PNEG-1807CE

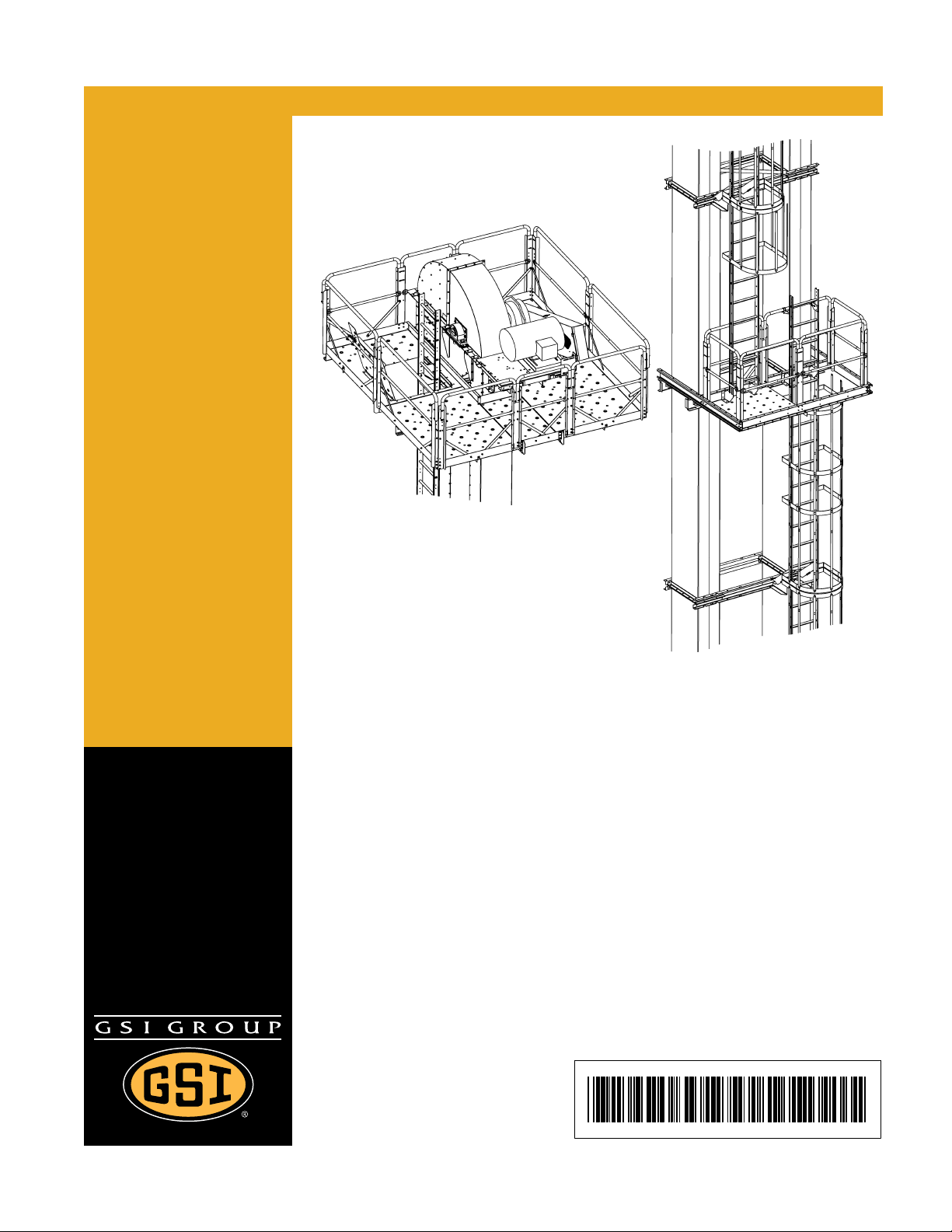

CE Compliant 16"-24" Bucket

Elevator Platform and Ladder

“X” Series

Installation Manual - Original Instructions

PNEG-1807CE

Date: 05-16-14

Use of the equipment information page will help you identify the equipment in the case that you need to

call your dealer or installer. This information should be filled out and kept on record.

Equipment Information

Model #:___________________________________________

Serial #:____________________________________

Date Purchased:____________________________________

Dealer/Distributor Name and Phone #:___________________________________________

Material Handling

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

2 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

Table of Contents

Contents

Chapter 1 Introduction .......................................................................................................................................... 4

Chapter 2 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 6

Chapter 3 Decal Location ...................................................................................................................................... 8

Chapter 4 Overview ............................................................................................................................................... 9

Chapter 5 Ladder Assembly ............................................................................................................................... 10

Typical Ladder/Cage Setup ................................................................................................................. 18

Chapter 6 Tie Angles, Ladder Brackets and Safety Cages .............................................................................. 19

Attach Tie Angle to Boot Trunking ................................................ ... ... ... .... ... ... ... .... ... ... ... ... .... ...... ... ... 19

Attach Boot Ladder Support Brackets and Boot Ladder Section ........................................................ 20

Install Boot Ladder Section ................................................................................................................. 22

Tie Angles to Trunking ........... ... ... .... ... ... ... ... .......................................... .... ... ... ... .... ... ......................... 24

Ladder Support Brackets .................................................................................................................... 27

Attach Ladders to Ladder Brackets ............................... ... ... ... .... ... ... .......................................... ...... ... 30

Safety Cage Installation ......... ... ... .... ... .......................................... ... ... ... .... ... ... ... .... ... ... ... .......... ... ... ... 31

Install Safety Cage .............................................................................................................................. 32

Chapter 7 Rest Platform ...................................................................................................................................... 35

Rest Platform Tie Angles to Bucket Elevators .................................................................................... 35

Attach Rest Platform Channel to the Rest Platform Tie Angle ............................ .... ... ... ... ... .... ... ... ... ... 38

Rest Platform Cross Channel to Rest Platform Mounting Channels ................................................... 39

Ladder Support ................................................................................................................................... 44

Chapter 8 16"-24" Head Platform Assembly ..................................................................................................... 45

Attach Main Support Channels to Lower Head ................................... ... .... ... ... ... .... ... ... ... ................... 45

Install Deck A and Toe Board ............................................................................................................. 46

Install Deck A to Main Support Channels ............................................................................................ 47

Install Deck C and Toe Board ............................................................................................................. 49

Install Deck C to Main Support Channels ........................................................................................... 50

Install Deck E ...................................................................................................................................... 51

Install Adapter Bracket for 16" Platforms ............................................................................................ 53

Install Hatch Filler Plate ...................................................................................................................... 54

Install Rail Supports to Deck E ......................... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ...................................... 54

Install “W” Posts (“Corner Posts” x 4) ................................................................................................. 55

Install Platform Posts .......................................................................................................................... 56

Install Intermediate Handrails .............................................................................................................. 58

Install Upper Handrails ........................................................................................................................ 60

Install Tie Braces (Safety Cage Bars) ................................................................................................. 61

Chapter 9 Install Hatch ........................................................................................................................................ 62

Chapter 10 4 x 5 Distributor Platform (Optional) .............................................................................................. 65

16"-24" Clamp Band Installation ........................................................................................................ 65

Assemble Supports (16"-24") ............................................................................................................ 69

Assemble Decking and “W” Corner Post .............................. ................................................. ............ 71

Install Handrail Posts - Non Entrance Side ....................................................................................... 73

Install Intermediate Handrails ............................................................................................................ 75

Install Safety Bar Cross Supports ...................................................................................................... 76

Install Top Handrails .......................................................................................................................... 77

Safety Gate Package (Optional) ........................................................................................................ 78

Chapter 11 Warranty ............................................................................................................................................ 79

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 3

1. Introduction

Chapter 1: Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of

lading to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

4 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Chapter 2: Safety

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 5

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet, and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately. Replace worn or broken parts. Remove any

built-up grease, oil, and debris.

Maintain Equipment

and Work Area

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area . Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

2. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 7

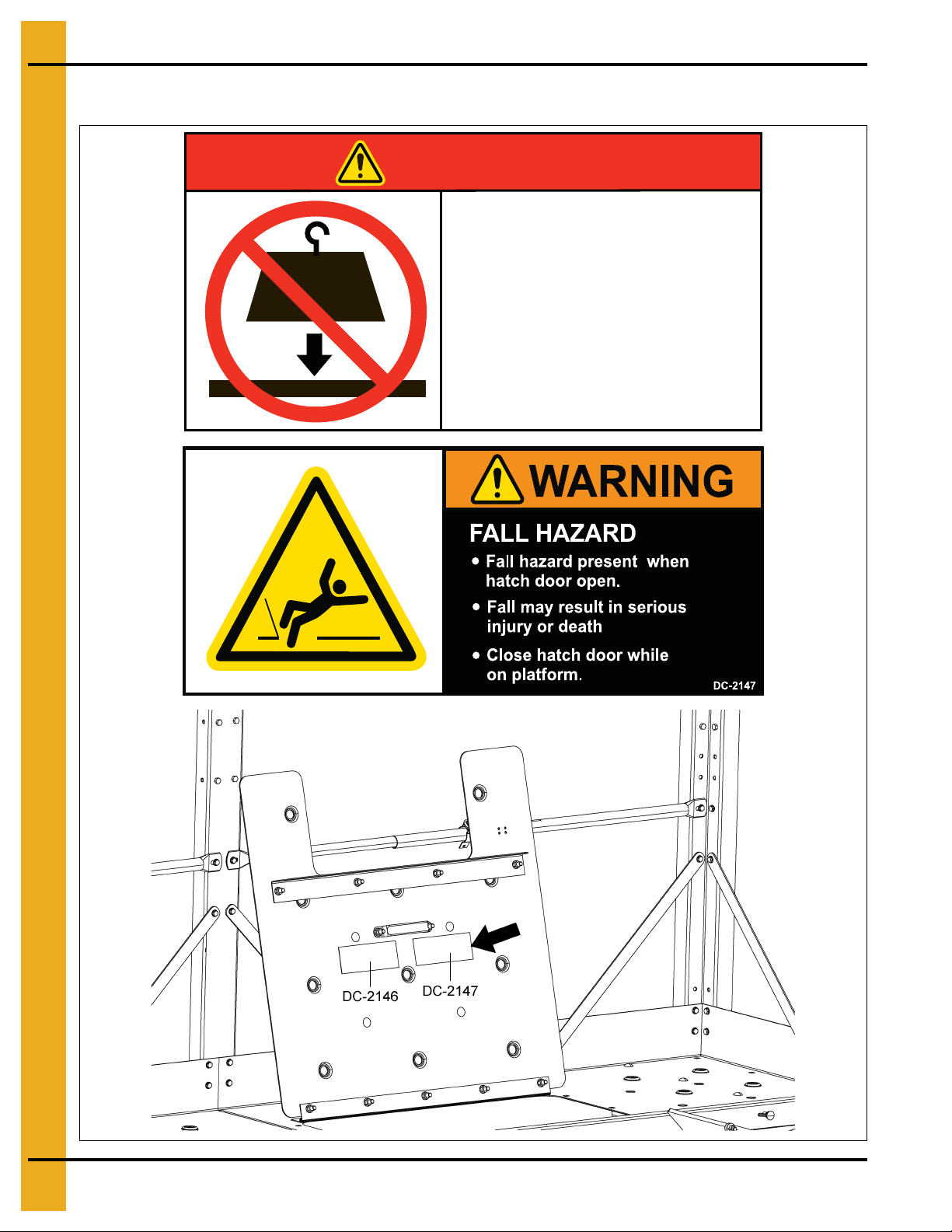

3. Decal Location

DO NOT EXCEED

PLATFORM LOAD LIMIT

DC-2146

Excessive load will damage

platform and cause

platform to fall.

Load limit = 500 LBS. (2.25 kN)

DANGER

> 500 lbs

(2.25 kN)

Injury or death will result.

Chapter 3: Decal Location

8 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

4. Overview

Chapter 4: Overview

This section is intended to provide a general, high-level overview of platform assembly for your GSI bucket

elevator. Detailed instructions are given in the pages to come.

This section should be used for reference only and is intended to provide general guidance about the

overall process only.

1. Support Channels:

Proper orientation of channels is based upon the size of the bucket elevator (16", 24", 30" or 36")

AND the right/left hand position of the drive. This must be installed correctly at the start or nothing

else will install correctly.

2. Ladders and Safety Cages:

Ladder sections mount directly to the trunking sections of the bucket elevator. Typical lad der layouts

and charts identifying the support height for ladder packages can be fou nd on Pages 10 through 16.

3. Tie Angles to Trunking:

• Proper orientation of the tie angles is critical for correct installation.

• Note differences from up-leg and down-leg installations.

Be sure to follow the instructions for the size and drive position.

Throughout this manual, particular attention is given to the initial orientation of channels and aligning

bolt holes. Failure to complete these initial steps correctly will significantly impede the assembly and

installation of the bucket elevator platforms.

4. Decking and Toe Boards:

Decking is etched with alpha characters to assist with orienting decks and aligning holes for

connections. Decking connections should be finger-tight only initially so that adjustments can be

made once all decks and toe boards are in place. Only then should all hardware be fully torqued.

5. Handrail Platform Posts:

The number and location of platform posts varies based upon platform and bucket elevator size.

6. Handrails:

Intermediate handrails (those at near knee level) may need to be field cut to fit. The amount to trim

varies based upon the size of the platform being installed. The smaller rail then fits inside of the larger

rail so that it “telescopes” between the posts. Always follow best practices of “measure twice cut

once” and verify the measurement is for the bucket elevator size. Upper handrails do not req uire any

alterations in the field prior to assembly.

7. Platform Braces:

Throughout this manual, safety cage bars (LDR-517BE) are used as platform braces. These are

required for support and stability. Please attach as described through the manual.

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 9

5. Ladder Assembly

14' (4.26 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

50'

40'

30'

HP

1636XRLAD30CE

1636XWLAD30CE

1636XRLAD40CE

1636XWLAD40CE

1636XRLAD50CE

1636XWLAD50CE

RP

RPRPHP

HP

Key: HP = Head Platform

RP = Rest Platform

10' (3.0 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

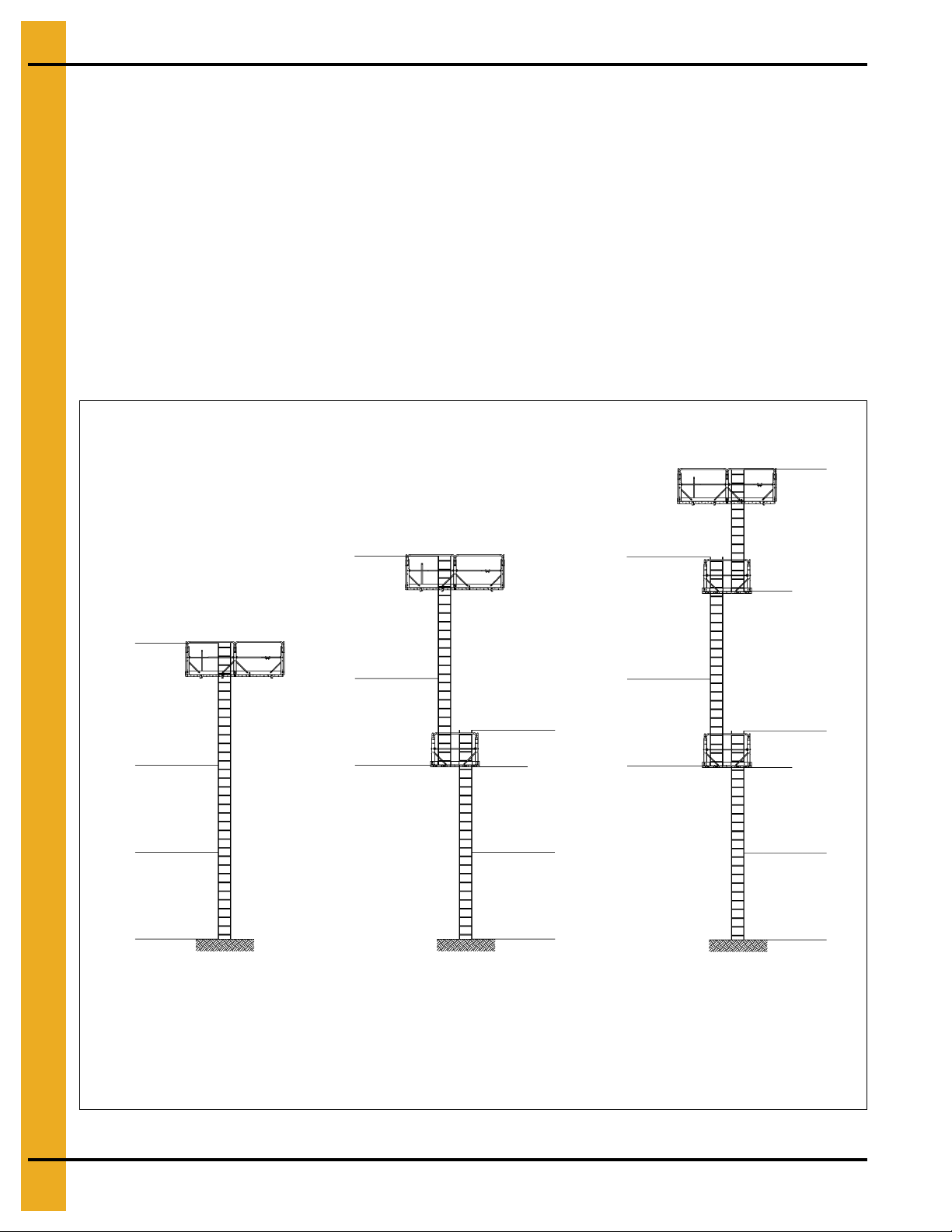

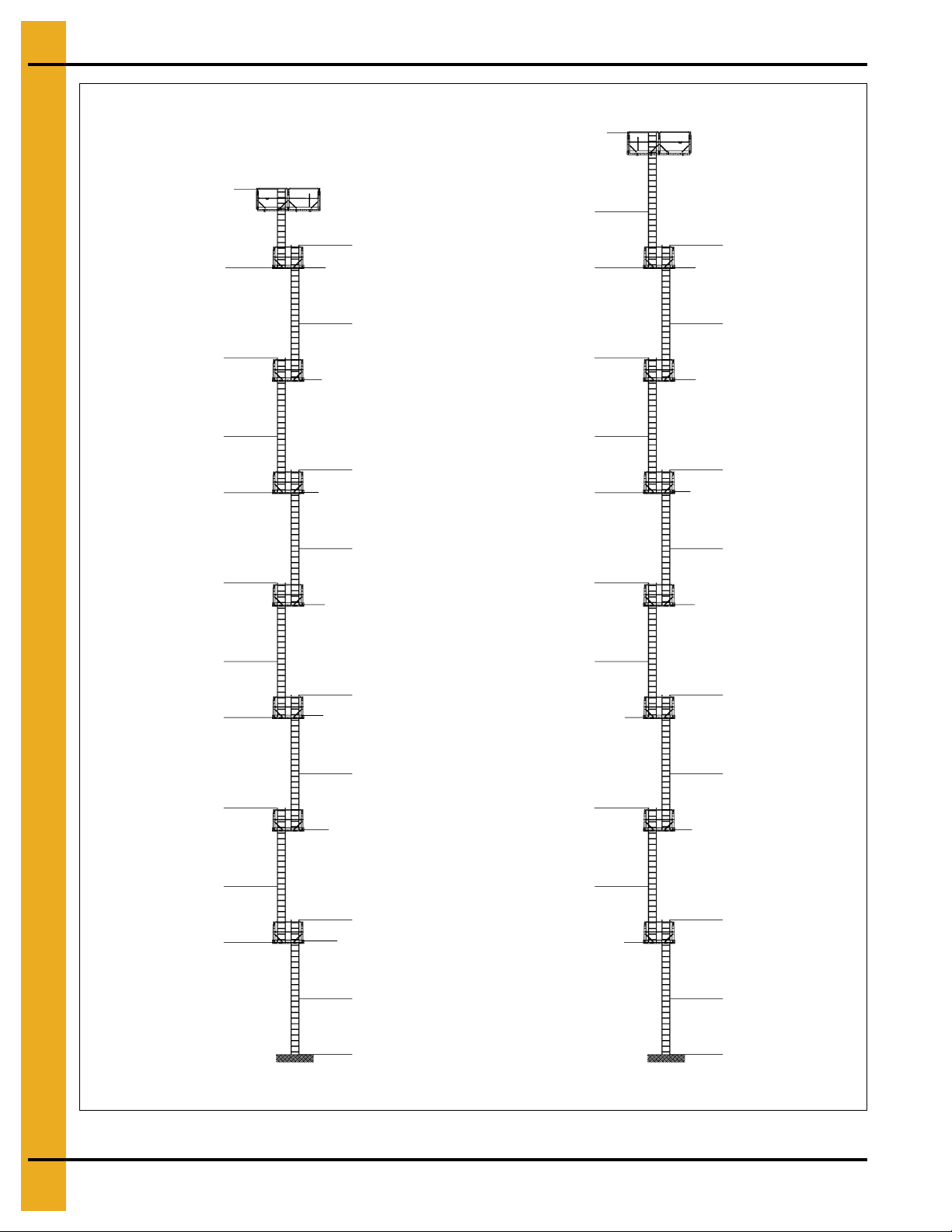

Chapter 5: Ladder Assembly

The ladder sections are to be mounted directly to the trunking sections. Quantities and section lengths

may vary depending on overall height of system. If you have a non-standard height system, refer to

supported bucket height reference chart for the correct ladder package for the system.

NOTE: Ladders are of a modular design for ease of modification in the field. These illustrations are only

to be used as a “general” guide to installation layout. The exact assembly may vary due to the

unique nature of each bucket elevator.

Ladder and Platform Layout for European CE Compliance

To comply with European Directives for CE marking, the maximum rest platform spacing is reduced,

in accordance with EN ISO14122-4:2004. Please follow the recommended layouts given below.

(See Figures 5A-5G on Pages 10-16.)

Figure 5A

10 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

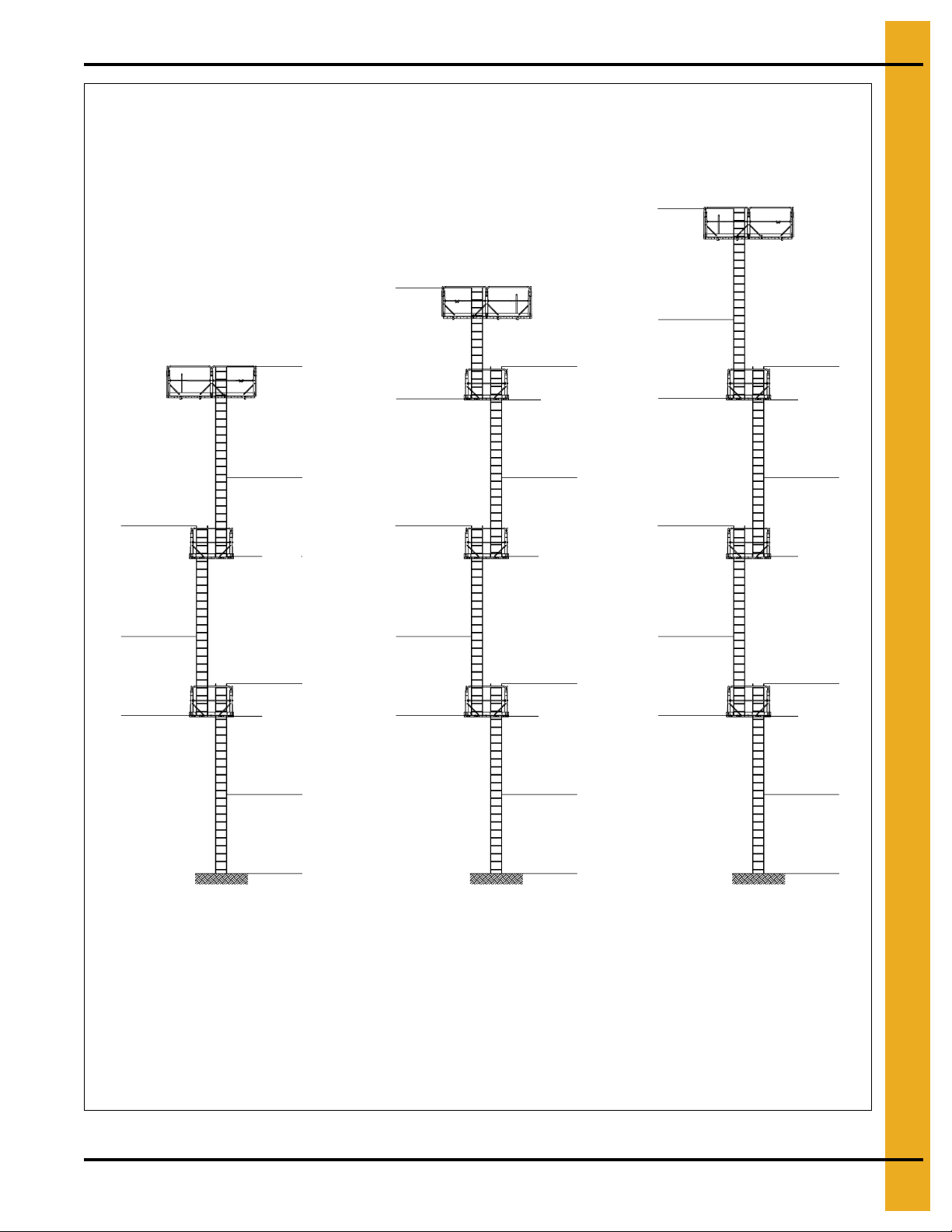

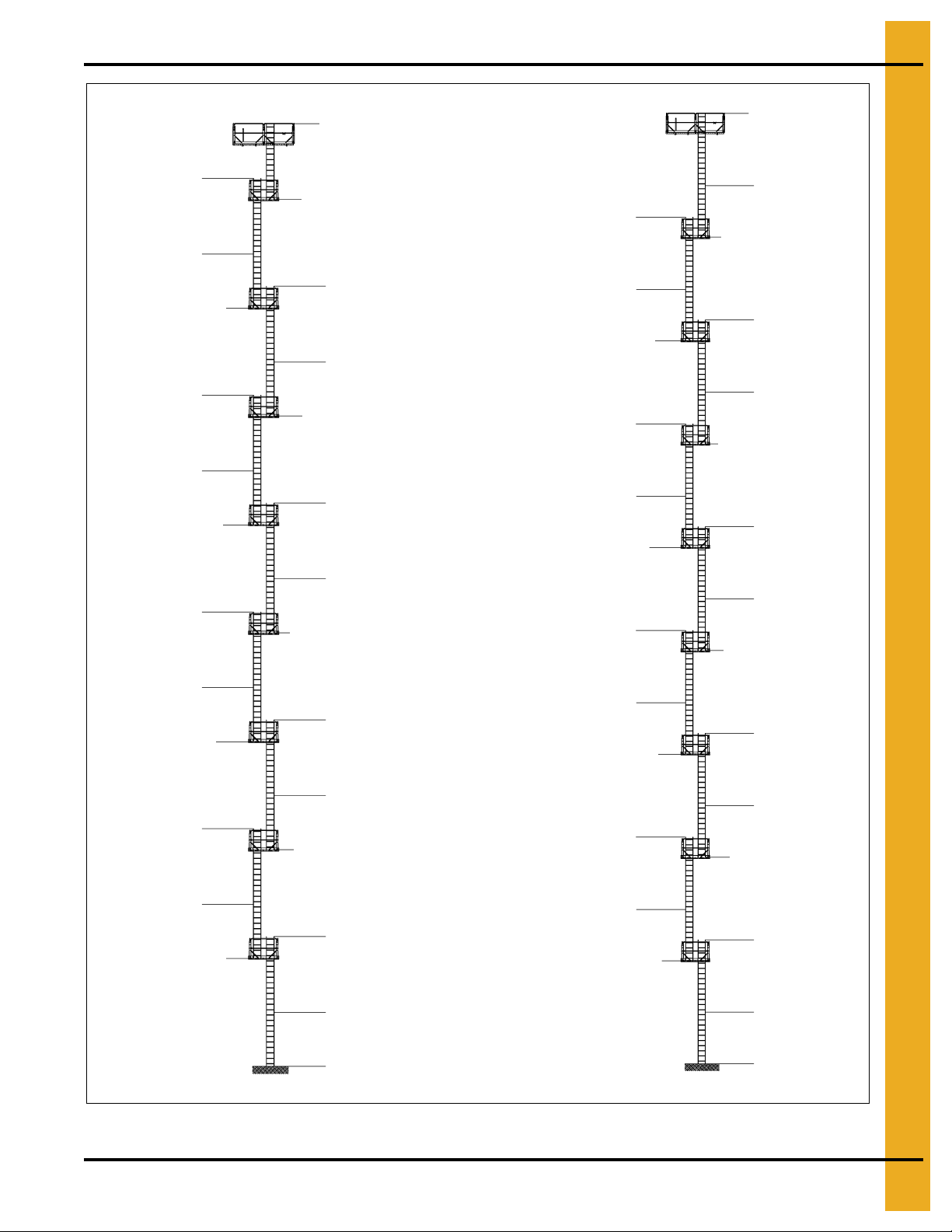

5. Ladder Assembly

14' (4.26 m)

Section

14' (4.26 m)

Section

80'

70'

60'

14' (4.26 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

1636XRLAD60CE

1636XWLAD60CE

1636XRLAD70CE

1636XWLAD70CE

1636XRLAD80CE

1636XWLAD80CE

RPRPRPRPRPRPRP

RP

HP

HP

HP

Key: HP = Head Platform

RP = Rest Platform

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 11

Figure 5B

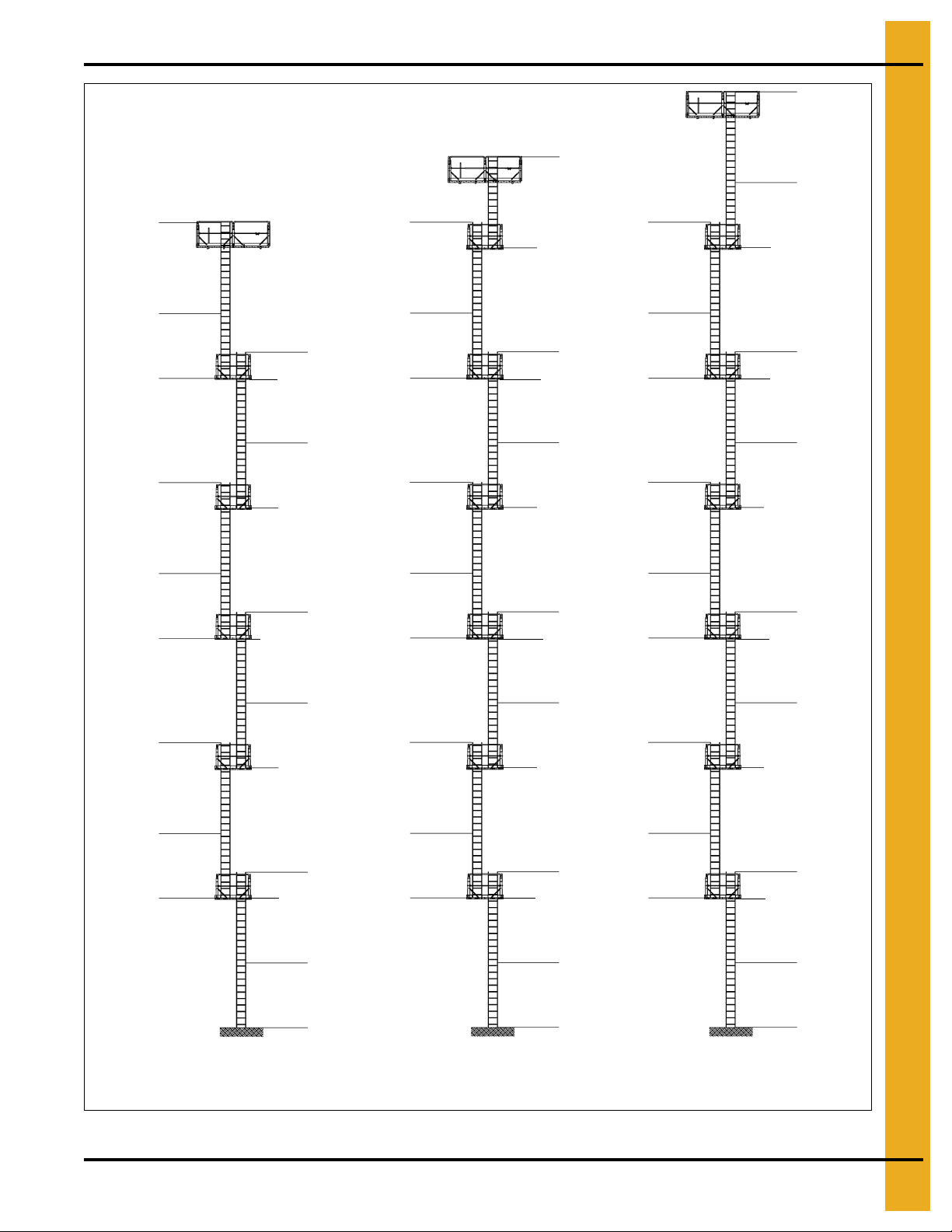

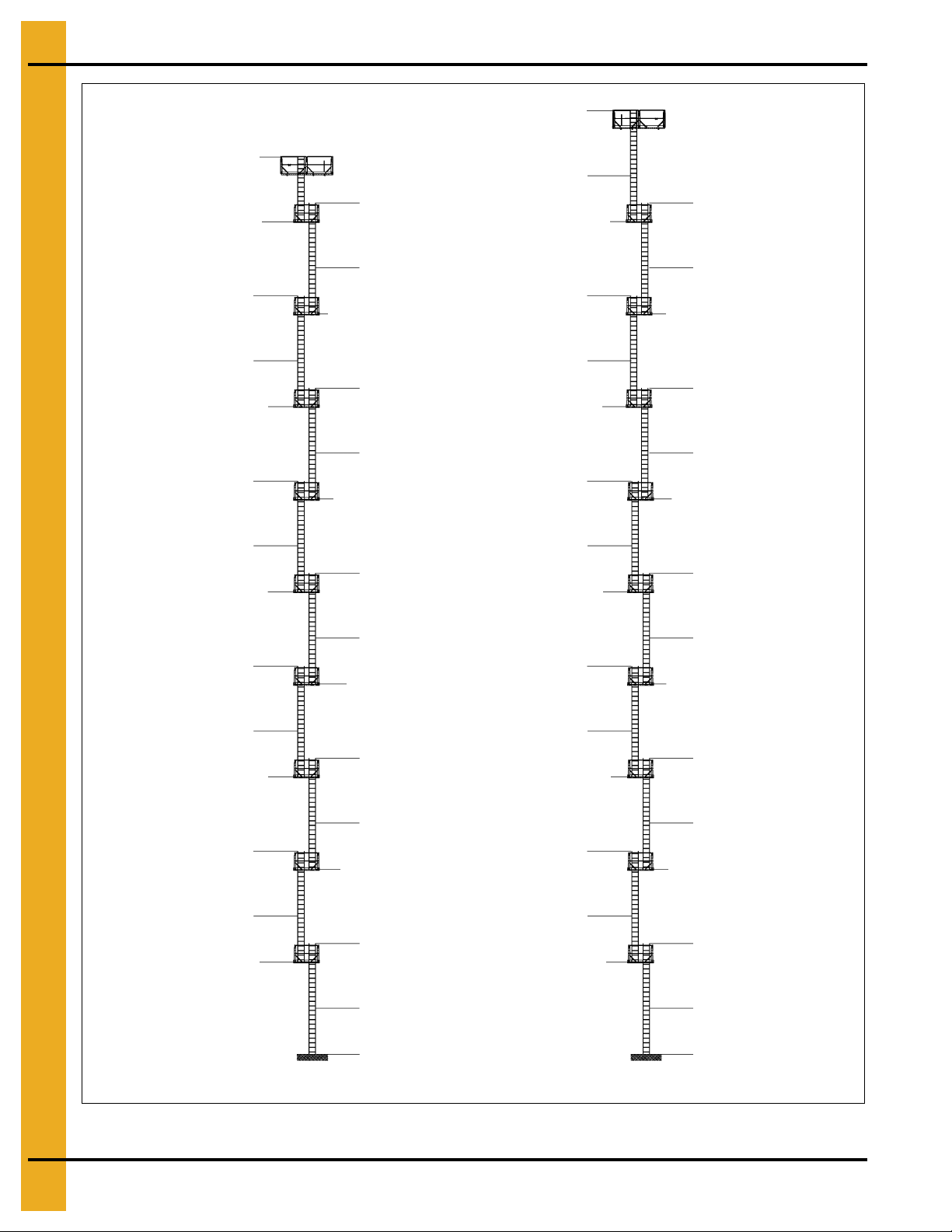

5. Ladder Assembly

14' (4.26 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

90'

14' (4.26 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

100'

110'

10' (3.0 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

1636XRLAD90CE

1636XWLAD90CE

1636XRLAD100CE

1636XWLAD100CE

1636XRLAD110CE

1636XWLAD110CE

RP

RPRPRP

RPRPRP

RP

RPRPRP

RP

Key: HP = Head Platform

RP = Rest Platform

HP

HP

HP

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

RP

Figure 5C

12 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

5. Ladder Assembly

14' (4.26 m)

Section

14' (4.26 m)

Section

120'

14' (4.26 m)

Section

14' (4.26 m)

Section

130'

140'

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

RP

RP

RPRPRP

RPRPRPRPRPRPRP

1636XRLAD120CE

1636XWLAD120CE

1636XRLAD130CE

1636XWLAD130CE

1636XRLAD140CE

1636XWLAD140CE

RP

RPRPRP

RP

HPHPHP

Key: HP = Head Platform

RP = Rest Platform

14' (4.26 m)

Section

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 13

Figure 5D

5. Ladder Assembly

150'

14' (4.26 m)

Section

160'

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

1636XRLAD150CE

1636XWLAD150CE

RP

RP

RP

1636XRLAD160CE

1636XWLAD160CE

RP

Key: HP = Head Platform

RP = Rest Platform

RPRPRP

14' (4.26 m)

Section

10' (3.0 m)

Section

RP

14' (4.26 m)

Section

10' (3.0 m)

Section

RP

14' (4.26 m)

Section

10' (3.0 m)

Section

RP

14' (4.26 m)

Section

10' (3.0 m)

Section

RP

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

RP

10' (3.0 m)

Section

14' (4.26 m)

Section

RP

RPHPHP

Figure 5E

14 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

5. Ladder Assembly

180'

1636XRLAD180CE

1636XWLAD180CE

180'

1636XRLAD170CE

1636XWLAD170CE

170'

10' (3.0 m)

Section

14' (4.26 m)

Section

RP

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

RP

RP

RPRPRP

RP

RP

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

RP

RPRPRP

RP

RPRPRP

Key: HP = Head Platform

RP = Rest Platform

HP

HP

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 15

Figure 5F

5. Ladder Assembly

190'

200'

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

RPRPRP

RP

RP

RP

RP

1636XRLAD200CE

1636XWLAD200CE

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

10' (3.0 m)

Section

14' (4.26 m)

Section

RPRPRPRPRPRPRPRPRP

Key: HP = Head Platform

RP = Rest Platform

HP

HP

RP

RP

1636XRLAD190CE

1636XWLAD190CE

Figure 5G

16 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

Down-leg

Up-leg

16" Boot Tie Angle

Chapter 6: Tie Angles, Ladder Brackets and Safety Cages

Attach Tie Angle to Boot Trunking

1. On the NON-LADDER SIDE, attach tie angle to the trunking using 1/2" x 1" bolts.

below and

a. For 16" Boot Tie Angle: With lip of tie angle up and outward, align tie angle so that it extends

beyond the trunking at each end. (See Figure 6A.)

Figure 6B on Page 18.)

(See Figure 6A

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 17

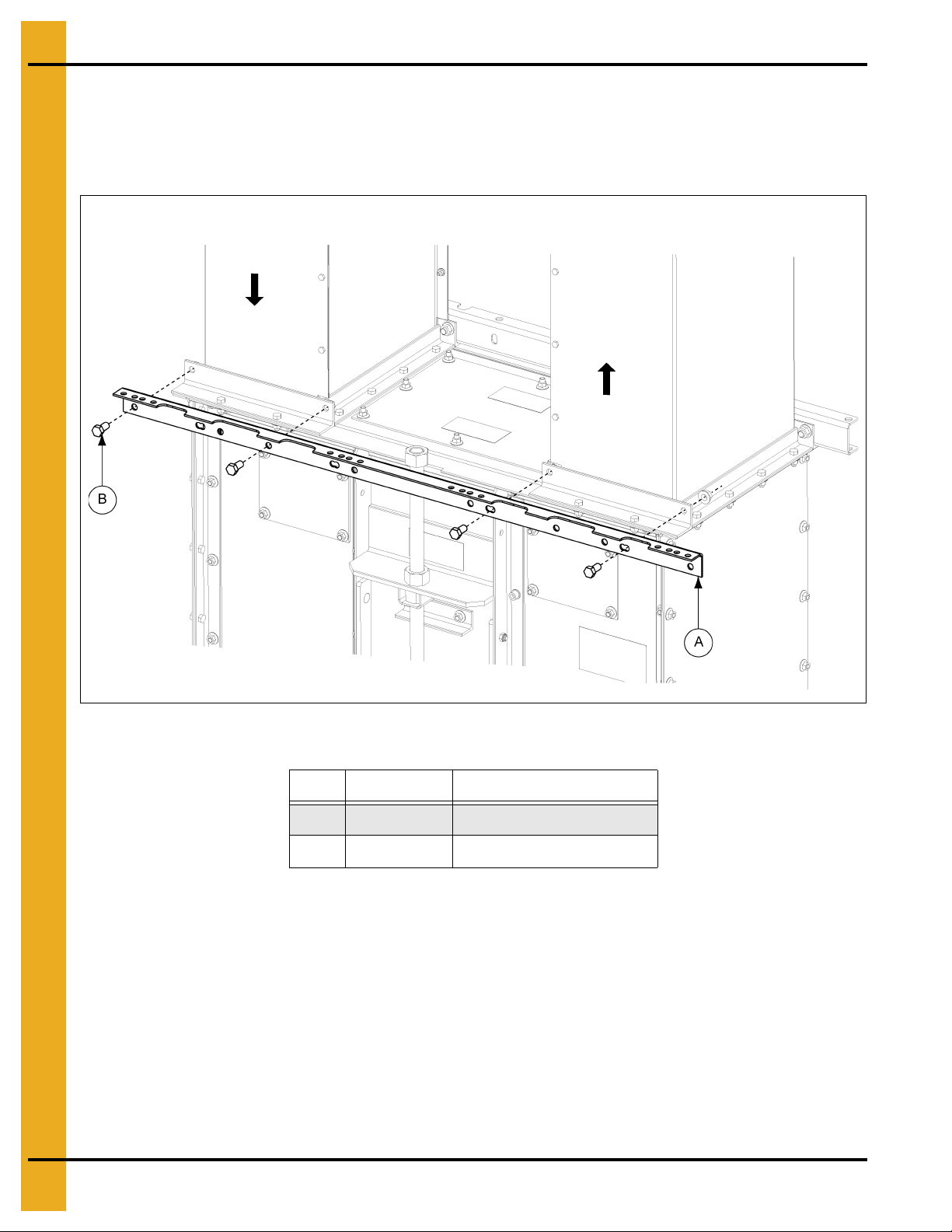

Figure 6A 16" Boot Tie Angle

Ref # Part # Description

A BECT1640FX Type “X” Tie Angle

B S-7935 12" x 1" Bolt

6. Tie Angles, Ladder Brackets and Safety Cages

Down-leg

Up-leg

24" Boot Tie Angle

Attach Tie Angle to Boot Trunking (Continued)

b. For 24" Boot Tie Angle: With lip of tie angle up and outward, align edge of tie angle to edge

of trunking at down-leg end. With this alignment, tie angle will extend slightly beyond the edge of

trunking at the up-leg end, as shown in Figure 6B.

Figure 6B 24" Boot Tie Angle

Ref # Part # Description

A BECT1640FX Type “X” Tie Angle

B S-7935 12" x 1" Bolt

18 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

Down-leg

Up-leg

16" Boot Bracket Down-Leg

Attach Boot Ladder Support Brackets and Boot Ladder Section

NOTE: Refer to ladder layout images, Figure 5A-5G on Pages 10-16.

NOTE: Ladders can be mounted to either the up-leg or down-leg end of the elevator depending on the

height and head platform hatch location.

NOTE: Both up-leg and down-leg bracket locations are shown in this manual. Actual installation location

on either the up-leg or down-leg will be determined by owner preference.

1. Using the holes indicated based on bucket elevator size in Figure 6C, attach ladder support brackets

to boot tie angle using 3/8" x 1" hex bolts. Remember to double check if the ladder should start on

the up-leg side or the down-leg side. (See Figures 6C-6H on Pages 19-24.)

a. 16" Down-leg boot bracket: Use 3/8 " x 1" hex bolts to attach the ladder support brackets to the

boot tie angle using the holes indicated in Figure 6C. Note the outer bracket uses the outer most

holes of the tie angle and the inner bracket will have two (2) empty holes beside it on the tie angle.

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 19

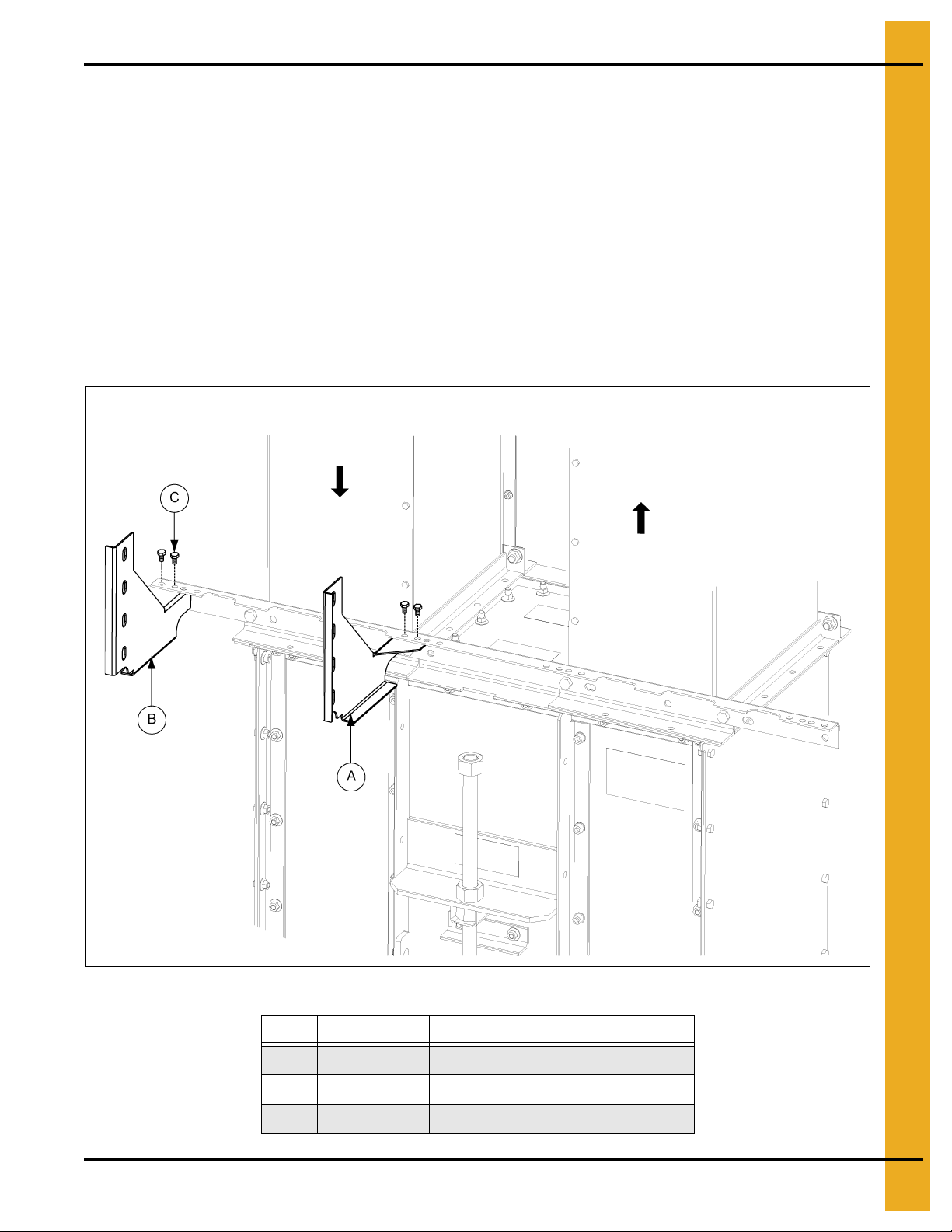

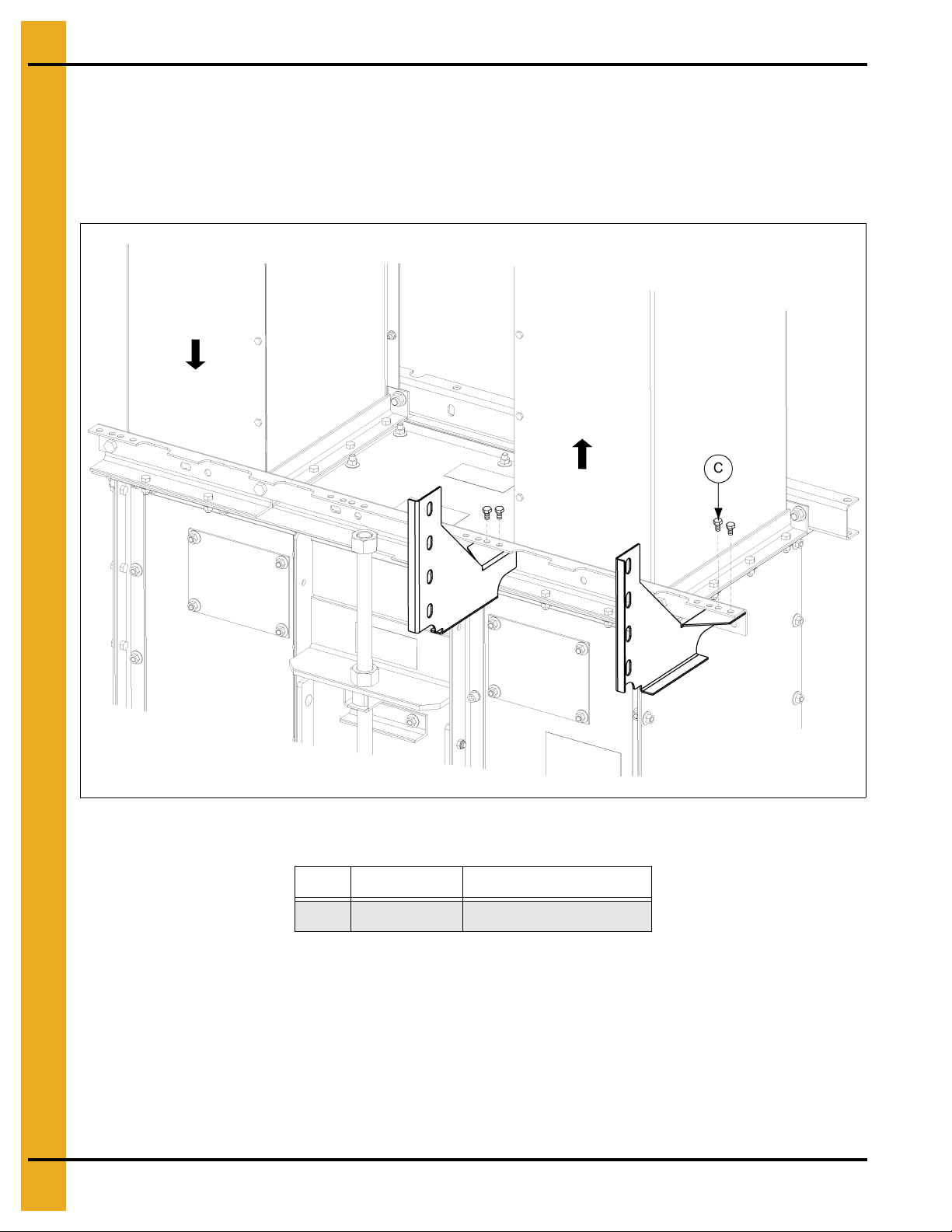

Figure 6C 16" Boot Bracket Down-Leg

Ref # Part # Description

A LAD1648TRH R.H. Side Trunk Support Bracket

B LAD1648TLH L.H. Side Trunk Support Bracket

C S-7469 3/8" x 1" Hex Bolt

6. Tie Angles, Ladder Brackets and Safety Cages

Down-leg

Up-leg

16" Boot Bracket Up-Leg

Attach Boot Ladder Support Brackets and Boot Ladder

Section (Continued)

b. 16" Up-leg boot bracket: Use 3/8" x 1" hex bolts to attach the ladder support brackets to the

boot tie angle using the holes indicated in Figure 6D. Note the outer bracket attaches to the tie

angle with two (2) empty holes remain on the outside.

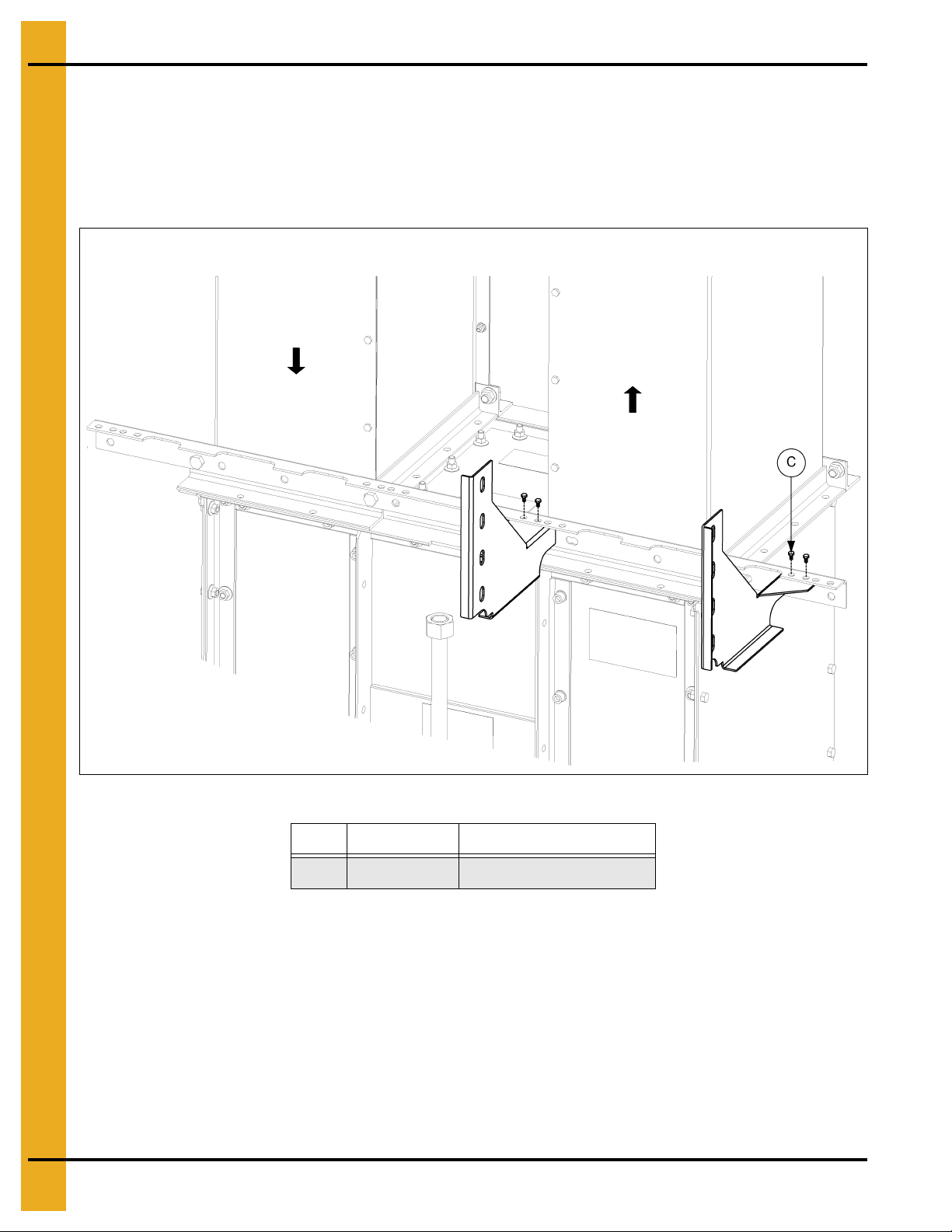

Figure 6D 16" Boot Bracket Up-Leg

Ref # Part # Description

C S-7469 3/8" x 1" Hex Bolt

20 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

Down-leg

Up-leg

24" Boot Bracket Down-Leg

Attach Boot Ladder Support Brackets and Boot Ladder

Section (Continued)

c. 24" Down-leg boot bracket: Use 3/8" x 1" h ex bolts to attach the ladder support brackets to the

boot tie angle using the holes indicated in Figure 6E. Note the outer bracket will have two (2)

empty holes to the outside of the connection at the tie angle.

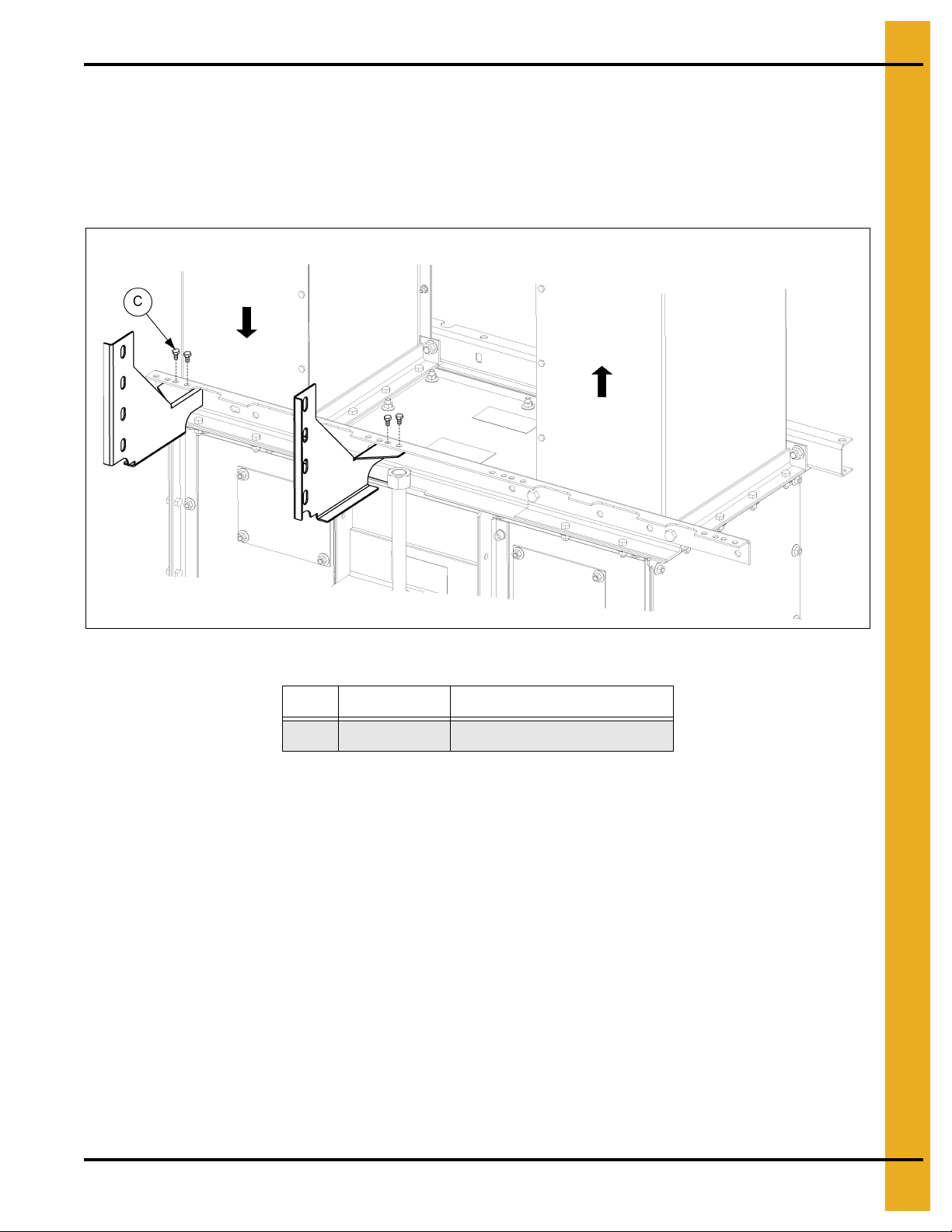

Figure 6E 24" Boot Bracket Down-Leg

Ref # Part # Description

C S-7469 3/8" x 1" Hex Bolt

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 21

6. Tie Angles, Ladder Brackets and Safety Cages

Down-leg

Up-leg

24" Boot Bracket Up-Leg

Attach Boot Ladder Support Brackets and Boot Ladder

Section (Continued)

d. 24" Up-leg boot bracket: Use 3/8" x 1" hex bolts to attach the ladder support brackets to the

boot tie angle using the holes indicated in Figure 6F. Note the outer bracket uses the two (2)

outer most set of holes on the tie angle.

Figure 6F 24" Boot Bracket Up-Leg

Ref # Part # Description

C S-7469 3/8" x 1" Hex Bolt

22 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

Trim Ladder to Ground

Install Boot Ladder Section

1. Trim a 10' ladder section to sit so that the first ladder rung is 12" from the ground. (See Figure 6G.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 23

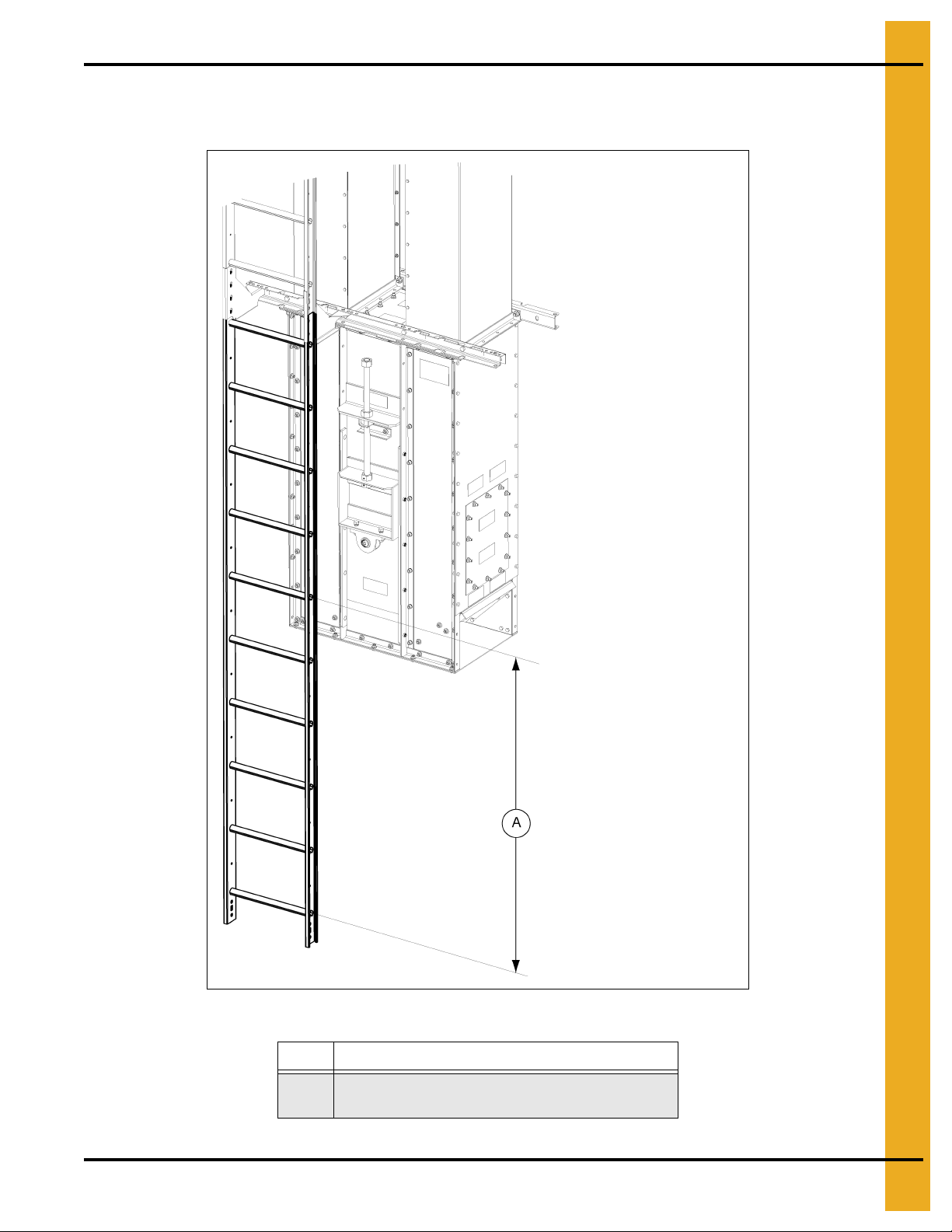

Figure 6G

Ref # Description

Cut this section of the ladder so bottom rung of the

A

ladder is 12" from the ground.

6. Tie Angles, Ladder Brackets and Safety Cages

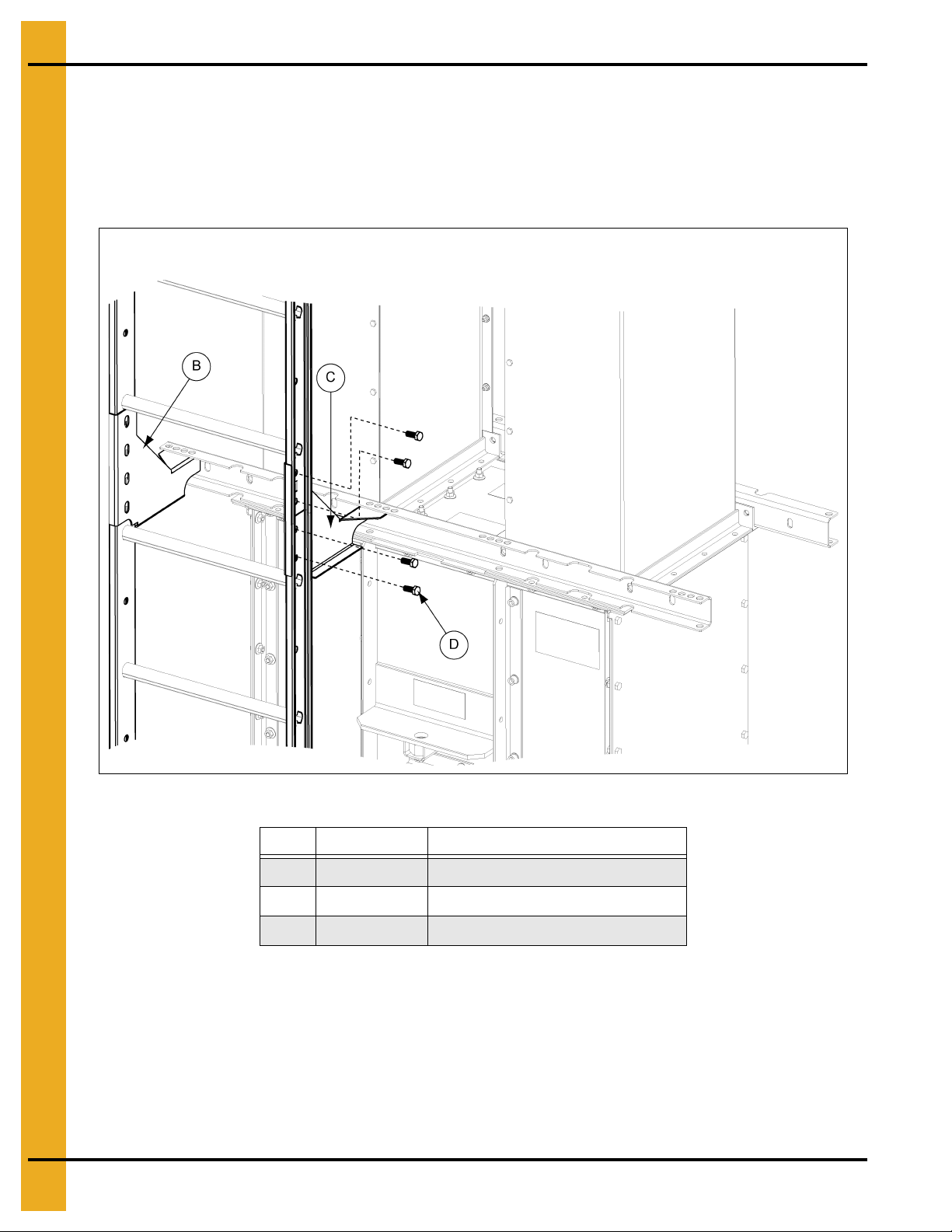

Ladder to Ladder Brackets

Install Boot Ladder Section (Continued)

2. Attach trimmed ladder section to the left and right ladder brackets using 1/2" x 1" hex bolts through

the bottom most set of holes.

3. Attach the next ladder section to the ladder brackets using 1/2" x 1" hex bolts through the top set of

holes. (See Figure 6H.)

Figure 6H

Ref # Part # Description

B LAD1648TLH Trunk Support Bracket L.H. Side

C LAD1648TRH Trunk Support Bracket R.H. Side

D S-7935 1/2" x 1" Hex Bolt

4. Secure the bottom of the ladder to the boot or ground. NOTE: Bracket for this step is not included.

24 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

Tie Angle Installation Locations

Down-leg side

Ladder Side

Ladder side

Up-leg side

Non-ladder side

Tie Angles to Trunking

1. On the LADDER SIDE, use 1/2" x 1" bolts. See Figures 6I-6K on Pages 25-27 for the correct location

of bolts for each elevator size.

Tie angle must be installed at every trunking seam. NOTE: The bottom tie angle will be replaced

with a rest platform tie angle (GECT1640FCRPX2) where a rest platform is to be installed.

(See Figure 6I.)

Ref # Part # Description

A BECT1640FX

A GECT1640FX

B S-7935 1/2" x 1" Hex Bolt

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 25

Figure 6I Tie Angle Installation Locations

16"-24" Type “X” Trunking Tie Angle

6. Tie Angles, Ladder Brackets and Safety Cages

Ladder side

Non-ladder side

16" Bolt Locations

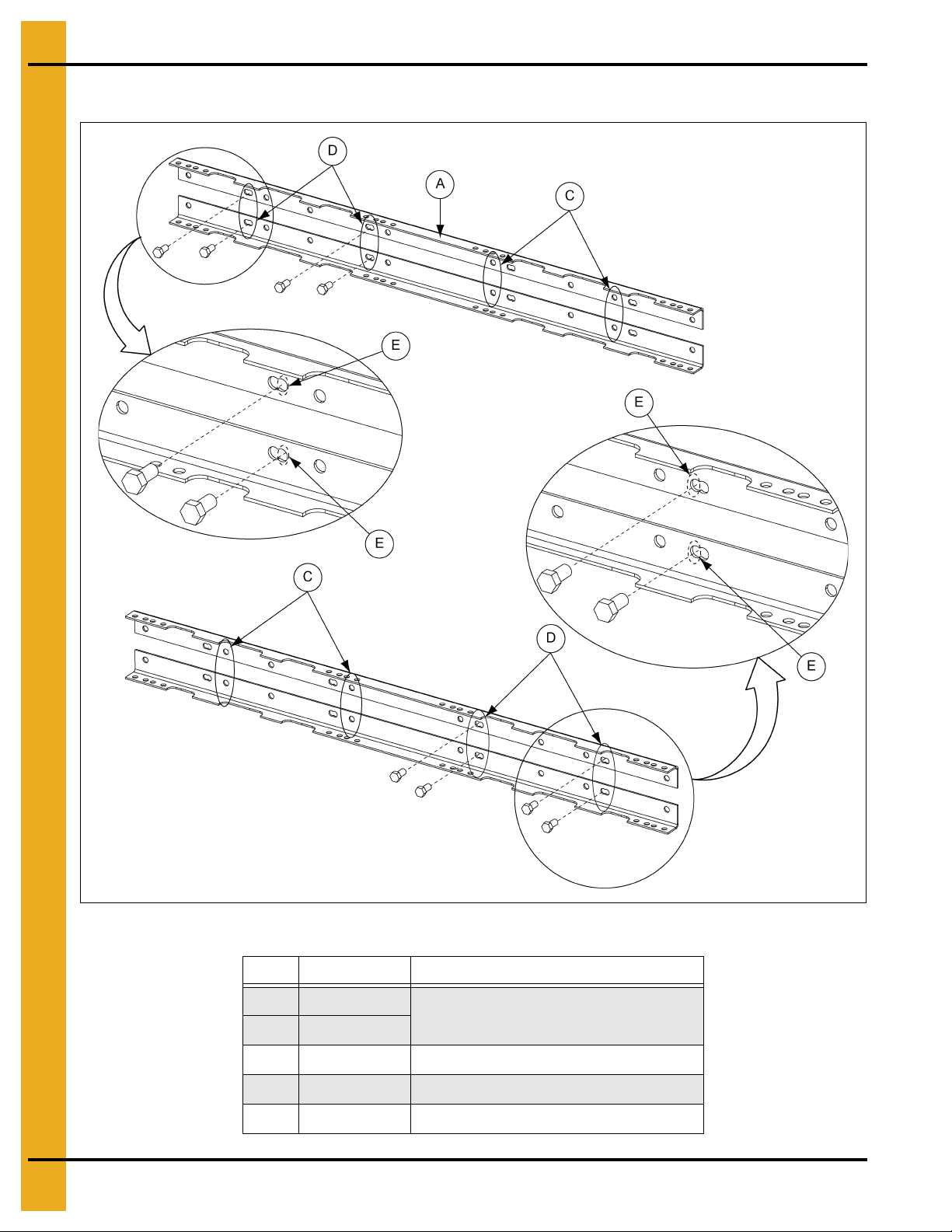

Tie Angles to Trunking (Continued)

Figure 6J 16" Bucket Elevator Tie Angles to Trunking Bolt Locations

Ref # Part # Description

A BECT1640FX

A GECT1640FX

C Up-Leg Set

D Down-Leg Set

E Install Bolt Here

26 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

16"-24" Type “X” Trunking Tie Angle

6. Tie Angles, Ladder Brackets and Safety Cages

24" Bolt Locations

Ladder side

Non-ladder side

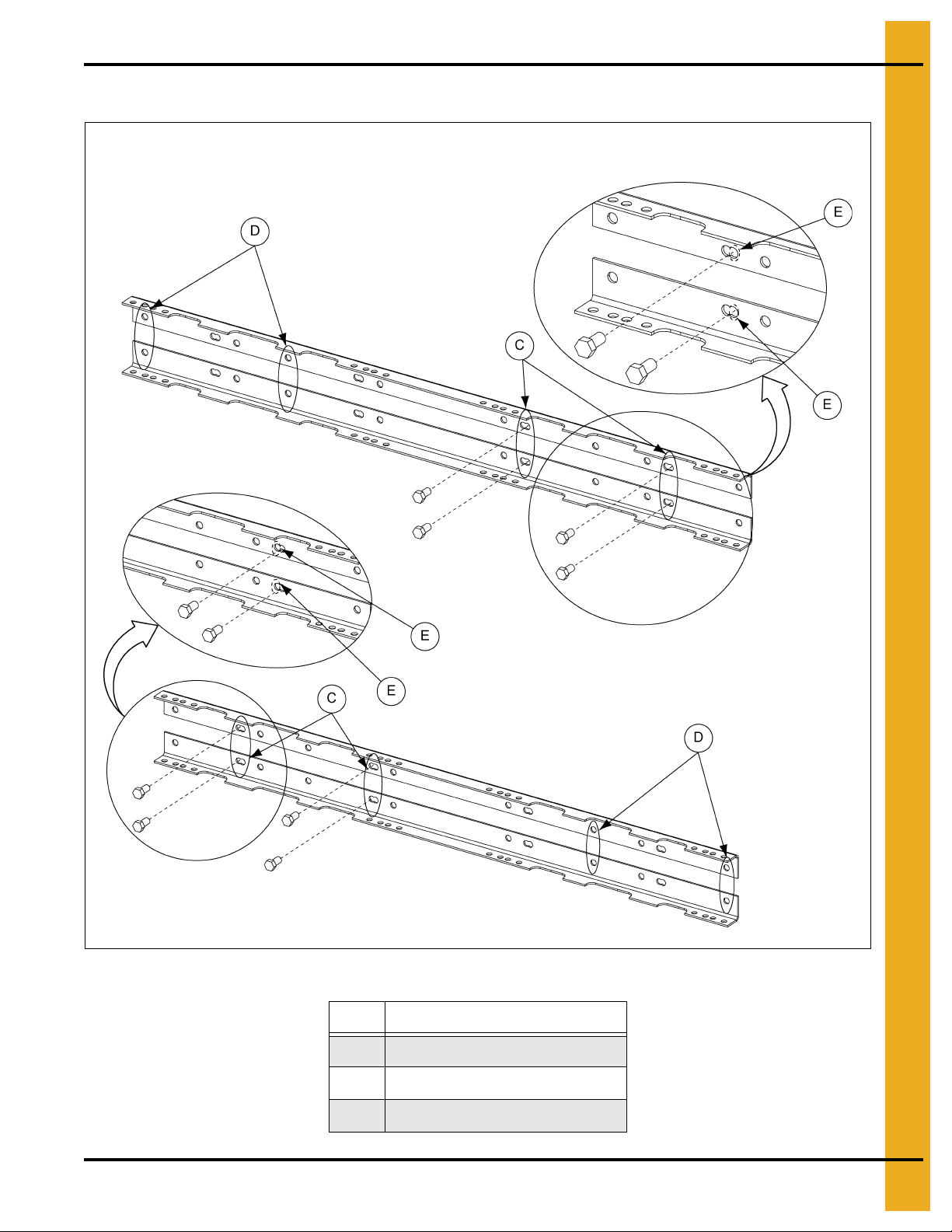

Tie Angles to Trunking (Continued)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 27

Figure 6K 24" Bucket Elevator Tie Angles to Trunking Bolt Locations

Ref # Description

C Up-Leg Set

D Down-Leg Set

E Install Bolt Here

6. Tie Angles, Ladder Brackets and Safety Cages

Ladder Support

Brackets Parts

Ladder Support Brackets

1. Attach ladder support brackets to tie angle using 3/8" x 1" hex bolts (S-7469). Use th e holes shown

in Figures 6L-6P on Pages 28-30 for each size elevator.

2. Mount the upper right and upper left hand ladder support brackets to the top tie angle wit h 3/8" bolts.

3. Mount the lower right hand and lower left hand ladder support brackets to the bottom tie angle with

3/8" bolts.

4. Secure the flanges of the ladder brackets together with 3/8" x 1" hex bolts.

NOTE: You will only use one set of ladder brackets, either the up-leg set or the down-leg set.

Figure 6L Ladder Support Bracket Parts

Ref # Part # Description

A LAD1648TLH1 Bottom Trunk Support Bracket L.H. Side

B LAD1648TLH2 Top Trunk Support Bracket L.H. Side

C LAD1648TRH1 Bottom Trunk Support Bracket R.H. Side

D LAD1648TRH2 Top Trunk Support Bracket R.H. Side

E Tie Angles

28 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

16" Ladder Brackets on Up-Leg

16" Ladder Brackets on Down-Leg

Ladder Support Brackets (Continued)

Figure 6M 16" Ladder Bracket Location for Up-Leg

Figure 6N 16" Ladder Bracket Location for Down-Leg

Ref # Part # Description

F BECT1640FX

F GECT1640FX

G S-7469 3/8" x 1" Bolt

H S-968 3/8" Flange Nut

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 29

16" Type “X” Trunking Tie Angle

6. Tie Angles, Ladder Brackets and Safety Cages

24" Ladder Brackets on Up-Leg

24" Ladder Brackets on Down-Leg

Ladder Support Brackets (Continued)

Figure 6O 24" Ladder Bracket Location for Up-Leg

Figure 6P 24" Ladder Bracket Location for Down-Leg

Ref # Part # Description

F BECT1640FX

F GECT1640FX

G S-7469 3/8" x 1" Bolt

H S-968 3/8" Flange Nut

30 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

24" Type “X” Trunking Tie Angle

6. Tie Angles, Ladder Brackets and Safety Cages

Attach Ladders to Ladder Brackets

1. Attach ladder sections to the ladder brackets using 1/2" x 1" hex bolts (S-7935). (See Figure 6Q.)

Figure 6Q

Ref # Part # Description

A LAD1648TLH1 Bottom Trunk Support Bracket L.H. Side

B LAD1648TLH2 Top Trunk Support Bracket L.H. Side

C LAD1648TRH1 Bottom Trunk Support Bracket R.H. Side

D LAD1648TRH2 Top Trunk Support Bracket R.H. Side

10FOOTRFX or

E

10FOOTX

F S-7935 1/2" x 1" Hex Bolt

G Ladder Section

10' Ladder Section

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 31

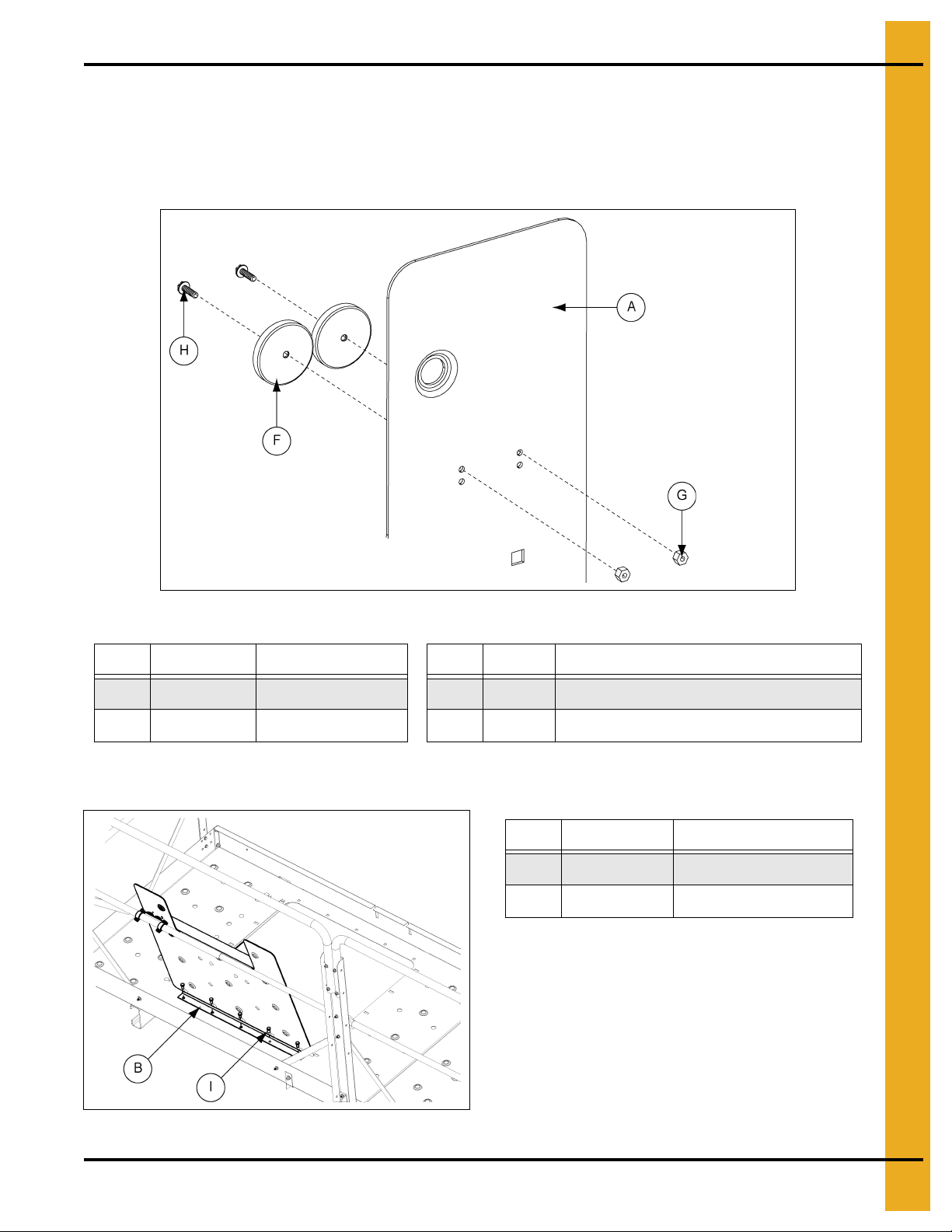

6. Tie Angles, Ladder Brackets and Safety Cages

Safety Cage Installation

Safety cage entrance must be installed to the ladders within 7'-8' from the ground or platform deck.

(See Figure 6R.)

Figure 6R

Ref # Description

A Safety Cage

32 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

6. Tie Angles, Ladder Brackets and Safety Cages

Install Safety Cage

Safety cages are 10' sections, with the exception of the 3' entrance section.

1. Locate safety cage hoops (LDR-BCKTBHP) along the ladder rails where the safety cage hoops will

be installed. NOTE: The end hoops of a 10' section are spaced 4' from the two (2) middle hoops,

which are spaced 2' apart. See Figure 6S for spacing. (See Figure 6S.)

Figure 6S 10' Safety Cage Section

Ref # Part # Description

A LDR-10FTCAGE 10' Safety Cage Strap

B LDR-3FTCAGE 3' Safety Cage Strap

C 3' Safety Cage Entrance Section

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 33

6. Tie Angles, Ladder Brackets and Safety Cages

Install Safety Cage (Continued)

2. Attach safety cage hoops to ladder using 1/2" x 1" bolts and nuts. (See Figure 6T.)

Figure 6T

Ref # Part # Description

D S-7935 1/2" x 1" HHCS Bolt

E S-8506 1/2" Flange Nut

10FOOTRFWX or

F

10FOOTX

G Safety Cage Hoop

34 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

10' Ladder Section

6. Tie Angles, Ladder Brackets and Safety Cages

Vertical Straps

Install Safety Cage (Continued)

3. Install the seven (7) 10' safety cage straps along the safety cage hoops using 5/16" x 3/4" bolts and

nuts. NOTE: Bolt heads should be to the inside of the hoop. (See Figure 6U.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 35

Figure 6U

Ref # Part # Description

A LDR-10FTCAGE 10' Safety Cage Strap

B LDR-3FTCAGE 3' Safety Cage Strap

H LDR-BCKTBHP Safety Cage Hoop Entrance

I S-7645 5/16" x 3/4" Bolt

J S-10268 5/16" Flange Nut

K LDR-BCKTHOOP Safety Cage Hoop Standard

L Bottom Holes

M Top Holes

N Leave these hole open for vertical bars.

7. Rest Platform

Tie Angle Etched Identification Holes

16" Tie Angle Bolt

Locations - Ladder Side

Down-leg

Up-leg

Chapter 7: Rest Platform

Rest Platform Tie Angles to Bucket Elevators

1. Install rest platform tie angles to the lower trunking on both the ladder side and non-ladder side of the

trunking. Use 1/2" x 1" bolts through the bolt holes indicated for the bucket elevator size being

installed. (See Figure 7A.)

NOTE: Bolt hole starting location on left side of tie angle is marked with the bucket size.

Figure 7A Tie Angle with Etched Numbers

Figure 7B 16" Rest Platform Tie Angle Bolt Locations - Ladder Side

Ref # Part # Description Ref # Part # Description

A GECT1640FCRPX2 16"-24" Rest Platform Tie Angle C S-8506 1/2" Flange Nut

B S-7935 1/2" x 1" Bolt

36 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

D Hole Marked 24" 16". Use Side Marked 16".

7. Rest Platform

24" Tie Angle Bolt Locations - Ladder Side

Down-leg

Up-leg

Rest Platform Tie Angles to Bucket Elevators (Continued)

Figure 7C 24" Rest Platform Tie Angle Bolt Locations - Ladder Side

Ref # Part # Description

A GECT1640FCRPX2 16"-24" Rest Platform Tie Angle

B S-7935 1/2" x 1" Bolt

C S-8506 1/2" Flange Nut

E Hole Marked 24" 16". Use Side Marked 24".

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 37

7. Rest Platform

16" Tie Angle Bolt Locations - Non-Ladder Side

Down-leg

Up-leg

Rest Platform Tie Angles to Bucket Elevators (Continued)

Figure 7D 16" Rest Platform Tie Angle Bolt Locations - Non-Ladder Side

Ref # Part # Description

A GECT1640FCRPX2 16"-24" Rest Platform Tie Angle

B S-7935 1/2" x 1" Bolt

C S-8506 1/2" Flange Nut

D Hole Marked 24" 16". Use Side Marked 16".

38 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

7. Rest Platform

24" Tie Angle Bolt Locations - Non-Ladder Side

Down-leg

Up-leg

Rest Platform Tie Angles to Bucket Elevators (Continued)

Figure 7E 24" Rest Platform Tie Angle Bolt Locations - Non-Ladder Side

Ref # Part # Description

A GECT1640FCRPX2 16"-24" Rest Platform Tie Angle

B S-7935 1/2" x 1" Bolt

C S-8506 1/2" Flange Nut

E Hole Marked 24" 16". Use Side Marked 24".

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 39

7. Rest Platform

16"-24" Tie Angle Bolt Locations - Mounting Channels

Down-leg

Up-leg

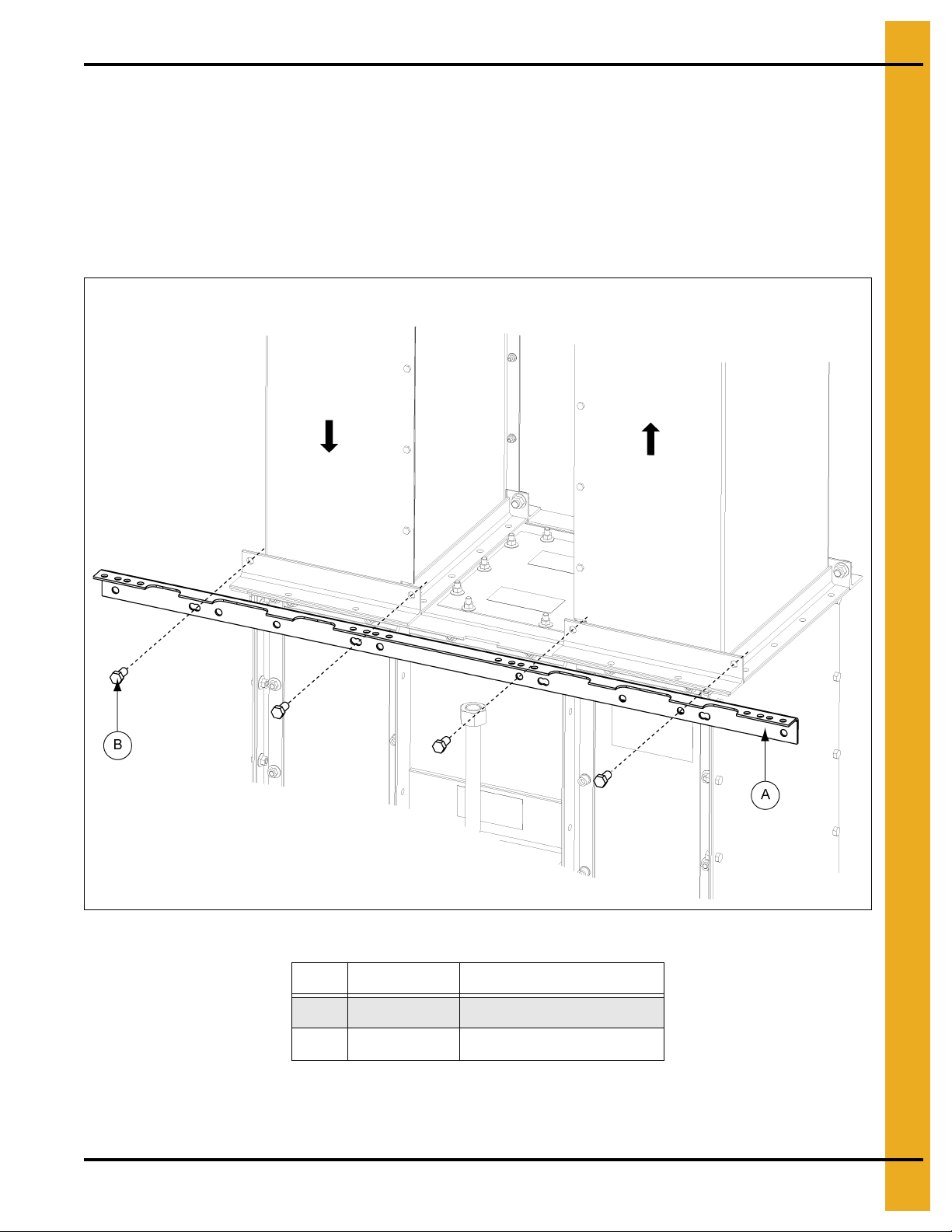

Attach Rest Platform Channel to the Rest Platform Tie Angle

1. Connect rest platform mounting channels to the rest platform tie angles using 1/2" x 1" bolts.

Bolt hole locations for 16"-24" bucket elevator will be the same. (See Figure 7F.)

Figure 7F Bolt hole locations for 16"-24" rest platform mounting channels to tie angles.

Ref # Part # Description

A GECT1640FCRPX2 16"-24" Rest Platform Tie Angle

B S-7935 1/2" x 1" Bolt

C S-8506 1/2" Flange Nut

D RP1636MCX 16"-36" Rest Platform Mounting Channel

40 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

7. Rest Platform

Rest Platform Channels

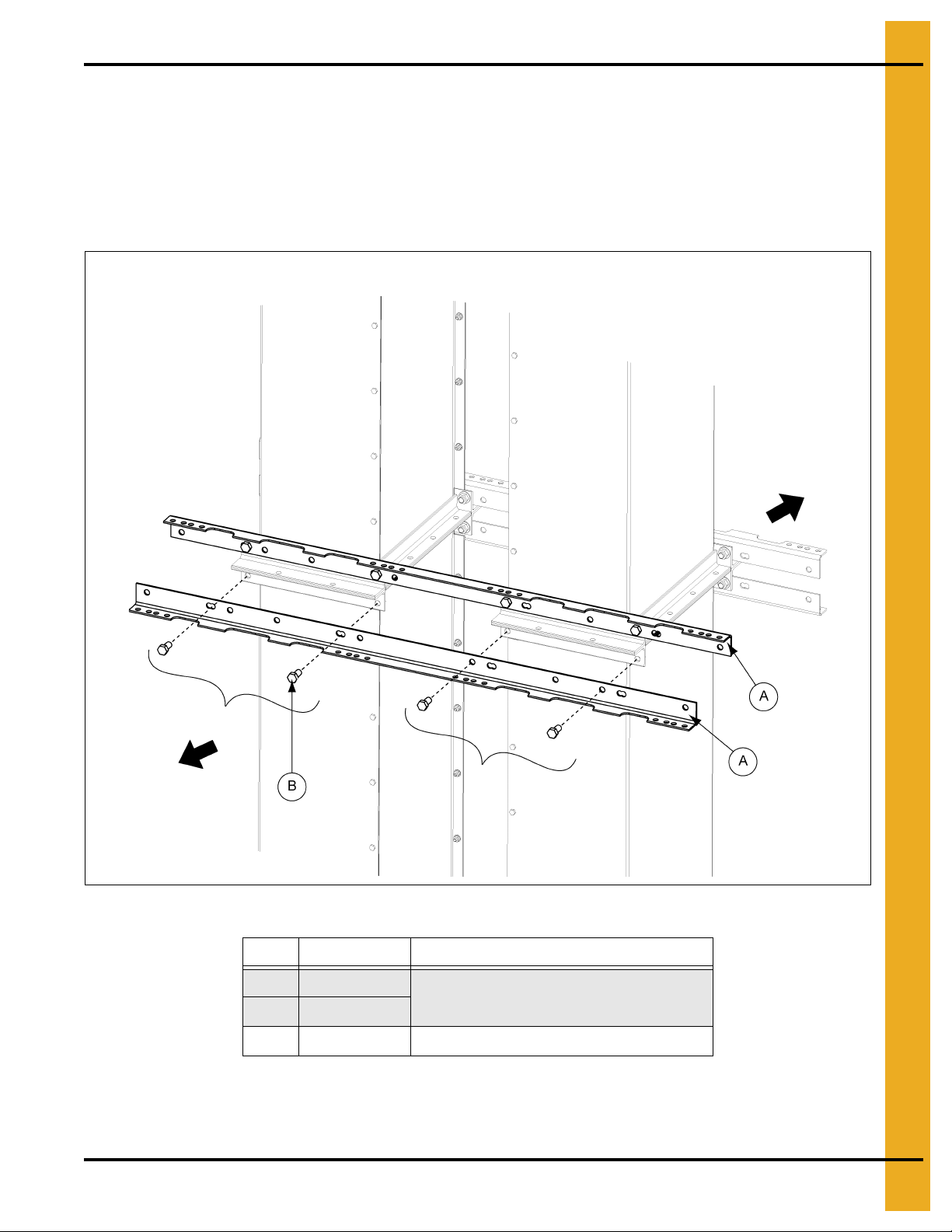

Rest Platform Cross Channel to Rest Platform Mounting Channels

1. Place the rest platform cross channels between the rest platform mounting channels and connect

those using 3/8" x 3/4" hex bolts. (See Figure 7G.)

Figure 7G Rest Platform Cross Channel to Rest Platform Mounting Channels

Ref # Part # Description

A RP1636CCX Rest Platform Cross Channel

B RP1636MCX Rest Platform Mounting Channel

C S-7105 3/8" x 3/4" Hex Bolt

D S-968 3/8" Flange Nut

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 41

7. Rest Platform

Rest Platform Deck Plate

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

2. Attach rest platform deck to the bottom of the rest platform mounting channels and rest platform

cross channels, using 3/8" x 3/4" hex bolts. Bolt heads should be installed against the deck plate.

(See Figure 7H.) NOTE: The deck plate can be mounted on either the right or left side, but the flange

must be mounted towards the opening.

Figure 7H Deck Plate

Ref # Part # Description

A RP1636CCX Rest Platform Cross Channel

B RP1636MCX Rest Platform Mounti ng Channel

C S-7105 3/8" x 3/4" Hex Bolt

D S-968 3/8" Flange Nut

E RP1636FDP Rest Platform Flat Deck Plate

F Deck Flange Towards Opening

42 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

7. Rest Platform

Rest Platform Handrail Posts

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

3. Install the handrail platform posts to the rest platform mounting channels and rest platform channels

using six (6) 5/16" x 3/4" flanged hex bolts for each post, four (4) bolt to the front and two (2) on the

side. (See Figure 7I.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 43

Figure 7I

Ref # Part # Description

G HP1648HCP Handrail Platform Posts

H S-6606 5/16" x 3/4" Flange Bolt

I S-10268 5/16" Flange Nut

7. Rest Platform

18"

Final length

Cut 18"

Cut 18"

Intermediate Handrails

18"

Final length

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

4. Assemble the intermediate handrails by sliding the small handrail into the larger handrail to create a

telescoping handrail that can be adjusted to the correct length between the posts. Two (2) of the

small intermediate handrails and two (2) of the large intermediate handrails will need to be cut to fit.

The starting length of each rail is 36". Cut 18" off the end of each rail so the final length of each rail

is 18". (See Figure 7J.)

Figure 7J

Ref # Description

J Cut Two (2) Small Intermediate Rails

K Cut Two (2) Large Intermediate Rails

44 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

7. Rest Platform

Telescoping Intermediate Handrail Posts

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

5. Install the front and back intermediate handrails to the platform posts using 5/16" x 3/4" flanged hex

bolts. Adjust the rail into position by sliding it out to the correct length.

6. After cutting the two (2) large and two (2) small intermediate handrails, slide them to the correct

length and install them to the handrail posts on the short sides of the platform using 5/16" x 3/4"

flanged hex bolts. (See Figure 7K.)

Ref # Part # Description

H S-6606 5/16" x 3/4" Flange Bolt

I S-10268 5/16" Flange Nut

L LDR-4087 Large Intermediate Handrail

M LDR-4088 Small Intermediate Handrail

N Slide Smaller Rail into Larger Rail

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 45

Figure 7K

7. Rest Platform

Handrails

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

7. Connect the front rest platform handrails and the side rest platform handrails to the handrail platform

post using 5/16" x 2" hex bolts. (See Figure 7L.)

Figure 7L

Ref # Part # Description

I S-10268 5/16" Flange Nut

O RP1648HF 57-1/2" Handrail

P RP1648HS 30.1" Handrail

Q S-7877 5/16" x 2" Flange Bolt

46 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

7. Rest Platform

Platform Braces

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

8. Platform braces must be installed from handrail posts to mounting and cross channels using

5/16" x 3/4" flanged hex bolts. Braces should be attached to the outside of the platform post and to

the inside of the mounting and cross channels. NOTE: Safety cage bars (LDR-517BE) are used

as platform braces/tie angle braces through out this installation. Bolt heads should be on inside of

platforms. (See Figure 7M.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 47

Figure 7M

Ref # Part # Description

A RP1636CCX Rest Platform Cross Channel

B RP1636MCX Rest Platform Mounting Channel

H S-6606 5/16" x 3/4" Flange Bolt

I S-10268 5/16" Flange Nut

R LDR-5171BE Brace

7. Rest Platform

Rest Platform Cross Channel to Rest Platform Mounting

Channels (Continued)

9. Install ladder support brackets to the rest platform cross channel using 3/8" x 3/4" hex bolts.

10. Attach ladders to ladder support brackets using 1/2" x 3/4" hex bolts. (See Figure 7N.)

Figure 7N

Ref # Part # Description

A RP1636CCX Rest Platform Cross Channel

C S-7105 3/8" x 3/4" Hex Bolt

S LAD1648BLH Ladder Support L.H. Bracket

T LAD1648BRH Ladder Support R.H. Bracket

U S-7932 1/2" x 3/4" Hex Bolt

48 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

Ladder Support

NOTE: Drill holes where necessary.

7. Rest Platform

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 49

Figure 7O

Ref # Part # Description

14FOOTRFWX or

A

14FOOTX

B RP1648LS Ladder Support Rest Platform

C RP1648HSX 48" HSP Sides 43.605" Outside Handrail

D S-10136 U-Bolt 1/4"-20 x 1-1/2"

14' Ladder Section

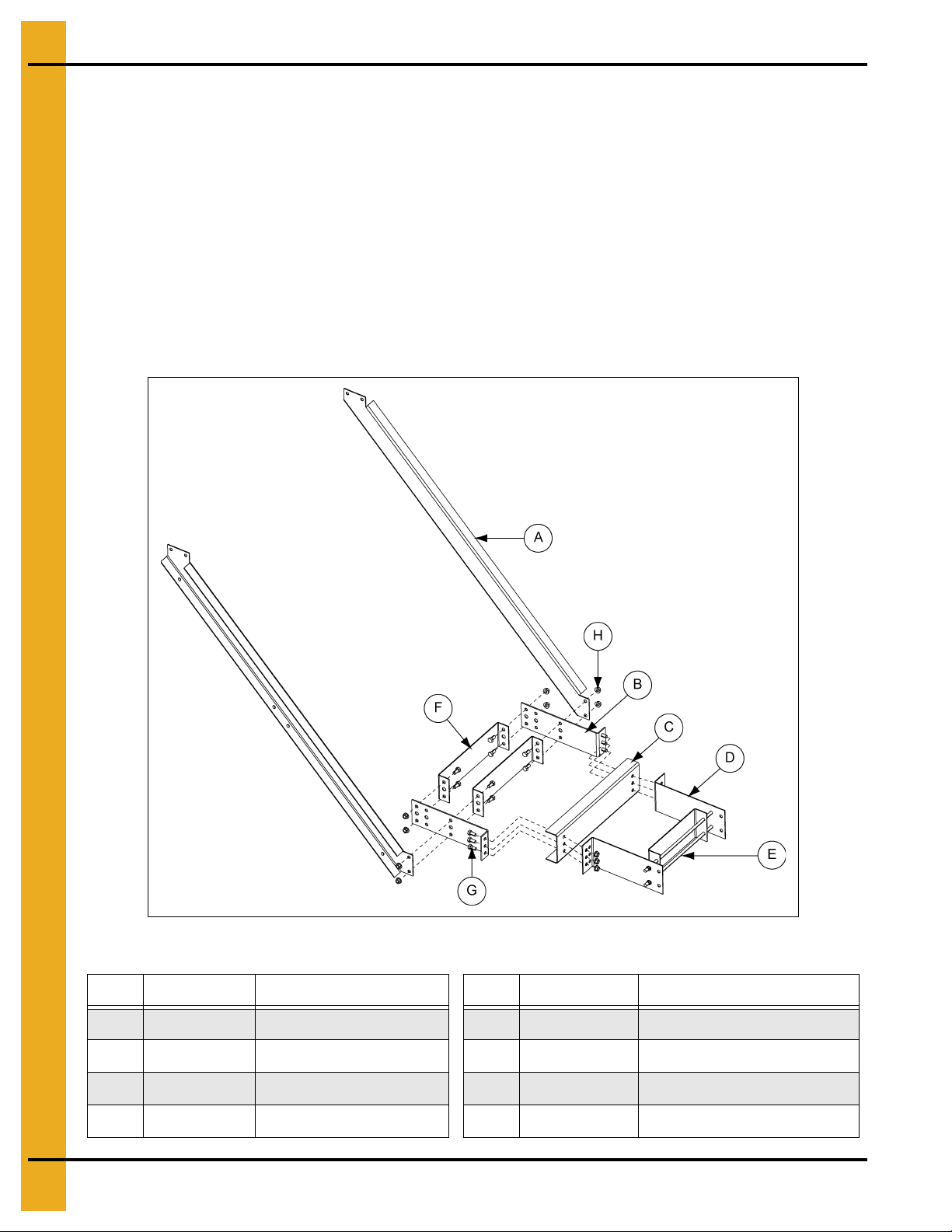

8. 16"-24" Head Platform Assembly

16"-24" Cross Deck Support

Channels to Head

Chapter 8: 16"-24" Head Platform Assembly

Considerable time is dedicated at the beginning of this manual to the proper orientation of channels and

decks. This is because the orientation of these elements is essential to the proper construction of the

head platform.

1. There are many ways to get the orientation wrong and only one way to get it right.

2. Proper orientation of the channels and decks is essential proper assembly.

3. Proper construction of the head platform can only be completed if the initial orientation of the

channels is done correctly.

Please take time to confirm that the orientation of these early elements is correct before you begin to

assemble the decking on to the channels.

Attach Main Support Channels to Lower Head

1. Place lower head section on solid and level surface.

2. At both the Discharge End and Up-Leg End, orient the channels so that lip/channel openings face

outward, away from the lower head.

3. Attach each Main Support Channel to the Lower Head Bracket at the top most set o f holes using

3/8" x 1" bolts and nuts and torque to standard specifications. (See Figure 8A.)

Figure 8A Cross Deck Support Channels Head

Ref # Part # Description

A S-7469 3/8" x 1" Bolt

B S-10028 3/8" Flange Nut

C HSP16001X 16"-24" Main Support Channel

50 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

A1

on Toe board

16"-24" Deck A Toe Board to Channel Mounting

A2

on Toe board

A3

on Toe board

DECK A

Install Deck A and Toe Board

1. Orient the lip of the side toe board (HP1624STBX) out/away from the lower head and slide into place

on non-drive side. Toe board hole A1 should be at the discharge end and A3 is at the up-leg end.

2. Locate pre-assembled Deck A, which consists of the hatch opening and connecting flanges.

3. Using a punch as needed for alignment, connect Deck A to the side toe board with 3/8" flange nuts

(S-10028) and 3/8" x 3/4" flange bolts (S-7105). Torque to standard specifications. (See Figure 8 B.)

a. Deck hole A1 to toe board hole A1.

b. Deck hole A2 to toe board hole A2.

c. Deck hole A3 to toe board hole A3.

NOTE: Due to snug fit, slide side toe board in place before securing Deck A or any subsequent decking.

Figure 8B Deck A Toe Board Channel Location

Ref # Description

NOTE: 24" Position shown. Only difference between

A

16" and 24" is location of discharge channel.

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 51

8. 16"-24" Head Platform Assembly

16"-24" Deck A to Support Channels

DECK A

Install Deck A to Main Support Channels

1. Using 3/8" x 1" carriage bolts (S-3585) and 3/8" flange nuts (S-10028), connect Deck A to main

support channel. IMPORTANT: Connect every hole. (See Figure 8C.)

Figure 8C Deck A to Support Channels

Ref # Part # Description

A S-3585 3/8" x 1" Carriage Bolt

B S-10028 3/8" Flange Nut

C HSP16001X Main Support Channel

D

52 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

NOTE: 16" will use this row of holes.

8. 16"-24" Head Platform Assembly

NOTE: 24" Shown. 16" Assemble the same.

16"-24" Deck A HP Deck Supports

DECK A

Install Deck A to Main Support Channels (Continued)

2. Install decking support (HP1624DS) to up-leg end of Deck A as shown, using 3/8" x 1" bolts (S-7105)

and 3/8" nuts (S-10028).

3. Install the hatch deck support bar (HP1624HDSX) to Deck A. This piece installs on the underside of

Deck A and extends the width of the deck from edge to edge.

Using 3/8" flange nuts (S-10028) and 3/8" x 3/4" flange bolts (S-7105), connect the hatch deck

support bar to Deck A kick plate and through the holes labeled A2 on Deck A and side toe board.

Torque to standard specifications. (See Figure 8D.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 53

Figure 8D Deck A HP Deck Supports

Ref # Part # Description

E HP1624HDSX Hatch Deck Support Bar

F HP1624DS Decking Support

8. 16"-24" Head Platform Assembly

16"-24" Deck C Toe Board

A1

on Toe board

A4

on Toe board

A3

on Toe board

DECK C

Install Deck C and Toe Board

1. Locate pre-assembled Deck C, consisting of two (2) planks and connecting tabs.

2. Slide side toe board into place on the drive side of the lower head.

3. Orient the side toe board so that the hole labeled A1 is at the up-leg end and A3 is at the discharge

end of the lower head.

4. Using a punch as needed for alignment, connect Deck C to side toe board using 3/8" x 1" carriage

bolts (S-3585) with flange nuts (S-10028) and torque to standard specifications. (See Figure 8E.)

a. Deck hole C1 to toe board hole A3.

b. Deck hole C2 to toe board hole A4.

c. Deck hole C3 to toe board hole A1.

NOTE: Due to snug fit, slide side toe board in place before securing Deck C or any subsequent decking.

Figure 8E 24" Deck C Toe Board

Ref # Part # Description

A S-7105 3/8" x 3/4" Flange Bolt

B S-10028 3/8" Flange Nut

C HP1624HDSX Hatch Deck Support Bar

D

54 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

NOTE: 24" Position shown. Only difference between

16" and 24" is location of discharge channel location.

8. 16"-24" Head Platform Assembly

16"-24" Deck C to

Support Channel

DECK C

16"-24" Deck C HP Deck

Support - Underneath View

Install Deck C to Main Support Channels

1. Using 3/8" x 1" carriage bolts (S-3585) and 3/8" flange nuts (S-10028), connect Deck C to main

support channel. IMPORTANT: Connect every hole. (See Figure 8F.)

2. Install decking support (HP1624DS) to up-leg end of Deck A as shown. Using five (5) 3/8" x 1" bolts

(S-7105) and 3/8" nuts (S-10028).

3. Install the hatch deck support bar (HP1624HDSX) to Deck C. This piece installs on the underside of

Deck C and extends the width of the deck from edge to edge.

a. Using 3/8" flange nuts (S-10028) and 3/8" x 3/4" flange bolts (S-7105), connect the hatch deck

support bar to the kick plate attached to Deck C and to the hole labeled

side toe board and lower head. Torque to standard specifications.

A2

on decking nearest the

(See Figure 8G.)

Figure 8F 16" Deck C to Support Channels

Figure 8G Deck C HP Deck Support as Viewed from Underneath.

Ref # Part # Description Ref # Part # Description

A S-3585 3/8" x 1" Carriage Bolt C HP1624DS HP1624 Decking Support

B S-10028 3/8" Flange Nut

D HP1624HD SX Hatch Deck Support Bar

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 55

8. 16"-24" Head Platform Assembly

DECK A

DECK C

16"-24" Decks E, A and C - Underneath View

DECK E

Install Deck E

NOTE: The orientation of the flanges on Deck E is important to prope r assembly. Deck E flanges should

be to the outside of Deck A and Deck C.

1. Locate Deck E. It is the smallest deck.

NOTE: Deck E will attach to Deck A, Deck C, both side toe boards and the main support channel.

2. Using a punch as needed for alignment, connect Deck E to the side toe board using 3/8" x 1" carriage

bolts (S-3585) with flange nuts (S-10028). Torque to standard specifications. (See Figure 8H.)

a. Deck E hole E1 to Deck A hole A5.

b. Deck E hole E2 to Deck A hole A4.

c. Deck E hole E3 to Deck C hole C5.

d. Deck E hole E4 to Deck C hole C4.

Figure 8H Deck E, Deck A and Deck C as Viewed from Underneath.

56 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

DECK A

DECK C

16"-24" Deck E to Support Channels

DECK E

Install Deck E (Continued)

3. Using 3/8" x 1" carriage bolts (S-3585) and 3/8" flange nuts (S-10028), connect Deck E to main

support channel. IMPORTANT: Connect every hole. (See Figure 8I.)

4. Align Deck E so the flanges are to the outside of Deck A and Deck C. Using 3/8" x 1" bolts (S-7105)

and 3/8" flange nuts (S-10028), connect Deck E to toe boards and flanges of Deck A and Deck C.

(See Figure 8J.)

Ref # Part # Description

A S-3585 3/8" x 1" Carriage Bolt

B S-10028 3/8" Flange Nut

C Deck E Flanges Outside Deck A and Deck C

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 57

Figure 8I 24" Deck E to Support Channels

8. 16"-24" Head Platform Assembly

DECK C

DECK A

Deck E

DECK E

Install Deck E (Continued)

Figure 8J 24" Deck E

Ref # Part # Description

B S-10028 3/8" Flange Nut

D S-7105 3/8" x 1" Bolt

58 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

16" Deck E

16" Deck E

Install Adapter Bracket for 16" Platforms

NOTE: The adapter bracket attaches to decking and toe boards. The flanges should be to the outside of

Deck A and Deck C.

1. Using three (3) 3/8" x 1" carriage bolts (S-3585) and 3/8" flange nuts (S-10028), install the adapter

bracket to cross deck support channel at the up-leg end of the platform between Deck A and side

toe board and between Deck C and side toe boards. (See Figure 8K.)

2. Attach deck adapter bracket (HP1624AB) to Deck A, Deck C and toe boards using four (4) 3/8" x 1"

bolts (S-7105) and nuts. (See Figure 8L.)

Figure 8K Deck Adapter Bracket to Channel Figure 8L Deck Adapter Bracket to Decks

Ref # Part # Description

A S-3585 3/8" x 1" Carriage Bolt

B HP1624AB 16" HP Adapter Bracket

Ref # Part # Description

B HP1624AB 16" HP Adapter Bracket

C S-7105 3/8" x 1" Bolt

D S-10028 3/8" Flange Nut

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 59

8. 16"-24" Head Platform Assembly

Hatch Filler Plate

Install Hatch Filler Plate

1. Using 3/8" x 1" carriage bolts (S-3585) and 3/8" flange nuts (S-10028), install the hatch filler plate

(HP1624HDF) over the un-used opening. (See Figure 8M.)

Figure 8M Deck Plate

Ref # Part # Description

A HP1624HDF Hatch Deck Filler Plate

B S-3585 3/8" x 1" Carriage Bolt

C S-10028 3/8" Flange Nut

60 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

Deck E Rail Support Brackets

Install Rail Supports to Deck E

1. Attach two (2) head platform rail supports (HP1648HSH) to Deck E as shown using 3/8" x 1" bolts

(S-7105) and 3/8" flange nuts (S-10028). (See Figure 8N.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 61

Figure 8N 24" Deck E Rail Support Brackets

Ref # Part # Description

A HP1648HSH Head Platform Rail Support

B S-7105 3/8" x 1" Bolt

C S-10028 3/8" Flange Nut

8. 16"-24" Head Platform Assembly

“W” Corner Posts

Install “W” Posts (“Corner Posts” x 4)

1. At each corner, align bottom edges of “W” corner posts (HP1648HWP) with bottom edge of

platform decking.

2. Attach each “W” corner post to decking using 5/16" x 3/4" flange bolts (S-6606) and 5/16" flange nuts

(S-10268). Torque to standard specifications. (See Figure 8O.)

Figure 8O

Ref # Part # Description

A HP1648HWP Head/Distributor “W” Corner Post

B S-6606 5/16" x 3/4" Flange Bolt

C S-10268 5/16" Flange Nut

62 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

Middle End Posts

Install Platform Posts

NOTE: Platform posts are not flush with bottom of deck.

1. At the up-leg end, align two (2) platform posts (HP1648HCP) as described and connect to the

decking where Deck E intersects with Decks A and C. Use 5/16" hex flange nuts (S-10268) and

5/16" x 3/4" flange bolts, connect the platform posts to the decking.

NOTE: Rail support braces should be between the posts.

2. At the discharge end, align platform posts as described and attach one platform posts (HP1648HCP)

to the edge of Deck C and Deck A nearest the lower head. (See Figure 8P.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 63

Figure 8P Middle End Posts

Ref # Part # Description

A HP1648HCP Platform Post

B S-6606 5/16" x 3/4" Flange Bolt

C S-10268 5/16" Flang e Nut

8. 16"-24" Head Platform Assembly

Platform Post

Install Platform Posts (Continued)

3. At the middle of Deck A and Deck C, install platform post (HP1648HCP) as shown and connect

to the decking through a rail support (HP1648HSH). Use 5/16" hex flange nuts (S-10268) and

5/16" x 3/4" flange bolts to connect the rail supports and platform posts to the decking.

(See Figure 8Q.)

Figure 8Q Deck A Post Bracket

Ref # Part # Description

A HP1648HCP Platform Post

D HP1648HSH Head Platform Handrail Support

64 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

Intermediate Handrails

Install Intermediate Handrails

IMPORTANT: Trim each rail as listed. Do NOT attempt to make entire adjustment by trimming only one

rail. Each rail must be trimmed and installed as stated for proper fit.

IMPORTANT: For safety purp oses, make sure head of bolt is to the inside of platform with nuts on o utside

at all connections.

1. Identify and separate the large and small intermediate handrails.

NOTE: The small intermediate handrail (LDR-4088) fits inside of the large intermediate handrail.

It is critical that large and small rails be properly identified in advance. Rails are cut to

size and cutting the wrong rail or to the wrong length will prevent proper installation.

(See Figure 8R.)

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 65

Figure 8R Intermediate Handrails

Ref # Part # Description

A LDR-4088 Sma ll Intermediate Handrail

B S-6606 5/16" x 3/4" Flange Bolt

C S-10268 5/16" Hex Flange Nut

D LDR-4087 Large Intermediate Handrail

E

F

G

H

Hatch side large intermediate handrail needs to be at

location of latch.

Cut 4" off of each intermediate large and small rail so

the remaining length for each is 32".

Cut 15" off of each intermediate large and small rail so

the remaining length for each is 21".

Cut 4" off of each intermediate large and small rail so

the remaining length for each is 32".

8. 16"-24" Head Platform Assembly

Cut 15"

Cut 15"

36"

Large Intermediate Rail

36"

Small Intermediate Rail

Telescoping Handrails

Cut 4"

Cut 4"

36"

Large Intermediate Rail

36"

Small Intermediate Rail

Telescoping Handrails

Install Intermediate Handrails (Continued)

2. Trim two (2) large and two (2) small rails by 15" each so that the remaining length of each rail, both

small and large, is 21". (See Figure 8S.)

a. Install these rails across the Deck A, Deck C, Deck E side of the platform and the opposite side

as shown.

b. Insert one small rail inside of one large rail and telescope the joined rails from the “W” corner post

to the platform post as shown in Figure 8R on Page 65.

c. Attach to “W” posts (corner posts) and platform posts using nuts (S-10268) and bolts (S-6066).

d. Torque to standard specifications.

Figure 8S 21" Telescoping Handrail

3. Trim two (2) large and two (2) small rails by 4" each so remaining length of each rail, both small and

large, is 32". (See Figure 8T.)

a. Install these rails across the up-leg and down-leg sides of the platform as shown.

b. Insert one small rail inside of one large rail telescope the joined rails from the “W” corner posts

to platform posts as shown in Figure 8R on Page 65.

c. Attach to “W” posts (corner posts) and platform posts using nuts (S-10268) and bolts (S-6066).

d. Torque to standard specifications.

Figure 8T 32" Telescoping Handrail

66 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

8. 16"-24" Head Platform Assembly

Top Rails

Install Upper Handrails

IMPORTANT: For safety purposes, make sure head of bolts is to the inside of platform with nuts on

outside at all connections.

NOTE: Upper handrails do not require any cutting prior to installation.

1. Attach two (2) 25.6" in length middle drive handrails (HP1624HMD) along Deck E and the lower head.

These are the two (2) shortest sections of upper handrail. Connect using 5/16" nuts (S-10268) and

5/16" x 2" bolts (S-7877). Torque to standard specifications. (See Figure 8U.)

2. Attach four (4) hatch handrails (HP1648HHS): one on each side of the middle drive at each end of

the platform. Handrails will fit without adjustment. Connect using 5/16" nut (S-10268) and 5/16" x 2"

bolts (S-7877). Torque to standard specifications.

3. Two (2) 59.183" far hatch handrails (HP1624HFH) and two (2) 54.65" handrails (HP1624HNH) opposite

each other along Deck A and Deck C using 5/16" x 2" bolts (S-7877) and 5/16" nuts (S-10268).

Figure 8U Top Rails

Ref # Part # Description

A HP1624HFH 59.183" Far Hatch Handrail

B HP1648HLH 36.895" Hatch Handrail

C HP1648HMD 26.7" Middle Drive Handrail

D HP1624HNH 54.65" Near Hatch

E S-7877 5/16" x 2" Bolt

F S-10268 5/16" Flange Nut

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 67

8. 16"-24" Head Platform Assembly

Tie Braces

(Safety Cage Bars)

Install Tie Braces (Safety Cage Bars)

NOTE: Safety cage bars (LDR-5171BE) are used as tie braces in this installation.

IMPORTANT: For safety purposes, make sure head of bolts are to the inside of platform with nuts on

outside at all connections.

1. At each of the four (4) “W” corner posts (HP1648HWP), attach two (2) tie braces (safety cage bar

LDR-5171BE) from the lower half of the post to the deck kick plate using 5/16" nuts (S-10268) and

5/16" x 3/4" flange bolts (S-6606). (See Figure 8V.)

NOTE: Tie braces may be oriented on the inside or outside of the decking kick plates based upon

installer preference.

Figure 8V Safety Cage Cross Brace

Ref # Part # Description

A LDR-5171BE 24" Safety Cage Bar

B S-6606 5/16" x 3/4" Flange Bolt

C S-10268 5/16" Hex Flange Nut

NOTE: See Page 69 for hatch door installation.

68 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

9. Install Hatch

Chapter 9: Install Hatch

1. Attach hatch hinge (HP1624HH) to the hatch deck door (HP1624HDD). Orient hinge so that it opens

the desired direction. (See Figure 9A.) Fasten using 3/8" x 1" carriage bolts hardware.

Figure 9A

Ref # Part # Description

A HP1624HDD Hatch Deck Door

B HP1624HH Hatch Hinge

C S-3585 3/8" x 1" Carriage Bolt

D S-10028 3/8" Hex Nut

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 69

9. Install Hatch

Install Hatch (Continued)

2. Install hatch support (HP1624HS) to the bottom of the hatch door using 3/8" x 1" carriage bolts

and nuts. (See Figure 9B.)

3. Fasten peak cap handle (PR-331) to the bottom of the hatch door using 3/8" x 1" carriage bolts

and nuts.

Figure 9B

Ref # Part # Description

A HP1624HDD Hatch Deck Door

C S-3585 3/8" x 1" Carriage Bolt

D S-10028 3/8" Hex Nut

E RP-331 Peak Cap Handle

70 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

9. Install Hatch

Hatch Deck Door -

Magnets

Install Hatch (Continued)

4. Slide two (2) magnets (16-0092) onto each MS #6 x 3/4" FHS flat head screw (S-7166). Position the

magnet so the screw head is countersunk into the magnet. (See Figure 9C.)

5. Insert screws with magnets through the hatch door and fasten with the #6 flange nut (S-10133).

Figure 9C

Ref # Part # Description Ref # Part # Description

A HP1624HDD Hatch Deck Door G S-2010 Nylock Nut #10-24 ZN Grade 2

F HP1648MAG Magnet

H Screw, MS #10-24 x 5/8" HWHS ZN Grade 2

6. Align holes on the hatch hinge with holes along the deck opening closest to the kick plates. Install

the hatch door to the decking using 3/8" x 3/4" bolts (S-7105) and nuts. (See Figure 9D.)

Ref # Part # Description

B HP1624HH Hatch Hinge

I S-7105 3/8" x 3/4" Bolt

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 71

Figure 9D

9. Install Hatch

Hatch Deck Door - Clamps

Install Hatch (Continued)

7. Assemble pipe clamps (S-10139) to the magnet mount hatch bracket (HP1648LMM). Insert

3/8" x 3/4" carriage bolts through the magnet mount hatch bracket, 1/2" flat washer and pipe clamp.

Fasten with 3/8" nut. (See Figure 9E.)

8. Attach pipe clamp around intermediate handrail and fasten loosely with bolts. Open hatch plate and

slide clamp along handrail until it lines up with the magnets on the hatch plate. Tighte n clamp to rail.

Figure 9E

Ref # Part # Description

J HP1648LMM Magnet Mount Hatch Bracket

K S-10139 Pipe Clamp 1" O.D. 3/8" Holes with Screw

L 3/8" Nut

M 1/2" Flat Washer

N 3/8" x 3/4" Carriage Bolt

72 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

10. 4 x 5 Distributor Platform (Optional)

16" Distributor Deck Top Clamp Band

Chapter 10: 4 x 5 Distributor Platform (Optional)

The distributor platform is optional and only used on bucket elevators that have a distributor spout. The

platform is used to access the distributor for maintenance and control adjustments. The platform should

be located below the distributor head. NOTE: That the clamp installation to the trunking is different for

16", 24" and the 30"-36" but the rest of the assembly is the same.

16"-24" Clamp Band Installation

Attach Top Clamp Band to Trunking (for 24" Instructions, see Steps 3 and 4.)

1. Slide rods of clamp rod weldment into inside set of holes of clamp bands for 16" assembly. Fasten

together using four (4) 1/2" hex flange nuts.

2. Line up the holes on the clamp strut with the set of holes closest to the bend on both of the

16"-24" long clamp clips and fasten all three (3) together using fou r (4) 1/2" x 1" b olts and nuts. This

will create the clamp strut assembly.

3. Assemble the clamp band weldment, clamp channel and clamp strut assembly at one time around

the trunking. Place clamp rod weldment assembly around the trunking leg and line up holes on

16"-24" long clips and clamp channel with the outside set of holes on the clamp rod weldment.

Fasten all three (3) together using six (6) 1/2" x 1" bolts and nuts.

4. Line up the holes located at the end of the distributor support channels with the holes at the end of

the 16"-24" long clamp clips. Fasten the support channels to the long clamp clips using four (4)

1/2" x 1" bolts and nuts. (See Figure 10A.)

Ref # Part # Description Ref # Part # Description

A GSB30210X Distributor Support Channel (+5") E DSP16005 Clamp Rod Weldment

B DSP1624TRF Long Clamp Clip for 16"-24"

C DSP16001 Clamp Channel G S-7935 1/2" x 1" Bolt

D DSP16002 Distributor Clamp Band

PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series 73

Figure 10A

F DSP1624RFS Clamp Strut for 16" Trunking

H S-8 506 1/2" Flange Nut

10. 4 x 5 Distributor Platform (Optional)

16" Distributor Deck Bottom Clamp Band

16" Attach Bottom Clamp Band to Trunking (for 24" Instructions, see Steps 2

3.)

and

1. Slide rods of clamp rod weldment into inside set of holes of clamp bands for 16" assembly. Fasten

together using four (4) 1/2" hex flange nuts.

2. Line up the holes on one of the clamp struts with the set of holes closest to the bend on both of the

16"-24" long clamp clips and fasten all three (3) together using four (4) 1/2" x 1" bolt and nut s. Tighten

only finger tight. Next orient the brace channels so the bends face outwards and line up the brace

channel holes with the holes located at the end of the long clamp clips and the remaining clamp strut.

Fasten all five (5) parts together using four (4) 1/2" x 1" bolt and nuts. Tighten finger tight. This will

make up the brace channel assembly.

3. Assemble the clamp rod weldment, clamp channel and brace channel assembly at same time around

the trunking. Place clamp rod weldment assembly around the trunking leg and line up holes on

16"-24" long clips and clamp channel with the outside set of holes on the clamp rod weldment.

Fasten all three (3) together using six (6) 1/2" x 1" bolts and nuts. (See Figure 10B.)

Figure 10B

Ref # Part # Description Ref # Part # Description

A GSB30147 Brace Channel E DSP16002 Distributor Clamp Band

B S-8506 1/2" Hex Flange Nut

C DSP1624TRF Long Clamp Clip fo r 16"-24" G S-7935 1/2" x 1" Bolt

D DSP16001 Clamp Channel

74 PNEG-1807CE CE Compliant 16"-24" Bucket Elevator Platform and Ladder “X” Series

F DSP16005 Clamp Rod Weldment

H DSP1624TRF S Clamp Strut for 16"-24" Trunking

10. 4 x 5 Distributor Platform (Optional)

24" Distributor Deck Top Clamp Band

24" Attach Top Clamp Band to Trunking

1. Slide rods of clamp rod weldment into inside set of holes of clamp bands for 24" assembly. Fasten

together using four (4) 1/2" hex flange nuts.

2. Line up the holes on the support channels with the inside set of holes on the 16"-24" long clamp clips

and fasten all four (4) together using eight (8) 1/2" x 1" bolt and nuts.

3. Assemble the 16"-24" long clamp assembly, clamp channel and clamp rod assembly at same time

around the trunking. Place clamp rod weldment assembly around the trunking leg and line up holes

on 16"-24" long clips and clamp channel with the outside set of holes on the clamp rod we ldment.

Fasten all three (3) together using six (6) 1/2" x 1" bolts and nuts. (See Figure 10C.)

Ref # Part # Description

A GSB30210X Distributor Support Channel (+5")

B DSP1624TRF Long Clamp Clip for 16"-24"

C DSP16001 Clamp Channel

D DSP16002 Distributor Clamp Band

E DSP16005 Clamp Rod Weldment

F S-8506 1/2" Hex Flange Nut

G S-7935 1/2" x 1" Bolt