GSI Technology GS8662R08-333, GS8662R09-333, GS8662R18-333, GS8662R36E-333, GS8662R08-300 Service Manual

...

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

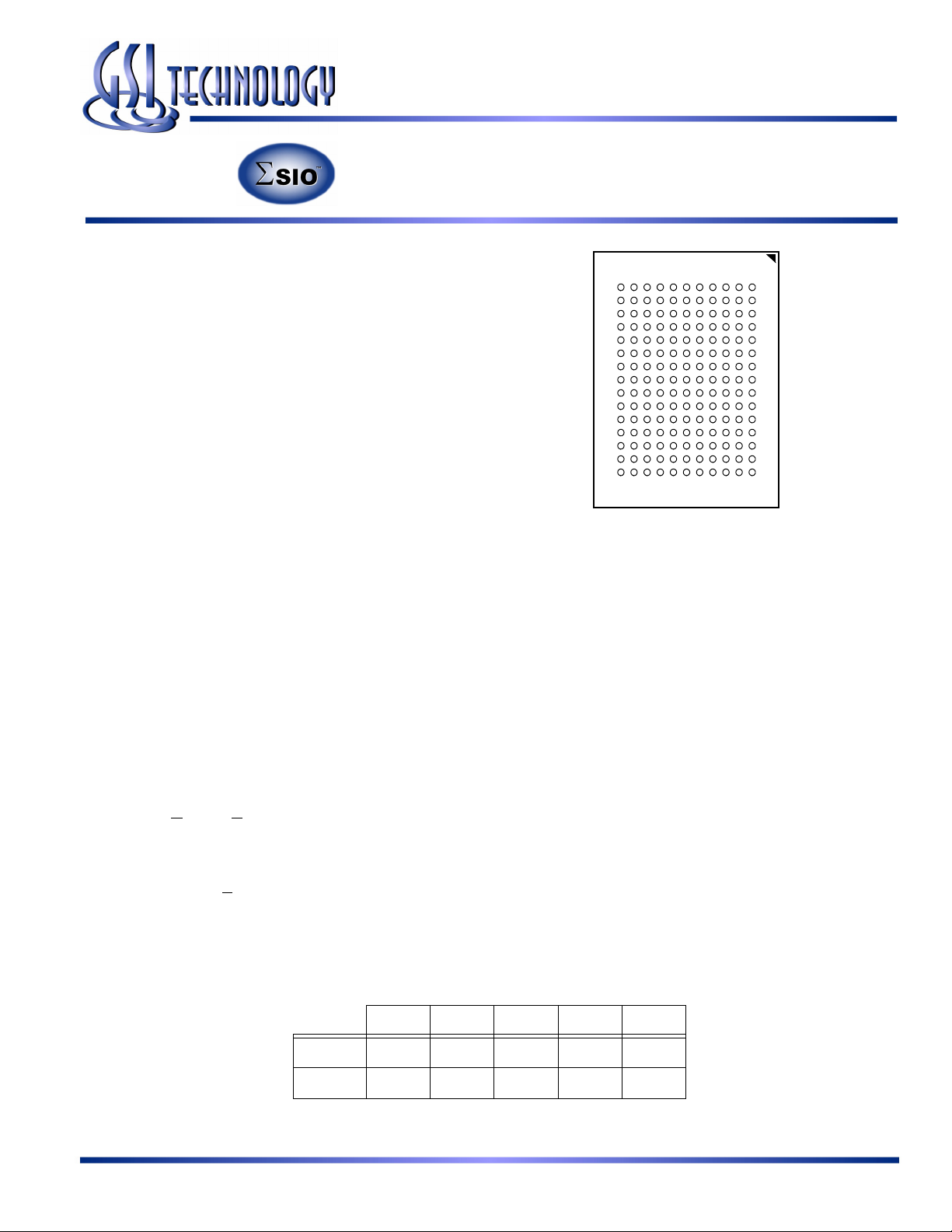

165-Bump BGA

72Mb SigmaCIO DDR-II

Commercial Temp

Industrial Temp

Burst of 4 SRAM

Features

• Simultaneous Read and Write SigmaCIO™ Interface

• Common I/O bus

• JEDEC-standard pinout and package

• Double Data Rate interface

• Byte Write (x36 and x18) and Nybble Write (x8) function

• Burst of 4 Read and Write

• 1.8 V +100/–100 mV core power supply

• 1.5 V or 1.8 V HSTL Interface

• Pipelined read operation with self-timed Late Write

• Fully coherent read and write pipelines

• ZQ pin for programmable output drive strength

• IEEE 1149.1 JTAG-compliant Boundary Scan

• Pin-compatible with present 9Mb, 18Mb, 36Mb and future

144Mb devices

• 165-bump, 15 mm x 17 mm, 1 mm bump pitch BGA package

• RoHS-compliant 165-bump BGA package available

SigmaCIO™ Family Overview

The GS8662R08/09/18/36E are built in compliance with the

SigmaCIO DDR-II SRAM pinout standard for Common I/O

synchronous SRAMs. They are 75,497,472-bit (72Mb)

SRAMs. The GS8662R08/09/18/36E SigmaCIO SRAMs are

just one element in a family of low power, low voltage HSTL

I/O SRAMs designed to operate at the speeds needed to

implement economical high performance networking systems.

Clocking and Addressing Schemes

The GS8662R08/09/18/36E SigmaCIO DDR-II SRAMs are

synchronous devices. They employ two input register clock

inputs, K and

inputs, not differential inputs to a single differential clock input

buffer. The device also allows the user to manipulate the

output register clock inputs quasi independently with the C and

C clock inputs. C and

K. K and K are independent single-ended clock

C are also independent single-ended

333 MHz–167 MHz

1.8 V V

DD

1.8 V and 1.5 V I/O

Bottom View

165-Bump, 15 mm x 17 mm BGA

1 mm Bump Pitch, 11 x 15 Bump Array

clock inputs, not differential inputs. If the C clocks are tied

high, the K clocks are routed internally to fire the output

registers instead.

Common I/O x36 and x18 SigmaCIO DDR-II B4 RAMs

always transfer data in four packets. When a new address is

loaded, A0 and A1 preset an internal 2 bit linear address

counter. The counter increments by 1 for each beat of a burst of

four data transfer. The counter always wraps to 00 after

reaching 11, no matter where it starts.

Common I/O x8 SigmaCIO DDR-II B4 RAMs always transfer

data in four packets. When a new address is loaded, the LSBs

are internally set to 0 for the first read or write transfer, and

incremented by 1 for the next 3 transfers. Because the LSBs

are tied off internally, the address field of a x8 SigmaCIO

DDR-II B4 RAM is always two address pins less than the

advertised index depth (e.g., the 4M x 18 has a 1024K

addressable index).

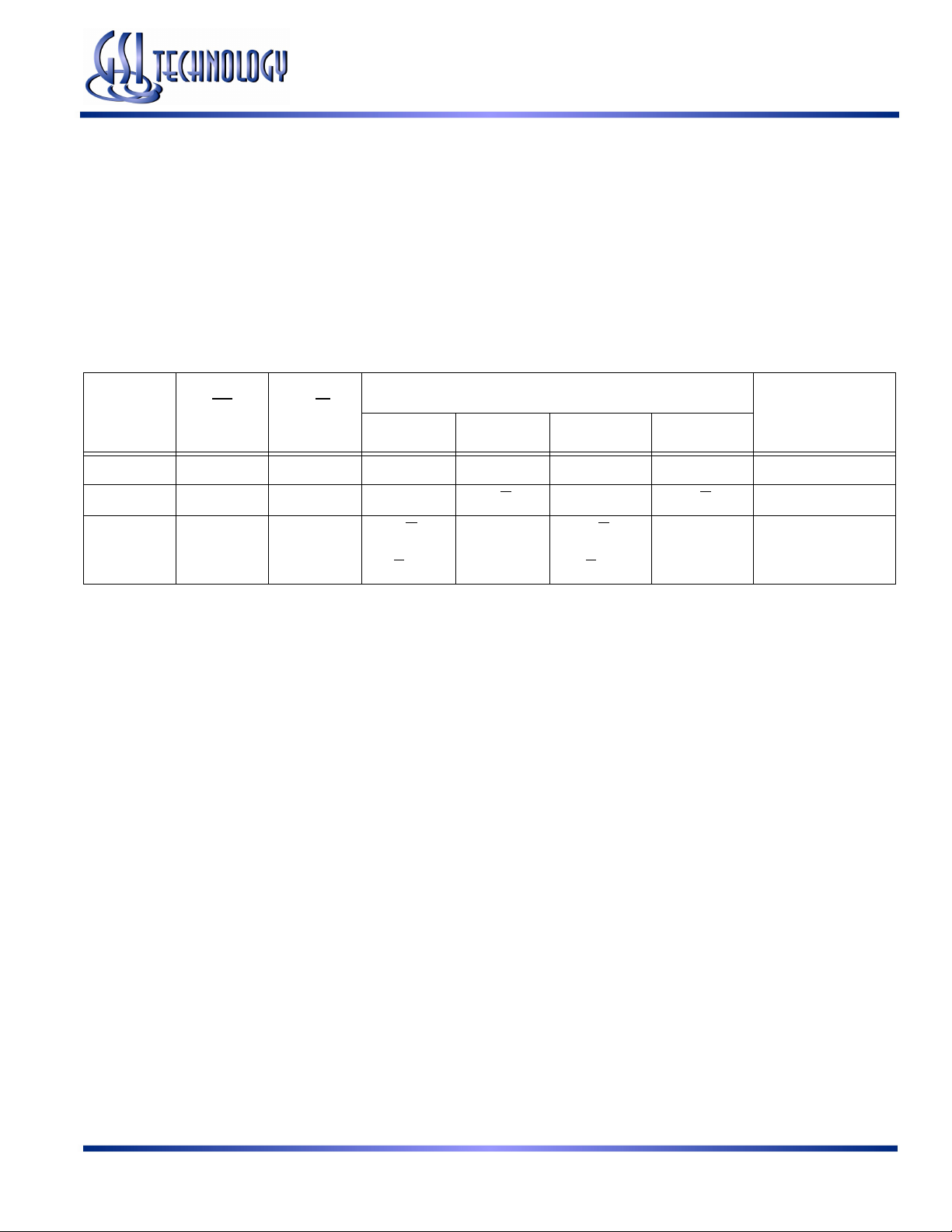

Parameter Synopsis

-333 -300 -250 -200 -167

tKHKH 3.0 ns 3.3 ns 4.0 ns 5.0 ns 6.0 ns

tKHQV 0.45 ns 0.45 ns 0.45 ns 0.45 ns 0.5 ns

Rev: 1.01 9/2005 1/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

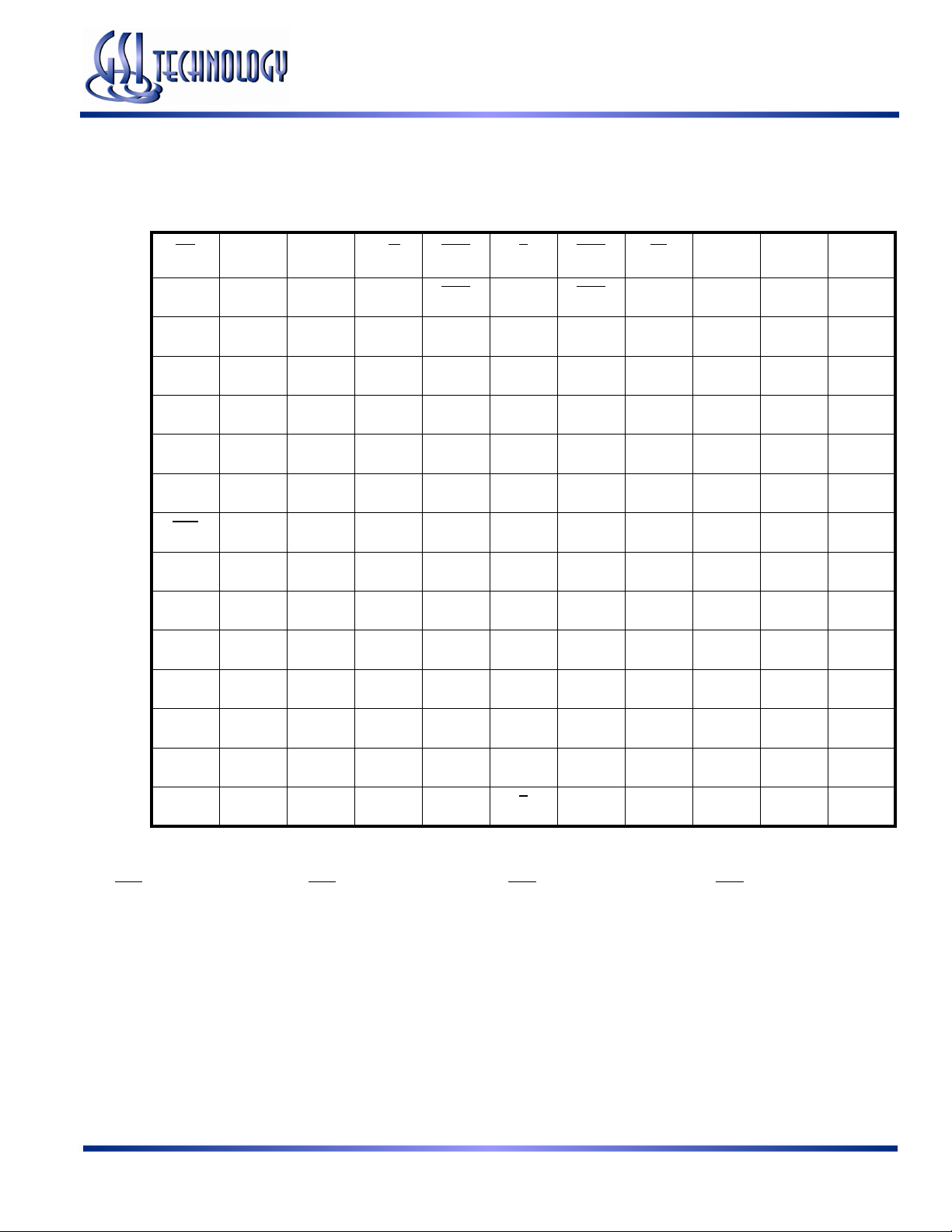

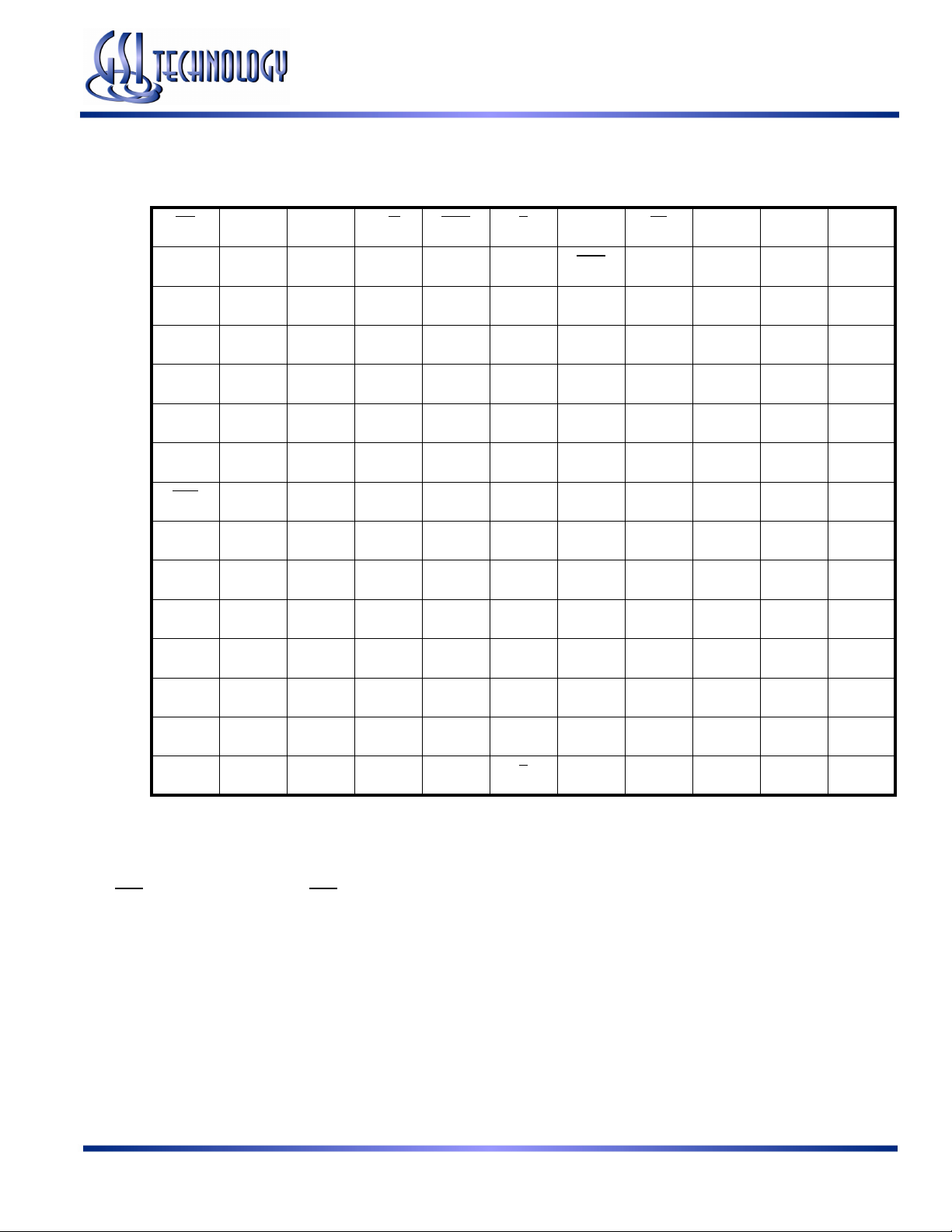

2M x 36 SigmaCIO DDR-II SRAM—Top View

1 2 3 4 5 6 7 8 9 10 11

A CQ

MCL/SA

(144Mb)

SA R/W BW2 K BW1 LD SA SA CQ

B NC DQ27 DQ18 SA BW3 K BW0 SA NC NC DQ8

C NC NC DQ28 V

D NC DQ29 DQ19 V

E NC NC DQ20 V

F NC DQ30 DQ21 V

G NC DQ31 DQ22 V

H Doff V

REF

V

DDQ

V

J NC NC DQ32 V

K NC NC DQ23 V

L NC DQ33 DQ24 V

M NC NC DQ34 V

SS

SS

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

SS

SA SA0 SA1 V

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

SS

V

SS

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

SS

NC DQ17 DQ7

NC NC DQ16

NC DQ15 DQ6

NC NC DQ5

NC NC DQ14

V

DDQ

V

REF

NC DQ13 DQ4

NC DQ12 DQ3

NC NC DQ2

NC DQ11 DQ1

ZQ

N NC DQ35 DQ25 V

SS

SA SA SA V

SS

NC NC DQ10

P NC NC DQ26 SA SA C SA SA NC DQ9 DQ0

R TDO TCK SA SA SA C SA SA SA TMS TDI

11 x 15 Bump BGA—13 x 15 mm2 Body—1 mm Bump Pitch

Notes:

1. BW0 controls writes to DQ0:DQ8; BW1 controls writes to DQ9:DQ17; BW2 controls writes to DQ18:DQ26; BW3 controls writes to

DQ27:DQ35

2. MCL = Must Connect Low

Rev: 1.01 9/2005 2/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

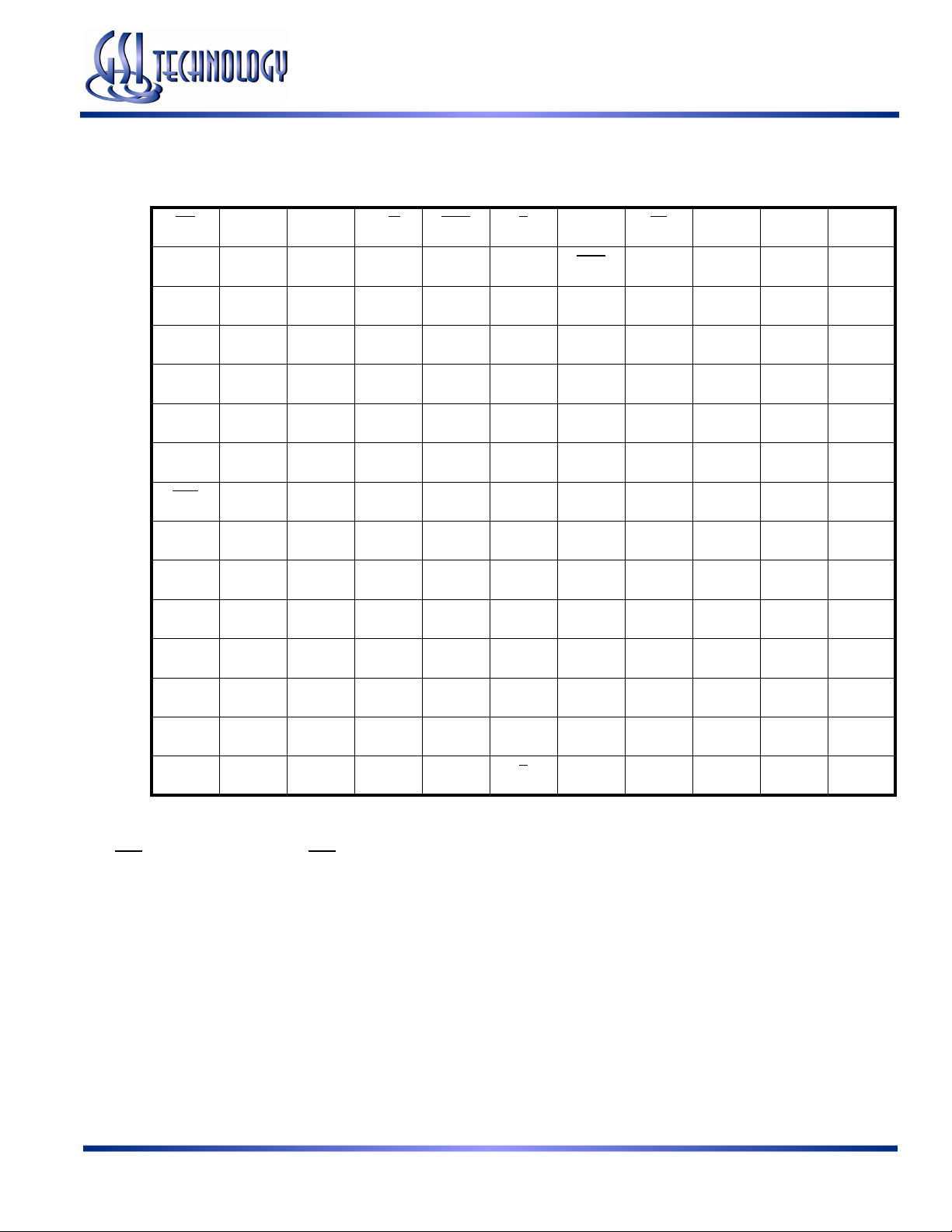

4M x 18 SigmaCIO DDR-II SRAM—Top View

1 2 3 4 5 6 7 8 9 10 11

A CQ SA SA R/W BW1 K NC LD SA SA CQ

B NC DQ9 NC SA NC K BW0 SA NC NC DQ8

C NC NC NC V

D NC NC DQ10 V

E NC NC DQ11 V

F NC DQ12 NC V

G NC NC DQ13 V

H Doff V

REF

V

DDQ

V

J NC NC NC V

K NC NC DQ14 V

L NC DQ15 NC V

M NC NC NC V

N NC NC DQ16 V

SS

SS

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

SS

SS

SA SA0 SA1 V

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

SA SA SA V

SS

V

SS

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

SS

SS

NC DQ7 NC

NC NC NC

NC NC DQ6

NC NC DQ5

NC NC NC

V

DDQ

V

REF

NC DQ4 NC

NC NC DQ3

NC NC DQ2

NC DQ1 NC

NC NC NC

ZQ

P NC NC DQ17 SA SA C SA SA NC NC DQ0

R TDO TCK SA SA SA C SA SA SA TMS TDI

11 x 15 Bump BGA—13 x 15 mm2 Body—1 mm Bump Pitch

Notes:

1. BW0 controls writes to DQ0:DQ8; BW1 controls writes to DQ9:DQ17

2. MCL = Must Connect Low

Rev: 1.01 9/2005 3/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

8M x 9 SigmaCIO DDR-II SRAM—Top View

1 2 3 4 5 6 7 8 9 10 11

A CQ SA SA R/W NC K NC LD SA SA CQ

B NC NC NC SA NC K BW SA NC NC DQ4

C NC NC NC V

D NC NC NC V

E NC NC DQ5 V

F NC NC NC V

G NC NC DQ6 V

H Doff V

REF

V

DDQ

V

J NC NC NC V

K NC NC NC V

L NC DQ7 NC V

M NC NC NC V

N NC NC NC V

SS

SS

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

SS

SS

SA NC SA V

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

SA SA SA V

SS

V

SS

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

SS

SS

NC NC NC

NC NC NC

NC NC DQ3

NC NC NC

NC NC NC

V

DDQ

V

REF

NC DQ2 NC

NC NC NC

NC NC DQ1

NC NC NC

NC NC NC

ZQ

P NC NC DQ8 SA SA C SA SA NC NC DQ0

R TDO TCK SA SA SA C SA SA SA TMS TDI

11 x 15 Bump BGA—13 x 15 mm2 Body—1 mm Bump Pitch

Notes:

1. Unlike the x36 and x18 versions of this device, the x8 and x9 versions do not give the user access to A0 and A1. SA0 and SA1 are set to

0 at the beginning of each access.

2. MCL = Must Connect Low

Rev: 1.01 9/2005 4/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

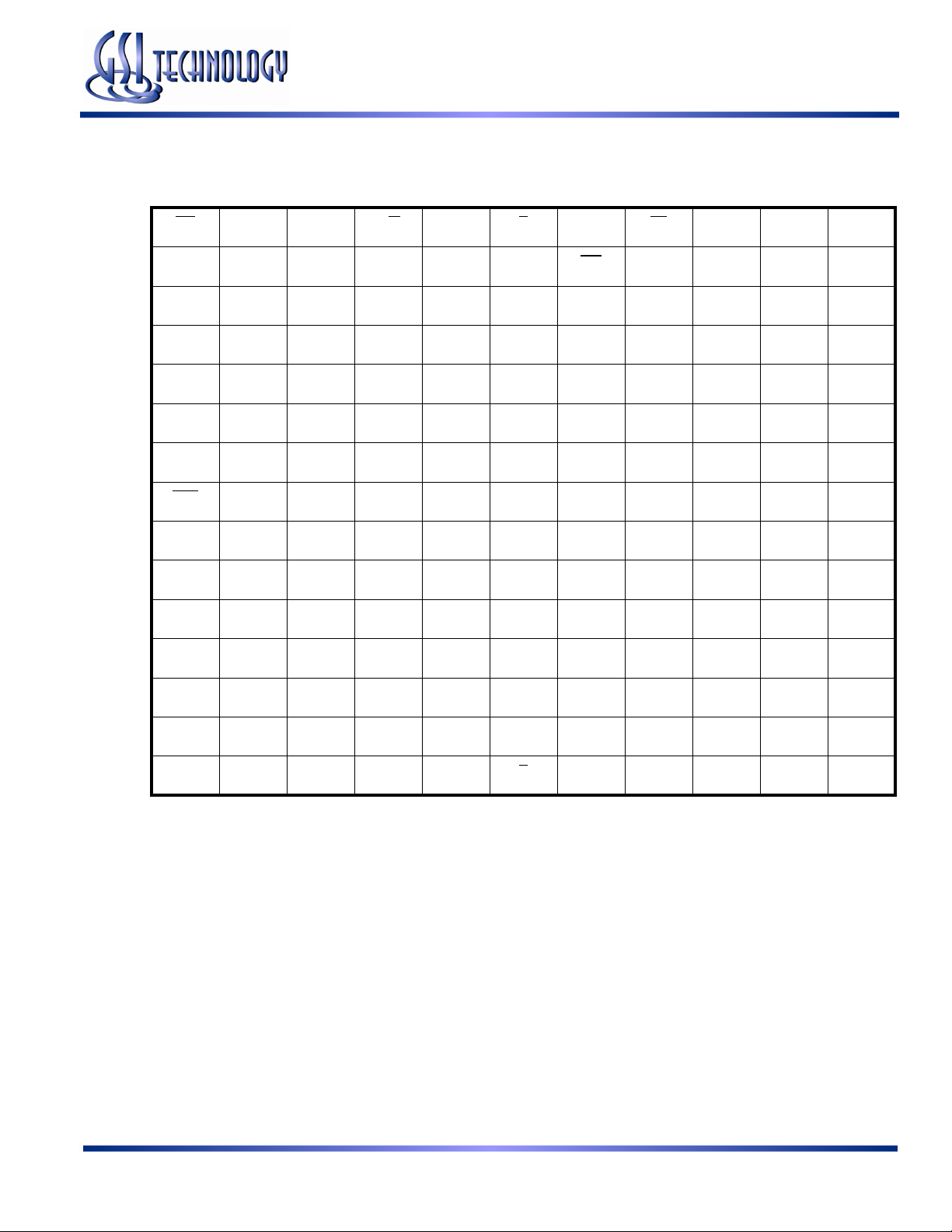

8M x 8 SigmaCIO DDR-II SRAM—Top View

1 2 3 4 5 6 7 8 9 10 11

A CQ SA SA R/W NW1 K NC LD SA SA CQ

B NC NC NC SA NC K NW0 SA NC NC DQ3

C NC NC NC V

D NC NC NC V

E NC NC DQ4 V

F NC NC NC V

G NC NC DQ5 V

H Doff V

REF

V

DDQ

V

J NC NC NC V

K NC NC NC V

L NC DQ6 NC V

M NC NC NC V

N NC NC NC V

SS

SS

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

DDQ

SS

SS

SA NC SA V

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

SA SA SA V

SS

V

SS

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

DDQ

V

SS

SS

NC NC NC

NC NC NC

NC NC DQ2

NC NC NC

NC NC NC

V

DDQ

V

REF

NC DQ1 NC

NC NC NC

NC NC DQ0

NC NC NC

NC NC NC

ZQ

P NC NC DQ7 SA SA C SA SA NC NC NC

R TDO TCK SA SA SA C SA SA SA TMS TDI

11 x 15 Bump BGA—13 x 15 mm2 Body—1 mm Bump Pitch

Notes:

1. Unlike the x36 and x18 versions of this device, the x8 and x9 versions do not give the user access to A0 and A1. SA0 and SA1 are set to

0 at the beginning of each access.

2. NW0 controls writes to DQ0:DQ3; NW1 controls writes to DQ4:DQ7

3. MCL = Must Connect Low

Rev: 1.01 9/2005 5/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS8662R08/09/18/36E-333/300/250/200/167

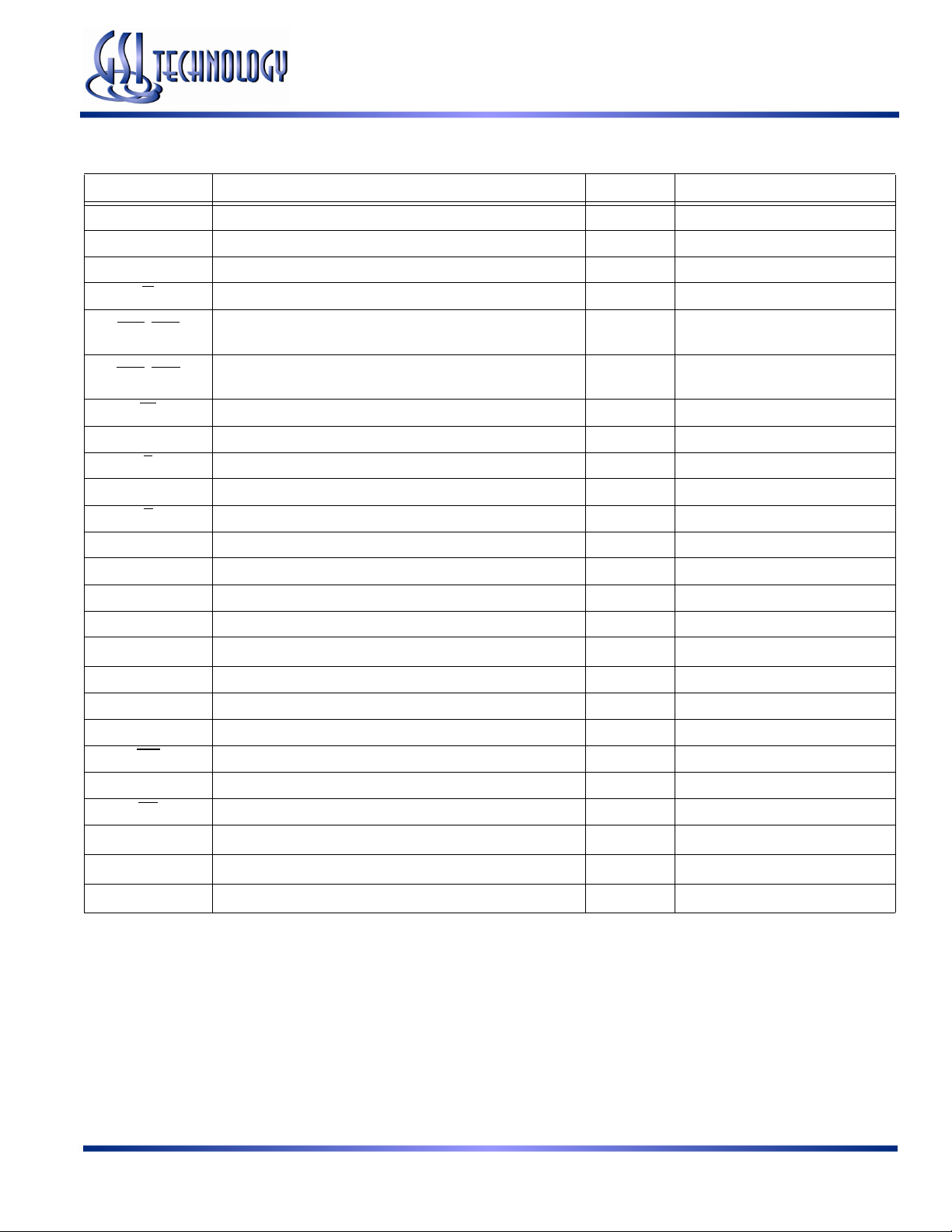

Pin Description Table

Symbol Description Type Comments

SA Synchronous Address Inputs Input —

NC No Connect — —

R Synchronous Read Input Active High

W Synchronous Write Input Active Low

BW0–BW3 Synchronous Byte Writes Input

NW0–NW1 Nybble Write Control Pin Input

LD Synchronous Load Pin Input Active Low

K Input Clock Input Active High

K Input Clock Input Active Low

C Output Clock Input Active High

C Output Clock Input Active Low

TMS Test Mode Select Input —

Preliminary

Active Low

x18/x36 only

Active Low

x8 only

TDI Test Data Input Input —

TCK Test Clock Input Input —

TDO Test Data Output Output —

V

REF

ZQ Output Impedance Matching Input Input —

MCL Must Connect Low — —

DQ Data I/O Input/Output Three State

Doff Disable DLL when low Input Active Low

CQ Output Echo Clock Output —

CQ Output Echo Clock Output —

V

DD

V

DDQ

V

SS

Note:

NC = Not Connected to die or any other pin

HSTL Input Reference Voltage Input —

Isolated Output Buffer Supply Supply 1.5 V Nominal

Power Supply Supply 1.8 V Nominal

Power Supply: Ground Supply —

Rev: 1.01 9/2005 6/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

Background

Common I/O SRAMs, from a system architecture point of view, are attractive in read dominated or block transfer applications.

Therefore, the SigmaCIO DDR-II SRAM interface and truth table are optimized for burst reads and writes. Common I/O SRAMs

are unpopular in applications where alternating reads and writes are needed because bus turnaround delays can cut high speed

Common I/O SRAM data bandwidth in half.

Burst Operations

Read and write operations are “burst” operations. In every case where a read or write command is accepted by the SRAM, it will

respond by issuing or accepting four beats of data, executing a data transfer on subsequent rising edges of K and K#, as illustrated

in the timing diagrams. It is not possible to stop a burst once it starts. Four beats of data are always transferred. This means that it is

possible to load new addresses every other K clock cycle. Addresses can be loaded less often, if intervening deselect cycles are

inserted.

Deselect Cycles

Chip Deselect commands are pipelined to the same degree as read commands. This means that if a deselect command is applied to

the SRAM on the next cycle after a read command captured by the SRAM, the device will complete the four beat read data transfer

and then execute the deselect command, returning the output drivers to high-Z.A high on the LD# pin prevents the RAM from

loading read or write command

inputs and puts the RAM into deselect mode as soon as it completes all outstanding burst transfer operations.

SigmaCIO DDR-II B4 SRAM Read Cycles

The status of the Address, LD# and R/W# pins are evaluated on the rising edge of K. Because the device executes a four beat burst

transfer in

response to a read command, if the previous command captured was a read or write command, the Address, LD# and R/W# pins

are ignored. If the previous command captured was a deselect, the control pin status is checked.The SRAM executes pipelined

reads. The read command is clocked into the SRAM by a rising edge of K. After the next rising edge of K, the SRAM produces

data out in response to the next rising edge of C# (or the next rising edge of K#, if C and C# are tied high). The second beat of data

is transferred on the next rising edge of C, then on the next rising edge of C# and finally on the next rising edge of C, for a total of

four transfers per address load.

SigmaCIO DDR-II B4 SRAM Write Cycles

The status of the Address, LD# and R/W# pins are evaluated on the rising edge of K. Because the device executes a four beat burst

transfer in response to a write command, if the previous command captured was a read or write command, the Address, LD# and R/

W# pins are ignored at the next rising edge of K. If the previous command captured was a deselect, the control pin status is

checked.The SRAM executes “late write” data transfers. Data in is due at the device inputs on the rising edge of K following the

rising edge of K clock used to clock in the write command and the write address. To complete the remaining three beats of the burst

of four write transfer the SRAM captures data in on the next rising edge of K#, the following rising edge of K and finally on the

next rising edge of K#, for a total of four transfers per address load.

Rev: 1.01 9/2005 7/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS8662R08/09/18/36E-333/300/250/200/167

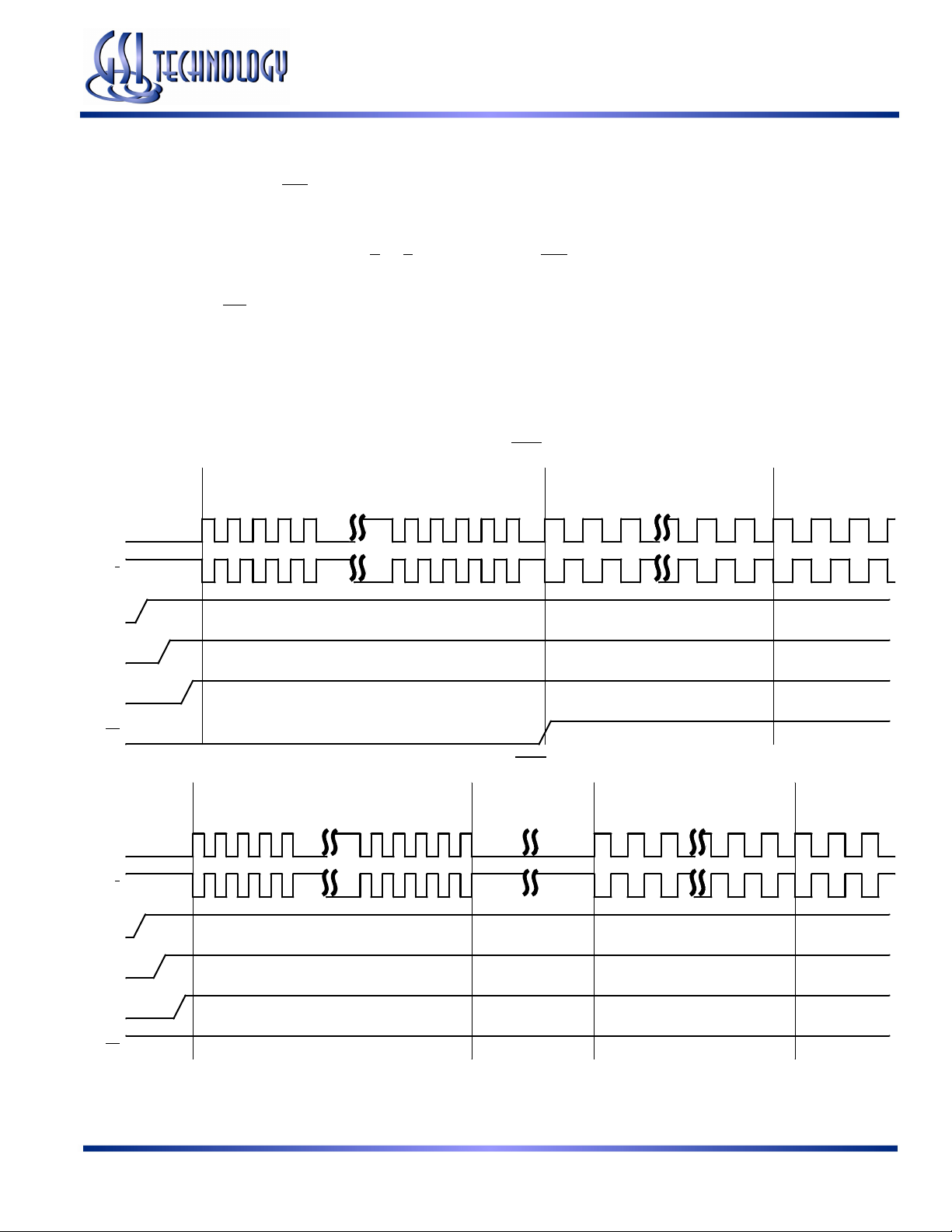

Power-Up Sequence for SigmaQuad-II SRAMs

SigmaQuad-II SRAMs must be powered-up in a specific sequence in order to avoid undefined operations.

Power-Up Sequence

1. Power-up and maintain Doff at low state.

1a. Apply VDD.

1b. Apply V

1c. Apply V

2. After power is achieved and clocks (K, K, C, C) are stablized, change Doff to high.

3. An additional 1024 clock cycles are required to lock the DLL after it has been enabled.

Note:

If you want to tie Doff high with an unstable clock, you must stop the clock for a minimum of 30 seconds to reset the DLL after the clocks become

stablized.

DLL Constraints

• The DLL synchronizes to either K or C clock. These clocks should have low phase jitter (t

• The DLL cannot operate at a frequency lower than 119 MHz.

• If the incoming clock is not stablized when DLL is enabled, the DLL may lock on the wrong frequency and cause undefined errors or failures during

the initial stage.

Power UP Interval Unstable Clocking Interval DLL Locking Interval (1024 Cycles) Normal Operation

.

DDQ

(may also be applied at the same time as V

REF

Power-Up Sequence (Doff controlled)

DDQ

).

on page 20).

KCVar

Preliminary

K

K

V

DD

V

DDQ

V

REF

Doff

Power-Up Sequence (Doff tied High)

Power UP Interval Unstable Clocking Interval Stop Clock Interval DLL Locking Interval (1024 Cycles) Normal Operation

K

K

V

DD

V

DDQ

30ns Min

V

REF

Doff

Note:

If the frequency is changed, DLL reset is required. After reset, a minimum of 1024 cycles is required for DLL lock.

Rev: 1.01 9/2005 8/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

Special Functions

Byte Write and Nybble Write Control

Byte Write Enable pins are sampled at the same time that Data In is sampled. A high on the Byte Write Enable pin associated with

a particular byte (e.g.,

stored at the current address at that byte location undisturbed. Any or all of the Byte Write Enable pins may be driven high or low

during the data in sample times in a write sequence.

Each write enable command and write address loaded into the RAM provides the base address for a 4 beat data transfer. The x18

version of the RAM, for example, may write 72 bits in association with each address loaded. Any 9-bit byte may be masked in any

write sequence.

Nybble Write (4-bit) write control is implemented on the 8-bit-wide version of the device. For the x8 version of the device,

“Nybble Write Enable” and “

Example x18 RAM Write Sequence using Byte Write Enables

BW0 controls D0–D8 inputs) will inhibit the storage of that particular byte, leaving whatever data may be

NBx” may be substituted in all the discussion above.

Data In Sample

Time

Beat 1 0 1 Data In Don’t Care

Beat 2 1 0 Don’t Care Data In

Beat 3 0 0 Data In Data In

Beat 4 1 0 Don’t Care Data In

BW0 BW1 D0–D8 D9–D17

Resulting Write Operation

Byte 1

D0–D8

Written Unchanged Unchanged Written Written Written Unchanged Written

Output Register Control

SigmaCIO DDR-II SRAMs offer two mechanisms for controlling the output data registers. Typically, control is handled by the

Output Register Clock inputs, C and

of the output registers by allowing the user to delay driving data out as much as a few nanoseconds beyond the next rising edges of

the K and

RAM to function as a conventional pipelined read SRAM.

K clocks. If the C and C clock inputs isare tied high, the RAM reverts to K and K control of the outputs, allowing the

Byte 2

D9–D17

Beat 1 Beat 2 Beat 3 Beat 4

Byte 1

D0–D8

C. The Output Register Clock inputs can be used to make small phase adjustments in the firing

Byte 2

D9–D17

Byte 1

D0–D8

Byte 2

D9–D17

Byte 1

D0–D8

Byte 2

D9–D17

Rev: 1.01 9/2005 9/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

LD

LD

LD

LD

R/W

A0–A

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

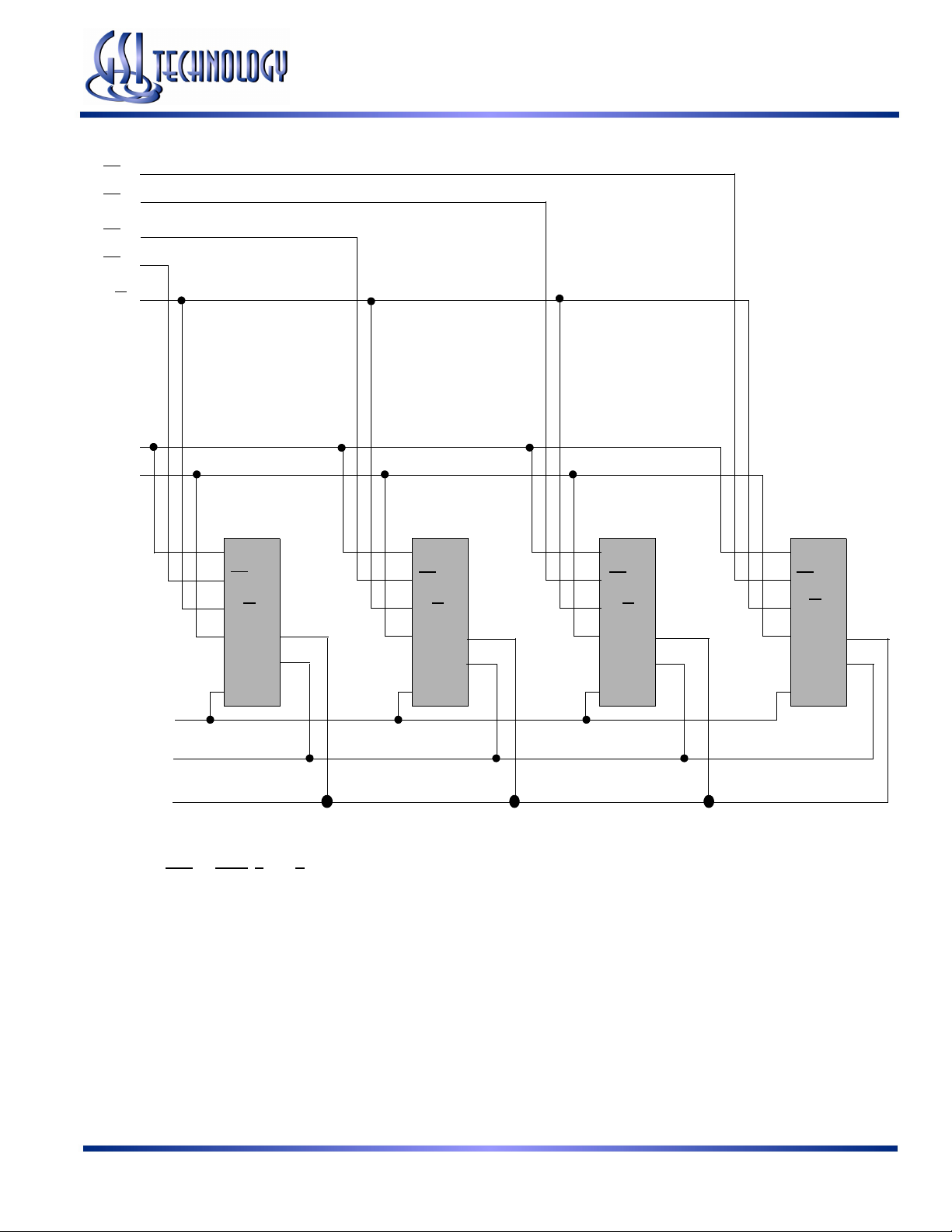

Example Four Bank Depth Expansion Schematic

3

2

1

0

n

K

C

DQ1–

CQ

Note:

For simplicity BWn

Bank 0

A

LD

R/W

CQ CQ CQ CQ

K

Bank 1 Bank 2

A

LD

A

LD

R/W R/W

K

K

Bank 3

A

LD

R/W

K

DQ DQ DQ DQ

CC CC

(or NWn), K, and C are not shown.

Rev: 1.01 9/2005 10/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

FLXDrive-II Output Driver Impedance Control

HSTL I/O SigmaCIO DDR-II SRAMs are supplied with programmable impedance output drivers. The ZQ pin must be connected

to V

via an external resistor, RQ, to allow the SRAM to monitor and adjust its output driver impedance. The value of RQ must be

SS

5X the value of the desired RAM output impedance. The allowable range of RQ to guarantee impedance matching continuously is

between 150Ω and 300Ω. Periodic readjustment of the output driver impedance is necessary as the impedance is affected by drifts

in supply voltage and temperature. The SRAM’s output impedance circuitry compensates for drifts in supply voltage and

temperature. A clock cycle counter periodically triggers an impedance evaluation, resets and counts again. Each impedance

evaluation may move the output driver impedance level one step at a time towards the optimum level. The output driver is

implemented with discrete binary weighted impedance steps. Updates of pull-down drive impedance occur whenever a driver is

producing a “1” or is High-Z. Pull-up drive impedance is updated when a driver is producing a “0” or is High-Z.

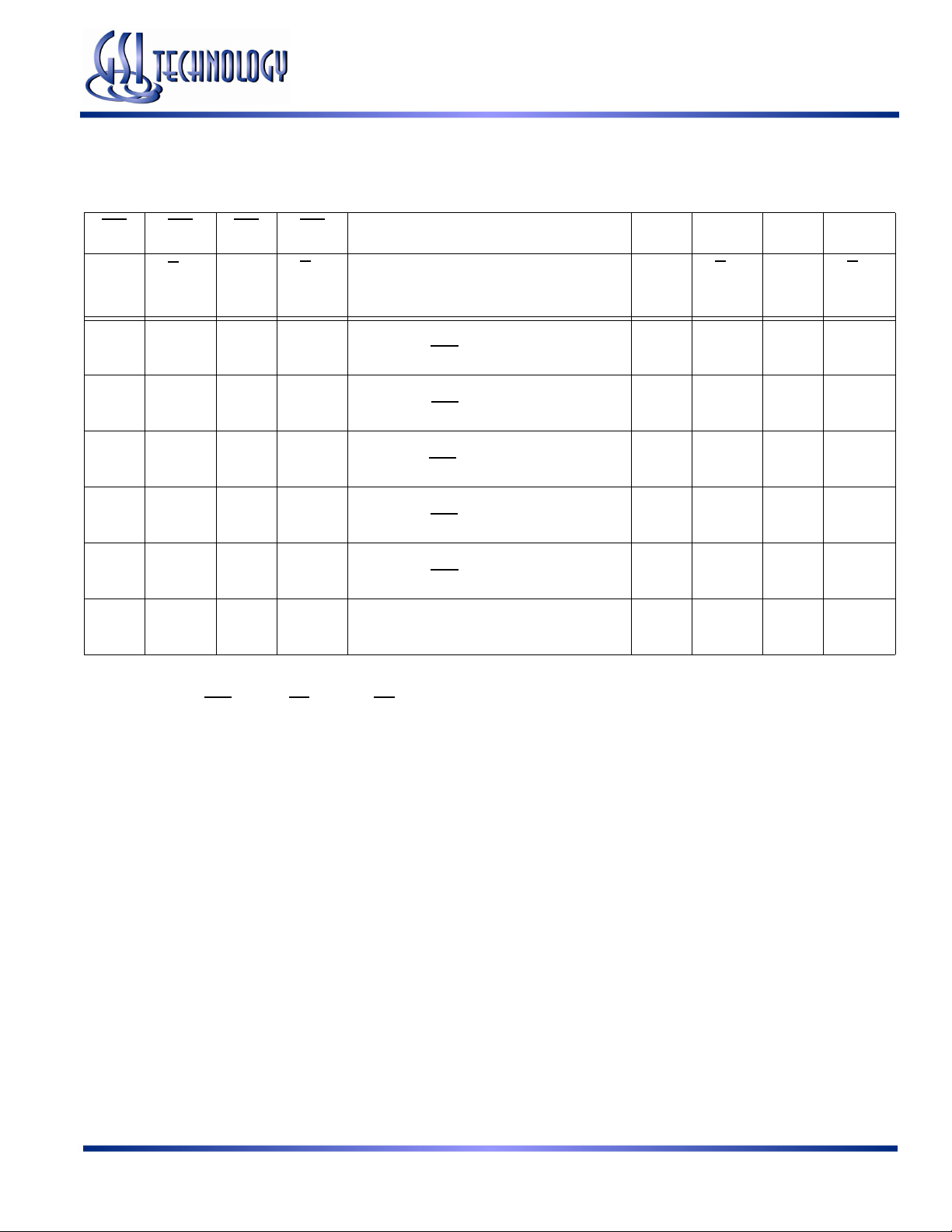

Common I/O SigmaCIO DDR-II B4 SRAM Truth Table

DQ

K

n

↑ 1 X Hi-Z Hi-Z Hi-Z Hi-Z Deselect

LD R/W

Operation

A + 0 A + 1 A + 2 A + 3

↑ 0 0 D@K

↑ 0 1

Note:

Q is controlled by K clocks if C clocks are not used.

Q@K

or

C

n+1

n+1

n+1

D@K

Q@K

or

C

n+2

n+1

n+2

D@K

Q@K

or

C

n+2

n+2

n+2

D@K

Q@K

or

C

n+3

n+2

n+3

Write

Read

Rev: 1.01 9/2005 11/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS8662R08/09/18/36E-333/300/250/200/167

B4 Byte Write Clock Truth Table

BW BW BW BW Current Operation D D D D

K ↑

(t

n+1

T T T T

T F F F

F T F F

F F T F

F F F T

F F F F

Notes:

1. “1” = input “high”; “0” = input “low”; “X” = input “don’t care”; “T” = input “true”; “F” = input “false”.

2. If one or more BWn = 0, then BW = “T”, else BW = “F”.

K ↑

(t

)

n+1½

K ↑

)

(t

n+2

K ↑

)

(t

)

n+2½

Dx stored if BWn = 0 in all four data transfers

Dx stored if BWn = 0 in 1st data transfer only

Dx stored if BWn = 0 in 2nd data transfer only

Dx stored if BWn = 0 in 3rd data transfer only

Dx stored if BWn = 0 in 4th data transfer only

No Dx stored in any of the four data transfers

K ↑

(tn)

Write

Write

Write

Write

Write

Write Abort

K ↑

(t

n+1

D0 D2 D3 D4

D0 X X X

X D1 X X

X X D2 X

X X X D3

X X X X

K ↑

)

(t

n+1½

K ↑

)

(t

)

n+2

(t

K ↑

n+2½

)

*Assuming stable conditions, the RAM can achieve optimum impedance within 1024 cycles.

Rev: 1.01 9/2005 12/37 © 2005, GSI Technology

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Loading...

Loading...