Page 1

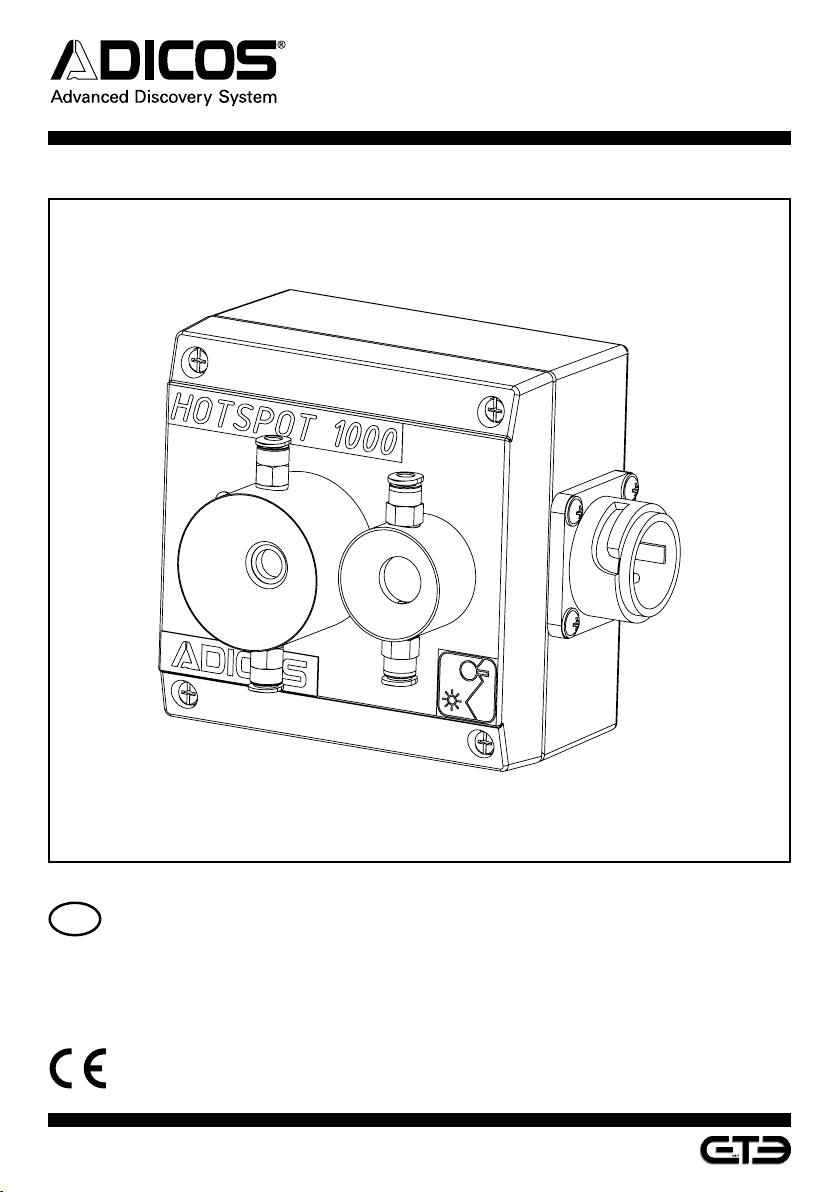

HOTSPOT-1000

410-2410-001 EN11

EN

Installation - Operation - Maintenance

Thermographic Surface Temperature Detector

HOTSPOT-1000

GTE Industrieelektronik GmbH

Helmholtzstr. 21, 38-40 | D-41747 Viersen, GERMANY | info@gte.de | +49(0)2162 / 3703-0 | www.gte.de

Page 2

ADICOS HOTSPOT-1000 Operating manual

Document version:410-2410-001 EN11

– Translation from German –

Manufacturer:

GTE Industrieelektronik GmbH

Helmholtzstr. 21, 38-40

41747 Viersen

GERMANY

Support hotline: +49 (0)2162 /37030

E-mail: service@adicos.de

© 2018 GTE Industrieelektronik GmbH – This document and all illustrations contained herein are protected by copyright and may not be copied and pasted, modified or distributed without the express consent of

the manufacturer!

Technical data is subject to change without notice!

Page 3

Brief Description

The Advanced Discovery System (ADICOS) is used for early detection of hot spots in industrial

environments. It is comprised of various separate detector units that are positioned and parameterized to facilitate a detection goal specified during the planning phase in a way that is not

susceptible to breakdown and malfunctioning.

The detector units are linked to a central unit through an ADICOS M-Bus.

In the central unit the parameterization of each detector is specified. All of the sensor data

needed for statistical analyses are also stored in the central unit.

The ADICOS HOTSPOT-1000 is an IR fire detector used for optical and spatially resolved fire

and heat detection. It is well suited for these applications:

■ Detection of hot surfaces

■ Detection of flaming fires

■ Detection of moving hot spots (pockets of embers)

■ Monitoring of machinery and parts

ADICOS HOTSPOT-1000

410-2410-001 EN11

I

Page 4

Table of Contents

1 About this Manual .......................................... 1

1.1 Objective ........................................... 1

1.2 Explanation of Symbols .................................. 1

1.3 Abbreviations......................................... 2

1.4 Storing this Manual ..................................... 2

2 For your Safety ............................................ 3

2.1 Intended Use ......................................... 3

2.2 Unintended Use ....................................... 3

2.3 Standards and Regulations ................................ 3

2.4 Qualification Required of Personnel .......................... 4

2.5 Modifications......................................... 4

2.6 Accessories and Spare Parts ............................... 4

3 Product Description.......................................... 5

3.1 Overview ........................................... 5

3.2 Sensor Specification .................................... 5

3.3 Potential Uses......................................... 6

3.4 Connecting Purge Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Signal Relays ......................................... 8

3.6 Detector Heater ....................................... 8

3.7 ADICOS M-Bus ....................................... 8

4 Functioning ............................................... 8

4.1 Configuration and Evaluation .............................. 9

4.2 LED Signals .......................................... 9

5 Installation ............................................... 10

5.1 Requirements of Mounting Location........................... 10

5.2 Mounting ........................................... 13

5.3 Wiring ............................................. 14

6 Commissioning ............................................ 22

II

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 5

7 Operation ............................................... 23

7.1 Software Access ....................................... 23

7.2 Alarm .............................................. 23

8 Maintenance.............................................. 25

8.1 Dirt and Condensation................................... 25

8.2 Checking Signal Relay Functioning........................... 26

8.3 Function Text ......................................... 26

8.4 Replacing Detectors..................................... 26

9 Failure .................................................. 27

10 Technical Data ............................................ 28

10.1 Measuring Range ...................................... 29

10.2 Precision of Standard Version ADICOS HOTSPOT-1000 ............ 29

10.3 Purge Air Requirements................................... 30

11 Disposal................................................. 30

ADICOS HOTSPOT-1000

410-2410-001 EN11

III

Page 6

ABOUT THIS MANUAL

1 About this Manual

1.1 Objective

This manual describes how to properly attach, wire, start up and operate the ADICOS detectors “HOTSPOT-1000.” Once the device has been successfully started up, this document

serves as a reference in the event of malfunctions.

It is intended to be used only by properly qualified personnel (–› Chap. 2, For your Safety).

1.2 Explanation of Symbols

This manual follows a certain structure to make it easy to work with and understand. The

following designations are used throughout.

Operational objectives

Operational objectives specify the result to be achieved by following the subsequent instructions. Operational objectives are shown in bold print.

Instructions

Instructions are the steps to be taken in order to achieve the previously stated operational

objective.

Instructions appear like this

► Indicates a single instruction

1 First of a series of instructions

2 Second of a series of instructions

3 etc.

Intermediate states

When it is possible to describe intermediate states or events resulting from the instruction steps

(e.g. screens, internal function steps, etc.), they are shown like this:

Z Intermediate state

Warnings

The following types of notes are used through this manual:

NOTE!

Indicates information relevant to further operation of the equipment.

1

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 7

WARNING!

Signals a hazard that can cause death or serious injury.

DANGER!

Indicates a hazard that will immediately cause death or serious injury.

1.3 Abbreviations

The following abbreviations are used through this manual:

Abbr. Meaning

ADICOS

AAB

BMZ

M-BM

NT

FDnet

LSN

BMA

Advanced Discovery System

ADICOS branching and connection box

ADICOS control panel BMZ-30

ADICOS M-BUSMASTER

ADICOS power supply unit NT V40-A3

Field Device Network (fire detection bus, SIEMENS fire detection systems)

Local Security Network (fire detection bus, BOSCH fire detection systems)

Fire detection system

ABOUT THIS MANUAL

1.4 Storing this Manual

Store this manual near the detectors, in a place where it can easily be accessed when needed

for reference.

ADICOS HOTSPOT-1000

410-2410-001 EN11

2

Page 8

FOR YOUR SAFETY

2 For your Safety

When properly installed, started up, operated and serviced, ADICOS HOTSPOTs ensure operational safety at your facility. But it is imperative that the manual, including all safety notes, be

read, understood and followed completely.

WARNING!

Incorrect installation and operating errors can cause death, serious

injury and damage to industrial equipment.

− Read the entire manual and follow the instructions!

2.1 Intended Use

The thermal imaging camera ADICOS HOTSPOT-1000 is designed in line with state-of-the-art

technology and accepted safety regulations.

The ADICOS HOTSPOT-1000 may be used only in compliance with the limits stated as technical operating specifications. These can be found in Chap. 10, »Technical Data«.

Intended use also includes following the instructions in this manual and complying with all

relevant local regulations.

The ADICOS HOTSPOT-1000 may not be used for any other purpose. If the device is used in

any other way, or if changes are made to the product, including in the course of installation

and maintenance, the warranty claim is no longer valid.

2.2 Unintended Use

The ADICOS HOTSPOT-1000 may not be installed in potentially explosive areas.

There are special HOTSPOT models available for use in potentially explosive areas.

2.3 Standards and Regulations

The safety and accident prevention regulations relevant to the specific application must be

complied with when installing, starting up, servicing and inspecting the detector.

The following standards and directives are particularly important when working in potentially

explosive atmospheres:

3

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 9

FOR YOUR SAFETY

Regulation Description

VDE 0100 Erection of power installations with rated voltages below 1000 V

VDE 0800 Telecommunications – general concepts; requirements and tests for the

safety of facilities and apparatus

VDE 0833 Alarm systems for fire

VdS 3189 IR camera units for monitoring temperatures in fire prevention

VDE 0845 Protection of telecommunication systems against lightning, electrostatic

discharges and overvoltages from electric power installations –

provisions against overvoltages

VdS 2095 Guidelines for automatic fire detection and fire alarm systems - planning

and installation

DIN 14675 Fire detection and fire alarm systems – setup and operation

2.4 Qualication Required of Personnel

Only properly trained and qualified persons may work on ADICOS equipment. Qualified persons are those who have received relevant professional training, have the required skills and

experience and who are aware of applicable regulations, enabling them to work on electrical

equipment and detect potential hazards.

WARNING!

Installation, startup, parameterization and maintenance may be performed only

by authorized and properly trained personnel.

2.5 Modications

WARNING!

All kinds of unauthorized modifications or additions to the equipment

are expressly prohibited!

− When in doubt, consult the manufacturer!

2.6 Accessories and Spare Parts

WARNING!

Only original spare parts and accessories provided by the manufacturer may

be used!

WARNING!

Original spare parts and accessories may be installed only by properly trained

personnel.

ADICOS HOTSPOT-1000

410-2410-001 EN11

4

Page 10

PRODUCT DESCRIPTION

3 Product Description

The ADICOS HOTSPOT-1000 is an infrared fire detector with an integrated signal evaluator

for which the parameters can be individually configured.

Because of its durable design, the ADICOS HOTSPOT-1000 can be used in adverse industrial

environments. It is ideal for monitoring bulk goods prone to spontaneous combustion as well

as conveyor lines.

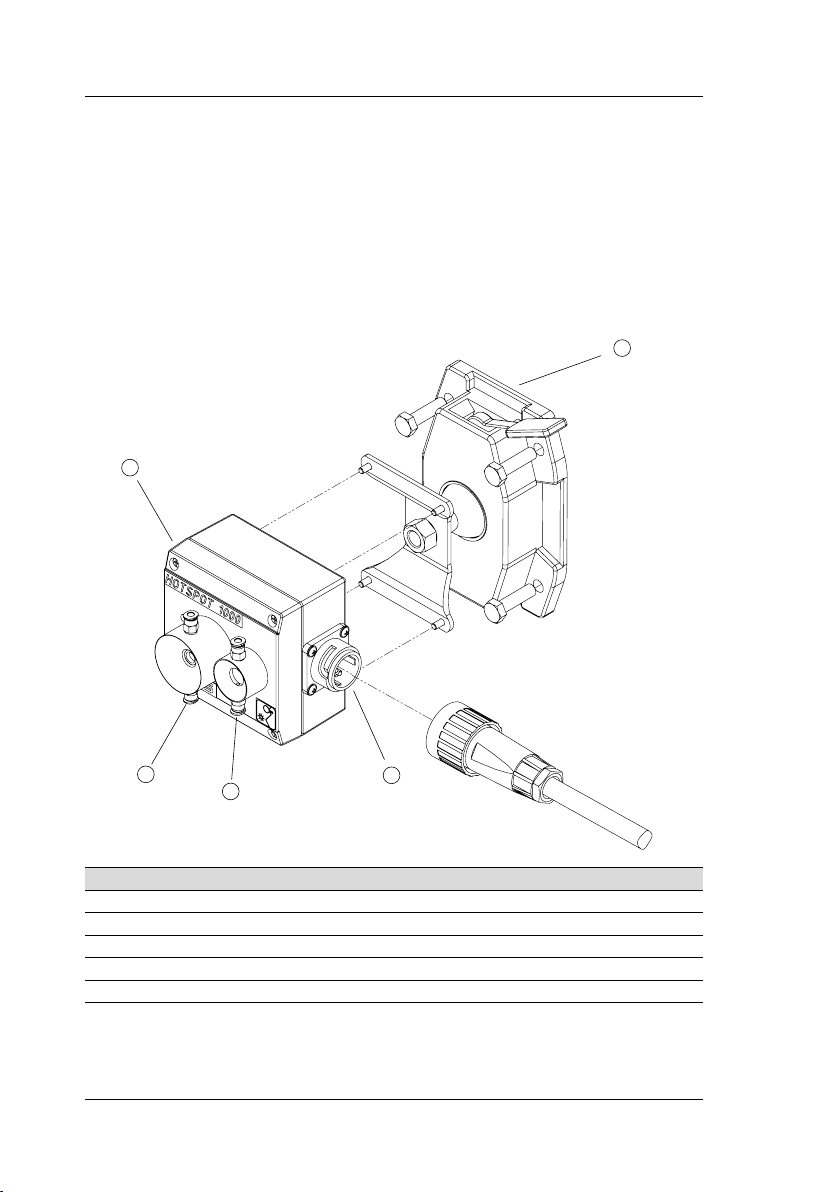

3.1 Overview

4

3

No. Description

Pre-assembled bayonet connection

Camera as installation aid

Purge air adapter with IR sensor array

HOTSPOT-1000 enclosure

Adjustable mounting bracket

5

1

2

3.2 Sensor Specication

5

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 11

PRODUCT DESCRIPTION

Type Pixels Capture angle

Object resolution

at a distance

of 5 meters

HOTSPOT-1000 32 x 31 53° x 52° 14 cm

3.3 Potential Uses

3.3.1 Moving Objects

Because of the quick reaction time of 100 milliseconds, the ADICOS HOTSPOT-1000 is ideal

for monitoring moving objects, e.g. transport and conveyor belts. This means that hot spots on

transport and conveyor belts can be found early.

When installing the ADICOS HOTSPOT-1000, ensure that the detector always has a clear,

unobstructed view of the transport or conveyor belt to be monitored. If it is not possible to scan

and monitor the entire moving object with a single ADICOS HOTSPOT-1000, you can install

multiple detectors, positioning them such that together they can scan and monitor the whole

object.

3.3.2 Stationary Objects

The ADICOS HOTSPOT-1000 can monitor immobile, stationary objects as well, ensuring

early detection of any hot spots that may be forming. The detector also senses overheated

drives, shaft bearings and reels early.

And the ADICOS HOTSPOT-1000 can be used in conjunction with the GSME to monitor bulk

goods stored above storage sites or in silos and to quickly detect any hot spots.

As with moving objects, you can use multiple ADICOS HOTSPOT-1000s at the same time, if it

is not possible to scan and monitor the entire area required with only a single device.

3.4 Connecting Purge Air

The ADICOS HOTSPOT-1000 optics can be found in an air settling tube that prevents dust

from collecting on the lens at low air flow or turbulence. But when the air flow is greater or

the air rate is faster, the air settling tube can no longer prevent the ADICOS HOTSPOT-1000

optics from getting dirty. The ADICOS HOTSPOT-1000 has a purge air connection to ensure

that the optics stay clean even when exposed to strong turbulence and high wind speeds.

It is essential to provide a continuous supply of purge air as long as dust residue can be anticipated.

ADICOS HOTSPOT-1000

410-2410-001 EN11

6

Page 12

PRODUCT DESCRIPTION

Purge air connection

The oil-free and dust-free compressed air available on site is used. The compressed air for

the sensor/camera is supplied to the purge air connection through a throttle valve (T-fitting).

The purge air has to be adapted to the temperature of the air around the HOTSPOT-1000 to

prevent condensation from forming on the lens of the IR sensor.

Purity classes required for purge air

Dust class 2

Water content class 3 (-20 °C dewpoint)

Oil content class 2 (< 0.1 mg/m3)

Required air ow rate

In dusty, settled air >2 l/min

In dusty, flowing air >10 l/min

Testing is advisable in severely turbulent, dusty air.

The purge air supply must remain uninterrupted as long as dust residue can be expected. The

air flow rate can be restricted with throttle valves; one per detector, e.g. from the Festo series

GR-QS4-LF, Festo art. no. 193966.

7

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 13

FUNCTIONING

3.5 Signal Relays

The ADICOS HOTSPOT-1000 has two signal relays: one for the state “Alarm” and

one for the state “Failure”. The “Alarm” relay is a make contact (NO) and the “Failure” relay is a break contact (NC). The signal lines for the relays are integrated into the

ADICOS connection cable.

3.6 Detector Heater

The ADICOS HOTSPOT-1000 is equipped with an internal heater. It heats the enclosure,

thus preventing humidity from the environment from forming condensation. When the heater is

operating, it can be activated and deactivated via the ADICOS service software. The detector

heater has a power consumption of up to 10 VA and is delivered in an inactive state.

The heater switches off automatically when undervoltage occurs. When the undervoltage has

been remedied, the detector heater is not activated again until the ADICOS HOTSPOT-1000

has been reset.

The enclosure temperature is monitored to limit the heating function. If the default upper temperature limit of 40 °C is exceeded, the detector heater switches off automatically until the

enclosure temperature has fallen again. The limit may need to be adjusted in the event of

a high ambient temperature along with high humidity. Details can be found in the software

documentation.

3.7 ADICOS M-Bus

The ADICOS M-Bus is a two-wire data line used to transmit all of the detector parameters as

well as the operating and measurement data to the central unit (ADICOS BMZ-30/M-Busmaster) used. These data can be displayed and archived using the ADICOS service software. The

parameters for all of the connected detectors can be set via the ADICOS M-Bus as well. The

M-Bus lines are integrated into the ADICOS connection cable.

4 Functioning

When the ADICOS HOTSPOT-1000 is in operation, it triggers an alarm according to the set

limit combinations. When an ADICOS central unit (ADICOS BMZ-30, ADICOS M-Busmaster)

is used, the detector also transmits all sensor and operating data via M-Bus to the ADICOS

service software to be displayed.

If the ADICOS HOTSPOT-1000 is connected to a fire panel (ADICOS BMZ-30 or a fire panel

from a different supplier), the fire panel controls the detector’s alarm display.

ADICOS HOTSPOT-1000

410-2410-001 EN11

8

Page 14

FUNCTIONING

4.1 Conguration and Evaluation

One of the outstanding features of the ADICOS HOTSPOT-1000 is its capacity to flexibly and

quickly detect hot spots. The detector has a separate alarm threshold for each individual pixel.

In addition to overtemperature, it also detects flames. Each detector has two sets of limits.

Standard conguration

In the standard configuration, the temperature threshold of the ADICOS HOTSPOT-1000 is

set to 60 °C.

Individual modications to conguration

The ADICOS service software can be used to change the limit of the ADICOS

HOTSPOT-1000 irrespective of the standard (default) configuration upon delivery.

4.2 LED Signals

The current state of the ADICOS HOTSPOT-1000 is indicated by three LEDs.

The following table explains the respective illumination.

LED State Functioning

Green Flashing Initialization / not yet able to trigger an alarm

On Normal operation

Off Detection system off / detector, circuit breaker or

cable defective

Yellow On Malfunction mode

Off Normal mode

With re panel interface:

Red Flashing Detector alarm, but without alarm at the fire panel

On alarm at the fire panel

Off Normal mode

With pre-alarm module:

Red Flashing Pre-alarm

On Alarm

Off Normal operation

Without re panel interface:

Red On Alarm

Off Normal operation

9

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 15

INSTALLATION

5 Installation

WARNING!

Incorrect installation of ADICOS detectors can cause malfunctioning, leading to

failure of the fire detection system.

− Only properly trained personnel may perform installation work.

5.1 Requirements of Mounting Location

DANGER!

Standard model ADICOS HOTSPOTs may not be installed

in potentially explosive areas!

There are special HOTSPOT models available for use in potentially explosive

areas.

WARNING!

The correct position and direction of the ADICOS HOTSPOT-1000 are essential

to proper and reliable detection. If the device is not placed correctly,

the detector could be completely ineffective!

5.1.1 Protective Measures

To ensure smooth operation of the ADICOS HOTSPOT-1000, always consider the following

factors when choosing a place to attach the device.

Temperature

Even under the most unfavorable conditions, the ambient temperature at the mounting location

must remain within the temperature range specified for the ADICOS HOTSPOT-1000 (Refer to

Chap. „10 Technical Data“).

Dirt and condensation

The ADICOS HOTSPOT-1000 is equipped with a purge air connection that prevents dusty

air from polluting the optics. A detector heater is needed when there is a risk of condensation

forming on the device.

Moisture

When choosing a place to attach the ADICOS HOTSPOT-1000, take into consideration that it

may not be exposed to moisture. Keep in mind that water could be used for cleaning purposes

near the mounting location.

ADICOS HOTSPOT-1000

410-2410-001 EN11

10

Page 16

INSTALLATION

Vibration

The electronics contained in the ADICOS HOTSPOT-1000 can be damaged when subjected

to vibration. If there are any sources of strong vibration near where the ADICOS HOTSPOT-1000

is mounted, the detector has to be positioned such that it is immune to the vibration.

Electromagnetic radiation

The electronics contained in the ADICOS HOTSPOT-1000 can be impaired by electromagnetic radiation. So do not place the detector near high voltage equipment. And always use

shielded cable.

5.1.2 To Ensure Proper Detection

To ensure reliable and correct operation of the ADICOS HOTSPOT-1000 as well as proper

detection, always consider the following factors when choosing a place to attach the device.

Visibility

The ADICOS HOTSPOT-1000 must always have a clear, unobstructed view of the material to

be monitored. If the object to be monitored is obscured or is not within the visibility range of

the ADICOS HOTSPOT-1000, the device will not be able to detect any heat sources and

trigger an alarm.

Distance and detection area

The detection area is determined by the distance between the detector and the object to be

monitored. So the distance or the installation location should be selected such that the object to

be monitored can be covered completely by the detector’s field of view. This ensures maximum

sensitivity.

Detection area when positioned vertically: tan(26.5) x 2 x height

Example:

An 80 cm wide conveyor belt is to be monitored to detect any moving hot spots. So the

HOTSPOT detector should be installed about 80 - 100 mm above the transport belt.

Distance [m] Object resolution [cm] Width of detection area [m]

1 3 1

3 10 3

5 16 5

10 32 10

15 48 15

11

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 17

52

distance (h)

object to be monitored

detection area

INSTALLATION

As the distance increases, so do the size of the total detection area and the area detected by

a single sensor pixel. So the object resolution of the IR detectors is a factor of the distance.

Disruptions

Certain disruptive variables can have a negative impact on functioning of the ADICOS

HOT-SPOT-1000, leading to a false alarm. When setting the alarm thresholds, take into con-

sideration intended heat sources, e.g. motor vehicles.

ADICOS HOTSPOT-1000

410-2410-001 EN11

12

Page 18

INSTALLATION

5.2 Mounting

WARNING!

ADICOS HOTSPOT-1000 detectors have to be installed with the enclosure

closed.

− Do not open the enclosure!

1

Select a suitable mounting location.

2 Install the GTE connection box near the ADICOS HOTSPOT-1000.

3 If applicable, use a 4 mm hose to connect the ADICOS HOTSPOT-1000 to a purge

air supply. This prevents residue from forming on the ADICOS HOTSPOT-1000 optics.

4 Connect the components to one another (Refer to chapter 5.3).

5 Connect the components to the supply voltage.

5.2.1 Installation Requirements

The most important requirement for properly detecting a heat source is that the detector must

have a clear, unobstructed view of the equipment parts and/or objects to be monitored within

the detection area.

Before mounting the device, determine the detection area of a single detector, or adjust it as a

factor of the installation location. When doing this, take into consideration the mounting angle

of the detector as well as the angle of detection.

5.2.2 Mounting the ADICOS HOTSPOT-1000

NOTE!

The ADICOS HOTSPOT-1000 may be installed only by properly trained personnel.

Attaching to a mounting plate

The aluminum enclosure of the ADICOS HOTSPOT-1000 has four mounting bores with a

thread cut of M5 in the lower part. These mounting bores/threads can be used to mount the

detector directly or to attach it to a mounting plate. A standard mounting plate is available as

an accessory.

The person installing the device must verify that the mounting plate is positioned such that

the equipment parts to be monitored are within the detection area of the ADICOS HOT-

SPOT-1000.

13

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 19

INSTALLATION

Attaching to a mounting bracket

The ADICOS HOTSPOT-1000 is also available with a ball joint. The ball joint is connected

to the detector with a screw fitting in the center of the back of the enclosure. There is a lever

that can be released to adjust the detector to the proper angle, allowing it the best view of the

detection area. The ball joint gives the ADICOS HOTSPOT-1000 a tilting range of +/- 50°

from the vertical position towards the narrower side and +/- 30° from the vertical position

towards the wider side.

5.3 Wiring

WARNING!

Incorrect installation of the ADICOS HOTSPOT-1000 can cause malfunctioning

and failure of the detection system.

− Only properly trained personnel may wire the equipment! (–› Chap.

2.4, Qualication Required of Personnel)

− Deenergize the entire detection system before wiring any part of it!

− Use only ADICOS connection cables and ADICOS branching and con-

nection boxes to connect the detector!

ADICOS HOTSPOT-1000

410-2410-001 EN11

14

Page 20

INSTALLATION

5.3.1 Cable Assignment

Color Signal Potential-free contact

Red

Black

Operating voltage

24 ... 40 V DC, non-polarized

Yellow Relay output X6 e Alarm (NO)

White Relay output X6 a Alarm (NO)

Brown Relay output X7 a Failure (NC)

Green Relay output X7 e Failure (NC)

Pink Fire panel interface B – in Auxiliary assembly (option-

Blue Fire panel interface A – in

al, added at factory)

Violet Fire panel interface B – out

Gray Fire panel interface A – out

Blue/red

Gray/

pink

M-Bus

Max, 40 V, non-polarized

1

With series resistor, standard 680 Ω

1

1

15

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 21

Optional re panel interfaces

Color Signal Siemens FDnet BOSCH LSNi

Pink Fire panel interface B – in FDnet-A (–) LSN b1 in

Blue Fire panel interface A – in FDnet (+) LSN a in

Violet Fire panel interface B – out FDnet-B (–) LSN b2 out

Gray Fire panel interface A – out FDnet (+) LSN a out

Optional analog signal

Color Signal Analog signal

Pink Analog signal – protected

4 ... 20 mA

against polarity reversal

Blue Analog signal – protected

4 ... 20 mA

against polarity reversal

Violet Analog signal 0 ... 5 V

0 ... 10 V

Gray Analog signal 0 V

Optional pre-alarm relay

INSTALLATION

Color Plug assignment Pre-alarm module

Pink 8 NC (break contact)

Blue 9 Violet 10 M (center tap)

Gray 11 NO (make contact)

The pre-alarm relay is linked to set 2 of the trigger limits. The pre-alarm functionality is ensured

as long as the limits programmed in set 2 are less sensitive than the limits in set 1.

ADICOS HOTSPOT-1000

410-2410-001 EN11

16

Page 22

INSTALLATION

5.3.2 Attaching ADICOS Connection Cable to ADICOS HOTSPOT-1000

1 Press the bayonet lock on the ADICOS connection cable against the

detector connection.

2 Carefully turn the entire bayonet lock to find the proper position for the

twist protection.

3 Firmly turn the bayonet ring on the connector to secure the cable.

17

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 23

INSTALLATION

5.3.3 Attaching ADICOS Connection Cable to ADICOS-AAB

The exact way in which the ADICOS connection cable and the ADICOS branching and connection box (ADICOS-AAB) are wired is a factor of the system and detector configuration. The

following procedure applies to all wiring variations.

CONNECTION BOX

BMZ30 / M-BM

NT V40-A3

+24 V

X7 (St)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

+24 V

0 V

0 V

PE

PE

+24 V

0 V

M-Bus A

M-Bus BB1A1B2A2

+24 V

0 V

X7 (St)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

X6e

X7e

X6a

X7a

ADICOS HOTSPOT-1000

BMZ-Module

R

R

1

2

Alarm relay

Standard

R1 = 680 Ω R2 = ∞

HOTSPOT

410-2410-001 EN11

R

3

Failure relay

R3 = 0 Ω R4 = ∞

R

4

Standard

18

Page 24

INSTALLATION

Wiring ADICOS-AAB

1

Open the cover on the ADICOS-ABB enclosure

2 Open the lower cable gland on the ADICOS-ABB

3 Thread the ADICOS connection cable through the lower cable gland and into the ADI-

COS-ABB

4 Connect the cable cores to the ADICOS-ABB connecting terminals as shown in the wiring

diagram

5 Close the cable gland on the ADICOS-ABB

6 Close the cover on the ADICOS-ABB enclosure

NOTE!

More information on how to install the ADICOS branching and connection box

can be found in the GTE manual, no. 430-2410-001!

5.3.4 Wiring Variations

The actual wiring of the detector to the ADICOS branching and connection box can vary

depending on the system configuration. The following wiring diagrams show the most common

system configurations and wiring variations.

ADICOS BMZ / M-BM and external NT

ADICOS BMZ-30

M-Busmaster

ADICOS Power supply unit

NT V40-A3

19

+ (24 V)

− (24 V)

M-Bus

M-Bus

0 V

+40

+24 V

ADICOS-AAB

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

0 V

+24 V

PE

PE

V

+24 V

red

0 V

black

M-Bus A

yellow

M-Bus B

green

B1

white

A1

brown

B2

A2

pink

blue

X6e

violet

X7e

gray

X6a

X7a

blue/red

gray/pink

+

24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

to next

ADICOS-AAB

ADICOS-connection cable for detector

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 25

Limit value detection lines “Failure” and “Alarm”

INSTALLATION

External fire detector

Failure

Alarm 1

Alarm 2

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

0 V

+24 V

PE

PE

ADICOS-AAB

B1

0 V

+24 V

M-Bus B

M-Bus A

red

white

black

green

yellow

A1

brown

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

At the end of the line:

B2

A2

X6e

X7e

X6a

X7a

pink

blue

gray

violet

blue/red

gray/pink

Terminating resistor

wire break detection

ADICOS connection cable for detector

External re detector LOOP with LSN / FDnet (internal re panel interface)

External fire detector

(with Siemens FDnet

or Bosch LSN)

LOOP B

LOOP A

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

0 V

+24 V

PE

PE

ADICOS-AAB

B1

0 V

+24 V

M-Bus B

M-Bus A

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

A1

B2

A2

X6e

X7e

X6a

X7a

3k3

to next

ADICOS-AAB

to next

ADICOS-AAB

ADICOS connection cable for detector

ADICOS HOTSPOT-1000

red

black

yellow

green

white

brown

pink

blue

410-2410-001 EN11

violet

gray

blue/red

gray/pink

*

Detector with integrated

*

FDnet or LSNi module

20

Page 26

INSTALLATION

External re detector LOOP with other bus (external re panel interface)

External fire detector

(fire alarm bus)

LOOP B

LOOP A

External fire panel interface

LOOP B

LOOP A

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

0 V

+24 V

PE

PE

+24 V

red

0 V

black

Alarm 1

Alarm 2

Störung 1

Störung 2

ADICOS-AAB

B1

A1

B2

A2

M-Bus B

M-Bus A

pink

blue

white

green

brown

yellow

X6e

violet

X7e

gray

X6a

X7a

blue/red

gray/pink

LOOP B

LOOP A

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

to next

fire panel

interface

ADICOS connection cable for detector

Primary cable shield

ADICOS-AAB

+24 V

Primary cable Primary cable

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

0 V

+24 V

PE

PE

+24 V

0 V

X7 (Stoer)

X6aus (Al)

X6ein (Al)

LOOP B

LOOP A

M-Bus A

M-Bus B

21

B1

A1

0 V

+24 V

M-Bus B

M-Bus A

410-2410-001 EN11

B2

A2

X6e

X7e

X6a

X7a

ADICOS HOTSPOT-1000

Page 27

6 Commissioning

DANGER!

ADICOS systems work with electrical current, which can cause equipment damage and fire if not installed properly.

− Before switching on the system, verify that all detectors are properly

mounted and wired.

− Startup may be performed only by properly trained personnel.

WARNING!

Before startup, check that all of the detector enclosure covers are completely

closed; otherwise the ADICOS will not work. If the enclosure cover is not closed

properly, a false alarm can be triggered or the detector can fail.

NOTE!

The ADICOS detectors do not have to each be started up separately. When the

ADICOS central unit is switched on, all of the detectors start automatically.

NOTE!

The ADICOS HOTSPOT-1000 indicates a malfunction until

the startup process is completed.

COMMISSIONING

► Supply voltage to the device to start up the ADICOS HOTSPOT-1000.

► Start up the ADICOS system as described in the manual for the central unit used (ADICOS

BMZ-30/M-Busmaster).

Z Startup begins automatically and takes about ten seconds.

Z The green signal LED “Operation” flashes briefly.

Z The detector electronics are initialized.

Z Once startup is completed, the green signal LED “Operation” remains illuminated.

ADICOS HOTSPOT-1000

410-2410-001 EN11

22

Page 28

OPERATION

7 Operation

During operation, the ADICOS HOTSPOT-1000 monitors the area within its field of view and

triggers an alarm when the limits are exceeded. The scan interval is 100 milliseconds.

7.1 Software Access

When an ADICOS central unit (BMZ-30, M-Busmaster) is used, detailed information on the

detector can be called up via the M-Bus. To be able to access the detector information, you

will need a PC on which the ADICOS service software is installed and that is connected to the

ADICOS central unit.

The communication number (COM or K.N.) shown on the ID plate and on the front of the detector is used to access detailed information on the detector in the software. Parameterization

of the ADICOS HOTSPOT-1000 is also done in the software. However, only properly trained

personnel may perform this task. And in the software you can also look at the current thermal

image of the detector, enabling potential sources of ignition to be revealed.

7.2 Alarm

If the temperature limits set in the ADICOS HOTSPOT-1000 are exceeded, the ADICOS

HOTSPOT-1000 triggers an alarm. The internal alarm relay is engaged and the red LED lights

up. The alarm signal is transmitted to the connected fire panel via the ADICOS M-Bus or the

fire detection lines.

If an alarm delay has been set, the alarm is not triggered until the alarm conditions have been

met for longer than the set duration.

7.2.1 Fire Detection System Operation

If the ADICOS HOTSPOT-1000 is connected to a fire panel, the alarm is transmitted to the fire

panel via the fire detection system module. The fire detection system triggers the ADICOS

HOTSPOT-1000 alarm. And the alarm relay is triggered and the red signal LED ADICOS

HOTSPOT-1000 lights up. If despite all of this the fire detection system does not trigger the

ADICOS HOTSPOT-1000 alarm, the red LED flashes.

7.2.2 Resetting Alarm

The ADICOS HOTSPOT-1000 remains in a state of alarm until the temperatures fall below the

set limits again. Scans occur at 100 millisecond intervals to determine whether the temperatures

have fallen below the limits. When the temperatures have fallen below the alarm limits and the

alarm conditions are no longer met, the alarm state is automatically canceled. If an alarm duration time has been set, the signal LED “Alarm” is not reset until after a respective delay.

If the alarm LED is controlled by a fire detection system, the alarm state can be reset with the

alarm reset contact on the fire detection system.

7.2.3 Alarm Duration

The alarm duration is a parameter that can optionally be set via the ADICOS service software.

23

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 29

OPERATION

The purpose of the alarm duration is to ensure that, once the alarm conditions are no longer

met, the signal LED “Alarm” is not reset unit after a respective delay. The default alarm duration

is 7.5 minutes.

7.2.4 Alarm Delay

The alarm delay is a parameter that can optionally be set via the ADICOS service software.

The purpose of the alarm delay is to prevent the alarm from being triggered until the alarm

conditions have been met for a previously defined minimum time (in minutes).

WARNING!

Incorrect parameterization of the alarm delay can cause the detector to fail.

− Detector parameters may be modied only by properly trained per-

sonnel!

− When in doubt, consult the manufacturer!

7.2.5 Pre-alarm

If the ADICOS HOTSPOT-1000 is equipped with a pre-alarm module and properly configured, set 2 of the saved limit combinations automatically acts as the trigger criterion for the

pre-alarm. If the limits specified in set 2 are exceeded, the pre-alarm module relay switches and

the red signal LED “Alarm” flashes.

7.2.6 Day/Night Mode

If the ADICOS HOTSPOT-1000 is operated in conjunction with a ADICOS BMZ-30, the feature “Day/night mode” can be used. When the parameterization has been modified for this

purpose in the ADICOS service software, the determination of whether an alarm is triggered is

based on set 1 of the stored limit combinations during the day and set 2 at night. This means

that different alarm thresholds can be monitored for day and night mode. This is particularly

helpful when during the day there may be disturbances that could trigger an alarm, e.g. motor

vehicle exhaust.

7.2.7 Peak Suppression

In some cases it makes sense to ignore when thresholds being exceeded only briefly. For example: In a building where combustibles are stored and where vehicles drive in and out, the

short-term effects of the passing vehicles can be ignored. The hot tailpipes or reflections from

the shiny metal surfaces should not trigger an alarm.

ADICOS HOTSPOT-1000

410-2410-001 EN11

24

Page 30

MAINTENANCE

8 Maintenance

The following maintenance measures should be performed at least at the intervals stated here.

Visual inspection of the optics to check for dirt or condensation should occur as needed or as

a factor of the ambient conditions.

Measure Daily Every 3

Check for fault indications via the

fire panel or the software

•

Visual inspection for condensation on the

detector enclosure

Visual inspection for damage to detector,

mounting device and connection cable

months

•

•

Every

year

Visual inspection for dirt on the optics •

Functional testing of signal relays “Alarm” and

“Failure”

Functional testing with

ADICOS HOTSPOT test device

•

•

8.1 Dirt and Condensation

To prevent the detector from getting dirty, it should be mounted such that the optics face down

whenever possible. This way only minimal dust and dirt can settle on the detector. If the detector is mounted such that the optics have a vertical view or almost vertical view downward, the

optics will remain clean for many years.

When the detector is used in areas where there is frequent dust turbulence, it is advisable to

use purge air (Refer to Chap. „3.4 Purge Air Connection“); when the dust is moist, purge air

is essential.

A liquid film on the detector can prevent a heat source from being recognized. So it is important to prevent condensation from forming on the optics. The detector may not be used in areas

in which grease is used and particularly not near splashing. Panes of glass or plastic cannot

be used to protect the optics. The most common glass and plastic panes are completely impermeable in the relevant wave length range of 8 – 12 µm. In the event that condensation forms

on the optics, switch on the detector heater.

Cleaning

The ADICOS HOTSPOT-1000 may be cleaned with water and dishwashing liquid. Acids and

bases may not be used; do not apply water pressure to clean. Always use a damp, soft cloth,

never rough materials or sponges. The ADICOS HOTSPOT-1000 will not function correctly if

it is not cleaned properly,

25

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 31

MAINTENANCE

8.2 Checking Signal Relay Functioning

The signal relays “Alarm” and “Failure” should be checked every year to verify that they function

properly. They can be switched for testing purposes via the ADICOS service software.

NOTE!

Functional testing of the signal relays triggers an alarm or failure state on the

connected fire panel.

− Switch the re panel to walk test mode before testing functioning!

8.3 Function Text

ATTENTION!

It is essential to use the test device ADICOS HTL-2 to verify that the detector is

working properly. Please follow the instructions in the GTE manual

no. 410-2410-008.

− Test proper alarm triggering at least once a year!

NOTE!

Functional testing of the signal relays triggers an alarm or failure state on the

connected fire panel.

− Switch the re panel to walk test mode before testing functioning!

8.4 Replacing Detectors

ATTENTION!

Replace the ADICOS HOTSPOT-1000 no later than eight years after initial

startup!

8.4.1 General Notes

The ADICOS HOTSPOT-1000 has to be replaced with a similar detector or newer product

version after eight years of operation.

ADICOS HOTSPOT-1000

410-2410-001 EN11

26

Page 32

FAILURE

8.4.2 Replacing the ADICOS HOTSPOT-1000

An old ADICOS HOTSPOT-1000 has to be replaced when

– The serviceable life of the detector has been exhausted

– It is foreseeable that functioning will decline prematurely

– A change in the operating conditions requires a different type of detector

When the ADICOS HOTSPOT-1000 is replaced, the parameter set from the previous device

can be imported if the following conditions are met:

– The detector is mounted in the same position.

– There is a data backup of the parameterization available.

– The detector is not being replaced because the build-

ing is to be used for a different purpose.

To replace the detector, deenergize the system and detach the old detector. Install the new

detector as described in this manual.

9 Failure

Failure of the ADICOS HOTSPOT-1000 is indicated by the yellow signal LED lighting up as

well as by the “Failure” signal relay deenergizing.

The ADICOS HOTSPOT-1000 recognizes the following states and causes of failure:

Failure Description Measure

Undervoltage /

current failure

Checksum ROM/EEPROM The checksum is no longer

Test failure The ADICOS service

Sensor fault The IR sensor is defective Replace detector

Undertemperature Failure is triggered below

Operating voltage falls below 20 V (even only briefly).

right after restart or reset.

software was used to

trigger a false failure

for test purposes.

the default temperature

limit (standard: -15 °C)

Check supply voltage

and wiring; use a more

powerful or additional

power pack; self-resetting

Replace detector

Cancel test failure with

ADICOS

service software

Use the detector heater or insulate the device sufficiently

Use the ADICOS service software to precisely analyze the failure states!

27

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 33

TECHNICAL DATA

10 Technical Data

Environmental class A

Power supply 24 – 40 V DC (A fault indication is

Power consumption (without heater / with heater)

Device temperature range -10 – 50 °C. Failure is triggered below the

Relative humidity: 20 – 99 % relative humidity

Enclosure Coated die cast aluminum (corrosion-resis-

Dimensions (H x W x L) 90 x 100 x 100 mm (not in-

Weight 0.6 kg

Degree of protection IP 64

Mounting Overhead / diagonally / on the ball joint

Electrical connection ADICOS connection cable

Service bus M-Bus: 40 V, 2 - 20 mA per node, 4800

Startup time (ready for operation) After about 10 seconds

Resolution 32 x 31 pixels

Capture angle 53° x 52°

Reaction time < 1 second

Temporal resolution 0.1 second or 1 second

triggered when voltage falls below 20 V)

1 VA / 10 VA. Power consumption is briefly higher upon startup

default temperature limit (standard: -15 °C)

– Non-condensing

– With continuous condensation, when

optional detector heater is built in

tant)

cluding dust/splash guard)

(12-lead) with bayonet lock

baud; maximum cable capacity 200 nF

(depending on configuration)

ADICOS HOTSPOT-1000

410-2410-001 EN11

28

Page 34

TECHNICAL DATA

10.1 Measuring Range

The standard temperature detection range is 0 – 100 °C. The temperature ranges can be expanded. Such individual requests must be stated upon ordering so that they can be taken into

consideration when calibrating the equipment and performing the production test.

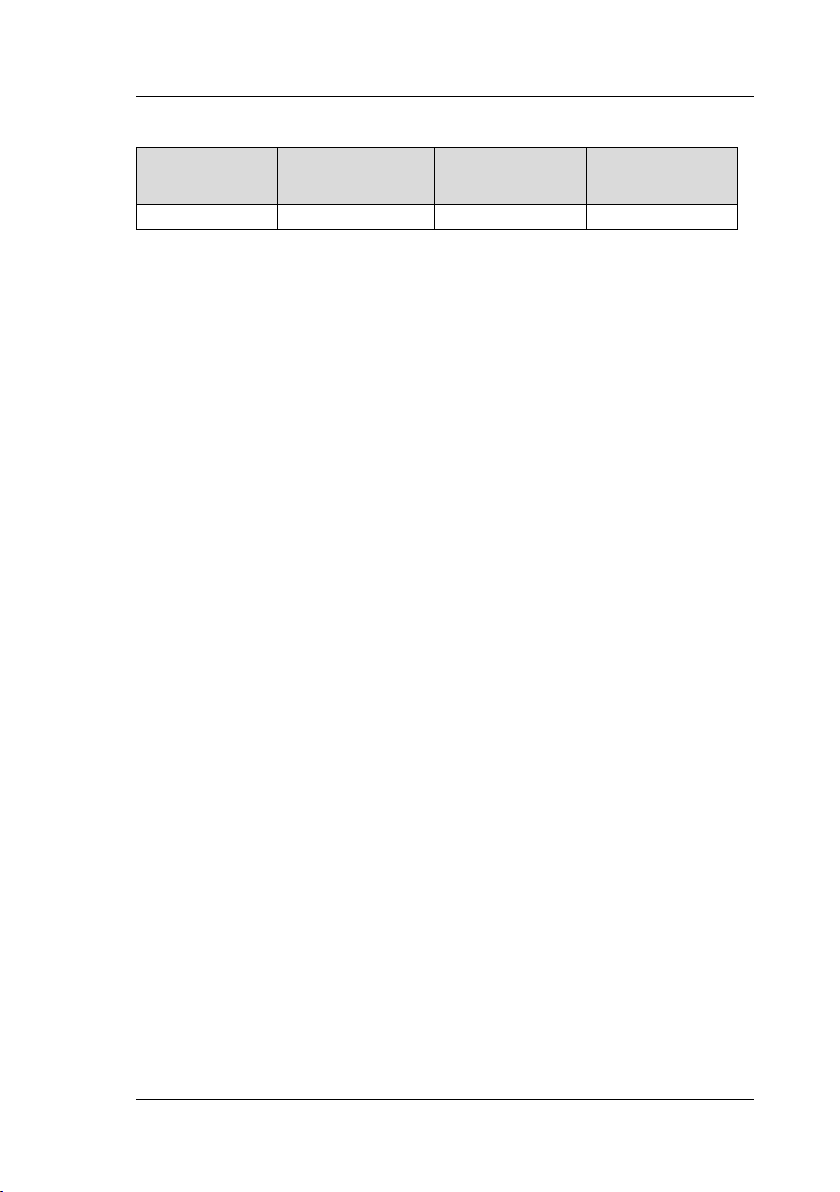

10.2 Precision of Standard Version ADICOS HOTSPOT-1000

In regard to the precision of the temperature detection capacity of the ADICOS

HOTSPOT-1000, the

following requirements can be stated:

– The emission coefficient of the monitored surfaces must be taken into consideration.

– The ambient temperature is near the device temperature.

– The size of the detected object is the same as the sensing range of one pixel.

Statistical precision of temperature detection at device temperatures between 10 °C

and 30 °C (room temperature)

Temperature dif-

ferential [°C]

between object

and device (dT)

Absolute precision Relative precision [°C]

(pixel-pixel)

0 –10 < 10 % or < 2 °C < 2

10 – 40 < 10 % or < 4 °C < 3

40 – 80 < 15 % or < 5 °C < 4

80 –180 < 20 % or < 10 °C < 5

180 – 500 < 20 % or < 30 °C < 10

Statistical precision of temperature detection at device temperatures below 10 °C or

above 30 °C

Temperature dif-

ferential [°C]

between object

and device (dT)

Absolute precision Relative precision [°C]

(pixel-pixel)

0 – 10 < 15 % or < 4 °C < 2

10 –40 < 15 % or < 5 °C < 3

40 – 80 < 20 % or < 8 °C < 4

29

410-2410-001 EN11

ADICOS HOTSPOT-1000

Page 35

DISPOSAL

Temperature dif-

ferential [°C]

between object

and device (dT)

Absolute precision Relative precision [°C]

(pixel-pixel)

80 – 180 < 20 % or < 10 °C < 5

180 – 500 < 20 % or < 30 °C < 10

Deviation

Averaging method (depending on detector conguration)

Deviation

Average of ten measurements Typically 1 °C

Maximum value of ten measurements Typically 3 °C

With the model 0 – 500 °C Typically 10 °C

10.3 Purge Air Requirements

Purity classes required for purge air

Dust Class 2

Water content Class 3 (-20 °C dewpoint)

Oil content Class 2 ( < 0.1 mg/m³)

Required air ow rate

In dusty, settled air > 2 l/min

In dusty, flowing air > 10 l/min

Testing is advisable in severely turbulent air.

11 Disposal

Return the device to the manufacturer when it reaches the

end of its serviceable life. The manufacturer will ensure that

the components are disposed of properly, in an environmentally friendly manner.

ADICOS HOTSPOT-1000

410-2410-001 EN11

30

Page 36

Loading...

Loading...