GSI Outdoors PNEG-1153 User Manual

CALC-U-DRI

MOISTURE/MATIC/MANAGER

Owner’s Manual

PNEG-1153

Date: 03-20-07

PNEG-1153

2 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

Table of Contents

Contents

Chapter 1 Introduction ....................................................................................................................... 4

Chapter 2 Safety .................................................................................................................................. 5

Operator Qualifications ....................................................................................................... 5

Chapter 3 Safety Decals ..................................................................................................................... 6

Chapter 4 Installation ......................................................................................................................... 7

Sensor Location and Cutout Instructions ............................................................................ 7

Moisture/Matic Electrical Box and Sensor Installation Instructions ................................... 14

Chapter 5 Start-Up and Operation ................................................................................................... 18

Chapter 6 Printer Installation (Optional) ......................................................................................... 21

Service for Modular Printer Assembly ............................................................................... 24

Chapter 7 Wiring Diagrams .............................................................................................................. 25

Wiring Diagram for Moisture/Matic .................................................................................... 25

Wiring Diagram for Moisture/Matic Printer ........................................................................ 26

Chapter 8 Parts List .......................................................................................................................... 27

Moisture/Matic/Manager Module Subassembly ................................................................ 28

Moisture/Matic/Manager Control Box (Plain) .................................................................... 30

Moisture/Matic/Manager Control Box (Printer) .................................................................. 32

Printer Module Subassembly ............................................................................................ 34

Calc-U-Dri Moisture/Matic/Manager Parts ........................................................................ 36

Chapter 9 Troubleshooting Guide ................................................................................................... 38

Chapter 10 Wiring Examples ........................................................................................................... 40

Chapter 11 Warranty ......................................................................................................................... 45

PNEG-1153 CALC-U-DRI Moisture/Matic/Manager 3

1. INTRODUCTION

DMC’s Calc-U-Dri Moisture/Matic is a grain drying control specifically designed for continuous

flow, out-of-bin grain dryers with an SCR control and a DC motor on the metering rolls.

The Calc-U-Dri Moisture/Matic will automatically increase or decrease the speed of the metering

rolls to maintain a desired moisture content. The Moisture/Matic is available as a base unit or

with an optional chart recorder or printer for convenient record keeping.

The metering roll speed control potentiometer in the dryer control panel is replaced by the main

speed control in the Moisture/Matic. A DC voltmeter is provided to indicate the voltage applied

to the metering roll motor, which will change from fast, medium or slow. The speed is selected

by comparing the actual moisture of the grain being discharged from the dryer to the moisture

Set Point.

As the grain moisture increases, the Moisture/Matic will slow the metering rolls down. The slower

grain movement will increase the time the grain spends in the dryer, which will reduce the

moisture. As the moisture nears the moisture Set Point the unit will switch from slow to main

speed. As long as the grain moisture is at or near the Set Point the main speed is retained.

Should the moisture start to get dryer, the unit will switch to high speed. The three speeds are

adjustable to match the dryer to the grain that is being dried.

4 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

A

E

2

.

S

T

F

CAUTION

SAFETY INFORMATION PLEASE READ.

WATCH FOR THIS SYMBOL!

IT POINTS OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS ATTENTION - “BECOME ALERT! YOUR SAFETY IS INVOLVED!”

It is recommended that you review the entire contents of this manual, paying particular attention

to items preceded by this symbol.

FAILURE TO HEED THESE INSTRUCTIONS

CAN RESULT IN PERSONAL INJURY!

Y

Operator Qualifications

Operation of this farmstead equipment shall be limited to competent and experienced persons.

In addition, anyone who will operate or work around power equipment must use good common

sense. In order to be qualified, he must also know and meet all other requirements, such as:

1. Some regulations specify that no one under the age of 16 may operate power machinery.

This includes farmstead equipment. It is your responsibility to know what these regulations

are in your own area or situation.

2. Current O.S.H.A. regulations state in part: “At the time of initial assignment and at least

annually thereafter, the employer shall instruct every employee in the safe operation and

servicing of all equipment with which the employee is, or will be involved”.*

3. Unqualified persons are to stay out of the work area. The “Work Area” is defined as any

area within the grain drying and storage complex where this equipment is installed.

4. A person who has not read and understood all operating and safety instructions is not

qualified to operate the machine.

*Federal Occupational Safety & Health Standards for Agriculture Subpart D, Section 1928.57 (a) (6).

PNEG-1153 CALC-U-DRI Moisture/Matic/Manager 5

3. SAFETY DECALS

BE A SAFE OPERATOR

1. Read and understand the Owner’s Manual.

2. Disconnect all electrical power before servicing or opening control box, adjusting or

lubricating the equipment.

3. All electrical hook-ups should be in accordance to the National Electrical Code.

4. Ground all electrical equipment as well as bin itself.

5. Only knowledgeable and trained personnel should operate this equipment.

6. NEVER WORK WITH BELTS OR AUGERS WITH POWER “ON”...

automatic controls may start without warning! Stay clear of motors, belts and augers.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE.

THE DECAL SHOWN ON THIS PAGE MUST BE DISPLAYED AS SHOWN

REPLACEMENTS ARE AVAILABLE UPON REQUEST

Note:

1.The decal on this page is NOT actual size.

2. Keep all decals wiped clean at all times.

3. All decals must be replaced if they are

destroyed, missing, painted over, or can no

longer be read.

Contact:

WRITE TO: DMC

1600 12th street N.E

MASON CITY, IA, USA 50401

OR CALL: 641-423-6182

DMC Part Number: 801L010

6 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

T

4

L

A

L

S

.

T

I

N

A

I

Sensor Location and Cutout Instructions

Sensor Location

Locations for sensor installation are dependent on the following factors all being present for

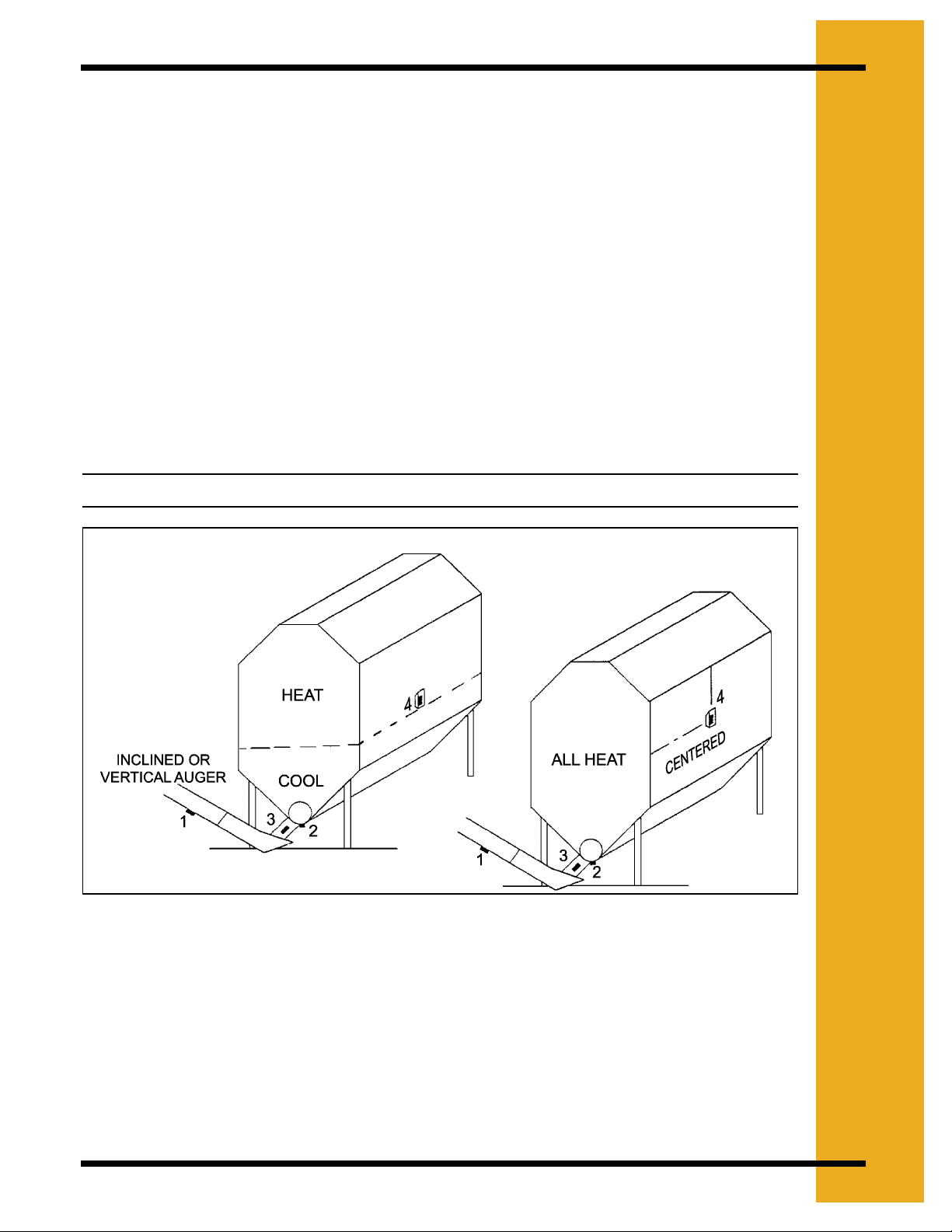

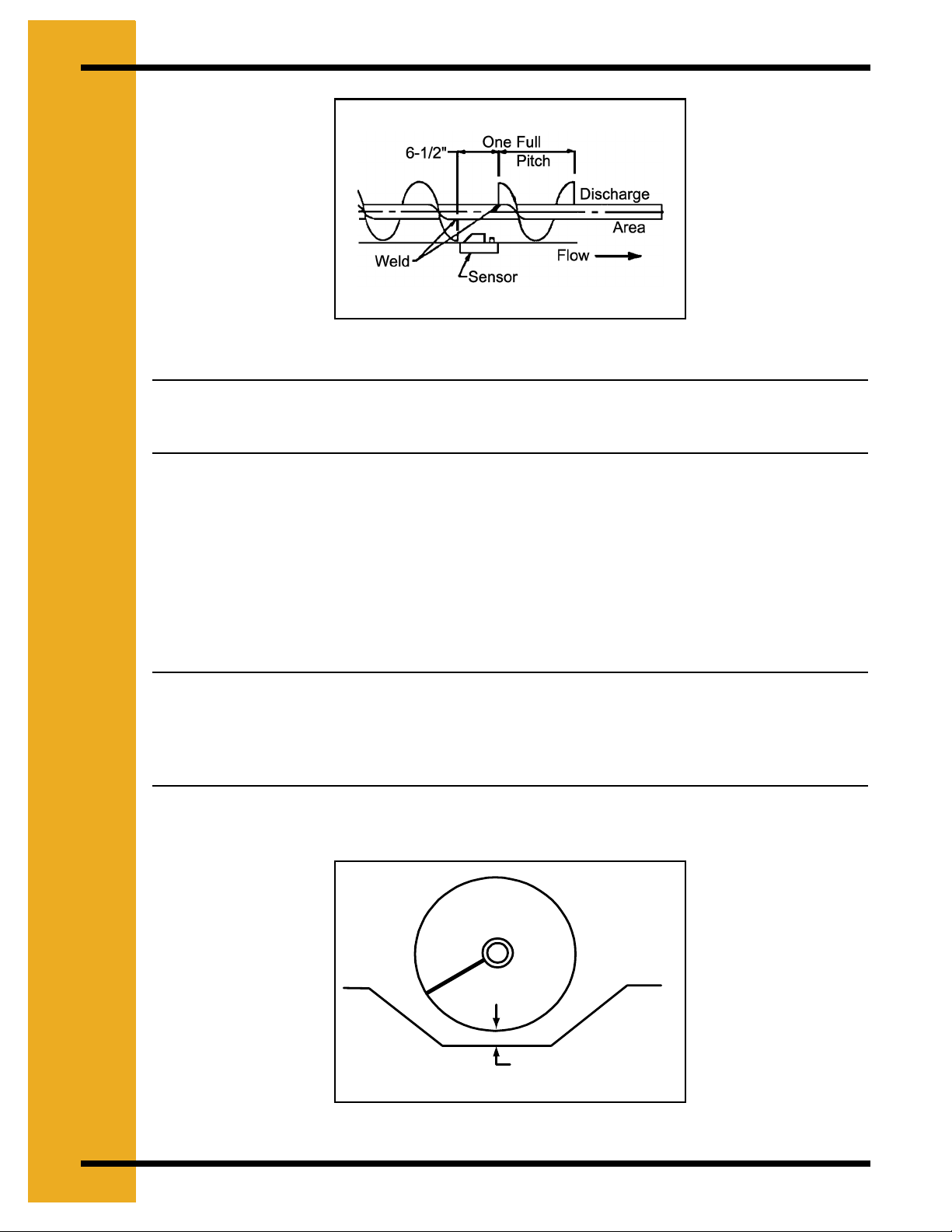

proper operation. (See Figure 4A).

1. Installation in a six (6) or eight (8)" diameter auger or a flat bottom pan.

2. The auger can be horizontal, vertical or inclined. It is recommended that the clearance

between the flighting and the tube be 5/8" or less.

3. The auger must have a minimum of 225 bushels per hour flow rate of grain across the

sensor.

4. The auger must have one full pitch of flight before and after the sensor.

5. Avoid placing the sensor in a location that will be affected by condensation.

Note: If help is needed for sensor location, contact your DMC dealer.

O

N

Continuous Flow Dryers - Moisture/Matic Calc-U-Dri

Figure 4A Control Sensor Location - Order of Preference

a. Take-away auger.

b. Discharge auger - 1 full pitch of flighting before and after flighting. Flighting to tube

clearance less than 5/8". Condensation from dryer may affect sensor.

c. Discharge spout - Use a funnel-type of restrictor.

d. Column - Column sensor is usually in the lowest part of the heating section or in the

highest part of the cooling section (centered if all heat). There must be no restriction in

air flow near the sensor. Use column sensor bracket #602N175.

PNEG-1153 CALC-U-DRI Moisture/Matic/Manager 7

4. INSTALLATION

Sensor Cutout Instructions

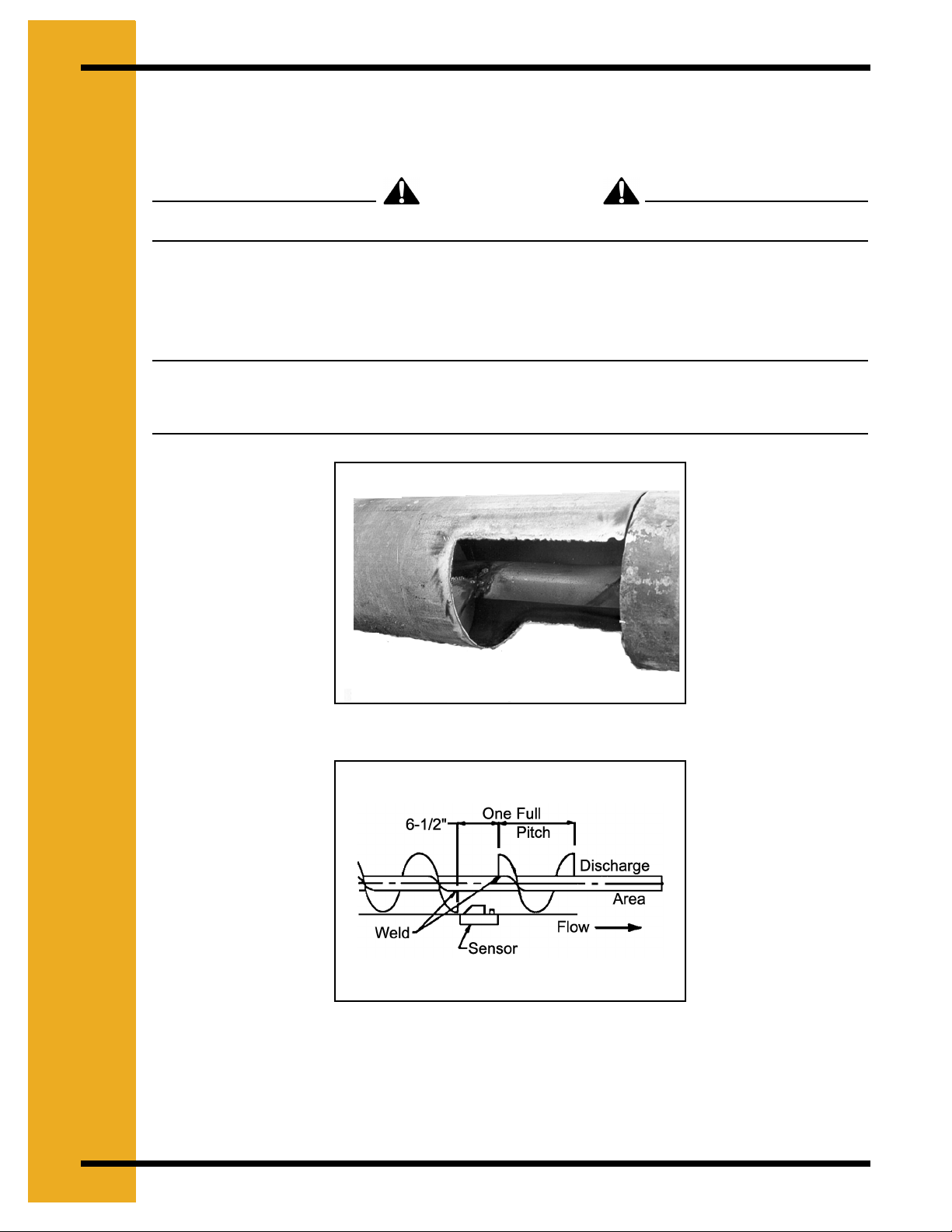

Sensor Cut-Out Instructions for Six (6)" and Eight (8)" Augers

CAUTION

DISCONNECT POWER TO THE AUGER MOTOR BEFORE PROCEEDING ANY FURTHER!

1. Look at the discharge tube and determine where the sensor can be located.

(See Figure 4C). There must be at least one (1) full pitch of flighting on the discharge auger

before and after the sensor to move the grain over the sensor blade.

Note: If the unit has a connecting band, determine if it can be removed and replaced with

a 12" long connecting band. If it is a structural supporting connecting band,

additional support may be needed during removal of the connecting band.

Figure 4B

Figure 4C

8 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

4. INSTALLATION

2. Position the sensor connecting band on the discharge tube so that the rectangular hole is

toward the discharge end. Mark the outline of the rectangular hole and the edges of the

band on the discharge auger tube. Cut a hole in the discharge tube eight (8)" long so the

outline of the rectangular hole is removed (stay inside the total overall length marks of the

band). Cut up one side of the discharge tube about one third (1/3) of the way around the

tube. This extra room is for ease of removing flighting in the next step. (See Figure 4B).

3. Replace the connecting band on the discharge tube in the same position as in Step 2

(above) and mark the flighting at each end of the rectangular hole. Weld the discharge

auger flighting to the shaft 3/8" beyond each of the marks. After the flight is welded at these

points, cut out six and one half (6-1/2)" of the flighting all the way to the center shaft.

4. Smooth all the rough edges from the cut area and position the sensor hole centered over

the six and one half (6-1/2)" area, then tighten the connecting band.

5. Before installing the sensor, see Sensor Installation page 14.

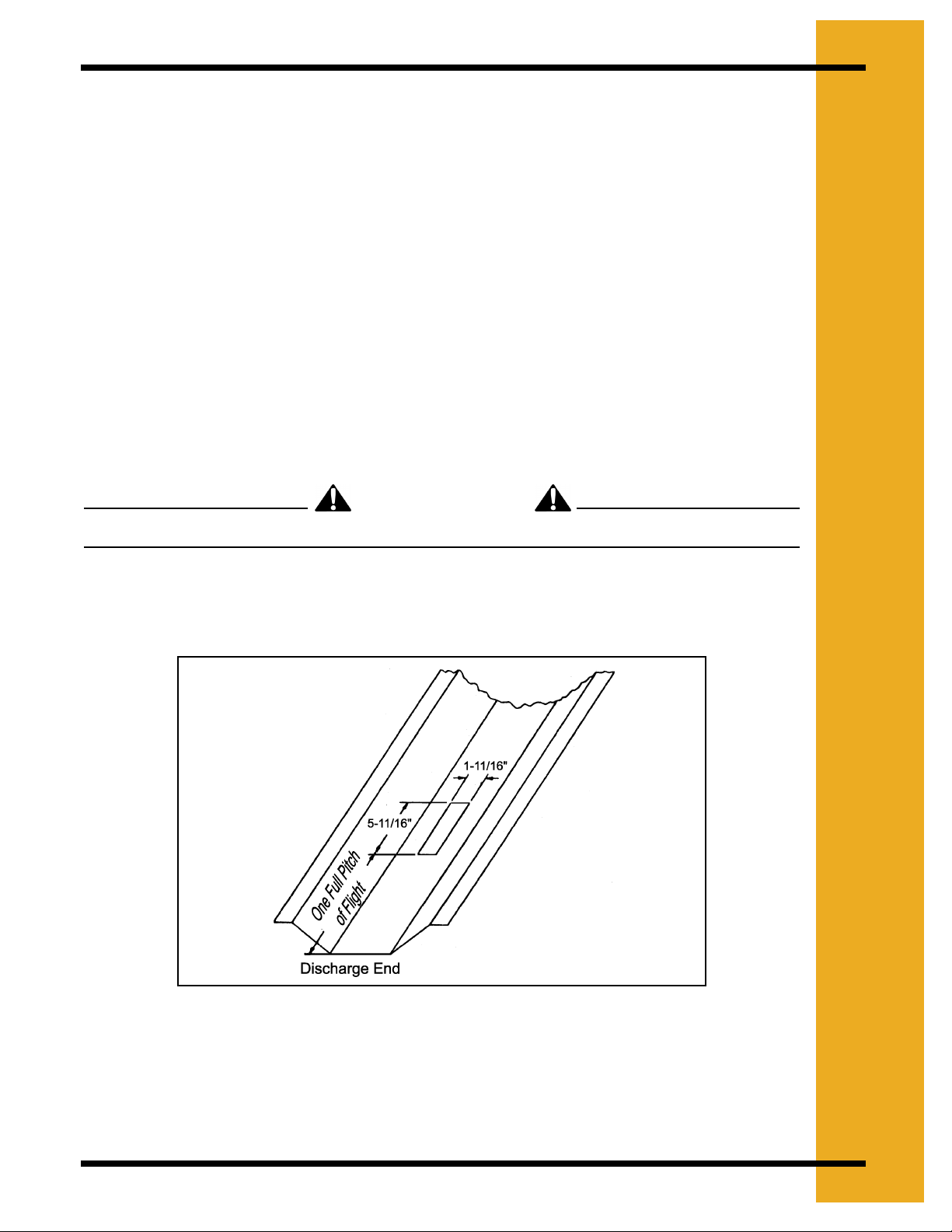

Sensor Cut-Out for Flat Bottom Discharge Units

CAUTION

DISCONNECT POWER TO THE AUGER MOTOR BEFORE PROCEEDING ANY FURTHER!

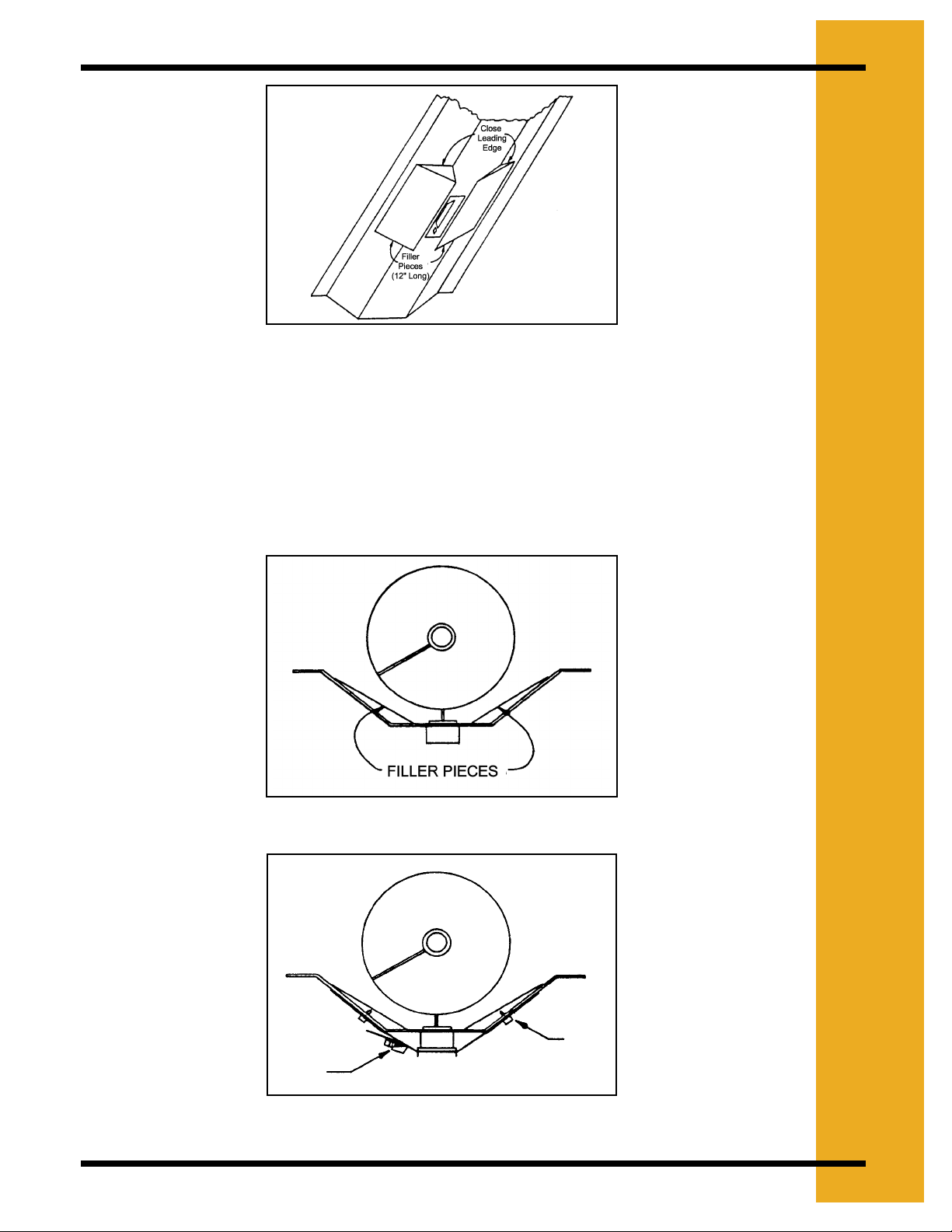

1. Determine where the sensor can be located. (See Figure 4D). There must be at least one

full pitch of flight before and after the sensor. (See Figure 4E).

Figure 4D

PNEG-1153 CALC-U-DRI Moisture/Matic/Manager 9

4. INSTALLATION

(Do not use

5/8")

Figure 4E

Note: If there is more than 5/8" gap between the bottom pan and the outer edge of the

flighting, do not use a sensor in that location. Use another location, such as a

take-away auger. (See Figure 4F).

2. Remove the flat bottom pan and mark the sensor cutout area at least one (1) pitch length

of the auger from the discharge area. This allows for good pickup of the grain when it leaves

the sensing area. Cut the sensor rectangle 1-11/16" x 5-11/16" with a saber saw (do not

torch cut) and check so the sensor block fits into it with the stepped edge. (See Figure 4D).

3. Hold the pan up to the unit and mark the flighting where the sensor hole is located. Remove

the pan and mark the flighting about 3/8" away from marks just made, so the new marks

are six and one half (6-1/2)" apart.

Note: For seven (7)" flight or less, cut the flight to the shaft. Weld the auger flight to the

shaft at each end of the six and one half (6-1/2)" cutout marks, then cut out the six

and one half (6-1/2)" of flighting from the auger, leaving only the drive tube. For eight

(8)" or larger diameter flighting, one-half (1/2)" of flighting can be left as a ribbon

around the shaft in the cutout area. (See Figure 4E).

4. Smooth all the rough edges from the cutout area.

5/8" Max. Clearance

if over

Figure 4F

10 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

4. INSTALLATION

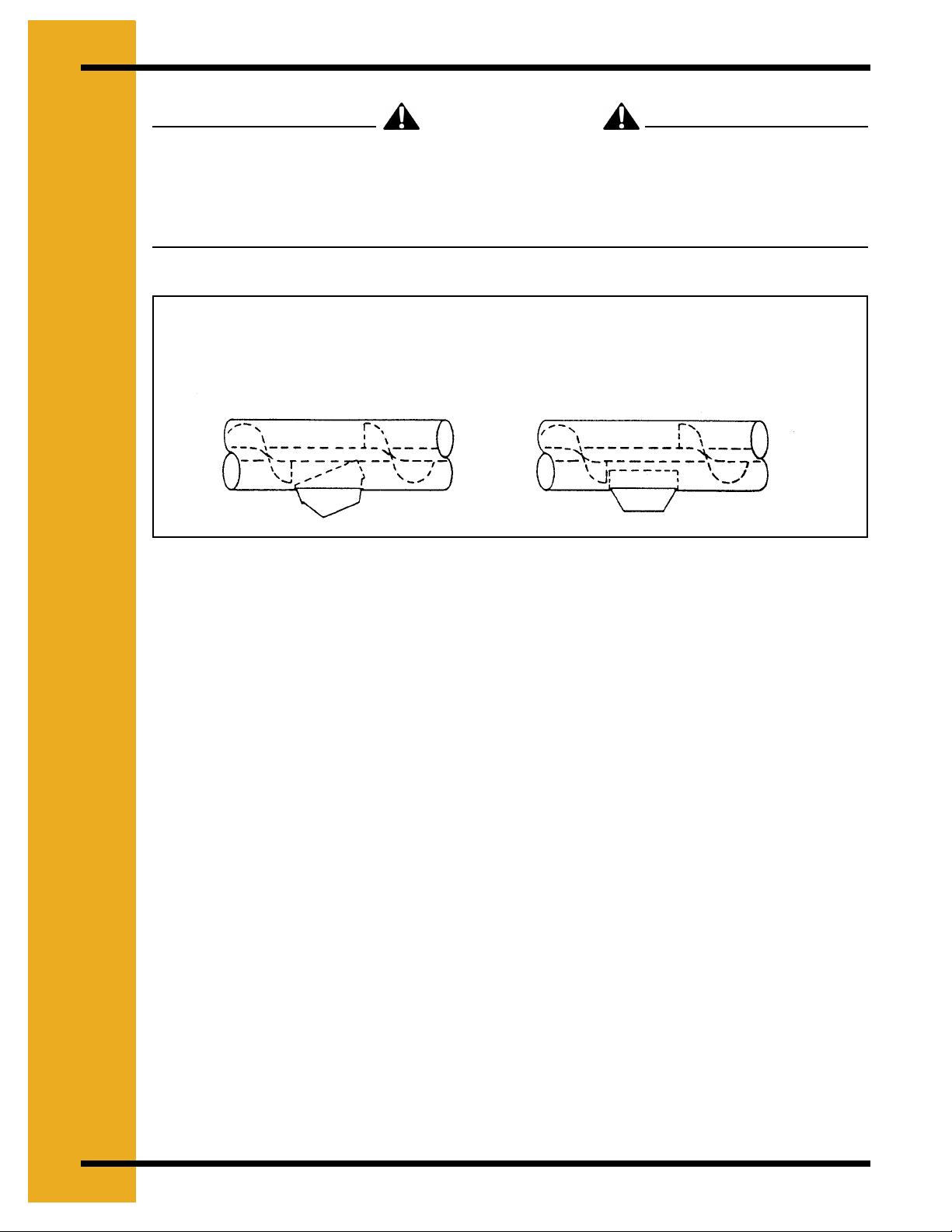

Figure 4G

5. On the flat bottom pan, make some filler pieces 12" long to keep the grain closer to the

sensor flag. See Figure 4G, See Figure 4H, and See Figure 4I. Be sure the leading edge

is closed so grain cannot get under the pieces. Weld the pieces in place as shown.

(See Figure 4G).

6. Remount the pan and check all the clearances and alignments. Before installing the sensor,

insert the clearance gauge into the cutout. (See Figure 4J).

Figure 4H

Figure 4I

PNEG-1153 CALC-U-DRI Moisture/Matic/Manager 11

4. INSTALLATION

CAUTION

SLOWLY ROTATE THE AUGER BY HAND ONE COMPLETE REVOLUTION. THE

FLIGHTING MUST MISS THE GAUGE COMPLETELY AND NOT RUB ON THE FILLER

PIECES. IF THERE ARE AREAS OF BINDING OR HITTING, CORRECT THE SITUATION

NOW.

!! DISCONNECT POWER !!

HOW TO INSERT GAUGE GAUGE AND FLIGHT PROPERLY INSTALLED

Figure 4J

7. Securing the sensor to the flat pan will require modified clamps. Cut the end off the clamp

and mount it with a self-drilling screw to the tapered side so the screw tip goes under the

filler pieces added earlier. Attach the screw end of the clamp or the other side with a

self-drilling screw. Have the length such that the screw is beside the sensor as show in

Figure 4I.

8. When installing the sensor, follow the instructions on the sensor decal for the correct

direction of grain movement.

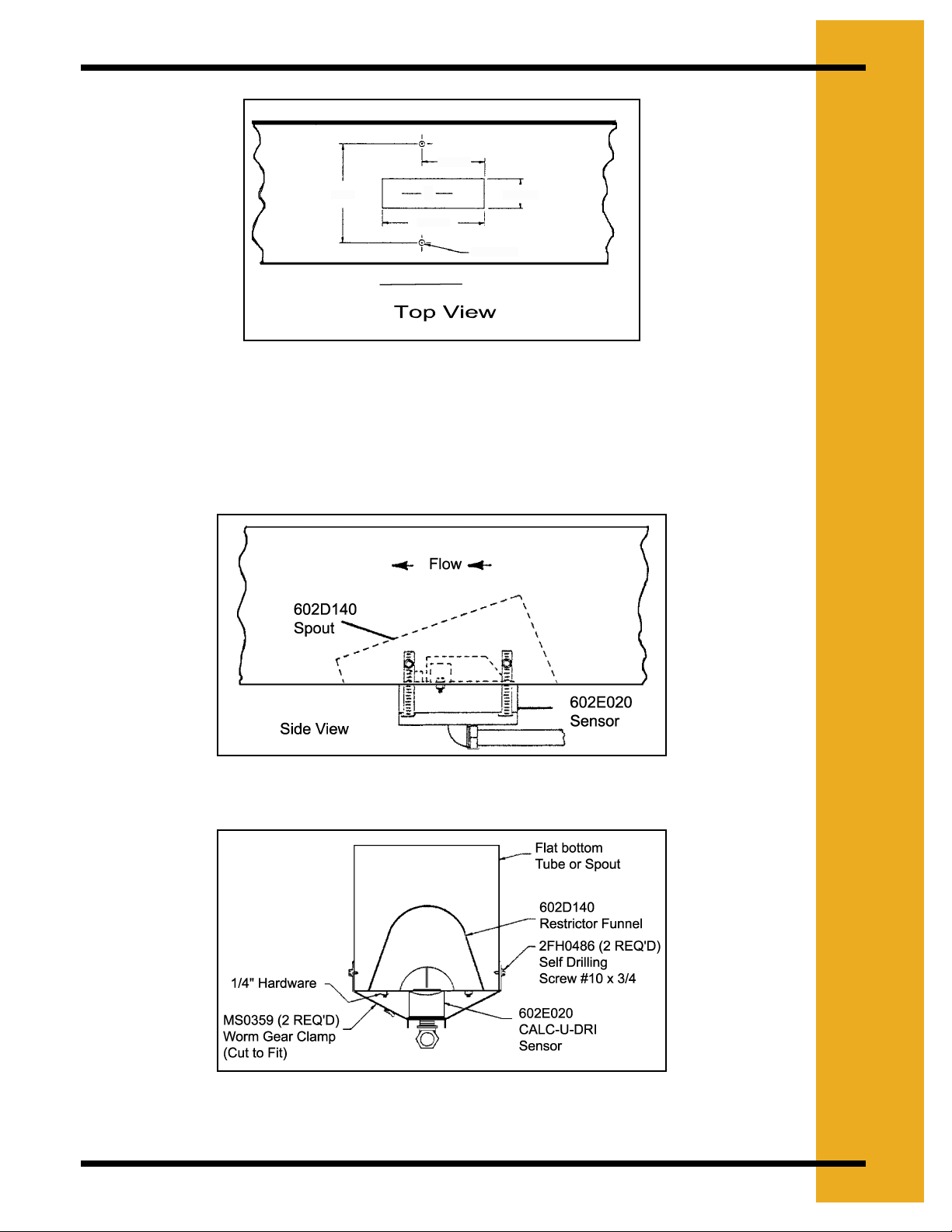

Sensor Cut-Out for Flat Bottom Down Spout

1. When using a down spout, there must be a constant density of grain flowing over the sensor

for accurate readings. This flow must be independent of the total flow or velocity of the

stream of grain. To do this, the installation of the restrictor spout or flats angled to create a

funnel is recommended.

The sensor should be located in an accessible location, so it can be periodically inspected

for trash buildup.

2. Cut a hole in the bottom of the spout (1-11/16" x 5-11/16") and drill two 5/16" diameter holes

3-1/2" toward the discharge end and 5-1/2" apart as shown in Figure 4K. Use a saber saw

for the hole, not a torch. Remove burrs and check so the sensor block fits into the stepped

edge.

12 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

4. INSTALLATION

3-1/2

C

5-1/2

HOLE CUT-OUT

L

5-11/16

Figure 4K

3. Secure the restrictor spout to the flat bottom with 1/4" hardware. Secure the sensor by

cutting the end off of the strap and mounting with a self-drilling screw to the edge of the flat

spout. Attach the screw end of the clamp on the other side of the flat spout with a

self-drilling screw. (See Figure 4L). and (See Figure 4M).

1-11/16

5/16 DIAM

Figure 4L

Figure 4M

PNEG-1153 CALC-U-DRI Moisture/Matic/Manager 13

4. INSTALLATION

4. For conditions where straw or chaff can accumulate in the restrictor funnel, the grain can

be channeled over the sensor with angled brackets in the down spout. (See Figure 4N).

Figure 4N

Sensor Cut-Out for Round Down Spouts

1. When using a sensor in a down spout, there must be a CONSTANT density of grain flowing

over the sensor for accurate readings. This flow must be independent of the flow or velocity

of the grain stream. It is recommended that a restrictor be used to slow the grain speed over

the sensor such as used in Step . A modified open top version may have to be used.

Moisture/Matic Electrical Box and Sensor Installation Instructions

1. The Calc-U-Dri Moisture/Matic can be near the unit’s main control box, discharge auger, or

other locations that are easily accessible and of convenient height for you to observe and

use. Mount the electrical box using four (4) 5/16" x 1-1/2" bolts, lock washers and nuts.

2. Included with the Calc-U-Dri Moisture/Matic are 27 feet of one-half (1/2)" liquidtite conduit.

This is to be used to protect the sensor wire between the Calc-U-Dri Moisture/Matic box

and the sensor.

3. A 4 x 4 junction box, sensor wire, and liquidtite is available to extend the sensor wire up to

250 feet, if required. Determine the shortest distance from the sensor to the junction box.

Use the 27 feet of one-half (1/2)" liquidtite conduit and feed the sensor wire through it using

the connector provided. There should be six (6)" of sensor wire inside the junction box. Any

excess wire or conduit may be cut off. Be sure not to cut off too much since both the conduit

and the sensor wire need to be connected at the other end to the Moisture/Matic box.

4. Connect the Calc-U-Dri sensor wires in the 4 x 4 junction box to the top of the terminal strip.

The leads from the Moisture/Matic box go to the bottom of the terminal block. Be careful to

match the color coded wires to each other - red to red, etc., (See Figure 4O). Then attach

the junction box lid.

14 PNEG-1153 CALC-U-DRI Moisture/Matic/Manager

Loading...

Loading...