Page 1

TM

1The Roll-Up III

Roll-Up III

The Portable Large Format Digitizer

User’s Guide

Page 2

The Roll-Up III2

We at GTCO CalComp are proud of our digitizer products. We strive to bring you the best the technology has

to offer. We urge you to visit our Web site, where we will

post the latest information regarding updates and changes

that may impact the information in this User’s Guide.

Navigate to:

www.gtcocalcomp.com

Page 3

Table of Contents

What is Roll-Up III? 5

Parts Checklist 6

What You Will Need to Use Roll-Up III 6

Setting Up Your Roll-Up III 7

Software Configuration 7

Configuring Non-Wintab Applications 7

Installing the TabletWorks Driver 7

Hardware Configuration 8

USB Connection 9

RS232 Serial Connection 10

3The Roll-Up III Table of Contents

Using the SuperSet Menu 11

Changing the Digitizer’s Orientation 12

Turning the Alarm Off and On 12

Configuring Your Roll-Up III for Specific Applications 13

Example: Configuring for a Specific Application 13

Table 1: SuperSet Menu Codes for Selected Applications 14

Table 2: Configuration Details for SuperSet Menu Codes 20

Roll-Up III Tones 23

Table 3: Roll-Up III Tones 23

Introduction to the Custom Configuration Menu 24

Communication Options 24

Output Format Options 24

Mode Options 25

Using the Custom Configuration Menu 26

Care and Handling of Roll-Up III 28

Transporting Roll-Up III 29

Troubleshooting Guide 30

Procedure A: Begin Troubleshooting 31

Procedure B: Troubleshooting 32

The Tablet Configuration Utilities 34

Page 4

The Roll-Up III4 Table of Contents

Regulatory Statements and Warranty 36

Radio and Television Interference 36

Canada 36

Declaration of Conformity 37

Japan 38

Bescheinigung des Herstellers/Importeurs 38

European Union Directives 39

Limited Warranty for the Roll-Up III 40

Page 5

Overview

What is the Roll-Up III?

The Roll-Up III belongs to a class of computer input devices called

graphic tablets, or digitizers. A digitizer is an electronic tablet work

surface. The position of a transducer, a handheld cursor or stylus, on the

work surface of the Roll-Up III is converted—digitized—into data for computer processing. Data output from the Roll-Up III digitizer is in the form

of an X/Y coordinate pair that pinpoints the location of the transducer on

the tablet surface. The Roll-Up III is a specialized graphic digitizer that is

specifically designed to be portable, so it can be taken to the job site.

The Roll-Up III uses an electrostatic technology for digitizing

with blueprints and nonconductive inks. If you are using black

line drawings with conductive ink, the Super L Series Digitizers

are more appropriate.

The Roll-Up III works with many graphic, CAD, and estimating applications. These applications use the digitized data from the Roll-Up III to:

5The Roll-Up III

Determine the dimensions of objects on drawings and blueprints

Move the pointer on the display screen

Create and manipulate objects in a graphic composition

Trace a drawing, or other source material, to create an image on the

display screen

Select commands or functions from an application menu placed on

the tablet surface

Select items from a pull-down menu on the display screen

In order to send data from your Roll-Up III to your digitizing application,

your Roll-Up III must be physically connected to your computer, and it

must be able to transmit that data in such a way that the digitizing application recognizes and understands it. Before you set up your Roll-Up III,

you should determine:

The requirements of the digitizing software application you are using

Whether your digitizing application requires software drivers to communicate with the Roll-Up III

The hardware communications connection (Serial or USB) you will be

using between the Roll-Up III and the computer

Page 6

The Roll-Up III6 Checklist

Parts Checklist

Roll-Up III digitizing tablet

Transducer (stylus/pen, 4-button cursor, or 16-button cursor)

USB Cable

A CD (TabletWorks drivers, documentation, or third party software

drivers)

Accessory case – Do not discard

Cardboard tube, insert and end caps – Do not discard

Roll-Up III Quick Start

Optional Equipment

Computer interface cable with 9-pin connector for serial connection

Power supply – required only for serial installations

Deluxe Travel Bag

(Can be purchased separately)

What You Will Need to Use Roll-Up III

A computer running a Windows operating system with a USB port, or

an RS232C serial communication port. (Serial signal levels must conform to EIA RS232C specifications.)

Application software that accepts digitizer input via the Wintab API,

or application software that directly accepts digitizer input via the

computer’s RS232C serial port.

Page 7

Setting Up Your Roll-Up III

The instructions below describe how to set up your Roll-Up III. Before

you begin, please take a moment to fill out and mail the Warranty Registration Card.

Software Configuration

Software drivers provide the communication bridge between your digitizing software application and your Roll-Up III. You should install only the

drivers necessary for the Roll-Up III to work with your application software. The GTCO CalComp-supplied TabletWorks CD supports reduced

functionality Wintab and TabCon-compatible applications. If you are not

sure which drivers are required, check Table 1 on page 14, or consult

with your application vendor. A driver does not need to be installed if

you are using the Roll-Up III with the GTCO CalComp QuikRuler III.

Configuring Non-Wintab Applications

7The Roll-Up III Installation

Many application programs provide configuration information for specific

digitizers. If the Roll-Up III digitizer is not listed, you can use the configuration for GTCO Digi-Pad Type 5 or Type 5A (T5/T5A), Roll-Up II, CalComp

9100/9500, or Summagraphics Microgrid III or ID Series.

Installing the TabletWorks Driver

Insert the CD into the CD-ROM drive on your computer. The installer will

autoload. If it doesn’t, click on the Start button on the Windows Task Bar

and select Run from the menu. Type X:\setup.exe (X represents the CD

drive letter). Follow the onscreen prompts to complete the installation.

A TabletWorks icon

Task Bar. Right-click on the icon to display the TabletWorks Menu, which

provides access to all the TabletWorks features.

will display in the System Tray on the Windows

Page 8

The Roll-Up III8 Installation

Hardware Configuration

When you are using the USB interface, no data output configuration is

required. However, when you choose the optional serial interface, the

Roll-Up III must be configured to send data in a format that is compatible

with the application software. Different applications have different requirements when interacting with a digitizer. The Roll-Up III has been

designed to provide the appropriate serial requirements for a wide variety

of graphic, CAD, and estimating applications using a simple code system.

The SuperSet Menu on the surface of the Roll-Up III is used to enter the

appropriate code for the software you are using. A table in the Using the

SuperSet Menu section of this manual lists the SuperSet Codes for a wide

variety of applications.

Determine, if you haven’t already, which communication connection you

will be using—USB or Serial.

Conductive materials, inks, or electronic devices on, under, or

near the Roll-Up III can cause improper operation. See the

Troubleshooting section for more details.

1 Select a large, flat, nonmetal surface on which to place the Roll-Up III.

Clear all items from the surface.

2 Remove the Roll-Up III from its cardboard tube container and unroll it

on the selected surface.

3 Connect the transducer

– cursor or stylus – to

the appropriate jack on

the digitizer’s Connector

Panel. The connector is

Power

(DC IN)

Serial

(RS232)

Transducer

(POINTER)

USB

(USB)

Housing

keyed and will fit only

the correct jack. Do not

force it.

Roll-Up III Connector Panel

Do not attempt to remove the controller from the housing.

Doing so could damage the digitizer and void your warranty.

Page 9

9The Roll-Up III Installation

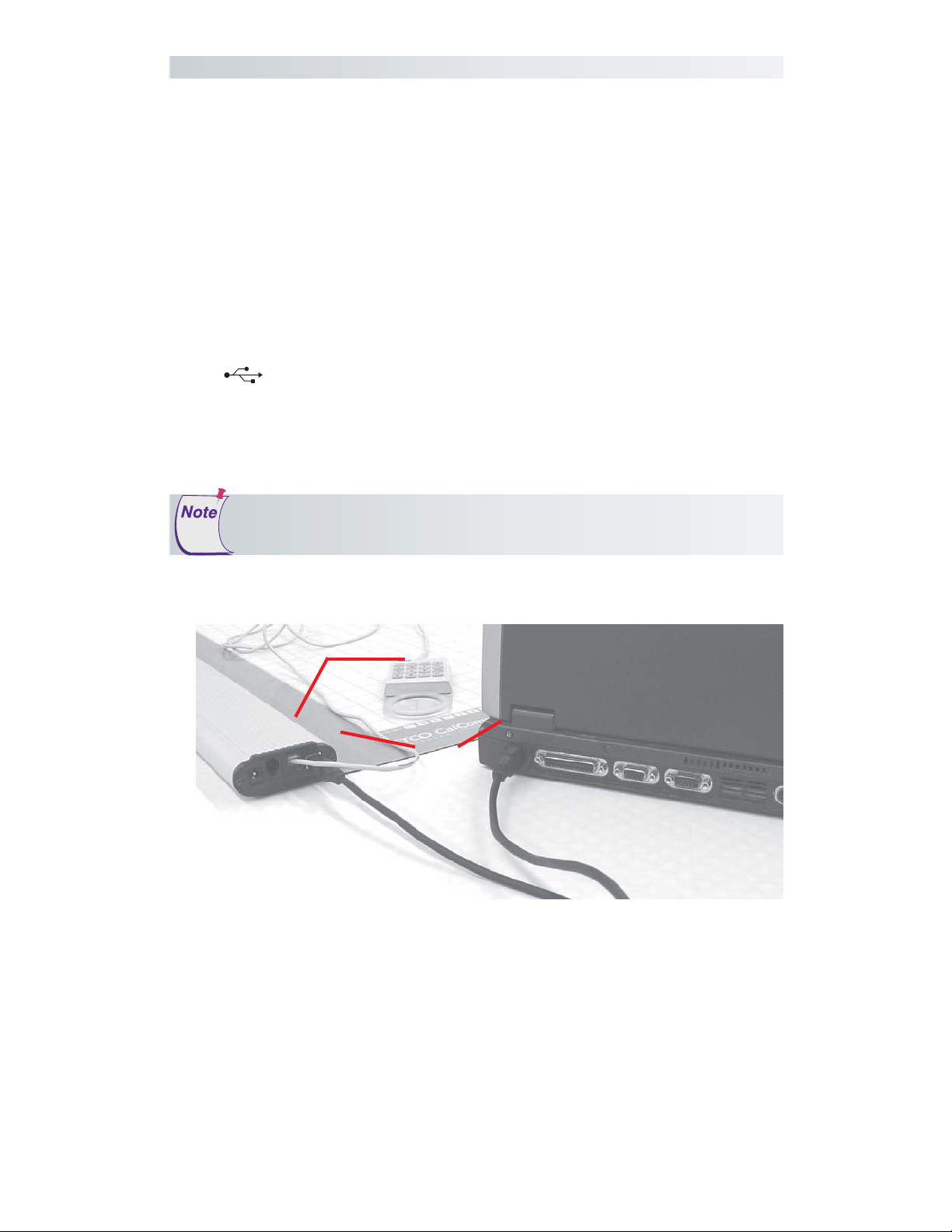

USB Connection

The Roll-Up III USB port connection is USB 1.1 and 2.0 compatible.

When the digitizer is connected to the USB port, Windows will recognize

that there is a new device connected. If Windows displays the Found

New Hardware prompt, follow the onscreen instructions to complete the

driver installation.

1 Connect the interface cable to the USB jack on the Roll-Up III Con-

nector Panel. The connector is keyed and will fit only the correct jack.

Do not force it.

2 Connect the other end of the USB cable to any one of the USB ports

on your computer or USB hub. The digitizer will beep four short

tones, indicating it is powered On. See the Roll-Up III Tones section

on page 23 for a complete table of the Roll-Up III tones.

3 SuperSet Codes are not applicable when using the USB connection.

Power is supplied through the USB port. No additional power

source is needed for this installation.

USB Connections

Transducer

Computer

USB

Page 10

The Roll-Up III10 Installation

RS232 Serial Connection

If your software application is not Wintab-compliant, be sure to set the

correct two-digit Application SuperSet Code before connecting the serial

cable to the computer. SuperSet Codes can be found in Table 1. If your

application is not listed in Table 1, find the configuration settings that

apply to your application in Table 2 and use the corresponding SuperSet

Code. If an appropriate SuperSet Code is not listed in Table 2, use the

Custom Configuration Menu stored in the slot on the end of the Roll-Up

III housing to configure your Roll-Up III.

1 Plug the power supply into an AC outlet. Connect the power supply

to the appropriate jack on the Connector Panel. The digitizer will

beep four short tones (see the Roll-Up III Tones section on page 23 for

a complete table of Roll-Up III tones), indicating it is powered On.

2 Connect the RS232 serial cable to the serial jack on the Connector

Panel. The connector is keyed and will fit only the correct jack. Do not

force it.

3 Configure the SuperSet Code. The Roll-Up III comes from the factory

with the SuperSet Code

pre-configured. (See Using the

SuperSet Menu.)

Serial Connection

Transducer

Power

Serial

Computer

Page 11

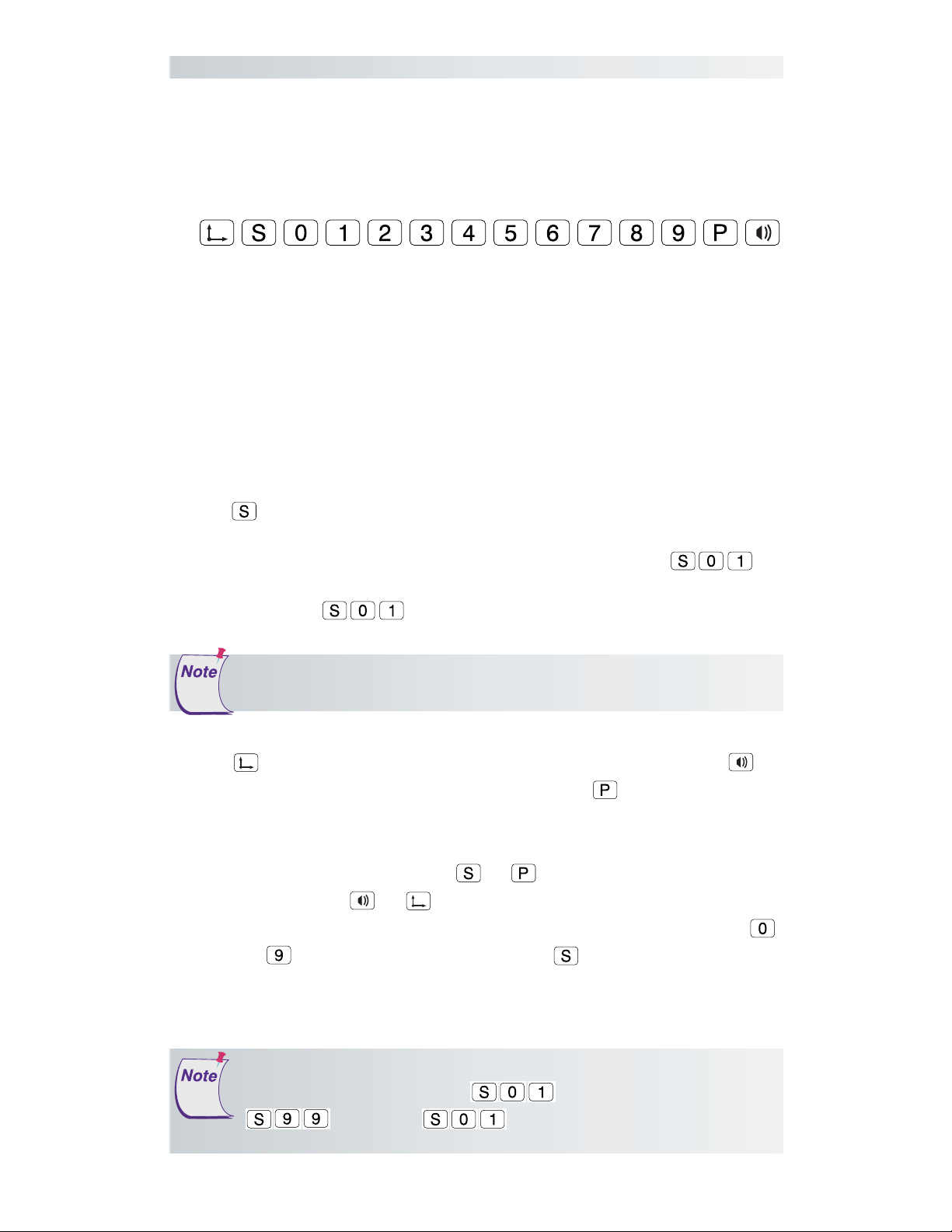

Using the SuperSet Menu

The SuperSet Menu is the row of buttons printed in the lower left and

upper right corners of the digitizer.

The SuperSet Menu makes it possible for you to configure your Roll-Up III

so that it sends the appropriate information for a serial connection to the

software you’re using on your computer (see Table 1 on page 14 for an

extensive list of digitizer software applications and their codes). It is used

to prepare the digitizer to receive specific, detailed custom configuration

information from the Custom Configuration Menu for some serial installations. In addition, the SuperSet Menu can be used for both serial and USB

connection configurations, to set and change the digitizer orientation,

and to turn the digitizer alarm off and on. Use your stylus or cursor to

click on the menu buttons to make your selections.

11The Roll-Up III The SuperSet Menu

The

are entered after Select Mode is activated. Most software supports Wintab using the TabletWorks drivers, whose SuperSet Code is

the SuperSet Menu. The Roll-Up III comes from the factory with the

SuperSet Code

The menu button sets your preferred digitizer orientation. The

button toggles the digitizer alarm off and on. The button activates the

Custom Configuration menu.

When using the SuperSet Menu, a tone will sound indicating a successful

selection when you click on the

when you click on

23 for a complete table of the Roll-Up III tones.) The number buttons

through

menu button initiates the Select Mode. Two-digit numeric codes

pre-configured.

The Select Mode will not work with the USB interface. USB talks

to Wintab drivers exclusively.

or

or

are active only after clicking on for Select Mode.

. (See the Roll-Up III Tones section on page

buttons. Four tones will sound

on

Units built before October 8, 2004, have serial Plug-N-Play

enabled for SuperSet Code

instead of

same settings, but Plug-N-Play is disabled.

. This SuperSet Code has the

. On these units, use

Page 12

The Roll-Up III12 The SuperSet Menu

Changing the Digitizer’s Orientation

The Roll-Up III lets you choose between two different digitizer orientations:

you can orient the digitizer with the controller Housing on your right (the

factory default), or you can orient it with the Housing on your left.

To change the orientation of the digitizer:

1 Turn the digitizer to the desired orientation.

2 Relocate the origin by clicking on the

Menu that is located in the lower left corner of the digitizer. You will

hear four short tones when you do this.

The orientation of the 20X24 Roll-Up III cannot be changed.

button on the SuperSet

Turning the Alarm Off and On

You can disable the alarm if you don’t want to hear a tone each time the

transducer button is pressed. When the alarm is off, you will still hear

diagnostic and menu-related tones.

To turn the alarm off and on:

Click on the

SuperSet Menu.

button – which toggles the tones on or off – on the

Page 13

RS232 Configurations

The following is relevant only for RS232 serial installations. USB

does not require configuration.

13The Roll-Up III

Configuring Your Roll-Up III for Specific Applications

To configure your Roll-Up III for use with specific applications:

1 In Table 1, find the application program you will be using with your

Roll-Up III. Note the corresponding SuperSet Code.

If your application program is not listed in Table 1, find the configuration settings in Table 2 that your application program requires and use the corresponding SuperSet Code.

If an appropriate SuperSet Code is not listed in Table 2, then use

the Custom Configuration Menu (see the Using the Custom Con-

figuration Menu section on page 26) to set up your Roll-Up III.

2 On the SuperSet Menu, click on the

digits of the SuperSet Code indicated for your application.

You will hear four short tones after a successful menu configuration.

Example: Configuring for a Specific Application

Suppose you wanted to configure your Roll-Up III to operate with

Autodesk’s AutoCAD application. You would:

1 Find the entry for AutoCAD in Table 1. The SuperSet Code is 01.

2 Click on the

short tone, indicating the digitizer is in Select Mode.

3 Click on the button on the SuperSet Menu. You will hear one

short tone. This enters the first digit of the SuperSet Code for

AutoCAD.

4 Click on the

digit of the SuperSet Code for AutoCAD.

You will hear four short tones, indicating that the configuration is complete. The Roll-Up III is now configured to operate with AutoCAD. Select

Mode is no longer active. You can begin digitizing.

button on the SuperSet Menu. You will hear one

button on the SuperSet Menu. This enters the second

button, then click on the two

For more information about

digitizer software application driver requirements,

please go to the

Technical Support section of the GTCO CalComp Web site.

Page 14

The Roll-Up III14 Table 1

Table 1: SuperSet Menu Codes for Selected Applications

SuperSet

Program Company Code

Access Bautech 39

Advanced Construction Estim. Software Shop Systems 28

A.G.E. CEIA, Inc. 75

AGTEK Earthwork Engineering (DOS) AGTEK Development Co. 09

APS Gunold & Stickma 52

ARC/CAD ESRI 01

ARC/INFO (DOS) ESRI 12

ARC/INFO ESRI 01

ARC/GIS ESRI 01

ARC/View ESRI 01

ARCT, ACA 47

ArenaSoft Estimating Arena Soft 01

ATLAS*DRAW low res Strategic Locations Planning 07

ATLAS*DRAW high res Strategic Locations Planning 08

ATLAS GIS Strategic Mapping 01

AutoCAD Autodesk, Inc. 01

Autodesk 3D Studio Autodesk, Inc. 01

AutoSketch Autodesk, Inc. 01

Autoship Coastdesign 01

Autoyacht Coastdesign 01

Autumn Zenographics 36

Batisoft 46

Best Est II Bird Construction Software 23

Bid Team Construction Data Control, Inc. 58

Bidpoint Vertigraph, Inc. 01

Bidworx for DOS Vertigraph, Inc. 31

Bidworx for Windows Vertigraph, Inc. 01

BP-340 Barudan America, Inc. 77

BuildNet Homesphere 09

Buildsoft Homesphere 09

BuildWare 1SqFt 01

BVH-Gregg Estimating BVH Gregg Incorporated 04

Cadkey low res Cadkey 18

Cadkey high res Cadkey 25

Callidus Oak Leaf Software 81

Calrson Takeoff Carlson Software 01

Carpet Estimating Systems Ramco 54

Civilcad Bloomfield Computer Services 03

CMS Estimating Contractor Management Systems 29

CNG Survey CNG Survey 05

Page 15

15The Roll-Up III Table 1

SuperSet

Program Company Code

Coastal Oceanographics 42

Cogo-PC Plus Civilsoft 01

COINS Estimating Shaker Computer & Management 41

Composer Gold Building Systems Design 42

Computer Methods Est. Computer Methods 45

Comquest Pinnacle Technology 38

Conception 3D Serbi 22

Construction Link The Construction Link 04

Contour Plus Civilsoft 01

Cost Engineer, The Cost Engineering Technologies 49

Counterpoint Counterpoint 04

CPS/SP Radian Corp. 34

Curve Digitizer West Coast Consultants 33

Cut & Fill (DOS) Paydirt Systems, Inc. 31

Cut & Fill/Precision (DOS) Paydirt/Timberline 42

Datacad Microtecture 14

DATAMINE Datamine International 82

Deed Mapping System US Soft Tech 13

DEEM Met-Coil, Ltd. 69

Design CAD American Small Business Computers 01

Designer Micrografix 02

DigiPlus Civilsoft 01

DigiPro Prosoft 66

Digitool Roctek Corp. 24

DigiWin Prosoft 68

DMS Premiere Tally Systems 57

DQ 2000 DQ Technologies, Inc. 85

DrawPlus Micrografix 02

Earth Graphics - Deluxe Earth Graphics 01

Earthwork Civilsoft 01

Earthwork 3D AGTEK Development Co. 01

Earthwork Estimating Ground Rules 01

Earthworks Tally Systems, Inc. 01

Earthworks (for Windows) Trakwear 01

-OREarthworks (for Windows) Trakwear 56

Easydij EJBIN#4 Geocomp, Ltd. 16

Easydij EJAF#2 Geocomp, Ltd. 35

Easydij EJBIN#30 Geocomp, Ltd. 19

Easy Cad Easy Cad 01

Eclare Prosoft, Inc. 66

Edge, The (DOS) Advanced Estimating 01

Page 16

The Roll-Up III16 Table 1

SuperSet

Program Company Code

Edge, The Advanced Estimating 01

Equinox Roctek Corp. 64

ESI 6000 Estimating System McCormick Systems 09

EST-Duct Estimating Technical Sales International 01

EST-Mechanical Technical Sales International 01

Estimagic Estimagic 63

Estimat-All Safeharbor Software, Inc. 54

Estimate Software Estimate Software 04

Estimation, Inc. (700 Series) Estimation, Inc. (Tradepower) 89

Estimation, Inc. (800 & Win Series) Estimation, Inc. (Tradepower) 88

Execucom Execucom Systems Corp. 36

Expose Roctek Corp. 64

Fastcad Evolution Computing 26

FastPIPE - Gold FastEST, Inc. 01

Floor Rite RFMS 01

GAP 01 GTCO CalComp 39

Gemini Excel 79

Generic CADD Generic Software, Inc. 01

Geoquest Softdesk 08

GM-SYS NW Geophysics Association, Inc. 13

GraphPlus Micrografix 02

GTCOTEST (default) GTCO CalComp 01

GTCO Wintab Driver GTCO CalComp 01

HALO products Media Cybermetics 13

Hotdij Geocomp, Ltd. 35

IBM GFIS IBM 55

Ice System, The (DOS) MC2 56

ICE 2000 MC2 01

IDRISI Clark University 74

IKE (DOS) Comput-Ability, Inc. 72

IKE Comput-Ability, Inc. 42

Imagine 8.X ERDAS, Inc. 61

Insite Earthwork Estimating Software Shop Systems 19

Insite 2 Software Shop Systems 28

Insite Sitework Insite Software 01

Insulcomp Technical Sales International 42

JAVA Jandel Scientific 24

Job Boss Small Systems Design, Inc. 39

Job Power Job Power 42

Page 17

17The Roll-Up III Table 1

SuperSet

Program Company Code

Kolvin Pro Damon, Inc. 01

Landmarke Cambridge Software, Inc. 23

Lasercad The Software Machine 01

Logdigi, Planimeter The Logic Group 12

Lumena Time Arts, Inc. 10

Mach Lite Ziatek, Inc. 04

Mach 2 Ziatek, Inc. 04

Mach 4 Ziatek, Inc. 83

MapGrafix Comgrafix, Inc. 02

Market America CACI 11

MasterBuilder (DOS) Intuit 86

MasterBuilder (2003, 2004) Intuit 01

Master Touch Integrated Measurement Systems 35

Measure Mate Measure Mate (Australia) 01

Measuremate/Measuring Calc. Paladin Measuring Systems 64

Measure Master Estimator’s Corner 51

Mechanical Construction Manager Mechanical Professional Services 73

Melco Melco 78

Metricom ADII Dynalog 71

Micromine Micromine Pty., Ltd. 27

Microstation PC Intergraph Corp. 09

MIKE (DOS) Comput-Ability, Inc. 68

MIKE Comput-Ability, Inc. 42

Mirage Zenographics 36

Molitors & Zimmer Molitors & Zimmer Estimating Syst. 67

NCE Estimator 2000 National Computer Est., Inc. 01

On Screen Take-Off OnCenter Software 01

Pagemaker Aldus Corp. 02

PAD ModaCAD 50

Paydirt Cross-Section (DOS) Spectra-Physics Laserplan, Inc. 31

Paydirt Roadwork (DOS) Spectra-Physics Laserplan, Inc. 31

Paydirt Sitework (DOS) Spectra-Physics Laserplan, Inc. 31

Paydirt Sitework Basic (DOS) Spectra-Physics Laserplan, Inc. 31

Paydirt Sitework 3.01 for Windows Spectra-Physics Laserplan, Inc. 05

Paydirt Sitework 3.2 for Windows Spectra-Physics Laserplan, Inc. 01

Paydirt Trimble Navigation 01

P-CAD Personal CAD Systems, Inc. 20

PC.BAT 46

Page 18

The Roll-Up III18 Table 1

SuperSet

Program Company Code

PC Paintbrush Z Soft 10

PC Paintbrush/Windows Z Soft 02

PC3D Jandel Scientific 24

PDS/SHADOW Polygon Software & Technologies 53

PG01 Hirsch International 22

Phoenix Estimator Phoenix Estimating 87

Picturemaker Cubicomp Corp. 15

Piping/DWV Estimating Esscomate 32

Polynest Polygon Software 40

Power Takeoff Ziatek, Inc. 04

Precision Estimating/Digitizer (DOS) Timberline Software 37

Precision Estimating/Digitizer Timberline Software 01

ProBid Promation 06

Procad Teksoft 13

Prodesign II American Small Bus. Comp., Inc. 01

ProEst Estimating Digitizer Takeoff CMS 04

ProExcel Excel 80

Professional Estimating Enterprise Computer Systems, Inc. 01

PTO CDCI 58

QED Roctek Corp. 64

Quest Earthwork Quest Solutions 01

Quest Estimator Quest Solutions 01

QuickBid OnCenter Software 01

QuickCalc Constructive Computing 58

QuickCALC - Windows Constructive Computing 01

QuickDirt Constructive Computing 23

QuickDirt - Windows Constructive Computing 01

QuickDirt II/QuickEst III Constructive Computing 58

QuickEst Constructive Computing 43

QuickEst - Windows Constructive Computing 01

QuickMeasure Tally Systems, Inc. 01

QuickPen AutoBid QuickPen International 04

QuickPen CAD QuickPen International 09

QuickPen Estimating QuickPen International 59

QuoteExpress Quote Software 01

Ramco Estimating System Ramco 54

Remodeling Estimator National Computer Estimating, Inc. 01

Right Hand Man Johnston & Associates, Inc. 04

Roadeng Softree Technical Systems, Inc. 27

Robocad, Robosolid RoboSystems International 21

Rock-it Ziatek 04

Roof Cad True North Estimating Systems 12

Page 19

Table 1

19The Roll-Up III

SuperSet

Program Company Code

Roof Estimator 3000 Essential Technology 65

SDP Civilsoft 01

Sheetmetal/Ductwork Esscomate 32

SigmaPlot Jandel Scientific 24

SigmaScan Jandel Scientific 24

SiteCalc Eagle Point 01

Smartcam Point Control Co. 17

Softplan Softdesk 08

Sonnet CAD Interworld Electronics 03

Sonnet Gap Interworld Electronics 20

Subway Roctek Corp. 64

Starbid Geac 29

Super-Duct, Super-Pipe Wendes Mechanical Consulting 48

Surpac Surpac Mining Systems 27

Takeoff 2000+ Comput-Ability 42

Takeoff Pro WinEstimator, Inc. 01

TakeoffTool US Cost 01

Terra Model (DOS) Plus 3 Software 09

Terramodel Trimble Navigation 01

Terrasoft Digital Resource Systems 01

Topographics IIID CEIA, Inc. 75

Tops II Digitizer Software Shop Systems 28

TOSCA Clark University 74

Tradesman Tradesman Software 01

Turbo Map CAD U.S. Softtech 01

Versacad Versacad Corp. 01

Vision Bidtek 70

Visual Takeoff + Comput-Ability, Inc. 42

Wall to Wall Estimator Ramco 11

WenDuct Takeoff Wendes Systems, Inc. 48

WenPipe Wendes Systems, Inc. 48

Wilcom Ltd. Wilcom Ltd. 76

Windows Microsoft 01

WinEst Pro & WinEst Pro Plus WinEstimator, Inc. 11

WinEx & WinEx Pro Roctek Corp. 01

WinMeasure DeLoach Corporation 01

WinScale Roctek Corp. 01

2D CAD West Coast Consultants 33

Page 20

Table 2

The Roll-Up III20

Table 2: Configuration Details for SuperSet Menu Codes

≈≈

Max

≈ 100 coordinates/second

≈≈

lpi = lines per inch lpmm = lines per millimeter

Code Commun. Output Options ASCII Options

01 9600,N,8,1 GTCO Binary, 1000 lpi, Cont Max

02 9600,N,8,1 GTCO Binary, 1000 lpi, Cont Incr

03 9600,N,8,1 GTCO Binary, 1000 lpi, Cont Max

04 9600,N,8,1 GTCO Binary, 1000 lpi, Point

05 9600,N,8,2 GTCO Binary, 1000 lpi, Cont 100

06 9600,N,8,1 GTCO Binary, 1000 lpi, Point

07 9600,N,8,1 GTCO Binary, 200 lpi, Cont 100

08 9600,N,8,1 GTCO Binary, 1000 lpi, Cont 100

09 9600,N,8,1 GTCO Binary, 1000 lpi, Cont 12

10 9600,N,8,1 GTCO Binary, 200 lpi, Cont Max

11 9600,N,8,1 GTCO Binary, 1000 lpi, Cont Max, Alarm

12 9600,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

13 9600,N,8,1 GTCO Binary, 1000 lpi, Cont 12

14 9600,N,8,1 GTCO Binary, 200 lpi, Cont 100

15 9600,N,8,2 GTCO Binary, 200 lpi, Cont 100

16 9600,E,7,1 GTCO Binary, 200 lpi, Point

17 9600,E,7,2 GTCO Binary, 200 lpi, Cont Max

18 9600,E,7,2 GTCO Binary, 200 lpi, Cont Max

19 9600,N,8,1 GTCO Binary, 1000 lpi, Point

20 1200,N,8,1 GTCO Binary, 1000 lpi, Cont 100

21 4800,N,8,1 GTCO Binary, 40 lpmm, Cont 12

22 4800,N,8,1 GTCO Binary, 1000 lpi, Cont Max

23 2400,N,8,1 GTCO Binary, 1000 lpi, Cont 12

24 9600,N,8,2 GTCO Binary, 1000 lpi, Cont Max

25 9600,N,8,2 GTCO Binary, 1000 lpi, Cont Max

26 9600,N,8,2 GTCO Binary, 200 lpi, Point

27 9600,N,8,1 GTCO ASCII, 40 lpmm, Point Pb, Sp, LF

28 4800,O,7,2 GTCO ASCII, 100 lpi, Point Sp, CR, LF

29 1200,O,7,2 GTCO ASCII, 1000 lpi, Point Pb, CR, LF

30 1200,N,8,1 GTCO Binary, 40 lpmm, Cont 12

31 9600,O,7,2 GTCO ASCII, 1000 lpi, Point Pb, CR, LF

32 9600,E,7,2 GTCO ASCII, 1000 lpi, Point Sp, CR

33 2400,E,7,1 GTCO ASCII, 100 lpi, Cont 12 Pb, Sp, CR, LF

34 9600,E,7,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

35 9600,E,7,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

Page 21

Table 2

21The Roll-Up III

Code Commun. Output Options ASCII Options

36 9600,E,7,1 GTCO ASCII, 1000 lpi, Cont 12 Sp, CR, LF

37 2400,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

38 2400,E,7,2 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

39 1200,O,7,1 GTCO ASCII, 1000 lpi, Cont 12 Pb, CR

40 1200,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

41 9600,E,7,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR

42 9600,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

43 1200,E,7,1 GTCO ASCII, 1000 lpi, Point, Alarm Pb, Sp, CR

44 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont 12, Alarm Pb, Sp, CR, LF

45 9600,N,8,2 GTCO ASCII, 100 lpi, Point, Alarm Pb, CR, LF

46 9600,E,7,2 GTCO Binary, 1000 lpi, Cont 100

47 9600,O,7,2 GTCO ASCII, 1000 lpi, Cont 100 Pb, CR

48 9600,E,7,1 GTCO ASCII, 1000 lpi, Point CR, LF

49 1200,E,7,1 GTCO ASCII, 1000 lpi, Cont 12 Pb, CR

50 9600,E,8,1 GTCO ASCII, 40 lpmm, Point, Alarm Pb, Sp, CR, LF

51 1200,N,7,2 GTCO ASCII, 1000 lpi, Point Pb, CR, LF

52 9600,E,8,1 GTCO Binary, 1000 lpi, Cont 100, Alarm

53 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont Max Pb, CR

54 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont 12 Pb, CR

55 9600,O,7,2 GTCO ASCII, 1000 lpi, Cont Max, Alarm Pb, CR

56 9600,E,7,2 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

57 9600,O,7,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

58 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont 12 Pb, CR, LF

59 1200,E,7,1 GTCO ASCII, 1000 lpi, Point, Alarm Pb, Sp, CR

60 9600,O,7,1 GTCO ASCII, 1000 lpi, Point, Alarm Pb

61 4800,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, CR, LF

62 2400,N,8,1 GTCO ASCII, 1000 lpi, Cont 12 Pb, CR, LF

63 1200,O,7,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

64 9600,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

65 2400,N,8,1 GTCO Binary, 1000 lpi, Cont 100

66 9600,O,7,2 GTCO ASCII, 1000 lpi, Point Pb, Sp, CR, LF

67 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont 12, Alarm Pb, CR

68 9600,O,7,2 GTCO ASCII, 100 lpi, Point Pb, Sp, CR, LF

69 9600,E,7,1 GTCO ASCII, 40 lpmm, Point CR, LF

70 1200,N,8,1 GTCO ASCII, 100 lpi, Point, Max, Alarm Sp, CR

Page 22

Table 2

The Roll-Up III22

Code Commun. Output Options ASCII Options

71 9600,N,8,1 GTCO Binary, 40 lpmm, Cont

72 1200,O,7,2 GTCO ASCII, 100 lpi, Point Pb, Sp, CR, LF

73 9600,N,8,1 GTCO ASCII, 1000 lpi, Point CR, LF

74 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont 100, Alarm Pb, Sp, CR, LF

75 9600,N,8,1 Calcomp ASCII 3, 1000 lpi, Point CR

76 9600,N,8,1 Summa ASCII 2, 10 lpmm, Point CR

77 9600,N,8,1 Summa ASCII 2, 10 lpmm, Cont 100 CR

78 2400,N,8,1 Summa Binary, 10 lpmm, Point

79 9600,O,7,2 Summa ASCII 1, 10 lpmm, Cont 100 LF

80 9600,O,8,1 Summa Binary, 10 lpmm, Point, Alarm

81 9600,E,7,2 Summa ASCII UIOF, 40 lpmm, Point CR, LF, Decimal

82 9600,N,8,1 GTCO ASCII, 1000 lpi, Point, Max, Alarm Pb, Sp, CR, LF

83 9600,N,8,1 GTCO ASCII, 1000 lpi, Cont Incr Pb, Sp, CR

84 9600,N,8,1 GTCO ASCII, 1000 lpi, Point Pb, LF

85 9600,N,8,1 Summa ASCII UIOF, 1000 lpi, Point Pb, LF

86

*Special

87 *Special

88 *Special

89 *Special

90-98 User configuration storage locations

99 9600,N,8,1 GTCO Binary, 1000 lpi, Cont Max

*86-89 require special firmware to activate.

Page 23

Alarm Tones

Roll-Up III Tones

The Roll-Up III produces an alarm in the form of audio tones to inform

you of various events. The table below describes the kinds of tones you

might hear while operating the digitizer.

Table 3: Roll-Up Tones

Length Number of times Meaning

Short Four at power up Diagnostics passed

Short Four Successful end of menu mode

Short Once Transducer switch pressed, if the

alarm tone is enabled

Short, Continuously Transducer not attached

once per second

Medium Three Menu mode aborted

Medium Three at power up Configuration error*

Medium, Continuously Configuration Menu mode;

once per second waiting for Alignment Point 1

Short, Continuously Configuration Menu mode;

twice per second waiting for Alignment Point 2

Long, once per second, Eight long beeps, Grid disconnected*

followed by short followed by four short

Continuously on At power up Diagnostics failed*

23The Roll-Up III

Short = 1/16 second Medium = 1/4 second Long = 1/2 second

*Configuration error tones, Grid disconnected tone, or Diagnostics failed

tones indicate a serious problem. If you hear any of these tones, call GTCO

CalComp Technical Support at 410.312.9221.

You might hear tones produced by the Roll-Up III which are

actually sent by your application program. (Programs can send

commands to the digitizer to turn the audio tone generator on

and off.) If you hear tones during digitizing, and they don’t

correspond to the tones listed in the table above, they are

produced by the application program.

Page 24

The Custom Configuration Menu

This information applies to serial installations only.

The Roll-Up III24

Introduction to the

Custom Configuration Menu

The Custom Configuration Menu is used to relay configuration information to the Roll-Up III in those cases where Table 1 and Table 2 do not

supply that information or a SuperSet Menu Code for the graphic application software you are using. You will use the Custom Configuration Menu

to configure the Roll-Up III for a specific baud rate, data format and other

operating characteristics that your software requires for communication

with the digitizer. The Custom Configuration Menu is located in the slot

at the end of the Roll-Up III housing.

The configuration parameters for the Roll-Up III are divided into three

categories:

Communication Options

Output Format Options

Mode Options

Communication Options

Baud The rate, in bits/second, at which characters are transmitted

across the RS232C serial interface. Choices are: 1200, 2400, 4800,

9600, 19200, or 38400.

Data Bits Data bits represent the actual data being sent from one

device to another. Both devices must be set for the same number of

data bits. Choices are: Seven (7), or Eight (8).

Stop Bits Each character has one or two stop bits, which tell the

receiving device that a character is complete. The number of stop bits

usually does not matter. Setting for two stop bits instead of one may

overcome a mismatch in parity or data bits. Choices are: One (1), or

Two (2).

Parity One bit can be allocated for parity (parity is a simple errordetecting scheme). Both devices (sending and receiving) must be set

for the same parity—either odd parity, or even parity—-or they must be

set for no parity. Choices are: None (N), Even (E), or Odd (O).

Output Format Options

GTCO Selects GTCO-compatible formats. See Advanced Programming Information in the Roll-Up III Online Help for greater detail on

GTCO format structure. Choices are: Binary, or ASCII.

Page 25

The Custom Configuration Menu

CalComp Selects CalComp-compatible formats. See Advanced

Programming Information in the Roll-Up III Online Help for greater

detail on CalComp format structure. Choices are: Binary, ASCII 1,

ASCII 2, ASCII 3, or ASCII 4.

Summa Selects Summagraphics-compatible formats. See Advanced

Programming Information in the Roll-Up III Online Help for greater

detail on Summagraphic format structure. Choices are: Binary, or

ASCII.

ASCII formats can be modified by including, or excluding, a button code,

space, decimal point, carriage return, or line feed, depending on whether

GTCO, CalComp, or Summa formats have been selected.

Button Defines whether the Pushbutton (Pb) value is included in the

ASCII output report. This option is available only with GTCO formats.

Choices are: Include, or Exclude.

Space Defines whether the Space (Sp) character (hex 20) is included

in the ASCII output report as a delimiter between the X and Y coordinate values. This option is available only in GTCO formats. Choices

are: Include, or Exclude.

25The Roll-Up III

Decimal Defines whether the period character (hex 2E) is included

in the ASCII output report between the units and tenths digits. This

option is available only in Summagraphics formats. Choices are:

Include, or Exclude.

Return Defines whether the Carriage Return (CR) character (hex 0D)

is included in the ASCII output report as a terminator. This option is

available in GTCO and Summagraphics formats. Choices are: Include,

or Exclude.

Line Feed Defines whether the Line Feed (LF) character (hex 0A) is

included in the ASCII output report as a terminator. This option is

available in GTCO, CalComp and Summagraphics formats. Choices

are: Include, or Exclude.

Mode Options

Mode Defines how output reports are sent from the digitizer.

Choices are: Point, Line, Continuous, Line Incremental, or

Continuous Incremental.

Rate Determines how fast output reports will be transmitted from

the digitizer. Choices are: 12, 50, or 100 reports per second.

Resolution The smallest reported value returned by the digitizer.

Choices are: 1000 lpi, 2000 lpi, 4000 lpi, 40 lpmm, 100 lpmm, or 150

lpmm.

See the Advanced Programming Information section in the Roll-Up III

Online Help at www.gtcocalcomp.com for more details.

Page 26

The Custom Configuration Menu

The Roll-Up III26

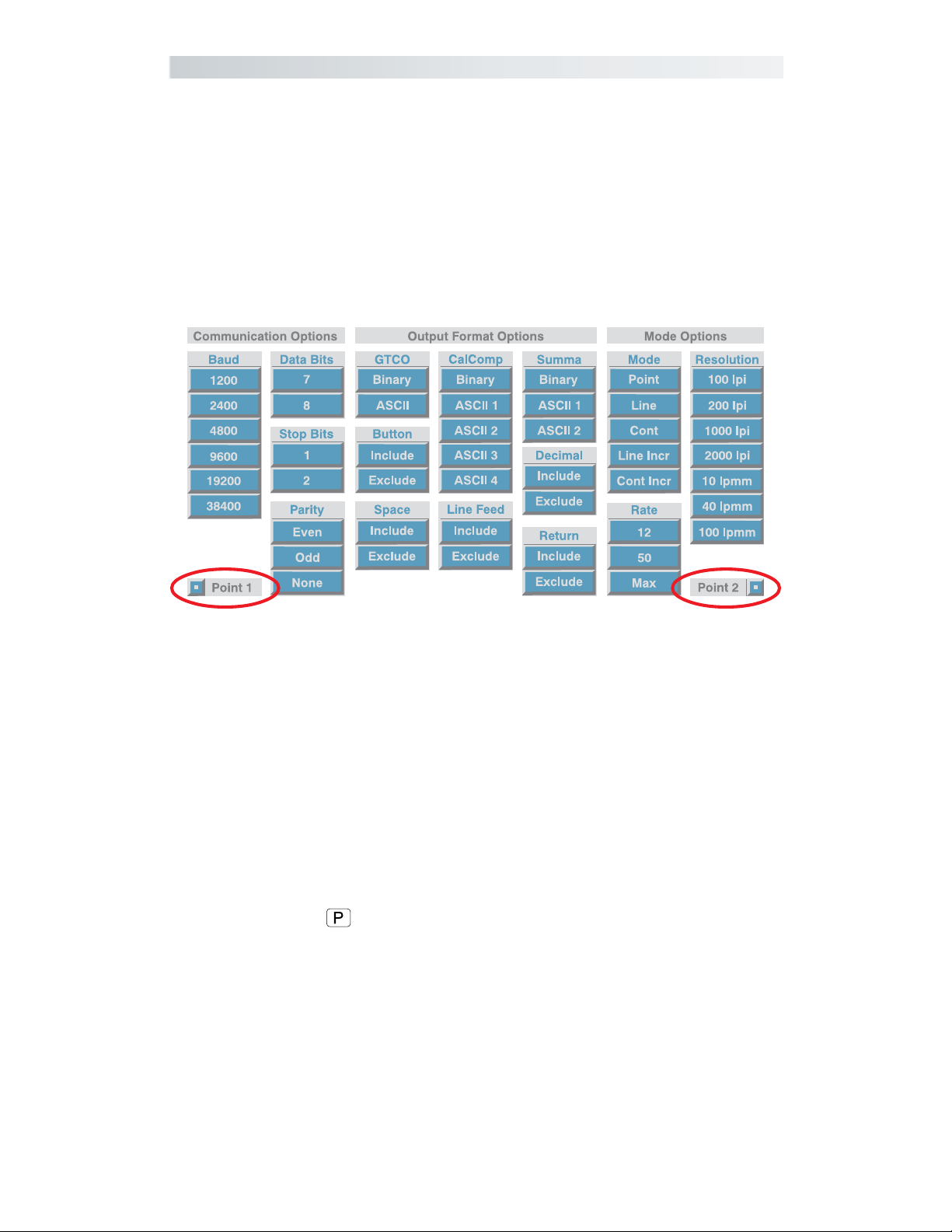

Using the Custom Configuration Menu

If your application is not represented in the SuperSet Menu and does not

have a SuperSet Code, or if a different configuration is required, you can

use the Custom Configuration Menu to configure the Roll-Up III. The

Custom Configuration Menu, pictured here, is stored in the slot at the

end of the Roll-Up III housing. The Custom Configuration Menu replaces

the 24 switches that were associated with older GTCO digitizers.

Custom Configuration Menu Alignment Points

The configurations you set up can be stored for recall at a later time in

any of the nine user-definable SuperSet Menu locations—codes 90

through 98. This allows the Roll-Up III configuration to be easily switched

between applications, when you have such a requirement.

To configure the Roll-Up III using the Custom Configuration Menu:

1 Place the Custom Configuration Menu card, or the copy, anywhere in

the active area of the digitizer. The entire menu must be in the active

area. A piece of tape can be used to keep it in place during the configuration process.

2 Click on the

slowly, indicating that the Custom Configuration Menu Mode is now

ready to receive Alignment Point information.

3 You will tell the Controller where the Custom Configuration Menu is

physically located on the digitizer by clicking on the Alignment Points.

Click on Alignment Point 1, the white dot in the small blue square

labeled Point 1, in the lower left corner of the menu. The alarm will

beep rapidly, indicating that the system is waiting to receive Alignment Point 2.

button on the SuperSet Menu. The alarm will beep

4 Click on Alignment Point 2, the white dot in the small blue square

labeled Point 2, in the lower right corner of the menu. After Alignment

Page 27

The Custom Configuration Menu

27The Roll-Up III

Point 2 is selected, the alarm will sound only if the transducer passes

over an active block on the menu.

If invalid alignment points are selected, or if the menu is not

entirely in the digitizer’s active area, the Custom Configuration

Menu Mode will be aborted. This is indicated by three medium

tones from the alarm.

5 Configure the Roll-Up III by selecting the function blocks that corre-

spond to the settings your software will need to communicate with

the digitizer.

6 Review the configuration to ensure that the proper settings have been

selected. Pass the transducer down each group of options; the alarm

will sound when the transducer is over the active choice. Some

groups may be inactive, based on the options selected. Click on a

desired setting in a group to change it. To cancel all settings, click in

the active area outside the menu.

7 When you have finished making your selections, you can save the

configuration. If you choose to save it temporarily, the configuration

will be remembered only until another SuperSet Code is entered. If

you never change the configuration of your Roll-Up III from the custom one you just entered, the temporary configuration will always be

used. However, if you expect to be switching between configurations

and want to save the custom one for later recall, you can assign the

configuration to a special user-definable SuperSet Code.

To save the configuration temporarily:

Click on the button on the SuperSet Menu. You will hear four

short tones to indicate you successfully saved the custom configuration. The configuration is saved in a temporary location, where it

will be retained even when the unit is powered off or reset. However, if another SuperSet Code is entered, this temporary configuration is lost and cannot be recalled without configuring the RollUp III again.

To save the configuration in a user-definable location:

As indicated in Table 2, the codes 90 through 98 are available as

storage locations for user-defined custom configurations. Simply

click on the

90 and 98. Your custom configuration will be saved under that

code number for future recall. You will hear four short tones when

you successfully save the custom configuration. Saved configurations allow you to switch quickly between applications. Storage

locations 90 through 98 retain the saved configurations even when

the Roll-Up III is turned off or reset.

button and click on a two-digit number between

Page 28

Care and Handling

The Roll-Up III28

Care and Handling of Roll-Up III

The Roll-Up III was designed to be both portable and durable. As with any

product, it requires proper care and handling for reliable operation. By

following these recommendations, your Roll-Up III digitizer will provide

you with many years of service:

Always use the Roll-Up III on a flat surface, where no part of the unit is

unsupported.

Before moving the digitizer, disconnect the transducer, interface

cable, and power supply, if connected.

Before moving the digitizer, roll it up. The housing along the side of

the digitizer is designed as a rolling aid and it allows you to easily

control the rolling action. (See the Transporting Roll-Up III section on

the next page for specific moving instructions.)

Don’t permanently attach anything to the digitizer.

Don’t use sharp instruments on or near the Roll-Up III to avoid

scratching or cutting it. Cuts in the digitizer will void your warranty.

Don’t crease, dent, or abuse the digitizer. Creases can damage the

digitizer structure. Severe creases or abuse will void your warranty.

Clean your Roll-Up III with any mild, nonabrasive household cleaner.

Rubbing alcohol is recommended. Do not apply liquid directly to the

surface of the Roll-Up III. Spray the cleaning solution on a cloth and

wipe it over the surface. After cleaning, dry the surface to avoid

possible digitizing errors.

Page 29

Transporting Roll-Up III

You must transport your Roll-Up III using the factory-supplied shipping

materials—heavy gauge cardboard tube, insert and end caps. Failure to do

so could result in serious damage to the unit and may void your warranty.

1 Disconnect the transducer and interface cable from the Roll-Up III and

the computer. Remove all material from the digitizer.

2 Grasp the controller housing firmly with both hands and roll it toward

the opposite side of the digitizer. The housing and the printing on the

digitizer surface must be on the inside of the roll. The roll diameter

should be just smaller than the inside diameter of the factory-supplied

shipping tube. When correctly rolled, only the digitizer’s black back

will be exposed.

Do not roll the Roll-Up III too tightly. Rolling too tightly

could damage the electronic grid.

29The Roll-Up III Transporting

3 Insert the rolled digitizer into the shipping tube and allow it to fully

unroll against the inside of the tube. Place the factory-supplied insert

into the center of the rolled digitizer for support.

4 Place the accessories in the accessory case and put it inside the

hollow insert. Place the factory-supplied end caps on the tube to seal

it. Place the tube in the optional Deluxe Travel Bag.

The Deluxe Travel Bag is intended to be used only in

conjunction with the factory-supplied heavy gauge cardboard

tube, insert and end caps. The Deluxe Travel Bag does not

provide complete protection if used alone. The product will

be subject to damage not covered by the warranty, if not

protected by the tube, insert and end caps. If you have misplaced or disposed of these items, contact GTCO CalComp

(410.381.6688) for replacements.

Page 30

The Roll-Up III30 Troubleshooting Guide

Troubleshooting Guide

As with any computer peripheral, Roll-Up III problems sometimes do

occur. Most of these problems are easy to find and correct. This troubleshooting guide provides clear instructions for finding and solving all

common digitizer problems. In most cases, you will be able to quickly

take care of the problem yourself by following these steps:

1 Install properly first.

This troubleshooting guide assumes you have already correctly installed

your Roll-Up III according to the detailed instructions in the Setting Up

Your Roll-Up III section. If you have not followed the step-by-step instructions in that section, do so now.

2 Work through the troubleshooting flowcharts on the following

pages in this troubleshooting guide.

Record any unusual observations. Your notes will be useful if you need

assistance from GTCO CalComp later.

3 If your system still doesn’t work...

Call our Technical Support Department at 410.312.9221. Be prepared to

discuss the observations you made while troubleshooting. A Technical

Support Specialist will help you resolve the problem as quickly as possible.

Refer to the Roll-Up III Tones table on page 23, while using this

Troubleshooting Guide.

If you are experiencing erratic behavior with your digitizer, make sure

that no conductive materials are being used. This includes the graphite in

pencil lead, some black plotter ink, and digitizing on plastic or Mylar. No

electronic devices should be sitting on or near the digitizer, including

keyboards, mice, calculators, etc. If any of these describes normal working

conditions, the Super L Series Digitizers would be more suited to your

environment.

Tablet Not Found: If you are using a USB connection and the

digitizer is not found, either disconnect and reconnect the USB

cable, or restart the system.

Load Driver: If a window pops up telling you to load a driver

every time you power-on, and your application software doesn’t

use a driver, you should change the power-on default SuperSet

Code to

, or load the driver from the TabletWorks CD.

Page 31

Troubleshooting Guide

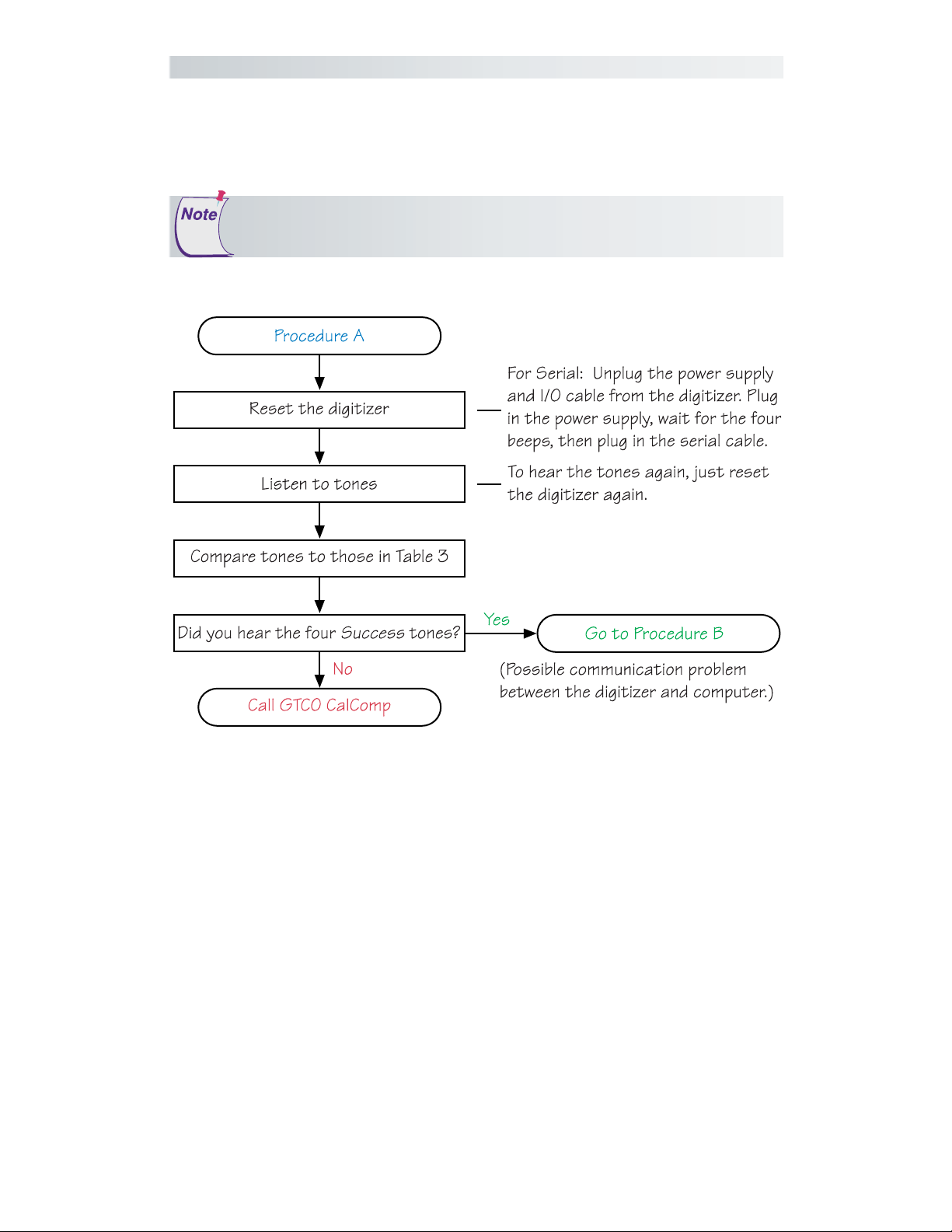

Procedure A: Begin Troubleshooting

This procedure should only be used to troubleshoot serial connections.

31The Roll-Up III

Page 32

Troubleshooting

Procedure B: Troubleshooting

The Roll-Up III32

Page 33

33The Roll-Up III

This page left blank intentionally.

Page 34

The Tablet Configuration Utilities

The Roll-Up III34

Using the Tablet Configuration Utilities

If your application is not represented in the SuperSet Menu and does not

have a SuperSet Code, or if a different configuration is required, you can

use the Tablet Configuration Utilities to configure the Roll-Up III. The

Tablet Configuration Utilities replace the 24 switches that were associated

with older GTCO digitizers and the Custom Configuration Menu Card

used with the Roll-Up II.

To configure the Roll-Up III with the Tablet Configuration Utilities:

1 Make sure the Roll-Up III is plugged into a Serial Port, powered On,

and all the tablet drivers have been uninstalled or disabled.

2 Install the Tablet Configuration Utilities from the Select Utility Software

to Install section on the TabletWorks CD, or download them from

www.gtcocalcomp.com.

3 After the installation has completed, run the Tablet Configuration

Utilities from the Programs list under GTCO CalComp TCU.

4 The Tablet Configuration Utilities will begin searching the Serial Ports

for a supported tablet.

a) If the tablet is found, information about the tablet will display

under Device Info near the bottom of the screen.

b) If the tablet is not found, a message will appear under Device Info

near the bottom of the screen.

i) If Wintab files were found, it is possible that the TabletWorks)

driver has the Serial Port open.

ii) If the Serial Port is open by another application, it will not be

displayed under System Info. Close any application, or uninstall

any driver that is using the Serial Port and select Refresh System

Info from the File drop-down list at the top of the screen. Click

on the Serial Port icon under System Info to search that Serial

Port.

The Tablet Configuration Utilities can use the TabletWorks driver

to test the tablet, but it must be communicating directly with the

tablet, via the Serial Port, in order to configure it.

5 Once the Roll-Up III has been found on a Serial Port, select Advanced

Configuration from the Options drop-down list at the top of the

screen.

a) If Advanced Configuration is not an option, make sure Wintab

Compatible Driver is not listed under Device Info.

Page 35

The Tablet Configuration Utilities

6 Select a predefined, 01 through 55, SuperSet Code, or select one of

the User Defined, 90 through 98, SuperSet Codes to customize.

a) User Defined (90 through 98) SuperSet Codes are initially read

from the tablet when the Advanced Configuration screen opens.

This is to prevent loss of custom settings. Selecting Read Current

Settings from the Options menu will:

i) Read the Power-Up settings and User Defined SuperSet Codes

from the tablet.

ii) Overwrite all Custom Settings not yet saved to the tablet.

b) Restore Factory Settings from the Options menu will prompt for:

i) Power-Up settings reset to factory default and set current.

ii) User Defined SuperSet Codes cleared and reset to factory

default.

7 After making your selections, choose one of the following from the

File menu at the top of the screen.

35The Roll-Up III

a) Save Temporary Settings will configure the tablet as shown until

the tablet is powered off, reset, or another SuperSet Code is

selected.

i) After saving temporary settings, select File/Exit to test with

other applications. This will leave the tablet configured to the

temporary settings selected and close the Serial Port, enabling

other applications to communicate with the tablet.

b) Save Power-Up Settings will configure the tablet as shown. Every

time the tablet is powered off and back on, or reset, it will restore

these settings.

c) Save Custom Settings will reconfigure all nine of the tablet’s User

Defined SuperSet Codes to the settings specified in the corresponding SuperSet Code drop-down list.

i) You can click on the SuperSet Menu buttons on the tablet

using the tablet’s cursor to activate these configurations:

S plus 90 through 98.

8 When you have finished, select Exit or Close from the File menu.

a) Exit will close the Tablet Configuration Utilities.

b) Close will exit the Advanced Configuration Screen and return to

the Tablet Configuration Utilities window.

Page 36

Regulatory Statements

The Roll-Up III36

Regulatory Statements and Warranty

Radio and Television Interference

The user is cautioned that any changes or modifications not expressly

approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This equipment has been tested and found to comply with the limits of a

Class B digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee the interference will

not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna

Increase the separation between the equipment and the receiver

Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

Reorient or coil cables.

Consult the dealer or an experienced Radio/TV technician for help.

Any cables the user adds to the device must be shielded to

be in compliance with the FCC standards. Any unauthorized modification to this device could result in the revocation of the end user’s authority to operate this device.

Canada

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus as set out in the radio interference

regulations of the Canadian Department of Communications.

Le present appareil numérique n’emet pas bruits radioelectriques depassant

les limites applicables aux appareils numériques de Classe B prescrites dans

le réglement sur le brouillage radioelectrique edicte par le Ministere des

Communications du Canada.

Page 37

Declaration of Conformity

The “CE” mark on this device indicates compliance under the EMC 89/

336/EEC Directive.

Declaration of conformity according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: GTCO CalComp, Inc.

Manufacturer’s Address: 7125 Riverwood Drive

Columbia, MD 21046

U.S.A.

Importer’s Name: GTCO CalComp GmbH

Importer’s Address: Kreiller Strasse 24

Munich 81673

Germany

declares, that the product

37The Roll-Up III Declaration of Conformity

Product Name: Roll-Up III Digitizer

Model Numbers: RUD3-2024, RUD3-3036, RUD3-3648

Product Options: All

conforms to the following product specifications:

Safety: EN60950-1:2001, IEC60950:2001 IEC60950:1999-04

UL60950-1/CSA-C22.2 NO.60950-1-03

EMC: EN55022:1998, A1:2000 A2:2003

EMI: EN55024:1998, A1:2000 A2:2003

EN 61000-3-2 Harmonic Current Emissions

EN 61000-3-3 Voltage Fluctuations and Flicker

EN 61000-4-2; Direct ESD/Indirect ESD

EN 61000-4-3; Radiated Susceptibility:

EN 61000-4-4; Electrical Fast Transients:

EN 61000-4-5; Surge:

EN 61000-4-6; Conducted RF:

EN 61000-4-8; Magnetic Field:

EN 61000-4-11; Voltage Dips and Interruptions:

RoHS: “-R” labelled products conform to DIRECTIVE

2002/95/EC. These products are RoHS-compliant.

following the provisions of Council Directive 89/336/EEC (EMC Directive)

and Couuncil Directive 73/23/EEC (Low Voltage Directive) where applicable.

Scottsdale, Arizona, U.S.A. 6-15-2004 Dana Doubrava

Location Date Engineering Manager

Page 38

Japan

Bescheinigung des Herstellers/Importeurs

Heirmit wird bescheinigt, dass der/die/das

3036R

The Roll-Up III38 Regulatory Statements

(Geraet, Typ, Bezeichnung)

im Uebereinstimmung mit den Bestimmungen der

Vfg 1046/1984

(Amtsblattverfuegung)

Funk-Entstort ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses Geraetes

angezeigt und die Berechtigung zur Ueberpruefung der Serie auf

Einhaltung der Bestimmungen eingeraumt.

GTCO CalComp, Inc.

(Name des Herstellers/Importeurs)

Dieses Geraet wurde einzeln sowohl als auch in einer Anlage, die einen

normalen Anwendungsfall nachbildet, auf die Einhaltung der Funkentstoerbestimmungen geprueft. Es ist jodoch moeglich, dass die Funkentstoerbestimmungen unter unguenstigen Umstaenden bei anderen

Geraetekombinationen nicht eingehalten werden. Fuer die Einhaltung

der Funk-entstoerbestimmungen seiner gesamten Anlage, in der dieses

Geraet betrieben wird, ist der Betrieber verantwortlich.

Einhaltung mit betreffenden Bestimmungen kommt darauf an, dass

geschirmte Ausfuhrungen gebraucht werden. Fuer die beschaffung

richtiger Ausfuhrungen ist der Betrieber verantwirtlich.

Page 39

39The Roll-Up III European Union Directives

European Union Emission Directive

This product is in conformity with the protection requirements of EU

Council Directive 89/366/ECC on the approximation of the laws of the

Member States relating to electromagnetic compatibility.

This product has been tested and found to comply with the limits for

Class B Information Technology Equipment according to CISPR 22/

European Standard EN55022. The limits for Class B equipment were

derived for typical industrial environments to provide reasonable protection against interference with licensed communication devices.

European Union WEEE Directive

The manufacture of this equipment required the extraction and use of

natural resources. It may contain hazardous substances that could impact

health and the environment.

• In order to avoid the dissemination of the hazardous substances into

the environment and to diminish the pressure on our natural resources, we encourage you to return this product to the appropriate

take-back system facility. These facilities reuse or recycle most of the

materials in this equipment in a responsible way.

• The crossed-out wheeled bin symbol below invites you to use these

take-back systems.

• If you need more information about the collection, reuse and recycling systems in your area, please contact your local or regional waste

authority.

• Further information about the responsible end-of-life management of

this and other GTCO CalComp products is available on our Web

site at www.gtcocalcomp.com.

European Contact:

GTCO CalComp GmbH

Kreiller Strasse 24

81673 Munich

Germany

Tel: + 49 (0) 89 370012-0

Fax: + 49 (0) 89 370012-12

Page 40

Warranty

The Roll-Up III40

Limited Warranty for the Roll-Up III

GTCO CalComp, Inc. warrants these products to be free from defects in material and workmanship

under the following terms. Complete and return the enclosed warranty registration card to ensure that

your products are covered with this warranty.

Coverage

Parts and labor are warranted for two (2) years from the date of the first consumer purchase for the

digitizer tablet, controller, transducers, and tablet accessories. Power supply and cables are warranted

for one (1) year. This warranty applies to the original consumer purchaser only.

Within the European Union, the warranty period is two (2) years, as mandated by the EU. Contact your

local dealer or distributor for additional warranty information.

Warranty is only valid if original consumer’s purchase or lease date is less than or equal to six months

from the original GTCO CalComp sale date. This information will be captured by the system serial

number and confirmed by the reseller’s purchase order.

A nominal Warranty Handling Fee will be charged after the first year of use and calculated from the

date of original consumer purchase. This payment may be made by Visa, MasterCard or American

Express. A copy of the sales receipt or invoice will be required for warranty verification.

Conditions

Except as specified below, this warranty covers all defects in material or workmanship in the products.

The following are not covered by the warranty:

1 Any product on which the serial number has been defaced, modified or removed (if applicable).

2 Damage, deterioration or malfunction resulting from:

a Accident, misuse, abuse, neglect, fire, water, lightening or other acts of nature, unauthorized

modification for any purpose, unauthorized product modification, or failure to follow

instructions supplied with the product.

b Repair or attempted repair by anyone not authorized by GTCO CalComp.

c Any damage in shipment of the product (claims must be presented to the carrier).

d Any other cause which does not relate to a manufacturing defect.

3 Any product not sold or leased to a consumer within six months of GTCO CALCOMP’s original

sale date.

GTCO CalComp will pay all labor and material expenses for covered items, but we will not pay for the

following:

1 Removal or installation charges.

2 Costs for initial technical adjustments (set up), including adjustment of user controls.

3 Certain shipping charges. (Payment of shipping charges is discussed in the next section of this

warranty.)

4 Packaging costs. (Customers should keep their boxes.)

Warranty Service Procedures

1 To obtain service on your GTCO CalComp product, contact the Technical Support Department to

receive a Return Material Authorization Number (RMA#) and shipping instructions by calling:

In United States: (425) 223-4311 (PST)

In Europe: +49 (0) 89 370012-0 (CET)

2 Ship the product to GTCO CalComp with the RMA# marked clearly on the outside of the box.

Without a clearly marked RMA# on the shipping box, GTCO CalComp reserves the right to refuse

shipment.

3 Although you must pay any shipping charges to ship the product to GTCO CalComp for warranty

service, GTCO CalComp will pay the return shipping charges for ground shipment. Other shipping

options are available at an additional fee.

4 Whenever warranty service is required, the original dated sales invoice (or a copy) must be

presented as proof of warranty coverage, and should be included in shipment of the product.

Please also include your name, address, telephone number, fax number, email address, and a

description of the problem.

5 If GTCO CalComp determines that the unit is not defective within the terms of the warranty, the

consumer shall pay the cost of all freight charges, as well as any repair charges.

Technical Support

Web-based Technical Support is available free of charge at:

driver releases, as well as comprehensive technical support, troubleshooting, Technical Bulletins and

www.gtcocalcomp.ca, where current

Page 41

Warranty

FAQs can be found.

Please contact our Technical Support Department:

In United States: (425) 223-4311 (PST)

In Europe: +49 (0) 89 370012-0 (CET)

You can also fax your request to:

In United States: (425) 223-4311 (PST)

In Europe: +49 (0) 89 370012-12 (CET)

Disclaimer of Unstated Warranties

The warranty printed above is the only warranty applicable to this purchase. ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

DISCLAIMED. Assuming the warranty above stated is otherwise applicable, it is expressly understood

and agreed that GTCO CalComp’s sole liability whether in contract, tort, under any warranty, in

negligence or otherwise shall be for the repair or replacement of the defective parts and under no

circumstances shall GTCO CalComp be liable for special, indirect or consequential damages. The price

stated and paid for the equipment is a consideration in limiting GTCO CalComp’s liability.

Notice

Some states and provinces do not allow the exclusion or limitation of incidental or consequential

damages, so the above exclusion may not apply to you. This warranty gives you specific legal rights,

and you may have other rights, which vary from state to state, or province to province.

To obtain service on your GTCO CalComp product, call our Technical Support Department at (425)223-4311

(PST), or fax us at (877) FAX-IECI (PST); in Europe call +49 (0) 89 370012-0 (CET), or fax us

at +49 (0) 89 370012-12 (CET).

We can also be contacted through our Web site at

www.gtcocalcomp.ca.

41The Roll-Up III

Important! All products returned to GTCO CalComp for service must have prior approval in the form

of a Return Merchandise Number (RMA#), which can be obtained by calling the Technical Support

Department.

Page 42

The Roll-Up III42

Corporate Headquarters

7125 Riverwood Drive

Columbia, Maryland 21046

Tel: 425.223.4311

Support: 425.223.4311

Sales: 877.902.2979

Fax: 877.FAX.IECI

www.gtcocalcomp.ca

Support:

European Headquarters

GTCO CalComp GmbH

Kreiller Strasse 24

81673 Munich

Germany

Tel: + 49 (0) 89 370012-0

Fax: + 49 (0) 89 370012-12

425.223.4311

TM

ROLL-UP III

Copyright© 2008 GTCO CalComp, Inc.

Roll-Up III is a trademark of GTCO CalComp, Inc.

All other products and company names are the trade-

marks or registered trademarks of their

respective owners.

The information contained in this document is subject to change

without notice. GTCO CalComp assumes no responsibility for technical,

or editorial errors, or omissions that may appear in this document, or

for the use of this material. Nor does GTCO CalComp make any

commitment to update the information contained in this document.

This document contains proprietary information which is protected

by copyright. All rights reserved. No part of this document can be

photocopied or reproduced in any form without the prior, written

consent of GTCO CalComp, Inc.

37-00811-01 Rev. G

Loading...

Loading...