GTAKE GK600-2T3.7B, GK600-2T0.4B, GK600 Series, GK600-2T1.5B, GK600-2T5.5B User Manual

...

IMPORTANT NOTES

Please assure the intactness of product enclosure and all safety covers before

installation .Operation must conform to the requirements of this manual and local industrial

safety regulations and/or electrical codes.

Contents of this manual may be subject to appropriate modification as a result of product

upgrade, specification change and update of the manual.

In the event of damage or loss of user manual, users may ask local distributors, offices or

our Technical Service Department for a new one.

If any item as stated in this manual is not clear, please contact our Technical Service

Department.

If any anomaly occurs after power up or during the operation, it is essential to stop the

machine and identify the fault or seek technical services as soon as possible.

Telephone number of our Technical Service Department: +86-755-86396685.

Preface

Thank you for choosing GTAKE GK600 Series General Purpose AC Motor Drives. This user

manual presents a detailed description of GK600 series with respect to product features,

structural characteristics, functions, installation, parameter setting, troubleshooting,

commissioning and daily maintenance, etc. Be sure to carefully read through the safety

precautions before use, and use this product on the premise that personnel and equipment

safety is ensured.

Chapter 2

1

Nameplate information altered.

2

Product models GK600-2T0.4 ~ GK600-2T110,

GK600-4T0.75G/1.5LB ~ GK600-4T1.5G/2.2LB, and GK600-4T500G

~ GK600-4T630G, as well as their part drawings, appearance,

dimensions and weight added.

3

Frame type (not size) of GK600-4T90 changed.

Chapter 3

1

Related information of all new-added models added, including those

requiring input voltage 220VAC.

Chapter 5

1

Parameter group H1: Profibus-DP communication parameters added.

2

Following parameter names, parameter values and/or their defaults

changed: A0-07, A0-01~A0-09, b1-05, b1-08, b1-10, b1-11, b1-12,

b2-13, b2-14, C0-01~C0-10, C0-17, C1-00~C1-03, C2-00,

C3-00-C3-02, C3-11, d0-00, d0-04, d0-05, d0-22, d1-16, d1-17, d3-05,

d4-16, d4-17, E1-01, E1-07, E1-13, F0-08, F0-09~F0-13, H0-00,

H0-02, L0-03, L1-00, U0-05, U0-18, U0-34, U1-00, U1-01~U1-26.

3

Parameters added: c0-21, c2-29, H1-00 ~ H1-21.

Chapter 6

1

Specification of above-mentioned parameters in Chapter 5 updated or

added.

Chapter 7

1

Fault code PFS and its specification added.

Appendix

1

Information of Table 1, Table 3, Table 6, Table 10, Table 13, table 14,

table 15, table 19, table 21, table 25, table 27, table 28, table 29, table

30, table 31, table 32, table 33, table 34, table 35, table 36, table 37,

table 38, table 39, table 40, table 41, table 42, and table 43 updated.

Summary of Changes

The information below summaries changes made in April 2016 for GK600 Series General

Purpose AC Motor Drives User Manual, version A01-EN.

Besides there are some changes on the manner of writing, error correction, and designation

replacement like control panel instead of keypad, following is the material new or updated

information in this user manual.

Table of Contents

Preface .............................................................................................................................. - 1 -

Chapter 1 Safety Precautions .......................................................................................... - 1 -

1.1 Safety Considerations ...................................................................................... - 1 -

1.2 Other Considerations ....................................................................................... - 5 -

Chapter 2 Product Information ........................................................................................ - 7 -

2.1 Model Explanation............................................................................................ - 7 -

2.2 Nameplate Information ..................................................................................... - 7 -

2.3 Information of Product Model ........................................................................... - 8 -

2.4 Technical Features of GK600 .......................................................................... - 11 -

2.5 Parts Drawing ................................................................................................ - 14 -

2.6 Appearance, Mounting Dimensions and Weight ............................................. - 16 -

2.7 External Dimensions of Control Panel ............................................................ - 21 -

2.8 External Dimensions of Control Panel Bracket ............................................... - 22 -

Chapter 3 Installation and Wiring .................................................................................. - 23 -

3.1 Installation Environment ................................................................................. - 23 -

3.2 Minimum Mounting Clearances ...................................................................... - 23 -

3.3 Remove & Mount Control Panel and Cover .................................................... - 25 -

3.4 Configuration of Peripheral Devices ............................................................... - 29 -

3.5 Terminal Configuration ................................................................................... - 34 -

3.6 Main Circuit Terminals and Wiring .................................................................. - 34 -

3.7 Control Terminal Wiring .................................................................................. - 40 -

3.8 Control Terminal Specification ........................................................................ - 44 -

3.9 Control Terminal Usage .................................................................................. - 45 -

3.10 Instruction of Signal Switches ......................................................................... - 51 -

3.11 EMI Solutions ................................................................................................. - 51 -

Chapter 4 Operation and Run Instructions ................................................................... - 54 -

4.1 Operation of Control Panel ............................................................................. - 54 -

4.2 First-time Power up ........................................................................................ - 70 -

Chapter 5 List of Parameters ......................................................................................... - 71 -

Chapter 6 Specification of Parameters ........................................................................ - 115 -

Group A System Parameters and Parameter Management ....................................... - 115 -

Group A0 System Parameters ............................................................................. - 115 -

Group A1 User-defined Display Parameters ......................................................... - 118 -

Group b Run Parameter Setting ...............................................................................- 120 -

Group b0 Frequency Setting ................................................................................- 120 -

Group b1 Start/Stop Control .................................................................................- 133 -

Group b2 Accel/Decel Parameters .......................................................................- 139 -

Group C Input and Output Terminals ........................................................................- 145 -

Group C0 Digital Input .........................................................................................- 145 -

Group C1 Digital Output .......................................................................................- 158 -

Group C2 Analog and Pulse Input ........................................................................- 165 -

Group C3 Analog and Pulse Output .....................................................................- 170 -

Group C4 Automatic Correction of Analog Input...................................................- 175 -

Group d Motor and Control Parameters ....................................................................- 176 -

Group d0 Parameters of Motor 1 ..........................................................................- 176 -

Group d1 V/f Control Parameters of Motor 1 ........................................................- 180 -

Group d2 Vector Control Parameters of Motor 1 ..................................................- 187 -

Group d3 Parameters of Motor 2 ..........................................................................- 191 -

Group d4 V/f Control Parameters of Motor 2 ........................................................- 192 -

Group d5 Vector Control Parameters of Motor 2 ..................................................- 193 -

Group E Enhanced Function and Protection Parameters ..........................................- 194 -

Group E0 Enhanced Function ..............................................................................- 194 -

Group E1 Protection Parameters .........................................................................- 198 -

Group F Application ..................................................................................................- 202 -

Group F0 Process PID .........................................................................................- 202 -

Group F1 Multi-step Frequency............................................................................- 208 -

Group F2 Simple PLC .......................................................................................... - 211 -

Group F3 Wobble Frequency and Fixed Length Count ........................................- 220 -

Group H Communication Parameters .......................................................................- 224 -

Group H0 MODBUS Communication Parameters ................................................- 224 -

Group H1 Profibus-DP communication parameters ..............................................- 226 -

Group L Keys and Display of Control Panel ..............................................................- 226 -

Group L0 Keys of Control Panel ...........................................................................- 226 -

Group L1 Control Panel Display Setting ...............................................................- 228 -

Group U Monitoring ..................................................................................................- 230 -

Group U0 Status Monitoring .................................................................................- 230 -

Group U1 History Fault ........................................................................................- 234 -

Chapter 7 Troubleshooting ...........................................................................................- 236 -

7.1 Fault Causes and Troubleshooting ................................................................- 236 -

Chapter 8 Maintenance .................................................................................................- 244 -

8.1 Routine Inspection ........................................................................................- 244 -

8.2 Regular Maintenance ....................................................................................- 245 -

8.3 Replacement of Vulnerable Parts ..................................................................- 246 -

8.4 Storage .........................................................................................................- 247 -

Appendix Communication Protocol .............................................................................- 249 -

1. Networking Mode ...............................................................................................- 249 -

2. Interface Mode ...................................................................................................- 249 -

3. Communication Mode ........................................................................................- 249 -

4. Protocol Format .................................................................................................- 250 -

5. Protocol Function ...............................................................................................- 252 -

6. Operation Instructions ........................................................................................- 264 -

7. LRC/CRC Generation ........................................................................................- 268 -

GK600 User Manual Chapter 1 Safety Precautions

WARNING

Do not touch control terminals, circuit boards and any other electronic parts and

components with bare hands.

Do not use the drive whose component(s) is/are missing or damaged. Failure to comply

may result in more faults and/or personal injury even death.

ATTENTION

Check if the product information indicated on the nameplate is consistent with the order

requirements. If not, do not install it.

Do not install the drive in the event that the packing list does not match the real

equipment.

WARNING

Only qualified personnel familiar with adjustable frequency AC drives and associated

machinery should plan or implement the installation. Failure to comply may result in

equipment damage and/or personnel injury even death.

Chapter 1 Safety Precautions

Safety Precautions

Safety signs in this manual:

WARNING: indicates the situation in which the failure to follow operating requirements

may result in fire or serious personal injury or even death.

ATTENTION: indicates the situation in which the failure to follow operating requirements

may cause moderate or slight injury and damage to equipment.

Users are requested to read this chapter carefully when installing, commissioning and repairing

this product and perform the operation according to safety precautions as set forth in this

chapter without violation. GTAKE bears no responsibility for any injury and loss as a result of

any violation operation.

1.1 Safety Considerations

1.1.1 Prior to Installation

1.1.2 Installation

- 1 -

Chapter 1 Safety Precautions GK600 User Manual

This equipment must be mounted on metal or other flame retardant objects. Failure to

comply may result in fire.

This equipment must be mounted in an area which is away from combustibles and heat

sources. Failure to comply may result in fire.

This equipment must in no case be mounted in the environment exposed to explosive gases.

Failure to comply may result in explosion.

Never adjust mounting bolts of this equipment, especially the ones with red marks. Failure to

comply may result in equipment damage.

ATTENTION

Handle the equipment gently and take hold of its sole plate so as to avoid foot injury or

equipment damage.

Mount the equipment where its weight can be withstood. Failure to comply may result in

equipment damage and/or personnel injury if falling happens.

Make sure the installation environment conforms to the requirements as stated in

Section 2.4. If not, de-rating is necessary. Failure to comply may result in equipment

damage.

Prevent drilling residues, wire ends and screws from falling into the equipment during

installation. Failure to comply may result in faults or equipment damage.

When mounted in a cabinet, this equipment should be provided with appropriate heat

dissipation. Failure to comply may result in faults or equipment damage.

WARNING

Only qualified personnel familiar with adjustable frequency AC drives and associated

machinery should plan or implement the wiring. Failure to comply may result in personnel

injury and/or equipment damage.

Wiring must strictly conform to this manual. Failure to comply may result in personnel

injury and/or equipment damage.

Make sure the input power supply has been completely disconnected before wiring.

Failure to comply may result in personnel injury and/or equipment damage.

All wiring operations must comply with EMC and safety regulations and/or electrical

codes, and the conductor diameter should conform to recommendations of this manual.

Failure to comply may result in personnel injury and/or equipment damage.

Since overall leakage current of this equipment may be bigger than 3.5mA, for safety's

sake, this equipment and its associated motor must be well grounded so as to avoid risk

of electric shock.

Be sure to implement wiring in strict accordance with the marks on this equipment‟s

1.1.3 Wiring

- 2 -

GK600 User Manual Chapter 1 Safety Precautions

terminals. Never connect three-phase power supply to output terminals U/T1, V/T2 and

W/T3. Failure to comply may result in equipment damage.

Install braking resistors at terminals and B2 only. Failure to comply may result in

equipment damage.

Install DC reactor at terminals and , and remove the jumper connected at

and . Never connect this jumper and DC reactor to any other terminals. Failure to

comply may result in short circuit and equipment damage.

Wiring screws and bolts for main circuit terminals must be screwed tightly. Failure to

comply may result in equipment damage.

AC 220V signal is prohibited from connecting to other terminals than control terminals

RA, RB and RC. Failure to comply may result in equipment damage.

ATTENTION

Since all adjustable frequency AC drives from GTAKE have been subjected to hi-pot

test before delivery, users are prohibited from implementing such a test on this

equipment. Failure to comply may result in equipment damage.

Signal wires should be away from main power lines to the best of the possibility. If this

cannot be ensured, vertical cross-arrangement shall be implemented, otherwise

interference noise to control signal may occur.

If motor cables are longer than 100m, it is recommended output AC reactor be used.

Failure to comply may result in faults.

The coder must be provided with shielded cables whose shielded layer must be well

grounded.

WARNING

Drives which have been stored for more than 2 years should be used with voltage

regulator to gradually boost the voltage when applying power to the drives. Failure to

comply may result in equipment damage.

Be sure to implement the wiring as per Section 3.4 before applying power to the drive.

Failure to comply may result in equipment damage and/or electric shock hazard.

Be sure to confirm the completion and correctness of the drive wiring and close the

cover before applying power to the drive. Do not open the cover after applying power.

Failure to comply may result in electric shock hazard.

After applying the power, never touch the drive and peripheral circuits no matter what

state the drive is under, otherwise there will be electric shock hazard.

Prior to running the drive, make sure there is no person in surrounding area who can

reach the motor so as to prevent personal injury.

+ 2/B1

+ 1

+ 2

+ 1

+ 2

1.1.4 Run

- 3 -

Chapter 1 Safety Precautions GK600 User Manual

When the drive is running, foreign bodies should be prevented falling into the

equipment. Failure to comply may result in faults and/or equipment damage.

Only qualified technicians familiar with adjustable frequency AC drives are allowed to

perform signal test during operation. Failure to comply may result in equipment damage

and/or personal injury.

Never change the drive parameters at will. Failure to comply may result in equipment

damage.

ATTENTION

Make sure the number of phases of power supply and rated voltage are consistent with

product nameplate. If not, contact the seller or GTAKE.

Check there are no short circuits in peripheral circuits connected with the drive, and

make sure the connection is tight. Failure to comply may result in equipment damage.

Make sure the motor and associated machinery are within allowable range of service

prior to operation. Failure to comply may result in equipment damage.

Never touch fans, heat sink and braking resistor with bare hands. Failure to comply may

result in equipment damage and/or personal injury.

It is not allowed to start & stop the drive frequently via direct switching power on or off.

Failure to comply may result in equipment damage.

Make sure the drive is in a non-output status before switch-on/switch-off of the drive

output and/or contactor. Failure to comply may result in equipment damage.

WARNING

Only qualified technicians are allowed to implement the maintenance, and

troubleshooting.

Never implement the maintenance, and troubleshooting before power supply has been

turned off and discharged completely. Failure to comply may result in equipment

damage and/or personal injury.

To avoid an electric shock hazard, wait at least 10 minutes after the power has been

turned off and make sure the residual voltage of the bus capacitors has discharged to

0V before performing any work on the drive.

After the replacement of the drive, be sure to perform the same procedures in strict

accordance with the above-noted rules.

1.1.5 Maintenance

- 4 -

GK600 User Manual Chapter 1 Safety Precautions

ATTENTION

Do not touch the electric components with bare hands during maintenance, and

troubleshooting. Failure to comply may result in component damage due to ESD.

All pluggable components can be inserted or pulled out only when power has been

turned off.

1.2 Other Considerations

1.2.1 Input Power Supply

This series of drives are not applicable to applications out the range of operating voltage as set

forth in this manual. If necessary, please use booster to rise or drop the voltage to regulated

voltage range.

This series of drives support common DC bus input. Users are suggested to consult GTAKE

technical personnel before use.

1.2.2 Surge Protection

This series of drives are furnished with surge suppressor that has certain resistance to lightning

induction. However, users in areas where lightning occurs frequently need to mount an external

surge suppressor in front of power input side of the drive.

1.2.3 Operation of Contactor

As to the configuration of peripheral devices recommended by this manual, it is necessary to

mount a contactor between the power supply and input side of the drive. Such a contactor

should not be used as a control device to start and stop the drive, as frequent charging &

discharging shall reduce the service life of internal electrolytic capacitors.

When it is necessary to mount a contactor between the drive output and the motor, it should be

ensured the drive is in a non-output status before switch-on/switch-off of such a contactor.

Failure to comply may result in damage to the drive.

1.2.4 Output Filter

Since the drive output is PWM high frequency chopping voltage, mounting filter devices such

as an output filter and an output AC reactor between the motor and the drive shall effectively

reduce output noise, avoiding interference to other surrounding equipment.

If the length of cable between the drive and the motor exceeds 100m, an output AC reactor is

recommended to use with the purpose of preventing drive fault as a result of overcurrent

- 5 -

Chapter 1 Safety Precautions GK600 User Manual

caused by excessive distributed capacitance. An output filter is optional depending on the field

requirements.

Be sure not to mount phase-shifting capacitor or surge absorber at output side of the drive

since this may cause damage to the drive as a result of over-temperature.

1.2.5 Insulation of the Motor

In view of the fact that the drive output is PWM high frequency chopping voltage accompanied

by higher harmonics, the noise, temperature rise and vibration of the motor is higher compared

with sinusoidal voltage. Particularly this debases motor insulation. Therefore, the motor should

be subjected to insulation inspection before initial use or reuse after being stored for a long

period of time. The motor in regular service should also be subjected to regular insulation

inspection so as to avoid damage to the drive as a result of motor insulation damage. A 500V

voltage mode mega-ohmmeter is recommended to use for the measurement of the motor

insulation, during which, it is essential to disconnect the motor from the drive. Normally, the

insulation resistance of the motor should be bigger than 5MΩ.

1.2.6 Derating

Due to the thin air in high-altitude areas, the radiating performance of the drive with forced air

cooling may degrade while the electrolyte of electrolytic capacitors is more volatile, which can

result in reduction in product life. Drive should be derated when used in an area at the altitude

above 1000 meters. It is recommended to derate 1% for every 100m when the altitude is above

1000 meters.

- 6 -

GK600 User Manual Chapter 2 Product Information

GK600 S - 4 T 7.5G/11L B- XX - XX

产品大系列代号

A0~Z9:code of customized

01~99:软件非标代号

7.5G:7.5kW(恒转矩/重载)

11L:11kW(变转矩/轻载)

S:单相

T:三相

缺省:无内置制动单元

B:内置制动单元

行业专用系列代号

缺省:通用系列

B:供水专用系列

S:拉丝机专用系列

M:机床专用系列

W:纺织专用系列

2:200V level

4:400V level

6:690V level

Master series code of product

Industry-specific series code

Default: general-purpose series

S: for drawing machine

I: for injection molding machine

…

A0-Z9: customized hardware code

01-99: customized software code

Default: without inbuilt brake chopper

B: with inbuilt brake chopper

7.5G: 7.5kW (constant torque/heavy

duty)

11L: 11kW (variable torque/light duty)

S: Single-phase

T: three-phase

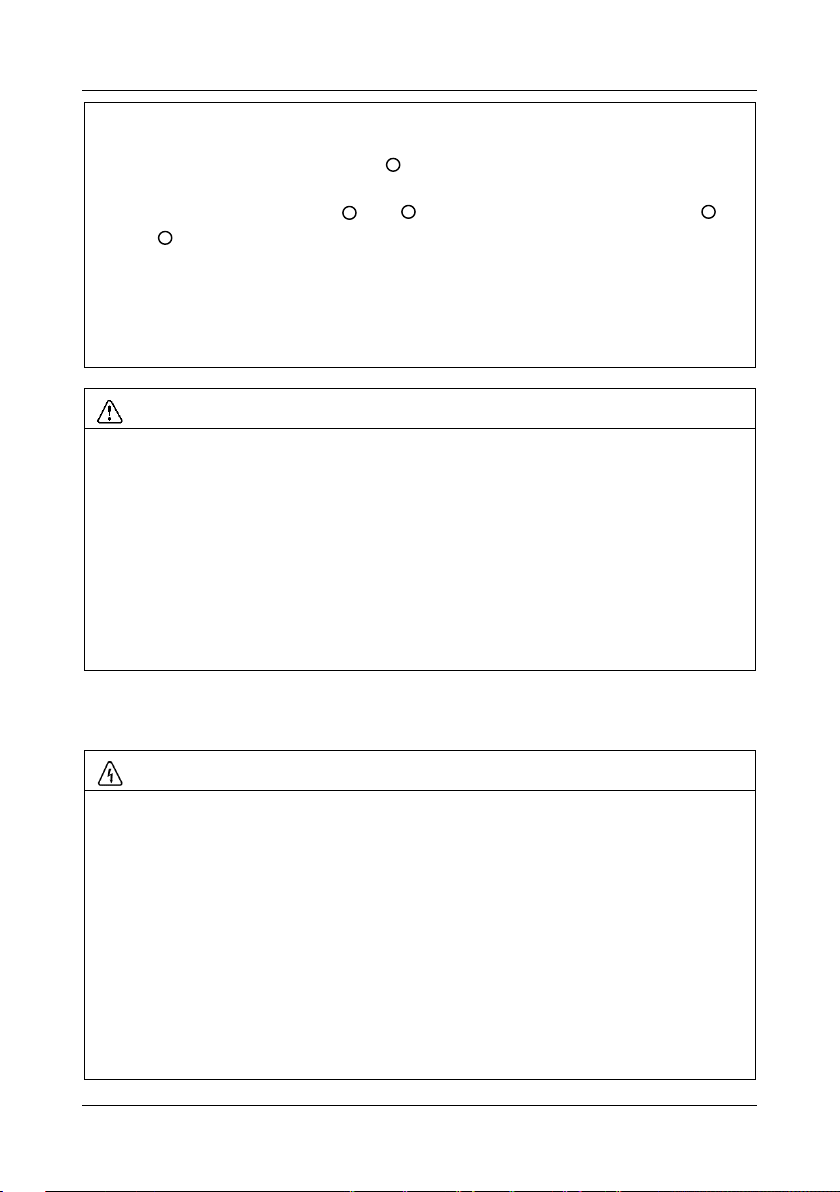

Chapter 2 Product Information

2.1 Model Explanation

Model shown on product nameplate indicates the series name, applicable type of power supply,

power class and the version of software and hardware, etc. via the combination of numbers,

symbols and letters.

Fig. 2-1 Product model explanation

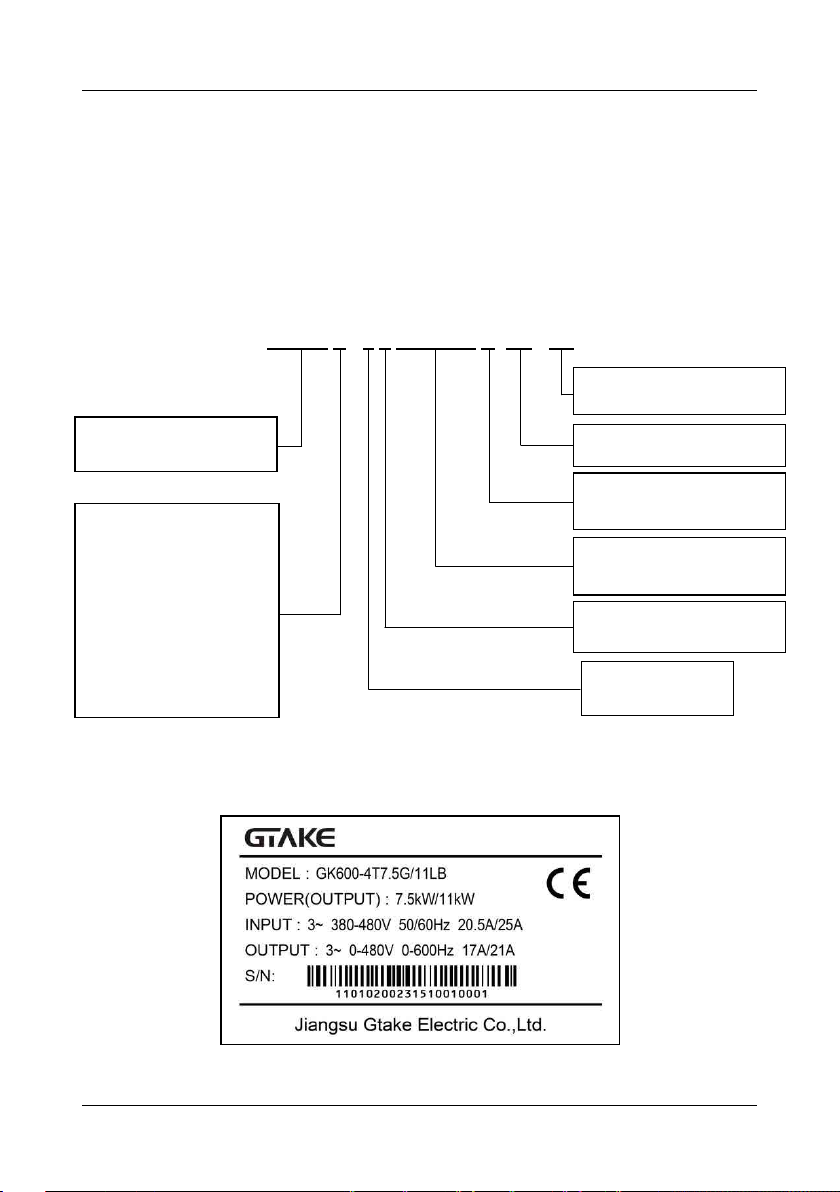

2.2 Nameplate Information

Fig. 2-2 Nameplate information

- 7 -

Chapter 2 Product Information GK600 User Manual

Drive model

Power

rating (kW)

3-phase

rated

output

current (A)

1-phase

rated input

current (A)

3-phase

rated input

current (A)

Applicable

motor (kW)

Brake

chopper

GK600-2T0.4B

0.4

2.6

5.5

3.2

0.4

Inbuilt

GK600-2T0.75B

0.75

4.5

9.2

6.3

0.75

GK600-2T1.5B

1.5

7.5

14.5

9

1.5

GK600-2T2.2B

2.2

11

23

15

2.2

Drive model

Power

rating

(kW)

3-phase rated

output current

(A)

3-phase rated

input current

(A)

Applicable

motor (kW)

Brake

chopper

GK600-2T3.7B

3.7

16.5

20.5

3.7

Inbuilt

GK600-2T5.5B

5.5

24

29

5.5

GK600-2T7.5B

7.5

30

35

7.5

GK600-2T11(B)

11

45

50

11

Inbuilt

optional

GK600-2T15(B)

15

60

65

15

GK600-2T18.5(B)

18.5

73

80

18.5

GK600-2T22(B)

22

91

95

22

GK600-2T30(B)

30

112

118

30

GK600-2T37(B)

37

144

150

37

GK600-2T45

45

176

160

45

Externally

mounted

when

needed

GK600-2T55

55

210

192

55

GK600-2T75

75

288

266

75

GK600-2T90

90

350

326

90

GK600-2T110

110

430

403

110

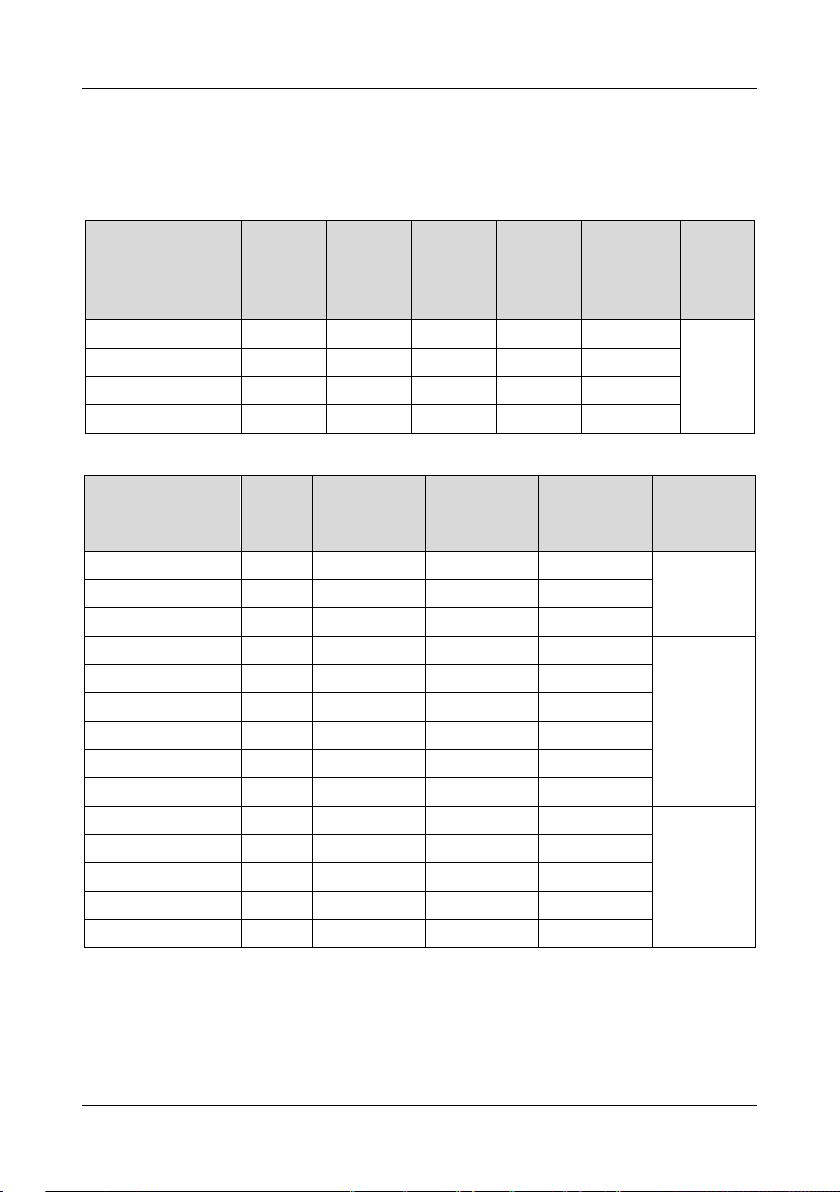

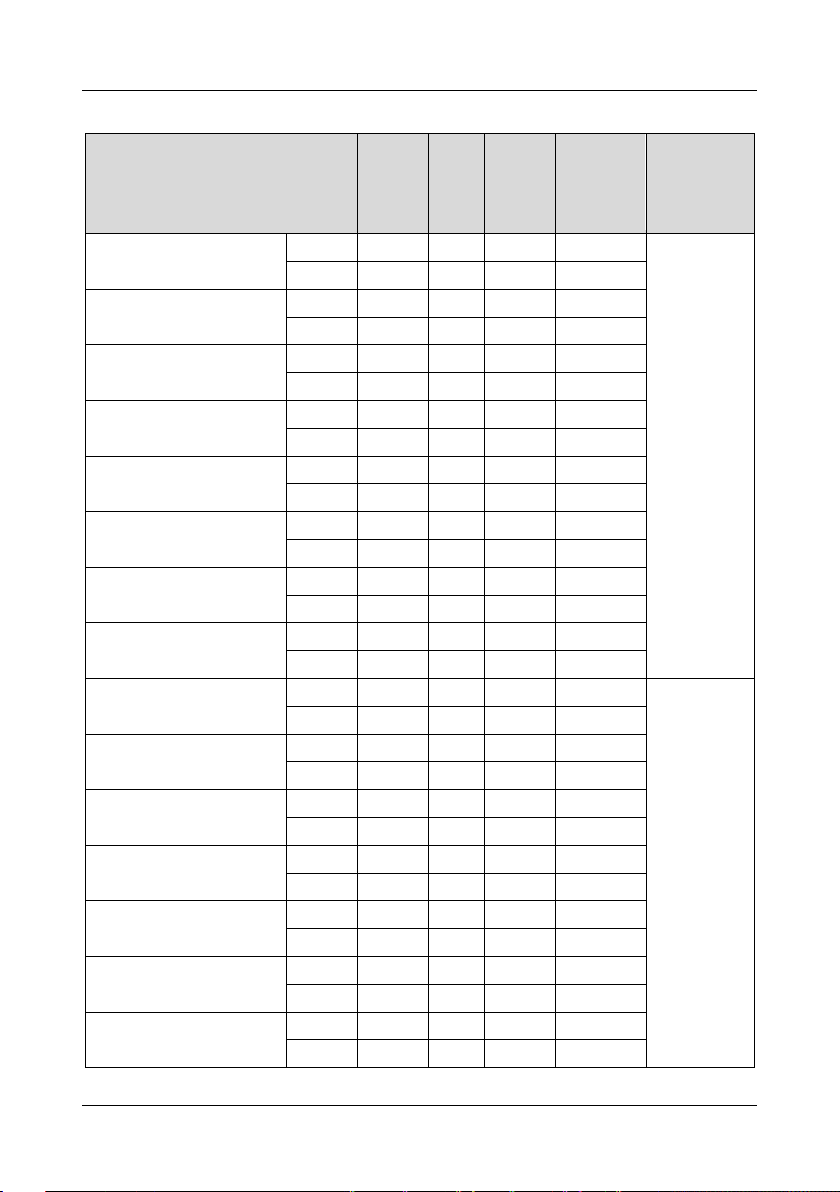

2.3 Information of Product Model

Table 2-1 Product model and technical data

■ GK600-2T□□□B, single/ three-phase 220V input, heavy duty

■ GK600-2T□□□□, three-phase 220V input, heavy duty

- 8 -

GK600 User Manual Chapter 2 Product Information

Drive model

Power

rating

(kW)

Rated

output

current

(A)

Rated

input

current

(A)

Applicable

motor (kW)

Brake

chopper

GK600-4T0.75G/1.5LB

0.75G

0.75

2.5

3.5

0.75

Inbuilt

1.5L

1.5

3.8

5.0

1.5

GK600-4T1.5G/2.2LB

1.5G

1.5

3.8

5.0

1.5

2.2L

2.2

4.8

5.5

2.2

GK600-4T2.2G/3.7LB

2.2G

2.2

5.5

6.0

2.2

3.7L

3.7

8.0

10

3.7

GK600-4T3.7G/5.5LB

3.7G

3.7

9.0

10.5

3.7

5.5L

5.5

11

14

5.5

GK600-4T5.5G/7.5LB

5.5G

5.5

13

14.6

5.5

7.5L

7.5

16

20

7.5

GK600-4T7.5G/11LB

7.5G

7.5

17

20.5

7.5

11L

11

21

25

11

GK600-4T11G/15LB

11G

11

24

29

11

15L

15

30

35

15

GK600-4T15G/18.5LB

15G

15

30

35

15

18.5L

18.5

36

40

18.5

GK600-4T18.5G/22L(B)*

18.5G

18.5

39

44

18.5

Inbuilt

optional

22L

22

45

50

22

GK600-4T22G/30L(B)*

22G

22

45

50

22

30L

30

56

60

30

GK600-4T30G/37L(B)*

30G

30

60

65

30

37L

37

72

76

37

GK600-4T37G/45L(B)*

37G

37

75

80

37

45L

45

91

95

45

GK600-4T45G/55L(B)*

45G

45

91

95

45

55L

55

112

118

55

GK600-4T55G/75L(B)*

55G

55

112

118

55

75L

75

142

148

75

GK600-4T75G/90L(B)*

75G

75

150

157

75

90L

90

176

180

90

■ GK600-4T□□□G/□□□L□, three-phase 400V input, heavy duty/ light duty

- 9 -

Chapter 2 Product Information GK600 User Manual

Drive model

Power

rating

(kW)

Rated

output

current

(A)

Rated

input

current

(A)

Applicable

motor (kW)

Brake

chopper

GK600-4T90G/110L

90G

90

176

160**

90

Externally

mounted

when needed

110L

110

210

192**

110

GK600-4T110G/132L

110G

110

210

192**

110

132L

132

250

230**

132

GK600-4T132G/160L

132G

132

253

232**

132

160L

160

304

280**

160

GK600-4T160G/185L

160G

160

310

285**

160

185L

185

350

326**

185

GK600-4T185G/200L

185G

185

350

326**

185

200L

200

380

354**

200

GK600-4T200G/220L

200G

200

380

354**

200

220L

220

430

403**

220

GK600-4T220G/250L

220G

220

430

403**

220

250L

250

470

441**

250

GK600-4T250G/280L

250G

250

470

441**

250

280L

280

520

489**

280

GK600-4T280G/315L

280G

280

520

489**

280

315L

315

590

571**

315

GK600-4T315G/355L

315G

315

590

571**

315

355L

355

650

624**

355

GK600-4T355G/400L

355G

355

650

624**

355

400L

400

725

699**

400

GK600-4T400G/450L

400G

400

725

699**

400

450L

450

820

790**

450

GK600-4T450G/500L

450G

450

820

790**

450

500L

500

860

835**

500

GK600-4T500G

500G

500

860

835**

500

GK600-4T560G

560G

560

950

920**

560

GK600-4T630G

630G

630

1100

1050**

630

* means brake chopper is optionally inbuilt. Take 18.5G/22L for example: the model without brake chopper is

- 10 -

GK600 User Manual Chapter 2 Product Information

Power input

Rated input

voltage

3-phase

AC208V/AC220V/AC230V/AC240V/AC380V/AC400V/

AC415V/AC440V/AC460V/AC480V

1-phase

AC220V/AC230V/AC240V

Frequency

50Hz/60Hz, tolerance ±5%

Voltage

range

Continuous voltage fluctuation ±10%, short fluctuation

-15%~+10%, i.e. 200V: 170V~264V, 400V: 323V~528V

Voltage out-of-balance rate <3%, distortion rate as per the

requirements of IEC61800-2

Rated input

current

See Section 2.3

Power output

Applicable

motor (kW)

See Section 2.3

Rated

current (A)

See Section 2.3

Output

voltage (V)

3-phase: 0~ rated input voltage, error < ±3%

Output

frequency

(Hz)

0.00~ 600.00Hz; unit: 0.01Hz

Overload

capacity

150% - 1min, 180% - 10s, 200% - 0.5s every 10 min

Control

characteristics

V/f patterns

V/f control

Sensor-less vector control 1

Sensor-less vector control 2

Range of

speed

regulation

1:100 ( V/f control, sensor-less vector control 1)

1:200 (sensor-less vector control 2)

GK600-4T18.5G/22L, and the model with brake chopper is GK600-4T18.5G/22LB. Braking resistor needs to be

mounted externally with reference to 3.4.3.

** means the rated input current configured a DC reactor. The drive GK600-4T90G/110L - GK600-4T500G is

provided with an external-mounted DC reactor in shipment as default. Be sure to connect the DC reactor. Failure to

comply may result in drive abnormal run. GK600-4T560G and GK600-4T630G are cabinet type, whose DC reactor

and output AC reactor are inbuilt as default.

2.4 Technical Features of GK600

Table 2-2 Technical Features of GK600

- 11 -

Chapter 2 Product Information GK600 User Manual

Control

characteristics

Speed

accuracy

±0.5% (V/f control)

±0.2% (sensor-less vector control 1 & 2)

Speed

fluctuation

±0.3% (sensor-less vector control 1 & 2)

Torque

response

< 10ms (sensor-less vector control 1 & 2)

Starting

torque

0.5Hz: 180% (V/f control, sensor-less vector control 1)

0.25Hz: 180% (sensor-less vector control 2)

Basic

functions

Start

frequency

0.00~ 600.00Hz

Accel/

Decel time

0.00~60000s

Switching

frequency

0.7kHz~16kHz

Frequency

setting

Digital setting + control panel ∧/∨

Digital setting + terminal UP/DOWN

Communication

Analog setting (AI1/AI2/EAI)

Terminal pulse setting

Motor

start-up

methods

Started from starting frequency

DC brake start-up

Flying start

Motor stop

methods

Ramp to stop

Coast to stop

Ramp stop + DC brake

Basic

functions

Dynamic

braking

capacity

Brake chopper working voltage:

200V level: 325-375V / 400V level: 650V-750V

Service time: 0-100.0s; brake chopper for

GK600-4T75G/90L and below are inbuilt or can be inbuilt

optionally. See table 2-1

DC brake

capacity

DC brake start frequency: 0.00~600.00Hz

DC brake current: 0.0~100.0%

DC brake time: 0.0~30.00s

Input

terminals

6 digital inputs, one of which can be used for high-speed

pulse input, and compatible with active open collectors

NPN, PNP and dry contact input. Digital inputs can be

extended to 7

2 analog inputs, one of which is voltage/current

programmable, and the other supports voltage only.

Analog inputs can be extended to 3, and the extended one

is voltage/current programmable

- 12 -

GK600 User Manual Chapter 2 Product Information

Basic

functions

Output

terminals

1 high-speed pulse output, 0~50kHz square wave signal

output. It can output signals such as frequency setting, or

output frequency, etc.

1 digital output

1 relay output (can be extended to 2)

1 analog output (can be extended to 2), voltage/current

output programmable; can output signals such as

frequency setting, or output frequency, etc.

Featured

functions

Parameter copy, parameter backup, common DC bus, free switchover

between two motors‟ parameters, flexible parameter displayed & hidden,

various master & auxiliary setting and switchover, flying start, a variety of

Accel/Decel curves optional, automatic correction of analog, brake

control, 16-step speed control programmable (2-step speed supports

flexible frequency command), wobble frequency control, fixed length

control, count function, three history faults, over excitation brake, over

voltage stall protection, under voltage stall protection, restart on power

loss, skip frequency, frequency binding, four kinds of Accel/Decel time,

motor thermal protection, flexible fan control, process PID control, simple

PLC, multi-functional key programmable, droop control, autotuning,

field-weakening control, high-precision torque restraint, V/f separated

control

Protection

functions

Refer to Chapter 7- Troubleshooting

Environment

Place of

operation

Indoors, no direct sunlight, free from dust, corrosive

gases, flammable gases, oil mist, water vapor, water drop

or salt, etc.

Altitude

0-2000m. De-rate 1% for every 100m when the altitude is

above 1000 meters

Ambient

temperature

-10℃-40℃. The rated output current should be derated

1% for every 1℃ when the ambient is 40℃-50℃

Relative

humidity

0~95%, no condensation

Vibration

Less than 5.9m/s2 (0.6g)

Storage

temperature

-40℃~+70℃

Others

Efficiency at

rated Amps

Rated power

7.5kW and below: ≥93%

11~ 45kW: ≥ 95%

55kW and above: ≥98%

Installation

560kW and 630kW are cabinet type,

the others are wall-mounted

IP grade

IP20

Cooling

method

Forced air cooling

- 13 -

铭牌

下壳体

安装孔

底板

风扇罩

防尘盖板

操作面板

盖板

中壳体

盖板

操作面板

安装孔

机箱

铭牌

风扇

托板

铭牌

机箱

安装孔

风扇

下盖板

操作面板

托板

上盖板

Fan cover

Dust cover

Control

panel

Cover

Control

panel

Cover

Base plate

Mounting

holes

Mounting

holes

Mounting

holes

Control

panel

Lower

casing

Nameplate

Nameplate

Nameplate

Middle casing

Control

panel

Fans

Enclosure

Fans

Enclosure

Control

panel

bracket

Upper

cover

Lower

cover

Nameplate

Chapter 2 Product Information GK600 User Manual

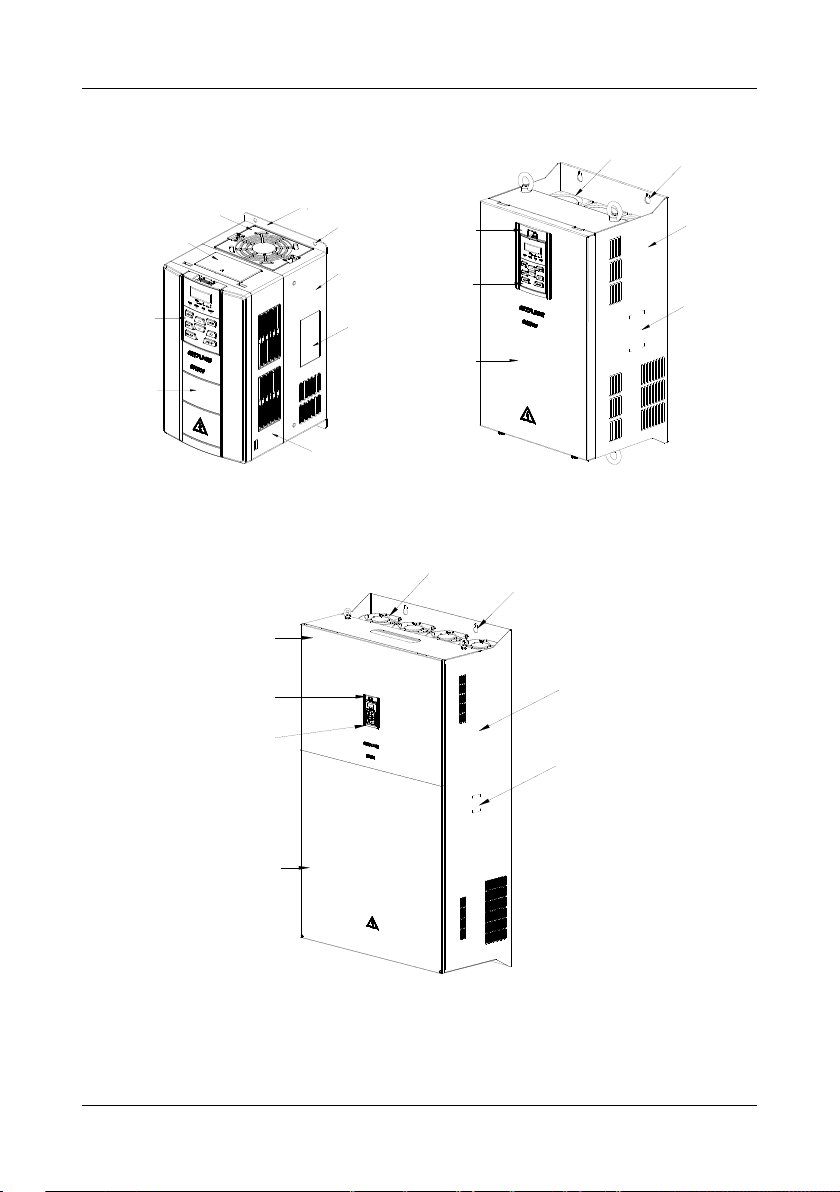

2.5 Parts Drawing

a) GK600-2T7.5B and below b) GK600-2T11(B) ~ GK600-2T37

GK600-4T15G/18.5LB and below GK600-4T18.5G/22L ~ GK600-4T75G/90L(B)

c) GK600-2T45 ~ GK600-2T110, GK600-4T90G/110L~ GK600-4T500G

- 14 -

GK600 User Manual Chapter 2 Product Information

机柜

操作面板

托板

前门

底座

Control

panel

Control panel

bracket

Cabinet

Front

door

Cabinet

base

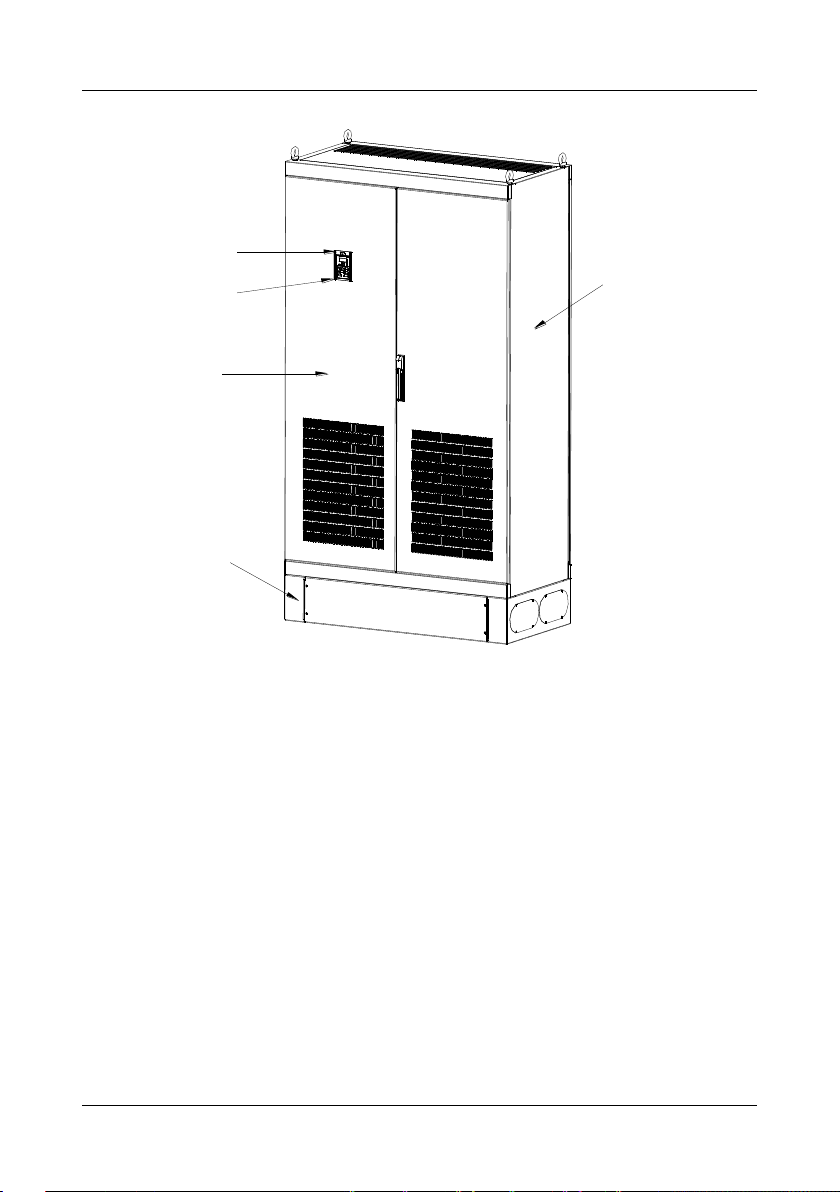

d) GK600-4T560G and GK600-4T630G

Fig. 2-3 Parts drawing

- 15 -

Chapter 2 Product Information GK600 User Manual

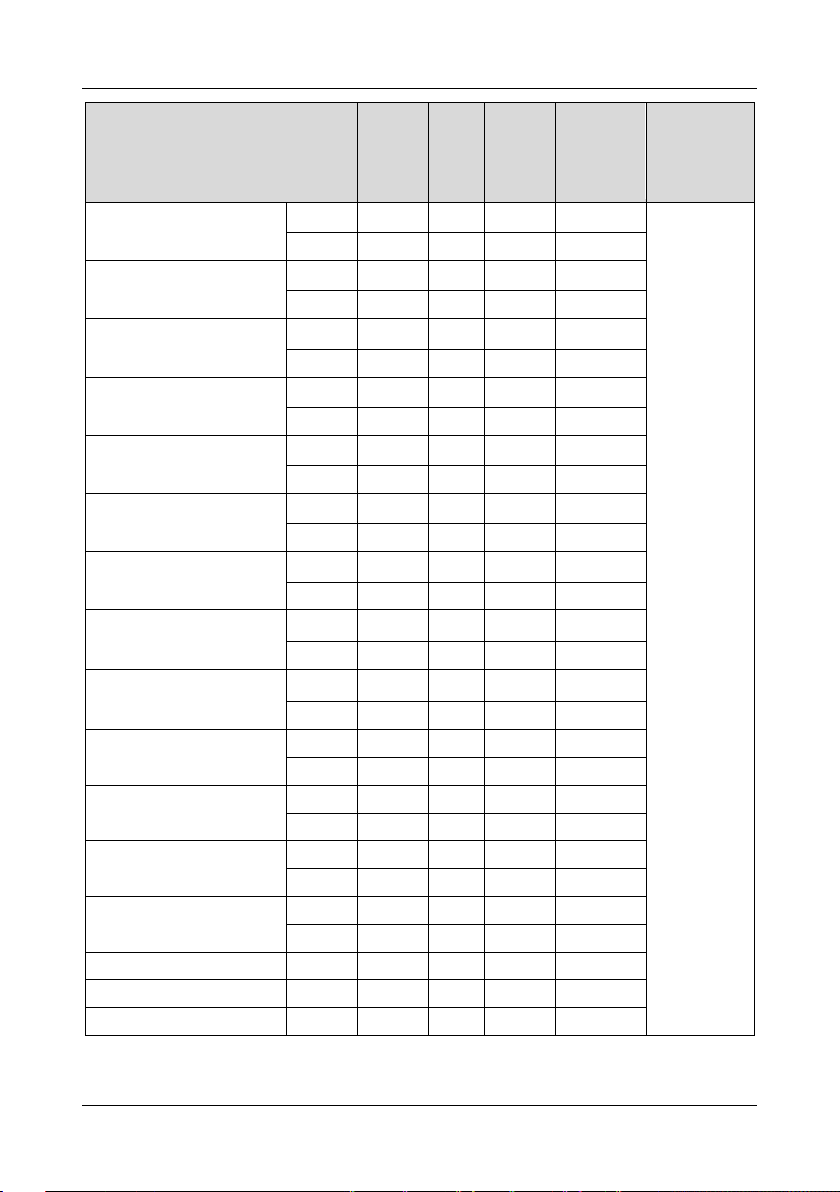

2.6 Appearance, Mounting Dimensions and Weight

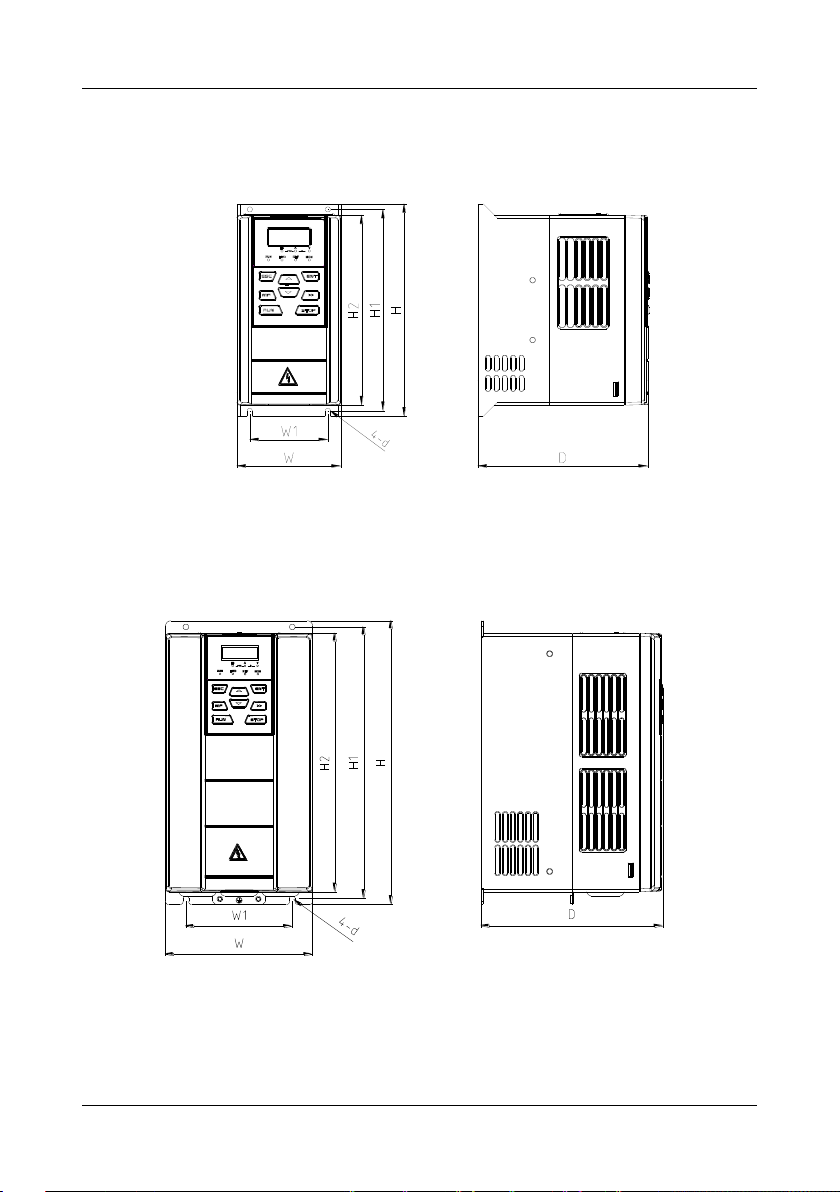

a) GK600-2T0.4B ~ GK600-2T1.5B and

GK600-4T0.75G/1.5LB ~ GK600-4T1.5G/2.2LB

b) GK600-2T2.2B ~ GK600-2T7.5B, GK600-4T2.2G/3.7LB ~ GK600-4T15G/18.5LB

- 16 -

GK600 User Manual Chapter 2 Product Information

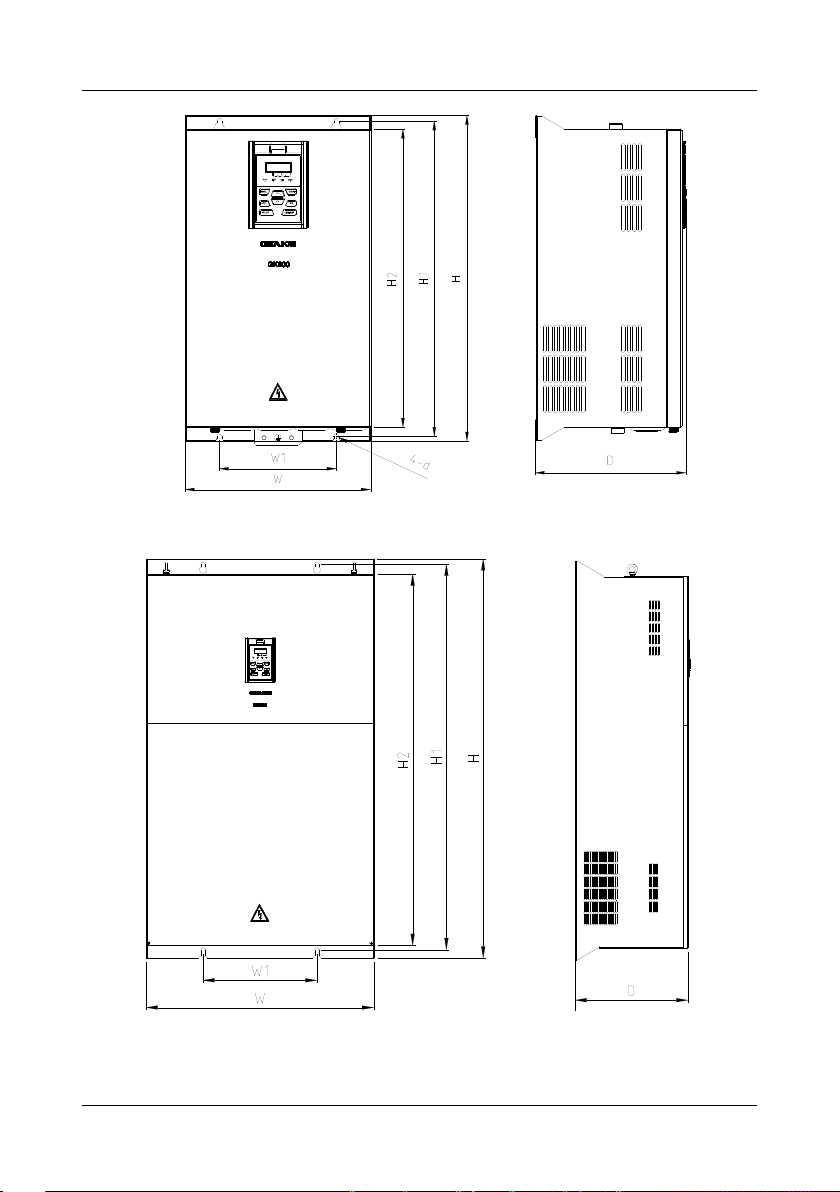

c) GK600-2T11(B) ~ GK600-2T37, GK600-4T18.5G/22L(B) ~ GK600-4T75G/90L(B)

d) GK600-2T45 ~ GK600-2T75, GK600-4T90G/110L ~ GK600-4T160G/185L

- 17 -

Chapter 2 Product Information GK600 User Manual

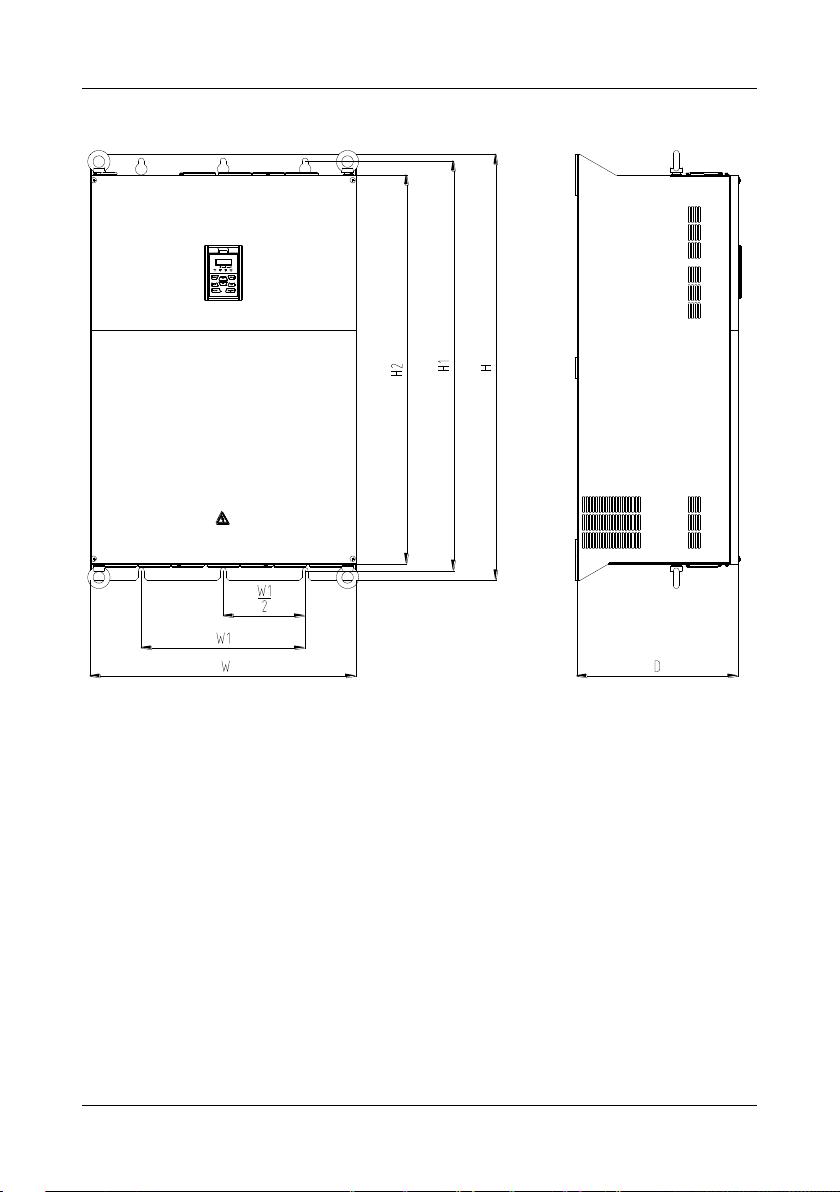

e) GK600-2T90 ~ GK600-2T110, GK600-4T185G/200L ~ GK600-4T500G

- 18 -

GK600 User Manual Chapter 2 Product Information

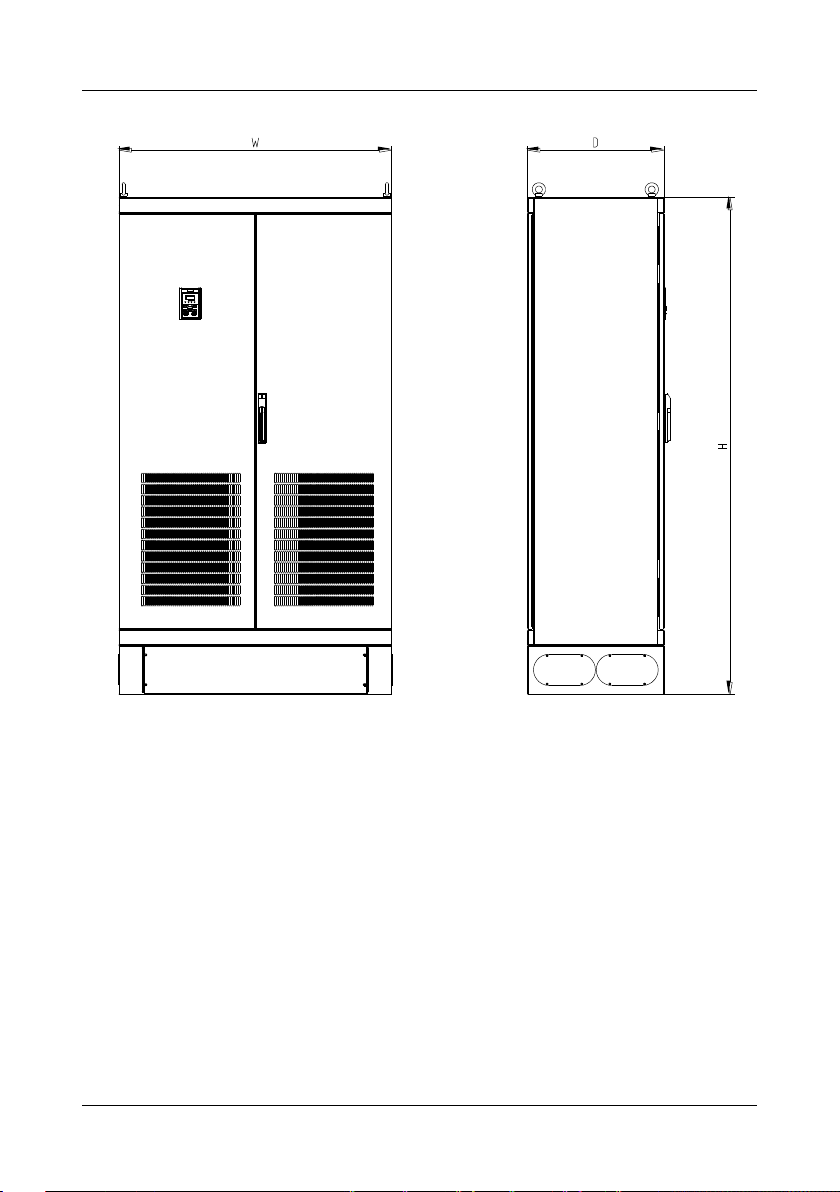

f) GK600-4T560G ~ GK600-4T630G

Fig. 2-4 External dimensions

- 19 -

Chapter 2 Product Information GK600 User Manual

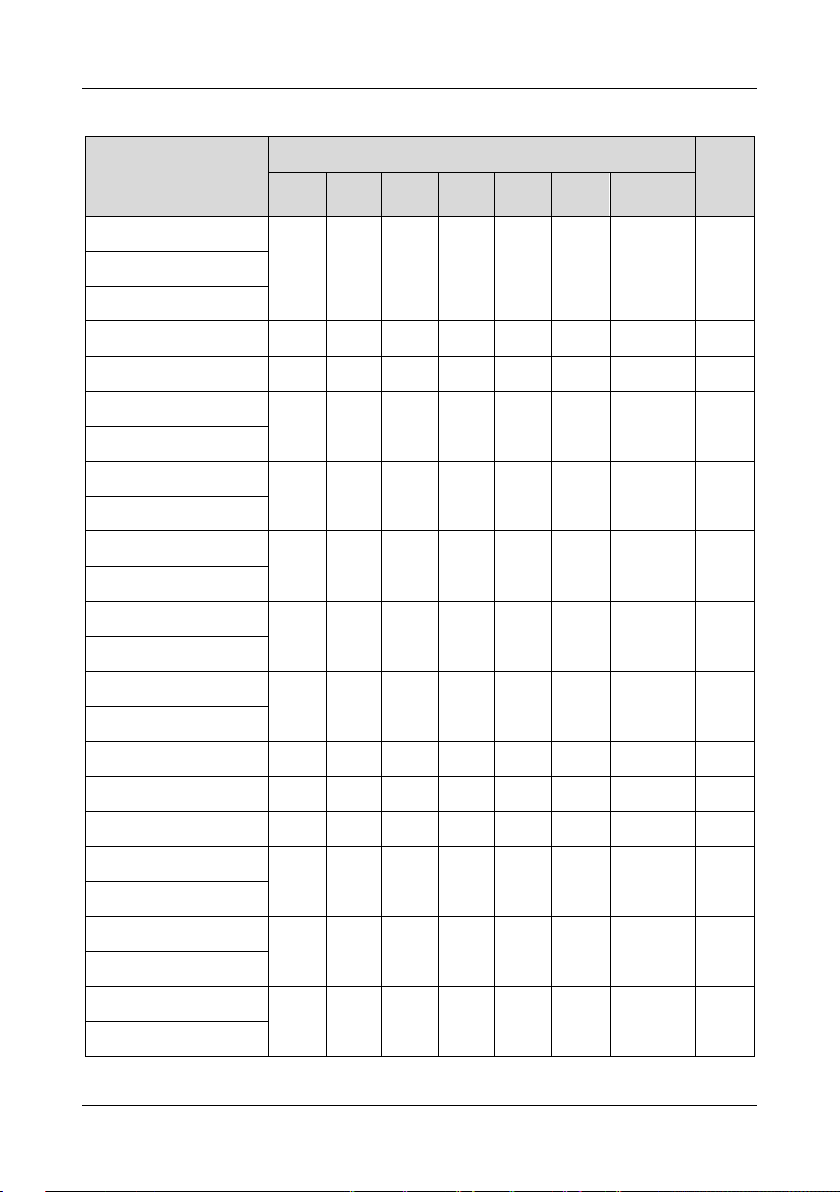

Model

External and installation dimensions (mm)

Weight

(kg)

W H D

W1

H1

H2

Mounting

hole dia.

GK600-2T0.4B

93

190

152

70

180

172

4.5

1.4

GK600-2T0.75B

GK600-2T1.5B

GK600-2T2.2B

120

245

169

80

233

220

5.5

2.9

GK600-2T3.7B

145

280

179

105

268

255

5.5

3.9

GK600-2T5.5B

190

365

187

120

353

335 6 6.2

GK600-2T7.5B

GK600-2T11(B)

270

475

220

170

460

435 8 15.5

GK600-2T15(B)

GK600-2T18.5(B)

320

568

239

220

544

515

10

24

GK600-2T22(B)

GK600-2T30

385

670

261

260

640

600

12

37

GK600-2T37

GK600-2T45

395

785

291

260

750

705

12

50

GK600-2T55

GK600-2T75

440

900

356

300

865

820

14

66

GK600-2T90

500

990

368

360

950

900

14

88

GK600-2T110

650

1040

406

400

1000

950

14

123

GK600-4T0.75G/1.5LB

93

190

152

70

180

172

4.5

1.4

GK600-4T1.5G/2.2LB

GK600-4T2.2G/3.7LB

120

245

169

80

233

220

5.5

2.9

GK600-4T3.7G/5.5LB

GK600-4T5.5G/7.5LB

145

280

179

105

268

255

5.5

3.9

GK600-4T7.5G/11LB

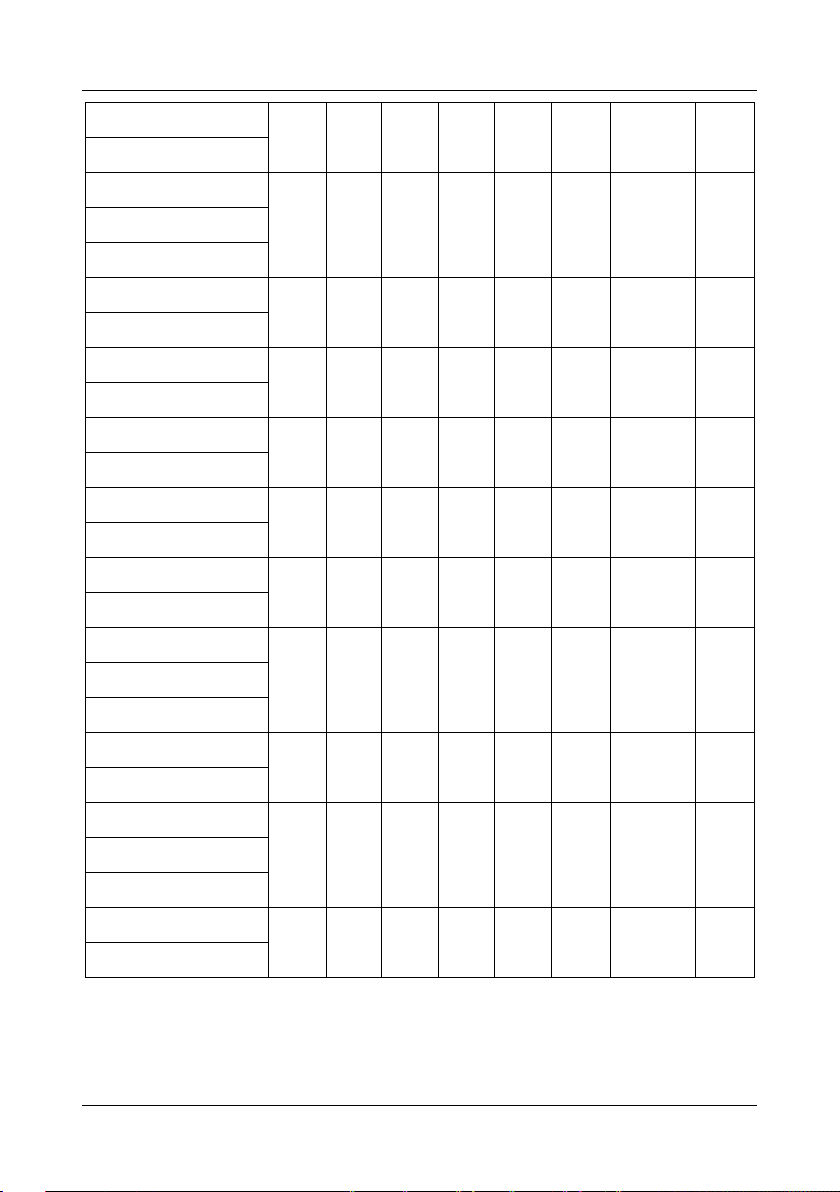

Table 2-3 Appearance, mounting dimensions and weight

- 20 -

GK600 User Manual Chapter 2 Product Information

GK600-4T11G/15LB

190

365

187

120

353

335 6 6.2

GK600-4T15G/18.5LB

GK600-4T18.5G/22L(B)

270

475

220

170

460

435 8 15.5

GK600-4T22G/30L(B)

GK600-4T30G/37L(B)

GK600-4T37G/45L(B)

320

568

239

220

544

515

10

24

GK600-4T45G/55L(B)

GK600-4T55G/75L

385

670

261

260

640

600

12

37

GK600-4T75G/90L

GK600-4T90G/110L

395

785

291

260

750

705

12

50

GK600-4T110G/132L

GK600-4T132G/160L

440

900

356

300

865

820

14

66

GK600-4T160G/185L

GK600-4T185G/200L

500

990

368

360

950

900

14

88

GK600-4T200G/220L

GK600-4T220G/250L

650

1040

406

400

1000

950

14

123

GK600-4T250G/280L

GK600-4T280G/315L

GK600-4T315G/355L

815

1300

428

600

1252

1200

14

165

GK600-4T355G/400L

GK600-4T400G/450L

815

1300

428

600

1252

1200

14

165

GK600-4T450G/500L

GK600-4T500G

GK600-4T560G

1100

2000

550 / / / /

515

GK600-4T630G

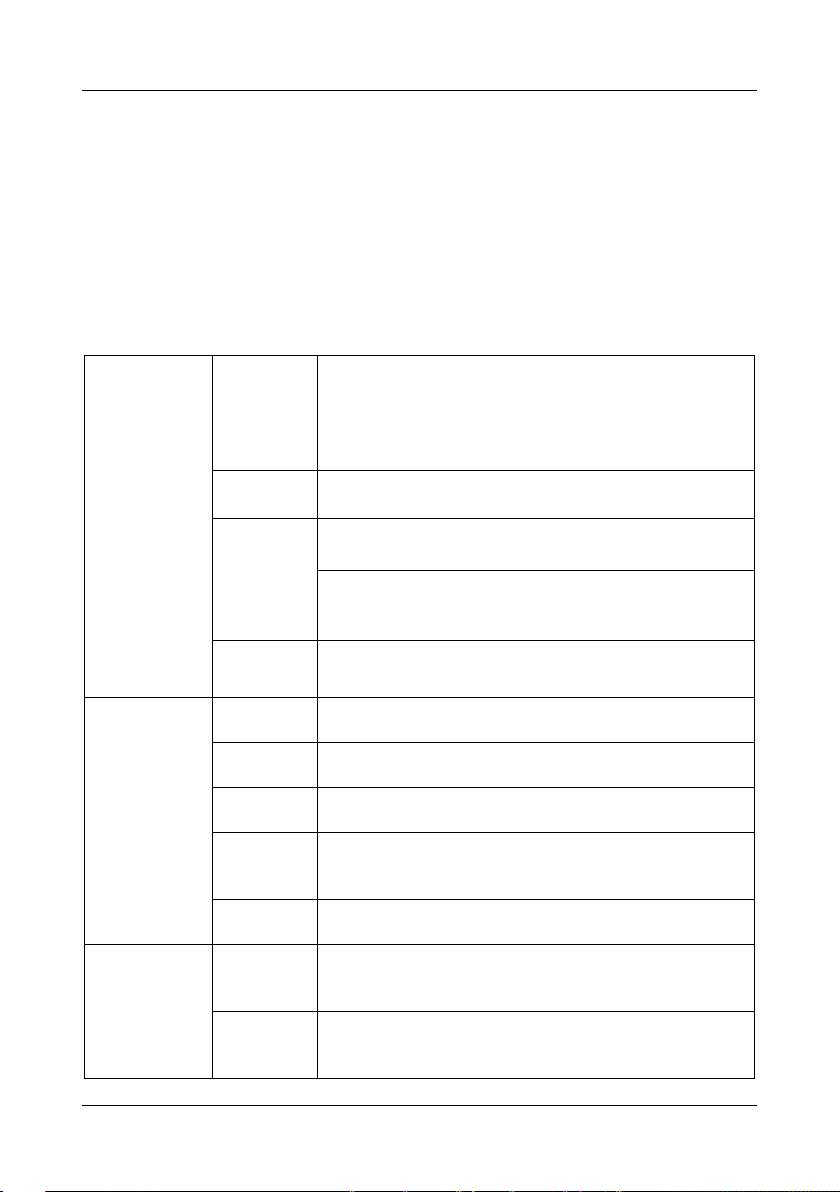

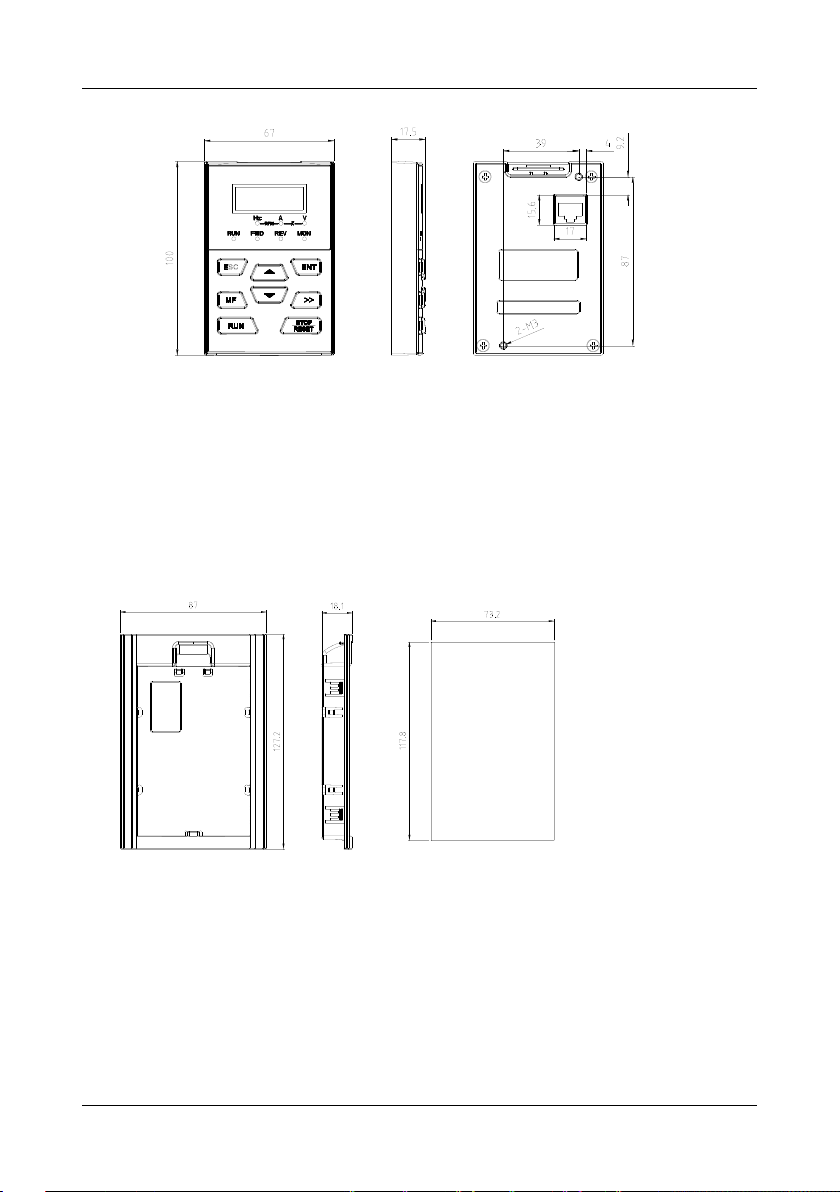

2.7 External Dimensions of Control Panel

Control panel model of GK600 series general purpose AC motor drive is KBU-BX1 whose

appearance and external dimensions are shown in Fig. 2-5.

- 21 -

Chapter 2 Product Information GK600 User Manual

Panel TH Hole WTH

1.2mm 73.2mm

1.5mm 74.4mm

2mm 75.5mm

Fig. 2-5 External dimensions of KBU-BX1

2.8 External Dimensions of Control Panel Bracket

A bracket should be provided to support the panel and a hole in the cabinet needs to be opened

when the control panel KBU-BX1 needs to be remotely used. Bracket model is KBU-DZ1

whose external dimensions are shown in Fig. 2-6 a). Fig. 2-6 b) shows applicable hole

dimensions in the cabinet.

a) External dimensions of KBU-DZ1 b) Hole dimensions in the cabinet

Fig. 2-6 External dimensions of KBU-DZ1 and cabinet hole dimensions

- 22 -

Loading...

Loading...