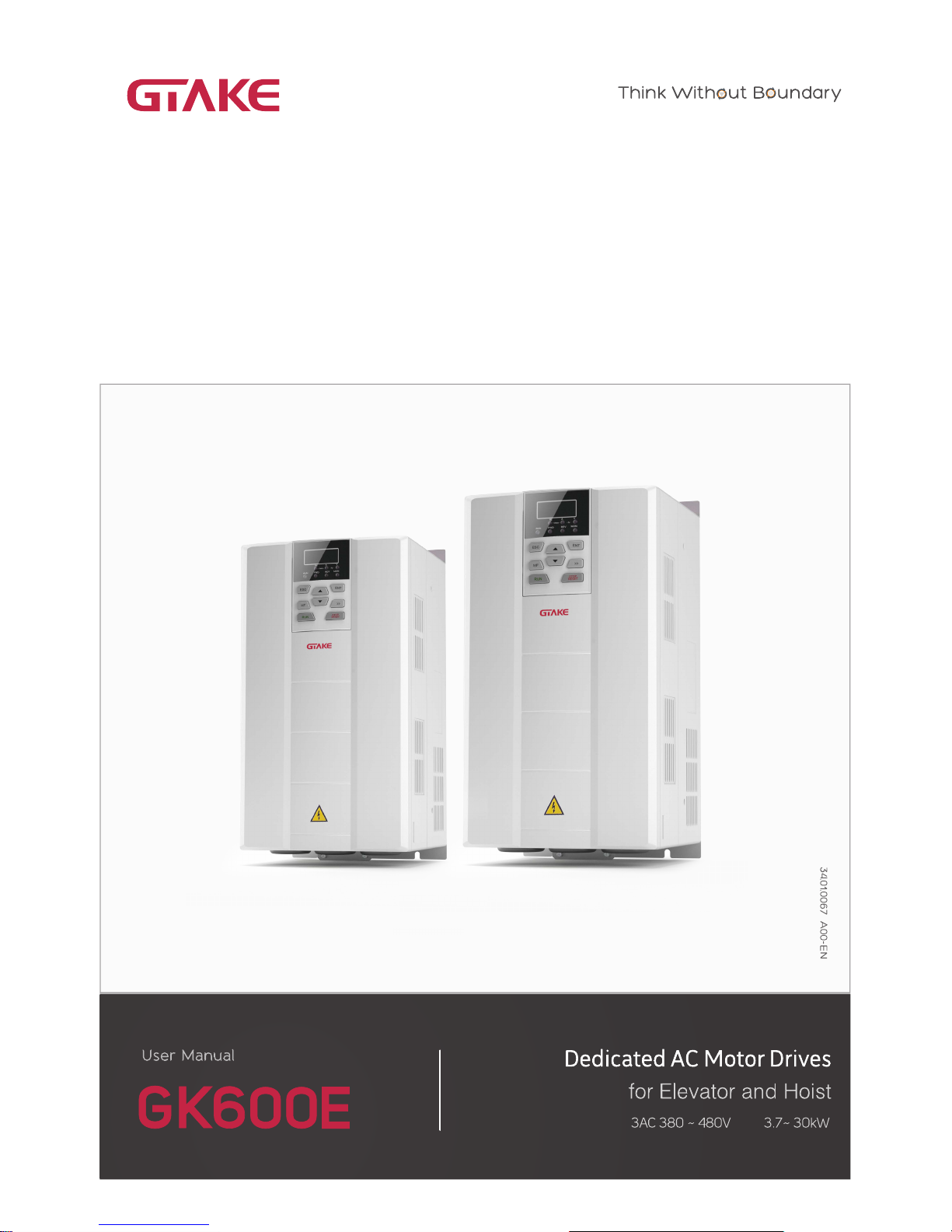

GTAKE GK600E-4T5.5B, GK600E-4T3.7B, GK600E-4T18.5B, GK600E-4T22B, GK600E-4T30B User Manual

...

Preface

Thank you for choosing GTAKE GK600E Series Elevator Dedicated Drives. This user

manual presents a detailed description of GK600E series with respect to product features,

structural characteristics, functions, installation, parameter setting, troubleshooting,

commissioning and daily maintenance, etc. Be sure to carefully read through the safety

precautions before use, and use this product on the premise that personnel and equipment

safety is ensured.

IMPORTANT NOTES

Please assure the intactness of product enclosure and all safety covers before installation.

Operation must conform to the requirements of this manual and local industrial safety

regulations and/or electrical codes.

Contents of this manual may be subject to appropriate modification as a result of product

upgrade, specification change and update of the manual.

In the event of damage or loss of user manual, users may ask local distributors, offices or

our Technical Service Department for a new one.

If any item as stated in this manual is not clear enough, please contact our Technical

Service Department.

If any anomaly occurs after power up or during the operation, it is essential to stop the

machine and identify the fault or seek technical services as soon as possible.

Telephone number of our Technical Service Department: (+86) 0755-86392601.

Table of Contents

Chapter 1 Safety Precautions ............................................................................................- 1 -

1.1 Safety Considerations ........................................................................................- 1 -

1.2 Other Considerations .........................................................................................- 5 -

Chapter 2 Product Information ..........................................................................................- 7 -

2.1 Model Explanation..............................................................................................- 7 -

2.2 Nameplate Information .......................................................................................- 7 -

2.3 Information of Product Model .............................................................................- 8 -

2.4 Technical Features of GK600E...........................................................................- 8 -

2.5 Parts Drawing...................................................................................................- 11 -

2.6 Appearance, Mounting Dimensions and Weight...............................................- 12 -

2.7 External Dimensions of Control Panel ..............................................................- 13 -

2.8 External Dimensions of Control Panel Bracket.................................................- 13 -

Chapter 3 Installation and Wiring ....................................................................................- 15 -

3.1 Installation Environment ...................................................................................- 15 -

3.3 Remove & Mount Control Panel and Cover......................................................- 16 -

3.4 Configuration of Peripheral Devices .................................................................- 21 -

3.5 Terminal Configuration .....................................................................................- 24 -

3.6 Main Circuit Terminals and Wiring ....................................................................- 24 -

3.7 Control Terminal Wiring ....................................................................................- 26 -

3.8 Control Terminal Specification ..........................................................................- 30 -

3.9 Control Terminal Usage ....................................................................................- 31 -

3.10 Instruction of Signal Sw itches...........................................................................- 37 -

3.11 EMI Solutions ...................................................................................................- 37 -

Chapter 4 Operation and Run Instructions .....................................................................- 40 -

4.1 Operation of Control Panel ...............................................................................- 40 -

Chapter 5 Elevator Dedicated Parameters ......................................................................- 55 -

5.1 Standard Wiring ...............................................................................................- 55 -

5.2 Elevator Sequence ...........................................................................................- 56 -

5.3 Startup Manual .................................................................................................- 57 -

Chapter 6 List of Parameters ...........................................................................................- 75 -

Chapter 7 Troubleshooting ............................................................................................- 108 -

7.1 Fault Causes and Troubleshooting.................................................................- 108 -

Chapter 8 Maintenance................................................................................................... - 117 -

8.1 Routine Inspection.......................................................................................... - 117 -

8.2 Regular Maintenance ..................................................................................... - 118 -

8.3 Replacement of Vulnerable Parts ................................................................... - 119 -

8.4 Storage...........................................................................................................- 120 -

GK600E User Manual Chapter 1 Safety Precautions

- 1 -

Chapter 1 Safety Precautions

Safety Precautions

Safety signs in this manual:

WARNING: indicates the situation in which the failure to follow operating requirements

may result in fire or serious personal injury or even death.

ATTENTION: indicates the situation in which the failure to follow operating requirements

may cause moderate or slight injury and damage to equipment.

Users are requested to read this chapter carefully when installing, commissioning and repairing

this product and perform the operation according to safety precautions as set forth in this

chapter without violation. GTAKE bears no responsibility for any injury and loss as a result of

any violation.

1.1 Safety Considerations

1.1.1 Prior to Installation

WARNING

Do not touch control terminals, circuit boards and any other electronic parts and

components with bare hands.

Do not use the drive whose component(s) is/are missing or damaged. Failure to comply

may result in more faults and/or personal injury even death.

ATTENTION

Check if the product information indicated on the nameplate is consistent w ith the order

requirements. If not, do not install it.

Do not install the drive in the event that the packing list does not match the real

equipment.

1.1.2 Installation

WARNING

Only qualified personnel familiar with adjustable frequency AC drives and passenger lift

should plan or implement the installation. Failure to comply may result in equipment damage

and/or personnel injury even death.

Chapter 1 Safety Precautions GK600E User Manual

- 2 -

This equipment must be mounted on metal or other flame retardant objects. Failure to

comply may result in fire.

This equipment must be mounted in an area which is away from combustibles and heat

sources. Failure to comply may result in fire.

This equipment must in no case be mounted in the environment exposed to explosive gases.

Failure to comply may result in explosion.

Never adjust mounting bolts of this equipment, especially the ones with red marks. Failure to

comply may result in equipment damage.

ATTENTION

Handle the equipment gently and take hold of its sole plate so as to avoid foot injury or

equipment damage.

Mount the equipment where its weight can be w ithstood. Failure to comply may result in

equipment damage and/or personnel injury if falling happens.

Make sure the installation environment conforms to the requirements as stated in

Section 2.4. If not, de-rating is necessary. Failure to comply may result in equipment

damage.

Prevent drilling residues, wire ends and screws from falling into the equipment during

installation. Failure to comply may result in faults or equipment damage.

When mounted in a cabinet, this equipment should be provided with appropriate heat

dissipation. Failure to comply may result in faults or equipment damage.

1.1.3 Wiring

WARNING

Only qualified personnel familiar with adjustable frequency AC drives and passenger lift

should plan or implement the wiring. Failure to comply may result in personnel injury and/or

equipment damage.

Wiring must strictly conform to this manual. Failure to comply may result in personnel

injury and/or equipment damage.

Make sure the input power supply has been completely disconnected before wiring.

Failure to comply may result in personnel injury and/or equipment damage.

All w iring operations must comply with EMC and safety regulations and/or electrical

codes, and the conductor diameter should conform to recommendations of this manual.

Failure to comply may result in personnel injury and/or equipment damage.

Since overall leakage current of this equipment may be bigger than 3.5mA, for safety's

sake, this equipment and its associated motor must be well grounded so as to avoid risk

of electric shock.

Be sure to implement w iring in strict accordance w ith the marks on this equipment’s

GK600E User Manual Chapter 1 Safety Precautions

- 3 -

terminals. Never connect three-phase power supply to output terminals U/T1, V/T2 and

W/T3. Failure to comply may result in equipment damage.

Install braking resistors at terminals and B2 only. Failure to comply may result in

equipment damage.

Install DC reactor at terminals and , and remove the jumper connected at

and . Never connect this jumper and DC reactor to any other terminals. Failure to

comply may result in short circuit and equipment damage.

Wiring screws and bolts for main circuit terminals must be screwed tightly. Failure to

comply may result in equipment damage.

AC 220V signal is prohibited from connecting to other terminals than control terminals

RA, RB and RC. Failure to comply may result in equipment damage.

ATTENTION

Since all adjustable frequency AC drives from GTAKE have been subjected to hi-pot

test before delivery, users are prohibited from implementing such a test on this

equipment. Failure to comply may result in equipment damage.

Signal wires should be away from main power lines to the best of the possibility. If this

cannot be ensured, vertical cross-arrangement shall be implemented, otherwise

interference noise to control signal may occur.

If motor cables are longer than 100m, it is recommended output AC reactor be used.

Failure to comply may result in faults.

1.1.4 Run

WARNING

Drives which have been stored for more than 2 years should be used with voltage

regulator to gradually boost the voltage when applying power to the drives. Failure to

comply may result in equipment damage.

Be sure to implement the wiring as per Section 3.4 before applying power to the drive.

Failure to comply may result in equipment damage and/or electric shock hazard.

Be sure to confirm the completion and correctness of the drive wiring and close the

cover before applying power to the drive. Do not open the cover after applying power.

Failure to comply may result in electric shock hazard.

After applying the power, never touch the drive and peripheral circuits no matter what

state the drive is under, otherwise there will be electric shock hazard.

Prior to running the drive, make sure there is no person in surrounding area who can

reach the motor so as to prevent personal injury.

When the drive is running, foreign bodies should be prevented falling into the

equipment. Failure to comply may result in faults and/or equipment damage.

+ 2/B1

+ 1

+ 2

+ 1

+ 2

Chapter 1 Safety Precautions GK600E User Manual

- 4 -

Only qualified technicians familiar with adjustable frequency AC drives are allowed to

perform signal test during operation. Failure to comply may result in equipment damage

and/or personal injury.

Never change the drive parameters at will. Failure to comply may result in equipment

damage.

ATTENTION

Make sure the number of phases of power supply and rated voltage are consistent w ith

product nameplate. If not, contact the seller or GTAKE.

Check there are no short circuits in peripheral circuits connected with the drive, and

make sure the connection is tight. Failure to comply may result in equipment damage.

Make sure the motor and associated machinery are within allowable range of service

prior to operation. Failure to comply may result in equipment damage.

Never touch fans, heat sink and braking resistor with bare hands. Failure to comply may

result in equipment damage and/or personal injury.

It is not allowed to start & stop the drive frequently via direct switching power on or off.

Failure to comply may result in equipment damage.

Make sure the drive is in a non-output status before switch-on/sw itch-off of the drive

output and/or contactor. Failure to comply may result in equipment damage.

1.1.5 Maintenance

WARNING

Only qualified technicians are allowed to implement the maintenance, and

troubleshooting.

Never implement the maintenance, and troubleshooting before power supply has been

turned off and discharged completely. Failure to comply may result in equipment

damage and/or personal injury.

To avoid an electric shock hazard, wait at least 10 minutes after the power has been

turned off and make sure the residual voltage of the bus capacitors has discharged to

0V before performing any work on the drive.

After the replacement of the drive, be sure to perform the same procedures in strict

accordance with the above-noted rules.

GK600E User Manual Chapter 1 Safety Precautions

- 5 -

ATTENTION

Do not touch the electric components with bare hands during maintenance, and

troubleshooting. Failure to comply may result in component damage due to ESD.

All pluggable components can be inserted or pulled out only when power has been

turned off.

1.2 Other Considerations

1.2.1 Input Power Supply

This series of drives are not applicable to applications out the range of operating voltage as set

forth in this manual. If necessary, please use booster to rise or drop the voltage to regulated

voltage range.

1.2.2 Surge Protection

This series of drives are furnished with surge suppressor that has certain resistance to lightning

induction. However, users in areas where lightning occurs frequently need to mount an external

surge suppressor in front of power input side of the drive.

1.2.3 Operation of Contactor

As to the configuration of peripheral devices recommended by this manual, it is necessary to

mount a contactor between the power supply and input side of the drive. Such a contactor

should not be used as a control device to start and stop the drive, as frequent charging &

discharging shall reduce the service life of internal electrolytic capacitors.

When it is necessary to mount a contactor between the drive output and the motor, it should be

ensured the drive is in a non-output status before switch-on/switch-off of such a contactor.

Failure to comply may result in damage to the drive.

1.2.4 Output Filter

Since the drive output is PWM high frequency chopping voltage, mounting filter devices such

as an output filter and an output AC reactor between the motor and the drive shall effectively

reduce output noise, avoiding interference to other surrounding equipment.

Be sure not to mount phase-shifting capacitor or surge absorber at output side of the drive

since this may cause damage to the drive as a result of over-temperature.

Chapter 1 Safety Precautions GK600E User Manual

- 6 -

1.2.5 Insulation of the Motor

In view of the fact that the drive output is PWM high frequency chopping voltage accompanied

by higher harmonics, the noise, temperature rise and vibration of the motor is higher compared

with sinusoidal voltage. Particularly this debases motor insulation. Therefore, the motor should

be subjected to insulation inspection before initial use or reuse after being stored for a long

period of time. The motor in regular service should also be subjected to regular insulation

inspection so as to avoid damage to the drive as a result of motor insulation damage. A 500V

voltage mode mega-ohmmeter is recommended to use for the measurement of the motor

insulation, during which, it is essential to disconnect the motor from the drive. Normally, the

insulation resistance of the motor should be bigger than 5MΩ.

1.2.6 Derating

Due to the thin air in high-altitude areas, the radiating performance of the drive with forced air

cooling may degrade while the electrolyte of electrolytic capacitors is more volatile, which can

result in reduction in product life. Drive should be derated when used in an area at the altitude

above 1000 meters. It is recommended to derate 1% for every 100m when the altitude is above

1000 meters.

GK600E User Manual Chapter 2 Product Information

- 7 -

Chapter 2 Product Information

2.1 Model Explanation

Model shown on product nameplate indicates the series name, applicable type of power supply,

pow er class and the version of software and hardware, etc. via the combination of numbers,

symbols and letters.

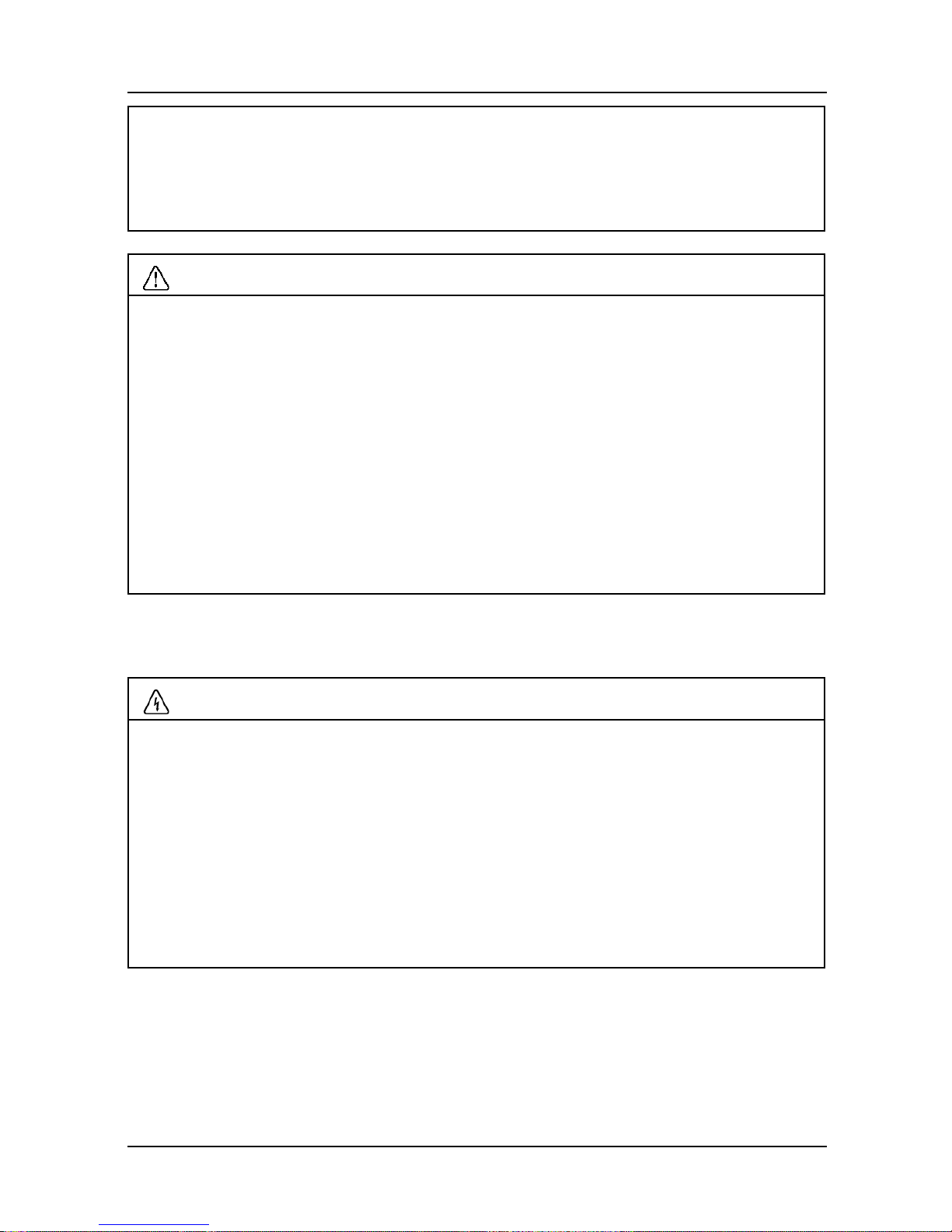

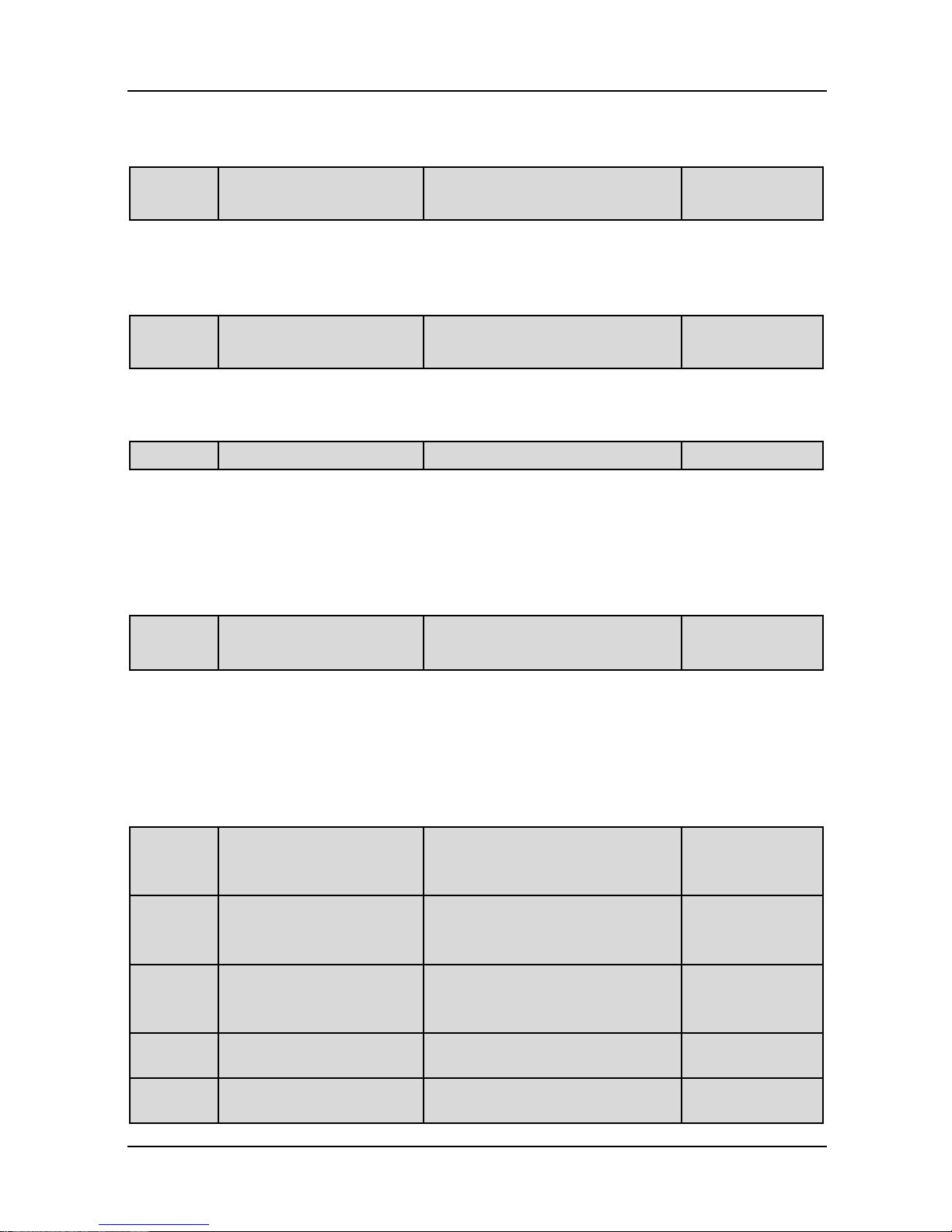

GK600 E - 4 T 7.5 B

Fig. 2-1 Product model explanation

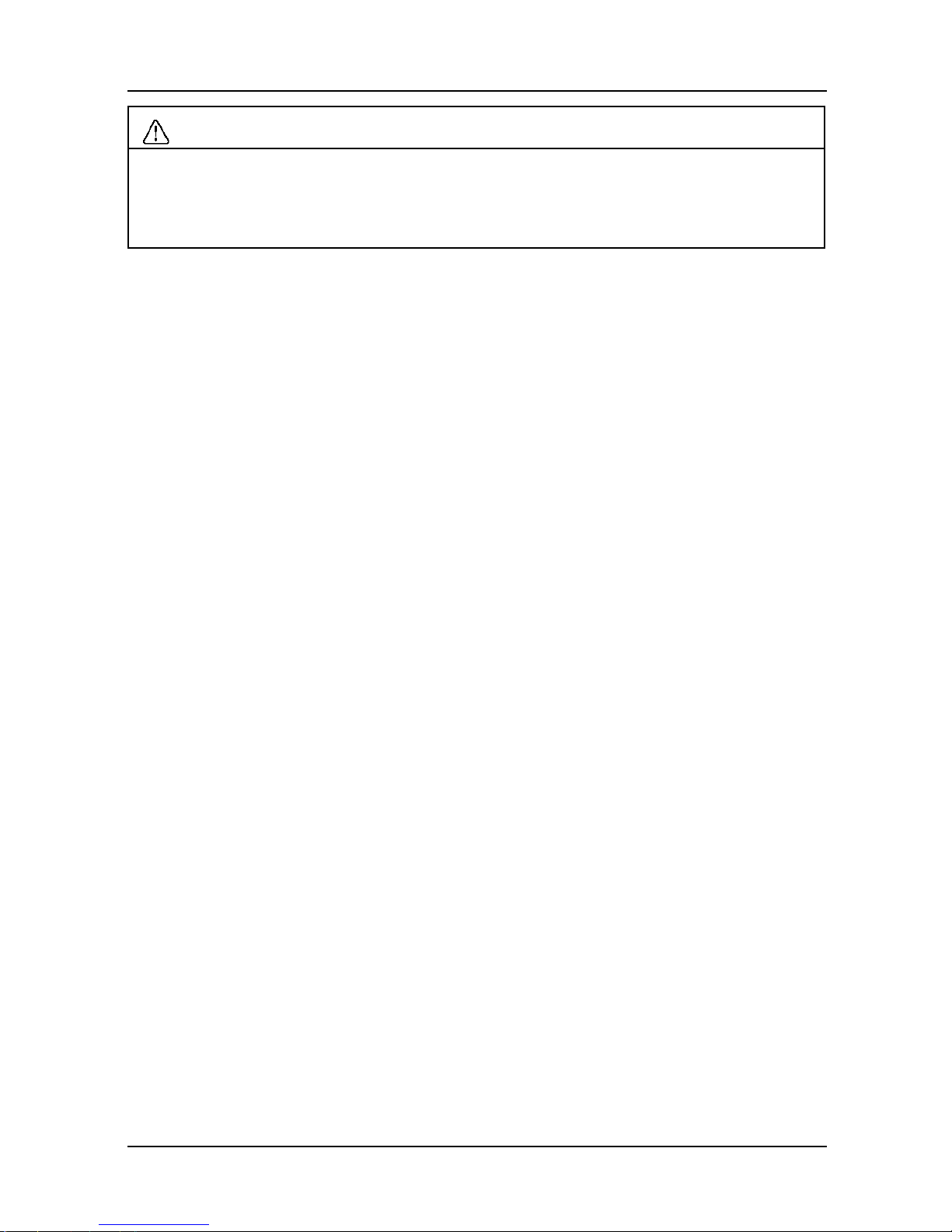

2.2 Nameplate Information

Fig. 2-2 Nameplate information

Dedicated drive

E:Elevator

4:Power 400 V AC

T:Power triphase

B: Brake chopper inbuilt

Product Platform

Chapter 2 Product Information GK600E User Manual

- 8 -

2.3 Information of Product Model

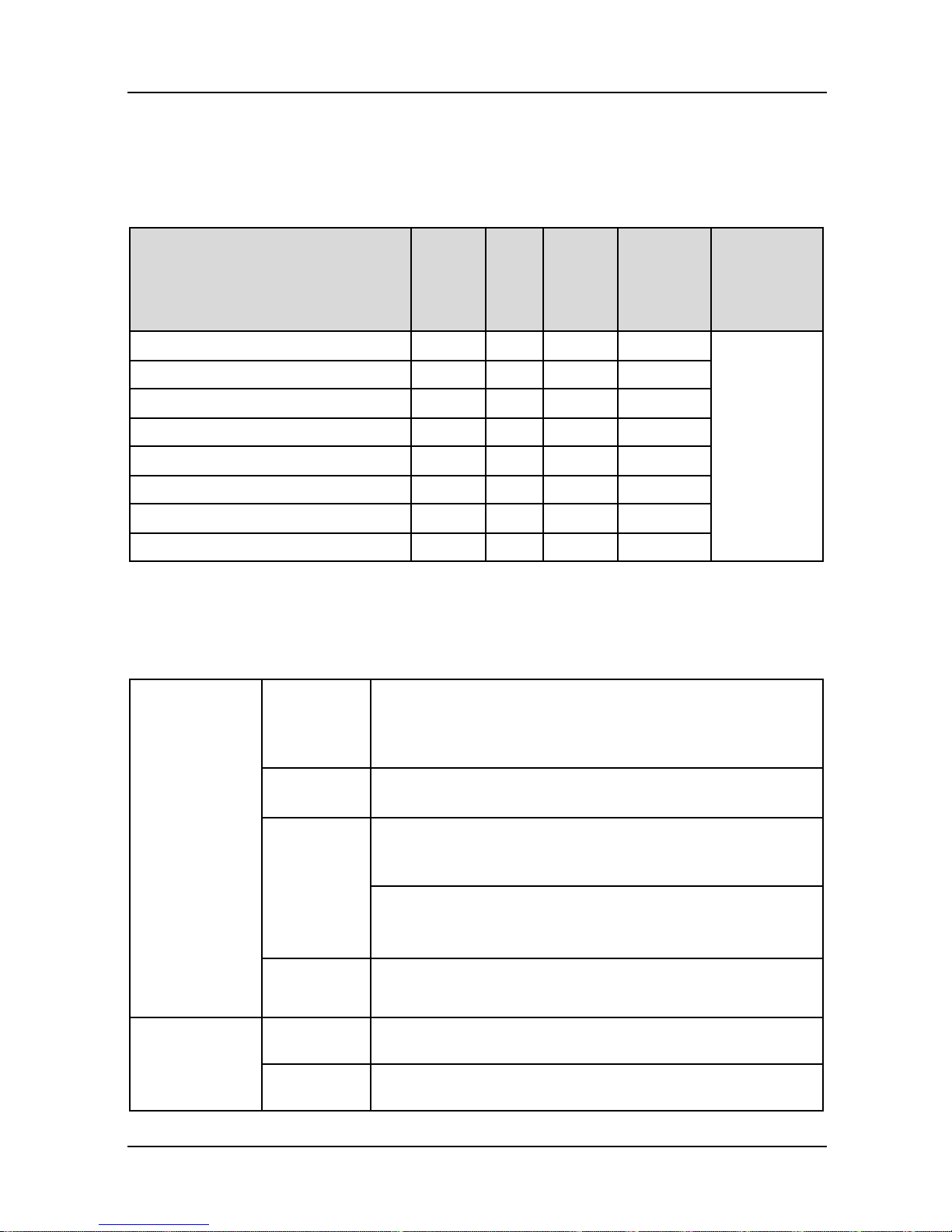

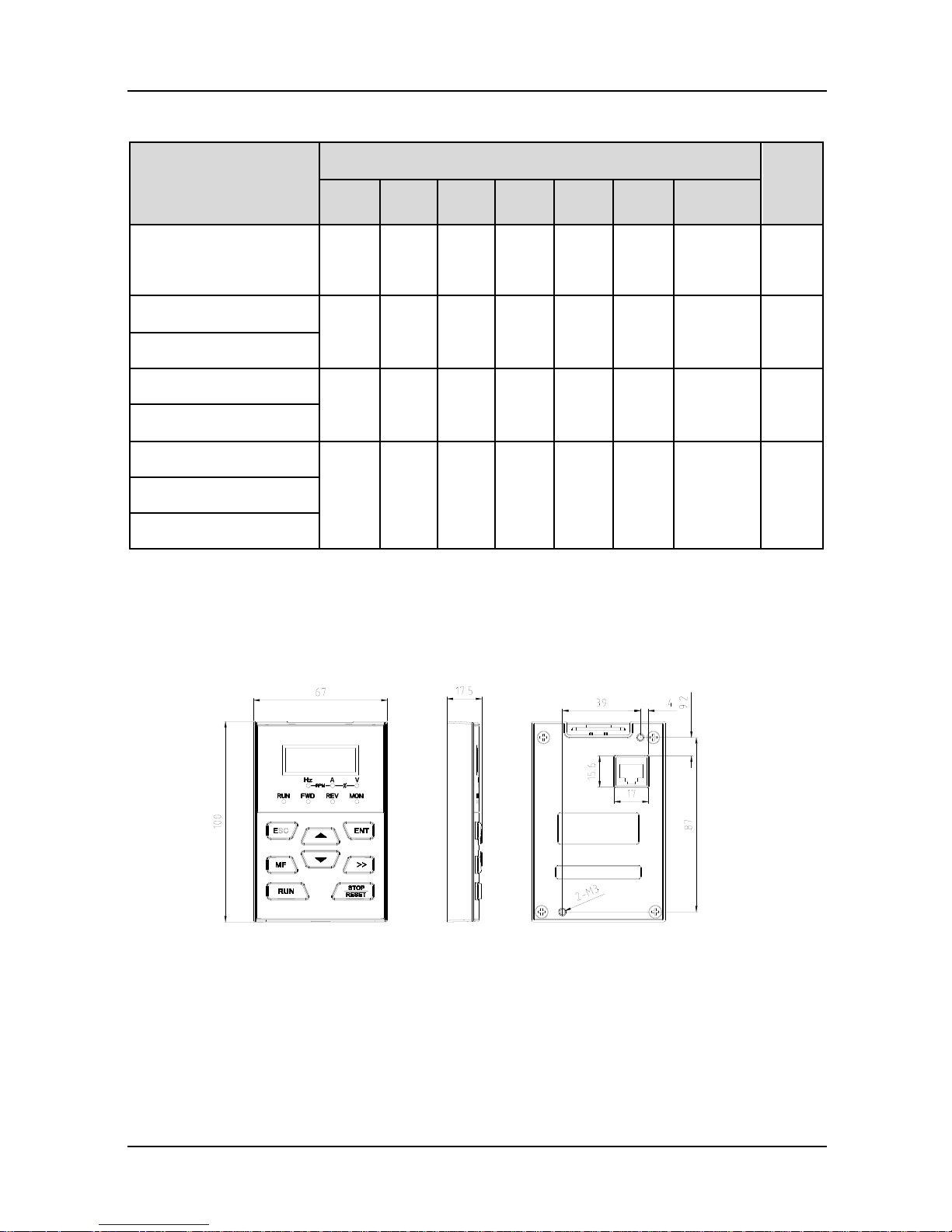

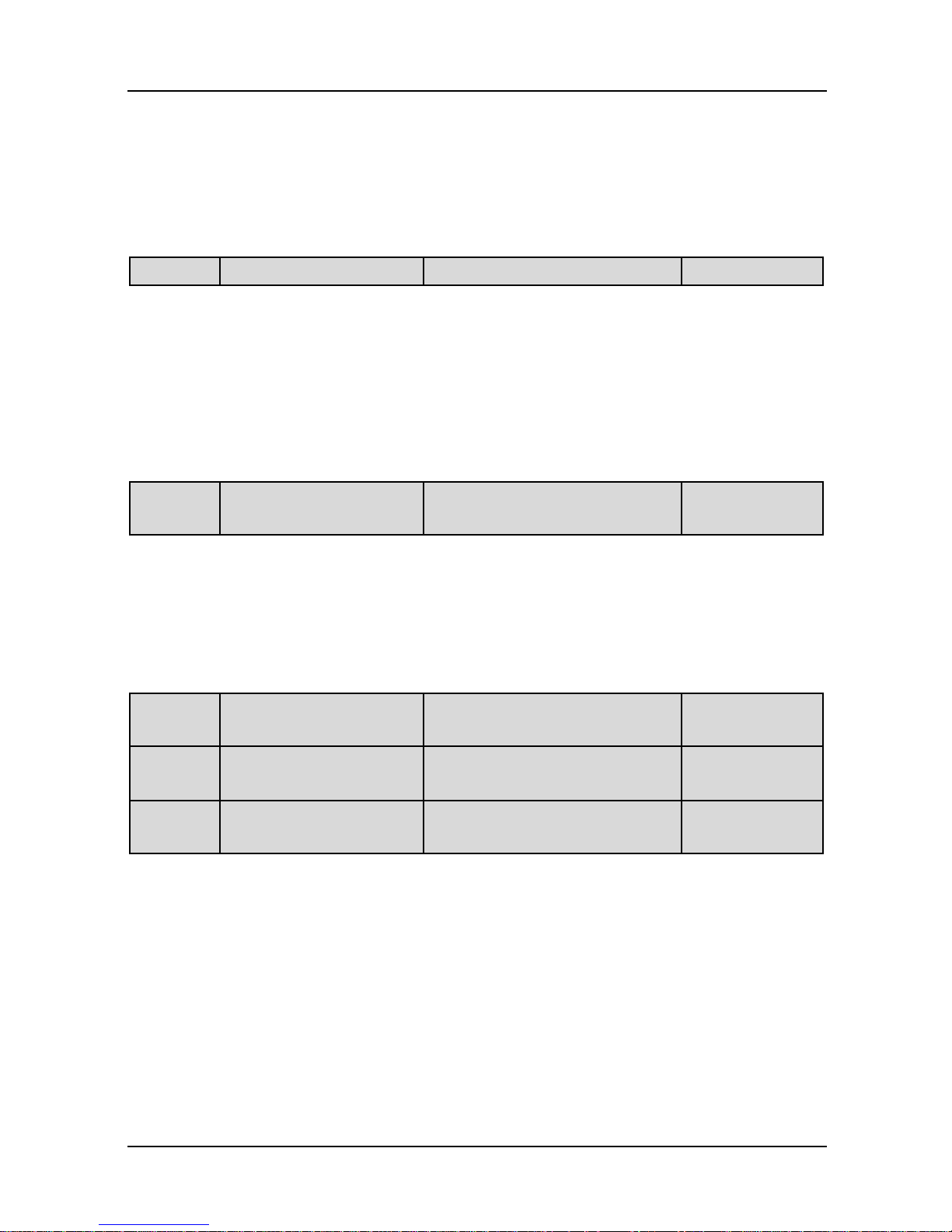

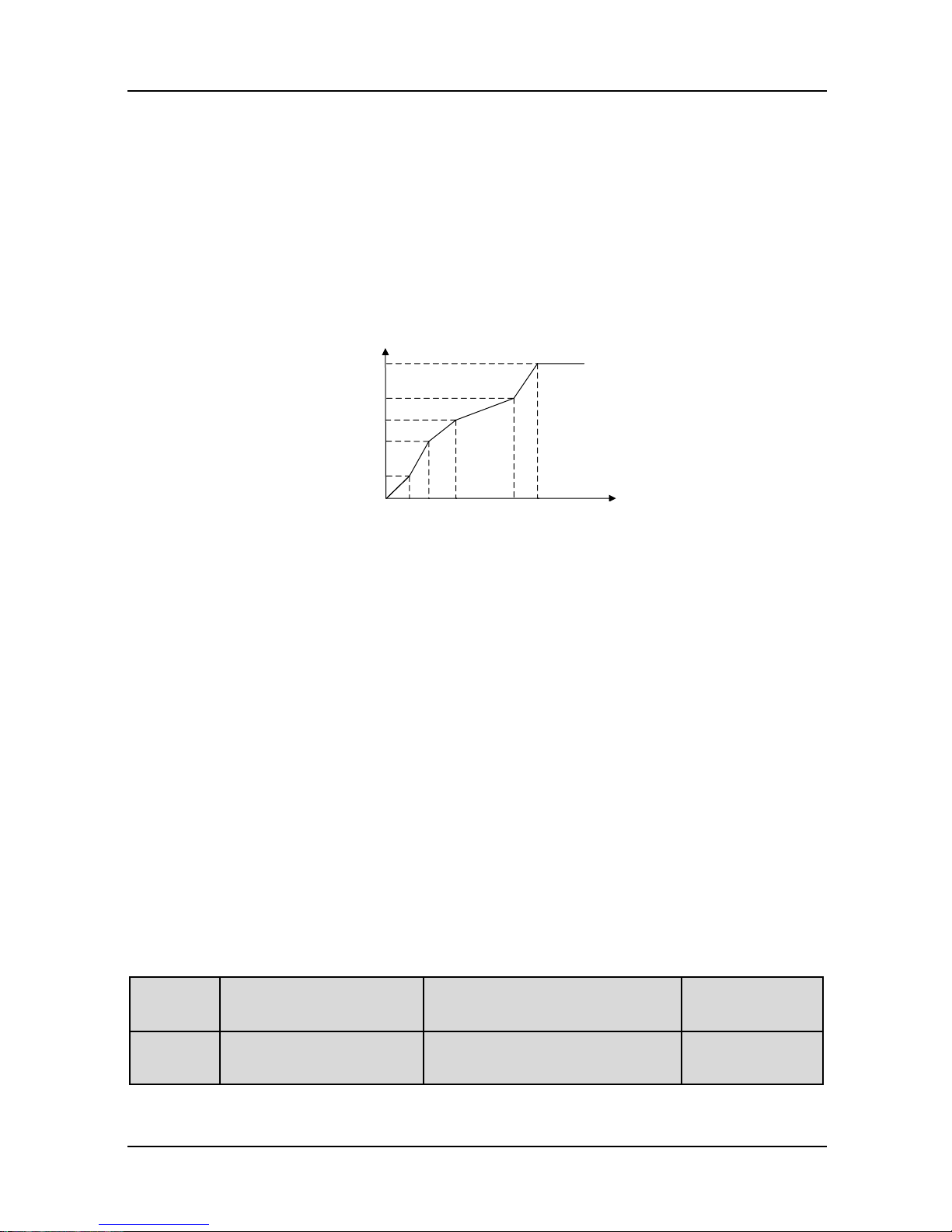

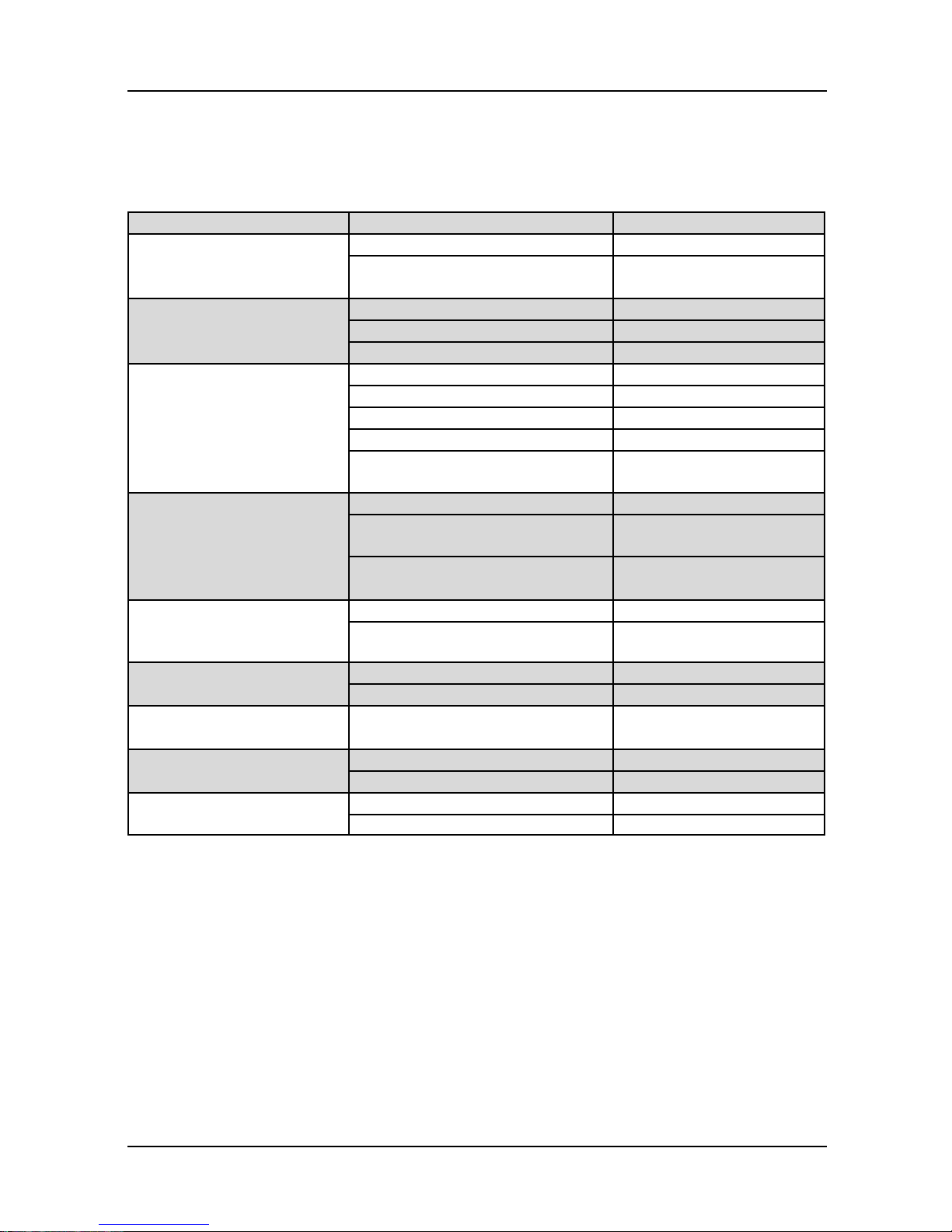

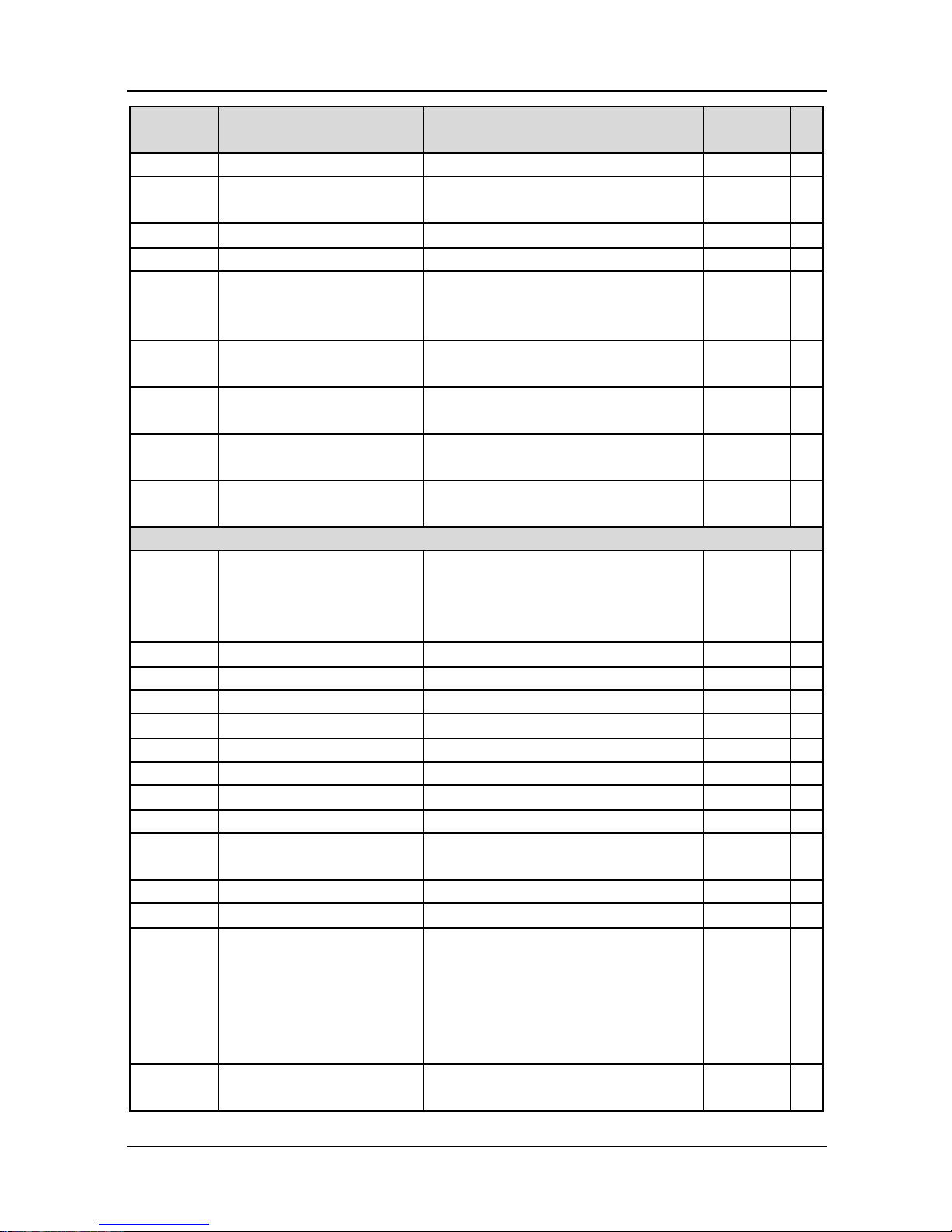

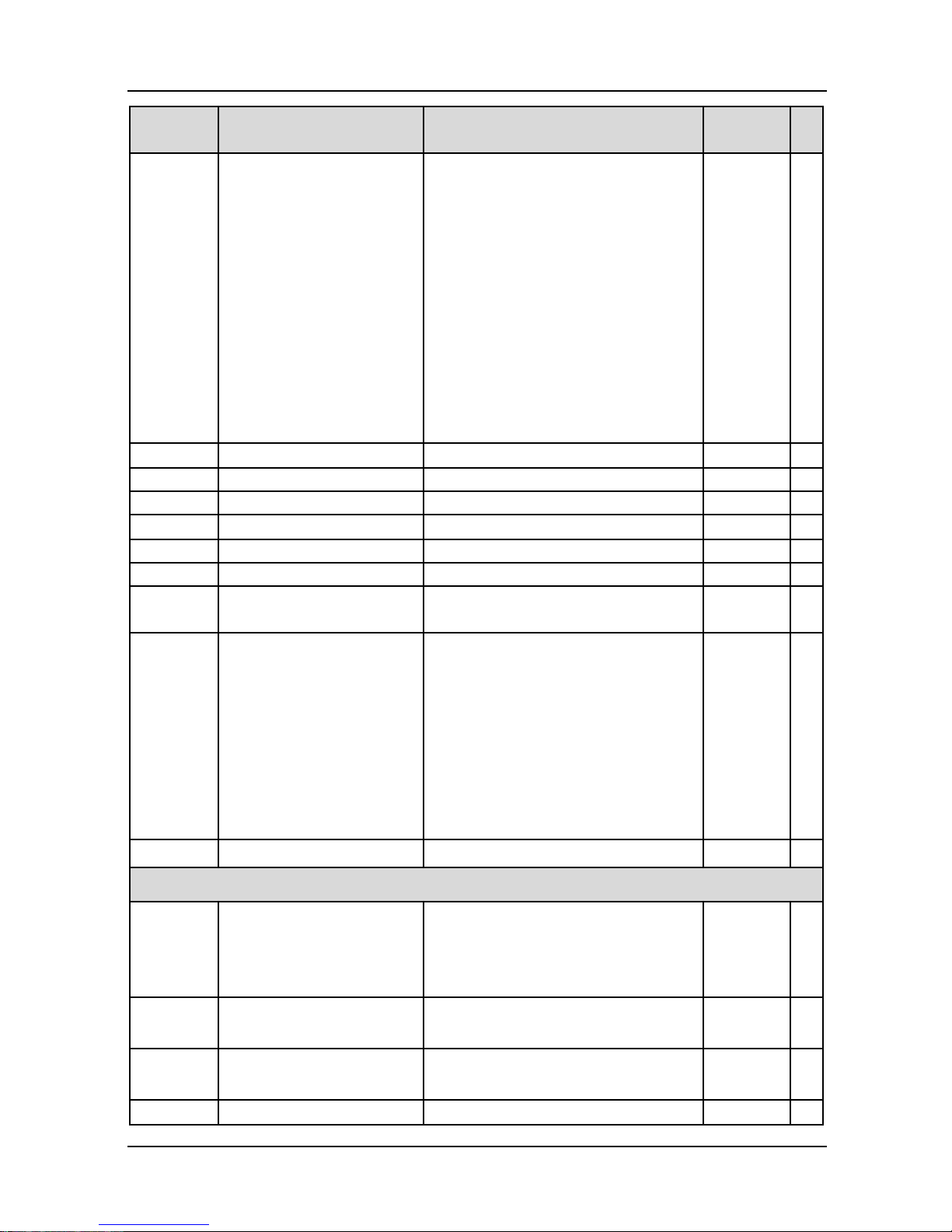

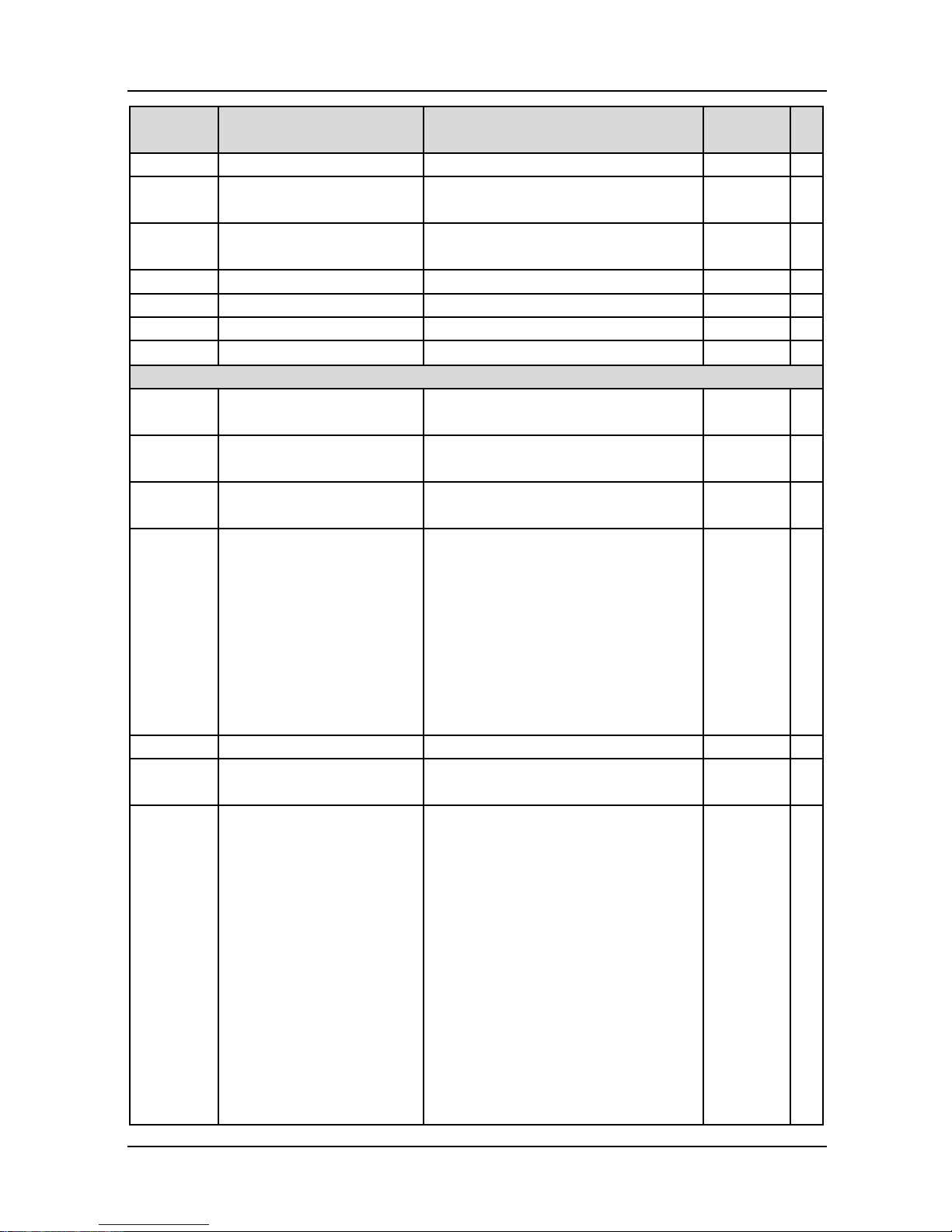

Table 2-1 Product model and technical data

■ GK600E-4T □□□, three-phase 400V input, heavy duty

Drive model

Pow er

rating

(kW)

Rated

output

current

(A)

Rated

input

current

(A)

Applicable

motor (kW)

Brake

chopper

GK600E-4T3.7B

3.7

9.0

10.5

3.7

Inbuilt

GK600E-4T5.5B

5.5

13

14.6

5.5

GK600E-4T7.5B

7.5

17

20.5

7.5

GK600E-4T11B

11

24

29

11

GK600E-4T15B

15

30

35

15

GK600E-4T18.5B

18.5

39

44

18.5

GK600E-4T22B

22

45

50

22

GK600E-4T30B

30

60

65

30

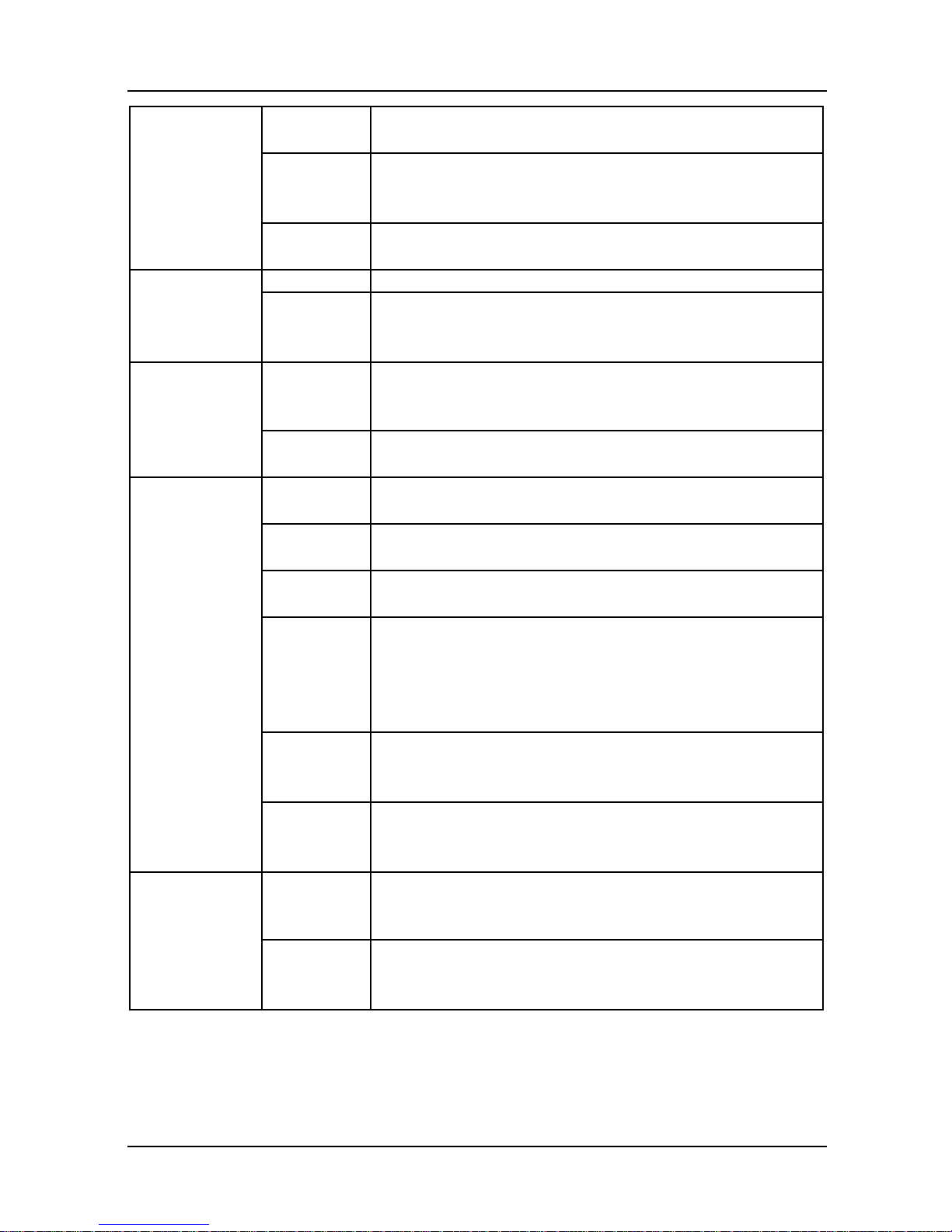

2.4 Technical Features of GK600E

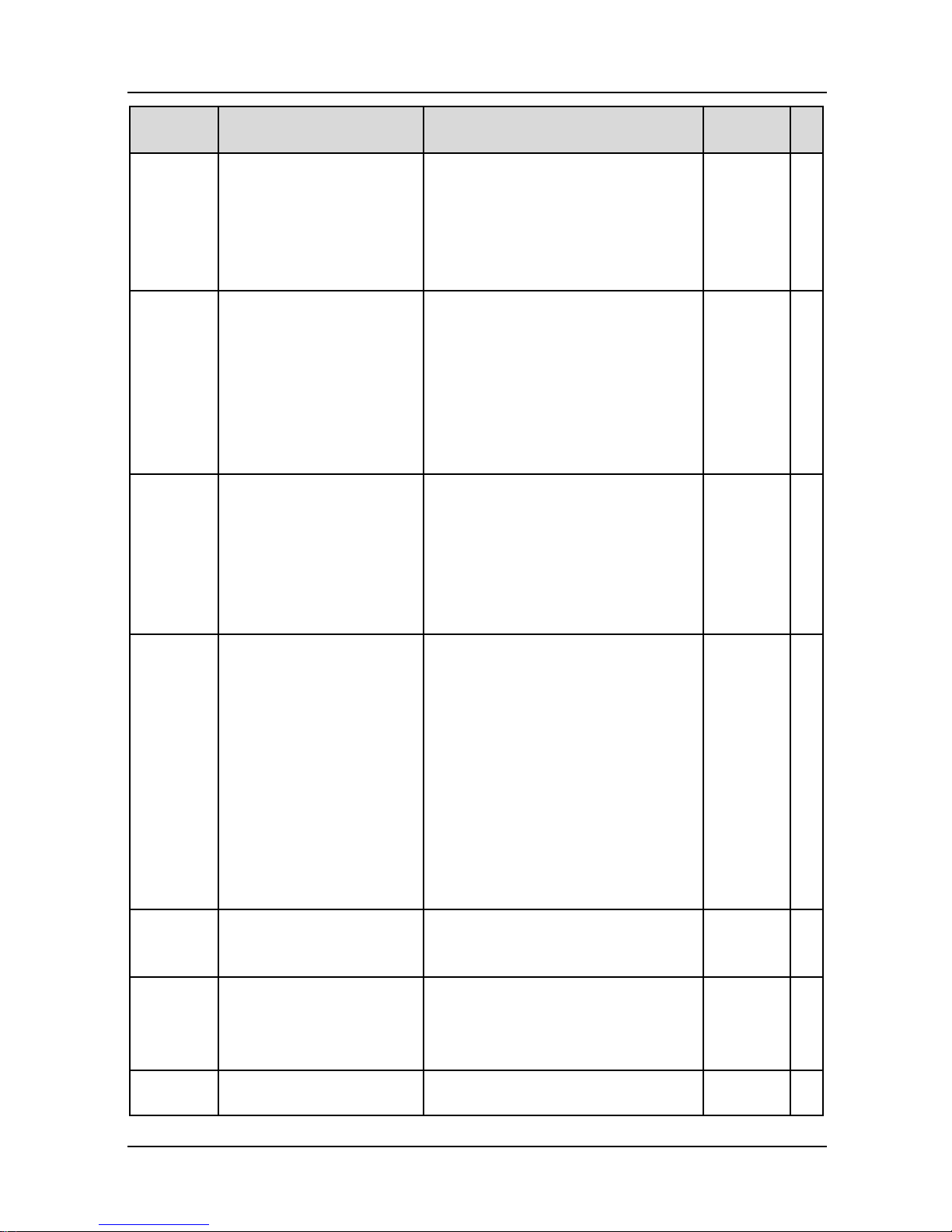

Table 2-2 Technical Features of GK600E

Pow er input

Rated input

voltage

3-phase

AC380V/AC400V/

AC415V/AC440V/AC460V

Frequency

50Hz/60Hz, tolerance ±5%

Voltage

range

Continuous voltage fluctuation ±10%, short fluctuation

-15%~+10%, i.e. 400V: 323V~528V

(emergency input: UPS 220VAC, 1-phase)

Voltage out-of-balance rate <3%, distortion rate as per the

requirements of IEC61800-2

Rated input

current

See Section 2.3

Pow er output

Applicable

motor (kW)

See Section 2.3

Rated

current (A)

See Section 2.3

GK600E User Manual Chapter 2 Product Information

- 9 -

Output

voltage (V)

3-phase: 0~ rated input voltage, error < ±3%

Output

frequency

(Hz)

0.00~ 600.00Hz; unit: 0.01Hz

Overload

capacity

150% - 1min, 180% - 10s, 200% - 0.5s every 10 min

Control

characteristics

V/f patterns

V/f control

Range of

speed

regulation

1:100

Control

characteristics

Speed

accuracy

±0.5%

Start

torque

0.5Hz: 180%

Basic

functions

Start

frequency

0.00~ 600.00Hz

Accel/

Decel time

0.00~60000s

Switching

frequency

0.7kHz~16kHz

Frequency

setting

Digital setting + control panel ∧/∨

Digital setting + terminal UP/DOWN

Communication

Analog setting (AI1/AI2/EAI)

Terminal pulse setting

Motor

start-up

methods

Started from starting frequency

DC brake start-up

Flying start

Motor stop

methods

Ramp to stop

Coast to stop

Ramp stop + DC brake

Basic

functions

Dynamic

braking

capacity

Brake chopper working voltage: 650V-750V

Service time: 0-100.0s; brake chopper is inbuilt as default

for GK600E lift dedicated drives at GTAKE

DC brake

capacity

DC brake start frequency: 0.00~600.00Hz

DC brake current: 0.0~100.0%

DC brake time: 0.0~30.00s

Chapter 2 Product Information GK600E User Manual

- 10 -

Basic

functions

Input

terminals

7 digital inputs, one of which can be used for high-speed

pulse input, and compatible with active open collectors

NPN, PNP and dry contact input.

2 analog inputs, one of which is voltage/current

programmable, and the other supports voltage only.

Output

terminals

1 high-speed pulse output, 0~50kHz square wave signal

output. It can output signals such as frequency setting, or

output frequency, etc.

1 digital output

2 relay output

1 analog output, voltage/current output programmable; can

output signals such as frequency setting, or output

frequency, etc.

Protection

functions

Refer to Chapter 7- Troubleshooting

Environment

Place of

operation

Indoors, no direct sunlight, free from dust, corrosive

gases, flammable gases, oil mist, water vapor, water drop

or salt, etc.

Altitude

0-2000m . De-rate 1% for every 100m when the altitude is

above 1000 meters

Ambient

temperature

-10℃-40℃. The rated output current should be derated

1% for every 1℃ when the ambient is 40℃-50℃

Relative

humidity

0~95%, no condensation

Vibration

Less than 5.9m/s2 (0.6g)

Storage

temperature

-40℃~+70℃

Others

Efficiency at

rated Amps

Rated power

7.5kW and below : ≥93%

11~ 30kW: ≥ 95%

Installation

wall-mounted

IP grade

IP20

Cooling

method

Forced air cooling

GK600E User Manual Chapter 2 Product Information

- 11 -

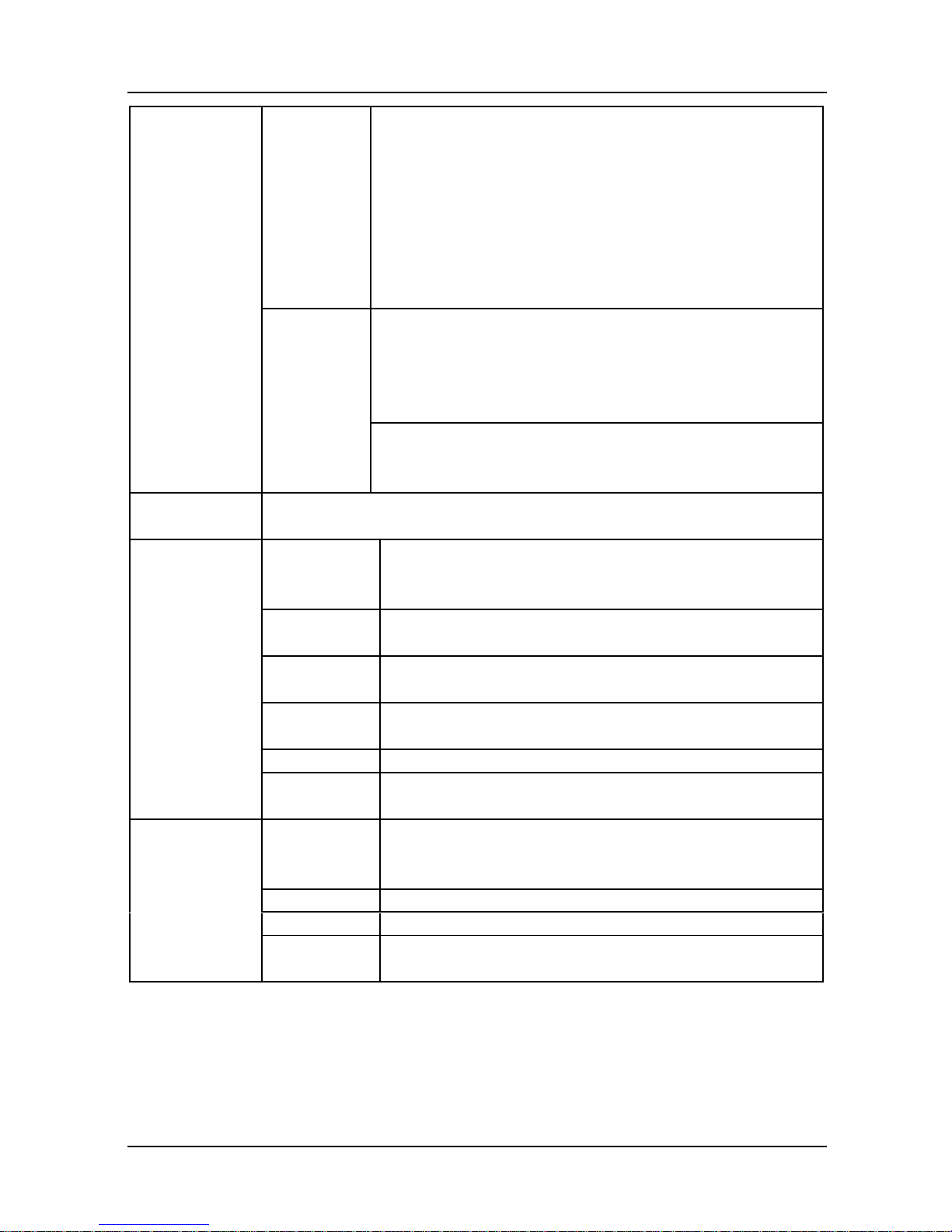

2.5 Parts Drawing

a) GK600E-4T15B and below b) GK600E-4T18.5B ~ GK600E-4T30B

Fig. 2-3 Parts drawing

铭牌

下壳体

安装孔

底板

风扇罩

防尘盖板

操作面板

盖板

中壳体

盖板

操作面板

安装孔

机箱

铭牌

风扇

托板

Fan cov er

Dust cover

Control

panel

Cov er

Control

panel

Cov er

Base plate

Mounting

holes

Mounting

holes

Lower

casing

Nameplate

Middle casing

Control

panel

Fans

Enclosure

Nameplate

Chapter 2 Product Information GK600E User Manual

- 12 -

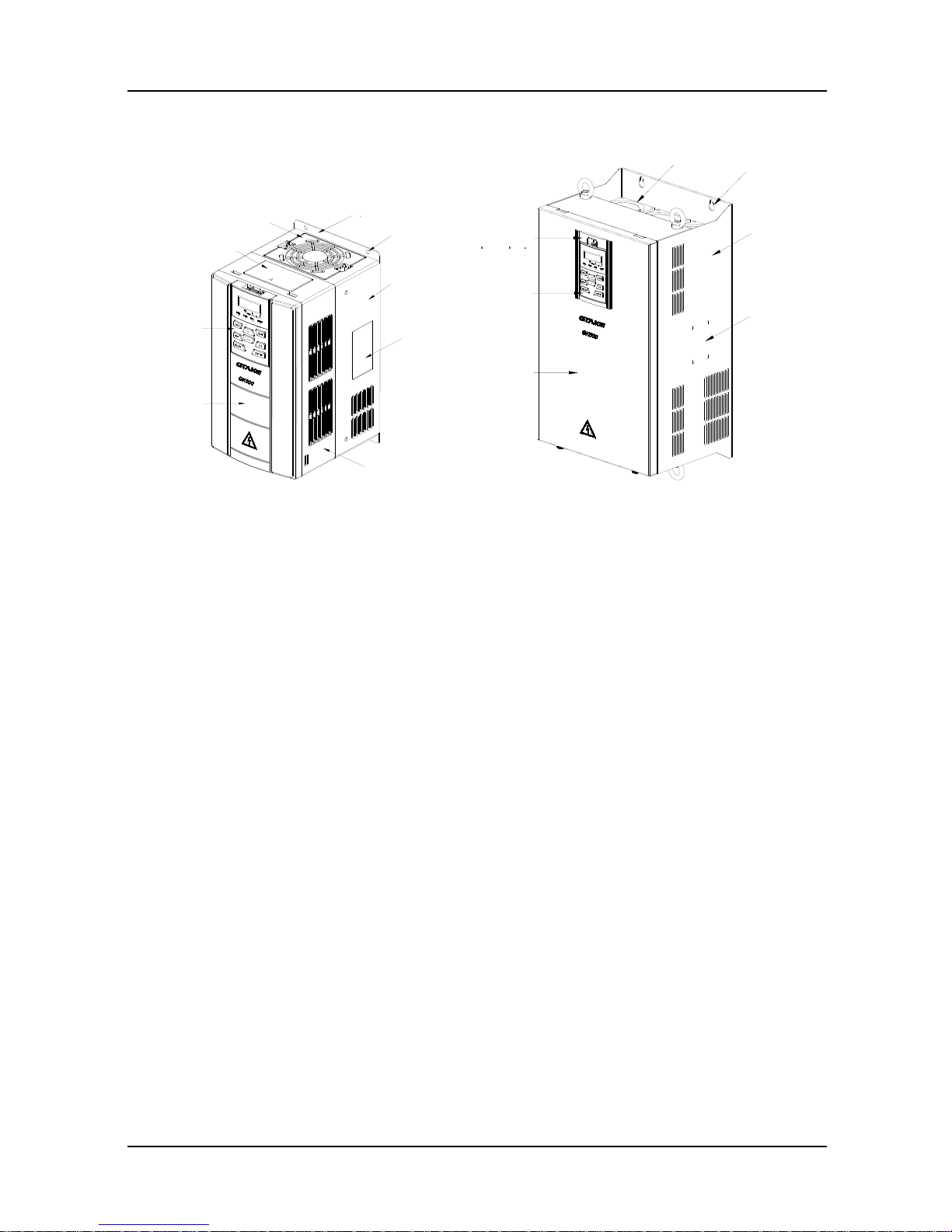

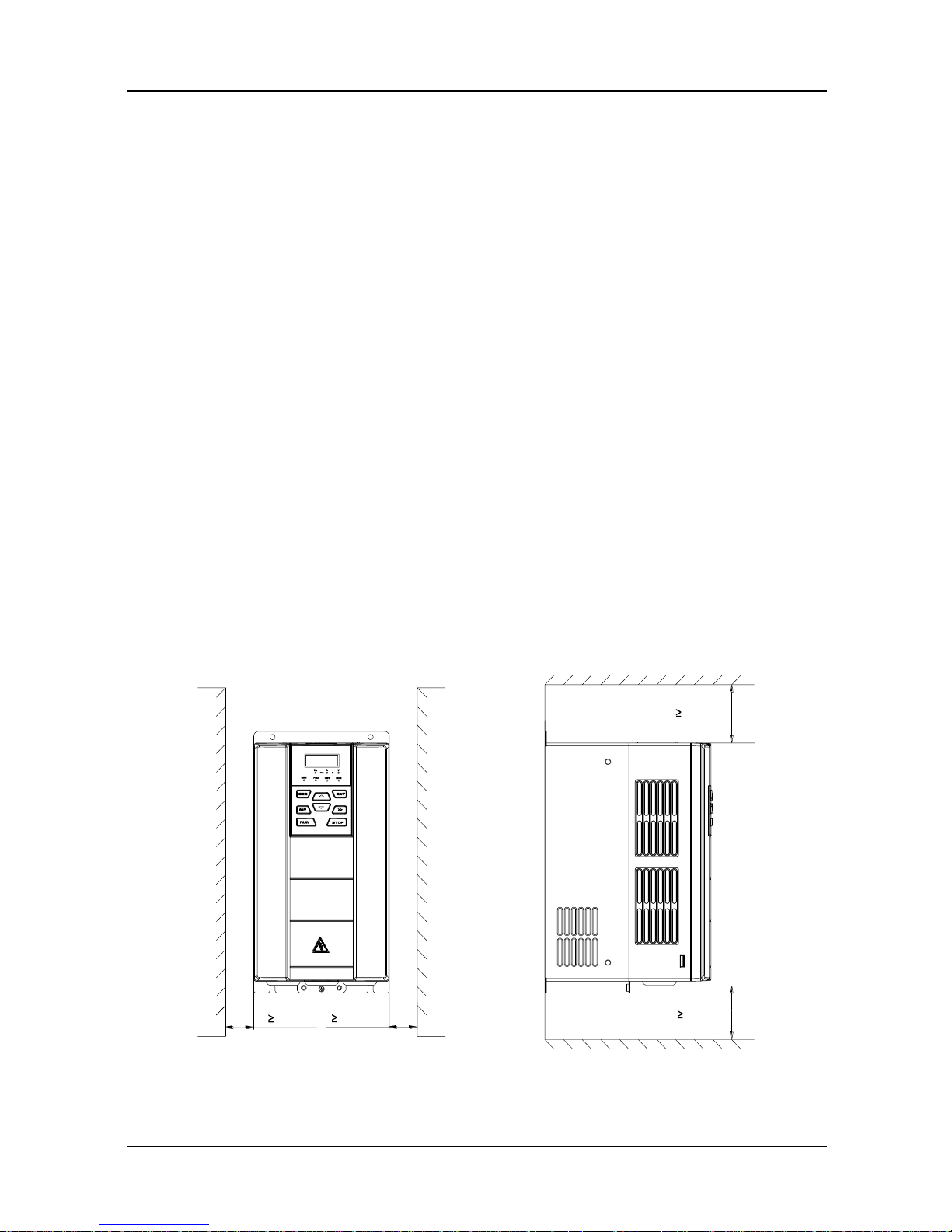

2.6 Appearance, Mounting Dimensions and Weight

a) GK600E-4T3.7B ~ GK600E-4T15B

b) GK600E-4T18.5B ~ GK600E-4T30B

Fig. 2-4 External dimensions

GK600E User Manual Chapter 2 Product Information

- 13 -

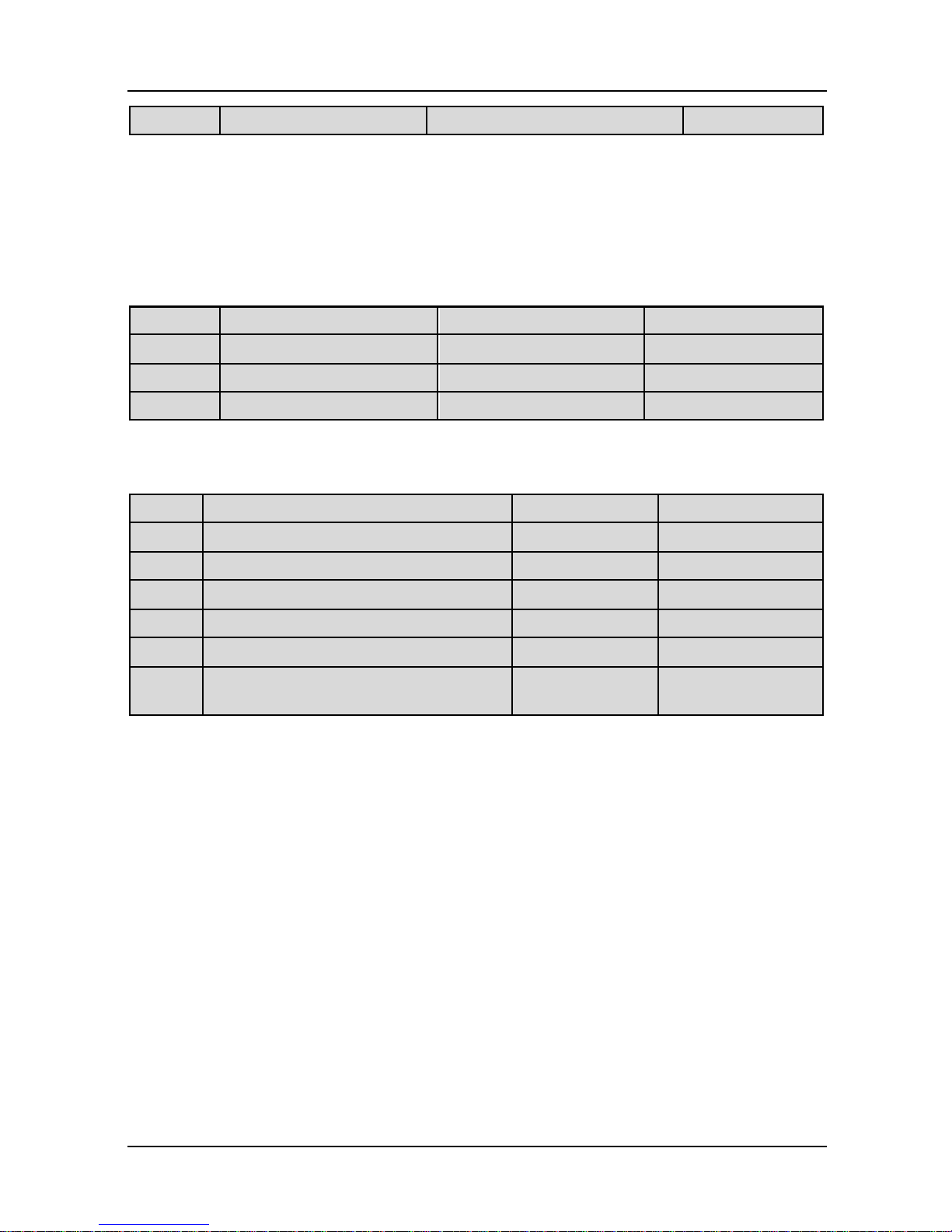

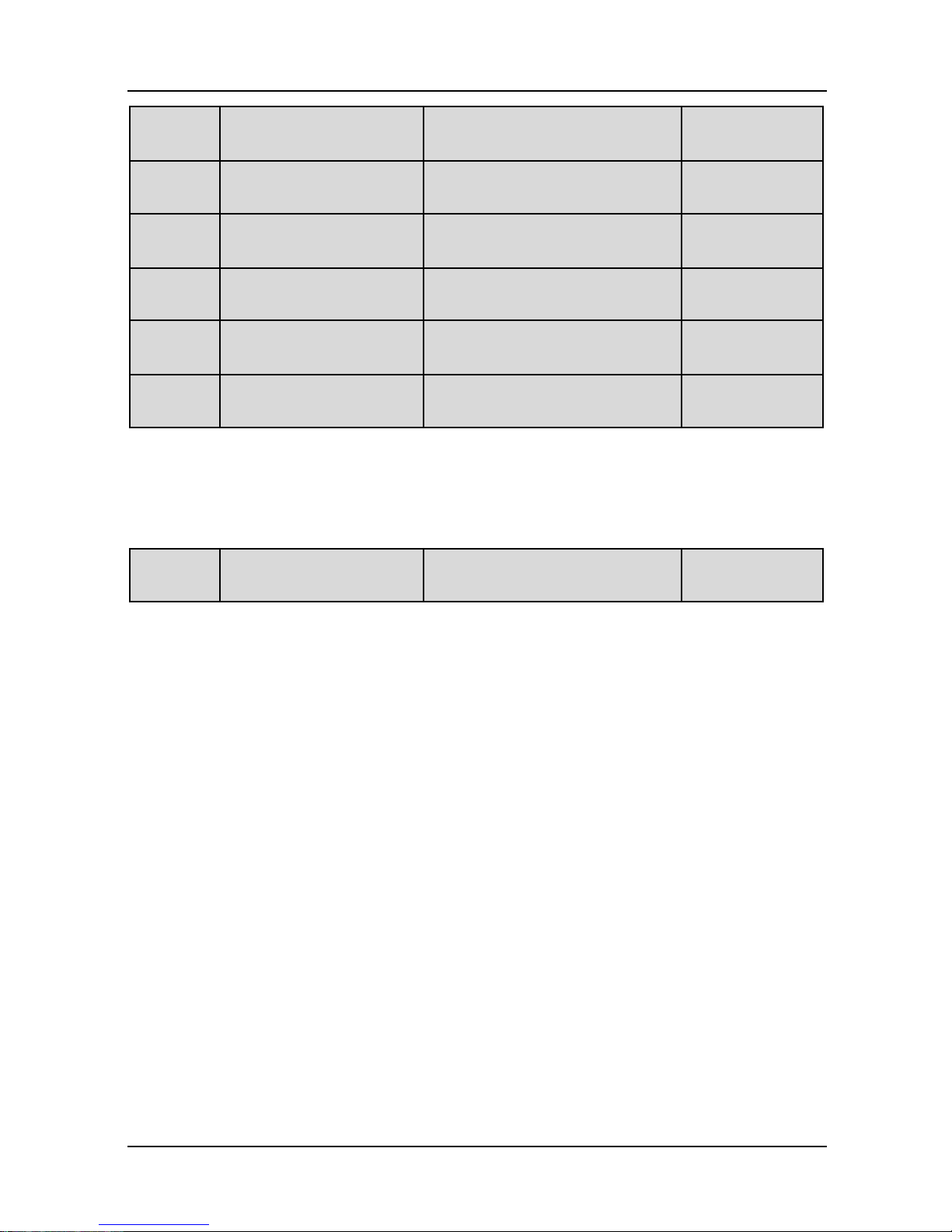

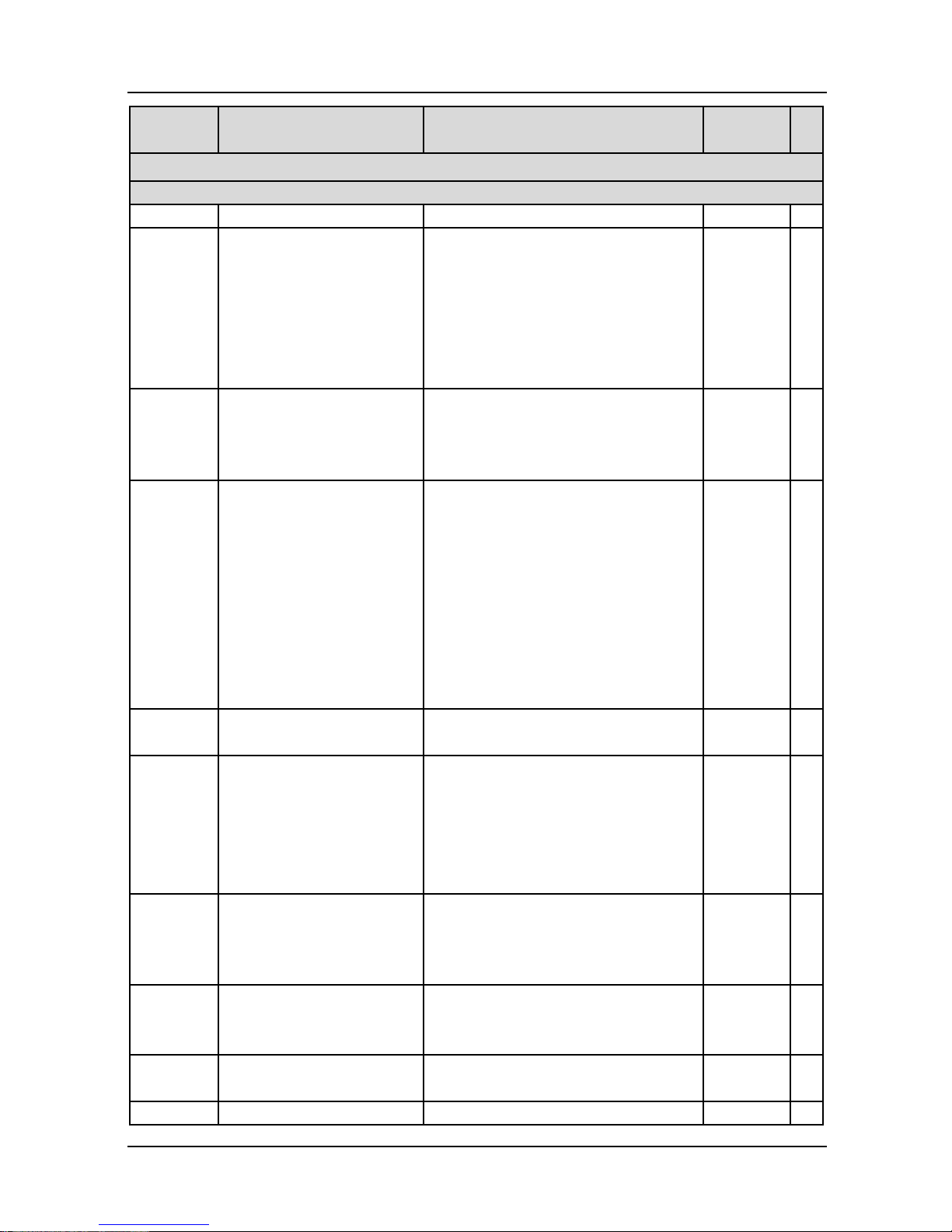

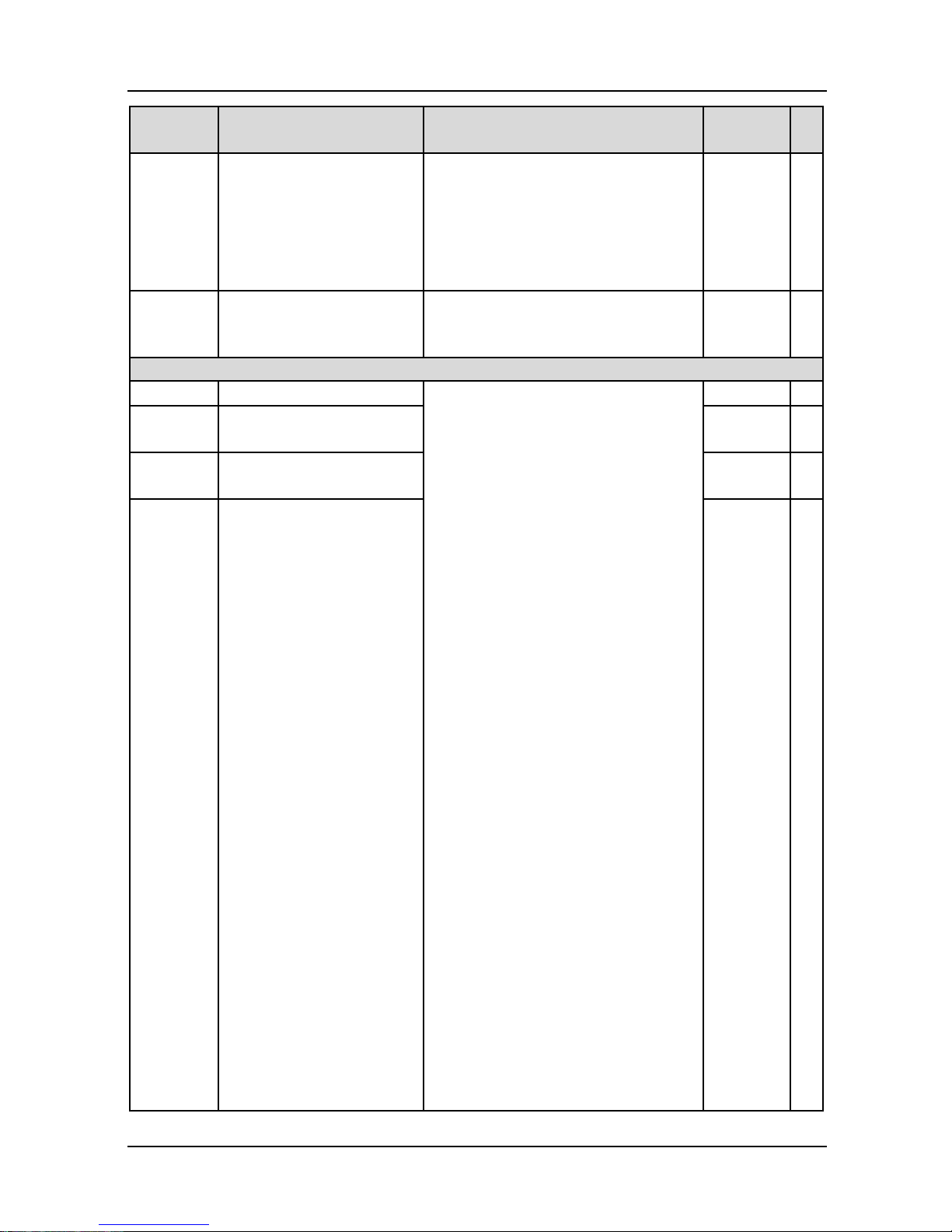

Table 2-3 Appearance, mounting dimensions and weight

Model

External and installation dimensions (mm)

Weight

(kg)

W H D

W1

H1

H2

Mounting

hole dia.

GK600E-4T3.7B

120

245

169

80

233

220

5.5

2.9

GK600E-4T5.5B

145

280

179

105

268

255

5.5

3.9

GK600E-4T7.5B

GK600E-4T11B

190

365

187

120

353

335 6 6.2

GK600E-4T15B

GK600E-4T18.5B

270

475

220

170

460

435

8

15.5

GK600E-4T22B

GK600E-4T30B

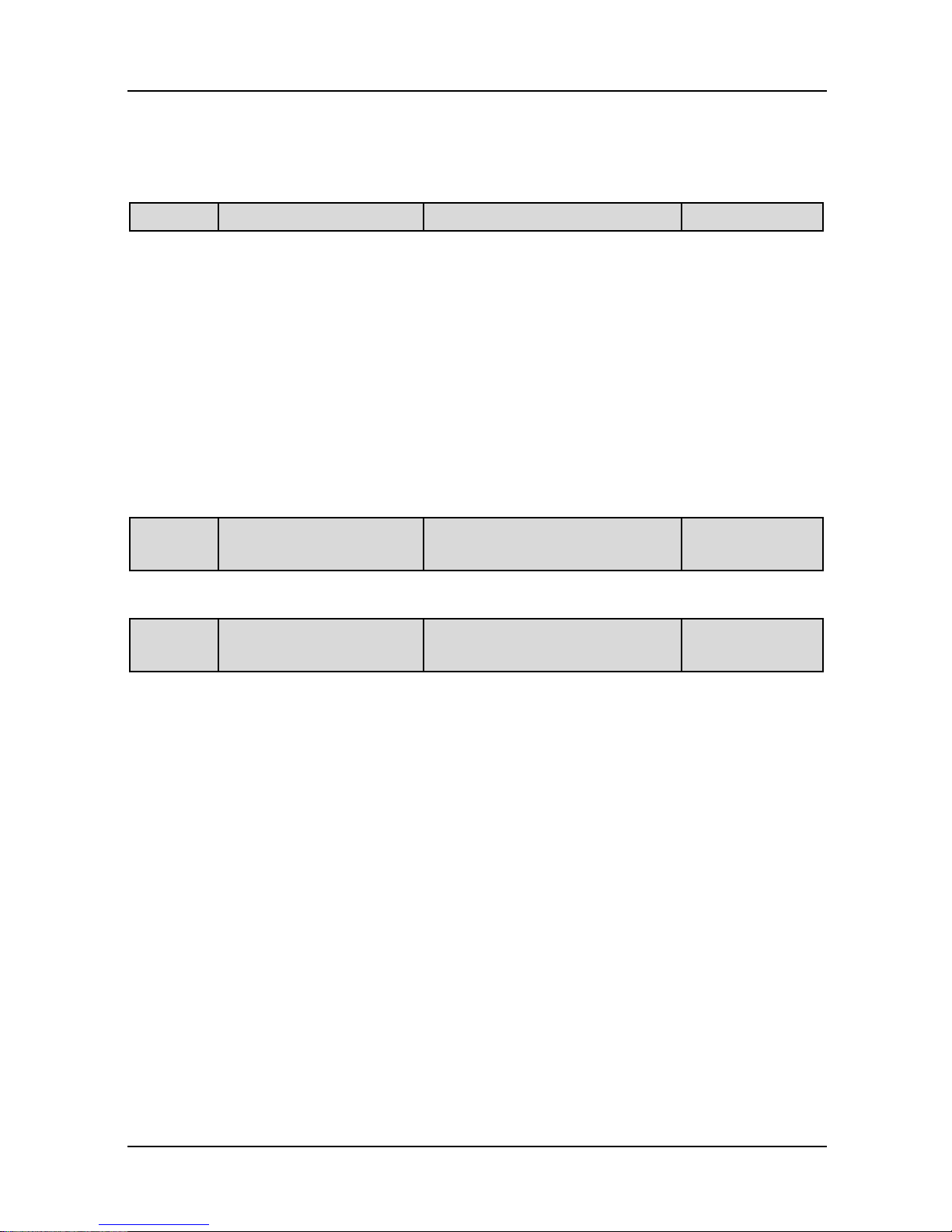

2.7 External Dimensions of Control Panel

Control panel model of GK600E series Elevator Dedicated Drives is KBU-BX1 whose

appearance and external dimensions are shown in Fig. 2-5.

Fig. 2-5 External dimensions of KBU-BX1

2.8 External Dimensions of Control Panel Bracket

A bracket should be provided to support the panel and a hole in the cabinet needs to be opened

when the control panel KBU-BX1 needs to be remotely used. Bracket model is KBU-DZ1

whose external dimensions are shown in Fig. 2-6 a). Fig. 2-6 b) shows applicable hole

Chapter 2 Product Information GK600E User Manual

- 14 -

dimensions in the cabinet.

a) External dimensions of KBU-DZ1 b) Hole dimensions in the cabinet

Fig. 2-6 External dimensions of KBU-DZ1 and cabinet hole dimensions

Panel TH Hole WTH

1.2mm 73.2mm

1.5mm 74.4mm

2mm 75.5mm

GK600E User Manual Chapter 3 Installation and Wiring

- 15 -

Chapter 3 Installation and Wiring

3.1 Installation Environment

1) Ambient temperature is in the range of -10℃~ 40℃.

2) Drive should be installed on surface of flame retardant object, with adequate surrounding

space for heat dissipation.

3) Installation should be performed w here vibration is less than 5.9m/s2 (0.6g).

4) Protect from moisture and direct sunlight.

5) Protect the cooling fan by avoiding oil, dust and metal particles.

6) Do not expose to an atmosphere with flammable gases, corrosive gases, explosive gases

or other harmful gases.

7) Prevent drilling residues, wire ends and screws falling into drive.

8) Ventilation part of the drive should be installed outside from harsh environment (e.g. textile

facilities with fiber particles and chemical facilities filled with corrosive gases.

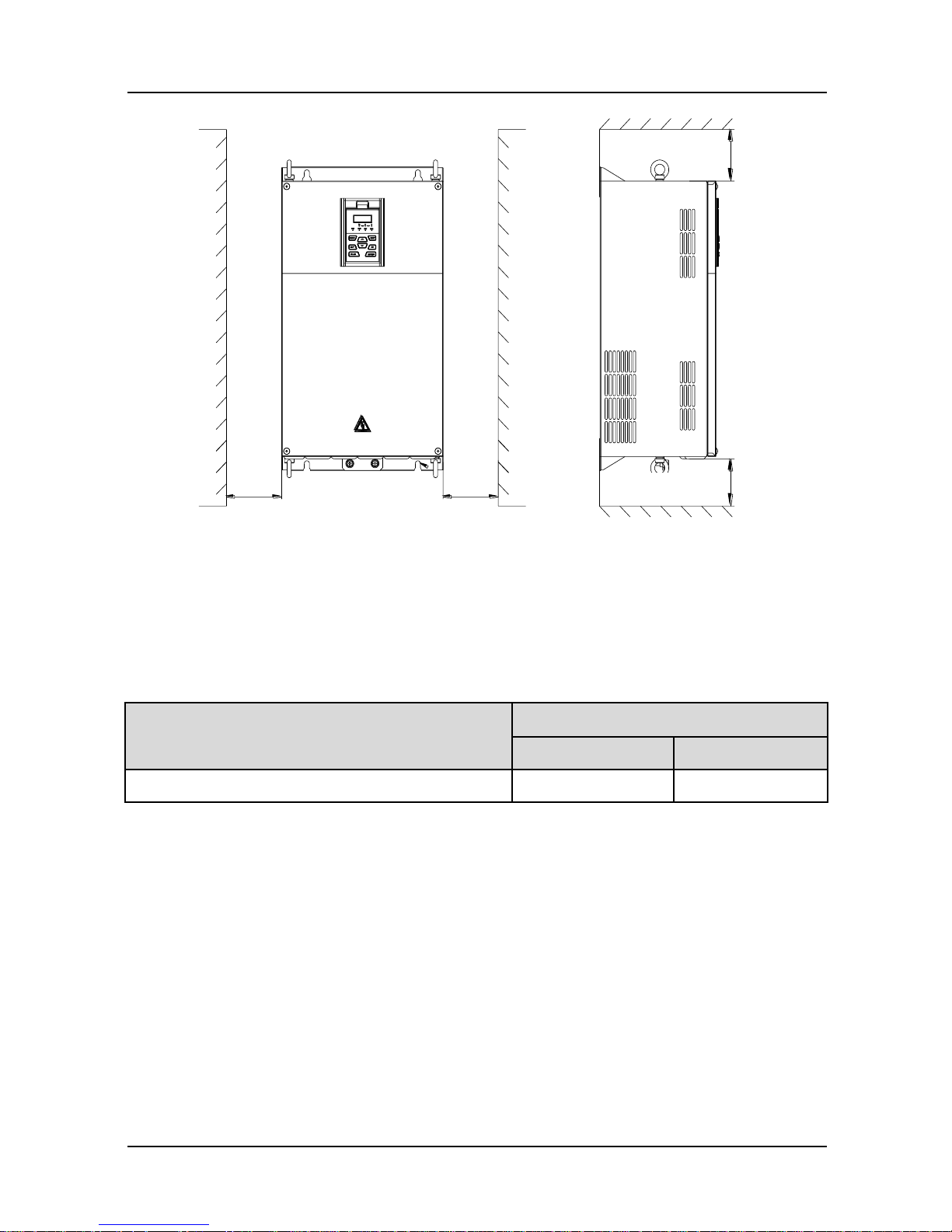

3.2 Minimum Mounting Clearances

To ensure favorable heat dissipation, mount the drive upright on a flat, vertical and level surface

as per Fig. 3.1. For installation inside cabinet, the product shall be mounted side by side to the

greatest extent while adequate surrounding space shall be preserved for favorable heat

dissipation.

Fig. 3-1 Minimum mounting clearances of GK600E-4T15B and below

空气流通位置

100mm

100mm

空气流通位置

30mm

30mm

Vent clearance

Vent clearance

Chapter 3 Installation and Wiring GK600E User Manual

- 16 -

Fig. 3-2 Minimum mounting clearances of GK600E-4T18.5B and above

ATTENTION:

When mounting a drive GK600E-4T18.5B or above, the minimum mounting clearances as

set forth in Table 3-1 should be assured.

Table 3-1 Requirement of minimum mounting clearances

Drive model

Mounting clearances (mm)

A

B

GK600E-4T18.5B ~ GK600E-4T30B

≥50

≥200

3.3 Remove & Mount Control Panel and Cover

3.3.1 Remove and Mount Control Panel

Remove control panel

Press the buckle of control panel as indicated by number "1" in Fig. 3-3, then pull the panel

out to release as indicated by "2".

Mount control panel

Slightly slant the panel in the direction as indicated by number "1" in Fig. 3-4 and align it to

clamping port at lower part of panel bracket, then press it in as indicated by "2". When a

"click" sound heard, it indicates clamping has been properly made.

空气流通位置

B

空气流通位置

B

A A

Vent clearance

Vent clearance

GK600E User Manual Chapter 3 Installation and Wiring

- 17 -

Fig. 3-3 Remove the control panel Fig. 3-4 Mount the control panel

3.3.2 Open & Mount the Covers of GK600E-4T3.7B ~ GK600E-4T15B

Remove the control panel

Use the remove method as stated in Section 3.3.1.

Open the cover

Method 1: loosen the captive cover screws as shown in Fig. 3-5 a) (provided only for

11/15kW model), hold the left and front sides of middle housing with left hand, put the right

thumb into the buckle and press tightly on cover with the other four fingers, pull the lower

part of the cover out to release, as indicated by number "2".

Method 2: loosen the captive cover screws, as indicated by number "1" in Fig. 3-5 b)

(provided only for 11/15kW model), use a sizeable slotted screwdriver to push the buckle

slightly at the low er part of the cover to make buckle naturally off the groove, as indicated

by "2", pull the cover out to release, as indicated by number "3".

a) Method 1 b) Method 2

Fig. 3-5 Open the cover

1

2

1

2

1

1

螺丝刀

Screwdriver

Chapter 3 Installation and Wiring GK600E User Manual

- 18 -

Mount the cover

On the completion of w iring, insert the buckle at higher part of the cover into the grooves at

middle housing as indicated by number "1" in Fig. 3-6, then push in the lower part of the

cover as indicated by "2". When a "click" sound heard, it indicates clamping has been

properly made. Tighten the screws (provided only for 11/15kW model) in buckle grooves

as finish.

Fig. 3-6 Mount the cover

Mount the control panel

Use the mounting method as stated in Section 3.3.1.

ATTENTION:

Be sure to remove the control panel before opening the cover and mount the cover before

mounting the control panel.

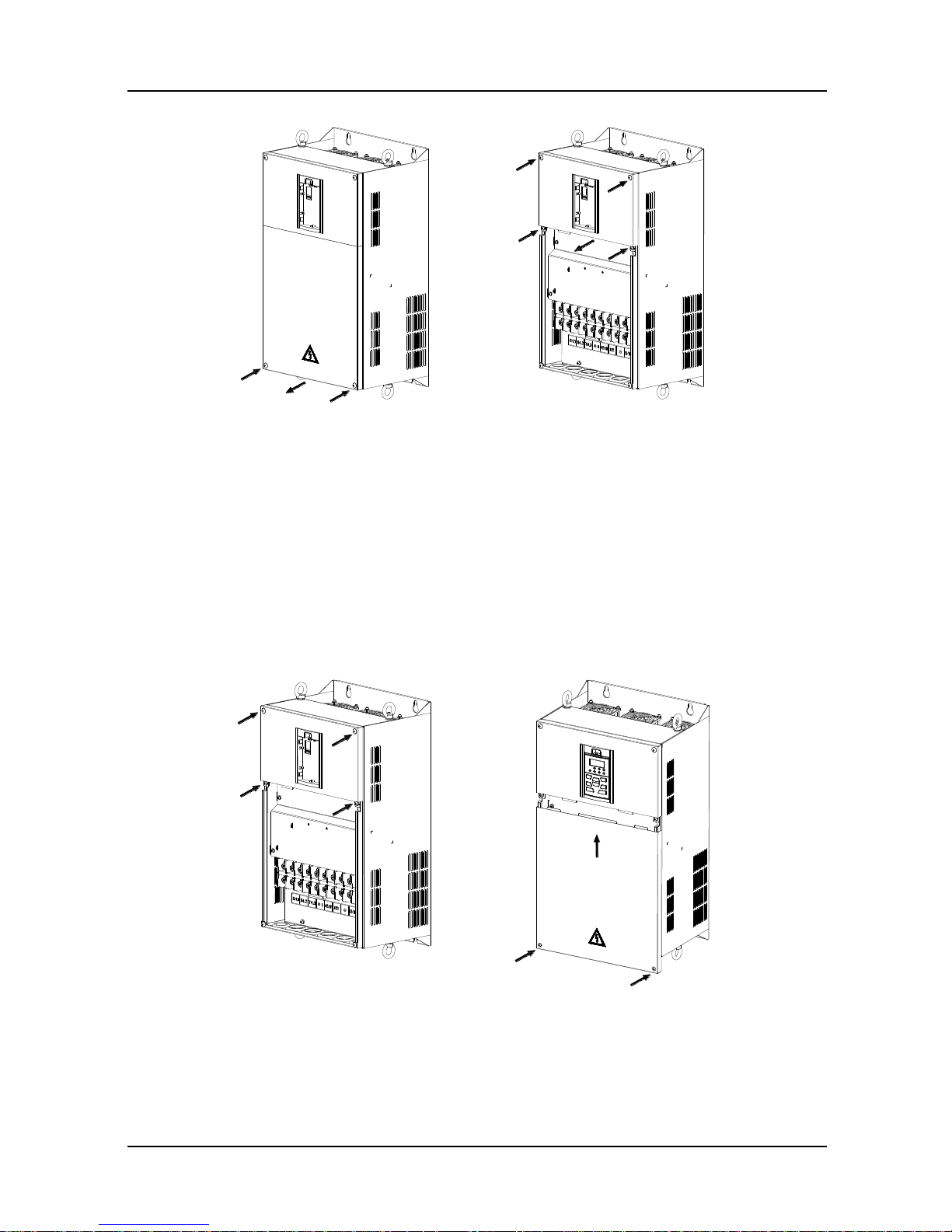

3.3.3 Open & Mount the Covers of GK600E-4T18.5B and above

Remove the control panel

Use the remove method as stated in Section 3.3.1.

Open the lower cover

Loosen the two captive cover screws at lower part of the lower cover by using cross

screwdriver, as indicated by number "1" as shown in Fig. 3-7, then pull the cover out and

up as indicated by number "2".

Open the upper cover

Loosen the two captive cover screws at lower part of the lower cover by using cross

screwdriver, as indicated by number "3" and “4” as shown in Fig. 3-7, then pull the cover

out and up as indicated by number "5".

1

1

2

GK600E User Manual Chapter 3 Installation and Wiring

- 19 -

Fig. 3-7 Open & mount the covers

Mount the upper cover

Insert the upper part of the cover into mounting groove as shown in Fig. 3-8 (left), close the

upper cover, use cross screwdriver to tighten the four captive screws, as indicated by

number “1” and "2".

Mount the lower cover

Insert the lower cover into upper cover in the direction as indicated by number 3 in Fig. 3-8

(right), close the lower cover and tighten the two captive screws, as indicated by number

"4".

Fig. 3-8 Mount the upper and lower covers

Mount the control panel

Use the mounting method as stated in Section 3.3.1.

1

1

2

3

4

4

5

3

1

2

2

1

3

4

4

Chapter 3 Installation and Wiring GK600E User Manual

- 20 -

ATTENTION:

Be sure to remove the control panel before opening the cover and mount the cover before

mounting the control panel.

GK600E User Manual Chapter 3 Installation and Wiring

- 21 -

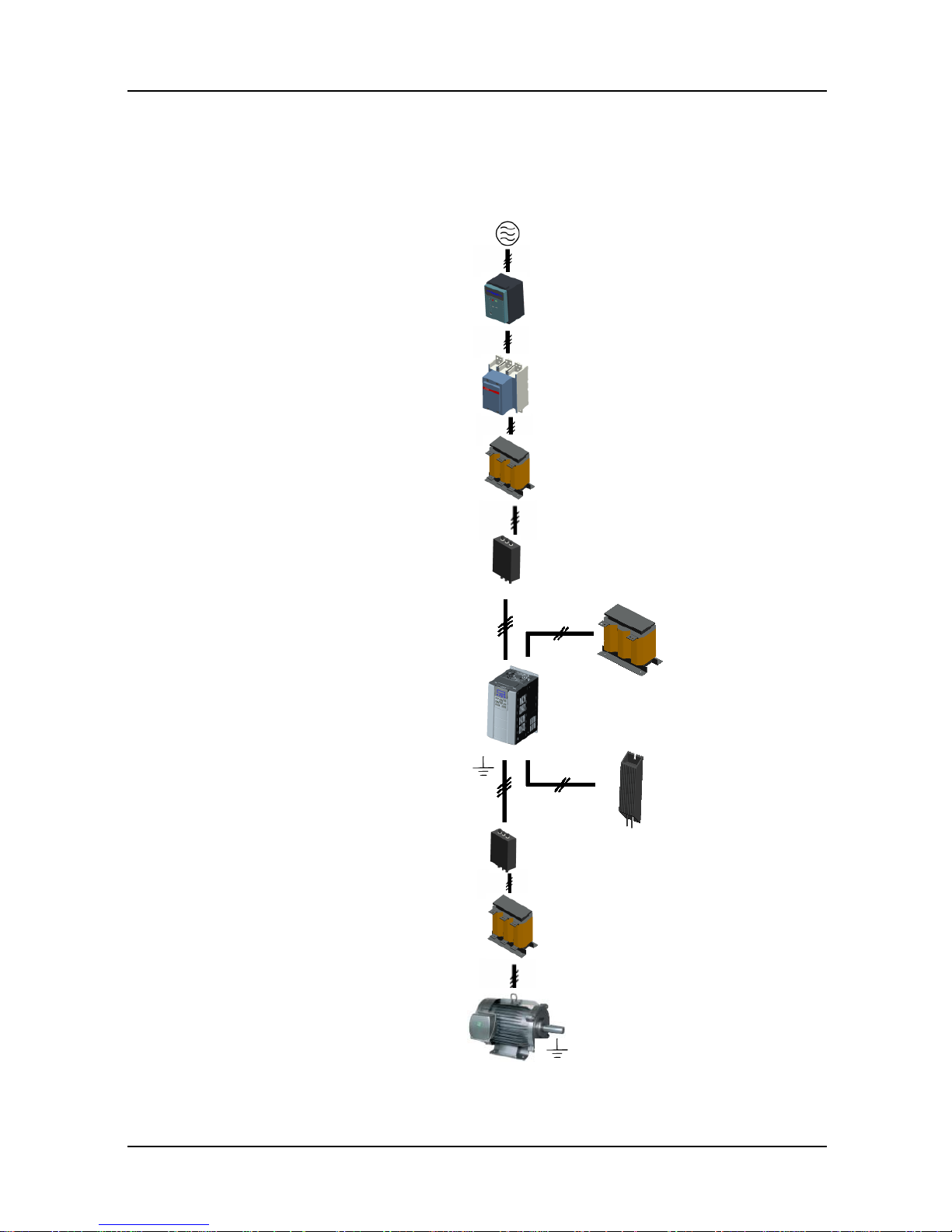

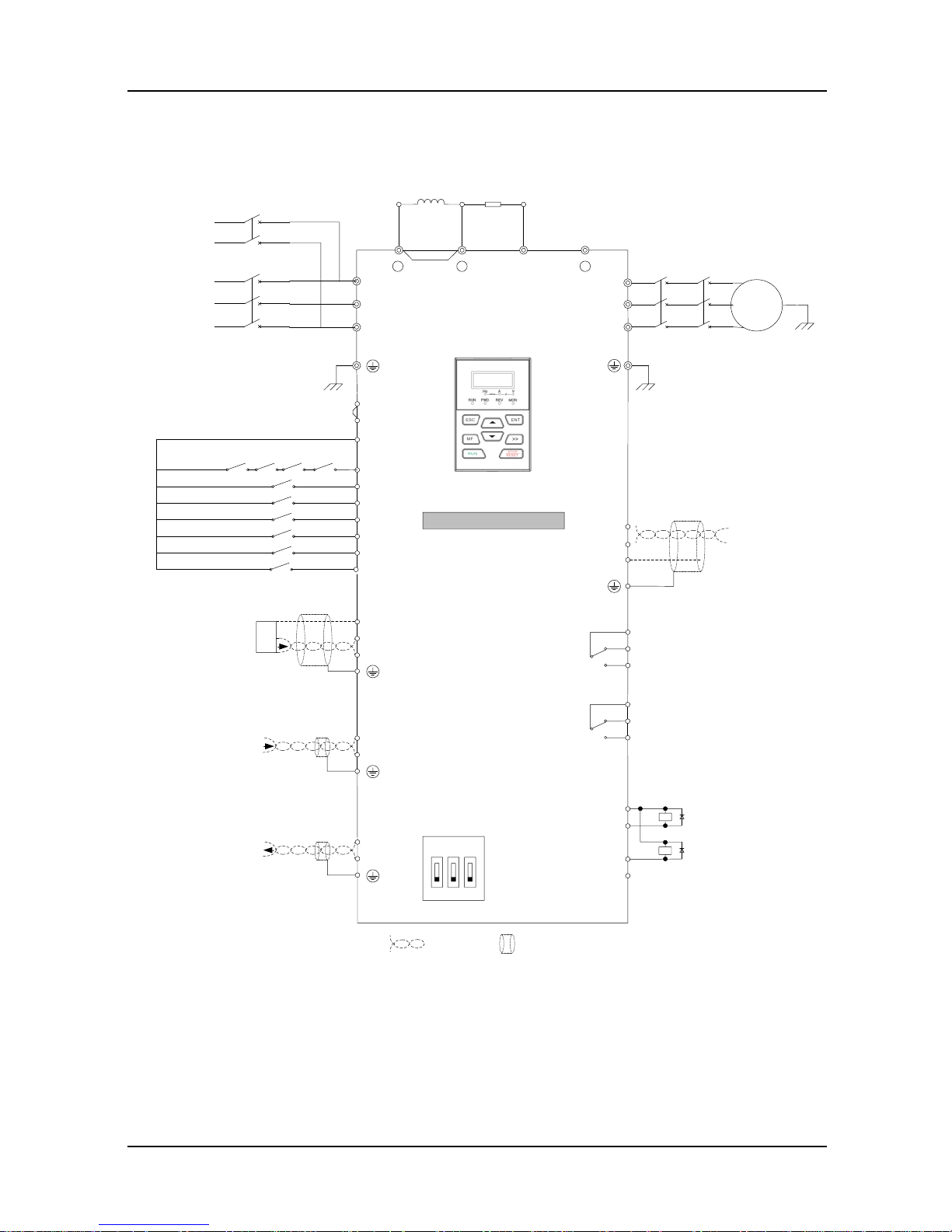

3.4 Configuration of Peripheral Devices

3.4.1 Standard Configuration of Peripheral Devices

Fig. 3-9 Standard configuration of peripheral devices

Output AC Reactor

Braking Resistor

Pow er Supply

Circuit Breaker or RCD

Contactor

Input AC Reactor

DC Choke

Output Filter

AC Motor Drive

PE

Motor

PE

Input Filter

Chapter 3 Installation and Wiring GK600E User Manual

- 22 -

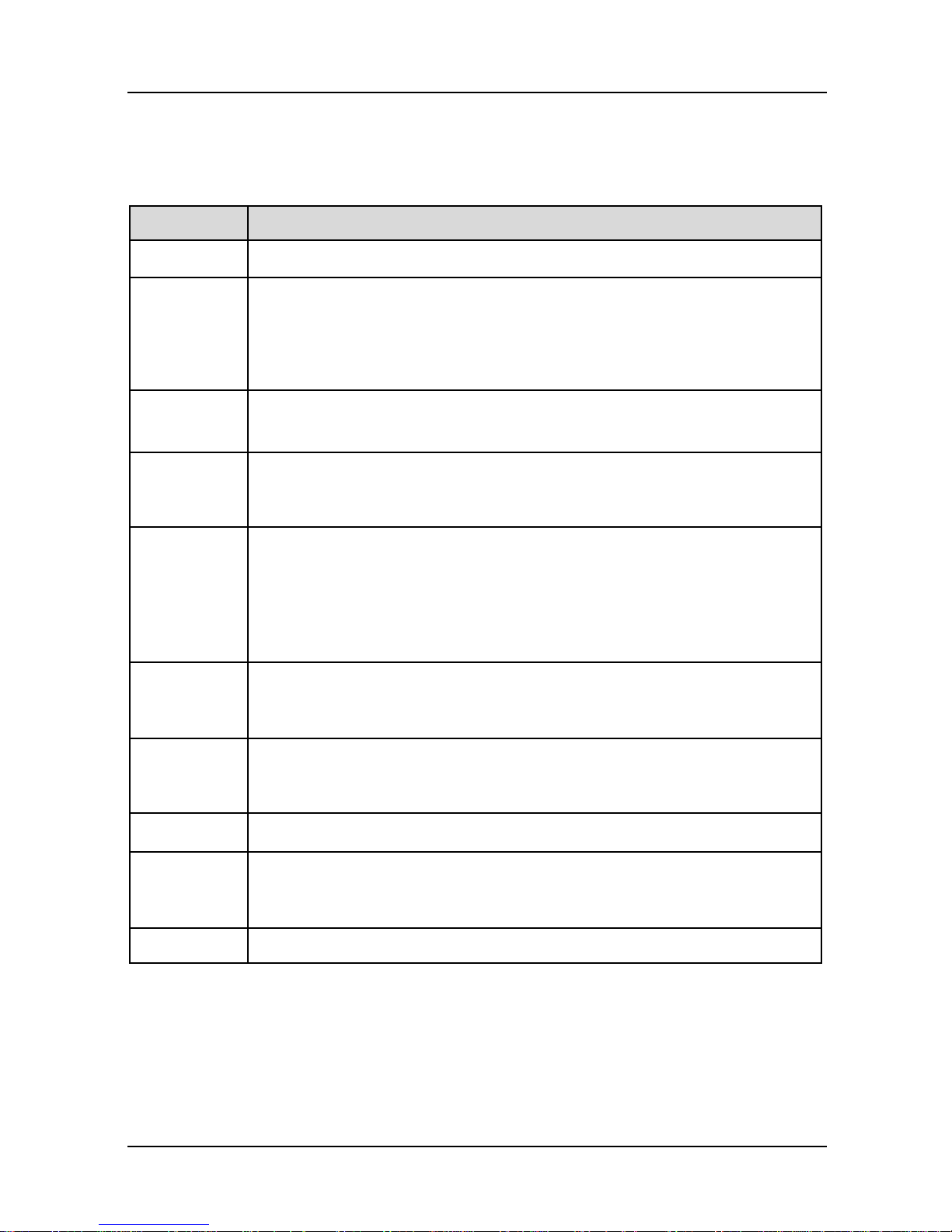

3.4.2 Instructions for Peripheral Devices

Table 3-2 Instructions for peripheral devices

Name

Instructions

Pow er

supply

Input three-phase AC pow er supply should be in the range as specified in

this manual

Circuit

breaker

Purpose: disconnect power supply and protect the equipments in case of

abnormal overcurrent occurs

Type selection: breaking current of circuit breaker is defined to be 1.5~2

times the rated current of the drive

Breaking time characteristic of circuit breaker should be selected based on

overload protection time characteristic of the drive

RCD

Purpose: since the drive outputs PWM HF chopping voltage, HF leakage

current is inevitable

Type selection: type B dedicated RCD is recommended

Contactor

For safety's sake, do not frequently close and break the contactor since this

may bring about equipment faults

Do not control the start & stop of the drive directly through switch on and off

the contactor since this w ill result in a reduction on the product life

Input AC

reactor or

DC choke

Improve power factor

Reduce the impact of imbalanced three-phase input AC power supply on

the system

Suppress higher harmonics and reduce the conducted and radiated

interference to peripheral devices

Restrict the impact of impulse current on rectifier bridges

Input filter

Reduce conducted interference from power supply to the drive, improve the

immunity of the drive from noise

Reduce conducted and radiated interference of the drive to peripheral

devices

Brake unit

and

braking

resistor

Purpose: consume motor feedback energy to attain quick brake

Type selection: Contact GTAKE technical personnel for type selection of

brake unit. Refer to type selection of braking resistor in Table 3-3 Type

Selection of Peripheral Devices.

Output filter

Reduce conducted and radiated interference of the drive to peripheral

devices

Output AC

reactor

Avoid the motor insulation damage result from harmonic voltage

Reduce frequent protection from the drive caused by leakage current

In case the cable connecting drive and motor is over 100 meters, output AC

reactor recommended

Motor

Should match the drive

GK600E User Manual Chapter 3 Installation and Wiring

- 23 -

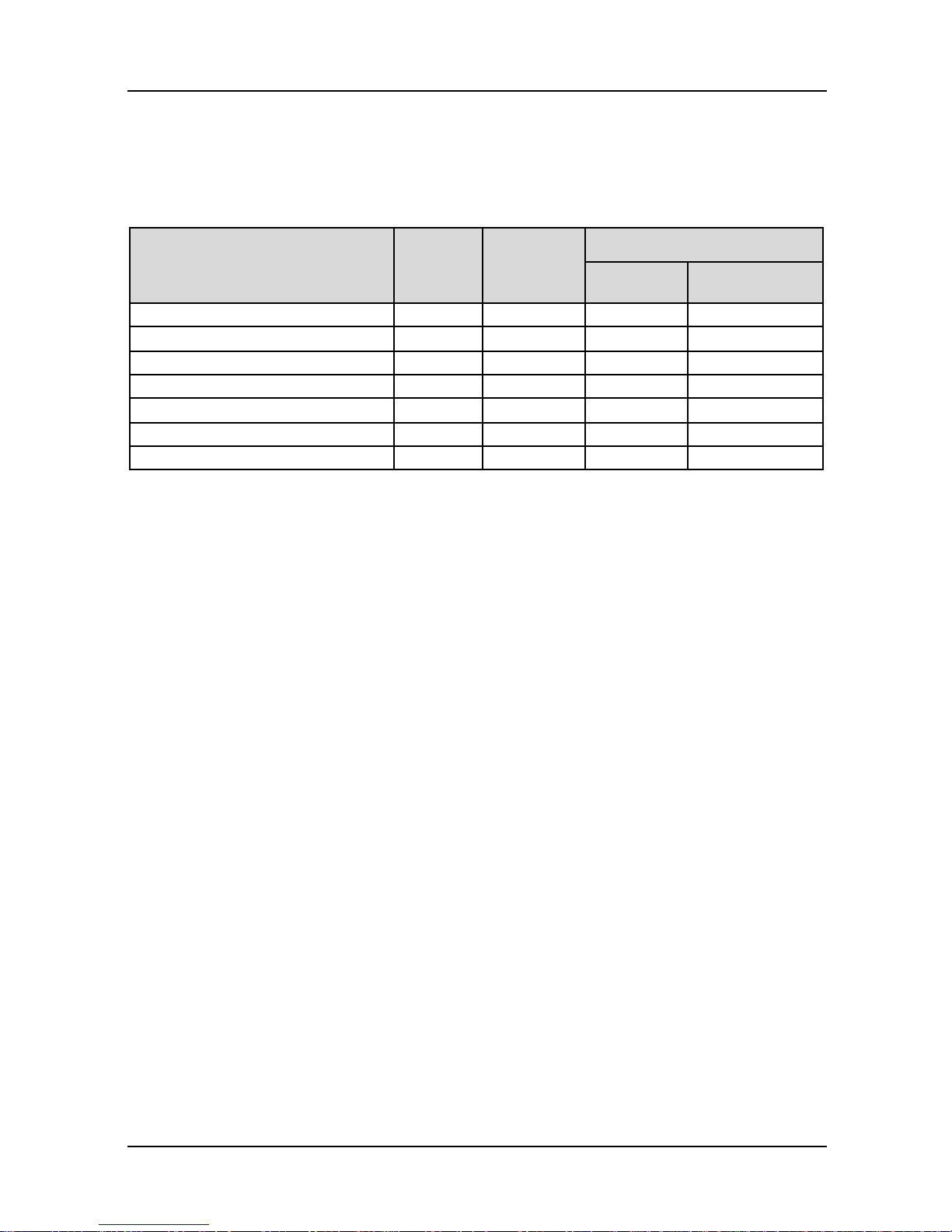

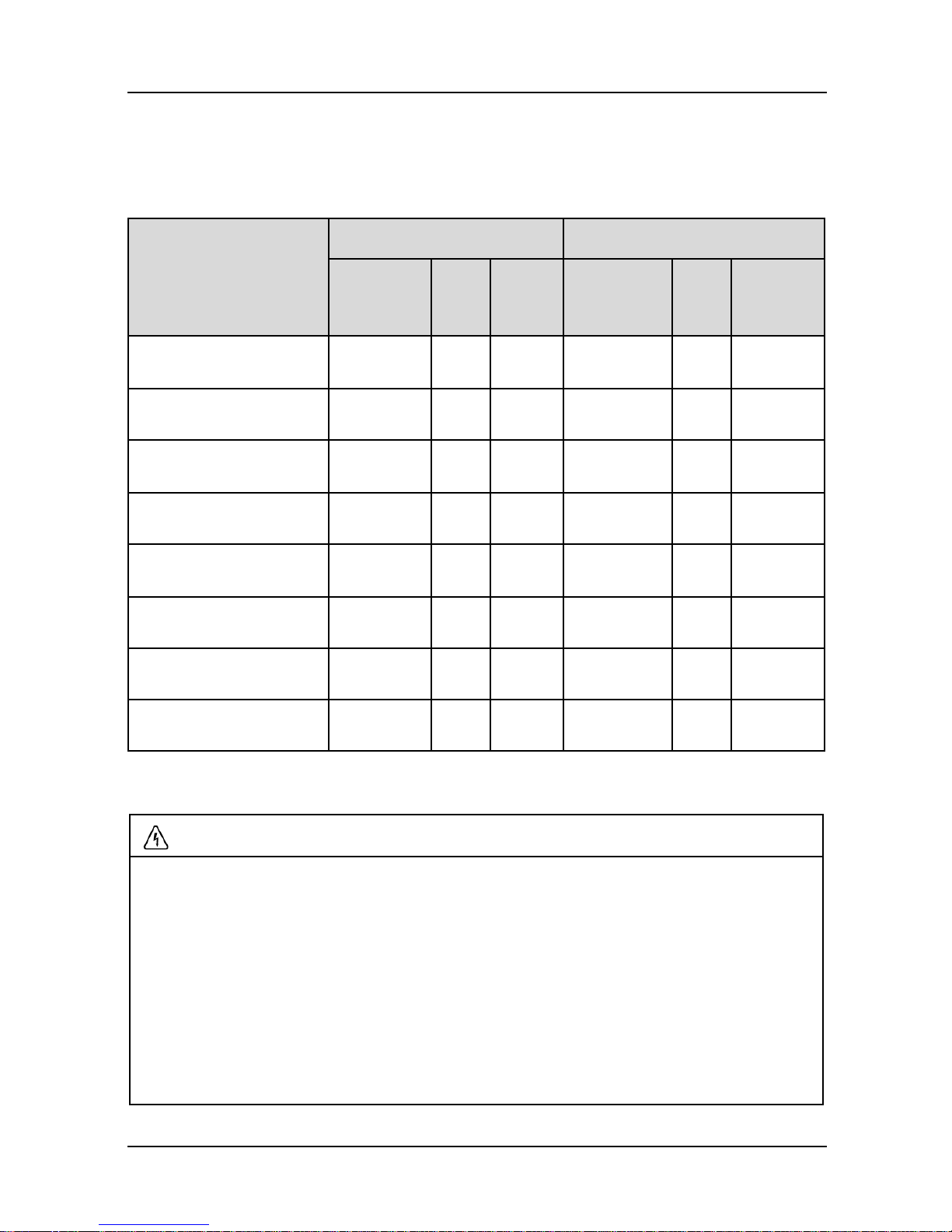

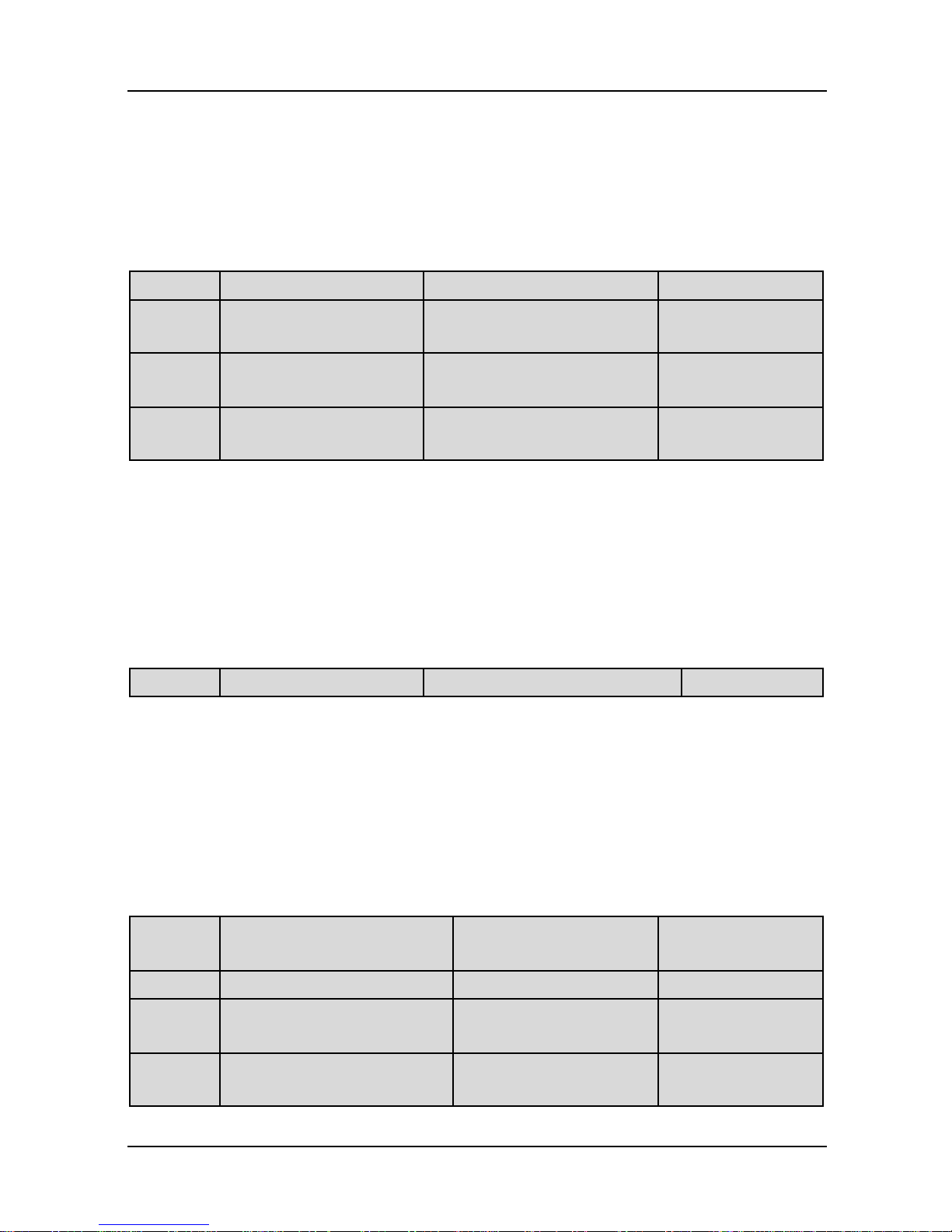

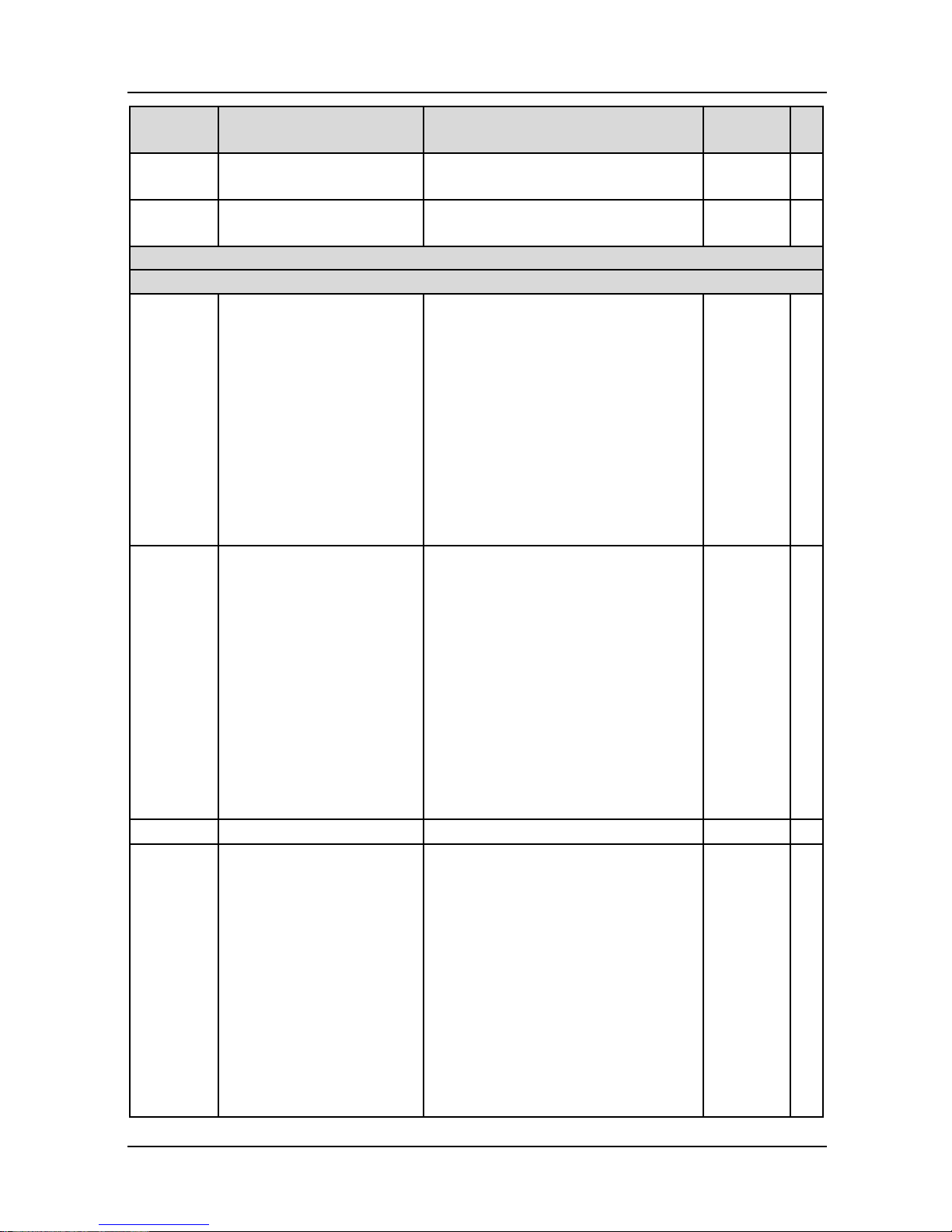

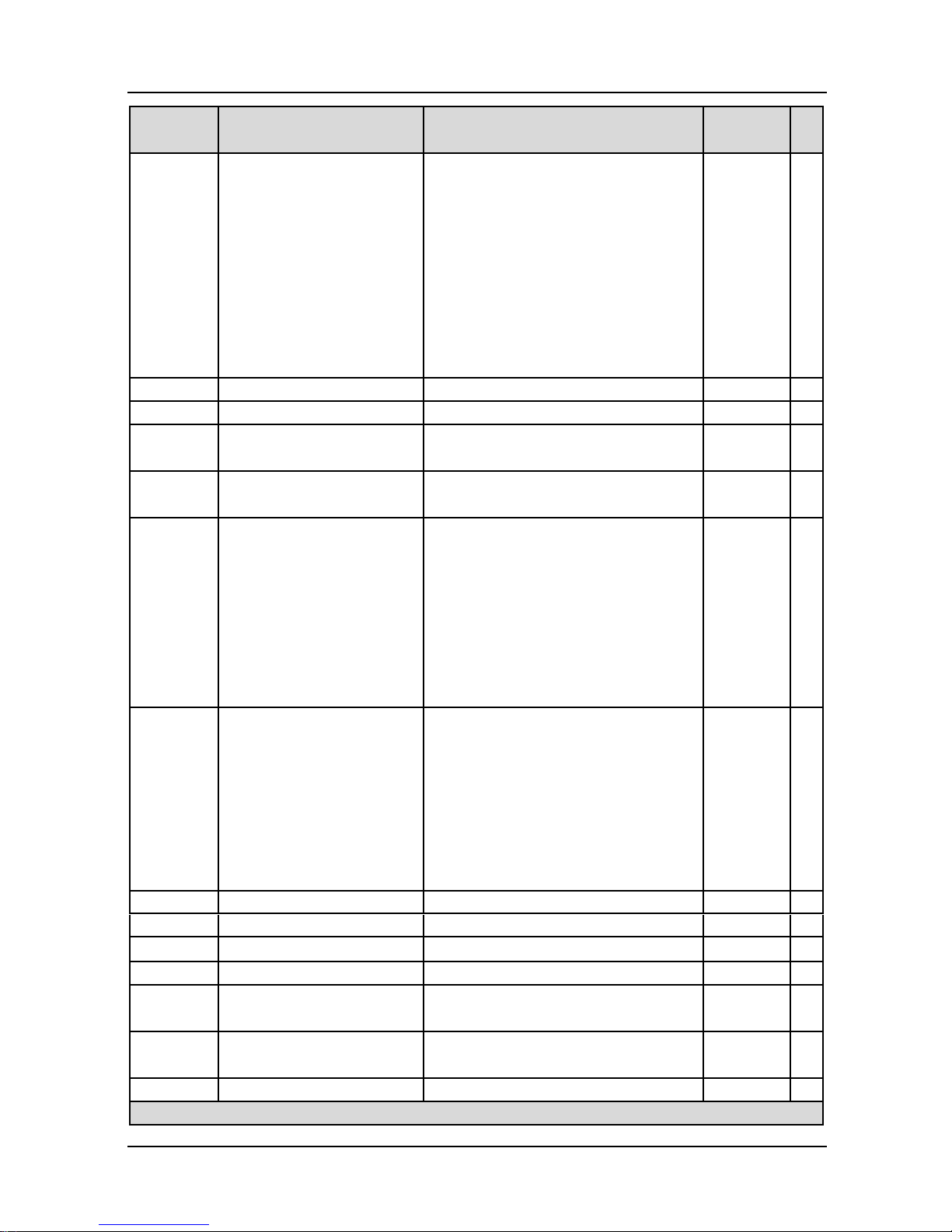

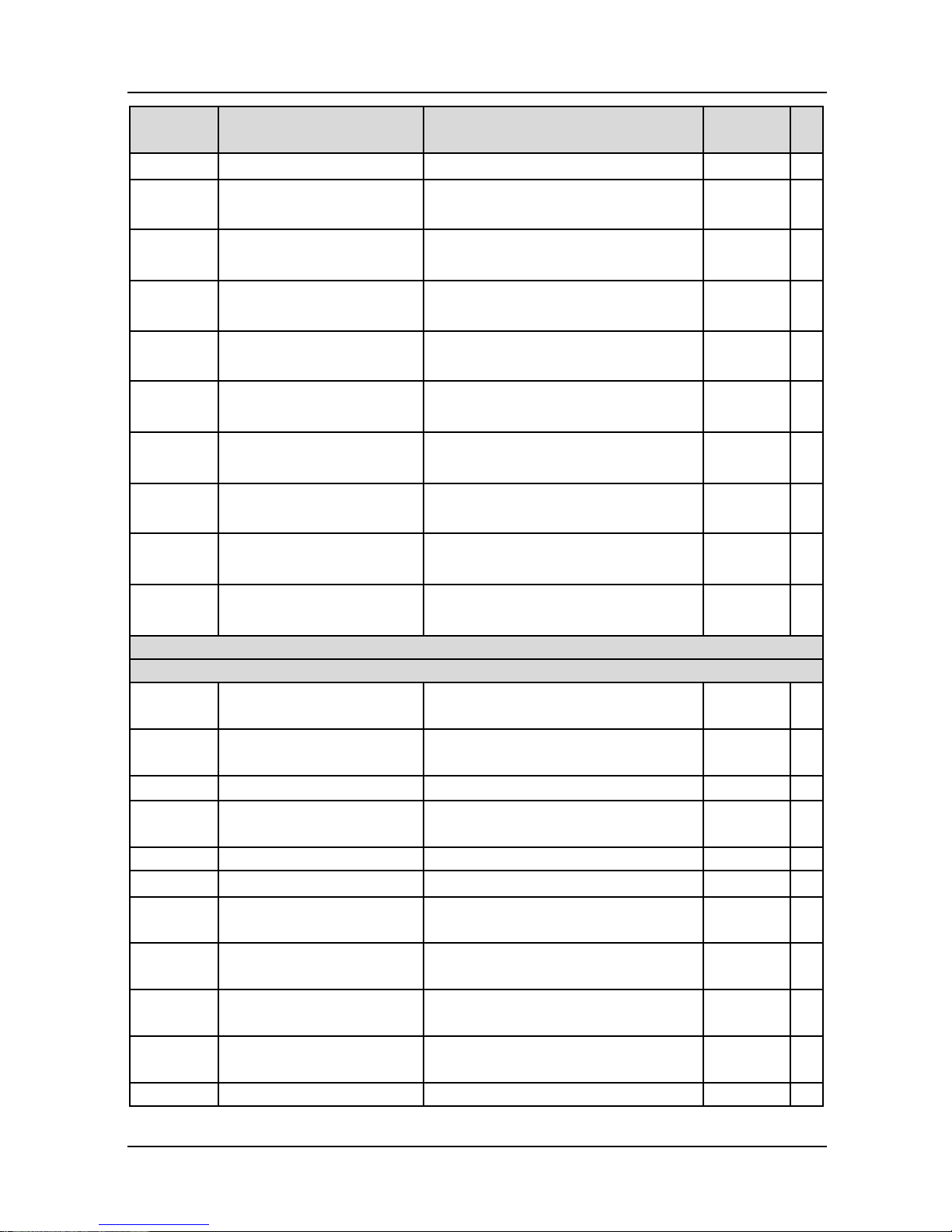

3.4.3 Selection of Peripheral Devices

Table 3-3 Selection of peripheral devices

■GK600E-4T B, Three phase 400V input

Drive model

Circuit

breaker

(A)

Contactor(A)

Brake resistor /Brake chopper*

Pow er (W)

Resistance (Ω)

GK600E-4T3.7B

16

12

450

≥75

GK600E-4T5.5B

20

18

500

≥75

GK600E-4T7.5B

32

25

500

≥75

GK600E-4T11B

40

32

800

≥30

GK600E-4T18.5B

63

50

1300

≥16

GK600E-4T22B

63

50

1500

≥16

GK600E-4T30B

100

65

2000

≥16

* On the premise of fulfilling brake requirement, brake resistance value might be bigger than the minimum value as

stated in the table. Failure to comply may result in damage to the resistor and the drive. Brake resistors are not

built in and need to be sourced additionally.

Chapter 3 Installation and Wiring GK600E User Manual

- 24 -

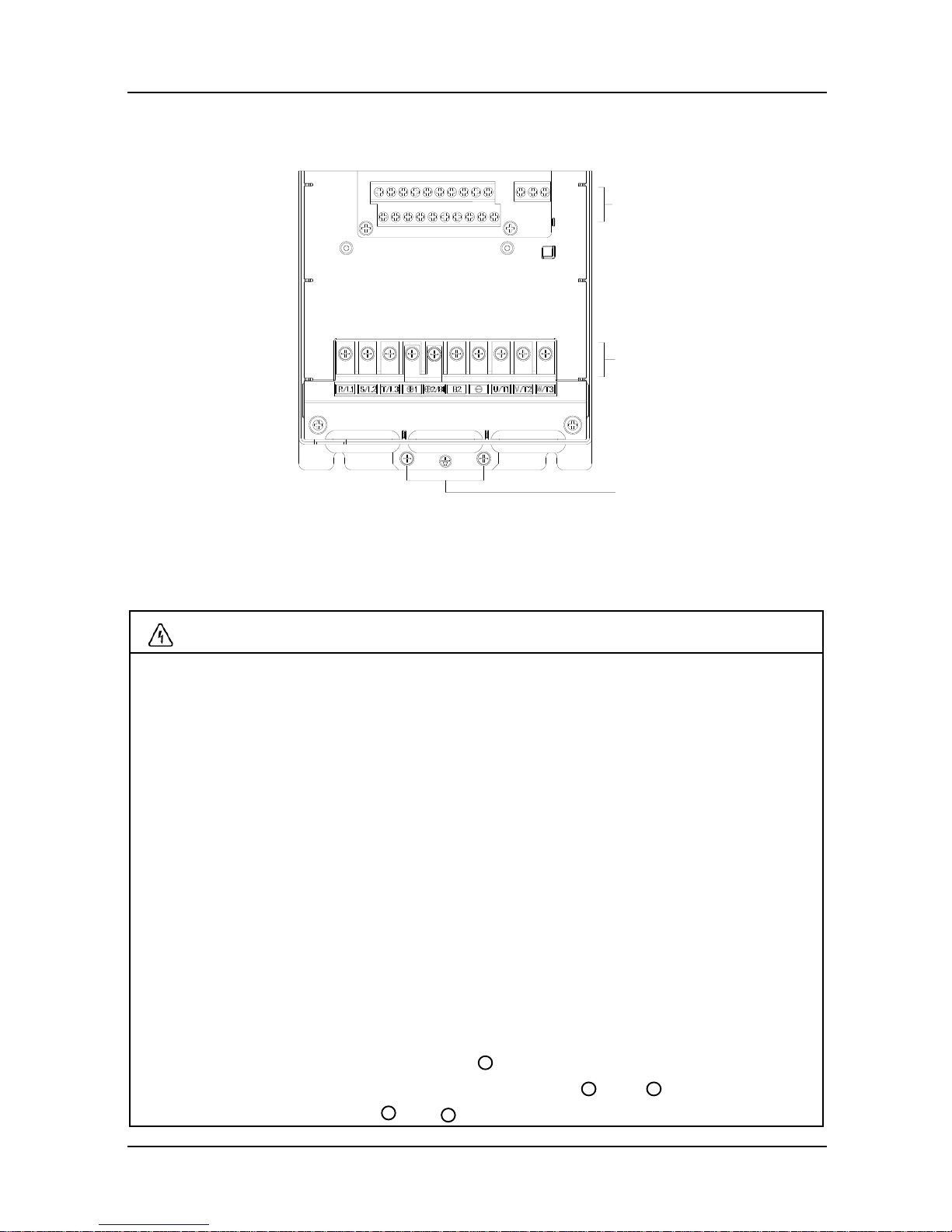

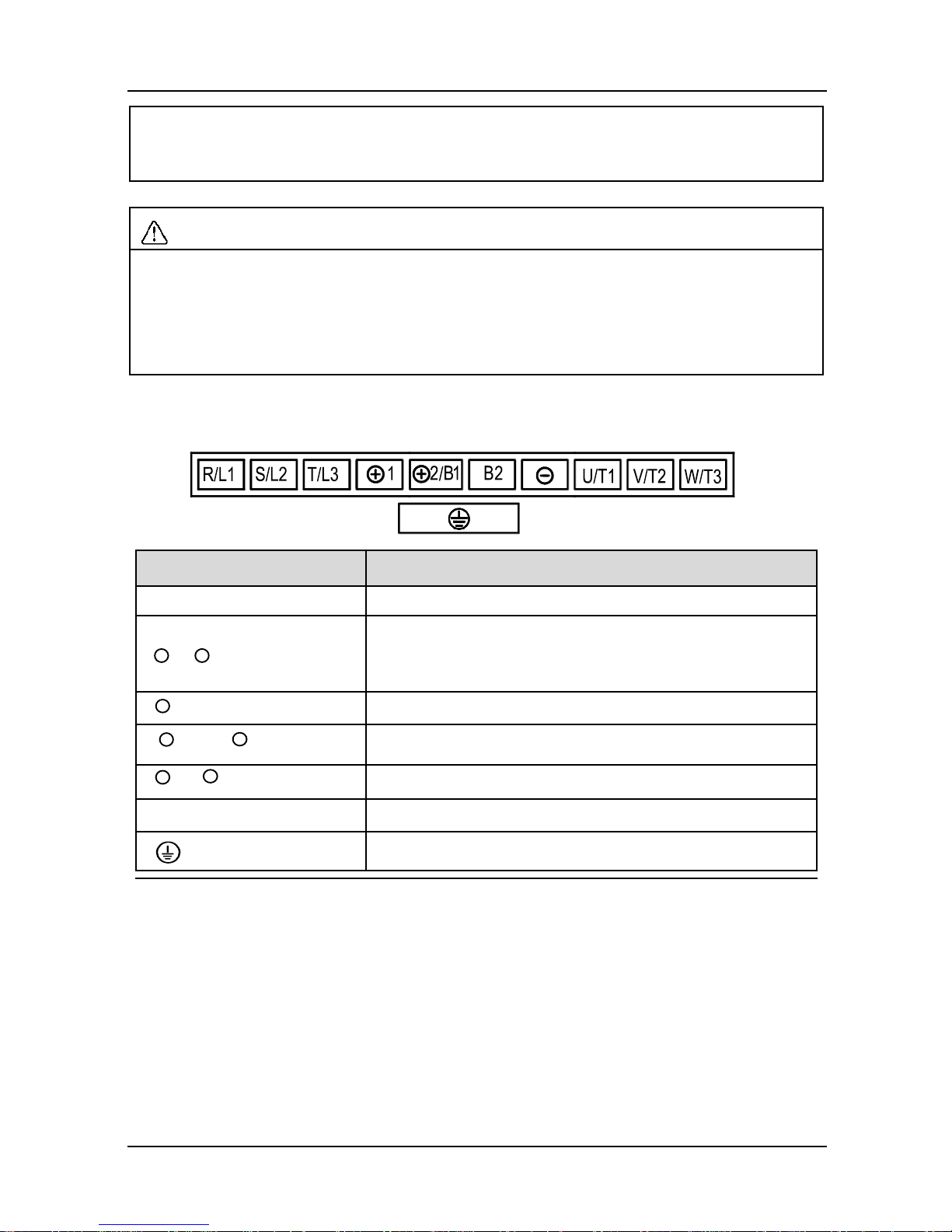

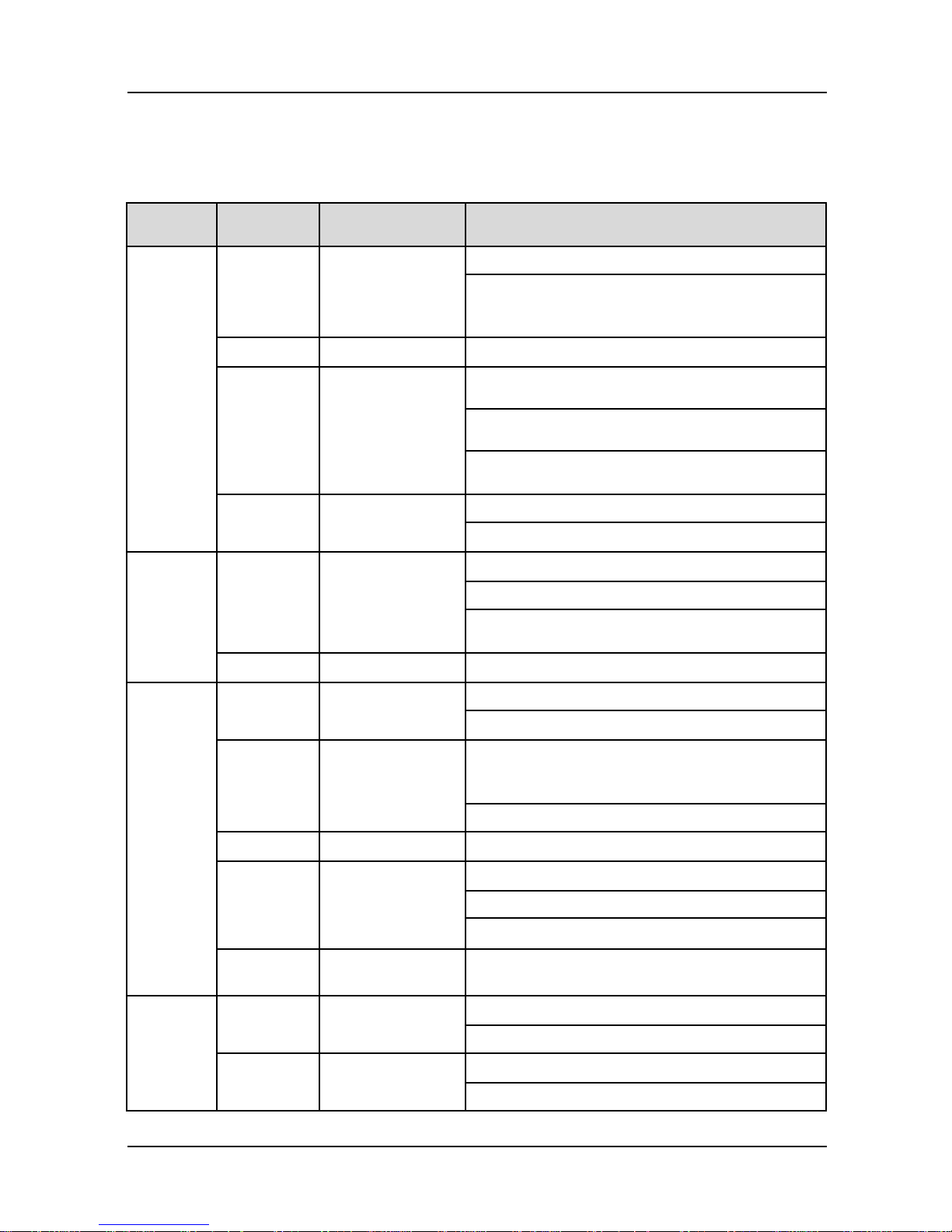

3.5 Terminal Configuration

Fig. 3-10 Terminal configuration

3.6 Main Circuit Terminals and Wiring

WARNING

Only qualified personnel familiar w ith AC motor drives and passenger lift are allowed to

implement wiring. Failure to comply may result in equipment damage and/or personnel

injury even death.

Wiring should be in strict accordance with this manual, otherwise hazard of electric

shock or equipment damage exists.

Make sure input power supply has been completely disconnected before wiring

operation. Failure to comply will result in personnel injury even death.

All w iring operations and lines should comply with EMC and national and local industrial

safety regulations and/or electrical codes. The conductor diameter should be in

accordance with recommendations of this manual. Otherwise, hazard of equipment

damage, fire, and/or personnel injury exists.

Since leakage current of the drive may exceed 3.5mA, for safety's sake, the drive and

the motor must be grounded so as to avoid hazard of electric shock.

Be sure to perform w iring in strict accordance with the drive terminal marks. Never

connect three-phase power supply to output terminals U/T1, V/T2 and W/T3. Failure to

comply will result in equipment damage.

Only mount braking resistors at terminals and B2.

When needed, only mount DC reactors at terminals and , and remove the

jumper connected between and . Never connect the jumper and DC reactor to

控制回路端子

主回路端子

接地端子

Control circuit terminals

Main circuit terminals

+ 2/B1

+ 1

+ 2

+ 1

+ 2

Grounding terminals

GK600E User Manual Chapter 3 Installation and Wiring

- 25 -

other terminals since this will result in short circuit and equipment damage.

Wiring screws and bolts for main circuit terminals must be screwed tightly. Failure to

comply may result in faults and/or equipment damage.

ATTENTION

Signal wires should be away from main power lines to the best of possibility. In the

event that this cannot be ensured, vertical cross arrangement should be adopted,

reducing EMI interference to the signal wires as much as possible.

In case the motor cable exceeds 100m, an appropriate output reactor should be

mounted.

3.6.1 Main Circuit Terminals of GK600E-4T3.7B ~ GK600E-4T30B

Terminal marks

Designation and function of terminals

R/L1, S/L2, T/L3

Three-phase AC input terminals

,

DC reactor connection terminals. Connected w ith a

jumper as factory default

, B2

Built-in brake unit connection terminals*

,

DC input terminals of externally mounted brake unit

,

DC power supply input terminals

U/T1, V/T2, W/T3

Three-phase AC output terminals

Ground terminal PE

-

+ 1

+ 2/B1

+ 2/B1

+ 2/B1

-

+ 1

Chapter 3 Installation and Wiring GK600E User Manual

- 26 -

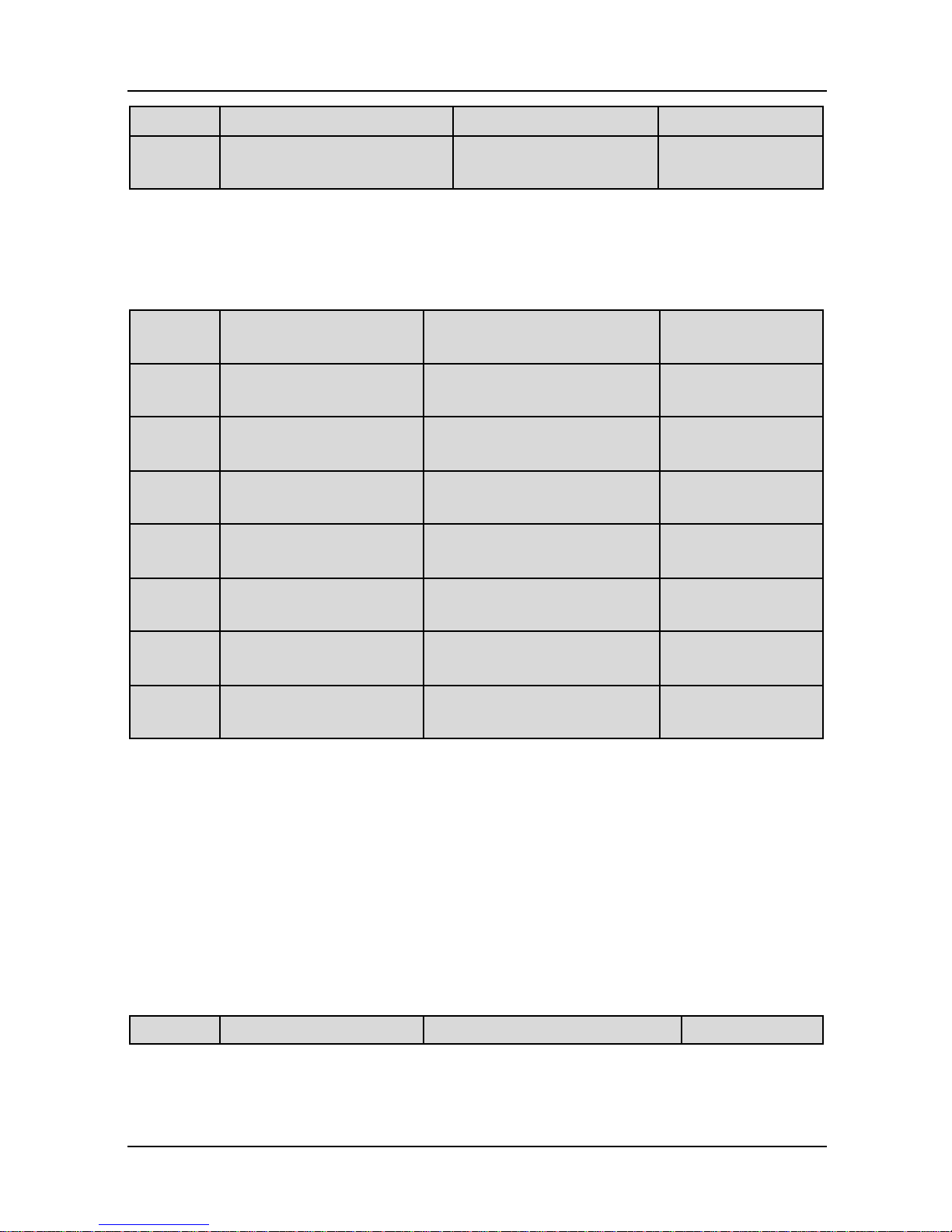

3.6.2 Terminal Screw and Wiring Requirement

Table 3-4 Terminal screw and wiring requirement

■GK600E-4T B Three-phase 400V input

Drive model

Pow er terminal

Ground terminal

Cable

requirement

(mm2)

Screw

Torque

(kgf.cm)

Cable

requirement

(mm2)

Screw

Torque

(kgf.cm)

GK600E-4T3.7B

2.5

M4

14±0.5

2.5

M4

14±0.5

GK600E-4T5.5B

4

M4

14±0.5

4

M4

14±0.5

GK600E-4T7.5B

4

M4

14±0.5

4

M4

14±0.5

GK600E-4T11B

6

M5

28±0.5

6

M4

14±0.5

GK600E-4T15B

10

M5

28±0.5

10

M4

14±0.5

GK600E-4T18.5B

10

M6

48±0.5

10

M6

48±0.5

GK600E-4T22B

16

M6

48±0.5

16

M6

48±0.5

GK600E-4T30B

25

M6

48±0.5

16

M6

48±0.5

3.7 Control Terminal Wiring

WARNING

Only qualified personnel familiar w ith AC motor drives and passenger lift are allowed to

implement wiring. Failure to comply may result in equipment damage and/or personnel

injury even death.

Wiring should be in strict accordance with this manual, otherwise hazard of electric

shock or equipment damage exists.

Make sure input power supply has been completely disconnected before wiring

operation. Failure to comply will result in personnel injury even death.

All w iring operations and lines should comply with EMC and national and local industrial

safety regulations and/or electrical codes. The conductor diameter should be in

accordance with recommendations of this manual. Otherwise, hazard of equipment

GK600E User Manual Chapter 3 Installation and Wiring

- 27 -

damage, fire, and/or personnel injury exists.

Screw s or bolts for terminal wiring must be screwed tightly.

AC 220V signal is prohibited from connecting to terminals other than control terminals

RA, RB and RC.

ATTENTION

Signal wires should be away from main power lines to the best of possibility. If this

cannot be ensured, vertical cross arrangement should be adopted, reducing EMI

interference to the signal wires as much as possible.

The encoder must be provided with shielded cables whose shielded layer must be

properly grounded.

Chapter 3 Installation and Wiring GK600E User Manual

- 28 -

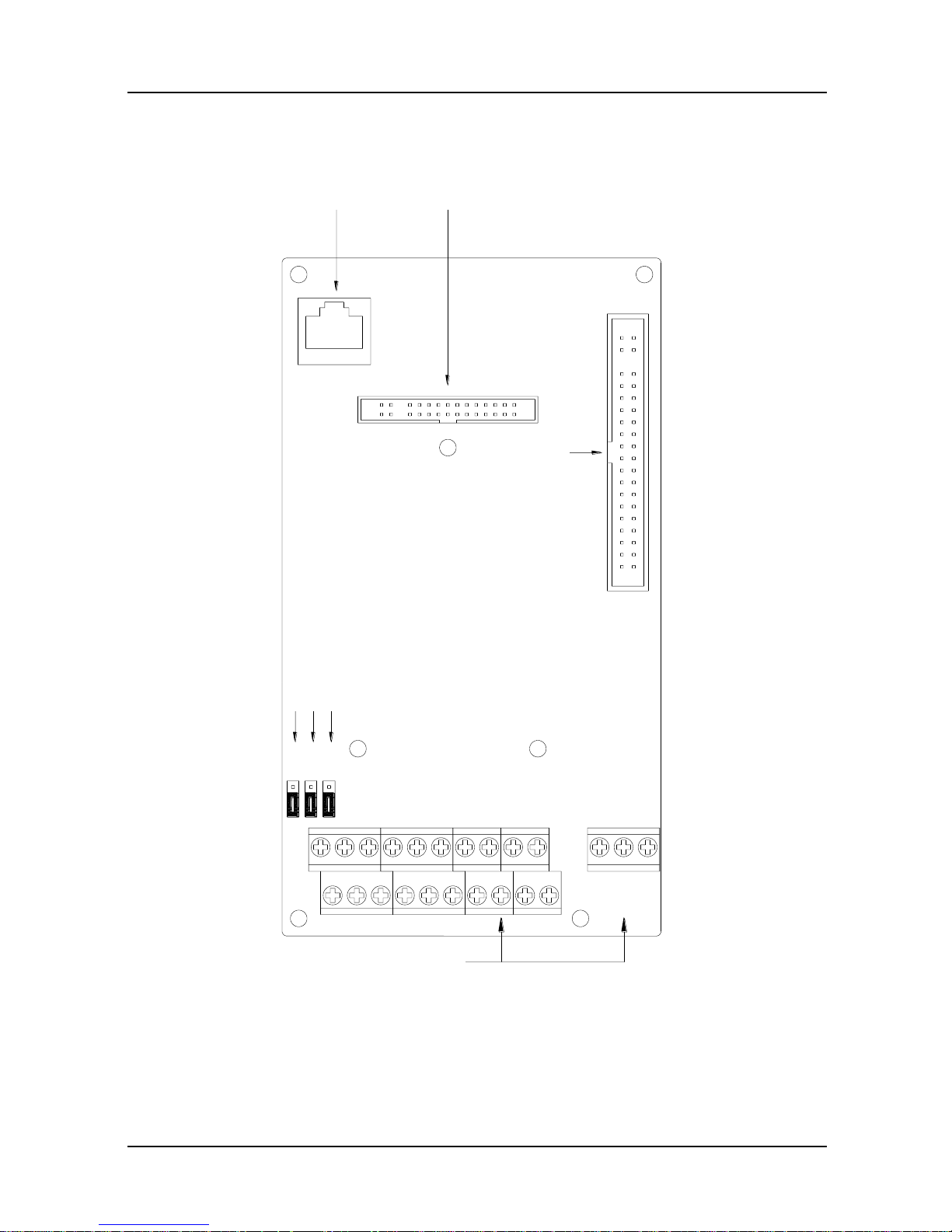

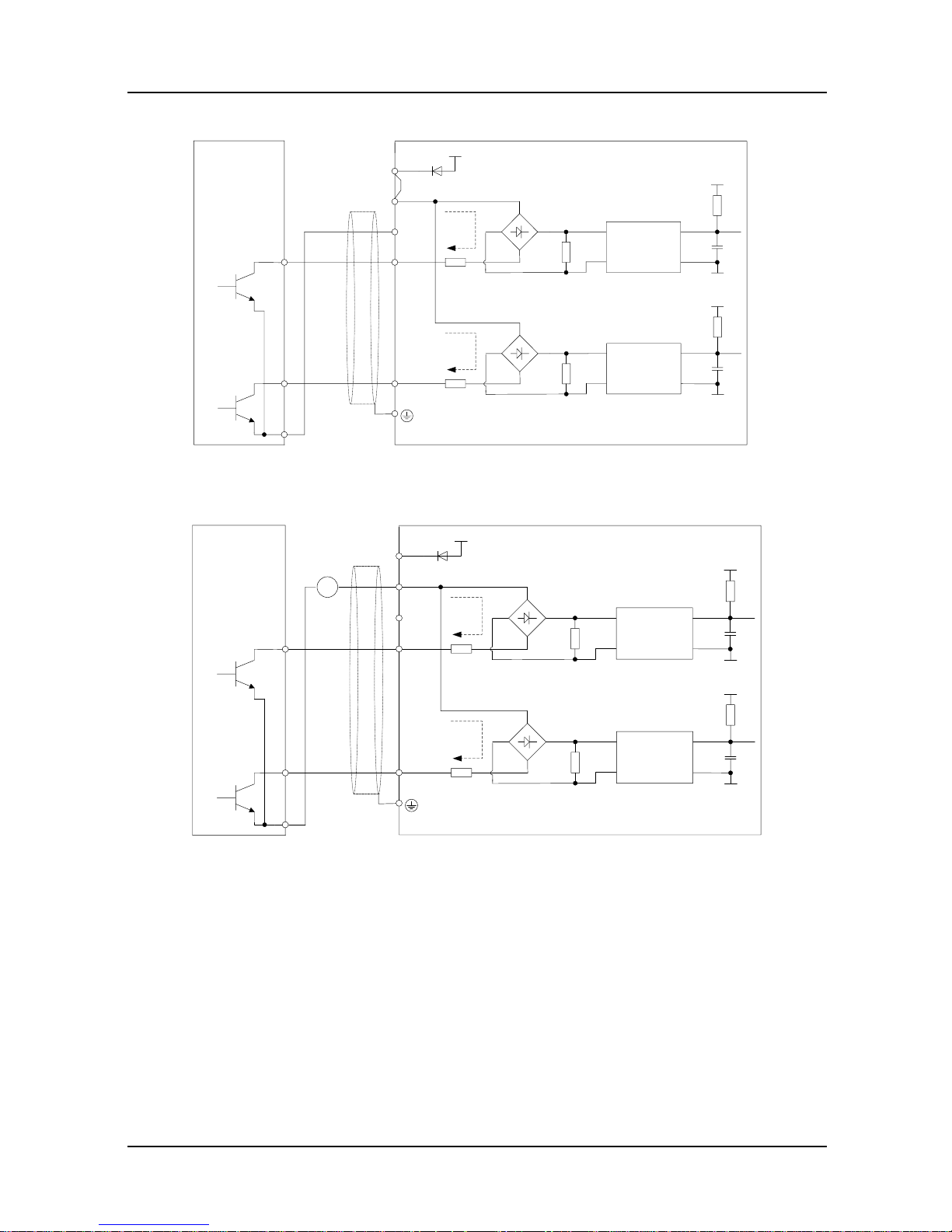

3.7.1 Control Board Diagram

Fig. 3-11 Control board diagram

OFF

ON

AI1 AO1485

I

VV

I

S2S1 S3

主信号接口

操作面板485接口

扩展卡接口

用户信号端子

端

子

通

讯

终

端

电

阻

选

择

模

拟

量

输

入

1

电

压

电

流

选

择

模

拟

量

输

出

1

电

压

电

流

选

择

Control panel 485 interface

Option board interface (engaged

by EPC-TM1 as default)

Main signal

interf ace

S1: Terminal resistor selection for terminal communication

S2: Analog input 1 voltage/current option

S3: Analog output 1 voltage/current option

User signal

terminal

GK600E User Manual Chapter 3 Installation and Wiring

- 29 -

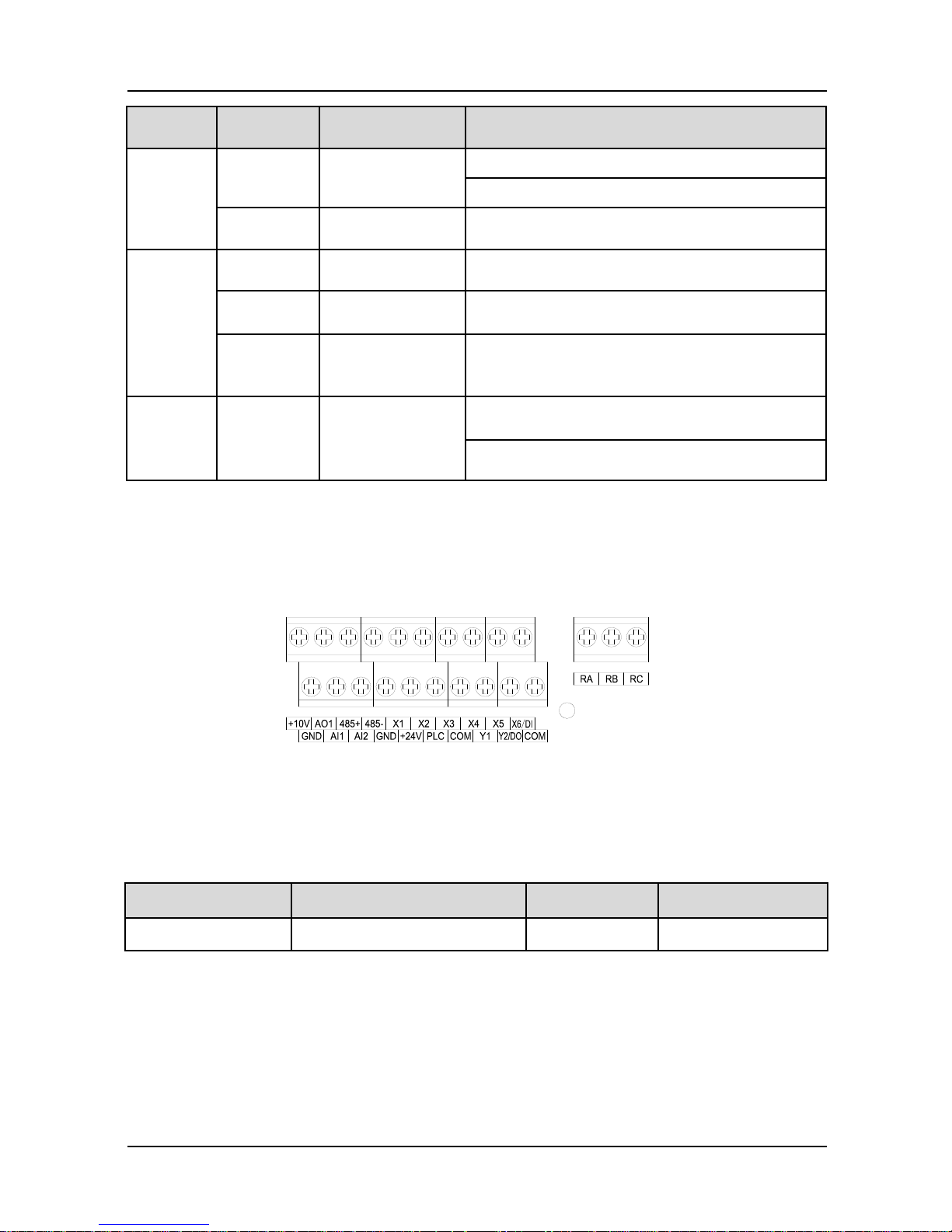

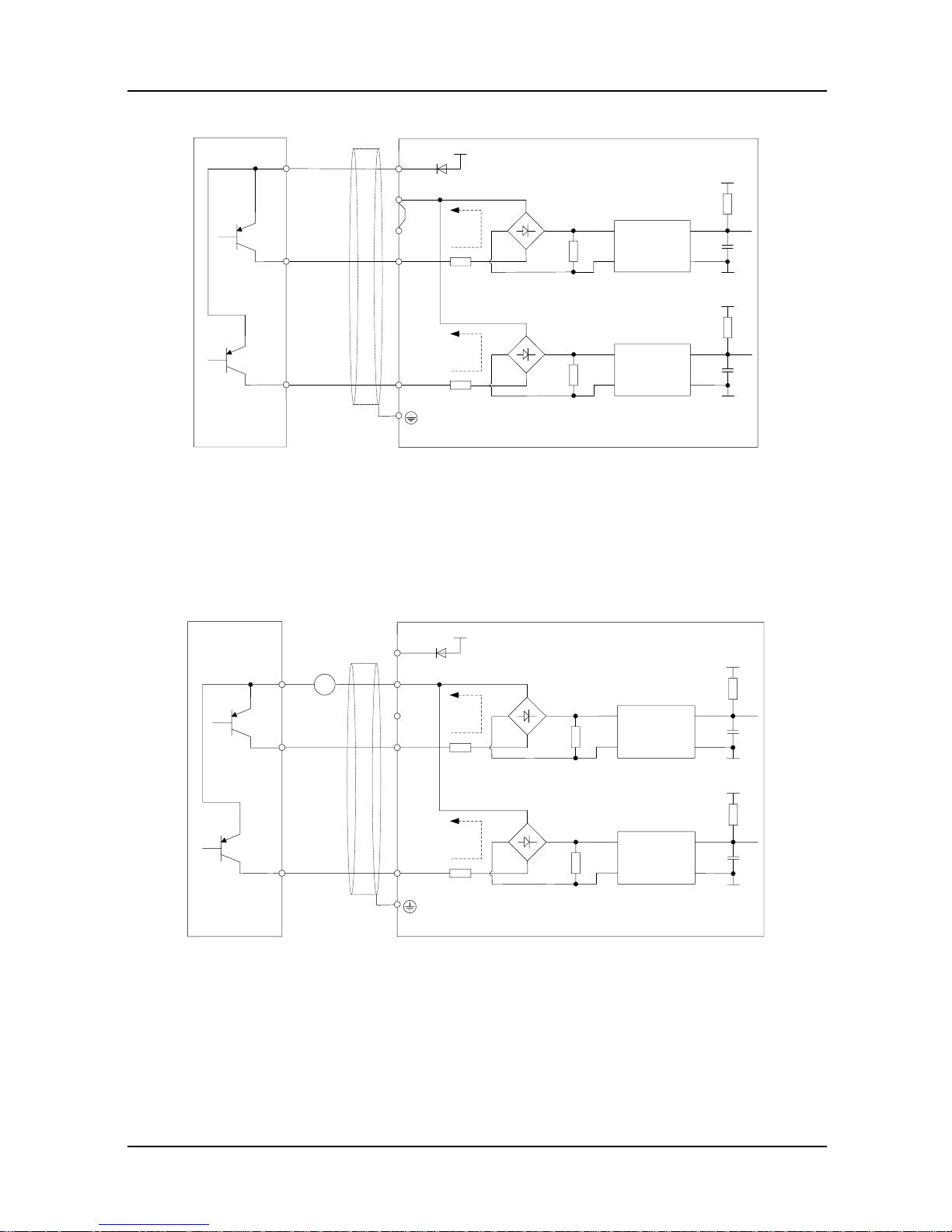

3.7.2 Wiring Diagram

Fig. 3-12 Wiring diagram

M

DC Reactor

Jumper

Braking

Resistor

Motor

Ground

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

Power

Supply

Ground

++

1

2/B1

B2

UPS

1-phase

220VAC

Three-phase

Power Supply

380V-460V

50/60Hz

+24V

PLC

X1

X2

X3

X4

X5

X6

COM

Enable

Run Fwd

Run Rev

Multi-speed sel 1

Multi-speed sel 2

Multi-speed sel 3

RA

RB

RC

+24V

Y1

Y2/DO

COM

+10V

AI1

GND

Relay Output

250V AC/3A

30V DC/3A

Open Collector Output 1

Open Collector Output 2

High-speed Pulse Output

Option Board Interface

CN2

GK600E

Jumper

Analog In Reference

Voltage

POT

OFFONV

IVI

485 AI1 AO1

AI2

GND

485 MODBUS

Communication

485+

485-

AO1

GND

GND

Paired

Cable

Shielded

Cable

Analog In

DC: 0~10V/0~20mA

Analog In

DC:-10V~10V

Analog Out

DC:0~10V/0~20mA

Control Panel

-

KM1

KM4

KM1

KM2

KM3

Safety Contacts

X7 (On Option Board)

Emergency Speed

Relay Output

(On Option Board)

250V AC/3A

30V DC/3A

RA

RB

RC

KM2 KM3

Chapter 3 Installation and Wiring GK600E User Manual

- 30 -

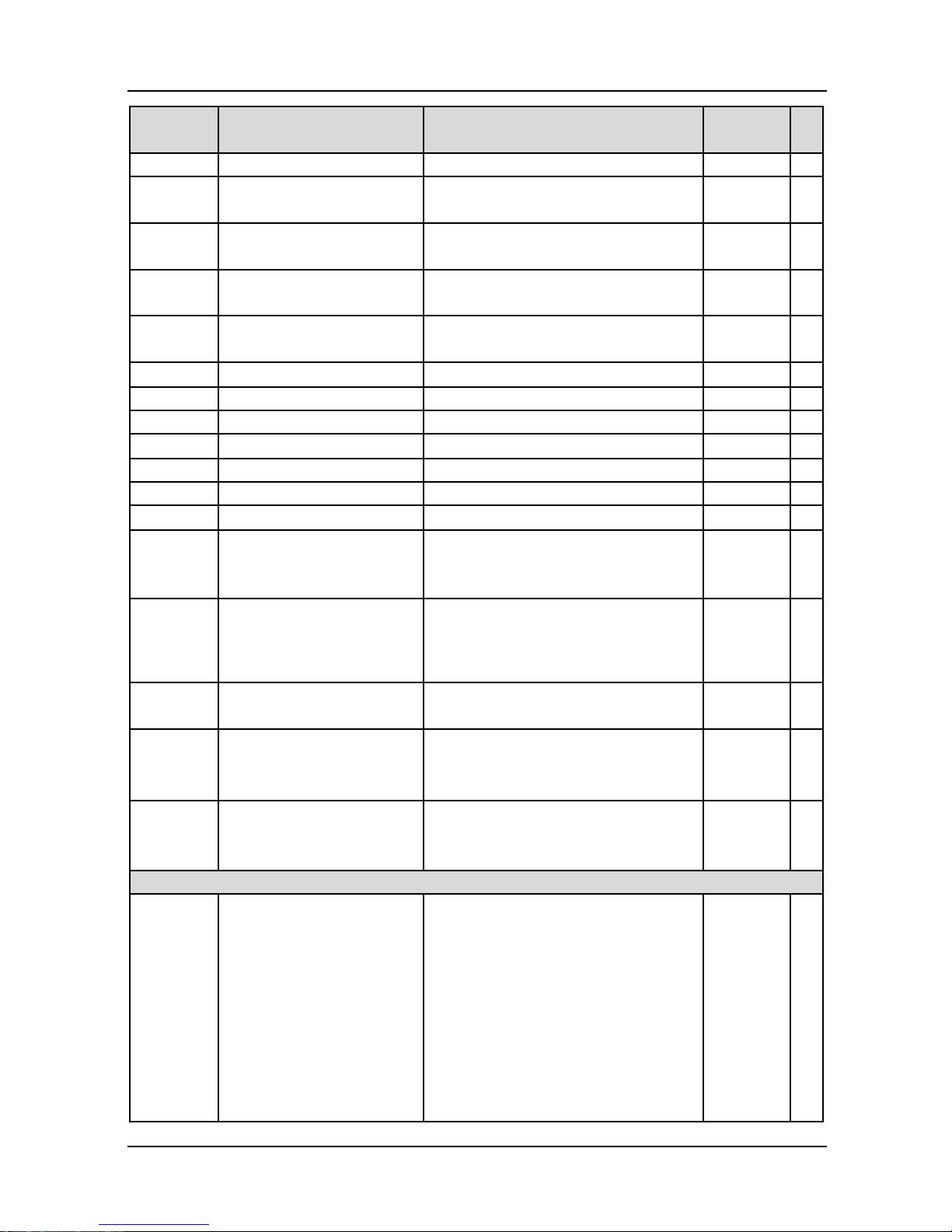

3.8 Control Terminal Specification

Table 3-5 Control terminal specification

Category

Terminal

Terminal

designation

Specification

Analog

input

+10V

Analog input

reference

voltage

10.3V ±3%

Maximum output current 25mA

The resistance of external potentiometer

should be larger than 400Ω

GND

Analog ground

Isolated from COM interiorly

AI1

Analog input 1

0~20mA: input impedance - 500Ω, maximum

input current - 25mA

0~10V: input impedance - 22kΩ,

maximum input voltage - 12.5V

Switch S2 on control board for jumping from

0~20mA and 0~10V, factory default: 0~10V

AI2

Analog input 2

-10V~10V: input impedance - 25kΩ

Range: -12.5V~+12.5V

Analog

output

AO1

Analog output 1

0~20mA: impedance - 200Ω~500Ω

0~10V: impedance ≥ 10k

Switch S3 on control board for jumping from

0~20mA to 0~10V, factory default: 0~10V

GND

Analog ground

Isolated from COM interiorly

Digital

input

+24V

+24V

24V±10%, Isolated from GND interiorly

Maximum load - 200mA

PLC

Digital input

Common

terminal

Used for sw itching between high and low

levels, short-circuited with +24V when

delivery, i.e. low value of digital input valid

External power input

COM

+24V ground

Isolated from GND interiorly

X1~X6

Digital input

Terminals 1~5

Input: 24VDC, 5mA

Range of frequency: 0~200Hz

Range of voltage: 10V~30V

X7

Digital input (on

option board)

Digital input: same as X1~X5

Digital

output

Y1

Open collector

output

Range of voltage: 0~24V

Range of current: 0~50mA

Y2/DO

Open collector

out / Pulse out

Open collector output: same as Y1

Pulse output: 0~50kHz;

GK600E User Manual Chapter 3 Installation and Wiring

- 31 -

Category

Terminal

Terminal

designation

Specification

Relay

output

RA/RB/RC

Control board

relay output

RA-RB: NC; RA-RC: NO

Contact capacity: 250VAC/3A, 30VDC/3A

RA/RB/RC

Option board relay

output

Same as control board relay output

Terminal

485

Interface

485+

485 differential

signal +

Rate:

4800/9600/19200/38400/57600/115200bps

485−

485 differential

signal -

Maximum distance - 500m (standard network

cable used)

GND

485

communication

shield grounding

Isolated from COM interiorly

Control

panel

485

interface

CN4

Control panel

485 interface

Maximum communication distance is 15m

when connected to Control panel

Use standard network cable

3.9 Control Terminal Usage

3.9.1 Lay-out of Control Terminals

Fig. 3-13 Lay-out of control terminals

3.9.2 Control Terminal Screw and Wiring Requirement

Table 3-6 Terminal screw and wiring specification

Cable type

Cable requirement (mm2)

Screw

Torque (kgf.cm)

Shielded cable

1.0

M3

5±0.5

3.9.3 Instructions of Analog Input/Output Terminals

Being particularly vulnerable to noise, analog input & output signal cables should be as short as

possible, shielded, and their shielded layers should be properly grounded close to the side of

drive. The cables should not exceed 20m.

Chapter 3 Installation and Wiring GK600E User Manual

- 32 -

Control cables shall be kept no less than 20cm away from main circuit and strong current lines

(e.g. power lines, motor lines, relay lines and contactor lines) and should not be arranged in

parallel with strong current lines. In case it is inevitable to intersect strong current line, vertical

wiring is recommended to avoid drive faults as a result of noise.

Where analog input & output signals are severely interfered, the side of analog signal source

should be provided w ith filter capacitor or ferrite core.

3.9.4 Instructions of Digital Input/Output Terminals

Digital input & output signal cables should be as short as possible, shielded, and their shielded

layers should be properly grounded close to the side of drive. The cables should not exceed

20m. When active drive is selected, take necessary filtering measures against power crosstalk,

for which dry contact control is recommended.

Control cables shall be kept no less than 20cm away from main circuit and strong current lines

(e.g. power lines, motor lines, relay lines and contactor lines) and should not be arranged in

parallel with strong current lines. In case it is inevitable to intersect strong current line, vertical

wiring is recommended to avoid drive faults as a result of noise. Operating instructions for

sw itching value input terminal

Instructions of digital input terminal

Dry contact

1

6

X1

X6/DI

COM

+24V

PLC

+3.3V

GND

24V

Drive

External

Controller

Shielded

Cable

Near-end

Ground

+-

Jumper

OC

+3.3V

GND

+-

OC

Fig. 3-14 Internal power supply dry contact

GK600E User Manual Chapter 3 Installation and Wiring

- 33 -

1

6

X1

X6/DI

COM

+24V

PLC

+3.3V

GND

24V

Drive

External

Controller

Shielded

Cable

Near-end

Ground

+-

OC

+3.3V

GND

+-

OC

+ -

20~30V

Fig. 3-15 External power supply dry contact

ATTENTION:

When external power supply is used, the jumper between +24V and PLC must be removed.

Otherwise, it may result in equipment damage.

The voltage range of external power supply should be DC20~30V. Otherwise, normal

operation could not be assured and/or result in equipment damage.

Chapter 3 Installation and Wiring GK600E User Manual

- 34 -

Open collector NPN connection

X1

X6/DI

COM

+24V

PLC

+3.3V

GND

24V

Drive

Shielded

Cable

Near-end

Ground

+-

Jumper

OC

+3.3V

GND

+-

OC

1

6

External

Controller

Fig. 3-16 Internal power supply open collector NPN connection

X1

X6/DI

COM

+24V

PLC

+3.3V

GND

24V

Drive

Shielded

Cable

Near-end

Ground

+-

OC

+3.3V

GND

+-

OC

+ -

20~30V

1

6

External

Controller

Fig. 3-17 External power supply open collector NPN connection

ATTENTION:

When external power supply is used, the jumper between +24V and PLC must be removed.

The voltage range of external power supply should be DC20~30V, otherwise normal

operation could not be assured and/or hazard of equipment damage exists.

GK600E User Manual Chapter 3 Installation and Wiring

- 35 -

Open collector PNP connection

X1

X6/DI

COM

+24V

PLC

+3.3V

GND

24V

Drive

Shielded

Cable

Near-end

Ground

+-

Jumper

OC

+3.3V

GND

+-

OC

1

6

External

Controller

Fig. 3-18 Internal power supply open collector PNP connection

ATTENTION:

When PNP connection is adopted, it is necessary to remove the jumper between +24V and

PLC, and connect the jumper to PLC and COM.

X1

X6/DI

COM

+24V

PLC

+3.3V

GND

24V

Drive

Shielded

Cable

Near-end

Ground

+-

OC

+3.3V

GND

+-

OC

20~30V

1

6

External

Controller

+-

Fig. 3-19 External power supply open collector PNP connection

ATTENTION:

When external power supply is used, the jumper between +24V and PLC must be removed.

The voltage range of external power supply should be DC20~30V. Otherwise, normal

operation could not be assured and/or hazard of equipment damage exists.

Chapter 3 Installation and Wiring GK600E User Manual

- 36 -

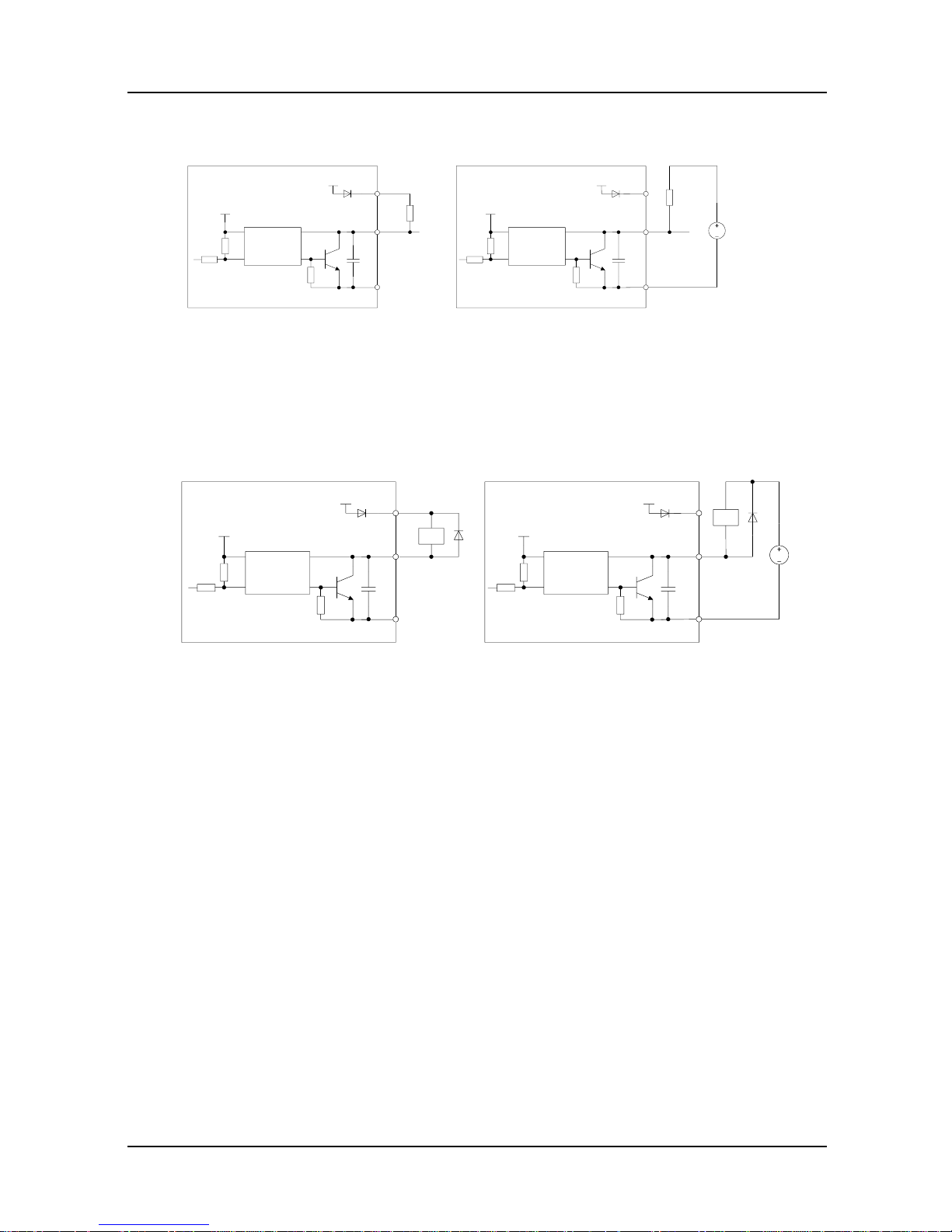

Instructions of digital output terminal

Instructions of Y1 and Y2/DO output terminals

a) Internal power supply b) External power supply

Fig. 3-20 Wiring when Y1 and Y2/DO output with pull-up resistor

ATTENTION:

When set to be pulse output, Y2/DO terminal shall output 0~50kHz pulse signal.

a) Internal power supply b) External power supply

Fig. 3-21 Wiring when Y1 and Y2/DO drive relay

ATTENTION:

When relay coil voltage is low er than 24V, a resistor as voltage divider should be mounted

between relay and output terminal, based on coil impedance.

Wiring instruction of relay output terminal

Control board of GK600E series drive is provided with a group of programmable relay dry

contact outputs. RA/RB/RC are relay contacts. RA and RB are normally closed, while RA

and RC are normally open. See parameter C1-02 for details.

ATTENTION:

In case inductive load (e.g. electromagnetic relay or contactor) is to be driven, a surge

voltage absorbing circuit such as RC absorbing circuit (note that its leakage current shall be

less than holding current of controlled contactor or relay), piezoresistor or fly-wheel diode

etc. shall be mounted (be sure to pay close attention to polarity in case of DC

electromagnetic circuit). Absorbing devices should be mounted close to the ends of relay or

contactor.

Y1、Y2/DO

COM

+24V

+5V

24V

Drive

OC

Y1、Y2/DO

COM

+24V

+5V

24V

Drive

OC

=30V

Pull-up

Resistor

Pull-up

Resistor

Y1、Y2/DO

COM

+24V

+5V

24V

Drive

OC

Y1、Y2/DO

COM

+24V

+5V

24V

Drive

OC

=30V

Relay Relay

GK600E User Manual Chapter 3 Installation and Wiring

- 37 -

3.10 Instruction of Signal Switches

Fig. 3-22 Jumper diagram of signal switching

3.11 EMI Solutions

Due to its working principle, the drive will inevitably produce certain noise that may influence

and disturb other equipment. Moreover, since the internal weak electric signal of drive is also

susceptible to the interference of drive itself and other equipment, EMI problems shall be

inevitable. In order to reduce or avoid the interference of drive to external environment and

protect drive against interference from external environment, this section makes a brief

description of noise abatement, ground handling, leakage current suppression and the

application of power line filters.

3.11.1 Noise Abatement

When peripheral equipment and drive share the power supply of one system, noise from the

drive may be transmitted to other equipment in this system via power lines and result in

misoperation and/or faults. In such a case, the following measures could be taken:

Mount input noise filter at input terminal of the drive;

Mount power supply filter at power input terminal of affected equipment;

Use isolation transformer to isolate the noise transmission path between other equipment

and the drive.

As the wiring of peripheral equipment and the drive constitutes a circuit, the unavoidable

earthing leakage current of the drive will cause equipment misoperation and/or faults.

Disconnect the grounding connection of equipment may avoid this misoperation and/or faults

Sensitive equipment and signal lines shall be mounted as far away from the drive as possible.

Designation

Function

Default

setting

S1

Selection of 485 termination resistor; ON :100Ω termination

resistor provided; OFF: no termination resistor

OFF

S2

Type Selection of AI1 analog signal:

I: current input (0~20mA); V: voltage input (0~10V)

V: 0~10V

S3

Type Selection of AO1 analog signal:

I: current output (0~20mA); V: voltage output (0~10V)

V: 0~10V

ON

OFF

AI1 AO1485

V

II

V

S2S1 S3

Chapter 3 Installation and Wiring GK600E User Manual

- 38 -

Signal lines should be provided with shielded layer and reliably grounded. Alternatively, signal

cable could be put into metallic conduits between which the distance shall be no less than

20cm, and shall be kept as far away from the drive, its peripheral devices, and cables as

possible. Never make signal lines in parallel with power lines or bundle them up.

Signal lines must orthogonally cross power lines if this cross is inevitable. Motor cables shall be

placed in thick protective screen like more than 2mm-thick pipelines or buried in cement groove,

also, power lines can be put into metallic conduit and grounded well with shielded cables.

Use 4-core motor cables of which one is grounded at close side of the drive and the other side

is connected to motor enclosure.

Input and output terminals of the drive are respectively equipped with radio noise filter and

linear noise filter. For example, ferrite common mode choke can restrain radiation noise of

power lines.

3.11.2 Grounding

Recommended ground electrode is shown in the figure below:

Drive

Other

Devices

PE

PE

Fig. 3-23 Grounding

Use to the fullest extent the maximum standard size of grounding cables to reduce the impedance

of grounding system.

Grounding wires should be as short as possible. Grounding point shall be as close to the drive as

possible.

One w ire of 4-core motor cables shall be grounded at the drive side and connected to grounding

terminal of motor at the other side. Better effect will be achieved if motor and drive are provided

with dedicated ground electrodes.

When grounding terminals of various parts of system are linked together, leakage current turns

into a noise source that may influence other equipment in the system, thus, grounding terminals of

the drive and other vulnerable equipment should be separated. Grounding cable shall be kept

away from inlet & output of noise-sensitive equipment.

GK600E User Manual Chapter 3 Installation and Wiring

- 39 -

3.11.3 Leakage Current Suppression

Leakage current passes through the line-to-line and ground distributed capacitors at input &

output sides of drive, and its size is associated with the capacitance of distributed capacitor and

the switching frequency. Leakage current is classified into ground leakage current and

line-to-line leakage current.

Ground leakage current not only circulates inside drive system, but may also influence other

equipment via ground loop. Such a leakage current may result in malfunction of RCD and other

equipment. The higher the switching frequency of drive is, the bigger the ground leakage current

will be. The longer the motor cables and the bigger the parasitic capacitance are, the bigger the

ground leakage current will be. Therefore, the most immediate and effective method for

suppression of ground leakage current is to reduce the sw itching frequency and minimize the

length of motor cables.

The higher harmonics of line-to-line leakage current that passes through between cables at output

side of drive will accelerate the aging of cables and may bring about malfunction of other

equipment. The higher the switching frequency of drive is, the bigger the line-to-line leakage

current will be. The longer the motor cables and the bigger the parasitic capacitance are, the

bigger the line-to-line leakage current w ill be. Therefore, the most immediate and effective method

for suppression of ground leakage current is to reduce the switching frequency and minimize the

length of motor cable. Line-to-line leakage current can also be effectively suppressed by mounting

additional output reactors.

3.11.4 Use of Power Supply Filter

Since AC drives may generate strong interference and are also sensitive to outside

interference, power supply filters are recommended. Pay close attention to the following

instructions during the use:

Enclosure of the filter needs to be reliably grounded;

Input lines of the filter shall be kept as far away from output lines as possible so as to avoid

mutual coupling;

Filter shall be as close to the drive side as possible;

Filter and drive must be connected to the same common ground.

Chapter 4 Operation and Run Instructions GK600E User Manual

- 40 -

Chapter 4 Operation and Run Instructions

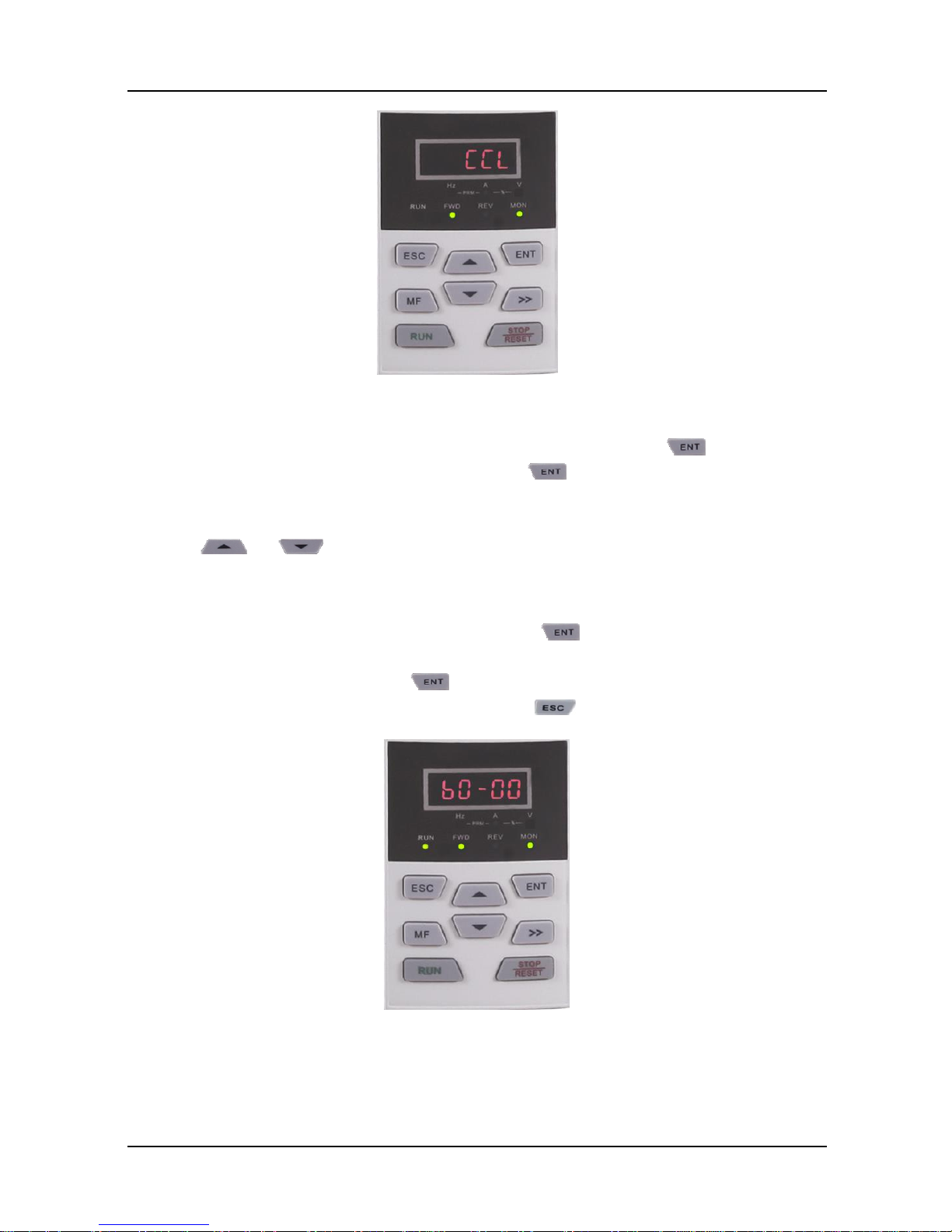

4.1 Operation of Control Panel

As a human-machine interface, control panel is the main part for the drive to receive command

and display parameters.

Fig. 4-1 Control panel

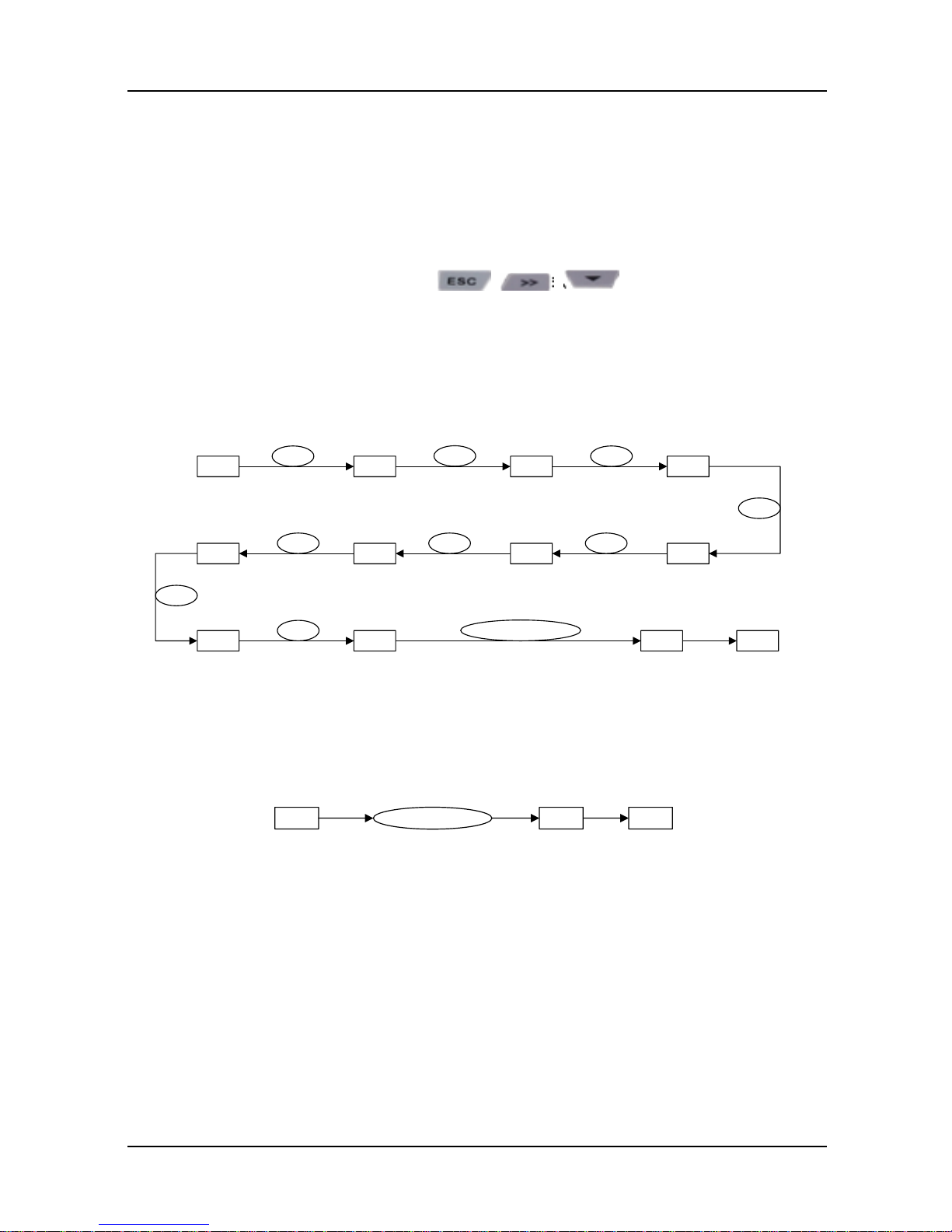

4.1.1 Key Functions on Control Panel

On the control panel there are 8 keys whose functions are as shown in Table 4-1.

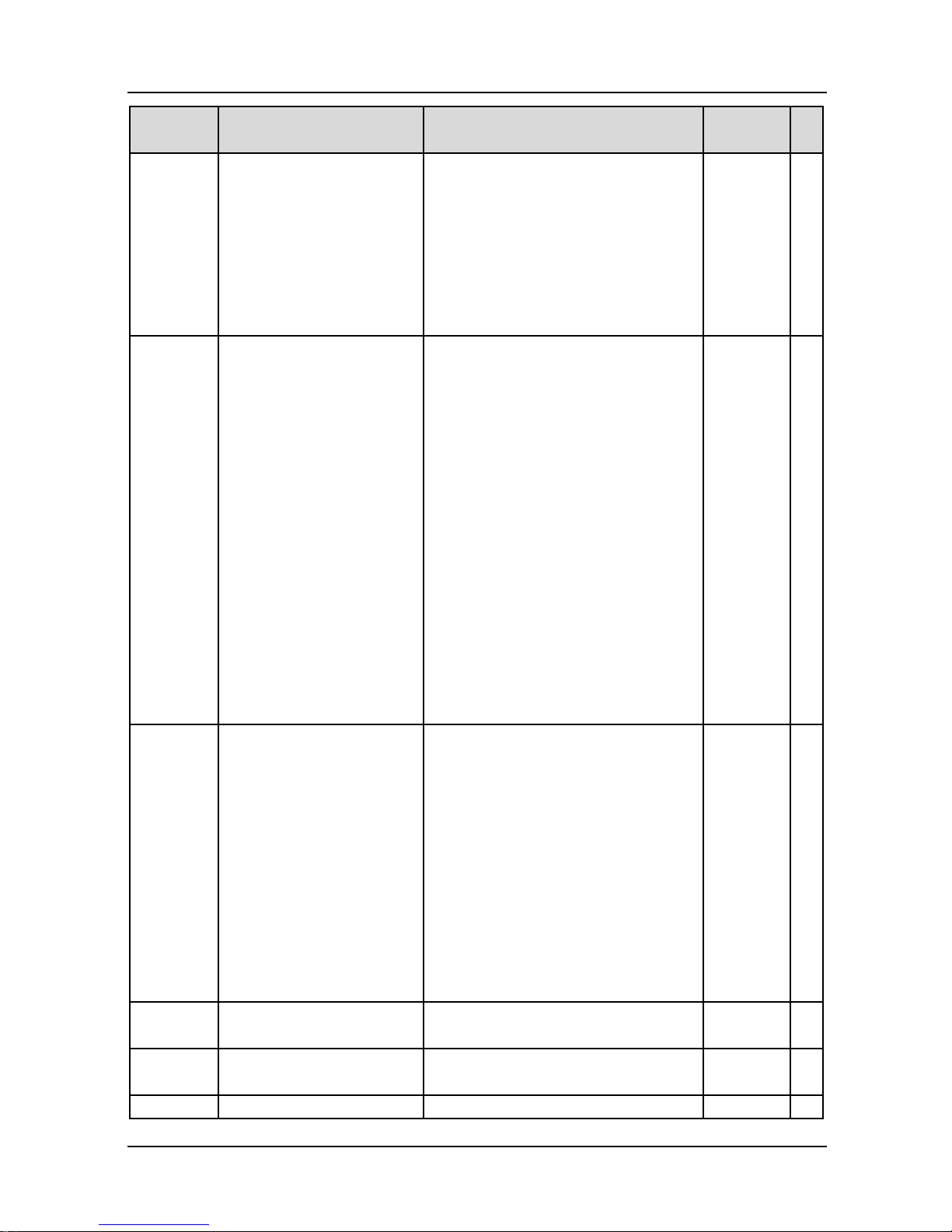

Table 4-1 Key functions on control panel

Symbol

Key name

Meaning

Enter key

1) Parameter edition enter

2) Confirmation of parameter settings

3) Confirmation of MF key function

Escape key

1) Return function

2) Invalid parameter edit value

Increase key

1) Increase of selected bit of parameter value

2) Increase of selected bit of parameter value

3) Increase of set frequency

Decrease key

1) Decrease of selected bit of parameter

2) Decrease of selected bit of parameter value

3) Decrease of set frequency

Shift key

1) Selection of parameter bit

2) Selection of parameter value bit

3) Selection of stop/run status display parameter value

4) Fault status switches to parameter value display status

Run key

Run

GK600E User Manual Chapter 4 Operation and Run Instructions

- 41 -

Stop/reset key

1) Stop

2) Fault reset

Multi-function

key

See Table 4-2 " MF key function definition"

Table 4-2 MF key function definition

L0-00 set

value

Function of MF key

Meaning

0

Disabled

MF key disabled

1

Forward JOG

Forward JOG function

2

Reverse JOG

Reverse JOG function

3

Forward/Reverse

sw itch

Run direction forward and reverse switching

4

Emergency

STOP 1

Press to STOP, w ith ramp-down time b2-09

5

Emergency

STOP 2

Coast to stop, the drive cuts off output

6

Run command

setting mode

sw itch

Control panel control -> Terminal control ->

Communication control -> Control panel control, press

to confirm w ithin 5 seconds

4.1.2 Control Panel Indicators

Control panel is furnished w ith 7 indicators whose descriptions are as below

Table 4-3 Description of indicators

Indicator

Designation

Meaning

Hz

Frequency indicator

ON: currently displayed parameter value is run

frequency or the current parameter unit is

frequency

Flash: currently displayed parameter value is set

frequency

A

Current indicator

ON: currently displayed parameter value is current

V

Voltage indicator

ON: currently displayed parameter value is voltage

Hz+A

Run speed indicator

ON: currently displayed parameter value is run

speed

Flash: currently displayed parameter value is

setting speed

A+V

Percentage indicator

ON: currently displayed parameter value is a

percentage value

All OFF

No unit

No unit

MON

Run command setting

mode indicator

ON: Control panel

OFF: Terminal

Flash: Communication

RUN

Run status indicator

ON: Run

Chapter 4 Operation and Run Instructions GK600E User Manual

- 42 -

Indicator

Designation

Meaning

OFF: Stop

Flash: Stopping

FWD

Forward indicator

ON: If the drive in stop status, forward command

enabled. If the drive in run status, the drive is

running forward

Flash: Forward is being transferred to reverse

REV

Reverse indicator

ON: If the drive in stop status, reverse command

enabled. If the drive in run status, the drive is

running reversely.

Flash: Reverse is being transferred to forward

4.1.3 Control Panel Display Status

Control panel indicates eight types of status, STOP parameters display, Run parameters

display, Fault display, parameter number edition, parameter setting, Password authentication,

Direct frequency modification and Prompt message. The operation relating to these statuses

and the sw itching among these statuses is described as follows.

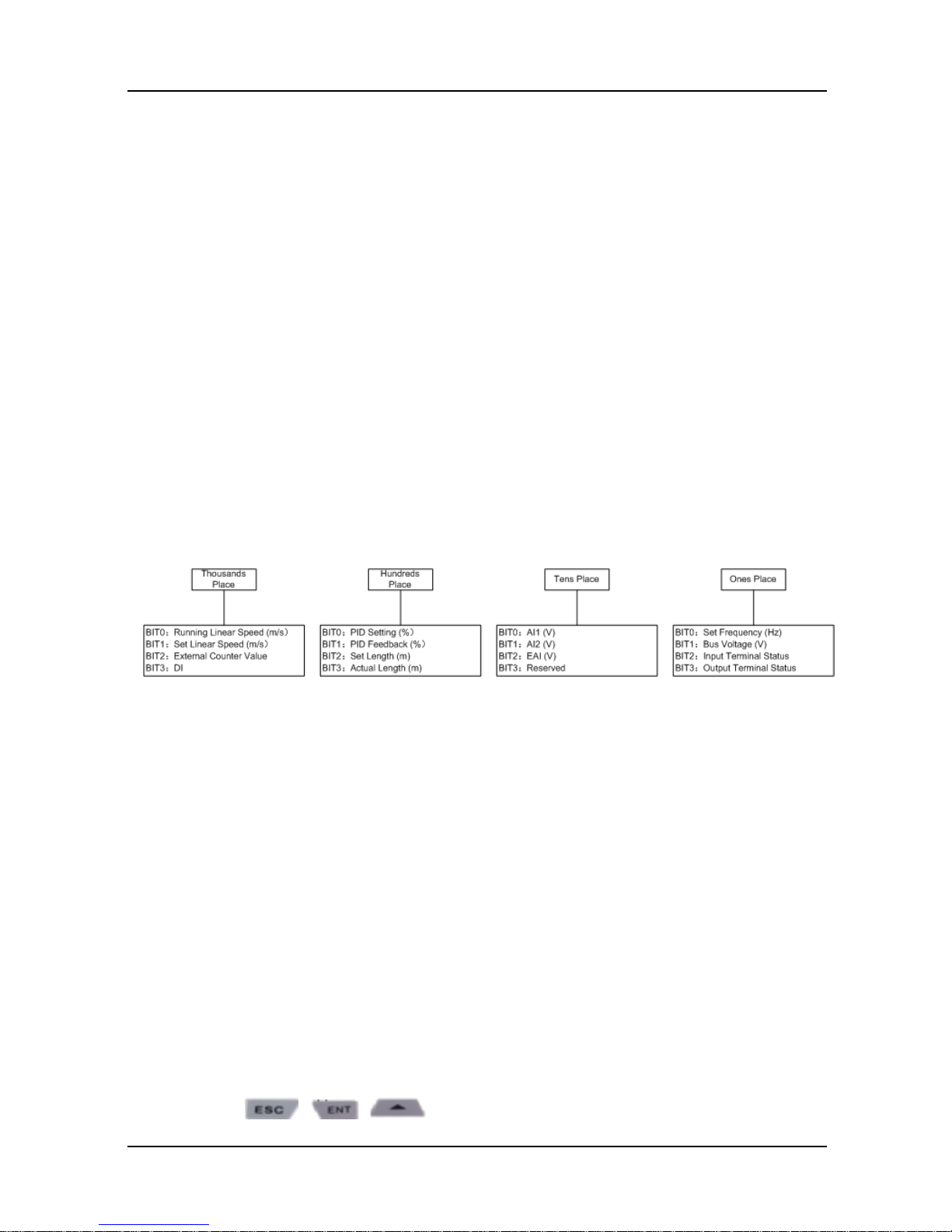

4.1.3.1 Display of STOP Parameters

The drive normally gets into STOP parameters display once run has been stopped. By default,

set frequency is displayed in such a status, and other parameters can be displayed through

setting of L1-02 parameters and the key. For example, when users need to check set

frequency as well as the values of bus voltage and AI1 value in stop status, set L1 -02=0013

(refer to setting method of parameters) and press the key to display the value of bus

voltage and then press again to display the value of AI1.

Fig. 4-2 Stop parameter display status (Displaying setting frequency – 50.00Hz)

Run status w ill be enabled immediately upon receipt of run command in stop status. Press

GK600E User Manual Chapter 4 Operation and Run Instructions

- 43 -

to get into parameter edit status (get into password authentication status if parameter

under password protection). Directly get into frequency modification status when receive

UP/DOWN command from terminal, or and pressing on control panel. Switch to

fault display status once a fault occurs or an alarm is given.

4.1.3.2 Run Parameter Display Status

In case there is no fault, the drive will get into run parameters display status upon receipt of run

command. Default display is run frequency, and other parameters can be displayed through

setting of L1-00 and L1-01 and press to shift. For example, in run status, when users

need to check bus voltage, motor speed, and input terminals status, please set L1-00= 0084

and L1-01= 0004, and press to shift to the display of bus voltage, then press

again to display motor speed, and then press to display input terminals state value.

Fig. 4-3 Run parameter display status (Displaying run frequency – 50.00Hz)

Stop status w ill be enabled immediately upon receipt of stop command in such a status. Press

to get into parameter edit status (get into password authentication status if parameter

under password protection). Directly get into frequency modification status when receiving

UP/DOWN command from terminal, or pressing or . Sw itch to fault alarm display

status once a fault occurs or an alarm is given.

4.1.3.3 Fault Alarm Display Status

In case a fault occurs or an alarm is given, the drive will get into fault or alarm display status.

Chapter 4 Operation and Run Instructions GK600E User Manual

- 44 -

Fig. 4-4 Fault or alarm display status (CCL: Contactor act fault)

In such a status, the drive gets into stop status upon receipt of pressing , and would get

into parameter edit status when receiving pressing command again (if parameter is

under password protection, the drive would get into password authentication status). Directly

get into frequency modification status when receiving UP/DOWN command from terminal, or

pressing or .

4.1.3.4 Parameter Edit Status

Enter parameter edit status immediately upon pressing in STOP status, run parameters

display status, and direct frequency modification status. This status could also be entered upon

receipt of consecutive twice pressing in fault display status. The drive shall quit current

status and be previous status upon receipt of pressing .

Fig. 4-5 Parameter edit status

GK600E User Manual Chapter 4 Operation and Run Instructions

- 45 -

4.1.3.5 Parameter Value Setting Status

Enter parameter value setting status upon receipt of pressing when in parameter value

edit status. When pressing or command is received in such a state, escape

parameter edit status.

Fig. 4-6 Parameter value setting status (b0-02 is set to 49.83Hz)

4.1.3.6 Password Authentication Status

On condition that parameters are under password protection, users would have to go through

password authentication when they want to modify function code parameter value. Only A0-00

is visible in such a state.

Under password protection, the password authentication status will be first entered upon the receipt

of pressing in STOP parameter display status, run parameter display status, or direct

frequency modification status (refer to the setting method of parameters). It will enter parameter edit

status upon the completion of password authentication.

4.1.3.7 Direct Frequency Modification Status

In the status of STOP, fault or run, the drive will enter frequency modification status when

terminal UP/DOWN is enabled, or pressing or .

Chapter 4 Operation and Run Instructions GK600E User Manual

- 46 -

Fig. 4-7 Direct frequency modification status

4.1.3.8 Prompt Message Status

Prompt message status shall be displayed upon the completion of some operations. For

instance, the "bASIC" prompt message would be displayed upon the completion of parameter

initialization.

Fig. 4-8 Prompt message status

Prompt message characters and their meanings are shown as specified in Table 4-4.

Table 4-4 Prompt characters

Prompt

symbol

Meaning

Prompt

symbol

Meaning

bASIC

When A0-01 is set to 0

CPyb1

Backup parameter value

dISP1

When A0-01 is set to 1

LoAd

Parameter upload to

control panel

GK600E User Manual Chapter 4 Operation and Run Instructions

- 47 -

USEr

When A0-01 is set to 2

dnLd1

Parameter download from

control panel (motor

parameter excluded)

ndFLt

When A0-01 is set to 3

dnLd2

Parameter download from

control panel (motor

parameter included)

LoC-1

Control panel locked 1 (full locked)

P-SEt

Passw ord has been set

LoC-2

Control panel locked 2 (all locked

except RUN, STOP /RESET)

P-CLr

Passw ord cleared

LoC-3

Control panel locked 3

(all locked except STOP/RESET)

TUNE

Motor parameter

identification in process

LoC-4

Control panel locked 4

(all locked except shift )

LoU

Drive undervoltage

PrtCt

Control panel protection

CLr-F

Clear fault record

UnLoC

Control panel lock cleared

dEFt1

Restore to factory default

parameters (motor

parameter excluded)

rECy1

Read the backup parameter value to

parameter

dEFt2

Restore to factory default

parameters (motor

parameter included)

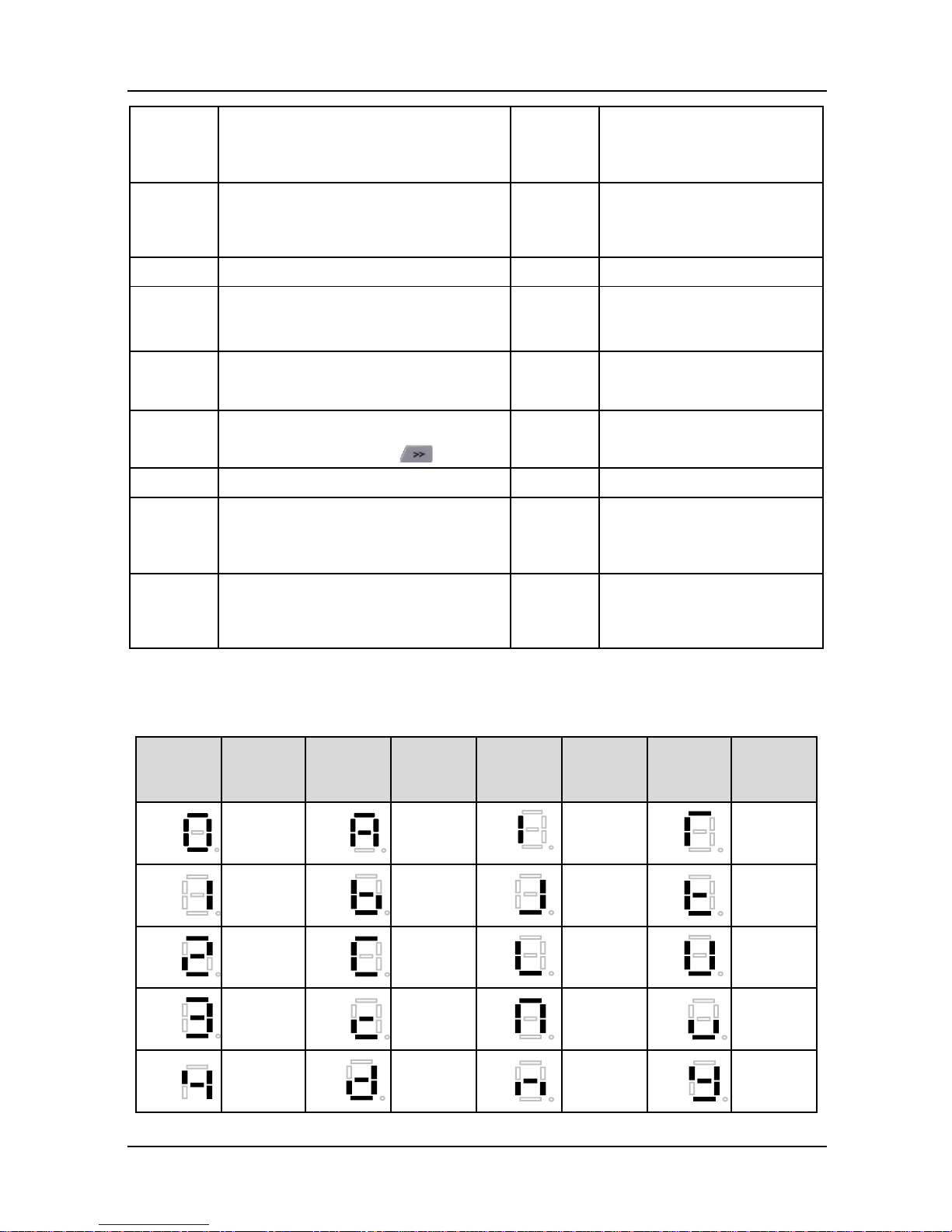

Table 4-5 shows meanings of the characters displayed on control panel.

Table 4-5 Meanings of displayed characters

Displayed

character

Character

Meaning

Displayed

character

Character

Meaning

Displayed

character

Character

Meaning

Displayed

character

Character

Meaning

0 A I T

1

b J t

2 C L U

3 c N v

4 d n y

Chapter 4 Operation and Run Instructions GK600E User Manual

- 48 -

Displayed

character

Character

Meaning

Displayed

character

Character

Meaning

Displayed

character

Character

Meaning

Displayed

character

Character

Meaning

5 E o

-

6

F P 8.

7 G

q .

8 H

r

9 h

S

4.1.4 Setting Method of Parameters

4.1.4.1 Parameter System

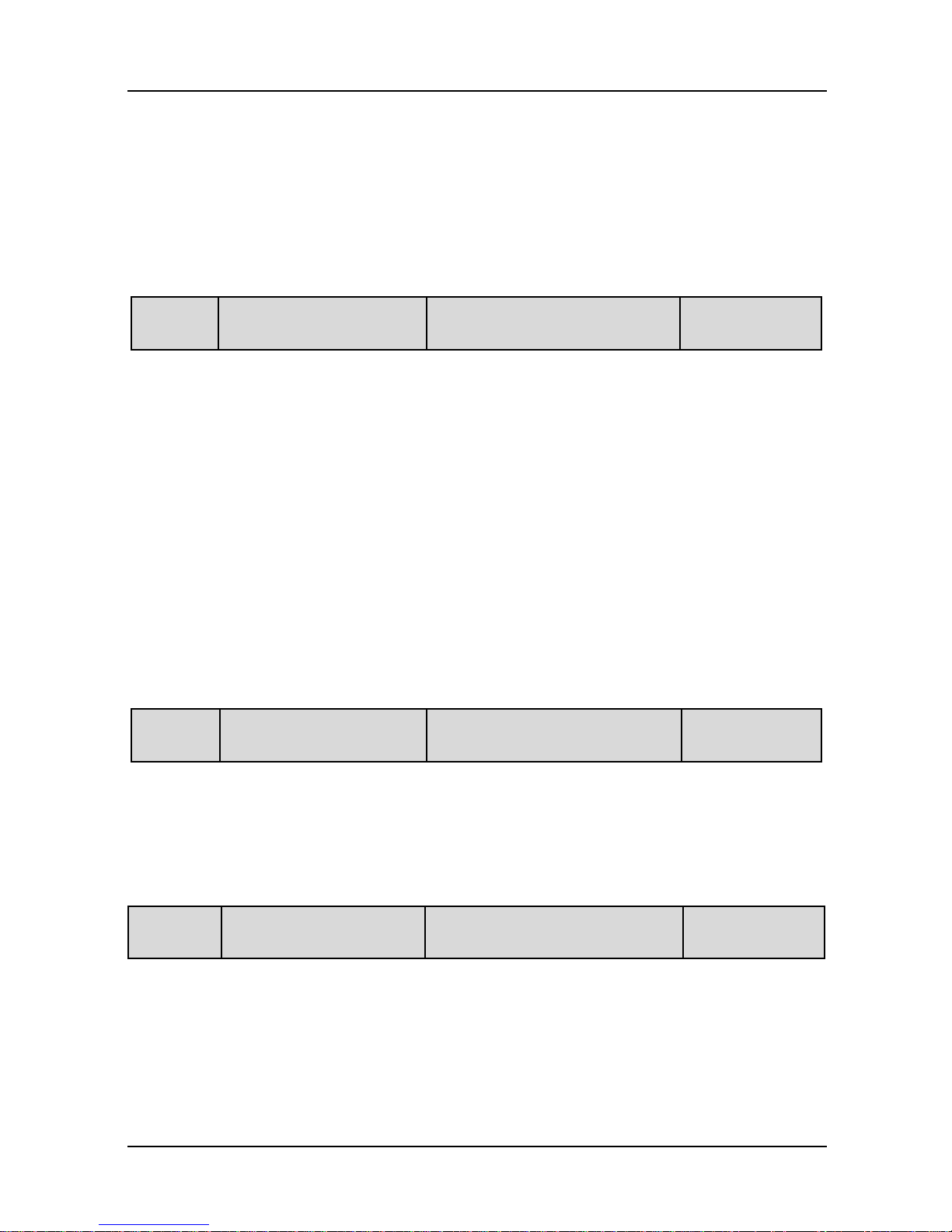

GK600E series drive parameter groups: A0, A1, b0, b2, C0, C4, d0, d2, E0, E1, F1, F6, H0, L0,

L1, U0, U1. Each parameter group contains a number of parameters. Parameters are identified

by the combination "parameter group character + parameter subgroup number + parameter

number". For instance, "F3-07" indicates the seventh parameter at subgroup 3, group F.

4.1.4.2 Parameter Display Structure

Parameters and the parameter values are subject to a two-tier structure. Parameters

correspond to first-tier display, while parameter values correspond to second-tier display.

First-tier display shown in Fig. 4-9:

GK600E User Manual Chapter 4 Operation and Run Instructions

- 49 -

Fig. 4-9 First-tier display of parameter

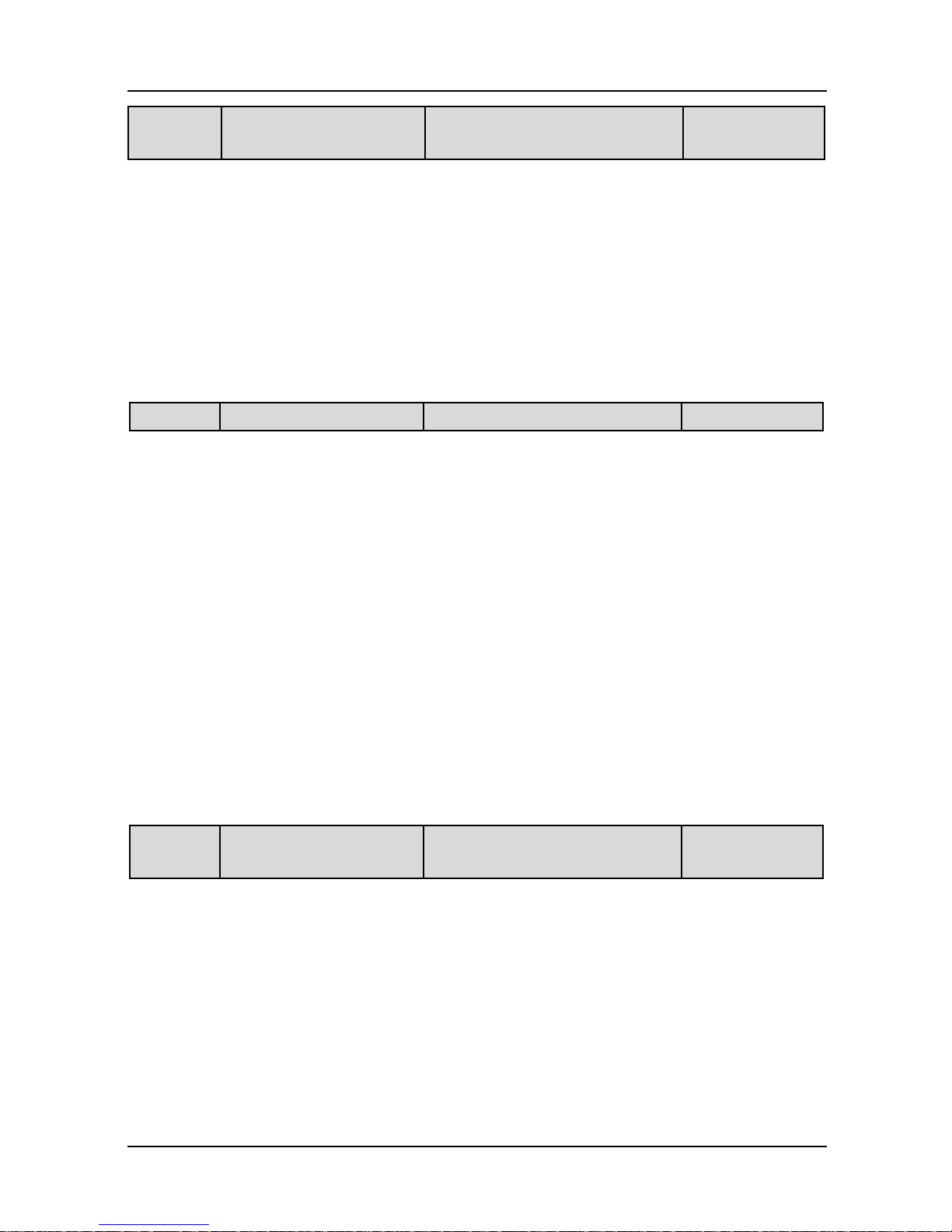

Second-tier display shown in Fig. 4-10:

Fig. 4-10 Second-tier display of parameter ("3" is the value of b0-00)

4.1.4.3 Example of Setting of Parameter

Parameter values are divided into decimal (DEC) and hexadecimal (HEX) values. When a

parameter value is expressed by a hexadecimal, all its bits are independent of each other

during edition and the range of value would be (0~F). Parameter value is composed of the unit,

tens place, hundreds and kilobit. Shift Key is used to select the bit to be changed, while

and are used to increase or decrease numerical value.

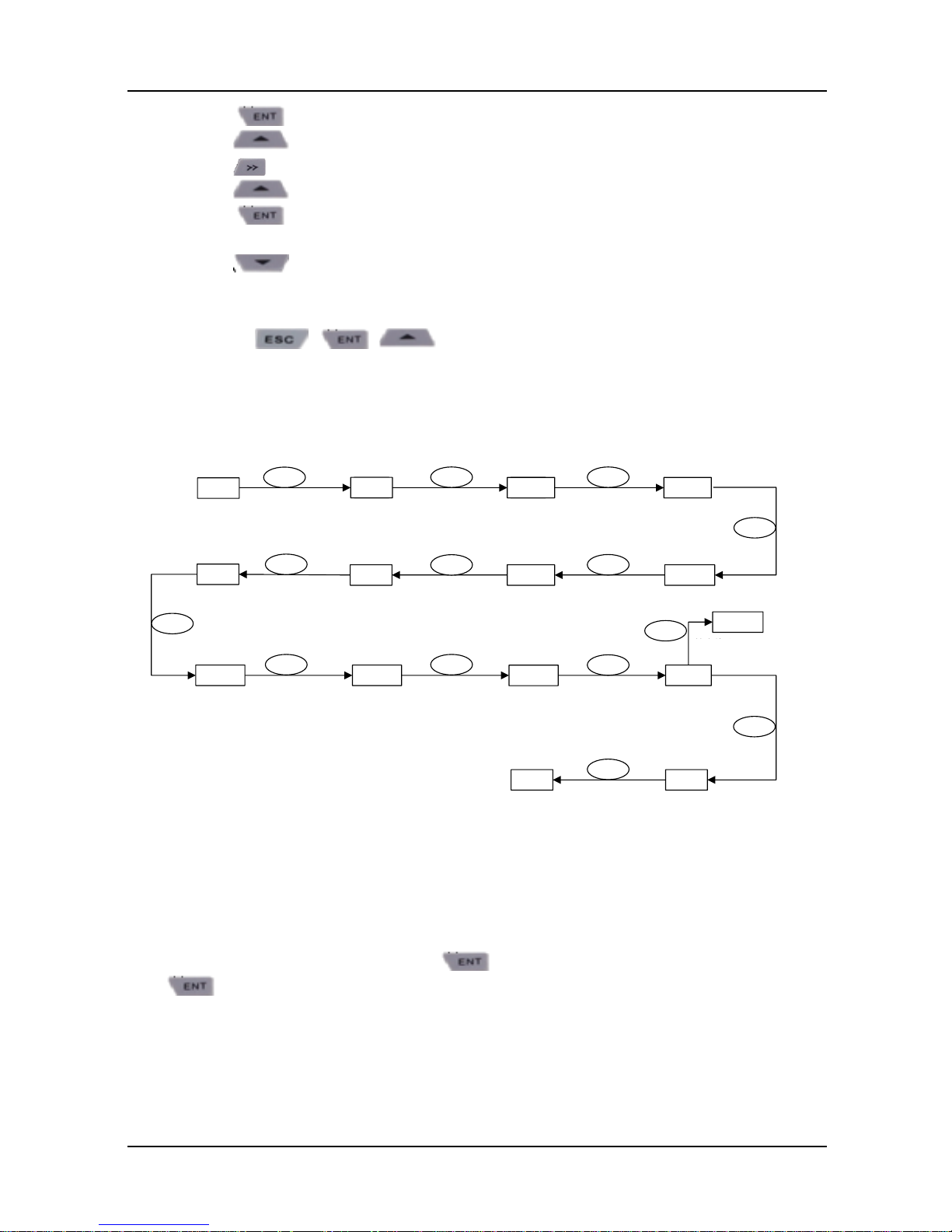

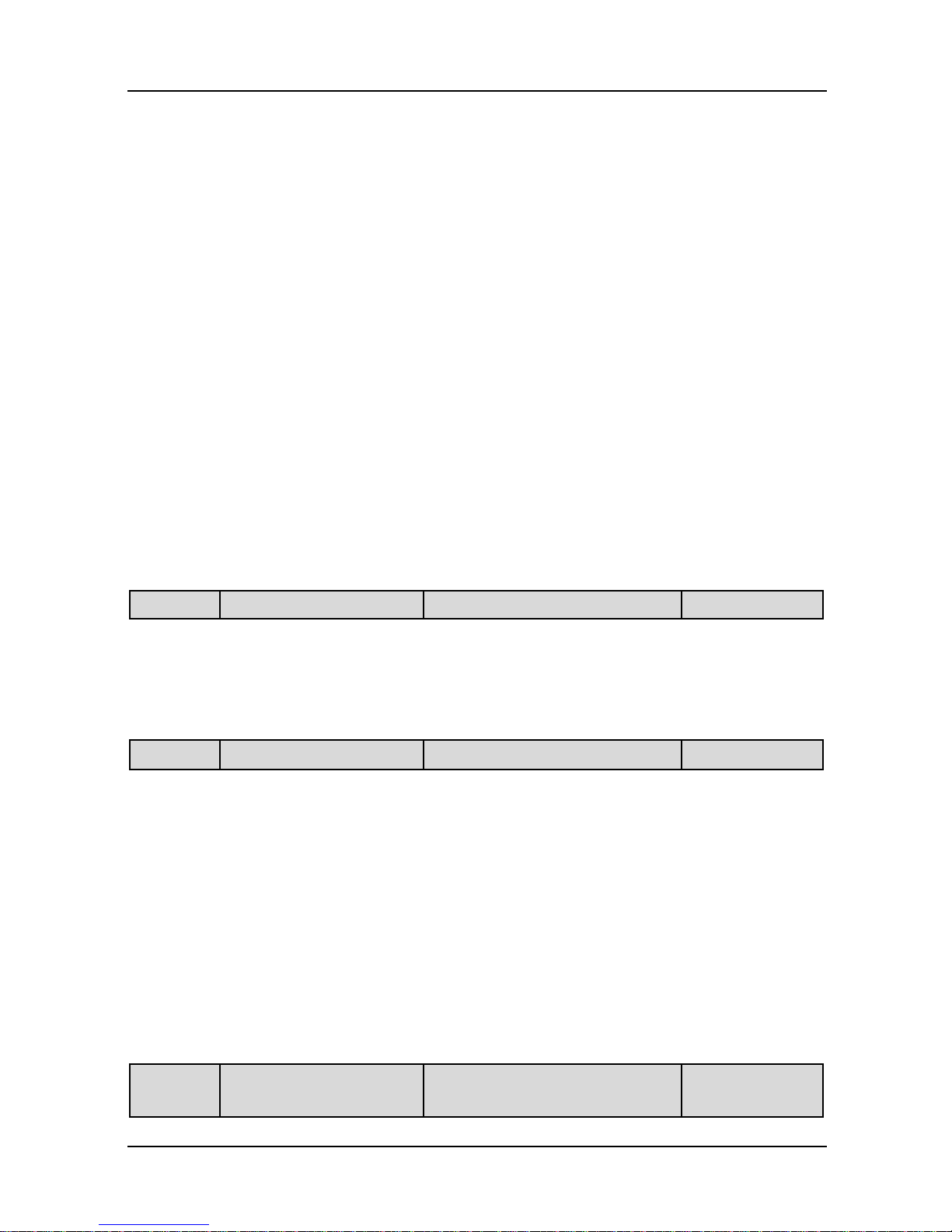

Example of parameter password setting

Setting of password (A0-00 is set to 1006)

1) In non-parameter edit status, it displays current parameter A0-00 when

pressing .

Chapter 4 Operation and Run Instructions GK600E User Manual

- 50 -

2) Press to display parameter value 0000 that belongs to A0-00;

3) Press for six times to change the rightmost digit "0" to "6";

4) Press to move the flashing digit to the leftmost bit;

5) Press once to change "0" in leftmost bit to "1";

6) Press to save the value of A0-00, then Control panel will switch to display the

next parameter A0-01;

7) Press to change A0-01 to A0-00;

8) Repeat steps 2) till 6). A0-01 w ill be displayed after control panel displaying P-SEt;

9) There are three methods for users to bring the password setting above into effect:

① Press + + simultaneously (PrtCt displayed), ②w on’t

operate control panel within 5 minutes, ③ restart the drive.

Flow chart of user password setting:

Fig. 4-11 Flow chart of user password setting

ATTENTION:

User's password is successfully set when step 8 finished, but will not take effect until the

completion of step 9.

Password authentication

In non-parameter edit status, press to enter first-tier display A0-00, then press

to enter second-tier display 0.0.0.0. Control panel will implement the display of

other parameters only w hen correct password entered.

Clear password

After successful password authentication, it w ill access password setting code A0-00.

Passw ord can be cleared by writing value 0000 into A0-00 twice.

放弃修改

50.00 50.00 0.0.0.60.0.0.0

A0-00

50.00

ENT

ENT

▲

>>

0.0.0.61.0.0.6A0-01

A0-00

ENT

▲

▼

ENT

0.0.0.0

0.0.0.6

0.0.0.6

1.0.0.6

A0-0150.00

A0-00

ESC

▲

>>▲

ENT

ESC

Escape modification

GK600E User Manual Chapter 4 Operation and Run Instructions

- 51 -

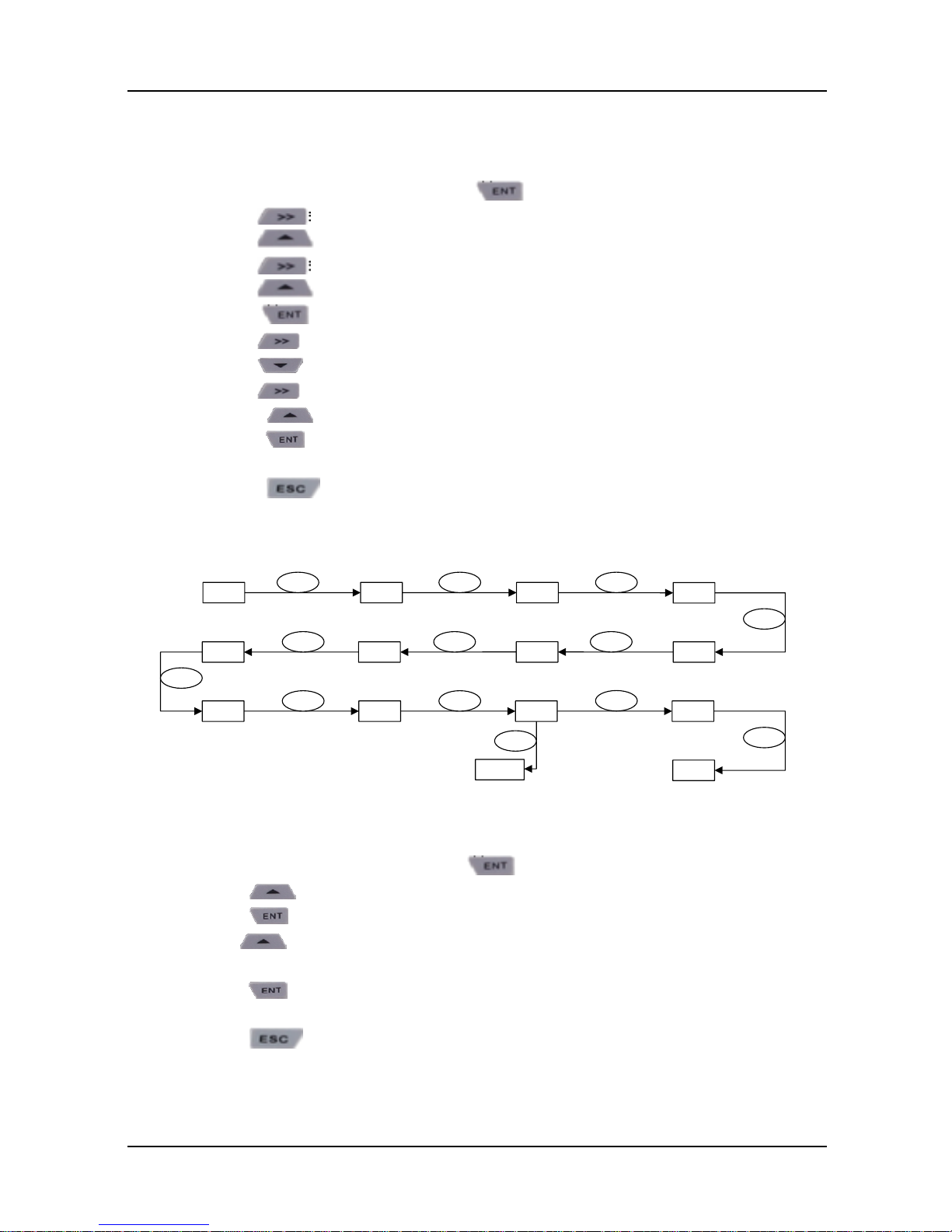

Example of parameter setting

Example 1: modify upper limit frequency from 600Hz to 50Hz (change b0-09 from

600.00 to 50.00)

1) In non-parameter edit status, press to display current parameter A0-00;

2) Press to move flashing digit to modification bit (A flashes);

3) Press once to change "A" to "b";

4) Press to move flashing to modification bit (0 in ones place flashing);

5) Press nine times to change "0" to "9";

6) Press to view the parameter value (600.00) of b0-09;

7) Press to move flashing digit to modification digit (6 flashing);

8) Press six times to change "6" to "0";

9) Press once to move flashing digit rightwards by one bit;

10) Press for five times to change "0" to "5";