1. GENERAL SAFETY RULES

IR

MEASURE

WARNING

!

• CAUTION—use of controls or adjustments or performance

of procedures other than those specied herein may result

in hazardous radiation exposure.

• DO NOT operate this instrument in areas where there is risk

of re or explosion, like in the presence of ammable liquids,

gases, dust, etc.

• DO NOT disassemble the instrument. There are no user

serviceable parts inside. Disassembling the instrument will

void all warranties on the product.

• DO NOT modify the instrument in any way. Modifying the

instrument may result in hazardous laser radiation exposure.

• To ensure that the instrument is used safely, follow all safety

and operating instructions in this manual. If the instrument

is not used as described in this operation manual, the safety

features of this device may be impaired.

• To avoid personal injuries and damage to the instrument, use

extreme caution when working around hot machine or engine parts,

such as radiators, exhaust manifolds, catalytic converters, etc.

• Repair and servicing must always be performed by qualied

repair personnel. Repairs performed by unqualied personnel

could result in serious injury.

• This instrument is designed for indoor use at temperatures

between 32°F and 122°F (0°C to 50°C), altitudes up to 6500

ft. (2,000 m), and 10% to 90% relative humidity.

Read all instructions. Failure to follow all

instructions listed below may result in

hazardous radiation exposure, electric

shock, re, and/or serious injury.

2. LASER SAFETY RULES

This label is on your

laser instrument

for your safety.

ALWAYS BE AWARE

of its location when

using the tool.

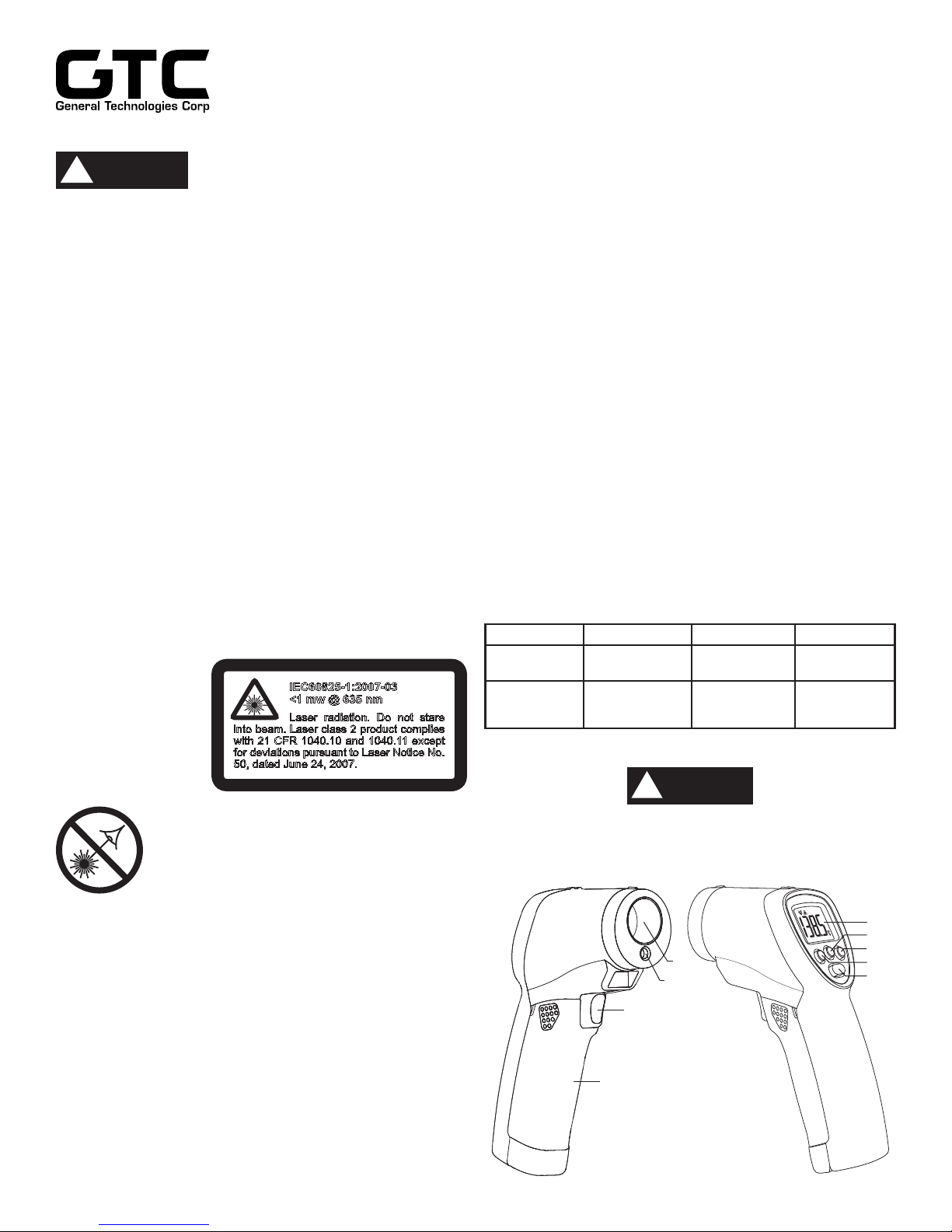

DO NOT direct the laser beam at persons or

animals and do not stare into the laser beam

yourself. This tool produces class 2 laser

radiation and complies with 21 CFR 1040.10 and

1040.11 except for deviations pursuant to Laser

Notice No. 50, dated June 24, 2007. This can lead

to persons being blinded.

Working safely with this instrument is possible only when the

operating and safety information are read completely and the

instructions contained therein are strictly followed.

• Never make the warning labels on the instrument unrecognizable.

• Never aim the beam at a workpiece with a reective surface.

• Mirrors or similar reective surfaces are not recommended for laser

use, as these could reect the beam back towards the operator.

• Do not point the laser beam at persons or animals and do not look

into the laser beam yourself, not even from a long distance.

• Do not use laser viewing glasses as safety goggles, because they

do not protect against laser radiation.

• Do not allow children to use the measuring tool without supervision.

They could unintentionally blind other people.

• ALWAYS: Make sure that any bystanders in the vicinity of use are

made aware of the dangers of looking directly into the instrument.

into beam. Laser class 2 product complies

with 21 CFR 1040.10 and 1040.11 except

for deviations pursuant to Laser Notice No.

50, dated June 24, 2007.

IEC60825-1:2007-03

<1 mw @ 635 nm

Laser radiation. Do not stare

TA110

3. TECHNICAL SPECIFICATIONS

3.1 General Specications

Display: 5-digit LCD, with measuring unit, low

battery and laser on target indicators.

Resolution: ±(0.05%+1 Digit)

Operating temperature: 32°F to 122°F (0°C to 50°C)

Response time: 0.5 seconds (over 120 RPM)

Range selection: Auto ranging

Memory: Maximum, minimum, and display

hold.

Distance to target: 2” to 20” (50 mm to 500 mm)

Laser class: 2

Laser type: < 1 mW @ 635 nm

Power source: 9 V battery type NEDA 1604,

IEC6F22 IEC 6LR61

Battery life: Approx. 20 hours (w/alkaline batteries)

Power saving: Automatic shut off after 7 seconds

Dimensions: 3.13”x 1.88”x 7.0” (80 x 48 x 178 mm)

Weight: 7.6 oz. (215 g) including battery

Accessories: User’s manual, 3 x 20 cm self-adhesive

reective tape, soft pouch, and 9 V

alkaline battery

3.2 Measurement Specications

•Accuracies are ±(% of reading + number of least signicant digits)

at 23°C ±3°C (73°F ± 6°F) ambient temperature, with less than 75%

relative humidity.

Function Range Acuracy Resolution

RPM

COUNT

(total revolutions)

1 to 99,999 RPM

1 to 99,999

4. OPERATION

!

Use of controls or adjustments or performance of procedures other

than those specied herein may result in hazardous radiation exposure.

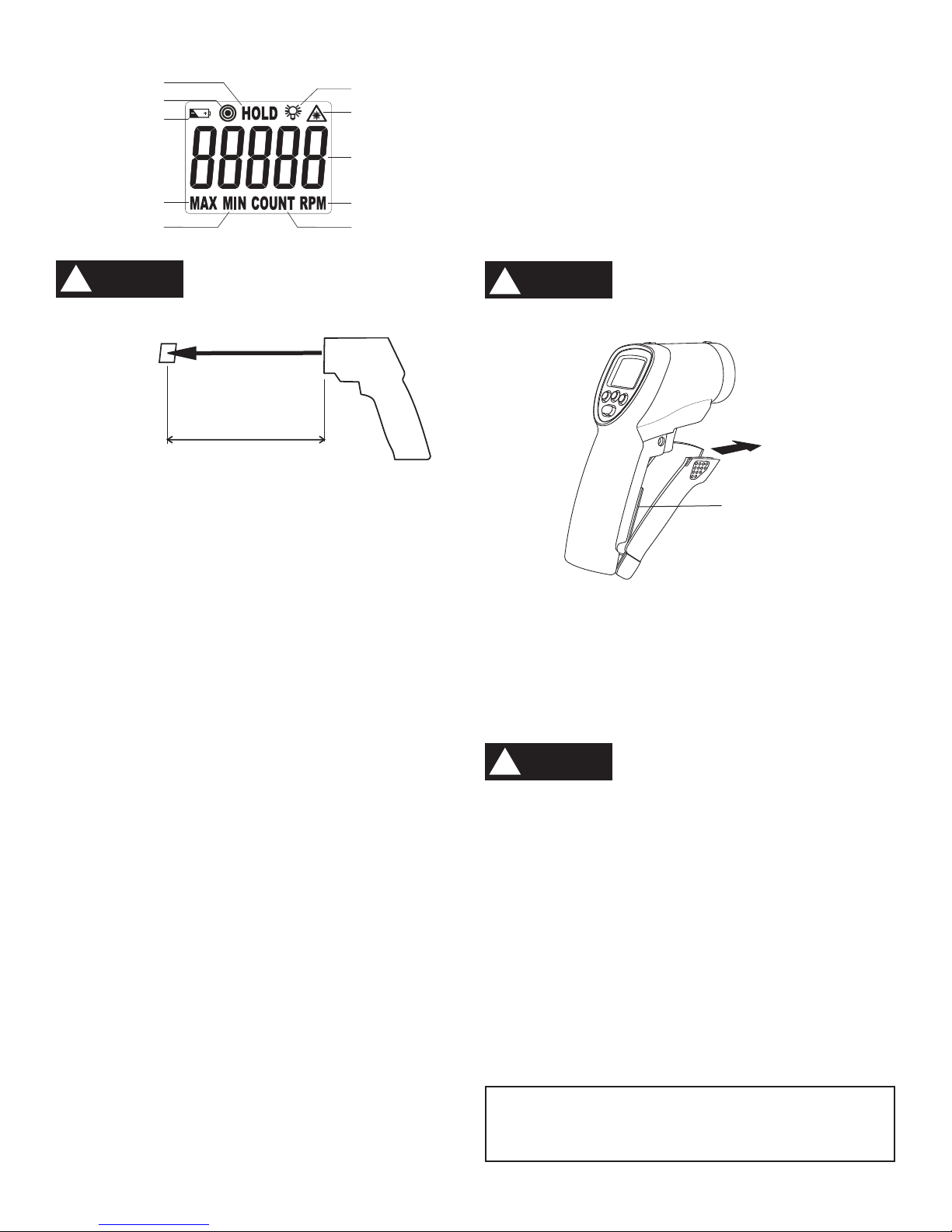

4.1 Instrument Description

8

1) LCD display

2) Backlight on/off button

3) Minimum select button

9

4) Maximum select button

5) RPM/Count button

6) IR sensor aperture

7) Laser aperture

8) Measurement trigger

9) Battery cover

±(0.05%+1 Digit)

±(0.05%+1 Digit)

CAUTION

6

7

1 RPM

1 COUNT

1

2

3

4

5

4.2 Display Description

5

HOLD indicator

On target indicator

Low battery

MAX indicator

MIN indicator

Backlight indicator

Laser output warning

Numeric reading

RPM indicator

COUNT indicator

4.3 Measurement Procedures

CAUTION

!

4.3.1 RPM/COUNT Measurement

Reective

tape

• Apply a reective mark or a piece of reective tape to the rotating

object under measurement.

• Press the Measurement trigger and verify if the RPM or COUNT

Indicator is shown in the display. The selected function can be

changed by pressing the RPM/COUNT button.

• Press the Measurement trigger and aim the laser beam at the

reective mark or tape on the rotating object.

• Verify that the on target indicator appears on the display to

conrm the instrument is detecting the rotation of the object and

the reective mark on it.

• Proceed to read the RPM or Count on the digital display.

4.3.2 Reective marks

• Cut a 1/2” (1.25 cm) length of the reective tape provided, peel off

the backing to expose the adhesive, and attach it to the rotating

part or shaft to be measured, following these recommendations:

- The non-reective area must be larger than the reective piece of tape.

- If the object or shaft to be measured is reective, rst cover it with

a matte tape or paint it black before attaching the reective tape.

- Ensure the surface is clean and smooth before applying the tape.

4.3.3 Very low RPM measurements

To measure slowly rotating parts, it may be advantageous to

follow the procedure below to increase the update rate of the

measurement:

• Depending on the size of the rotating object or shaft, attach

multiple reective marks, evenly spaced along its circumference.

• Proceed to measure RPM as described in 4.3.1, and divide the

reading by the number of reective marks, in order to obtain the

correct RPM.

Use of controls or adjustments or performance

of procedures other than those specied herein

may result in hazardous radiation exposure.

Laser beam

2 to 20”

5 to 50 cm

4.4 Other Functions

4.4.1 Display Hold

• The instrument will automatically hold the last measurement

reading for approximately 7 seconds after the Measurement

trigger has been released.

4.4.2 Display Backlight

• Make sure the instrument is turned on, if not, press the

Measurement trigger to turn it on.

• Pressing the Backlight on/off button, will turn the display backlight

on and off.

• When the backlight is not needed, turn it off to prolong battery life.

4.4.3 MAX and MIN functions

• The instrument automatically stores in its internal memory the

maximum and minimum values measured during a measuring

cycle. A measuring cycle starts when the Measuring trigger is

pressed, and nishes when the Measuring trigger is released.

• While the instrument is on, press once the MAX or MIN button,

the corresponding indicator will appear on the display, and the

maximum or minimum value stored in memory will be shown.

• Once the MAX or MIN function is selected, if the Measurement

trigger is pressed again, the maximum and minimum values

stored in memory will be cleared and then updated with the new

measurement. To turn the MAX or MIN function off, press the

corresponding function button once.

Note: The values stored in memory (maximum and minimum) will

be deleted when the unit turns itself off (automatic shut off),

or when a new measuring cycle is started.

5. MAINTENANCE

5.1 Battery Replacement

In order to avoid laser radiation exposure

CAUTION

!

opposite to the display) is pointing away from any person, animal,

or reective surface.

• When the battery is low and needs to be replaced, the “Low battery

indicator” symbol will appear on the lower left hand side of the display.

• To replace the battery, open the battery compartment cover

(located at the front of the handle) by pulling on the nger indents

near the trigger, and remove the battery.

• Replace with a new 9 V alkaline battery type NEDA 1604 or

IEC6F22 observing the proper polarity when connecting the battery

terminals, and close the battery cover.

when removing or replacing the battery

always make sure the laser aperture (located

Pull to open

battery cover

Battery

5.2 Cleaning

In order to avoid laser radiation exposure,

CAUTION

!

remove the battery before performing any

cleaning of the lens or exterior of the instrument.

5.2.1 Lens Cleaning

Debris or dirt on the lens may cause obstruction and reduce the

accuracy of the tachometer. If this occurs, either wipe the lens

with a cotton swab (moistened with water only) or blow the loose

particles off with clean compressed air. Do not use solvents on the

lenses, as they may damage the instrument.

5.2.2 Exterior Cleaning

Periodically wipe the enclosure with a soft damp cloth and mild

household cleanser. Do not use abrasives or solvents. Ensure that

no water gets inside the instrument to prevent possible short circuits

and damage.

6. WARRANTY

One year limited warranty, excluding batteries and fuses. For

details see Standard Warranty Information on our web page or

request a printed copy.

General Technologies Corp.

#121 - 7350 72nd Street Tel.: (604) 952-6699

Delta, BC Fax: (604) 952-6690

Canada V4G 1H9 www.gtc.ca

© Copyright 2016 General Technologies Corp.

Loading...

Loading...