Page 1

30303644 Issue 1.05

Features

Electronically addressed. The address is

modified in field.

Built-in microprocessor can store 14 history

records.

Drift compensation, to suit environment changing

extensively.

Self-diagnostic.

Standard: UL 268.

Description

I-9102(UL) Intelligent Photoelectric Smoke Detector

(the detector) can form fire alarm system connecting

with fire alarm control panel. The detector illuminates

indicators to indicate fire alarm status and transmits

the fire signal to the control panel.

Using infrared scattering technology, the detector

receives very weak infrared light under normal

smokeless condition. If smoke particles enter the

chamber, the received light signal will increase by

scattering. When smoke density reaches a pre-set

level, the detector will alarm out. In order to reduce

interference and power consumption, the emitting

circuit works in pulse mode to prolong the life of IR

LED.

Connection and Cabling

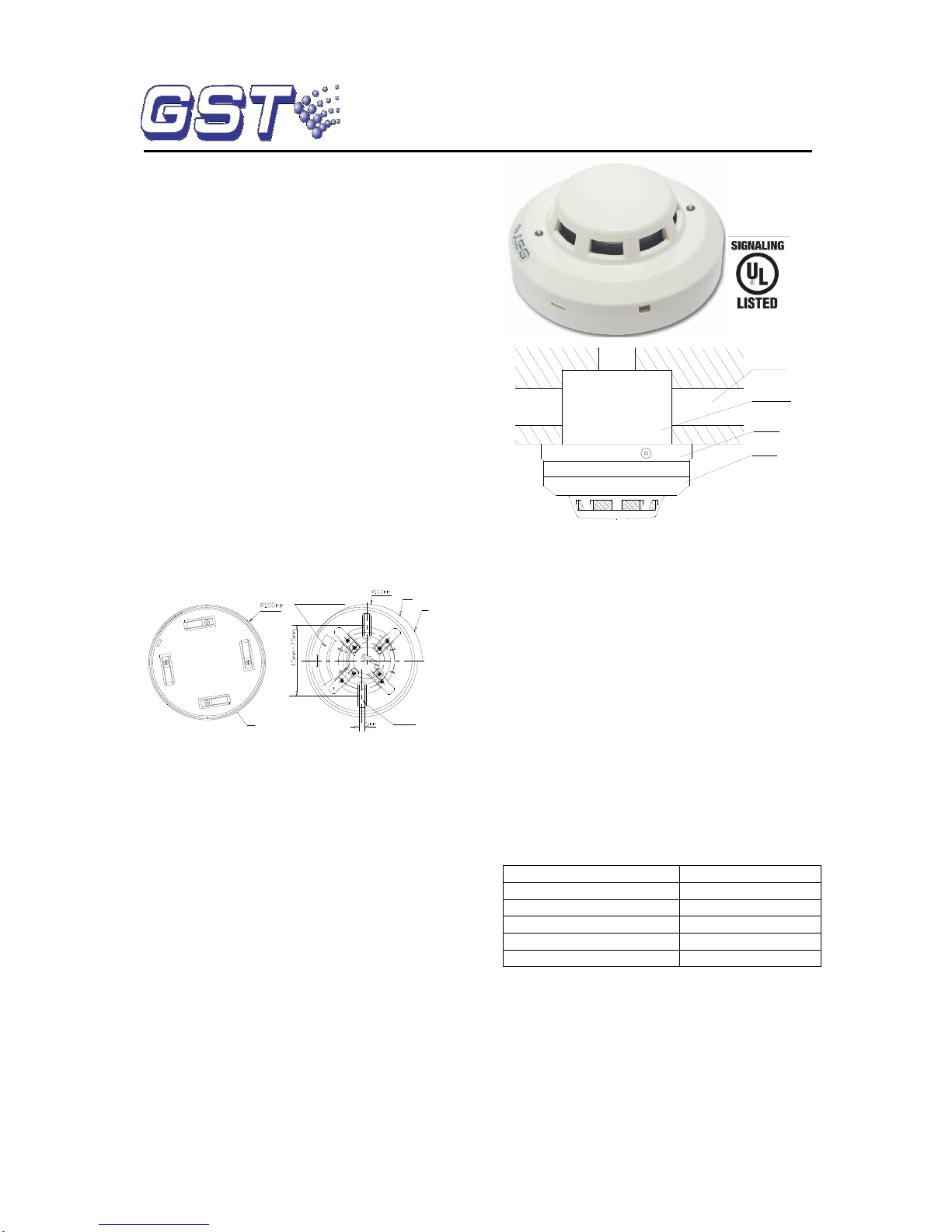

Fig.1 shows the detector bottom and Fig. 2 the base.

C

D

Z

-

0

3

A

B

Base Record Label

Mounting Hole

Distance

Fig. 1 Fig. 2

There are four conducting piece on the base, each

carrying a terminal with numbers. The detector loop in

the conduit can be connected with any two diagonal

conducting pieces (polarity-insensitive). The other two

are used to fix the detector accessorily.

Recommended Cabling

1.0mm2 or above fire cable for detector loop, subject to

local codes.

UL Listed Compatible Control Panel: GST-M200

Installation

A fixed installation direction is ensured by the location

elements on the detector and the base. Fix the base

with two tapping screws, and then align mark C on the

detector with A on the base, rotate the detector to align

mark C with mark B (Refer to Fig. 1 and 2 for the

position of the marks), the detector will be fitted to the

base. Mounting of the detector is shown in Fig. 3.

Application

The detector is applicable to hotels, restaurants, office

buildings, teaching buildings, banks, warehouses,

libraries, computer rooms and switch rooms, etc.

Address can be programmed through programmer in

field. Refer to the P-9910B Hand Held Programmer

Installation and Operation Manual for further details.

Detector

Base

Back Box

Conduit

Fig. 3

Testing

Before testing, notify the proper authorities that the

system is undergoing maintenance, and will temporarily

be out of service. Disable the zone or system

undergoing maintenance to avoid unwanted alarms.

All detectors must be tested after installation and

periodically thereafter. Testing methods must satisfy the

Authority Having Jurisdiction (AHJ). Detectors offer

maximum performance when tested and maintained in

compliance with NFPA 72. The detector can be tested in

the following way:

The Trutest model 300 Aerosol Smoke Detector Tester

can be used for smoke entry testing. Set the generator

to represent 4%/ft to 5%/ft obscuration as described in

the Trutest manual. Using the bowl shaped applicator,

apply aerosol until the panel alarms.

Additionally, canned aerosol simulated smoke (canned

smoke agent) may be used for smoke entry testing of

the smoke detector. Recommended aerosol smoke

products are:

Manufacturer

Model

Trutest

AERO400

Home Safeguard Industries

25S

SDi

CHEK02 and CHEK06

SDi

SOLOA4

SDi

SMOKESABRE-01

When used properly, the canned smoke agent will

cause the smoke detector to go into alarm. Refer to the

manufacturer’s published instructions for proper use of

the canned smoke agent.

Warning: Canned aerosol simulated smoke (canned

smoke agent) formulas will vary by manufacturer.

Misuse or overuse of these products may have long

term adverse effects on the smoke detector. Consult the

canned smoke agent manufacturer’s published

instructions for any further warnings or caution

statements.

I-9102(UL)

Intelligent Photoelectric Smoke Detector

Page 2

30303644 Issue 1.05

When testing is complete, restore the system to normal

operation and notify the proper authorities that the

system is back in operation.

Maintenance

1. The detector must be cleaned once a year to

ensure normal operation of the system.

2. Before cleaning, notify the proper authorities that

the system is undergoing maintenance and will

temporarily be out of service. Disable the zone or

system undergoing maintenance to avoid unwanted

alarms.

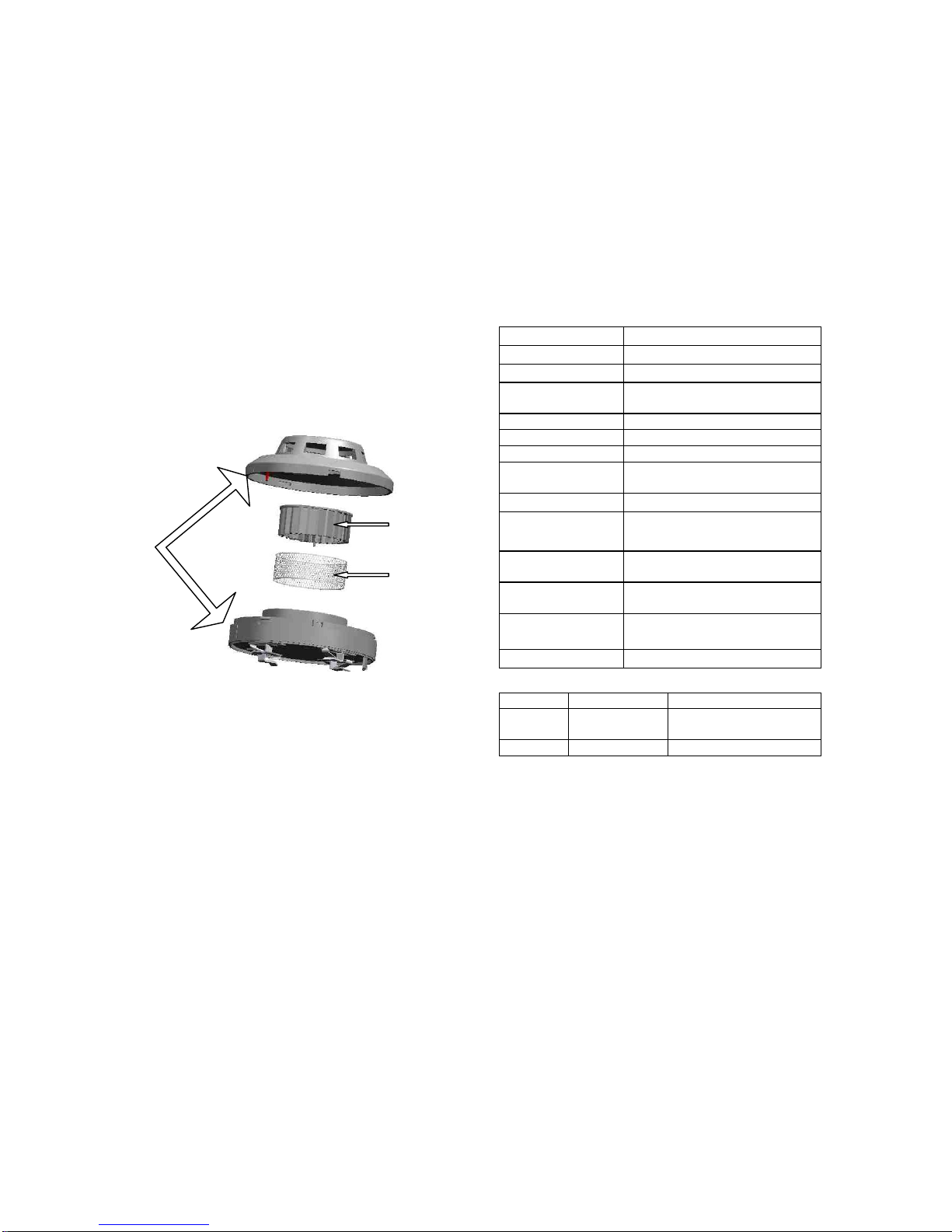

3. Remove the detector from base. Use straight

screwdriver to prize the top cover through three small

grooves. Use a vacuum cleaner or cleaned,

compressed air to remove dust and debris from the

insect guard. If the dust is too much to clean up, you

can remove the sensing chamber and pull the insect

guard to clean or replace. Use a vacuum cleaner or

cleaned, compressed air to remove dust and debris

from the sensing chamber. Reinstall the sensing

chamber and insect guard properly. Aligning the marks

on enclosure, install the top cover again. Refer to

Fig.4.

Fig. 4

4. The detector should be tested again after

re-installed.

Cautions

1. Dust cover can’t be removed until the project is

plunged. Protect the dust cover for the future use.

2. Dust cover provides limited protection against

airborne dust particles. So, remove the detector prior

to heavy remodeling or construction and inform the

proper authority.

3. Be careful not to damage the detector in

maintenance.

4. The smoke detector may not sense fire that where

smoke cannot reach it, such as in chimneys, in walls,

on roofs, or on the other side of closed doors.

5. The detector cannot monitor the place beyond

protection area.

6. The detector may not warn you about fires caused

by insufficient safety measures, violent explosions,

leaking gas, improper storage of flammable materials

like diluents and other safety hazards, arson or

children playing with fire.

7. The alarm of a smoke detector used in high

velocity environment will be delayed due to dilution of

smoke by frequent and fast airflow.

8. The smoke detector cannot last forever. In order to

keep the detector working in good condition, please

maintain the equipment continuously according to

recommendations from manufacturers and relative

nation codes and laws.

9. The detectors must be tested regularly, at least

once a year.

Specification

Operating Voltage

Loop 24V(16V~28V)

Standby Current

≤0.8mA

Alarm Current

≤2.0mA

Indicators

Red, flash in normal, illuminate

when alarming

Programming Mode

Electronically addressed

Code Range

One address within 1~242

Wiring

Two-wire, polarity-insensitive

Ambient

Temperature

32℉(0℃)~100℉(+37.8℃)

Relative Humidity

≤95%, non condensing

Ingress Protection

Rating

IP23

Material and Color

of the Enclosure

ABS, White (RAL 9010)

Dimensions

Diameter 100mm

Height: 43mm (without base)

Mounting Hole

Distance

45mm~75mm

Weight

About 120g

Accessories and Tools

Model

Name

Remark

P-9910B

Hand Held

Programmer

Order separately

DZ-03

Base

Order separately

Limited Warranty

GST warrants that the product will be free of charge

for repairing or replacing from defects in design,

materials and workmanship during the warranty period.

This warranty does not cover any product that is found

to have been improperly installed or used in any way

not in accordance with the instructions supplied with

the product. Anybody, including the agents,

distributors or employees, is not in the position to

amend the contents of this warranty. Please contact

your local distributor for products not covered by this

warranty.

Sensing

Chamber

Insect

Net

Marks on side

This Data Sheet is subject to change without notice. Please contact GST for more information or questions.

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei, P. R. China 066004

Tel: +86 (0) 335 8502434 Fax: +86 (0) 335 8502532

service.gst@fs.utc.com www.gst.com.cn

Loading...

Loading...