GSI Outdoors PNEG-214 User Manual

12'-18' Diameter Bins

Cor-Lok and Cut-Lok Flooring

and Grandstand Layout

Installation Manual

PNEG-214

Date: 03-07-08

PNEG-214

2 PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring

Table of Contents

Contents

Chapter 1 Safety ..................................................................................................................................................5

Safety Guidelines ................................................................................................................................5

Safety Instructions ...............................................................................................................................6

Chapter 2 Recommended Method for Full Floor Installation .........................................................................8

Fan Placement Diagram ......................................................................................................................8

Grain Systems Recommended Method for Full Floor Installation ....................................................... 9

Chapter 3 Grandstand Identification ...............................................................................................................11

20 Gauge Grandstand Identification ..................................................................................................11

Chapter 4 Flashing Installation ........................................................................................................................12

Grain Systems Formed Flashing Installation .....................................................................................12

Chapter 5 Grandstand Layout at Center Well for Recirculating System .....................................................13

Chapter 6 12' Cut-Lok/Cor-Lok Plank Order and Grandstand Layouts ........................................................14

12' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 3-7 Rings and 4.00" Corrugated Bins 3-5 Rings ...........................................15

Chapter 7 15' Cor-Lok/Cut-Lok Plank Order and Grandstand Layouts ........................................................16

15' Cut-Lok/Cor-Lok Plank Order ......................................................................................................16

15' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 4 and 5 Rings and 4.00" Corrugated Bins 3 Rings .......................................17

15' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 6 Rings and 4.00" Corrugated Bins 4 Rings .................................................18

15' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 7 Rings and 4.00" Corrugated Bins 5 Rings .................................................19

Chapter 8 18' Cor-Lok/Cut-Lok Plank Order ...................................................................................................20

Chapter 9 18' Grandstand Layout for Recirculating System ........................................................................21

18' 20 Gauge Grandstand Layout for Recirculating System

Cut-Lok or 18 Gauge Cor-Lok Floors ................................................................................................21

Chapter 10 18' Cut-Lok/Cor-Lok and Grandstand Layouts ...........................................................................22

18' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 5 and 6 Rings and 4.00" Corrugated Bins 3 and 4 Rings ............................22

18' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 7 and 8 Rings and 4.00" Corrugated Bins 5 and 6 Rings ............................23

18' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 9-11 Rings and 4.00" Corrugated Bins 7 and 8 Rings .................................24

18' Cor-lok/cut-lok and 20 Gauge Grandstand Layout

2.66" Corrugated Bins 12 Rings ......................................................................................................25

18' Cor-Lok/Cut-Lok and 20 Gauge Grandstand Layout

4.00" Corrugated Bins 9 Rings ........................................................................................................26

PNEG-214 12'-18 Cor-Lok and Cut-Lok Flooring 3

Table of Contents

Chapter 11 20 Gauge Floor Support Requirements .......................................................................................27

20 Gauge Grandstand Chart - 2.66" Corrugation ............................................................................27

20 Gauge Grandstand Chart - 4.00" Corrugation ............................................................................28

Chapter 12 Flashing Support Stiffeners ..........................................................................................................29

Stiffener Flashing Support Instructions for Internal

Universal Stiffeners ..........................................................................................................................29

Chapter 13 Air Flow Support Instructions ......................................................................................................30

Installation of Air Flow Supports ......................................................................................................30

Chapter 14 Warranty .........................................................................................................................................37

SEE PAGE 27 AND PAGE 28 FOR 20 GAUGE FLOOR

SUPPORT REQUIREMENTS.

4 PNEG-214 1 2'-18 Co r-Lo k and Cu t-Lok Flo oring

1. Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

NOTE indicates information about the equipment that you

should pay special attention.

PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring 5

1. Safety

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want

to keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requ irements, hazards and p recautions

exist, and to inform all personnel associated with the equipment or in the area . Safety precautions may

be required from the personnel. Avoid any alterations to the equipment. Such alterations may produce

a very dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Rotating Flight

Grain augers can kill or dismember.

Keep clear of all augers and never enter the bin unless all

power is disconnected and locked out. Failure to do so will

result in serious injury or death.

Read and Understand Manual

Rotating Flight

6 PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate

to the job.

1. Safety

Keep Emergency Equipment

Quickly Accessible

Eye Protection

Remove all jewelry.

Long hair should be tied up and back.

Safety glasses should be worn at all times to protect eyes

from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel toe boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoe strings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear hard hat to help protect your head.

Gloves

Steel Toe Boots

Respirator

Hard Hat

PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring 7

2. Recommended Method for Full Floor Installation

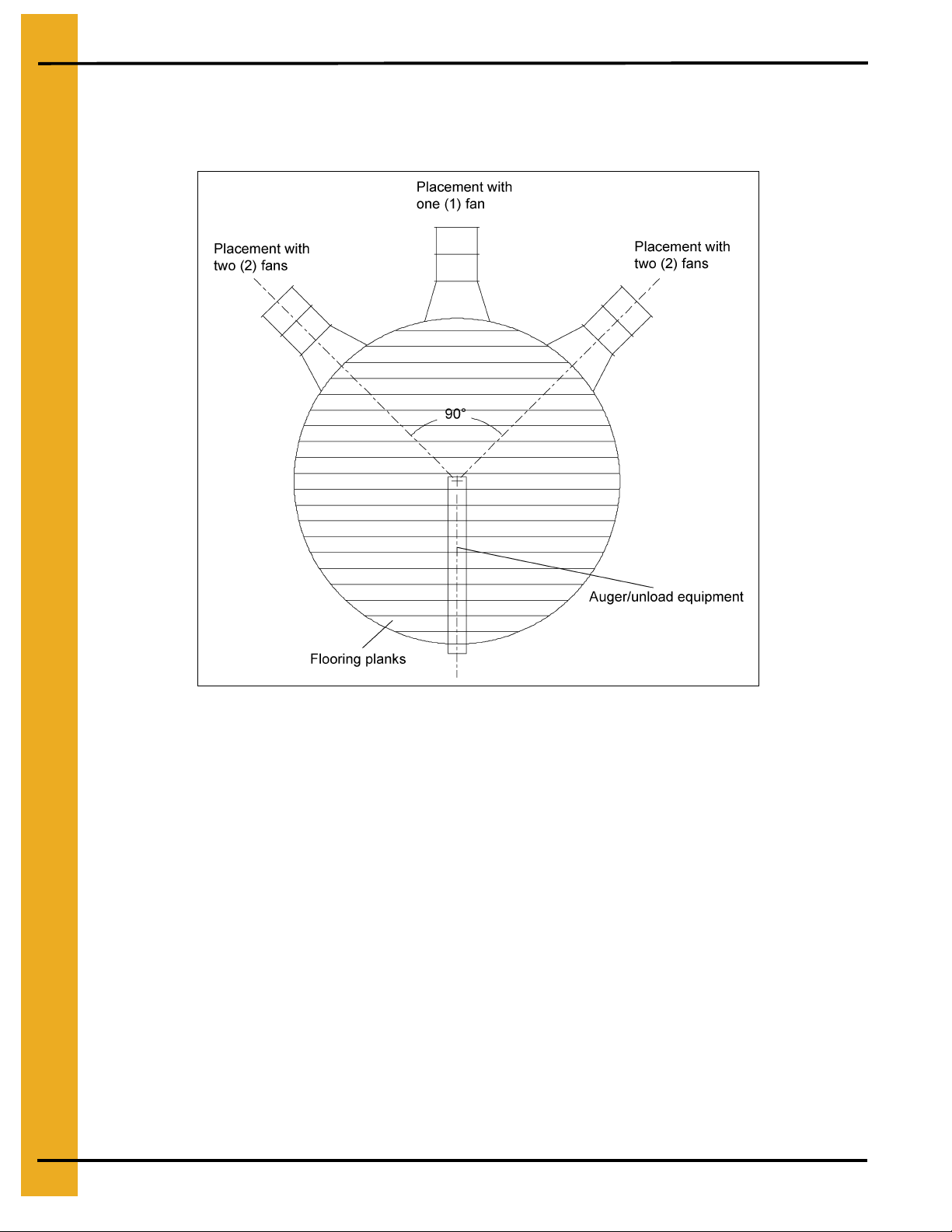

Fan Placement Diagram

For uniform air flow, place the fans in relation to the unloading tube a s shown in Figure 2A. Floor planks

should be perpendicular to the unloading tube.

Figure 2A

8 PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring

2. Recommended Method for Full Floor Installation

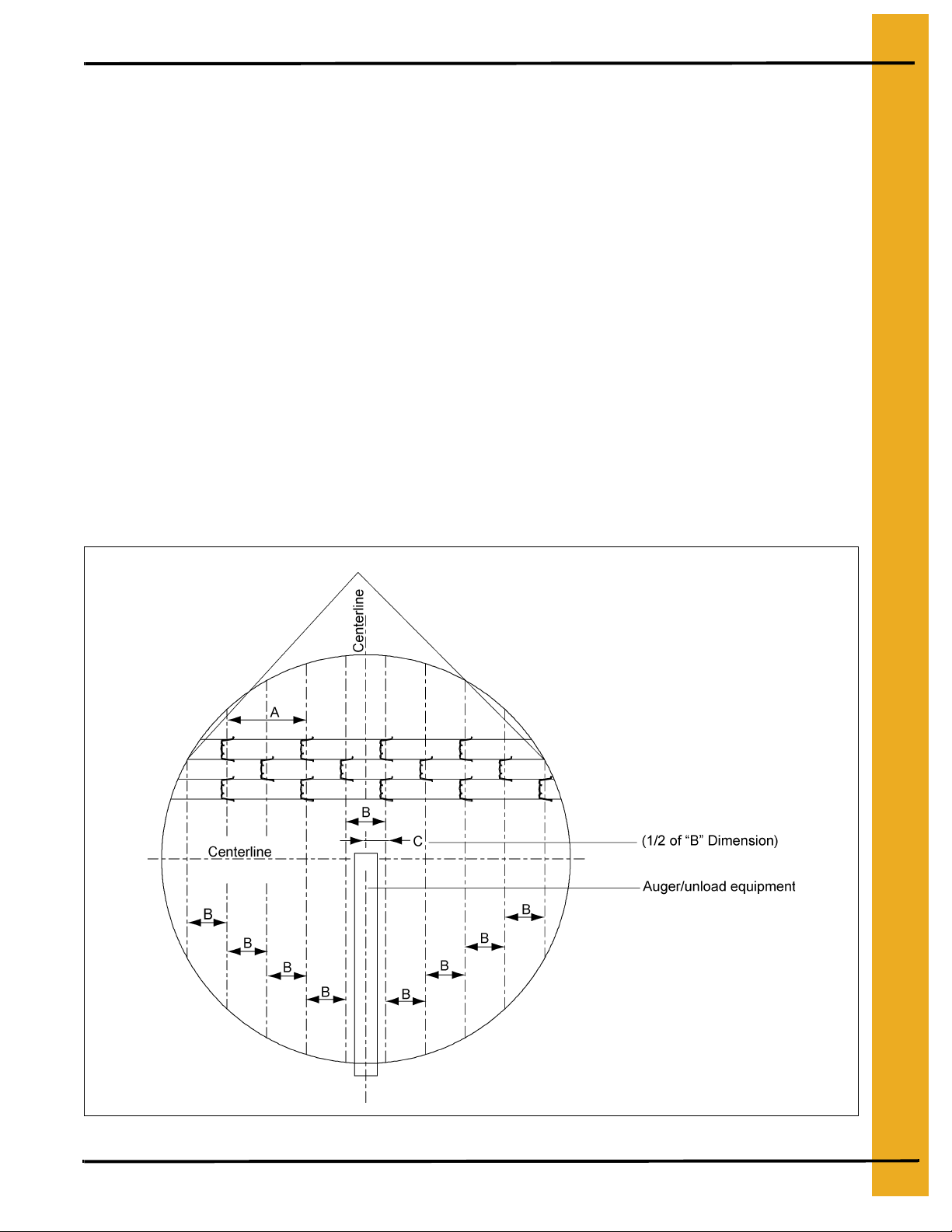

Grain Systems Recommended Method for Full Floor Installation

Using the GSI recommended method for full floor installation should save construction time and

eliminate the problem of improper installation which could invalidate your warranty. Note the following

dimensions as shown in Figure 2B.

• Dimension “A” is the leg-to-leg spacing along the centerline of a given plank.

• Dimension “B” is the amount of stagger between supports under adjacent planks

and is half of Dimension “A”.

• Dimension “C” is the distance from the center of the unload auger to the nearest rows of

supports and is half of Dimension “B”.

Dimensions “A”, “B” and “C” are shown on the appropriate grandstand layout for wall heights under

32 feet. For taller bins, grandstand quantity as well as dimensions “A” and “B” are given on Page 27 and

Page 28 for 20 gauge.

1. Layout centerlines of tank. Make sure one centerline is in line with the direction of the flooring

planks while the other centerline is perpendicular with the flooring planks. See Figure 2B.

2. From the centerline that is perpendicular to the flooring planks, measure the distance of

“C” Dimension and mark a chalk line. See Figure 2B.

3. From the line chalked in the previous step, measure over the distance of “B” Dimension and chalk

another line. Repeat this procedure across the bin until reaching the wall in both directions.

When completed, there should be a set of parallel lines (perpendicular to the floor planks) with

“B” Dimension distance between each line. See Figure 2B.

Chalked lines referred to Ste p 2

Figure 2B

PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring 9

2. Recommended Method for Full Floor Installation

IMPORTANT: First pie ce of floori ng must start at

the proper distance from centerline of bin. Refer to

floor layout on Page 14. First piece may need to be

trimmed for length to fit at the proper location.

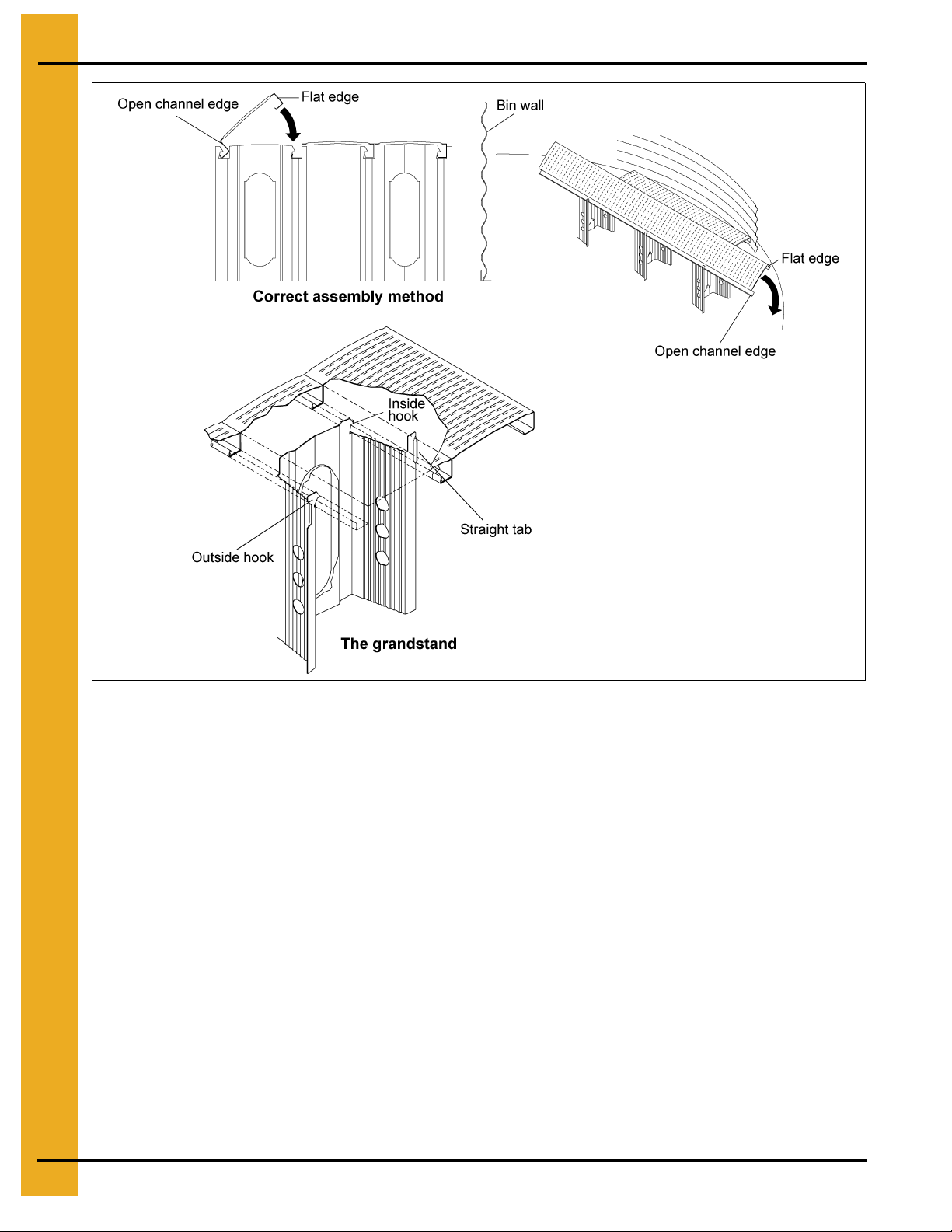

Figure 2C

4. Install flooring starting at the bin wall on the opposite side of the unload auger. Floor planks should

be placed perpendicular to the unload auger with the outside edge the correct distance from the

center of the bin.

(See Figure 6A on Page 14.)

bin wall and the open channel edge is facing tow ards the center of the bin.

Be sure the flat edge of the floor plank is facing the

(See Figure 2C.)

Position

the supports for the first/shortest floor plank according to the number of bin rings and corrugatio n as

shown in the illustrations

on Pages 21-26

flashing to flooring and bin w a ll to hold plank in place. (

or stated in the charts on

See Page 12

on Pages 27-28

. Attach the

for flashing installation.)

5. POSITION THE NEXT ROW OF SUPPORTS ACCORDING TO THE CHALK LINES and support

layout. The straight tab should “snap” under the first (previous) floor piece. After the supports in the

row are correctly positioned, install the next floor piece by hooking the open channel edge under

the outside hooks of the floor supports. Push down sharply on the edge of the floor piece until it

snaps into the previous floor piece. (See Figure 2C.) Continue this process for the rest of th e floor

cutting planks for center and intermediate wells as needed. See Figure 5A on Page 13 for center

well support locations.

NOTE: Whenever there is more than Dimension B divided by three inches (B/3") of plank unsupported

beside the bin wall, there should be a support on that plank or a support on each of the

planks adjacent to it such that no more than Dimension B divided by three inches (B/3") is

unsupported. For example: 2.66" bin with 8 rings has a “B” dimension of 22". Take 22"/3" = 7.33"

(Round to 7"). Therefore, there should be no more than 7" of unsupported floor plank.

10 PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring

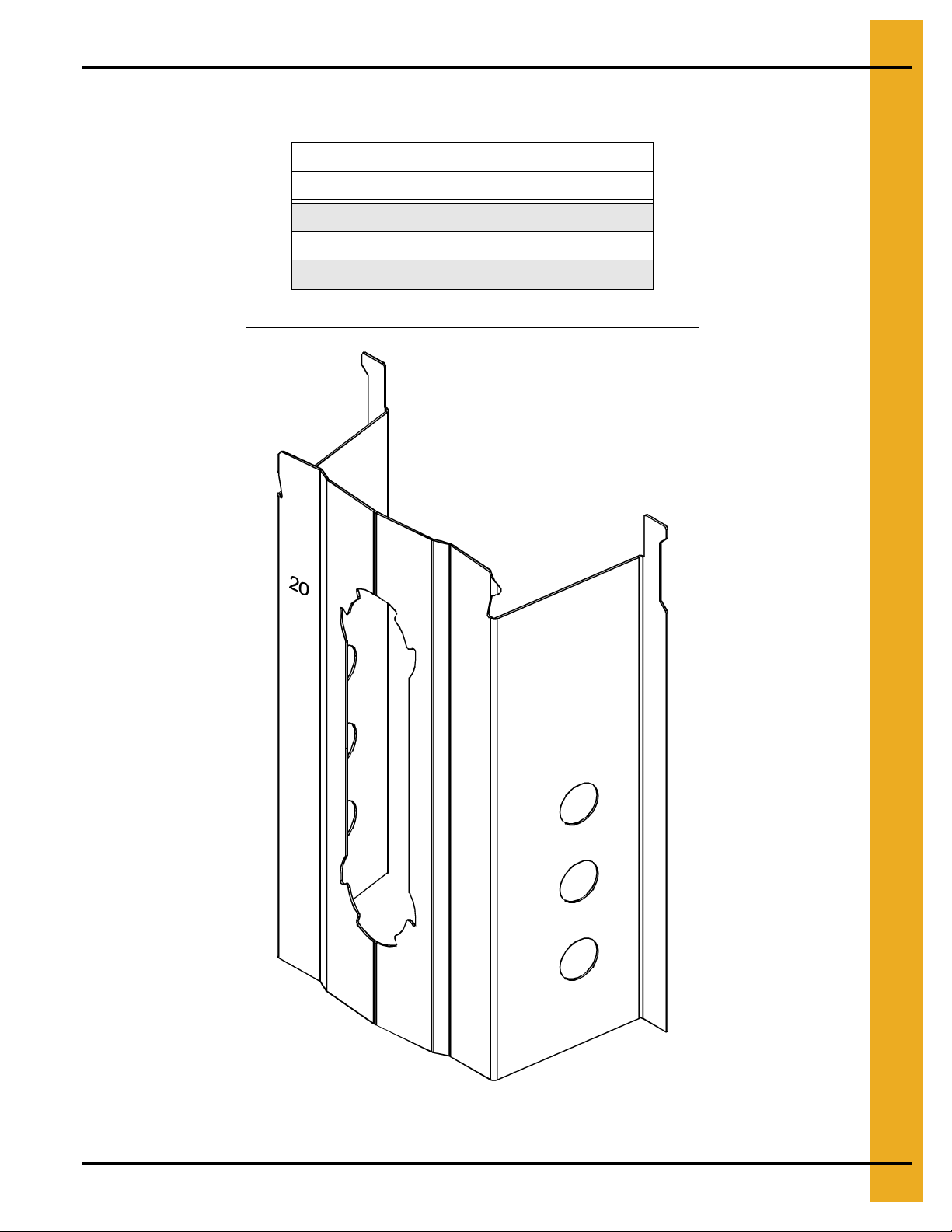

20 Gauge Grandstand Identification

20 Gauge

Plenum Clearance Grandstand Color Code

11-7/8" Blue

14-3/8" White

17-3/16" Yellow

3. Grandstand Identification

Figure 3A

PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring 11

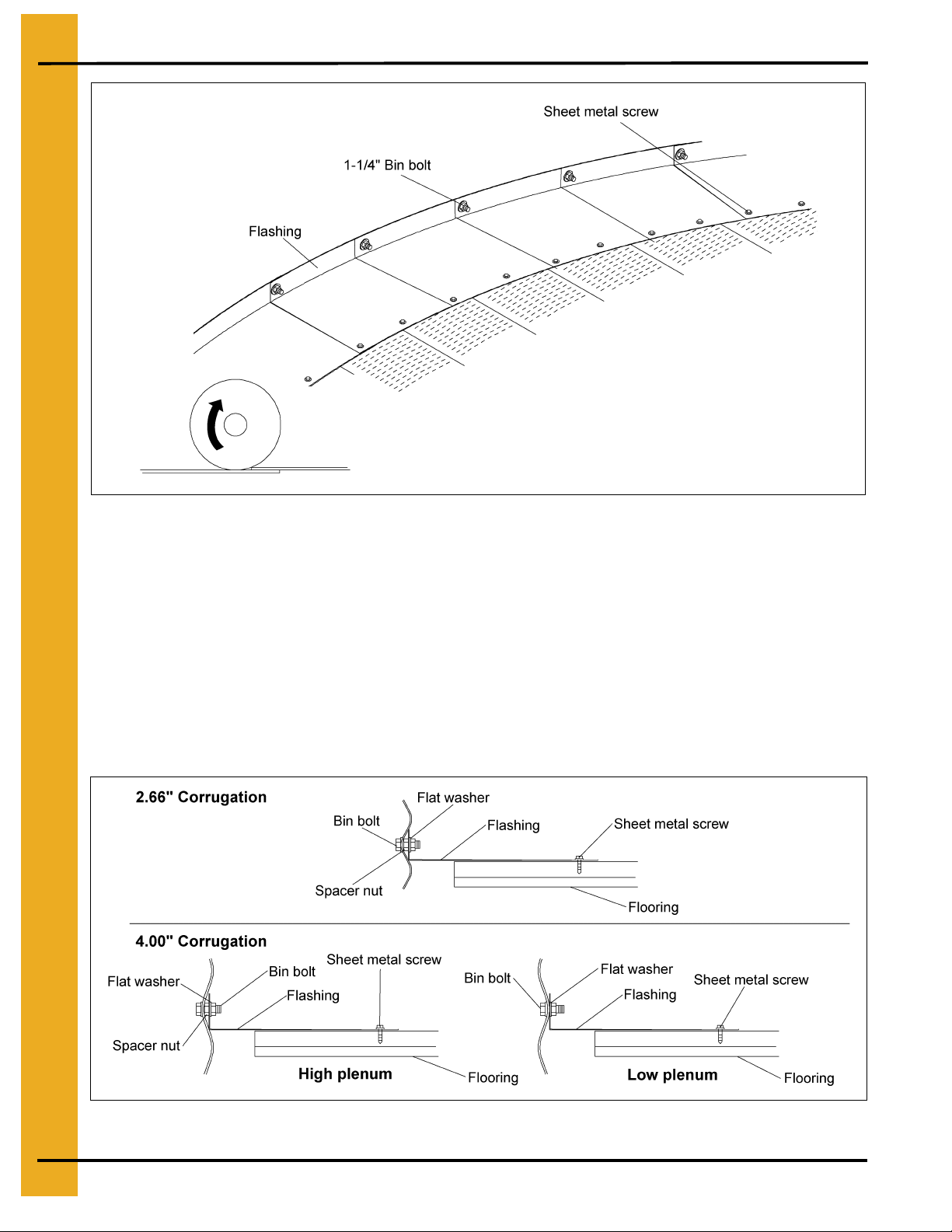

4. Flashing Installation

Figure 4A

Grain Systems Formed Flashing Installation

If a bin sweep auger will be used, overlap flashing so that the sweep with climb up on to the next flashing

section when rotating (usually clockwise). (See Figure 4A.) This will prevent the rotating/slipping outer

wheel of the sweep from catching on the flashing edges. (All GSI power sweeps and carry-in sweeps

manufactured after April 2002 run clockwise.)

After floor is in place, place 1-1/4" bolts through pre-punched holes in sidewall. Bolt heads should be on

outside of bin. See Figure 4B to determine the correct sequence for placing the nuts and washers. Finger

tighten the nuts until all flashing is installed, then go back and fully tig hten. While holding the flashing flat

and pushing in towards the bin wall, fasten the flashing to the floor with two sheet metal screws.

Figure 4B

12 PNEG-214 12'-18' Cor-Lok and Cut-Lok Flooring

Loading...

Loading...