Lamellar Grinding Machines

T-20/T-25 11/2012

Instruction Manual

T 20

GS-Schleiftechnik Am Kiebitzengraben 4 91315 Höchstadt DE

Tel.0700-24681234- e-mail: info@gs-de.eu - Internet: www.gs-de.de

1

Contents as of 12/01/12

1. General

1.1 Warranty Information

1.2 Description and Features

1.3 Overview

1.4 Technical Data and Dimension

2. Start-up

2.1 Package Contents

2.2 Installation

2.3 Electrical Connection

2.4 Rotation check-up

3. Cleaning

3.1 Preparation for cleaning

3.2 Cleaning instructions

3.3 Grinding machine made ready for work

4. Operation

4.1 Safety Instructions

4.2 Grinding of Tools

4.3 Honing of Tools

5. Maintenance/Replacement

5.1 Maintenance

5.2 Exchanging Discs

6. Electrical Circuit Diagram

7. Spare part list and exploded drawing

2

1. General Information

Warranty information and how to use the Lamellar Grinding Machines T-20/25

The user manual must be read carefully prior to operate the machine.

Before bringing the machine into service it is essential to check:

Is the machine placed safely? Is the direction of the rotation correct?

The machine must only be connected by a qualified electrician!

1.1 Use and maintenance of the Lamellar Grinding Machines T-20/25

- In the event of unauthorized electrical installation, faulty operation, improper use

according to instructions, structural alterations, removal of protective equipment,

use of Non-ORIGINAL spare parts and accessories, we disclaim any liability. The user

employs our machines at own risk and peril in such cases. If any damage occurs

because of this, the user bears full responsibility himself. -

- Do use only GENUINE spare parts and accessories!

- Defects and damages caused by natural wear and tear do not constitute any claims

against Geiselsöder GS-Schleiftechnik.

- The operator has to be carefully instructed to follow this manual in the operation

and maintenance of T-2 w / d Lamellar Grinding Machines.

- Geiselsöder GS-Schleiftechnik machines fully comply with accident prevention

regulations.

Pay attention to instructions and memorize them!

In line with our warranty conditions we grant warranty for 24 months for the

Geiselsöder GS-Schleiftechnik Lamellar Grinding MachinesT-20/25. The

illustrated presentations of the machines may, according to country-specific

regulations and as a result of technical progress of the machines supplied,

slightly differ. This however is of no influence to our manual.

1.2 Description and Features

The T-20/25 Lamellar Grinding Machines serve to sharpen cutting tools such as:

- Cutting knife

- Cutter knife

- boning Knife

- Cleaver

in the butcher and catering area

3

1.3 Technical manual

Table-top devices of the latest state-of-the art developments for modern and economic

tool grinding

-Space-saving and closed construction

Design according to the requirements of international safety regulations

-Impact-resistant aluminum housing

-High performance drive with optimum disc speed

-Lamellar grinding disc

Polishing disc for honing

Features

-Modern design

-Long economic life-time

-Time saving due to a fast simple operation and easy cleaning

-Low injury risk due to a highly effective protection against accidents

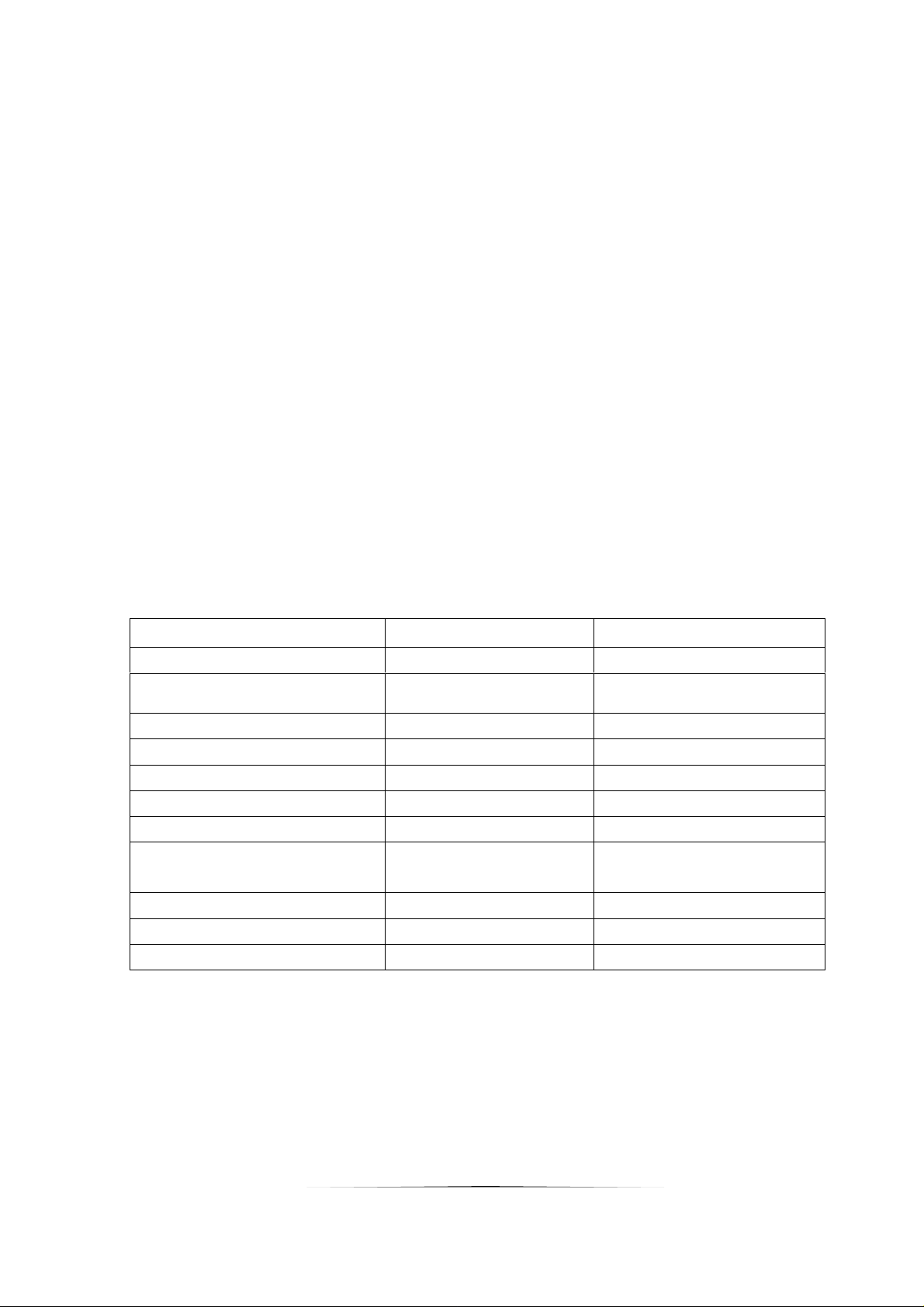

Technical Data: T20 T25

Dimension HxWxD 250 x 340 x 290 300 x 480 x 300

Power Supply:

Single phase alternating

current

Voltage/Frequency 230 [1~50Hz] 400 [3~50Hz]

Power [W] 550 2200

Input Power A 3.5 4.5

Fuse Protection A 16 3x16

Rpm 2900 2900

Lamellar grinding

200 x 50 x 16 250 x 50 x 20

disc in mm

Polishing Disc in mm 200 x 35 x 12 250 x 50 x 14

Utility Space in mm 340 x 240 450x400

Weight in kg 12 28

Three phase alternating

current

4

2. Start-up

2.1 Unpacking and checking of the contents

The following items belong to the scope of delivery:

- Lamellar grinding disc

- Polishing disc

- Polishing paste

- Manual

2.2 Installation

The Lamellar Grinding Machines T-20/25 must be installed in a dry working area only.

You have to provide:

- a sufficient work space for operation and cleaning

- a foot-sure floor for the operator

- a smooth, even working surface

2.3 Electrical connection

- Compare the power supply with type plate details

- Electrical socket must correspond to VDE regulations* and be earthed

- the installation of the Lamellar grinding machines must be made by a qualified

electrician , as the rotation direction of the machines must be checked.

Switch on machines only when ready for operation!!

2.4 Rotation direction check-up

- Switch on the grinding machine

- Grinding disc must rotate in direction of the marked arrow

*(VDE mark is the German Association for Electric and Electronic Technologies)

5

3. Cleaning

3.1 Preparation for cleaning

For cleaning the Lamellar Grinding Machines T-20/25 must be unplugged from the

electrical power supply (unplug from power plug).

3.2 Cleaning instructions

The Lamellar Grinding Machines T-20/25 must not be cleaned with a

high-pressure cleaner or be put into water!

The polishing honing disc must not come into contact with water.

Clean the dismantled parts of the Grinding Machines with a brush or a rag.

3.3 Get grinding machine ready-to-operate

Install the cleaned parts in reverse order.

4. Operation

4.1 Safety Instructions!

Prior to working with the Grinding machines T-20/25, the following safety instructions

must be observed:

- Focus on your work

- Do not talk to and with people

- Do not touch the grinding area

- Keep working area clean and dry / safe footing

Hold the cutting-edge of the tools always in direction of the discs, see arrow,

- For grinding and polishing always wear safety goggles!

Injuries are possible because of free-running discs. These cannot be covered due to

convex grinding.

Besides, when the machines are used carelessly, minor injuries can happen, because

of the unused but freely revolving abrasive disc on the opposite side.

ATTENTION!

Instead of the lamellar grinding disc, the polishing or honing disc, or a felt disc, no

ceramic or resin bonded abrasive discs or any tools, other than provided by us, must be

used.

The legal accident prevention regulations must be observed!

6

4.2 Sharpening of tools with the lamellar grinding disc

Pre-grinding (changes in shape of the cutting edge) and finest regrinding are achieved if

the tool is moved in a simple alternating motion in a longitudinal direction (somewhat

parallel to the motor axis) and by varying the grinding pressure. The lamellar disc adapts

itself automatically to the cutting edge of the tool, in way, that if required, the existing blade

shape is fully maintained. Enhanced cooling of the lamellar disc prevents tarnishing of the

tools.

IMPORTANT!

The tool cutting edge must be always held in the rotation direction of the abrasive disc. As

soon as a fine burr is formed on the cutting edge, the grinding operation has to be

terminated.

4.3 Honing of the tools

The polishing, honing or felt disc respectively, fixed at the left side of the machine is used

for honing. Only this way the tools get their fine, burr-free cutting edge.

IMPORTANT!!

Hold the cutting edge always in rotation direction of the disc.

The cutting tools have to be cleaned after grinding and honing!

5. Maintenance/Exchange of wearing parts

5.1 Maintenance

Apart from cleaning at times, the machine does not need any greasing or maintenance.

The ball-bearings are sufficiently supplied with fat lasting for several years.

5.2 To assemble and/or disassemble the lamellar grinding disc, the polishing and

honing disc

- Disengage the Hexagonal Nut SW 22

- Remove the polishing-honing disc, the lamellar grinding disc respectively and the

- safety washer from the grinding shaft.

7

EU conformity declaration

According to the EC

EC - Machinery Directive 2006/42/EC

for the

Knife Grinder T 20 from Serial No.: 20100001 going

The Company: GS Schleiftechnik, Leyher Str 61, 90431 Nürnberg

Herewith declares as manufacturer of sole responsibility, that

the knife grinder T - 20 is consistent with the requirements of the said Directive above.

The following harmonized standards were applied:

DIN EN ISO 12100-1:2003, DIN EN ISO12100-2: 2003, Safety of

machinery,

VDE 0100, VDE 0701/0702

For changes on the knife grinder T - 20, without consulting us

this declaration loses validity.

GS-Schleiftechnik stocks a complete technical documentation ready for examination.

The manual belonging to this machine is available in its original version.

The conformity for the knife grinder T - 20 is ensured.

D-90431 Nürnberg, 01.11.2012 GS-Schleiftechnik

Geschäftsleitung

8

EU conformity declaration

According to the EC

EC - Machinery Directive 2006/42/EC

for the

Knife Grinder T 25 from Serial No.: 20100001 going

The Company: GS Schleiftechnik, Leyher Str 61, 90431 Nürnberg

Herewith declares as manufacturer of sole responsibility, that

the knife grinder T - 25 is consistent with the requirements of the said Directive above.

DIN EN ISO 12100-1:2003, DIN EN ISO12100-2: 2003, Safety of

The following harmonized standards were applied:

machinery,

VDE 0100, VDE 0701/0702

For changes on the knife grinder T - 25, without consulting us

this declaration loses validity.

GS-Schleiftechnik stocks a complete technical documentation ready for examination.

The manual belonging to this machine is available in its original version.

The Conformity for the knife grinder T - 25 is ensured.

D-90431 Nürnberg, 01.11.2012 GS-Schleiftechnik

Geschäftsleitung

9

T 20

Part list

Item

Specification T-20

Serial no.:

2

Side Part left

GS200-2-2

1

Bottom

GS200-2-2

1

Cover

GS200-6-2

2

Protection inside

2

Protection outside

1

Dirt Trap

2 Welding Work Cover/Lid

2 Safety Washer for polishing disc

12 691 007 001

1 Nut M 12 for Polishing Disc

1

Clamping Flange for Lamellar Disc inside

1

Clamping Flange for Lamellar Disc outside

1

Nut M 16 left for Lamellar disc

4

Rubber feet red

1

Motor EMG EKF71

1 Polishing Disc 200x35x12

25 250 501 410

1 Lamellar Disc 200x50x16

27 200 351 400

1 High Polish Honing Paste green

1 Type Label

1

Instruction Plate Rotation Direction

2

Rotation Direction Arrow

1 Button

1

Contactor

1

Connection Cable

1

Strain relief

10

T 20

Part List

Item

Specification T-25

Serial No.:

1 1

Basic Housing

11 400 250 502

2

3 1

Engine Console

11 225 300 300

4 1

Cover Grinding Motor

11 225 300 310

5 1

Bottom Cover Metal Plate

11 225 332 001

6 6

Rubber Buffer

12 20 25 6 18

13

14

15 2

Safety Washer for Polishing Disc

12 691 007 001

16 1

Nut M 14 for Poliishing Disc

18 093 414 001

17 1

Clamping Flange for Lamellar disc inside

12 225 300 001

18 1

Clamping Flange for Lamella disc outside

12 225 300 002

19 1

Nut M 20 left for Lamellar disc

18 093 414 002

20 2

Cover for Polishing Disc

11 225 320 000

21 2

Lid for Polishing Disc cover

11 225 300 251

22 23 4

Welding Work Cover/Lid

24

25

26 4

Rubber feet red

12 482 530 101

27 28 29 1

Motor Type : DKF 80 G

14 225 330 030

30 35

36 1

Switch ON/Off A 105/6.026

15 132 253 000

37 1

2 m Connection Cable 2m 4x1,5 mm² CEE-Plug

15 114 152 700

38 1

PG 11 Cable Gland with Bend Protection

15 141 110 601

39 1

Nut PG 11 for Cable Gland

15 141 116 900

40

41

42 43

44 45 1

Polishing- and Honing Disc 250x50x14

27 200 352 000

46 1

Lamellar Disc 250x50x20 (grain size of disc 240)

25 250 502 010

47 1

High Polishing Honing paste green

29 100 000 000

48 1

Type Plate

49 1

Instruction Plate Rotation Direction

12 225 330 031

50 2

Rotation Direction Arrows

11

T 20

Datum Name Benennung

Ansicht:

Z-Nr.

GS-Schleiftechnik

90431 Nürnberg

Material:

10.10.12

0

12

Loading...

Loading...