GSN PATROL 501 Installation Instructions Manual

w

PATROL – 501

DIGITAL

ACOUSTIC GLASS

BREAK DETECTOR

INSTALLATION

INSTRUCTIONS

www.gsncompany.com

For creating an alarm, both a

low-frequency sound of the glass

impact and a high-frequency glass

breakage sound must be registered

ithin a predetermined time frame.

Since both detector channels

must register the actual glass

breakage, false alarms are

practically excluded.

The program of microcontroller,

based on the mathematical

algorithm, analyzes signals

and detects only the actual

breakage of all standard framed

glass types.

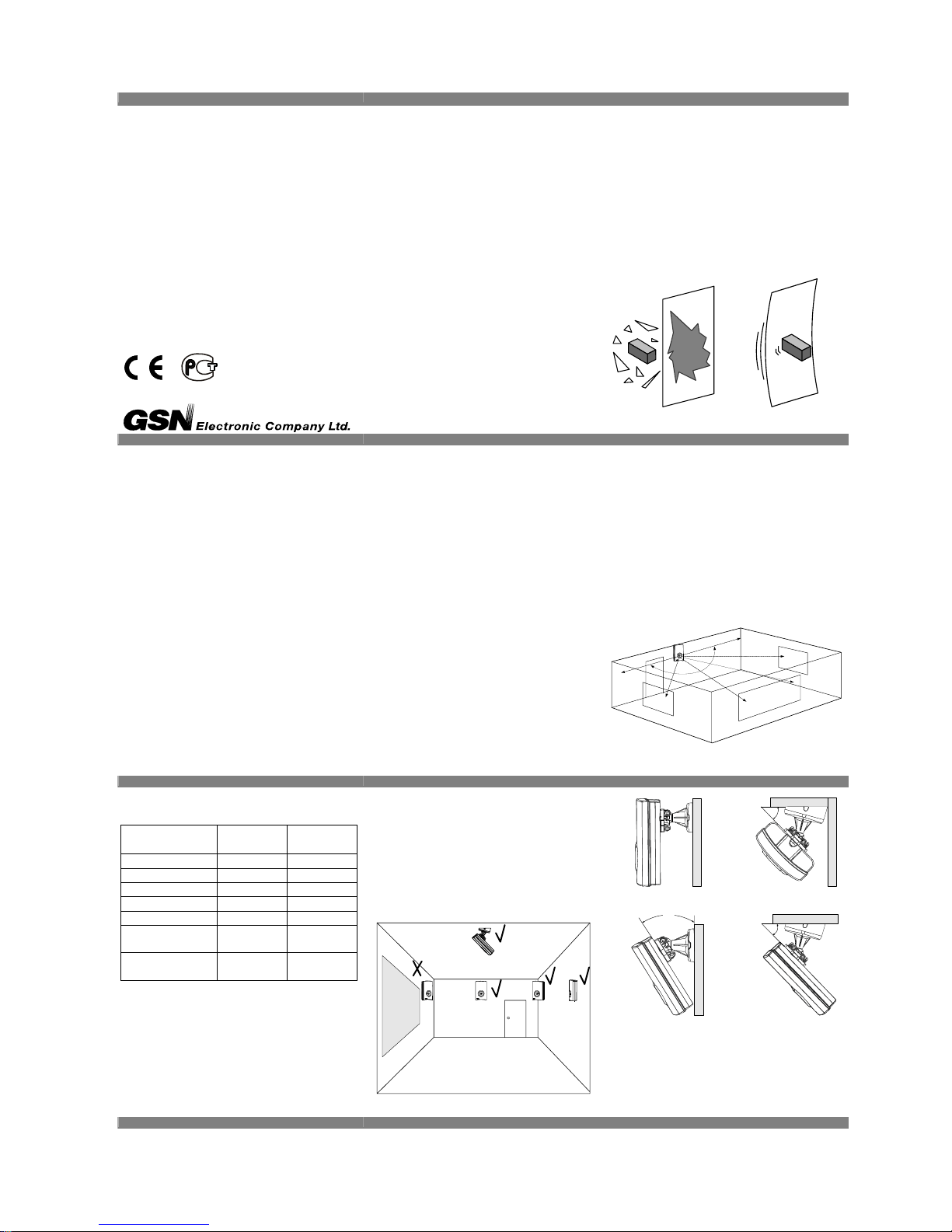

PROTECTED GLASS TYPES.

Glass

Type

Plate 2 mm 10 mm

Tempered 3 mm 8.4 mm

Patterned 3 mm 10 mm

Laminated ¹ 3.2 mm 14.3 mm

Wired 5 mm 6.4 mm

Coated ²

(Triplex)

Sealed

Insulating ¹

Min.

Thickness

2,5 mm 8.4 mm

3.2 mm 6.4 mm

¹ Laminated and sealed insulating

glass types are protected only

if both glass plates are broken.

² For glass coated with plastic film

on the inner surface, effective range

is reduced to 6m.

Max.

Thickness

INTRODUCTION.

The PATROL-501 recognizes

particular sound patterns emitted

by glass breakage.

The PATROL-501 provides

complete protection of all known

framed glass types.

The PATROL-501 uses unique

algorithm, based on two-channel

recognition analysis of the

characteristic frequencies and

signal sequence of framed pane

glass breakage.

The LED will light continuously

for 3 seconds and the alarm relay

will be open on alarm.

PATROL-501 RELIABILITY.

Due to the unique program and

perfectly adjusted filters the

PATROL-501 provides excellent

protection from false alarms in

extremely harsh environments.

Highly selective sensitivity of the

high frequency channel enables the

PATROL-501 to detect real glass

breakage with high accuracy among

a variety of background noises.

The above features enable the

PATROL-501 to be used in

extremely harsh environments,

such as airports, industrial plants

as well as in the vicinity of noisy

restaurants, bars, etc.

SELECTING MOUNTING

LOCATION. MOUNTING ON

SWIVEL BRACKET.

V – Correct installation.

X – Incorrect installation.

DESCRIPTION.

Low-frequency sound occurs upon

the impact on the glass.

High-frequency sound occurs upon

the glass breakage.

HIGH-FREQUENCY LOW-FREQUENCY

SOUND SOUND

High RFI and EMI immunity allows

the detector to be mounted next to

radio and electromagnetic emission

sources.

PATROL-501 COVERAGE

RANGE.

Maximum detection range:

12 meters X 170º.

1

2

m

e

o

t

e

170

r

s

(

M

A

X

)

o

45

A) B)

o

30

C)

) Vertical mounting.

B) Corner mounting.

C) Surface mounting - 30º.

D)

o

45

D) Ceiling mounting - 45º.

r

w

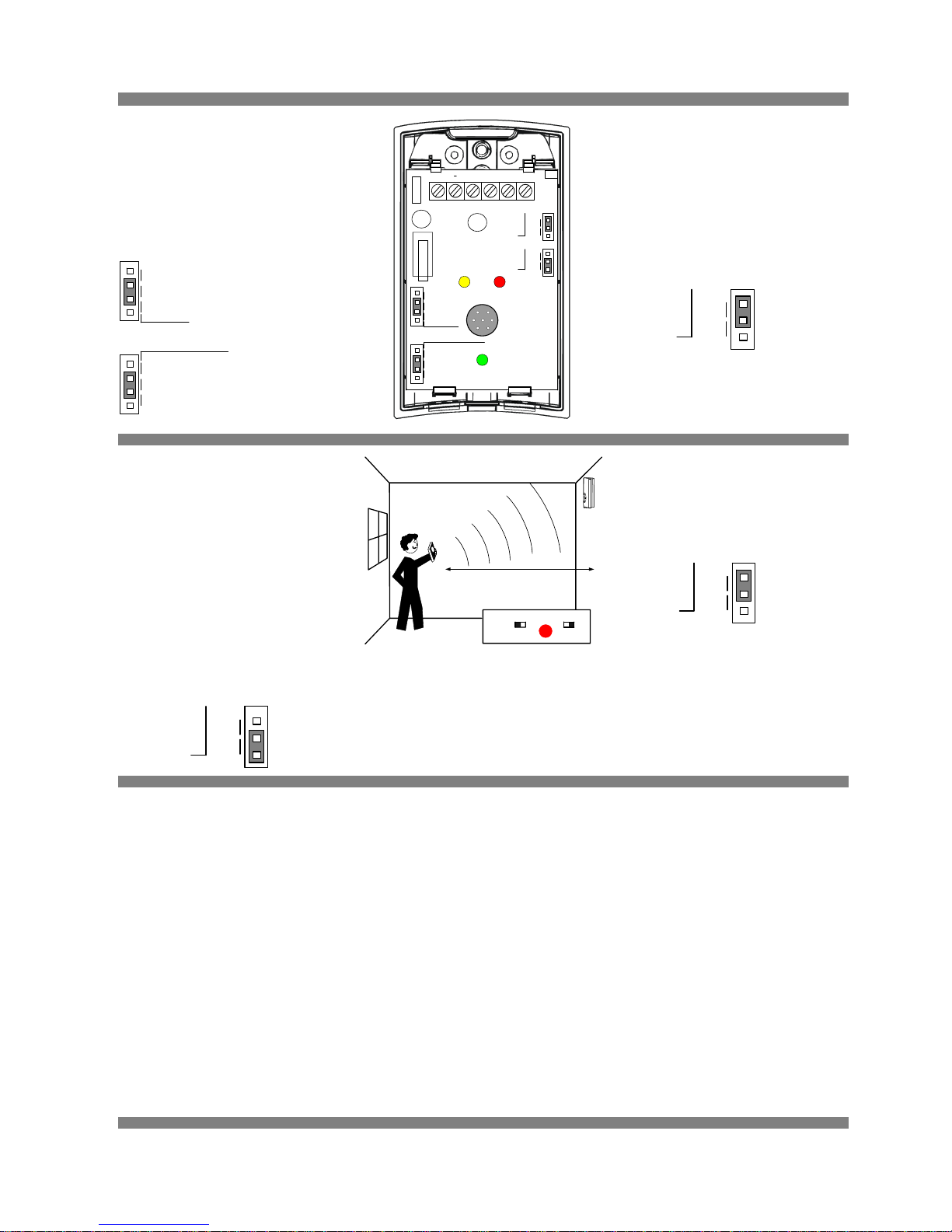

SELECTING GLASS TYPE

AND COVERAGE RANGE.

Set the jumper W1 according to the

distance to the protected glass.

Set the jumper W2 according to the

protected glass type (see the figure).

W2

PL

TM

LW

GLASS TYPE

RANGE ADJUSTMENT

M

6

M

9

M

12

W1

TM position – for most glass types.

- PLATE

PL

*

TM

- TEMPERED

- PATTERNED

LW - LAMINATED

- WIRED

- COATED

- SEALED INSULATING

*

(TRIPLEX)

GLASS BREAK

SIMULATION TEST.

1. Set jumper S2 to “ON” position.

The yellow LED will be ON – the

detector is in the “TEST” mode.

2. Replace the cover.

3. Use “FG-701” or “RG-65” Glass

Break simulator or any other models

to simulate the high frequency signal

of the glass breakage. The

ed LED

ill flash on each simulator

activation.

S2

OFF

ON

GLASS TEST

TECHNICAL SPECIFICATIONS.

Power input:.…...………..9 - 16VDC

Current consumption

In stand-by mode:...………..17.8mA

In alarm mode:...…………...18.7mA

Alarm period:...…..………….…3sec.

Warm up period: ………………2sec.

Detection range:...……..12m x 170º

Relay output:………….……………..

……………..N.C; 60V; 120mA; 16

Tamper:…..........................N.C.10

RELAY

J1

OFF

ON

GLASS TEST

ON

OFF

MEMORY

DIGITAL

ACOUSTIC

GLASS BREAK

DETECTOR

BUTTON

OF START

CS

S2

S3

W2

GLASS TYPE

RANGE ADJUSTMENT

W1

ATTENTION!

TAMPER

+ 12V

S1

PATROL-501

YELLOW RED

PL

TM

LW

6m

9m

GREEN

12m

HIGH FREQUENCY TEST

NO MORE THAN 12 METERS

GLASS BREAK SIMULATOR

ACTIVATE TEST FLEX MAN

G.S.N.

ELECTRONIC

COMPANY LTD.

– MODEL FG-701

During the “Glass Break Test” the

alarm relay is opened. After the

“Glass Break Test” set jumper S2

to “OFF” position (operating mode).

Microphone type:…...………………..

omnidirectional electret microphone

Operating temperature

range:……………..…– 30°C + 50°C

Storage temperature

range:………….…….– 40°C + 80°C

RFI immunity:…………..30 V/m at a

frequency range 10MHz-1000MHz

EMI immunity:.……………..50 000V

Dimensions:…….…….87x52x24mm

Weight:…………………………..58gr.

LAST EVENT MEMORY.

Set the jumper S3 to “ON” position

for LED to provide indication of event

memory function for last 30 minutes.

LED starts blinking on alarm.

After the period of 30 minutes the

memory is automatically erased.

ON

OFF

MEMORY

S3

SHOCK & GLASS BREAK

SIMULATION TEST.

The test is conducted in operating

mode (“OFF” position).

OFF

ON

GLASS TEST

S2

Replace the cover. Tap gently the

protected glass and activate the

simulator at the same time.

The red LED will be ON for 3 sec.

WARRANTY.

GSN Electronic Company Ltd.

warrants the product to be free

from defects in materials and

workmanship under condition of

observance of service regulations

and to be repaired or replaced

under absence of mechanical

damages for a limited period of

five years from the date of sale.

P/N: USM0E501 REV.A PRINTED IN ISRAEL

Loading...

Loading...