Page 1

The Intelligent Solution

Features

High bright red LEDs are used as light source.

High sound level.

Circuitry and base are twisted together.

Standard: EN 54-3.

Description

C-9404(Ex) Explosion Proof Conventional

Sounder and C-9403(Ex) Explosion Proof

Conventional Sounder Strobe (hereinafter called the

sounder/sounder strobe) is a kind of audible/audible

and visual alarm device used to warn people in field

when fire occurs. It’s applicable to zone 1 and zone 2

of areas with explosion-proof requirement in

petroleum and chemical industries. It can match with

I-9333 Interface.

Both shallow base with 25.5mm high and deep base

with 40mm high are available, it employs deep base

if there is no special statement in this manual.

Explosion Proof Conventional Sounder Strobe

C-9404(Ex)

Explosion Proof Conventional Sounder

C-9403(Ex)

Knock-off Hole

Conduit

Electrical Box

sounder/Sounder Strobe

Connection & Wiring

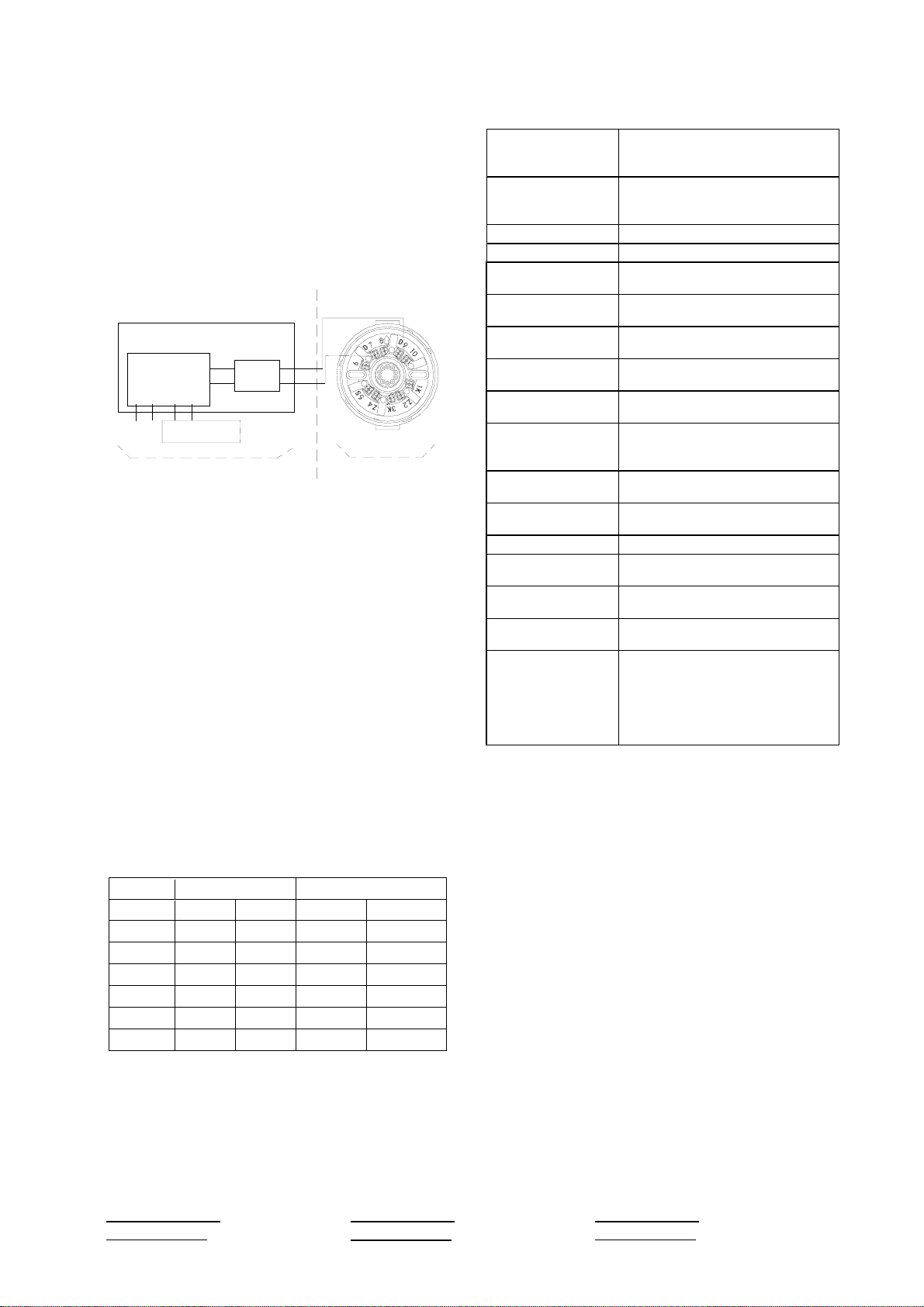

Terminals on the base are shown in Fig. 2.

97.5mm

5mm

Arch knock off Hole

80mm

55mm

D

2

S

D

1

G

1

K

Z

2

Z

1

2

K

Fig. 1 Fig. 2

D1+(9), D2- (7): Connected with I-9333

Interface, polarized. D1 is connected with (3) of the

safety barrier and D2 to (4).

Recommended Wiring

Intrinsically safe cable with cross section not less

than 1.5mm2, subject to local codes.。

Installation

When the sounder/sounder strobe is surface

mounted, it should be placed 0.2m from the ceiling

for normal space height. When conduit is embedded,

the base can be mounted on the electrical box.

When conduit is surface mounted, the deep base

should be adopted. Knock the knock-off hole, then

connect the conduit with it. The mounting hole

spacing and mounting direction are shown in Fig. 2.

Mounting method is shown in Fig. 3a and Fig. 4.

When the shallow base is required, the

sounder/sounder strobe only adopts conduit

embedded. Its mounting method is shown in Fig. 3b.

Fig. 3a

Conduit

Electrical Box

sounder/Sounder Strobe

Fig. 3b (shallow base)

Conduit

sounder/Sounder Strobe

Fig. 4

The base and the sounder/sounder strobe are

twisted together. When mounting, remove the

sounder strobe, thread cables through the cable

entry in the base and connect with corresponding

terminals, then twist the sounder/sounder strobe

onto the base.

30302556 Issue 2.03

Page 2

If the sounder/sounder strobe is required

anti-removal, knock down the arch knock-off hole as

shown in Fig. 1 and fix it with ST2.9×6.5 tapping

screws (in this case, it must be removed by a special

tool).

Application

Specification

Power Loop

voltage when

activating

Power Loop

voltage in standby

24VDC(16VDC~28VDC)

7VDC(5VDC~8VDC)

state

the sounder/sounder strobe can match I-9333

Interface to form an intrinsically safe system. The

system wiring is shown in Fig. 5.

Safety Area

Hazardous Area

standby current ≤5mA

active current ≤50mA

Wiring Polarized two-wire with I-9333

Interface

Sound Level See the above sound level data

table

I-9333 Interface

I-9333 Circuit

Board

D1 D2 Z1 Z2

24VDC

Fire Alarm Control Panel

1(+)

L+

NF928 Zener

2(-)

Safety Barrier

L-

3(+)

4(-)

S

D

D

1

2

G

1

K

1

2

Z

2

Z

K

Flashing

Frequency

Tone Modification

Period

Explosion-proof

marking

Security Barrier

1.4×(1±20%)Hz(C-9403(Ex))

0.7s±20%

ExibⅡCT6

U =28V,I =93mA

0 0

Parameters

Non-intrinsincally Safe Loop

Intrinsincally Safe Loop

(NF928)

Ingress Protection

IP33

Rating

Fig. 5

Cautions

1. I-9333 Interface should be installed in safety

area, the wires of "Safety Area" should be

separated from those of "Hazardous Area", and

be kept a certain distance (at least 50mm).

2. The safety barrier should be well grounded.

The screws should not be loose. Ground

resistance should not be over 1Ω. The

parameters assigned in the intrinsically safe

loop should not be over the specified value, that

is, the capacity assigned among cables should

not be over 0.02μF, the inductance assigned

not over 2mH.

Operating

-10℃~+50℃

Temperature

Relative Humidity ≤95%, non condensing

Material and Color

ABS,red(PANTONE 1795C)

of Enclosure

Dimension

(L×W×H)

Mounting Hole

ф110mm×97.5mm (deep base)

ф110mm×83mm(shallow base)

55mm~80mm

Spacing

Weight C-9404(Ex):

About 340g(deep base)About

312.2g(shallow base)

C-9403(Ex):

About 350g(deep base)About

322.2g(shallow base)

3. During maintenance, products passing the

explosion-proof test should not be replaced and

Limited Warranty

parts and structure affecting explosion-proof

functions should not be modified.

Sound Level Data (Complies to EN54-3)

Fixed tone, Maximum Volume

Angle Horizontal Vertical

18V 28V 18V 28V

15° 74.47 78.16 71.95 75.55

45° 81.85 86.44 82.03 85.36

75° 88.06 92.47 87.88 91.66

105° 88.15 91.93 89.14 92.92

GST warrants that the product will be free from

defects in design, materials and workmanship during

the warranty period. This warranty shall not apply to

any product that is found to have been improperly

installed or used in any way not in accordance with

the instructions supplied with the product. Anybody,

including the agents, distributors or employees, is

not in the position to amend the contents of this

warranty. Please contact your local distributor for

products not covered by this warranty.

135° 80.50 85.54 82.48 87.07

165°

This document is subject to change without notice. Please contact GST for more information or questions.

GST China

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Roa ,

QETDZ, Qinhuangdao, Hebe

P. R. China 066004

Tel: +86 (0) 335 8502528

Fax: +86 (0) 335 8508942

Usales@gst.com.cn

HTUwww.gst.com.cnUTH

62.32 66.37 73.93 78.07

d

i,

GST UK

Global System Technology PLC

Lion Court, Staunton Harold Hall,

Melbourne Road, Ashby de la Zouch,

Leicestershire, England LE65 1RT

Tel: +44 1283 225 478

Fax: +44 1283 220 690

HTUinfo@gst.uk.comUTH

HHTUwww.gst.uk.comUTHH

GST Dubai

Global System Technology PLC

PO Box 17998 Unit ZA04

JEBEL ALI Free Zone,

Dubai, UAE

Tel: +971 (0) 4 8833050

Fax: +971 (0) 4 8833053

HTUinfo@gst.uk.comUTH

HHTUwww.gst.uk.comUTHH

30302556 Issue 2.03

Loading...

Loading...