GTC POWERED CASE TRIMMER Instruction Manual

Giraud Tool Company, Inc.

Giraud Powered Case Trimmer

U.S. Patent #6,484,616

Description and Instructions for Giraud Powered Case Trimmer

The Giraud Powered Case Trimmer is designed for the quality conscious shooter or reloader

needing a dependable medium volume case trimmer for bottleneck rifle cartridge cases. This

trimmer will provide the user with the best equipment available for uniform trimming and

chamfering of rifle cartridges outside of a military type arsenal.

The trimmer comes complete and ready to use, set up in one caliber. Presently, there are over

175 different available sizes. A list is shown on the last page of this Instruction manual.

Additionally, if you have a chamber reamer for other wildcat sizes, they can be accommodated by

finishing a blank case holder with that reamer.

Giraud Tool Company, Inc.

3803 Dawn Lane

Richmond, TX 77406-7601

281-238-0844, Orders M-F, 9am to 5pm CST

281-232-0987, Fax, 24/7

713-907-2695, Info/Questions only, after 6pm CST

Giraud Tool Company, Inc. GIRAUD POWERED CASE TRIMMER

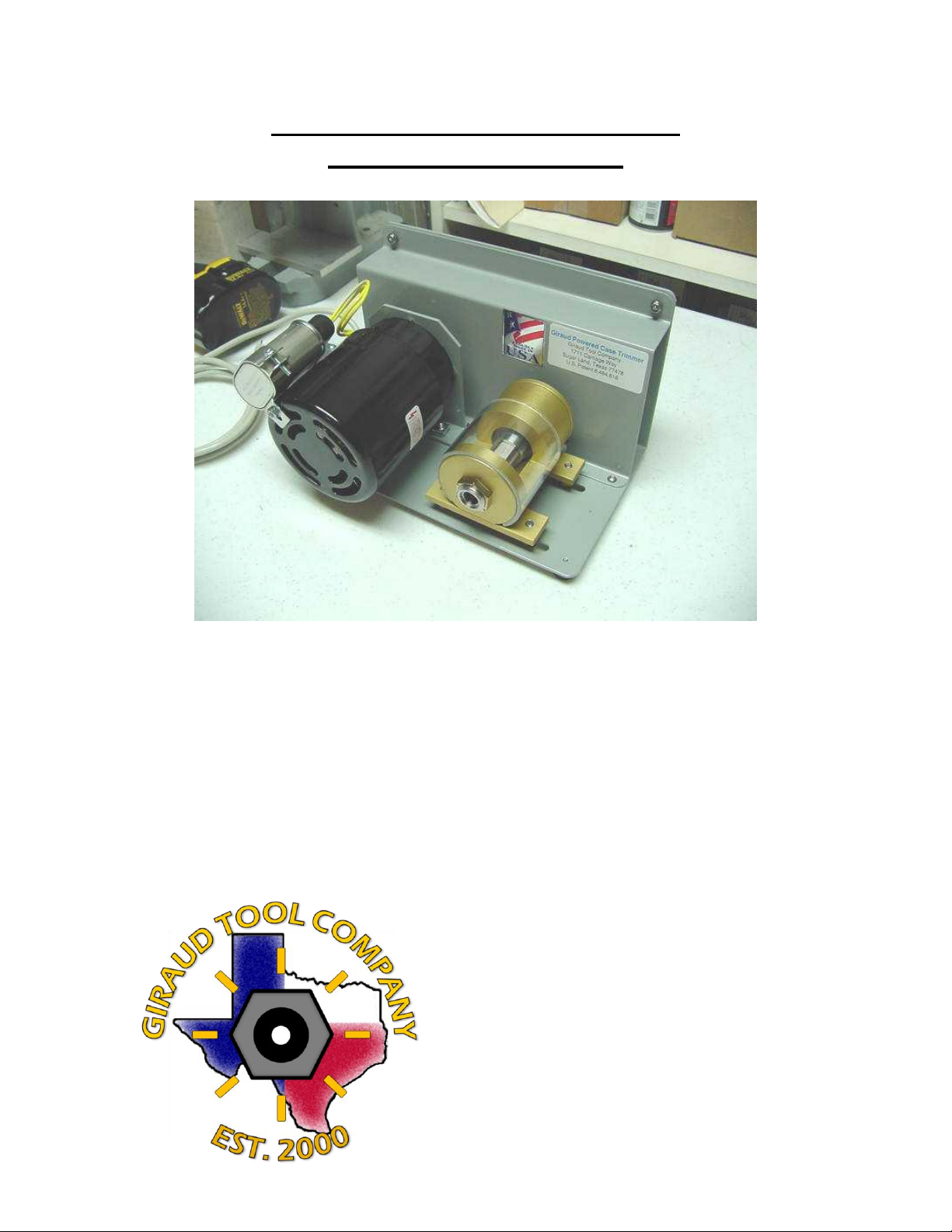

Figure 1 - Trimmer setup and ready to use.

Receiving and Setting Up

The trimmer comes complete in one caliber as it leaves the box. Set the trimmer

on a sturdy, level surface and examine for any signs of damage from shipping. If

any are found, contact Giraud Tool Company,Inc. (GTC) as soon as found.

Together we can determine if the trimmer can be fixed or needs to be returned to

GTC for repair. GTC will repair or replace these trimmers for the original

purchaser for life. If the parts or problems are determined to be due to defective

parts GTC made, GTC will repair or replace them free of charge. If the parts or

problems are determined to be due to defective parts not made by GTC, such as

the motor or switches, GTC will replace them for you at cost or as inexpensively

as possible. Unfortunately, GTC cannot control somebody else's products

against defective parts or material. GTC will get the trimmer fixed for you as best

as possible, no BS, simple as that.

Once the trimmer is setup on a sturdy work surface with the trimmer shaft

horizontal to the floor, plug the power cord in and make sure there are no

hazards around the trimmer. Check and make sure the power cord does not

touch the rotating pulleys or belt. Make sure there are no liquids around the

trimmer that could cause problems with the electric motor or switch. See Fig. 1

below.

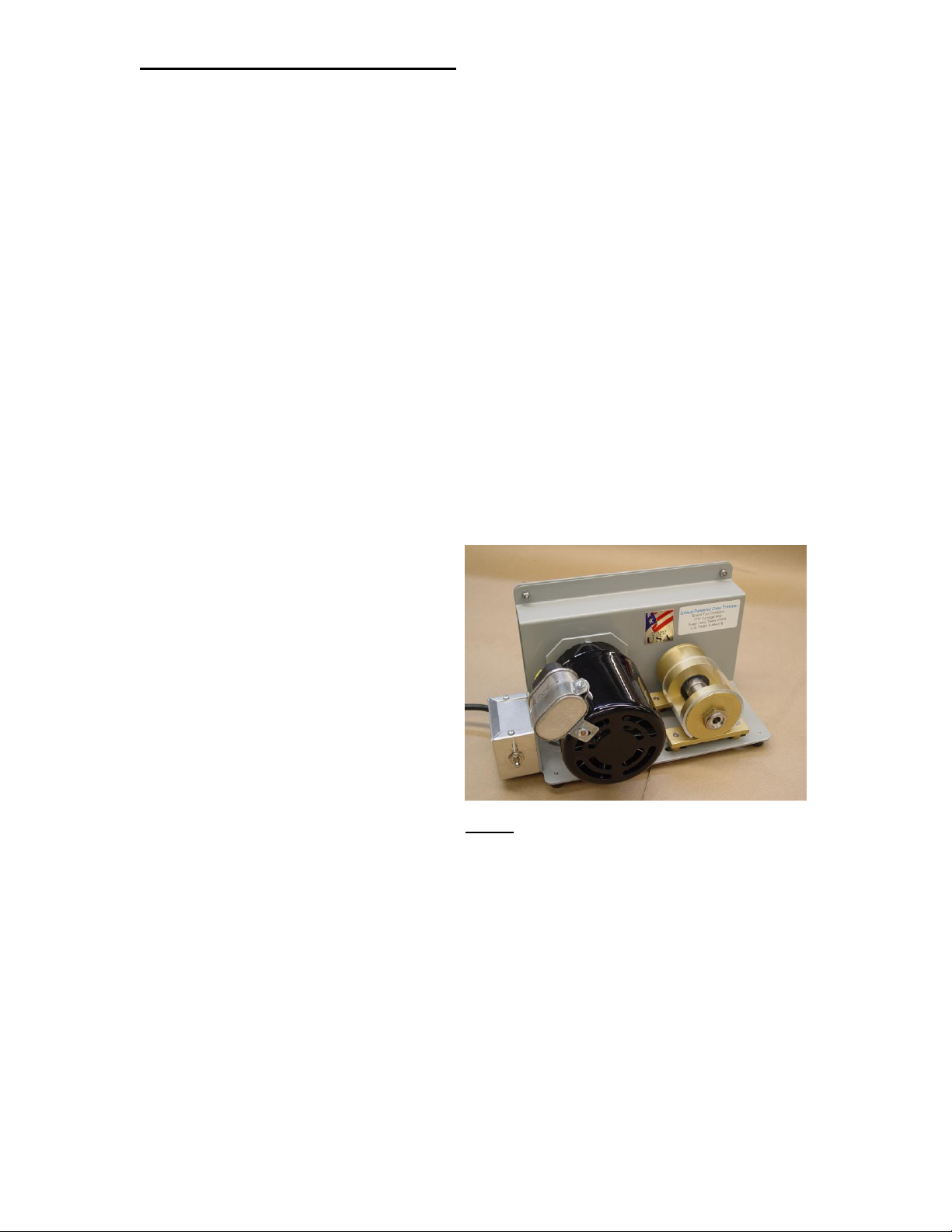

Each trimmer is sent with a sample

case attached to the sheet metal in

a small ziplock style bag with the

caliber noted. This case was the

last case trimmed with that specific

trimmer before being packaged for

shipment. There are also two

spanner wrenches enclosed in the

white foam packing material on the

right side of the shipping box.

There is usually some marking to

help locate these wrenches before

discarding the shipping box.

Examine the sample case to see

what a proper trim and chamfer looks like, and measure the case to determine

what length the trimmer is currently set for. Turn the power switch on and verify

the motor works properly and runs without undue vibrations or noises.

If everything appears okay, you are ready to proceed with trimming some brass.

If the case length of the sample case is longer or shorter than your desired

length, you can adjust it at this point using the spanner wrenches provided. Each

trimmer unit is now provided with engraved witness marks on the front face of the

trimmer body. Each of these marks are located around the case holder at 45º

increments. If you mark the face end of your threaded case holder with a marker

or felt tip pen, you can determine how far the case holder is twisted in or out by

comparing the witness marks on the trimmer to the mark on the end of the case

Page 2 of 10

Giraud Tool Company, Inc. GIRAUD POWERED CASE TRIMMER

Figure 2 - A properly trimmed case has a chamfer that is

even and smooth around the entire case mouth, both

inside and outside.

holder. Rotating the case holder from one mark to another (45º) with move the

case holder approximately 0.009”

With some of your older or scrap RESIZED cartridge cases, trim a few cases to

check out the operation of your new trimmer. Insert a case into the shell holder

and press the case into the trimmer blade while the machine is running. If the

motor is bogged down or stops, the speed at which you inserted the case is too

fast. Gently but firmly will do, you don't have to jam it in there. As you press into

case holder, you will feel the vibration as the carbide blade removes material

from the case mouth, when it stops, simply twist the still inserted case with your

finger tips to even out the freshly cut surfaces.

Check the case mouth on your first case. You should see the case mouth bright

and shiny where the brass has been trimmed. If the case mouth is not uniformly

trimmed around the entire diameter, it is because the runout between the cutting

blade and case holder are just slightly out of alignment or the case neck is not

concentric with the case body. It only takes a thousandth or two to cause that.

But you can easily correct or overcome this by twisting the case a half turn or

more while the case is touching the rotating blade. As the case rotates and

blade rotates, the entire case mouth makes contact with the entire travel of the

blade. It sounds more complicated than it really is. Just give them a twist and

they come out pretty uniform.

Next, check your overall length of the

trimmed case with a caliper. I will set

the length fairly close, but it will really

depend on how you size your brass.

Since the case trimmer locates each

case by the case shoulder, if your

headspace dimensions on the resized

brass are not consistent, then the

case can't be trimmed to a uniform

dimension. I suggest the use of some

type of headspace measuring device

to monitor your resizing operation.

Several different brands of tools are

available from Stoney Point, Midway,

mounts to the jaw of your dial caliper and lets you measure the consistency of

each case quickly and easily.

Using the Trimmer

Trim and measure three cases. If your dimensions are within +/- 0.002" on the

overall length, you are in the ballpark. With a little use and consistent technique,

your cases should come out within 0.001" of each other, every time. If the overall

length you measured is the length you want the finished cases to be, you are

ready to trim some brass. If the length is too long or too short, loosen the jam nut

Neal Jones, Sinclair, and RCBS, just

to name a few. The simplest device

Page 3 of 10

Loading...

Loading...