtech.com

To suggest or request updates to this manual, please contact your Field Services

Engineering (FSE) Representative or send an email to #Field Services

Engineering or ttssdocs@gtech.com and it will be forwarded.

RH-ii GTECH Technical Training and Support Services

Page 7

Table of Contents

Revision History

Chapter 1

Introduction

Overview of Accutherm Ultra....................................1-2

Mechanical Specifications..........................................1-3

Environmental Specifications ....................................1-4

Electrical Specification ..............................................1-4

Standard Printer Features ...........................................1-5

Mechanism.................................................................1-7

Print Head ................................................................1-7

Paper Motion............................................................1-8

Cutter .......................................................................1-8

Sensors.....................................................................1-8

Power Supply...........................................................1-8

Control Electronics.....................................................1-9

Overview..................................................................1-9

Processor and Memory ............................................1-9

Print Head Interface...............................................1-10

Motor Controllers ..................................................1-10

Sensor Interface .....................................................1-11

Power Supply Circuitry .........................................1-11

Communications Interface.....................................1-12

Chapter 2

Installation

Introduction................................................................2-1

Installation Instructions..............................................2-2

Loading Paper ............................................................2-6

Page 8

Chapter 3

Configuration

Chapter 4

Operation

Chapter 5

Diagnostics

Printer Self Test..........................................................5-2

Self-Test Mode.........................................................5-3

Normal Operation Errors .........................................5-4

Extended Diagnostics.................................................5-6

Chapter 6

Download

AccuTherm® Ultra Firmware Install Procedure........6-2

Chapter 7

Disassembly

Warranty Information.................................................7-1

Required Tools...........................................................7-2

Disconnect the Power Cable ......................................7-2

Disconnect the USB Communications Cable.............7-3

Remove the Cover Assembly.....................................7-4

Remove the Power Supply from the Base

Assembly...................................................................7-7

Remove the Printer Mechanism Assembly from

the Base Assembly....................................................7-8

Remove the Main Controller PCB Assembly

from the Printer Mechanism Assembly ....................7-9

TOC-ii GTECH Technical Training and Support Services

Page 9

Remove the Print Head Assembly from the Printer

Mechanism Assembly (Lower Print Mechanism) ..7-11

Remove the Rotary Knife from the Printer

Mechanism Assembly (Lower Print Mechanism) ..7-13

Remove Paper Path Assembly from Printer

Mechanism..............................................................7-14

Remove Stacker Guide Assembly from the

Printer Mechanism Assembly.................................7-18

Remove Platen from the Knife/Stacker Assembly...7-20

Remove Fixed Blade from the Knife/Stacker

Assembly.................................................................7-21

Chapter 8

Troubleshooting

Introduction to Troubleshooting.................................8-1

Troubleshooting Steps for FST’s ...............................8-2

Troubleshooting Steps for RLT’s...............................8-5

Loading Paper ............................................................8-9

Clearing a Paper Jam................................................8-11

Chapter 9

Preventive Maintenance

General Cleaning........................................................9-1

Cleaning the Print Head .............................................9-2

Cleaning the Top-of-Form/ Paper Low Sensor..........9-3

Cleaning the Jam Detection Sensor............................9-4

Cleaning the Platen.....................................................9-4

Service Manual for the Accutherm Ultra Printer TOC-iii

Page 10

Appendix A

Handling Precautions

ESD HANDLING .....................................................A-ii

What is ESD?..........................................................A-ii

Becoming “Static Safe” ..........................................A-ii

ESD-Induced Failure Modes..................................A-iii

Typical Symptoms of ESD Damage......................A-iii

Common False Assumptions Concerning ESD.....A-iii

ESD Precautions Checklist....................................A-iv

GTECH Manufacturing Specification ..................A-vii

PACKAGING ........................................................A-viii

General Packaging Procedures ............................A-viii

Appendix B

Diagrams

Appendix C

Spare Parts and Tools

In-Warranty Service.................................................C-iii

Post-Warranty Service..............................................C-iv

Ordering Spare Parts from Assembly Drawings......C-vi

Printer Assembly.....................................................C-vii

Assembly-Base (16-2054-01E)................................C-ix

Assembly-Paper Bucket (16-2056-01E) ................... C-x

Assembly - Mid-Frame (16-2055-01E)....................C-xi

Assembly-Paper Cover............................................C-xii

Assembly-Lower Mechanism ................................C-xiii

Assembly-Knife/Slacker (15-3737-01E)................C-xvi

Assembly-Paper Path (15-3746-01E).....................C-xix

Tools List.................................................................C-xx

TOC-iv GTECH Technical Training and Support Services

Page 11

Appendix D

Product Safety & Approvals

Safety Instructions......................................................D-i

Radio Interference.....................................................D-ii

FCC.........................................................................D-ii

Industry Canada......................................................D-ii

European Union......................................................D-ii

Telecom....................................................................D-iii

FCC........................................................................D-iii

Industry Canada.....................................................D-iv

Replaceable Batteries................................................D-v

Wireless Device Option ............................................D-v

Appendix E

Acronyms & Abbreviations

Service Manual for the Accutherm Ultra Printer TOC-v

Page 12

Page 13

Introduction

The Accutherm® Ultra Printer is a stand-alone thermal printer designed for use

with GTECH Lottery Terminals for printing lottery receipts.

1

Service Manual for the Accutherm Ultra Printer 1-1

Page 14

Overview of Accutherm Ultra

• Print Line Width— 640 dots @ 8dots/mm centered on 82.5 mm (3.25 in)

paper.

• 7.5 inch diameter paper roll

• Jam Detection

• Full cut auto-cutter

• Ticket Stacker with capability > 75 tickets

• User Flash Memory

• 1M bytes User Graphics Memory

• 128K bytes User Data Memory

• Font/System Flash Memory:

• 2M bytes for Fonts and System files.

• Manual configuration mode

•

Self test diagnostics

• Loadable Enhanced Diagnostics

• Internal Auto-Ranging (90-264 VAC) power supply

•

USB interface built into main controller PCB

• Power and Error LED

• Easy paper loading

1-2 GTECH Technical Training and Support Services

Page 15

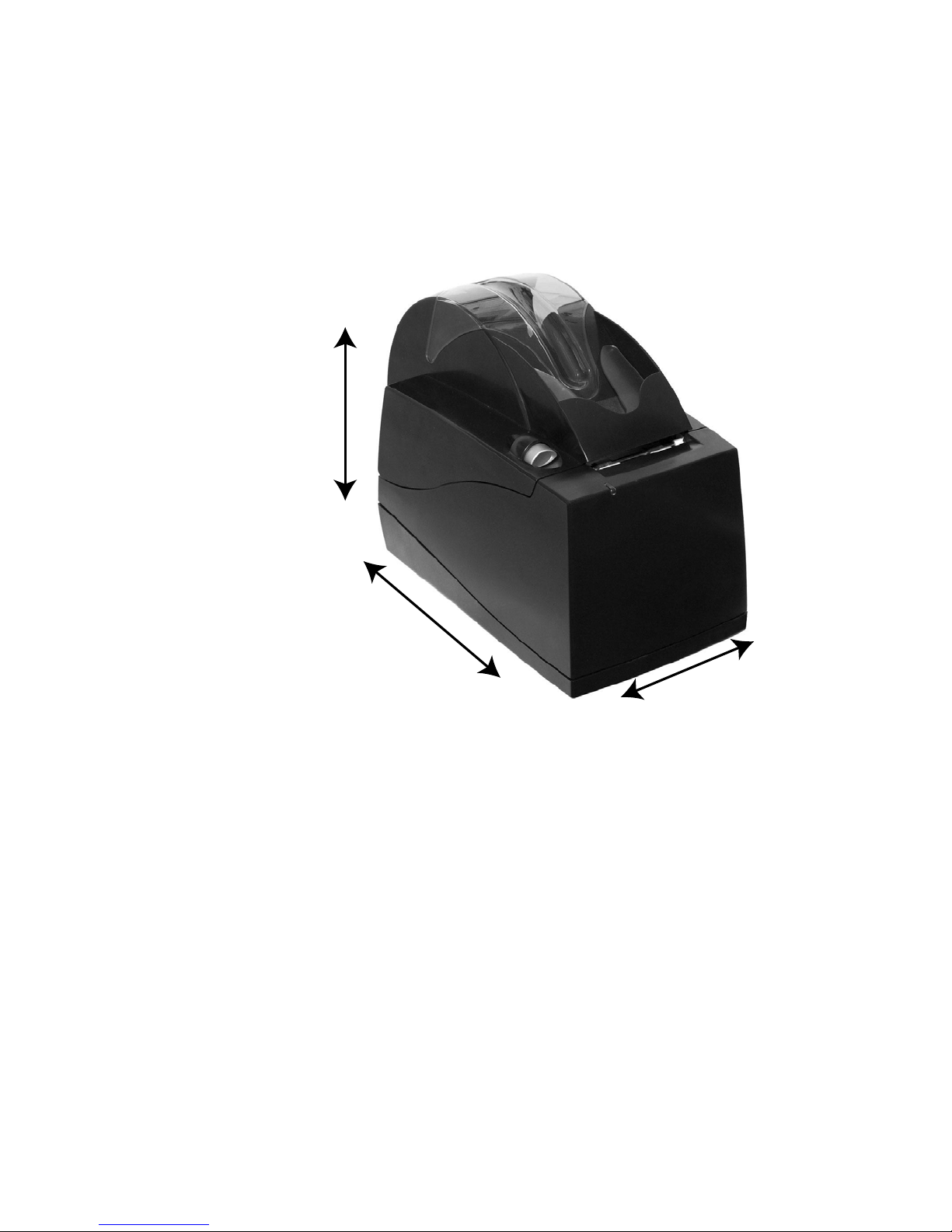

Mechanical Specifications

6.5 “ (165.1 mm)

13.26” (336.8 mm)

8.81” (223.77 mm)

• Height: 8.81" (223.77 mm)

• Width: 6.5" (165.1 mm)

• Depth: 13.26" (336.80 mm)

Introduction

Service Manual for the Accutherm Ultra Printer 1-3

• Weight: Approximately 4.9 lbs, 2.22 kg.

• Inter

• Printer Type: Fixed 80 mm.linear therma

face Type: USB

l head.

Page 16

Environmental Specifications

• Operating Temperature Range:5°C ~ 50°C (41°F ~ 122°F)

• Shipping/Storage Temperat ure Range:-10°C ~ 50°C (14°F ~ 122°F)

• Operating Humidity Range:10% ~ 90% @ 40°C (104°F) noncondensing only

• Shipp

ing/Storage Humidity Range:10% ~ 90% non-condensing only

(excluding paper)

Electrical Specification

AC Power Requirements: The Accutherm Ultra Printer is designed to be AC

self-powered. The printer is equipped with a universal input power supply that is

designed to operate worldwide without modification.

Supply

Supply Voltage

Rating (VAC)

100-240 90-264 47-63 20 watts

Voltage Range

(VAC)

Frequency

(Hz) Power Consumption

1-4 GTECH Technical Training and Support Services

Page 17

Standard Printer Features

Standard features of the Accutherm® Ultra printer include:

• High-speed (10 inches per second) thermal receipt printing

• Black dot - Top of Form and Paper Low Sensing capabilities

• Jam Detection

• Multiple barcode printing capabilities

•2 of 5

• EAN-8

• EAN-13

•UPC-A

•3 of 9

•UPC-E

•Codabar

Introduction

• Code 128

• Code 93

• PDF417 2D Stacked

•Data Matrix

• RSS GS1

• Print-Line Width of 640 dots @ 8 dots/mm centered on 3.25 in (82.5 mm)

Paper

•

Up to a 7.5 in (190 mm) Diameter Paper Roll

• Long-life auto ticket cutter

• Standard variable length stacking module capable of handling from 2.75 to

10 inch (70 to 254 mm) length tickets

• Ticket stacking capability (greater than 75 tickets)

• Modular printer design for easy servicing

• Internal Auto-Ranging (90-264 VAC) Power Supply

• Power and Error LED Indicator

• User Flash Memory

• 1M bytes User Graphics Memory

• Font/System Flash Memory:

Service Manual for the Accutherm Ultra Printer 1-5

• 128K bytes User Data Memory

• 2M bytes for Fonts and System files.

Page 18

• Manual configuration mode

• Self test diagnostics

• Loadable Enhanced Diagnostics

• USB interface built into main controller PCB

1-6 GTECH Technical Training and Support Services

Page 19

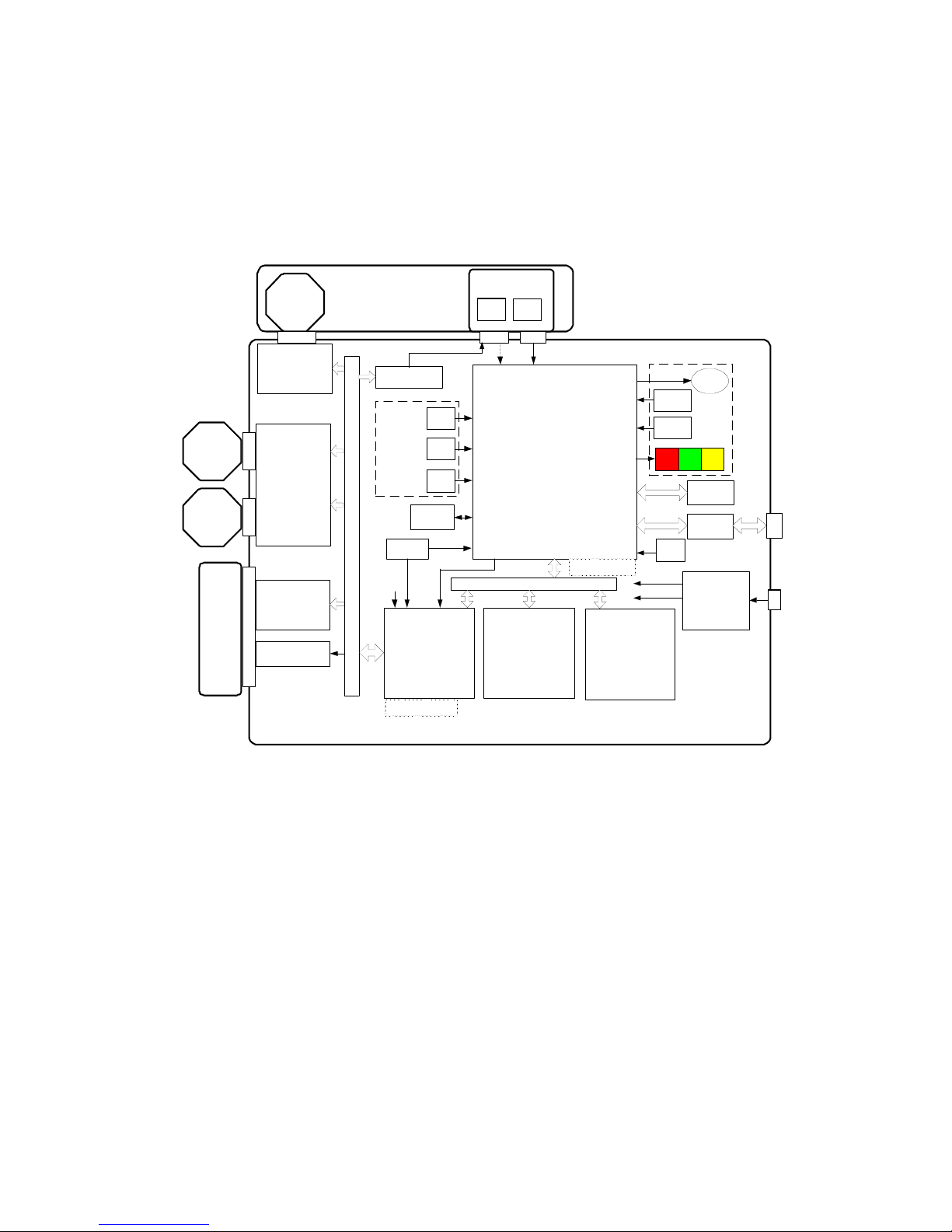

Mechanism

Top C ov e r

Paper Feed

Motor

Dual Step Motor

Driver

Allegro A 3988

(1000ma)

Step Motor Driver

Allegro A3 983

(400ma)

Knife Motor

Stack er Moto r

MCF5353

Processor

(BGA)

RAM

4Mb x 1 6

(BGA)

FLA SH

2Mb x 16

(BGA)

FPGA

(BGA)

Print

Head

Power Supply

and So ft Start

Address/Data Bus

+

Clock

Oscillator

Cover

EEPROM

RS2 32

Driver

+24 VDC

from

internal

power

brick

+3.3V

+1.5V

Paper

Cut

Home

TOF JAM

On board

sensors

(Interruptive)

Off board sensors

(reflective)

TOF Cur r e n t

Adjust

F

P

G

A

I

/

O

+

Print Head

Buffer

Print Head

Voltage Contro l

LED

Test

Switch

Feed

Switch

On Board

Operator

Inte rface

LED LED

USB

Protection

Beeper

USB

Clock

Debug Header

Program Header

Not

Populated

+1.5V

This section explains the Accutherm Ultra’s theory of operations.

Introduction

Print Head

The print head in the Accutherm Ultra is a high speed, thick film device

configured as single row of 640 dots spaced at 8 dots/mm for a total printable

width of 80mm (3.15”). Print data is sent from the controller board as a serial data

stream at 8 MHz.The head elements are then activated by signals from the main

controller board to form the image on the paper. The Accutherm Ultra uses a two

level energy control system to compensate for dot history with all timing

controlled by the controller board electronics. The head also contains a thermistor,

which is used to monitor the temperature of the head substrate. Dot energy is

continually adjusted based on head temperature, supply voltage, dot history, and

paper sensitivity. The print head connects to the controller through a 28 position

Flexible Flat Cable (FFC).

Figure 1-1. Printer Block Diagram

Service Manual for the Accutherm Ultra Printer 1-7

Page 20

Paper Motion

Paper motion is accomplished by a hybrid, 1.8 degree step motor running at a

maximum speed of approximately 3000 steps per second. The gear train is

designed such that one motor step equals.0833mm of paper motion resulting in a

paper feed speed of 250 mm/sec (10 in/sec).

Cutter

The cutter mechanism consists of a rotary blade mounted to the mechanism,

which operates against a fixed b lade located in the paper cover. The rotary blade is

driven by a 7.5 degree “tin can” step motor mounted to the mechanism frame,

acting through a lever arm and follower. The rotary blade home position is

determined by means of an optical sensor located on the controller board and a

flag located on the cutter drive gear. The motor operates one direction to activate

the cutter and then reverses direction to return the cutter to its home position with

a total cut cycle time of approximately 350 ms.

Sensors

There are two types of sensors used on the Accutherm Ultra printer. One type is

mounted directly on the controller board and is activated by mechanical flags on

the mechanism. These sensors are optical interruptive type and are used to detect

Cutter Home, Paper Out, and Cover Open conditions. The second type are

mounted in the printer mechanism and are connected by harnesses to the

controller. These are optical reflective sensors, which are used to detect black

marks and paper low stripes on the reverse side of the paper, as well as the

presence of tickets in the printer . Th e black mark/paper low detection sensor can

be auto-calibrated using on-board diagnostics.

Power Supply

The power supply for the Accutherm Ultra is a small, universal input, fully

enclosed module located within the printer cabinet. The 24 VDC output of the

supply connects to the controller board by means of a cable. The AC input

connector on the supply is accessible from the rear of the printer and accepts a

Standard, C6 style, 3-wire power cord.

1-8 GTECH Technical Training and Support Services

Page 21

Control Electronics

Overview

The printer has a main controller board containing microprocessor, FPGA,

memory, motor drivers, and sensor conditioning circuits used to control the

mechanism. The basic system clock was chosen to be 19.6608 Mhz. This clock is

multiplied in the main processor with a PLL to maximize execution speed and

used by the FPGA for optimum thermal print head load speed. External

communications is USB only.

Processor and Memory

The processor used in the Accutherm Ultra is a Motorola ColdFire MCF5253

running at 140 Mhz. with integrated USB controller. The processor interfaces,

through a 16 bit external bus, to a 64Mb Synchronous Dynamic Ram (SDRAM),

32Mb of Flash Memory, 8Kb of EEPROM, and a 2,910 logic element Field

Programmable Logic Array (FPGA). The processor contains general purpose I/O

pins which are used to directly control many of the printer functions including:

Introduction

• Status LEDs

• USB Communications

• Print Head Data and Timing

• Print Head Temperature and Voltage monitoring

• Programming the FPGA

The remaining printer functions are

• Stacker motor control

• Cutter motor control

• Paper feed motor control

• Thermal print head loading and protection

controlled though the FPGA including:

Service Manual for the Accutherm Ultra Printer 1-9

Page 22

Print Head Interface

Print data is formatted by the MCF5253 and transmitted to the FPGA through a

byte serial, memory mapped I/O interface for each dot row. This interface allows

rapid transmission of data with minimal software overhead. Once the transmission

is completed, the FPGA parses, loads, and latches the data into the print head

registers using two simultaneous serial channels. Strobe timing (dot energy

control) is calculated and applied to the print head by the MCF5253. For each line

of dots printed, the head is energized twice to compensate for dot history. The

MCF5253 provides a watchdog timer that is gated in the FPGA with the strobe

signals to protect the thermal print head from overheating. All head interface lines

are buffered and resistance matched to the connecting ribbon cable.

Motor Controllers

Both the paper feed and cutter step motors are controlled by an Allegro A3988

DMOS motor driver that provides two dual-bridge, bipolar, PWM, micro-stepping

motor drivers. These drivers operate from the 24-volt supply and apply up to

1.5A/phase of output current. The drivers are micro-step capable; the controller

must provide both phase and current level information to the driver . S tepper motor

control lines are driven by FPGA outputs latched from MCF5253 processor.

The paper feed motor is set for a maximum motor current of 1A/ phase. Control

lines operate this stepper motor in ¼ step mode up to approx. 500 equivalent full

steps/sec followed by modified half step mode up to 3600 equivalent full steps/

sec.

The cutter motor circuit is also set for a maximum current level of 1A/ phase.

Control lines operate this stepper motor in modified half step mode up to approx.

1000 equivalent full steps/sec.

The stacker motor is controlled by a dedicated Allegro A3983DMOS microstepping motor driver with translator. The driv er i s configured to operate the

stacker motor in modified half step mode at a maximum current of 500ma/phase

and is matched for stepping speeds to receive tickets passed off from the paper

feed motor.

1-10 GTECH Technical Training and Support Services

Page 23

Sensor Interface

There are three, on-board infrared optical interruptive sensors, which are activated

by plastic flags attached to the mechanism. These devices have an open collector,

photo transistor output and provide a low level signal when blocked. The output

switches to a high level when the sensor is unblocked by a flag. The outputs of

these sensors are buffered with Schmitt triggers before being presented as inputs

to the MCF5253. The state of these sensors is as follows:

The controller board also has connections for two external optical reflective

sensors. One sensor is used to detect the Top of Form (TOF) mark and paper low

stripes on the back of the paper. The other sensor is used to detect paper jam

(JAM) conditions.

Introduction

Table 1-1. Sensor State

Sensor Blocked Unblocked

OP1 Cutter home Cutter not home

OP2 Paper cover closed Paper cover open

OP3 Paper present Paper not present

The LED current of the TOF/Paper Low sensor is adjustable by the processor in 8

steps from 8ma to 21ma and is auto calibrated using diagnostics resident in the

printer. The output of this sensor is presented in analog form to the MCF5253’s

AD converter for calibration and Schmitt trigger buffered on another input for fast

reading during normal operation.

The LED current of the JAM sensor is fixed to approx. 18ma. Its output is Schmitt

trigger buffered for fast reading by the MCF5253 processor.

Power Supply Circuitry

There are four different power supply voltages used in the Accutherm Ultra.

Table 1-2. Power Supply Circuitry

Voltage Derived From Used For

24 VDC Modular Power Supply Print Head, Step Motors

3.3 VDC Derived from +24V using a buck

converter circuit

Processor I/O,USB

communications, SDRAM, flash

memory, print head logic,

sensors

Service Manual for the Accutherm Ultra Printer 1-11

Page 24

Table 1-2. Power Supply Circuitry

Voltage Derived From Used For

1.8 VDC Derived from 3.3V using an internal

regulator resident in the MCF5253

1.5 VDC Derived from 3.3V using a TI

TPS73601 low drop linear regulator

A power supply supervisor chip monitors the 3.3V and provides reset control for

the processor and FPGA.

Communications Interface

The communications interface is resident on the main controller PCB. The

Accutherm Ultra is available with one interface; USB.

Processor core

FPGA core

1-12 GTECH Technical Training and Support Services

Page 25

Installation

Introduction

Follow the instructions in this chapter in order to properly install the Accutherm®

Ultra printer. The Accutherm® Ultra can be used with a number of GTECH

terminals, including the GT1100 and GT1200.

2

GTECH hardware products and peripherals require properly grounded outlets. It

is critical that this grounding requirement is enforced on all installations of

GTECH hardware products and peripherals.

Service Manual for the Accutherm Ultra Printer 2-1

Page 26

Installation Instructions

Accutherm® Ultra

Printer

The following steps describe the procedure for installing the Accutherm Ultra

printer:

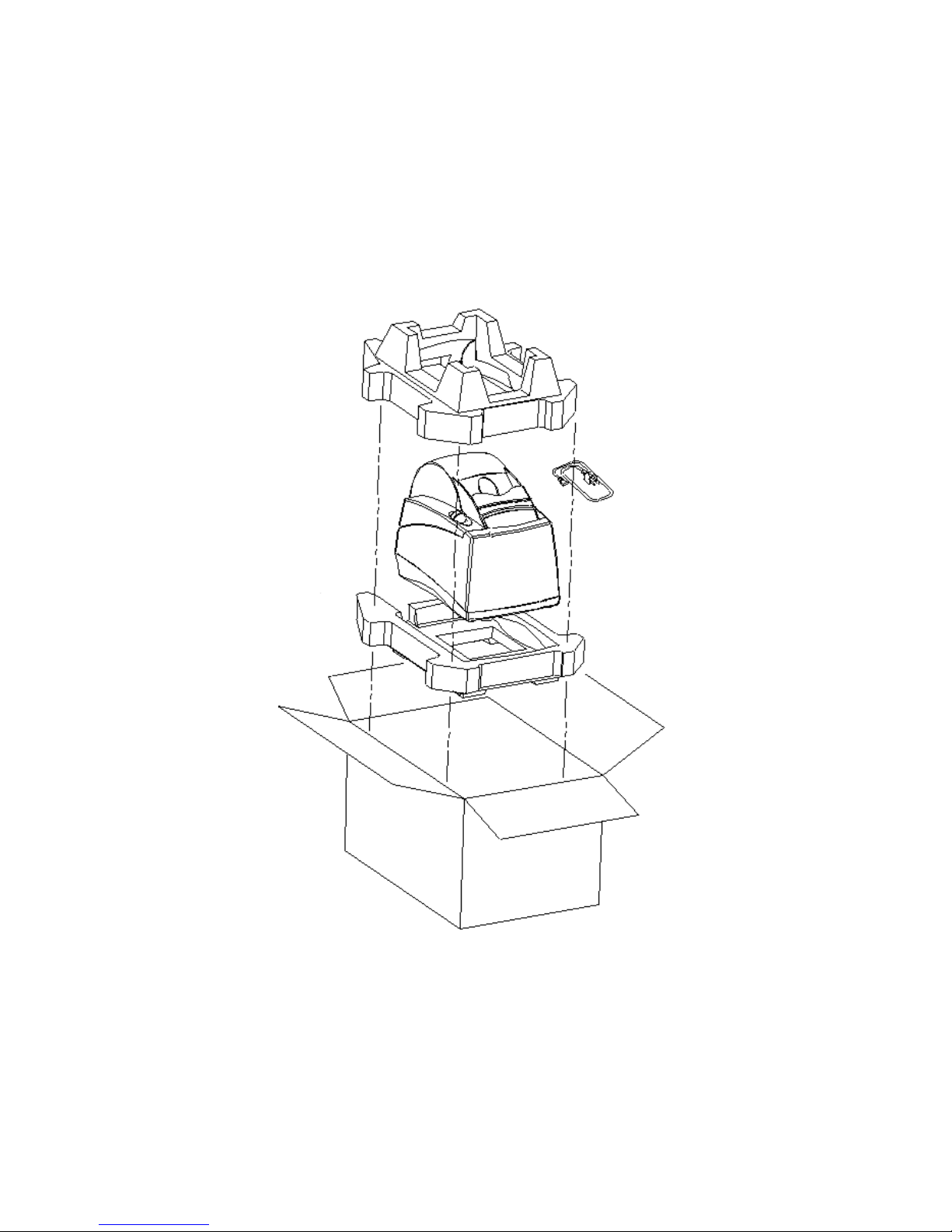

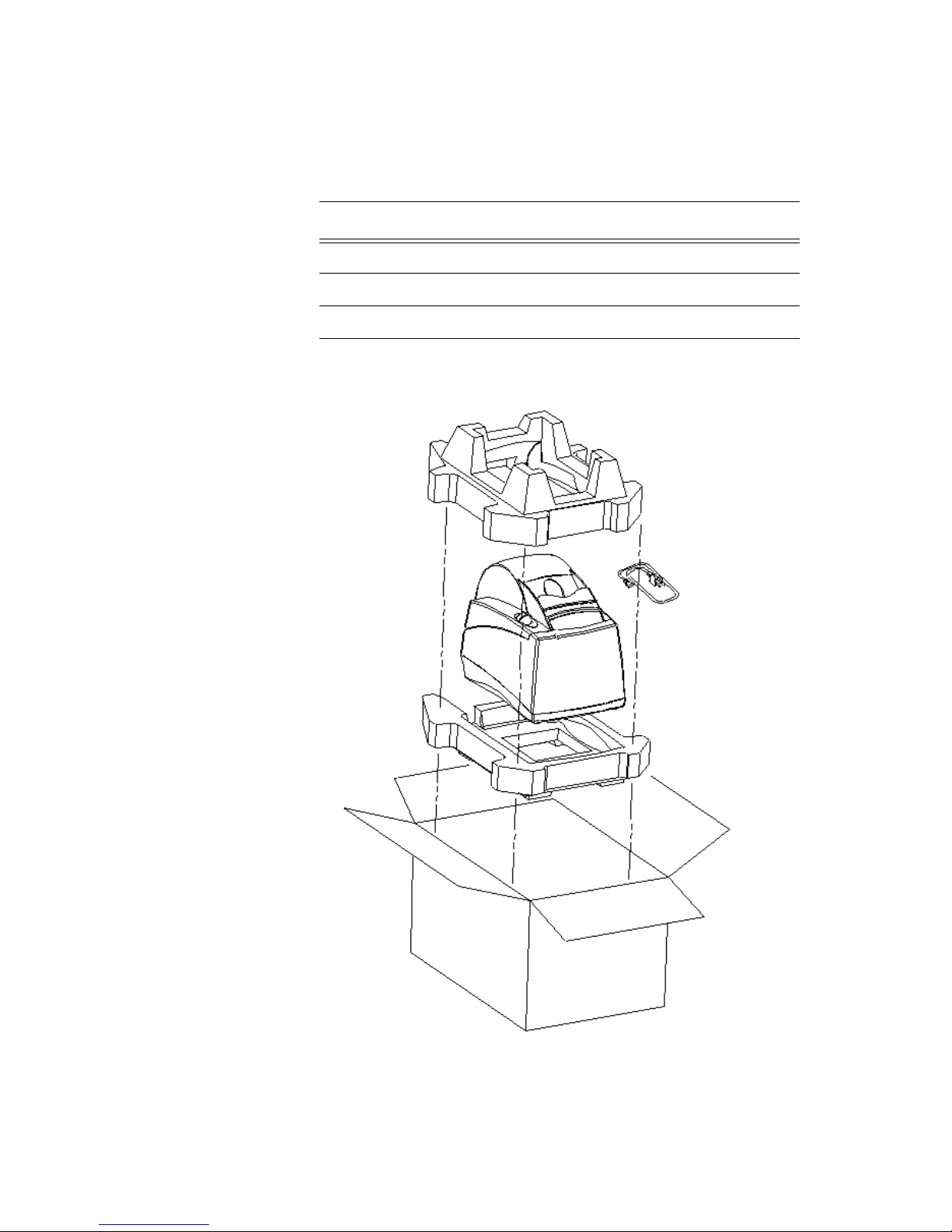

1. Remove the printer and cables from its pac

kaging.

Figure 2-1. Remove Accutherm Ultra from Packaging

2-2 GTECH Technical Training and Support Services

Page 27

Installation

Strain Relief

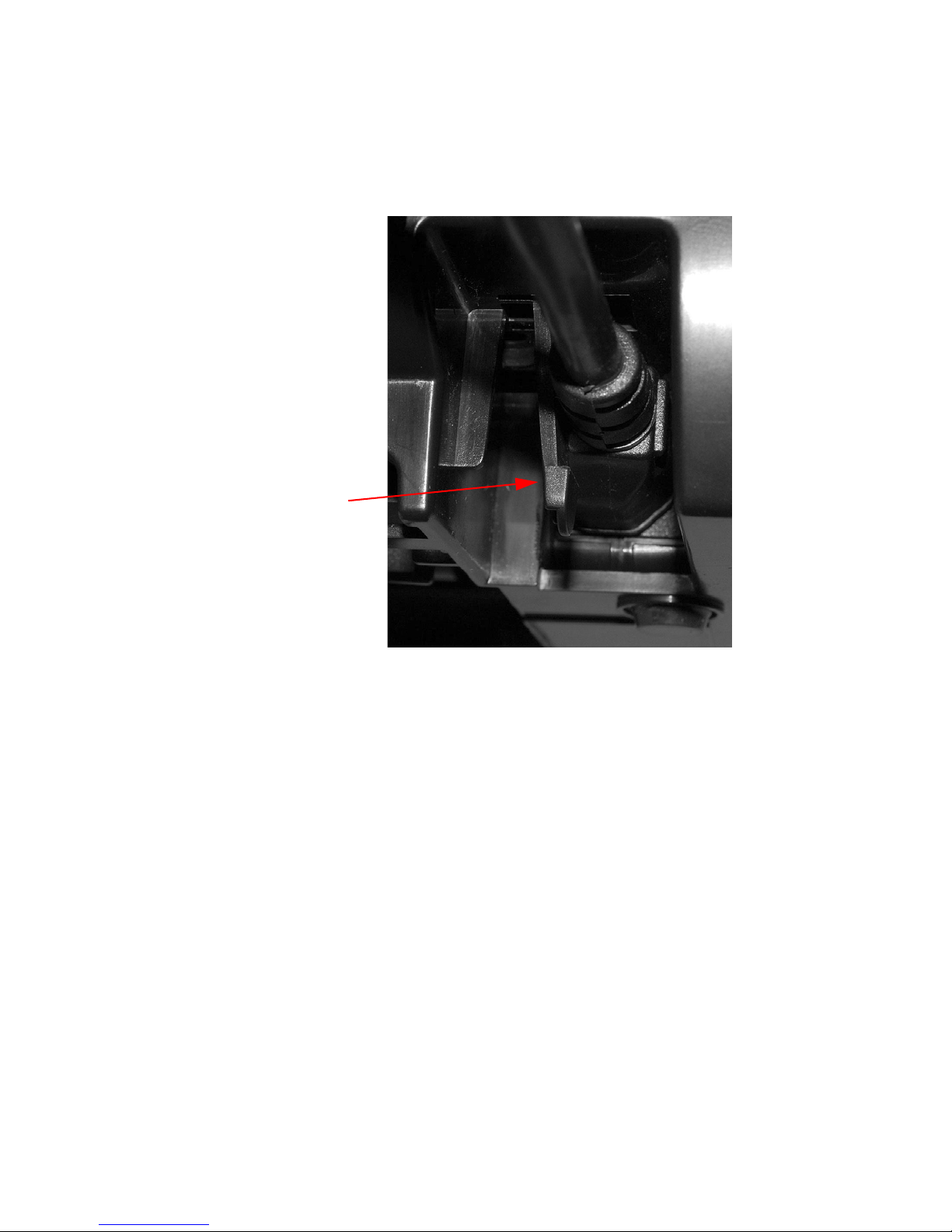

2. Move the Strain Relief lever (Figure 2-2) to the left and then plug the power

cord into the power connector, located at t

he rear of the printer.

Figure 2-2. Plug Power Cord into P

rinter

Service Manual for the Accutherm Ultra Printer 2-3

Page 28

3. Plug the printer’s USB data cable into the Main Controller PCB, located on

Main Controller PCB USB

connection

Note how the USB cable routes

through the plastic guides on the

bottom of the printer.

the bottom of the Accutherm Ultra (Figure 2-3).

Figure 2-3. Plug USB Cable into Printer

2-4 GTECH Technical Training and Support Services

Page 29

Installation

USB

USB

4. Plug the Accutherm Ultra’s USB data cable into the USB connector on your

terminal. See Figure 2-4 and Figure 2-5 for GT1200 and GT1 100 connections.

Figure 2-4. GT1200 USB Connection

5. Install a paper roll into the printer (see page 2-6 for paper loading

instructions).

6. Complete all required connections for

7. Apply power to both pieces of equipment.

Service Manual for the Accutherm Ultra Printer 2-5

Figure 2-5. GT1100 USB Connections

the terminal.

Page 30

Loading Paper

Follow the instructions below to load a new roll of paper into the Accutherm®

Ultra printer. Reference the photos that follow each step for the illustrated

procedure.

1. Press back on the gray cover latch button and raise

position.

2. T ear of f the first layer of the paper roll. Place the paper roll into the printer , so

that the paper unwinds from the bottom (front).

the paper cover to the open

3. Leave a few inches of paper outside of the printer.

2-6 GTECH Technical Training and Support Services

Page 31

Installation

4. Close the paper cover firmly so that it latches securely. Paper will feed

automatically to align itself and then the printer will automatically cut off the

excess paper.

Service Manual for the Accutherm Ultra Printer 2-7

Page 32

Page 33

Configuration

This chapter does not apply to the Service Manual for the Accutherm Ultra

Printer, as all printers are configured at manufacturing and updates are maintained

via the lottery terminal to which it is connected.

3

Service Manual for the Accutherm Ultra Printer 3-1

Page 34

Page 35

Operation

PLEASE NOTE!

There are no operating instructions for the Accutherm Ultra Printer, other than

installation and configuration. Please see Chapter 5, Diagnostics and Chapter 8,

Troubleshooting for information on problems encountered with powering up and

using the printer.

4

Service Manual for the Accutherm Ultra Printer 4-1

Page 36

Page 37

Diagnostics

The Accutherm® Ultra Printer provides printer self-test and diagnostics

features.This chapter provides information about these tests.

• “Printer Self Test” on page 5-2

• “Normal Operation Errors” on page 5-4

5

• “Extended Diagnostics” on page 5-6

Service Manual for the Accutherm Ultra Printer 5-1

Page 38

Printer Self Test

Service

Button

The Accutherm® Ultra printer is configured with two self-test operations.

• The first occurs each time the printer cover is closed and paper is present

after which, a receipt is printed that contains a header and the printe r

firmware revision and serial number.

• The second self-test is available by pressing the Service button as shown

in Figure 5-1 on the underside of the printer, at which time the printer

enters self-test mode.

Figure 5-1. Service Button Underneath Printer

When servicing the printer, you should verify the firmware version and serial

number that

5-2 GTECH Technical Training and Support Services

are printed on the receipt.

Page 39

Self-Test Mode

Pressing the Service button on the underside of the printer activates the self-test

mode that provides several print tests, plus access to the printer configuration and

factory tests.

To access the printer test display:

Diagnostics

1. Press and hold the Service button to

begin scrolling through the tests.

2. To select a test release the Service button at the desired test prompt,

follow the instructions.

The available printer test options

include the following:

• Print Test Ticket - Prints a sample ticket

• Print GTECH Ticket - Prints a GTECH sample ticket

• Configuration - Enters Configuration mode.

• User Stats – Provides information for 3 Groups

Group 1:

• Number of Line Feeds

• Characters Printed

• Cover Opens (sensor triggers)

• Paper Out (sensor triggers)

Group 2:

• Auto Cutter Cycles

• Auto Cutter Faults

then

• Pr

• Marker Calibration - Verifies that the Top of Form marker sensing is

• Continu

Service Manual for the Accutherm Ultra Printer 5-3

• Auto Cutter ReHome

Group 3:

• Level 1 Jams

• Level 2 Jams

int Head Test - Prints a test pattern to verify that all print elements are

working and clean.

working.

ous Print - Prints the test ticket continuously to verify stacker

functionality.

Page 40

Normal Operation Errors

During Normal operation, the Power LED remains on unless an error is indicated.

There are two classes of errors: soft errors and hard errors. Soft errors are

recoverable without power cycling the printer. Hard errors are not recoverable

without removing power from the printer, correcting the problem, and reapplying

power.

• Error Indicators

• Power -> Green

• Error -> Red

• Paper -> Yellow

Soft Errors

Soft errors may be recovered by the host or by opening and closing the printer

cover. All of these errors are indicated by a 5 second repeating blink pattern.

Soft Error State Indicators

Power (Green) Error (Red) Paper (Yellow)

Powering Down Fast Blink On Off

Cover Open 4 Blinks On Off

Print Head Over Temp 9 Blinks Slow Blink Off

Power Bad 2 Blinks Slow Blink Off

Out of Paper 2 Blinks On On

Jam 5 Blinks On Fast Blink

Missed Top of Form (TOF) 6 Blinks Off Fast Blink

Invalid Command 7 Blinks On Fast Blink

Paper Low Error On On Slow Blink

Paper Low On Off Slow Blink

Electronic Journal Low On Off 2 Blinks

5-4 GTECH Technical Training and Support Services

Page 41

Hard Errors

Hard errors have a similar pattern to Soft errors only they are slower and repeat

every 10 seconds. In general they occur during level 0 diagnostics and are not

recoverable.

Hard Error State Indicators

Power (Green) Error (Red) Paper (Yellow)

EEPROM read fault 2 Blinks On Off

EEPROM write fault 3 Blinks On Off

Error Vector Taken 4 Blinks On Off

Knife Error 5 Blinks On Off

Flash File system Error 7 Blinks On Off

Diagnostics

Flash Read/Write Error 9 Blinks On Off

Dynamic Memory Allocation 10 Blinks On Off

Font system Fault 11 Blinks On Off

Static Memory Allocation 12 Blinks On Off

Communications Fault 14 Blinks On Off

Kernel Fault 15 Blinks On Off

Head Connection Fault 16 Blinks On Off

NOTE! When the YELLOW and RED LEDs are illuminated at the

same time, the LED will illuminate as

ORANGE/AMBER.

Service Manual for the Accutherm Ultra Printer 5-5

Page 42

Extended Diagnostics

Accutherm® Ultra Extended Diagnostics are performed using the diagnostics on

the terminal to which the printer is connected. The printer may also be tested

using the general Terminal Qualify Diagnostics and further tested through the

Extended Diagnostics Peripherals menu.

5-6 GTECH Technical Training and Support Services

Page 43

Download

Downloads occur automatically via the terminal applicati on to which the printer is

connected. Should the RLT need to update the firmware manually, please contact

your Field Services Engineering (FSE) Representative or send an email to #Field

Services Engineering to obtain the latest and greatest firmware version for your

site.

6

Service Manual for the Accutherm Ultra Printer 6-1

Page 44

AccuTherm® Ultra Firmware Install Procedure

1. Connect the printer data cable to printer and

USB port in PC.

2. Connect the power cable to printer (do not

connect

3. Press and hold the diagnostics button while

ap

4. The LED on the front of printer will flash

slowly

(printer is in download mode (Transact boot loader)).

5. The USB Link is active and will communicate with the PC.

You must have the printer connected before starting the download

program. Otherwise, the download program will not see the USB port.

6. Run Download.exe.

7. Select the USB001

port or the active

USB port from the

drop-down menu.

to AC power yet).

plying power to printer.

. Release the diagnostics button

8. Click “Get Printer Information” to verify that you can communicate with the

printer.

9. To select firmware version:

a. click the “Select file to download” button.

b. Open the file containing the files you exported to the PC.

c. Double click PK5107_000_162Full.cbt file and select “Download Now”.

DO NOT INTERRUPT THE DOWNLOAD

The firmware file will be transferred to the pr

be activated if it is incorrect. The download program is not aware of the

verification process and assumes it loaded correctly.

You MUST wait at least 10 seconds after the download program says it’s

done as the printer takes 5 or 10 more seconds to finish writing the update to

flash. The easiest way to tell when the printer is done is to press the “Get

Printer Information” button after the download and when the printer

responds it’s done.

inter. It is self verifying and will not

6-2 GTECH Technical Training and Support Services

Page 45

Download

ADDITONAL INFORMATION:

The update has not yet occurred so the old revisions will be displayed, but

that’s OK. You can now power cycle the printer. (Wait at least 10 seconds

before re-connecting printer power for printer power supply to completely

discharge). Verify that the new firmware is active by opening and closing

the cover, then reading the printout.

Service Manual for the Accutherm Ultra Printer 6-3

Page 46

Page 47

Disassembly

Warranty Information

The Accutherm® Ultra Printer is under warranty from the manufacturer. Prior to

performing any printer disassembly, you MUST verify that the printer is out of

warranty with your Te chnical Services Manager. Performing any of the steps in

this chapter may VOID warranty and is therefore PROHIBITED until advised by

Management.

7

Caution: The Power Supply is

replaced in the field (FST) after warranty. All other subassemblies must

only be replaced by an RLT.

Before disassembling any part of the printer, be sure the power is

turned off. The Controller Board, the Thermal Print Head, and the

Interface Board can be damaged by static electricity. Observe ESD

precautions. Wear a grounded wrist strap and use a static mat or

other protected work surface.

Service Manual for the Accutherm Ultra Printer 7-1

the only sub-assembly approved to be

Page 48

Strain Relief

Thread Forming Screws - To prevent stripping the mating holes in

plastic components when replacing screws, turn the screw counterclockwise until a “click” is heard, then tighten normally.

Required Tools

The following tools are required to disassemble the Accutherm® Ultra printer:

• #1 Phillips screwdriver

• 5.5mm nut driver or wrench

Disconnect the Power Cable

To disconnect the power cable:

1. Unplug the power connector, located at the

2. Move the strain relief to left

while disconnecting the cable (Figure 7-1).

rear of the printer.

Figure 7-1. Disconnect Power Cable

7-2 GTECH Technical Training and Support Services

Page 49

Disassembly

Note that the

USB cable is

routed along the

bottom of the

printer via plastic

guides.

USB cable

connector

Disconnect the USB Communications Cable

To disconnect the USB data cable:

Unplug the USB cable from the Main Controller PCB, located on the

bottom of the printer (Figure 7-2).

Figure 7-2. Disconnect USB Cable

Service Manual for the Accutherm Ultra Printer 7-3

Page 50

Remove the Cover Assembly

# 6 Screws

To remove the cover assembly:

1. Open the Paper Cover Assembly and remove the Paper Roll, if present.

2. Turn the printer over and remove the four

the Midframe (Figure 7-3).

(4) #6 screws holding the Base to

7-4 GTECH Technical Training and Support Services

Figure 7-3. Remove Screws Holding Base

to Midframe

Page 51

Disassembly

# 6 Screws

3. Unscrew two (2) #6 thread-forming screws, holding Mid-frame to Paper

Bucket (Figure 7-4).

Figure 7-4. Remove Screws Holding Midframe to Paper

Bucket

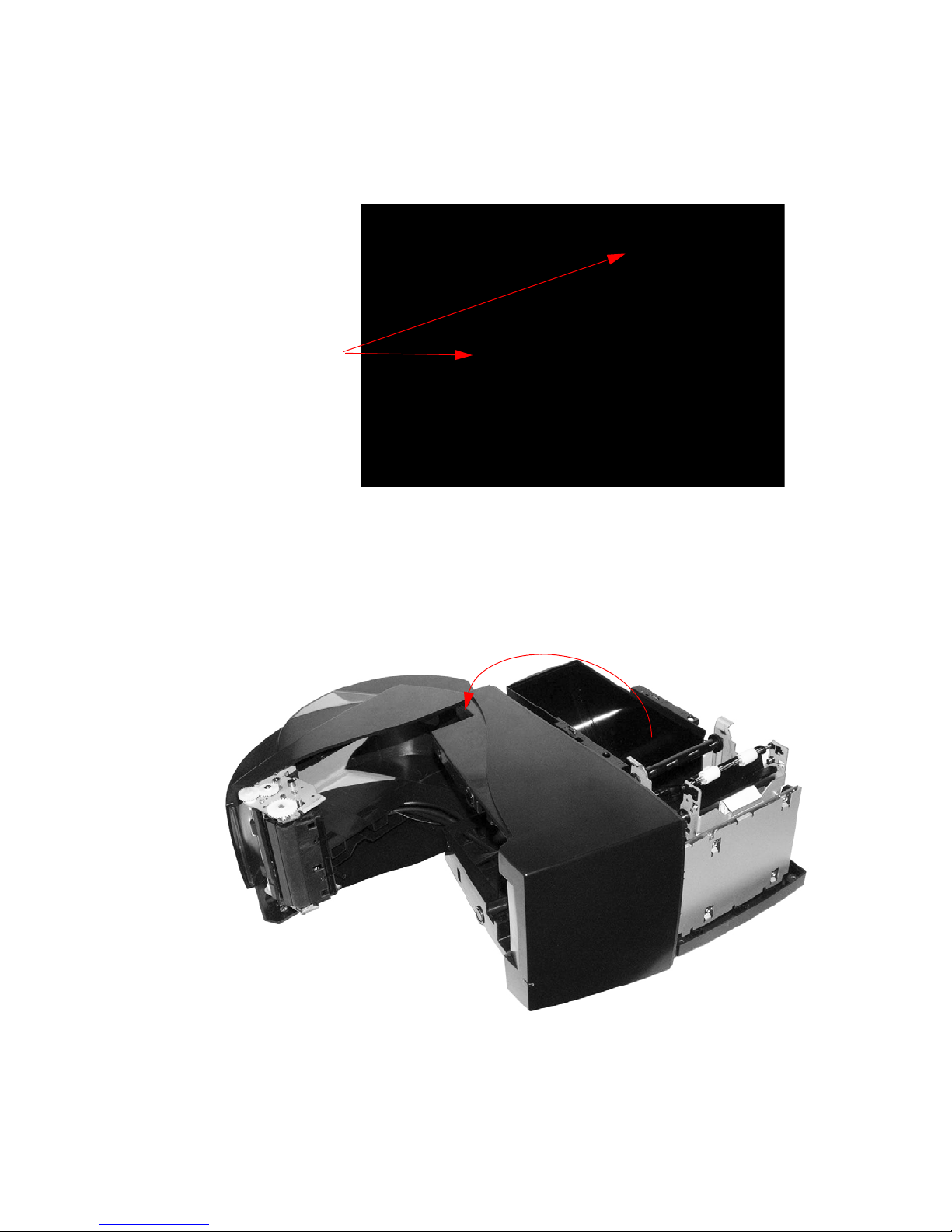

4. Lift and rotate the Mid-frame/Cover Assembly sideways, and then separate it

from the Ba

se Assembly, as shown (Figure 7-5).

Figure 7-5. Separate Midframe/Cover from Base Assembly

Service Manual for the Accutherm Ultra Printer 7-5

Page 52

5. Unplug the Top of Form Harness Assembly, Anti-Jam Sensor Harness

5

6

Assembly, Stacker-Motor Harness Assembly, and Power Supply Connector

from the Main Controller PCB Assembly.

6. Unplug the Ground Wire from the Printer Mechanism.

Figure 7-6. Unplug Harness Assemblies

7-6 GTECH Technical Training and Support Services

Page 53

Remove the Power Supply from the Base

Power Supply

Power Supply Release

Clip and Plug

Assembly

Disassembly

1. Unplug the Power Supply from the Main

press on locking clip to release the plug from the PCB Assembly (see inset).

2. Lift the Power Supply out of

When you reinstall the Power Supply, make sure that the label faces

inward; otherwise, it will not plug in correctly.

Service Manual for the Accutherm Ultra Printer 7-7

Figure 7-7. Remove Power Supply

Controller PCB Assembly. To do so,

the Base Assembly.

Page 54

Remove the Printer Mechanism Assembly

# 6 Screws

Printer

Mechanism

Make sure you

don’t lose or forget

to replace the

ground bracket

from the Base Assembly

REMEMBER TO USE ESD PRECAUTIONS

To remove the Printer Mechanism Assembly from the Base Assembly:

1. Remove four (4) #6 Thread Forming Screws holding the

Printer Mechanism

Assembly to the Base Assembly.

2. Rock the Printer Mechanism Assembly

and then slide it forward and out from

the Base Assembly. Slacker springs will separate from the bushings.

Figure 7-8. Remove Printer Mechanism Assembly from Base Assembly

7-8 GTECH Technical Training and Support Services

Page 55

Disassembly

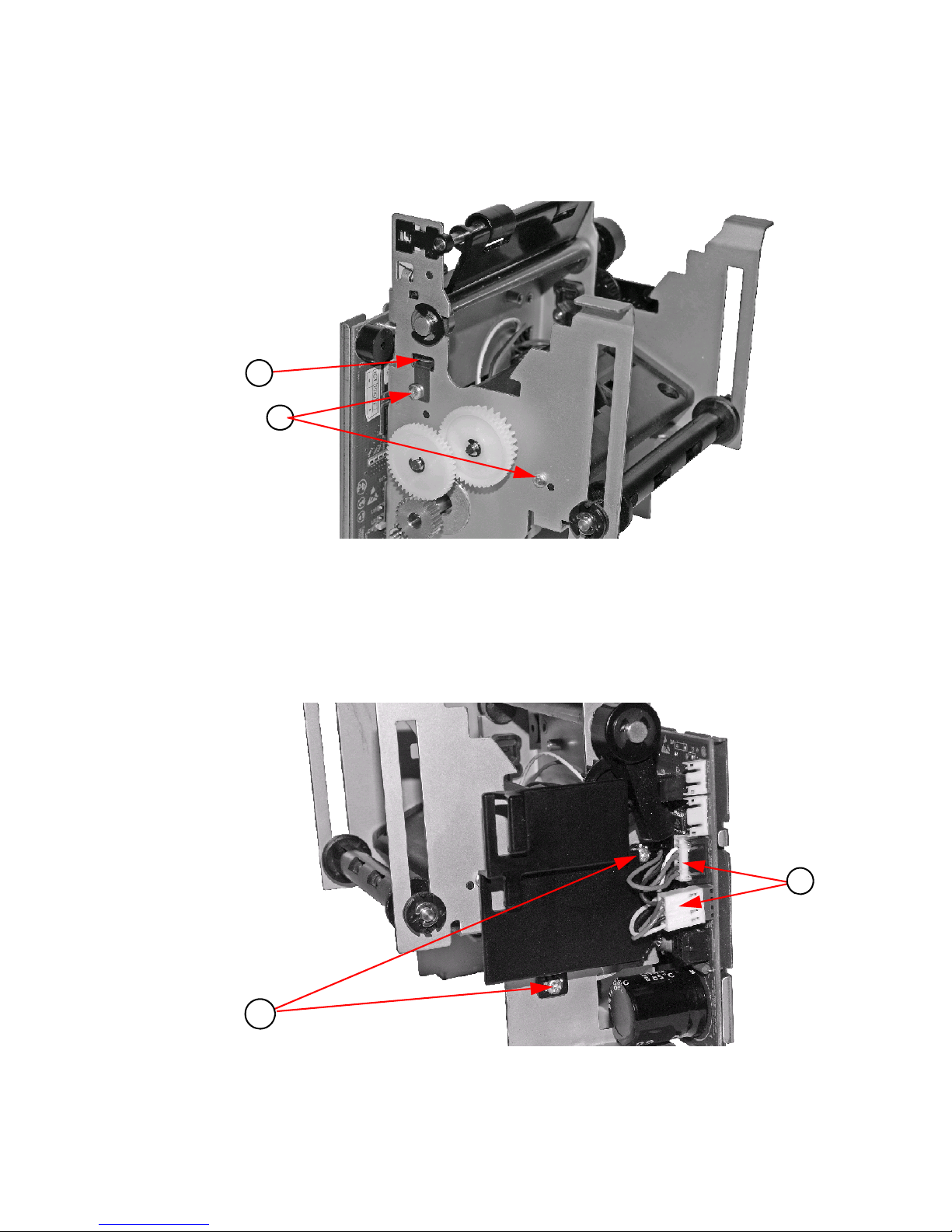

Remove the Main Controller PCB Assembly

from the Printer Mechanism Assembly

REMEMBER TO USE ESD PRECAUTIONS

To remove the Main Controller PCB Assembly from the Printer Mechanism

Assembly:

1. Unplug all connector Harness Assemblies from

callouts #5 and #6 in Figure 7-6 on page 7-6.

2. Make sure that the Power Supply cable is unplugged. See Figure 7-7 on

page 7.

3. Unplug the Thermal Print-head Ribbon Cable

See callout #2 in Figure 7-9 on page 7-10.

When reassembling the Thermal Print-head Cable make certain that

the full length of the connector is seated firmly and centered in the

mating connector on the Controller PCB and Thermal Print Head.

Otherwise, you could cause the print head to burn out.

4. Unscrew the four (4) M3 screws (callo

holding the Shield-PCB and the Main Controller

Mechanism Assembly.

ut #3 in Figure 7-6 on page 7-6)

the Main Controller PCB. See

from the Main Controller PCB.

PCB Assembly to the Printer

Service Manual for the Accutherm Ultra Printer 7-9

Page 56

1

3

2

Figure 7-9. Removing Main Controller PCB Assembly from Printer Mechanism Assembly

7-10 GTECH Technical Training and Support Services

Page 57

Disassembly

Remove the Print Head Assembly from the

Printer Mechanism Assembly (Lower Print

Mechanism)

REMEMBER TO USE ESD PRECAUTIONS

To remove the Print Head Assembly from the Printer Mechanism Assembly:

1. Rotate the Knife Stepper motor gear train unti

parallel to the bottom of the Printer Mechanism Assembly (Home position).

2. Orient the Printer Mechanism Assembly so that the Print-head Assembly

face

s you as shown in Figure 7-10 on page 12.

3. Push on the Print Head Assembly until the

from the alignment slots in the Paper Path Assembly.

4. Push down on the Print Head Assembly

Assembly toward you.

You should now be able to easily remove the Print Head Assembly.

When removing the Print Head assembly, be careful not to lose the

small tension spring behind it.

When reinstalling, make certain that the Rotary Knife Blade is parallel

to the bottom of the Printer Mechanism Assembly (Home Position), or

you may do damage to the blade, or the printer may fail to restart

without running it through a power cycle.

l the Rotary Knife Blade is

upper set of alignment pins escape

, and then rock the Print Head

Service Manual for the Accutherm Ultra Printer 7-11

Page 58

1

3

4

Position the Print Head

Assembly to face you.

Figure 7-10. Remove Print Head Assembly from Printer Mechanism Assembly

7-12 GTECH Technical Training and Support Services

Page 59

Disassembly

3

1

4

5

2

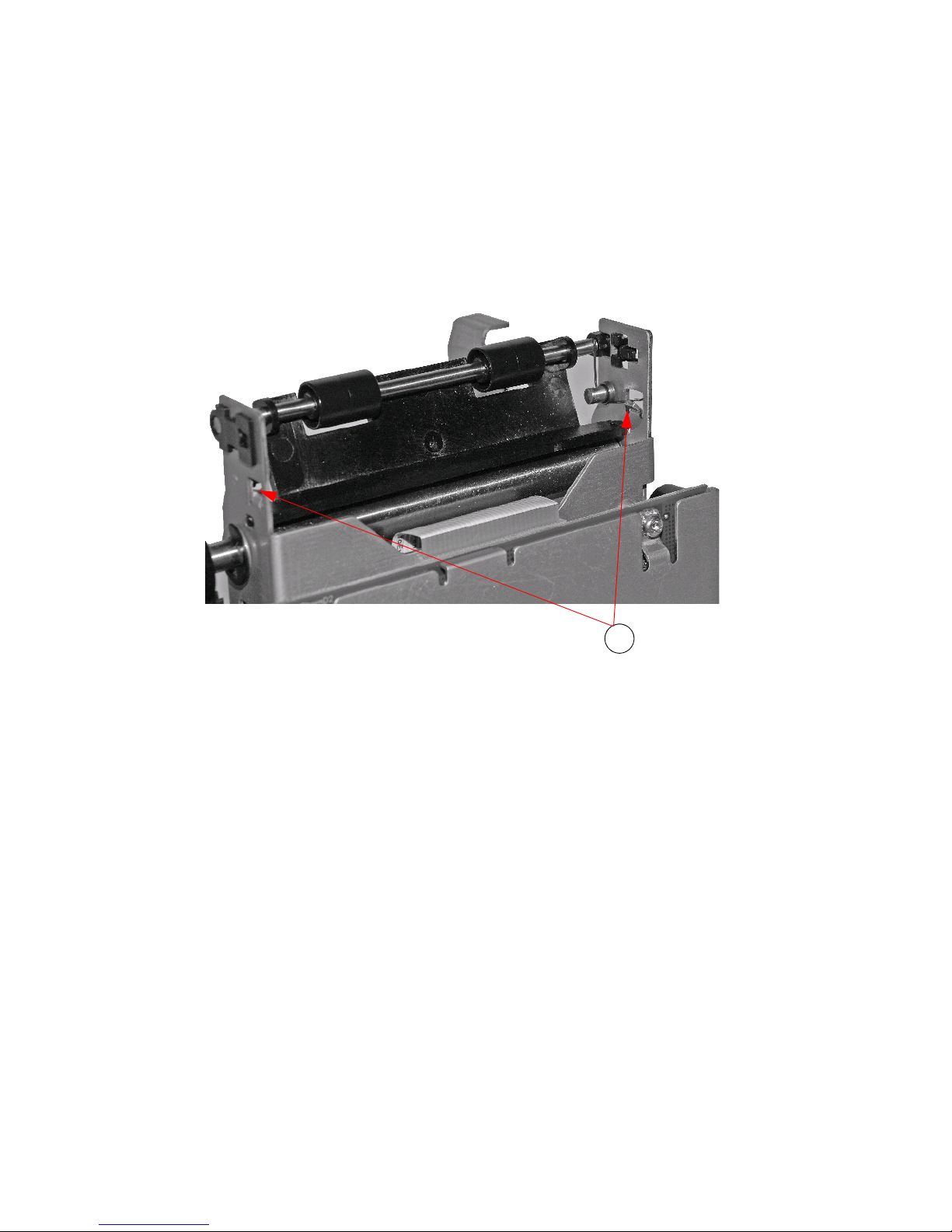

Remove the Rotary Knife from the Printer

Mechanism Assembly (Lower Print

Mechanism)

REMEMBER TO USE ESD PRECAUTIONS

To remove the Rotary Knife from the Printer Mechanism Assembly:

1. Rotate the Knife Arm forward until it clears the Gear Cover.

2. Remove the outside E-Clip, allowing

3. Remove the left and right E-Clips from

4. Remove the left and right bushings.

5. Press the Print Head in and down to provide

removal.

you to pull the arm off the shaft.

the Rotative Blade.

access for the rotary knife blade

Now you should be able to remove

the rotary knife blade.

Figure 7-11. Remove Rotary Knife from

Service Manual for the Accutherm Ultra Printer 7-13

Printer Mechanism Assembly

Page 60

Remove Paper Path Assembly from Printer

1

2

Mechanism

REMEMBER TO USE ESD PRECAUTIONS

1. Unplug Print Head cable from the PCB.

When reassembling the Thermal Print Head Cable ensure the cable is

centered in the mating connector on the PCB.

2. Remove the Print Head Assembly as shown in the section “Remove the Print

Head Assembly from the Printer Mechanis

Mechanism)” on page 7-11.

m Assembly (Lower Print

Figure 7-12. Remove Print Head Cable and Print

7-14 GTECH Technical Training and Support Services

Head Assembly

Page 61

3. Remove the two (2) #4 Thread forming Screws.

3

4

5

6

4. Remove the Print Head Ground.

Disassembly

Figure 7-13. Remove 2 Thread Forming sc

rews and Print Head Ground

5. Unplug connectors.

6. Remove two (2) M3 screws holding PCB Shield/Knife Motor

(Optional - Replace one (1) M3 screw to hold the

Motor in position for

remaining disassembly).

to frame.

Figure 7-14. Unplug Connectors and Remove Two (2) M3 Screws

Service Manual for the Accutherm Ultra Printer 7-15

Page 62

7. Remove E-Clip.

7

8

9

10

11

12

8. Remove Knife Arm.

9. Remove Rotative Blade Pin.

10. Remove three (3) Gears.

Figure 7-15. Remove E-Clip, Knife

Arm, Rotative Blade Pin and Three (3) Gears

11. Remove Two (2) #4 Thread Forming Screws.

12. Remove Print Head Ground.

Figure 7-16. Remove Two (2) #4 Thread

Forming Screws and Print Head Ground

7-16 GTECH Technical Training and Support Services

Page 63

Disassembly

13

13. Remove Paper Path Assembly from Frame being careful not to damage sensor

flags.

Reassemble by reversing the previous steps, taking care that the locating

bosses are aligned with the mating holes in the frame.

Figure 7-17. Remove Paper Path Assembly from Frame

When reassembling the Thermal Print Head Cable ensure the cable is

centered in the mating connector on the PCB.

Service Manual for the Accutherm Ultra Printer 7-17

Page 64

Remove Stacker Guide Assembly from the

1

Printer Mechanism Assembly

REMEMBER TO USE ESD PRECAUTIONS

1. Unhook Left/Right Validation Compensatio

Figure 7-18. Unhook Validation Springs and Remove.

n Springs and remove springs.

2. Slide Stacker Shaft to the right to remove.

3. Remove two (2) Transport Rollers.

7-18 GTECH Technical Training and Support Services

Page 65

Disassembly

3

2

4

Figure 7-19. Slide Stacker Shaft to Right and Remove, then Remove Two Transport Rollers

4. Remove Stacker Guide from Frame being careful not to bend the

Reassemble reversing the above steps. Ens

ure the Compensation Bearings, the

frame tabs.

shaft and rollers move freely in the frame.

Service Manual for the Accutherm Ultra Printer 7-19

Page 66

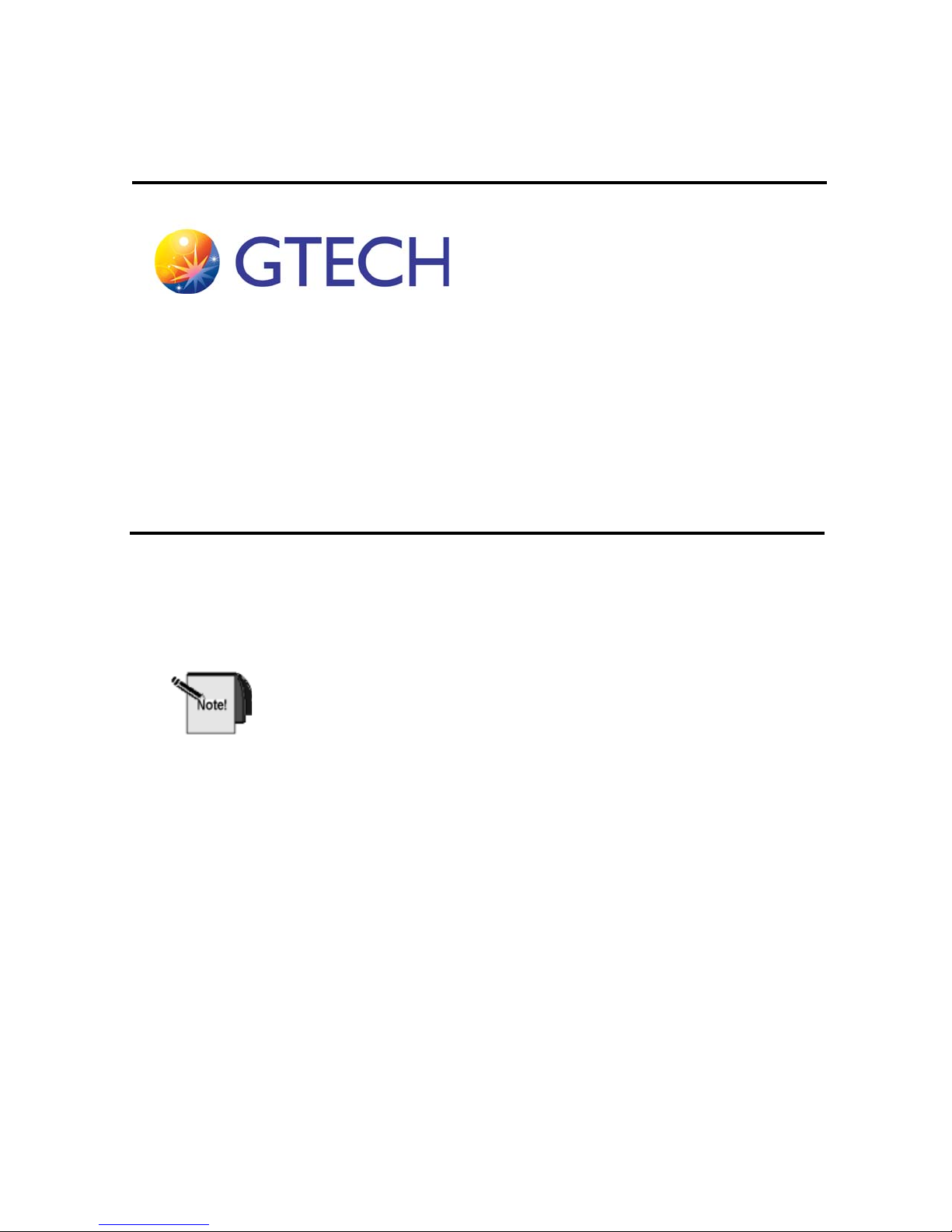

Remove Platen from the Knife/Stacker

3

4

2

5

1

Assembly

REMEMBER TO USE ESD PRECAUTIONS

To remove the platen from the knife/stacker assembly:

1. Remove the Platen Gear.

2. Loosen #4 thread forming screw -

3. Remove #4 thread forming sc

4. Remove Bearing Retainer - typ left/right sides.

5. Slide Platen, Stripper, and L/R bearings

typ left/right sides.

rew - typ left/right sides.

forward to remove from side plates.

Figure 7-20. Remove Platen from Knife

When installing Platen, Stripper, and Bearings ensure the Stripper

locating bosses are aligned with mating holes in the L/R Side Plates and

then tighten screws. Platen should spin freely when assembly is

completed.

7-20 GTECH Technical Training and Support Services

/Stacker Assembly

Page 67

Disassembly

1

1

2

Remove Fixed Blade from the Knife/Stacker

Assembly

REMEMBER TO USE ESD PRECAUTIONS

To remove the fixed blade from the Knife/Stacker Assembly:

1. Remove (6) #6 thread forming screws retaining knife/stac

cover.

Figure 7-21. Remove #6 Screws

2. Remove knife/stacker assembly from the

from the wire retention features in the cover.

paper cover. Remove wire harnesses

ker assembly to the

Figure 7-22. Remove Knife/Stacker Assembly from Paper Cover

Service Manual for the Accutherm Ultra Printer 7-21

Page 68

3. Remove Stacking Gear

3

4

5

6

7

4. Remove Stacking Gear/Retaining Ring.

5. Remove Platen Gear.

Figure 7-23. Remove Stacking Gear, Retaining Ring and Platen Gear

6. Remove one (1) #4 Thread Forming Screw.

7. Remove the Right Platen Bearing

Retainer.

Figure 7-24. Remove Screw and Right Platen Bearing Retainer

7-22 GTECH Technical Training and Support Services

Page 69

8. Remove one (1) #4 Thread Forming Screw.

8

9

10

11

9. Remove the Left Platen Bearing

Retainer.

Disassembly

Figure 7-25. Remove #4 Screw

and Left Platen Retainer

10. Remove Stacker Bearing.

11. Remove two (2) #4 Thread Forming screws.

Figure 7-26. Remove Stacker Be

Service Manual for the Accutherm Ultra Printer 7-23

aring and Two (2) #4 Screws

Page 70

12. Remove Right Side Plate Assembly.

12

13

14

13. Remove Platen, Stripper, a

nd L/R Platen Bearings.

Figure 7-27. Remove Right Side Plate Assy, Platen, Stripper, and L/R Platen Bearings

14. Remove Fixed Blade Spring.

Figure 7-28. Remove Fixed Blade Spring

7-24 GTECH Technical Training and Support Services

Page 71

15. Remove Latch Arm Hub.

15

16

16. Remove Retaining Ring.

Disassembly

Figure 7-29. Remove Latch Arm Hub and Retaining Ring

Position remaining assembly in a vertical orientation for

disassembly.

remaining

Figure 7-30. Position Remaining Assembly Vertically

Service Manual for the Accutherm Ultra Printer 7-25

Page 72

17. Remove Knife Pivot Shaft.

17

18

19

18. Remove Latch Arm Pivot

19. Remove Fixed Blade Assembly.

Figure 7-31. Remove Knife Pivot Shaft, Latch Arm Pivot, and

Fixed Blade Assy

7-26 GTECH Technical Training and Support Services

Page 73

20. Ensure Latch Arm Hub is in proper location for reassembly.

20

Disassembly

Figure 7-32. Check Location of Latch Arm Hub

Reverse Steps 1 through 20 for reassembly.

When installing Platen, Striper, and Bearings, ensure the Striper

locating bosses are aligned with the mating holes in the Left and Right

Side Plates, and then tighten screws. Platen should spin freely when

assembly is complete.

Service Manual for the Accutherm Ultra Printer 7-27

Page 74

Page 75

Troubleshooting

Introduction to Troubleshooting

These steps are a general guideline for Field Service Technicians to follow in the

event of a specific fault. After each step, the printer should be checked to

determine whether or not the step cleared the fault. If the fault is not cleared with

the first step, the next step is performed in an attempt to clear the fault on the

printer. If the fault cannot be cleared, the printer should be sent for repair.

8

Prior to performing any of the FST or RLT steps that follow, ensure that the

printer’s warranty status has been determined. If a printer is still In-Warranty, you

may only perform cleaning procedures in an attempt to clear a fault, disassembly

procedures are not allowed. Any hard failures must be sent to the OEM for repair.

These steps are a general guideline for RLT’s to follow in the event of a specific

fault. After each step, the printer should be checked to determine whether or not

the step cleared the fault. If the fault is not cleared with the first step, the next step

is performed, and so on until the fault is cleared or until the problem is further

identified.

Performing the steps in this chapter may VOID the warranty and is

therefore PROHIBITED until advised by Management.

Service Manual for the Accutherm Ultra Printer 8-1

Page 76

Troubleshooting Steps for FST’s

Problem Action

Printing

correctly

In

Colored stripe on the

receipt

Print is light or spotty 1 . Make su re the paper is loaded correctly

Vertical column of

print is missi

Receipt does not come

all of

the way out

Printer starts to print,

but stops while the

eceipt is being

r

printed

ng

1. Check the paper level.

2. If paper is low, change th

“Loading Paper” on page 3-6.

3. Clean the Top-of-Form / Paper Low sensor

w

ith 91% isopropyl alcohol and cotton swabs.

See “Cleaning the Top-of-Form/ Paper Low

Sensor” on page 9-3.

4. Swap the printer.

to “Loading Paper” on page 3-6.

2. Ensure the use of the recommended thermal

receipt paper

3. Swap the printer.

Swap the printer

1.Open the receipt cover and clear any jammed

paper. Refer to “Clearing a Paper Jam” on page

8-10).

2. Swap the printer.

1.Open the receipt cover and clear any jammed

paper. Refer to “Clearing a Paper Jam” on page

8-10).

2. Swap the printer.

.

e paper. Refer to

. Refer

Receipt is not cut 1. Open the receipt cover and clear any jammed

One side of receipt is

missing

8-2 GTECH Technical Training and Support Services

. Refer to “Clearing a Paper Jam” on page

paper

8-10).

2. Swap the printer.

Swap the printer.

Page 77

Problem Action

Troubleshooting

Printer Is Not

Working

Printer Status

D is

LE

blinking

No Power 1. Check that the terminal has power.

2. Check that printer cables are properly

co

nnected on both ends.

3. Ensure the latch and receipt cover is closed.

4. Verify the printer co

nfiguration and re-

configure if necessary.

5. Ensure that the printer is being operated in the

per room temperature (not too hot or too

pro

cold). If necessary, move the printer to a warmer/

cooler location.

6. Swap the Power Supply . Refer to “Remove the

Power Supply from the Base Assembly” on page

8-7.

7. Swap the printer.

During Normal operation, the Power

LED remains on unless an error is

indicated. There are two classes of

errors: soft and hard. Soft errors are

recoverable without power cycling the

. Hard errors cannot be recovered

printer

from without removing power from the

printer, correcting the problem, and

then reapplying power.

Error Indicators:

• Power—Green

Error—Red

•

• Paper - Yellow

Note: Wh

en the Indicators for Error and Paper are both illuminated an

Orange/Amber color displays.

Soft Errors: Soft errors

may be recovered by the host or by opening and

closing the printer cover. The following soft errors are indicated by a 5

second repeating blink pattern. Refer to “Soft Errors” on page 5-4 for

specific error information.

Out of Paper 1. Change the paper. Refer to “Loading Paper”

on page 3-6.

2. Swap the printer.

Paper Low Error 1. Change the paper. Refer to “Loading Paper”

on page 3-6.

2. Swap the printer.

Service Manual for the Accutherm Ultra Printer 8-3

Page 78

Problem Action

Printer Status

LED is

blinking

(contin.)

Cover Open 1. Close the printer cover securely.

2. Swap the printer.

Jam Detected 1.Open the receipt cover and clear any jammed

. Refer to “Clearing a Paper Jam” on page

paper

8-10.

2. Swap the printer.

Missed Top of Form

OF)

(T

1. Clean top-of-form sensor with 91% isopropyl

alcohol and cotton swabs.

2. Swap the printer.

Invalid Command 1. T urn the printer off, wait

60 seconds, then turn

it on again.

2. Swap the printer.

Printer Head Over

mperature

Te

1. Ensure that the printer is being operated in the

proper room temperature (not too hot or too

cold).

2. If necessary, move the printer to a warmer/

cooler location.

3. Swap the printer.

Power Problem 1. Turn the printer off, wait

60 seconds, then turn

it on again.

2. Swap the printer.

Hard Errors:

Hard errors have a similar pattern to Soft

repeat every 10 seconds.

In general they occur during level 0 diagno

all cases of Hard Errors, swap the printer.

errors only they are slower and

stics and are not recoverable. In

8-4 GTECH Technical Training and Support Services

Page 79

Troubleshooting Steps for RLT’s

Problem Action

Troubleshooting

Printing

orrectly

Inc

Colored stripe on the

receipt

Print is light or

spotty

Missing Print Replace the print head. Refer to “Remove the

1. Check the paper level.

2. If paper is low, change the paper. Refer to

“Loading Paper” on page 8-8.

3. Clean the Top-of-Form / Paper Low sensor

with 91%

1. Make sure the paper is loaded correctly

to “Loading Paper” on page 8-8.

2. Ensure the use of the recommended thermal

rece

3. Clean thermal print head with 91% isopropyl

alcohol

4. Check thermal print head cable connections

5‘. Replace the printer mechanism. Refer to

“Remove the Printer Mechanis

the Base Assembly” on page 7-8.

Print Head Assembly from the Printer

Mechanism Assembly (Lower Print

Mechanism)” on page 7-11.

isopropyl alcohol and cotton swabs.

. Refer

ipt paper.

and cotton swabs.

m Assembly from

.

Vertical column of

s missing

print i

Receipt does not

come

all of the way

out

Printer starts to

but stops while

print,

the receipt is being

printed

Service Manual for the Accutherm Ultra Printer 8-5

Replace the print head. Refer to “Remove the

Print Head Assembly from the Printer

Mechanism Assembly (Lower Print

Mechanism)” on page 7-11.

Open the receipt cover and clear any jammed

paper. Refer to “Clearing a Paper Jam” on page

8-10.

Open the receipt cover and clear any jammed

paper. Refer to “Clearing a Paper Jam” on page

8-10.

Page 80

Problem Action

Printing

Incorrectly

(contin.)

Sensors are not

working

operly

pr

Printer Errors

LED is blinki

ng

Error Indicators:

Power -> Green

Error -> Red

Paper -> Yellow

Receipt is not cut 1. Open the receipt cover and clear any jammed

paper. Refer to “Clearing a Paper Jam” on page

8-10.

2. Check the connections to the Main Controller

B.

PC

3. Replace the Main Controller PCB Assembly.

4. Replace

the printer mechanism. Refer to

“Remove the Printer Mechanism Assembly from

the Base Assembly” on page 7-8.

1. Open the printer.

2. Remove the printer cover.

3. Clean the optical sensors (Paper Out, Top-ofForm/Paper

Low , Anti-Jam, and Paper Cover

Opened) with isopropyl alcohol and cotton

swabs.

Soft & Hard Errors:

Soft Errors: Soft errors may be

recovered by the host or by opening

and closing the printer cover. All of

these errors are indicated by a 5 second

repeating blink pattern. Refer to “Soft

Errors” on page 5-4 for specific error

information.

Out of Paper 1. Change the paper. Refer to “Loading Paper”

on page 8-8.

2. Clean all sensors with 91% isopropyl alcohol

and cotton

swabs.

3. Replace the Main Controller PCB Assembly.

Paper Low Error 1. Change the paper. Refer to “Loading Paper”

on page 8-8.

2. Clean all sensors with 91% isopropyl alcohol

and cotton

swabs.

3. Replace the Main Controller PCB Assembly.

Cover Open 1. Close the printer cover securely.

2. Clean all sensors with 91% isopropyl alcohol

and cotton

swabs.

3. Replace the Main Controller PCB Assembly.

8-6 GTECH Technical Training and Support Services

Page 81

Problem Action

Troubleshooting

Printer Status

LED is blinking

(contin.)

Missed Top of Form 1. Clean all sensors with 91% isopropyl alcohol

and cotton swabs.

2. Replace the Main Controller PCB Assembly

Jam Detected 1.Open the receipt cover and clear any jammed

pap

er. Refer to “Clearing a Paper Jam” on page

8-10.

2. Clean all sensors with 91% isopropyl alcohol

and cotton

swabs.

3. Replace the Main Controller PCB Assembly

Invalid Command 1. Turn the printer off and then on again.

2. Reload firmware.

Printer Head Over

T

emperature

1. Ensure that the printer is being operated in the

proper room temperature (not too hot or too

cold).

2. If necessary, move the printer to a warmer/

cooler location.

3. Replace the Main Controller PCB Assembly

.

.

.

Power Problem 1. Check that the terminal has power

.

2. Check that printer cables are properly

connected on both ends

.

3. Ensure the latch and receipt cover is closed.

4. Verify the printer configuration and reconfigure if ne

5. Ensure that the printer i

cessary.

s being operated in the

proper room temperature (not too hot or too

cold). If necessary, move the printer to a warmer/

cooler location.

6. Swap the Power Supply . Refer to “Remove the

Power Supply from the Base Assembly” on page

7-7.

7. Swap the printer.

Hard Errors:

Hard Errors have a similar pattern to Soft errors only they are

slower and repeat every 10

seconds. In general they occur during level 0 diagnostics and are not recoverable. Refer to “Hard

Errors” on page 5-5 for specific error information.

In all cases of Hard Errors, replace the printer mechanism. See “Remove the Printer Mechanism

Assembly from the Base Assembly” on page 7-8.

Service Manual for the Accutherm Ultra Printer 8-7

Page 82

Loading Paper

Follow the instructions below to load a new roll of paper into the Accutherm®

Ultra printer. Reference the photos that follow each step for the illustrated

procedure.

1. Press back on the gray cover latch button and raise

position.

2. T ear of f the first layer of the paper roll. Place the paper roll into the printer , so

that the paper unwinds from the bottom (front).

the paper cover to the open

3. Leave a few inches of paper outside of the printer.

8-8 GTECH Technical Training and Support Services

Page 83

Troubleshooting

4. Close the paper cover firmly so that it latches securely. Paper will feed

automatically to align itself and then the printer will automatically cut off the

excess paper.

Service Manual for the Accutherm Ultra Printer 8-9

Page 84

Clearing a Paper Jam

1. Press back on the cover latch

button.

2. Raise the paper cover to the Open

position.

3. Grasp the jammed paper and gently

pull t

o un-jam it from the inside of

the printer.

4. Advance the paper roll so that the

jammed portion

additional inches are outside of the

printer.

and a few

5. Close the paper cover firmly so

tha

t latches securely.

6. The paper will feed automatically

to align itself and

automatically cut off the excess

paper.

8-10 GTECH Technical Training and Support Services

the printer will

Page 85

9

Preventive Maintenance

General Cleaning

Be sure to follow ESD precautions when performing maintenance on

the printer. This is stressed particularly when performing any cleaning

of the print head, as ESD discharge directly onto the print head can

cause failures.

Once the unit is opened, the paper path is accessible for cleaning or clearing paper.

Use a soft brush to clean the paper dust from inside the printer. The paper dust

should also be removed from the sensor optics.

Service Manual for the Accutherm Ultra Printer 9-1

Page 86

Cleaning the Print Head

TO BE PERFORMED BY RLT ONLY USING ESD PRECAUTIONS

After printing, the print head can be very hot. Be careful not to touch it

and let it cool down before you clean it. Do not damage the print head

by touching it with your fingers or any hard object.

If streaking on the printed ticket is evident, the

cleaned (Figure 9-1). This can be with a cotton swab moistened with 91%

isopropyl alcohol.

thermal print head may need to be

Figure 9-1. Cleaning Print Head (Use ESD Precautions)

9-2 GTECH Technical Training and Support Services

Page 87

Preventive Maintenance

Cover Open and

Paper Out Indicators

Top-of-Form/

Paper Low

Sensor

Cleaning the Top-of-Form/ Paper Low Sensor

Clean the Top-of-Form / Paper Low sensor with a cotton swab moistened with

91% isopropyl alcohol (Figure 9-2).

Figure 9-2. Clean TOF Sensor and Check Paper Out Indicators

Service Manual for the Accutherm Ultra Printer 9-3

Page 88

Cleaning the Jam Detection Sensor

Platen

Jam

Detection

Sensor

Clean the Jam Detection Sensor with a cotton swab moistened with 91% isopropyl

alcohol (Figure 9-3).

Cleaning the Platen

Use a cloth dampened with alcohol to wipe the platen of any debris, as needed

(Figure 9-3).

Figure 9-3. Cleaning the Jam Detection Sensor and Platen

9-4 GTECH Technical Training and Support Services

Page 89

Handling Precautions

This chapter explains the proper handling of Electrostatic Discharge (ESD)

sensitive modules and devices, the proper transport of terminals and other parts,

how terminals and devices should be packaged for returns to depots or retailers,

and the proper storage of extra or backup devices and parts.

A

Service Manual for Accutherm Ultra Printer A-i

Page 90

ESD HANDLING

All GTECH Printed Circuit Boards (PCBs) are static-sensitive. In order to prevent

damage to electronic components through ESD, please take the precautions

presented in this chapter whenever:

• Performing any work on a PCBs and equipment containing PCBs

What is ESD?

Static is the electrical charge created by the friction of two dissimilar materials

moving against each other. Electro Static Discharge, or ESD, is the unintended

dissipation of that charge, typically by short circuiting the charge to another

device or to ground.

Our bodies can create as much as 25,000 volts of static electricity across our 100

to 250 picofarads of capacitance to ground. In the worst case work environment,

voltages on some objects could exceed 50,000 volts. This more than exceeds the

static-tolerance threshold of most transistors, resistors, op-amps, and digital

computer chips. Some MOS families, for instance, can be damaged by a charge as

low as 150 volts.

Usually the damage is such that it goes undetected for some time but eventually

creates either an intermittent or hard failure in the field. Insulators, or nonconductors of electricity, pose the greatest static discharge threat to electronic

devices because of their inability to bleed their static charges.

• Removing subassemblie

s or components

Becoming “Static Safe”

Equipment or component failures that result from ESD can be difficult to identify

but can be avoided at minimal cost with proper handling techniques.

A static electricity-safe workplace is an environment in which anything that can

generate static charges is eliminated or is drained of its charge. Such a workplace

employs conductive and static dissipative materials for its table tops, floor

surfaces, clothing, and material handling bins, boxes and bags. Machines, tools

and test fixtures should be properly grounded. Technicians or anyone handling

electronic components should wear wrist straps and even ankle straps at all times

when working on or near ESD sensitive electronic modules, PCBs and devices.

GTECH has created this chapter to help you identify ESD failures and to

implement correct handling procedures. Please read the following sections

carefully.

A-ii GTECH Technical Training and Support Services

Page 91

ESD-Induced Failure Modes

Radiated Electromagnetic Fields

Radiated electromagnetic fields induce low-level voltages in unshielded signal

conductors. These can cause intermittent unit halts from which the operator may

recover. Older products are more sensitive to these fields. Products manufactured

today are designed with covers and shielded external cables to protect them from

most induced voltages.

Conducted Charges

Conducted charges (usually at points where the operator touches the unit) may

transfer directly to components and result in either intermittent or permanent

failures.

Typical Symptoms of ESD Damage

Handling Precautions

Hard failures such as blown semiconductor junctions, cracked oxide layers, fused

metallization or bond wires can result from ESD, however, intermittent failures

are the most common result of ESD. The device becomes temperature sensitive,

input thresholds shift, output levels and drive ability degrade, etc.

Increased failure rates are also typical. Normal stresses such as temperature

swings, power surges, or another “zap” could permanently disable a device

previously exposed to ESD, even if no symptoms existed from the first exposure!

Common False Assumptions Concerning ESD

• MYTH: Only MOS devices are ESD sensitive.

FACT: All semiconductor materials are sensitive to ESD. Some devices

are just more sensitive than others.

• MYTH: A component cannot be damaged once it is installed in a board.

FACT: It may be even more susceptible to induced fields due to the

antenna effect of the etch or wire connected to it.

• MYTH: If the device works after I replaced it, I got lucky and did not

damage it.

FACT: Most failures are not catastrophic and only reveal themselves as

intermittent or latent failures.

• MYTH: A grounded metal table top is a good anti-static work surface.

Service Manual for Accutherm Ultra Printer A-iii

FACT: A much better way to dissipate electrostatic fields is to use an antistatic mat and a 1-Megohm discharge current limiting resistor c o n n e c t ed t o

earth ground so that the charge is drained in a controlled manner.

Page 92

• MYTH: Wrist straps present a personal shock hazard when working on

live circuits because they ground your body.

FACT: As long as the 1-Megohm resistor is connected between the strap

and the ground connection the wrist strap does not increase your risk of

suffering a shock hazard. The 1-Megohm resistor limits the current to a

safe value for low-voltage circuits.

• MYTH: We don’t take precautions and we don’t have ESD problems at

our depot.

FACT: You may not realize the damage that you are causing, but it is

there. GTECH Engineering can determine if hard and intermittent failures

are due to ESD damage by examining individual components, but such

damage is not something that a technician can readily identify.

• MYTH:

FACT: Our ter

like any other electronic device.

The GTECH terminal is not susceptible to static damage.

minals can be damaged or destroyed by static discharge just

ESD Precautions Checklist

Recommended Devices

• Wrist straps at the bench

• Wrist strap tester

• Only tools or parts made out of conducting materials (i.e., no plastic solder

vacuums, tweezers, etc.).

• 3M® anti-static vacuum cleaners

• Static-dissipative ma ts connected to earth ground for bench tops and

flooring

• Static-dissipative bags, boxes, bins and/or totes for handling PCBs (bags

and totes must remain closed during transport - no part of the item can

“stick out” of the bag or the bag is ineffective)

• Static-free floor mats, static-dissipative shelving, and 3M black conductive

PCB storage bags used at all times (stockroom)

A-iv GTECH Technical Training and Support Services

Page 93

Handling Precautions

Precautionary Practices

• Minimize handling of components.

• Keep parts in static-dissipative packaging until ready for use.

• Use ESD-protective containers for handling and transporting small

components.

• Handle IC’s by the body, not the leads.

• Do not slide static sensitive devices over any surface.

• Eliminate static generators from your work area, for example plastic, vinyl,

styrofoam, etc.

• Use a static-free workstation whenever handling parts in the office, in the

field or anywhere.

Recommended Handling - Example

A typical scenario for a technician at a bench to properly retrieve parts from a

stock area is as follows:

• You, the technician, are seated at a bench, connected to electrical ground

via a wrist strap.

• The bench surface has a clean, grounded, static-dissipative bench mat

connected to earth ground. All tools are conductive.

• When rising from the bench to retrieve a PCB (for example), disconnect

the wrist strap.

• Proceed to the storage location and back to the bench, keeping the board in

the exist i n g , c lo s e d static-dissipative packaging.

• Re-attach the wrist strap, remove the

the terminal, which is sitting on the static-dissipative mat.

NOTE!

After leaving and returning to the static-dissipative area, always

reconne

touching any static sensitive parts.

ct to a static wrist strap connected to electrical ground before

board from the bag, and install it in

Service Manual for Accutherm Ultra Printer A-v

Page 94

Proper Grounding Technique

RLTs and FSTs must follow proper ESD precautions. This includes the items

mentioned throughout this section: wrist straps, anti-static mats, anti-static

vacuum cleaners, and antistatic bags.

• FSTs in the field must be grounded by a wrist strap connected to the

terminal which in turn is connected to earth ground when servicing that

terminal and all boards being transported must be stored enclosed within

static-dissipative packaging.

• RLTs must work in a static-safe enviro

nment. The workbenches must have

anti-static mats which are connected to earth ground and the RLT must

observe proper ESD precautions, utilizing static wrists straps and proper

anti-static packaging.

Note!

Vacuum cleaners are generators of static electricity. When purchasing

a vacuum clea

ner, choose one with an antistatic nozzle (such as the

one recommended in the Spare Parts and Tools Chapter). If unable to

purchase antistatic vacuum cleaners, the nozzle of the hose must be

wrapped with antistatic (conductive) tape from the nozzle to the handle.

The picture below shows a properly grounded technician. Notice that the

technician is grounded to the anti-static mat and the mat is grounded to earth

ground at the AC outlet.

A-vi GTECH Technical Training and Support Services

Page 95

When servicing the terminal in the field the FST first must ground himself to the

terminal chassis which is powered off and connected to earth ground, as shown in

the picture below.

GTECH Manufacturing Specification