GT STREET MACHINE User Manual

Operating Manual and

Service Instructions

NEW

recumbent-

technology

2002

HP

Velotechnik

July 2002

General safety instructions

Intended use – 3

The first miles – 3

Legal requirements – 3

Load capacity – 4

Carrying luggage – 4

Transport in the car – 5

Do not take kids with you – 5

Trailers – 5

Added parts and accessories – 5

Fairings – 5

Replacement of parts – 6

No alteration of parts – 6

Final assembly – 6

Screws and bolts – 6

Adjusting your new bike

Adjusting the leg length – 7

Adjusting the seat position – 11

Adjusting the handlebars – 13

Adjusting the suspension – 16

Handling instructions

Learning the new riding technique – 24

Wear protective clothing – 25

Use cleatless pedals – 25

Slowly increase the strain – 26

Do not ride freehand – 26

How to ride correctly and safely – 26

Quick release levers – 27

Brakes – 28

Gear system – 30

Light system – 31

Prop stand – 32

Table of Contents

-

HP

Velotechnik

Maintenance and care

Wear and Tear – 33

Brakes – 33

Gear system – 35

Chain – 36

Chain tubes – 38

Chain roller – 40

Suspension fork – 41

Rear suspension element – 45

Swing arm pivot – 47

Seat – 48

Seat cushion – 49

Water bottle cage – 50

Mudguards – 50

Wheels – 51

Cleaning and conservation – 52

Storing the bicycle – 54

Screws and bolts – 54

Tightening torques for screws – 55

Warranty Pass

Warranty – 56

Warranty Pass – 57

Service Plan – 58

Proofs of service – 62

Revision July 2002. For latest product information, please check out our website at

www.hpvelotechnik.com. All trademarks belong to their respective owners.

HP V

ELOTECHNIK

Bleichstrasse 5

65830 Kriftel / Germany

Tel. ++49 (0) 61 92 - 97 99 2-0

Fax ++49 (0) 61 92 - 91 02 18

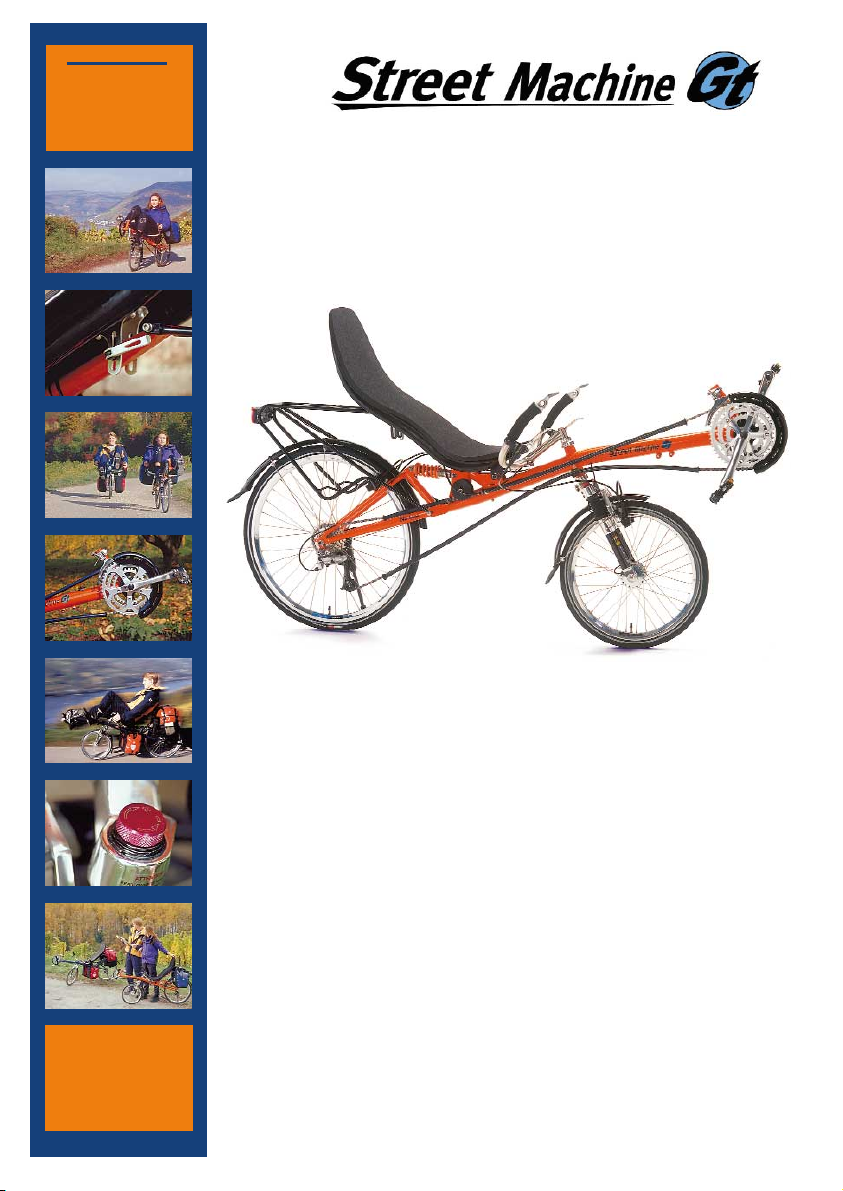

thank you for buying a recumbent bike designed by HP VELO-

TECHNIK and congratulations on the purchase of your new

Street Machine GT! With the Street Machine GT, a high-quality

touring bike, you will enjoy many years of exhilarating riding

pleasure.

Your safety and your satisfaction are our main concern. On the

following pages, this manual will inform you about important

safety issues as well as maintenance and care instructions.

Even if you have many years of experience with bicycles please

do take your time to read this manual carefully before the first

ride.Your recumbent bike is designed with the latest bicycle

technology by HP V

ELOTECHNIK that partly needs special treat-

ment and care.

In this manual you will find detailed instructions on how to

optimize your Street Machine GT to meet your demands and

riding style as well as your size and weight.

In addition to this, we have put together a collection of information on care and maintenance as well as special technical advice from our engineers.

This guide helps you to keep your Street Machine GT in perfect

condition so that you will always have maximum fun, comfort

and safety.

Enjoy yourselves and have a great ride!

Paul J.W. Hollants, Dipl.-Ing. Daniel Pulvermüller

and the HP V

ELOTECHNIK team

1

HP

Velotechnik

Introduction

Dear customer,

To this user manual also belong the original

manuals of component manufacturers such as

the brake manufacturer, the gear system manufacturer and the pedal manufacturer.These manuals tell you in detail how to operate and

maintain those specific parts. Please do read

the manuals of the part manufacturers as carefully as the manual on hand. Please have other

users of your recumbent also read the manuals before using the bike.

The maintenance and adjustment of this recumbent partly require special tools and skills.

Do only work within your limits and, in the

interests of your own safety, do not go beyond. Should you be uncertain at any point, get

in contact with your local dealer.

The instructions in this manual apply only to a

completely assembled Street Machine GT with

standard parts from the series production of

HP VELOTECHNIK.

On special demand HP V

ELOTECHNIK delivers

frame kits with which a specialist dealer can

assemble a bicycle individually. In this case the

manuals on the operation and maintenance of

the parts only represent a guideline, please do

read every manual of every part manufacturer.

The specialist dealer is responsible for the expert assembly, please contact him for detailed

advice! A bicycle that has been assembled from

a frame kit must always be tested and approved by a qualified bicycle mechanic before your

first ride.

Introduction

2

HP

Velotechnik

Caution! The texts in the gray boxes are

particularly important for your safety.Texts

that begin with "Danger!" mark an immediate danger for your life and your health.

Please do read them carefully.

General safety instructions

3

HP

Velotechnik

Legal requirements

When you ride your bike on the public road it

must comply with national legislation and guidelines.These will vary from country to country.

In general, there are minimum standards for

brakes, reflectors and lighting systems, as well

as usually a general duty to ensure that your

vehicle is in roadworthy safe condition.There

will also be a duty to ride in a safe and responsible manner. If you ride your HP V

ELOTECHNIK

bike in traffic you should be sure to observe

all the applicable laws and regulations.

In most countries, including Germany and the

UK, two independent braking systems are required. Do not ride with only one brake working!

Please contact your local dealer to find out about your legal obligations.

General Safety Instructions

Intended use

Your Street Machine GT is a bicycle for the

use on streets and surfaced roads.

This bicycle is not designed for the use in racing and off-road riding, for jumping or acrobatics, and you must not ride across kerbs, stairs,

etc.

Damage through inappropriate use, assembly

errors, accidents or similar activities and willful

damage results in the loss of any warranty.

The intended use also includes the precise observation of the prescribed usage and maintenance regulations and instructions.

The first miles

The first 300 km are an important phase in

which you break in the bicycle. During the first

use of a new bicycle the screws may bed in

and come loose. Cables and spokes may

stretch. Please be very attentive during that

period.

After 300 km or after two months at the latest you will have to take your bicycle to a bicycle mechanic for the first service. Please record this first service and the tasks performed

in the warranty pass on page 57.This first service is the prerequisite for further use of the

bicycle and for your warranty claims.

4

HP

Velotechnik

Load capacity

The maximum load (rider + luggage) is 120 kg

(276 lbs).The maximum total weight (bicycle +

rider + luggage) is 140 kg (322 lbs).The lower

limit is valid. It is important to adjust the

spring stiffness of the suspension according to

the load, see the chapter about adjusting the

suspension in this manual, page 16.

Carrying luggage

Luggage transport is only allowed with the

special rear racks, lowrider racks and luggage

boxes offered by HP Velotechnik .

Maximum load:

Rear rack 25 kg (57 lbs)

Lowrider under the seat 25 kg (57 lbs)

Luggage box (Speedbag) 10 kg (23 lbs)

When a rear rack or a Speedbag is mounted

you have to make sure that when the rear suspension is fully compressed there is at least a

1 cm (

1

/3") distance between the rear tire or

mudguard and the rear rack. If you want to increase this distance you have to decrease the

suspension travel of the rear suspension element with clip-on spacers. For that purpose

please consult your local dealer.

Additional loading can influence thehandling of

your bike considerably. If you plan on riding

with heavy luggage we advise you to make a

test ride on a street with no traffic to adjust

to the new situation.

The load should be placed as close to the body of the rider as possible, since this leads to a

more stable performance.You can also improve the handling of the bike by positioning the

center of gravity of the luggage as low as possible, so pack heavy items in the bottom of

your panniers. Hang heavy panniers on the lowrider rack preferably to the rear rack.

Be careful that your luggage on the racks or in

the Speedbag is safely stored. Bags must be

tightly fastened to the rack so they can not

move. In no case may loose parts like straps or

belts touch the wheels, the derailleur or the

suspension.

We recommend waterproof bicycle bags by

the German manufacturer O

RTLIEB.You can buy

them with extra large hooks matching the

oversized tubes of the rack.You can also refit

those large hooks later.

Take care that your luggage does not cover

the lighting system and the reflectors of your

bicycle and that they stay fully functional.

In case you want to park your bicycle take care to lean it on a wall or any other solid object.With the kickstand alone it is not possible

to safely park a bicycle loaded with luggage, it

could fall down and be damaged.

General Safety Instructions

General safety instructions

5

HP

Velotechnik

Transport in the car

The best way of transporting your bicycle is

inside the car. See that it does not lie on the

derailleur.

If you want to transport it outside the car we

recommend a roof-rack or a rear carrier.Take

care to fasten your bicycle at the frame only.

Please remove any part that could come loose

during transport (seat cushion, water bottles,

luggage bags, pumps, pennants, etc.).

Do not take kids with you

The Street Machine GT is not designed for the

transport of children.You are not allowed to

mount a child's seat. It is only allowed to

transport children in a trailer that has been

specially designed for that purpose.

Trailers

You are allowed to use trailers up to 30 kg (68

lbs) with the Street Machine GT. Always check

that the suspension and the trailer still work

properly after you have mounted the trailer.

Take care that the trailer does not damage the

frame in case the bicycle falls over.

Added parts and accessories

Additional accessories may impair the function

of your Street Machine GT. We advise you to

generally ask your dealer before you mount

any special parts or accessories to your bicycle.

Take care that the handlebar and the suspension always stay mobile.You may not add any

parts to the handlebar or the seat that might

endanger the rider through sharp edged or

pointed shapes while steering, getting on and

off the bike or bumping against something.

Before you purchase a bell or a lighting system

make sure that these accessories conform to

your national laws and regulations.

Fairings

As front fairing for the Street Machine GT, you

may use the Streamer offered by HP

V

ELOTECHNIK. Please take care to assure a good

vision over the fairing and sufficient freedom

of movement below.

Please take into account that any fairing makes

the bicycle more prone to crosswind influences. In strong wind or gusts of wind unsafe situations may occur. Please remove the fairing

in such weather conditions before riding.

Caution! Do not fasten your bicycle at the

handlebar or, with disassembled wheels, at

the dropouts.The wind causes violent forces

that can stress the parts and therefore may

cause damage. Such damage may not be noticed immediately.

Caution! Mounting additional parts or accessories is at your own risk. It is important

that you carefully read the installation guide

of the manufacturer.Additions to the handlebar like fairings, handlebar fittings, bottle holders, etc. may impair your safety due to additional loading or clips with sharp edges.

6

HP

Velotechnik

Replacement of parts

The replacement of parts relevant for safety

(especially brakes, light system, stem, handlebar,

fork, drive train, suspension elements) should

only be done with original parts by a bicycle

mechanic, since it requires a certain degree of

skill, suitable tools and mechanical aptitude.

Any technical change you perform on your

own is at your own risk!

No alteration of parts

Final assembly

Your bike has been delivered to your specialist

dealer only partly assembled.

Your dealer has carefully finished the assembly,

perhaps altered the spefication of your bike to

meet your special requirements and performed a test ride. Please make sure that this

pre-delivery service is recorded in the warranty document at the end of this manual.

All screws must be checked and tightened, especially on the handlebar, stem, fork, swing arm

pivot and wheels. Please follow the tightening

torque settings listed in the table on page 55.

Rear derailleur and brakes must be checked

and adjusted. Please follow the instructions in

the manuals of the parts manufacturers that

come with this manual.

Screws and bolts

General Safety Instructions

Danger! If any part is deformed (e.g. due to

an accident or overload), especially frame,

fork, handlebar, seat mounts, pedals, cranks

and brakes, it is not allowed to use it any

further or repair it. Do not try to straighten

bent parts.You must replace them for your

own safety. If you do not replace a damaged

part it can result in a total failure of the part

and you may be seriously injured!

Caution! You are not allowed to perform

any work on the parts of the bicycle, especially frame, fork, handlebar and seat, which

might endanger their solidity.

These works include drilling holes, welding,

brazing, paint methods that add heat or any

other chemical treatment. If any of these

works is done improperly it may result in a

loss of strength through direct damage or

increased susceptibility to corrosion.

Caution! Screws must be tightened with

prescribed tightening torque. In this manual

tightening torques are given in "Nm“

(Newtonmeter).Always use a torque

wrench wherever a torque setting is given in

this manual. Never rely on "feel". Screws

tightened too much or not enough can

break, which can lead to dangerous accidents. In case you don't own a torque

wrench have your bicycle mechanic do the

respective work.You will find a table with

the prescribed torque settings on page 55 in

this manual.

Adjusting your new bike

7

HP

Velotechnik

Before the first ride: adjusting your

new Street Machine GT

The seating position is essential for your riding

comfort, well-being and efficient cycling on the

Street Machine GT.Therefore you should adjust the frame, seat, handlebar and suspension

to your individual requirements.

In order to adapt the Street Machine GT as

closely as possible to your body dimensions

and to find the ideal seating position you need

to adjust the front boom, seat and handlebars.

Adjusting the leg length: moving the

front boom

In order to adjust the leg length you have to

move the front boom (the front part of the

frame where the cranks are mounted) within

the main frame. Unscrew the screw M8x35 under the main tube with a 6 mm Allen key.Take

a grip on the front changer tube or both

cranks and move the front boom into the frame or pull it out while cautiously turning it.

When you pull out the front boom shift the

chain on the smallest chain ring and sprocket

and turn the cranks a little bit backwards while pulling.Thus the chain is not under tension.

Adjusting the leg length

Danger! All procedures described here re-

quire a certain degree of skill, suitable tools

and mechanical aptitude.After any adjustment perform a static check and take a testride on a quiet street, away from traffic. If

you have any doubts please contact your local dealer.

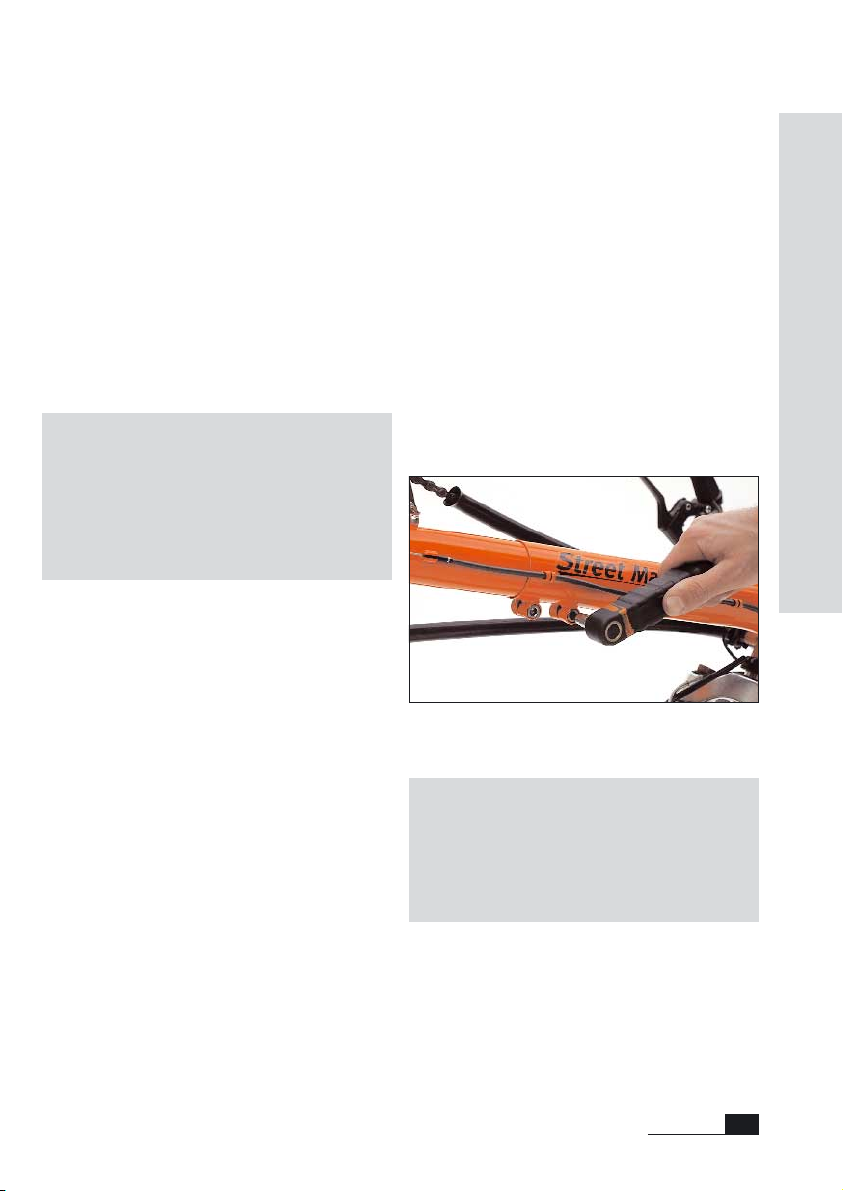

Caution! After you have unscrewed the

clamping screws take them off and examine

them for deformation. Lubricate threads and

heads thoroughly.Then re-fit the screws. If

they don't turn easily you will have to replace the screws.

Unscrew the clamping screw to adjust the front boom.

8

HP

Velotechnik

In order to check the adjustments have another person hold the bicycle while you are sitting on the recumbent.

Adjust the front boom in such a way that your

leg is fully extended when your heel (wearing

flat shoes) is in the foremost position on the

pedal. Experience shows that the pedal-to-seat

distance on a recumbent can be slightly longer

than on a conventional bike.

While you are pedaling, the ball of your foot

should be positioned over the center of the

pedal axle.

It is important that your leg is not fully straightened when the crank is in the foremost position. If the distance is too great it is difficult to

overcome this dead point, pedaling becomes

uncomfortable and there is too much strain on

the sinews of your feet and legs. If the distance

is too short you may suffer from knee pain or

your legs bump on the handlebar.

For riders with a short leg length the front

boom has to be cut by a bicycle mechanic, so

that it can be inserted to the maximum. It is

important to trim the end of the tube neatly.

The bare metal of the shortened tube end has

to be protected against corrosion with a paint

stick or wax spray.

The opening of the main frame is padded with

a plastic paper sleeve that accomplishes the required clamping and protects the surface of

the front boom.When the front boom has

been completely removed take care not to damage the plastic paper adding while inserting it

again.

Adjusting the leg length

Adjust the front boon so that your knee will not be fully straightened when pedaling.

Caution! The minimum insertion depth of

the front boom into the main frame is 10

cm (4"). In no case may the end of the front

boom be visible in the clamping slot when

you look at the main frame from below, since it may result in a damage of the frame.

The rear end of the front boon must never be visible in the clamping slot.

Adjust the front boom so that the bottom

bracket axle is horizontal when you look at it

from the front. For that purpose look beyond

the bottom bracket shell at the rear wheel axle and align the front boom parallel to it.Align

your eyes with the bottom bracket axle and

not the front changer tube above.Then sit on

your bicycle and check the position. (Hint:

When you have the impression that the bottom bracket is turned alternately to the left

and then to the right when cycling you will have found the correct middle position).

Tighten the screw with a torque wrench (tightening torque 14-16 Nm). On your first ride

check whether there is sufficient clamping.

In order to move the bottom bracket tube

your specialist dealer has to adjust the chain

length. By default the Street Machine GT comes with a very long chain so that the adjustment range of the bicycle can be fully used without the need to lengthen the chain.

After the first adjustment of the leg length that

you have done together with your specialist

dealer while handing over the bicycle, the

chain has to be shortened so that the arm of

the derailleur is not fully turned forward while

shifting on the big chain ring in front and the

big sprocket behind.The derailleur must still

be able to compensate a length change of the

chain of at least 4 cm. In order to choose the

right chain length, please consult the manual of

the derailleur manufacturer.

Adjusting your new bike

9

HP

Velotechnik

Danger!If the screw is tightened too much

or bent, the screw can break! If the clamping

is insufficient the front boom can turn during a ride which may cause your feet to slip

from the pedals and lead to a dangerous fall.

Danger! After the chain has been shortened it has to be closed with a special closing

link or a chain riveting tool that expands the

rivet while riveting (i.e. R

OHLOFF- Revolver).

A poorly joined chain may break and thus

lead to a fall. Have adjustments of the chain

length or the changing of the chain be done

by your bicycle mechanic.

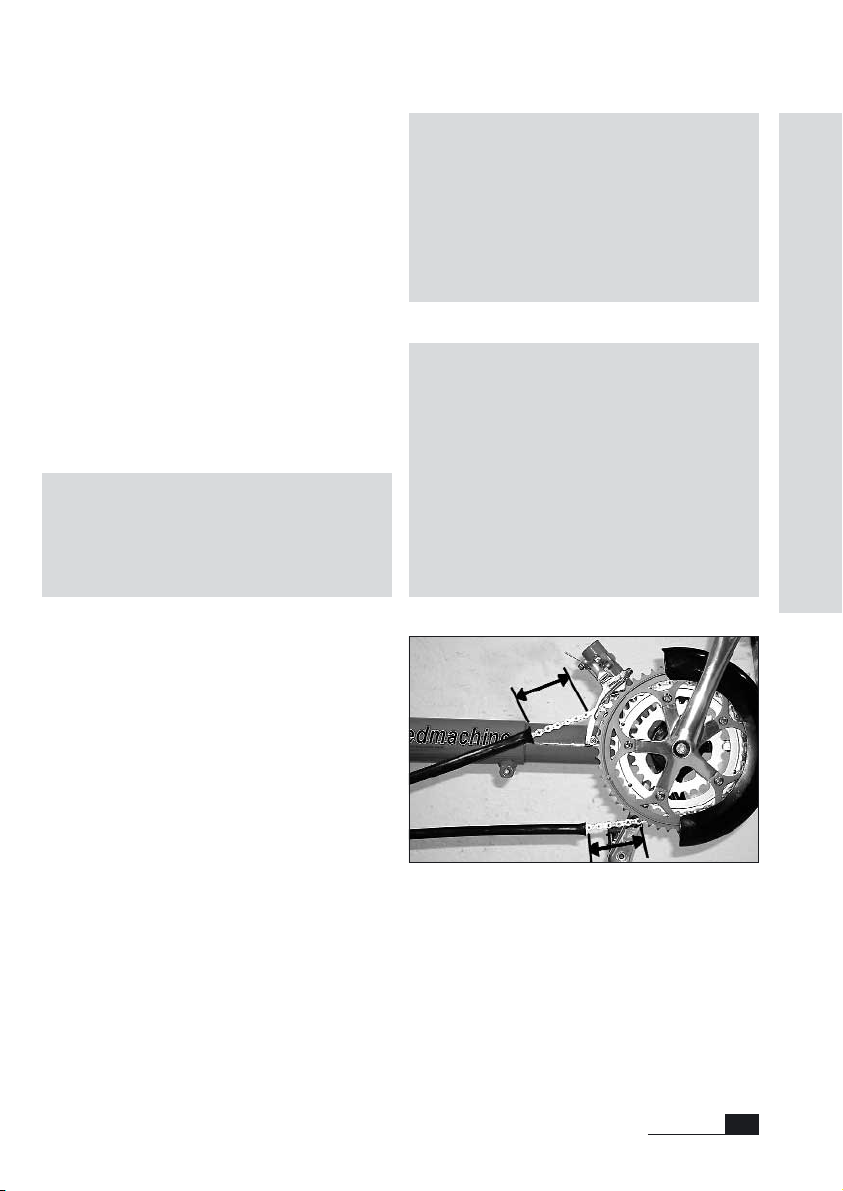

Caution! Take care that the chain tubes have at least a clearance of 5 cm (2") to the

rear derailleur and the front changer even

under maximum tension of the chain and

that the tubes stay tight in their fastenings.

Shorten the tubes if necessary. If the end of

the chain tube gets into the rotating drive

train it could be locked-up and destroyed.

The end of the rear chain tube has to be

tightly secured with a cable tie behind the

retention spring.

Check that there is at least a 5 cm (2") clearance between the

end of the chain tube and other parts of the drive train.

10

HP

Velotechnik

After you have adjusted the front boom you

should seal the gap in the clamping slot between the front boom and the main frame with

wax or silicone in order to protect your frame

from the penetration of water and dirt and

hence damage through corrosion which may

lead to a broken frame.

We recommend you to slightly readjust the

front boom every 3 months so that knee, muscless and ankles will be used differently, and

you might find a more comfortable and more

efficient riding position.

A wrong adjustment may lead to pain in your

knees and inefficient pedaling. In addition we

recommend to ride with a high pedaling cadence, which means to pedal fast and with little pressure. Pedaling with too much pressure

may also lead to pain in the knees.You will find

more information about this on page 26.

Adjusting the leg length

Adjusting your new bike

11

HP

Velotechnik

Choose the right size

The selection of the right seat size and the

proper seat angle is crucial for a comfortable

feeling while riding a recumbent.

By the time you read this manual, you will already have chosen the correct seat size together

with your specialist dealer. In the following

section you will find the most important items

very briefly, in case you don't feel comfortable

with your current seat size.

The upper curve of the seat in the area of the

shoulder blades determines the correct seat

size:Through this shape the shoulder and neck

area is lifted from the recumbent position so

that the head rests in a natural and relaxed

position. For this reason you shouldn't need a

head rest if you have the right seat position. In

practice, a head rest is not very advisable because it makes it difficult to turn your head to

see the traffic behind you and it transfers unpleasant vibrations, even on a well suspended

bicycle.

In order to adjust the seat to your back length

the seat comes in four different sizes:

Approximate values are: Under a height of

1,73 m (5' 8") we recommend seat size S, up

to 1,83 m (6' 4") height seat size M, up to 1,93

m (6' 7") height seat size L, and above we recommend seat size XL. Since however the

length and the shape of the back differ from

person to person we recommend you to carry

out an extensive test ride before ordering. If

you are in doubt we advise you to choose the

larger size, since it will be more comfortable in

most cases.

The seat is too small when you have the impression that your back is pressed too much

into a "hunchback". It is too large when you

have the impression that the seat angle is too

far back when you are in the most upright position, or when you hit the upper seat edge

with the back of your head when you look upwards. Please note that our seat sizes only refer to the length of the seat; the seat width remains the same on all sizes.

Altering the seat shape

You can alter the seat shape individually to

match the shape of your back by adding foam

material under the seat cushion.The seat has a

special channel down the center for your spine

with an extra layer of foam for the spine in the

seat form.Thus, the spinal processi of the vertebrae are comfortably padded. Some people

have single vertebrae that stick out particularly. If your spine is like this you can cut out some padding material at the respective spot in

the spine channel.

The foam cushion in the spine channel is fastened with Velcro and is thus adjustable. Some

users find it comfortable when the seat rises a

little bit at the front edge.This raise gives a

little more hold to the front and can reduce a

possible feeling of slipping out, especially when

the seat position is upright.You can try it out

by fastening the foam cushion so that the lower end under the seat cushion forms a little

bump.You can purchase a special add-on for

your seat to permanently form such a bump.

Adjusting the seat position

HP VELOTECHNIK’s seats feature a special channel for the spine.

You can individually adjust the padding.

12

HP

Velotechnik

Adjusting the seat angle

A big advantage of the Street Machine GT is

that you can adjust the seat angle very quickly.

For beginners or rides in the city you can

choose an upright seat position for a better

view, and for longer travels you can choose a

flat position for better aerodynamics.

The seat is fastened with two quick release levers on slotted aluminum seat mounts.You can

adjust the angle by 10 degrees by simply opening the two quick release levers. In the medium seat position the angle is about 35° from

horizontal.

Because of the special cam shape of the two

slotted holes, the seat effectively pivots around

a central axis, approximately in the area of the

lower lumbar vertebrae.This is the place where you support the biggest part of your pedaling force while riding, so this point determines

the distance to the pedals.The advantage of

this design is that you adjust the distance from

the seat to the bottom bracket only once as

described above, a change in the seat angle

does not require an adjustment of the front

boom.

Adjusting the seat with mounted

Speedbag

A mounted Speedbag impedes the access to

the rear quick release for the adjustment of

the seat angle.

Therefore you should adjust your seat prior to

mounting the Speedbag.You have to screw the

Speedbag to the seat afterwards.

It is possible to simplify the adjustment of the

seat by replacing the knurled nut of the rear

quick release by a big washer and a self-locking

hex headed nut.This allows you to tighten or

loosen the seat mounts with a tool you insert

from behind.

Adjusting the seat position

Caution! The two quick releases have to be

closed firmly (tightening force 15-20 kg / 45

lbs) to safely hold the seat.You are not allowed to open them while riding.After they

have been closed the imprint "close" must

be visible. If the quick releases are not tightened appropriately the seat can move while

riding and you may no more be able to

handle your bicycle.

Adjusting your new bike

13

HP

Velotechnik

Adjusting the handlebars

As standard equipment the Street Machine GT

comes with under seat steering.The position

of the handlebars is under the legs.

Alternatively, we offer above seat steering

where the handlebars are above the legs.

The handlebars are connected with the front

fork through a stem.There are different stems

for under seat steering in use:

a) a vertically adjustable stem that is inserted

in the steerer tube

b) a stem that is clamped onto the steerer

tube and at the same time fixes the

steering head bearing (so called "A head

stem")

Starting at the fork, both stems have to point

backwards to the seat.

a) Adjusting the stem - vertically adjustable

stem

Remove the rubber plug and undo the hex-headed screw that lies below. If the stem still

doesn't move then you can undo the clamping

in the stem shaft with a gentle punch on the

Allen key.

Mount your bicycle, fix the front wheel with

your feet and align the stem parallel to the

front wheel.

At the same time insert the stem so far in the

steerer tube that the handlebars move freely

under the seat even when the seat is in its

most upright position.The minimum distance

between seat and handlebars is 5 mm.Take care that the minimum distance between the

handlebar clamping at the stem and the frame

of your bike is 5 mm.

Adjusting the handlebars

Tighten the screw with 14-16 Nm. Check the

clamping by trying to turn the stem against the

front wheel. Remount the rubber cap.

b)Adjusting the stem - A head stem

The A head stem is clamped onto the steerer

tube with two screws.At the same time it fixes the steering head bearing.

Adjusting the stem

In case you only want to adjust the already

mounted stem parallel to the front wheel you

don't have to undo the screw on the cap.

Mount your bicycle, fix the front wheel with

your feet and align the stem parallel to the

front wheel.

Then tighten both clamping screws alternately

with 8-10 Nm. Check the clamping by trying

to turn the stem against the front wheel.

Check the play of the steering head bearing,

see below.

Danger! Adjusting the stem also requires

some work at the steering head bearing. In

case of assembly errors the danger of accidents is increased. If you are in doubt have

your bicycle mechanic adjust the stem.

Danger! The hex-headed screw in the cap

adjusts the play of the steering head bearing.

This screw does not help to clamp the stem

tightly to the steerer tube. It does not secure it against turning.Take care that both

clamping screws on the side are tightened as

prescribed after you have finished your

works at the stem. Otherwise the stem may

turn while riding and cause an accident.

Adjusting the head set bearing play

The head set bearing has to be adjusted so

that the fork with the front wheel turns easily

without showing play.

To check the bearing play pull the front brake

and grab with your other hand the upper bearing cup. Now move your bicycle back and

forth. If the steering head bearing has play the

upper cup moves noticeably in contrast to the

fixed part. In that case undo the clamping

screws and tighten the screw in the cap a bit

more.

To check whether the front wheel turns

smoothly lift your bicycle at the frame so that

the front wheel moves freely above the

ground. Lean your bike to the side. Now the

handlebars should moove smoothly immediately.When you hold the frame straight and

push the handlebars slightly they should move

smoothly from their middle position. If the bearing is too tight undo the clamping screws at

the side and loosen the hex-headed screw in

the cap a little bit by turning it anti clockwise.

Now move the stem upwards by swinging it a

little bit.

After you have adjusted the bearing play check

if the stem is adjusted in a parallel position to

the front wheel and tighten the two clamping

screws alternately with 8-10 Nm. Check the

clamping by trying to turn the stem against the

front wheel.

Check whether the handlebars move freely without touching the frame or the seat.

14

HP

Velotechnik

Removing/mounting the stem

Remove the lower quick release of the seat

mount and lift the seat.

Take off the cap of the steerer tube and remove the hex-headed screw in the cap completely.

Undo both clamping screws at the side of the

stem. Now you can remove the stem upwards.

To mount the stem put it on the lubricated

steerer tube.Tighten the clamping screws at

the side a little bit, put on the cap and tighten

the hex-headed screw again through the cap.

Adjust the steering head bearing. (see below).

Then tighten the two clamping screws alternately with 8-10 Nm. Check the clamping by trying to turn the stem against the front wheel.

Adjusting the handlebars

Caution! The stem fixes the steering head

bearing and holds the front fork with the

wheel.After the stem has been removed

these parts are no longer supported and

may fall down off the frame. Hold the fork

with one hand or secure the fork e.g. with a

cable tie at the frame.

While riding you should allow your arms to

rest in a relaxed position on the handlebars.

Do not pull on the handlebars. If the handlebars turn in the stem clamping during the ride

stop immediately and tighten the clamping

screw of the handlebars again. If the handlebars turn in a stem that is not sufficiently

clamped the handlebars or the stem might be

damaged or deformed. In that case a secure

clamping of the screw can no longer be guaranteed, even with the correct tightening torque, and handlebars and stem have to be exchanged.

You can make smaller adjustments by moving

the cables in their guides at the frame and the

handlebar, so that there is enough room at all

mobile parts. For this purpose you can move

the cable for the front changer a little bit into

or out of the frame. If this proves not to be

sufficient you will have to have your specialist

dealer shorten the cables or replace them by

longer cables.

Handlebar grips

The grips on the handlebar are susceptible to

wear and tear. Have your grips replaced by

your bike shop once they don't feel comfortable anymore.The grips always need to be attached firmly to the handlebar.

Adjusting your new bike

15

HP

Velotechnik

Adjusting the angle of the handlebars

By changing the angle of the handlebars you

can adjust the position of the grip to the

length of your upper body and your arms.

Most riders are comfortable with a 45° angle

so that the grip points diagonally to the front

and up.The more upright the grip position the

lesser is the maximum possible cramp of the

handlebars, since it touches your legs earlier.

In order to change the angle, undo the screw

of the handlebars clamping by some turns.Turn

the handlebars until they are in your favorite

position. Check that the stem clamps the

handlebars exactly in the middle.Tighten the

clamping screw with 10-12 Nm. Check the

correct clamping of the handlebars by mounting your bike and pulling the handlebars. In

doing so they must not turn.

Please take care that the clamping area of the

stem is thoroughly trimmed and does not have

any sharp edges which may lead to a rupture

of the handlebars.

Caution! After you have adjusted the handlebar position you also have to adjust the

length of the brake cables and shifter cables.

The cables have to run smoothly without

any sharp turns and they may not be bent or

stretched beyond their elastic limit when the

handlebar is at maximum cramping.Also avoid large arches that could be caught up in

other parts.

Danger! Every time you undo the clamping

connection you'll have to check the screw. It

must not be bent, corroded or damaged. In

addition to this you'll have to check the welded-on thread nut of the clamping.The thread must not be damaged and the screw

must turn easily. In case of damage or deformation you have to exchange the clamping

screw immediately.

16

HP

Velotechnik

Purpose of the adjustment of the

suspension

Your Street Machine GT is fitted with a suspension fork for the front wheel and a rear

swing arm for the suspension of the rear

wheel.This system compensates small bumps

on the road so that riding is comfortable and

the strain on your bicycle is reduced.

A well-adjusted suspension improves the traction of your bicycle. Especially in bends this

does not only allow a higher speed but it also

increases your safety.

In order to achieve maximum riding comfort,

the suspension settings have to match your

weight as well as the road condition.

The goals of the adjustment are:

● maximum use of the available suspension

travel without the suspension frequently

bottoming out

● quick reaction of the suspension without

obvious oscillation after having passed

a bump

● avoiding self inforcing oscillations, that means

increasing oscillations of the suspension

system due to pedaling influence, rhythmic

body movements or permanent wavy

underground

Suspension and damping

The suspension systems of the suspension fork

and the rear swing arm are fitted with the actual springs and dampers, which are mounted

separately.

Often, the terms suspension and damping are

used inappropriately in everyday language.

The spring is the elastic element that compresses and decompresses through the load,

which occurs on bumpy roads.While decompressing the spring releases the same energy it

has saved during compression.

The Street Machine GT is fitted with coil

springs of steel at the suspension fork and the

rear fork swing arm. In addition to this the

suspension fork contains springs made of microcellular foam elastomers. (MCU).

The damper slows down the process of compression and decompression.That means that

the bicycle after having passed a bump does

not immediately "spring" back to the initial position or even further than that.The damper

converts spring energy into friction and finally

into heat, and thus takes away energy from the

suspension system.That way the damper prevents that the spring swings uncontrolled after

an initial stimulation. In addition the damper

helps to avoid self inforcing oscillations of the

suspension that may be caused by reoccurring

stimulation like pedaling forces within a crank

revolution or the rhythmic up and down movement of the legs.

The hydraulic damping of the rear suspension

is adjustable, in case you have mounted the optional suspension element DMM ST8ARC.

Adjusting the suspension

Adjusting to load

The luggage carriers of the Street Machine GT

are mounted to the suspended part of the frame.That way your luggage is also fully suspended and it spares the material. Most notably,

even under heavy load the suspension will

compensate an uneven road much better and

quicker compared to a design where the luggage carrier would be mounted to the unsuspended parts, e.g. the rear swing arm.

Additional luggage changes the load of the

wheels and their suspension.The suspensions

are more compressed through the load.That

way, there is less suspension travel for bumps

while riding.Your suspension could seize up

more often.

The suspension of the front wheel is less affected since luggage at the rear rack almost only

puts weight on the rear wheel. Only in case of

heavy luggage on the lowrider under the seat

is there an influence on the front wheel.

In order to compensate the variations in the

load you can change the pre-load. For details

see the following chapter.

Theoretically this can compensate for a load

change of approx. 10 kg (23 lbs) at the rear

wheel. In case of higher variations in the load

you would have to exchange the spring for another spring with another spring stiffness. In

practice you can often do without it: the

Street Machine GT offers with 90 mm (3

1

/2") a

lot of suspension travel for a touring bike.

When you choose the spring stiffness so that

the full 90 mm are at your disposal when your

recumbent is under maximum load, you will

have a somewhat smaller but still very comfortable suspension travel when you ride without

luggage.

Adjusting your new bike

17

HP

Velotechnik

You should always set the damping as low as

possible to give the bicycle the possibility to

quickly react even to several bumps in a row.

You can ride the Street Machine GT with a

considerably lower damping than for example

a MTB: due to the relaxed and steady position

of the body the recumbent does not experience extreme variations in the load as it is

known from dancing on the pedals while riding

uphill on a mountain bike.

In addition to this, varying pedaling forces have

very little influence on the suspension of the

bicycle due to the No Squat design of the suspension system of the Street Machine GT. So

when you adjust the damping, always start with

a low damping.

It is necessary to choose the correct spring

stiffness to have a well operating suspension

system.The spring stiffness is a measure for

the compression of a spring at a certain load.

It is either given in "N/mm" (Newton per

Millimeters) or "lbs./inch" (Pounds per Inch).

Sometimes you only find "lbs." printed on the

springs.

The suspension is designed in a way that the

spring compresses considerably when you

mount your bicycle.This is called negative suspension travel and it enables the bicycle to decompress on bumpy roads. (Which is in fact a

definitely positive feature.) You should choose

a spring stiffness with which this negative suspension travel takes up around 30% of the

overall suspension travel.This value usually

provides a very comfortable ride on your fully

suspended recumbent bike designed by HP

V

ELOTECHNIK.

The knob must turn easily. If a knob does not

turn any further you have reached the final position. In that case turn the knob again in the

other direction about half a turn.

Do not turn the knob by force beyond the final position since this will damage the plastic

thread inside.

18

HP

Velotechnik

Adjusting the suspension

Adjusting the suspension fork

The front fork of the Street Machine GT comes with telescopic suspension forks from

BALLISTIC or M

EKS.

At your request different types of suspension

forks can be mounted to your Street Machine

GT, please notice the manuals of the suspension fork manufacturer that are possibly enclosed.

The suspension travel of the B

ALLISTIC fork is

approx. 40 mm (1

1

/2"), of the MEKS fork ap-

prox. 50 mm (2").

The suspension fork should compress by 30%

while mounting the bike, which corresponds to

10-12 mm.

You set this value by adjusting the pre-load of

the spring, provided you chose the correct

spring stiffness (page. 19).

Every model has a turning knob on the fork

legs that allows a simple adjustment of the

pre-load.

The suspension forks B

ALLISTIC XL-600All and

MEKS Carbon All have springs in both fork legs,

the suspension fork MEKS Carbon AC has

springs only in the left fork leg since the other

fork leg contains a hydraulic damping cartridge.

By turning the knobs clockwise you increase

the pre-load, by turning them anti clockwise

you decrease the pre-load.

It is sufficient to set the pre-load in the two

fork legs to approximately the same level. It is

not necessary to match them exactly.

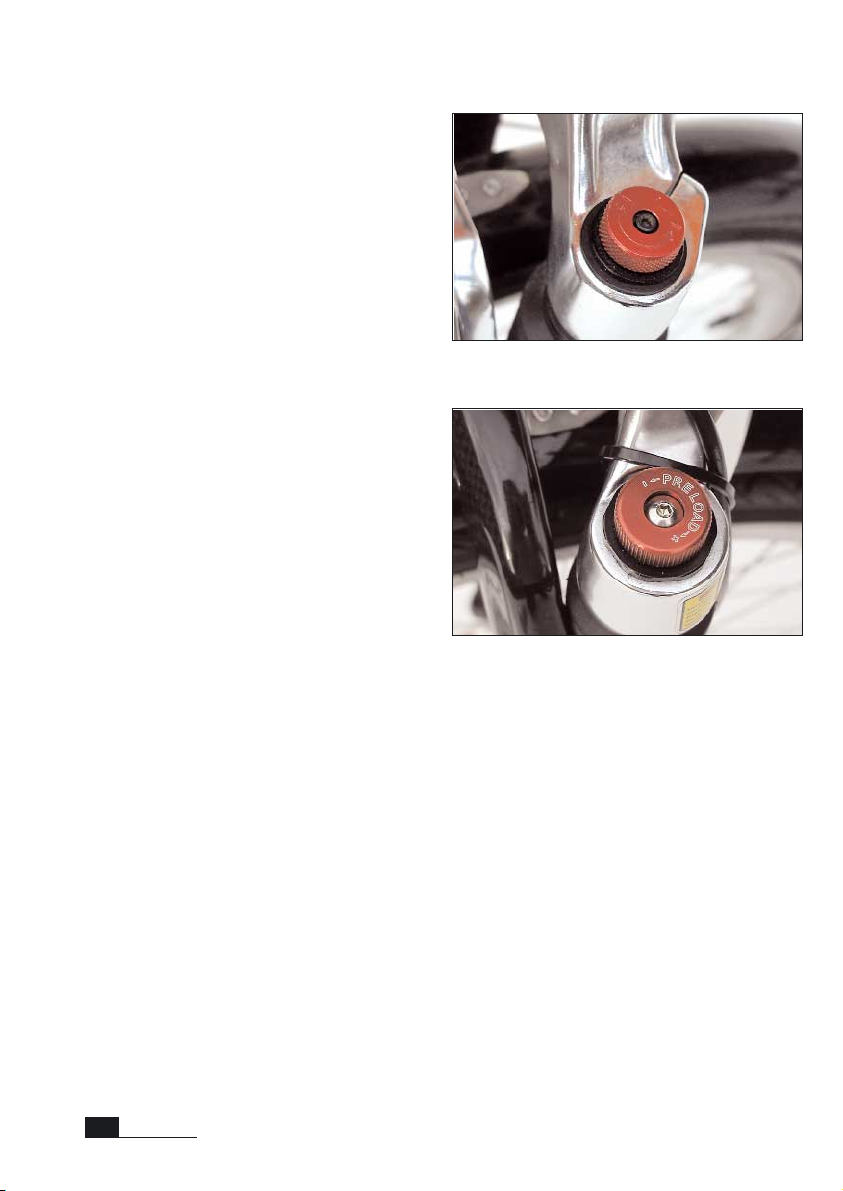

Turning knob for the pre-load of the suspension fork BALLISTIC

XL-600All

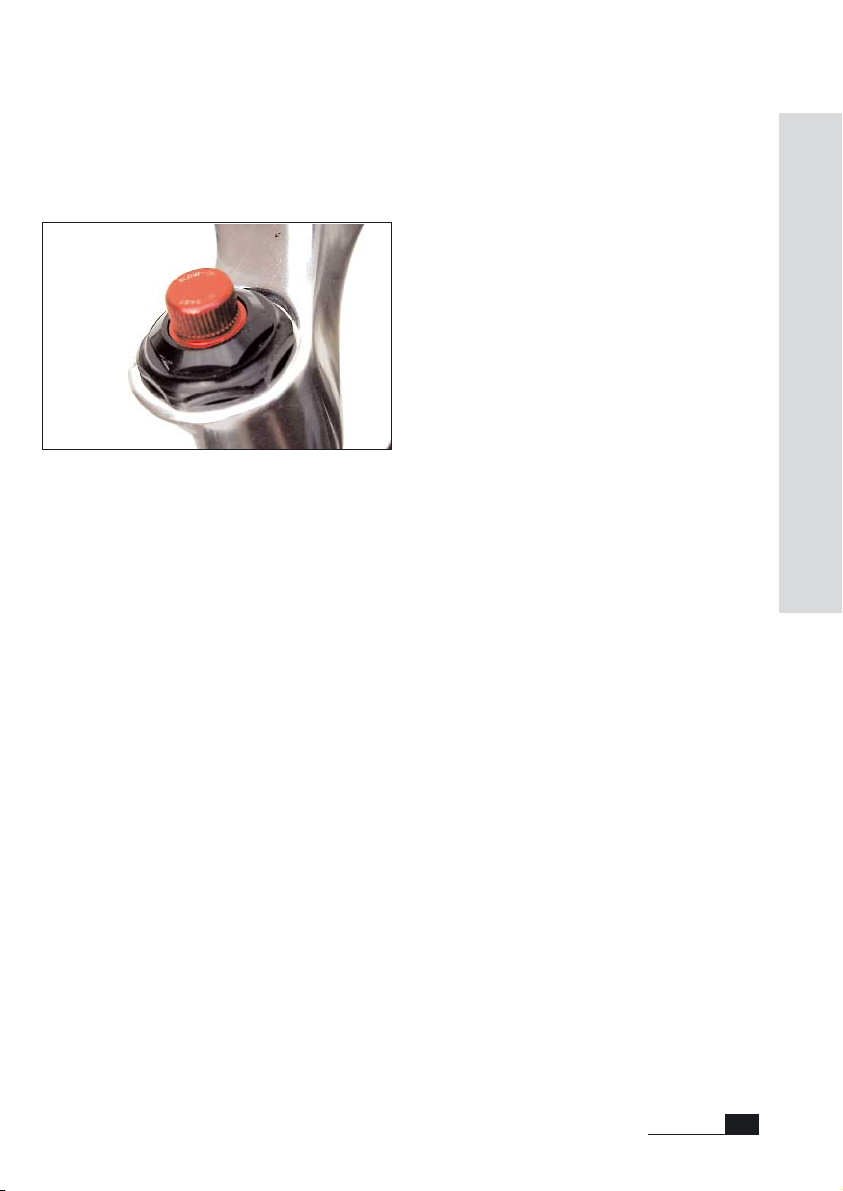

Turning knob for the pre-load of the suspension forks MEKS

Carbon AC and M

EKS

Carbon All

Adjusting your new bike

19

HP

Velotechnik

Choosing the spring stiffness of the

suspension fork

Your suspension fork comes by default with a

standard spring that covers a wide range of load and riding styles.

If the spring stiffness should not meet your requirements after adjusting the pre-load or if

the suspension bottoms out too much, you

can order a spring with another spring stiffness through your dealer and have it mounted

there. For more information see page 41.

It is not important to exactly follow the recommended values for the negative travel, rather follow your feeling how the bicycle behaves during a ride, depending on the road situation.

While riding you should only seldom feel the

suspension bottoming out. However, in case

this never occurs the spring might be to hard

which means you don't use the total suspension travel.

The suspension fork MEKS Carbon AC is fitted

with a hydraulic damping unit. On the right

fork leg is a turning knob to adjust the damping.

You increase the damping by turning the knob

clockwise.

We recommend you to start with the lowest

possible damping. Only when the fork oscillates more than once after you have gone over a

bump should you increase the damping.

When the fork works fine when passing a single bump but stiffens distinctly when passing

several bumps that come quickly in a row, the

damping is too high. However, when the fork

"jumps" during the rebound movement the

damping has to be increased.

Turning knob for the adjustment of the damping of the suspension fork M

EKS Carbon AC.

Loading...

Loading...