Page 1

Roll-Up II 1

Standard Operating Information

Parts Checklist

Introduction

What You Need to Use Roll-Up II

Care and Handling

Transporting the Roll-Up II

Installing the Roll-Up II

Using the SuperSet Menu

Changing the Tablet’s Orientation

Configuring for Specific Application Programs

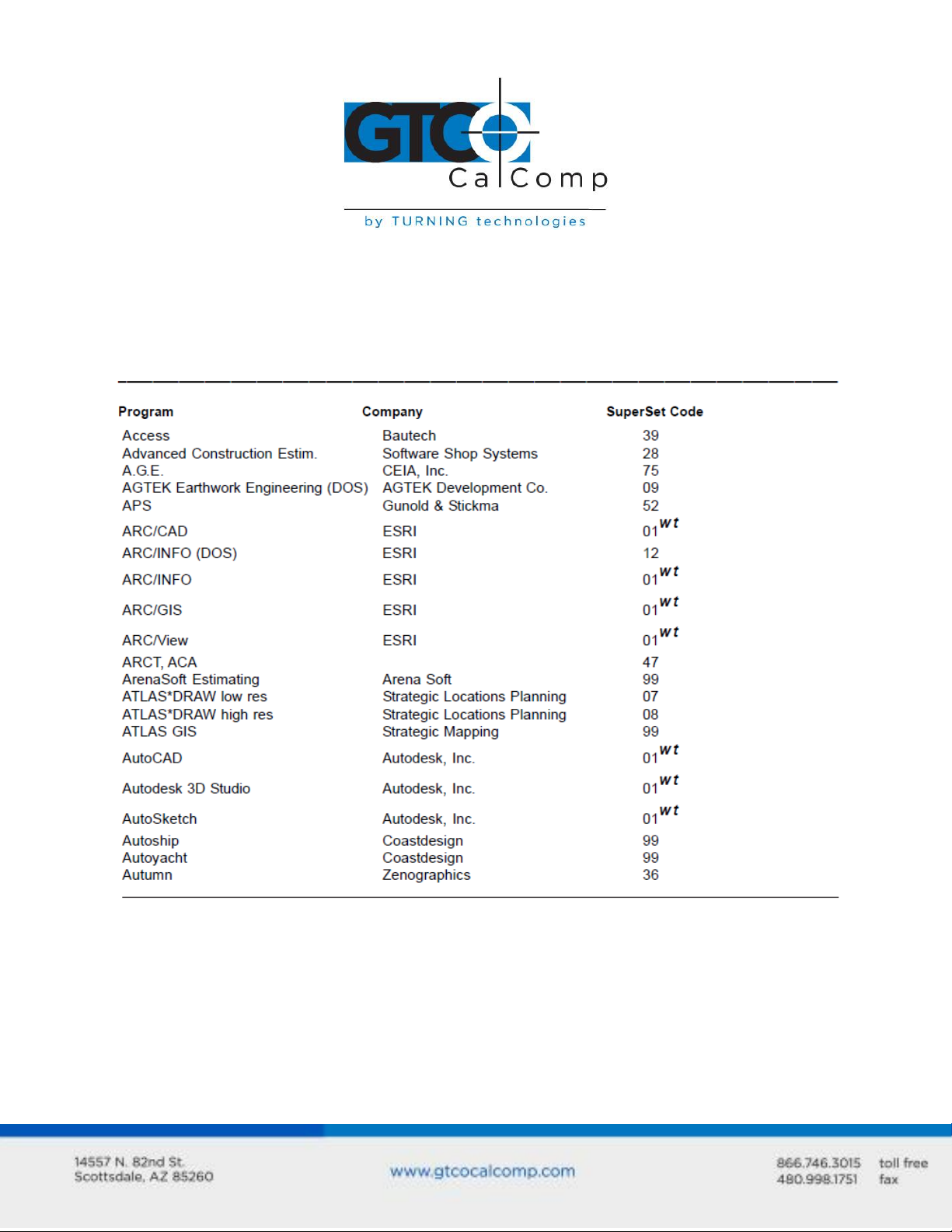

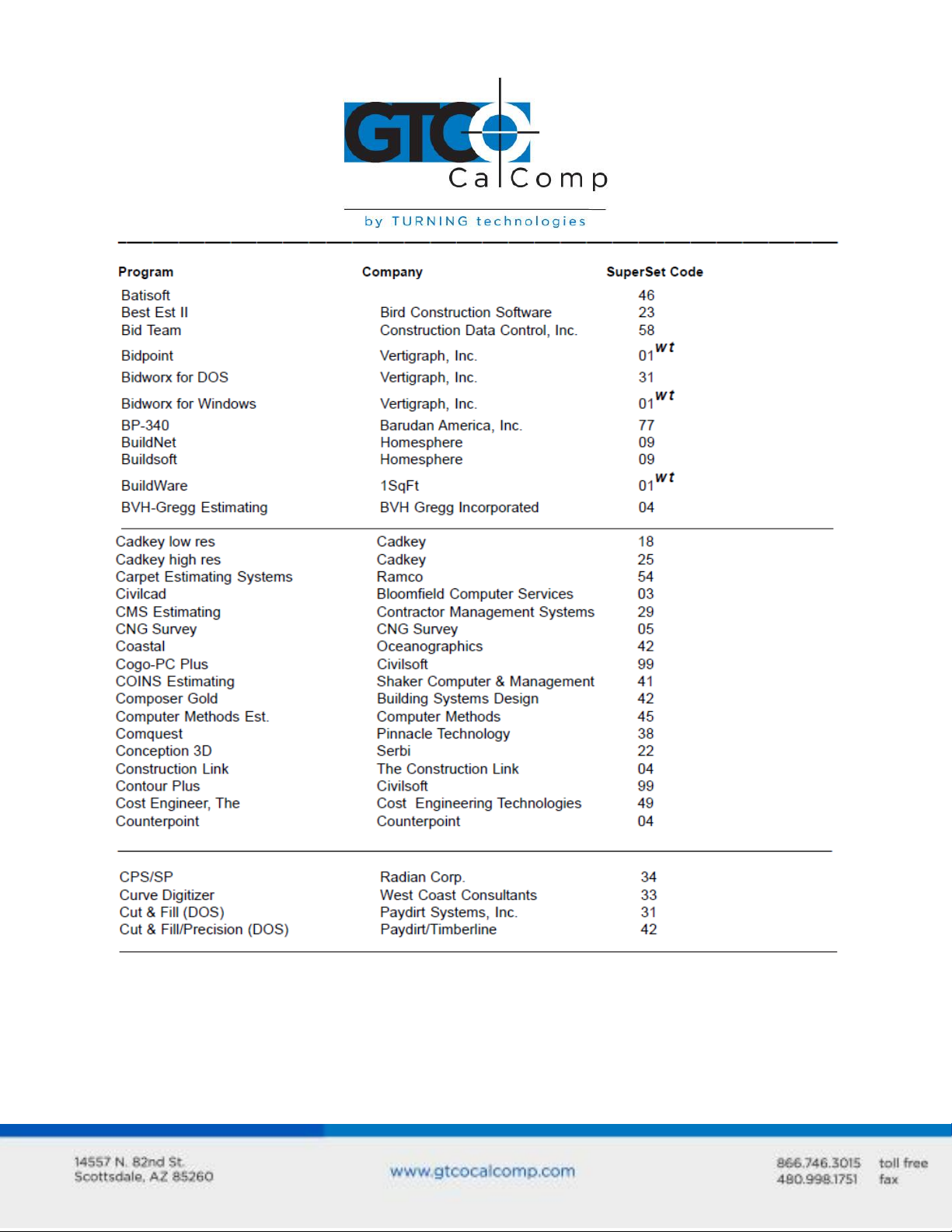

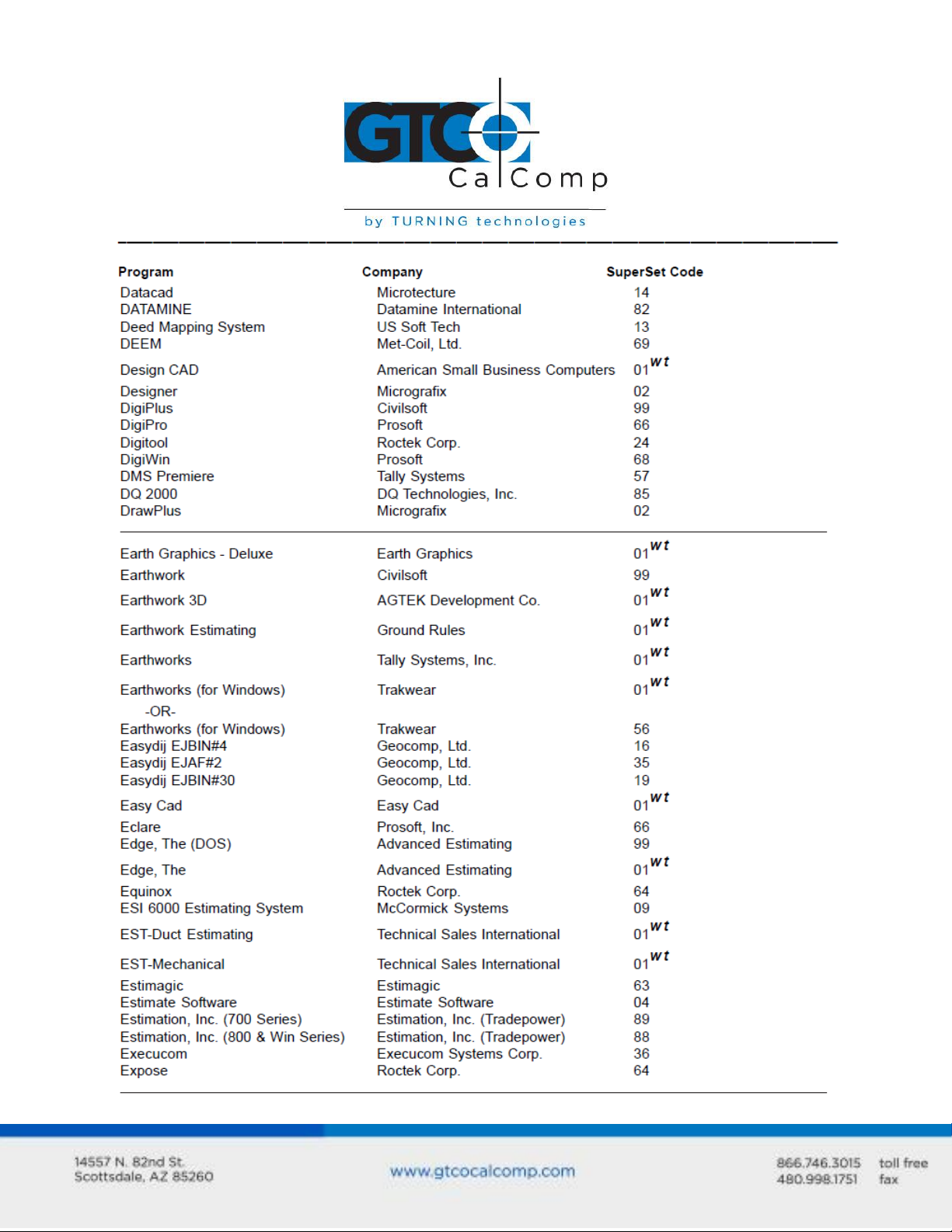

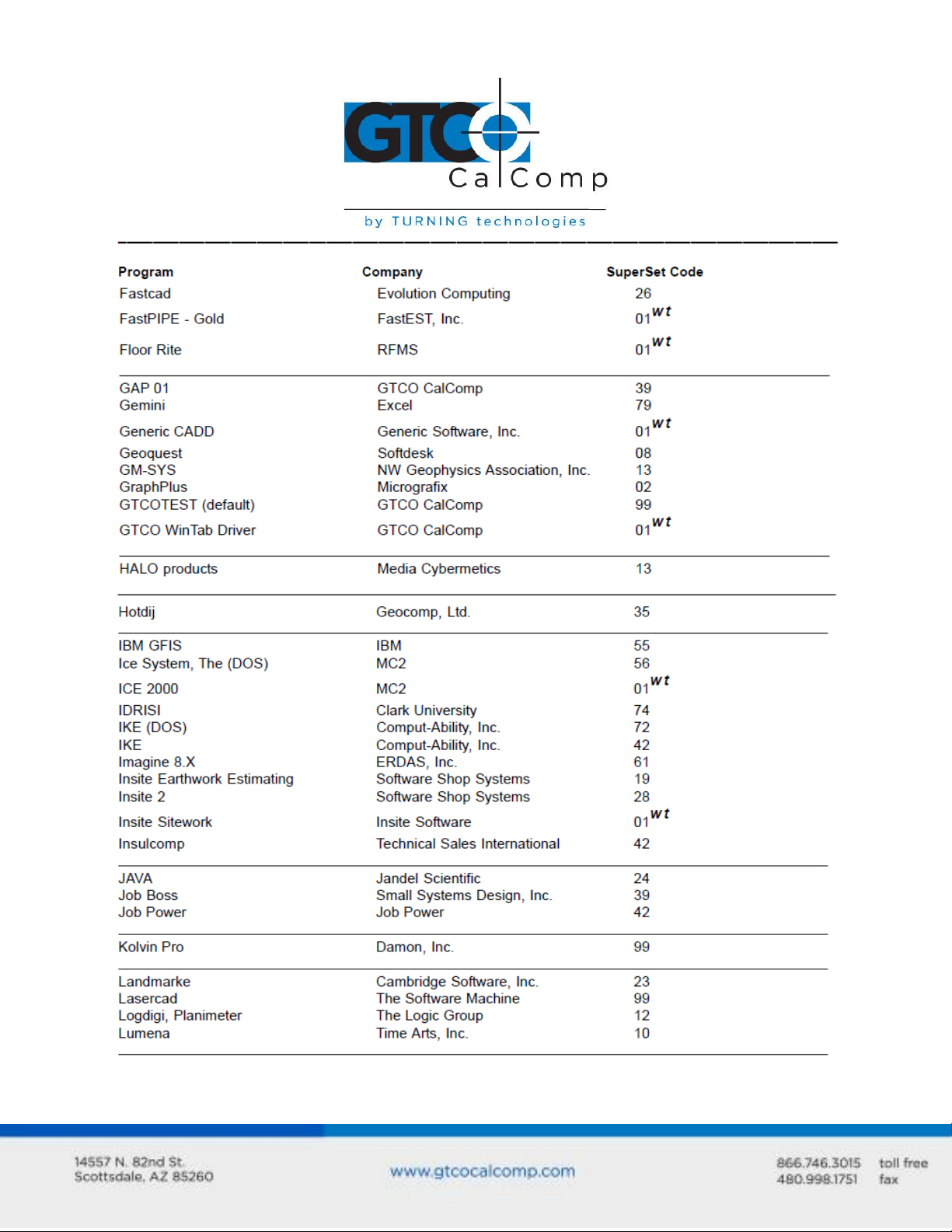

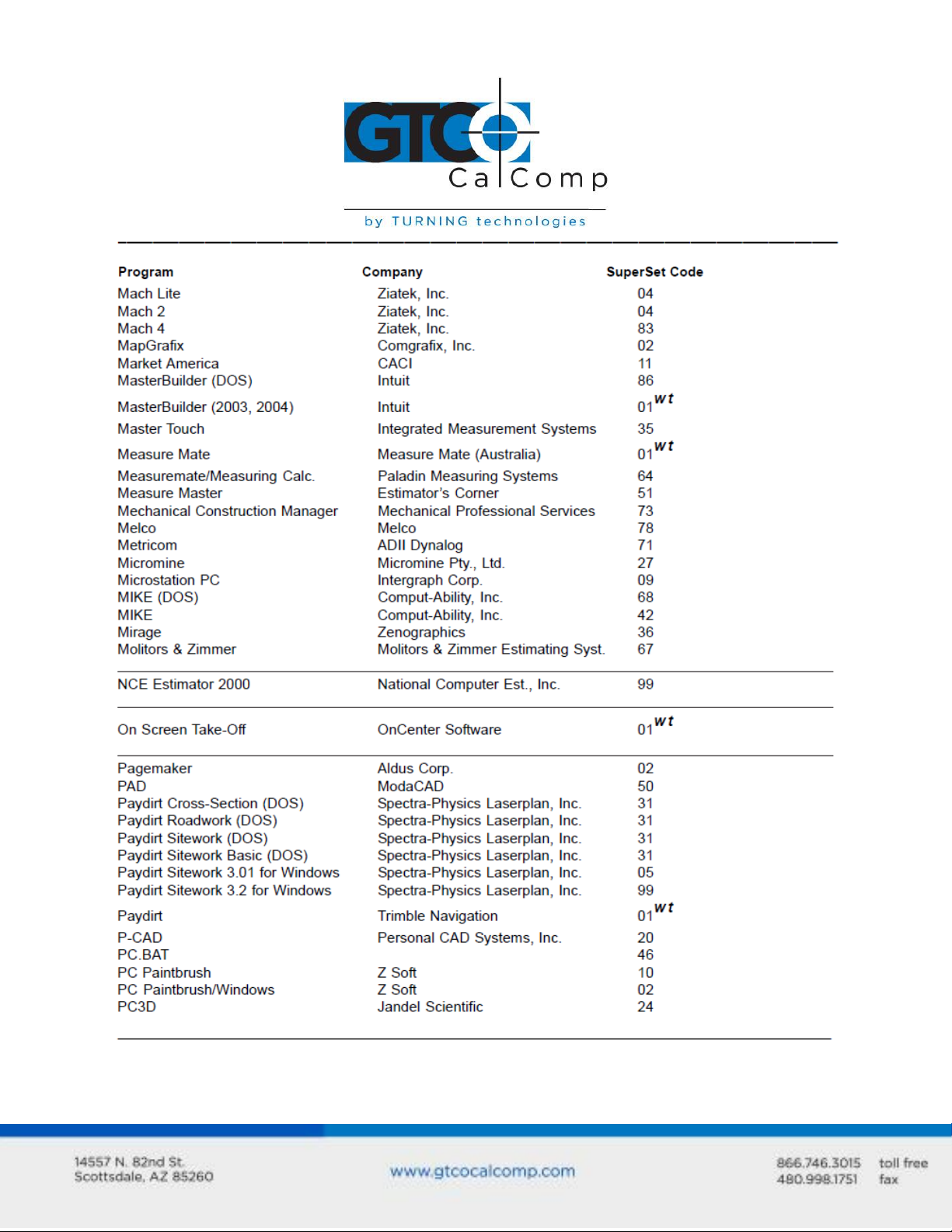

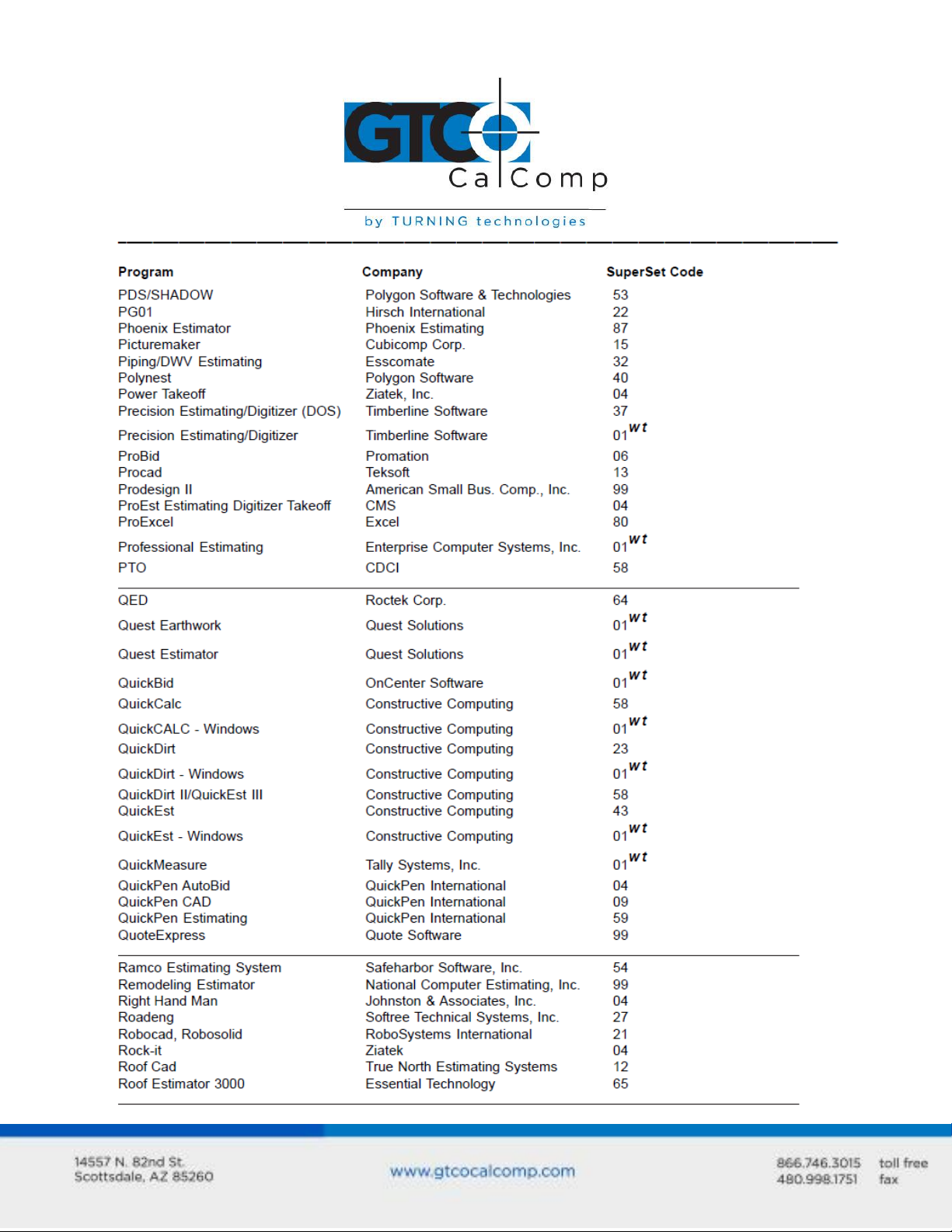

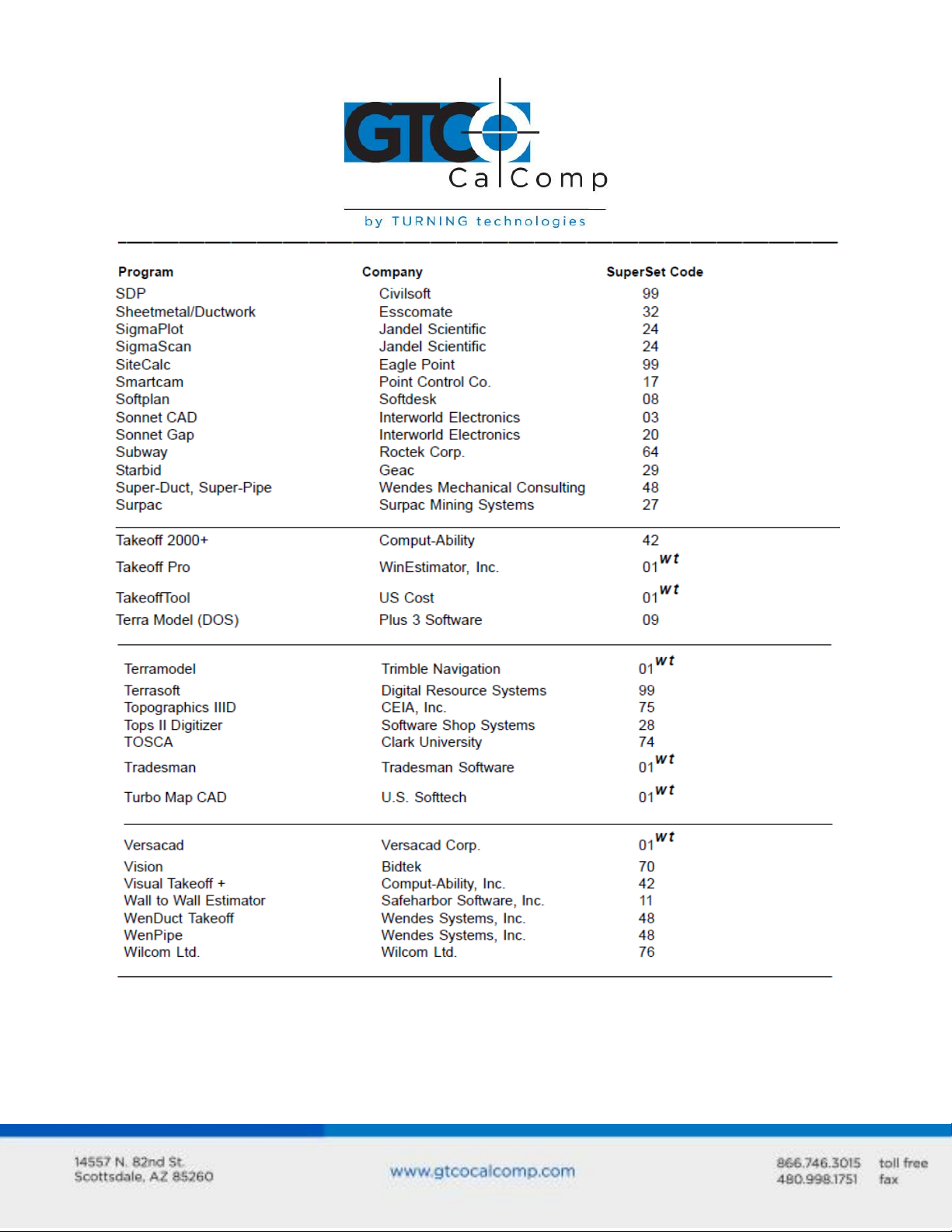

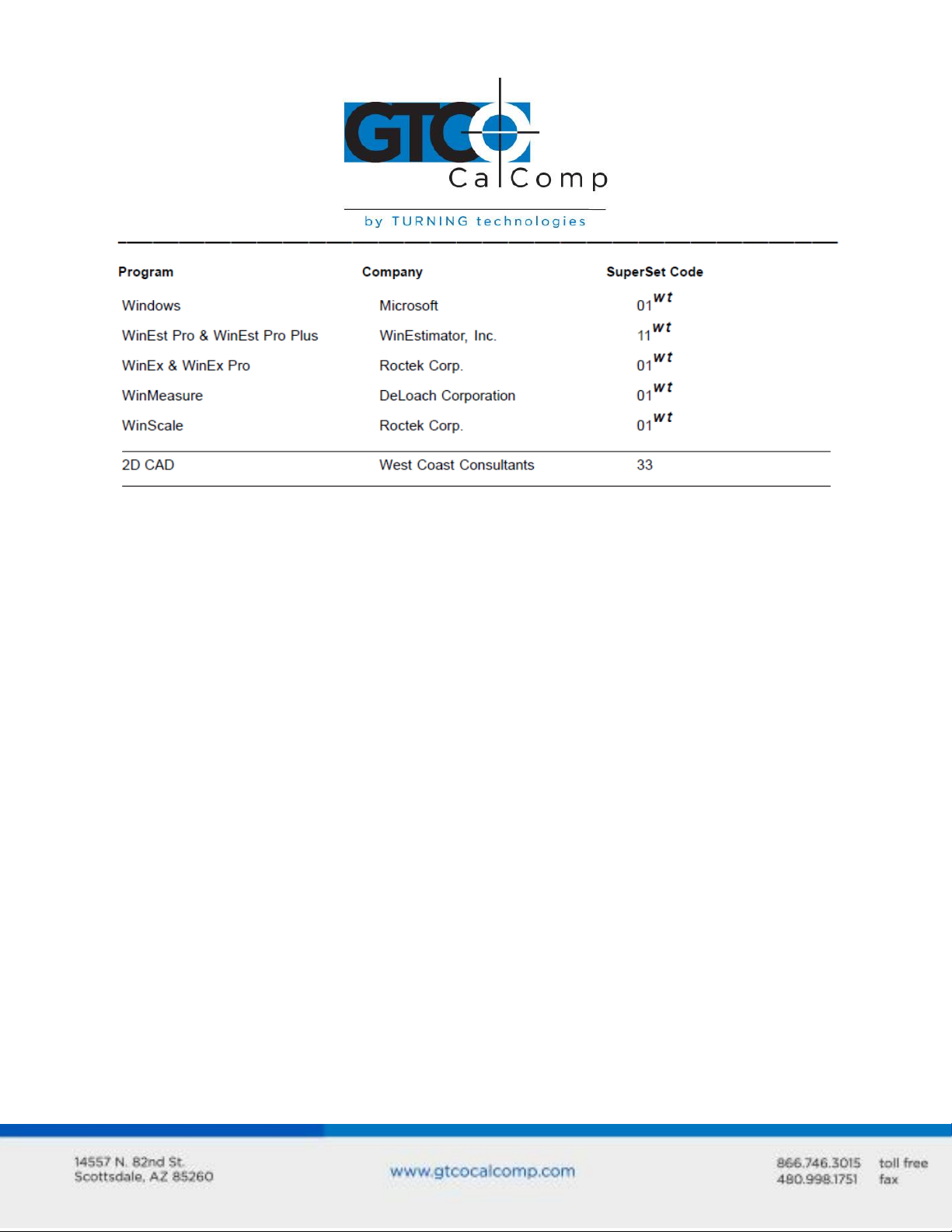

Table 1: SuperSet Menu Codes for Applications

Table 2: Configuration Details for SuperSet Menu Codes

Introduction to the Custom Configuration Menu

Communication Options

Output Format Options

Mode Options

Using the Custom Configuration Menu

Custom Configuration Menu

Controlling the Alarm

Roll-Up II Tones

Troubleshooting Guide

Procedure A: Begin Troubleshooting

Procedure B: Troubleshooting

Procedure C: Troubleshooting

Using GTCOTEST

Technical Specifications

Advanced Operating Information

Roll-Up II Interfacing

Character Format and Baud Rate

Cabling

3

3

3

4

4

4

5

7

7

8

9

17

20

21

21

22

22

24

24

25

25

26

27

28

29

30

32

32

33

33

Table of Contents

Page 2

Roll-Up II 2

Flow Control

Remote Commands

GTCO Roll-Up II Command Summary

Functional Control Commands

Format Selection Commands

Alarm Commands

Diagnostic Commands

CalComp Emulation Commands

Summagraphics Emulation Commands

Command Mode Basics

A Hint for Programmers

Advanced Programming Information

Coordinate Formats

Binary Formats

GTCO/CalComp Binary Format

Summagraphics Binary Format

Low Resolution Binary Format

Cursor Button Codes in Binary Formats

ASCII Formats

Cursor Button Codes in ASCII Formats

Measurement Scales

Digitizing Modes

Point Mode

Line Mode

Continuous Mode

Line Incremental Mode

Continuous Incremental Mode

Remote Request Mode

Programming Examples

General Product Information

Radio and Television Interference

Bescheinigung des Herstellers/Importeurs

Limited Warranty for Roll-Up II

33

34

35

36

39

40

40

42

44

46

47

49

49

49

50

51

52

53

54

57

57

58

59

60

60

61

61

61

62

65

65

66

67

Page 3

Roll-Up II 3

Roll-Up II digitizing tablet

Transducer (stylus or 4-button cursor

or 16-button cursor)

Computer interface cable with 9-pin

connector

9- to 25-pin adapter

Power supply

TabletWorks CD

Accessory pouch

Deluxe Travel Bag (optional)

Cardboard tube, insert and end caps

Standard Operating Information

Parts Checklist

NOTE: The Deluxe Travel Bag is intended to be used only in conjunction with the heavy

gauge cardboard tube, insert and end caps supplied. The Deluxe Travel Bag does not

provide complete protection if used alone. The product will be subject to damage, not

covered by the warranty, if not protected by the tube, insert and end caps. If you have

misplaced or disposed of the items, contact GTCO CalComp by Turning Technologies at

1.866.746.3015 for replacements.

Introduction

The Roll-Up II belongs to a class of computer input devices called graphic tablets or

graphic digitizers. A graphic digitizer consists of a transducer (usually a handheld cursor

or stylus) and an electronic tablet work surface. The Roll-Up II converts the position of the

transducer into data for computer processing. Data output from the digitizer is in the form

of an XY coordinate pair that pinpoints the location of the transducer on the tablet surface.

Roll-Up II works with a wide variety of graphic application software programs. It can

be used to:

Move a pointer on a display screen.

Create and manipulate objects in a graphic composition.

Trace a drawing (or other source material) to create an image on the screen.

Select commands or functions from a menu of such items placed on the tablet

surface.

Choose items from a pull-down menu on the screen.

Determine dimensions of objects on drawings and blueprints.

Page 4

Roll-Up II 4

What You Will Need to Use Roll-Up II

PC with an RS-232C serial communication port. (Signal levels must conform to EIA

RS2320 specifications.)

Graphic application software that accepts digitizer input via the computer’s RS-232C

serial port.

Care and Handling of Roll-Up II

The Roll-Up II was designed to be both portable and durable. As with any product, it

requires proper care and handling for reliable operation. By following these

recommendations, the Roll-Up II will provide you with many years of service:

Always use the digitizer on a flat surface.

Before moving the digitizer, disconnect the transducer and the interface cable.

Before moving the digitizer, roll it up. The housing along the side of the tablet is

designed as a rolling aid and it allows you to easily control rolling action. (See

Transporting Roll-Up II for specific moving instructions.)

Do not permanently attach anything to the tablet.

Do not use sharp instruments on or near the tablet, to avoid scratching or cutting it.

Cuts in the tablet will violate the warranty.

Do not crease, dent or abuse the tablet. Creases can damage the tablet structure.

Severe creases or abuse will violate the warranty.

Clean the tablet with any mild, nonabrasive household cleaner. Rubbing alcohol is

recommended. After cleaning, wipe the surface dry to avoid possible digitizing

errors.

Transporting Roll-Up II

You MUST transport the Roll-Up II with the factory-supplied shipping materials (heavy

gauge cardboard tube, insert and end caps). Failure to do so could result in serious

damage to the unit and may violate the warranty.

1. Disconnect the transducer and interface cable from the Roll-Up II and the computer.

Remove all material from the tablet.

2. Grasp the housing firmly with both hands and roll it toward the opposite side of the

tablet. The housing and the printing on the digitizer surface must be on the inside

of the roll. The roll diameter should be just smaller than the inside diameter of the

Page 5

Roll-Up II 5

factory-supplied shipping tube. When correctly rolled, only the digitizer’s black back

will be exposed.

3. Insert the rolled digitizer into the shipping tube and allow it to fully unroll against

the inside of the tube. Place the factory-supplied insert into the center of the rolled

digitizer for support.

4. Place the accessories in the accessory case and put it inside the hollow insert. Set

the factory-supplied end caps on the tube to seal it. Place the tube in the optional

Deluxe Travel Bag (optional).

NOTE: The Deluxe Travel Bag is intended to be used only in conjunction with the factorysupplied heavy gauge cardboard tube, insert and end caps. The Deluxe Travel Bag does

not provide complete protection if used alone. The product will be subject to damage not

covered by the warranty, if not protected by the tube, insert and end caps. If you have

misplaced or disposed of these items, contact GTCO CalComp by Turning Technologies

(1.866.746.3015) for replacement parts.

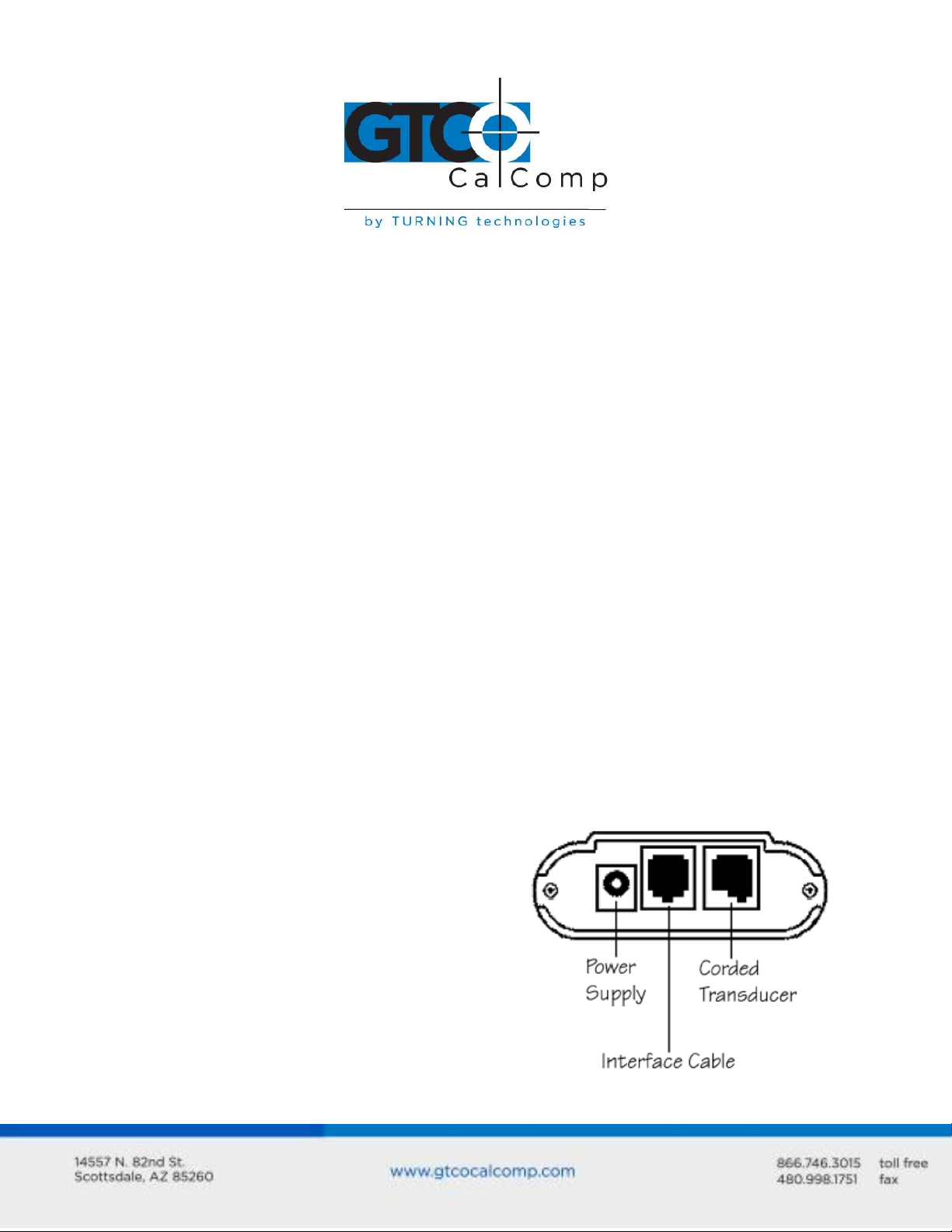

Installing Roll-Up II

Follow the instructions below to set up Roll-Up II.

1. Select a large, flat surface on which to place the Roll-Up II. Clear all items from the

surface. Please be cautious that conductive materials on, under or near the Roll-Up

II may cause improper operation.

2. Remove Roll-Up II from its container and

unroll it on the selected surface.

3. Connect the stylus or cursor to the

appropriate jack on the tablet’s

connector panel. (The connector is

keyed and will fit only the correct jack.)

4. Plug the power supply into an AC outlet.

Attach the power supply to the jack on

the connector panel. The digitizer should

produce four short tones.

Page 6

Roll-Up II 6

5. Connect the interface cable to the appropriate jack on the connector panel. (The

connector is keyed and will fit only the correct jack.)

6. Join the 9-pin connector of the interface cable to the serial port on the computer. If

necessary, use the 9- to 25-pin adapter to connect to a PC-compatible (DTE male)

port.

7. Orient the tablet (see Changing the Tablet’s Orientation section) as desired.

8. Use the SuperSet Menu to select the two-digit SuperSet Code (shown in Table 1) for

the application program.

If the application program is not listed in Table 1, find the configuration

settings that apply to the application program in Table 2 and use that

SuperSet Code.

If an appropriate SuperSet Code is not listed in Table 2, use the Custom

Configuration Menu to set up the Roll-Up II.

9. Configure your computer for use with Roll-Up II:

Arrange the graphic application software to operate with the Roll-Up II. A

wide variety of application programs provide configuration information for

specific digitizers. If Roll-Up II digitizer is not listed, use the configuration for

GTCO Digi-Pad Type 5 or Type 5A (T5/T5A), CalComp 9100/9500 or

Summagraphics Microgrid III or ID Series.

Page 7

Roll-Up II 7

If necessary, install the appropriate digitizer driver(s) from the Digitizer Driver

Diskette supplied (AutoCAD, Windows and mouse drivers are included).

Insert the diskette into drive A or B. From the DOS prompt, type a:\install or

b:\install and follow the on-screen instructions.

NOTE: Install only the drivers necessary for Roll-Up II to work with the application software.

10. Begin digitizing.

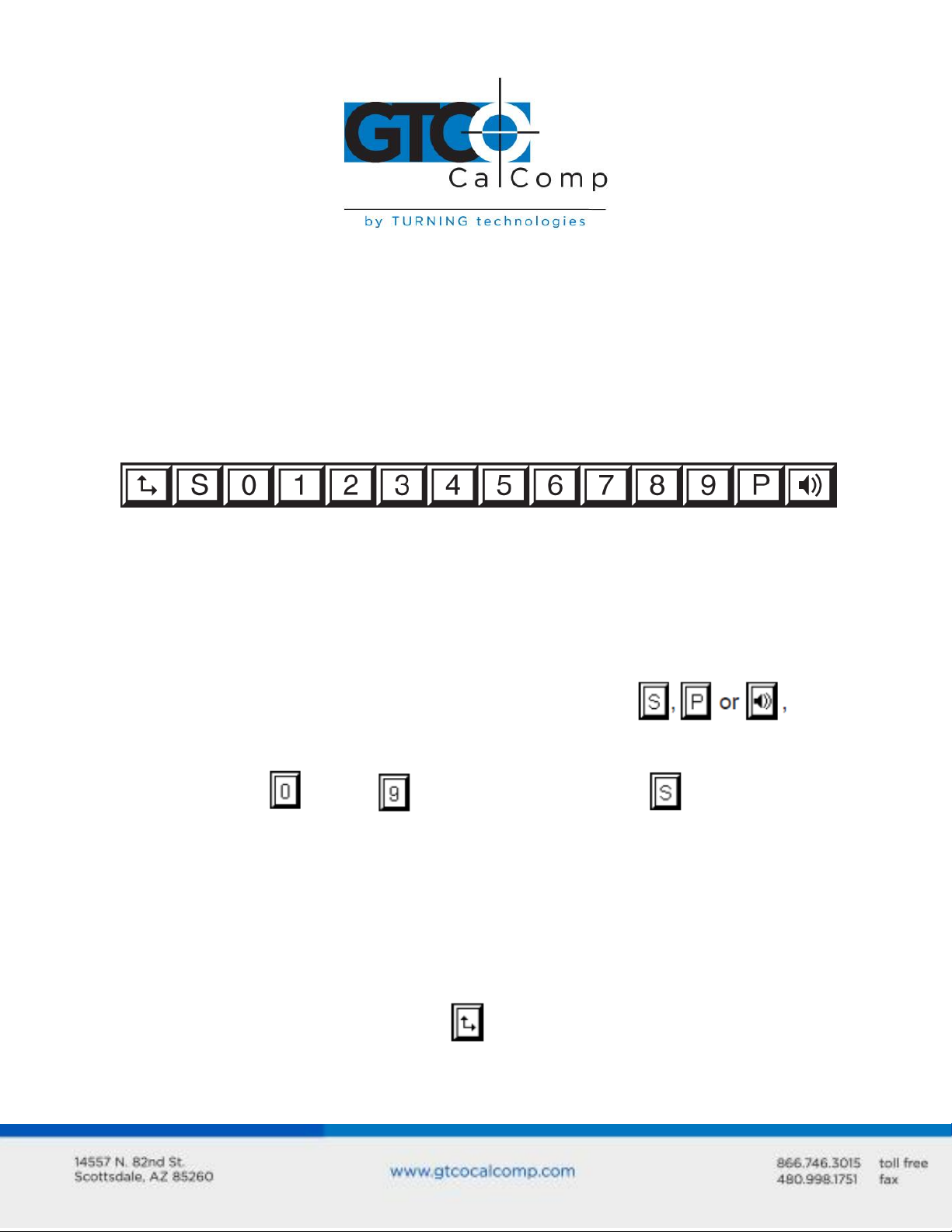

Using the SuperSet Menu

Use the SuperSet Menu to:

Change the tablet’s orientation

Configure Roll-Up II for specific application programs

Use the Custom Configuration Menu

Control the alarm

When using the SuperSet Menu, a tone will sound when selecting

indicating a successful selection.

The number blocks through are active only after selecting .

Changing the Tablet’s Orientation

Roll-Up II allows the user to choose between two different tablet orientations: orient the

tablet with the housing on the right (factory default) or on the left.

To change the orientation of the tablet:

1. Turn the tablet to the desired orientation.

2. Relocate the origin by selecting the block on the lower SuperSet Menu. You

should hear four short tones when you do this.

NOTE: The orientation of the 20x24 Roll-Up II cannot be changed.

Page 8

Roll-Up II 8

Configuring for Specific Application Programs

To configure Roll-Up II for use with specific application programs:

1. In Table 1, find the application program being used with Roll-Up II. Note the

corresponding SuperSet Code.

If the application program is not listed in Table 1, find the configuration

settings that apply to the application program in Table 2 and use that

SuperSet Code.

If an appropriate SuperSet Code is not listed in Table 2, then use the Custom

Configuration Menu to set up Roll-Up II.

2. Select on the SuperSet Menu and then choose the two digits of the SuperSet

code for the application program.

3. You will hear four short tones after a successful menu configuration. An example of

configuring for a specific application program follows.

Page 9

Roll-Up II 9

Table 1: SuperSet Menu Codes for Selected Application Programs

NOTE: This tablet has been updated to reflect the most current information available at the

time of the release of Roll-Up III. The wt superscript indicates WinTab-compliant

applications. SuperSet Code 99 now designates a non-Plug-N-Play Mode. Plug-N-Play

serial connections and USB support are not available on the Roll-Up II. (12-12-2003)

Page 10

Roll-Up II 10

Page 11

Roll-Up II 11

Page 12

Roll-Up II 12

Page 13

Roll-Up II 13

Page 14

Roll-Up II 14

Page 15

Roll-Up II 15

Page 16

Roll-Up II 16

Page 17

Roll-Up II 17

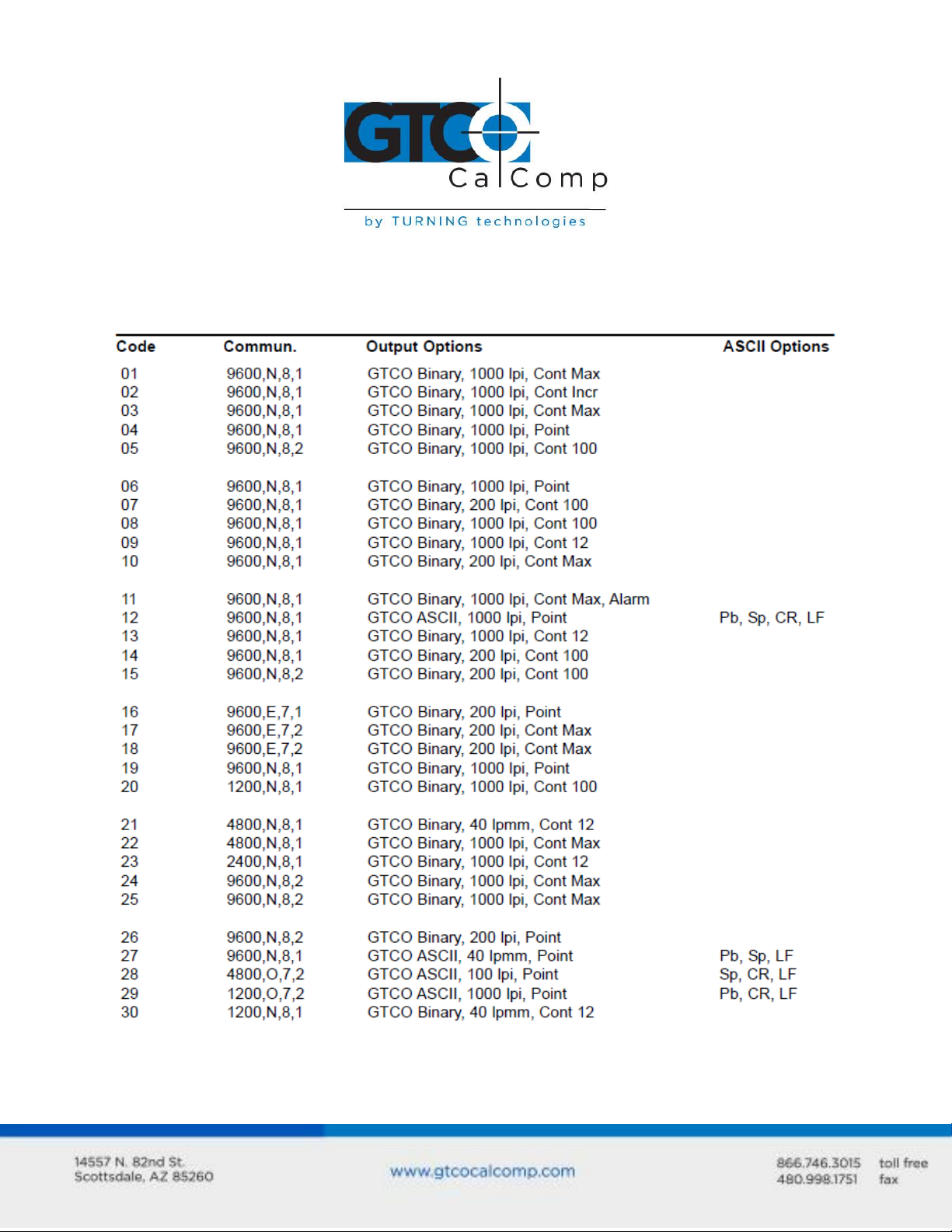

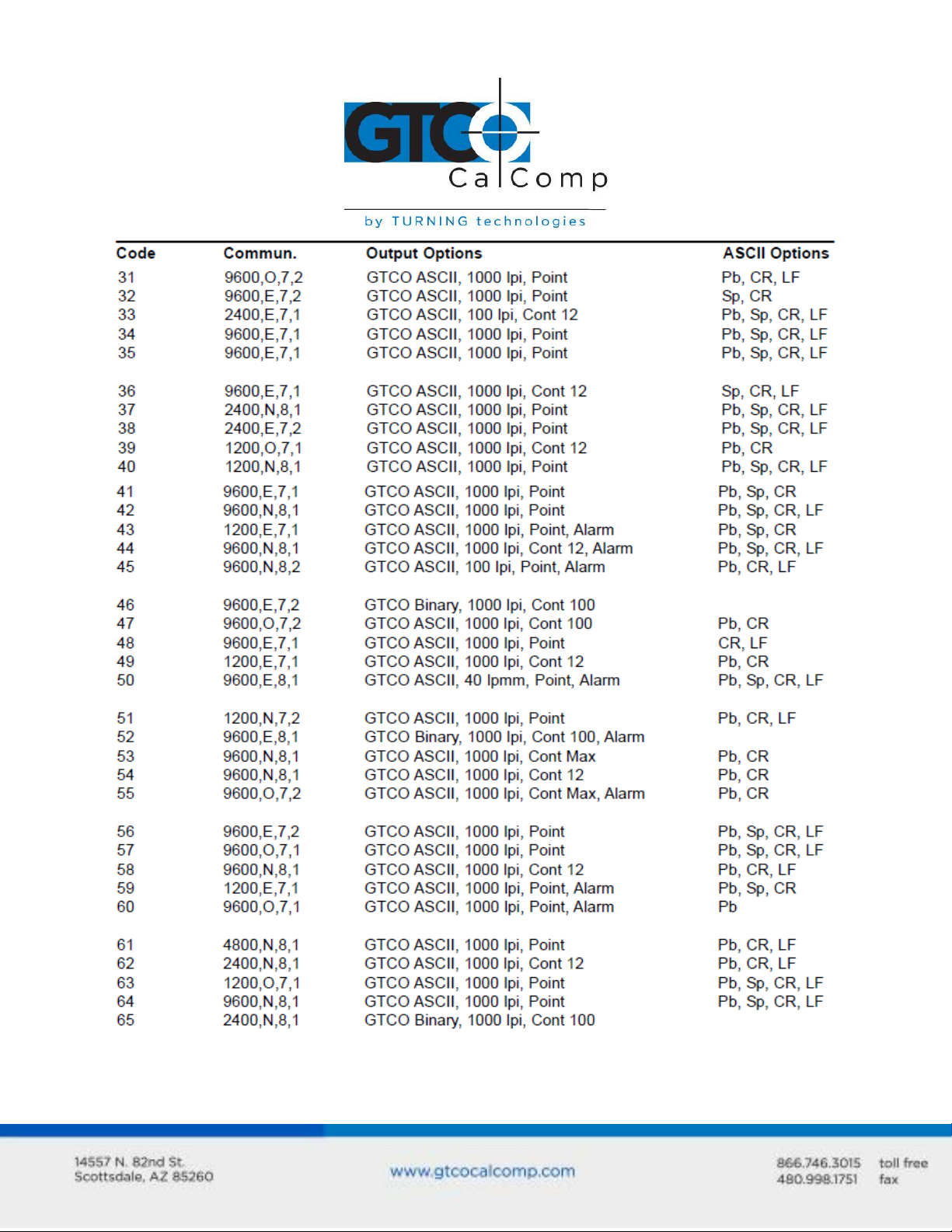

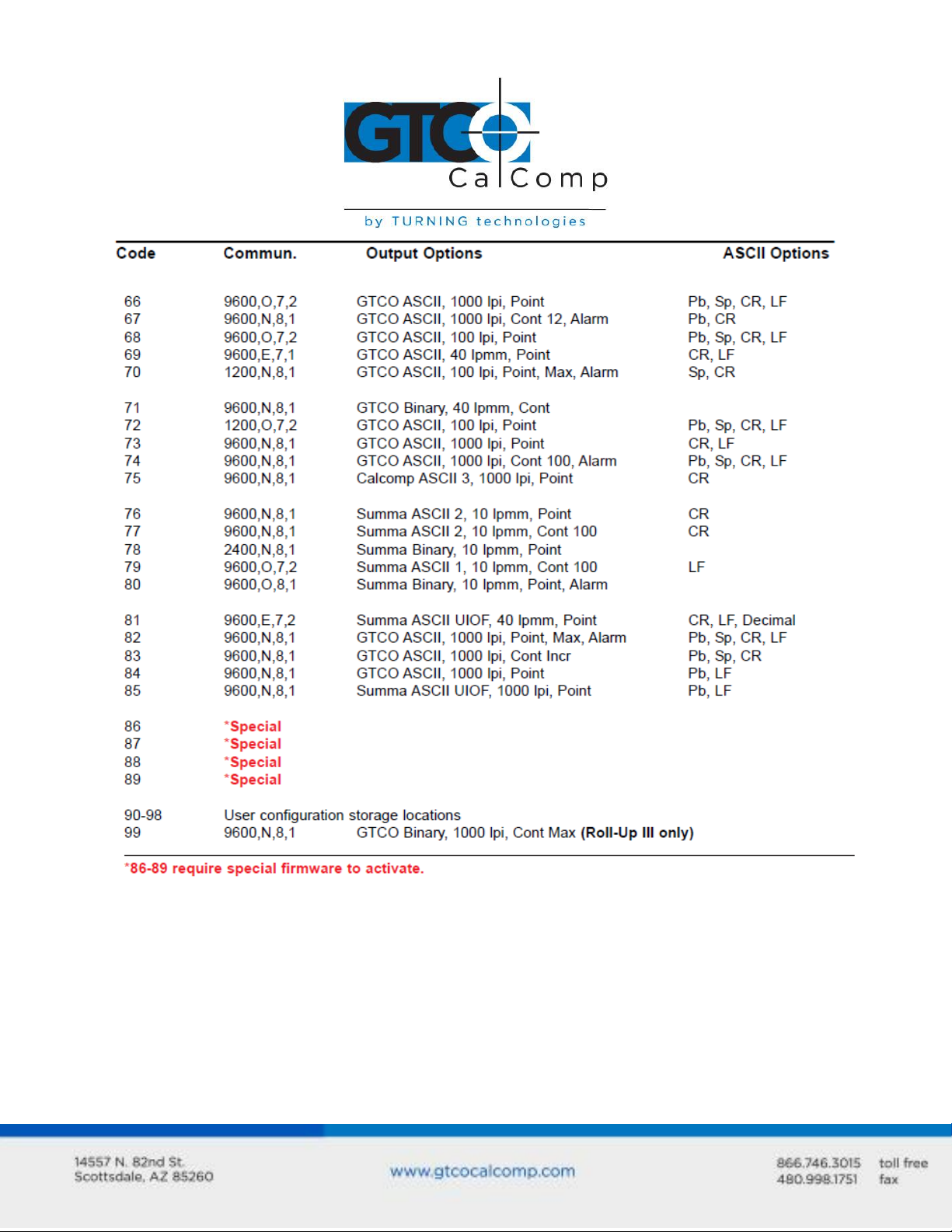

Table 2: Configuration Details for SuperSet Menu Codes

NOTE: MAX = 140 coordinates/second

lpi = lines per inch lpmm = lines per millimeter

Page 18

Roll-Up II 18

Page 19

Roll-Up II 19

Page 20

Roll-Up II 20

Example: Configuring for Specific Application Programs

To configure Roll-Up II to operate with Autodesk’s AutoCAD application program:

1. Find the entry for AutoCAD in Table 1. The SuperSet code is 01.

2. Select on the SuperSet Menu. This places the digitizer in Select Mode.

3. Choose on the SuperSet Menu. This enters the first digit of the SuperSet code

for AutoCAD.

4. Select on the SuperSet Menu. This enters the second digit of the SuperSet

code for AutoCAD.

5. You will hear four short tones, indicating that the configuration is complete. The

Roll-Up II is now configured to operate with AutoCAD. Select Mode is no longer

active.

NOTE: After beginning Select Mode, you must digitize only in the number blocks to

properly enter a SuperSet code. If you digitize in the tablet’s active area during Select

Mode, the sequence will be terminated and the previous configuration will be retained (you

will hear three medium-length tones after an aborted sequence). To cancel a sequence if

the first digit is entered incorrectly, digitize in the tablet’s active area.

Introduction to the Custom Configuration Menu

Roll-Up II uses the Custom Configuration Menu to control baud rate, data format and other

operating characteristics. The Custom Configuration Menu card is stored in one end of the

digitizer’s housing.

Configuration parameters for Roll-Up II are divided into three categories:

Communication Options

Output Format Options

Mode Options

Page 21

Roll-Up II 21

Communication Options

Baud: The rate, in bits/second, at which characters are transmitted across the RS-

232C serial interface. Choices are: 1200, 2400, 4800, 9600, 19200 and 38400.

Data Bits: Data bits represent the actual data being sent from one device to

another. Both devices must be set for the same number of data bits. Choices are:

Seven (7) or Eight (8).

Stop Bits: Each character has one or two stop bits, which tell the receiving device

that a character is complete. The number of stop bits usually does not matter.

Setting for two stop bits instead of one may overcome a mismatch in parity or data

bits. Choices are: One (1) or Two (2).

Parity: One bit can be allocated for parity (parity is a simple error-detecting

scheme). Both devices (sending and receiving) must be set for the same parity –

either odd parity or even parity – or they must be set for no parity. Choices are:

None (N), Even (E) or Odd (O).

Output Format Options

GTCO: Selects GTCO-compatible formats. See Advanced Programing Information

for greater detail on GTCO format structure. Choices are: Binary or ASCII.

CalComp: Selects CalComp-compatible formats. See Advanced Programming

Information for greater detail on CalComp format structure. Choices are: Binary,

ASCII 1, ASCII 2, ASCII 3 or ASCII 4.

Summa: Selects Summagraphics-compatible formats. See Advanced Programming

Information for greater detail on Summagraphic format structure. Choices are:

Binary or ASCII.

ASCII formats can be modified by including or excluding a button code, decimal point,

carriage return or line feed, depending on whether GTCO, CalComp or Summa formats

have been selected.

Button: Defines whether the Pushbutton (Pb) value is included in the ASCII output

report. This option is available only with GTCO formats. Choices are: Include or

Exclude.

Page 22

Roll-Up II 22

Space: Defines whether the Space (Sp) character (hex 20) is included in the ASCII

output report as a delimiter between the X and Y coordinate values. This option is

available only in GTCO formats. Choices are: Include or Exclude.

Decimal: Defines whether the period character (hex 2E) is included in the ASCII

output report between the units and tenths digits. This option is available only in

Summagraphics formats. Choices are: Include or Exclude.

Return: Defines whether the Carriage Return (CR) character (hex 0D) is included in

the ASCII output report as a terminator. This option is available in GTCO and

Summagraphics formats. Choices are: Include or Exclude.

Line Feed: Defines whether the Line Feed (LF) character (hex 0A) is included in the

ASCII output report as a terminator. This option is available in GTCO, CalComp and

Summagraphics formats. Choices are: Include or Exclude.

Mode Options

Mode: Defines how output reports are sent from the digitizer. Choices are: Point,

Line, Continuous, Line Incremental or Continuous Incremental.

Rate: Determines how fast output reports will be transmitted from the digitizer.

Choices are: 12, 50 or 100 reports per second.

Resolution: The smallest reported value returned by the digitizer. Choices are:

1000 lpi, 2000 lpi, 4000 lpi, 40 lpmm, 100 lpmm and 150 lpmm.

See the Advanced Programming Information section for more details.

Using the Custom Configuration Menu

If the application does not have a SuperSet Menu code, or if a different configuration is

required, then use the Custom Configuration Menu card to configure Roll-Up II. The

Custom Configuration Menu replaces the 24 switches that were associated with older

GTCO CalComp by Turning Technologies digitizers.

Configurations set up can be stored in any of ten user-definable SuperSet locations (codes

90 through 99) for recall at a later time. This allows Roll-Up II to be easily switched between

applications.

Page 23

Roll-Up II 23

To configure Roll-Up II using the Custom Configuration Menu:

1. Remove the Custom Configuration Menu card from its storage location in one end

of the housing. Place the card in the active area of the tablet (the entire menu must

be in the active area). Hold or temporarily tape the card in place to keep it from

moving during the configuration process.

2. Select on the SuperSet Menu. The alarm will beep slowly, indicating that the

Custom Configuration Menu mode is now ready to receive alignment Point 1.

3. Inform the Controller where the Custom Configuration Menu card is located on the

tablet. Choose alignment Point 1 (small blue square) in the lower left corner of the

menu area. The alarm will beep rapidly, indicating that the system is waiting to

receive alignment Point 2.

4. Pick alignment Point 2 (small blue square) in the lower right corner of the card.

After alignment Point 2 is selected, the alarm will sound only of the transducer

passes over an active menu block on the card.

NOTE: If invalid alignment points are selected or if the menu card is not entirely in the

active area, the menu mode will be aborted. This is indicated by three medium tones from

the alarm.

5. Configure Roll-Up II by selecting the menu blocks that correspond to the settings

you want.

6. Review the configuration to ensure that the proper settings have been selected.

Pass the transducer down each group of options; the alarm will sound when the

transducer is over the active choice.

7. After making your selections, you can save the configuration as a temporary

configuration or save the configuration in a user-definable location for later recall,

To save the configuration temporarily:

Select on the SuperSet Menu. You will hear four short tones when you successfully

save a configuration. The configuration is saved in a temporary location, where it will be

Page 24

Roll-Up II 24

retained even if the unit is powered off or reset. However, if another SuperSet code is

entered, this temporary configuration is lost and cannot be recalled without configuring

Roll-Up II again.

To save the configuration in a user-definable location:

Choose and then select a two digit value ranging from 90 to 99 on the SuperSet Menu.

You will hear four short tones when you successfully save a configuration. Saved

configurations allow you to switch between applications quickly. Locations 90 through 99

retain configurations even if Roll-Up II is turned off or reset.

8. The configuration setup is now complete. Store the Custom Configuration Menu

card in the tablet housing.

Custom Configuration Menu

Click on menu blocks for description of each menu option group:

Controlling the Alarm

Disable the alarm (for transducer pressed) if you do not want to hear it while using the

digitizer. When the alarm is off, you will still hear diagnostic and menu-related tones.

To turn the alarm on and off:

Select the block on the SuperSet Menu.

Page 25

Roll-Up II 25

Roll-Up II Tones

The Roll-Up II produces an “alarm” in the form of audio tones to inform the user of various

events. The table below describes the kinds of tones you may hear while operating the

digitizer.

Table 3: Roll-Up II Tones

NOTE: You might also hear tones produced by the Roll-Up II which are sent by the

application program. (Programs can send commands to the digitizer to turn the audio tone

generator on and off.) If you hear tones during digitizing and they do not correspond to

tones listed in the table above, they are produced by the application program.

Troubleshooting Guide

As with any computer peripheral, Roll-Up II problems sometimes do occur. This

troubleshooting guide provides clear instructions for finding and solving all common RollUp II issues. In a majority of cases, you will be able to quickly resolve the problem yourself

by following the below steps.

1. Install properly first.

This troubleshooting guide assumes you have already correctly installed Roll-Up II

according to the detailed instructions in the Installing the Roll-Up II section. If you

have not followed the step-by-step instructions in that section, do so now.

Page 26

Roll-Up II 26

2. Work through the troubleshooting flowcharts on the following pages in this

troubleshooting guide.

3. If your system still does not work.

Call GTCO CalComp by Turning Technologies Technical Support Department at

1.866.746.3015. Be prepared to discuss the observations you made while

troubleshooting. A Technical Support Specialist will help you resolve the problem as

quickly as possible.

NOTE: Refer to the Roll-Up II Tones table on the previous page while using this guide.

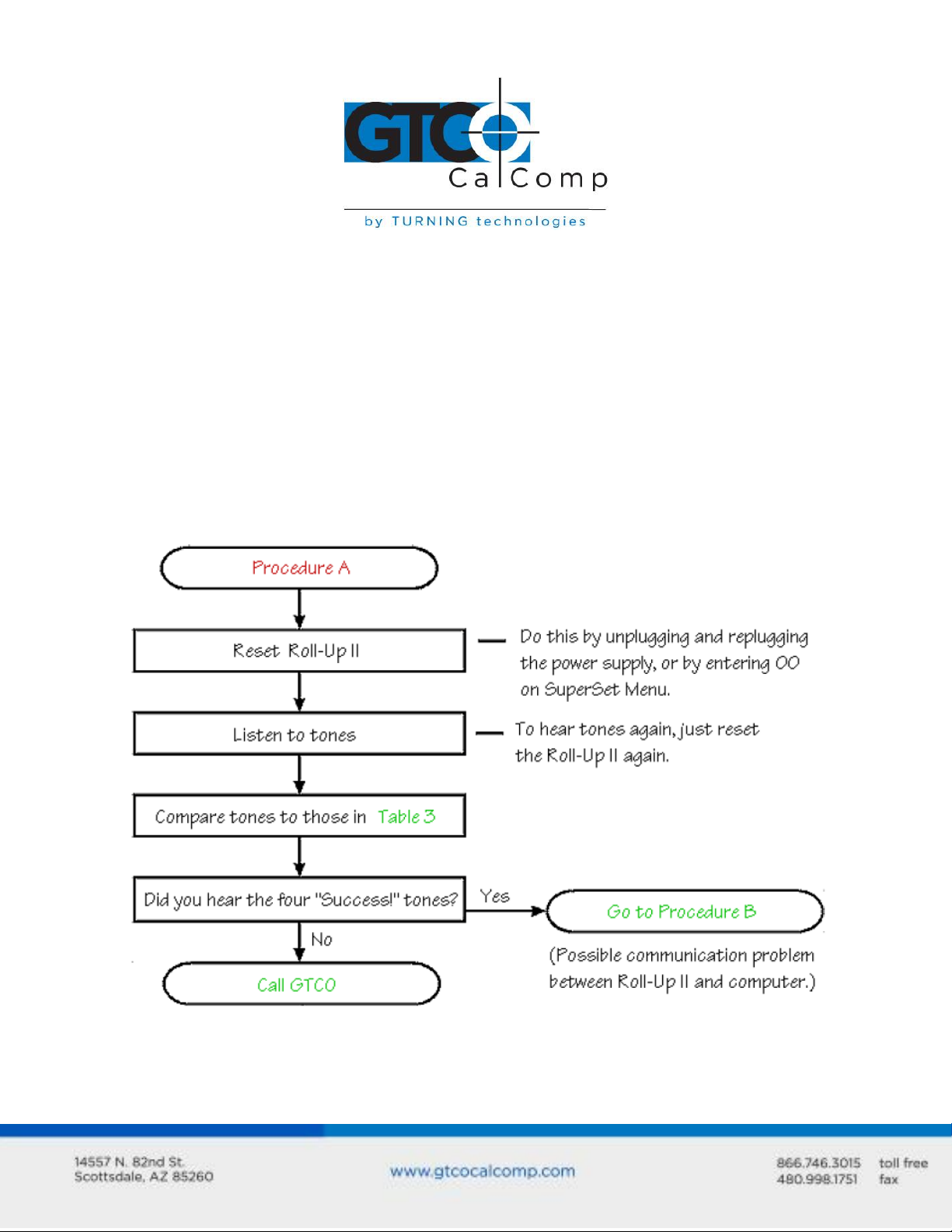

Procedure A: Begin Troubleshooting

Page 27

Roll-Up II 27

Procedure B: Troubleshooting

Page 28

Roll-Up II 28

Procedure C: Troubleshooting

Page 29

Roll-Up II 29

P = pushbutton code

XXXXXX = X coordinate data

YYYYYY = Y coordinate data

Using GTCOTEST

GTCOTEST is a program that runs on the PC. It can be used to perform communication and

diagnostic tests on an installed Roll-Up II. GTCOTEST is provided on the diskette with your

system.

1. Select SuperSet Code 01 on the Roll-Up II (9600, N, 8, 1, GTCO Binary, 1000 lpi, Cont,

100).

2. To run GTCOTEST, insert the TabletWorks CD in the CD-ROM drive. GTCOTEST will

work only if no Wintab drivers are installed. From the directory listing of the CD,

switch to the folder that contains the gtcotest.exe files. Type gtcotest and follow

the on-screen instructions.

3. Once GTCOTEST’s third screen has been reached, the pull-down menu headings will

read: Communications, Diagnostics, Setup and Check Output. Select Read

Switches in the diagnostics window. Communication has been established if 0’s

and 1’s appear in the display box.

If GTCOTEST displays the Serial input timeout error message, try selecting

another COM port in the Communications window.

If GTCOTEST displays the Cannot open COM port error message, try selecting

another COM port in the Communications window. (Each PC serial port has

a physical address that corresponds to a specific COM port. If there is only

one serial port installed in the computer, it will be assigned as COM

1regardless of its physical address. GTCOTEST examines only the physical

address.)

4. Once communication is established, select the Read Tablet Size and Read Version

options, making a note of the responses. This can easily be done with your print

screen key if a printer is connected to your computer.

5. Select Check Output and then choose High Res Binary.

6. Place the transducer in the active area on the tablet.

7. If everything is working properly, you should see data displayed on the computer

screen in the following format: p XXXXXX YYYYYY

8. When you move the transducer around the active area, the X and Y coordinate data

should change. When you press different cursor buttons, the pushbutton code

should change.

Page 30

Roll-Up II 30

Technology

Electromagnetic

Resolution

Up to 2000 lpi (lines/inch) or 100 lpmm (lines/millimeter)

Lock Height

0.5 inch (12.7 mm)

Coordinate Origin

Selectable (Factory default: lower left corner)

Recommended Roll Diameter

8 inches (200 mm)

Operating Temperature

41° to 115° F (5° to 46° C)

Storage Temperature

-4° to 158° F (-20° to 70° C)

Humidity Range

0% to 100%, non-condensing

Operating Modes

Point, Line, Continuous, Line Incremental, Continuous

Incremental, Remote Request

Baud Rates

1200, 2400, 4800, 9600, 19200 and 38400

Cursor Switches

Elastomeric keypad, rated life over 1 million actuations

Emulations

GTCO T5A, CalComp 9100/9500, Summagraphics

Microgrid and ID Series

Power Supply

Output voltage +9VDC at 500mA, Center positive

Interface

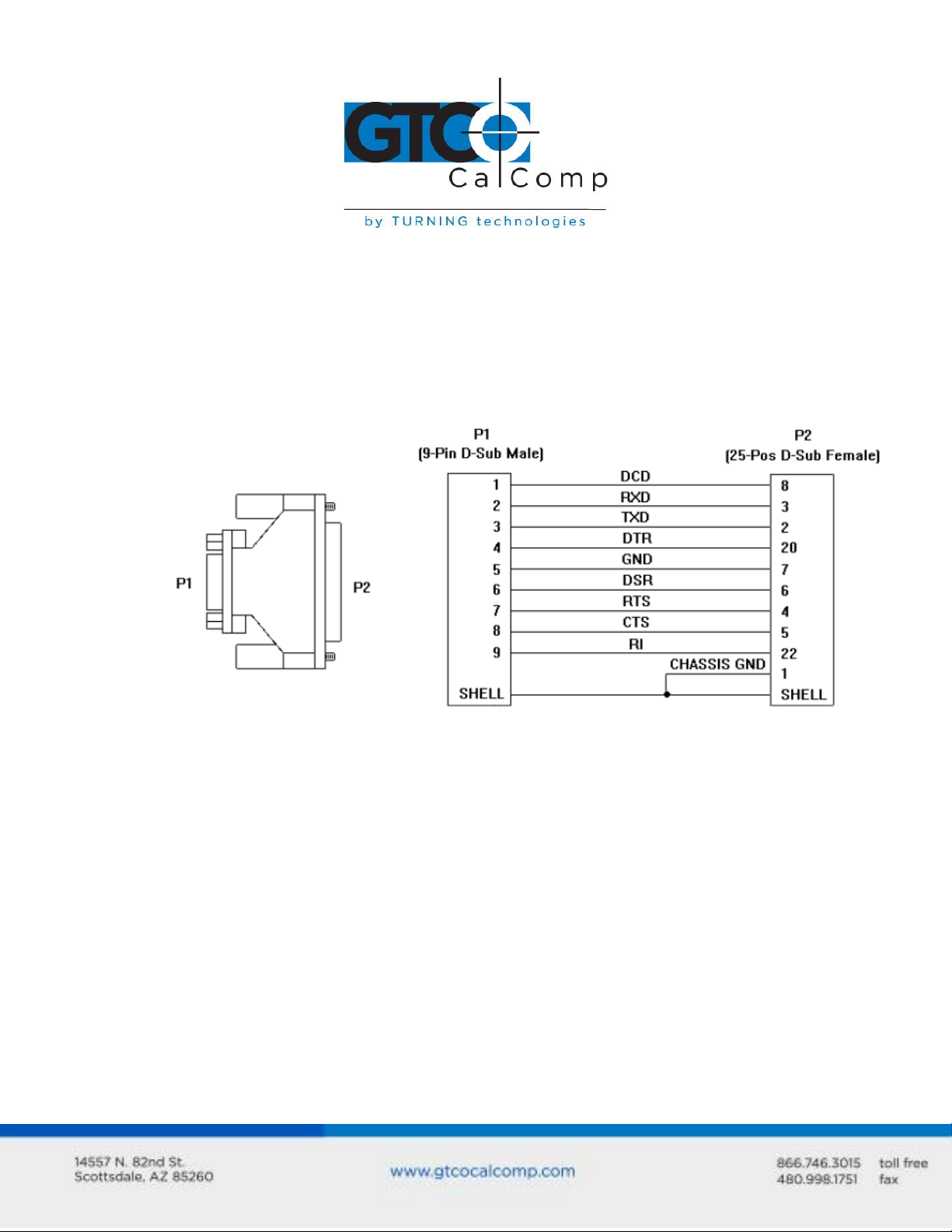

RS-232C (See Figure 4)

Adapter

9- to 25-pin (See Figure 5)

9. If GTCOTEST indicates that the digitizer is functioning properly, check your software

application setup and SuperSet code for accuracy. If you have any questions about

your results or need assistance running GTCOTEST, contact our Technical Support

Department.

Roll-Up II Technical Specifications

Page 31

Roll-Up II 31

Figure 3: Power Supply Connector

Figure 4: RS-232C Interface

Page 32

Roll-Up II 32

Figure 5: 9- to 25-Pin Adapter

Advanced Operating Information

Roll-Up II Interfacing

The following information is not required for normal Roll-Up II operation.

Connecting Roll-Up II to a computer is usually a straight forward process (see Installing

Roll-Up II section in this manual). If you do not have a typical interfacing situation, the

information in this section will offer assistance to setting up the Roll-Up II and connect it to

another device.

The Roll-Up II is equipped to communicate via RS-232C, a widely used serial interface

between computers and peripherals. RS-232C is a (more or less) standard interface, and

cables and connectors are available from a variety of sources. A majority of computers and

peripherals either have an RS-232C interface or can be equipped with one.

A mini-tutorial on RS-232C interfacing

This section provides basic information about RS-232C communications. There are three

areas to consider when using RS-232C:

Character Format and Baud Rate

Cabling

Flow Control

Page 33

Roll-Up II 33

Character Format and Baud Rate

Character format and baud rate govern how bits are assembled to form characters and the

speed of transmission. Both Roll-Up II and the computer must have identical formats and

rates. These are the parameters you must set for both devices:

Data Bits: Data bits represent the actual data being sent from one device to

another. Both devices must be set for the same number of data bits. Choices are:

Seven (7) or Eight (8). If they are not set the same, some or all of the data may be

garbled.

Parity: One bit can be allocated for parity (parity is a simple error-detecting

scheme). Both devices (sending and receiving) must be set for the same parity –

either odd parity or even parity – or they must be set for no parity. Most digitizing

application software does not check for parity.

Stop Bits: Each character has one or two stop bits, which tell the receiving device

that a character is complete. The number of stop bits usually does not matter.

Setting for two stop bits instead of one may overcome a mismatch in parity or data

bits. Choices are: One (1) or Two (2).

Baud: The rate, in bits/second, at which characters are transmitted across the RS-

232C serial interface. Choices are: 1200, 2400, 4800, 9600 and 19200 baud (bits per

second). The 9600 rate is popular for digitizing.

Cabling

Cabling carries data from one device to the other. The interface cable, shown in Figure 4,

supplied with the Roll-Up II is terminated in a 9-pin subminiature D connector. It attaches

to a standard AT-compatible RS-232C connector.

The computer may have a 25-pin RS-232C connector, rather than a 9-pin connector. If so,

use the 9- to 25-pin adapter, shown in Figure 5, supplied with the Roll-Up II.

Flow Control

Flow control is the process of regulating the traffic or flow of data between two RS-232C

devices. Flow control prevents the transmission and subsequent loss of data if the receiver

is not ready to accept it. Examples of devices that use flow control are: a printer to signal

Page 34

Roll-Up II 34

buffer full; a modem to indicate carrier detect; and a time-shared computer that services

multiple users on a time-available basis.

There are two kinds of flow control:

■ Software flow control is often used over communication links where only a 3-wire cable

is used (Transmit Data, Receive Data, Ground) or over telephone lines. The Roll-Up II is

equipped for software flow control. It will immediately stop sending data when it receives

an ASCII XOFF character (CTRL-S, hex 13). Transmission will resume when it receives an

ASCII XON character (CTRL-Q, hex 11). Character flow control will work with the straight

through cable and the null modem cable.

■ Hardware flow control (also called modem lead flow control) uses one or more lines in

the RS-232C cable to send status signals from one device to another. The Roll-Up II is not

equipped for hardware flow control.

Remote Commands

NOTE: The following information is not required for normal Roll-Up II operation.

Roll-Up II can receive commands from other devices through its RS-232C port. Commands

cause the Roll-Up II to change the way it operates, to use certain coordinate formats and to

do other things directed by you or by an application program.

Commands offer another way to control Roll-Up II operation besides the Custom

Configuration Menu. Certain Roll-Up II functions can be carried out only through

commands.

If you are developing your own application software, be cautious about using commands in

your program. An interruption in power to the Roll-Up II or a Reset will cause it to discard

any command changes it has received. This could leave the program confused about what

the Roll-Up II is doing. A full system reset would then be needed to get the digitizer and

computer coordinated again.

Roll-Up II responds to three kinds of commands:

GTCO Roll-Up II Standard Commands (with some omissions and additions)

CalComp Emulation Commands

Summagraphics Emulation Commands

Page 35

Roll-Up II 35

GTCO CalComp by Turning Technologies Roll-Up II Command Summary

Page 36

Roll-Up II 36

Select Point Mode

Select Line Mode

Select Continuous Mode

Select Line Incremental Mode

Select Continuous Incremental Mode

Select Remote Request Mode

Code: PT

Code: LN

Code: CN

Code: IC

Code: CL

Code: RM

Functional Control Commands

Reset Code: RS

The Reset command will reset the Controller to the last known configuration, clearing all

previous commands sent to the Controller. If a SuperSet Menu configuration has been

selected, the Reset command will reset the Controller to the SuperSet Menu value.

Page 37

Roll-Up II 37

Read Current Coordinate

Code: hex 02 (Ctrl-B)

Set Increment Value

Code: IV

Send Coordinates 0,0 When Transducer is Out of Active Area

No Output When Transducer is Out of Active Area

Code: OP

Code: IP

The Read Current Coordinate causes the Roll-Up II to output a coordinate while it is in

Remote Request Mode. This command can be sent to the Roll-Up II only when it is

digitizing and only when Remote Request Mode is in Command Mode. Please note that

this command is not two ASCII characters. It is the one-byte-long STX character, CTRL-B

(hex 02). Roll-Up II responds to the Read Current Coordinate command by transmitting

one format.

In Line Incremental and Continuous Incremental modes, the Roll-Up II outputs a coordinate

when the transducer is moved beyond a certain incremental distance in either the X or Y

direction. The default increment is 0.01”. The Set Increment Value command allows the

user to select the distance which the transducer must move to initiate coordinate output.

It works as follows:

1. Enter Command Mode by sending a CTRL-A.

2. After receiving the > prompt, send IV and a <CR> (hex 0D).

3. The Controller will respond with a <.

4. After receiving the <, send a three-digit string ranging from 000 to 999. This string

represents an increment value of 0.000 to 0.999 inch.

5. When the Controller receives the last character it will respond with a > prompt and

await the next command.

Certain situations require that the Roll-Up II be able to send a coordinate when the

transducer is out of the active area. Command OP permits coordinates to be sent under

this condition. Since valid coordinates are not available when the transducer is out of the

active area, coordinates 0,0 are substituted in the format. When this command has been

executed, digitizing modes operate normally, whether the transducer is in the active area

or not. Command IP returns Roll-Up II to the default condition, in which coordinates are

sent only when the transducer is in the active area.

Page 38

Roll-Up II 38

Set Digitizing Rate

Code: Rx

Digitizing rate, formats/second

Digitizing rate command

12 100 100 5 10 50

R1 R2 R3 R4 R5 R6

Change Mode Character

Code: MC

Select English Measurement Scale

Select Metric Measurement Scale

Code: IN

Code: MT

Enable Echo Mode

Disable Echo Mode

Code: EM

Code: hex 0F (Ctrl-O)

Coordinates can be sent from the Roll-Up II at rates from 5 to 140 coordinates per second.

The second character in this command sets the rate, as shown in the table below. Actual

rates are limited by the communication baud rate and coordinate type you have selected.

The rates shown here are, therefore, maximum rates.

Rate Commands

Some applications may have a predefined meaning for the SOH (CTRL-A) character used to

invoke Command Mode. If so, invoking Command Mode may cause your system to do

something else. You can set the Roll-Up II so that a character other than SOH is used to

begin Command Mode. Here is how to make the substitution:

1. Enter Command Mode.

2. Send MC, followed by a <CR>. Roll-Up II responds with the prompt message: ENTER

NEW COMMAND MODE CHARACTER:.

3. Enter the desired mode change character. The new mode character can be any

character except ESC (CTRL-[, hex 1B), <CR> (CTRL-M, hex 0D), CAN (CTRL-X, hex 18),

VT (CTRL-K, hex 0B), XON (CTRL-Q, hex 11) or XOFF (CTRL-S, hex 13).

Now, when you want to enter the Command Mode, send the new character. All other

command operations remain unchanged.

Invoking these commands causes the Roll-Up II to scale coordinates in the desired

measurement system. Roll-Up II measures in only one scale at a time. See Measurement

Scales for additional information on how scale selection affects coordinate data.

These commands control echoing by the Roll-Up II. When enabled, echoing transmits each

received character back to the sending device.

Page 39

Roll-Up II 39

ASCII Format Output

Code: AS

Command causes coordinates to be transmitted in ASCII. ASCII coordinates can be

modified by the Low/High/Highest Resolution, Pushbutton, Space, Carriage Return and Line

Feed commands and by menu settings.

Binary Format Output

Code: BI

Command causes coordinates to be transmitted in binary format. Binary coordinates can

be modified by the Low/High/Highest Resolution commands and by menu settings.

Low Resolution

Code: LR

Command modifies ASCII and binary formats. If ASCII formats have been selected, the Low

Resolution command causes the least significant digit to represent 0.001 inch or 0.025

millimeter, depending on whether English or metric scale has been selected. Both X and Y

portions of each ASCII format will be four digits long if in English scale or five digits long if in

metric scale.

If the binary format is selected, the least significant bits represent 0.001 inch or 0.025

millimeter, depending on whether English or metric scale has been selected.

High Resolution

Code: HR

Command modifies ASCII and binary formats. If ASCII formats have been selected, the

High Resolution command causes the least significant digits to represent 0.00025 inch or

0.0067 millimeter, depending on whether English or metric scale has been selected. Both X

and Y portions of each ASCII format will be six digits long.

If binary formats have been selected, the least significant bits represent 0.001 inch or 0.025

millimeter, depending on whether English or metric scale has been selected.

Pushbutton Include

Pushbutton Exclude

Code: PI

Code: PE

Format Selection Commands

Format Selection Commands, Cont.

Page 40

Roll-Up II 40

Space Include

Space Exclude

Code: SI

Code: SE

Carriage Return Include

Carriage Return Exclude

Code: CI

Code: CE

Line Feed Include

Line Feed Exclude

Code: LI

Code: LE

Enable Alarm

Disable Alarm

Code: AE

Code: AD

Sound Tone

Tone Pause

Code: T1

Code: T0

Transmit Version Number

Code: VR

Display Tablet Active Area Size

Code: SZ

These commands control the presence of the corresponding characters in ASCII formats.

Pushbutton codes and where they appear in coordinates are described in the Advanced

Programming Information section. When included, the space is an additional character

separating the X and Y components of the coordinate data. When included, the LINE FEED

is an additional character following the <CR>.

Alarm Commands

These commands enable or disable the audible alarm. When enabled, a short tone will

sound when a transducer switch is pressed. When disabled, the alarm will not sound in

response to transducer switch presses, but it may be sounded by remote commands and

will be active during diagnostics and in the menu modes.

The Sound Tone command allows a remote device to sound the Roll-Up II’s audible alarm.

Tone Pause provides a pause between tones. Tones and pauses are in 0.25 second

intervals. Tone commands are not affected by the Disable Alarm command.

Diagnostic Commands

Command causes Roll-Up II to determine and transmit the version number of the firmware

currently installed.

Roll-Up II automatically determines the size of the attached tablet’s active area when it is

turned on or reset. This command can be used to send the information to another device.

Page 41

Roll-Up II 41

Read Tablet Diodes

Code: RD

The size is encoded as four digits: two digits representing vertical size in inches followed by

two digits representing horizontal size in inches. For example, the 36” x 48” Roll-Up II sends

the digits 3648 in response to this command.

Diagnostic command causes the Roll-Up II to examine the attached tablet and send the

results to another device for display. A “1” means a diode is present and a “0” represents a

diode is missing.

Page 42

Roll-Up II 42

CalComp Emulation Commands

Roll-Up II recognizes a subset of the CalComp 9500 command set. Space does not permit a

detailed description of CalComp commands. However, most of the commands in this

subset have equivalent Roll-Up II commands. For further information about the operation

of those commands, please refer to the Roll-Up II command or function description in the

GTCO CalComp by Turning Technologies Roll-Up II Command Summary.

NOTE: CalComp commands must be terminated with a <CR>, which is not shown in the

codes listed here. Commands can be strung together by substituting an @ character for

the <ESC>% sequence after the first command and postponing the <CR> until the end of

the multiple command string.

Page 43

Roll-Up II 43

Page 44

Roll-Up II 44

Summagraphics Emulation Commands

Roll-Up II recognizes a subset of the Summagraphics UIOF command set. Space does not

permit a detailed description of Summagraphics commands. However, most of the

commands in this subset have equivalent Roll-Up II commands. For further information

about the operation of those commands, please refer to the Roll-Up II command or

function description in the GTCO CalComp by Turning Technologies Roll-Up II Command

Summary.

NOTE: Summagraphics commands do not require a terminator.

Page 45

Roll-Up II 45

Page 46

Roll-Up II 46

Command Mode Basics

To enter GTCO CalComp by Turning Technologies Command Mode:

Send an ASCII CTRL-A (hex 01) character to the Roll-Up II. When the Roll-Up II receives the

CTRL-A, two things happen:

Digitizing stops and new coordinates are not generated. If Command Mode is

invoked during transmission of a coordinate, that coordinate transmission will be

completed.

Page 47

Roll-Up II 47

Roll-Up II sends a “>” (hex 3E) as a prompt to the commanding device. The Roll-Up II

is now ready to accept commands.

A command consists of two upper case ASCII letters or numbers followed by a delimiter.

The delimiter lets the Roll-Up II know the command is complete. There are two kinds of

delimiters:

<CR> (carriage return, hex 0D): indicates end of current command and more

commands will follow. If the command just sent is valid, it will be carried out. The

Roll-Up II then sends another > prompt and awaits the next command.

<ESC> (escape, hex 1B): indicates end of current command and no more commands

will follow. If the command is valid, it will be carried out. Then the Roll-Up II will exit

Command Mode and return to Digitizing Mode.

If you are entering several commands, end each one with a carriage return delimiter. After

each <CR>, the Roll-Up II carries out the command and sends a new command prompt.

After the last command or if you are entering only one command, use an <ESC>. The

Escape delimiter takes you directly back to Digitizing Mode.

If the command entered is not recognized as a valid command, it will be ignored and RollUp II will send a “?” (question mark). If the delimiter following an invalid command was an

<ESC> (indicating your desire to leave Command Mode), Roll-Up II stays in the Command

Mode, awaiting a valid command.

A command may be aborted before entering a delimiter by sending a CTRL-X (hex 18). The

Roll-Up II then ignores the preceding one or two characters and responds with a new

prompt.

To Leave Command Mode:

Send an <ESC> (hex 1B). The <ESC> may follow a command code or it can be sent in

response to the Roll-Up II’s prompt. Roll-Up II returns to digitizing, now operating

according to the commands sent to it.

A Hint for Programmers

Here is the most efficient method for sending commands:

1. Send the CTRL-A and wait until the Controller responds with the prompt >. A loop

that retrieves one byte at a time from the serial port and checks for the > is best.

Page 48

Roll-Up II 48

2. Send the command one character at a time. The Controller will respond by echoing

each character. Waiting for the character to be echoed will ensure that the

Controller has received the character and is waiting for the next one.

3. Once the command is complete, send a <CR> or <ESC> (hex 1B) to exit command

mode.

4. If you send a <CR>, go into a loop and grab one byte at a time until a > prompt is

received. Then continue sending commands as described in step 2.

Programming Example: To Send Version Command and Display Results

The QBASIC program interacts with the Roll-Up II in Command Mode. In this example, the

program activates Command Mode, sends the VR command and displays the resulting

firmware version transmitted by the Roll-Up II.

1. Configure Roll-Up II for 9600, N, 8, 1, GTCO ASCII, Point (SuperSet 42).

2. Enter and run this QBASIC program:

Page 49

Roll-Up II 49

Advanced Programming Information

NOTE: The following information is not required for normal Roll-Up II operation.

If you are programming for the Roll-Up II product line, the topics listed below will be useful:

Coordinate Formats

Measurement Scales

Digitizing Modes

Programming Examples

These topics refer to commands that put Roll-Up II in a different operating state. The

previous Remote Commands section contains detailed information about remote

commands.

Command emulations for CalComp and Summagraphics digitizer SuperSet menu selection.

Only Roll-Up II commands, however, are referenced in this section.

Coordinate Formats

Coordinate format refers to the way the Roll-Up II encodes XY coordinate information

before it sends the data out through a communication interface. The Roll-Up II and your

application program must speak the same coordinate “language” for information to be

properly transferred.

You have three basic format choices to make:

GTCO versus CalComp or Summagraphics emulation

Binary versus ASCII coordinates

Coordinate resolution

The sections that follow describe the formats available and show you how to select them.

If you are developing your own software, these sections will also help you choose a format

that suits your needs.

Binary Formats

Binary formats encode coordinate information compactly. Binary coordinate formats are

shorter than ASCII formats, transmit faster and take up less space if stored. On the other

hand, binary formats cannot be directly displayed on a terminal or printed-they must be

converted first into displayable characters.

Page 50

Roll-Up II 50

Binary formats use the high order bit in each byte as a synchronization bit. The first byte in

each format has its high order bit set to 1. The remaining bytes have their high order bits

set to 0. The application program must examine the high order bit of each byte to

determine when a format begins.

Roll-Up II can produce two kinds of binary formats: one is compatible with GTCO Roll-Up II

and CalComp digitizers, and the other is compatible with Summagraphics digitizers. They

are quite different and are described separately in the following topics.

GTCO/CalComp Binary Format

This six-byte format is compatible with the GTCO Roll-Up II high resolution binary format. It

also emulates the CalComp binary format. Table 4 shows the structure of this format at

the bit level.

Table 4: GTCO/CalComp High Resolution Binary Format

Page 51

Roll-Up II 51

To set up the GTCO/CalComp Binary Format:

Custom Configuration Menu:

1. Select GTCO Binary or CalComp Binary (under Output Format Options).

2. Choose the desired resolution (under Mode Options).

GTCO Commands:

1. Send command BI for Binary format.

2. Send command IN for English or command MT for metric measurements.

3. Send command HR for 1000 lpi/40 lpmm or command H1 for 2000 lpi/100 lpmm

resolution.

Summagraphics Binary Format

This eight-byte format is compatible with the Summagraphics 2000 lpi UIOF format. Table

5 shows the structure of this format at the bit level.

To set up the Summagraphics Binary Format:

Custom Configuration Menu:

1. Select Summa Binary (under Output Format Options).

2. Choose the desired resolution (under Mode Options).

Page 52

Roll-Up II 52

Table 5: Summagraphics Binary Format

Low Resolution Binary Format

Low resolution binary format conforms to an existing industry standard method of

encoding small digitizer coordinate data. It is a fast, efficient and commonly used format.

Low resolution binary formats are appropriate for applications needing low precision and

using tablets up to 20” x 20”. This format is five bytes long and is frequently transmitted at

9600 baud. It is used whenever the system resolution is set to 100 lpi, 200 lpi or 10 lpmm.

Table 6 shows the structure of this format at the bit level.

Page 53

Roll-Up II 53

Table 6: GTCO Low Resolution Binary Format

Cursor Button Codes in Binary Formats

Cursor button codes are always included in binary formats. You can define certain

pushbuttons on your transducer to represent information that is relevant to your task. For

example, the buttons on a 4-button cursor could represent four line widths or four colors.

By examining the button code in the format, the application program can use this

information appropriately.

Binary formats include five bits which encode the button. The bits transmitted in the

format depend on the button pressed. Table 7 and Table 8 show which bits will be sent.

Page 54

Roll-Up II 54

Table 7: Cursor Button Codes for 4-Button Cursor

Table 8: Cursor Button Codes for 16-Button Cursors

ASCII Formats

ASCII is a commonly used method for encoding text. ASCII coordinate formats can be

directly displayed on most printers and terminals, and can be easily handled by QBASIC

programs. On the other hand, ASCII coordinate formats are longer than binary ones, so

they take longer to transmit and they occupy more space when stored in memory.

Page 55

Roll-Up II 55

Table 9, Table 10 and Table 11 show the range of ASCII formats available on the Roll-Up II.

Besides the GTCO formats, emulations are provided for CalComp (in four variations) and

Summagraphics ASCII formats. All the formats are influenced by the resolution currently in

effect (higher resolutions require an additional digit of X and an additional digit of Y).

Depending on the format, you can also choose to include or exclude certain optional

characters (cursor button code, space, decimal point, carriage return and line feed).

To set up basic ASCII Formats:

Custom Configuration Menu:

1. Select GTCO ASCII, CalComp ASCII 1-4 or Summagraphics ASCII (under Output

Format Options).

2. Select an English or metric resolution (under Mode Options).

GTCO Commands:

1. Send command AS for ASCII format.

2. Send command IN for English or command MT for metric measurements.

3. Send command LR for 100 lpi/10 lpmm, command HR for 1000 lpi/40 lpmm or

command H1 for 2000 lpi/100 lpmm resolution.

Then, you still have more decisions to make regarding the optional characters. Each of the

optional characters can be selected by using the Custom Configuration Menu or by

Remote Command. Check the tables under cursor button codes in ASCII formats to

determine which optional characters can be included in the format you have selected.

To include a Cursor Button Code, Space, Decimal Point or Line Feed in an ASCII

Format (where permitted):

Custom Configuration Menu: Select the “Include” option for the corresponding character.

GTCO Commands:

Send command PI to include the Cursor Button Code character.

Send command SI to include the Space character.

Send command CI to include the Carriage Return character.

Send command LI to include the Line Feed character.

To remove a Cursor Button Code, Space, Decimal Point or Line Feed in an ASCII

Format (where present):

Page 56

Roll-Up II 56

Custom Configuration Menu: Select the “Exclude” option for the corresponding character.

GTCO Commands:

Send command PE to exclude the Cursor Button Code character.

Send command SE to exclude the Space character.

Send command CE to exclude the Carriage Return character.

Send command LE to exclude the Line Feed character.

Table 9: GTCO ASCII Formats

Table 10: CalComp ASCII Formats

Page 57

Roll-Up II 57

Table 11: Summagraphics ASCII Formats

Cursor Button Codes in ASCII Formats

When the cursor button code is included in an ASCII format, the character transmitted in

the format depends on the button pressed. Table 7 and Table 8 show which character will

be sent. Instructions in the previous sections show how to include or exclude the cursor

button character in certain of the ASCII formats.

Measurement Scales

You can choose either English or metric scaling for the coordinates you digitize. Roll-Up II

applies the required conversion factor before constructing a coordinate format for output.

The numbers appearing in coordinate formats depend on resolution. Table 12 shows how

the resolution settings affect the data in coordinate formats.

To set the measurement scale:

Custom Configuration Menu: Select a resolution in the “Resolution” column of Mode

Options.

GTCO Commands:

1. Send command IN for English or command MT for metric measurements.

2. Send command LR for 100 lpi/200 LPI/10 lpmm, command HR for 1000 lpi/40 lpmm

or command H1 for 2000 lpi/100 lpmm resolution.

Metric example: The distance between two points is 2032 counts in the 40 lpmm binary

format. Each count represents 0.025 mm (from Table 12). Then, 2032 counts x 0.025

mm/count = 50.8 mm.

Page 58

Roll-Up II 58

Table 12: Measurement Scales

Digitizing Modes

Digitizing mode refers to the method Roll-Up II uses to determine when to output a

coordinate format. Six digitizing modes are available, but only one can be used at a time:

Point Mode

Line Mode (sometimes called Switched Stream Mode)

Continuous Mode (sometimes called Stream Mode)

Line Incremental Mode

Continuous Incremental Mode

Remote Request Mode

Table 14 will help you compare digitizing modes.

Table 13: Rate Commands

Page 59

Roll-Up II 59

Custom Configuration Menu:

GTCO Commands:

Select the Point option under Mode.

Send command PT.

Table 14: Results of Active Area and Pushbutton Changes in Digitizing Modes

Point Mode

In Point Mode, one coordinate is sent when a transducer button is pressed. Output occurs

only when the transducer is in the active area.

To select Point Mode:

Page 60

Roll-Up II 60

Custom Configuration Menu:

GTCO Commands:

Select Line Mode.

Send command LN.

Custom Configuration Menu:

GTCO Commands:

Select 12, 50 or 100 under Rate.

Send command Rx (where x = 1-6), as

shown in Table 13.

Custom Configuration Menu:

GTCO Commands:

Select the “Cont” option under Mode; select

12, 50 or 100 under Rate.

Send command CN; to select a rate, send

command Rx (where x = 1-6), as shown in

Table 13.

Line Mode

In Line Mode, coordinates are sent as long as a transducer button is pressed. Output

occurs only when the transducer is in the active area.

To select Line Mode:

To set the rate at which coordinates are sent in Line Mode:

Note that digitizing rate is also dependent on the communication baud rate and format

type you have selected. The rates shown in Table 13 are therefore maximum rates.

Surprisingly, if your system seems to respond slowly to digitizer input, it may be because

the digitizer coordinate output rate is set too high. This may occur when a program buffers

excess coordinate data, thus causing a time delay.

Continuous Mode

In Continuous Mode, coordinates are sent continuously, at the specified output rate.

Output occurs only when the transducer is in the active area. Output occurs continuously,

whether or not a transducer button is pressed.

To select Continuous Mode:

Page 61

Roll-Up II 61

Custom Configuration Menu:

GTCO Commands:

Select the “Line Incr” option under Mode.

Send command IC; to set a new increment

value, send command IV and at the prompt,

send three digits representing the new

increment in units of 0.001”.

Custom Configuration Menu:

GTCO Commands:

Select the “Cont Incr” option under Mode.

Send command CL; to set a new increment

value, send command IV and at the prompt,

send three digits representing the new

increment in units of 0.001”.

Custom Configuration Menu:

GTCO Commands:

Not available.

Send command RM.

Line Incremental Mode

In Line Incremental Mode, one coordinate is sent when the transducer is moved farther

than a preset increment and a transducer button is pressed. Default increment is 0.01”.

Output occurs only when the transducer is in the active area.

To select Line Incremental Mode:

Continuous Incremental Mode

In Continuous Incremental Mode, one coordinate is sent when the transducer is moved

farther than a preset increment or a transducer button is pressed or released. Default

increment is 0.01”. Output occurs only when the transducer is in the active area.

To select Continuous Incremental Mode:

Remote Request Mode

In Remote Request Mode, one coordinate is sent when the Controller receives a Read

Current Coordinate command (CTRL-B).

To select Remote Request Mode:

Page 62

Roll-Up II 62

Programming Example: To Ready and Display Roll-Up II Formats

The following example QBASIC programs will allow users to experiment with reading and

displaying Roll-Up II formats:

To read and display ASCII formats

To read and display high resolution binary formats

To send version command and display results

Programming Example: To Read ASCII Formats

1. Configure Roll-Up II for 9600, N, 8, 1, GTCO ASCII, Continuous (SuperSet 74).

2. Enter and run this QBASIC program:

Page 63

Roll-Up II 63

Programming Example: To Read High Resolution Binary Formats

1. Configure Roll-Up II for 9600, N, 8, 1, GTCO Binary, Continuous (SuperSet 01).

2. Enter and run this QBASIC program:

Page 64

Roll-Up II 64

Programming Example: To Send Version Command and Display Results

This QBASIC program interacts with the Roll-Up II in Command Mode. In this example, the

program activates Command Mode, sends the VR command and displays the resulting

firmware version transmitted by the Roll-Up II.

1. Configure Roll-Up II for 9600, N, 8, 1, GTCO ASCII, Point (SuperSet 42).

2. Enter and run this QBASIC program:

Page 65

Roll-Up II 65

General Product Information

Radio and Television Interference

The user is cautioned that any changes or modifications not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits of a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee the interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and the receiver.

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Reorient or coil cables.

Consult the dealer or an experienced Radio/TV technician for help.

NOTE: Any cables the user adds to the device must be shielded to be in compliance with

the FCC standards. Any unauthorized modification to this device could result in the

revocation of the end user’s authority to operate this device.

Page 66

Roll-Up II 66

Bescheinigung des Herstellers/Importeurs

Heirmit wird bescheinigt, dass der/die/das

3036R

(Geraet, Typ, Bezeichnung)

im Uebereinstimmung mit den Bestimmungen der

Vfg 1046/1984

(Amtsblattverfuegung)

Funk-Entstort ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses Geraetes angezeigt und die

Berechtigung zur Ueberpruefung der Serie auf Einhaltung der Bestimmungen eingeraumt.

GTCO CalComp by Turning Technologies, Inc.

(Name des Herstellers/Importeurs)

Dieses Geraet wurde einzeln sowohl als auch in einer Anlage, die einen normalen

Anwendungsfall nachbildet, auf die Einhaltung der Funkentstoerbestimmungen

geprueft. Es ist jodoch moeglich, dass die Funkentstoerbestimmungen unter

unguenstigen Umstaenden bei anderen Geraetekombinationen nicht eingehalten

werden. Fuer die Einhaltung der Funk-entstoerbestimmungen seiner gesamten Anlage,

in der dieses Geraet betrieben wird, ist der Betrieber verantwortlich. Einhaltung mit

betreffenden Bestimmungen kommt darauf an, dass geschirmte Ausfuhrungen

gebraucht werden. Fuer die beschaffung richtiger Ausfuhrungen ist der Betrieber

verantwirtlich.

Page 67

Roll-Up II 67

Limited Warranty for Roll-Up II

GTCO CalComp by Turning Technologies, Inc. warrants these products to be free from defects in

material and workmanship under the following terms. Complete and return the enclosed warranty

registration card to ensure that your products are covered with this warranty.

Coverage

Parts and labor are warranted for two (2) years from the date of the first consumer purchase for the

digitizer tablet, controller, transducers and tablet accessories. Power supply and cables are also

warranted for two (2) years. This warranty applies to the original consumer purchaser only.

Within the European Union, the warranty period is two (2) years, as mandated by the EU. Contact

your local dealer or distributor for additional warranty information.

Warranty is only valid if original consumer’s purchase or lease date is less than or equal to six

months from the original GTCO CalComp by Turning Technologies sale date. This information will

be captured by the system serial number and confirmed by the reseller’s purchase order.

A nominal Warranty Handling Fee will be charged after the first 90 days of use and calculated from

the date of original consumer purchase. This payment may be made by Visa, MasterCard or

American Express. A copy of the sales receipt or invoice will be required for warranty verification.

Conditions

Except as specified below, this warranty covers all defects in material or workmanship in the

products. The following are not covered by the warranty:

1. Any product on which the serial number has been defaced, modified or removed (if

applicable).

2. Damage, deterioration or malfunction resulting from:

a. Accident, misuse, abuse, neglect, fire, water, lightning or other acts of nature,

unauthorized modification for any purpose, unauthorized product modification, or

failure to follow instructions supplied with the product.

b. Repair or attempted repair by anyone not authorized by GTCO CalComp by Turning

Technologies.

c. Any damage in shipment of the product (claims must be presented to the carrier).

d. Any other cause which does not relate to a manufacturing defect.

3. Any product not sold or leased to a consumer within six months of GTCO CALCOMP BY

TURNING TECHNOLOGIES original sale date.

GTCO CalComp by Turning Technologies will pay all labor and material expenses for covered items,

but will not pay for the following:

1. Removal or installation charges.

Page 68

Roll-Up II 68

2. Costs for initial technical adjustments (setup), including adjustment of user controls.

3. Certain shipping charges. (Payment of shipping charges is discussed in the next section of

this warranty.)

4. Packaging costs. (Customers should keep their boxes.)

Warranty Service Procedures

1. To obtain service on your GTCO CalComp by Turning Technologies product, contact the

Technical Support Department to receive a Return Material Authorization Number (RMA#)

and shipping instructions by calling: 1-866-746-3015.

2. Ship the product to GTCO CalComp by Turning Technologies with the RMA# marked clearly

on the outside of the box. Without a clearly marked RMA# on the shipping box, GTCO

CalComp by Turning Technologies reserves the right to refuse the shipment.

3. Although you must pay any shipping charges to ship the product to GTCO CalComp by

Turning Technologies for warranty service, GTCO CalComp by Turning Technologies will pay

the return shipping charges for ground shipment. Other shipping options are available at an

additional fee.

4. Whenever warranty service is required, the original dated sales invoice (or a copy) must be

presented as proof of warranty coverage and should be included in shipment of the product.

Please also include your name, address, telephone number, fax number, email address and

a description of the problem.

5. If GTCO CalComp by Turning Technologies determines that the unit is not defective within

the terms of the warranty, the consumer shall pay the cost of all freight charges, as well as

any repair charges.

Technical Support

Web-based Technical Support is available free of charge at: www.gtcocalcomp.com, where current

driver releases, as well as comprehensive technical support, troubleshooting, Technical Bulletins and

FAQs can be found.

Telephone Technical Support is available free of charge to the original consumer for a period of 90

days from the date of purchase of the product. Please contact our Technical Support Department

at: 1-866-746-3015 or fax your request to: 480.998.1751.

Disclaimer of Unstated Warranties

The warranty printed above is the only warranty applicable to this purchase. ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. Assuming the

warranty above stated is otherwise applicable, it is expressly understood and agreed that GTCO

CalComp by Turning Technologies sole liability whether in contract, tort, under any warranty, in

negligence or other shall be for the repair or replacement of the defective parts and under no

circumstances shall GTCO CalComp by Turning Technologies be liable for special, indirect or

Page 69

Roll-Up II 69

consequential damages. The price stated and paid for the equipment is a consideration in limiting

GTCO CalComp by Turning Technologies liability.

Notice

Some states and provinces do not allow the exclusion or limitation of incidental or consequential

damages, so the above exclusion may not apply to you. This warranty gives you specific legal rights,

and you may have other rights, which vary from state to state, or province to province.

To obtain service on your GTCO CalComp by Turning Technologies product, call our Technical

Support Department at: 1-866-746-3015 or fax us at (480) 998-1751. We can also be contacted

through our website at www.gtcocalcomp.com (in US); at EUOffice@gtcocalcomp.com (in Germany);

at infos@calcomp.fr (in France).

Important!

All products returned to GTCO CalComp by Turning Technologies for service must have prior

approval in the form of a Return Merchandise Authorization Number (RMA#), which can be obtained

by calling the Technical Support Department.

Page 70

Roll-Up II 70

Corporate Headquarters

14557 N. 82nd Street

Scottsdale, Arizona 85260

Tel: 1-866-746-3015

Support: 1-866-746-3015

Fax: 480-998-1751

Support: 1.866.746.3015

Copyright© 2014 GTCO CalComp by Turning Technologies, Inc.

Roll-Up II is a trademark of GTCO CalComp by Turning Technologies, Inc.

All other products and company names are the trademarks or registered trademarks of

their respective owners.

The information contained in this document is subject to change without notice. GTCO CalComp by

Turning Technologies assumes no responsibility for technical, or editorial errors, or omissions that may

appear in this document, or for the use of this material. Nor does GTCO CalComp by Turning

Technologies make any commitment to update the information contained in this document. This

document contains proprietary information which is protected by copyright. All rights reserved. No part of

this document can be photocopied or reproduced in any form without the prior, written consent of GTCO

CalComp by Turning Technologies, Inc.

Loading...

Loading...