Page 1

Page 2

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page I

CONTENTS

1 Overview .................................................................................................................. 1

2 Specification ............................................................................................................ 1

3 Construction and Operation Principle ................................................................... 2

3.1 Construction ........................................................................................................ 2

3.2 Adjustment Frame ............................................................................................... 3

3.3 Operation Principle ............................................................................................. 3

4 Installation and Connection ................................................................................... 3

4.1 Installation ........................................................................................................... 3

4.2 Connection.......................................................................................................... 4

5 Testing ...................................................................................................................... 6

6 Operation ................................................................................................................. 6

7 Application ............................................................................................................... 7

8 Troubleshooting ...................................................................................................... 7

9 Maintenance............................................................................................................. 8

10 Caution ................................................................................................................... 8

11 Accessories ........................................................................................................... 8

Page 3

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 1

1 Overview

Dual-band infrared light detection for fire alarm.

Sensitive to flame from material containing carbon. Suitable for fire happen with

flame at the start.

Addressable (connecting GST fire alarm control panel) and non-addressable

(through relay contact) working modes optional.

Flame-proof. Applicable to either commercial or hazardous industrial areas, such

as explosive Zone 1 and 2, and flammable dust atmosphere.

2 Specification

Operating Voltage:

Loop 24V come from control panel Z1,Z2 terminals(addressable mode

application) or power supply(non-addressable mode application)

24VDC come from 24VDC power supply

Operating Current:

Loop: Standby current≤1mA, alarm current≤1mA, Maximum Consumption

28mW

24VDC: Standby current≤20mA, alarm current≤30mA, Maximum

Consumption:840mW

Classifications:

The detector has 3 classifications. The factory default sensitivity is class 1,

which can be reduced in field using GST handheld programmer.

Detection Distance:

Class 1 : 25m (furthest)

Class 2: 17m

Class 3: 12m

Test Fire: 33cm×33cm n-heptane fire.

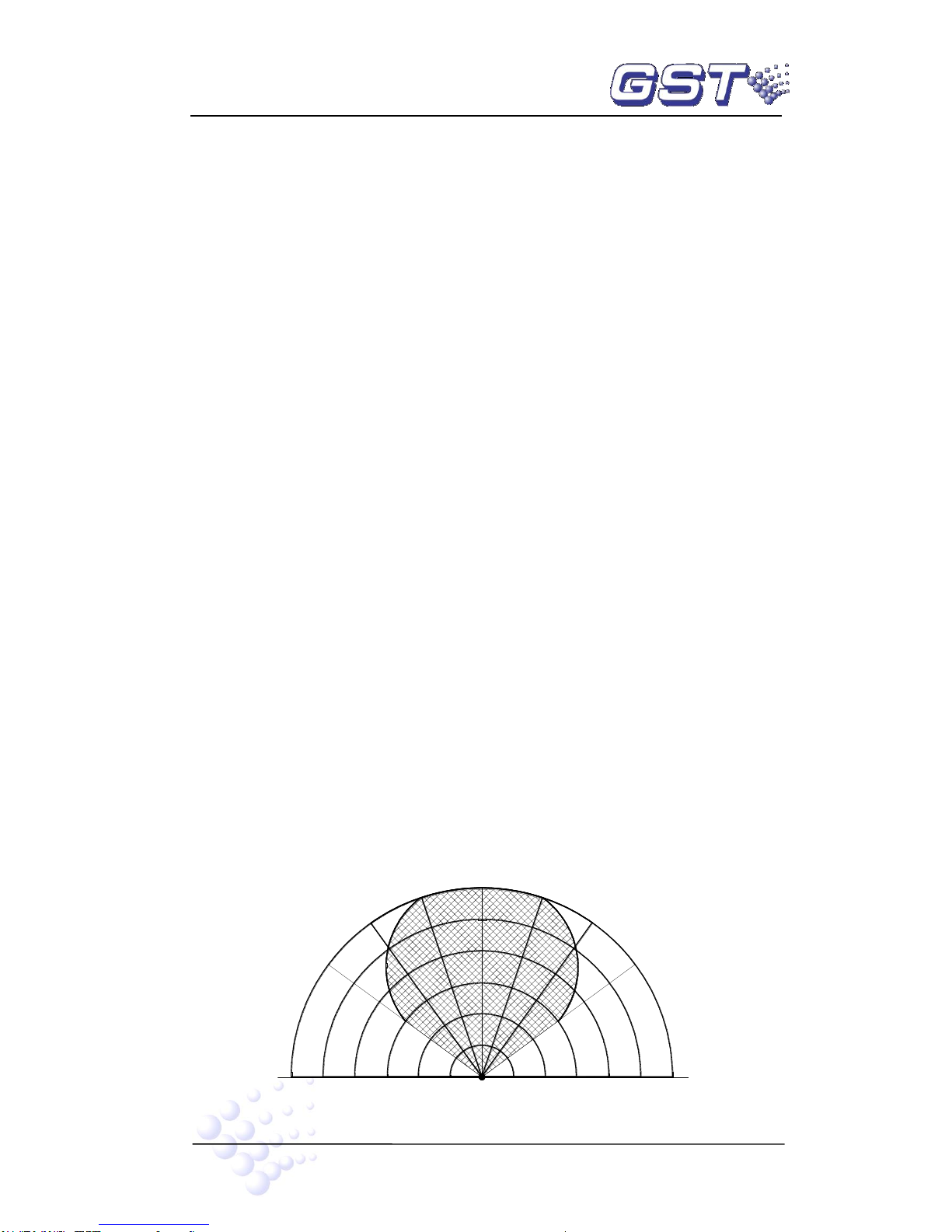

The correlation between detection distance and angle is shown in Fig. 1. The

shaded area is detectable.

The semicircle in the figure represents the detection distance in percentage.

100%

50%

15

30

15

45

30

0

45

Detector

furthest

50%

100%

o

o

o

o

o

o

o

Fig. 1

Page 4

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 2

Note: The detection angle to all directions are the same. Fig. 1 only gives a section

illustration.

Response Spectral Range: 4.4μm±0.5μm

Response Time ≤30s

Indicators:

In addressable mode and non-addressable mode ,

Red LED: Flashes periodically in standby state, and steadily illuminates in fire

alarm.

Yellow LED: Off in standby state, and steadily illuminates in fault.

Contact Output:

Fire alarm contact: 1A/25VDC, normally closed in fire alarm, and normally

open in other states.

Fault contact: 1A/25VDC, normally open in fault state, and normally closed in

other states.

Operating Environment:

Temperature: -20℃~+55℃

Relative Humidity: ≤95%, non-condensing

Ingress Protection: IP65

Dimensions: 166mm×235mm×199mm (with adjustment frame)

Installation Hole Space: 125.5mm×80mm

Installation Hole for Cable Entry: M27×2

Material and Color of Enclosure: Stainless steel, metallic grey

Weight:

Detector: 4.8kg

Adjustment frame: 1.3kg

Explosion-proof Mark: Exd IIC T6 Gb/Ex tb IIIC T85℃ Db

Explosion-proof Certificate Number: Presafe 14 ATEX 5548X

Standard: EN60079-0:2009,EN60079-1:2007,EN60079-31:2009

3 Construction and Operation Principle

3.1 Construction

The construction of the detector is shown in Fig. 2.

Fig. 2

Adjustment

Frame

Securing Bolt

Earth

Axes

Fire LED

Detection

Cable Junction

Blanking element

Fault LED

Page 5

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 3

3.2 Adjustment Frame

The adjustment frame can rotate by 60°around the axe, as shown in Fig. 3.

Fig. 3

3.3 Operation Principle

The detector uses two pyroelectric infrared sensors to detect the change of light signal

of flame and background light signal at two bands of infrared spectrum through two

signal processing channels. Its microprocessor analyzes the signal through the flame

channel and background channel to judge if there is flame.

4 Installation and Connection

4.1 Installation

Before installation, check first if the enclosure is in good condition with all necessary

markings. Then set the detector address and classifications (please refer to Section 6

Operation), and then install it according to Fig. 4.

Fig. 4

Wall

Base

Frame

Bolt

M5 screw

cover

hexagon socket cap

screws M8

×

25

Step 1

Step 2

Step 3

Step 4

Page 6

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 4

Step 1: Install the adjustment frame.

Fix the adjustment frame securely on the wall using 4 M6 expansion bolts.

Step 2: Install the base.

Remove the protective cover (Fig. 5) from the base leaving the screws and washer with

the base, and install the base onto the adjustment frame using a M5 screw.

Fig. 5

Step 3: Cable connection. Pleaser refer to “Connection” section.

Step 4: Install the cover. Remove the protective washer, insert the ribbon cable to XT3 of

the base circuit, and then install the enclosure onto the base with reference to the

aligning element with the U-shaped slot and secure the four screws using an Allen key.

Note: The base and enclosure shall be securely installed. There shall not be any

scratches or cracks on the detection window. The enclosure shall be earthed.

Fig. 6

Finally, adjust the frame to make sure the detection window is facing the protected area,

and fix the screws after adjustment.

Note: The detector shall be installed in compliance with relative installation

codes and make sure the enclosure is in good condition. Please always contact

your installer in case of any off-normal condition. Never conduct maintenance or

repair with the power on.

4.2 Connection

(1) It is recommended to use multi-core copper cable with core cross

section≥1.0mm

2

, and external diameter 8mm~10mm.

(2) The cable shall meet field requirements on resistance to explosion, heat,

Aligning Element

Protective Cover

U-shaped slot

Protective washer

Page 7

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 5

corrosion and fire.

(3) The cable layout for hazardous explosive area must comply with

corresponding codes. The connecting cable can be copper-core screened

cable or explosion-proof hose with suitable junction thread matching with the

detector taper thread of the cable nut (Fig. 7).

(4) The cable must enter the detector through the junction nut, and there must be

an O-ring, a seal and a washer, as shown in Fig. 7.

Fig. 7

(5) Connect the screen cover of the cable with the protective earth inside the

detector.

(6) Terminals on the base are shown in Fig. 8.

FT1 FT2 AL1 AL2

Fig. 8

Z1, Z2: Communication loop input from fire alarm control panel. Polarity

insensitive.

D1, D2: 24VDC power input. Polarity insensitive.

AL1, AL2: Fire alarm contact output. Normally open contact. Closed in fire

alarm.

FT1, FT2: Fault contact output. Normally closed contact. Open in fault.

The loop cable and the power shall enter the detector through a cable nut, and the

signal cable through another cable nut (Fig. 9). If no signal cable is needed, the cable

outlet shall be inserted with an blanking element with O-ring.

If Z1 and Z2 does not connect with the loop, they must be connected with D1 and D2

polarity-insensitively.

Page 8

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 6

Fig. 9

(7) After connection, screw down the cable nut.

5 Testing

Warning: Power up only after all detectors are installed.

1 The detector must be tested after installation and regular maintenance.

2 Tests:

(1) Connect the detector to loop and 24VDC, it should be able to be registered by

the control panel, and the red LED should flash periodically. After the detector

is powered up for 20 minutes, igniting an infrared light source at 1.5m distance

in front of it, it shall report a fire alarm to the control panel within 30s and light

the fire LED, and it should be reset from the control panel to standby state.

(2) Connect the detector to 24VDC only, the red LED should flash periodically in

standby state. After the detector is powered up for 20 minutes, igniting an

infrared light source at 1.5m distance in front of it, it shall give fire signal within

30s and light the fire LED.

3 After testing, reset the detector from control panel if it connects to the loop. If it’s not

connected to loop, disconnect 24VDC power and re-power it up. Notify the proper

authorities the system is back in operation.

4 If a detector fails in testing, clean and test it again. If it still fails, return it for repair.

6 Operation

1 The address and classifications can be programmed using a handheld programmer.

Please refer to the manual for the programmer.

The range of address is 1~242.

For setting classifications, number 1 represents class 1, number 2 for class 2 and

number 3 for class 3.

2 If the detector connects with the loop, it needs to be programmed with an address

to be identified by the control panel. If it doesn’t connect with the loop, no address

setup is required. But terminal Z1 and Z2 must be connected with D1 and D2 in an

Contact Signal cable outlet

Loop and 24VDC cable inlet

NPT 1/2

M24×1.5

Threaded entry type:M27×2

Page 9

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 7

polarity-insensitive way.

7 Application

1 Fig. 10 shows the connection of the detector with GST fire alarm control panel.

Fig. 10

2 Connection of the detector with control panels of other suppliers are shown in Fig. 11.

Infrared Flame Detector

Power

Fire Alarm

Signal Input

Fault Signal

Input

AL2

AL1

FT2

FT1

Z2

Z1

D2

D1

Control Unit

Fig. 11

8 Troubleshooting

Possible Problem

Resolution

The indicator doesn’t flash

Check the cable connection. If there is no problem,

replace the detector.

Incorrect contact signal

Registration failure

Other problems

D1

D2 Z1 Z2

FT1

FT2

AL1

AL2

Fire Alarm Control Panel

Power

Loop

Infrared Flame Detector

Page 10

D-9107RExd

Digital Flame Proof Dual IR Flame Detector

Installation and Operation Manual

Page 8

9 Maintenance

1 The detection window should be cleaned at least every three months.

2 Before cleaning, notify relative departments that the system is undergoing

maintenance and will be out of service. Disable the zone or system in maintenance

to avoid unwanted alarms.

3 After cleaning, install the detector back and test again.

10 Caution

(1) The detector should be handled with care during maintenance to avoid damage.

(2) Installation and maintenance should strictly comply with relative codes for

explosive and hazardous areas.

(3) Never open the cover for maintenance in field.

(4) The enclosure must be earthed.

(5) False alarms may occur if there is arc welding operation within 5 meters to the

detector.

(6) The following places are not suitable for the detector:

Where flameless fires are to be expected.

Where intensive smoke spreads before flames.

Where the "view" of the detector is easy to be obscured.

Where the sun can directly shine the detection window.

Where the detector may encounter frequent vibration.

(7) Special conditions for safe use:Repairs of the flameproof joints must be made in

compliance with the structural specifications provided by the manufacturer. Repairs

must not be made on the basis of values specified in tables 1 and 2 of IEC 60079-1.

(8) The screws used for the assembly must be of yield stress higher or equal to

700N/mm2.

(9) The threaded entries comply with following parameters:

Threaded entries type: M27×2

Position on the equipment: see Fig 9

The number permitted: one is installed in back cover, and two at most

Sealing and washer size: Sealing and washer size: 11mm(internal diameter)

×21mm(external diameter)×22mm(thickness)

Cable external diameter 8mm~10mm is recommended.

The torque for cable nut is 25 N.m to compress sealing ring.

(10) One blanking element of threaded entries type M27×2 is delivered with the

detector and installed in back cover.

11 Accessories

1 installation and operation manual

4 M6×60 expansion bolts

1 M5×10 screws

1 adjustment frame

1 Allen Key

Page 11

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei,

P. R. China 066004

Tel: +86 (0) 335 8502434

Fax: +86 (0) 335 8502532

service.gst@fs.utc.com

www.gst.com.cn

Loading...

Loading...