GSI Outdoors 2TFC, 2TAF, 2TF User Manual

2000 Autoflow

Control Installation

MODEL # 2TF - __ __ - __ __ __

MODEL # 2TFC- __ __ __ __ __

Series 2000

Autoflow

Fan/Heater

Instructions

MODEL # 2TAF - __ __ __ __

Installation

Manual

PNEG-673

1

1

2000 Autoflow

This equipment shall be installed in accordance iwth the current INSTALLATION CODES

FOR GAS BURNING APPLICANCES AND EQUIPMENT, CAN1_B149.1 and B149.2, or

applicable provincial regulations which should be carefully followed in all cases. Authorities

having jurisdiction shuld be consulted before installations are made.

2

2

2000 Autoflow

Roof W arning, Operation & Safety ................................................................................4

Safety Alert Decals.......................................................................................................5

Safety Precautions........................................................................................................6

Safety Sign-off Sheet...................................................................................................7

Fan/Heater and Control Box Mounting..............................................................................8

Autoflow Control Box Bolt Pattern.................................................................................10

Fill System Control Box Mounting.............................................................................11

Fill System Control Bolt Pattern..................................................................................12

Actuator Control Box Mounting.................................................................................13

Multi-Grain T emperature Sensor Wiring.........................................................................15

Grain T emperature Sensor Mounted to Leveling Band Post........................................16

Close-up of Grain T emperature Sensor Wiring.............................................................17

Plenum T emperature Sensor Installation..........................................................................18

Airswitch Installation.................................................................................................19

W et Supply Rotary Switch..........................................................................................21

Storage Chamber High Limit Rotary Switch Installation...........................................22

Drying Chamber Rotary Switches...............................................................................25

Drying Chamber Low-Level Rotary Switch Installation............................................26

Drying Chamber High-Level Rotary Switch Installation...........................................28

Drying Chamber Overflow Switch Installation.............................................................30

LP Fuel Specifications and Recommendations................................................................32

NG Fuel Specifications and Recommendations...............................................................33

Conduit Runs................................................................................................................34

Electrical Power Supply....................................................................................................35

Figure 12: Ground Rod.....................................................................................................36

Power/Motor Wiring........................................................................................................37

Main Power Schematic.................................................................................................37

Electrical Load Information.............................................................................................38

Wire Size Information................................................................................................39

Fill System Control Box Electrical Load Information.................................................40

Autoflow to Master Fan/Heater Unit Interconnect...........................................................42

Autoflow to Actuator Interconnect.............................................................................43

Autoflow to W et Supply Rotary Switch Interconnect.................................................44

Autoflow to Storage Chamber Rotary Switch Interconnect.......................................45

Autoflow to Drying Chamber Rotary Switches Interconnect..........................................46

Autoflow to Fill System Control Box Interconnect....................................................48

Autoflow to Ground Interconnect.............................................................................. 49

Master to Slave Interconnect......................................................................................50

Slave to Slave Interconnect.........................................................................................51

Battery Hook-Up.........................................................................................................52

Dump Chute Cable Installation...................................................................................53

W arranty .......................................................................................................................55

TABLE OF CONTENTS

3

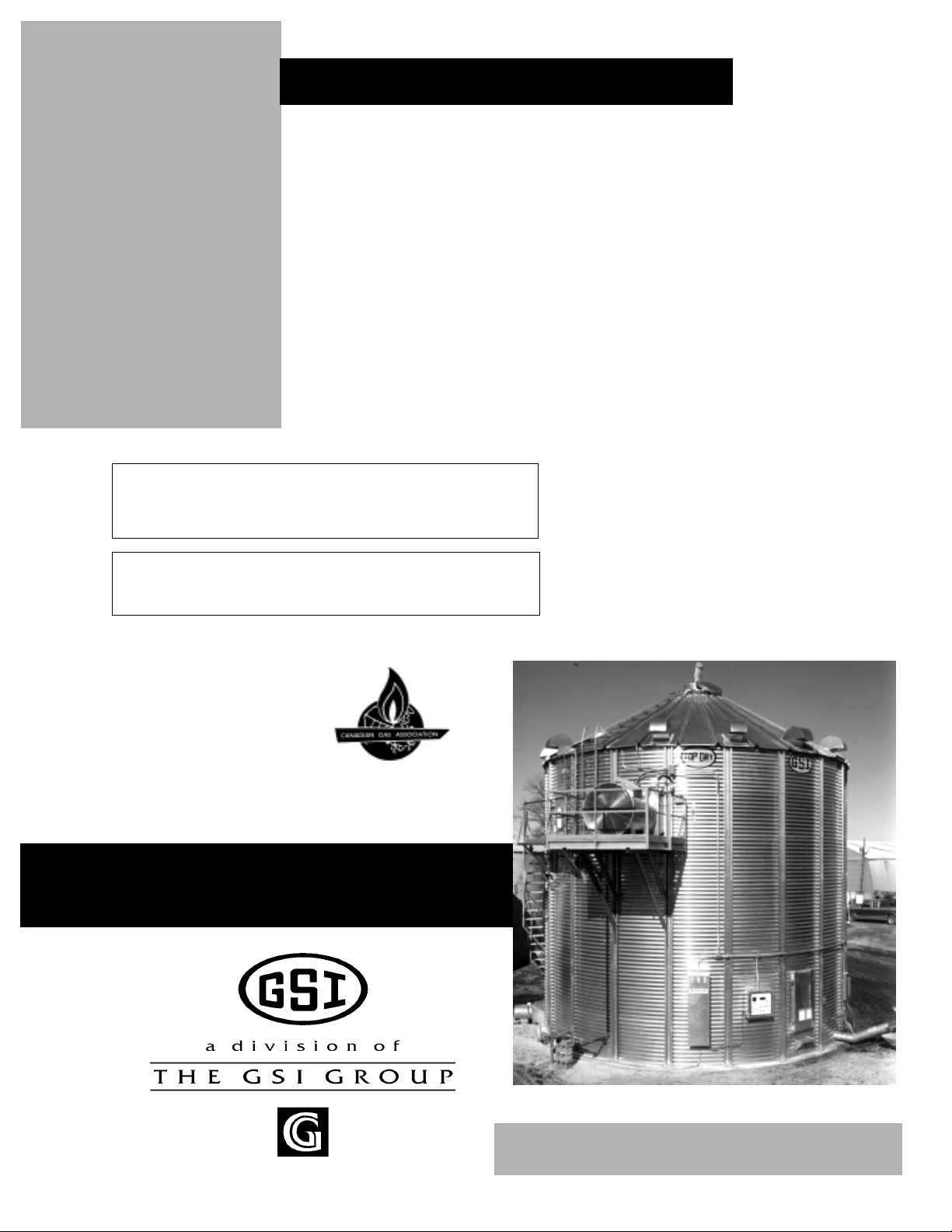

ROOF WARNING, OPERATION & SAFETY

Roof Damage Warning and Disclaimer

GSI DOES NOT WARRANT ANY ROOF DAMAGE

CAUSED BY EXCESSIVE VACUUM OR INTERNAL PRESSURE FROM FANS OR OTHER AIR

MOVING SYSTEMS. ADEQUATE VENTILATION

AND/OR "MAKEUP AIR" DEVICES SHOULD BE

PROVIDED FOR ALL POWERED AIR HANDLING

SYSTEMS. GSI DOES NOT RECOMMEND THE

USE OF DOWNWARD FLOW SYSTEMS (SUCTION). SEVERE ROOF DAMAGE CAN RESULT

FROM ANY BLOCKAGE OF AIR P ASSAGES. RUNNING FANS DURING HIGH HUMIDITY/COLD

WEATHER CONDITIONS CAN CAUSE AIR EXHAUST OR INTAKE PORTS TO FREEZE.

2000 Autoflow

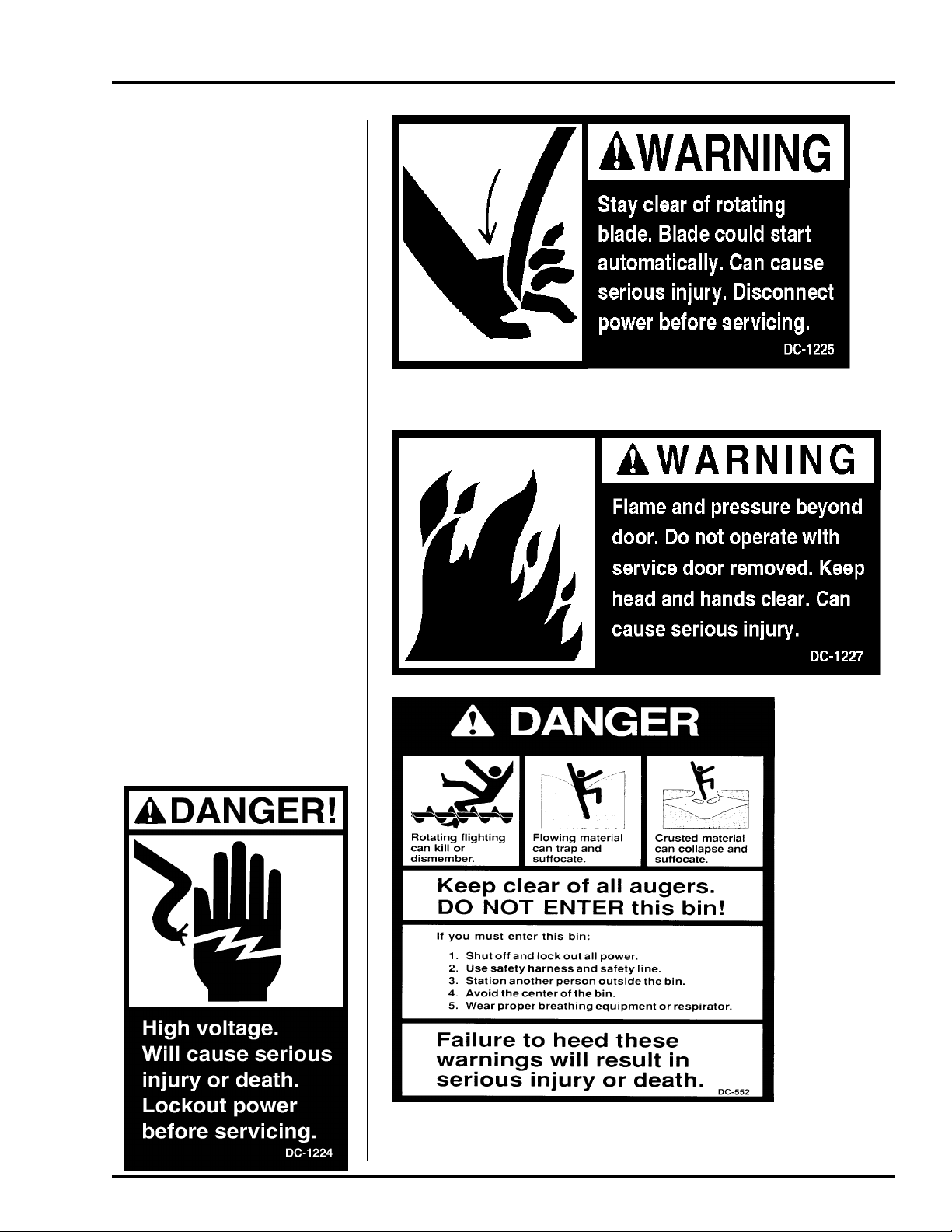

Series 2000 Autoflow Installation & Operating Instructions

Thank you for choosing a Top Dry Series 2000

Autoflow unit. It is designed to give excellent performance and service for many years.

This manual describes the installation for all

standard production T op Dry Series 2000 single fan,

multi-fan and 2000 Series Autoflow units. Different models are available for liquid propane or natural gas fuel supply, with either single phase 230 volt,

or three phase 208, 220, 380, 460 or 575 volt electrical power.

The principal concern of the GSI Group, Inc.

("GSI") is your safety and the safety of others associated with grain handling equipment. This manual

Safety Alert Symbol

The symbol shown is used to call your

attention to instructions concerning

your personal safety. Watch for this

symbol; it points out important safety

precautions. It means "A TTENTION",

"WARNING", "CAUTION", and

"DANGER". Read the message and

be cautious to the possibility of personal injury or death.

is written to help you understand safe operating

procedures, and some of the problems that may be

en-countered by the operator or other

personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist, and to inform all personnel associated with the equipment, or who are in the fan area.

A void any alterations to the equipment. Such alterations may produce a very dangerous situation,

where serious injury or death may occur.

WARNING! BE ALERT!

Personnel operating or working

around electric fans should read this

manual. This manual must be

delivered with the equipment to its

owner. Failure to read this manual

and its safety instructions is a

misuse of the equipment.

4

2000 Autoflow

The GSI Group, Inc. recommends contacting your local

power company, and having a

representative survey your installation so the wiring is compatible with their system, and adequate power is supplied to your

unit.

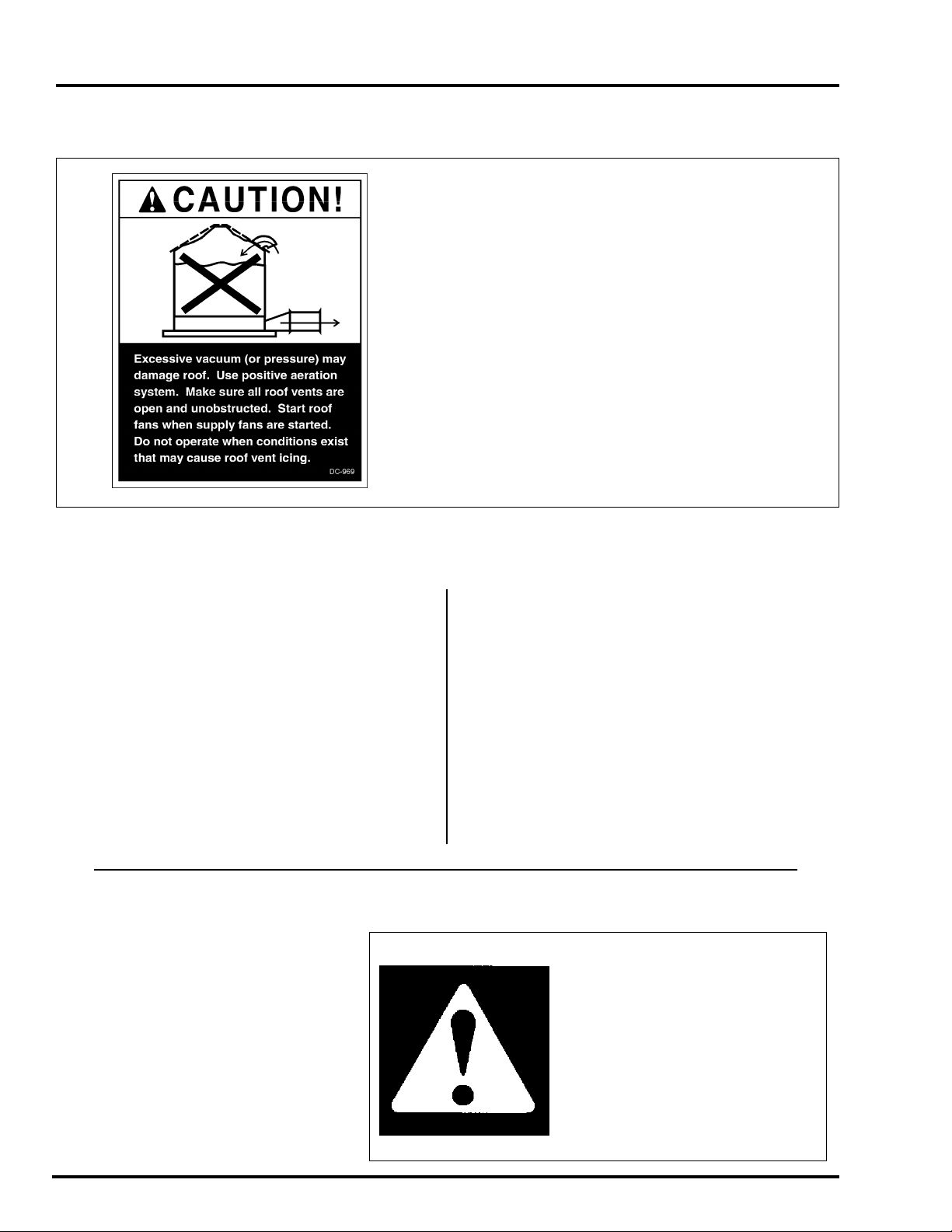

Safety decals should be read

and understood by all people in

the grain handling area. The rotating blade, fire warning decals

and voltage danger decal must be

displayed on the fan can. The

bottom right decal should be

present on the inside bin door

cover of the two ring door, 24"

porthole door cover and the roof

manway cover.

If a decal is damaged or is

missing contact:

The GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to

you.

SAFETY

5

SAFETY PRECAUTIONS

READ THESE INSTRUCTIONS

BEFORE OPERATION AND SERVICE

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the

dryer.

2. Power supply should be OFF for service of electrical components. Use

CAUTION in checking voltage or other procedures requiring power to

be ON.

3. Check for gas leaks at all gas pipe connections. If any leaks are detected, do not operate the dryer. Shut down and repair before further

operation.

4. Never attempt to operate the dryer by jumping or otherwise bypassing

any safety devices on the unit.

5. Set pressure regulator to avoid excessive gas pressure applied to burner

during ignition and when burner is in operation. Do not exceed maximum recommended drying temperature.

6. Keep the dryer clean. Do not allow fine material to accumulate in the

plenum or drying chamber.

2000 Autoflow

Use Caution in the

Operation of this

Equipment

The design and manufacture of this

dryer is directed toward operator

safety. However, the very nature of

a grain dryer having a gas burner,

high voltage electrical equipment

and high speed rotating parts, does

present a hazard to personnel, which

can not be completely safeguarded

against, without interfering with efficient operation and reasonable access to components.

Use extreme caution in working

around high speed fans, gas-fired

heaters, augers and auxiliary conveyors, which may start without

warning when the dryer is operating on automatic control.

7. Use CAUTION in working around high speed fans, gas burners, augers

and auxiliary conveyors which START AUTOMATICALLY.

8. Do not operate in any area where combustible material will be drawn into

the fan.

9. Before attempting to remove and reinstall any propellor, make certain to

read the recommended procedure listed within the servicing section of

the manual.

10. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture.

Proper Use of Product

This product is intended for the use of drying small grains only.

Any other use is a misuse of the product!

This product has sharp edges! These sharp edges may cause serious

injury. To avoid injury handle sharp edges with caution and use proper

protective clothing and equipment at all times.

Guards are removed for illustrati on purposes only . All guards must be

in place before and during operation.

KEEP THE DRYER CLEAN

DO NOT ALLOW FINE

MATERIAL TO ACCUMULATE

IN THE PLENUM CHAMBER

OR SURROUNDING THE

OUTSIDE OF THE DRYER

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable

drying system, follow the recommendations within this manual, and

make it a practice to regularly inspect the operation of the unit for

any developing problems or unsafe

conditions.

Take special note of the safety precautions listed above before attempting to operate the dryer.

6

2000 Autoflow

SAFETY SIGN-OFF SHEET

Date Employer’s Signature Employee

________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________

_______________________________________________________________________________________________________________________

_____________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

Employees working on or around grain drying equipment

must read this manual and sign-off on this sheet.

7

INSTALLATION

2000 Autoflow

Fan and Heater Mounting

1. Inspect the fan platform for proper installation

per instructions in the T op Dry erection manual.

2. Raise the Top Dry fan and heater units to the

platform. Use the table to the right to determine

the height of the platform from the base of the

TopDry unit.

3. Mount the Top Dry fan and heater units to the

bin entrance sheets. Fan legs should set on the

platform.

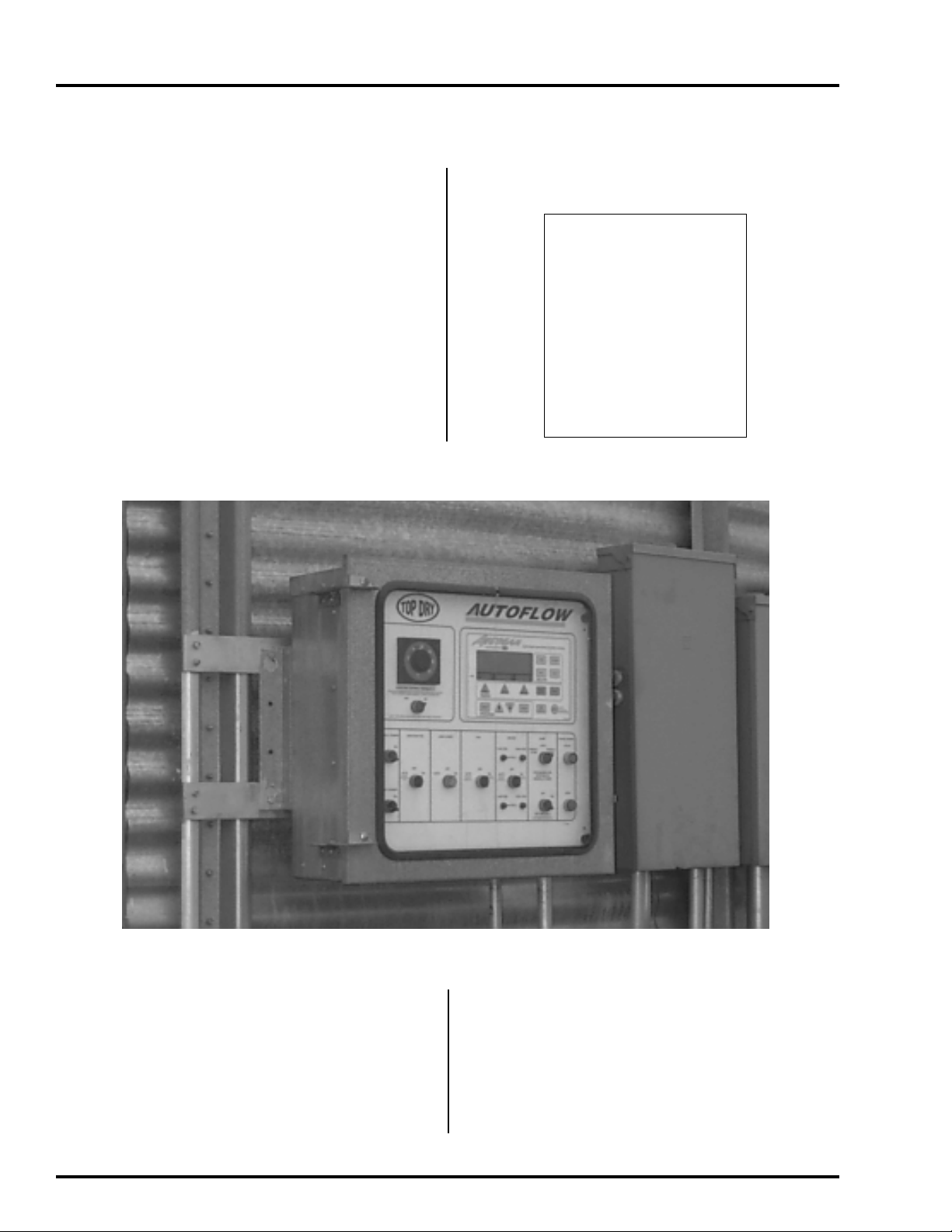

Autoflow Control Box Mounting

Top Dry Bin Eave Height

Number

of Rings

5

6

7

8

9

10

11

Eave

Height

18-5

22-1

25-9

29-5

33-1

36-9

40-5

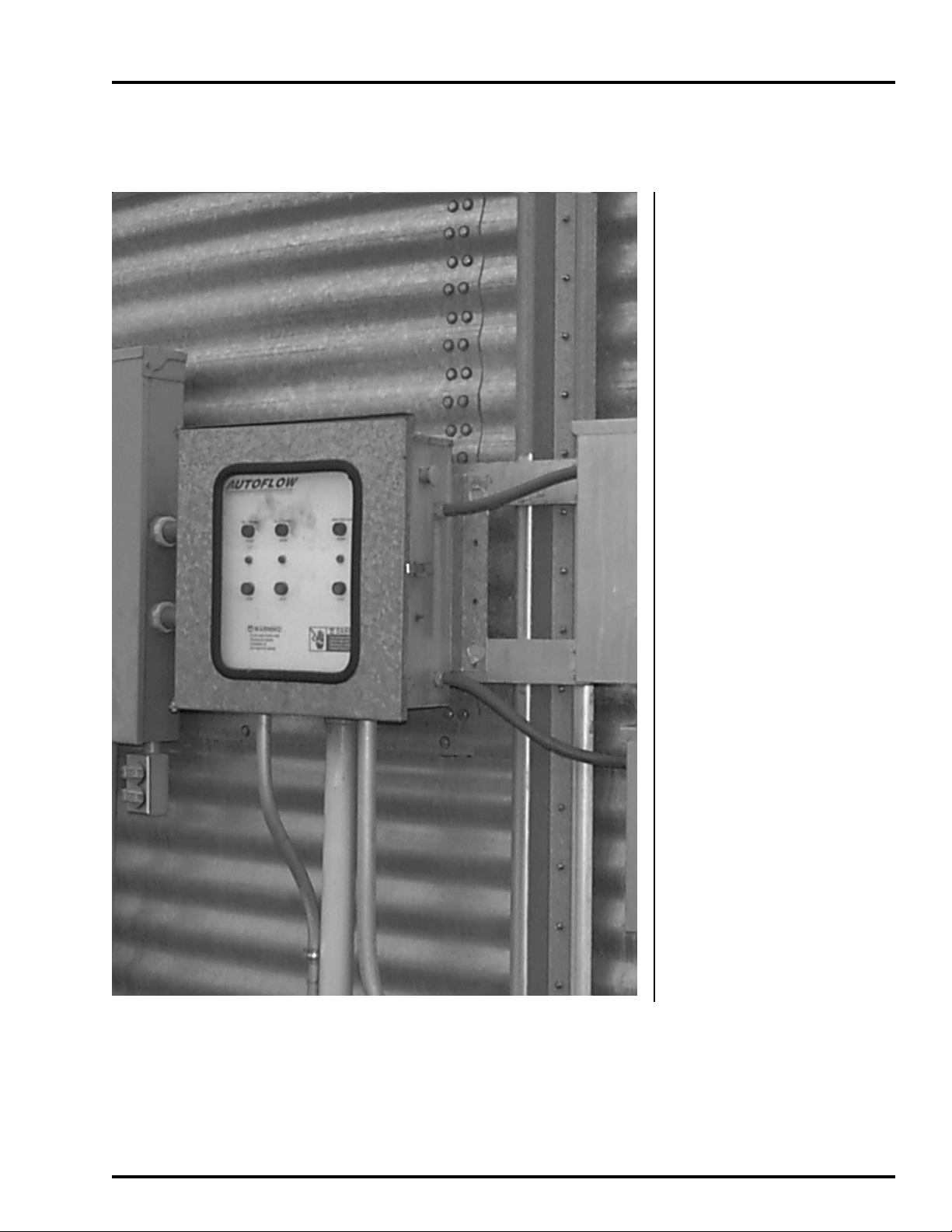

Save for Control box mounted on Bin picture

Autoflow Control box mounted on bin.

1. The Autoflow Control Box should be

mounted at eye-level. Make sure to mount

the Autoflow control box so that the fan

and heater unit(s) are in view.

2. Keep in mind that wire will be used to inter

connect the Autoflow control Box with the

fan and heater unit(s), Fill System Control

Box, Actuator and all rotary switches.

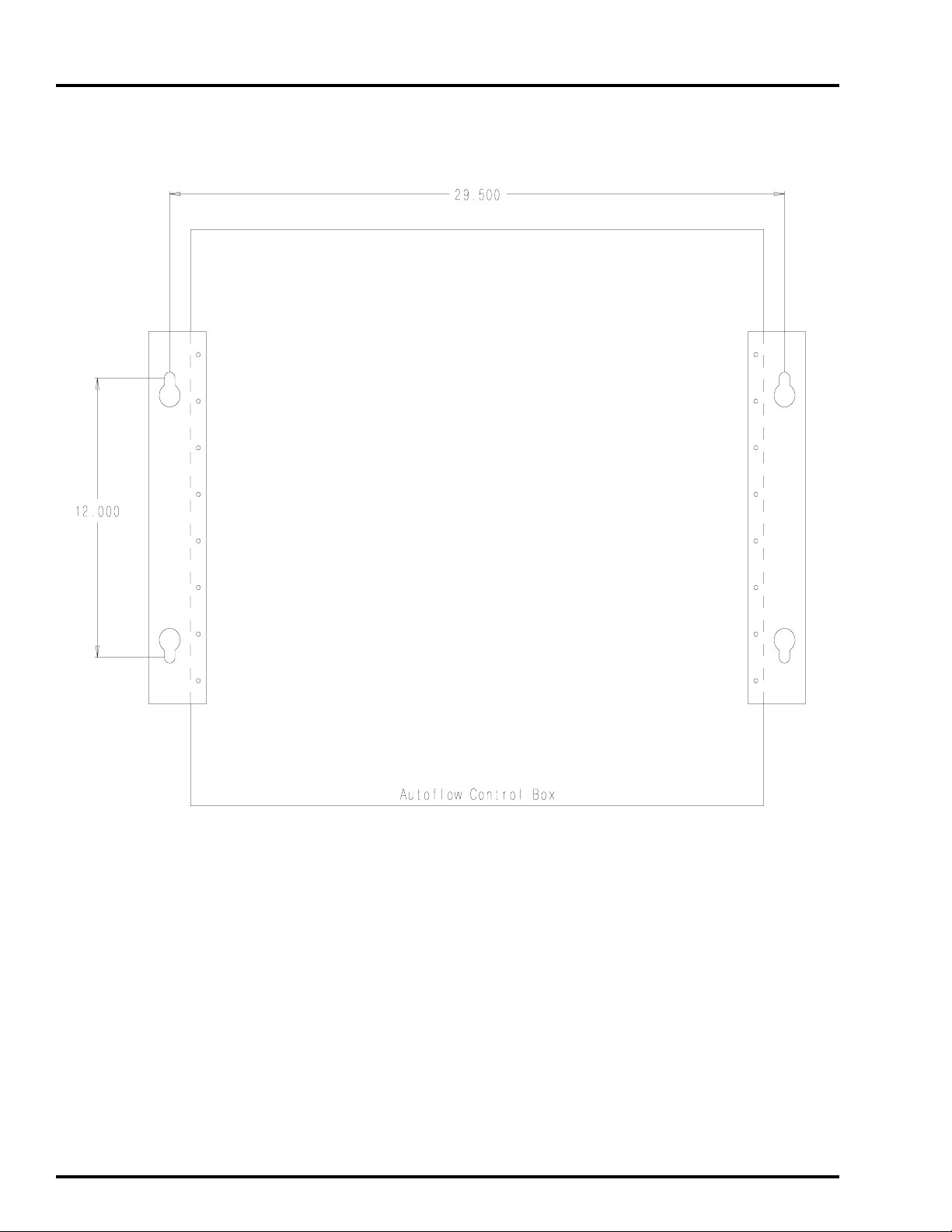

3. Use the hole pattern in Figure 1 to drill holes

for mounting the Autoflow Control Box.

8

2000 Autoflow

INSTALLATION

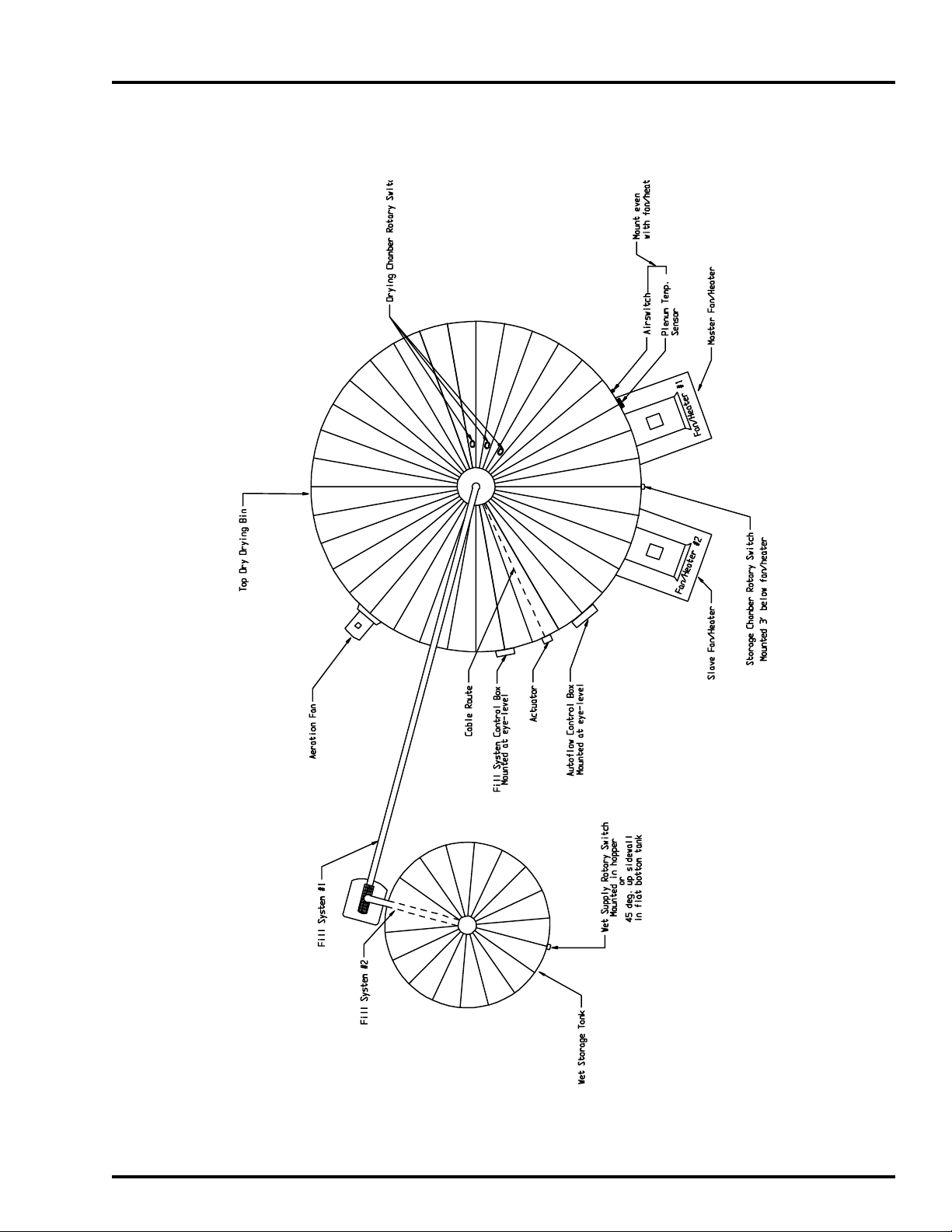

Component Placement

9

INSTALLATION

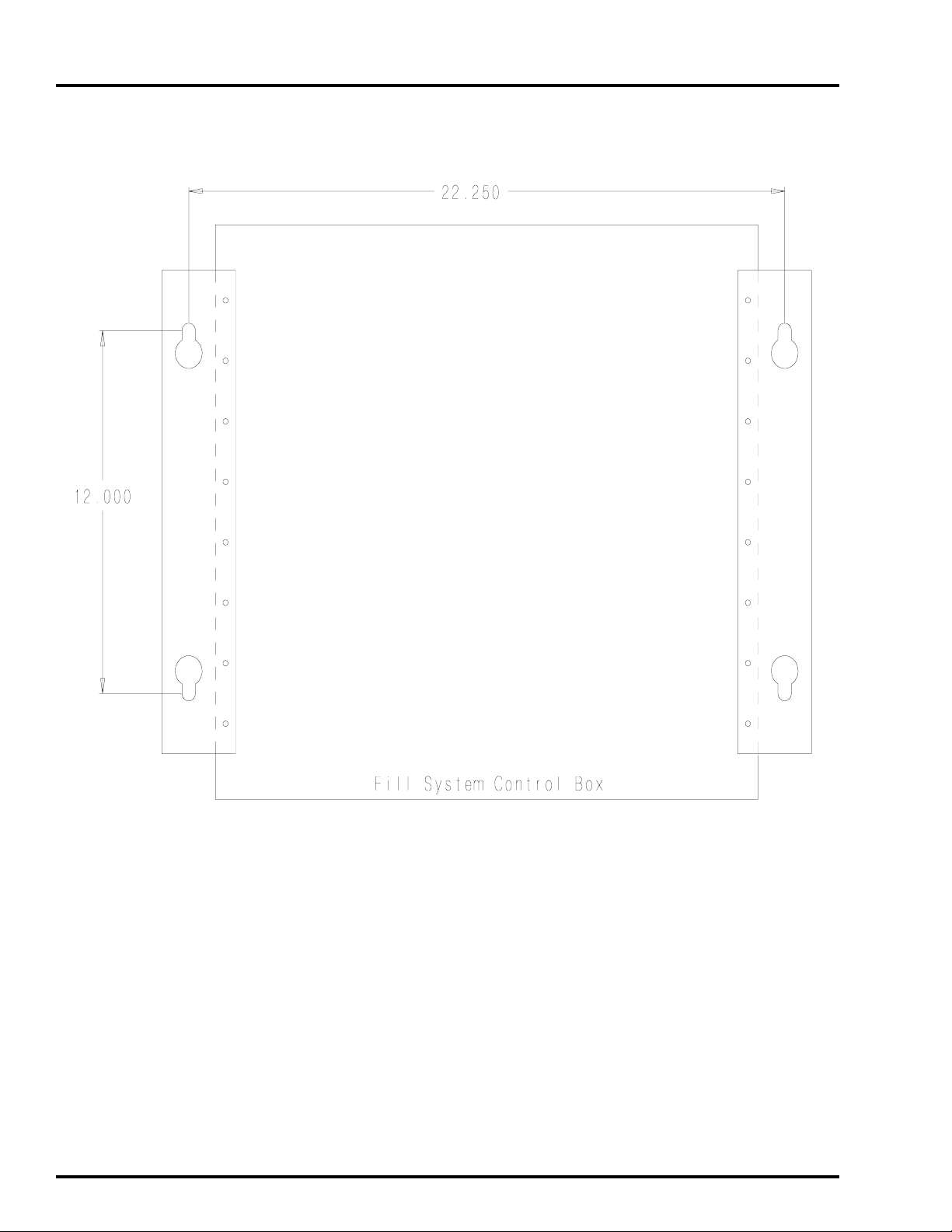

Series 2000 Autoflow Control Box Bolt Pattern

2000 Autoflow

10

Figure 1: Illustration of the bolt pattern for the Autoflow control box.

2000 Autoflow

CONTROL BOX MOUNTING

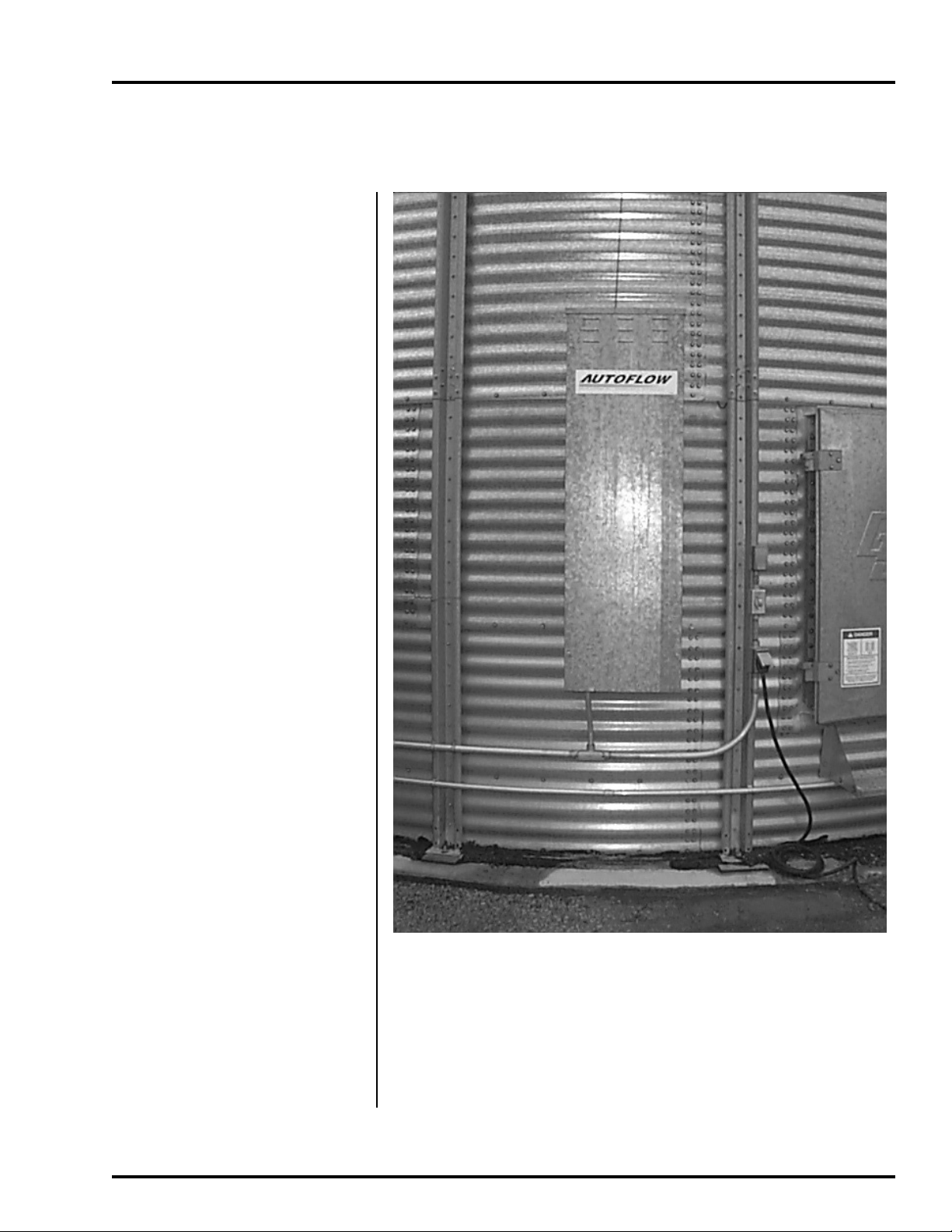

Fill System Control Box Mounting

1) The Fill System

control Box should be

mounted at eye-level.

Make sure to install

the Fill System

Control Box so that

the Fill System(s) and

Aeration fan are in

view.

2) Keep in mind that

wire will be used to

interconnect the Fill

System Control Box

with the Autoflow

Control Box; and,

that power wires will

have to be run from

the entrance panel to

the Fill System

control Box to power

the Fill System and

Aeration fan motors,

which will also run

from the Fill System

Control Box.

Fill System Control Box Mounted to Bin

3) Use the pattern in

Figure 2 to drill

holes for the Fill

System Control Box.

11

CONTROL BOX MOUNTING

Fill System Control Box Mounting

2000 Autoflow

12

Figure 2: Fill System Control Box Bolt Pattern

2000 Autoflow

1) Mark the third sidewall

ring from the ground to

indicate the cable path if

dump chutes and cable are

already installed.

2) Make sure that all dump

chutes and chains are

EVENL Y adjusted so that

when one chute is level

the others are level as

well.

3) Keep in mind that wire

will be used to

interconnect the Actuator

Control Box with the

Autoflow Control Box;

and, that a 110V power

supply will need to run

from the entrance panel to

the Actuator Control Box

to power the 24V DC

battery charger.

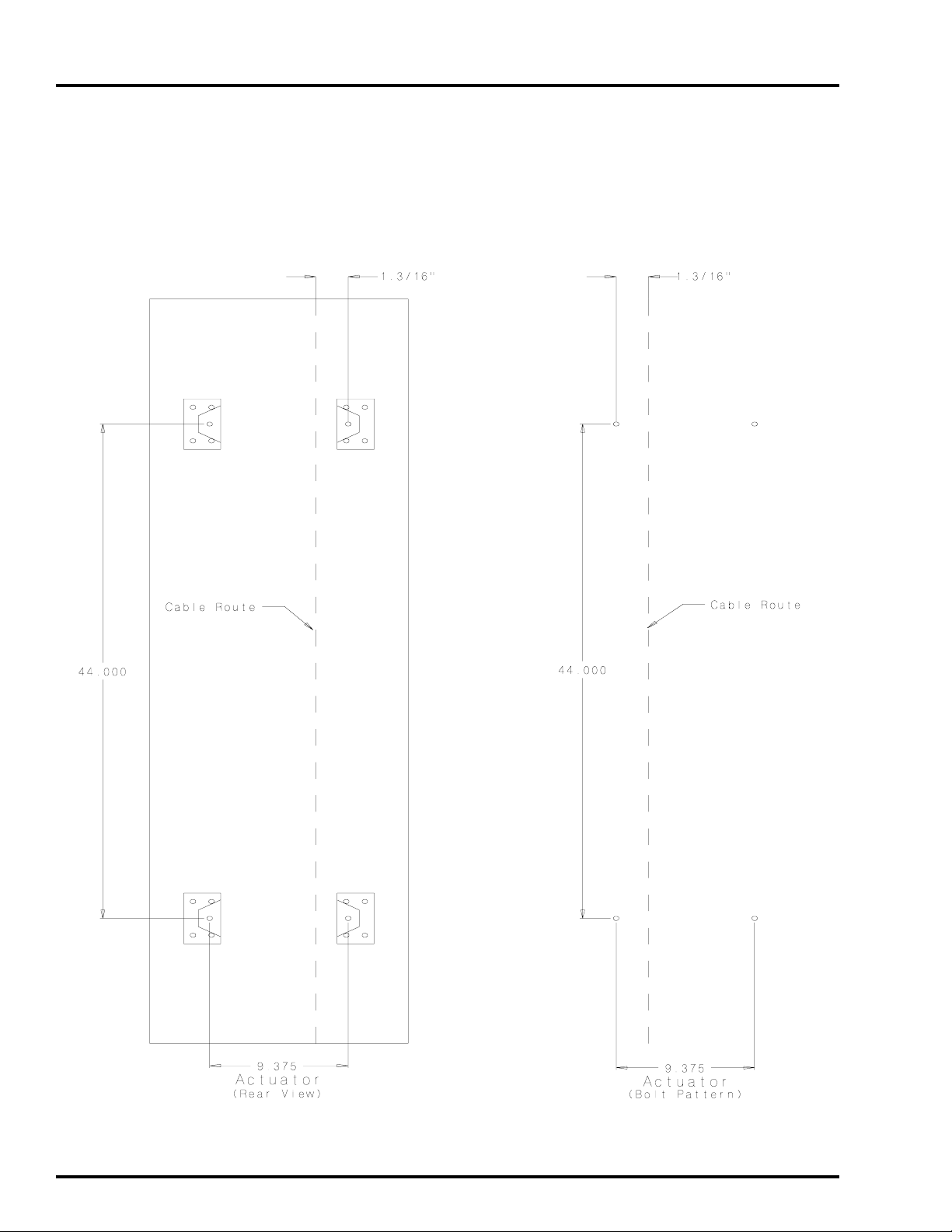

CONTROL BOX MOUNTING

Actuator Control Box Mounting

4) Use the pattern in Figure

3 to drill holes for the

Actuator Control Box.

5) If the horizontal seam

bolts are within 1”

horizontally of the hole

pattern shown, existing

holes may be used to

attach the actuator.

6) Use four 5/16” x 1.1/4”

bin bolts and washers

with bolt heads to the

Actuator Control Box Mounted to Bin

inside of the bin.

7) Do not attach the dump chute cable to the actuator at

this time. The cable should not be installed until after

the actuator unit is completely wired and tested.

13

CONTROL BOX MOUNTING

Actuator Control Box Mounting

2000 Autoflow

14

Figure 3: Bolt pattern to drill holes for the Actuator Control Box

2000 Autoflow

INSTALLATION

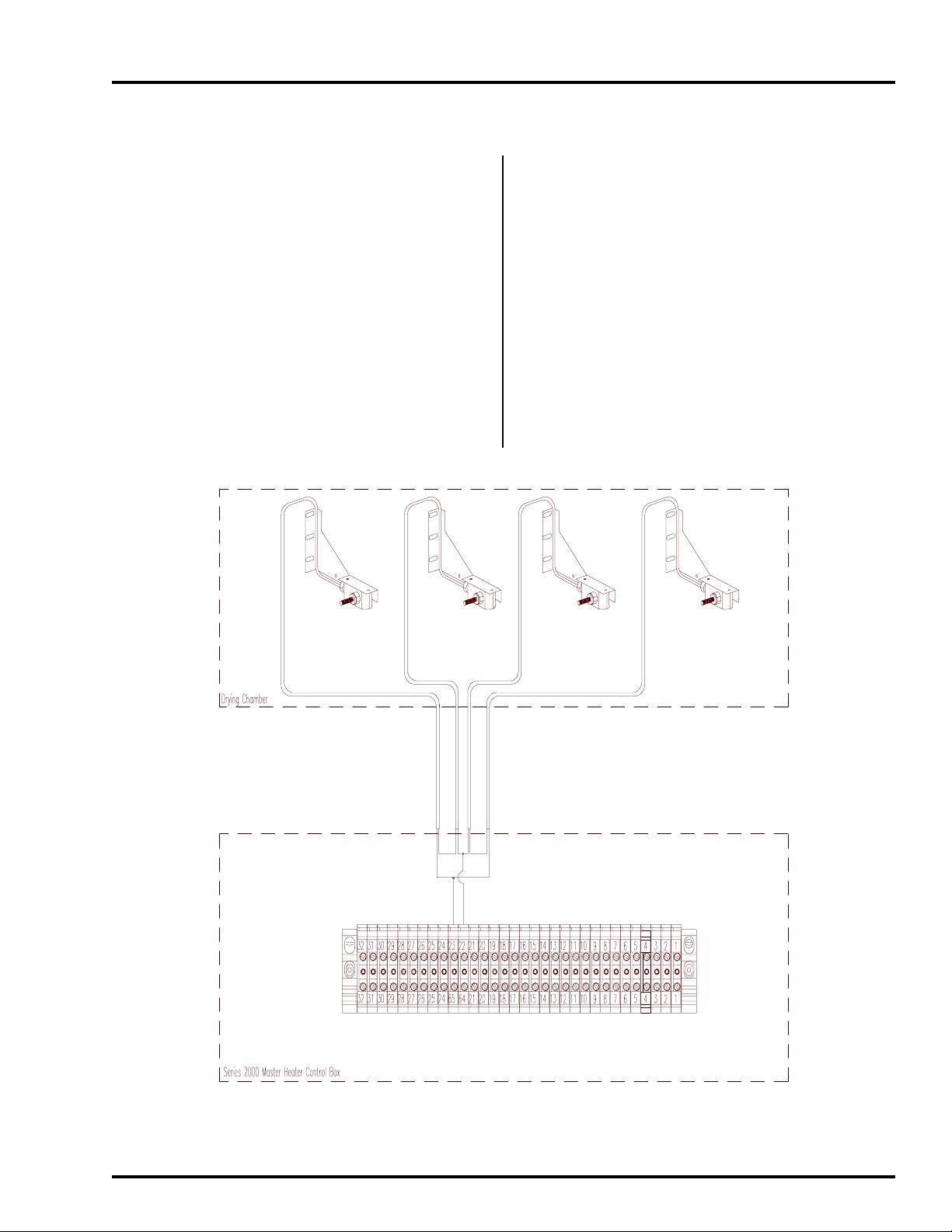

Multi-Grain Temperature Sensor

1. Remove the two wires attached to the grain tem-

perature sensor connected to terminal #22 and

terminal #23 in the fan control box.

2. Mount the four grain temperature sensor brackets evenly around the drying chamber on out

side leveling band posts (figure 5).

3. With bin bolts mount the bracket so the sensor is

10.1/2” above the floor sheet rib.

4. Wire tie the cords so they feed up the leveling

band post, and across the top leveling band.

5. T ake the cords through the space between the roof

and the top sidewall sheet. There should be enough

on all temperature sensor brackets to exit the dry

ing chamber at the same place.

6. Run the cords back into the fan control box.

7. Wire the four temperature sensors into terminal

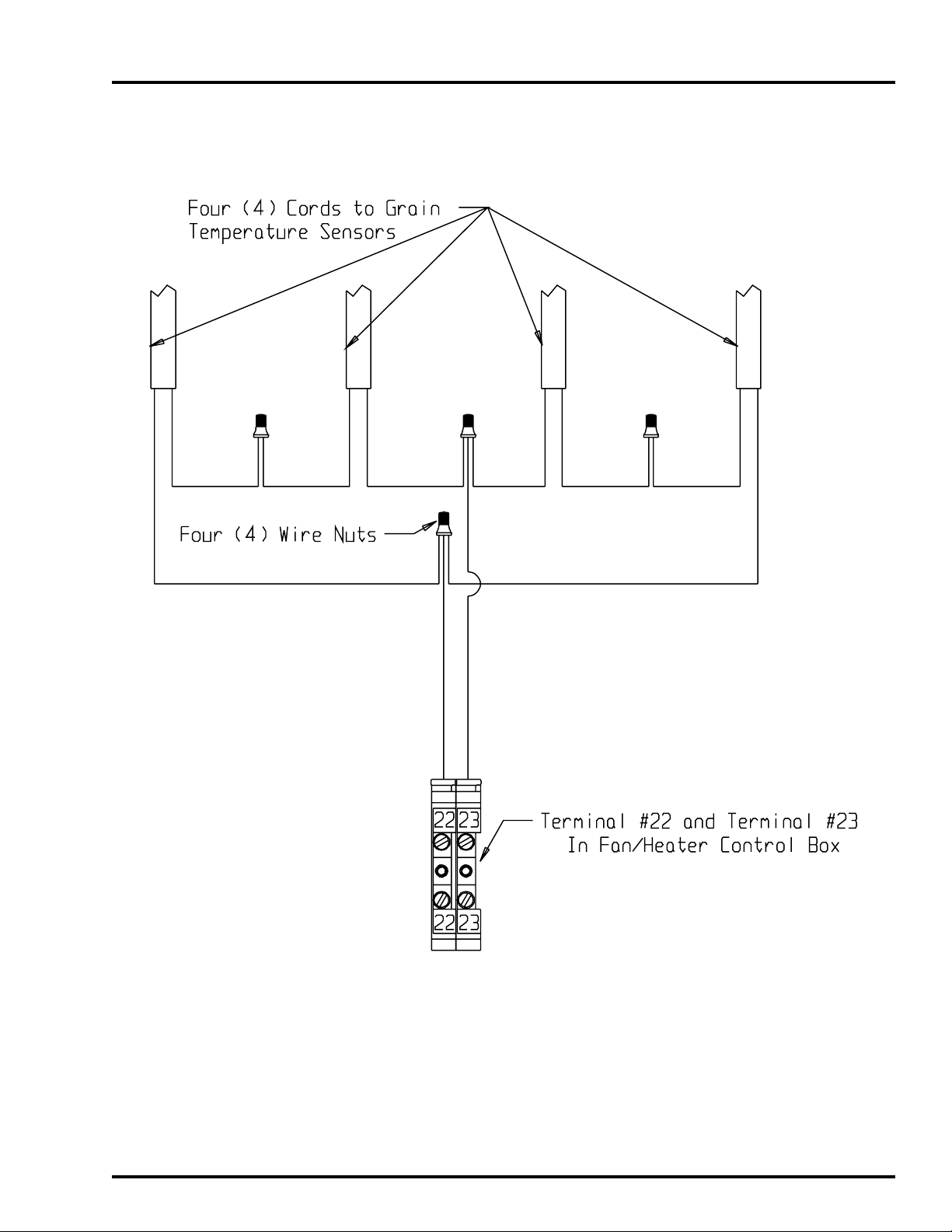

#22 and terminal #23 as detailed in Figure 4 and

the close up detail on page 17.

Figure 4: Illustration of the connection between the master heater control box and multiple sensors in the

drying chamber.

15

INSTALLATION

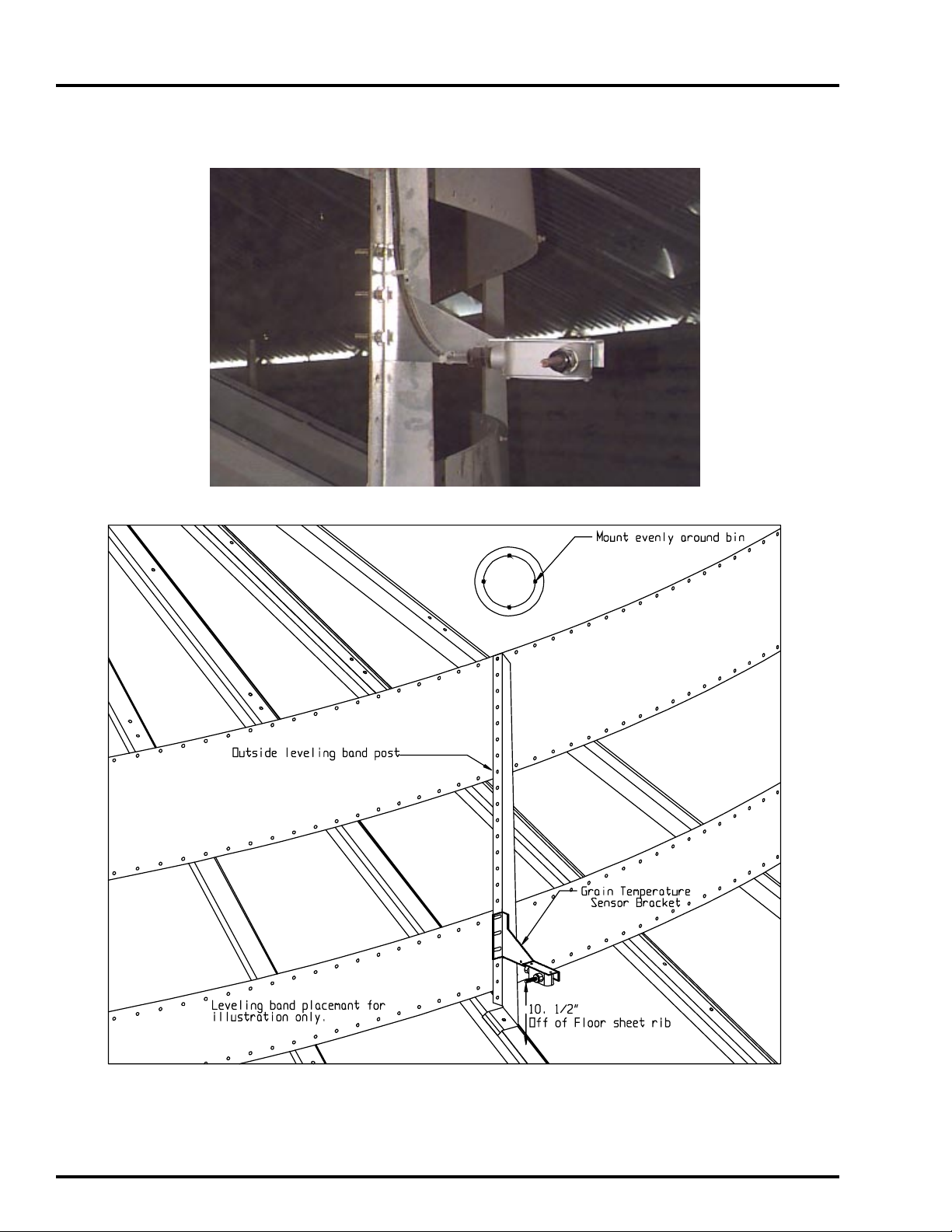

Grain Temperature Sensor Mounted to Leveling Band Post

2000 Autoflow

16

Figure 5: Illustration of grain temperature sensor mounted on outside leveling band post.

2000 Autoflow

INSTALLATION

Close-Up Detail of Grain Temperture Sensor Wiring

17

INSTALLATION

The plenum temperature sensor is

the small grey PVC junction box attached by a cord to the fan/heater

control box on the master fan/heater

unit.

1. On either side of the fan/heater,

drill one 3/4” hole even with the

fan/heater unit in a valley on the

bin sidewall.

2. Insert the probe through the

3/4” hole.

2000 Autoflow

Plenum Temperature Sensor

3. Position the housing so the cord

exits the housing horizontally,

and the tabs fall on the sidewall

peaks.

4. Use two self drilling screws to

mount the housing to the bin

sidewall.

5. Caulk between the housing and

the sidewall to seal.

Important!

If the Top Dry is a two fan unit,

do not mount the plenum temperature sensor between the two

fan/heater units.

Plenum temperature sensor on the bin sidewall.

18

Loading...

Loading...