GST DI-9104Exd Quick Start Manual

M3×16

UV Flame Detector

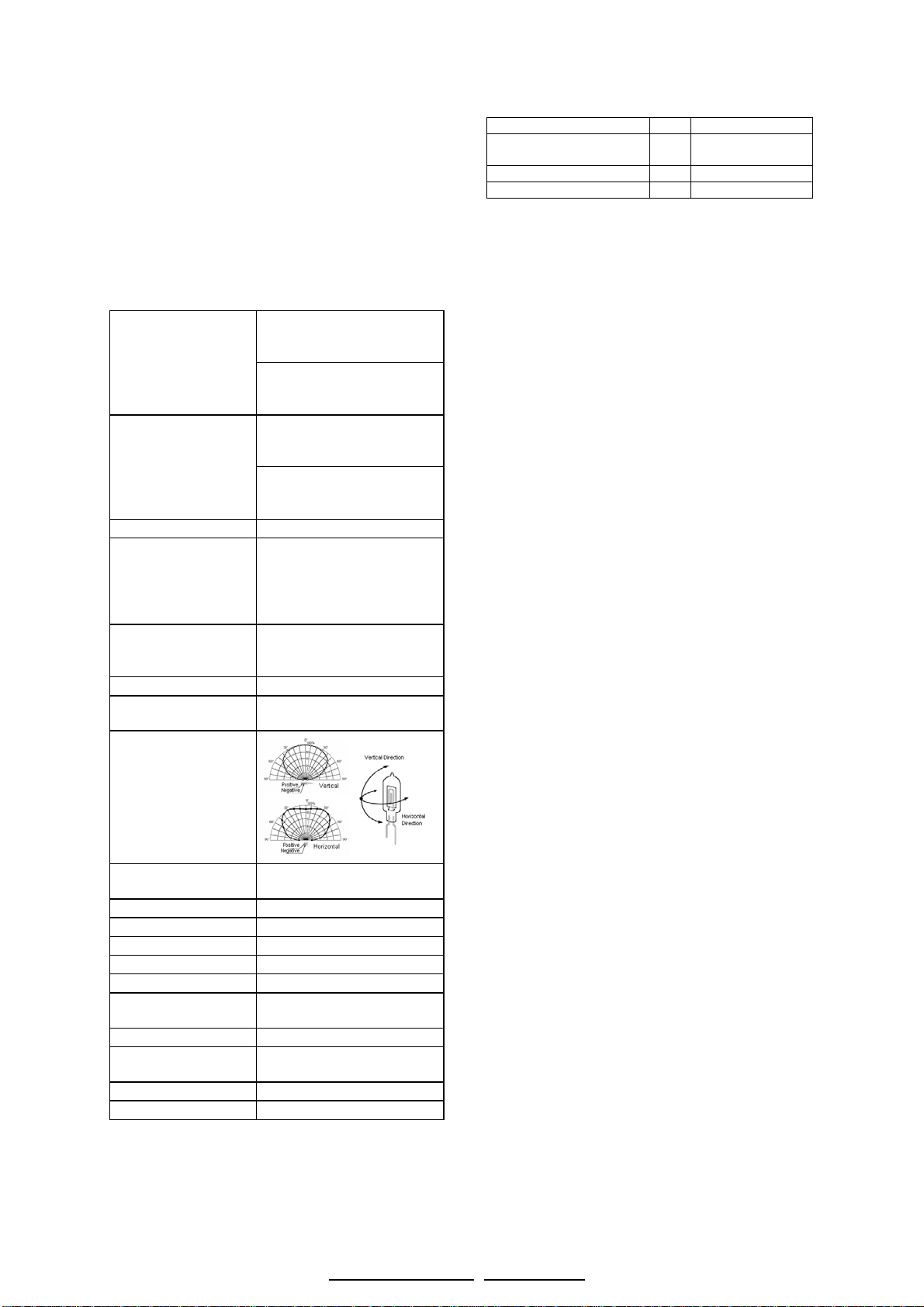

FACP

Z1

Z2

Z1

Z2

K1

K2

DI-9104Exd Detector

Hazardous Area

Safety Area

Input Equipment

Z1

Z2

K1

K2

DI-9104Exd Detector

24VDC

Signal

Input

Hazardous Area

Safety Area

DI-9104Exd Digital Flame Proof

Features

Built-in MCU processes signals and controls

communication digitally.

Intelligent algorithm ensures quick response to

reduced false alarms.

3 classifications available.

High sensitivity, reliable performance, and

dust-proof, damp-proof and corrosion-proof

abilities.

Description

DI-9104Exd is a light-sensitive detector that detects

fire by picking up the ultraviolet light from flaming

material. It’s designed for areas where an open fire is

li able to occ ur with la rge amou nt of radiation and no

smoldering st ag e, or w her e q u i c k r es po n s e t o a f ir e i s

required. This detector can be applicable to zone 1

and 2 of explosive hazardous areas.

The detector is able to work either in addressable

mode connecting with GST intelligent fire alarm

control panel(FACP) to transmit signal through

detecti on loop or in non-addressable mode connecting

to 24VDC power supply to transmit signal by

outputting di f ferent resistan ce values.

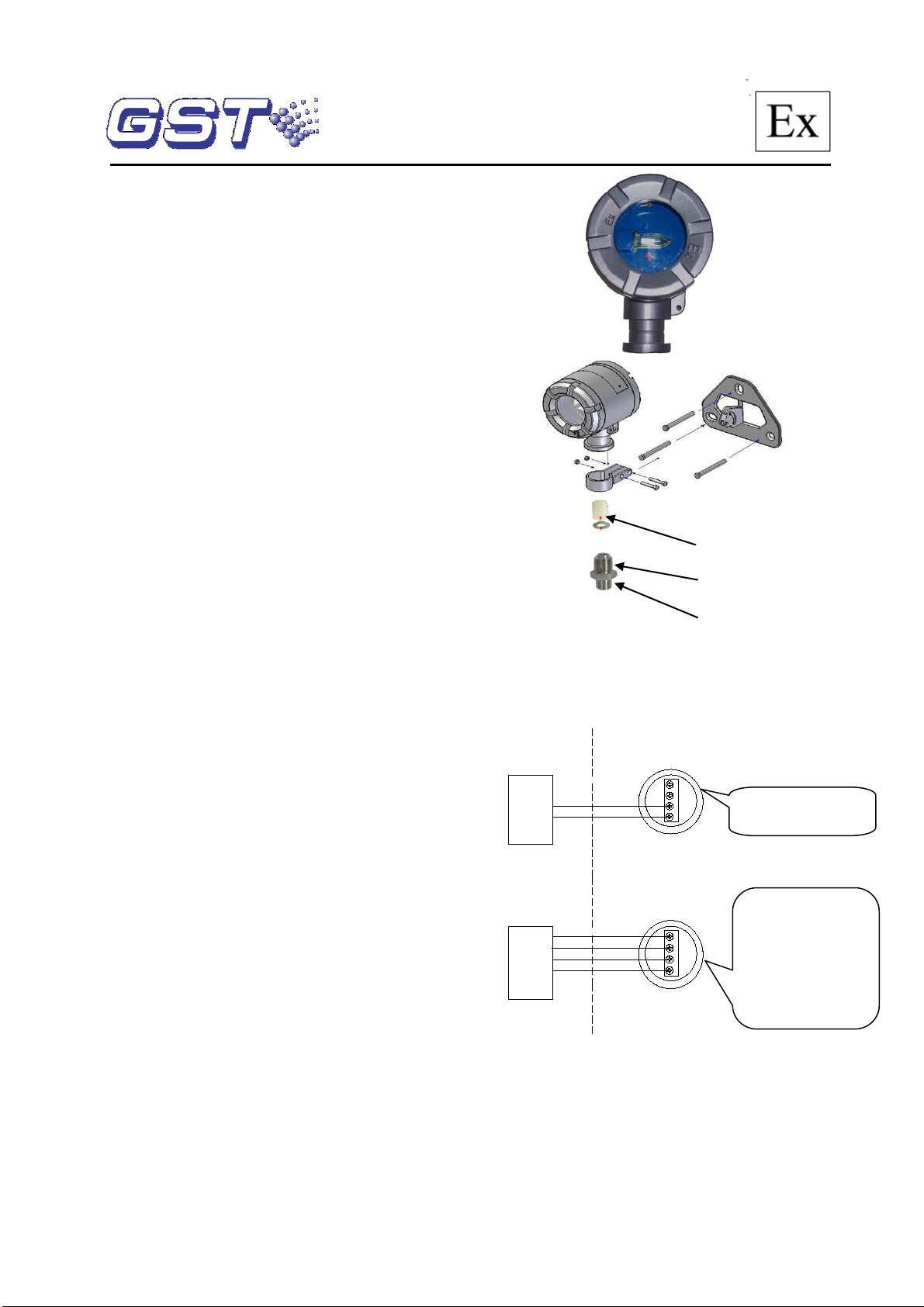

M6×60

Sealing and washer,

φ8mm(inter nal di ameter )

M24×1.5

Connection and Wiring

Screened 2-core cable with cross section 1mm2 or

abo ve, an d outer diameter φ8 mm is required for field

wir ing. Please foll ow the steps bel ow:

(1) Rotate down the back cover and the pressing nut.

(2) Thread a proper length of the cable through the

pressing nut, metal washer and joint washer in

sequence.

(3) Peal away the outer layer of the cable with 5mm of

metal core exposed, rotate in the cable together

with the joint washer, metal washer and the nut into

the detector housing, and fasten the nut using a

spanner.

(4) Connect the cables to corresponding terminals of

the detector, and the screen layer to the safety

earth position inside the housing.

(5) Fast en the back cover with tools, and make sur e

the detector is earthed through its safety earth

position on the cover.

Installation

(1) Fig. 1 is the schematic diagram for installing the

detector.

(2) Pl ease check the following after installation:

There shall not be any crack or air bubbles.

The back cover and the detector shall be

securely fastened.

There shall not be any scratch or crack on the

detecting window.

There shall be joint washer in the wiring hole.

The joint washer matches with the cable

diameter.

The pressing nut is locked.

There is earth cab le at th e “ earth” mark .

The det ecti on win dow shal l face t he pro tected

area.

Note: The d etector shall be in stalled in compliance

with relative installation codes. Make sure the

housing is in good condition.

30309304 Issue 1.06

NPT 1/2

Fig. 1

Application

Schematic of system connection is shown in Fig. 2

(addressable mode) and Fig .3 (non-addressable mode).

Z1and Z2 connects w ith the loop

of FACP, polarity-ins ensitive.

Fig. 2

Z1, Z2: Pow er inpu t ,

polarity-insensitiv e.

K1, K2: Signal output.

Resistance between the

terminals is 4.7kΩ norma lly.

Shorted in fire alarm

condition.

Open in fault condition.

Fig. 3

Operation

The detector powered by 24VDC voltage, which may

come from control panel in addressable working mode

or 24VDC power suppl y in non-addressable working

mode.

In addressable mode, Terminal Z1 and Z2 are to be

connected with the loop of FACP polarity-insensitively.

The FACP p olls the detector status through the loop,

and displays its fau l t and fire alarm mes sages.

Operating Voltage

Addressable Mode:

fr om FACP Z1,Z2 terminals

Non-addressable Mode:

power supply

Operating Current

Addressable Mode:

Alarm current ≤ 3mA

Non-addressable Mode:

Alarm current ≤ 23mA

Power-up Time

≤10s

Indicator

In addressable mode and

illuminates steadily in alarm.

Programming Mode

Electronic programming.

Occupying one loop

address.

Address Range

1~242

Spec trum R esponse

Range

185nm~260nm

Detection Angle

Detection

Distance※

25m for Class 1, 17m for

Class 2 and 12m for Class 3.

Alarm Respon se time

≤30s

Ingress P rotection

IP66

Ambient Temperatur e

-20 ℃~+60 ℃

Relativ e Humidity

≤95%RH, non-condensing

Dimensions

147mm×106mm×92mm

Mat erial and Color

ZL102 alumi num alloy,

silvery grey.

Weight

1.5kg

Installation Hole

Spacing

110mm×72mm

ATEX Cert i ficate NO.

Presafe 14 ATEX 5547

Explosion-proof Mark

Ex dⅡCT6Gb

Nam e and Mod el

Qty.

Remarks

P-9910B Hand Held

Programmer

1

Ord er separa tely

Expansion Bolt M6×60

3 Screws M3×16

2

Gulf Security Technology Co., Ltd.

In non-addressable mode, 24VDC power supply can

be directly applied to Terminal Z1 and Z2. K1 and K2

output different resistance in different conditions. I f the

resistance is 4.7kΩ, t he det ector is in no rmal s tandb y

state; if the terminals are shorted, the detector is in fire

condition; if the terminals are open, the detector is in

fault condition.

The d etec to r h as 3 classifications. The factory default

is Class 1. The addr ess and sensiti vity can be read

and changed using P-9910B Programmer. Please

refer to P-9910B Hand Held Programmer Operation

Manual for details.

Specification

Loop voltage: 24VDC come

Voltage: 24VDC come from

Standby current ≤ 2mA

Standby current ≤ 13mA

non-addressable mode,

indic ator is red. It flashes

when polling, and

Accessories and Tools

Maintenance

(1) The detector shall be cleaned at least once a year

to ensure normal operation of the system.

(2) Before cleaning, notify the proper authorities that

the system is undergoing maintenance and will

temporarily be out of service. Disable the zone or

system undergoing maintenance to avoid

unwanted alarms.

(3) The detector shall be tested after being cleaned

and re-installed. After testing, notify the proper

authorities the system is back in operation.

Caution

(1) The detector should be handled with care during

storage, transportation, installation, commission

and maintenance to avoid damage from falling,

im pact, ou t side f orce an d f riction.

(2) Instal lation and maintenance should strictly comply

with relative codes for explosive and hazardous

areas.

(3) Never open the cover for maintenance in field.

(4) The enclosure must be earthed.

(5) The len only endures low impact energy, so the

detector shall be installed the position wher e the

foreign objects can’t attack it.

(6) The following places are not suitable for the

detector:

Where flameless fire is to be exp ected.

Where intensive smok e spread s before flames.

Where the "view" of the det ector is opt to be

obscured.

Where the sun can directly shine or i ndir ectly

shine the d etecti on window.

Wher e ther e is st rong UV lig ht so urce in fiel d,

like a tungsten halogen lamp.

Where open fire, welding, X rays, arc or sparks

may exist in normal condition.

(7) The threaded entries comply with following

parameters:

Position on the equ ipment: see Fig.1

The number permitted:1

Sealing and washer size: φ8mm(internal

diameter) × φ18mm(external diameter) ×

20mm(thickness)

Cable external diameter φ6~φ8 mm is

recommended

The torque for cable nut is 25 N .m t o c om pr es s

sealing ring

※Test fi re: Th e flam e generat ed by 200 0g of alc ohol

(concentration above 90% ) in a c ont ai n er wi th b ot tom

area 33cm×33cm and height 5cm.

This Data Sheet is subject to change without notice. Please contac t GST for more infor mation or que stions.

30309304 Issue 1.06

Limit ed Warranty

GST warrants that the product will be free from defects

in design, materials and workmanship during the

warranty period. This warranty shall not apply to any

product that is found to have been improperly installed

or used in any way not in accordance with the

instructions supplied with the product. Anybody,

including the agents, distributors or employees, is not

in the position to amend the contents of this warranty.

Please contact your local distributor for products not

covered by this w ar ranty.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei, P. R. China 066004

Tel: +86 (0) 335 8502434 Fax: +86 (0) 335 8502532

service.gst@fs.utc.com www.gst.com.cn

Loading...

Loading...