Page 1

Page 2

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

CONTENTS

I Overview........................................................................................1

II Features.........................................................................................1

III Technical Specifications.................................................................2

IV Structure and Operation Principle..................................................4

V Mounting and Wiring...................................................................... 5

VI Commission .................................................................................13

VII Operation .....................................................................................15

VIII Troubleshooting ...........................................................................17

IX Maintenance.................................................................................19

X Caution.........................................................................................19

XI Accessories..................................................................................20

Page 3

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

1

I Overview

D-9105RExd Digital Flame Proof Reflective Beam Detector is able to

output signal in two ways: loop output and contact output. When the

detector is connected with GST fire alarm control panel, information

between the detector and the control panel is transmitted through the

detection loop. The detector address can be programmed ranging from

1 to 242 using GST programmer. When the detector is not connected

with the control panel, fire and fault information can be transmitted

through contacts.

The detector must be used together with a reflector. The number of

reflector(s) to be used (one or four) depends on the distance from the

detector.

With excellent built-in microprocessor, the detector has strong ability of

analysis and judgment.The detector can carry out system commission,

compensation of environmental variation, and judgment of fire and fault

through fixed algorithm. Digital bus technology ensures quick and

complete information transmission. With new and reasonable design,

flexible judgment and precise alignment, it’s aesthetically pleasing and

easy to install and adjust. Its sensitivity can be set with hand held

programmer in field, decreasing the demand for cleanliness of field

conditions, and enlarging application areas.

The detector is applicable to either commercial areas or hazardous

industrial areas, such as Zone 1 and 2 of explosive gas areasand Zone

21 and 22 of combustible dust areas.

II Features

1. Wide operating voltage range, large monitoring areas.

2. Combination of transmitter and receiver ensures easy installation

and accurate optical pathway.

Page 4

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

2

3. Built-in microprocessor enables intelligent judgment of fire alarm

and fault.

4. The detector can calibrate automatically, which ensures one

person to complete adjustment in short time. It’s also convenient to

operate.

5. Self-diagnosis function can monitorfault with itself.

6. Automatic compensation for factors weakening received signals,

such as a certain amount of dust contamination, positional

excursion and ageing transmitter.

7. Compatible to digital bus protocol, easy to control and operate.

8. Electronically addressed.The address can be programmed in field.

9. Two sensitivity levels can be set in field.

10. The detector’s optical pathway is designed with strong

anti-interference ability.

11. SMT processing technology.

12. Attractive and decent appearance.

III Technical Specifications

1. Operating Voltage:Power supply voltage 15VDC~28VDC

Loop voltage 15V~28V

2. Operating Current:

Power current: Commission current ≤20mA

Standby current ≤12mA

Alarm current ≤22mA

Loop current≤2mA

3. Fire, fault contact output:

Fire relay: contact capacity is 28V/2A. Normally open in normal

state, closed in fire condition.

Fault relay: contact capacity is 28V/2A. Normally open in normal

state, and closed in fault condition.

Page 5

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

3

4. AdjustmentAngle: Vertical ±30 degrees, horizontal ±45 degrees

5. Maximum angular misalignment: ±0.5°

6. Sensitivity Level:

Level 1: high sensitivity

Level 2: low sensitivity

7. Indication of Detector State:

Commission: Green LED and yellow LED illuminatesorflashes in

a certain way. Refer to Section VI Commission for details.

Normal monitoring state: Red LED flashes periodically.

Fire: Red LED illuminates and fire output contact is closed when

the detector reports fire alarm. The fire signal can be transmitted to

the control panel through loop and has to be cleared by the control

panel. If it’s not connected with GST fire alarm control panel, the

fire signal has to be cleared by rebooting.

Fault: Yellow LED illuminates. The detector clears the fault signal

automatically if the fault condition disappears.

Optical pathway is obscured totally:the detector first gives fault

signal, turns on yellow LED and closes fault relay. 20 secondslater,

it reportsfire alarm, turns on red LED and closes fire relay. Yellow

LED is turned off,fault relay is disconnected. Note: In this case, it

does not necessarily mean there is a fire. After the

obscuration is removed, the detector clears the fault signal

automatically.

8. Operating Environment:

Temperature: -20C~+40C

Relative Humidity≤95%, non condensing

9. MonitoringArea: Maximum monitoring area: 14×100=1400m

2

Maximum width: 14m

10. Length of Optical Pathway:8m~100m

11. Ingress Protection Rating: IP66

12. Dimensions:

Page 6

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

4

Length: 344mm

Width: 240mm

Depth: 212mm(with adjustment frame)

13. Material and Color of Enclosure: Stainless steel, metallic gray

14. Weight: Detector: 6kg Adjustment frame: 3.8kg

15. Mounting Hole Spacing:

Spacing for embedding: 70mm x 50mm

16. Explosion-proof mark: ExdIICT6/DIPA21TA,T6

IV Structure and Operation Principle

1. Appearance of the detector is shown in Fig. 1.

Fig. 1

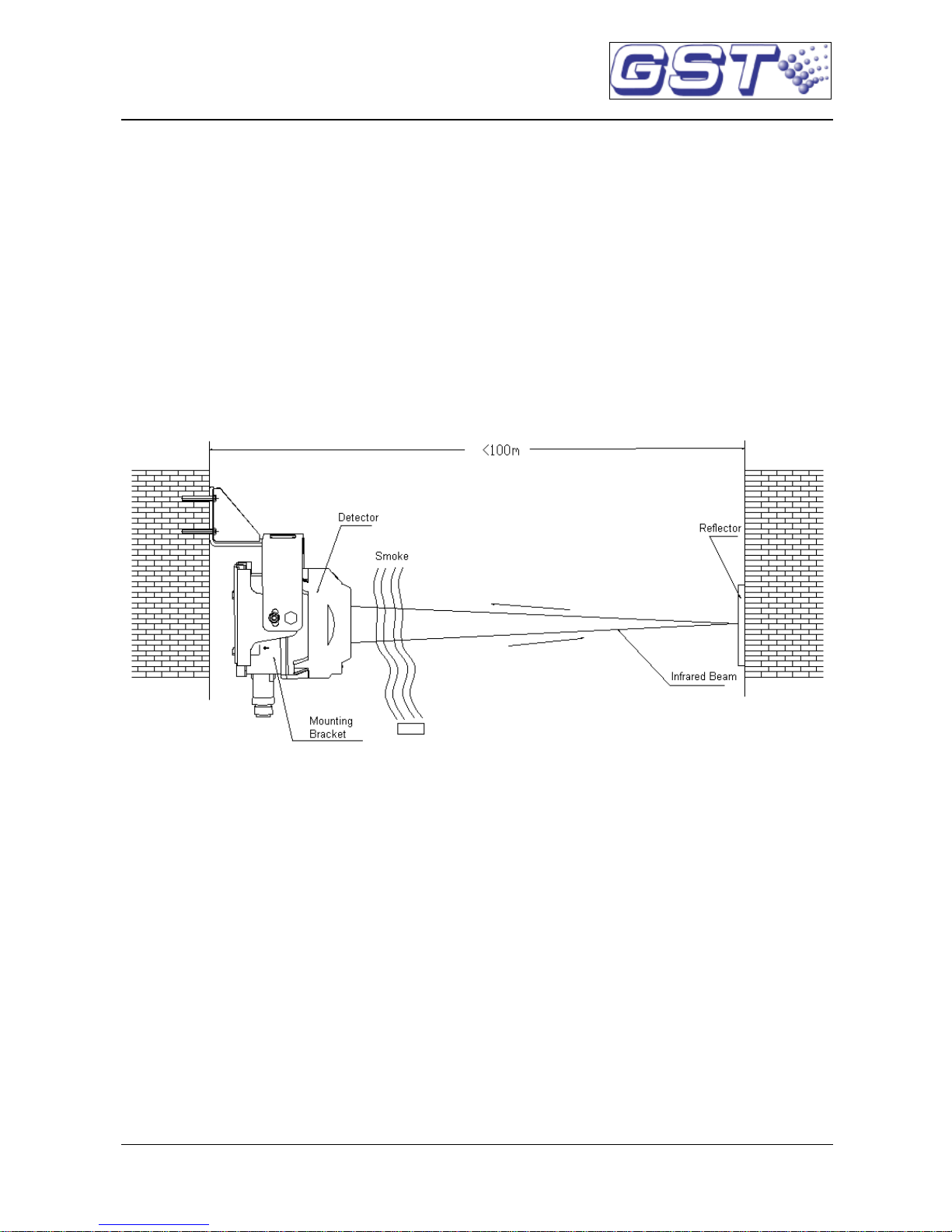

2. Operation Principle

The detector and reflector are placed oppositely. The detector includes

a transmitter and a receiver. Infrared beam of certainintensity sent out

from the transmitter is reflected by the right-angle prisms of the reflector,

and then received by the receiver. The receiversimultaneously collects

and amplifies the returned infrared beam, analyze and judge the

Adjustment

Frame

Screw

Receiving

Window

Transmitting

Window

Detector

Wiring Hole

LED

Screw

Page 7

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

5

collected signals through its microprocessor. When the detector is in

normal monitoring state, the intensity of infrared beam received by the

receiver is steady at a certain level. When smoke particles enter the

detecting area, the intensity of infrared light reaching the receiver falls

owing to light scattering. When the smoke particles reach a certain

density, and the intensity of infrared light received is reduced below the

preset threshold value,the detector alarms fire and illuminates red LED.

The fire signal will be transmitted to fire alarm control panel connected

with the detector. Operation principle is shown in Fig. 2.

Fig. 2

V Mounting and Wiring

1. Ambient Conditions for Installation

The detector works on light obscuration principle, so any fixed or

moving obscuration in its optical pathway must be avoided when

locating it.

The wall for mounting either the detector or the reflector should be firm

and smooth. The detector is mounted vertical to the wall. The wall may

seem to be smooth, but corrugated or uneven, or may be changed by

the environment (in rainy season or in winter) and the installer should

Page 8

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

6

ensure the detector not affected by these factors. If the detector is

installed on sustaining rack similar to metal tube, make sure the

sustaining rack is installed firmly.

Not Fit For Locations where:

The heightof the roof is over 40m.

There is no roof at all.

The space is lower than 1.5m.

There are a lot of dust, powder or vapor.

It is clean normally, but can be dusty in some special cases.

Temperature is high. Note: Temperature at top part of a

workshop with transparent roof may be over 50℃ when

there is sunshine.

There is no access for maintenance.

The Mounting wall or fitting is greatly affected by mechanical

vibration.

There are fixed or moving objects within 1m from the

detector’s optical pathway.

There is strong magnetic field.

2. Mounting Height and Position

The mounting height of the detector and reflector should be most

accessible by smoke into beam zone. The following recommendations

are for reference:

(1) When space height is not over 5m, the detector and reflector should

be mounted on the two facing walls 0.5m from the ceiling, as shown

in Fig. 3.

Page 9

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

7

Reflector

Detector

4.5m

5m

Fig. 3

(2) When space height is between 5m and 8m, the detector and

reflectorshould be mounted on the two facing walls 0.5m to 1m from

the ceiling, as shown in Fig. 4.

Reflector

Detector

7m

6m

Fig. 4

(3) When space height is more than 8m, the roof is normally gabled

without ceiling, the detector and reflector should be mounted on the

two facing walls about 8m from the floor, ensuring that the vertical

Page 10

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

8

distancebetween the detector/reflectorand top of the building is not

less than 0.5m, as shown in Fig. 5.

Reflector

Reflector

Detector

Detector

12m

8m

Fig. 5

(4) For gable structure with space height about 8m, the detector and

reflector should be mounted on the two facing walls 1.5m from the

gabled girder,as shown in Fig. 6.

Detector

Detector Detector

Reflector Reflector

Reflector

6.5m

8m

Fig. 6

(5) If the surroundings are glass or transparent plastic, please place the

detector on the south wall in a building. If the detector cannot be

Page 11

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

9

mounted northward, then place the detector on the west wall. For

applications where sunlight can reach the detector after reflected,

please consider mounting a sunshade over the detector’s optical

pathway or contact our field application engineer for a solution.

3. Mounting

(1) Setting Length of Optical Pathway

Before installation, you need to set the length of optical pathway

first by setting device typeof the detector. The detector can work at

two length ranges. When mounting distance between the detector

and the reflector is not lessthan40m (but not more than100m),the

detector type should be set at “52”(factory default). When the

mounting distance between the detector and the reflector is less

than 40m (but more than 8m), the detector type should be set at

“51”. Refer to Section VII Operation for detailed setting methods.

(2) Mounting the detector

Align the detector and the reflector horizontally on the two facing

walls of the monitoring area, as shown in Fig. 2.

The detector is wall-mounted. First mount the adjustment frame

on the wall, then hang the detector on it, and finally secure them to

the wall. The steps are as follows:

a. Installing the adjustment frame

Secure the adjustment frame on the wall using an M6 expansion

bolt, as shown in Fig. 7.

Page 12

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

10

Fig. 7

b. Installing and adjusting the detector

Hang the detector with the lining board onto the adjusting frame

and secure them using M5 screw (Fig. 8).

Fig. 8

c. Installing the reflector

The reflector is mounted opposite the detector but in line with it.

When the distance between the detector and the reflector is more

Page 13

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

11

than 8m(less thanor equalto 40m), one reflectoris enough. When

the distance is more than 40m (less than or equal to 100m), four

reflectors are needed. Two 6 plastic expansion bolts are needed

to fix a single reflector. Mounting size is shown in Fig.9a. If four

reflectors are needed, place them seamlessly as shown in Fig. 9b.

Fig. 9a Fig. 9b (Not to Scale)

4. Wiring

(1) It is recommended to use multi-core copper cable with core cross

section≥1.0mm2, and external diameter 8mm~10mm in Zone 1

and 2. The cable shall meet field requirements on resistance to

heat, corrosion and fire. If there’s no special requirement, 10

screenedcable can be used. Connectthe screenlayer to the safety

earth position inside the housing. Cable layout shall also meet

requirement in explosive environment. It’s prohibited for the cable

to have jointsin explosiveenvironment.If a joint is necessary under

special condition, it’s only allowed in Zone 2 with the joint protected

with explosion-proof junction box.

(2) Connect 24VDC power cable (without polarity) to terminal D1 and

D2 of the detector. K11, K12 are volt-free fire output contacts. K21

and K22 are volt-free fault output contacts. No cable connection is

necessaryfor the reflectors. Terminals are shown in Fig. 12. Z1 and

Z2 are for polarity-insensitive connection with FACP loop. Refer to

Page 14

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

12

Fig. 10 for terminals.

K11K12K22 K21 D2 D1 Z2 Z1

Fig. 10

If the detector does not connected with GST fire alarm control panel,

D1 and D2 are to be connected with 24VDC power cable

polarity-insensitively, K11 and K12 are used as volt-free fire alarm

output contact, and K21 and K22 volt-free fault output contact, as in Fig.

11.

Fig. 11

(3) Connect the earth cable to the earth point on the housing.

(4) Connect the ribbon cable of the detector body to XT4 on the

interface board on the base, and then install the detector body onto

the base. Make sure the location element on the base in align with

the U-shaped groove on the detector body.

(5) Secure the body with the base with the 4Allen screws.

(6) After installation, double-check the following: If there is cracks or

holes on the surface of the housing; if the base and detector body

Wiring hole for

24VDC Power supply

Wiring hole for

contact signal

Page 15

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

13

are securely installed; if there is scratches or cracks in the glass

detector window; if there is sealing ring at the wiring hole; if the

sealing ring matches the cable gauge; if the locking nut at the

wiring hole is locked; if there is earth cable at earth mark position.

Note:

(1) If the detector connects with GST fire alarm control panel, only one

wiring hole is needed. The other one should be stopped with an

end cap, as shown in Fig. 1.

(2) If the detector does not connected with GST fire alarm control

panel, the two wiring holes are both needed, as shown in Fig. 11.

VI Commission

1. Steps

a) Take off the protective membrane carefully on the surface of the

reflector and the detector. Do not scratch or contaminate their

surfaces.

b) Power up the control panel and detector. Put the commission area

of the commission tool close to the part of detector with a mark

○

M .There may be two cases with the LEDs:

(1) Green LED flashes.

(2) Green LED illuminates continuously.

Then take away the commission tool.

c) If green LED flashes, it means the received light is quite weak (the

slower the flashing frequency, the weaker the received light signal

is). Tune the adjusting wheel and rotary rack on the detector to align

the light beam until green LED is lit continuously, showing that the

light received by the detector is strong. Then stop regulating and

enter step d).

If green LED illuminates continuously, it means the received light is

Page 16

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

14

quite strong, you can go straight to step d).

Note: Observe the detector’s optical pathway carefully to ensure

that the received light signal is reflected by the reflector rather

than by obscurations like wall, ceiling, or pillar. If uncertain, verify

by covering the reflector with opaque objects. If the green LED

flashes, it means the light is from the reflector. If the green LED

constantly lights, then the light is not from the reflector. The

optical pathway should be adjusted again.

d) Gently tighten the screws at the top middle and on the two sides of

the adjusting frame.

e) Put the magnet of commission tool close to the area marked with

○

M until yellow LED illuminates constantly, then remove the

commission tool quickly and make sure there is no obscuration on

the optical pathway. About 5 seconds later, the detector begins to

adjust automatically. Yellow LED flashing means weak light, green

LED flashing means strong light. If red LED, yellow LED and green

LED flash alternately, this means the detector failed to adjust

automatically and cannot enter normal monitoring state. Please

open the detector’s top cover and do adjustment from step b). If

yellowLED and green LED illuminate no more, and red LED flashes

periodically, this means the detector is at the best position and has

entered normal monitoring state. The commission is finished.

2. Fire alarm test

After the detector has been in normal monitoring state for 20 seconds,

cover the receiving window and transmitting window with the IR Light

Filter (please use the part for fire alarm test), the detector should report

fire alarm in 30 seconds and red LED should turn on. Remove the filter

and clear the fire alarm from the FACP,the red LED should go out, and

the detector should resume normal standby state.

Page 17

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

15

3. Fault test

Cover the receiving or transmitting window of the detector quickly with

the IR Light Filter to obscure the optical pathway. Yellow LED of the

detector should be turned on. Taking off the filter immediately, yellow

LED of the detector should be turned off.

4. Defect Detectors

For detectors failing in testing, please repair them following the

instructions in the sections of Troubleshooting and Maintenance, and

re-test them. If they fail again, return them to factory for repair.

VII Operation

The detector address, device type and sensitivity level can be simply

programmed by P-9910B hand held programmer. Open the detector’s

top cover, connect the ribbon cable from the detector body to XT2 of

the small connector board coming with the detector, and then connect

the I2C cable of hand held programmer (PS/2 cable) with XT1 of the

connector board (or directly connect the ribbon cable of the detector

body with the connector on the base, and the I2C cable to XT3 of the

interface board). Turn on the power of hand held programmer, input 2,

5, 9 and Function to enter I2C programming mode, the screen shows a

“0”. After programming, input 2, 5, 9 and Function again to exit I2C

programming mode and return to power-on state.

1. Reading Information

Using the hand held programmer, you can easily get original

information of the detector, such as the address. Refer to details

below:

(1) Enter I2C programming mode, the screen shows a “0”.

(2) Press Test, the screen shows the address code of the detector.

(3) Press Up, the screen shows sensitivity level and device type in

sequence.

(4) Press Down, the screen shows above contents in opposite way

Page 18

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

16

2. Setting Address Code

The detector offers address code programming for field application.

Refer to operation below:

(1) Enter I2C programming code, and the screen is a “0”.

(2) Input address code for programming (1~242).

(3) Press Program to start programming. “P”will be shown when

successful, otherwise an “E”will be shown.

(4) If programming is successful, press Clear, the screen will show a

“0”, and you can go on with further operations.

(5) If programming fails, pressClear, the screen will show a “0”, input

address code once again.

3. Setting Sensitivity Level

The hand held programmer can set two sensitivity levels to the

detector. 2 is sensitivity one, and 3 is sensitivity two, as detailed

below:

(1) Enter I2C programming mode of hand held programmer, and the

screen shows a “0”.

(2) Input unlock password, press Clear,and open the lock.

(3) Press Function then the figure “3”, the screen shows a “-”.

(4) Input sensitivity level to be set, and press Program to begin

programming. The screen will show a “P”if programming is

successful, otherwise it will show an “E”.

(5) Clear pressed, the screen shows “0”, and you can go on with

further operations.

4. Setting the Device Type

You can also set the device type of the detector through a programmer,

as detailed below:

(1) Enter I2C mode of the programmer, and the screen shows

“0”.

(2) Input unlock password, press Clear, and open the lock.

Page 19

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

17

(3) Press Function and then figure “4”, the screen shows “-”.

(4) Input the device type to be set, press Program to begin

programming. “P”will be shown when successful, otherwise “E”

will be shown.

(5) Pressing Clear shows “0”on the screen, and you can go on with

further operations.

5. Other Functions

(1) Automatic Compensation of Light

When dust exists in the working environment of the detector, the

transmitting window, receiving window and reflector may be covered

with dust, which will affect normal operation. In order to solve the

problem, the detector is designed withautomaticcompensation of light.

When there is dust on windows, the detector can judge the amount of

dust, and compensate the received signal through internal program

and circuit to ensure the detector can continue working normally. The

detector gives fault signal when dust on the lens and reflector surface

reaches a certain level and light compensation reaches the limit for the

detector to work normally.

(2) Self-diagnosis on Optical Signal

The detector has functions of checking transmitting, receiving and

amplifying circuit. When there is fault with these three parts of circuit

during operation, the detector will generate fault information.

VIII Troubleshooting

If the detector reportsfault after long time running,please first check

if it’s damaged. Make sure it’s securely installed on the wall or other

fixed supporters. Then check the dust accumulation level and

position deviation to see if these has resulted in fault in automatic

compensation, and then consider other types of fault.

If the surface of the transmitting/receiving window or the reflector is

Page 20

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

18

found to be contaminated,please clean it with soft clothand alcohol.

Avoid scratching the surface. Do not clean the surface using water

or other chemicals. After cleaning, please commission the detector

again to make it work in normal standby state.

Common problems and repair methods are as shown in Table 1.

Table 1

Problems Reasons Repair Methods

Working LEDs

not lit after

power up.

a) 24V power off

b) Working LEDs damaged.

c) Transient suppressor VD12 damaged.

d) DiodeVD1, VD2, VD10, VD11

breakdown resulting in short circuit

with ground.

e) N1, N2 damaged.

f) The flexible cable inside was not

connected, or not connected correctly.

If the problems are

mentioned in a) ~ e) ,

replace the component

with problem.

If in f) connect again in

right way.

Fault LED

constantly

illuminates

after power up

a) Device type

read by programmer is

not 51 or 52.

b) The optical pathway is not well

aligned.

a) Correct the device type.

b) Commission the

detector again. If

commissioning fails for

3 time, please return the

detector for repair.

Reports loop

fault after

power-up

a) Diode VZ1, VZ2, VD3 or VD4 is

broken, and is shorted to earth.

b) TVS diode VC13 is damaged.

Commission once more.

FACP reports

detector fault

after

registration.

The detector does not enter normal

operation state.

Re-commission the

detector.

The FACP

does not

register the

detector after

power-up

a) Loose connection with FACPloop.

b) 24V power is not applied.

c) N3 or N4 is damaged.

d) The flexible cable inside the detector

is not connected or not connected

well.

e) N1 or N2 is damaged.

Replace the faulty

component, re-connect the

flexible cable or re-register

the detector.

Green LED

flashes after

power-up

despite

adjustment

a) Transmitting diode or circuit is

damaged.

b) Receiving diode or amplifying circuit

is damaged.

Replace the faulty

component.

Page 21

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

19

Reports fault

after a period

of normal

operation

The detector cannot work normally. Commission once more

Reports fire

after operation

for some time,

and reports

fault after

restarted

The detector has deviated due to

external vibration.

Commission once more

Fire signal

cannot be

cleared

a) There is obscuration on the optical

pathway between the detector and

the reflector.

b) The angle of optical pathway has

changed and need to be aligned

again.

c) The transmitting diode or circuit

damaged.

d) The photodiode or amplifying circuit

damaged.

For a) andb), commission

once again.

For c) and d), replace the

faulty component.

The control

panel can’t

receive

fire or fault

signals.

No registration. Register again.

IX Maintenance

The detector is fire protection product, operation of which must be

well recorded by the personnel on duty and shift.

Personnel on duty should be familiar with the functions and

operation process of the device to avoid mis-operation.

Test alarm function once every 6 months.

X Caution

Protect the detectorfrom damage in maintenance.

Install and maintain the detector in strict compliance with safety

regulations for explosive and hazardous areas.

Never open the housing with power on.

The detector housing should be earthed.

Page 22

D-9105RExd

Digital Flame Proof Reflective Beam Detector

Installation and Operation Manual The Intelligent Solution

20

Power up only after all devices are connected.

Commissionthe detector after installation and maintenance.

During commissioning, the FACP may report detector fault which

does not affect commissioning.

The detectorbase should be fixed directlyon solid wall or frame that

will not be deformed by vibration. Any deformable material such as

paperboard, plastic board, foam board or thin wood board should

not be placed between the base and the wall or the bracket.

XI Accessories

Accessories provided with the detector are as follows:

FourM6 x 60 expansion bolts.

Four M5 cross recessed pan head screws.

One adjustment bracket.

One IR Light Filter.

One Commission Tool.

OneAllen key M8.

One connector board.

Page 23

GST China

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei,

P. R. China 066004

Tel: +86 (0) 335 8502528

Fax: +86 (0) 335 8508942

Email: sales@gst.com.cn

www.gst.com.cn

GST UK

Global System Technology PLC

Lion Court, Staunton Harold Hall, Melbourne Road, Ashby de la Zouch,

Leicestershire, England LE65 1RT

Tel: +44 1283 225 478

Fax: +44 1283 220 690

Email: info@gst.uk.com

www.gst.uk.com

GST Dubai

Global System Technology PLC

PO Box 17998 Unit ZA04 JEBELALI Free Zone,

Dubai, UAE

Tel: +971 (0) 4 8833050

Fax: +971 (0) 4 8833053

Email: info@gst.uk.com

www.gst.uk.com

Loading...

Loading...