GSW ANSI Z21.10.1 - CSA 4.1, RESIDENTIAL GAS WATER HEATERS Installation And Operating Manual

Installation and Operating Manual

RESIDENTIAL GAS WATER HEATERS

DIRECT VENTED GAS MODELS

NOT FOR USE IN MANUFACTURED (MOBILE) HOMES

www.gsw-wh.com

ALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE CONTACT THE COMPANY LISTED ON THE RATING PLATE ON THE WATER HEATER.

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

1404 327539-000

• For Your Safety •

AN ODOURANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE . . . . . . . . . . .3

GENERAL SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Qualifi ed Installer Or Service Agency . . . . . . . . . . . . 6

Preparing For The Installation. . . . . . . . . . . . . . . . . . 6

TYPICAL INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . .7

Get To Know Your Water Heater - Gas Models

(List Referencing Figures 1-5). . . . . . . . . . . . . . . . . . 7

Replacement Parts And Deliming Products . . . . . . . 8

Combo Heating Inlet And Outlet Side Taps . . . . . . . . 8

High Limit Controls (Energy Cut Off). . . . . . . . . . . . . 8

Thermostat/Water Temperature

LOCATING THE NEW WATER HEATER. . . . . . . . . . . . . .9

Facts To Consider About The Location . . . . . . . . . . . 9

External/Internal Damage . . . . . . . . . . . . . . . . . . . . . 9

Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Confi ned Space Installations. . . . . . . . . . . . . . . . . . 10

Clearances To Combustibles

Floors With Carpeting

Clearance For Servicing

Chemical Vapour Corrosion . . . . . . . . . . . . . . . . . . 10

Storage Of Flammable Liquids . . . . . . . . . . . . . . . . .11

Insulation Blankets . . . . . . . . . . . . . . . . . . . . . . . . . .11

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water Pressure

Mixing Valves

INSTALLING THE NEW WATER HEATER . . . . . . . . . . . 13

Water Piping Installation . . . . . . . . . . . . . . . . . . . . . 13

Closed Water Systems . . . . . . . . . . . . . . . . . . . . . . 13

Thermal Expansion . . . . . . . . . . . . . . . . . . . . . . . . . 13

Temperature-Pressure Relief Valve. . . . . . . . . . . . . 14

T&P Valve Discharge Pipe Requirements:

Temperature-Pressure Relief Valve And

Pipe Insulation

Filling The Water Heater . . . . . . . . . . . . . . . . . . . . . 15

Space Heating And Potable Water Systems . . . . . . 16

Combo Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Requirements

Installation

Gas Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sediment Trap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

High Altitude Installations . . . . . . . . . . . . . . . . . . . . 19

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Vent Terminal Clearances . . . . . . . . . . . . . . . . . . . . 20

DV Termination Safety Cover . . . . . . . . . . . . . . . . . 21

Vent Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Locating Clearance Hole For Vent . . . . . . . . . . . . . 21

Standard Vent Arrangement . . . . . . . . . . . . . . . . . . 21

Vent Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Securing Vent Termination Assembly To

The Exterior Wall. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Vent Restricter Plate . . . . . . . . . . . . . . . . . . . . . . . . 22

Uncompressing The Corrugated Tubing . . . . . . . . . 22

Vent Connection To The Water Heater . . . . . . . . . . 23

Offset Vent Arrangement. . . . . . . . . . . . . . . . . . . . . 23

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . 25

LIGHTING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . .26

TEMPERATURE REGULATION . . . . . . . . . . . . . . . . . . .27

Temperature Regulation . . . . . . . . . . . . . . . . . . . . . 27

Temperature Adjustment

Operating The Temperature Control System. . . . . . 27

Water Temperature Adjustment

Operating Modes And Settings

FOR YOUR INFORMATION. . . . . . . . . . . . . . . . . . . . . . . 28

External Damage . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Start Up Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 28

Condensate

Smoke/Odour

Thermal Expansion . . . . . . . . . . . . . . . . . . . . . . . . . 28

Strange Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operational Conditions . . . . . . . . . . . . . . . . . . . . . . 29

Smelly Water

“Air” In Hot Water Faucets

High Water Temperature Shut Off System

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Housekeeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Flood Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Venting System Inspection . . . . . . . . . . . . . . . . . . . 30

Pilot And Main Burner . . . . . . . . . . . . . . . . . . . . . . . 30

Burner Flames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Servicing The Water Heater . . . . . . . . . . . . . . . . . . 31

Removing And Replacing The Gas Control Valve/

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing The Gas Control Valve/Thermostat:

Replacing The Gas Control Valve/Thermostat:

Removing The Manifold/Burner Assembly . . . . . . . 31

Removing The Burner From The Manifold/Burner

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Natural Gas (Low Nox) & Propane (LP) Gas Burner

Replacing The Pilot/Thermopile Assembly . . . . . . . 32

Replacing The Manifold/Burner Assembly . . . . . . . 33

Piezoelectric Igniter System . . . . . . . . . . . . . . . . . . 34

Testing The Igniter System . . . . . . . . . . . . . . . . . . . 34

Temperature-Pressure Relief Valve Test . . . . . . . . . 34

Draining, Refi lling And Flushing . . . . . . . . . . . . . . . 34

To Drain The Water Heater Storage Tank

To Refi ll The Water Heater Storage Tank

To Flush The Water Heater Storage Tank

Drain Valve Washer Replacement . . . . . . . . . . . . . 35

Anode Rod Maintenance. . . . . . . . . . . . . . . . . . . . . 35

To Remove The Anode Rod:

To Install The Anode Rod:

LEAKAGE CHECKPOINTS . . . . . . . . . . . . . . . . . . . . . . .37

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

REFERENCE PARTS LISTING . . . . . . . . . . . . . . . . . . . .38

TROUBLESHOOTING GUIDELINES. . . . . . . . . . . . . . . .40

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

2 www. gsw-wh .com

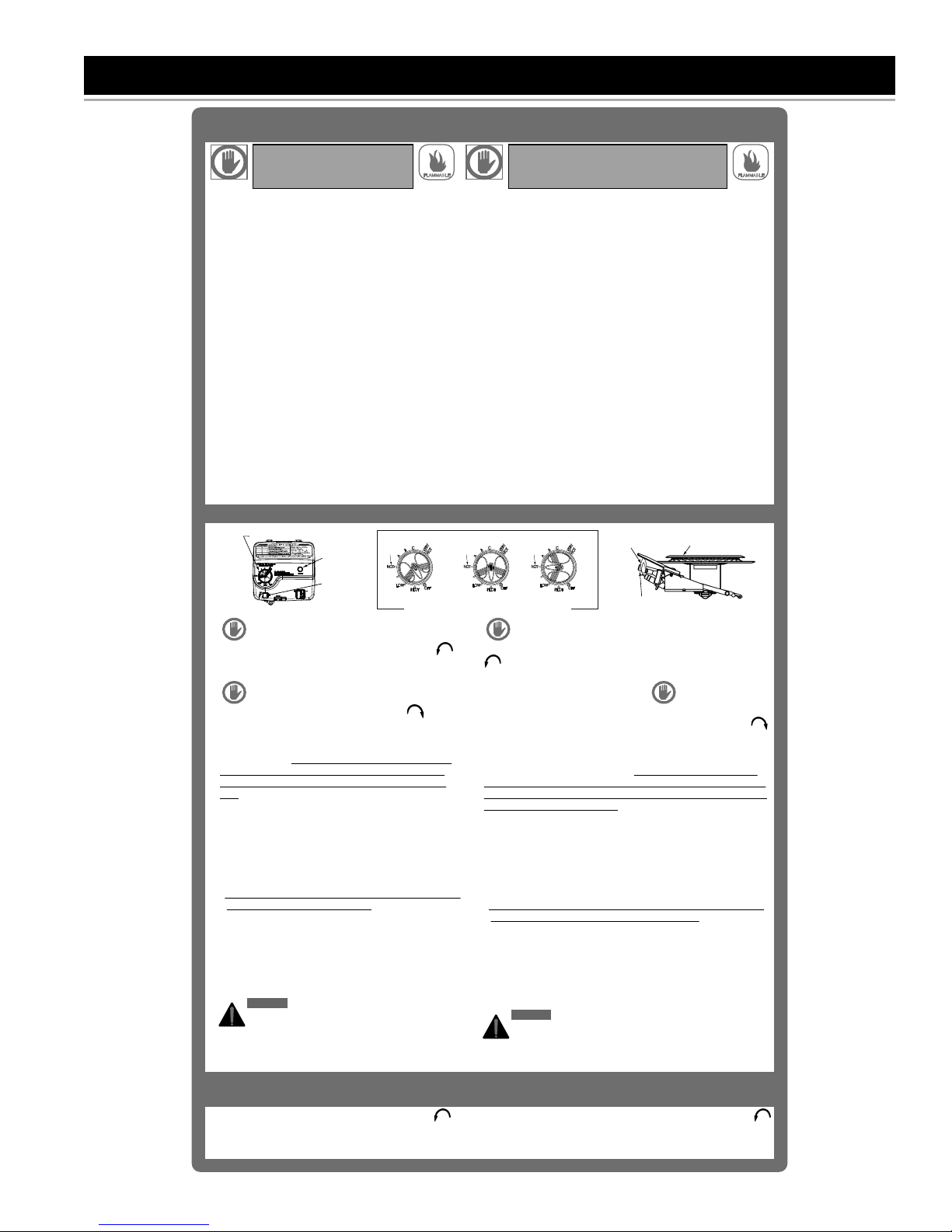

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you

and others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very

important that the meaning of each safety message is understood by you and others who install, use or service this water heater.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

CAUTION

hazardous situation which, if not avoided,

will result in death or injury.

WARNING indicates a potentially

hazardous situation which, if not avoided,

could result in death or injury.

CAUTION indicates a potentially

hazardous situation which, if not avoided,

could result in minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, could

result in property damage

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message

and how to avoid the risk of injury.

IMPORTANT DEFINITIONS

Qualifi ed Installer: A qualifi ed installer must have ability equivalent to a licensed tradesman in the fi elds of plumbing,

air supply, venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas

Code as it relates to the installation of gas fi red water heaters. The qualifi ed installer must also be familiar with the

design features and use of fl ammable vapor ignition resistant water heaters and have a thorough understanding of this

Installation and Operating manual.

Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the fi elds of plumbing, air

supply, venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas Code

as it relates to the installation of gas fi red water heaters. The service agency must also have a thorough understanding

of this Installation and Operating manual, and be able to perform repairs strictly in accordance with the service guidelines

provided by the manufacturer.

Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning appliances

within this application. The gas supplier typically has responsibility for the inspection and code approval of gas piping

up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers also offer service

and inspection of appliances within the building.

www. gsw-wh .com 3

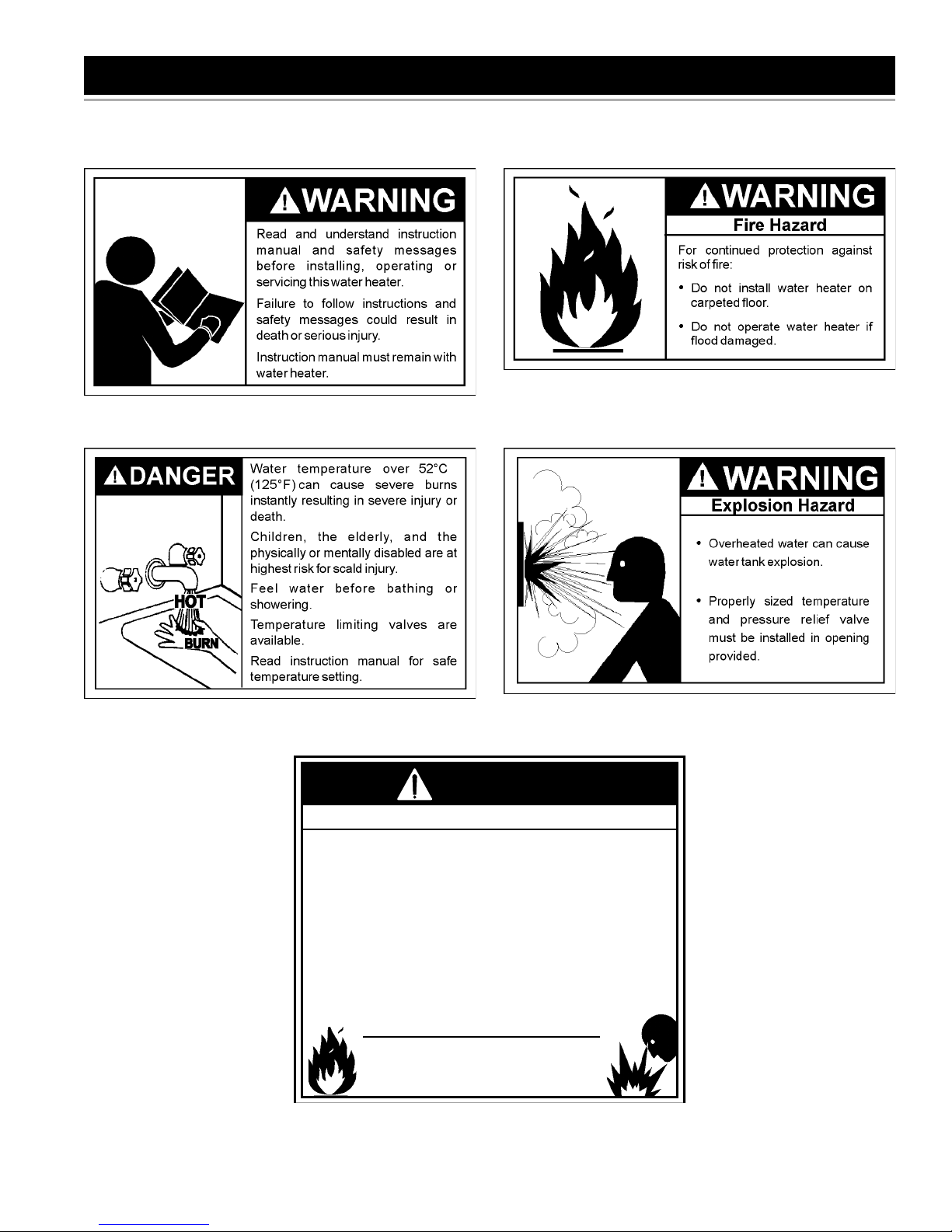

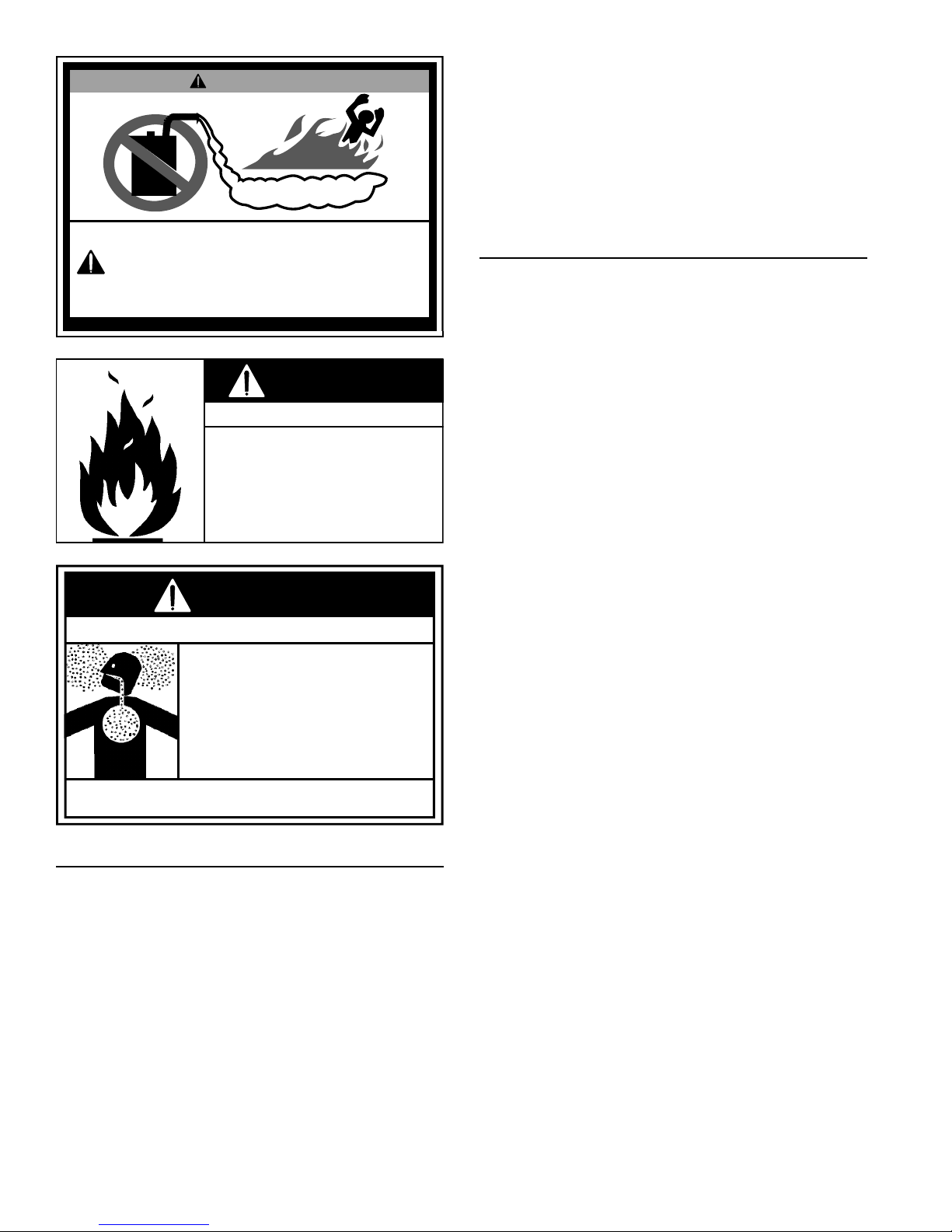

GENERAL SAFETY

• Do not store or use gasoline or other flammable

• Avoid all ignition sources if you smell gas.

• Do not expose water heater control to excessive

• Use only gas shown on rating plate.

• Maintain required clearances to combustibles.

• Keep ignition sources away from faucets after

4 www. gsw-wh .com

WARNING

Fire or Explosion Hazard

vapours and liquids in the vicinity of this water

heater, the vent termination hood or any other

appliance.

gas pressure.

extended period of non-use.

Read instruction manual before

installing, using or servicing

water heater.

GENERAL SAFETY

DANGER

WARNING

Breathing Hazard - Carbon Monoxide Gas

• Install vent system in accordance with codes.

• Do not operate water heater if flood damaged.

• For operation above 2347m (7,700’), a high

altitude orifice must be installed.

• Do not operate if soot buildup is present.

• Do not place chemical vapor emitting products

near water heater or vent termination hood.

• Gas and carbon monoxide detectors are

available.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

FLAMMBLE

Vapours from flammable

liquids may explode and

catch fire causing death or

severe burns.

Do not use or store

flammable products such as

gasoline, solvents or adhesives in the same room or

area near the water heater or

the vent termination hood.

Keep flammable products:

1. far away from heater,

2. in approved containers,

3. tightly closed and

4. out of children's reach.

Installation: Do not install the water heater or the vent termination hood where flammable products will be stored or used.

Flammable Vapours

Water heater has a main

burner and pilot. While

operating, the pilot flame:

1. is in continuous operation

and

2. will ignite flammable

vapours.

Vapours:

1. cannot be seen,

2. are heavier than air,

3. go a long way on the floor

and

4. can be carried from other

rooms by air currents.

www. gsw-wh .com 5

INTRODUCTION

Thank You for purchasing this water heater. Properly

installed and maintained, it should give you years of trouble

free service.

This water heater is suitable for potable water heating

and space heating applications but not for space heating

only applications.

Abbreviations found in this Installation and Operating

manual:

• CSA - Canadian Standards Association

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

This gas-fi red water heater is design certifi ed by CSA

International, under Water Heater Standard ANSI

Z21.10.1 • CSA 4.1 (current edition).

QUALIFIED INSTALLER OR SERVICE AGENCY

Installation and service of this water heater requires ability

equivalent to that of a Qualifi ed Agency (as defi ned by

ANSI below) in the fi eld involved. Installation skills such

as plumbing, air supply, venting, gas supply and electrical

supply are required in addition to electrical testing skills

when performing service.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualifi ed Agency” - “Any

individual, fi rm, corporation or company that either in

person or through a representative is engaged in and is

responsible for (a) the installation, testing or replacement

of gas piping or (b) the connection, installation, testing,

repair or servicing of appliances and equipment; that

is experienced in such work; that is familiar with all

precautions required and that has complied with all the

requirements of the authority having jurisdiction.”

If you are not qualifi ed (as defi ned by ANSI above) and

licensed or certified as required by authority having

jurisdiction to perform a given task, do not attempt to

perform any of the procedures described in this manual.

If you do not understand the instructions given in this

manual do not attempt to perform any procedures outlined

in this manual.

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section of this manual

fi rst and then entire manual carefully. If you don’t

follow safety rules, the water heater will not operate

properly. It could cause DEATH, SERIOUS BODILY

INJURY AND/OR PROPERTY DAMAGE. This manual

contains instructions for installation, operation,

and maintenance of the gas-fi red water heater. It

also contains warnings throughout the manual that

you must read and be aware of. All warnings and

instructions are essential to proper operation of the

water heater and your safety. Since we cannot put

everything on the fi rst few pages, READ ENTIRE

MANUAL BEFORE ATTEMPTING TO INSTALL OR

OPERATE THE WATER HEATER.

2. The installation must conform with these instructions

and local code authority having jurisdiction. In

absence of local codes, installation must comply with

current editions of the “Natural Gas and Propane

Installation Code” B149.1 and “Canadian Electrical

Code (C22.1), Part I” . All documents are available

from:

Canadian Standards Association,

5060 Spectrum Way,

Mississauga, Ontario, Canada

L4W 5N6

3. If after reading this manual you have any questions or

do not understand any portion of the instructions, call

the local gas utility or the manufacturer whose name

appears on the rating plate.

4. Carefully plan the place where you are going to put

the water heater. Correct combustion, vent action, and

vent pipe installation are very important in preventing

death from possible carbon monoxide poisoning and

fi res (see Figure 6). Examine the location to ensure

the water heater complies with the “Locating The New

Water Heater” section in this manual.

5. For installation in areas subject to earthquakes, this

water heater must be braced, anchored, or strapped to

avoid falling or moving during an earthquake. Contact

local utilities for code requirements in your area.

6. This product is certifi ed to comply with a maximum

weighted average of 0.25% lead content as required

in some areas.

6 www. gsw-wh .com

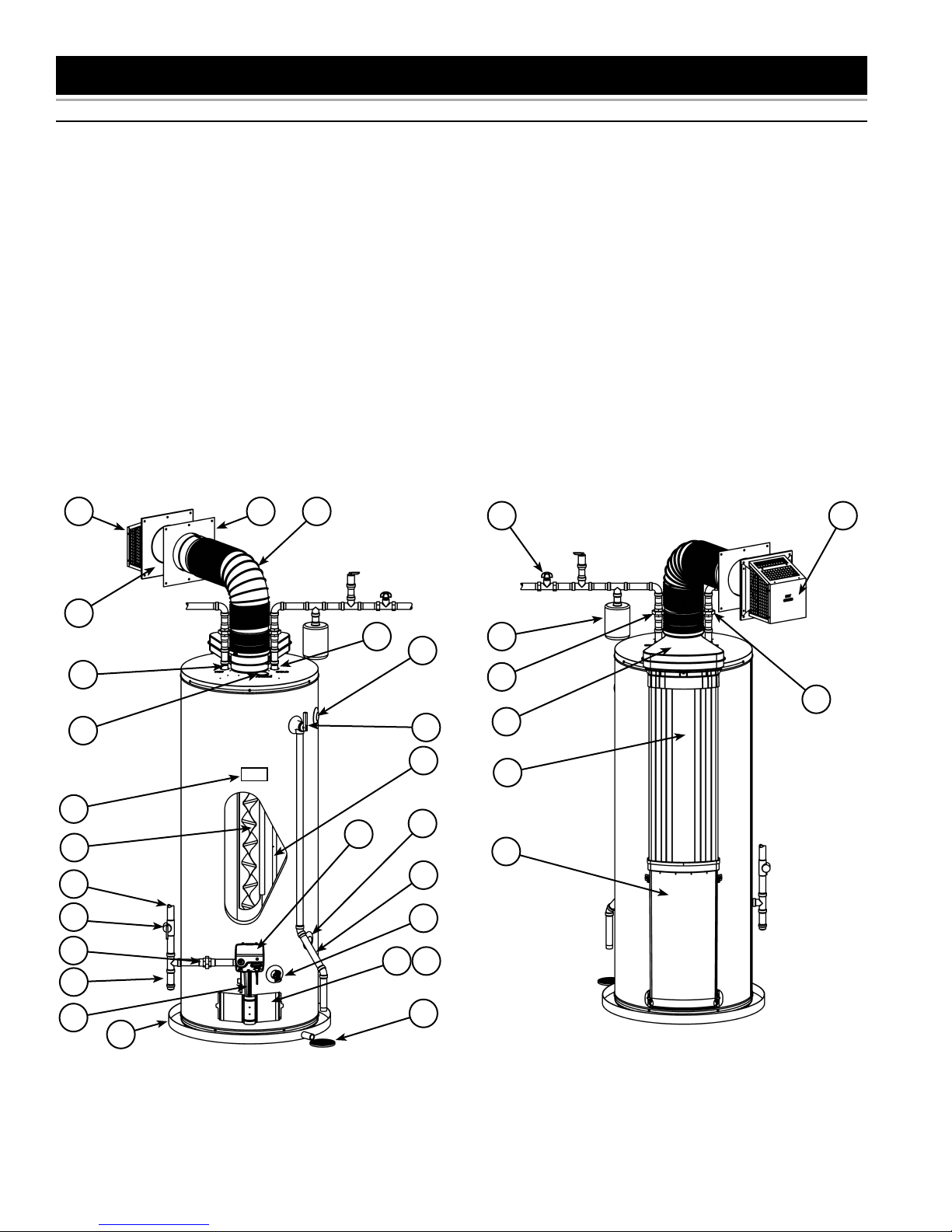

GET TO KNOW YOUR WATER HEATER - GAS MODELS (LIST REFERENCING FIGURES 1-5)

1 Vent Termination Hood

2 Wall Plate

3 ***Vent Pipe

4 Cold Water Inlet Nipple/Diptube

5 **Combo Heating System Supply

Outlet (Optional)

6 T&P Valve

7 Gas Control Valve/Thermostat

(Honeywell)

8 **Combo Heating System Return

Inlet (Optional)

9 *Discharge Pipe

10 Drain Valve

11 Outer Gas Door

12 Manifold Door Assembly (behind

outer door) (see Figure 3 &

Figure 4)

13 *Floor Drain

14 *Metal Drain Pan

15 Flexible Manifold Tube (see

Figure 3 & Figure 4)

TYPICAL INSTALLATION

16 *Sediment Trap

17 *Ground Joint Union (gas

connection)

18 *Main Manual Gas Shut-off Valve

19 *Gas Supply

20 Baffl e Assembly

21 Rating Plate

22 Anode (under cap)

23 Hot Water Outlet Nipple (or

Optional Nipple/Anode)

24 *Inlet Water Shut-off Valve

25 *Union (water connection)

26 Air Inlet Snorkel

27 Air Tower

28 ***Airbox

29 *Thermal Expansion Tank (required

for all closed systems)

30 Sheet Metal Burner (see Figure 3 &

Figure 4)

31 Gas Orifi ce (see Figure 3 &

Figure 4)

32 Gas Manifold (see Figure 3 &

33 Manifold Door Gasket (see Figure 3

34 Manifold Door (see Figure 3 &

35 Two Piece Grommet With Clip (see

36 Viewport (see Figure 3 & Figure 4)

37 Flexible Manifold Tube (see

38 Pilot (see Figure 3 & Figure 4)

39 Thermopile (see Figure 3 &

40 Pilot Shield (see Figure 3 &

*, **, *** see notes on following page

Figure 4)

& Figure 4)

Figure 4)

Figure 3 & Figure 4)

Figure 3 & Figure 4)

Figure 4)

Figure 4)

1 32

2

23

22

21

20

19

18

17

16

7

4

11 12

5

6

4

8

9

10

24

29

25

28

27

26

1

25

15

14

Front View

Figure 1

www. gsw-wh .com 7

13

Rear View

Figure 2

37

36

39

38

30

40

Vacuum relief valve

install per local

codes (not supplied

with heater).

31

Figure 5

35

Natural gas and Propane (LP)

main burner with igniter assembly

for 38k to 42k Btu/hr models

Figure 3

Natural gas and Propane

(LP) main burner with igniter

assembly for 47k Btu/hr

models

4039

38

37

36

35

34

32

33

30

31

32

33

34

Notes:

* Items not supplied with the water heater.

** The side recirculation loop connections may not be

used as the primary water inlet and outlet connections.

See “Combo Heating Inlet And Outlet Side Taps”

below.

*** During operation the vent pipe and airbox can get hot.

REPLACEMENT PARTS AND DELIMING PRODUCTS

Replacement parts and recommended delimer may be

ordered through authorized servicers or distributors. When

ordering parts, provide complete model and serial numbers

(see rating plate), quantity and name of part desired.

Standard hardware items may be purchased locally.

COMBO HEATING INLET AND OUTLET SIDE TAPS

Models equipped with Combo Heating capabilities are

shipped with the two side plumbing taps OPEN (items 5

and 8 in Figure 1 and see also Figure 8). If the heater is to

be operated without using the side taps, these openings

must be closed with the two pipe plugs supplied with

the heaters.

HIGH LIMIT CONTROLS (ENERGY CUT OFF)

Thermostat/Water Temperature

This feature is a part of the gas control valve/thermostat

(see Figure 1, item 7) and limits the maximum water

temperature. In the event of the water overheating, this

safety feature shuts off the fuel supply to the burner.

Figure 4

8 www. gsw-wh .com

LOCATING THE NEW WATER HEATER

FACTS TO CONSIDER ABOUT THE LOCATION

Carefully choose an indoor location for the new water

heater because the placement is a very important

consideration for the safety of the occupants in the building

and for the most economical use of the appliance. This

water heater is not for use in manufactured (mobile) homes

or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must

be observed:

1. Select a location indoors as close as practical to the

vent termination position. Figure 27 shows the venting

distances that the heater can be from the outside wall.

Ensure the vent termination position maintains the

clearances as outlined in Figure 27 thru Figure 29.

2. Selected location must provide adequate clearances

for servicing and proper operation of the water heater.

3. Avoid locations that could cause the water heater to

freeze from outside air.

4. Avoid locations that expose the water heater to direct

sunlight.

5. Keep combustibles such as boxes, magazines,

clothes, etc., away from the water heater area.

CAUTION

• Water supply shut-off devices that activate based on

the water pressure differential between the cold water

and hot water pipes connected to the water heater.

• Devices that will turn off the gas supply to a gas water

heater while at the same time shutting off its water

supply.

EXTERNAL/INTERNAL DAMAGE

Do not operate the water heater until it has been fully

checked out by a qualifi ed technician, if the water heater:

• Has been exposed to fi re or damage.

• Displays evidence of sooting.

• Produces steam or unusually hot water.

If the water heater has been fl ooded it must be replaced.

Property Damage Hazard

• All water heaters eventually leak.

• Do not install without adequate drainage.

Installation of the water heater must be accomplished

in such a manner that if the tank or any connections

should leak, the fl ow of water will not cause damage to

the structure. For this reason it is not advisable to install

the water heater in an attic or upper fl oor. In all cases, a

metal drain pan should be installed under the water heater.

Metal drain pans are available at your local hardware store.

Such a metal drain pan must have a clearance of at least

25mm (1”) greater than any point on the water heater’s

outer jacket and must be piped to an adequate drain. The

pan must have a maximum depth of 45mm (1.75”).

Water heater life depends upon water quality, water

pressure and the environment in which the water heater

is installed. Water heaters are sometimes installed in

locations where leakage may result in property damage,

even with the use of a metal drain pan piped to a drain.

However, unanticipated damage can be reduced or

prevented by a leak detector or water shut-off device used

in conjunction with a piped metal drain pan. These devices

are available from some plumbing supply wholesalers and

retailers, and detect and react to leakage in various ways:

• Sensors mounted in the metal drain pan that trigger an

alarm or turn off the incoming water to the water heater

when leakage is detected.

• Sensors mounted in the metal drain pan that turn off

the water supply to the entire building when water is

detected in the metal drain pan.

www. gsw-wh .com 9

AIR REQUIREMENTS

For safe operation an adequate supply of fresh,

uncontaminated air must be provided for combustion.

This gas-fi red water heater is a direct vent model. It

connects directly to the outside of the building through

the vent termination hood. The hood operates as both

the combustion air intake and the heater exhaust port

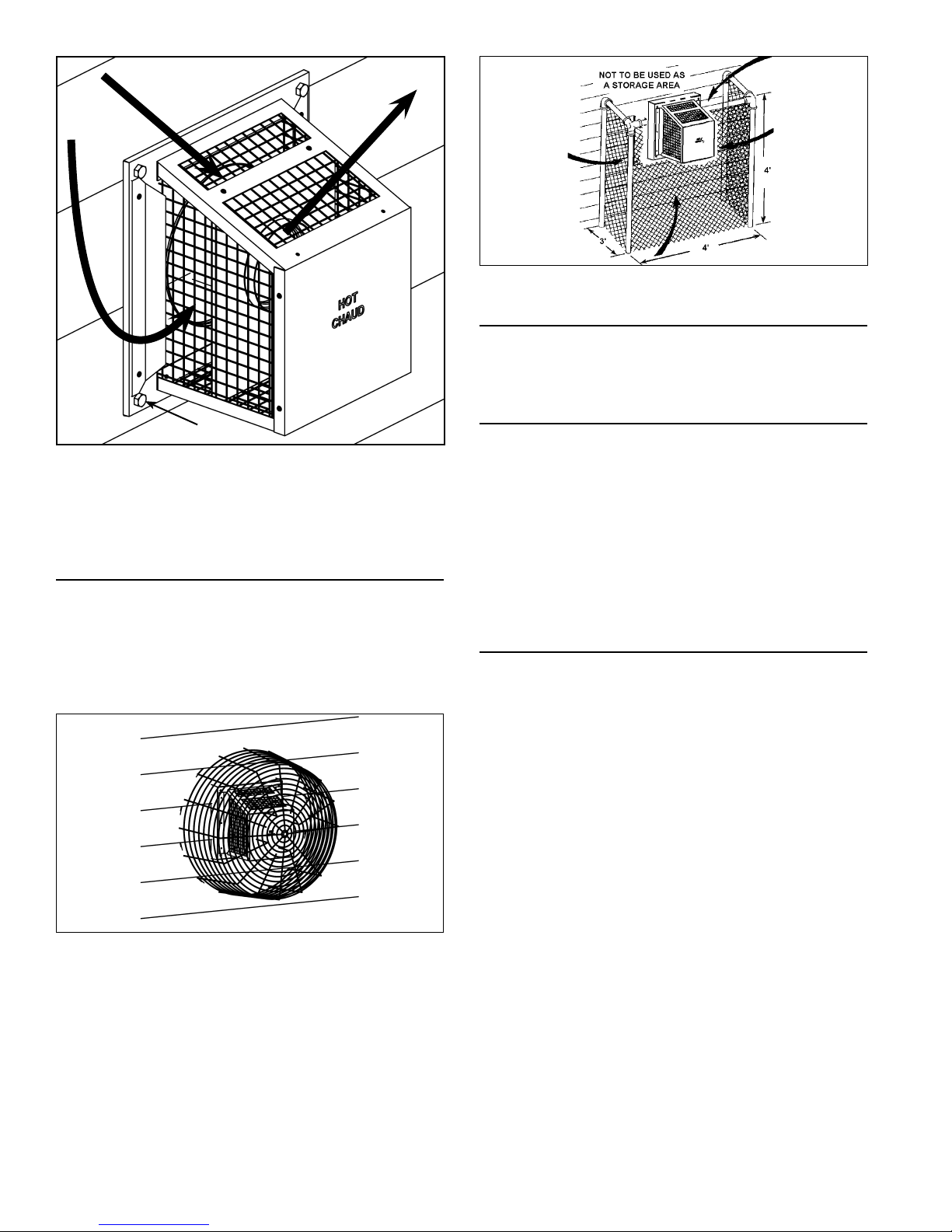

(see Figure 15).

All combustion air is obtained from outside the building

through this hood. Ensure the area around the termination

hood is always kept clear and that the air supply is not

exposed to contamination or fl ammable vapours.

CONFINED SPACE INSTALLATIONS

This water heater connects to the vent termination hood

using the sealed air intake and exhaust piping (see Figure

1 and Figure 2).

During operation this piping can become hot, especially in

areas experiencing high ambient temperatures.

When installed in a confi ned space such as a closet, it is

recommended that the confi ned space be ventilated to

minimize the buildup of heat around the heater. Figure 6

and Figure 7 show an examples of ventilating a confi ned

space.

0mm

(0”) MIN.

TOP VIEW

OF CLOSET

WITHOUT DOOR

0mm

(0”) MIN.

(5.5”) MIN.

140mm

TOP VIEW OF

CLOSET WITH

DOOR

0mm

(0”) MIN.

Figure 6

ROOM AIR

FLOW

VENTILATION

AIR

OPENING

Floors With Carpeting

This water heater must not be installed directly on

carpeting. Carpeting must be protected by a metal or wood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 76mm (3”) in

every direction, or if the appliance is installed in an alcove

or closet, the entire fl oor must be covered by the panel.

Failure to heed this warning may result in a fi re hazard.

Clearance For Servicing

Adequate clearance of 610mm (24”) for servicing this

appliance should be considered before installation, such

as changing the anodes, etc.

A minimum clearance of 140mm (5.5”) must be allowed

for access to replaceable parts such as thermostats, drain

valve and relief valve.

When installing the heater, consideration must be given to

proper location. Location selected should be as close to

the wall as practicable and as centralized with the water

piping system as possible.

CHEMICAL VAPOUR CORROSION

CORROSION OF THE FLUEWAYS AND VENT SYSTEM

MAY OCCUR IF AIR FOR COMBUSTION CONTAINS

CERTAIN CHEMICAL VAPOURS. SUCH CORROSION

MAY RESULT IN FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and

air conditioning refrigerants, swimming pool chemicals,

calcium and sodium chloride (water softener salt), waxes,

and process chemicals are typical compounds which are

potentially corrosive. Do not store products of this sort

near the heater or the vent termination hood. Air which is

brought in contact with the heater or the vent termination

hood should not contain any of the chemicals. The Limited

Warranty is voided when failure of water heater is due

to a corrosive atmosphere. See “Limited Warranty” for

complete terms and conditions.

ROOM AIR

FRONT VIEW

OF DOOR

FLOW

Figure 7

Clearances To Combustibles

Minimum clearances between water heater and

combustibles are 0mm (0”) at the sides and rear, 140mm

(5.5”) from the front and 305mm (12”) from top. Minimum

clearances from vent piping to combustibles is 25mm

(1”) except as noted in Figure 20. If clearances stated

on the heater differ from these clearances, install water

heater according to clearances stated on the heater (see

Figure 6).

10 www. gsw-wh .com

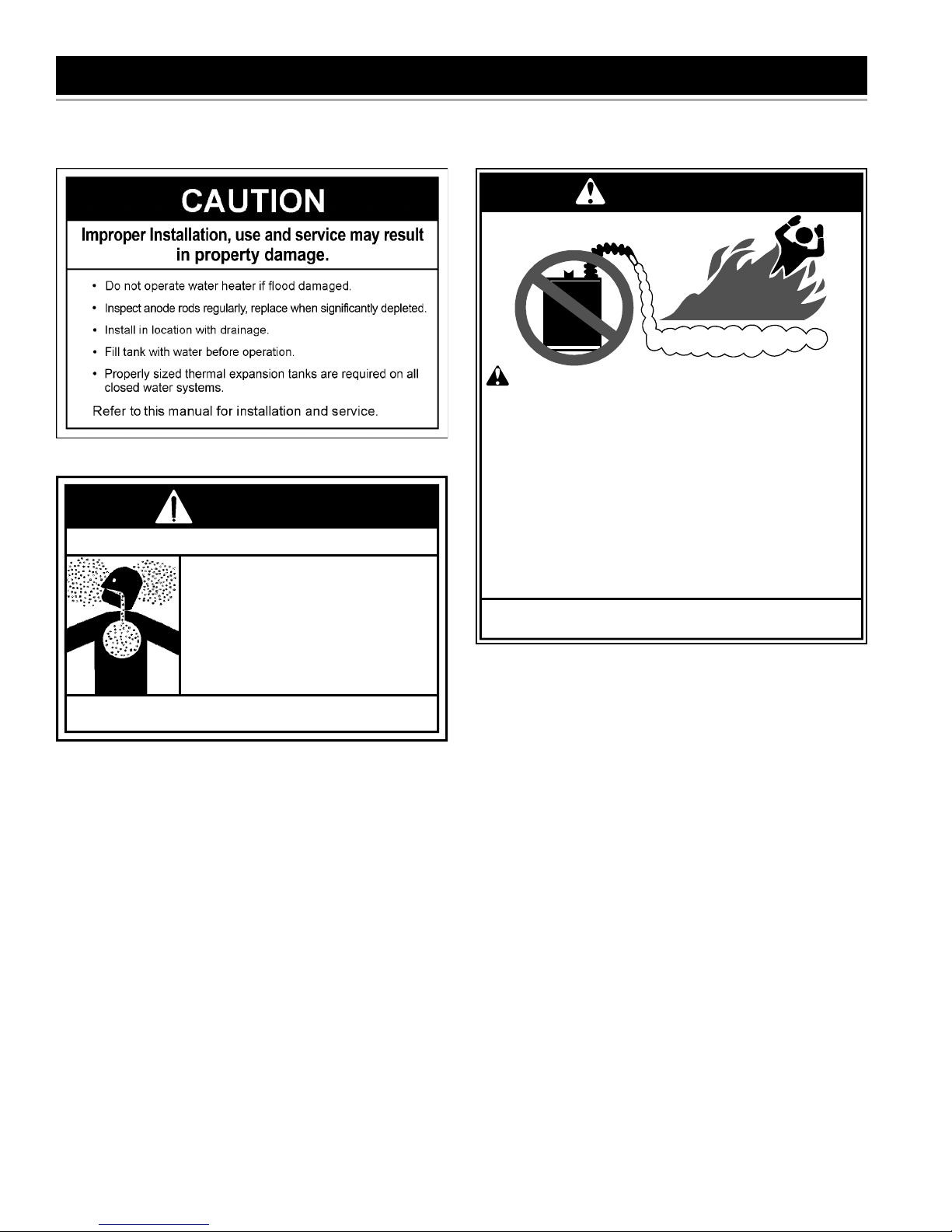

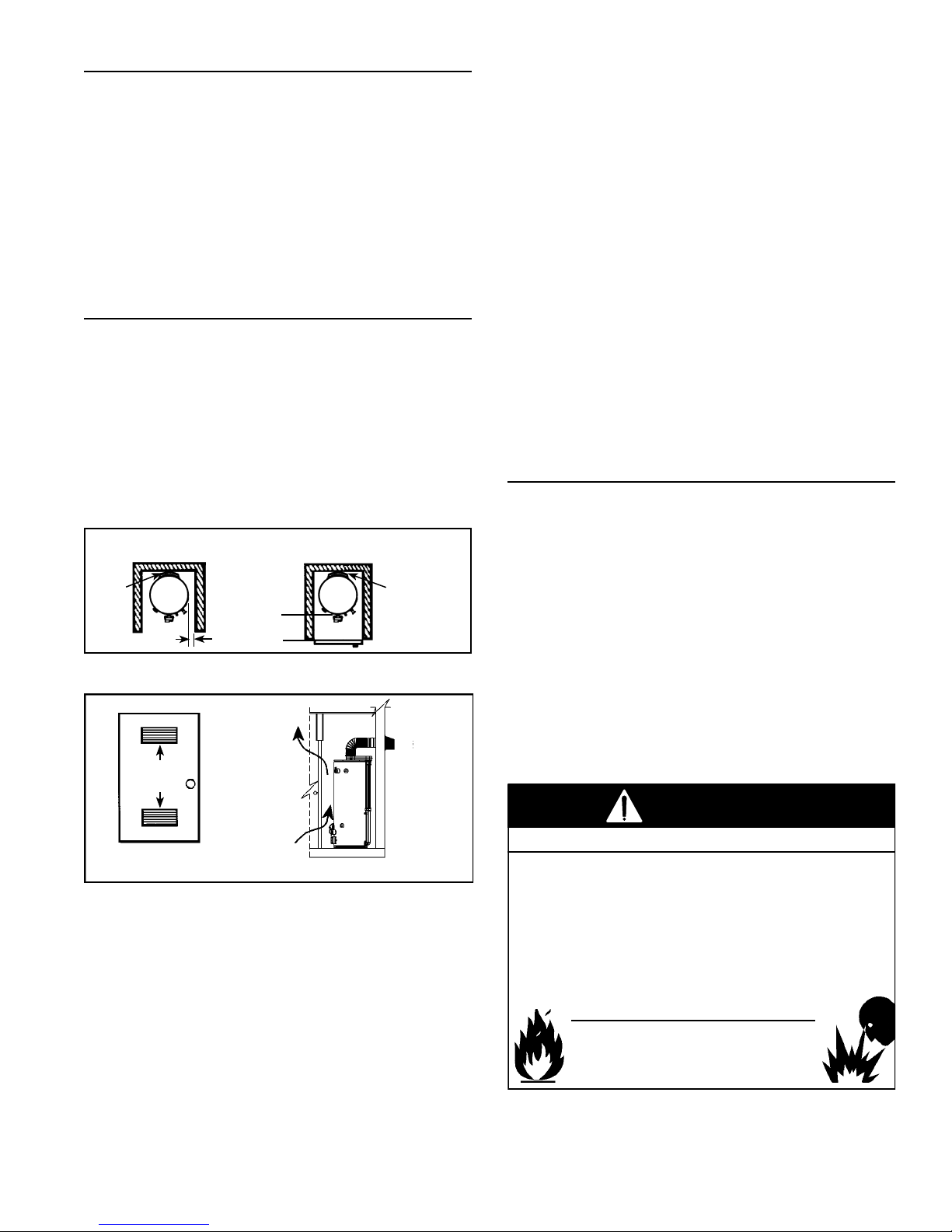

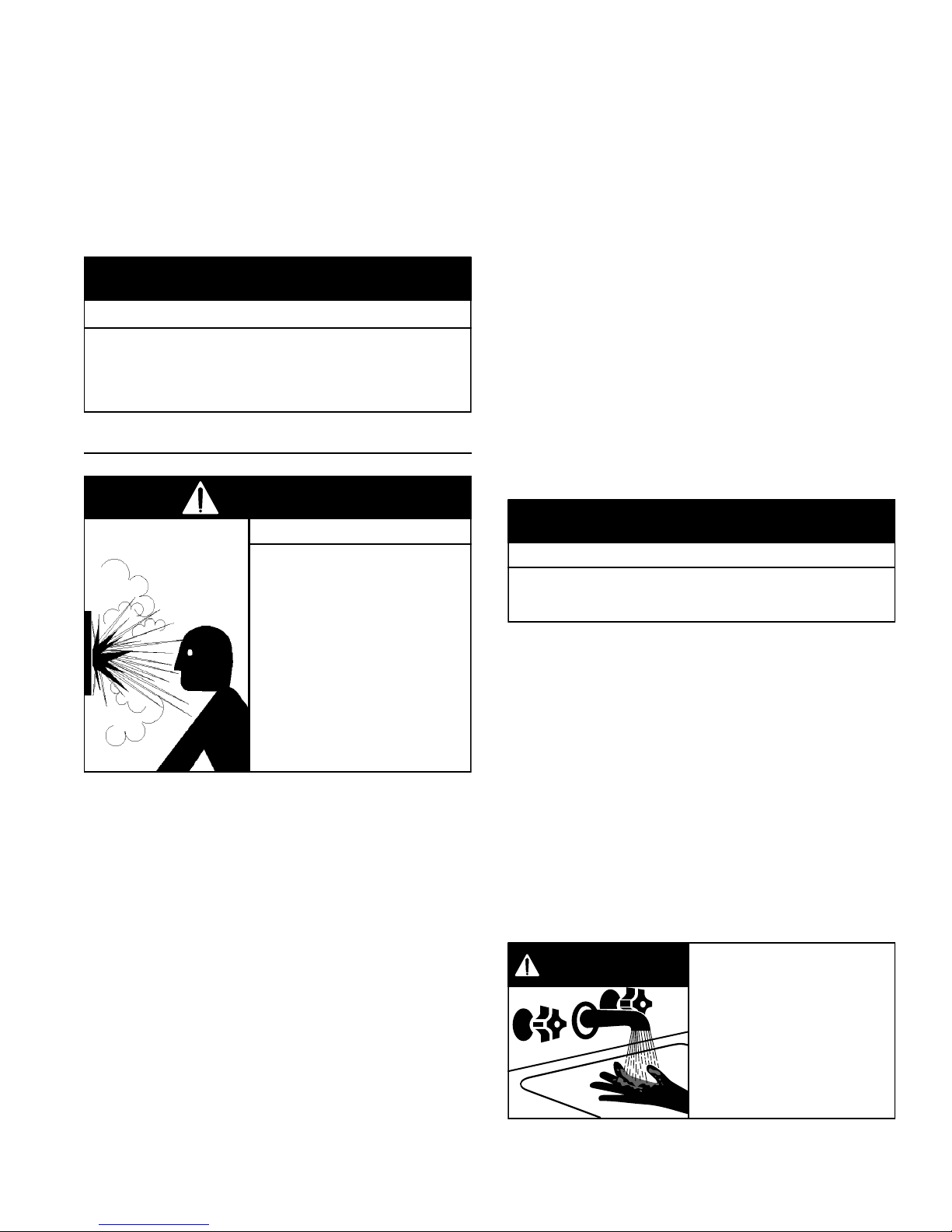

WARNING

Fire or Explosion Hazard

• Do not store or use gasoline or other flammable vapours

and liquids in the vicinity of this water heater, the vent

termination hood, or any other appliance.

• Avoid all ignition sources if you smell gas.

• Do not expose water heater control to excessive gas

pressure.

• Use only gas shown on rating plate.

• Maintain required clearances to combustibles.

• Keep ignition sources away from faucets after extended

period of non-use.

Read instruction manual before

installing, using or servicing

water heater.

WARNING

FLAMMABLES

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Storage or

use of gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance can result in serious injury

or death.

Flammable Vapors

WARNING

Fire Hazard

For continued protection against

risk of fire:

• Do not install water heater on

carpeted floor.

• Do not operate water heater if

flood damaged.

The water heater must be located and/or protected so it

is not subject to physical damage by a moving vehicle.

Propellants of aerosol sprays and volatile compounds,

(cleaners, chlorine based chemicals, refrigerants, etc.) in

addition to being highly fl ammable in many cases, will also

react to form corrosive hydrochloric acid when exposed to

the combustion products of the water heater. The results

can be hazardous, and also cause product failure.

INSULATION BLANKETS

Insulation blankets are available to the general public for

external use on gas water heaters but are not necessary

with these products. The purpose of an insulation blanket is

to reduce standby heat loss encountered with storage tank

heaters. Your water heater meets or exceeds the current

standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

Do not install any insulation blankets on this water heater.

WARNING

Breathing Hazard - Carbon Monoxide Gas

• Install water heater in accordance with the

instruction manual and B149.1.

• To avoid injury, combustion air must be taken

from outdoors.

• Do not place chemical vapor emitting products

near water heater or near the vent termination

hood.

• Do not obstruct the vent termination hood.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

STORAGE OF FLAMMABLE LIQUIDS

Flammable liquids (such as gasoline, solvents, propane

(LP or butane, etc.) and other substances (such as

adhesives, paints, etc.) emit fl ammable vapours which can

be ignited by a gas water heater’s pilot or main burner. The

resulting fl ashback and fi re can cause death or serious

burns to anyone in the area.

Even though this water heater is a fl ammable vapours

ignition resistant (FVIR) water heater and is designed to

reduce the chances of fl ammable vapours being ignited,

gasoline and other fl ammable substances should never

be stored or used in the same vicinity or area containing a

gas water heater, the vent termination hood, or other open

fl ame or spark producing appliance. Examples of such

locations are garages, storage and utility areas.

www. gsw-wh .com 11

WATER PIPING

Water Pressure

The water supply pressure should not exceed 80 psi. If this

occurs, a pressure reducing valve with a bypass should be

installed in the cold water inlet line. This should be placed

on the supply to the entire house in order to maintain equal

hot and cold water pressures. See also “Closed Water

Systems” and “Thermal Expansion” sections.

Mixing Valves

HOT WATER CAN SCALD:

Water heaters are intended to heat water. Water heated

to a temperature which will satisfy space heating, clothes

washing, dish washing, cleaning and other sanitizing

needs can scald and permanently injure you upon contact.

Short repeated heating cycles caused by small hot water

uses can cause a temperature increase of the hot water by

11C° (20F°) higher than the heater’s temperature settings.

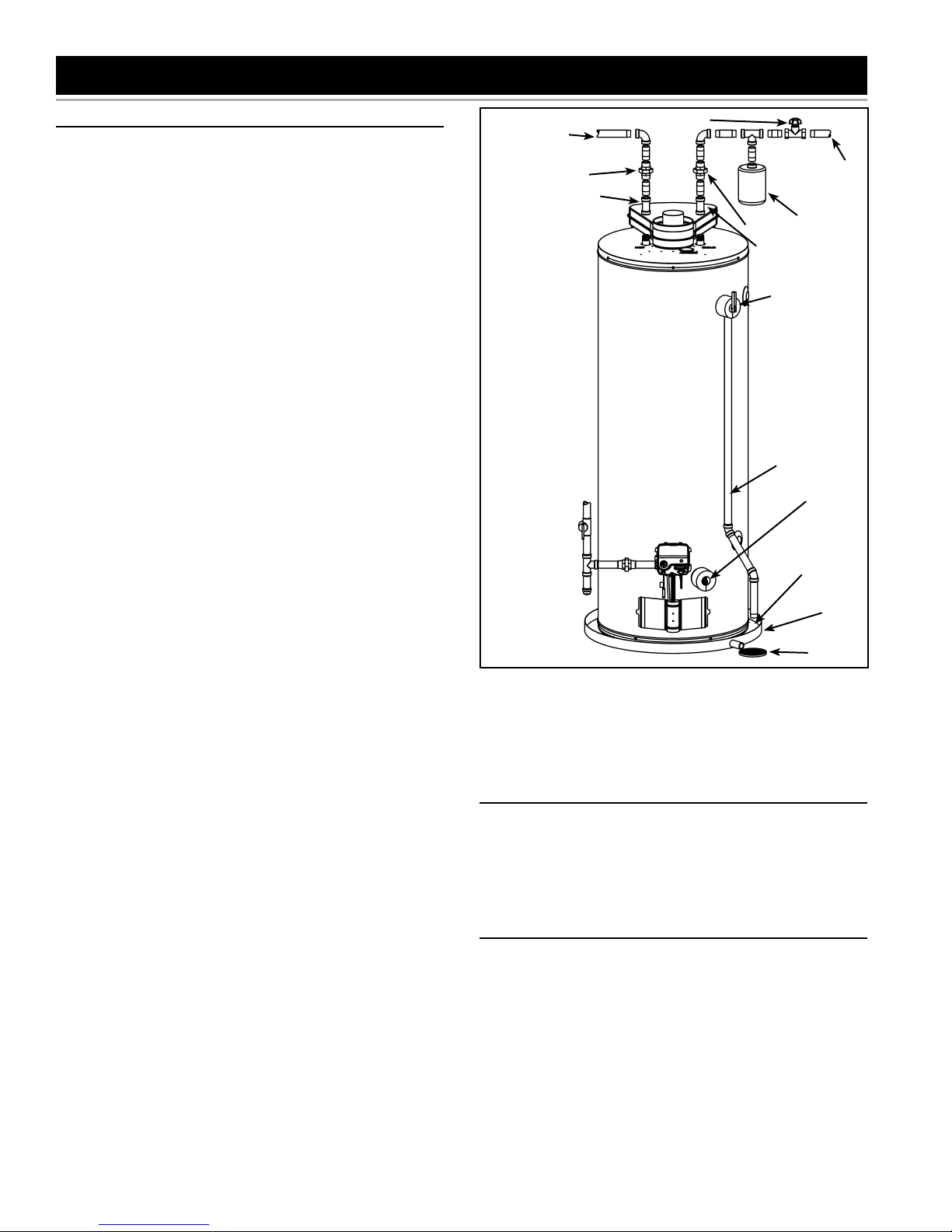

SUGGESTED PIPING

ARRANGEMENT FOR

TOP CONNECTIONS

MIXING VALVE

TEMPERED

POTABLE WATER

SHUT-OFF

VALV E

COLD WATER

INLET

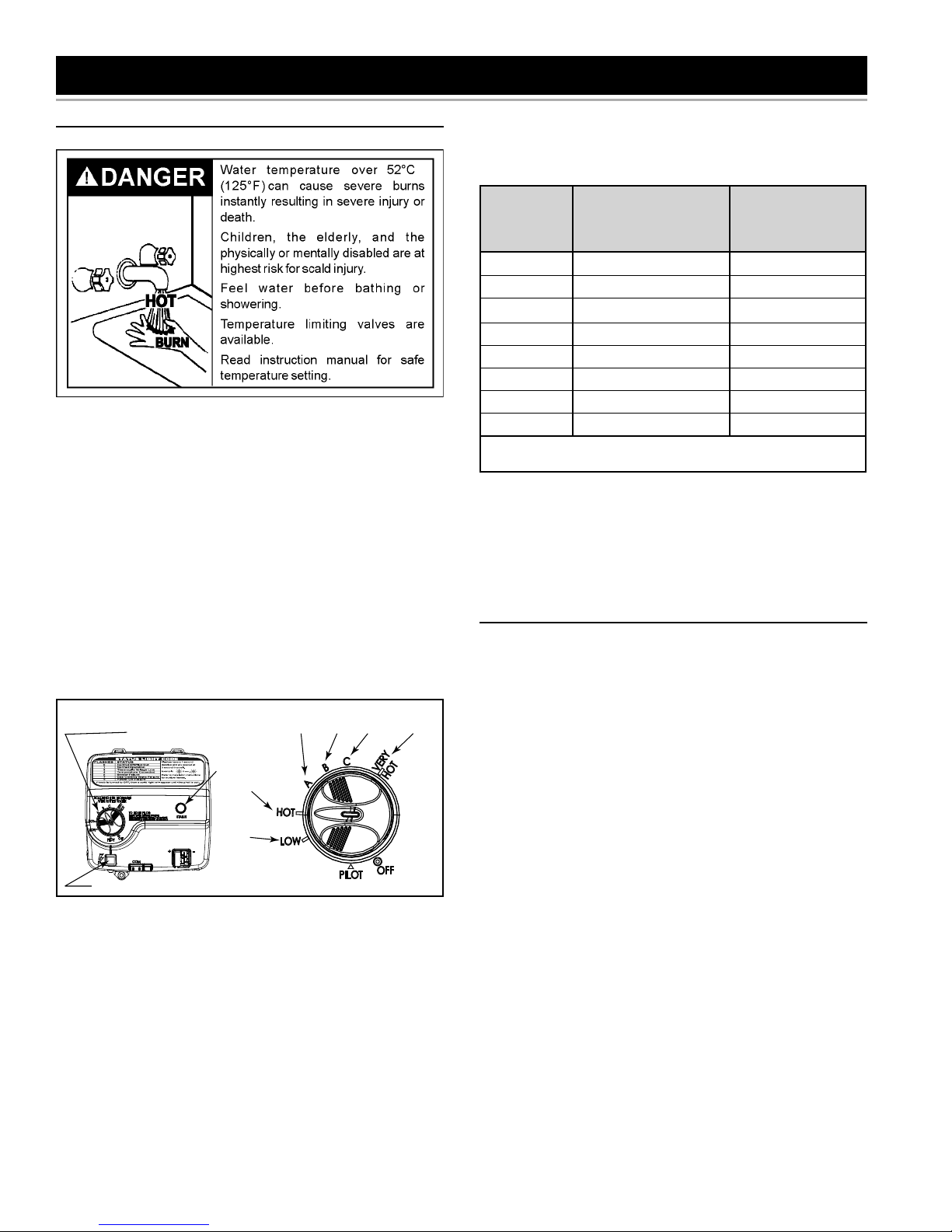

Water temperature over

DANGER

52°C (125°F) can cause

severe burns instantly

resulting in severe injury or

death.

Children, the elderly and the

disabled and are at highest

risk of scald injury.

Feel water before bathing or

showering.

HOT

HOT

Temperature limiting devices

such as mixing must be

installed when required by

BURN

codes and to ensure safe

temperatures at fixtures.

Some people are more likely to be permanently injured

by hot water than others. These include the elderly,

children, the infi rm and the physically/mentally disabled.

Table 1 (published by U.S. Government Memorandum,

1978) shows the approximate time-to-burn relationship

for normal adult skin. If anyone using hot water provided

by the water heater being installed fi ts into one of these

groups or if there is a local code or state law requiring a

certain water temperature at the point of use, then special

precautions must be taken (see Figure 8).

TEMPERATUREPRESSURE

RELIEF VALVE

DISCHARGE

PIPE (DO NOT

CAP OR PLUG)

GAS

SUPPLY

305mm

( 12”)

MAX. AIR

GAP*

Figure 8

CERTAIN

MODELS ARE

EQUIPPED WITH

SIDE PLUMBING

CONNECTIONS

FOR SPACE

HEATING. THE HOT

AND COLD FITTING

ASSEMBLIES

(PART #9001262)

CAN BE ORDERED

THROUGH THE

MANUFACTURER

METAL DRAIN

PAN

DRAIN

VALV E

Water

Temperature

°C (°F)

Time for 1st

Degree Burns

(Less Severe Burns)

Time for Permanent

Burns 2nd & 3rd

Degree (Most

Severe Burns)

44 (110) (normal shower temp.)

47 (116) (pain threshold)

47 (116) 35 minutes 45 minutes

50 (122) 1 minute 5 minutes

55 (131) 5 seconds 25 seconds

60 (140) 2 seconds 5 seconds

65 (149) 1 second 2 seconds

68 (154) instantaneous 1 seconds

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong,

Sept. 15,1978)

Table 1

In addition to using lowest possible temperature setting

that satisfi es demand of application, a mixing valve should

be installed at the water heater (see Figure 8) or at hot

water taps to further reduce system water temperature.

Mixing valves are available at plumbing supply stores.

Consult a Qualifi ed Installer or Service Agency. Follow

mixing valve manufacturer’s instructions for installation

of the valves. Before changing the factory setting on the

thermostat, read the “Operating The Temperature Control

System” section in this manual.

12 www. gsw-wh .com

INSTALLING THE NEW WATER HEATER

WATER PIPING INSTALLATION

Note: Water piping and vent piping occupy the space

above the water heater. Plan the water piping to ensure

it does not cause interference with the vent piping (see

“Venting”).

• The system should be installed only with piping that is

suitable for potable (drinkable) water such as copper,

CPVC, or polybutylene. This water heater must not be

installed using iron piping or PVC water piping.

• Use only pumps, valves, or fi ttings that are compatible

with potable water.

• It is recommend that only full fl ow ball or gate valves

are used in water piping installations. The use of valves

that may cause excessive restriction to water fl ow is

not recommended.

• Use only 95/5 tin-antimony or other equivalent solder.

Any lead based solder must not be used.

• Piping that has been treated with chromates, boiler

seal, or other chemicals must not be used.

• Chemicals that may contaminate the potable water

supply must not be added to the piping system.

Piping, fi ttings, and valves should be installed according

to the installation drawing (see Figure 9). If the indoor

installation area is subject to freezing temperatures, the

water piping must be protected by insulation.

Important: Heat must not be applied to the water fi ttings on

the heater as they may contain nonmetallic parts. If solder

connections are used, solder the pipe to the adapter before

attaching the adapter to the hot and cold water fi ttings.

Important: Always use a good grade of joint compound

and be certain that all fi ttings are drawn up tight.

1. Install the water piping and fi ttings as shown in Figure

9. Connect the cold water supply (3/4” NPT) to the cold

water inlet fi tting. Connect the hot water supply (3/4”

NPT) to the hot water outlet fi tting.

Important: These models may contain energy saving heat

traps to minimize the migration of heat to the pipes. Do

not remove the inserts within the heat traps.

2. The installation of unions in both the hot and cold water

supply lines is recommended for ease of removing the

water heater for service or replacement.

3. If installing the water heater in a closed water system,

install an expansion tank in the cold water line as

specifi ed under “Closed Water Systems” and “Thermal

Expansion”.

4. Install a shut-off valve in the cold water inlet line. It

should be located close to the water heater and be

easily accessible. Know the location of this valve and

how to shut off the water to the heater.

5. After piping has been properly connected to the water

heater, remove the aerator at the nearest hot water

faucet. Open the hot water faucet and allow the tank

to completely fi ll with water. To purge the lines of

any excess air, keep the hot water faucet open for

3 minutes after a constant fl ow of water is obtained.

Close the faucet, reinstall the aerator and check all

connections for leaks. Repair as needed.

HOT WATER

OUTLET

UNION

3/4” SWEAT

FITTING

SOME

COMPONENTS

NOT SHOWN

FOR CLARITY.

SHUT-OFF

VALV E

UNION

EXPANSION

3/4” SWEAT

FITTING

TEMPERATUREPRESSURE

RELIEF VALVE

DISCHARGE PIPE

(DO NOT CAP

OR PLUG)

DRAIN

VALV E

305mm ( 12”)

MAX.

AIR GAP

FLOOR

DRAIN

COLD

WATER

INLET

TANK

METAL

DRAIN

PAN

Figure 9

Figure 9 shows typical attachment of water piping to the

water heater. The water heater is equipped with 3/4” NPT

water connections.

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others,

have installed devices such as pressure-reducing valves,

check valves, and back fl ow preventers. Devices such

as these cause the water system to be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a

closed system, the volume of water will increase when

heated. As the volume of water increases, there will be a

corresponding increase in water pressure due to thermal

expansion. Thermal expansion can cause premature tank

failure (leakage). This type of failure is not covered under

the limited warranty. Thermal expansion can also cause

intermittent temperature-pressure relief valve operation:

water discharged from the valve due to excessive pressure

build up. The temperature-pressure relief valve is not

intended for the constant relief of thermal expansion. This

condition is not covered under the limited warranty.

www. gsw-wh .com 13

A properly-sized and charged thermal expansion tank must

be installed on all closed systems to control the harmful

effects of thermal expansion. Contact a plumbing service

agency or your retail supplier regarding the installation of

a thermal expansion tank.

Note: To protect against untimely corrosion of hot and cold

water fi ttings, it is recommended that di-electric unions or

couplings be installed on this water heater when connected

to copper pipe.

CAUTION

designated opening nor plugged. The T&P valve must

be installed directly into the fi tting of the water heater

designed for the relief valve. Install discharge piping so

that any discharge will exit the pipe within 305mm ( 12”)

above an adequate fl oor drain, or external to the building.

In cold climates it is recommended that it be terminated at

an adequate drain inside the building. Be certain that no

contact is made with any live electrical part.

The discharge opening must not be blocked or reduced

in size under any circumstances. Excessive length (over

9.14m [30’]), or use of more than four elbows can cause

restriction and reduce the discharge capacity of the valve.

Property Damage Hazard

• Avoid water heater damage.

• Install thermal expansion tank if necessary.

• Do not apply heat to cold-water inlet or hot-water outlet.

• Contact qualified installer or service agency.

TEMPERATURE-PRESSURE RELIEF VALVE

WARNING

Explosion Hazard

• Temperature-pressure relief

valve must comply with ANSI

Z21.22-CSA4.4 and ASME

code.

• Properly sized temperature-

pressure relief valve must be

installed in opening provided.

• Do not plug, block, or cap the

discharge line.

• Failure to follow this warning

can result in excessive tank

pressure, serious injury or

death.

This water heater is provided with a properly rated/sized

and certifi ed combination Temperature-Pressure Relief

Valve (T&P valve) by the manufacturer. The valve is

certifi ed by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed

equipment of materials as meeting the requirements for

Relief Valves for Hot Water Supply Systems, ANSI

Z21.22-CSA 4.4, and the code requirements of ASME.

No valve or other obstruction is to be placed between

the T&P valve and the tank. Do not connect discharge

piping directly to the drain unless a maximum of 305mm

( 12”) air gap is provided. To prevent bodily injury, hazard

to life, or property damage, the relief valve must be

allowed to discharge water in adequate quantities should

circumstances demand. If the discharge pipe is not

connected to a drain or other suitable means, the water

fl ow may cause property damage.

CAUTION

Water Damage Hazard

• Temperature-pressure relief valve discharge pipe

must terminate at an adequate drain.

T&P Valve Discharge Pipe Requirements:

• Shall not be smaller in size than the outlet pipe size

of the valve, or have any reducing couplings or other

restrictions.

• Shall not be plugged or blocked.

• Shall not be exposed to freezing temperatures.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage

of both the temperature-pressure relief valve and the

discharge pipe.

• Must terminate a maximum of 305mm ( 12”) above a

fl oor drain or external to the building. In cold climates, it

is recommended that the discharge pipe be terminated

at an adequate drain inside the building

• Shall not have any valve or other obstruction between

the relief valve and the drain.

If replaced, the new T&P valve must meet the requirements

of local codes, but not less than a combination temperaturepressure relief valve rated/sized and certifi ed as indicated

in the above paragraph. The new valve must be marked

with a maximum set pressure not to exceed the marked

hydrostatic working pressure of the water heater (150 psi)

and a discharge capacity not less than the water heater

Btu/hr input rate as shown on the water heater’s model

rating plate.

For safe operation of the water heater, the temperaturepressure relief valve must not be removed from its

14 www. gsw-wh .com

DANGER

HOT

HOT

BURN

• Burn hazard.

• Hot water discharge.

• Keep clear of

temperature-pressure

relief valve discharge.

The T&P valve must be manually operated at least once

a year. Caution should be taken to ensure

1. no one is in front of or around the outlet of the

discharge line, and

2. the water manually discharged will not cause any

bodily injury or property damage because the water

may be extremely hot.

If after manually operating the valve, it fails to completely

reset and continues to release water, immediately close

the cold water inlet to the water heater, follow the draining

instructions in this manual, and replace the temperaturepressure relief valve with a properly rated/sized new one.

Note: The purpose of a temperature-pressure relief valve

is to prevent excessive temperatures and pressures in

the storage tank. The T&P valve is not intended for the

constant relief of thermal expansion. A properly sized

thermal expansion tank must be installed on all closed

systems to control thermal expansion, see “Closed Water

Systems” and “Thermal Expansion” sections.

Temperature-Pressure Relief Valve And Pipe

Insulation

The T&P valve installed on this water heater is covered by

insulation to minimize heat loss. The insulation has a hole

on the bottom side to accommodate the valve outlet and

allow for the piping connection. Do not restrict the outlet

opening of the T&P valve.

1. Locate the hot water (outlet) and cold water (inlet)

pipes to the water heater.

2. Locate the slit running the length of a section of pipe

insulation.

3. Spread the slit open and slip the insulation over the

cold water (inlet) pipe. Apply gentle pressure along

the length of the insulation to ensure that it is fully

seated around the pipe. Also, ensure that the base

of the insulation is fl ush with the water heater. Once

seated, secure the insulation with duct tape, electrical

tape, or equivalent.

4. Repeat steps 2 and 3 for the hot water (outlet) pipe.

5. Add additional sections of pipe insulation as needed.

FILLING THE WATER HEATER

CAUTION

Property Damage Hazard

• Avoid water heater damage.

• Fill tank with water before operating.

• Never use this water heater unless it is completely full

of water. To prevent damage to the tank, the tank must

be fi lled with water. Water must fl ow from the hot water

faucet before turning “ON” gas to the water heater.

T&P Relief Valve Insulation

(Outlet opening on underside)

Manual Relief Lever

T&P Relief Valve

T&P Relief Valve

Drain Line

Figure 10

Locate the temperature and pressure relief valve on the

water heater (also known as a T&P relief valve) (see

Figure 10).

1. Locate the slit running the length of the T&P relief

valve insulation.

2. Spread the slit open and fi t the insulation over the T&P

relief valve (see Figure 10). Apply gentle pressure to

the insulation to ensure that it is fully seated on the

T&P Relief Valve. Once seated, secure the insulation

with duct tape, electrical tape, or equivalent.

Important: The insulation and tape must not block the

discharge opening or hinder access to the manual relief

lever (Figure 10). Ensure a discharge pipe is installed into

the T&P valve discharge opening per the instructions in

this manual.

To fi ll the water heater with water:

1. Close the water heater drain valve by turning handle

to the right (clockwise). The drain valve is on the lower

front of water heater (see Figure 9).

2. Important: If the heater is equipped with plumbing

side taps and they are not connected to piping, ensure

the side taps have been closed with pipe plugs.

3. Open all hot water faucets served by the water heater

to allow air to escape from the tank and the water

piping. Ensure any shut-off valves between the heater

and the faucets are in the open position.

4. Open the cold water supply valve to the water heater.

Notes:

• The cold water supply valve must be left open when

the water heater is in use.

• Avoid water leakage when fi lling the tank. Do not

allow the insulation of the water heater to get wet as

water can reduce the effectiveness of the insulation.

5. Allow water to run until a constant fl ow is obtained.

This will let air out of the water heater and the piping.

6. Check all water piping and connections for leaks.

Repair as needed.

www. gsw-wh .com 15

SPACE HEATING AND POTABLE WATER SYSTEMS

This appliance has been design certifi ed as complying

with American National Standard/CSA Standard for water

heaters and are considered suitable for Water (Potable)

Heating and Space Heating. Note: This water heater

may be used in combination potable water/space heating

system. Do not use in a space heating only application.

WARNING

Toxic Chemical Hazard

• Do not connect to non-potable water system.

Note: Ensure the water heater has been properly sized

to accommodate the needs of the hot water demand and

space heating load. Undersizing the water heater can

result in insuffi cient hot water, excessive condensation

and ineffi cient operation.

• This water heater should not be connected to any

heating systems or components previously used with

a non-potable water heating appliance.

• All piping components connected to this unit for space

heating applications should be suitable for use with

potable water.

• Pumps, valves, piping and fi ttings must be compatible

with potable water.

• Toxic chemicals, such as those used for boiler treatment

shall not be introduced into the potable water used for

space heating.

• When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a mixing valve must be installed. Please refer

to Figure 8 for suggested piping arrangement.

• Be sure to follow the manual(s) shipped with the air

handler or other type heating system.

• This water heater is not to be used as a replacement

for an existing boiler installation.

• Do not use with piping that has been treated with

chromates, boiler seal or other chemicals and do not

add any chemicals to the water heater piping.

• A properly installed fl ow control valve is required to

prevent thermosiphoning. Thermosiphoning is the

result of a continuous fl ow of water through the air

handler circuit during the off cycle. Weeping (blow off)

of the temperature-pressure relief valve (T&P) or higher

than normal water temperatures are the fi rst signs of

thermosiphoning.

• The hot water line from the water heater should be

vertical past any mixing valve or supply line to the

heating system to remove air bubbles from the system.

16 www. gsw-wh .com

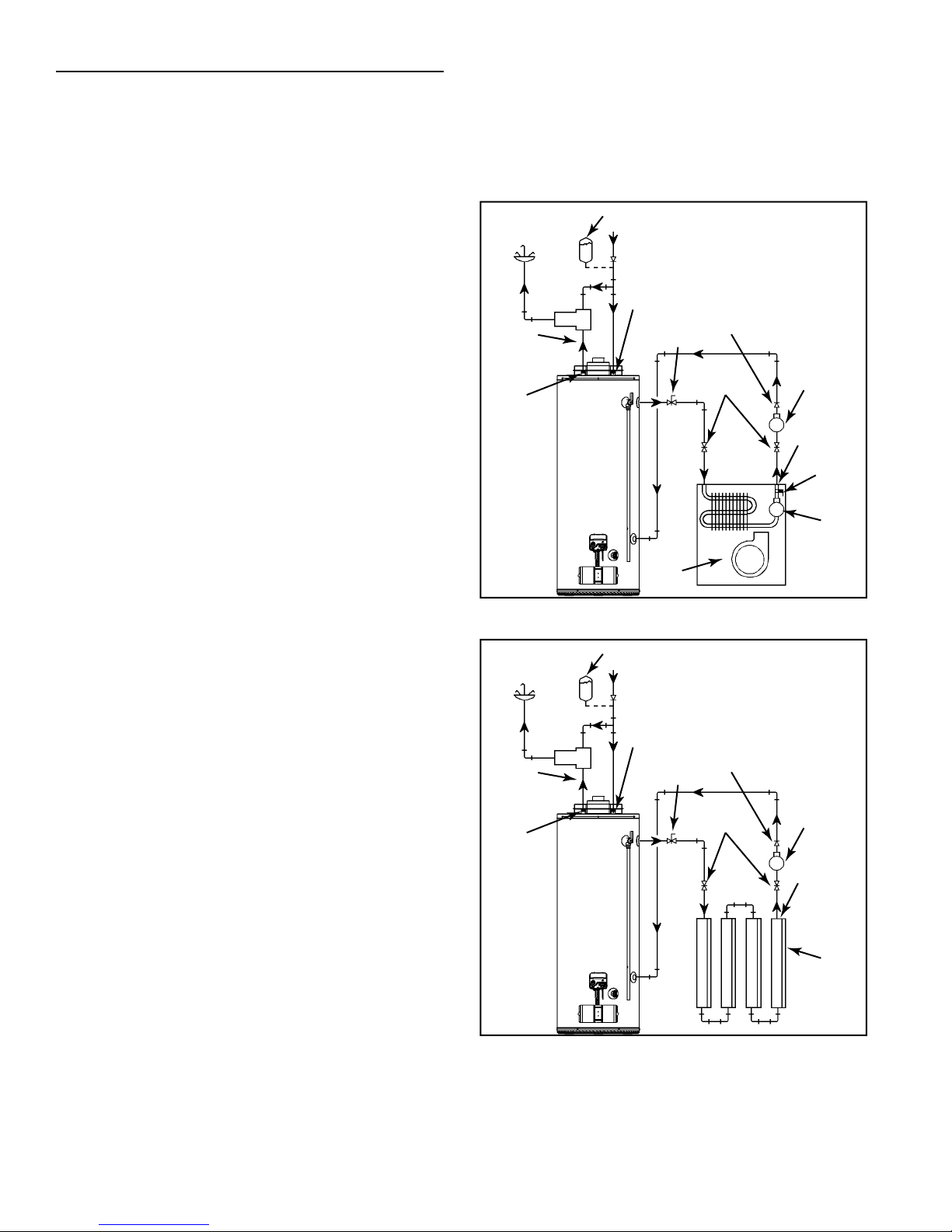

COMBO HEATING

This section serves as a guide for the installation and use

of “Combo” heating systems utilizing a domestic water

heater that has been specifi cally approved for such use.

It is written for those knowledgeable in the required trades

and professionals involved in the design and installation

of Combo Heating Systems.

It is the responsibility of the installer/designer to follow all

applicable codes to ensure the effectiveness and safety

of the installation.

System Requirements

The following requirements must be met for the installation

of Combo Heating Systems:

1. All components used for the distribution of water in

the heating loop must be suitable for potable water.

These include all piping, fi ttings, solder and fl uxes,

pumps for circulation of water, valves, etc.

2. The water heater must not be connected to a hydronic

heating system that has been used previously.

3. No boiler treatment chemicals of any kind shall be

introduced into the system.

4. The Combo System components must be selected

and sized to meet and maintain the total calculated

demands for both domestic service hot water

and space heating requirement. The sizing and

installation must be performed in accordance with

good engineering practice such as “ASHRAE

Handbooks”, HRAI’s Unifi ed Combo Guidelines,

“Hydronics Institute Manuals”, ANSI Z223.1, CSA

F280, National/Provincial Building Codes, ANSI

and/or codes having jurisdiction.

5. The air handler (fan coil) and/or the circulating pump

in a baseboard hydronic loop will require a dedicated

120V circuit. This must be provided and identifi ed for

this purpose.

6. All piping between the water heater and the air handler

or hydronic baseboard loop must be adequately

insulated to reduce heat loss.

7. If the local jurisdiction requires a back-fl ow preventer

in the cold water line, an expansion tank of adequate

size must be installed.

8. “Combo” Heating Systems require higher water

temperatures than other applications. When the

system is used to supply water for Combo Heating

applications, a means, such as mixing valve, must be

installed to temper the water in order to reduce scald

hazard potential (see Figure 11 & Figure 12).

Installation

The heating mode may be one of the following options:

A. A fan coil/air handler (Figure 11).

B. A hydronic baseboard (fi nned tube) loop/In fl oor heating

(Figure 12).

The following is a list of requirements for the installation

of option A or B.

1. Install shut-off valves and unions so that the water

heater can be isolated from the heating module should

servicing of the water heater become necessary.

2. Install a drain valve at the lowest point of the heating

loop so that water can be drained from the heating

module without affecting the water heater.

3. If the air handler does not have a venting means at

the highest point of the piping arrangement, install

an air bleed at the highest point of the plumbing

arrangement.

HOT WATER

TO HOUSE

FIXTURE

8 in TO

12 in MAX.

HOT

OUTLET

EXPANSION TANK (OPTIONAL)

COLD SUPPLY

CHECK VALVE (IF USED

REQUIRES EXPANSION TANK)

MIXING

VALV E

M

C

H

WATER

HEATER

COLD INLET

FLOW

CONTROL

AIR

HANDLER

CHECK

VALV E

HOSE BIB

(OPT.)

SUPPLY

EXTERNAL

CIRCULATOR

RETURN

DRAIN/

PURGE

VALV E

INTERNAL

CIRCULATOR

Figure 11

HOT WATER

TO HOUSE

FIXTURE

8 in TO

12 in MAX.

HOT

OUTLET

EXPANSION TANK (OPTIONAL)

COLD SUPPLY

CHECK VALVE (IF USED

REQUIRES EXPANSION TANK)

MIXING

VALV E

M

C

H

WATER

HEATER

COLD INLET

FLOW

CONTROL

CHECK

VALV E

HOSE BIB

(OPT.)

SUPPLY

EXTERNAL

CIRCULATOR

RETURN

HYDRONIC

BASEBOARDS

(SERIES

CONNECTED

SHOWN)

Figure 12

www. gsw-wh .com 17

GAS PIPING

WARNING

Fire and Explosion Hazard

• Do not use water heater with

any gas other than the gas

shown on the rating plate.

• Excessive pressure to gas

control valve can cause serious

injury or death.

• Turn off gas lines during

installation.

• Contact qualified installer or

service agency.

WARNING

Explosion Hazard

Have a qualified technician make sure that the L.P.

gas operating pressure does not exceed 13" water

column.

Failure to do so can result in death, explosion, or

fire.

Make sure the gas supplied is the same type listed on the

model rating plate. The inlet gas pressure must not exceed

13 inch w.c. for natural gas and propane (LP) gas. The

minimum inlet gas pressure shown on the rating plate is

that which will permit fi ring at rated input.

All gas piping must comply with local codes and ordinances

or with the “Natural Gas and Propane Installation Code”

B149.1 . Copper or brass tubing and fi ttings (except that

which is certifi ed for gas usage) should not be used.

If the gas control valve/thermostat is subjected to

pressures exceeding 1/2 psi (14 inch w.c.), the damage

to the gas control valve/thermostat could result in a fi re or

explosion from leaking gas.

There must be:

• A readily accessible manual shut-off valve in the gas

supply line serving the water heater, and

• A sediment trap ahead of gas control valve/thermostat

to help prevent dirt and foreign materials from entering

the gas control valve/thermostat.

• A fl exible gas connector or a ground joint union between

the manual gas shut-off valve and gas control valve/

thermostat to permit servicing of the unit.

Be sure to check all the gas piping for leaks before lighting

the water heater. Use a soapy water solution, not a match

or open fl ame. Repair and retest as required. When

fi nished, rinse off soapy solution and wipe dry.

WARNING

Fire and Explosion Hazard

• Use joint compound or tape

compatible with propane.

• Leak test before operating

heater.

• Disconnect gas piping and

shut-off valve before pressure

testing system.

Use pipe joint compound or Tefl on tape marked as being

resistant to the action of gases.

The appliance and its gas connection must be leak tested

before placing the appliance in operation.

The appliance and its individual manual gas shut-off

valve should be disconnected from the gas supply piping

system during any pressure testing of that system at test

pressures in excess of 1/2 psi. It should be isolated from

the gas supply piping system by closing its individual

manual gas shut-off valve during any pressure testing of

the gas supply piping system at test pressures equal to

or less than 1/2 psi.

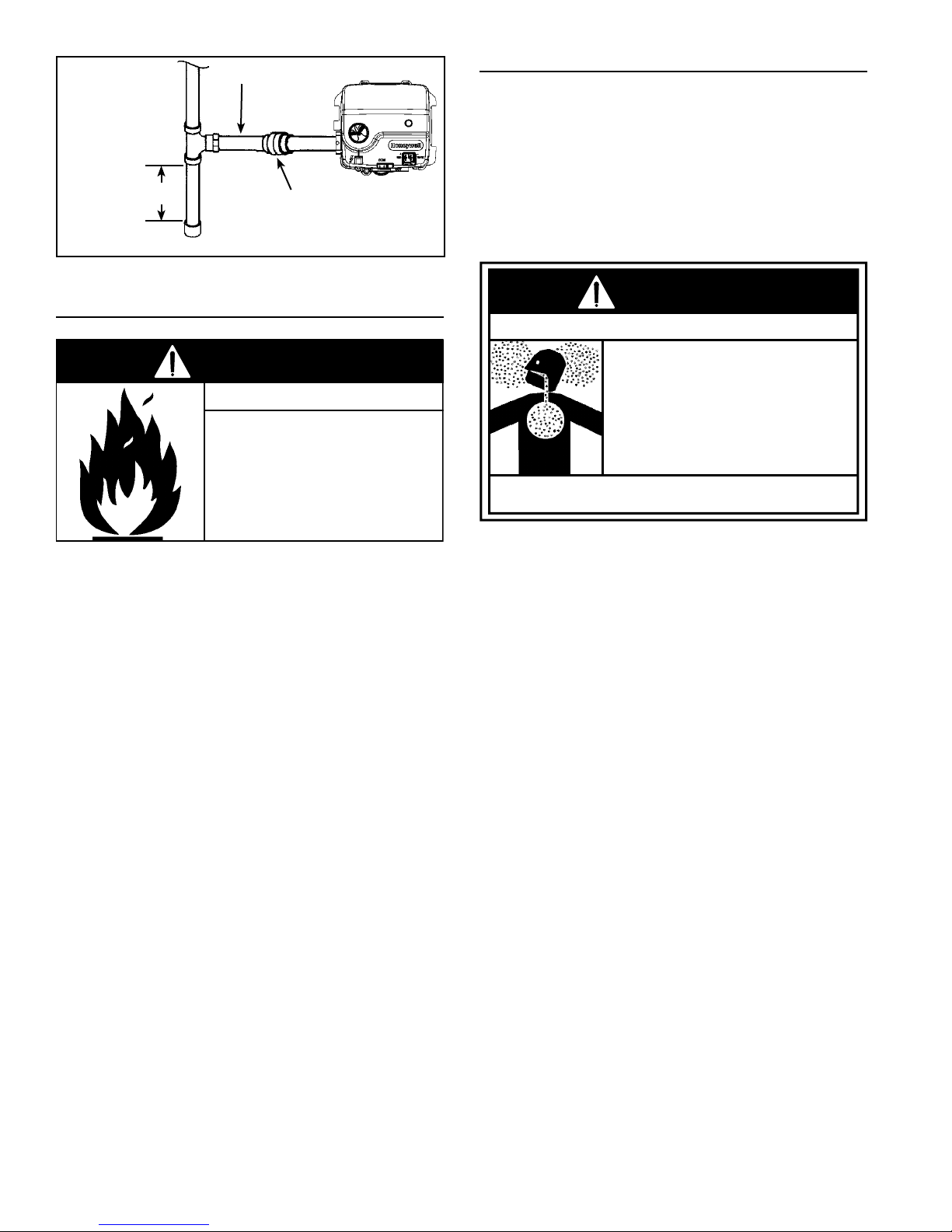

Connecting gas piping to the gas control valve/thermostat

of water heater can be accomplished by the method shown

in Figure 13.

If the main gas line shut-off serving all gas appliances is

used, also turn “OFF” the gas at each appliance. Leave

all gas appliances shut “OFF” until the water heater

installation is complete.

A gas line of suffi cient size must be run to the water

heater. Consult the current edition of the “Natural Gas

and Propane Installation Code” B149.1 and your gas

supplier concerning pipe size.

18 www. gsw-wh .com

BLACK PIPE

Installations above 2,347m (7,700’). require replacement

of the burner orifice in accordance with the current

edition of the “Natural Gas and Propane Installation

Code” B149.1 . Failure to replace the orifi ce could result

in improper and ineffi cient operation of the appliance,

HIGH ALTITUDE INSTALLATIONS

76mm

(3”) MIN.

SEDIMENT

CAP

TRAP

GROUND

JOINT

UNION

(OPTIONAL)

GAS

CONTROL

VALV E

producing carbon monoxide gas in excess of safe limits,

which could result in serious personal injury or death.

Contact your gas supplier for any specifi c changes which

may be required in your area.

Figure 13

SEDIMENT TRAP

WARNING

Fire and Explosion Hazard

• Contaminants in gas lines can

cause fire or explosion.

• Clean all gas piping before

installation.

• Install sediment trap in accor-

A sediment trap should be installed as close to the inlet of

the water heater as practical at the time of water heater

installation. The sediment trap should be either a tee fi tting

with a capped nipple in the bottom outlet or other device

recognized as an effective sediment trap. If a tee fi tting is

used, it should be installed in conformance with the method

of installation shown in Figure 13.

Contaminants in the gas lines may cause improper

operation of the gas control valve/thermostat that may

result in fi re or explosion. Before attaching the gas line be

sure that all gas pipe is clean on the inside. To trap any

dirt or foreign material in the gas supply line, a sediment

trap (sometimes called a dirt leg) must be incorporated in

the piping. The sediment trap must be readily accessible.

Install in accordance with the “Gas Piping” section. Refer

to the current edition of the “Natural Gas and Propane

Installation Code” B149.1 .

dance with B149.1.

WARNING

Breathing Hazard - Carbon Monoxide Gas

• High altitude orifice must be

installed for operation above

2,347 metres (7,700 ft.).

• Contact a qualified installer or

service agency.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

www. gsw-wh .com 19

VENTING

This direct vent water heater uses a sealed venting

system to supply fresh combustion air to the heater and

to exhaust the products of combustion (fl ue gases) to the

outdoors. The venting is a “pipe in a pipe” system. The

inner (3”) piping carries out the exhaust fl ue gases while

the outer (6”) piping carries in fresh combustion air. The

corrugated end of the vent piping connects to the top of

the water heater and the opposite end connects to the vent

termination hood which will be mounted on the exterior wall

(see Figure 15). Figure 15 shows the hot exhaust gas exit

and the location of the combustion air intake.

Figure 18 thru Figure 25 show how to assemble and

connect the venting system.

Figure 27 thru Figure 29 show various installation options.

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS AND LIQUIDS IN THE VICINITY

OF THE VENT TERMINATION HOOD.

WARNING

Breathing Hazard - Carbon Monoxide Gas

• Install vent system In accordance with codes.

• Do not operate water heater if flood damaged.

• Install water heater in accordance with the

instruction manual.

• Do not operate if soot buildup is present.

• Do not obstruct water heater air intake.

• Do not place chemical vapor emitting products near

water heater or vent terminal hood.

• Gas and carbon monoxide detectors are available.

• Never operate the heater unless it is vented to the

outdoors and has adequate air supply to avoid risks

of improper operation, fire, explosion or asphyxiation.

• Analyze the entire vent system to make sure that

condensate will not become trapped in a section of

vent pipe and therefore reduce the open cross

sectional area of the vent.

• Chemical corrosion of flue and vent system can

cause serious injury or death.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

NEVER OPERATE THE WATER HEATER UNLESS IT IS

VENTED TO THE OUTDOORS AND HAS ADEQUATE AIR

SUPPLY TO AVOID RISKS OF IMPROPER OPERATION,

FIRE, EXPLOSION OR ASPHYXIATION.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION

AND VENTILATION MUST BE PROVIDED FOR SAFE

OPERATION.

VENT TERMINAL CLEARANCES

The vent system must terminate so that proper clearances

are maintained as cited in local codes or the current edition

of the “Natural Gas and Propane Installation Code”

B149.1 as follows:

Figure 14

20 www. gsw-wh .com

FRESH

COMBUSTION

AIR IN

HOT

EXHAUST

GAS OUT

Figure 17

VENT CONNECTIONS

After the location for the vent terminal has been selected

as outlined in Figure 6 & Figure 14, use the following

illustrations for installation:

SCREW

Figure 15

Be sure venting is properly connected to prevent escape

of dangerous flue gases which could cause deadly

asphyxiation.

DV TERMINATION SAFETY COVER

When the heater is in operation the vent termination hood

will be hot (see Figure 15).

A Safety cover (see Figure 16) is available to prevent

accidental contact with the vent terminal. Contact your

Customer Service Department for ordering information.

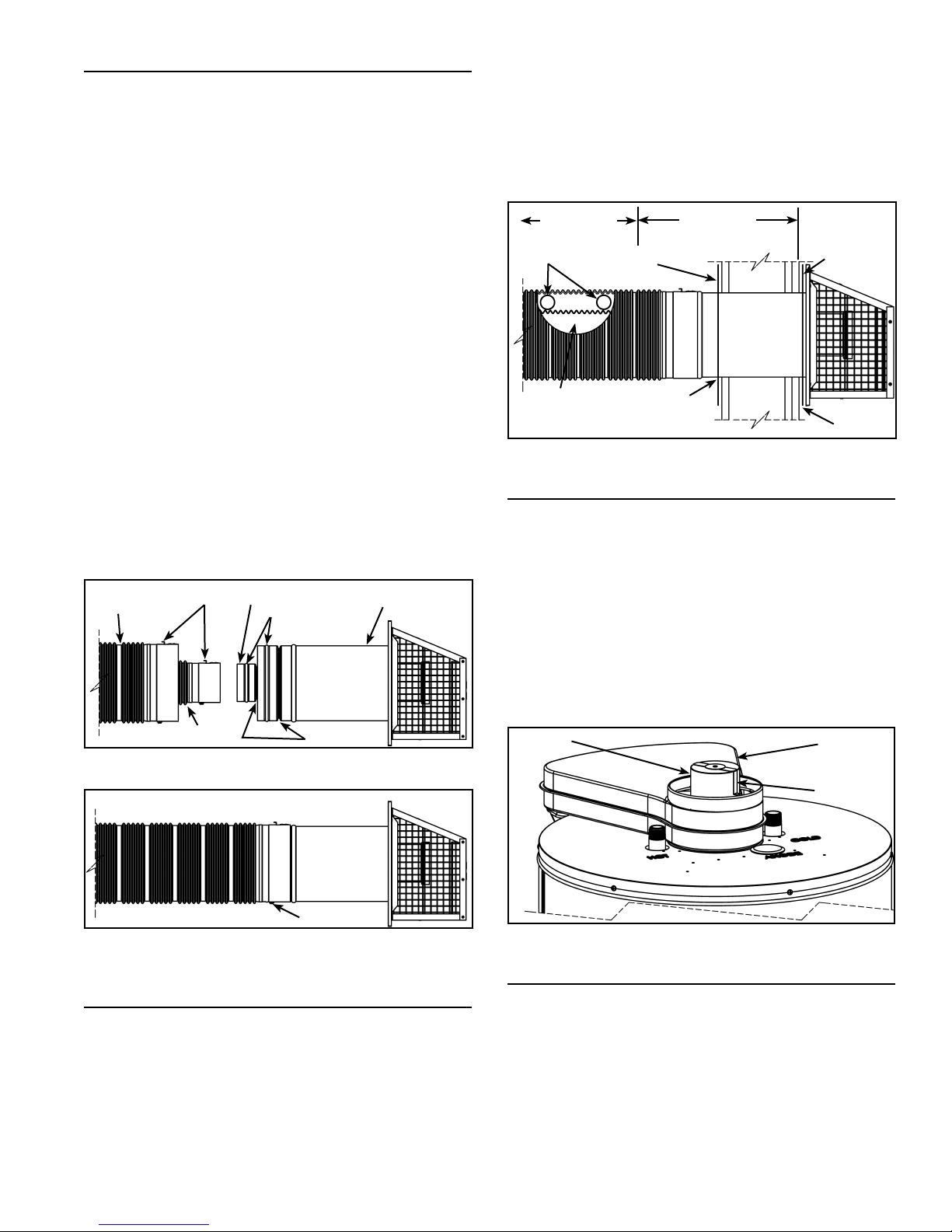

LOCATING CLEARANCE HOLE FOR VENT

Cut a clearance hole, approximately 178mm (7”) in

diameter, through the exterior wall for the vent assembly.

The recommended height is 1.62m (64”) for 151l (40 gal.)

models, 1.85m (73”) for 189l (50 gal.) models and 1.88m

(74”) for 189l (50 gal.) Hi-Input models, as measured from

the hole center to bottom of water heater. Where the wall

is combustible and the wall thickness is over 356mm (14”),

25mm (1”) clearance to combustible surfaces around the

vent terminal is needed. The fi rst 356mm (14”) is zero

clearance (see Figure 20).

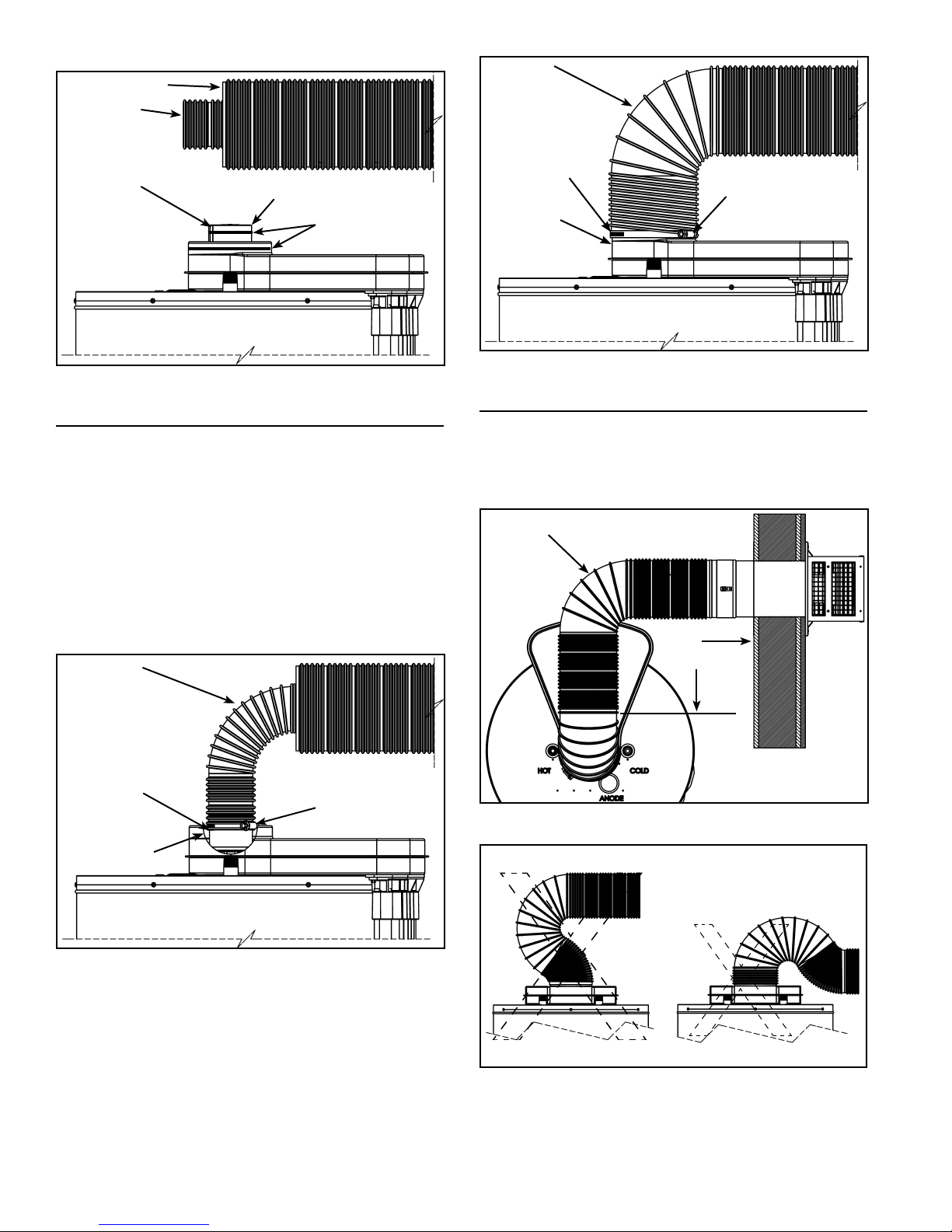

STANDARD VENT ARRANGEMENT

* If the horizontal length of the venting is less than 762mm

(30”) the restricter plate must be installed (see Figure 21,

Figure 27 thru Figure 29).

• Do not use the restricter plate in an offset installation

(see Figure 25).

• Do not use the restricter plate the horizontal length of

the venting is greater than 762mm (30”).

Note: The length of “unstretched” corrugated tube could

cause the length of the vent run to exceed the minimum. In

this case cut off a piece of the corrugated tube to achieve

the 432mm (17”) minimum vent length.

Figure 16

Alternatively, a wire mesh or louvered fencing guard can

be built around the termination as shown in Figure 17.

www. gsw-wh .com 21

VENT ASSEMBLY

The vent piping and the vent termination hood are to be

connected as shown in Figure 19.

Maintain vent clearances to combustibles as shown in

Figure 20.

Depending on your access to where the vent termination

passes through the wall, you may wish to connect the

piping and vent termination hood together fi rst.

Inside the vent piping there are springs that hold the two

corrugated pipes in position. When the pipes are stretched

to the required length, the springs will remain properly

spaced.

To connect the vent piping to the vent termination hood,

fi rst slide the inner (3”) corrugated pipe over the inner vent

termination pipe. Continue this action until the locking

clip on the corrugated pipe snaps into position in the

corresponding groove (see Figure 18). Secure corrugated

pipe with screw (supplied) inserted through hole opposite

the locking clip.

Repeat this process with the outer (6”) corrugated pipe and

lock it into position on the outer pipe on the vent termination

(see Figure 18). Secure corrugated pipe with screw

(supplied) inserted through hole opposite the locking clip.

Note: To reduce the friction between the corrugated pipe

and the O-rings, it is recommended to dampen the O-rings

with water.

The completed connection is shown in Figure 19.

OUTER

CORRUGATED

PIPE

LOCKING

CLIP

INNER VENT

TERMINATION PIPE

O-RING

OUTER VENT

TERMINATION PIPE

junction of the vent terminal base plate and the exterior

wall with exterior type sealant (not included). Slide the trim

plate (inside) over the outer corrugated tube and fasten the

trim plate to the interior wall. Caulk the junction of the outer

corrugated tube and the trim plate (inside) with suitable

sealant. The vent termination hood attaches to the vent

piping as shown in Figure 19.

25mm (1”)

CLEARANCE

SPRING

CUTAWAY TO

SHOW SPRING

PLACEMENT

TRIM PLATE

(INSIDE)

APPLY

SEALANT

356mm

(14”) ZERO

CLEARANCE

TRIM PLATE

(OUTSIDE)

APPLY

SEALANT

Figure 20

VENT RESTRICTER PLATE

The vent restricter plate (see Figure 21) is required for

short horizontal runs on low vent installations (see Figure

28) and high vent installations (see Figure 29).

For short horizontal vent runs (see Figure 28) place the

restricter plate over the fl ue tube reducer before connecting

the inner corrugated tube to the fl ue tube reducer. DO NOT

use the restricter plate if the horizontal run is greater than

762mm (30”).

For high vertical runs use the restricter plate only when

the vertical run of the venting above the heater is greater

than 1.21m (48”) (see Figure 29).

INNER

CORRUGATED PIPE

LOCKING CLIP

GROOVE

Figure 18

SCREW

Figure 19

SECURING VENT TERMINATION ASSEMBLY TO

THE EXTERIOR WALL

Some models are supplied with trim plates which may

be used to cover the holes in the wall (see Figure 1 and

Figure 20). Slide one trim plate (if supplied) over the outer

corrugated tube, then insert the outer corrugated tube

through the clearance hole from exterior wall. Secure

the trim plate to the exterior wall, then secure the vent

terminal to the exterior wall with 4 screw anchors (included)

appropriate for the type of wall construction. Caulk the

FLUE TUBE

REDUCER

UPPER AIR

INLET BOX

RESTRICTER

PLATE

Figure 21

UNCOMPRESSING THE CORRUGATED TUBING

1. Pull the inner corrugated tube towards the water heater

and leave some length over the water heater’s center

for bending (see Figure 22).

2. Pull the outer corrugated tube toward the water

heater and leave it 50mm (2”) shorter than the inner

corrugated tube.

3. Make sure there are two springs evenly spaced at the

bend in the tube.

4. Use metal hangers to keep venting level or with a

slope upward from the heater to terminal.

22 www. gsw-wh .com

OUTER

CORRUGATED PIPE

INNER

CORRUGATED

PIPE

RESTRICTER

PLATE

FLUE TUBE

REDUCER

APPLY

SILICONE

SMOOTH,

EASY CURVE

APPLY

SILICONE

TO AIRBOX

BEFORE

ATTACHING

PIPING

SECURE

WITH A

SHEET METAL

SCREW

GEAR

CLAMP

Figure 22

VENT CONNECTION TO THE WATER HEATER

Bend both the corrugated pipes toward the fl ue connection

on the water heater. Pull and connect the inner corrugated

pipe to the water heater’s fl ue tube reducer with hi-temp

red silicone (included) and gear clamp. Make sure this

connection is tight and leak proof (see Figure 23).

*The sealant between the inner corrugated pipe and water

heater’s fl ue tube reducer must be hi-temp red silicone

or other material suitable for 315°C (600°F) continuous

service.

Note: If you are using the vent restricter plate, the inner

vent pipe is to go over the side legs and down the stops.

SMOOTH,

EASY CURVE

RESTRICTER

PLATE STOP

GEAR

CLAMP

Figure 24

OFFSET VENT ARRANGEMENT

Where a straight vent arrangement is impossible, a

horizontal 90° maximum bend can be made. Use the

water heater casing outer diameter as a template to form

the corrugated tube.

SMOOTH,

EASY CURVE

90°

MAXIMUM

BEND

Figure 25

CUTAWAY TO

SHOW DETAILS

Figure 23

Apply hi-temp red silicone (included) around the collar on

air manifold box. Pull the outer corrugated pipe all the way

on to collar and secure with the gear clamp. Pull the free

end of the corrugated pipe past the gear clamp and secure

with one sheet metal screw (see Figure 24).

www. gsw-wh .com 23

Figure 26

Note: To ensure good exhaust gas fl ow, bend vent piping

using a smooth, easy curve as shown in Figure 23 thru

Figure 25. Do not use reverse or compound curves as

shown in Figure 26.

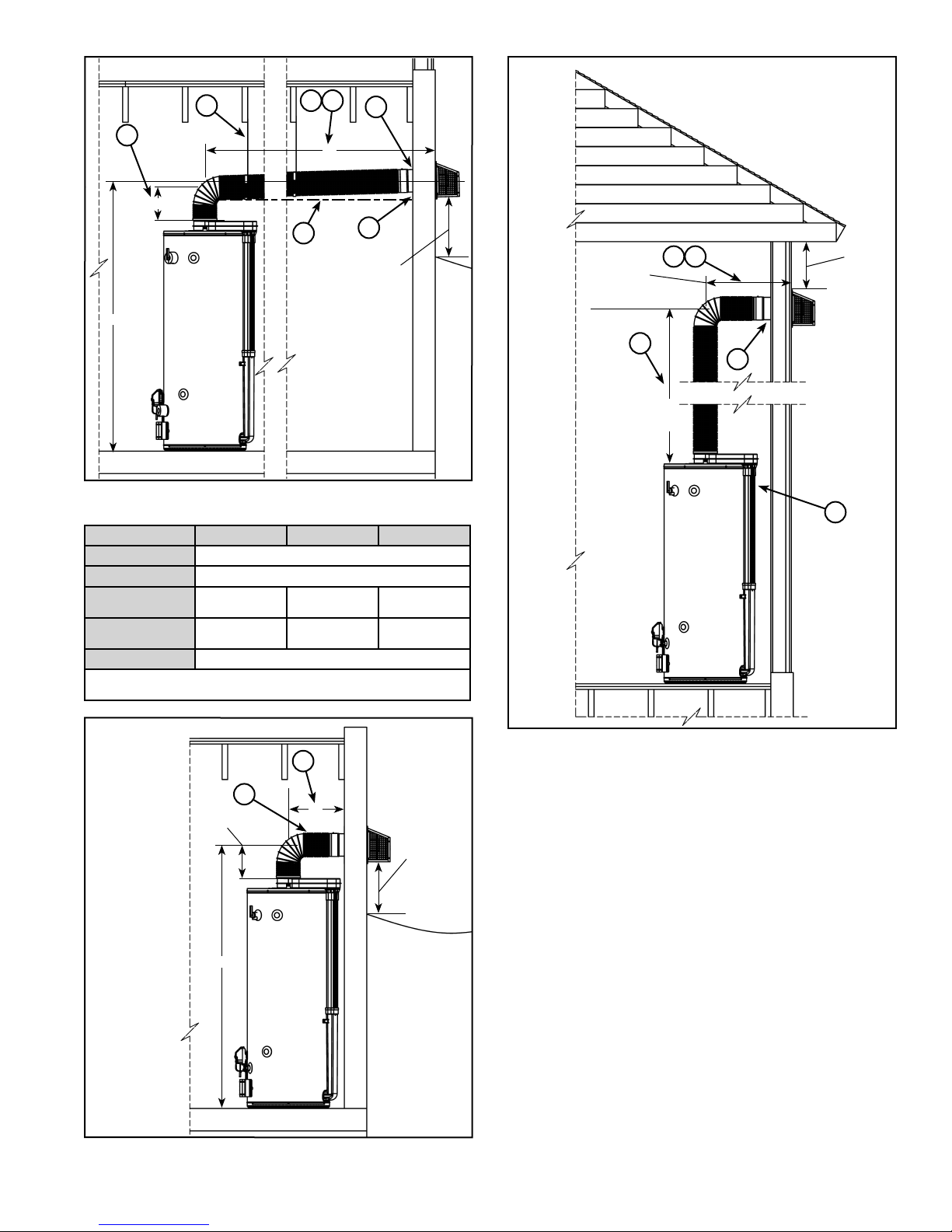

Low Vent installation

9

High Vent installation

1

5

6

1

A

B

7

C

8

ABOVE

ANTICIPATED

SNOW LEVEL

OR 305mm

(12”) ABOVE

GRADE

Figure 27

DIM. 4038 5040 5047

A 2.03m (80”) MAX.

B 228mm (9”) MIN.

C

(RECOMMENDED)

C

(MINIMUM)

D 362mm (14.25”) MIN.

NOTE: Dimension “C” is the height above to fl oor to the center of the

termination hole through the exterior wall.

1.62m (63.63”) 1.85m (73.00”) 1.88m (74.00”)

1.54 (60.75) 1.75 (69.50) 1.79 (70.50)

432mm

(17”)

MIN.

1

1.83m

(72”)

MAX.

51

305mm

(12”) MIN.

BELOW

SOFFIT

6

2

Minimum Vent installation

3

228mm

(9”)

C

Figure 28

Figure 29

4

NOTES: (applies to Figure 27 thru Figure 29)

1. In any installation the total of dimension “A” plus

ABOVE

D

ANTICIPATED

SNOW LEVEL

OR 305mm

(12”) ABOVE

GRADE

dimension “B” must not exceed 2.26m (89”).

2. This heater can be installed with 0mm (0”) clearance

to a wall.

3. Minimum vent pipe clearance to combustibles is 25mm

(1”) (see Figure 20).

4. Minimum distance from center of heater to wall is

362mm (14.25”).

5. Dimension “A” includes wall thickness.

6. Hole diameter in wall is 178mm (7”).

7. Venting must slope up away from the heater a

minimum of 6.4mm per 305mm (0.25” per foot) of

length to prevent condensation from collecting

and to provide suffi cient draft.

8. Distance above horizontal at full extension is 50mm

(2”).

9. Use support stays to hold the venting to avoid sags

or valleys.

24 www. gsw-wh .com

INSTALLATION CHECKLIST

Note: Use and complete this checklist before lighting the

heater. Correct any conditions that do not meet these

instructions.

Water Heater Location

Centrally located with the water piping system.

Located as close to gas piping and vent pipe system

as possible.

Located indoors and in a vertical position. Protected

from freezing temperatures.

Proper clearances from combustible surfaces

maintained and not installed directly on a carpeted

floor.

Provisions made to protect the area from water

damage. Metal drain pan installed and piped to an

adequate drain.

Installation area free of corrosive elements, flammable

material and flammable vapour emitting products.

Sufficient room to service the water heater.

Gas Supply and Piping

Gas supply is the same type as listed on the water

heater data plate.

Gas line equipped with shut-off valve, union and

sediment trap.

Adequate pipe size and of approved material.

Approved pipe joint compound or tape used.

Chloride-free soap and water solution or other

approved means used to check all connections and

fittings for possible gas leaks.

Vent Termination Hood

Securely fastened to exterior wall.

Above anticipated snow level or 305mm (12”) above

grade.

Proper clearances from windows, doors, corners,

other vent openings etc.

Area around vent termination hood clear and

unobstructed.

No flammable vapour emitting products stored nearby.