GSW WATER HEATING User Manual

GSW WATER HEATING

599 Hill Street West

Fergus, ON, Canada N1M 2X1

STORAGE BOOSTER TANKS

INSTALLATION AND OPERATING INSTRUCTIONS

Read and understand these instructions thoroughly before starting

TABLE OF CONTENTS

I) Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II) Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

III) Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

IV) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

V) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

PLEASE RETAIN THESE INSTRUCTIONS IN A

SAFE LOCATION FOR FUTURE REFERENCE

WARNING:

Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency, or the electric utility.

FOR YOUR SAFETY

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• Installation and service must be performed by a qualified installer, service

agency or the electric utility.

WARNING:

If the information in these instructions is

not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

GSW Water Heating is a division of GSW Water Products Inc.

PART NO. 71772 C (05-02)

I) INTRODUCTION

Thank you for purchasing this storage booster tank.

Properly installed and maintained, it will provide years of

trouble free service.

The warranty on this storage booster tank is in effect only

when the tank is installed and operated in accordance with

these instructions. The manufacturer of this tank will not be

liable for any injury or property damage resulting from failure to comply with these instructions.

IMPORTANT: Read and understand these instructions

before installing and operating your storage booster tank.

Description

The JOHN WOOD series of storage booster tanks, available in 40, 50 or 80 gallon sizes, have been designed to

supply hot water for domestic use when combined with a

tankless coil boiler or other water heating source. Each tank

is equipped with an adjustable thermostat, pre-wired and

ready for connection to a circulator pump (not supplied).

These tanks are not constructed to ASME requirements and

should not be used for such applications.

III) INSTALLATION

WARNING

Excessive Weight Hazard

Use two or more people to move and install

storage booster tank. Failure to do so can

result in back or other injury.

CAUTION

Hydrogen gas can be produced in a hot water system

served by this storage tank that has not been used for a

long period of time (generally two (2) weeks or more).

Hydrogen gas is extremely flammable and can ignite

when exposed to a spark or flame. To reduce the risk of

injury under these conditions, it is recommended that the

hot water faucet be opened for several minutes at the

kitchen sink before using any electrical appliance connected to the hot water system. Use caution in opening

faucets. When hydrogen is present, there will probably be

an unusual sound such as air escaping through the pipe

as the water begins to flow. There should be no smoking

or open flame near the faucet at the time it is open.

II) SAFETY

Relief Valve Requirements

WARNING

For protection against excessive temperatures and pressure, install temperature and pressure protective equipment required by local codes, but no less than a combination Temperature and Pressure (T&P) Relief Valve certified as meeting the requirements for Relief Valves and

Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22, by a nationally recognized test-

ing laboratory that maintains periodic inspection of production of listed equipment or materials. The valve shall

be marked with a maximum set pressure not to exceed

the maximum working pressure of the storage tank. The

T&P valve shall be rated for the BTU INPUT of the entire

system.This T&P valve may be in addition to any T&P

valve that is required on the boiler, or other energy supply

system. Install the valve into the opening provided on the

storage tank, or other approved system location. Provide

tubing so that any discharge from the valve will exit within

152mm (6 in.) above, or any distance below the structural floor and cannot contact any live electrical part. The end

of the relief pipe opening should terminate near the floor

drain or other suitable location. Do not place a valve(s) or

any other blockage or restrictions between the tank and

the T&P valve.

T&P Valve Check

Inspect the relief valve annually to ensure proper operation.

This involves opening the valve to check that it is flowing

freely and that there are no blockages and letting it snap

shut (see “MAINTENANCE” section).

Local Codes

The installation of this storage tank must be In accordance

with these Instructions and all applicable local codes.

Location

IMPORTANT:

This storage booster tank must be installed strictly in

accordance with the instructions enclosed, and local electrical, fuel and building codes. It is possible that connections to the tank, or the tank itself, may develop leaks. IT

IS THEREFORE IMPERATIVE that the storage booster

tank be installed so that any leakage of the tank or related water piping is directed to an adequate drain in such a

manner that it cannot damage the building, furniture, floor

covering, adjacent areas, lower floors of the structure or

other property subject to water damage. This is particularly important if the tank is installed in a multi-story building,

on finished flooring or carpeted surfaces. GSW WILL NOT

ASSUME ANY LIABILITY for damage caused by water

leaking from the storage booster tank, pressure relief

valve, or related fittings. Select a location as centralized

within the piping system as possible. In any location

selected, it is recommended that a suitable drain pan be

installed under the storage booster tank. This pan must

limit the water level to a MAXIMUM depth of 45mm (1 3/4

in.) and have a diameter that is a minimum of 50mm (2 in.)

greater than the diameter of the storage booster tank.

Suitable piping shall connect the drain pan to a properly

operating floor drain.

Locate the storage tank in a clean dry area close to the

water heating source and preferably central to the piping

system. Adequate clearance for accessibility to permit main-

- 2 -

tenance and service must be provided. Water lines and the

storage tank should be protected from freezing temperatures. Do not install the storage tank in outdoor unprotected

areas. It is desirable to have a floor drain nearby to permit

easy draining if necessary.

WARNING

The water heating source piping and components connected to the tank must be suitable for potable water use.

TOXIC chemicals such as used for boiler treatment must

not be introduced into the tank.

Circulator Pump

A circulator pump is not supplied. Use only a bronze body

model rated for 110/120 volts, 60Hz. Install in accordance

with the pump manufacturer’s instructions using standard

plumbing practices.

Plumbing Connections

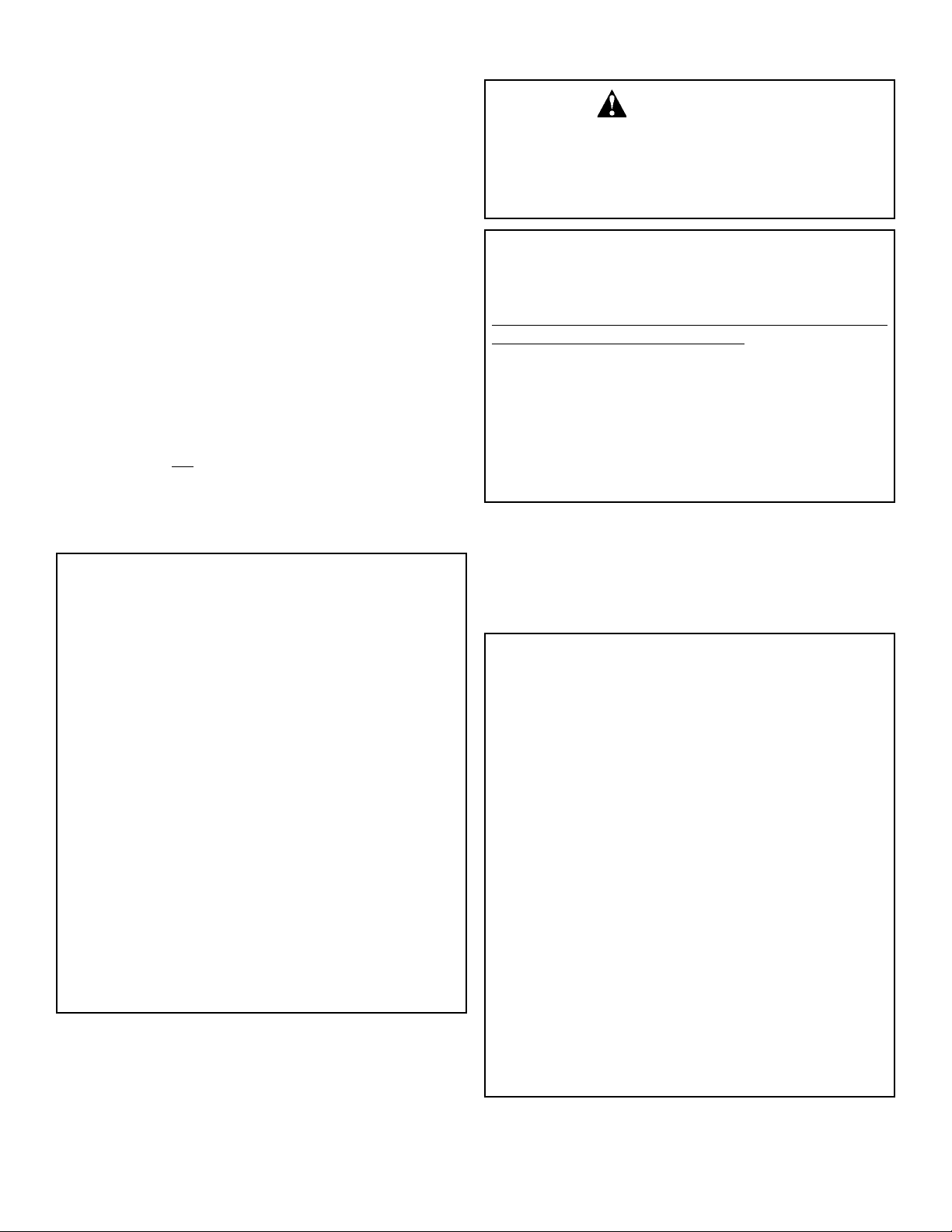

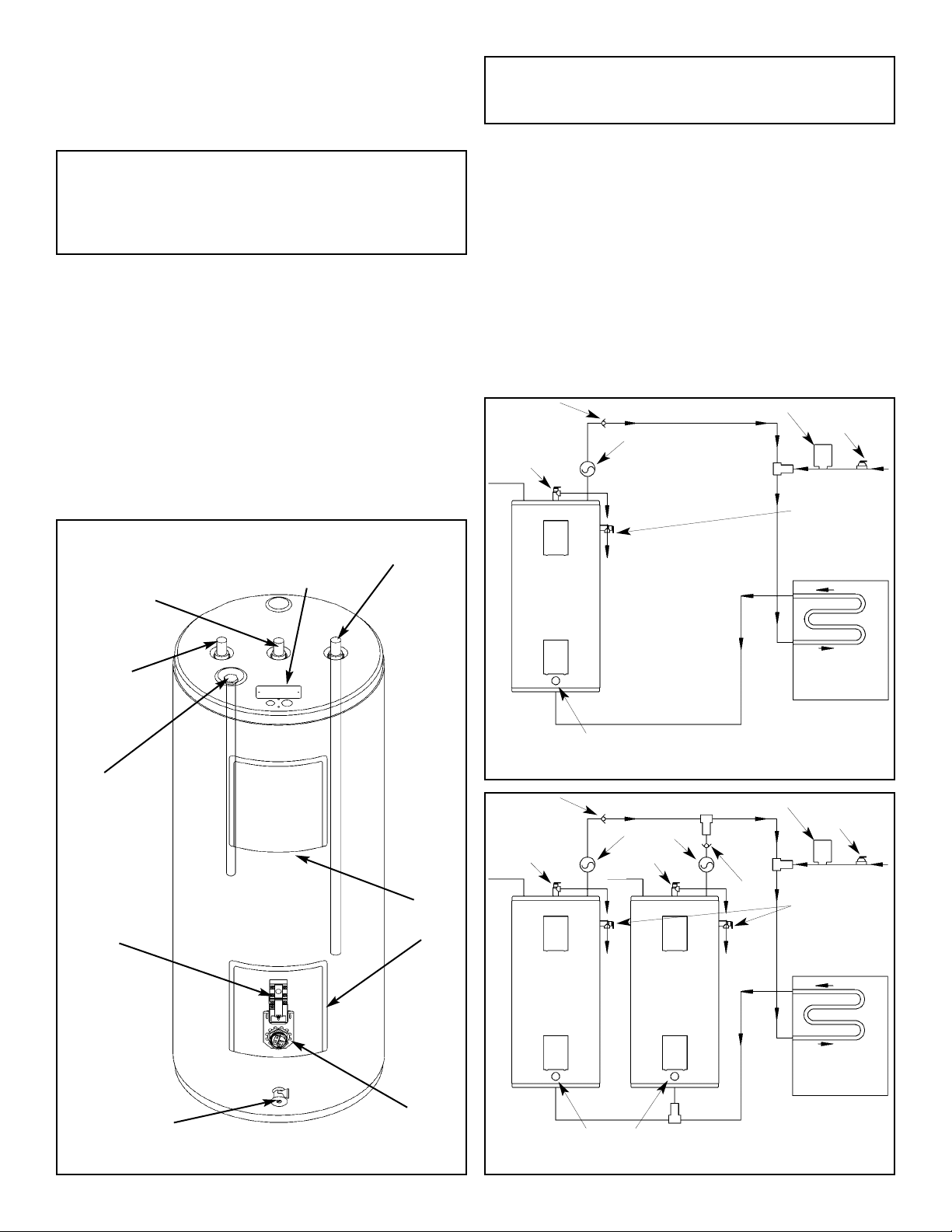

The main parts and features of your storage booster tank

are identified in Figure 1. Install plumbing according to

Figure 2 for single storage tank and according to Figure 3

for multiple storage tank systems.

1. Ensure the storage tank is level before starting installation.

T&P VALVE (SOME

MODELS WILL HAVE

A SIDE MOUNT FOR

THIS VALVE)

JUNCTION BOX

SUPPLY (TO BOILER

TANKLESS COIL)

IMPORTANT

Do not apply heat directly to tank fittings when making

sweat connections. They contain non-metallic material.

2. Install circulation loop as shown using 19mm (¾ in.)

copper pipe.

3. Install the cold water supply piping into a tee between

the circulator discharge and the boiler coil inlet.

4. Connect the boiler supply line to the combination return

and drain valve.

5. Connect hot water supply to top tank fitting.

6. Install 19mm (¾ in.), 150 psi Temperature and Pressure

Relief Valve into the tank as shown.

7. A check valve may be installed between the cold water

tee connection and the circulator. This will force the cold

water through the coil first.

NOTE: The check valve can often be noisy and cause

reduced supply pressures. For multiple storage tank sys-

CHECK VALVE

T&P VALVE

HOT

STORAGE

BOOSTER

TANK

CIRCULATOR

PUMP

EXPANSION TANK (OPTIONAL)

HOT

REGULATOR

T&P VALVE

(FOR SOME

MODELS)

PRESSURE

(OPTIONAL)

COLD

HOT

WATER

OUTLET

ANODE

THERMOSTAT

CONTROL

ACCESS

DOORS

TANKLESS

COIL BOILER

COMBINATION RETURN

& DRAIN VALVE

Figure 2: Single Storage Booster Plumbing Diagram

CHECK VALVE

T&P VALVE

HOT

STORAGE

BOOSTER

TANK

CIRCULATOR

T&P VALVE

HOT

EXPANSION TANK (OPTIONAL)

PUMP

STORAGE

BOOSTER

TANK

CHECK

VALVE

HOT

T&P VALVE

(FOR SOME

MODELS)

TANKLESS

COIL BOILER

PRESSURE

REGULATOR

(OPTIONAL)

COLD

COMBINATION

RETURN &

DRAIN VALVE

Figure 1: Main Parts and Features

THERMOSTAT

RETAINER

COMBINATION RETURN

& DRAIN VALVE

Figure 3: Multiple Storage Booster Plumbing Diagram

- 3 -

Loading...

Loading...