GSI Outdoors PNEG-630 User Manual

GSI

Competitor

Portable Dryer

Models

Troubleshooting and

Reference Manual

& EMCS

2004 Revised Edition

PNEG-630

Competitor Series 2000 Dryer

Portable Dryer Troubleshooting

Safety..................................................................................................................................................................... 3

Safety Sign Off Sheet ............................................................................................................................................ 8

EMCS Portable Dryer (1993-1998)

Safety Voltage Check Points .................................................................................................................................9

Programming Instructions for EMCS Grain Dryers .............................................................................................. 10

EMCS Display Board ............................................................................................................................................ 11

Input/Output Board Identification .......................................................................................................................... 12

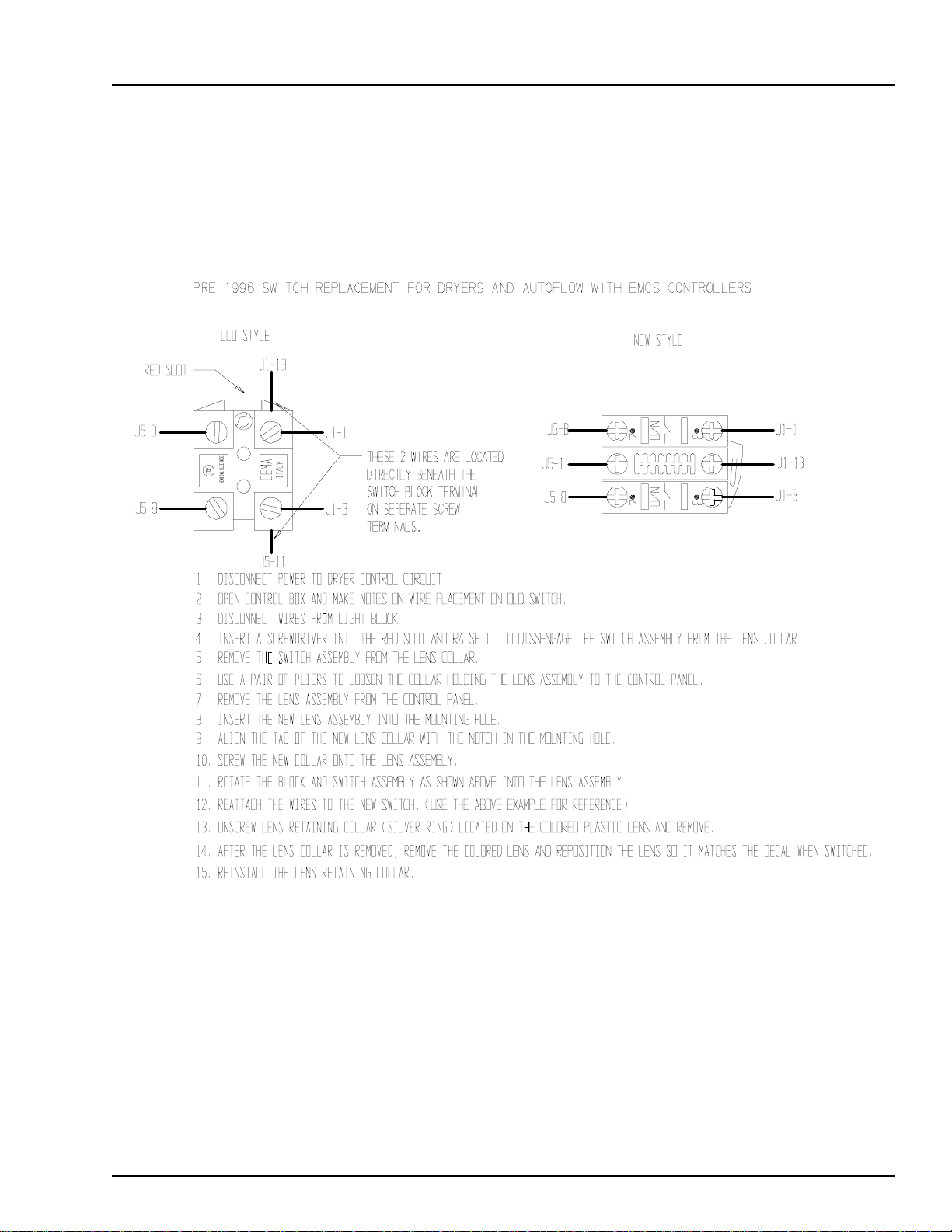

EMCS Switch Replacement.........................................................................................................................13

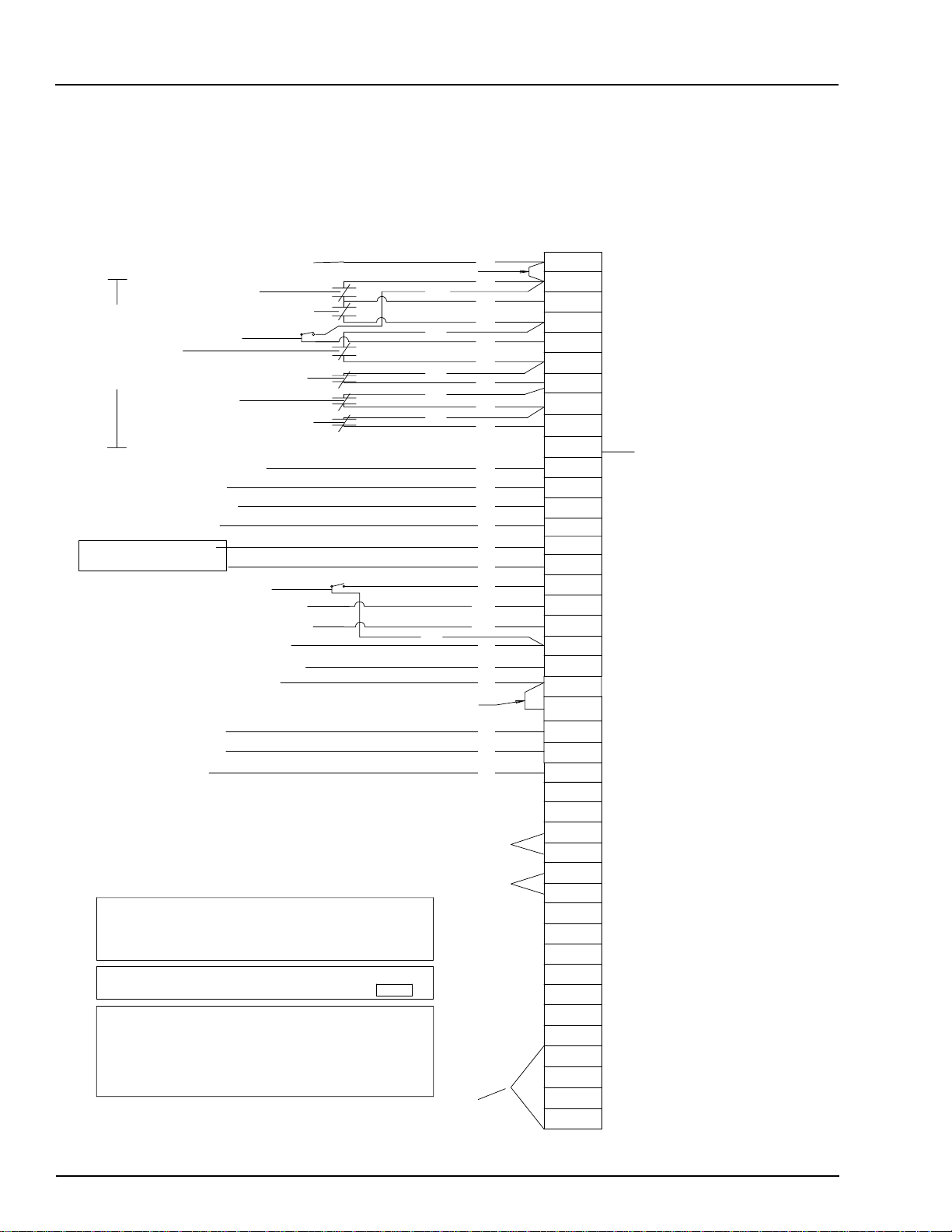

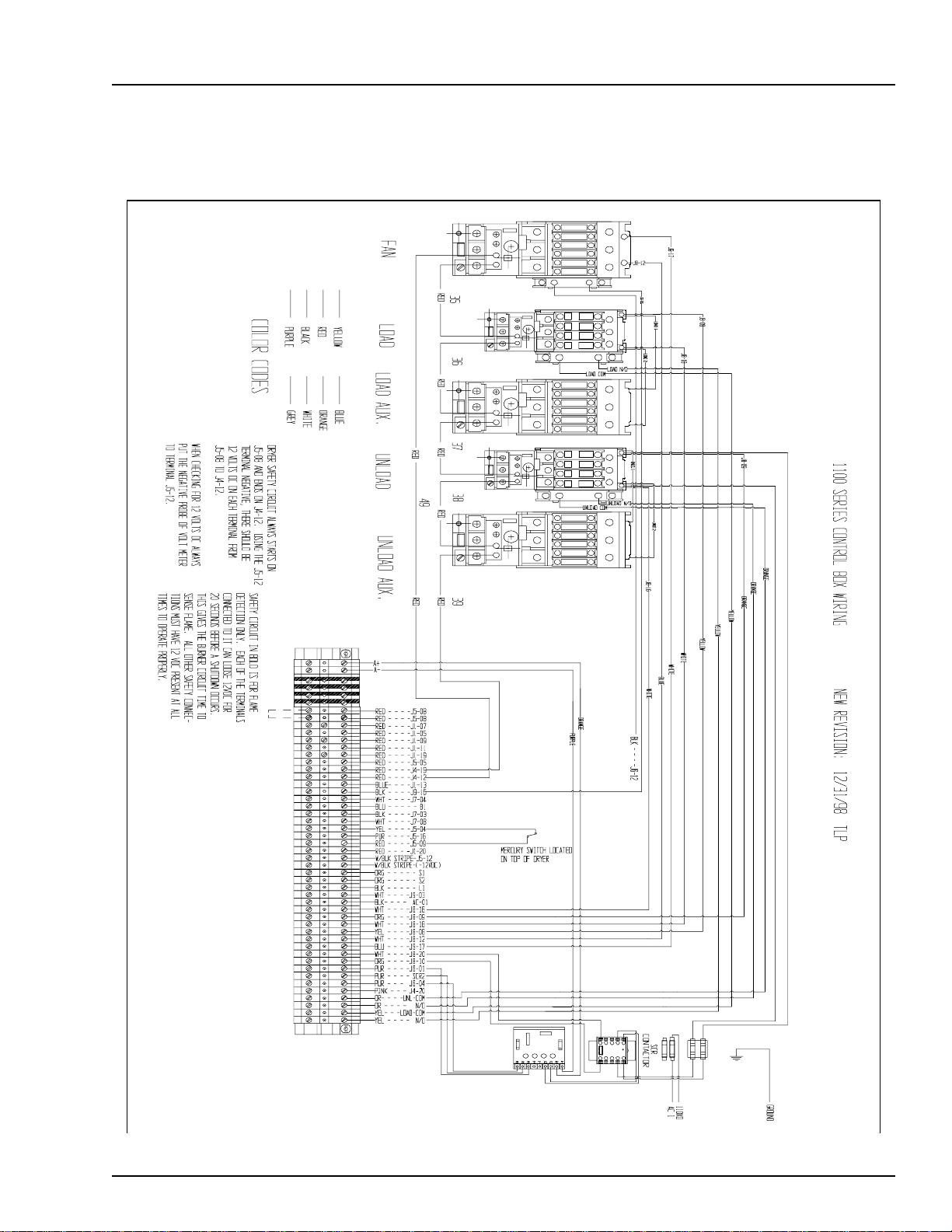

1100 Series Control Box W iring ............................................................................................................................. 14

1100 Series Control Box W iring (New) ................................................................................................................. 15

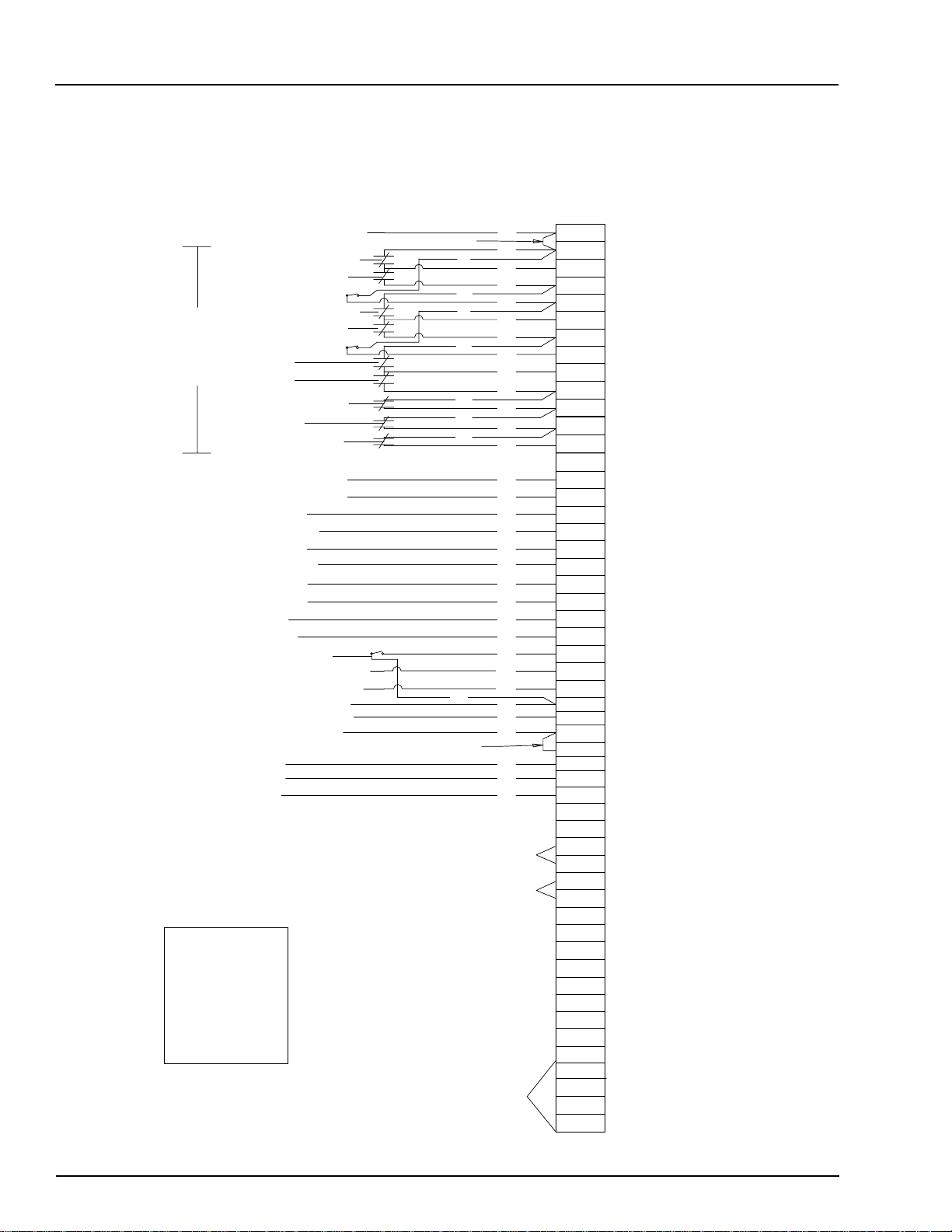

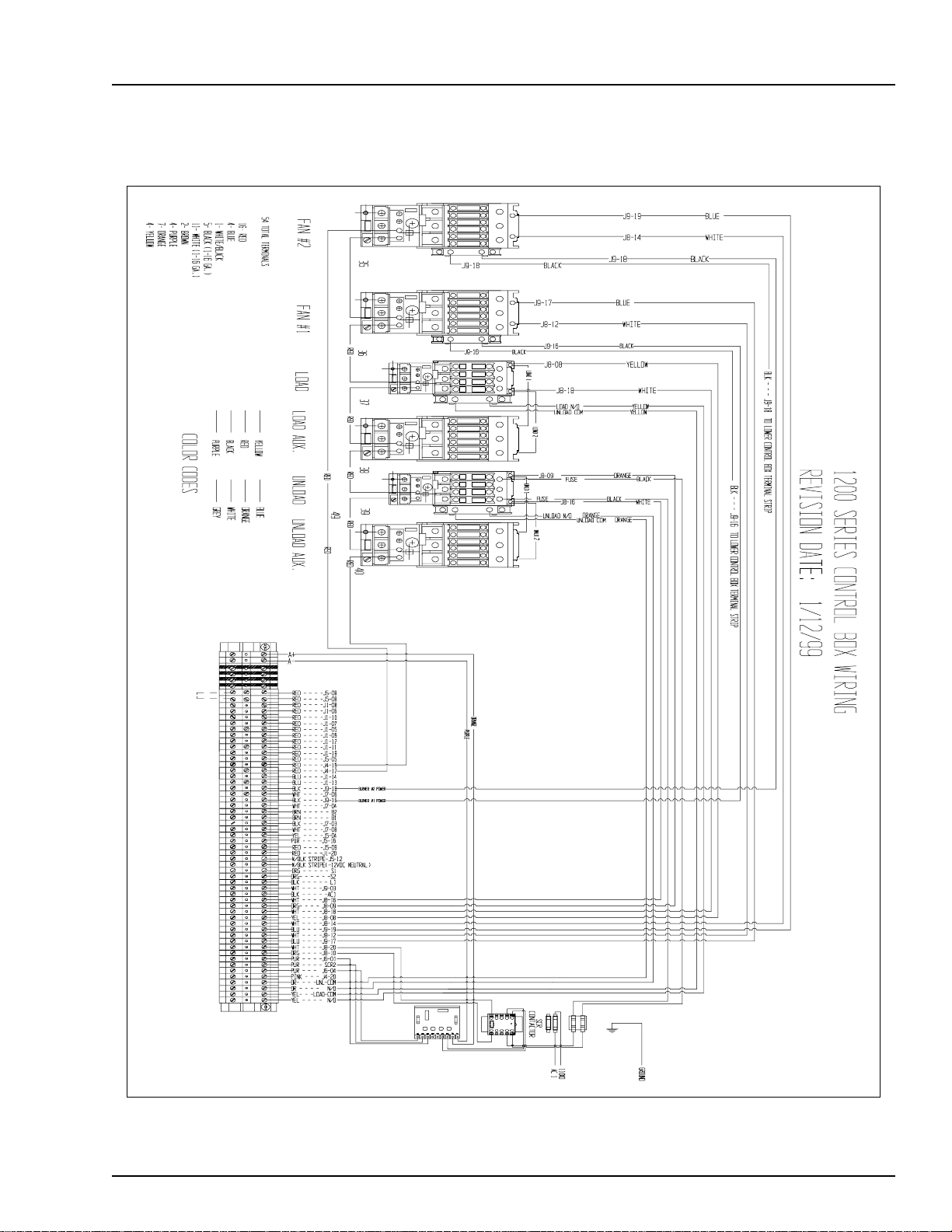

1200 Series Control Box Wiring............................................................................................................................. 16

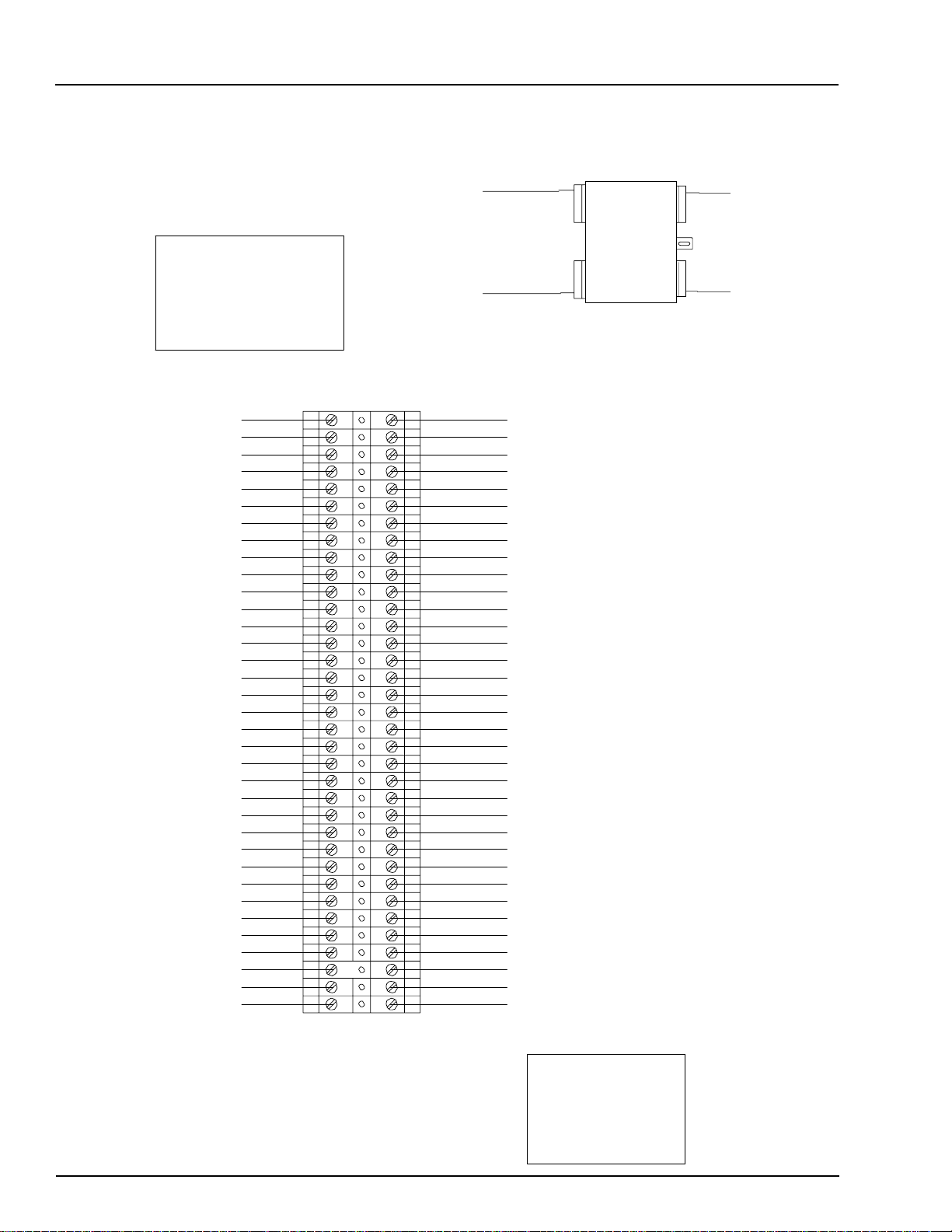

1200 Series Control Box Wiring (New)................................................................................................................. 17

1100 Fan Lower Control Box Interconnect Strip................................................................................................... 18

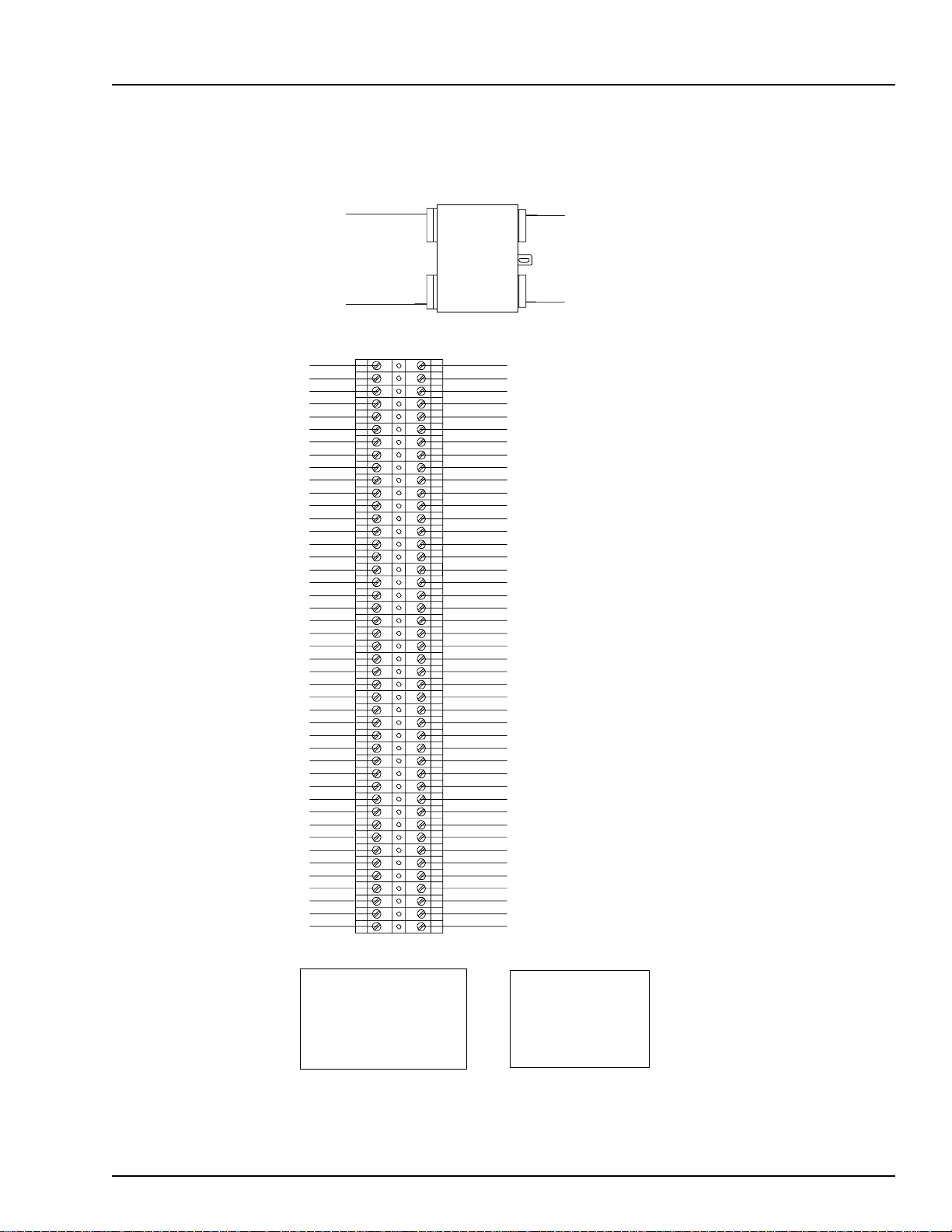

1200 Fan Lower Control Box Interconnect Strip .................................................................................................. 19

Upper Control Box External Wiring....................................................................................................................... 20

Fan Housing and V apor Hi-Limit Circuit ............................................................................................................... 21

Plenum Hi-Temperature Switch ............................................................................................................................22

Fixed Grain Hi-Limit .............................................................................................................................................. 23

Grain & Plenum Hi-Limit Circuit........................................................................................................................... 24

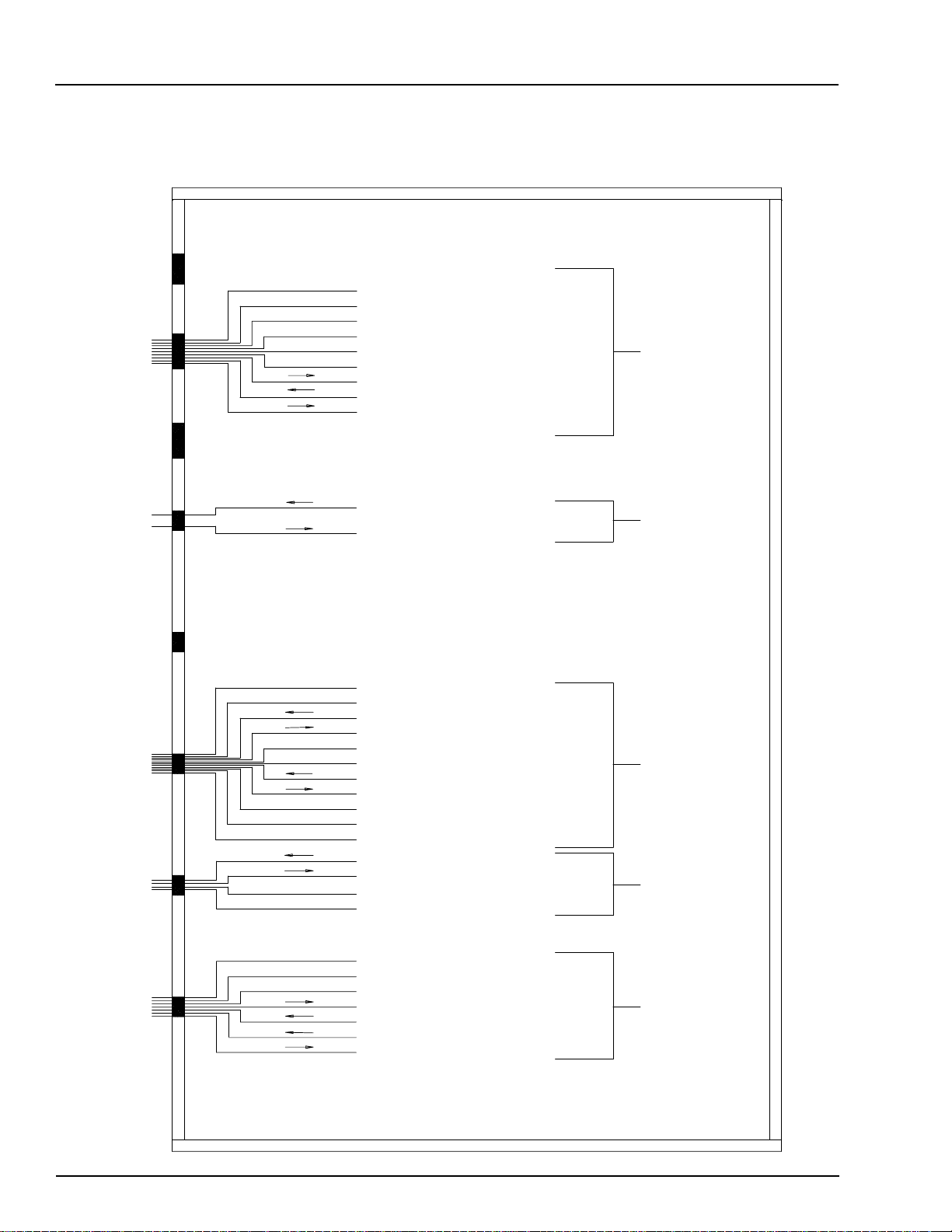

T wo Fan Plenum and Grain Limit Switch Wiring ..................................................................................................25

Rear Discharge & Emergency Cooling Circuit ..................................................................................................... 26

Rear Discharge Mercury Switch...........................................................................................................................27

Adjustable Hi-Limit & Emergency Cooling Circuit ............................................................................................... 28

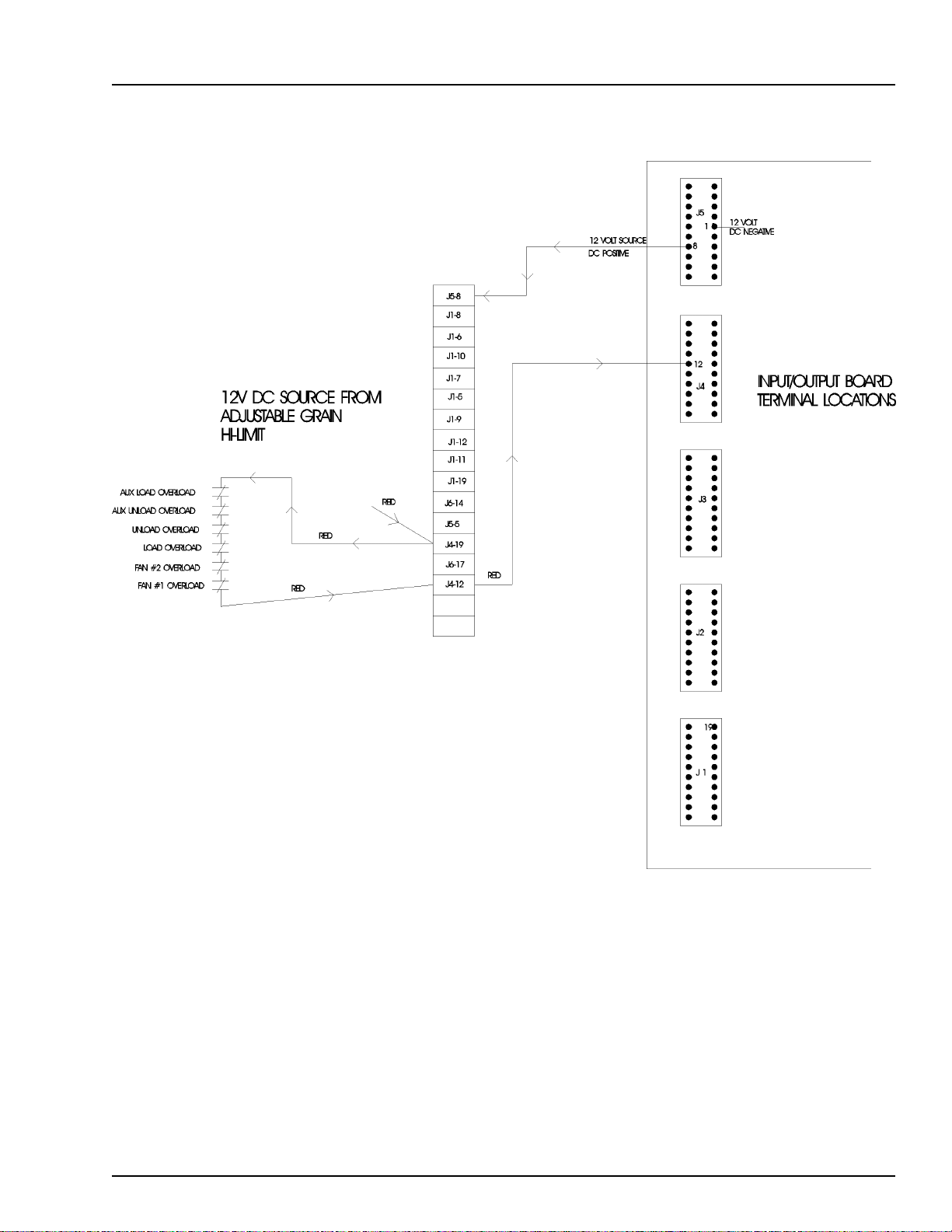

Motor Overloads .................................................................................................................................................... 29

Air Pressure Switch............................................................................................................................................... 30

Air Pressure Switch Drawing................................................................................................................................ 31

Out of Grain Safety Circuit....................................................................................................................................32

Out of Grain Safety Circuit Drawing..................................................................................................................... 33

Upper Junction Box Wiring.................................................................................................................................... 34

Meter Roll Sensor .................................................................................................................................................. 35

Meter Roll Sensor Wiring ......................................................................................................................................36

Meter Roll Reversing............................................................................................................................................. 37

Lower Junction Box Wiring ................................................................................................................................... 38

New Fenwal Board Wiring.......................................................................................................................... 39

New Fenwal Board Troubleshooting.............................................................................................................40

Flame Control Circuit............................................................................................................................................. 41

Fan Burner Circuit for Canadian Models .............................................................................................................. 42

Conversion Diagram for C Series Dryers to a Switchable Hi/Low or On/Off Burner ......................................... 43

Fan 28 LP Hi/Low-On/Off....................................................................................................................................44

Fan 28 LP On/Off Burner with Mercoid...............................................................................................................45

Fan 28 NG Hi/Low-On/Off ................................................................................................................................... 46

Fan 28 NG On/Off Burner with Mercoid .............................................................................................................. 47

Fan 42 LP Hi/Low-On/Off....................................................................................................................................48

Fan 42 LP On/Off Burner with Mercoid...............................................................................................................49

Fan 42 NG Hi/Low-On/Off ................................................................................................................................... 50

Fan 42 NG On/Off Burner with Mercoid .............................................................................................................. 51

SCR Drive Circuit.................................................................................................................................................. 52

RTD Temperature Sensor...................................................................................................................................... 53

Test Procedure for EMCS Dryers ......................................................................................................................... 54

Temperature Charts ............................................................................................................................................... 55

EMCS Troubleshooting Tips........................................................................................................................ 56

Table Of Contents

1

Table Of Contents

Competitor Series 2000 Dryer (Picture of Dryer)(1995 to Present)......................................................65

220 Volt Single (1) Phase Power Drawing ............................................................................................................ 66

220 Volt Single (1) Phase Power Drawing (New Version) .................................................................................. 67

220 Volt Three (3) Phase Power Drawing ............................................................................................................ 68

220 Volt Three (3) Phase Power Drawing (New Version) ................................................................................... 69

220 Volt 1 Phase Power Circuit (Ladder Diagram)........................................................................................70

220 Volt 3 Phase Power Circuit (Ladder Diagram)........................................................................................71

440 Volt 3 Phase Power Circuit (Ladder Diagram)........................................................................................72

Upper Control Box Internal Wiring........................................................................................................................ 73

Series 2000 Control Box Wiring (New Version) .................................................................................................... 74

Series 2000 Control Box Wiring............................................................................................................................. 75

Series 2000 Control Box Wiring (380-460-575 3 Phase).................................................................................76

Upper Terminal Strip...................................................................................................................................77

Upper Terminal Strip (Moisture Control Hook-Up)........................................................................................78

Upper Terminal Strip (Moisture Control Relay Hook-Up)...............................................................................79

Moisture Manager to Dryer Wiring...............................................................................................................80

Input/Output Board & T erminal Strip .................................................................................................................... 81

Control Circuit (CPU/Display)(Ladder Diagram)......................................................................................... 82

Control Circuit (I/O Board)(Ladder Diagram)...............................................................................................83

Control Circuit (SCR Drive Board)(Ladder Diagram)....................................................................................84

SCR Board (Installing & Calibrating)............................................................................................................85

Upper Control Box External Wiring....................................................................................................................... 88

Input/Output Board 12 Volt .................................................................................................................................... 89

CPU Board Wiring.................................................................................................................................................90

Programming Instructions for Competitor Series Grain Dryers ............................................................................91

Programming Hook Up Diagram...........................................................................................................................92

Back of Switch Panel Layout ................................................................................................................................ 95

Back of Switch Panel Wiring................................................................................................................................. 96

Air Switch Assembly ............................................................................................................................................. 97

Air Switch Adjusting...................................................................................................................................98

Fixed Grain Hi-Limit & T emperature Sensor ........................................................................................................ 99

Out of Grain Sensor...................................................................................................................................100

Grain Temperature Sensor..........................................................................................................................101

Grain Sensor Testing..................................................................................................................................102

Grain Sensor (Locating,Testing,& Replacing)...............................................................................................103

Sensor Resistance/Temperature Chart.........................................................................................................105

Plenum Sensor (Locating,Testing & Replacing)............................................................................................106

Stern and Capacitor Diagram......................................................................................................................108

Operation Hints..........................................................................................................................................109

Series 2000 Error Conditions.......................................................................................................................111

Heater Circuit............................................................................................................................................113

Fan Burner Circuit for Canadian Models Only..............................................................................................114

Series 2000 LP 26"/28" Fan ........................................................................................................................115

Series 2000 Natural Gas 26"/28" Fan............................................................................................................116

Series 2000 LP 36"/42" Fan.........................................................................................................................117

Series 2000 Natural Gas 36"/42" Fan............................................................................................................118

Warranty....................................................................................................................................................119

Portable Dryer Troubleshooting

2

Portable Dryer Troubleshooting

Dryer Safety

Instructions and

Information

Thank you for choosing an GSI

Grain Dryer. It is designed to provide excellent performance and service for many years.

This manual refers to the troubleshooting of the E.M.C.S.and Series

2000 Competitor models. Different

models are available for liquid propane or natural gas fuel supply, with

either single phase 230 volt, or three

phase 230, 460, 575 volt electrical

power. (Also 380 volt 50Hz).

The GSI Group Inc. recommends

contacting your local power company, and having a representative

survey your installation so the wiring is compatible with your system

and adequate power is supplied.

The principal concern of the GSI

Group, Inc. ("GSI") is your safety

and the safety of others associated

with grain handling equipment. This

manual is written to help you understand safe operating procedures, and some of the problems

that may be encountered by the operator or other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist,

and to inform all personnel associated with the equipment, or who are in the dryer area. Avoid any alterations to

the equipment. Such alterations may produce a very dangerous situation, where serious injury or death may

occur.

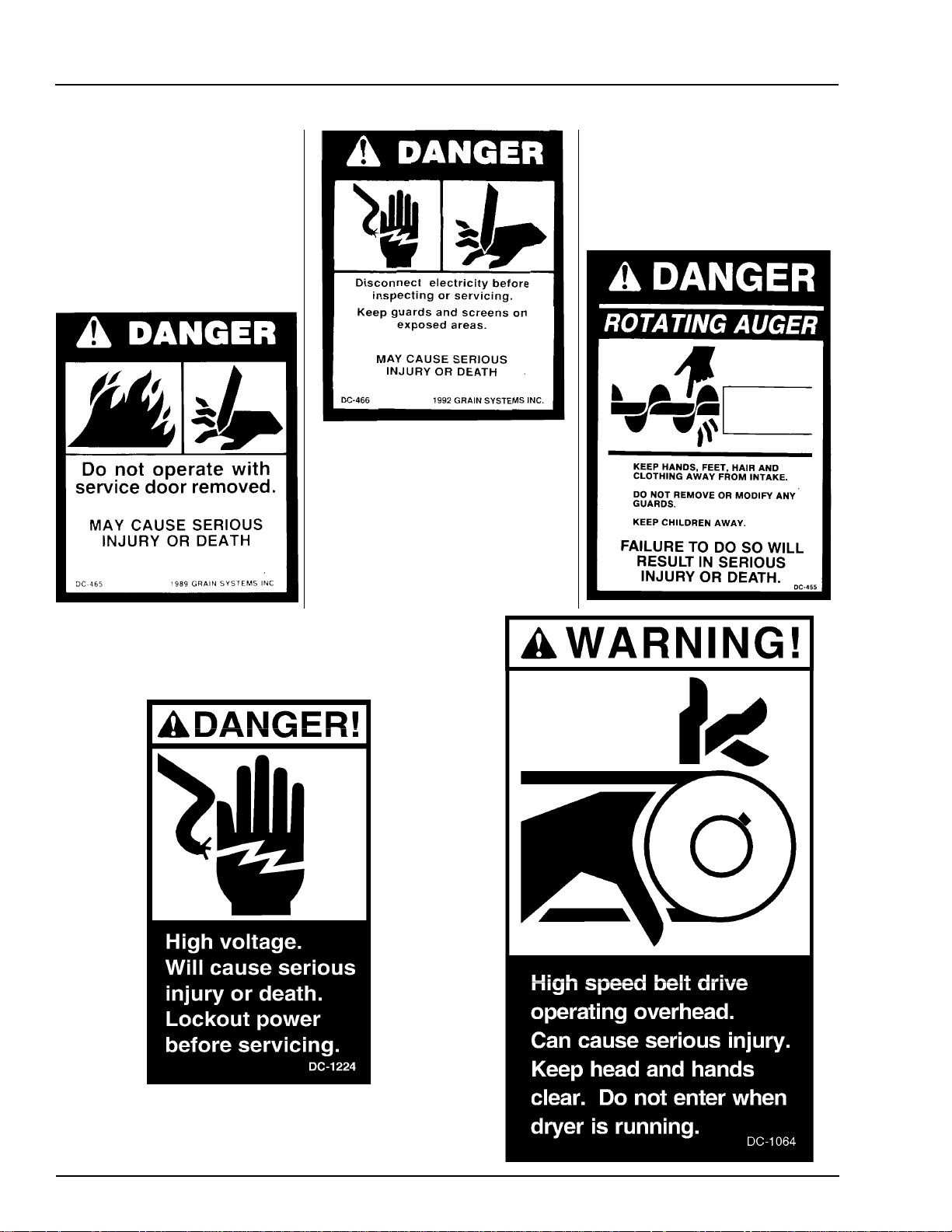

Safety

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a

misuse of the equipment.

Safety Alert Symbol

The symbol shown is used to call your

attention to instructions concerning your

personal safety . Watch for this symbol;

it points out important safety precautions. It means "ATTENTION",

"WARNING", "CAUTION", and "DANGER". Read the message and be cau-

tious to the possibility of personal injury or death.

3

Safety

Portable Dryer Troubleshooting

Grain Systems, Inc. recommends

you contact your local power company and have a representative survey your dryer installation, so your

wiring will be compatible with their

system and you will have adequate

power supplied to your unit.

A CAREFUL OPERATOR

IS THE BEST INSURANCE

AGAINST AN ACCIDENT

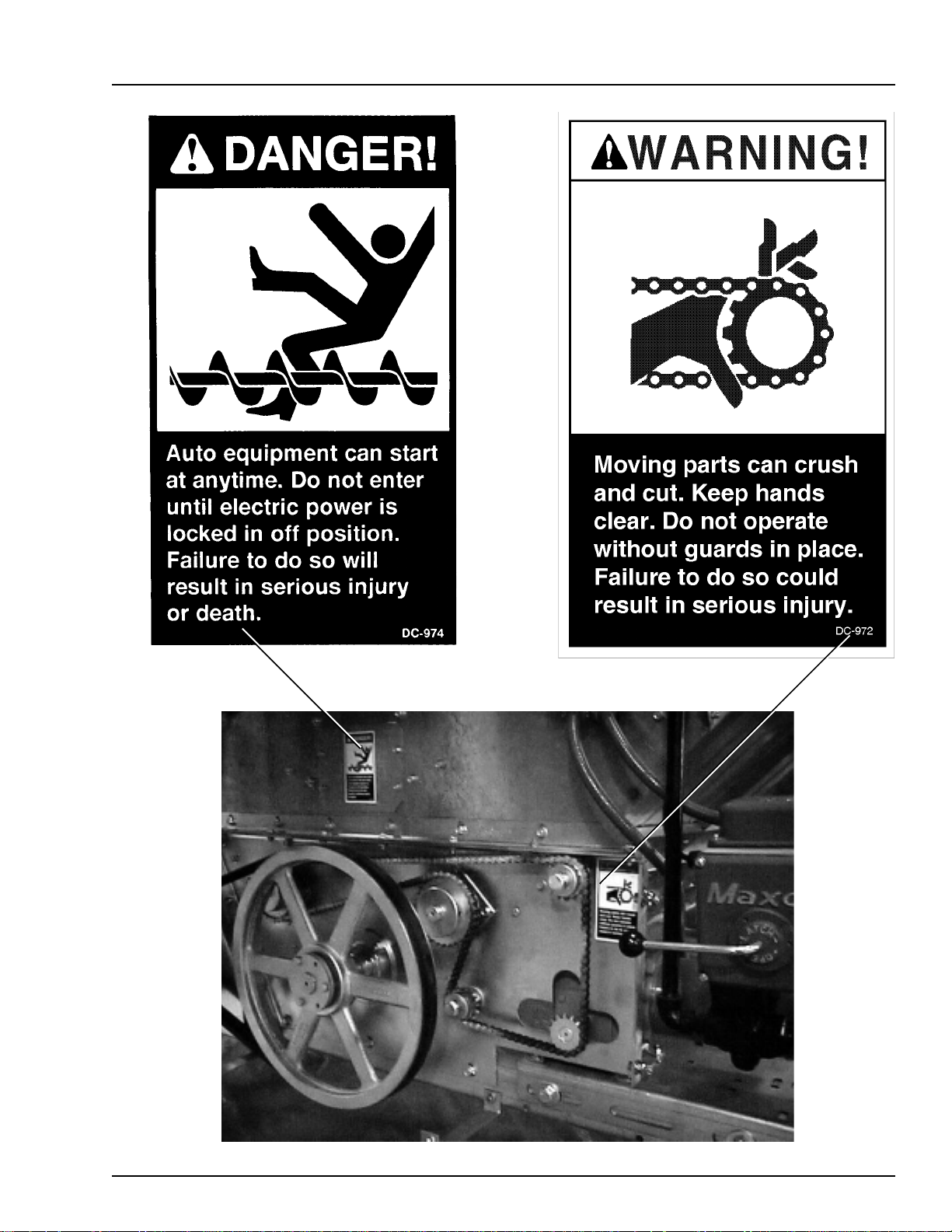

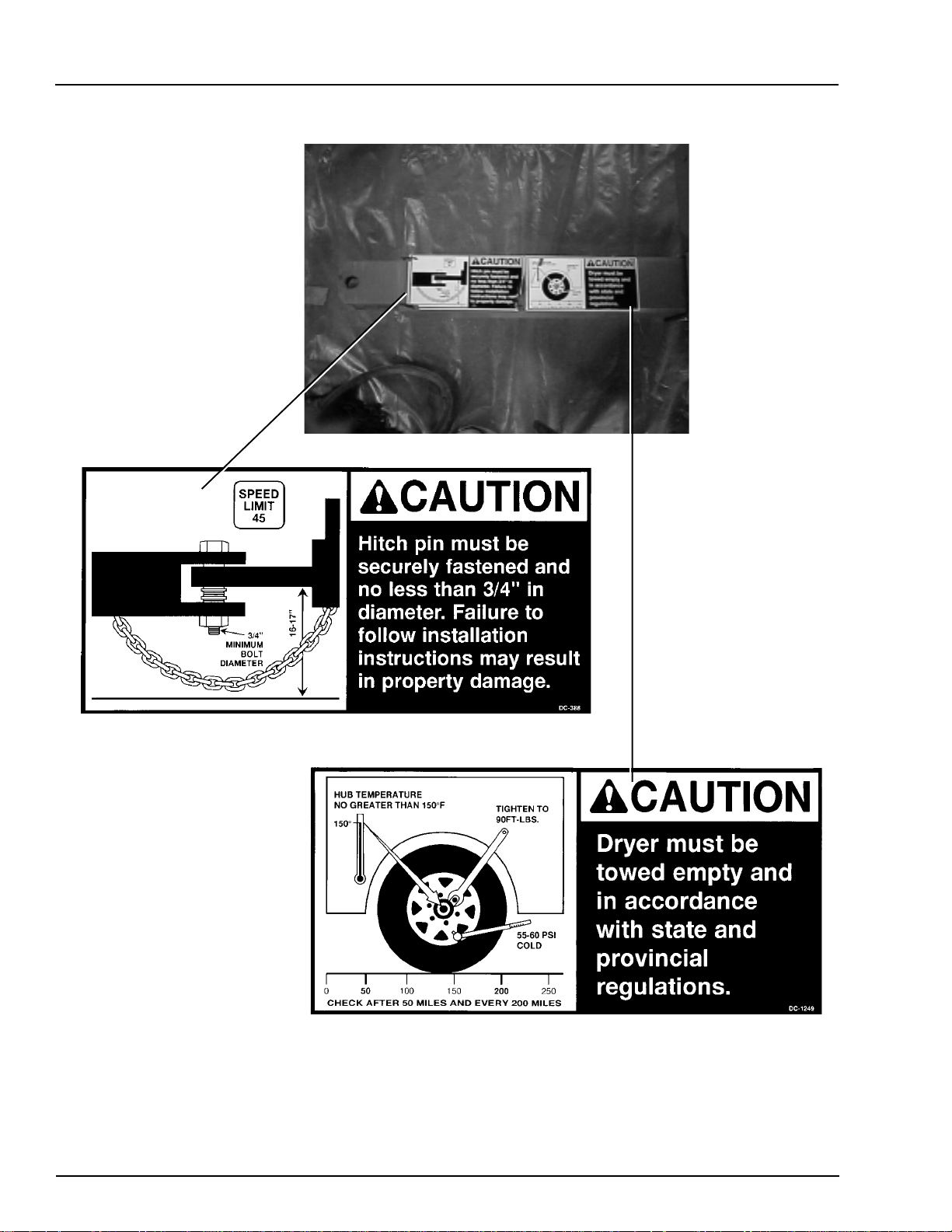

Safety decals should be read and

understood by all people in and

around the dryer area. If the following safety decals are not displayed

on your dryer, or if they are damaged, contact Grain Systems, Inc. for

replacement.

4

Portable Dryer Troubleshooting

Safety

5

Safety

Portable Dryer Troubleshooting

6

Portable Dryer Troubleshooting

READ THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maximum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

Safety Precautions

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature of

a grain dryer having a gas burner,

high voltage electrical equipment

and high speed rotating parts, does

present a hazard to personnel, which

can not be completely safeguarded

against, without interfering with efficient operation and reasonable access to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary conveyors, which may start without

warning when the dryer is operating on automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propeller, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

This product is intended for the use of grain handling only. Any other

use is considered a misuse of the product.

Some edges of the product components can be sharp. It is recommended

that each component of this product be examined to determine if there

are any safety considerations to be taken. Any and all necessary personal

protective equipment should be worn at all tines when handling, assembling, installing and operation of the product and/or components.

Guards are removed for illustration purpose only. All guards must be

in place before/during operation.

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE

OUTSIDE OF THE DRYER

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommendations within this manual, and

make it a practice to regularly inspect the operation of the unit for

any developing problems or unsafe

conditions.

Take special note of the safety precautions listed at left before attempting to operate the dryer.

7

Safety Sign-Off Sheet

Portable Dryer Troubleshooting

Date Employer’s Signature Employee

________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

8

Portable Dryer Troubleshooting

Safety Voltage Check Points

Wiring Reference

123456

FAN #

Error Message - + - + - + - + - + - + RESULT

Plenum # High Temperature J5-12 J1-11 J5-12 J1-12 J5-12 J2-11 J5-12 J2-12 J5-12 J3-11 J5-12 J3-12 12VDC

Burner # Flame not Detected J5-12 J1-9 J5-12 J1-10 J5-12 J2-9 J5-12 J2-10 J5-12 J3-9 J5-12 J3-10 12VDC

Fan # Housing High Tempera ture J5-12 J1-7 J5-12 J1-8 J5-12 J2-7 J5-12 J2-8 J5-12 J3-7 J5-12 J3-8 12VDC

Burner # Vapor High Temperature J5-12 J1-5 J5-12 J1-6 J5-12 J2-5 J5-12 J2-6 J5-12 J3-5 J5-12 J3-6 12VDC

Burner # Shutdown Loss of Airflow J5-12 J1-13 J5-12 J1-14 J5-12 J2-13 J 5-12 J2-14 J5-12 J3-13 J5-12 J3-14 Note 1

Fan # Failure No Airflow J5-12 J1-13 J5-12 J1-14 J5-12 J2-13 J 5-12 J2-14 J5-12 J3-13 J5-12 J3-14 Note 2

the fan is on.

in the closed postition. No voltage should be present if the

dryer is stopped.

3 The condition for this error will occur if the air switch is stuck

1100/1200/1300 2200/2300/2400 3300/3400/3600

Motor Ov er lo a d J5-12 J4-12 1 T his error will occur if the fan and bur ner were both operating and

Upper Fixed Grain J5-12 N/A J5-12 J 4-4 J5-12 J4-2

Middle Fixed Grain J5-12 N/A J5-12 N /A J5-12 J4-4

Misc E r rors

Upper Adjustable Grain J5-12 N/A J5-12 J4-8 J5-12 J4-6

Middle Adjustable Grain J5-12 N/A J5-12 N/A J5-12 J4-8

Lower or Left Fixed Grain J5-12 J1-19 J5-12 J1-19 J5-12 J1-19

Fan # cannot Start Check Air Switch J5-12 J1-13 J5-12 J1-14 J5-12 J2-13 J5-12 J2-14 J5-12 J3-13 J5-12 J3-14 Note 3

Lower Adjustable or Right Fixed Grain J5-12 J4-19 J5-12 J4-19 J5-12 J4-19

Auxilliary Safety Shutd o w n J5-12 J1-20 Note:

Grain Discharge Warning J5-12 J5-5 the air switch opens which indicates loss of static pressure.

Maxon Valve Shut Warning J5-12 J5-2 12 volts should be present if the fan is on.

Unknow n S a fe ty Er ror J5-12 J5-10 2 This error will occ ur if after the fan has started the air switc h does

20 Second Safety Circuit Failure J5-12 J5-6 not detect any static pressure. 12 volts should be present if

9

Programming

Portable Dryer Troubleshooting

Programming Instructions for EMCS Grain Dryers

1. Turn Control Power on dryer to off.

2. Locate programming jack (P7) on back of computer. (See page 13).

3. Plug the DB-9 jack of the programmer into the computer's jack.

4. Be sure that the rotary switch on the programmer is set to position 8.

5. Turn on Control Power to the dryer .

6. The four (4) lights on the programmer will come on, then three (3) will go out leaving the power light still on.

7. Push the start button on the programmer to start the transfer of Software.

8. The busy light will flash until the transfer process is complete.

9. When completed the pass light will flash indicating a successful transfer.

10. If the fail light flashes then check your connections and repeat the above process.

11. T urn Control Power on dryer to off and remove the cable.

12. Turn on the dryer and the opening screens should indicate the newer version of software.

10

Portable Dryer Troubleshooting

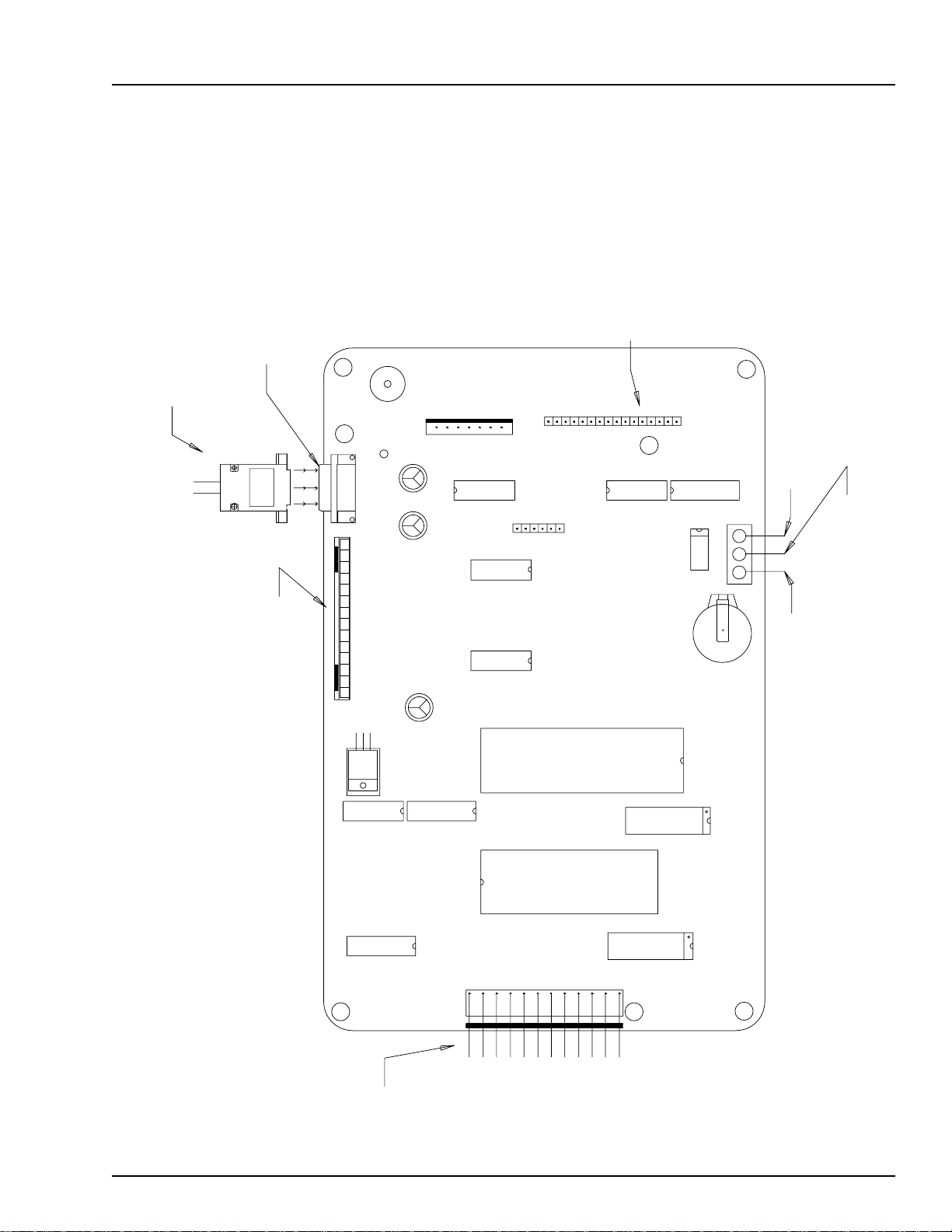

EMCS Display Board

COMPUTER

PROGRAMMING

JACK

PROGRAMMER

JACK (DB9)

SOUND

S1

P5

Programming

KEY PAD RIBBON

P4

P7

P8

COMMUNICATIONS CABLE

TO I/O BOARD

P6

TO STOP SW.

P3

3

21

U12

BATTERY (TIC)

TO START &

TO START SW.

STOP SWS.

DISPLAY

RIBBON

P1

11

Wiring Reference

0

Portable Dryer Troubleshooting

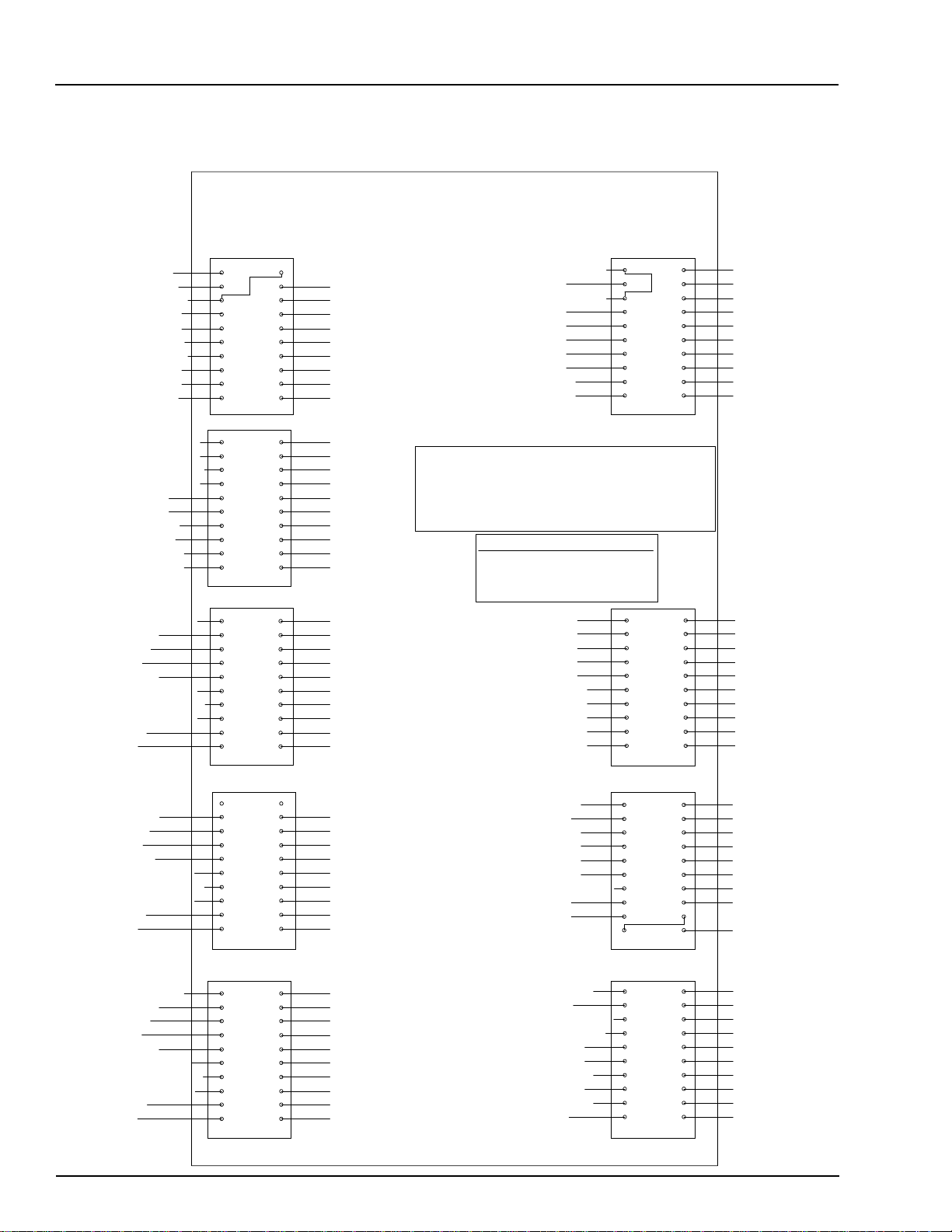

Input/Output Board Identification

120 VOLT AC OUTPUTS12 VOLT DC INPUTS

+12 LIMIT OUTPUT

12 VOLT DC NEUTRAL

METERING ROLL INPUT

12 VOLT DC NEGATIVE

12 VOLT DC NEGATIVE

SAFETY CIRCUIT INPUT

+12 VOLT LIMIT OUTPUT

FLAME SENSOR RETURN

OUT OF GRAIN SENSOR

MAXON VALVE SENSOR

MERCOID SFTY FAN#1 (CAN)

MERCOID SFTY FAN#2 (CAN)

MERCOID SFTY FAN#4 (CAN)

LOW MERCURY SWITCH (BO)

MOTOR OVERLOADS

MOISTURE CONTROL

ADJ. GRAIN (MIDDLE)

ADJ. GRAIN (UPPER)

FIXED GRAIN (MIDDLE)

FIXED GRAIN (UPPER)

BURNER #6 AUTO

BURNER #6 ON

FAN #6 AIR

FAN #6 PLENUM

FAN #6 FLAME DETECTION

FAN #6 HOUSING HIGH LIMIT

FAN #6 VAPOR HIGH LIMIT

FAN #6 AUTO

FAN #6 ON

20

19

18

17

15

16

14

13

12

11

J5

9

10

7

8

6

5

3

4

2

1

20

19

18

17

16

15

14

13

12

11

J4

10

9

7

8

6

5

3

4

1

2

20

19

18

17

16

15

14

13

12

11

J3

9

10

8

7

5

6

3

4

2

1

+12 LIMIT OUTPUT

12 VOLT DC NEGATIVE

12 VOLT DC NEGATIVE

12 VOLT DC NEGATIVE

+12 VOLT LIMIT OUTPUT

+12 VOLT LIMIT OUTPUT

REAR DISCHARGE

M.C. THERMOSTAT N.O. TERM #4

M.C. THERMOATAT N.C. TERM #6

LOWER ADJ. GRAIN HIGH LIMIT

2 SPEED UNLOAD

1 SPEED UNLOAD

UNLOAD BYPASS

LOAD SWITCH AUTO

LOAD SWITCH ON

BATCH MODE

CONTINUOUS FLOW

MERCOID SAFTY FAN#3 (CAN)

OUT OF GRAIN FOR LOAD #2

LO-HEAT THERMOSTAT (BO)HI-HEAT THERMOSTAT (BO)

BURNER #5 AUTO

BURNER #5 ON

FAN #5 AIR

FAN #5 PLENUM

FAN #5 FLAME DETECTION

FAN #5 HOUSING HIGH LIMIT

FAN #5 VAPOR HIGH LIMIT

FAN #5 AUTO

FAN #5 ON

JUMPER J1-9 TO J5-6 IS A HARDWARE TIMER FOR THE FLAME SENSOR SHUTDOWN

JUMPER J5-2 TO J5-20 IS A CONNECTION FOR THE MAXON VALVE SENS0R

JUMPER J4-12 TO J5-10 IS A HARDWARE TIMER FOR THE SAFETY SHUTDOWNS

JUMPER J1-20 TO J5-8 IS A CONNECTION FOR THE USER SUPPLLIED SAFETY

JUMPERS MUST BE INSTALLED FOR THE INPUT/OUTPUT BOARD TO OPERATE!!

120VAC POWER (INPUT)

AC NEUTRAL

120VAC POWER (INPUT)

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

FAN #1 POWER

FAN #2 POWER

JUMPERS TO BE INSTALLED FOR E-COOL

INSTALL JUMPER FROM J6-13 TO J1-5

INSTALL JUMPER FROM J6-14 TO J1-19

INSTALL JUMPER FROM J6-16 TO J5-5

INSTALL JUMPER FROM J6-17 TO J4-19

FAN #3 POWER

FAN #4 POWER

FAN #5 POWER

FAN #6 POWER

UNLOAD POWER

BUR # 4 NEUTRAL

BUR # 3 NEUTRAL

FAN # 4 NEUTRAL

FAN # 3 NEUTRAL

LOAD #2 NEUTRAL

1

2

3

4

5

6

7

8

9

10

J9

12

11

13

14

16

15

18

17

20

19

1

2

3

4

5

6

7

8

9

10

J8

11

12

13

14

15

16

18

17

20

19

120VAC POWER (OUTPUT)

AC NEUTRAL

120VAC POWER (OUTPUT)

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

AC NEUTRAL

BURNER #1 POWER

BURNER #2 POWER

BURNER #3 POWER

BURNER #4 POWER

BURNER #5 POWER

BURNER #6 POWER

LOAD POWER

SCR POWER

FAN #1 NEUTRAL

FAN #2 NEUTRAL

UNLOAD NEUTRAL

LOAD NEUTRAL

SCR NEUTRAL

12

BURNER #4 AUTO

BURNER #4 ON

FAN #4 AIR

FAN #4 PLENUM

FAN #4 FLAME DETECTION

FAN #4 HOUSING HIGH LIMIT

FAN #4 VAPOR HIGH LIMIT

FAN #4 AUTO

FAN #4 ON

USER SUPPLIED SAFETY

BURNER #2 AUTO

BURNER #2 ON

FAN #2 AIR

FAN #2 PLENUM

FAN #2 FLAME DETECTION

FAN #2 HOUSING HIGH LIMIT

FAN #2 VAPOR HIGH LIMIT

FAN #2 AUTO

FAN #2 ON

20

19

18

17

16

15

14

13

12

11

J2

10

9

7

8

5

6

3

4

1

2

20

19

18

17

16

15

14

13

12

11

J1

10

9

8

7

6

5

3

4

1

2

** IMPORTANT--JUMPERS LISTED ABOVE MUST BE INSTALLED

BURNER #3 AUTO

BURNER #3 ON

FAN #3 AIR

FAN #3 PLENUM

FAN #3 FLAME DETECTION

FAN #3 HOUSING HIGH LIMIT

FAN #3 VAPOR HIGH LIMIT

FAN #3 AUTO

FAN #3 ON

LOWER GRAIN HIGH LIMIT

BURNER #1 AUTO

BURNER #1 ON

FAN #1 AIR

FAN #1 PLENUM

FAN #1 FLAME DETECTION

FAN #1 HOUSING HIGH LIMIT

FAN #1 VAPOR HIGH LIMIT

FAN #1 AUTO

FAN #1 ON

LOAD #2 POWER

MAXON POWER

BUR #6 NEUTRAL

BUR #5 NEUTRAL

FAN #6 NEUTRAL

FAN #5 NEUTRAL

THERMOSTAT 110VAC (BO)

NC

NC

SCR P1 &

V1 FROM BR#1 (BO)

M.R.H POT 2

M.R.L POT 2 & HI SOLENOID BUR#2 (BO)

THERMOSTAT SENSOR S1

SENSOR 2 LOWER.

SENSOR 2 UPPER

ENERGENCY COOLING

AUX #6 B-COMMON

EMERGENCY COOLING

NC

1

2

3

4

5

6

7

8

9

10

J7

12

11

13

14

16

15

18

17

20

19

1

2

3

4

5

6

7

8

9

10

J6

12

11

14

13

16

15

18

17

19

20

PROCESS LIGHT

BURNER #1 NEUTRAL

BURNER #2 NEUTRAL

MAXON NEUTRAL

AC NEUTRAL

LO-HEAT POWER (BO)

HI-HEAT POWER (BO)

NC

M.R.H POT 3

M.R.L POT 3 &

HIGH SOLENOID BUR#1 (BO)

SCR P3 & V1 FROM BR#2 (B

SENSOR 1 LOWER

SENSOR 1 UPPER

THERMOSTAT SENSOR S2

AUX #6 A-N.C.

EMERGENCY COOLING

EMERGENCY COOLING

NC

NC

Portable Dryer Troubleshooting

Switch Replacement for EMCS Dryer

Switch Replacement

Switch N/O Contact Block - Part No. D63-0006

Switch Light Block - D01-0455

13

Wiring Reference

Portable Dryer Troubleshooting

1100 Series Control Box Wiring

1100 FAN TO CONTROL BOX WIRING

AIR PRESSURE SWITCH +12VDC

HOUSING HIGH LIMIT

VAPOR HIGH LIMIT (LP ONLY)

FLAME DETECTION

PLENUM

LEFT FIXED GRAIN HI LIMIT

SAFETY CIRCUIT

*REAR DISCHARGE

RIGHT FIXED GRAIN HI LIMIT

AIR PRESSURE SWITCH

BURNER POWER

BURNER NEUTRAL

BURNER LIGHT

USED ON SINGLE FAN

NAT GAS ONLY

K OTHER SIDE

N/C) SAFETY

5-8 OR J5-9 --

MAXON POWER

MAXON NEUTRAL

OUT OF GRAIN SENSOR

*

LEFT METERING ROLL SENSOR

*

RIGHT METERING ROLL SENSOR

METERING ROLL 12 VOLTS

CUSTOMER SUPPLIED SAFETY

METERING ROLL NEUTRAL

TEMP SENSORS

TEMP SENSORS

WORK LIGHT

DRYER SAFETY CIRCUIT ALWAYS STARTS ON J5-8 AND ENDS

ON J4-12.USING THE J5-12 TERMINAL FOR NEGATIVE,

THERE SHOULD BE 12 VOLTS DC ON EACH TERMINAL FROM

J5-8 TO J4-12.

WHEN CHECKING FOR 12 VOLTS DC ALWAYS PUT THE

NEGATIVE PROBE OF VOLT METER TO TERMINAL J5-12

SAFETY CIRCUIT IN BOLD IS FOR FLAME DETECTION ONLY.

EACH OF THE TERMINALS CONNECTED TO IT CAN LOOSE

12 VDC FOR 20 SECONDS BEFORE A SHUTDOWN OCCURS.

THIS GIVES THE BURNER CIRCUIT TIME TO SENSE FLAME.

ALL OTHER SAFETY CONNECTIONS MUST HAVE 12 VDC

PRESENT AT ALL TIMES TO OPERATE PROPERLY.

*LOCATED AT REAR OF DRYER

1100EW98.PRT REV. DATE 4/10/98

RELAY CONTACTS LOCATED

IN DRYER FAN CAN BOX

MERCURY SWITCH LOCATED

ON TOP OF DRYER

120VAC FOR AUX UNLOAD CONTACTOR COIL

120VAC FOR AUX LOAD CONTACTOR COIL

AUX CONTACT POINTS FOR LOAD AND UNLOAD SYSTEMS

ALL VOLTAGE SUPPLIED BY USER

42 TOTAL TERMINALS

WIRINGDESCRIPTION

NEED JUMPER

OR

YEL

RED

BRN

RED

BLK

NEED JUMPER

RED

RED

YEL

PUR

OR

BLU

OR

OR

OR

BLU

BLK

WHT

BRN

PUR

WHT

BLK

YEL

BLU

RED

BLK

WHT

BLK

RED

ALL SAFETIES MUST BE CLOSED FOR DRYER TO OPERATE

J5-8

J5-8

J1-7

J1-5

J1-9

J1-11

J1-19

J5-5

J4-19

J4-12

J1-13

J9-16

J7-4

B1

J7-3

J7-8

J5-4

J5-16

J5-19

J5-9

J1-20

J5-12

-12VDC

S1

S2

L1

J8-16

J8-9

J8-18

J8-8

J8-12

J9-17

J8-20

J8-10

J6-1

SCR 2

J6-4

U-COM

U-N/O

L-COM

L-N/O

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

MOTOR OVERLOADS

12 VOLTS DC (BLUE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

12 VOLTS DC (YELLOW)

METER ROLL PULSE (PUR)

NO LONGER USED

12 VOLTS DC (RED)

12 VOLTS DC (RED)BLK

12 VOLTS DC NEG (WHITE)

TEMP SENSOR (ORANGE)

TEMP SENSOR (ORANGE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)J9-3

120 VAC (BLACK)AC 1

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

120 VAC NEUT (WHITE)

120 VAC (YELLOW)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

CONTROL POT P1 (PUR)

CONTROL POT P2 (PUR)

CONTROL POT P3 (PUR)

UNLOAD AUX COM(ORANGE)

UNLOAD AUX N/O(ORANGE)

LOAD AUX COM (YELLOW)

LOAD AUX N/O (YELLOW)

COLORVOLTAGE

14

Portable Dryer Troubleshooting

1100 Series Control Box Wiring (New Version)

Wiring Reference

15

Wiring Reference

1200 Series Control Box Wiring

DESCRIPTION

WIRING

Portable Dryer Troubleshooting

52 TOTAL TERMINALS

TERMINAL

COLORVOLTAGE

HOOK OTHER SIDE

OF (N/C) SAFETY

TO J5-8 OR J5-9 --

53 TOTAL TERMINALS

15 - RED

4 - BLUE

1 - WHITE/BLACK

3 - BLACK (1-16GA)

9 - WHITE (1-16GA

2 - BROWN

4 - PURPLE

4 - ORANGE)

*LOCATED AT REAR OF DRYER

1200EW98.PRT REV. DATE 3/5/98

AIR PRESSURE SWITCH +12VDC

FAN #2 HOUSING HIGH LIMIT

FAN #2 VAPOR HIGH LIMIT

FAN #2 FLAME DETECTION

FAN #1 HOUSING HIGH LIMIT

FAN #1 VAPOR HIGH LIMIT

FAN #1 FLAME DETECTION

FAN #2 PLENUM

SAFETY CIRCUIT

FAN #1 PLENUM

FIXED GRAIN HIGH LIMIT

*REAR DISCHARGE

ADJ. GRAIN HIGH LIMIT

FAN #2 PRESSURE SWITCH

FAN #1 PRESSURE SWITCH

BURNER #2 POWER

BURNER #2 NEUTRAL

BURNER #1 POWER

BURNER #1 NEUTRAL

BURNER #2 LIGHT

BURNER #1 LIGHT

MAXON POWER

MAXON NEUTRAL

OUT OF GRAIN SENSOR

*LEFT METERING ROLL SENSOR

*RIGHT METERING ROLL SENSOR

METERING ROLL 12 VOLTS

CUSTOMER SUPPLIED SAFETY RED

METERING ROLL NEGATIVE

TEMP SENSOR

TEMP SENSOR

RELAY CONTACTS LOCATED

IN FAN CAN CONTROL BOX

RELAY CONTACTS LOCATED

IN FAN CAN CONTROL BOX

MERCURY SWITCH LOCATED

ON TOP OF DRYER

120VAC FOR AUX UNLOAD CONTACTOR COIL

120VAC FOR AUX LOAD CONTACTOR COIL

AUX CONTACT POINTS FOR LOAD AND UNLOAD SYSTEMS

ALL VOLTAGE SUPPLIED BY USER

NEED JUMPER

RED

RED

RED

BRN

RED

BLK

NEED JUMPER

RED

RED

OR

YEL

PUR

OR

OR

YEL

PUR

OR

YEL

BLU

OR

OR

RED

MOTOR OVERLOADS

BLU

BLU

BLK

WHT

BLK

WHT

BRN

BRN

PUR

WHT

BLK

YEL

BLU

RED

BLK

WHT

BLK

RED

ALL SAFETIES MUST BE CLOSED FOR DRYER TO OPERATE

J5-8

J5-8

J1-8

J1-6

J1-10

J1-7

J1-5

J1-9

J1-12

J1-11

J1-19

J5-5

J4-19

J4-12

J1-14

J1-13

J9-18

J7-6

J9-16

J7-4

B2

B1

J7-3

J7-8

J5-4

J5-16

J5-19

J5-9

J1-20

J5-12

-12VDC

S1

S2

L1 WORK LIGHT

J9-3

J8-16

J8-9

J8-18

J8-8

J8-14

J9-19

J8-12

J9-17

J8-20

J8-10

J6-1

SCR 2

J6-4

U-COM

U-N/O

L-COM

L-N/O

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC (BLUE)

12 VOLTS DC (BLUE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BROWN)

120 VAC (BROWN)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

12 VOLTS DC (YELLOW)

METER ROLL PULSE (PUR)

NO LONGER USED

12 VOLTS DC (RED)

12 VOLTS DC (RED)

12 VOLTS DC NEG (WHITE)

TEMP SENSOR (ORANGE)

TEMP SENSOR (ORANGE)

120 VAC (BLACK)

120 VAC NEUT (WHITE)

120 VAC (BLACK)AC 1

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

120 VAC NEUT (WHITE)

120 VAC (YELLOW)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC NEUT (WHITE)

120 VAC (BLUE)

120 VAC NEUT (WHITE)

120 VAC (ORANGE)

CONTROL POT P1 (PUR)

CONTROL POT P2 (PUR)

CONTROL POT P3 (PUR)

UNLOAD AUX COM(ORANGE)

UNLOAD AUX N/O(ORANGE)

LOAD AUX COM (YELLOW)

LOAD AUX N/O (YELLOW)

16

Portable Dryer Troubleshooting

1200 Series Control Box Wiring (New Version)

Wiring Reference

17

Wiring Reference

1100 Fan Lower Control Box Interconnect Strip

Portable Dryer Troubleshooting

J9-1

LOAD

LINE

AC-1

EMERGENCY COOLING JUMPERS

INSTALL J6-13 TO J1-5

INSTALL J6-14 TO J1-19

INSTALL J6-16 TO J5-5

INSTALL J6-17 TO J4-19

L1

B1

S1

S2

SCR2

J1-5

J1-7

J1-9

J1-11

J1-13

J1-19

J1-20

J4-12

J4-19

J5-4

J5-5

J5-8

J5-9

J5-12

J5-16

J5-19

J6-1

J6-4

J7-3

J7-4

J7-8

J8-8

J8-9

J8-10

J8-12

J9-3

EMI FILTER

D03-0181

BLACK - 120 VAC - OUTSIDE LIGHT

BROWN - 120 VAC - BURNER #1 LIGHT

ORANGE - TEMPERATURE SENSOR

ORANGE - TEMPERATURE SENSOR

PURPLE - CONTROL POT P2

RED - 12 VDC - FAN #1 VAPOR HIGH LIMIT

RED - 12 VDC - FAN #1 HOUSING HIGH LIMIT

RED - 12 VDC - FAN #1 FLAME DETECTION

RED - 12 VDC - FAN #1 PLENUM HIGHT LIMIT

BLUE - 12 VDC - FAN #1 AIR SWITCH

RED - 12 VDC - LOWER FIXED GRAIN LIMIT

RED - 12 VDC - USER SUPPLIED SAFETY

RED - 12 VDC - MOTOR OVERLOADS

RED - 12 VDC - LOWER ADJUSTABLE GRAIN HIGH LIMIT

YELLOW - 12 VDC - OUT OF GRAIN SENSOR

RED - 12 VDC - REAR DISCHARGE SWITCH

RED - 12 VDC - 12 VOLT SUPPLY

RED - 12 VDC - 12 VOLT SUPPLY

WHITE - 12 VDC NEG - 12 VOLT SUPPLY NEGATIVE

PURPLE -TIMING PULSE- LEFT METERING ROLL PULSE

PURPLE -TIMING PULSE- RIGHT METERING ROLL PULSE

PURPLE - CONTROL POT P1

PURPLE - CONTROL POT P3

BLACK - 120 VAC - MAXON POWER

WHITE - AC NEUTRAL - BURNER NEUTRAL

WHITE - AC NEUTRAL - MAXON NEUTRAL

YELLOW - 120 VAC - LOAD POWER

ORANGE - 120 VAC - UNLOAD POWER

ORANGE - 120 VAC - SCR POWER

WHITE - AC NEUTRAL - FAN #1 NEUTRAL

5VB1

J9-3

J8-16 WHITE - AC NEUTRAL - UNLOAD NEUTRAL

J8-18

J8-20

J9-16

J9-17

WHITE - AC NEUTRAL - LOAD NEUTRAL

WHITE - AC NEUTRAL - SCR NEUTRAL

BLACK - 120 VAC - BURNER #1 POWER

BLUE - 120 VAC - FAN #1 POWER

18

35 - D01-0531 ENTRELEC TERMINALS

2 - D01-0533 END STOPS

1 - D01-0532 BLANK PROTECTOR END

I/O BOARD JUMPERS

INSTALL J1-9 TO J5-6

INSTALL J5-2 TO J5-20

INSTALL J4-12 TO J5-10

INSTALL J1-20 TO J5-8

Portable Dryer Troubleshooting

1200 Fan Lower Control Box Interconnect Strip

Wiring Reference

J9-1

LOAD

J9-3

L1

B1

B2

S1 ORANGE - TEMPERATURE SENSOR

S2 ORANGE - TEMPERATURE SENSOR

SCR2

J1-5

J1-6

J1-7

J1-8

J1-9

J1-10

J1-11

J1-12

J1-13

J1-14

J1-19

J1-20

J4-12

J4-19

J5-4

J5-5

J5-8

J5-9

J5-12

J5-16

J5-19

J6-1

J6-4

J7-3

J7-4

J7-8

J8-8

J8-9

J8-10

J8-12

J8-18

J8-20

J9-16

LINE

5VB1

EMI FILTER

D03-0181

BLACK - 120 VAC - OUTSIDE LIGHT

BROWN - 120 VAC - BURNER #1 LIGHT

BROWN - 120 VAC - BURNER #2 LIGHT

PURPLE - CONTROL POT P2

RED - 12 VDC - FAN #1 VAPOR HIGH LIMIT

RED - 12 VDC - FAN #2 VAPOR HIGH LIMIT

RED - 12 VDC - FAN #1 HOUSING HIGH LIMIT

RED - 12 VDC - FAN #2 HOUSING HIGH LIMIT

RED - 12 VDC - FAN #1 FLAME DETECTION

RED - 12 VDC - FAN #2 FLAME DETECTION

RED - 12 VDC - FAN #1 PLENUM HIGHT LIMIT

RED - 12 VDC - FAN #2 PLENUM HIGHT LIMIT

BLUE - 12 VDC - FAN #1 AIR SWITCH

BLUE - 12 VDC - FAN #2 AIR SWITCH

RED - 12 VDC - LOWER FIXED GRAIN LIMIT

RED - 12 VDC - USER SUPPLIED SAFETY

RED - 12 VDC - MOTOR OVERLOADS

RED - 12 VDC - LOWER ADJUSTABLE GRAIN HIGH LIMIT

YELLOW - 12 VDC - OUT OF GRAIN SENSOR

RED - 12 VDC - REAR DISCHARGE SWITCH

RED - 12 VDC - 12 VOLT SUPPLY

RED - 12 VDC - 12 VOLT SUPPLY

WHITE - 12 VDC NEG - 12 VOLT SUPPLY NEGATIVE

PURPLE -TIMING PULSE- LEFT METERING ROLL PULSE

PURPLE -TIMING PULSE- RIGHT METERING ROLL PULSE

PURPLE - CONTROL POT P1

PURPLE - CONTROL POT P3

BLACK - 120 VAC - MAXON POWER

WHITE - AC NEUTRAL - BURNER #1 NEUTRAL

WHITE - AC NEUTRAL - BURNER #2 NEUTRALJ7-6

WHITE - AC NEUTRAL - MAXON NEUTRAL

YELLOW - 120 VAC - LOAD POWER

ORANGE - 120 VAC - UNLOAD POWER

ORANGE - 120 VAC - SCR POWER

WHITE - AC NEUTRAL - FAN #1 NEUTRAL

WHITE - AC NEUTRAL - FAN #2 NEUTRALJ8-14

WHITE - AC NEUTRAL - UNLOAD NEUTRALJ8-16

WHITE - AC NEUTRAL - LOAD NEUTRAL

WHITE - AC NEUTRAL - SCR NEUTRAL

BLACK - 120 VAC - BURNER #1 POWER

BLUE - 120 VAC - FAN #1 POWERJ9-17

BLACK - 120 VAC - BURNER #2 POWERJ9-18

BLUE - 120 VAC - FAN #2 POWERJ9-19

AC-1

J9-3

EMERGENCY COOLING JUMPERS

INSTALL J6-13 TO J1-5

INSTALL J6-14 TO J1-19

INSTALL J6-16 TO J5-5

INSTALL J6-17 TO J4-19

45 - D01-0531 ENTRELEC TERMINALS

2 - D01-0533 END STOPS

1 - D01-0532 BLANK PROTECTOR ENDS

I/O BOARD JUMPERS

INSTALL J1-9 TO J5-6

INSTALL J5-2 TO J5-20

INSTALL J4-12 TO J5-10

INSTALL J9-1 TO J9-5

19

Wiring Reference

Portable Dryer Troubleshooting

Upper Control Box External Wiring

BLACK FROM J9-16 TO L1 ON FENWAL BOARD 120VAC POWER

WHITE FROM J7-04 TO L2 ON FENWAL BOARD 120VAC NEUTRAL

BROWN TO B1 FROM V1 ON FENWAL BOARD 120VAC

ORANGE FROM J1-09 TO FLAME DETECTION RELAYS

ORANGE FROM J5-08 TO FLAME DETECTION RELAYS

WHITE/BLACK STRIP J5-12 12VDC NEGATIVE

YELLOW TO J1-07 FROM HOUSING HIGH LIMIT SWITCH

RED FROM J5-08 TO HOUSING & VAPOR HIGH LIMIT SWITCHES

PURPLE TO J1-05 FROM VAPOR HIGH LIMIT SWITCH

TO FAN CONTROL BOX

BLUE FROM J5-08 TO AIRSWITCH COMMON TERMINAL

BLUE TO J1-13 FROM AIRSWITCH N.O. TERMINAL

WHITE TO S1 FROM RIGHT GRAIN TEMPERATURE SENSOR

BLACK TO S2 FROM RIGHT GRAIN TEMPERATURE SENSOR

RED FROM J1-11 TO LEFT GRAIN HIGH LIMIT SWITCH

ORANGE TO J1-19 FROM LEFT GRAIN HIGH LIMIT SWITCH

PURPLE J7-03 MAXON POWER 120VAC (NATURAL GAS ONLY)

WHITE J7-08 MAXON 120VAC NEUTRAL (NATURAL GAS ONLY)

BROWN FROM J1-19 TO REAR DISCHARGE SWITCH

ORANGE TO J5-05 FROM REAR DISCHARGE SWITCH

RED 16 GA. A+ SCR DRIVE MOTOR

BLACK 16 GA. A- SCR DRIVE MOTOR

GREEN 16 GA. SCR DRIVE MOTOR GROUND

BLACK FROM J5-09 TO LOAD MERCURY SWITCH

BLACK TO J5-04 FROM LOAD MERCURY SWITCH

WHITE FROM J9-03 TO OUTSIDE LIGHT AC NEUTRAL

RED FROM L1 120VAC TO OUTSIDE LIGHT POWER

TO AIRSWITCH ASSEMBLY

TO LOWER JUNCTION BOX

TO UPPER JUNCTION BOX

20

YELLOW FROM J1-05 TO PLENUM HIGH LIMIT SWITCH

WHITE TO S1 FROM GRAIN TEMPERATURE SENSOR

BLACK TO S2 FROM GRAIN TEMPERATURE SENSOR

BLUE TO J1-11 FROM PLENUM HIGH LIMIT SWITCH

YELLOW FROM J1-05 TO PLENUM HIGH LIMIT SWITCH

RED FROM J5-05 TO RIGHT GRAIN HIGH LIMIT SWITCH

ORANGE TO J4-19 FROM RIGHT GRAIN HIGH LIMIT SWITCH

TO PLENUM AND RIGHT

FIXED GRAIN HIGH LIMIT

SWITCHES AND TEMPERATURE

SENSORS

Portable Dryer Troubleshooting

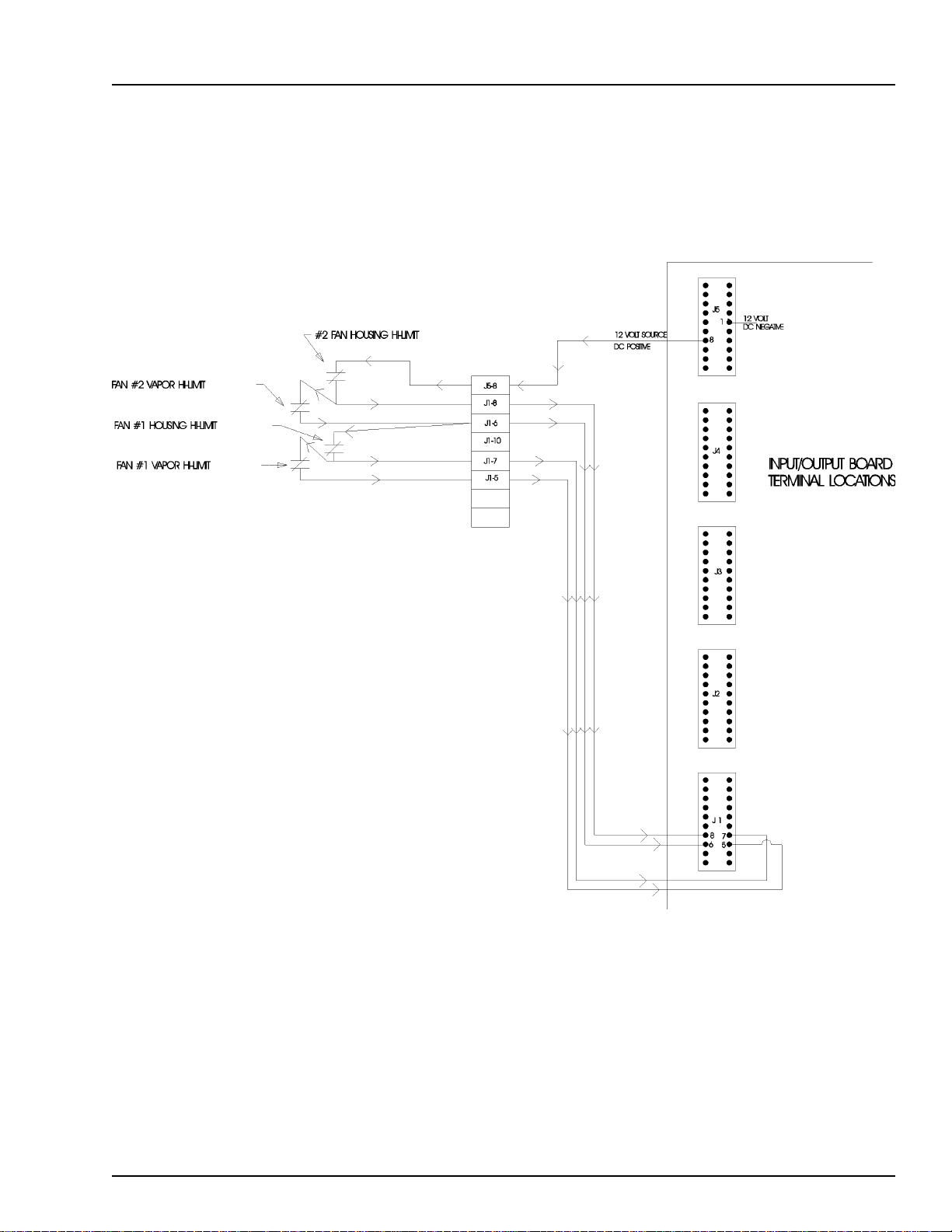

Fan Housing and Vapor Hi-Limit Circuit

Wiring Reference

21

Wiring Reference

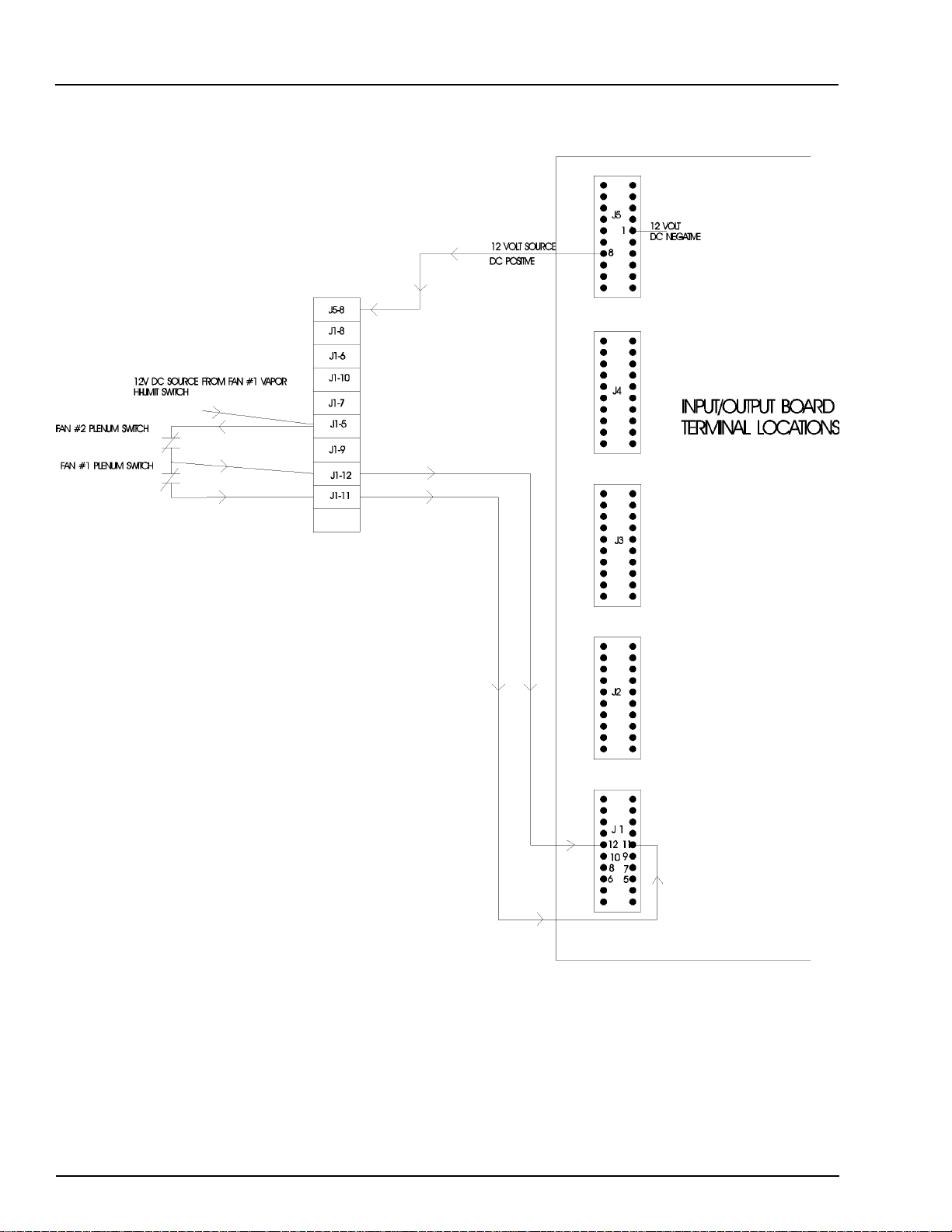

Portable Dryer Troubleshooting

Plenum Hi-Temperature Switch

22

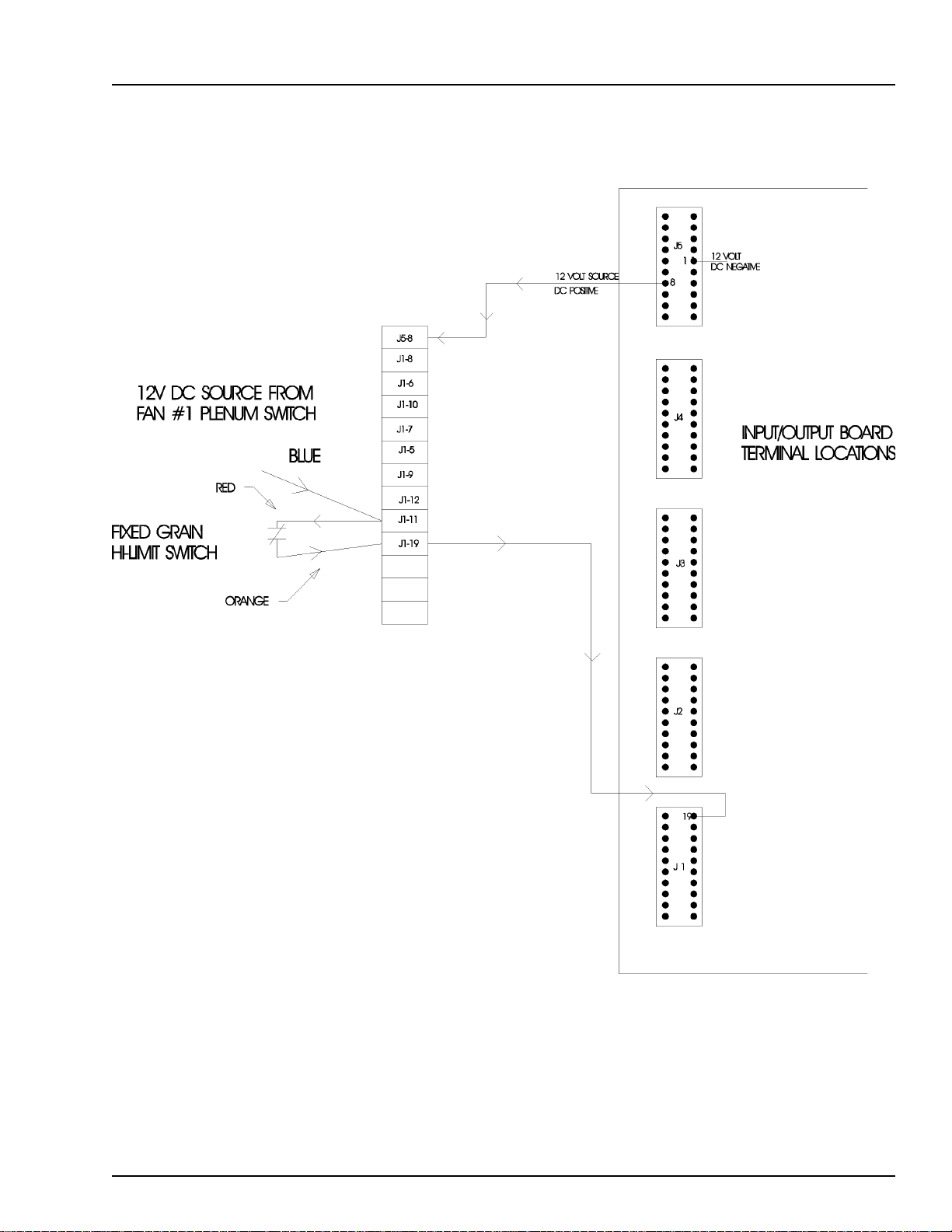

Portable Dryer Troubleshooting

Fixed Grain Hi-Limit

Wiring Reference

23

Wiring Reference

LOAD

MOTOR

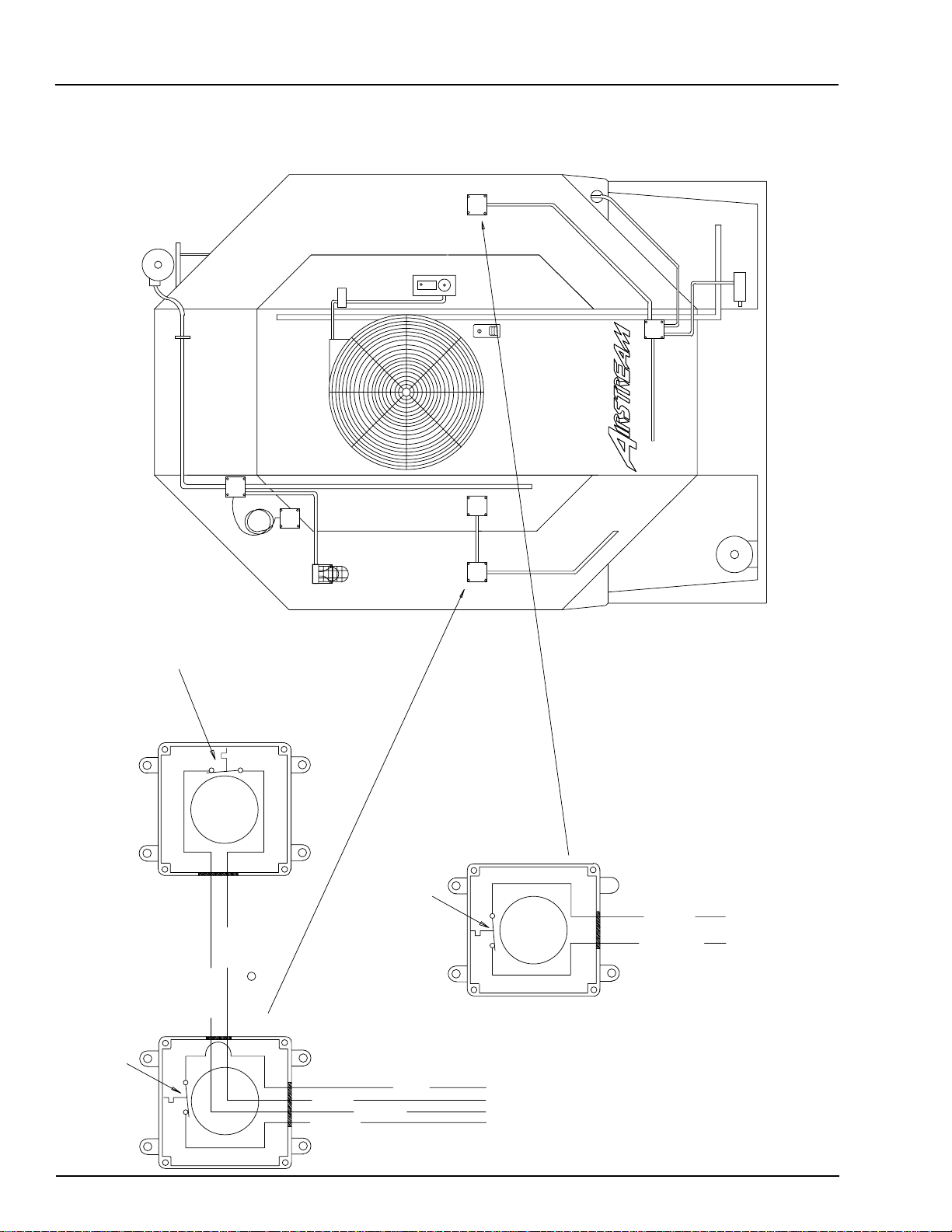

Portable Dryer Troubleshooting

Grain & Plenum Hi-Limit Locations

LIMIT

GRAIN HIGH

LEFT FIXED

TEMP. SENSORS

GAS PIPE TRAIN

11XX

BOX

UPPER

JUNCTION

OUTSIDE LIGHT

LOAD MERCURY SWITCH

PLENUM HIGH LIMIT SWITCH

D03-0004 300 DEGREE

SOLENOID

BURNER

HI-LOW

THERMO

PLENUM

LIMIT

GRAIN HIGH

RIGHT FIXED

TEMP. SENSORS

AIR SWITCH

FAN

BOX

LOWER

JUNCTION

SCR

MOTOR

UNLOAD

24

BLUE J1-11

YELLOW J1-05

RIGHT GRAIN HIGH LIMIT SWITCH

D03-0005 210 DEGREE

BLUE J1-11

YELLOW J1-05

ORANGE J4-19

LEFT GRAIN HIGH LIMIT SWITCH

D03-0005 210 DEGREE

RED J5-05

TO UPPER CONTROL BOX

RED J1-11

ORANGE J1-19

TO LOWER JUNCTION BOX

Portable Dryer Troubleshooting

Two Fan Plenum and Grain Limit Switch Wiring

LOAD

MOTOR

FIXED GRAIN

HI-LIMIT AND

THERMO SENSORS

Wiring Reference

MAXON

12XX

BOX

UPPER

JUNCTION

SOLENOID

LOAD MERCURY SWITCH

OUTSIDE LIGHT

BURNER #2

PLENUM #2

HI-LOW

THERMO

HI-LOW

BURNER #1

AIR

SWITCHES

FAN #2

THERMO

SOLENOID

PLENUM #1

LIMIT

ADJUSTABLE

GRAIN HIGH

TEMP. SENSORS

FAN #1

RED TO J1-11

SCR

MOTOR

UNLOAD

2FNLMTSW98.PRT REV. DATE 4/5/98

FAN #2

PLENUM HIGH LIMIT SWITCH

D03-0004 300 DEGREE

FIXED GRAIN HIGH LIMIT SWITCH

D03-0005 210 DEGREE

FAN #1

PLENUM HIGH LIMIT SWITCH

D03-0004 300 DEGREE

ORANGE TO J1-19

YELLOW TO J1-12

BLUE TO J1-11

RED TO J1-05

TO LOWER JUNCTION BOX

25

Wiring Reference

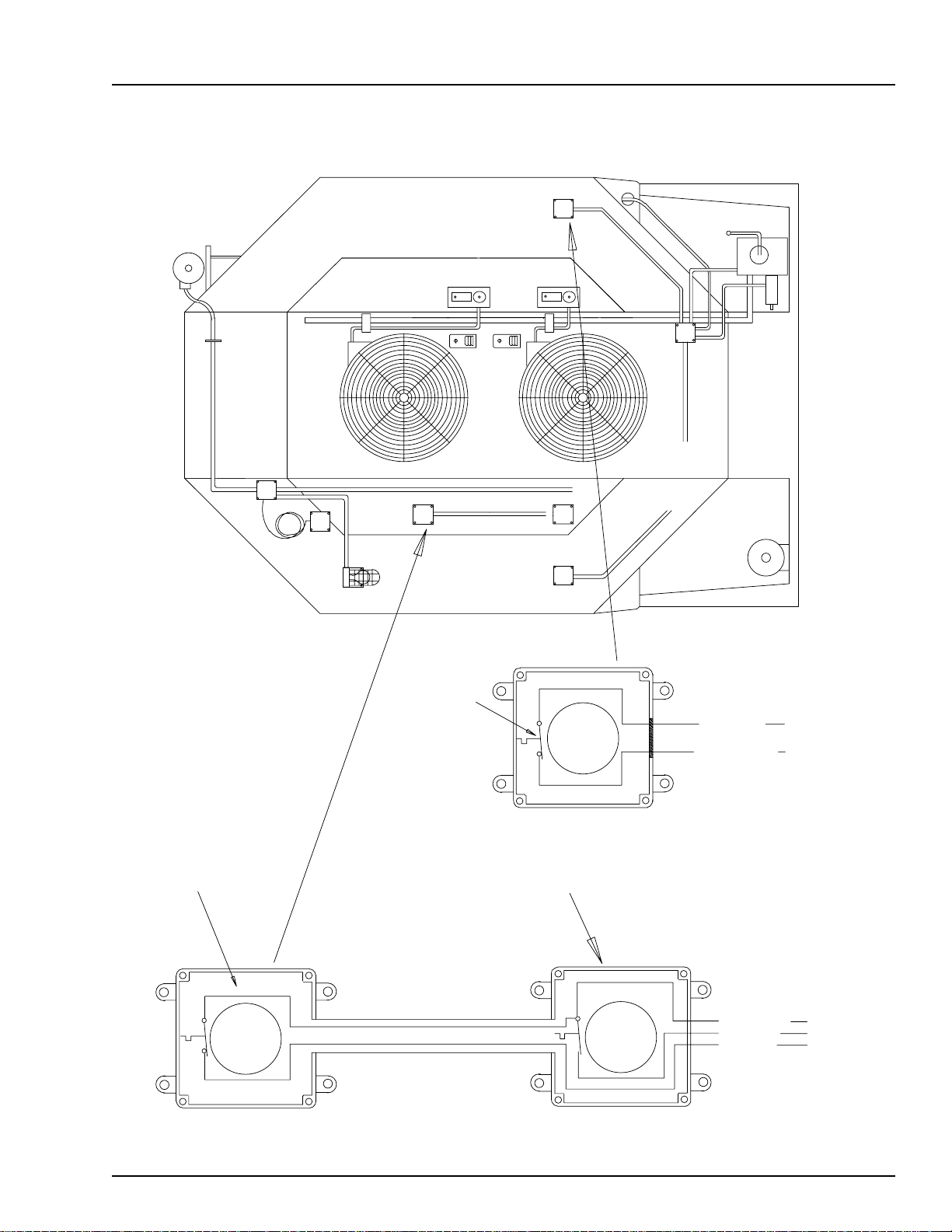

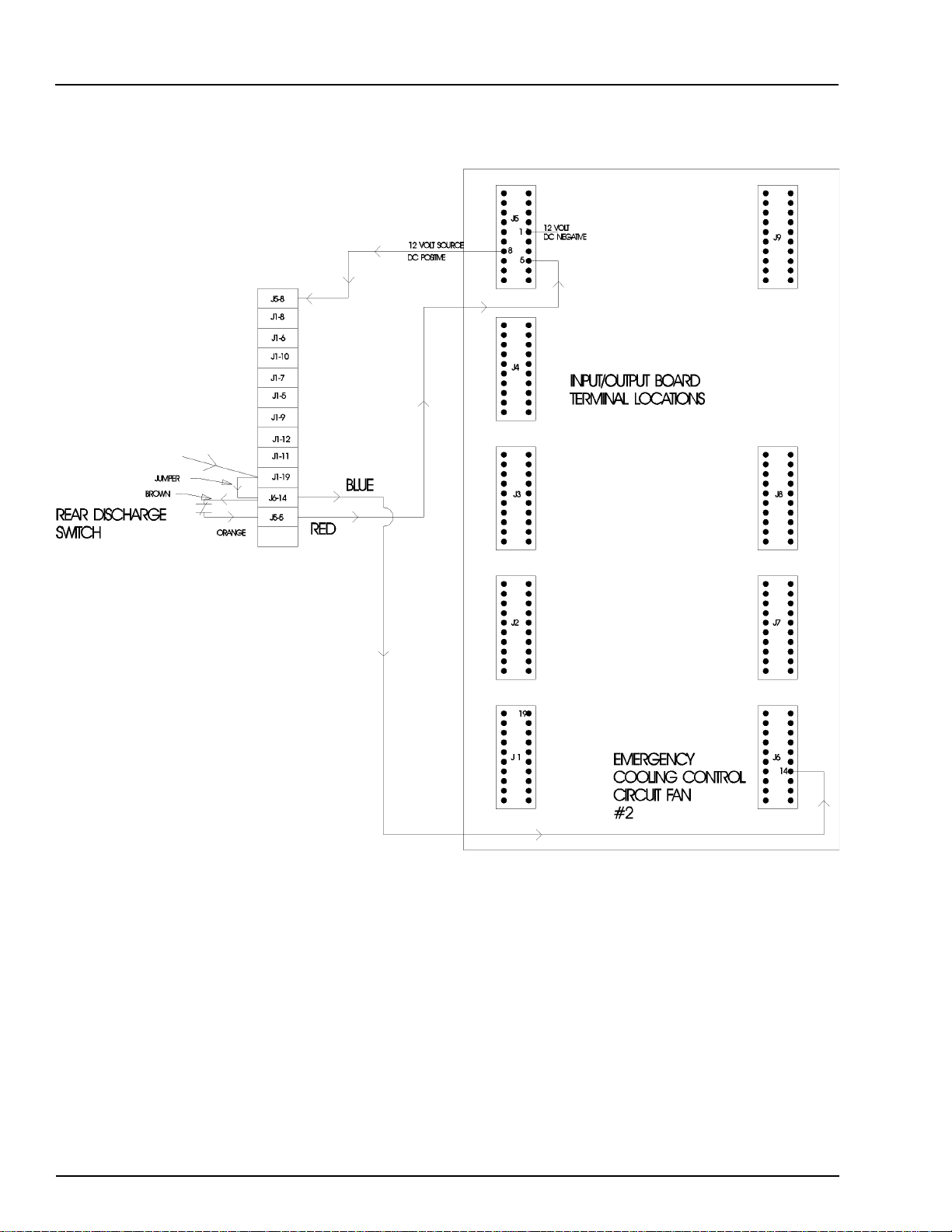

Rear Discharge & Emergency Cooling Circuit

Portable Dryer Troubleshooting

26

Portable Dryer Troubleshooting

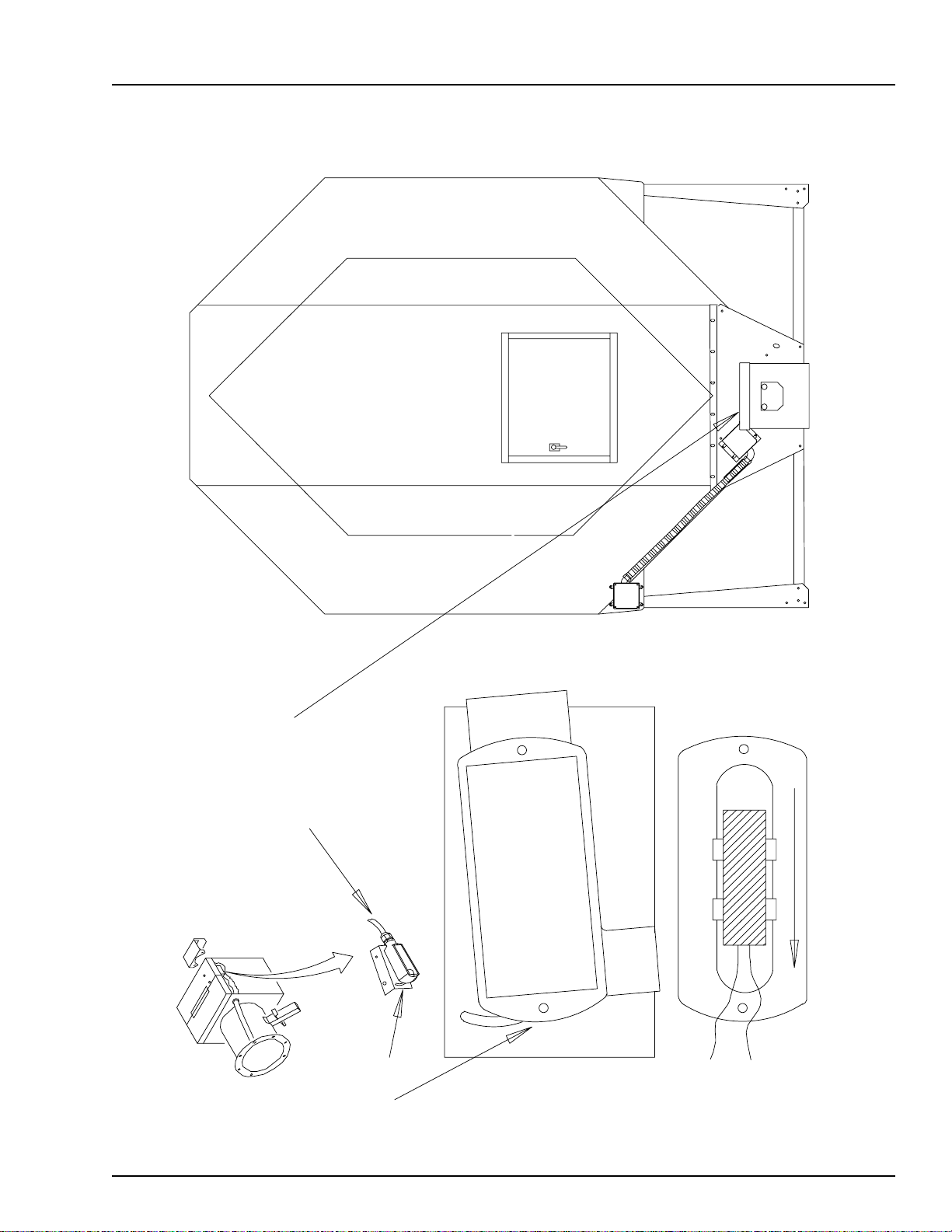

Rear Discharge Mercury Switch

Wiring Reference

POSITIONED WITH LID CLOSED AND

SJOW 18/2 CORD POINTED TOWARDS

THE FRONT OF THE DRYER CONNECT

INSIDE METER ROLL BOX TO BROWN

AND ORANGE WIRES.

LOOSEN SCREWS ON BRACKET

TO CHANGE SENSITIVITY

OF REAR DISCHARGE SWITCH

CONNECT TO SJOW CORD

INSIDE LRL BOX

27

Wiring Reference

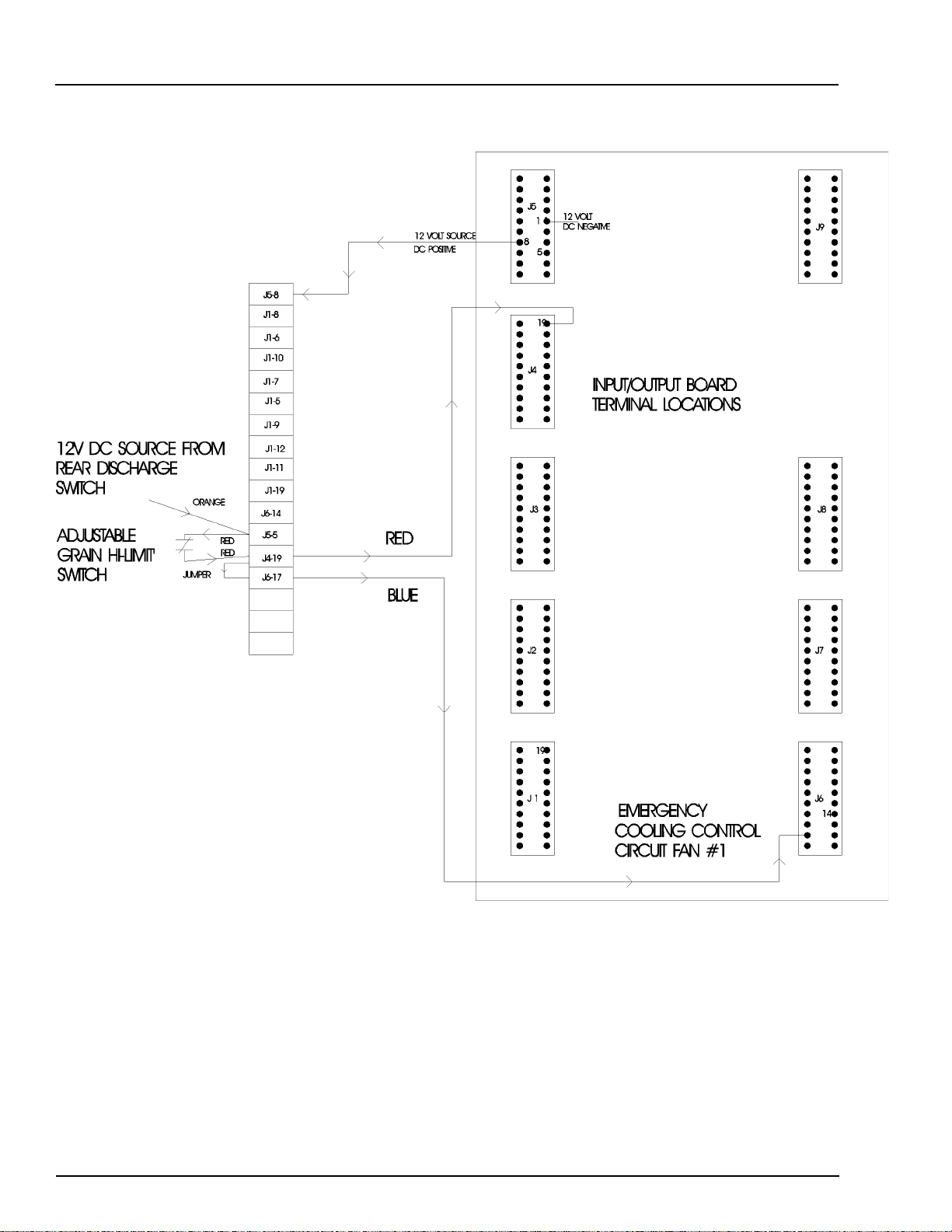

Adjustable Hi-Limit & Emergency Cooling Circuit

Portable Dryer Troubleshooting

28

Portable Dryer Troubleshooting

Wiring Reference

Motor Overloads

29

Loading...

Loading...