1

N14

N18

Knife grinding machine

N-1/14/18 01/2018

GS-Schleiftechnik, Am Kiebitzengraben 4, D-91315 Höchstadt

Telefon ++49(0)9193-5018696 Telefax ++49(0)9193-52018698

Operating instructions

2

Table of contents

A Safety

A.1 Dangers associated with the machine 4

A.2 Operation in accordance with intended use 4

A.3 Emissions 4

A.4 Sources of danger 4

A.5 The workplace 5

A.6 Authorised operators 5

A.7 Personal protective equipment 5

A.8 Machine safety measures on site 5

A.9 Behaviour in the event of an emergency 5

A.10 Safety information in this manual 5

B Setting up

B.1 Operating elements 6

B.2 Technical data 6

B.3 Installing and connecting the machine 7

B.4 Adjusting the grinding clearance guides 7

B.5 Replacing the grinding stones 7

C Operation

C.1 Grinding 7

C. Polishing and honing 7

CI.

D Cleaning and maintenance

D.1 Cleaning 8

D.2 Maintenance 8

D.3 Authorized cleaning agents 8

D.4 List of spare parts 9

Statement of warranty

This N-14/18 knife grinding machine carries a six month warranty from the date of delivery and is valid

for single-shift operation only. The warranty covers free replacement of damaged and defective parts.

Normal wear and tear, damage resulting from incorrect operation or negligence, and damage resulting

from improper use or unauthorised modifications are not covered by this warranty.,

3

Workplace

in front of the machine

Working position

standing

A. Safety

A.1 Dangers associated with the machine

The knife grinding machine is fitted with safety equipment, and has undergone a safety

examination and inspection. However, in the event of misuse or incorrect operation, the

operator, the machine and other assets of the owner may be endangered.

All personnel authorised to install, set up, operate and maintain the machine must read and

comply with the following instructions. Their safety is at stake.

A.2 Operation in accordance with intended use

The knife grinding machine is designed solely for grinding knives for the food industry.

Unauthorised modifications and alterations to the machine are not permitted for safety

reasons.

The manufacturer/retailer cannot be held liable for damage resulting from any operation which

is not in accordance with the intended use. In this event, the operator is solely responsible.

The N –14/18 knife grinding machine may be considered dangerous if:

- it is used by untrained personnel.

- it is used for a purpose other than that intended by the manufacturer.

Observation of the operating manual and the maintenance guidelines is also a prerequisite for

operation in accordance with the intended use.

A.3 Emissions

The A-assessed equivalent continuous sound pressure level of this machine is under 70

dB(A). No ear protection is necessary.

A.4 Sources of danger

Remove the mains plug before undertaking maintenance

or cleaning.

Never remove safety equipment or disable it by modifying

the machine.

Any alterations or repairs to the electrical system must

be carried out by a qualified electrician.

Only use original spare parts from GS-Schleiftechnik.

A.5 Workplace

4

Note:

Warning!

Danger!

Information regarding

economic operation of the

machine.

Instructions regarding the

prevention of damage or

accident.

Instructions regarding the

prevention of injury to

personnel or extensive

damage to property.

A.6 Authorised operators

Those responsible for the N-14/18 knife grinding machine must make the operating manual

available to the operator, and ensure that he/she has read and understood it.

Both the operator and his/her supervisor must ensure that only trained and authorised

personnel have access to the machine. The machine may only be operated by trained and

authorised personnel.

A.7 Personal protective equipment

No special protective equipment is required.

A.8 Machine safety measures on site

The N-14/18 knife grinding machine must be fixed to a flat, solid worktop. It is suited to working

in a humid environment. Ensure that the workplace is always kept clean and tidy by

appropriate instructions and inspections.

A.9 Behaviour in the event of an emergency

In the event of an emergency, remove the mains plug. If the machine's safety has been

compromised, shut it down immediately and inform the person or department responsible.

A.10 Safety information in this manual

5

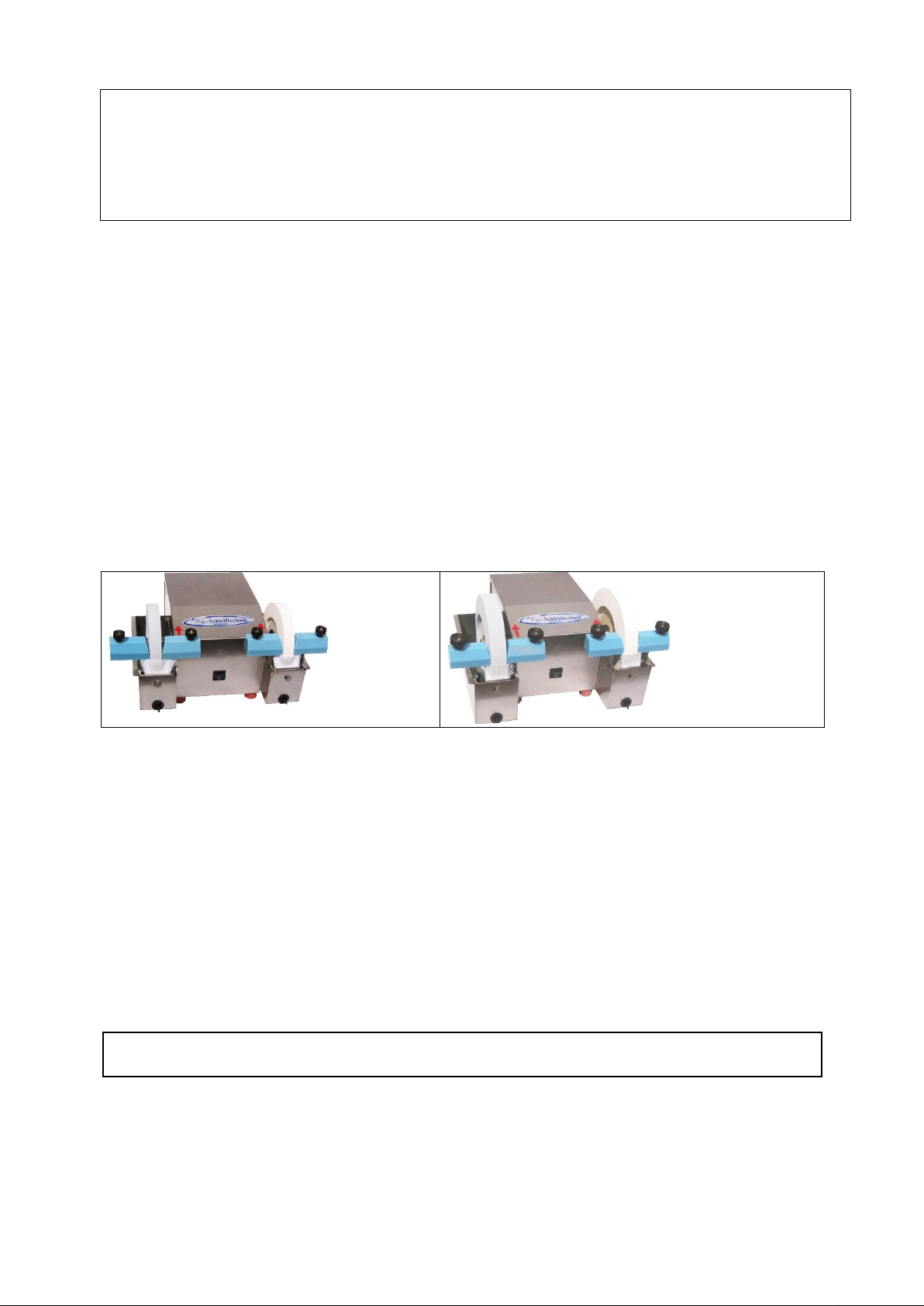

B.1 Operating elements

1 Casing

2 Water basin

3 Grinding clearance guides

4 Clamping levers

5 Water wiper brushes

6 On/off switch

7 Grinding disc

8 Polishing and honing disc

9 Water drain plug

Voltage supply

230V 1Ph 0,7A

Casing and water basin

Stainless steel

Width/height/depth

ca. 410x270x210

Grinding disc

140x25x14 / 175x32x14

Honing disc

140x25x14 / 175x32x14

Weight

N14/10 kg N18/12kg

B.2 Technical data

Remove the mains plug before undertaking maintenance

or cleaning.

Never remove safety equipment or disable it by modifying

the machine.

Any alterations or repairs to the electrical system must

be carried out by a qualified electrician.

Only use original spare parts from GS-Schleiftechnik.

B.3 Installing and connecting the machine

6

Mount the knife grinding machine on a solid, flat surface. The ventilation ducts on the

machine's underside must not be covered. Connect the machine to a 230 V AC supply

protected by a 16 A fuse, and fill the water basin with about 4 cm of water.

B.4 Adjusting the grinding clearance guides

After releasing the clamping levers, slide the grinding

clearance guides towards the grinding wheel to give a gap of

approx. 1/2 mm. Then retighten the clamping levers. If the

clamping lever is lowered it can be turned without slackening

the screw tension.

B.5 Replacing the grinding stones

Remove the grinding clearance guides. Hold the grinding stone in one hand, and loosen the

tensioner bolt with a 17 mm spanner in the turning direction of the grinding stone. The bolt on

the right side has a left-hand thread. Remove the bolt with the tensioner flange, and the

grinding disc can be pulled out from the side. Reassembly is the reverse of disassembly.

Before fully tightening the tensioner bolt, line up the grinding disc by gently tapping with a nylon

hammer or a block of wood.

C Operation

C.1 Grinding

Before grinding, remove any grease or other residue

from the knife. Place the knife in the grinding clearance

guide and slide it backwards and forwards along the

cutting edge with a small amount of pressure. Repeat

several times, on the right and the left of the grinding

disc. Make sure that the knife is correctly placed in the

grinding clearance guides so that it is sharpened

uniformly. Continue until both sides of the cutting edge

have a constant burr. This is likely to take some time

on an old, heavily used knife. The degree of hardness

of the knife's blade will also affect its sharpening time.

C.2 Polishing and honing

Repeat the procedure as for grinding, but using the polishing and honing stone. Within a short

time the cutting edge is polished. Then hone the blade with minimum pressure.

Once a knife has been properly ground and polished, the procedure does not have to be

repeated every time the blade needs sharpening. The knife only needs to be reground when

polishing and honing fails to sharpen the blade.

7

D Cleaning and maintenance

D.1 Cleaning

Over time, dust from the grinding process builds up on the polishing and honing disc. To

remove this, hold the supplied dressing stone hard against the grinding surface. If grease has

got onto the grinding stones despite cleaning the knives, just add solvent to the water.

The water basin should also be cleaned from time to time to remove grinding dust.

Warning!

D.2 Maintenance

The knife grinding machine is completely maintenance-free. In the unlikely event of a fault

occurring on your machine, please contact our customer service department.

Remove the mains plug before undertaking maintenance or

cleaning.

Never remove safety equipment or disable it by modifying the

machine.

Any alterations or repairs to the electrical system must be carried

out by a qualified electrician.

Only use original spare parts from GS-Schleiftechnik.

D.3 Authorized cleaning agents

Cleaning agents and procedures commonly used in the food industry can be used for cleaning

and disinfecting the machinery. Only use legally permitted cleaning agents.

8

Statement of CE conformity

In accordance with the EC Guidelines for Machines 2006/42/EG,,

for the

N-14 knife grinding machine, serial no. N14130001

GS-Schleiftechnik

Am Kiebitzengraben 4

91315 Höchstadt

Germany

states, as manufacturer and sole responsible party, that

the N-14 knife grinding machine

is in compliance with the requirements of the above guideline.

The following harmonised norms have been applied:

DIN EN ISO 12100-1:2003; DIN EN ISO12100-2:2003, Machine, Equipment and

Systems Safety VDE 0100, VDE 0701/0702

In the event of unauthorised alterations to the N-14 knife grinding machine,

this statement

shall become invalid.

GS-Schleiftechnik can provide the full technical documentation for

inspection.

The original version of the machine operating manual is also available.

The conformity of the N-14 knife grinding machine is ensured.

D-91315 Höchstadt, 21.10.2014 GS-Schleiftechnik

Management.

9

Statement of CE conformity

In accordance with the EC Guidelines for Machines 2006/42/EG,

for the

N - 18 knife grinding machine, from serial no. N18140001

GS-Schleiftechnik

Am Kiebitzengraben 4

91315 Höchstadt

Germany

states, as manufacturer and sole responsible party, that

the N - 18 knife grinding machine

is in compliance with the requirements of the above guideline.

The following harmonised norms have been applied:

DIN EN ISO 12100-1:2003; DIN EN ISO 12100-2:2003, Machine, Equipment and

Systems Safety VDE 0100, VDE 0701/0702,

In the event of unauthorised alterations to the N - 18 knife grinding machine,

this statement

shall become invalid.

GS-Schleiftechnik can provide the full technical documentation for

inspection.

The original version of the machine operating manual is also available.

The conformity of the N - 18 knife grinding machine is ensured.

D-91315 Höchstadt, 21.10.2014 GS-Schleiftechnik

Management.

10

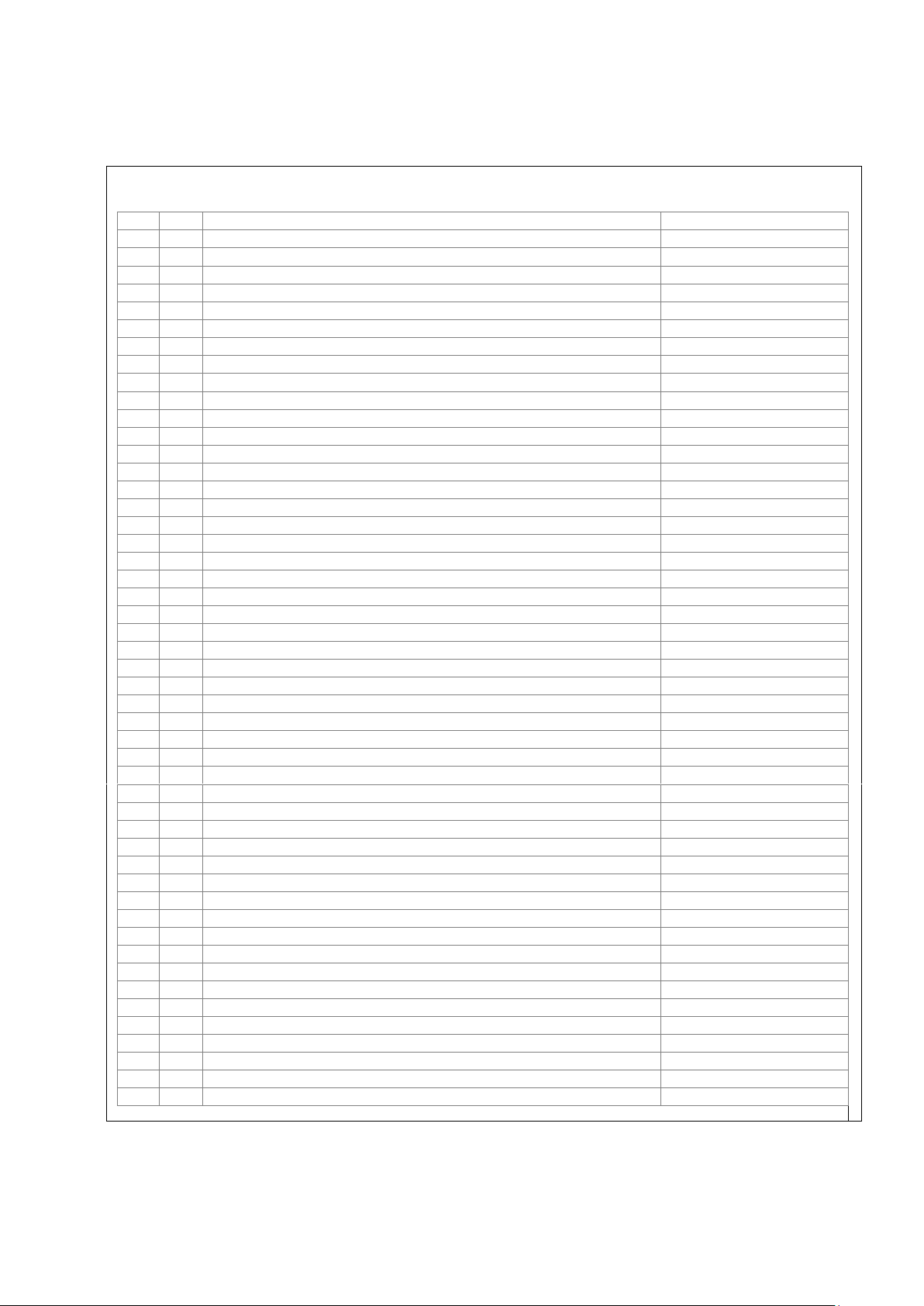

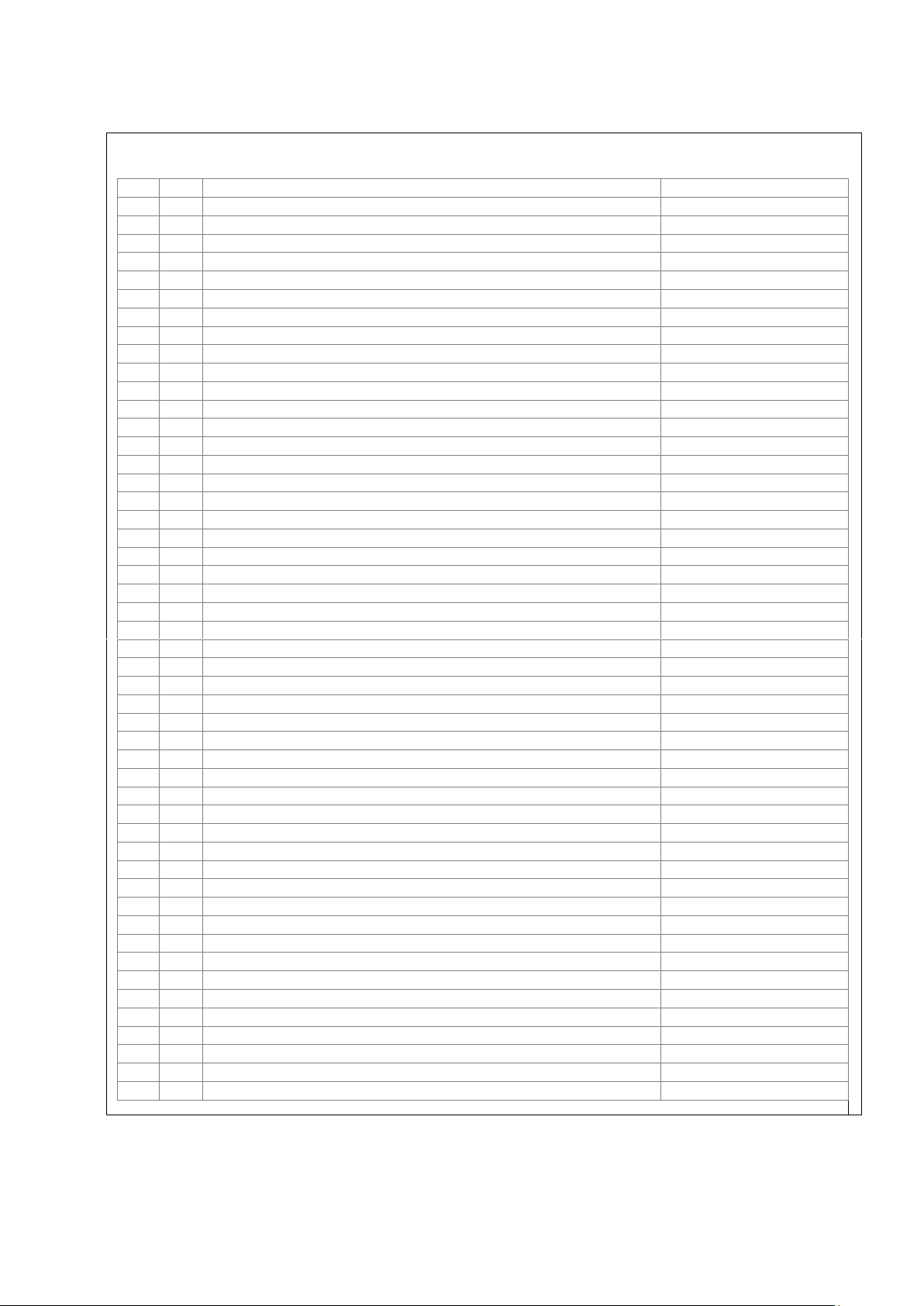

Stck

Bezeichnung

Art.Nr.:

1 1

Grundgehäuse

11 140 180 001

2 1

Gehäuse-Abdeckung

11 140 180 002

3 1

Motorwinkel

11 140 180 100

4 1

Wasserbecken rechts

11 140 000 012

5 1

Wasserbecken links

11 140 000 011

6 2

Wasserabstreifbürste

12 148 000 001

7 2

Schleifwinkelhalter

11 140 000 003

8 1

Bodenplatte

11 140 180 003

9 2

Schleifwinkelführung rechts

12 148 141 000

10 2

Schleifwinkelführung links

12 148 140 000

11 4

Rändelmutter f. Schleifwinkelführung

12 590 206 000

12 1

Spannscheibe für Kunstschleifscheibe innen

12 148 000 501

13 1

Spannscheibe für Kunstschleifscheibe außen

12 148 000 500

14 1

Spannscheibe für Abziehschleifscheibe innen

12 148 000 501

15 1

Spannscheibe für Abziehschleifscheibe außen

12 148 000 500

16 1

Schraube M10x24 rechts

18 148 000 020

17 1

Schraube M10x24 links

18 148 000 021

18 2

Lagergehäuse f. Gleitlager

12 148 601 720

19 2

Gleitlager 12 148 183 201

20 2

Seegerring

18 148 200 100

21 4

Gummifüße rot

12 482 530 101

22 2

Wasserablaufstopfen

12 630 141 500

23 1

Motor 14 140 180 000

24 1

Zahnrad für Motor 24 Zähne

13 140 180 024

25 1

Transformator 230/24V 100VA

15 148 000 000

26 1

Aluplatte mit Gleichrichter

15 140 180 001

27 1

Schraube M6x70 für Transformator

18 148 000 070

28 1

Ein-Aus Schalter

15140180000

29 1

Welle 140/18

12 140 024 517

30 1

Schwerspannstift

18 148 103 260

31 1

Zahnrad für Achse 35 Zähne Bohrung 18mm

13 140 180 036

32 1

Anschlusskabel 2m 3x0,75qmm m. Schuko-Stecker

15 113 203 000

33 1

Kabelverschraubung PG11

15 141 110 600

34 1

Mutter PG 11 für Kabelverschraubung

15 141 116 900

35

36 1

Kunstschleifscheibe 140x25x14

20 140 251 424

37 1

Abziehscheibe 140x25x14

22 140 251 400

38 1

Abrichtstein

24 200 000 000

39

40

41

42

43

44

45

46

47

48

Typenschild

49

Drehrichtungspfeile

50

Kabelbinder

Sho

Spareparts N-14

11

Spareparts N-18

Stck

Bezeichnung

Art.Nr.:

1 1

Grundgehäuse

11 140 180 001

2 1

Gehäuse-Abdeckung

11 140 180 002

3 1

Motorwinkel

11 140 180 100

4 1

Wasserbecken rechts

11 180 000 012

5 1

Wasserbecken links

11 180 000 011

6 2

Wasserabstreifbürste

12 148 000 001

7 2

Schleifwinkelhalter

11 180 000 003

8 1

Bodenplatte

11 140 180 003

9 2

Schleifwinkelführung rechts

12 148 141 000

10 2

Schleifwinkelführung links

12 148 140 000

11 4

Rändelmutter f. Schleifwinkelführung

12 590 206 000

12 1

Spannscheibe für Kunstschleifscheibe innen

12 148 000 501

13 1

Spannscheibe für Kunstschleifscheibe außen

12 148 000 500

14 1

Spannscheibe für Abziehschleifscheibe innen

12 148 000 501

15 1

Spannscheibe für Abziehschleifscheibe außen

12 148 000 500

16 1

Schraube M10x24 rechts

18 148 000 020

17 1

Schraube M10x24 links

18 148 000 021

18 2

Lagergehäuse f. Kugellager

12 148 110 000

19 2

Kugellager

12 620 200 001

20 2

Stellring 17mm

12 140 180 017

21 4

Gummifüße rot

12 482 530 101

22 2

Wasserablaufstopfen

12 630 141 500

23 1

Motor 14 140 180 000

24 1

Zahnrad für Motor 20 Zähne

13 140 180 020

25 1

Transformator 230/24V 100VA

15 148 000 000

26 1

Aluplatte mit Gleichrichter

15 140 180 001

27 1

Schraube M6x70 für Transformator

18 148 000 070

28 1

Ein-Aus Schalter A 107/50.0

15140180000

29 1

Welle 180/17

12 180 024 517

30 1

Schwerspannstift

18 148 103 260

31 1

Zahnrad für Achse 35 Zähne Bohrung 17mm

13 140 180 035

32 1

Anschlusskabel 2m 3x0,75qmm m. Schuko-Stecker

15 113 203 000

33 1

Kabelverschraubung PG11

15 141 110 600

34 1

Mutter PG 11 für Kabelverschraubung

15 141 116 900

35

36 1

Kunstschleifscheibe 175x32x14

20 175 321 424

37 1

Abziehscheibe 175x32x14

22 175 321 600

38 1

Abrichtstein

24 200 000 000

39

40

41

42

43

44

45

46

47

48

Typenschild

49

Drehrichtungspfeile

50

Kabelbinder

Sho

12

13

Loading...

Loading...